PROTECTING AND PREVENTING

Firefighters need to properly clean their gear and truck after a fire

by Kirk Hughes

Remember when overhaul wasn’t so complicated?

The fire had been stopped, property saved and the dirty work of salvage started? There was little thought or mention of the after effects of fire fighting – the soot, the smoke, the chemical mixture soup that made up water runoff and plastered equipment. Blackened hands, smeared bunker jackets and the light film that clung to the coloured shell of a fire helmet were all worn almost as a badge of honour. How times have changed.

Today, the fire service collectively has a better understanding of the destructive nature of the by-products of combustion, how they affect firefighter safety and long-term health, and just how deadly it can be. The actions to stop these side effects should happen immediately after the life-threatening situation ceases. How a firefighter decontaminates himself or herself postincident is a major preventative factor in avoiding the dreaded “C” word - cancer.

The most important thing any firefighter can do to reduce the risk of developing cancer is to always wear self-contained breathing apparatus (SCBA), from initial attack to the end of the salvage operations and decontamination. And not just having it on, but wearing it and wearing it properly.

If operating in areas where a full-mask system is not required, a partial respirator should be worn, especially in post-fire environments such as investigations and fire watch. Recommend and ensure others wear their full PPE too. Sometimes a reminder is all it takes.

Fit testing is highly recommended for anyone using any type of respirator. A solid first step in beginning the decontamination process is to have the firefighter, still fully-kitted in SCBA, stand up with his or her arms extended out in a “T” while another firefighter uses a small-diameter hose line to rinse him or her off. This is sometimes referred to as a “gross field decon”.

Ideally, a third firefighter would be using a hand brush, often found in the automotive section of a hardware store, to remove any large debris and help loosen stuck-on materials. This allows for a more thorough clean.

Research has shown that the Nomex balaclava hood performs highly in removing toxins associated with combustion. Removing the balaclava after active fire ground operations and wiping the neck area with a specialized cleanser towelette is statistically shown to reduce fire ground contaminates.

SPONSORED CONTENT

BullDog Hose Company proudly designs and manufactures premier fire and industrial equipment that are unmatched in quality and performance. Hundreds of North American fire departments depend on BullDog to get the job done safely and efficiently.

In 2018, BullDog Hose Company purchased assets from Angus Fire US, a hose manufacturing plant with equipment and product lines based in Angier, North Carolina. We are excited to continue the tradition of offering premium products, such as the Hi-Combat® attack hose, Hi-Vol® supply hose and Armour Guard™ industrial hose to customers across the United States and Canada.

No matter the scenario, when the call goes out, BullDog’s attack, supply, and general fire hose are ready to respond. Our durable, Americanmade hoses are depended on by fire departments of all sizes across North America. BullDog Hose Company provides top-tier firefighting solutions for departments of any size.

Fit testing is highly recommended for any person using any type of respirator.

Balaclavas worn inside a fire should be bagged and washed before being placed back into service. Advanced hoods have come on the market recently that block 99.9 per cent of potentially harmful particulates from being absorbed into the skin. Combining both methods only reduces the risk.

Doffing of the bunker gear should occur in an environment that doesn’t cross-contaminate fire apparatus interiors or clean gear. Contaminated bunker gear should be removed gently and placed in heavy-gauge plastic bags using a gloved hand. This gear should be transported to the fire station for machine cleaning.

A second set of clothing should be changed into for the ride back to the station. When and where practical, avoid wearing exposed fire gear in fire trucks.

Upon arrival at the fire station, a firefighter should complete some post-call activities that will reduce the exposure of hydrocarbons in the hall. Proper protective equipment should be worn, including such items as coveralls, gloves and N95 respirators.

Using exhaust extraction systems is a must. All equipment used at the fire hall should be removed from the truck, examined accordingly and properly cleaned with a soapy solvent solution to remove all contaminates. Hoses and nozzles should be washed, scrubbed and dried prior to reloading or returning to service.

