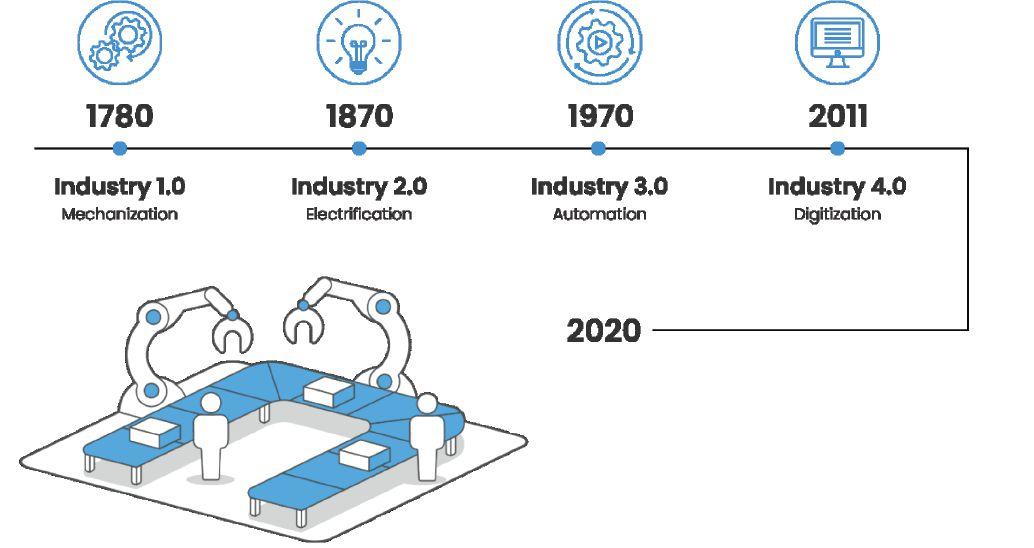

Industry 5.0 –

Industry 5.0 is a shift away from purely tech-driven advancements, integrating the creativity of people with intelligent systems.

While Industry 4.0 focuses on digitalization and manufacturing efficiency, Industry 5.0 looks to customize manufacturing.

4.0

Drive greater manufacturing speed, precision, and efficiency

Human roles are minimized and machines handle repetitive tasks with limited oversite

5.0

Enable highly personalized, on-demand manufacturing

Human roles are strategic, using creativity to solve complex needs rather than replacing them

Explore now

Enhance operational efficiency and productivity with innovative solutions from the Komax Group. Harness our combined expertise to access an extensive suite of products and services designed to deliver optimal performance, superior quality, and exceptional value to your wire processing operations. We are committed to providing smarter solutions and building stronger relationships.

Connect with us at EPTECH

Dear Exhibitors and Attendees,

On behalf of EP&T Magazine, it is my pleasure to welcome you to EPTECH 2025, Canada’s premier series of electronics trade shows. For more than four decades, EPTECH has brought together energetic minds and innovative companies in the electronics industry, fostering connections that drive technology forward. Whether you are here to source new components, explore test and production equipment, evaluate software solutions, find a CEM or establish new distribution channels, you are part of a thriving ecosystem that continues to shape the future of electronics.

Canada’s electronics sector is evolving at an unprecedented pace, with advancements in AI, semiconductor manufacturing, wireless communications, and embedded systems redefining the landscape. EPTECH provides a unique platform to stay ahead of these trends, offering direct access to suppliers, engineers, and industry leaders who are shaping the next generation of technology. These table-top trade shows are designed to maximize engagement, allowing attendees to discover cutting-edge products and services while networking in a focused, dynamic environment.

One of EPTECH’s greatest strengths is its reach across Canada, bringing the industry together from coast to coast. Whether you are visiting us in Vancouver, Calgary, Toronto, Montreal, Edmonton or Mississauga, EPTECH ensures that technology professionals have access to the latest innovations

right in their own regions. This accessibility is critical in keeping your finger on the pulse of Canada’s electronics market.

