Our expert service team ensures that your machinery is always at its peak performance, lifting your productivity and minimizing downtime with reliable, efficient support.

Lifting Your Productivity.

Prompt and Reliable Service

Preventive Maintenance Excellence

Expert Technicians and Original Parts

Customized Solutions and Support

The Trade Show Experience: Where Innovation Meets Opportunity.

Trade shows are not just about exhibitions; they are about seizing opportunities. We‘re excited to announce that Sturtz will be participating at the upcoming WINDOOR, November 13-14, 2024 , Palais des Congrès, Montréal, QC. - Join us at this event.

Fenestration Review 2024 Vol. 13 • Issue 2

Annex Business Media

P.O. Box 530, Simcoe, Ontario N3Y 4N5

Reader Service

Print and digital subscription inquires or changes, please contact Angelita Potal, Customer Service Rep.

Tel: (416) 510-5113 • Fax: (416) 510-6875

Email: sarul@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR | Patrick FLANNERY pflannery@annexbusinessmedia.com 226.931.0545

BRAND SALES

MANAGER |Leslie OSBORNE losborne@annexbusinessmedia.com 647.280.5885

ACCOUNT

COORDINATOR |Barb COMER bcomer@annexbusinessmedia.com 519.429.5171

MEDIA DESIGNER | Alison KEBA

AUDIENCE DEVELOPMENT MANAGER |Shawn ARUL sarul@annexbusinessmedia.com 416.510.5181

GROUP PUBLISHER | Danielle LABRIE dlabrie@annexbusinessmedia.com 226.931.0375

CEO | Scott JAMIESON sjamieson@annexbusinessmedia.com

Publication Mail Agreement #40065710. RETURN UNDELIVERABLE CANADIAN ADDRESS TO CIRCULATION DEPARTMENT, P.O. 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Printed in Canada, All rights reserved. Editorial material is copyrighted. Permission to reprint may be granted on request. ISSN 0843-7041

SUBSCRIPTION RATES

Canada - 1 Year $22.44 (plus applicable taxes)

U.S.A. - 1 Year $51.51 (in CDN dollars) Foreign – 1 Year $59.16 (in CDN dollars)

ANNEX PRIVACY OFFICER Privacy@annexbusinessmedia.com Tel: 800.668.2374

Occasionally, Fenestration Review will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

16 REGULATIONS ROUNDUP

10

NEW HORIZONS FOR NORTH STAR

A southwestern Ontario window manufacturer looks to level up with innovation.

18 HERE COMES GLASSBUILD

13 THE WINDOW GEEK

22 PHILIBUSTER Environmental groups are taking aim at plastics. by Phil Lewin 10 6 18

No fewer than four new regulatory regimes are being discussed for our industry.

4

EDITORIAL

The coming wave of regulation is concerning.

Here’s a look at what’s coming at the big Dallas show at the end of September.

14 FENESTRATION CANADA

Since you can’t know what isn’t in building code, you best find out what is. by Anton Van Dyk

15 FENESTRATION AND GLAZING INDUSTRY ALLIANCE

by Patrick Flannery

There’s a wave of new regulations on the way and we don’t have surfboards.

The industry conferences were a different experience this year. They were startling. It seemed that ever other session was discussing some new proposal for government intervention into our industry. And let’s just say that none of them seemed likely to help us make any more money. You can find a full explanation of the various new programs we heard about on page 16.

Adam Buist from NRCan told us about their latest project to develop a single harmonized label for window energy performance, resolving the various discrepancies between CSA, NFRC and Energy Star metrics. The labels wouldn’t certify compliance with any particular regime. They’d be like food labels – for information purposes only. However, they’d be required to appear on products shipped outside the province of manufacture. Until and unless individual provinces added them to their own code requirements, which one presumes would only be a matter of time.

Such labels could be a first step toward resolving the persistent enforcement problem of building inspectors not knowing whether the label they are looking at certifies a product as compliant in a particular installation. Making sure there is a label and getting rid of various labels listing different metrics would certainly help. But inspectors would still be challenged to read and interpret the numbers appearing on the One Label and decide whether they meet the criteria for the building as laid out by the provincial code and energy laws. We probably won’t approach the Promised Land of only compliant windows getting installed until it becomes a matter of the building plan calling for, say, a red label and the inspector only having to confirm the windows have red labels. Even if Buist’s program is implemented, there will still be a lot of steps between here and there.

Hysteria over plastics continues to roil the

minds of the environmentally conscious in Ottawa. The new federal Plastics Registry is alive and getting off Dr. Frankenstein’s table. It’s rotting hands will fasten themselves first around the neck of the single-use plastic packaging industry, but don’t worry, our turn will come. Your first hint that the monster has found you will be when you find yourself using all that spare time you don’t have to enter a whole bunch of information you don’t have into an online government portal that doesn’t work. Things will go downhill from there unless friends like Tony Vella at Vision are successful in dissuading the saviours of the planet from actually restricting the amount of plastic we are allowed to ship. Since PVC really has very little impact on the environment after it’s discarded, I suspect the whole initiative is really aimed at throttling the oil industry that provides our raw material.

PFAS reporting is being contemplated despite the trail of carnage such efforts have left and are leaving in the U.S. Apparently PFAS are inside us and are bad for us. Given we’ve been inundated with the stuff since at least the 1950s, I’m not sure why life expectancies keep going up but hey, what do I know. What I do know is that these chemicals are so ubiquitous in everything we make and use that any attempt to monitor or restrict them is going to result in a three-ring-circus of expensive futility where at least one or two clowns gets eaten by the lions.

Then there’s the looming spectre of embodied carbon reporting and restriction that may very well render the thousands every company has spent to develop very thermally efficient windows a waste. We’ve got to get off this product testing merry-go-round and just give each project a lifetime carbon budget and let the builders figure out how to hit it.

