FOOD BEVERAGE

The top priority when manufacturing food is maintaining hygiene standards.

For your gearbox rebuild program.

Learning from peer experiences.

Mario Cywinski mcywinski@ annexbusinessmedia.com (226) 931-4194 ACCOUNT CO-ORDINATOR Barb Vowles bvowles@ annexbusinessmedia.com (416) 510-5103 CIRCULATION MANAGER Beata Olechnowicz bolechnowicz@ annexbusinessmedia.com (519) 376-0470 (866) 323-4362

scasemore@emccanada.org

Water Here, Water There, Water Everywhere!

What is one of the most used elements in the food and beverage industry? Well, water of course. It is used for everything from washing the food, the utensils, the machines, worker’s hands, and you cannot have beverages without it.

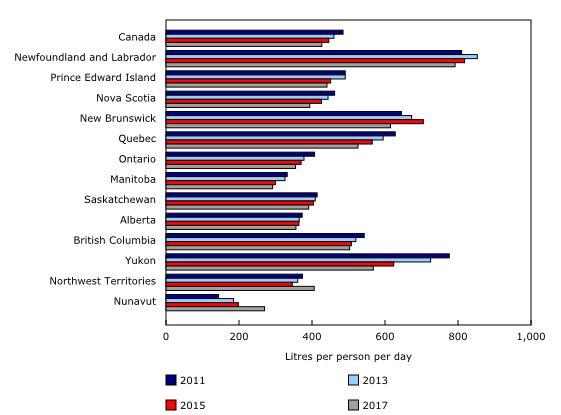

Earlier this year, Statistics Canada released a survey on Drinking Water Plants (2017), which outlined water use, capital expenditures, and operation and maintenance costs for water plants in Canada. The survey had some interesting findings, as it showed that while water use is on the decline, costs to deliver that water to the public is on the rise.

Looking closer, between 2011 and 2017, water use overall fell by 12 per cent. Total per capita water use (which includes commercial and industrial, as well as residential) fell to an average of 427 litres per person per day in 2017, from 485L in 2011.

This all sounds good, as usually when you have less of something it should cost less to maintain. However, the existing water infrastructure needs to be upgraded, and hence the costs are on the rise. In 2017, $871 million was spent on upgrading existing infrastructure and commissioning new components, an increase of 19 per cent over 2011 ($734 million). Statistics Canada included upgrades such as building and machinery improvements, processing equipment, and physical assets that get and treat the water. But they excluded water distribution infrastructure in those costs.

Maintenance and operation costs have also increased, 11 per cent to $1.1 billion in 2017. Of this labour was the biggest expense at $460 million, with energy ($258

million), materials ($240 million), and other costs ($173 million) rounding out the totals. What does all this mean to the food and beverage industry? As costs go up at the source end, the costs to get water will ultimately also continue to increase. Therefore, it is imperative that food and beverage companies (who use a lot of water) find ways to cut down on their water use, as a cost saving measure.

Mario Cywinski, Editor

FOOD BEVERAGE

& NEWS

CONTINENTAL

PLANT IN QUEBEC RECEIVES SANITARY STANDARDS CERTIFICATION

Continental’s industrial hose plant in Granby, Quebec has received a major sanitary standards certification from 3-A SSI for a selected range of food and beverage hoses.

The 3-A SSI is an independent, non-profit organization that leads

the development of standards for equipment and accepted practices for processing systems through a modern consensus processes based on ANSI (American National Standards Institute) requirements.

The certification No. 3727 and the designation 18-03 (for rubber and rubber like materials) received by Continental’s Granby plant places

them in a unique category.

“There is a distinct difference between compliance and certification,” said Laszlo Dobo, Continental Product Manager for Industry Hoses in North America. “Anyone can claim ‘compliance,’ but certification comes only from an independent organization. 3-A SSI has very strict standards because they represent the

end-users and the public. They provide special knowledge resources on hygienic equipment design to enhance professionalism and to serve the public health sector.”

