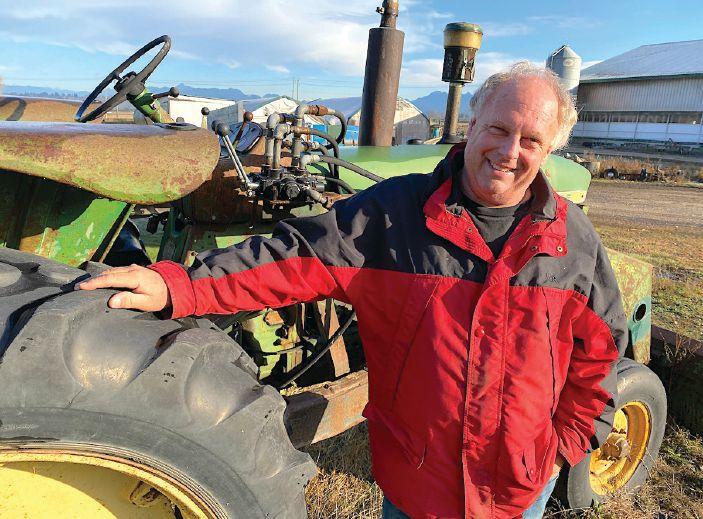

Colin Breukelman reflected on his decision, saying,

‘The

The fight continues Avian influenza continued to challenge producers last year, but stakeholders are working on gaining ground.

In a ground-breaking study, genetic editing showed it could potentially be a tool against avian influenza.

by Brett Ruffell

To get insights into the state of the poultry industry, I interviewed key leaders from the chicken, turkey, egg, and hatching egg sectors for a podcast series. They shared their views on the challenges and triumphs of the past year, shedding light on the industry’s trajectory for the coming months.

In my last column, I focused on key takeaways from these discussions around avian influenza and protecting supply management. Now, here are more highlights from my conversations.

Sustainability emerged as a central theme, with a focus on environmental responsibility, market dynamics, and strategic initiatives.

Drew Black, CEO of Egg Farmers of Canada, kicked off the discussions by delving into the egg industry’s major priorities over the last 12 months.

“We’ve really had two main priorities that have taken up a lot of our focus,” noted Black. “First one being sustainability.”

The egg industry committed to achieving net-zero greenhouse gas emissions by 2050, a monumental step that reflects a commitment to environmental stewardship. The organization conducted extensive consultations with stakeholders to understand the implications and garner insights into strengths, weaknesses, opportunities, and challenges in achieving the

net-zero goal.

Black emphasized the achievements made in the past year, with the net-zero commitment standing out as a cornerstone.

Additionally, consultations with various stakeholders provided valuable input, contributing to the industry’s broader strategy. “We’re looking at trying to roll out that roadmap for how are we going to get to net-zero by 2050,” Black stated.

The organization plans to release a comprehensive strategy for the sector in early 2024, focusing on practical solutions and recommendations.

The second priority Black cited, which I covered in my last column, is efforts to protect

“We’re looking at trying to roll out that roadmap for how are we going to get to net-zero by 2050.”

supply managed industries.

Shifting the focus to the turkey industry, Phil Boyd, executive director of Turkey Farmers of Canada, shared insights into the market dynamics and challenges faced post-COVID. “In our sector, post-COVID, we’re starting to see some nice market strength, ” said Boyd.

The industry had strategically reduced production before and during COVID to reset the market, but the post-COVID environment witnessed a resur-

gence in market strength. However, Boyd acknowledged the lingering uncertainty of avian influenza.

Reflecting on achievements and concerns, Boyd touched upon the positive results of a lifecycle assessment for turkey production, emphasizing the industry’s commitment to ongoing improvements. “It’s likely we would do another lifecycle assessment study in probably four or five years just to see what kind of progress the sector has been able to make, ” Boyd said.

The turkey industry is also in the process of finalizing a strategic plan for the next three years, focusing on key elements that will contribute to future growth and sustainability.

Tim Klompmaker, chair of Chicken Farmers of Canada, painted an optimistic picture of the chicken industry’s outlook. “We’re actually in a very positive place, ” Klompmaker asserted. The board of directors set a medium-term growth target at 2.5 per cent, anticipating positive growth in the coming years. Chicken consumption is on the rise, overtaking beef as the number one meat protein.

Klompmaker underscored the importance of branding strategies, stating, “The recognition that we’re getting around our brand, and also the way that we’re getting out to the public is an important piece that we’re doing in 2024.” He emphasized the need to communicate farmers’ stories about food safety, animal care programs, and sustainability to the public.

To hear my interviews with these leaders, visit canadianpoultrymag.com/podcasts.

canadianpoultrymag.com

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Service Rep. Tel: (416) 510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Brett Ruffell bruffell@annexbusinessmedia.com 226-971-2133

Brand Sales Manager

Ross Anderson randerson@annexbusinessmedia.com Cell: 289-925-7565

Account Coordinator

Julie Montgomery jmontgomery@annexbusinessmedia.com 416-510-5163

Media Designer Curtis Martin

Group Publisher Michelle Bertholet mbertholet@annexbusinessmedia.com

Audience Development Manager Anita Madden amadden@annexbusinessmedia.com 416-510-5183

President/COO Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 1703-2911

Subscription Rates

– 1 Year $33.15

– 3 years $78.54 (plus applicable taxes)

– 1 Year $93.33 CDN Foreign – 1 Year $105.57 CDN

GST - #867172652RT0001

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2024 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Our egg conveying systems safely transport a large volume of eggs from the nest to the processing area, which is why the majority of all eggs produced in the U.S. are riding on a LUBING egg conveying system.

Our conveying systems are flexible, and can be adapted to nearly any configuration with curves, angles, heights and distances.