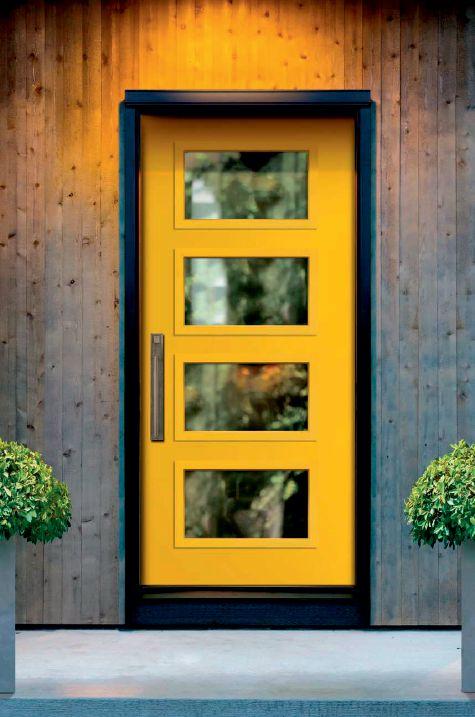

LIFT & SLIDE • FOLDING • ENTRANCE • TILT & TURN • CURTAIN WALL

With over 40 years of experience, our reputation in the fenestration industry continues to be at the top. Together with our European partners, Schüco and Reynaers, we push the limits of architectural design and engineering, in high performance windows and doors that stand up to North American conditions, meet Passive House, and Net Zero requirements.

Centra Windows and Centra Cares has announced the winners of their 2024 Home Renovation Contest. This year’s recipients, Tanya Trottier and her daughters Amelia and Elizabeth, were chosen from a pool of hundreds of nominees and have shown remarkable resilience in the face of personal loss and home-related challenges. Centra is honoured to award them with comprehensive, high-performance window and door upgrades that will greatly enhance their home and energy efficiency. Tanya Trottier’s life changed dramatically in 2018 with the sudden loss of her husband. Facing both disability and financial strain, she struggled with extensive water damage and a mishandled renovation project that left her home in disarray. Funds originally set aside for window replacement instead had to be used to repair the house, leaving her with serious issues in terms of home comfort. Built in 1959, Trottier’s home featured a mix of outdated windows, including rotting wood-framed ones that contributed to severe moisture build-up and drafts. Living near a busy port and under a flight path has further impacted the family’s comfort. The new, custom-made windows from Centra will

Mastergrain has announced the acquisition of Fibercraft Door Company based in Hanover, Ont. This strategic acquisition supports Mastergrain’s objective to lead the premium and luxury fiberglass door segment by integrating Fibercraft’s exceptional craftsmanship and innovative products. Fibercraft has pioneered large-format fibreglass pivot door systems and expanded its capabilities in the Canadian luxury door market. By integrating Fibercraft’s innovative products with Mastergrain’s offerings and distribution network, the companies hope to provide more choices to homeowners, builders, architects and designers across North America.

Chris Edwards, president of Mastergrain, expressed his enthusiasm. “We are thrilled to welcome Fibercraft into the Mastergrain family. This partnership enhances our manufacturing capabilities and instantly broadens our product offerings. Together, we will continue to develop and deliver doors with unparalleled quality and innovation to our customers.”

Bruce Schaus, president of Fibercraft, agreed. “Joining forces with Mastergrain opens new markets for Fibercraft’s products and accelerates our growth strategy. With Mastergrain’s support, we will innovate faster and more effectively, bringing our advanced fibreglass door systems to a broader North American market.”

Mastergrain and Fibercraft expressed their hope that the collaboration will drive more adoption of fibreglass entry door systems within the building products industry.

address these issues by improving energy efficiency, reducing noise, and boosting security. This marks Centra Cares’ sixth annual Home Renovation Contest.

“This contest really exemplifies who we are at Centra,” says CEO Garett Wall. “Our main driver as a company is to support families and our local communities. Seeing the difference these contests have made and all the effort our employee owners put in to help these deserving people is such a privilege and truly inspiring.”

Woodbridge, Ont.,-based Pro-Line Automation Systems, a manufacturer of machinery and automated manufacturing systems for U-PVC, aluminum and fiberglass fenestration products, has welcomed Ellis L. Dillen to the Pro-Line management staff as vice-president and chief operations officer. Starting in the industry in 1987 as a machine builder on the shop floor, Dillen quickly moved through the ranks holding leadership positions in service, sales and eventually as president and CEO of a well-known supplier of machinery from Europe.

“I have met many great people along the way that have helped me get to where I am today and through it all my philosophy has been to treat our customers right through service and support,” said Dillen. “A good salesperson can get the first order, but it’s the company’s dedication to servicing the customer that builds lasting relationships. I look forward to bringing this ideology to the new facility in Ohio.”

Vinode Ramnauth, president and CEO of Pro-Line, added, “I have known Ellis and his abilities for many years and I am happy that we were able to talk openly about our shared goals. In the end, I am extremely pleased that we were able to add Ellis to the team.”

The International Institute of Building Enclosure Consultants and Fenestration Canada have entered into a memorandum of understanding that extends IIBEC’s partnerships in the building enclosure industry while bolstering FenCan’s promotion, protection and advancement of the window, door and skylight industry across North America.

The MOU focuses on education, advocacy and collaboration on industry issues. Additionally, IIBEC and Fencan will make available speakers for each other’s conferences.

“We’re excited to establish yet another industry partnership that demonstrates IIBEC’s commitment to all six sides of the building,” said IIBEC executive vice-president and CEO, Brian Pallasch. “Fenestration Canada has shown its dedication to windows, doors and skylights, and we know our members will mutually benefit from working together more closely.”

“Our success in the fenestration field has been a major contributor to advancements in the building enclosure industry,” said Stephane Labelle, executive director of FenCan. “This MOU with IIBEC further raises FenCan’s profile while associating us with the best building enclosure experts in North America and around the globe.”

