How F&B processors can reduce emissions

Meet the company using drone technology to revolutionize asset inspection

AI-backed surveillance: The new era of food safety?

How F&B processors can reduce emissions

Meet the company using drone technology to revolutionize asset inspection

AI-backed surveillance: The new era of food safety?

EDITOR

Kirstyn Brown

kbrown@annexbusinessmedia.com (519) 429-5205

BRAND SALES MANAGER

Pat Lorusso

plorusso@annexbusinessmedia.com (416) 518-5509

ACCOUNT CO-ORDINATOR

Debbie Smith

dsmith@annexbusinessmedia.com (416) 510-5107

MEDIA DESIGNER

Graham Jeffrey

Beata Olechnowicz bolechnowicz@ annexbusinessmedia.com GROUP PUBLISHER

Anne Beswick

abeswick@annexbusinessmedia.com (416) 510-5248

PRESIDENT & CEO

Scott Jamieson sjamieson@ annexbusinessmedia.com

JP Giroux • jp.giroux@emccanada.org

VICE PRESIDENT AND GENERAL MANAGER

Amanda Doman • adoman@emccanada.org

VICE PRESIDENT, MANUFACTURING SECTOR PERFORMANCE

Scott McNeil-Smith • smcneilsmith@emccanada.org

MARKETING & COMMUNICATIONS MANAGER

Tiffany Robbins • trobbins@emccanada.org

F&B manufacturing.

FANUC Canada headquarters officially opens to the public. 10 HEALTH & SAFETY

Reviewing the importance of machine guarding.

14

How companies can take simple steps to reducingn emissions.

This Hamilton-based startup is taking asset inspections to new heights with drone technology.

17

Is AI the new era of food safety?

Hello again, and welcome to the first issue of what I’m sure will be an interesting year.

As we kick off 2025, many industries in Canada are at a crossroads, facing both challenges and opportunities in an increasingly complex global landscape. The food and beverage industry is no exception. The new year has barely begun, and already we’re anticipating substantial changes that could reshape the sector for years to come.

I’m, of course, referring to U.S. President Donald Trump’s proposed tariffs on imports from Canada, threatening to disrupt established supply chains and alter the competitive landscape. This potential upheaval comes at a particularly precarious time for Canadian food and beverage manufacturers, who are bracing for another challenging year.

As I was wrapping up this issue in mid-January, senior economists at Farm Credit Canada (FCC) released an economic outlook for the agriculture and agri-food sectors. The article highlights their vulnerability to increased trade protectionism, with the United States—our largest export market—accounting for 30 per cent of food processing and 10 per cent of beverage processing sales. The sugar and confectionery sector, in particular, is on shaky ground, with over 80 per cent of its sales dependent on U.S. exports.

Another report released by FCC in partnership with Food & Beverage Canada last December identified key challenges facing the industry. Based on survey results from businesses across the country, the report highlighted inflation, labour shortages, technology adoption and regulatory burdens as the four most pressing issues shaping the future of F&B. (You can read more about the survey on page 7.)

But it’s not all doom and gloom. While these challenges are significant, they also present opportunities for innovation, growth and adaptation.

A great example is the Hamilton, Ontario-based startup Skyguage, a company that develops specialized drone technology for remote asset inspections and maintenance of industrial infrastructure. These drones deliver precise measurements at various heights, not only improving safety but also speeding up inspections, reducing costs, minimizing downtime and addressing labour shortages.

It’s only one example, but Skygauge’s success speaks to the potential of innovation and technology in the food and beverage sector, particularly in maintenance and inspections. I encourage you to read our profile of the company on page 15, then let me know your thoughts.

In the meantime, I’ll end with this: As we move deeper into 2025, it will be crucial for all of us to not only navigate these challenges but to seize the opportunities they present. Whether it’s adopting new technologies, exploring new markets or rethinking traditional business models, the resilience and creativity of Canadians, across all industries, will play a pivotal role in determining our future.