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664-3811

Fax: (519) 664-3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

Les Equipments Avipor Cowansville, Quebec

Tel: (450) 263-6222

Fax: (450) 263-9021

Specht-Canada Inc.

Stony Plain, Alberta

Tel: (780) 963-4795

Fax: (780) 963-5034

The Poultry Industry Council (PIC) has announced the appointment of Tom Lewis as its new executive director, effective February 26th, 2024. With a rich background in the agriculture sector, Lewis brings extensive experience in program development, project management, communications, and public policy. He recently served as the industry relations/editor of Ontario Sheep News for Ontario Sheep Farmers and as the minister’s senior policy advisor at OMAFRA.

In late-January, the Feather Board Command Centre confirmed the presence of highly pathogenic avian influenza in a commercial poultry flock in the Town of Amherstburg in southwestern Ontario. The Canadian Food Inspection Agency did not reveal the type of poultry farm affected. The detection triggered a flurry of biosecurity measures and quarantine provisions.

In the January 2024 edition of Canadian Poultry magazine, we ran a feature in the Barn Spotlight section highlighting new hatching egg barns from Kamlah Farms. While we recognized the role of owner-operator Jeff Kamlah, we neglected to mention the essential role his wife Grejanka plays in the business. We also overlooked the role Eagle Builders played in building the new barns. We regret these omissions. An updated version of this article can be found at canadianpoultrymag.com.

Ontario chicken farms have been fortified with new reovirus insurance, as Chicken Farmers of Ontario leads in risk protection.

Chicken Farmers of Ontario (CFO) has introduced a new insurance peril aimed at safeguarding family run chicken farms in theprovince from the reovirus disease.

Recognizing reovirus as another potential threat, Opsteen notes the CFO Board’s proactive steps in enhancing the risk management strategy to better support farmers.

Reovirus becomes the second poultry disease covered by the CFO disease insurance platform.

Reovirus, a viral arthritis causing inflammation in poultry leg joints or tendons, becomes the second poultry disease covered by the CFO disease insurance platform, following the introduction of basic coverage for avian influenza in 2018.

Poultry Insurance Exchange (PIE), a reciprocal providing insurance and risk management services to the Canadian poultry industry, is responsible for delivering this new coverage.

Highlighting the ongoing challenges posed by diseases within the sector, Murray Opsteen, chair of CFO, stresses the global threat of avian influenza and the industry’s efforts in managing recent outbreaks since the spring of 2022.

The newly introduced PIE reovirus insurance coverage encompasses various aspects, including veterinary fees, laboratory fees, cleaning and disinfection fees, and a quantification model specifically designed to aid farmers in coping with potential income losses.

For detailed information on reovirus basic coverage elements and subscribers’ agreements, CFO farmers are encouraged to access the Farmer Dashboard.

This initiative reflects a proactive approach by the poultry industry in mitigating financial risks associated with diseases and underscores its commitment to supporting members through robust risk management strategies.

In a steadfast commitment to combat hunger across the nation, Canadian Hatching Egg Producers (CHEP) has once again demonstrated its dedication by making a substantial $50,000 donation to Food Banks Canada.

The soaring demand for food bank assistance in Canada has reached unprecedented levels, with many individuals and families struggling to make ends meet.

Recognizing the urgency of the situation, the generous contribution from CHEP is poised to make a significant impact in the battle against food insecurity.

Erin Filey-Wronecki, chief development and partnerships officer at Food Banks Canada, highlights the critical nature of this support.

“Food bank usage is at an all-time high as many are struggling to make ends meet,” Filey-Wronecki states. “Chicken

MARCH

MAR. 6, 2024

PIP Innovation Showcase, Webinar poultryinnovationpartnership.ca

MAR. 6, 2024

PIC’ S Poultry Producer Update, Webinar poultryindustrycouncil.ca

Left to right: Brian Bilkes, chair of the Canadian Hatching Egg Producers, with Don Armstrong, director food bank, and Warren Schatz, community ministries drector from the Salvation Army Care & Share Food Bank in Chilliwack, B.C.

protein is highly valued, needed, and appreciated.

“We are extremely grateful to the Canadian Hatching Egg Producers for their support at such a crucial time.”

The $50,000 donation comes as a timely boost to Food Banks Canada’s mission of providing essential food items to those facing food insecurity. Emphasizing the importance of protein-rich resources like chicken, the organization aims to address the nutritional needs of vulnerable populations.

Brian Bilkes, chair of CHEP, expresses the organization’s commitment to alleviating hunger and preventing it in the future. “As an organization dedicated to relieving hunger today while also preventing hunger tomorrow, we are honoured to support Food Banks Canada and contribute to their vital work,” Bilkes affirms.

$50K is the size of the donation CHEP made to help battle good insecurity.

MAR. 23, 2024

PIC’ S Raising Backyard Chickens, Webinar poultryindustrycouncil.ca

APRIL

APR. 3, 2024

PIP Innovation Showcase, Webinar poultryinnovationpartnership.ca

APR. 8-10, 2024

Restaurants Canada Show, Toronto rcshow.com

APR. 17-19, 2024

PEAK 2024

(Formerly MPF Convention), Minneapolis, Minn. midwestpoultry.com

APR. 17, 2024

PIC’ S Ag Advisor’ s Day, Elora, Ont. poultryindustrycouncil.ca

APR. 29-MAY 3, 2024

Shell Egg Academy, Virtual Event shelleggacademy.org

By Dr. Gigi Lin

Dr. Gigi Lin is a board-certified poultry veterinarian. She provides diagnostic, research, consultation, continuing education, and field services to all levels of the poultry industry in Western Canada. In this column, she will share case-based reviews of brooding best practices.