The Fenestration and Glazing Industry Alliance has updated a specification establishing performance requirements for fibre-reinforced thermoset profiles for use in fenestration products. AAMA 305-24, “Voluntary Specification for Fiber Reinforced Thermoset Profiles,” is now available for purchase in the FGIA online store. This document was last updated in 2022. Fenestration products made with fibrereinforced thermoset profiles that meet the requirements of this specification are expected to perform well in actual use, assuming adequate product design. The requirements include flexural strength, flexural modulus, water absorption, coefficient of thermal expansion, heat deflection temperature, weight tolerance, dimensions and lead content. These requirements define structural performance, physical requirements, weight and dimensional requirements and lead content to ensure that profiles do not contain lead over U.S. safety standards.

“The minimum performance requirements established in this specification are based on the experience and many years of research and testing by the fibreglass fenestration industry,” said Robb Plagemann of Marvin Composites, chair of the Fiber Reinforced Thermoset Profiles Update Task Group. “The fibreglass fenestration industry is comprised of resin, glass, additive and coating suppliers, profile manufacturers and fenestration fabricators and is represented by the Fiberglass Material Council of FGIA.”

This specification will assist architects, contractors, manufacturers, designers and owners in specifying fibrereinforced thermoset profiles for interior and exterior use in fenestration products, which may have to provide and maintain a standard level of weathering performance. This specification applies to profiles including the main frame, sash and all structural components related to glass retention and/or structurally divided lites.

Lindsay McGhie, marketing manager at Centennial Windows and Doors in London, Ont., was given Fenestration Canada’s President’s Award at the President’s Dinner at the Spring Conference in Kananaskis, Alta., on June 3. The President’s Award honours a member who has made an outstanding contribution to the association and the industry. The recipient must be an active volunteer on a committee and/or task group, contribute to Fenestration Canada’s goals and participate in Fenestration Canada and related industry events and meetings. The recipient also exemplifies the principles of professionalism and volunteerism by giving freely of their time and expertise in interest of the industry. McGhie has worked at Centennial for 12 years.

“She dedicates time to being the co-chair of our events committee and is always involved and participating in our events,” FenCan operations manger, Laine Atkins, reports. “She is also very professional, easy to get a hold of and willing to put in the work.”

“I’m incredibly honoured to be recognized by our current president, Cam Drew,” McGhie commented. “I place a lot of pride in the work I do while I represent Centennial with Fenestration Canada and it’s a great feeling to know my work is appreciated.”

A southwestern Ontario window manufacturer is pushing the envelope of what’s possible.

Already a popular and widespread brand, especially in southern Ontario, St. Thomas, Ont.,’s North Star Windows and Doors is taking a next step into groundbreaking innovation.

by PATRICK FLANNERY

LEFT: From left, Richard Krall, Sheldon Dyck and Glenn Schmitchen run the show at North Star’s St. Thomas location and are determined to take it to new heights.

RIGHT: Here’s the secret sauce that makes UltraStar reinforced profiles. Now that you’ve seen it, we’re going to have to shoot you.

Now into the sixth year of its absorption into Cornerstone Building Brands – a huge North American construction materials conglomerate – North Star is leveraging the deep pockets and bullish approach of its parent to invest heavily in processes and R&D. The work is bearing fruit. Under the guidance of director of operations, Sheldon Dyck; director of industrial engineering, Glenn Schmitchen; and plant manager, Richard Krall, North Star has imported customengineered European co-extrusion technology to produce window profiles incorporating a proprietary vinyl reinforcement technology they call UltraStar. That’s on the heels of its 2023 launch of the Sentinel fibreglass swing door featuring a unique welded frame construction. North Star has pushed boundaries in the areas of quality and efficiency since its 1985

founding by energetic London, Ont., entrepreneur, Peter Banman, growing from a 30-person shop in a 10,000-square-foot industrial unit to today’s 220,000-square-foot window manufacturing facility in St. Thomas backed by an 80,000-square-foot door manufacturing plant in Woodbridge, Ont., employing 450 workers. Now the company is looking at new goals and new horizons that may push the boundaries of the window manufacturing industry generally.

North Star’s sprawling St. Thomas facility has been the recipient of over $30 million in technology investment over the last five years. There are seven extrusion lines running 24/5 producing around 12 million pounds of vinyl profile per year. Two lamination lines do film bonding. A Forel insulating glass line installed in 2022 doubled production to an average 425 IG units per

shift, with capability for triple-IG and odd shapes. The Hegla cutting line, installed in 2020, runs on magnetic ways cutting 200 sheets per shift – an 80 percent increase over North Star’s previous cutting capacity. A newer Sturtz fabrication saw also takes care of all slots, routing and dimpling, making 250 units per shift. Sash assemblers are assisted by custom Armo software developed in-house to show the correct position of parts for all assemblies with lights indicating which bin the next needed part is in. Workers installing balances are assisted by laser lines to position the hardware properly in the assembly fixture. Ubiquitous lifting devices ensure no one lifts a patio door frame alone. Video screens at each process line display real-time production metrics. Krall says everyone watches them and finds them motivating.

But the star of the show at the moment is the UltraStar co-extrusion line built

by Austrian manufacturer, Exelliq. It’s making vinyl profiles co-extruded with a proprietary PVC and fibreglass hybrid material that adds two main benefits: structural strength and resistance to thermal distortion. The UltraStar profiles have almost twice the tensile strength of normal PVC and are over five times stiffer while only being 0.4 grams per cubic centimetre denser. Its thermal

conductivity is higher than PVC – 0.254 watts per meter-kelvin compared to 0.1 – but the coefficient of thermal expansion is eyebrow-raising at less than a third of what PVC is and one-seventh of the allowable under ASTM. North Star says they’ve tested it up to 82 C without detectable moving, shrinking or warping. All very useful, obviously, when building today’s oversized windows. Schmitchen

is also enthusiastic about the possibilities for longevity in Canada’s variable climate and stability with heavy triple-IG glazing.