Until next time,

Kirstyn Brown kbrown@annexbusinessmedia.com

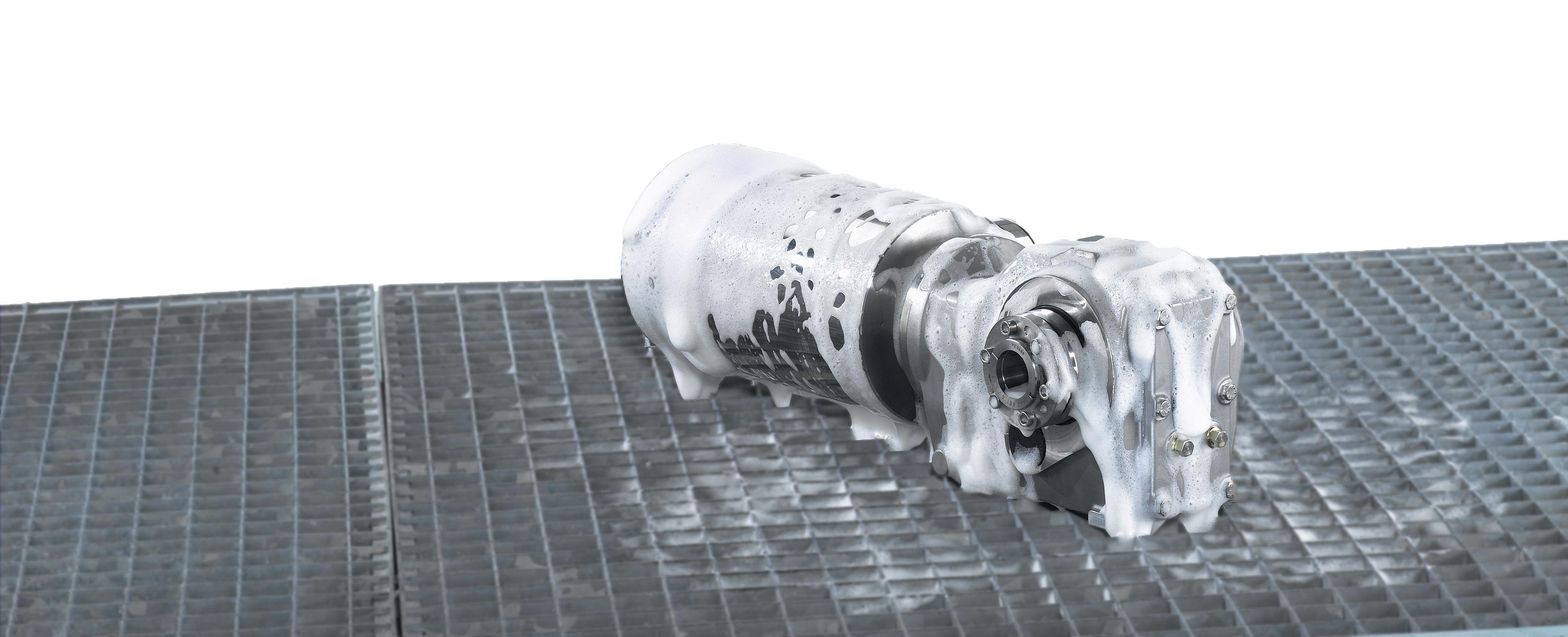

ABB, a manufacturer of NEMA motors, says it has improved its BaldorReliance Food Safe stainless steel motor product portfolio with a three-lead electrical connection design. This new motor solution is reportedly engineered to simplify installation, enhance reliability and improve workplace safety while integrating with existing 460V systems.

According to ABB, the enhanced three-lead design reduces installation time and simplifies the setup process. The company reports that by minimizing the number of leads, the risk of connection errors decreases, resulting in greater reliability with fewer inter-

ruptions. These improvements aim to allow facilities to boost productivity while lowering maintenance costs and reducing downtime. The nine-lead configuration is still available for variable speed drive operation and more complex electrical systems.

“This new configuration of the Baldor Reliance Food Safe stainless steel motor is a testament to ABB’s commitment to supporting our customers with reliable, efficient and industryleading technology,” said Brandon Canclini, global product manager for ABB’s NEMA Motors Division. “ABB is dedicated to developing solutions that address the unique demands of food processing environments.”

Protein Industries Canada announced a new project with partners

Alinova Canada Inc., Marusan Ai Co., Earth’s Own Foods and Flamaglo Foods to bring more soy processing home to Canada.

Alinova Canada Inc., a joint venture between DJ Hendrick International Inc (DJHII) and Marusan Ai Co., will lead the development and commercialization of a new soy powder. The project will see the pilot-scale facility built in Ontario, a region of high soy production in Canada. Both the operation of the new facility and its location will allow the partners to more efficiently focus on product development work and market testing, with Japan being a particular focus.

Bringing this processing into Canada is expected to add value to the country’s soy crop, the majority of which is currently exported for processing internationally.