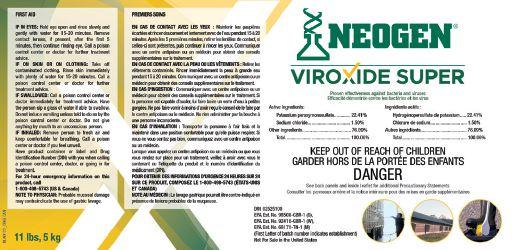

A broiler farm has experienced high chick mortality due to bacterial septicemia for three consecutive flocks. The brooding assessment revealed contamination of the water system with disease-causing bacteria. The case highlights the importance of routine waterline maintenance and sanitation.

A flock of four-day-old broiler chicks at Farm A experienced a sudden increase in mortality exceeding three per cent overnight. Postmortem examination showed that most chicks had lesions consistent with systemic bacterial infection, a condition where bacteria enter the bloodstream and cause a widespread infection throughout the body.

This marked the third consecutive flock with high chick mortality due to bacterial septicemia on this farm. In the two previously infected flocks, the producer suspected the chicks died from bacterial infection, specifically E. coli and poor chick quality. To uncover the root cause, the producer was convinced to perform a thorough investigation, including conducting a bacterial culture to rule out other potential pathogens and a comprehensive brooding assessment.

Bacterial culture of the yolk sacs and hearts revealed high levels of Pseudomonas aeruginosa, a common bacterium that can cause infection and high mortality in poultry, particularly in young chicks, and may even invade fertile eggs. Pseudomonas is a group of bacteria highly

“Pseudomonas is a group of bacteria highly resistant to commonly used antibiotics.”

resistant to commonly used antibiotics, and it is often not rewarding to treat the flock with antibiotics without other interventions. Therefore, it is extremely important to identify and eliminate the source of contamination.

Working with the producer, I conducted a comprehensive brooding assessment (remember the acronym TFLAWS) to eliminate stressors that predispose the chicks to infection. This group of bacteria grows extreme -

ly well in humid conditions; therefore, I gave extra attention to the entire water system.

Before we performed a thorough cleaning and disinfection of the water lines, I selected a few critical points for bacterial swabs to evaluate pathogen levels: the site of water intake and multiple drinker nipples in different sections in the barn. I also sampled the water filter, which had not replaced for over a year.

I detected a high level of P. aeruginosa from the water filter and the drinker nipples, confirming the potential sources of contamination. Following the discovery, we implemented a water system sanitation and maintenance protocol on the farm.

Other key considerations learned from this case:

• Keep up with routine maintenance of the water system to combat Pseudomonas species and reduce the load of other bacteria that may be harmful to poultry.

• Don’t forget to change the water filter regularly and assess all the critical points throughout the water system.

• Bacterial culture is an inexpensive diagnostic tool that can help to evaluate waterline cleanliness.

• The clinical signs and postmortem lesions of Pseudomonas infection are very similar to other bacteria; hence, it is important to perform routine bacterial culture to obtain an accurate diagnosis.

• Some organisms are highly resistant to antibiotics; thus, antimicrobial susceptibility testing is essential to guide poultry veterinarians to select the most effective treatment regime.

The National Environmental Sustainability and Technology Tool is a first-of-its-kind system that egg farmers can use to track, assess and benchmark the environmental impact of their farm.

How the tool can help you

You can use the tool to:

Understand the environmental impact of your farm

Compare your results to other egg farms

Improve your operations with tailored recommendations

Access the latest on-farm sustainability resources for egg farmers

How to access the tool

By using the tool, you’re supporting the broader movement of egg farmers who are collaborating and innovating for a more sustainable future.

All you need to get started is your Farm Registration ID!

Pioneers enter North America and new research shows improved hatchability and bird welfare.

By Treena Hein

On-farm hatching is a concept that’s grown in popularity across the European poultry industry over the last 20 years, and it’s now making inroads in the U.S. and Canada.

Two main equipment companies, Vencomatic Group and NestBorn, have recently entered the North American market, and another European manufacturer, One2born, may follow. Some farmers in Europe, North America and beyond have also devised their own systems.

A Canadian customer of the Vencomatic system is Groupe Westco in New Brunswick. “I only know of two broiler farmers confirmed to be using this method of hatching,” says Groupe Westco agrologist Marco Volpe, “us in New Brunswick and another one in Quebec. I know other

farmers in Canada are running some tests, but I can’t say how many and where.”

And while that’s a small number so far, Volpe says, “I expect more will adopt this type of hatching since Canadian Food Inspection Agency (CFIA) changed its policy. Since new regulations are in place, I expect more farms will adopt this practice in 2024. Before, CFIA was regulating every barn as a hatchery, so every barn needed a hatchery licence.”

But, with the changes from about 18 months ago in place, barns are “now regulated by Chicken Farmers of Canada with their Animal Care Program and On Farm Food Safety Program,” Volpe says.

In New Brunswick, Groupe Westco has installed systems in several three-storey broiler barns (40 feet wide with cross

ventilation, propane heat for brooding, shaving for bedding), with no changes needing to be made to the buildings. Volpe notes that in Quebec, the system is installed in two-storey barns.

ROI is of course unique to each operation and going to depend on factors such as whether the farm is integrated (and hatching success rate) or buys chicks (distance from existing hatchery and chick cost, etc.). In Volpe’s view, ROI mainly depends on how much automation is used.

“There are so many ways to look at ROI with all the different types of in-barn hatching,” he adds. “It could be as simple as collecting and putting the eggs directly on the floor manually to a more complex suspension system that won’t touch the floor and can spread the eggs evenly in the barn without having to walk to barn when placing and removing them.”