Schmitchen explains the genesis of the UltaStar project was an attempt to improve the structural stability of vinyl frames without using metal reinforcement. That was a three-year journey, involving daily phone calls to Austria to the machinery builder and finally a trip over for a team of six to approve the process and learn how to use the equipment. Then it was time to commit $1.5 million to bring the project to actuality over here. For that, ironclad intellectual property agreements needed to be put in place. North Star has a five-year exclusivity deal with Exelliq.

Having gotten the co-extruder running and making some window samples, it was time for testing, testing, testing. “Seemed to go pretty well,” Schmitchen remembers. “A few little challenges in there. But we thought we’d get that worked out. And then Rich [Krall] said, ‘Enough. We’ve got to set a day when we’re going to start selling this.’ Because you know if you left it to the engineer this would go on forever.” UltraStar debuted on the market in March of this year.

Dyck has been with North Star long enough to know that this commitment to innovation comes from its roots. He started as a draftsman at Banman’s Hargrieve Road shop in 1989, but there wasn’t enough work for a full-time draftsman so he did shipping and receiving in the afternoons. In those days, Banman was doing predominantly sunroom systems as well as shutters, eavestrough, siding and whatever else the customer wanted. They were buying windows from DM. Showing a pattern of behaviour that would come to define North Star, Banman became dissatisfied with relying on a third party for his window supply and began manufacturing his own under the name Canadian Replacement Windows. “In the early ‘90s we started the process of learning to extrude,” Dyck remembers. “We didn’t bring in any experts – we learned it ourselves. They weren’t technically engineers but they had that engineering mindset and a desire to learn.” Banman’s

brother, Jake, was one of the innovators working in a “secret” lab to figure out extrusion processes for then-CRW. It had to remain secret because Banman suspected his extrusion supplier at the time would not have reacted well to finding out he was developing his own system.

“It’s always been that way,” Dyck reflects. “We looked at grid bars and people wanted a contour grill. We didn’t offer it. So we just said ‘OK, how do we do this?’ We can buy roll form or do it ourselves with mullions. Let’s just do it ourselves. Screens. We were struggling with quality and performance from our patio door screen supplier. OK, let’s just design this thing and do it ourselves. That’s just the way we are. It’s cultural.”

North Star became part of Cornerstone Building Brands as the end point of a merry-go-round of mergers and acquisitions over the last decade. Banman sold the company to Atrium in 2007. In 2018, Atrium was acquired by Ply Gem’s venture capital owner and the two manufacturers merged, though North Star’s operations and products remained largely independent. Later that same year, the owners acquired NCI Building Systems, a larger manufacturer of many exterior construction products, and merged them again to form Cornerstone Building Brands. Having journeyed through it all,

Dyck says there are pros and cons to both small independent companies and large corporations.

“When you’re working for a familyowned business, it’s a lot more hands-on and a lot more interaction with your direct manager,” Dyck muses. “We were in the same building and everything was there so we could talk more frequently. Had a little bit more sway in the direction because we were able to set our own strategy. As far as sales and operations, we were more nimble for sure because we were smaller. But that goes to a limited scope because you have less money.”

Dyck reflects on how difficult it would have been to survive COVID in a smaller company. As part of Cornerstone, North Star was always at the top of the glass suppliers’ allocation lists during the postCOVID shortages. And, “I don’t think we’ve ever been told ‘no’ whenever we’ve gone for a capital request,” Dyck says.”

North Star ships about 300,000 units per year across North America generating $130 million in revenue. Canada and the northern U.S. states are its best markets. Dyck says the strongest growth recently has been in the American upper midwest.

After years of climbing the innovation hill, North Star has crested a peak where it can see a farther horizon than ever before.

by Anton Van Dyk

Make a plan rather than finding out the hard way.

Afew years ago, I got into a debate regarding the distance a window can be from the floor before it has to be tempered. This debate went back and forth about who was right and who was wrong and then it occurred to me: let’s look it up in the code!

Would you believe it, I could not find anything. Then I realized how hard it is to find something that might not exist in a book as thick as the building code. It turns out, there is nothing in the code that specifically requires a window to be tempered based on its proximity to the floor. There are safety glass requirements for door glass, but this can also be laminated glass and not necessarily tempered glass. There are requirements to design a window to meet guard load, but nothing prescriptive requires tempered glass.

Then, I was told, it was in older codes. So instead of arguing about this, I was able to look up codes that went back to the ‘80s. I searched the sections that I figured were relevant and nothing stood out as an obvious link to the distance a window can be to the floor before it needs to be tempered glass.

Is this one of those things that just evolves over time? Someone, somewhere (likely from a place of authority) made a comment that it is required and so then it was done. As time went on, it just became the norm. Let’s face it, to find out something does not exist in the code is hard to do unless you read the whole code book. It was at this point in my career that I realized reading the code from front to back when most others don’t will give me an advantage in any situation.

So, is your product code compliant? How do you know if it is or not? Do you leave it up to a building official? One of those tried to tell me that glass within eight inches from the floor had to be tempered. I recommend taking control and knowing if your product is code-compliant.

I have found that many window products are a few tests short of being compliant. With NAFS and NFRC becoming more and more important

due to higher awareness of efficiency and durability, we may not have that luxury for much longer. You hire an accountant to do your tax planning – what do you do to determine if you are codecompliant? Step one of this is to audit your current compliance strategy. Don’t worry if you don’t have one. Most manufacturers see compliance as a line in the sand to cross, not as a strategy for your business. But think about what an accountant does to help you strategize your tax plan at the start of the year. By doing this, you can strategically reduce your tax burden over the year and optimize your returns.

Once you have audited all your existing compliance documents, you can now align it with the current code requirements and highlight the gaps that exist. Remember, not all gaps need to be filled. This is because a compliance strategy needs to align with your overall business strategy. There is no point in filling in compliance gaps for a market you are not planning to sell into. A good example of this is Passive House windows. Do you need one, or do you just need a window that has a really low U-value? Some manufacturers do because that’s their market, while others do not.