The truck should be rinsed, scrubbed with a cleaner and washed off. The interior of any apparatus should be cleaned and items most often touched, like radios and computer screens,

should be wiped down with a disinfectant wipe. These areas contain heavy fire residue particles that have been known to linger for long periods of time after a fire. Venting of trucks by leaving doors and windows open after a fire is also recommended.

The personal kit should also be properly cleaned. This includes SCBA packs, bottles and helmets. Wipe your helmet down using a coarse paper towel, removing as much off the shell as possible. Remove the inner liner and place it with your balaclava for washing.

The SCBA harness and bottles should also be wiped down using a light spray cleaner and left to dry before being inspected and re-harnessed for duty

Once trucks have been returned to service, it is a good habit to change out of dirty clothing and take a long hot shower. Ideally, this happens at the fire station. However, in some smaller departments this can occur at home.

Showering thoroughly should include using scrub-type body shampoos with exfoliate properties to get a deep skin clean. Particular attention should be given to the neck, scalp/hair, underarms and neck. Anywhere that collects sweat is a potential absorption vector and should be washed.

Moist areas, like the nasal passages and eyes, should not be ignored. Nasal rinses can help clear congestion caused by smoke irritation. Be forewarned, it produces very black and ugly mucus. Eyes often require soothing eye drops, to simulate tears, and also help flush out any contaminates in the eye socket or tear duct.

Often the first physical indicator of a bad fire is a sore throat. Treatment to calm and clean the throats involves a simple mixture of warm water and salt for gurgling and spitting. Repeating this step is recommended.

Dirty clothing, either personal clothing or uniform items worn while fighting a fire, should be removed and washed in hot water with strong detergent. Specialized detergent for bunker gear is available and, although costly, is more effective in removing carcinogenic material from gear.

Wash your bunker gear. Dirty, sooty, blackened gear is no longer acceptable. Some departments allow the laundering of dirty clothes at the fire hall. This is the preferred option, as it is not advisable to ever take contaminated clothing home to be washed in the family laundry machine.

Firefighters, career or volunteer, should always have a second set of clothing stored at the hall for changing into. This includes clothing that is closest to the skin such as underwear and socks. Changing into fresh clothing after returning from a fire call is, not only advisable, but a good habit to get into.

Cleaning the truck and gear and changing into fresh clothes are all excellent ways to cleanse oneself after a call. Preventing toxins from entering the body should be as natural after a call as a debrief and firefighters should make it a priority. Remember, be an advocate for your health.

Kirk Hughes is the deputy fire chief of the M.D. of Taber Regional Fire Department in Alberta. A veteran of the Royal Canadian Mounted Police, Kirk has served with the Burlington, Ont., Portage la Prairie, Man., Deline, N.W.T., Fort Providence, N.W.T., and Behchoko, N.W.T., fire departments before taking a position with the M.D. of Taber as director of community safety. He can be reached at khughes@mdtaber.ab.ca.