EMC NAMES FIELD SERVICE ADVISOR

Excellence in Manufacturing Consortium (EMC) announced that

Leah Nacua will be taking over as Field Service Advisor for GTA consortiums.

She has over 18 years of experience in the manufacturing sector, spanning a wide breadth of industries including automotive, telecommunications, solar, medical devices, plastics, and food packaging. She has worked in a variety of areas such as engineering, quality, and continuous improvement.

Nacua is a long-time EMC supporter and has broad knowledge of manufacturing and EMC. In the coming months Leah will be in touch with members and community partners to ensure continuous support to

all consortium regions in the GTA.

Also at EMC, Stephanie Yakim ishyn is transitioning from Field Service Advisor to the Member Needs Help Program.

Yakimishyn has contributed significantly to shaping the role of a successful FSA, holding the role for nearly 20 years.

Ross Cooper, has been named to the role Field Service Advi sor for Barrie, Midland and Collingwood. Cooper has been a longstanding Senior AdvisorValue Added Programs, which he will continue with, in addition to his new role.

Summer Promo:

HYGIENE MEANS RESPONSIBILITY

The top priority when manufacturing food is maintaining hygiene standards.

BY REBECCA LORENZ

Mould spores, mouse droppings and cockroach nests, what food safety inspectors found in the production plant of a large German bakery a few years ago was anything but appetising. Unfortunately, shocking hygiene violations like these are not as rare as you might hope. Whether in Canada, the USA, Germany or China, new cases are constantly hitting the headlines.

As consumer confidence crashes, it is not uncommon for these incidents to end with the company in question closing its doors for good. After all, when it comes to food safety, both the authorities and consumers take matters very seriously.

It is no surprise then that hygiene regulations for the food industry are set out at both international level – as with ISO 22000, Hazard Analysis and Critical Control Points and the Codex Alimentarius – and national level. Keeping track of all these rules and regulations is no easy task, particularly for small and medium-sized business. However, it is not impossible, as Dutch food processor Huuskes has shown.

Established in 1956, Huuskes is a leading supplier of raw, frozen and convenience foods in the Netherlands, employing a workforce of over 800 and generating €100 million in sales.

“To make sure we don’t let our customers down, we are always looking to maximise quality and hygiene standards in production,” said Frank Hagmolen, Head of Technical Services, Huuskes.

What about legal requirements? They are the minimum standard at the company, as it is also implementing the latest guidelines from the European Hygienic Engineering and Design Group (EHEDG), which affect the working environment of the processing machinery.

Food production at Huuskes centres on state-of-the-art machine and plant technology, which is controlled on a largely automated basis with the aid of scanners. Hygienic design, for example, the engineering of hygienecompatible machinery, plants, housings and enclosures, is an important factor for product safety in food processing. Dirt must not be allowed to accumulate or remain on surfaces and must be easily removable.

“We would prefer it if all our suppliers could guarantee optimum ease of cleaning for their products,” said Hagmolen. “Since that isn’t the case, we do everything we can to find the best solutions ourselves.”

“We asked our colleagues [at Rittal] to take an unbiased look at our production environment. External feedback is important to us. That’s the only way we can be objective.”

For Hagmolen, the fact that Huuskes is certified to ISO 9001 and holds a Skal certificate for the storage and supply of organic products is a testament to the company.

“There’s no better proof of quality and hygiene. Ultimately, these certificates show our customers that we meet even the highest standards,” said Hagmolen.

Article written by Rebecca Lorenz, and provided by Rittal: be top - Magazine of the Friedhelm Loh Group.

During a detailed inspection, Rittal identified a problem in the production plant. The old plastic enclosures designed to protect the fire extinguishers from humidity and cleaning agents were unfit for purpose.