Once you have identified all the gaps, a work plan can be put into place over the course of a year or two to test, simulate and engineer solutions as you grow your business. This allows you to spread out your compliance costs over time and will help reduce your overhead. This strategy works well when combined with a sales and marketing strategy that empowers sales teams to tackle a market in a way that contributes to your brand and strengthens your overall market impact. So, are you wondering where to start? Step one is a simple audit of your current compliance documents. Step two, align them with the code. And step three, develop a long term plan that matches your growth plan.

Anton Van Dyk is a fenestration consultant at Layton Engineering.

The Spring Conference was great; WinDoor is going to be even better.

WinDoor 2024 is coming up and is on track to be a sold-out show. This year’s event will take place on Nov. 13 and 14 at the Palais des Congres in Montreal. We are looking forward to another wonderful experience with a great lineup of education, exhibits and networking events. Registration is open and we look forward to welcoming you soon to Montreal again.

This year’s education sessions will include presentations on Environmental Product Declarations and Life Cycle Assessments preparing for embodied carbon regulations, presented by Half Climate Design. Manufacturing facility energy systems will be the topic in our technology business session presented by Enerprox. JSA Machinerie will discuss automating the vinyl fabrication production floor. WSP will offer a commercial session discussing a case study on a commercial facade retrofit in Montreal. As usual, we will host our Manufacturers Council and Technical Committees including an update from NRCan and Energy Star. Other sessions will be announced soon.

The show floor hours have been extended again this year to meet the demand for more time to walk the floor and experience exhibitor booths. The floor opens on Nov. 13 from 9:00 to 4:00 and Nov.14 from 10:00 to 3:00.

We are excited to announce this year’s VP’s Auction Event, our bi-annual event raising money for the Fenestration Canada Scholarship fund. Join us this year as we cruise Montreal’s Harbour on the AML Cruise line. The event takes place on Nov. 13 after the first day of the show and your ticket includes a live auction, dinner and dancing. Boarding time is 6:00 with a

7:00 departure. Tickets for this event are limited. Tickets for WinDoor and the VP’s Auction can be purchased at windoorshow.ca.

Coming off a strong Spring Conference in late May, we want to keep the momentum going to create more exciting and educational events in the future, which is why we have already visited our 2025 location! In case you missed it, we had one of our most successful Spring Conferences in years on May 28 through 31 in Kananaskis, a beautiful scenic area of Alberta which welcomed us with its hospitality and nature. Energy was high as we kicked off the event with our President’s Dinner honouring this year’s recipient, Lindsay McGhie of Centennial Windows for a much-deserved honour. The conference continued with two days of education sessions, supplier showcases and networking events. We enjoyed an evening at Boundary Ranch which included carriage rides and the presentation of the MVP which was done a bit differently this year. Our Commodore, Greg Dickie, presented the recognition which ended in a tie breaking event we called the Kananaskis Derby that ultimately lead to Martin St-Arnaud receiving the winner’s belt. The event ended with a day of golf at the beautiful Kananaskis Country Golf Course where many golfers encountered wildlife during their day. All of our sessions are posted on our YouTube Channel – just search for Fenestration Canada. We look forward to welcoming you to Halifax in 2025 and planning is already underway for a great conference. In the meantime, we can’t wait to connect with our members and non-members at WinDoor. More information can be found at fenestrationcanada.ca or by reaching out to us directly at info@fenestrationcanada.ca.

A significant new reporting requirement is coming to our businesses.

by Amy Roberts

Launched in April, the Federal Plastics Registry obligates manufacturers to mandatorily report each year on the quantity and types of plastic they place on the Canadian market and how that plastic moves through the economy. It’s important to note that producers are responsible for reporting on plastics volumes even through the materials’ end of life, not just through the point of sale, which is challenging. Windows, doors, and skylights last for decades. Most fenestration manufacturers do not have traceability systems that can help determine what happens to their products post-sale. Companies need substantial resources and time to successfully design, test and implement systems that can track plastics throughout their life cycle. This was one of the concerns FGIA raised in joint letter along with the AVFQ and Jeld-Wen of Canada in response to a feedback request from Environment and Climate Change Canada earlier this year.

Window and door manufacturers, along with manufacturers of many other plastic products, are mandated to report the quantities of plastics they place on the Canadian market annually. Additionally, producers must report on the type and source of resin in the plastics. The government has identified 23 types of resin per the North American Product Classification System that need to be reported. Resin can be virgin fossil- or biobased conventional resin, post-consumer recycled resin, or post-industrial recycled resin. When it comes to packaging, producers must report on rigid and flexible packaging as well as unfilled (for instance, pallet wrap) and filled packaging (for example, a shrink-wrapped window) destined for primary, secondary and tertiary packaging.

Reporting will be required on the three waste streams of construction, renovation and demolition at residential and industrial, commercial and institutional facilities.

Producers, waste generators and service providers are obligated to provide information. A producer is a Canadian resident who is the brand owner or IP holder. If the brand owner is not a Canadian resident, then the first resident to manufacture or import a plastic product into Canada is considered as producer. If that person is not a Canadian resident, then the Canadian retailer who supplies the product to the consumer is deemed as producer. Entities sending plastic waste and plastic-containing packaging waste for disposal or diversion from their ICI facilities are also obligated to report. For example, a window fabricator removing pallet wrap from a pallet and sending it for landfill in Markham, Ont., would need to report.

According to ECCC, an entity is exempt from reporting if they manufacture, import, or place on the market less than 1,000 kilograms of plastic products or packaging per calendar year and generate less than 1,000 kilograms of packaging and plastic product waste at their ICI facility per calendar year.

Reporting will be phased in over time and by sector. By 2026, reporting requirements for resin manufacturers and importers will be added, as well as reporting on plastic placed on the market for the remaining categories destined for the residential waste stream.