Beyond the exhibition floor, EPTECH offers invaluable opportunities to gain industry insights and build strategic partnerships. The event attracts professionals from all corners of the industry, including designers, engineers, procurement specialists, and business leaders. Whether you are a seasoned exhibitor showcasing the latest solutions or an attendee looking for the right connections to fuel your projects, EPTECH is the ideal place to make those interactions happen.

I also want to take a moment to acknowledge and thank our exhibitors—your participation is what makes EPTECH a success year after year.Your dedication to innovation and commitment to advancing technology is evident in the products and solutions you present. Equally, to our attendees, thank you for making the time to explore and engage with the many companies exhibiting here.Your curiosity and drive to push the boundaries of what’s possible keep this industry moving forward.

As you navigate EPTECH 2025, I encourage you to take full advantage of all that the show has to offer. Ask questions, forge new relationships, and explore the latest breakthroughs that can help propel your business and projects to new heights. Our team at EP&T Magazine is thrilled to once again be the driving force behind this event, and we look forward to seeing the meaningful collaborations that will emerge from it.

Thank you for being part of EPTECH 2025. I wish you a productive and inspiring experience!

Stephen Law Editor, EP&T Magazine

3G METALWORX

2-90 Snow Blvd

Concord, ON L4K 4A2

Canada

Phone: (289) 845-3513

Email: mkovatch@3gmetalworx.com

Website: 3gmetalworx.com

Board shielding, enclosure shielding, microwave absorbers, and thermal solutions.

CANADA BRIO TECHNOLOGY LTD.

223 – 8678 Greenall Avenue, Burnaby,BC V5J 3M6

Canada

Phone:(604) 430-2027

Email: fiona.wu@brio-tech.ca

Website: brio-tech.ca

CCI CANADIAN CIRCUITS INC.

12 13140 88 Avenue Surrey,BC V3W 3K3

AMPCO MANUFACTURERS INC

101 -9 Burbidge Street

Coquitlam,BC V3K 7B2

Canada

Phone: (604)472-3841

Email: rick.gagne@ampcomfg.com

Website: ampcomfg.com

Membrane Switches and Graphic Overlays, Backlit Displays, Durable Nameplates and Decals

AUGUST ELECTRONICS INC.

1810 Centre Avenue Northeast

Calgary, AB T2E 0A6

Canada

Phone: (403)479-5344

Email: adove@aeicm.com

Website: aeicm.com

Electronic manufacturing services (EMS) provider

BRADY CANADA

710 Cochrane Drive

Markham,ON L3R 5N7

Canada

Phone: (416)433-9786

Email: jane_flemming@bradycorp.com

Website: bradycanada.ca

Printing Systems, Lockout Tagout.Identification Automation

Canada

Phone: (604)599-8600

Email: pam@canadiancircuits.com

Website: canadiancircuits.com

ELEMENT MATERIALS TECHNOLOGY

2425 Industrial Boulevard Chambly, QC J3L 4W3

Canada

Phone: (450)-279-1006

Email: magali.picotte@element.com

Website: element.com

Testing, Inspection, and Certification (TIC)

COMTREE INC.

54-6625 Kitimat Road Mississauga,ON L5N 6J1

Canada

Phone: (905) 673-7777

Email: jill@comtreeinc.com

Website: comtreeinc.com

JBC, AIM, Tagarno

EMA DESIGN AUTOMATION

Phone: (585) 334-6001

Email: chrisb@ema-eda.com

Website: ema-eda.com

OrCAD X|Allegro X|Sigrity X

EMX ENTERPRISES

250 Granton Dr. Richmond Hill, ON L4B 1H7

Canada

Phone: (647)271-4459

Email: clegiehn@emx.ca

Website: emx.ca

Product Development & Manufacturing

DB LECTRO INC.

3755 Place Jave 140

Brossard,QC J4Y 0E4

Canada

Phone: (450)444-1424

Email: fbergerodblectro.com

Website: dblectro.com, mornsun-power.com, gowinsemi.com, altechCorp.com

EPIC RESINS

Phone: 1-800-242-6649

Email: kbrown@epicresins.com

Website: epicresins.com

Epoxy and Polyurethanes for Industry

FORESEESON TECHNOLOGY

4460 Jacombs Road,Unit 101 Richmond,BC V6V 2C5

Canada

Phone: (778) 378-7637

Email: enicolas@foreseeson.com

Website: foreseeson.com

PCBA/EMS services

JBC TOOLS INC.