“Canada’s agriculture sector has a strong reputation for high-quality crops, and we can build on this by bringing the processing of those crops back home to Canadian soil. Valueadded processing and whole-seed utilization here at home will secure our position as a leading supplier of high-value ingredients and food products, while providing families here in Canada and around the world with a new selection of high-quality

protein options,” Protein Industries Canada CFO Kassandra Quayle said. As the pilot-scale facility is being built, Earth’s Own and Flamaglo Foods will test small batches of the new soymilk powder in products destined for grocery store shelves across Canada. Once the facility is built, Alinova Canada Inc. and Marusan Ai Co. will work to fully expand processing capacity of the soymilk powder and test its commercial viability in the Japanese market.

A total of $23.9 million has been committed to the project, with Protein Industries Canada investing $6.7 million and the partners together investing the remainder.

$15.4M TO MODERNIZE FOOD PROCESSING FACILITIES

The governments of Canada and Manitoba are investing in several major capital infrastructure and investment projects under the Sustainable Canadian Agriculture Partnership (Sustainable CAP) that will increase food processing capacity in Manitoba.

Through Sustainable CAP, the governments are investing up to $15.4 million over four years to 70 projects through four streams of the Capital Infrastructure and Investments program.

These projects aim to help support growth and expansion through capital investments in modernization activities that enhance efficiency, productivity and environmental sustainability.

Some of the companies and their funded projects include:

• Burnbrae Farms Limited spe cializes in egg production and egg based products. This funding is to modernize and improve efficiency at their Winnipeg plant and allow greater capacity.

• Kimberly Packing Corpora tion, under Kroeker Farms

Limited is a producer and processor of potatoes in southern Manitoba. This funding will allow them to package their product in Manitoba, a process cur rently done outside the province.

• Roquette Canada Limited is investing in new equipment for efficiency and reliability improvements at its Portage la Prairie pea protein plant, the largest pea protein processing plant in the world.

• Spenst Bros Premium Meats is a farm family owned pizza production facility, retail store and meat processing plant located in Winkler.

The project involves expanding the market for their popular frozen pizza products across Canada. Funding will also allow organizations to purchase equipment that will help bring new and innovative technologies into the production process, improving productivity and leading to increased employment and scaled up production.

Labour shortages and inflation are among the most pressing concerns shaping the future of F&B.

BY KIRSTYN BROWN

Anew survey, conducted by Food and Beverage Canada (FBC) in partnership with Farm Credit Canada (FCC), is offering a closer look at the challenges faced by Canada’s food and beverage manufacturing industry.

“The data we’ve gathered highlights both the challenges that weigh on dayto-day operations and the opportunities for innovation and growth,” said Kristina Farrell, CEO of FBC. “This survey also reflects the focus areas for our association, ensuring that we’re advocating for policies and programs that will make the biggest difference for our industry.”

The survey, which gathered insights from businesses across the country between June and September 2024, was supported by six provincial and regional food and beverage associations. The findings highlighted labour shortages, rising costs, technology adaptation and regulatory complexity as the four main challenges impacting the industry’s future.

Labour shortages undermine productivity and force businesses to operate below capacity and limit their

growth. Results of the survey found that 59 per cent of businesses identified skilled labour as their primary workforce challenge, with 22 per cent of respondents reporting they’ve al-

ready downsized their operations due to staffing difficulties.

The survey found inflation is a major

challenge, with 87 per cent of respondents reporting inflation has driven costs up by as much as 30 per cent, siting transportation and distribution costs as the most significant contributors. Rising costs eat into profit margins, reduce competitiveness and make it difficult for businesses to reinvest in innovation and growth.

portance in addressing labor shortages and improving efficiency. The main reasons for this hesitancy include financial barriers, high costs, and challenges related to implementation.

February 27, 2025 • 1-4 PM

“Focusing on increasing productivity is the single most important step to navigate the current economic landscape.”

Reluctance to adopt new technology hinders the industry’s ability to modernize and remain competitive on a global scale. However, less than half (42 per cent) of respondents viewed innovation and technology as critical to their operations—despite their im-

Lastly, the survey highlighted regulatory burdens as a key challenge for businesses, with 45 per cent identifying labeling and packaging as their most pressing regulatory concern. Cumbersome regulations slow down operations, divert resources and can put companies at a disadvantage in an intensely competitive global market.