ECCC is preparing a guidance document to help companies fulfil their reporting requirements for Phase One. It is also developing a new platform that’ll be designed to handle bulk uploads of data to reduce the administrative burden of reporting. User testing of the IT system is expected to take place in September-October. FGIA will be closely monitoring and sharing updates as they become available.

Amy Roberts is FGIA’s director of Canadian and technical glass operations.

After attending the industry conferences in the first half of this year, we’re counting no fewer than four new areas of regulation that Ottawa is either considering or actively implementing that will impact the window and door industry.

by PATRICK FLANNERY

Adam Buist, a standards engineer from Natural Resources Canada, told Fenestration Canada’s Spring Conference in Kananaskis, Alta., that his department is conducting an industry preconsultation on a proposal for a new federal labeling regime for windows. The idea is that window products, by 2028, would be required under the federal Energy Efficiency Act to display a standardized label replacing Energy Star and/or NFRC labels in order to be shipped across provincial or national borders. The labels would show energy performance information about the product using metrics harmonized between CSA, Energy Star and NFRC. The labeling requirement would apply to products regardless of their use in commercial or residential construction, however the proposed product definition would

Concern about the buildup of plastics waste in the environment is reaching new

levels.

normally apply to products used in Part 9 residential builds. Importantly, the labels would not require any kind of minimum performance standard or necessarily indicate compliance with any standards program (though consideration is being given to having the labels display certification logos if the products qualify) – they are for information purposes only. The labels would likely be used to indicate eligibility for future federal rebate programs. Since the labels would be required under the federal Energy Act, they would only be required for products shipped across provincial borders or exported to other countries – products produced and sold in the same province would not need to display the labels unless the province itself required it. Buist mentioned that the goal would be to build a database taking data from all the existing certification programs so manufacturers were not forced to report performance data multiple times in multiple ways to multiple different agencies. He also said it is likely the labels will not use Energy Star’s Energy Rating (ER) metric as a required item, though manufacturers may be able to display it if they wish. Buist also addressed the Fenestration and Glazing Industry Alliance Summer Conference in Montreal later that week with the same message.

Questions from the audience after Buist’s presentation focused mainly on the problem of enforcement. Manufacturers are frustrated with

additional layers of red tape that legitimate businesses make efforts to comply with only to be undercut by shady operators providing product without accountability for their performance. Buist emphasized that his department does have a mandate to enforce compliance with the Energy Act and compliance officers on staff to do so. However he admitted that they obviously do not have the resources to police all projects. The immediate plan seems to be to rely heavily on the concept that everyone – homeowners, building inspectors, builders – will come to expect the labels to be present and avoid buying unlabeled products.

The Federal Plastics Registry became a real thing in April of this year. Find a full explanation of it from the Fenestration and Glazing Alliance’s Amy Roberts on page 15.

Peter Mirtchev of the Chemical Industry Association of Canada told the FGIA about his members’ concerns with the registry at the Summer Conference in Montreal. In general, at this point, the registry is simply an attempt to gather information about plastic flows to the market and ultimately the environment. However the very broad and all-encompassing nature of the program creates several potential problems for reporting companies. “You can imagine how difficult it must be for, say, a brand owner to know how many pieces of plastic are in a dishwasher,” Mirtchev said. “There are hundreds of different pieces there. I mean, it’s almost impossible. This is the first time that anyone in the world has tried to collect this kind of information.

Mirtchev pointed to the many vectors of information the registry will demand: the type, quantity and source of all the plastics and the quantity of plastic collected at the end of its life, except for diversion, and whether it’s recycled, processed into chemicals, landfilled, incinerated or repaired, remanufactured or reused. “Basically, the takeaway here is they are throwing everything against the wall and just trying to see what kind of data they can get,” Mirtchev explained.

“Usually, when you have such poorly defined data asked for, you are going to get poor data back.” Duplication is a major threat in the registry’s system. “A resin manufacturer might know the identity and source of all the resins they use, but will their customer down the supply chain have that same information and will they have to report it? These are good questions we don’t have an answer to right now.”

Vancouver is already asking owners to report the embodied carbon in their projects and proposals are in place to put embodied carbon reporting in the 2025 National Building Code. This requires collecting data from far and wide to make environmental product declarations. Both the FenCan and FGIA conferences had excellent presentations on the topic by Phil Northcott of C-Change and Kayla Natividad of Pilkington, respectively. Northcott warned that window manufacturers need to obtain EPDs from their suppliers, pronto, and get to work using them to develop their own for their products. He’s developed a software tool to make finding and generating them easier, and the industry is going to need it because we probably won’t be able to deliver a window without one by 2030.

PFAS is the acronym for per- and polyfluoroalkyl substances. These are a massive category of thousands of different synthetic chemicals that are useful for imparting non-stick and grease- and water-repellent characteristics to materials. The most famous example is Teflon. Almost every artificial object around us has PFAS in it somewhere: most plastics, textiles, electronics, drugs, cosmetics and vehicles, to name just a few.

Another characteristic of PFAS is that their chemical bonds are extremely strong and they effectively never break down once synthesized. This causes them to build up in the environment and organic tissues over time. Studies have found correlations between high levels of PFAS exposure and a variety of illnesses,

though the links are not proven.

Canada banned the use and importation of many of the older and more dangerous forms of PFAS in 2006 and 2012. This year, Ottawa designated all PFAS as toxic chemicals, making them eligible for monitoring and regulation by public health authorities. Subsequent notices say the Ministry of Environment and Climate Change is not contemplating a regime of reporting or restriction but may explore a labelling regime detailing the levels of PFAS in products.