9296 Dielman Industrial Drive

Saint Louis, MS 63132

United States

Phone:(314) 624-9933

Email: isilva@jbctools.com

Website: jbctools.com

Soldering Tools

LEMO CANADA INC.

44 East Beaver Creek Rd. Unit 20 Markham, ON L4B 1G8

Canada

Phone: (905) 889-5678

Email: mcolacino@lemo.com

Website: lemo.com

Connector Cables and cable assemblies

KINGSTEC TECHNOLOGIES (NEW LOGO FOR 2025)

HAMMOND MANUFACTURING

601 Colby Drive Waterloo,ON N2V 1A1

Canada

Phone: (519)886-7170

Email: rnhammond@hammfg.com

Website: hammondmfg.com

Electronic enclosures, electrical enclosures, electronic transformers

HANSEN INDUSTRIES LTD

2871 Olafsen Ave

Richmond,BC V6X 2R4

Canada

Phone: (604)278-2223

Email: meiling@hanind.com

Website: hansenindustries.com

CNC Machined products, Custom made sheet metal products, Stamping samples

HEILIND ELECTRONICS

Phone: (425)286-5960

Email: aelford@heilind.com

Website: heilind.com

TE Connectivity|Molex|Amphenol

2335 Argentia Rd. Mississauga, ON L5N 8K5

Canada

Phone: (905) 712-2172

Email: rosa@kingstec.com

Website: kingstec.com

Custom cable assemblies and wire harnesses, PCB’s and assemblies.

KOKI SOLDER AMERICA INC.

Phone: (951) 245-8755

Email: shantanu@kokiamerica.com

Website: koki-global.com

Solder Paste|Solder Wire|Wave Soldering Flux

LEACH PCBA INC

107-7188 Progress Way

Delta,BC V4G 1M6

Canada

Phone: (778)222-3381

Email: julie@leach-pcba.com

Website: leach-pcba.com

Electronic assembly contract manufacturer, PCB Assembly offshore factory, turnkey assembly manufacturer

www.stencil-express.com

M W T ech are ronik

MECHWARETRONIK - STENCIL EXPRESS

215 - 12837 76th Avenue

Surrey,BC V3W 2V3

Canada

Phone: (778)590-0358

Email: orders@stencil-express.com

Website: stencil-express.com

SMT laser cut stainless steel Solder Paste stencils, precision tooling pallets, custom plastic enclosure cutouts

METALCRAFT TECHNOLOGY INC.

273 Schoolhouse St. Coquitlam, BC V3K 4Y1

Canada

Phone: (604) 515-1877

Email: feroz@metalcraft.ca

Website: metalcraft.ca

Sheet Metal Fabrication, Powder Coating

MOUSER ELECTRONICS

37 Glasgow Street Unit 475 A Kitchener, ON N2G 4X8

Canada

Phone: (800) 346-6873

Email: mauro.salomao@mouser.com

Website: mouser.com

NXP Texas Instrument Microchip, Digi, Amphenol, Infineon, etc.

Located in Burnaby, BC, SAPA Technologies is a one-stop EMS provider serving North American customer in a variety of industries including automotive, medical, lighting, communications and many more.

We provide high quality PCB assembly service at competitive prices, from prototyping to high-volume production, from consumer electronics to industrial controls, from Through Hole only to high mix design.

SERVICES INCLUDE:

• SMT and Through Hole Assembly

• Turnkey & Consigned solution

• Components sourcing & inventory management

• Cable and Enclosure Assembly

• Testing & Reworking

• Conformal Coating

• Design for Manufacturing

SPECIALTIES:

• High speed SMT line Lowcost for volume production

• LED board Expert: all types of LED (flat, ball, odd form), all types of PCB (flex, oversize, metal)

• Fine pitch, BGA, QFN and 0201 package

• BOM review for cost control

• 24hr rush service

ERP system with a client portal to manage and monitor orders on the go

X-ray inspection machine

X-ray counting machine

BGA reworking station

PCB cleaning machine

Batch conformal coating machine

Selective soldering machine And much more!