“Due to their surface quality and design features, plastic enclosures work out less hygienic in the long run. Bacteria and dirt can accumulate on the surfaces and in the dead spaces,” said Freddy van de Kolk, Key Account Manager, Rittal. “Because stainless steel cleans up very well, significantly less cleaning agent and disinfectant needs to be used.”

Supplied as standard with gap-free silicone seals, a sloping roof and a captive screw fastener, stainless steel enclosures satisfy all European standards and guidelines – and also improve safety.

“The Hygienic Design enclosures enable easy and reliable cleaning,” said Hagmolen. “That is an important requirement for us, as we simply can’t compromise on hygiene.”

CHOOSING THE BEST SEAL FOR YOUR GEARBOX REBUILD PROGRAM

In the strive for operation efficiency, it is well worth the effort to explore the best style of bearing isolator (seal) to be used for gearbox repair programs. To achieve this, we need to compare the differences between pumps, electric motors and large gearboxes. Many seal vendors tend to group gearboxes in with pumps and electric motors but there are many internal differences between these basic rotating machines.

To try and cover everything using labyrinth or lip seal technology is not a great idea. If your gearbox repair program has not been updated in the past few years, it will not have considered the recent evolution in seal technologies. In the

past, end-users have experienced the benefits of upgrading from lip seals to labyrinth seals and more recently, to magnetic flat-face seals. Based on over 40 years of rotating equipment experience, lip seals and labyrinth seals are not well-suited for large gearbox repair programs. For several reasons, including, neither seal design works well in aggressive flooded oil when shafts are rotating. Most large gearboxes use tapered roller bearings on all shafts and most pumps and electric motors use ball bearings. A tapered roller bearing is a great oil pump and when oil is introduced to the centre from the top of the double tapered bearing assembly, the oil will flow down into the

bearing set and exit out of both sides of the bearing. Half of the oil gets pumped back into the gearbox reservoir while the other half gets pumped aggressively toward the

lip or labyrinth seal. Labyrinth seals do not work well in a flooded oil condition because they have a leak path built into the design (figure 1). Some labyrinth

seal vendors claim that their internal O-ring design will move or adjust to block the leak path when the seal is not rotating. This O-ring concept has proven to be ineffective in the past (“Pump Zone” by Heinz Bloch). I’ve consulted with Bloch for years and agree that the inner O-ring does not work as designed. Even if the O-ring worked, a gearbox seal needs to retain oil in a dynamic flooded condition as well as static.

Lip seals will hold a head of oil but they do not last as long as most gearbox OEMs assume. Most effective gearbox designs have a drain on the seal side of the tapered roller bearing which returns the excess oil back into the reservoir. If this drain is too small or becomes blocked, a leaky seal is imminent. As part of your normal gearbox repair program you should inspect the oilreturn drain hole and make sure it is clean, clear and large enough for the amount of oil being pumped to each bearing location. Another issue with a lip seal is

that the lip cuts a groove in the shaft and causes expensive shaft damage (figure 2). This fact alone illustrates a strong argument for not using lip seals for high speed (input) shafts on gearboxes.

Gearboxes use heavier oil than most pumps and electric motors. Also, the shafts do not typically run as fast as these higher speed machines. On a normal parallel shaft gear reducer, you have one high-speed shaft that can run as fast as any motor or pump, but the lowspeed shaft rotates much slower in comparison. Most gearbox OEMs have a good lip seal design that utilizes two lip seals with a grease purge between the two lips to act as a barrier for contamination, and lubricating the lip surface. Due to the slower speed of the low-speed shaft, this special lip seal design may last for many years without any issues. Input seals run at a higher rotational speed so the risk of oil leaking or cutting a groove in the shaft is much greater than output seals. The size of the input

seal is also smaller, which keeps the cost of the aftermarket seal option lower than the larger output seal. This is not always the case for the output seal as they can be very large and expensive. If the output shaft seal has never leaked oil than it may not need to be upgraded. If the output shaft seal permits oil to leak or allows the ingress of contamination, than the more expensive aftermarket seal is definitely worth exploring. Lip seals are not a great barrier from outside contamination, especially once the lip wears a groove on the shaft surface. A better aftermarket seal is worth the extra cost for all input seals for every gearbox application.