Attempts to regulate PFAS have had a bad track record, Jacob Carter of the Window and Door Manufacturer’s Association told attendees at Fenestration Canada’s Spring Conference. An Environmental Protection Agency demand to test farm runoff for PFAS resulted in many farms being shut down in Maine in 2019, which snowballed into demands from the state government for manufacturers to track and report all the PFAS their products use. The ubiquitousness of PFAS in everything makes this effectively impossible and the state was forced to climb down and offer numerous exemptions and delays. Minnesota got in on the act with requirements to report PFAS in a broad range of products and says all manufacturers will have to report by 2032. 3M has been sued for over $10 billion for groundwater contamination in Minnesota and has announced it will cease all production of PFAS chemicals by 2026, which will affect about 25,000 of their products. Carter pointed out that even if Minnesota and many other states stick with their proposed PFAS bans, the country certainly lacks the lab capacity to do all the testing the tracking would require.

Many of the above measures are only proposals that the various Ministries and agencies are gathering feedback and research on. However, the cumulative effect if they all were to be implemented would be a crushing imposition of red tape on the industry. “If they go forward with all this stuff, there won’t be a single window and door manufacturer left in Canada,” Mike Bruno, president of Everlast, told the Spring Conference.

Here’s a quick preview of what’s planned at North America’s largest fenestration and glazing show.

GlassBuild takes place Sept. 30 through Oct. 2 in Dallas this year.

The Main Stage will host three days of learning, networking and industry celebration, centrally located on the trade show floor.

by PATRICK FLANNERY

The Women in Glass and Fenestration Keynote and Networking Breakfast takes place Oct. 2. This event is always wildly popular.

Main Stage sessions are open to all GlassBuild America attendees. The programming is presented by the National Glass Association and sponsored by NGA’s myglassclass.com, Glass Magazine and Window + Door magazine.

Blueprint for Collaboration

The NGA brings glass and glazing education directly to architects on Sept. 30. Architects are invited to the show floor for a day of AIAaccredited programming, including a keynote lunch-and-learn.

Day two at the main stage addresses companies’ biggest challenge: labour. Specifically, finding, training, keeping and protecting employees. Main Stage content will provide business owners with take-home strategies to address the ongoing workforce hurdles.

Main Stage will be a place for industry to come together to network and connect. Opportunities include the third annual Women in Glass and Fenestration Keynote and Networking Breakfast taking place on Oct. 2, and the Glass Magazine Awards reception.

Fenestration focus

The Main Stage highlights need-to-know content for the residential window and door community. Sessions include the latest from the Window and Door Market Survey, present by Chris Beard, director of building products research for John Burns Research and Consulting.

Date: Sept. 30 - Oct. 2

Location: Dallas, Texas

Venue: Kay Bailey Hutchison Convention Center

Exhibitors: 500

Attendees: 9,000

Admission: $105 USD (non-NGA members)

Glazing Executives Forum: $475 (non-NGA members)

Show site: glassbuildamerica.com

The Main Stage will host must-attend talks from speakers such as Connor Lokar, senior forecaster for ITR Economics; and Emily Pilloton-Lam, designer, builder, educator, author and founder and executive director of the nonprofit Girls Garage.

Forward-looking sessions with expert economists evaluating the path of the market ahead.

The Architectural Glass and Metal Certification Council will host its handson certification testing program for experienced glazing supervisors and technicians, live on the show floor. This marks the first time AGMT testing will occur in a public forum, with the opportunity for the glazing community to witness the testing process

AREA MAX. SIZE (in) MIN. SIZE (in) MAX. LOAD COMMENTS

CUTTING 130 X 204 4 X 15 750 lbs

FABRICATION 50 X 175 5 X 15 750 lbs

TEMPERING 126 X 200 4 X 15 1000 lbs

HEATSOAK 84 X 120 4 X 15 300 lbs

PAINT 82 X 180 4 X 15 750 lbs

Thickness - 3mm to 19mm Max. Long Polish 175” Max. Daigonal 160” Over the max size can be reviewed

Thickness - 4mm to 19mm

Over the max size can be reviewed Process meets ASTM C1048 and ANSI Z97.1

Over the max size can be reviewed Process in accordance to EN-14179-1

Rollcoat Spandrel (Opacicoat and Ceramic Frit)

98 X 177 4 X 15 750 lbs Silk Screeen and Digital Printer Ceramic Frit

LAMINATION 96

This premier event on Sept. 30 is an opportunity for glazing contractors to learn, network and tackle industry challenges. The program includes:

• Exclusive Construction Forecast: Insights from keynote speaker Connor Lokar, senior forecaster for ITR Economics

• Spotlight on Business Management for Glaziers: Sessions on risk management, estimating best practices and leveraging technology for marketing and recruitment

• New Workshop Tracks: Focused groups on AI, shower enclosures and effective recruitment strategies

• Networking Opportunities: Beer break and group lunch

• NGA Installing Committee Meeting: Hear about committee activities and opportunities to get involved, plus NGA initiatives for contract glaziers and full-service glass companies

BUSINESS PARTNERS

CERTIFICATIONS/STANDARDS

Here’s a look at what you can expect to see at GlassBuild 2024

8 ultrafab.com

Ultrafab embraces the current trend of black windows and doors by offering their topperforming sealing products in black. Its wide range of products not only caters to the popular choice of black but also provides colour matching for all standard industry colours across their sealing solutions, creating a comprehensive sealing system for fenestration products. Window manufacturers can

stay on-trend with Ultrafab’s seals, featured on the AAMA/ FGIA Class A verified components list, now available in black to seamlessly complement modern esthetics in

both residential and commercial settings with their precise design. Furthermore, Ultrafab achieves harmony with its black seals and Roto’s black hardware, completing the overall look. Together, Ultrafab and Roto offer a holistic solution for windows and doors, enhancing product longevity and ensuring a seamless match with any desired esthetic.

8 nucoat.com

NuCoat is set to make a substantial impact at GlassBuild America 2024 with the NuCoat VL 24 Series coatings, a product line designed for superior quality and performance. Meeting the stringent AAMA 615-20 standard for PVC/vinyl, the VL 24 Series ensures exceptional durability and long-term reliability. Designed for efficiency, these coatings provide full coverage in a single application, simplifying processes and reducing costs.