3202 Beta Ave, Burnaby, BC, Canada, V5G 4K4

Phone: 1-604 520 5611

Email: sales@sapatechs.com

NEMKO

303 River Road

Ottawa,ON K1V 1H2

Canada

Phone: (613) 266-9305

Email: gilles.philion@nemko.com

Website: nemko.com

Regulatory Testing|Inspections|Certifications

NORTHERN COATINGS LTD.

48 Centennial Rd

Orangeville, ON L9W 3T4

Canada

Phone: (519)941-7007

Email: maryann@northerncoatingsltd.com

Website: northerncoatingsltd.com

Conformal Coating Application, Conformal Coating Service

OMNION POWER

327 Parkview Road

Glenview, IL 60025

USA

Phone: (224)244-1589

Email: paul.ganvik@omnionpower.com

Website: omnionpower.com/ AC/DC single phase and three phase power supplies, DC/DC Isolated Power supplies, Rack mounted power systems

PHOENIX CONTACT

8240 Parkhill Drive

Milton,ON L9T 5V7

Canada

Phone: (800) 890-2820

Email: hbarriage@phoenixcontact.ca

Website: phoenixcontact.com/en-ca

Global player in Interconnection, Interface, and Automation Technologies

QAI LABORATORIES

3980 North Fraser Way Burnaby,BC V5J 5K5

Canada

Phone: (877)461-8378

Email: dgualdron@qai.org

Website: qai.org

Electromagnetic Compatibility Testing, Electromagnetic Compatibility Inspection, Electromagnetic Compatibility Certification

PRICE ELECTRONICS

638 Raleigh St Winnipeg, MB R2K 3Z9

Canada

Phone: (204)890-2947

Email: jordan.bettencourt@priceelectronics.ca

Website: priceelectronics.ca

Price Electronics offers a comprehensive range of services, including DFM review, rapid prototyping, turnkey solutions, PCB assembly, and more

PRODEXPORT TECHNOLOGIE INC.

1930, rue de l’Interlude, local 205 Quebec City, QC G3K 0R6

Canada

Phone: (418)266-7977

Email: achat@prodexport.ca Website: prodexport.ca

Electronic Manufacturing Services in Asia, Cost reduction and supply chain optimization, Custom cables and connectors

REBOUND ELECTRONICS

49 High Street Unit 309 Barrie, ON L4N 5J4

Canada

Phone: (705)315-5220

Email: canada@reboundeu.com

Website: reboundeu.com

Independent Distributor, Component Sourcing, Obsolescence Management, Shortages, PPV, Vendor Tail Management, Nujvonix Franchise

RMF DESIGN & MANUFACTURING

5675 Timberlea Blvd Mississauga,ON L4W 2S4

Canada

Phone: (905) 602-6777

Email: mdenicola@rmfdesign.com

Website: rmfdesign.com

Providing electronic engineering, programming, prototyping and manufacturing services

Author: Hector Barresi

(Source: KPs Photography / stock.adobe.com)

The manufacturing industry has always been at the forefront of technological innovations. From the advent of the steam engine in the 1700s to the invention of the assembly line by Henry Ford, manufacturing has been one of society’s greatest drivers of change.

Today, the manufacturing industry is once again experiencing a series of unprecedented changes.