WHAT IS THE BEST AFTERMARKET SEAL FOR YOUR GEARBOX REPAIR PROGRAM?

It is recognized that using labyrinth seals on pumps or electric motors has been the accepted tradition for many years for most end users. There are better, more modern options than the traditional

labyrinth for pumps and electric motors, but this discussion is based on gearbox repairs only.

The best style of seal that will work effectively on all large gearboxes is a magnetic flat face style seal, which can hold a head of oil (static and dynamic). There are several magnetic seals on the market today. The best magnetic seal has the least amount of seal faces, which creates less drag, less wear and less

heat, and allows for slight misalignment of the shafts.

One such magnetic seal does all these things with a single face seal and inner O-ring for misalignment.

The inner O-ring is nothing like the inner O-ring design found in labyrinth seal designs. The inner O-ring allows for the seal cartridge to adjust, accommodating for shaft misalignment. This O-ring has nothing to do with holding the oil pressure as the

seal faces retain the oil.

One magnetic seal has been carefully designed to accommodate for the heavier oil found in gearboxes. Figure 3 shows a magnetic seal design with the rotor (and rotor O-ring) on the outside. If the lip seal wore a groove in the shaft then this style of seal would avoid having the rotor O-ring sitting on the worn area of the shaft so the damaged area would not need to be replaced or repaired. Avoiding these extra repair costs would offset the extra cost for this innovative seal solution. This is a major cost saving for any end-user.

You can also request the seal with a bolt-on flange to fit existing bolt patterns of your gearbox. See figure 4 for this option for your gearbox repair program.

Nick Agius is a Rotating Equipment Specialist for Motion Industries (Canada). His Anti-Rotation Device (ARD) solution for Canada and the U.S. was first patented in 1996, followed by two other patents. For more information visit: MotionIndustries.com/MROMag.

It’s exciting to watch as manufacturers learn from peer experiences, gain new perspectives, and enhance skills.

Over the past 18 years, I am fortunate to have played an active role in sharing the wealth of opportunities available through involvement in Excellence In Manufacturing Consortium (EMC) activities. With a new decade starting, and resolutions for personal growth and development beginning to form for many, EMC provides a perfect means through which one can explore your potential.

Consider the development of leadership skills. A leader is someone who coaches, lends support, sees your potential, and encourages you to grow while continuing their own education and growth. There are several means to build knowledge and enhance skill development; through training initiatives, peer networking, connecting with others or building on lessons learned through larger activities such as conferences, forums or summit involvement.

NETWORKING OPPORTUNITIES:

Participation in EMC’s Strategic Interest Group (SIG) peer networking sessions, allow you to take stock of best practices, and provide the perfect forum to engage in discussion and to learn from plant tour opportunities.

During a best practice sharing event for the food and beverage sector, a CEO outlined his perspectives on the concept of leadership in manufacturing. It’s an age of considerable change, competitive environments, rising costs, talent shortages and general unpredictability. He said that through strong leadership and a culture that fosters and develops teamwork, great things can happen. We learned that a leader can create effective leadership through vision, accountability and energy; and that a leadership style and decision-making process is unique to everyone. As leaders, he challenged people to ask themselves “what is the

positive change that we want to create?”

One of the takeaways was a list of his top 100 books that inspired him in his role. Interestingly, the books ranged from days long past to new releases; beginning with the 1859 publication of Charles Darwin’s Origin of Species evoking thought on “The World Around Us.” As he reads, he summarizes and classifies books under categories such as strategy, personal development, operations, marketing and sales, leadership, human resources, and great ideas. The reading opened up the CEO’s mind and perspectives to the broader world while enhancing his knowledge on various aspects of the business at large. This is something we can all do, with countless articles and books that can engage a mind on this subject.