The benefits of on-farm hatching was well established. Giving newly hatched chicks immediate access to feed and water, and sparing them the stress of transport from hatchery, can provide health and bird welfare advantages.

However, here are some newish results involving Groupe Westco.

Scientists from Wageningen and Utrecht Universities in Europe conducted a two-year study with lab-scale trials but also commercial-scale trials during three consecutive cycles at Groupe Westco, where 150 tests were run comparing flocks of 7,500 to 9,700 Ross 308 or Cobb 500 broilers hatched on-farm with X-Treck or in the hatchery.

Data was collected on hatchability, mortality and body weight, as well as feed conversion ratio and number of foot lesions (an important welfare issue in broiler production).

Hatchability was found to be on average 2.5 per cent higher with X-Treck compared to hatchery chicks, with 10 per cent of the trials showing a boost of more than four per cent. Ross flocks had slightly higher hatchability (2.54 per cent) than Cobb (2.35 per cent), and young parent flocks (ages 27 to 29 weeks) had the largest increase in egg hatchability (3.69 per cent) with X-Treck.

“Mortality was studied during the entire production period, showing a decrease in first week mortality of 0.24 per cent for X-Treck chicks compared to hatchery-hatched chicks,” reports Vencomatic. “The difference in mortality is largest in the final stretch of the cycle, after 30 days of age. Total mortality was, on average, 0.32 per cent lower for X-Treck flocks, with decreases up to 9.4 per cent in some flocks.”

Cobb flocks with on-farm hatching showed an average decrease of 0.42 per cent in total mortality compared to 0.26 per cent for Ross flocks. And again, age of parent flocks had a small positive effect on mortality.

In addition, higher body weights were measured at all ages in X-Treck broilers compared to hatchery chicks (see Table 2 online) and body weights were highest for chicks of young parent flocks. Feed conversion ratio was slightly higher in onfarm hatched chicks.

Vencomatic Group

The newest addition to Big Dutchman’s line-up of cage-free true aviaries, the NATURA® Visio is a two-tier aviary system that we are excited to introduce into the market. It features patentpending designs that will increase overall egg quality and performance. Contact your local distributor or sales representative to learn more.

Regarding welfare, it’s well known that immediate access to feed and water for on-farm hatched chicks provides better development of the digestive system. “This can result in less wet manure, which is the main cause of foot pad lesions,” notes Vencomatic Group. “Only 22 per cent of the chicks hatched on-farm had foot pad lesions at the age of 21 days compared to 51 per cent of hatchery chicks (see Figure 2 online).”

Severe foot pad lesions were seen in only two per cent of on-farm hatched broilers compared to eight per cent of

those hatched in the hatchery. At day 35, similar differences were found.

Other recent studies have produced some similar results. Dr. Jennifer Timmons, associate professor at University of Maryland (Eastern Shore) recently noted a Ross chick study conducted in The Netherlands that found lower hatchability in the hatchery (4.25 per cent) compared to 2.3 per cent on-farm. Total mortality at 40 days was lower (3.4 per cent) in the flock that was hatched onfarm compared to hatchery chicks (4.01 per cent) and the litter was drier with

on-farm hatched chicks.

However, there were some differences between the studies in terms of welfare. The differences could be due to hatcheries varying in performance, bird genetics, on-farm management or other factors.

“The on-farm hatched chicks had a worse naval and hock score at day 0 compared to the score of the chicks that were hatched in the hatchery,” Timmons stated in a recent extension article. In addition, “the authors reported that the on-farm hatched chickens were heavier at 21 days of age compared to the weight of the chickens that were hatched at the hatchery. However, the weight of the birds at 40 days of age was similar regardless of the hatching process.”

As Volpe is on the front lines of using onfarm hatching in Canada, let’s give him the last word.

While Groupe Westco chose Vencomatic’s X-Treck system, he stresses that “there are a lot of different ways to hatch on farm. I know a lot of other ways for farmers to do it in Europe. Farmers need to look at all options and see which one would work best for them.”

By Jane Robinson

Nearly 20 years ago, Dr. Moussa Sory Diarra began looking at using food waste in animal feed to support a circular economy as part of his work as a research scientist at Agriculture and Agri-Food Canada (AAFC). He landed on berry pomace for a few reasons. Cranberries and blueberries are significant Canadian berry crops that would provide a consistent local supply.

The inherent antibacterial and antioxidative properties of berry fruit bioactive contents were well known, at least in human health. And like many scientists in animal agriculture, Diarra was very interested in investigating antibiotic alternatives to help mitigate the growing issue of antimicrobial resistance (AMR).

Since then, Diarra and his team at AAFC’s Guelph and Summerland Research Development Centres have examined the potential of berry pomace from many angles, and the former fruit waste is closer to

becoming an approved and proven poultry feed ingredient in Canada.

It started with juice. Diarra bought Canadian-grown berries and extracted the juice to evaluate its contents and potential for improving poultry health. He quickly noted a few things. “We had a lot of pomace left over after juicing, with lots of colour remaining in flesh, seeds and skin,” he says. He then confirmed there were more bioactives in pomace than juice – a powerhouse with fat, protein, minerals, vitamins and fibre – coupled with the fact that pomace was readily available as a byproduct of juice manufacturers.

Over the years, Diarra and his team conducted several research projects that

focused on many aspects of using pomace from cranberries and low bush or wild blueberries to improve bird health. As two popular berry crops in Canada, Diarra often collaborated directly with producer groups to access product for his research studies.

“We are always looking for anything we can use in broilers as an alternative to antibiotics that has a similar effect at controlling infection, disease and decreasing the emergence of antimicrobial related resistance. And it must be safe and cost effective.” Diarra says.

Two of his latest projects looked at the benefits of feeding broilers berry pomace in a dried form and evaluated the opportunities for a purer form of pomace extract.