“Focusing on increasing productivity is the single most important step to navigate the current economic landscape,” said Jean-Philippe Gervais, FCC Executive Vice-President, Strategy and Impact. “Two important drivers of productivity gains are introducing product innovations and finding process efficiencies within the business. They can lift competitiveness, resulting in sustainable growth in food and beverage production.”

This theme highlights the crucial role that CMMS software plays in achieving operational excellence and reducing downtime in various industries. It emphasizes the power of technology in streamlining maintenance processes, enhancing asset performance, and ultimately ensuring continuous operational efficiency.

• The Downtime Challenge

• CMMS as a Downtime Mitigator

• Case studies showcasing successful implementations of CMMS for downtime reduction.

• Features and Capabilities of Advanced CMMS

• Integration and Data Analytics: Integrating CMMS with other enterprise systems and Utilizing data analytics for predictive insights.

• Best practices for implementing and optimizing CMMS solutions.

FOR SPONSORSHIP INFORMATION, PLEASE CONTACT:

• Future Trends in CMMS: Emerging technologies in CMMS (e.g., IoT, AI, and machine learning).

• Q&A and Expert Panel: - Expert panel discussion on the evolving role of CMMS in downtime reduction.

The robotics and automation company celebrated its new facility with a grand opening event in November.

BY KIRSTYN BROWN

FANUC, a global provider of robotics and automation, officially opened its new Canadian Headquartersto the public in November 2024. The new facility in Mississauga, O.N. which will serve as a hub for robotics technology, hosted a ribbon-cutting celebration for more than 250 attendees that included industry partners, customers and media.

T he 73,000-square-foot facility, which opened strictly to employees in June 2024, includes a product showroom featuring interactive demonstrations of the company’s latest CNCs, robotics and ROBOMACHINEs., as well as FANUC’s sales team, training programs, engineering support and 24/7 customer service.

“Meeting the unique needs of our Canadian customers is at the heart of every decision we make,” said Peter Fitzgerald, general manager of FANUC Canada, Ltd. “That’s why we’re excited to unveil our new Canada headquarters and celebrate our expanded presence in this vibrant region. Whether it’s a large assembly operation or a start-up looking for their first robot, we’re eager to help Canadian manufacturers overcome today’s production challenges with our cutting-edge technologies.”

The FANUC team held a ribbon-cutting ceremony at their grand opening event.

At the grand opening event, attendees enjoyed interactive technology demonstrations that included FANUC’s latest products:

• Flexible Multi-Arm Welding: Featuring the R-1000iA/100F robot, an ARC Mate 100iD welding robot, and iRVision® 3DV, this dual-robot system showcased its coordinated motion, picking an auger from a rack and simulating welding as the part rotated

• AI Assisted Palletizing and Depalletizing: The M-710iD/50M robot, combined with two iRVision 3DV/1600 vision sensors and the FANUC iPC, used AI Box Detection software to locate difficult-to-distinguish boxes, depalletize and palletize them

• Cobot Palletizing: The CRX-30iA cobot—with a 30 kg payload and 1,756 mm of reach—used PalletTool 3 software to efficiently palletize two pallets from a single infeed using a multi-case gripper

• Food Assembly with Robots: The LR Mate 200iD tabletop industrial robot assembled cheeseburgers alongside the SR-6iA/C – both food-grade/ cleanroom robots – to pick and place buns, burgers and toppings

How fixed guards, interlocking devices and automatic shutdowns can help prevent injuries, reduce compliance risks and safeguard your workforce.

Could your last workplace incident have been prevented?

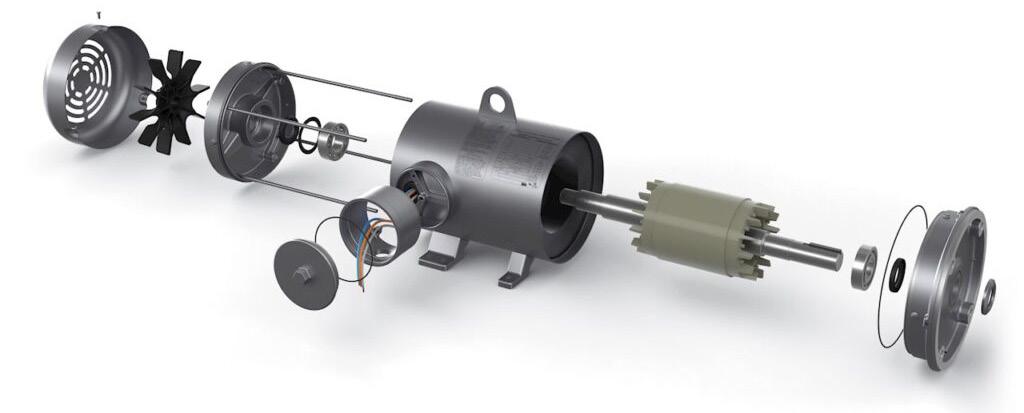

Manufacturing companies rely on industrial equipment for increasing efficiency; however, it’s essential to identify and protect workers from potential hazards such as the following:

• Impact and flying debris – certain processes may eject waste or material that could be dangerous to nearby workers

• Crushing, pinching – heavy machinery components can crush or pinch limbs

• Entanglement – rotating or moving parts such as flywheels, belts,

chains and gears can catch worker’s clothing or hair

• Cutting, shearing – sharp blades, tools, and moving parts pose dangers when left exposed

• Burning – parts that heat up can cause burns if contacted by workers

• Electrical shock – live electrical components present a safety risk Machine guarding protects against many hazards and increases compliance with applicable occupational health and safety regulations. Lack of compliant guards is a safety issue that should be identified and rectified before official inspections. However, lack of proper guarding

continues to be a source of notices of contraventions. Inspections from a recent machine guarding hazards initiative issued 189 orders to comply with legal requirements for employer failure to provide a guard to prevent access to an exposed moving part, and 157 orders for failure to provide a guard to prevent access to a pinch point. Every year in Canada

approximately 2,500 people are injured because of machine related incidents. That’s a large number of injuries that are so easily preventable. Failure to prevent incidents can be costly. The Workplace Safety and Insurance Board of Ontario recorded over $44 million in costs in 2022-2023 for claims related to being caught in or compressed by equipment or ob-

jects or collapsing material. Three types of machine guarding removed, interlocking devices automatically shut off the machine. To hazards. A safe workplace must provide an environment where worker training for workers. Additional information about Ma-

EMC is Canada’s largest manufacturing consortium, connecting manufacturers through community relationships, production, benchmarking and best practice sharing.

It sounds complicated, but F&B processors can take simple steps to reduce emissions.

BY JACK KAZMIERSKI

Succeeding in today’s highly competitive food manufacturing industry is more complicated than ever. Besides producing quality goods at competitive prices, food plants must think about their carbon footprint, energy consumption, waste generation, and their environmental, social and (corporate) governance (ESG) goals. It’s easy to set and publish ESG goals, but much harder to achieve them. The good news is that whether your goal is to reduce carbon emissions, waste or energy use, several third parties can help you navigate the uncertainties and challenges that are part of our industry’s collective journey towards a greener future.

For example, Armstrong International specializes in thermal systems, and they’ve been helping food plants around the globe reduce the amount of energy they use to heat and cool food during the manufacturing process.

According to Patricia Provot, president of the Americas at Armstrong International, food plants can cut their CO2 emissions by 70 per cent and their energy by 50 per cent, on average, by implementing key waste-heat recovery strategies.

“You can significantly reduce your energy consumption by not using steam where you don’t need it, and by direct waste-heat recovery with the use of heat

Food processors have several, easily adoptable options when it comes to creating a zero-waste company.

exchangers and heat pumps,” says Provot.

Most food facilities use steam, but since the temperatures these plants need are very low, hot water would be sufficient, believes Provot. “Plus, hot water systems are 99 per cent efficient, so that makes a big difference,” she adds.

Provot offers the example of an ice-cream manufacturing plant. First the ingredients must be heated, and then cooled. Both processes require energy. However, if the excess energy from the heating process can be captured and reused to power the cooling process, then overall energy consumption can be reduced.

While reusing energy sounds simple on paper, the implementation is com-

plex and time-consuming, so Provot recommends companies start working on their ESG goals sooner, rather than later.

“The challenge that most companies have is that they don’t monitor where all their energy goes,” Provot adds. “They know what comes in, but they don’t know how much energy goes to the dryer, or how much hot water goes to the pasteurizer, for example.”

Armstrong’s first order of business is to collect all this data through a process called thermal mapping. Once that’s done, Armstrong’s team can figure out where energy is being wasted, and how it can be collected and reused.

A good starting point in energy waste reduction would be replacing older equipment with newer, more energy-efficient options, suggests Provot.

Based in the Greater Toronto Area, U-Pak specializes in recycling and repurposing waste. Whatever can’t be recycled, reused or repurposed is turned into energy to power nearby factories.