The BC Lower Mainland SIG Consortium will be hosting a roundtable discussion on this concept at the end of the year and through general discussion and shared experiences will look at:

• What makes a great leader? What are the best attributes?

• How has leadership changed? What is the Leader’s role in change, growth and culture?

• What are the biggest challenges facing your company and your industry today?

• How do you develop, connect, engage your people and inspire engagement?

• How do you identify leadership potential and then cultivate that talent?

• What will tomorrow’s leaders need to take stock of to be successful?

There are over 60 Consortiums in EMC’s network across Canada who are meeting on a regular monthly basis sharing best practices on a broad range of topics and areas of interest. These are just a couple of examples from a peer networking standpoint, where participants have had the chance to build knowledge based on others’ experiences, broaden perspectives perchance, engage in discussion and hone skills when it comes to leadership development. The opportunities from a peer networking standpoint are endless.

EMC LEARNING CENTRE:

Leadership is also a very important component of EMC’s Learning Centre. Companies are keen to invest in growing and developing their talent and we have been able to offer courses that look at how best to coach, engage and help people find success. Whether perfecting facilitation skills, building supervisory abilities, increasing lean objectives, engaging a team, or managing conflict, there are a number of courses available publicly, in-house and online.

• Practice of Leadership Workshop

• Management Skills and Leadership Styles

• Trust, Teamwork and High Performance

• Lean Supervisor

• CI Facilitation Skills

• Communications for Supervisors and Managers

• Performance Management

• Managing and Mediating Workplace Conflict

• Harvard Supervisory Certificate Program

• MEC – Manufacturing Essential Certificate

• On-Line Skills and Learning Portal (1000’s of Topics)

For additional information on any of these reach out to the EMC Learning Centre.

SPECIAL CONFERENCES, SUMMITS, FORUMS:

The EMC National Advantage Through Excellence conference is a forum that presents everyone in attendance with the chance to learn from and engage in discussions on a variety of key focus areas. It’s a time to think about the future of manufacturing, garner insight, connect with industry experts, take back ideas to our own organizations, and build long-lasting relationships with like-minded peers from across Canada.

As 2020 unfolds, there will be a number of food and beverage conferences and related manufacturing summits to follow that enhance our skill development and knowledge. Take advantage of these opportunities when you can to learn and grow and bring ideas, concepts or insights back to others to aid in their growth.

Whether leading your team in a 5-S initiative in your maintenance shop, envisioning means to attract new talent, or strategizing ways to be more competitive in the global marketplace, at the end of the day, we all have a role to play when it comes to leadership within our organizations.

As you look to 2020 and consider your personal development and growth, what opportunities are you going to explore that enable you to inspire, assist and engage others in your projects or in your business at large? How will you share lessons learned? How will you develop your own leadership potential?

If you are interested in learning more about involvement in EMC’s programs and services including SIG or our special food and beverage sector networking sessions, feel free to reach out and we would be happy to share information on what is coming up in your region.

Excellence In Manufacturing Consortium (EMC) is a not for profit association of manufacturers that began in the mid-80s when a group of like-minded senior managers first came to the

UPCOMING FOOD AND BEVERAGE SECTOR TOPICS:

• Building a World-Class Food Safety Culture

EMC Food, Beverage, Bio and Ag Program Networking Topics for 2020

• Business Growth

• Leadership Development

• Retention and Attraction Best Practices

• Adoption of Technology

table seeking means in which to work together on common challenges. Today, with 1,000’s of members across Canada, we continue to develop programs, services and initiatives that enable competitiveness in industry for 2020 and the years to come.

How do you get involved? If you are interested in learning more about EMC and the Food Sector Initiative, please feel free to touch base with Bren de Leeuw, National Director – Program Delivery and EMC Food, Beverage and Bio Sector Program (bdeleeuw@emccanada.org) anytime.