“Our latest research is a significant leap forward to developing cost-effective antibiotic alternatives for poultry.”

Pomace proves good for the gut

Berry pomace requires minimal processing from its raw form. It is dried down and ground to the same size as feed mash to be added to a broiler diet. It’s rich in bioactive compounds called polyphenols including anthocyanins such as cyanidins (natural plants’ defences against microorganisms) and flavonols (quercetin).

These phenols compounds provide antibacterial, antioxidant and anti-inflammatory activities as well as acting to block the expression of genes conferring AMR. Polyphenols also help inhibit the growth of bad bacteria in the gut (E. coli, Salmonella, Listeria, etc.) and improve the bird’s ability to mount effective immune responses.

Diarra and his team compared the effect of feeding cranberry and blueberry pomaces – together and separately – in broiler diets. They found that diets supplemented with berry pomace resulted in birds with an improved gut microbiome – more good and less bad bacterial populations – plus an overall increase in immune response to arm the birds with a stronger defence against pathogenic bacteria.

“This latest discovery demonstrates how cranberry and blueberry pomaces can play an important role in the health and meat quality of chickens,” Diarra says. “When added to feed, pomace can be part of a long-term solution that gives Canadian poultry producers non-antibiotic strategies by creating an environment in the chicken gut that prevents colonization by disease-causing pathogens.”

efficacy against bad bacteria

To create and evaluate berry pomace extract required a further step to concentrate the phenolic compounds into a purer form. They assessed the extracts’ activities against pathogenic bacteria – E. coli, Salmonella and Listeria – common bacteria that can contaminate food during processing and induce foodborne illnesses.

“We know the extract is more expensive to produce and not as likely to be used onfarm, so we looked at another possible use, for example, in food processing or in therapy,” Diarra says.

Those results were also promising for pomace. “The results of this study helped establish minimum inhibitory concentrations (MICs) of berry pomace extracts that are showing promise for decreasing the colonization by pathogenic bacteria including E. coli, Salmonella and Listeria during processing,” Diarra says.

With these latest results, Diarra has some valuable insights on pomace for the poultry sector. “We showed that phenolic-rich extracts from berry pomaces were more effective for improving bird’s health than the native pomaces, but pomace is easier to produce and more cost effective,” Diarra says. “Phenolic-rich extracts also can potentiate activities of traditional antibiotics such as cephalosporins against resistant E. coli and protect the liver against colonization by Salmonella. That’s a win-win.”

Berry pomace also contains complex fibre that birds can’t use directly, but beneficial gut bacteria like Lactobacillus feed on the fibre and release bioactive compounds that birds can then use.

“You don’t need a lot of pomaces in broiler feed to make a measurable difference in the bird’s health,” he says. “And our latest research is a significant leap forward to developing cost-effective antibiotic alternatives for poultry.”

Cranberry and blueberry pomaces have specific effects at specific growth stages for boilers and are best if used separately – cranberry in starter feed and blueberry in grower feed.

On

Berry pomace is moving one step closer to being an approved feed additive in Canada by Canadian Food Inspection Agency (CFIA) and Health Canada. “We’ve taken a significant step by getting an experimental studies certificate to evaluate berry pomace on commercial farms,” Diarra says. “We’ve been collaborating with farmers who are very happy with the addition of pomace to broiler diets.”

There is definite interest in seeing pomace as a commercially available product in Canada and Diarra is now investigating the opportunities for pomace in layer diets, working on a new research project with the Egg Farmers of Canada.

He’ll also continue to work on optimizing berry pomace for broilers and layers, looking at ways to decrease the non-nutritional components in pomace – lignin, cellulose and tannins – that can affect the ability of the bird to access bioactive compounds.

“We’re also looking at standardizing the nutritional and polyphenolic profile of pomace as it can vary depending on the region where the fruit is grown, as well as during storage and drying practices,” he says.

• Pomace contains considerable amounts of polyphenols with antimicrobial and antioxidant properties – a key attribute with potential for managing harmful bacterial pathogens.

• When added to broiler feed, berry pomace has shown potential to manage bacteria and antibiotic resistance in broilers.

• Berry pomace can be developed into cost-effective compounds that can be used as alternative to traditional antibiotics.

• The use of pomace with help alleviate the environmental impact of the food byproduct ending up as landfill waste where it would support the growth of microorganisms and production of harmful noxious gases.

looking for six women making a difference in Canadian agriculture. Whether actively farming, providing agronomy or animal health services, or leading research, marketing or sales teams, we want to honour women who are driving Canada’s agriculture industry.

and submit your nomination.

By Ronda Payne

Farmers know all-too-well how hard it is when viruses strike, and livestock needs to be culled. Avian influenza, in particular, has been an explosive, unpredictable situation for Canadian poultry producers in recent years. It’s heart-wrenching and can be financially devastating, taking years for producers to recover emotionally and financially.

Mike Bose learned this firsthand. A councillor with the City of Surrey, B.C., and turkey farmer at Medomist Farms, his farm was hit this past fall during one of B.C.’s worst outbreaks.

“I’ve always been very sympathetic to people who have had to go through this because I know how hard it is,” he says. “I know how devastating it is. Now, having gone through it, you can’t explain it – it’s very stressful.”

Understandably so, as certain parts of Canada continued to see aggressive outbreaks of the virus last year. However, there are positives to be garnered from the situation around the ability to create more collaboration, shared learnings, and communication nationally.

Quebec and B.C. hit hard

B.C. and Quebec both saw heavy caseloads at different times last year. But Martin Pelletier, general manager of EQCMA (Équipe Québécoise de contrôle des maladies avicoles – The Quebec Poultry Disease Control Team), says emergency

management plans have helped in his province.