Mark Thompson, sales and marketing director for U-Pak, explains how his company can help customers in the food industry with their ESG goals.

“We process bakery waste, including cakes, bagels, corn, you name it. We then dehydrate it at our plant, pulverize it, bag it and sell it as cattle or chicken feed. Anything with meat in it is used

Armstrong International helps manufacturing facilities reduce energy use by implementing waste-heat recovery strategies.

for compost, and paper products are shipped to mills to be turned back into cardboard or other paper products.”

U-Pak’s customers typically have a number of

waste bins on site, some of which contain food waste, others paper products or single-use plastics that can’t be recycled. U-Pak picks up all the waste, and all nonrecyclable materials are used to create fuel.

“Our waste energy plant, known as Emerald Energy From Waste, takes in these non-recyclable products, and we burn it to superheat water and create steam,” Thompson explains. “That steam goes to a paper mill across the street where it’s used in the production of paper.”

The steam is also used to power turbines, which generate electricity.

“We’re producing 9 MW of electricity on a continual basis, which is enough to power 9,000 homes in the area,” Thompson adds. Some of that energy is sold back to the grid.

The idea of burning waste to create energy is controversial. An analysis by the Canadian Zero Waste Coalition found:

• waste-to-energy (WTE) is one of the most climate-polluting waste management approaches (more harmful than landfills); and

• WTE companies have in the past failed to deliver as promised and increased pollution by releasing toxins like mercury into the air.

“Across Canada incinerators have proven to be costly failures that waste millions of dollars in taxpayer funding, exceed emission limits, never meet operational targets and delay municipalities from taking actions that would actually reduce and divert organics and post-consumer goods,” said Liz Benneian, founder of the Ontario Zero Waste Coali-

tion, in a media statement released earlier this year.

Despite the alarm being raised by environmental groups, there’s a rise in incinerator proposals across Canada. The rise can be attributed to a 2023 federal report on municipal solid waste management in Canada which recognized modern incineration as an effective method for eliminating a wide range of wastes. According to the report, incineration can reduce the volume of municipal solid waste by 90 per cent. It also noted that modern incinerators “use advanced air pollution controls and can include technologies that remove 99 per cent of the dioxins and furans emitted from incineration.”

420 kW of electricity.

“That’s important,” Thompson adds, “because our customers want to show that there’s a repurposing of the materials, and that their waste is being put to good use.”

The final question has to do with carbon offsets. “Every metric ton of waste results in seven tons of carbon offset,” Thompson explains. “That comes from a combination of the fact that our customers are not putting the waste in a landfill where it’s going to generate methane, and they’re not shipping the waste to another city or state to put in their landfills.”

This approach allows food production facilities to achieve their zero-to-landfill goals, and according to Thompson, they can do so without breaking the bank.

{ “Our customers want to show that there’s a repurposing of the materials, and that their waste is being put to good use.”

As far as ESG goals are concerned, Thompson says every metric ton of waste when converted into energy saves 1 m3 of landfill space and can generate

“The cost is comparable to what they’re already doing,” Thompson adds. “Some of our clients find savings, some find a small cost increase. It really depends on how far from our plant they’re located. But they’ve made the commitment to spend the money to have a zero-to-landfill facility. It’s not the cost of doing business; it’s the necessity of doing business nowadays because consumers are demanding that companies do better and that they’re not wasteful.”

This article was originally published in the Aug./Sept. 2024 issue of Food in Canada.

By leveraging drone technology for ultrasonic testing, Skygauge is revolutionizing asset inspections, making them faster, safer and more cost-effective.

BY CANADIAN FOOD INNOVATION NETWORK

Just thinking about the day-to-day demands of a food manufacturing asset inspector are enough to invoke sweating palms and swirling vertigo. Ascending skyward through a combination of ropes, cranes and scaffolding, inspectors painstakingly traverse up and around tall, inaccessible food processing infrastructure like storage tanks and piping to physically access dozens of measurement points required for comprehensive ultrasonic testing.

It is demanding, dangerous work. It

Using drones for asset inspections can make dangerous work a lot safer.

is also time-consuming. With inspection rates averaging just six points per hour, a single storage tank assessment can consume an entire shift—if and when they are completed, that is.