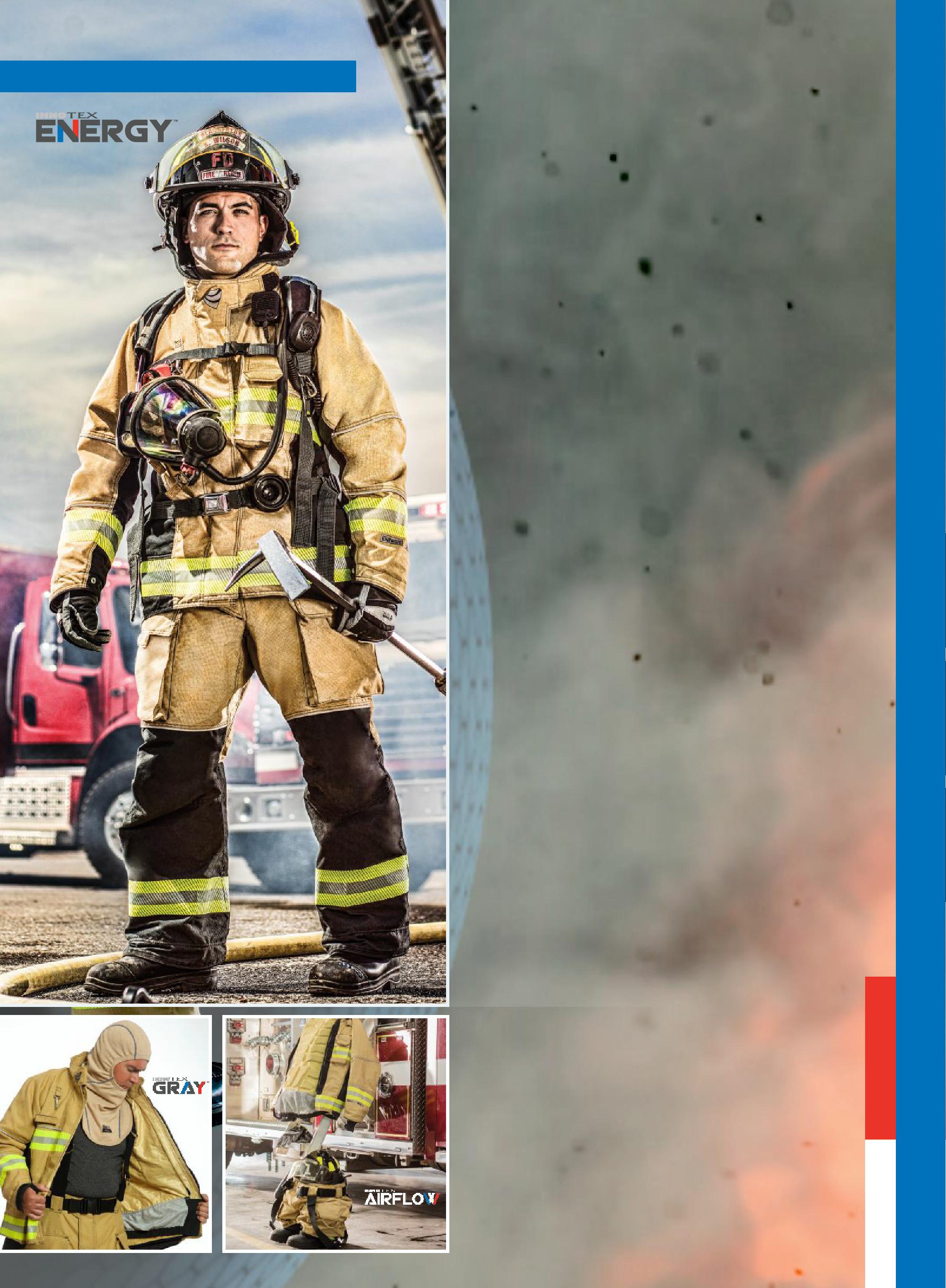

INNOTEX®: AT THE HEART OF INNOVATION

With nearly a dozen patent or patents pending to the company name, INNOTEX®’s general manager Claude Barbeau and his team have turned a passion for the firefighter health, safety and comfort into market leading technology.

FIREFIGHTER SAFETY FIRST

With the customer at its core, the team at INNOTEX® has made great strides in reducing a firefighter’s risk of developing cancer. This is best exemplified through its patent pending INNOTEX® GRAYTM line of particulate-blocking interfaces and hoods. The wristlet and sleeve well, storm band, pant closure and leg gaiter stop particulate from creeping in to the wearer’s jacket and pants at multiple touch points. The revolutionary particulate barrier technology blocks 99.9% of all particles as small as 0.1 to 1.0 microns, while its air permeability behaves as a filter reducing heat stress and keeping the firefighter comfortable.

DURABILITY AND COMFORT

INNOTEX® inspiration comes from many places, including sportswear and its own repair centre. When the company’s ENERGY™ Turnout Gear was being conceived, there were more than 75 points of performance up for improvement. The team goal was to design turnout gear that would optimize mobility, comfort and durability.