“It was in the fall of 2021 when the first case hit the Maritimes,” he says. “Right there, we knew that AI had come across the Atlantic Ocean and might be a threat for us.”

The first Quebec case was in April 2022. By spring of 2023, Quebec had logged nearly one million dead birds due to infection or euthanasia. Fortunately, last fall, the case load, while still potentially active, seemed less aggressive.

“In the fall, we had four cases,” he says. “We had one case in ducks, two cases in turkeys and one on the site where there were turkeys and broiler chickens. But with these four sites, in total, it was about 150,000 birds.”

Meanwhile, in B.C. there was a cluster of cases in the spring of 2022 as well and they just kept coming. In December 2023, the B.C. Ministry of Agriculture and Food

noted there were 52 farms infected with AI since October 2023.

The number of poultry deaths in the province over 2023 reached over five million. More than 2.3 million birds have been destroyed in B.C. since September 1, 2023, says Amanda Brittain, chief information officer for the B.C. Poultry Emergence Operations Centre.

“There’s a lot of studying and research that needs to be done, but we’ve been in this almost two years now and nobody’s had a chance to breathe,” she says. “I know CFIA is working on it, and I know universities are working on it, but we haven’t had a long enough break to get all the research done.”

Bose has been farming in Surrey since he was a toddler. “We raise flocks of 9,000. Seven flocks [a year],” he says. “My son and I, we run the farm.”

In mid-November, the birds were doing great. One flock was market-ready, and the other was three weeks old. Suddenly, there was a spike in mortalities.

His son contacted the sick bird line, and, per instructions, they placed a couple of dead birds in a garbage bag outside the farm’s gate for pick up and inspection. The results were positive for AI and both flocks were destroyed.

“We always get extremely nervous in the fall,” he says. “This is the first major outbreak of any disease we’ve ever had. We’ve always been able to solve our own problems.”

Theresa Burns, chief veterinarian with the B.C. Ministry of Agriculture and Food, says the pace of outbreaks in B.C. was faster than in other provinces.

“We had a small number of cases in the spring of 2022, but in the fall of 2022, we had a cluster of cases start and then we saw the number of outbreaks happen

much faster,” she says. “It was different than before. We were aware that it was a higher risk situation than what we saw prior to 2022.”

Bose found it challenging, absorbing all that had happened. From the destruction of the flocks to the clean-up and protocols and the financial losses, it was a significant and painful cost. “There were some

very, very dark days when you feel like a complete failure,” he says. “It’s really hard to get your thoughts straight.”

He described the clean-up protocol, including destruction of birds, composting them, dry-cleaning of the barns and recleaning, as “a complicated process, but I think it’s absolutely necessary.”

From destruction of birds to being approved to place a new flock takes two to three months or more.

Bose feels the weather caused the outbreak at his farm. With fields flooded, wild birds were landing in the water, then winds rolled in and blew across the fields into the curtain-sided barn.

While this can’t be proven as the cause, Burns says the province plans to address the wild bird component in the future. “We have a fairly robust wild bird program,” she says. “We know we’re on a very important and busy waterfowl migratory route.”

EQCMA has shared its colour-coded biosecurity protocols with other regions. Pictured are the protocols for codes green and orange.

Brittain adds that eliminating standing water like what Bose experienced is important, as it should all be considered infected.

EQCMA created colour-coded protocols that have been beneficial to both Quebec and B.C. It’s been just one of the many management tools shared across the country.

“When AI came about, then, when CFIA informed EQCMA that there is a high-risk submission to the lab, we use our geomatics tool to draw a three-kilometre circle around the area and we issue an enhanced biosecurity alert,” Pelletier says. “We inform the association of who the producers are in that zone and they contact them. They implement the orange code.”

A new code – yellow – will be added in 2024 for high migration periods.

“There’s a [migration] peak in March/ April as well as in October/ November,” he says.

In addition to colour-code protocols, the association has a third-party provider to conduct CO 2 destruction. It also provides some biosecurity supplies and offers

an emergency line.

“People know EQCMA so much now, so the line is not much used because they call us directly, which is good,” Pelletier says.

The organization also serves as an information hub between CFIA, associations, producers, and others in the industry like hatcheries and abattoirs. CFIA alerts and zones can be loaded into the geomatics tool and lists are created to ensure those in alert regions are updated. The website is another important tool with information about survival of AI in the environment and sanitation.

“We recognize that we should have more than one tool in our toolbox,” he says.

Jean-Pierre Vaillancourt, professor at the faculty of veterinary medicine at the University of Montreal, says wild waterfowl are the principal source. He adds that there are at least 273 bird species found to have AI and at least 40 species of mammalians (not including the recent finding of polar bears).

“The commercial flocks that are at greater risk are turkey flocks and duck flocks,” he explains. “It’s a major issue

Bonnets jetables

Paire de lunettes de protection de type « goggle », avec ventilation indirecte et antibuée

Masque jetable N95 NIOSH

Combinaisons jetables avec ou sans capuchon intégré

jetables Gants jetables

In an AI surveillance zone, producers are required to put all mortalities at the road for testing. Cornelis (Corry) Spitters, owner Oranya Farms, was surprised when a single bird from one of his Aldergrove, B.C., barns came back positive for the disease in early December.

“To my knowledge, they tested the barns, but not a single [other] result came back positive,” he says. “Regardless, our farm was deemed for destruction. We have no recourse.”

The birds were destroyed, staged for composting in the barn, sanitation completed, and a new flock was scheduled for placement February 12. It’s one of the fastest turnarounds seen in B.C. But this speed can’t begin to compensate for the losses.