The NuCoat Edge represents NuCoat’s commitment to offering versatile, technologydriven solutions that cater

to businesses of all sizes. Whether it’s a small-scale operation or a large manufacturer, NuCoat offers tailored solutions that integrate seamlessly into existing workflows. NuCoat’s technology solutions are designed for both manual and automated applications, providing flexibility to choose what works best for each operation. For those looking to enhance efficiency, automated systems deliver consistency and speed, while userfriendly manual applications ensure professional results with minimal training. This versatility is central to the NuCoat Edge, helping clients achieve superior outcomes regardless of scale or expertise. Additionally, NuCoat’s commitment to sustainability is evident in its low-VOC, ecofriendly formulations. These environmentally conscious solutions align with the growing demand for sustainable practices without compromising performance.

8 salemftg.com

Salem Fabrication Supplies will display the Winlet 915 glass manipulator at GlassBuild 2024. This advanced, off-road glass manipulator is engineered for challenging indoor and outdoor installations. The 915 combines great stability, precision and extra reach, making it an ideal choice for the glass and glazing industry. This machine has a maximum lifting height of 11 feet, four inches and can lift up to 915 pounds. It features electromagnetic brakes and powerful front wheel drive, providing optimal traction and stability. The 915 also features horizontal hydraulic side-shift

controlled from the front – essential for flush and pocket glazing applications, ensuring accuracy and consistency. This glass manipulator ensures operational safety through an intelligent overload monitoring system, a reliable two-circuit vacuum system and a dual button safety release. The Winlet 915 stands out as a reliable and efficient glass handling solution, combining high lifting capacity, precise control, and robust design.

8 roto-frank.com

The Roto DuoTilt hung window lock system is a versatile and innovative solution designed to enhance the functionality and security of

hung windows. Available in two styles, this system offers three sash lock actions: lock, unlock, and tilt, with a hidden tilt latch function for added convenience. Constructed with durable zinc alloy components, the DuoTilt system ensures durability and longevity for any vinyl profile. Its user-friendly design allows for dual actuation of the lock and tilt latch, simplifying the process of securing and adjusting the window. Visual sash lock markings clearly indicate the window’s status – locked, unlocked, or tilted –providing peace of mind and

ease of use. Additionally, the tactile lever feedback offers a physical indication when the lock changes position, enhancing the overall user experience. Installation is straightforward, thanks to the pre-assembled tilt latch and connector, which facilitate easy connection to the sash lock. The system has undergone rigorous internal testing, surpassing 10,000 cycles, and has been FER tested to ASTM F588-17 standards up to grade 40, ensuring reliability and performance. The DuoTilt system features a patent-pending design and is available in eight different finishes, allowing for customization to match various esthetic preferences. Passive sash locks are also available in the same finishes, providing a cohesive look for any window installation.

by Phil Lewin

Dark clouds are growing over the use and disposal of plastics. “

Ihave one word for you. Just one word... plastics.”

That’s advice given to Dustin Hoffman’s character, Benjamin, in the movie, The Graduate From an economic and career point of view, it was pretty good. I should know as I have spent most of my career in fenestration with companies making PVC windows. These days, plastic is everywhere. Frighteningly, that “everywhere” includes microplastics that have infiltrated our bodies and even our brains.

Full disclosure: I am not only someone who has profited from PVC, but also a user. The PVC windows in my home are at least 35 years old and, contrary to a window company’s anti-vinyl advertisement I keep seeing on TV, they look as good as they did when they were new. However, I do believe that, as a society, we have gone plastic-crazy.

According to Karen Wirsig of Environmental Defense Canada, “Escalating plastic production has detrimental effects, not only on the environment but also on our health and communities. Scientists are increasingly connecting plastics and the chemicals they’re made from (primarily petroleum – oil and gas!) to health issues, including cancers, infertility and heart disease. Sadly, communities nearest to plastic production and waste facilities bear the brunt – including marginalized and Indigenous communities.”

Another organization is called Toxic Free Future. It describes itself as a national leader in environmental health research and advocacy. On their website they lobby for, among other things, the elimination of many vinyl products.

Recycling PVC from siding and windows is not new. I remember being at an Ideas show in Montreal and standing with Raymond Dallaire, a founder of PH Tech, as we watched a hopper being filled with scrap from other booths

and out the other end came plastic patio chairs. (It was a big machine!). In the effort to keep rigid PVC out of landfills and recycle to lower the need for initial production of resin, there are companies starting to emerge. In Virginia, a company called Revinylize is active in this arena. Their website blurb reads, “The Revinylize Recycling Collaborative is a recycling initiative that includes dedicated installers, recyclers, collection sites (i.e. distributors and landfills) and many other advocates, in partnership with the Vinyl Siding Institute (VSI) and verified by GreenCircle Certified.” I tested out their website’s search for a local recycler and did find a Toronto listing.

So, what is GreenCircle? Per its website, “GreenCircle will certify your organization’s claim for carbon footprint reduction based on a detailed analysis of your operations, energy consumption, energy efficiency improvements, renewable energy use and greenhouse gas emissions.”

No surprise that there are groups such as Environmental Defense Canada lobbying for society to move away from plastics and commercial users of plastics trying to respond to historical issues with a new, progressive tone and hopefully real solutions. The Vinyl Institute of Canada’s web site describes a chemical management plan task force comprised of senior regulatory experts from within the vinyl industry in North America. Sounds like a good idea.

My take is that plastics, which are a backbone of our industry, will continue to be under severe scrutiny in the immediate future and we must work to resolve real issues with their production and use in order to remain viable. Failing success, we will be looking for alternative materials down the road.

Phil Lewin is technical director for SAWDAC.

Build your brand by instilling customer confidence. Grow your business by avoiding expensive callbacks. Enhance your value by increasing efficiency and quality.

Prove your window, door, frame, and glass products are a cut above with comprehensive quality control in manufacturing, components, and unit performance.

FGIA is the industry standard in fenestration and insulating glass. Learn more about product certification at FGIAonline.org/certification.