Asset inspections are critical to safety and efficiency of food processing operations, but a severe shortage of skilled asset inspection professionals is resulting in a critical bottleneck for food manufacturers across North America. However, through a groundbreaking project funded by the Canadian Food Innovation Network (CFIN),

Hamilton-based startup Skygauge Robotics is revolutionizing how these vital inspections are performed, making them safer, faster and more accurate than ever before.

Ultrasonic testing involves exceptional accuracy and diligence. Measurements demand direct contact with test surfaces, and a consistent contact force needs to be maintained. Because traditional drones cannot accomplish these feats

of precision, this sort of inspection work has largely resisted automation. Thanks to Skygauge, that is beginning to change. The company specializes in drone technologies designed specifically for ultrasonic testing of industrial infrastructure. What makes them unique from other commercial drones is a patented gimballed thrust system, which allows the drone rotors to be adjusted independently to maintain steady contact with surfaces. The drones are also equipped with an Olympus ultrasonic thickness gauge

and proprietary flight control software that maintains consistent contact force. These features enable accurate ultrasonic measurements at heights.

Supported by funding from the Canadian Food Innovation Network (CFIN) Skygauge is completing an ambitious project to complement the gimballed thrust system and flight control software of their drones with full 360-degree rotational capabilities. This would be transformative for food processing asset inspection, where infrastructure like sloped tank roofs, curved vessels and intricate piping networks present unique challenges. Unlike flat or vertical surfaces, these geometries require precise angled contact to accurately detect flaws or measure material thickness. Sloped tank roofs, for example, are common in liquid storage tanks and are notoriously difficult to access safely using scaffolding or rope systems. Similarly, the curved surfaces of process piping and vessels demand inspections from above, below, and various angles to ensure comprehensive assessments. By enabling full 360-degree drone contact, Skygauge is working to elimi-

nate the need for manual inspections entirely, ensuring that even the most complex geometries can be inspected efficiently, safely and at a reduced cost by technicians on the ground. This capability not only addresses a critical gap but also expands the range of assets that can be reliably inspected, making the entire inspection process more versatile and effective.

Skygauge’s technological breakthroughs have already demonstrated a fivefold increase in inspection speed compared to traditional methods. That

development accelerated in 2024 as Skygauge initiated a hardware redesign that will enable 360 degrees of angled contact on any sort of sloped and angled surface.

Through these industry-leading innovations, Skygauge Robotics is transforming how industrial clients approach inspections by addressing long-standing inefficiencies and safety risks. Early adopters in the food processing sector have already reported significant improvements, with inspections completed faster, more safely and at a fraction of traditional costs. By expanding their drone’s ability to inspect sloped and curved surfaces, which previously required combining multiple inspection methods, Skygauge helps its clients further drive down inspection costs by 50-90 per cent. It also increases speed tenfold— an asset inspection that would previously take an entire workday can now be completed in a single hour.

A s Skygauge continues its innova -

tive work into 2025, the company is pushing the capabilities of its drones further to fully automate inspections of the most complex and inaccessible food processing infrastructure.

B ut even at its current capability levels, the system represents a significant advance in food processing asset maintenance. As the industry grapples with labor shortages and aging infrastructure, Skygauge’s drone platform is showing how robotics can address these fundamental challenges while improving both safety and efficiency.

K eep your eyes on the sky, as the future of asset inspection may well be coming from above—and that future is arriving sooner than many expected.

CFIN funds transformative foodtech projects, stimulates collaboration, and fosters a growing community of food and beverage professionals. They’ve built the fastest growing and most engaged food business community in the country and their members come from across the globe, representing all parts of the food value chain.

Technology is revolutionizing the food and beverage industry, enhancing everything from product quality control to shelf inventory management. Here, learn how AI surveillance systems are helping Canadian companies ensure business continuity.

BY JASON CHIU

The food and beverage industry is a critical component of Canada’s economy, and maintaining business continuity in this sector is of paramount importance. Technology, including AI-backed surveillance systems, plays a vital role in enhancing efficiency and ensuring seamless operation. Their implementation has the opportunity to reshape operations in the industry,

offering new approaches to efficiency and reliability.

First, it’s important to understand that food and beverage manufacturers grapple with various challenges. Maintaining stringent health and safety standards, managing complex supply chains, ensuring operational efficiency and safeguarding against potential security threats require constant vigilance and quick decision-making.

Just recently, Statistics Canada released a statement that in 2022, Canada saw a decline in fresh fruits and vegetables due to several factors, including pandemic-related supply chain issues, such as shipping delays and shortages of labour and products. Robust surveillance systems and advanced analytics can be pivotal in mitigating some of these challenges, helping businesses ensure uninterrupted operations.