“We place, on average, anywhere from 15,000 to 20,000 birds a day, four days a week,” he says. “That particular farm – there’s 42 levels of production there. Placements are going to be placed over the next 17 weeks to fill that farm back up again.”

He estimates his losses at over a million dollars after being reimbursed for the birds themselves. Labour, utilities, mortgage payments all continued during the clean up after the destruction. He feels that when there are no exceptional signs of mortality, a deeper dive should be conducted, but he will continue his operation.

“We have no choice but to continue,” he says. “People are scared. We’ve got to stay the course.”

whenever you see ducks. That’s why they are vaccinating ducks in France.”

Leading the concerns is the fact that AI is changing at an alarming rate, making it much more challenging than it may have been in previous outbreaks. Additionally, as Vaillancourt explains, the virus has mutated to complete one of the four steps required to become zoonotic – able to transmit to humans.

“There are four steps for this virus to become the equivalent of a nuclear bomb,” he says. “We’ve reached the first one. We’re far from having this being the next COVID, but anybody that would say there is no risk that this could happen is either ignorant or lying. That’s why we need to control it as quickly as possible.”

forward

Biosecurity is job one, Brittain says, noting B.C. farms have been put under restric-

tions to eliminate the concerns of farm-tofarm transfer. Producers are adapting.

“There is virtually no lateral farm-to-farm transfer,” she says. “Changing your clothes or putting on coveralls to completely cover your clothes is very, very common. Farmers seem to be the most resilient people I’ve met in my entire life. They want to make sure that British Columbians have access to locally grown food.”

Burns says a combination of governments, associations and farmers ensure biosecurity remains top of mind, but adds that the B.C. lab’s speed and farmer responses have ensured positive strides forward.

“I’m seeing really strong collaboration between the CFIA, the poultry industry and governments to deal with this,” she says. “The challenge is we don’t exactly know what the avian influenza virus is going to do in the future. If we continue to have these

outbreaks for more than one or two more years, that puts a big strain on everyone who is involved in outbreak response.”

Testing wild birds is ongoing and the industry remains vigilant.

Vaillancourt says B.C., Alberta and Quebec are the provinces with the most movement of the virus now and that EQCMA and others in the industry will be sharing knowledge.

“Nobody is better positioned to provide information about the industry than industry people themselves,” he says. “I’m hoping we’ll be able to do some research [in B.C.] within days or weeks to do a case control study.”

Avian influenza has caused a lot of pain and losses in the poultry industry. However, it has also created stronger communication channels, improving information sharing and creating a borderless team to find solutions.

Wired or wireless: The DOL 2400 alarm system can be connected to traditional landline or cell network for alarm notifications. Use any mobile GSM carrier. If you want to switch providers simply insert a new SIM card.

• 7" or 10" touchscreen

• Can activate backup equipment in case of alarm (outputs)

& outputs, expandable to 100. Connect multiple barns using master/ slave mode using one dialer (less monthly fees)

• Phone call or text message (GSM units) notification options, as well as siren, flashing light or silent (burglary)

• Base units come configured as 10 inputs

• Status reports via text message (GSM units) NO DATA OR INTERNET REQUIRED

• Self learning temperature curves

• Optional fingerprint scanner for additional security

• Sensors available: temperature, humidity, CO2, ammonia, dry contact, power failure

In a ground-breaking study, genetic editing showed it could potentially be a tool against avian influenza.

By Melanie Epp

Scientists in the United Kingdom (UK) believe CRISPR technology could be the solution to preventing avian influenza outbreaks in chickens in the future. While results thus far look positive, much work still needs to be done – both in the lab and at the political level. The science, so far, has been positive, though.

A team of scientists from three UK research institutes, the Roslin Institute, Imperial College London and the Pirbright Institute, recently completed a research project that looked at whether or not genome editing, a technique that

subtly changes or edits the DNA of an animal, could make them alter the genes of chickens to make them resistant to avian influenza infections.

The project, which was funding by the UK government (the BBSRC), resulted in the discovery of a gene called ANP32.

The gene ANP32A, when modified, partially safeguards chickens from avian influenza.

Flu viruses are very small viruses and need to use the proteins of their infected host cell to be able to grow and make more viruses, explains Mike McGrew

“Our colleagues at Imperial discovered that one of the chicken host proteins used

by the flu virus is ANP32A,” he says. “At first, we didn’t want to completely remove the ANP32A protein. We thought that by changing the protein very subtly, changing two amino acids of the protein, the flu virus would not be able to interact with ANP32A and grow in the cell.”

If virus is not able to grow in a cell, it will not be able to grow in the whole animal, McGrew adds.

According to the study, once gene-edited chickens were introduced to the viral challenge, nine out of 10 cells showed no viral growth.

“This was extremely good finding and suggested that we stopped all viral growth in the chickens,” says McGrew. “We were very encouraged by this result.”

One of the challenges the researchers faced involved breakthrough cases. Since the flu virus can jump from birds to pigs and humans, they needed to be sure that the virus would not mutate and adapt to grow in chicken cells with the genetic change. This could result in mutated flu virus that has more potential to cause disease in chickens, pigs and humans. Flu, like coronavirus, is an RNA virus that mutates incredibly rapidly. For this reason,

the researchers challenged the chickens with 1,000 times the original dose. This allowed the flu virus more time to grow and divide in the chicken, mutating as it divided until a genetic change occurred that permitted the virus to grow in the altered host cells.

“That is exactly what we observed when we used a higher dose,” McGrew says. “This means that our small genetic change in ANP32A is not sufficient to stop avian influenza from growing in

Researchers in the UK, armed with CRISPR technology, are making strides in the battle against avian influenza outbreaks in chickens. Here are key takeaways from their initial results.

• Researchers in the UK leverage CRISPR to combat avian influenza outbreaks in chickens.