In noticing the high volume of cuff work happening at the repair facility, the team created the patent pending DuraHem sleeve hem. The ENERGY™ jacket and pant cuffs are designed with a rounded hem, instead of traditionally exposed stitching. The rounded hem edge is made of a polymer coated aramid that uses an internal piping to give it shape. The extra thickness of the piping puts the wear and tear on the cuff instead of the stitches. This is one of a number of traditional repair issues improved by ENERGY™ gear. No-Seam shoulders save wear and tear from the SCBA and improve mobility for the firefighter. Shifting the location of pant leg seams so they quit rubbing against one another keeps them in better shape. The bottom line for fire departments is money saved. The company estimates a 40%-60% savings on repairs versus traditional gear.

THINKING OUTSIDE-THE-BOX

Like many good inventors, the team looks outside the industry for ideas, and in this case, backpacking served as the inspiration for the one-of-a-kind AIRFLOW™ Padding System. “When you have a cheap backpack, with no gap between you, even if you wear a technical garment you are really going to sweat,” said Claude. Thus, the patented AIRFLOW™ system uses a perforated closed cell foam to create an air channel and 3-D cushioning between the SCBA and the firefighter. This allows for proper ventilation and superior comfort. The lightweight nature of INNOTEX® designs comes from decades of experience developing protective clothing for extreme sports. The company history dates back to its Canadian facility in 1889.

THE CORNERSTONES OF SUCCESS

All INNOTEX® designs adhere to the company’s four guiding principles: Protection without compromise, unmatched comfort, increased durability and efficient design. By adding imagination, the company has gone above and beyond.

“Through our innovative approach, over time, INNOTEX® has become the Canadian market leader for turnout gear. It couldn’t have happened without innovation.”

Air-permeable particulate-blocking interfaces

SHIELD YOURSELF AGAINST CONTAMINANTS

Risking your life to save others doesn’t mean you have to risk contamination from carcinogenic particles. INNOTEX® GRAY’s revolutionary particulate barrier technology acts as a filter, blocking 99.9% of all particles while allowing the unimpeded flow of clean air, thus reducing heat stress. Fight fire with INNOTEX® GRAYTM, and shield yourself from contaminants.

BUILT-IN PARTICULATE BARRIER

Blocks more than 99.9% of particles as small as 0.1 to 1.0 microns

AIR-PERMEABLE

Reduces the risk of heat stress

Maintains

WHAT’S IN YOUR POCKETS?

Firefighters should carry tools to help them on the job

by Mark van der Feyst

Every firefighter wears structural protective gear containing pockets on both the jacket and pants. The jacket will have a set of pockets with two side-pockets for the left and right hand – the other pockets are usually optional based upon department operations.

With these pockets available for us to use, the question we have to ask is, “What is in our pockets?”

Every firefighter will carry a variety of hand or personal tools in their pockets for many different tasks. Hopefully the tools they have are the ones they need.

A good rule of thumb to exercise each year is to inventory the tools you carry in your pockets to see which ones were used in the last year and which ones were not. Tools that were not used, remove them from your inventory and replace them with something different.

There are many firefighters who will overload themselves with personal tools, gadgets and trinkets, but carrying too many personal tools in your pockets can be overwhelming. Prudence is needed to whittle down the tools to what you really need. So, what are some good tools we should carry in our pockets?

The first item would be two sets of wire cutters – not one pair, but two. Each of the wire cutters should be placed in different locations for access. One set can be in the radio pocket on the jacket and the other set located in the opposing cargo pocket on the pants. This is for firefighter survival purposes. If you cannot reach one set perhaps you will be able to access the other.

The next item will be a length of webbing. The webbing should be a minimum of 10 feet in a closed loop. Webbing is a versatile tool that allows a firefighter to have options when it comes to things like dragging a person out of a residential structure fire, large area search, holding open doors on a car during auto extrication calls, dragging large-diameter hose when charged with water to remove kinks, etc. Roll up the webbing and place it inside a medical glove for easy storage and deployment.