Quality assurance is a critical aspect of the food and beverage industry. With the integration of AI-backed surveillance systems, real-time monitoring of production lines has become a reality. These sophisticated systems use advanced image recognition technology to identify defects, contaminants, or deviations from the standard procedures, reducing the risk of human error and product recalls.

For instance, Maple Leaf Foods, one of Canada’s leading food processing companies, has successfully incorporated AI surveillance in its quality assurance process. It employs

smart cameras and machine learning algorithms to gain a higher level of oversight regarding their animal processing plants. This allows Maple Leaf Foods to react faster to changing conditions within their plant, while also affording them more ac-

curate product bin weight estimates and meat quality grading. Additionally, product temperature safety is assured throughout the cooling process, to provide higher-quality, safer products to customers.

Network surveillance devices, such

as IP cameras and sensors, are key to real-time monitoring. They provide valuable visual and sensory data, giving businesses an eye on every stage of the production process. From monitoring raw material intake to tracking the packaging of finished goods, these devices provide a wealth of information. Besides, their networking capabilities facilitate remote monitoring, a critical aspect in today’s remote-first working paradigm. In addition, related technologies such as thermal imaging can aid in alerting of and proactively preventing incidents and factors which affect food safety and security.

Intelligent analytics turn raw data into meaningful insights. They employ advanced deep learning and artificial intelligence algorithms to identify patterns, predict trends, and detect anomalies. These systems are capable of analysing data from multiple sources, providing a comprehensive view of the operation. This is

invaluable in managing production efficiency, maintaining product quality, ensuring safety compliance, and optimizing inventory management.

The convergence of network surveillance and intelligent analytics offers a powerful solution for businesses in the food and beverage industry. Devices may now serve dual purposes, while being installed for safety and security, the real-time data from network surveillance devices feeds into the business intelligence systems, which then provide actionable insights. This allows businesses to identify bottlenecks, improve efficiency, and respond quickly to any potential disruptions. As a result, they can maintain a high level of service and ensure business continuity.

Numerous businesses in the food and beverage industry are already leveraging the power of network surveillance and intelligent analytics. A dairy company, for instance, might use thermal cameras to monitor the temperature of its production processes. Anomalies in the temperature data can help identify potential equip-

ment failures or quality issues before they lead to significant problems.

Similarly, a beverage company could use high-resolution cameras to inspect labels on bottles. The images captured by these cameras can be analysed in real-time by an intelligent analytics system to ensure the labels are correct and properly aligned. This not only helps maintain quality standards but also speeds up the production process.

By providing real-time data and insightful analytics, network surveillance devices and intelligent analytics systems can significantly enhance operational efficiency. In the long run, these improvements can lead to substantial cost savings and better productivity, contributing to business continuity.

Beyond the manufacturing process, AI-backed surveillance systems can come into play at the final stages of the food and beverage industry as customers frequent grocery stores. Few things are more upsetting to grocery shoppers than a desired product being

unavailable, or even worse being incorrectly listed as available online and out-of-stock in-person. AI surveillance can solve for both issues through the implementation of computer vision cameras, which can detect and recognizing products on a store shelf.

The application of this technology is varied, with the simplest use being automated, timely tracking of product stock. From there, this technology could be used to inform decision making across the grocery retail space. When products are approaching a low-stock threshold, automated notifications could be pushed to store associates. Items placed in incorrect locations could be tagged for replacement, and food wastage could be reduced with better ordering practices for perishable goods. Essentially, AI-backed surveillance systems can eliminate guesswork from this section of the supply chain.

As we look to the future, it’s clear that technologies such as AI, IoT and data science will continue to drive

advancements in network surveillance and intelligent analytics. They will enable more sophisticated data collection and analysis, resulting in even more accurate predictions and more efficient operations. As a result, the food and beverage industry will be better equipped to meet increasing demand.

AI-backed surveillance systems are playing an increasingly significant role in the Canadian food and beverage industry, helping to enhance safety and increase efficiency. As technology continues to evolve, these systems will become even more integral to the industry’s operations. The integration of AI surveillance promises a more robust, efficient, and safe food and beverage sector for Canada, ensuring that we can enjoy our favourite foods and drinks without interruption.

Jason Chiu is the professional services group manager with Axis Canada. He has a background in IT and networking and has spent over 15 years in the security industry, from being an integrator, consultant and manufacturer.