• ANP32A gene modification emerges as a key strategy for partial resistance.

• Challenges arise with higher viral doses, prompting exploration of proteins ANP32B and ANP32E.

• Global implementation faces hurdles, requiring robust genome editing regulations.

• Gene-editing technology shows transformative promise in livestock disease management.

• Experts stress the importance of understanding genetic consequences for effective application.

• Despite challenges, researchers anticipate a slow yet promising journey toward a flu-resistant chicken for producers.

chickens and potentially infecting other chickens.”

As part of the investigation, the researchers found two other proteins similar to ANP32A, called ANP32B and ANP32E. The virus can use these two proteins as host cells if ANP32A is not present. They are now investing if removing or changing all three proteins will make the chicken completely resistant to avian influenza. Gene-editing, if successful, will apply to all avian influenza variants.

“We tested many flu virus variants in cells and it seems that they all depend on the three ANP32 genes to grow,” says McGrew.

Several things need to happen before gene-editing technology can be used as a tool in the fight against avian influenza. In the lab, researchers need to find a genetic change that makes chickens completely resistant to avian influenza. They hope that that editing out all three ANP genes will do this.

“We think that this genetic change will make the chicken completely resistant to

Amplify by Annex is a full-service custom content studio, helping companies share their story, build brand awareness and garner trust through original content.

There are so many ways to reach a target audience. We’ll craft you content for any medium:

• Thought leadership – long-form or short-form articles

• Blogs, whitepapers, infographics and case studies

• Webinars, podcasts and video

• Tradeshow marketing content, with in-house commercial printing services

• Automated content marketing supported by first-party data ....and so much more!

T:

Connect with an account manager or scan to learn more

avian influenza,” says McGrew. “However, this, of course, comes with the caveat that the chickens need to remain healthy, happy, and productive with changes to all three genes.”

Politically, many countries will need to have more robust genome editing regulations in place so that gene-edited chickens can be sold to consumers in those countries.

“This is especially important for poultry as poultry is a global commercial product,” McGrew says.

McGrew expresses his regret that they cannot offer a flu-resistant chicken for

poultry producers.

“We think that we are on the right pathway,” he says. “The progress is slow, as we need to raise funding for every step of the research process, but we do believe that gene editing is a safe option to eliminate bird flu infections from chicken flocks.”

Christine Baes, chair of the Department of Animal Biosciences at the University of Guelph, called the study’s findings a “huge breakthrough”.

“This was extremely good finding and suggested that we stopped all viral growth in the chickens.”

“But it’s not implementable tomorrow,” she says. “There needs to be a lot of work done. It’s exciting, and it’s cool. There’s probably another five to 10 years of research that has to go into this before we can actually implement it.”

Gene-editing technology has shown incredible promise when it comes to tackling some of livestock production’s biggest disease challenges. According to Baes, what’s hindering the Canadian agricultural industry from applying gene editing is regulatory in nature, not technical in nature.

“Gene editing is not a silver bullet,” she says. “You need to understand the genetic consequences of the trait. Otherwise unintended consequences are possible.”

McGrew and the team plan to continue their studies in the coming years.

Broiler Chickens is a short practical book of guidelines and advice to good welfare practice in broiler chicken farming. With contributions from world expert researchers in poultry welfare, this book distils academic research into applied advice on the farm for industry and farm workers. The content covered includes health and disease impacts with a One Health focus, housing for optimal health, broiler breeders, hatchery management, broiler slaughter practices, transport, animal welfare assessment measures, and a discussion of welfare improvement measures on the farm.

Interested in Advertising in the Classifieds? Please contact: Ross Anderson 289-925-7565 randerson@ annexbusinessmedia.com

sales@county-line.ca 519-291-5012 www.omnivorecomposter.com

info@agprowest.ca 604-746-5376 www.agprowest.ca

Location

St-Justine-de-Newton, Que.

Sector

Layers and pullets

The business

Ferme Avicole St-Bruno Inc. stands as a testament to innovation and evolution. Owned and operated by Jimmy and Akshu Sarkaria, this egg farm has been a fixture in the poultry business since the mid-80s. It was founded by Jimmy’s father Manjinder Sarkaria.

The need

The producers were driven to build new barns by a desire to explore alternative housing. Having transitioned from traditional cage systems to enriched cages, the Sarkaria family, drawn by the prospect of improved bird welfare, took a bold step into free-run farming. Jimmy Sarkaria shares, “It’s kind of intimidating to go into free run, coming from such a background of caged systems — it seems like a big step.” But they felt confident making the leap after consulting with experts.

The barn

The crown jewels of the business now include a free-run pullet barn and two interconnected free-run layer barns. Vencomatic equipment, such as the Bolegg Starter and Bolegg Gallery with a VMS system, ensures optimal conditions. Construction began in April 2022, with the first pullet flock introduced in November 2022. The layer barns received their first birds in March 2023. Jimmy Sarkaria highlights the surprising health and happiness of the birds in the freerun system. Skepticism about the transition faded as low mortality rates and excellent feather coverage became evident.

NOW MORE THAN EVER.

Canadians want fresh, high-quality Canadian chicken and our farmers are proud to raise it to some of the highest standards for food safety, animal care, and sustainability. That’s what “Raised by a Canadian Farmer” means.

Introducing Poulvac® Procerta™ HVT-IBD. Timing is everything in a poultry operation, and Zoetis created its newest vector vaccine to put time back on your side. Backed by the latest science resulting in excellent overall protection, studies found that Poulvac Procerta HVT-IBD protected chickens fast against classic IBD and AL-2.1-3 It’s a quick way to full protection from infectious bursal disease. Contact your Zoetis representative or visit PoulvacProcerta.com.