The next item is a window punch. This will be used at all auto extrication calls. Whenever any extrication operation is mounted, the windows need to be removed. This will involve tempered glass and the window punch will be the perfect tool for the job. It is also small enough to fit inside the bottom of the coat pocket for easy access.

Along with the window punch, is the seatbelt cutter. Many times, the seatbelt cutter is stashed away in a toolbox requiring a person to look for it, but when it is carried in the coat pocket of a firefighter, it is readily available.

Two other items that are useful for the vehicle accident calls are the adjustable wrench and the socket wrench with a 10-millimetre-socket.

The battery terminals of most vehicles can be easily loosened using a 10-millimetre-socket. By doing this, the battery cables can be removed from the terminal and put back on if needed. The adjustable wrench can be used when you encounter the odd-size battery terminal nuts.

The next item is personal escape rope. This personal tool is to be kept in the right-side pant cargo pocket. If you are left-handed, then it will be kept on the left side. Personal escape rope is to be used when you are facing life and death and the only way out is to bail out of a window and descend to the ground.

There are systems that can be rigged up to an existing pant class 2 harness to make the bail-out system easier to use, or the basic system is wrapping the rope around your back and with two hands in the front holding onto the two ends, you roll out the window and descend to the ground. Of course, it has to be anchored to something in the room or on the structure.

The next item is a small straight screwdriver with a long shaft or neck. This small tool is useful for resetting pull stations at schools or other places. When an individual has pulled a pull station, it needs to be reset before the alarm panel can be reset – the screwdriver can hold down the tab as you push the pull tab back in place.

The last items are small nails wrapped with an elastic band. These nails can be used as door chocks to hold open doors. Place a nail between the door and the door hinge by positioning the one end on the hinge screw head and the other end against the door. Nails are smaller and easier to carry than wooden door chocks – for one door chock you can have 10 small nails.

Many firefighters will also have a personal kit bag that they carry with them on calls or in the fire truck they are assigned to for the day. This kit contains items you might need that can not be carried on your person everyday. In my personal kit bag, I carry the following: extra pairs of gloves; structural, auto ex and work gloves, an extra flash hood, two pairs of safety glasses; one pair clear and the other shaded, extra door wedges, extra winter hat, ear plugs, hose strap for high rise operations, naloxone kit. While this list is not an exhaustive or complete list, these are the items I have a need for on a day-to-day basis.

Your inventory will be different based on the types of calls you respond to, the climate and environment of your location and also personal preference.

Mark van der Feyst has been a member of the fire service since 1999 and is a full-time firefighter in Ontario. He teaches in Canada, U.S. and India, and is an FDIC instructor. He’s lead author of the Residential Fire Rescue book. Contact Mark at Mark@FireStarTraining.com.

FIGHT FIRE

WASH BUNKER GEAR

GEAR IN 48 HOURS DRY GEAR IN 1.5 HRS!

Introducing TG-Series Gear Dryers with 27% more airflow for faster drying. DRY GEAR FAST.

888-393-3379 | ramairgeardryer.com

Ram Air’s new TG-Series Gear Dryers have the same great quality you expect from Ram Air but feature a smaller footprint than their predecessors. Available in 4, 6 and 8-unit models with heated or ambient air, Ram Air TGSeries Gear Dryers safely and quickly dry all turnout gear and accessories including helmets, gloves, boots, face masks and SCBAs. The patented design uses powerful fans that push air through gear from the inside out—effectively drying the hard to reach areas and vapor barriers in gear that are prone to mold and mildew if not dried properly. With 27% more airflow than previous models, TG-Series Gear Dryers get you back to action in hours, not days.

Ram Air Gear Dryers are among the most structurally superior gear dryers available and as such feature an industry-leading 5-year warranty. All models align with gear manufacturer requirements and comply with NFPA 1851/FEMSA recommendations.

Sept. 28, 2019

Fire And Emergency Services Training Institute (FESTI) – Greater Toronto Airport Authority