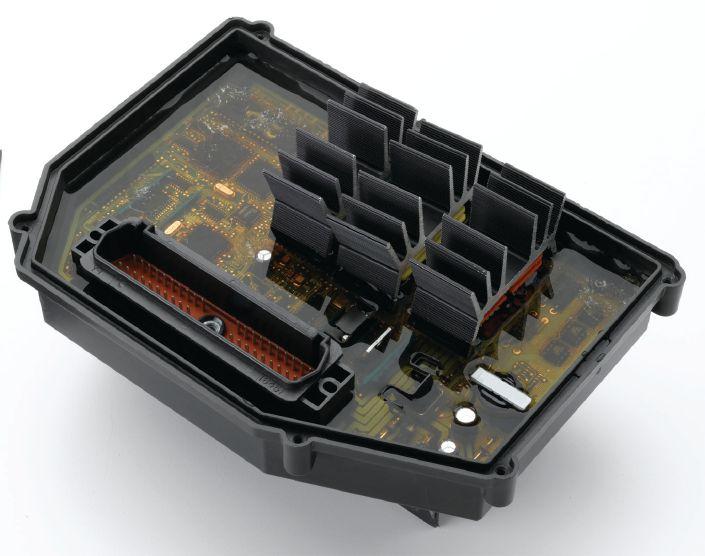

The proliferation of robotics, advanced sensors, device connectivity, and advanced analytics has led to modern Industry 4.0 manufacturing. Now, the field is poised for yet another change, with a transition into the world of Industry 5.0.

advancements such as the Internet of Things (IoT), artificial intelligence (AI), cloud computing,and edge computing. This era introduces the capability to gather, analyze, and use vast amounts of data in real time, which enhances decision-making processes, predictive maintenance, and overall operational efficiency. Ultimately, the result is a comprehensive advancement over Industry 3.0 to create more agile, efficient, and responsive manufacturing systems. However, Industry 4.0 remains focused mainly on the manufacturing side of things, answering questions about how to make more products faster, more consistently, of better quality, and at lower cost.

Industry 5.0 expands the technological advancements of Industry 4.0 and augments them by considering human factors. It seeks to redefine roles within manufacturing and beyond—encompassing supply chains and entire operational landscapes—to create a more cohesive, adaptive, human-centric, and sustainable industrial environment.

This blog discusses the differences between Industry 4.0 and Industry 5.0, the challenges facing the evolution from Industry 4.0 to Industry 5.0, and some ways to make the transition as seamless as possible. At present, most modern factories are classified as “Industry 4.0,” and are commonly referred to as “Smart Factories.”

Industry 4.0 is marked by a significant shift toward a more interconnected and intelligent manufacturing environment, leveraging

This paradigm shift moves beyond viewing machines as mere tools for productivity and advocates for a collaborative synergy in which technology enhances human capabilities, creativity, and decision-making processes. The fundamental aim is to achieve a balanced symbiosis between advanced technological systems and the unique insights and values

humans bring to the table, ensuring that industrial progress supports both efficiency and thewell-being of society at-large. Within this industrial revolution, a significant focus lies on fostering seamless communication and interactions between humans and machines.

While the differences between Industry 4.0 and Industry 5.0 are clear and defined, understanding the larger societal and geopolitical factors driving this evolution is essential.

One major driver of Industry 5.0 is resilience in the face of global challenges.

Starting in 2020, the COVID-19 pandemic and subsequent disruptions exposed vulnerabilities within global manufacturing networks. In the face of these challenges, Industry 5.0 emphasizes resilience and flexibility, aiming to build systems that can adapt and recover from unforeseen events more efficiently.

In a similar vein, the COVID-19 pandemic heightened consciousness surrounding worker health and safety. Industry 5.0 seeks to leverage the technological advancements of Industry 4.0—namely, sensors and vision systems—to mitigate risks, create safer work environments, and minimize accidents.

Naturally, another significant driver of this evolution is the demand for more innovative, sustainable, and reliable products that can reach the market faster. But how will Industry 5.0 enable these changes?

Industry 5.0 will leverage the integration of digital twins with generative AI, which simplifies the prototyping of new concepts. This integration accelerates the development process and enhances the quality of the final product by allowing for the evaluation of multiple design options in terms of cost, performance, quality, and durability before a product reaches the

market. Furthermore, Industry 5.0 has a major focus on sustainability, with products designed to be more recyclable and less polluting. Thus, driven by technological advancements and changing consumer demands, Industry 5.0 holds the promise of delivering innovative, high-quality, and sustainable products more efficiently.

Despite the clear benefits and reasons for moving toward Industry 5.0, the evolution is not without its challenges. Paradoxically, the still ongoing adoption of Industry 4.0 is a major hurdle to adopting Industry 5.0.

Between the advent of Industry 3.0 and the emergence of Industry 4.0, nearly four decades elapsed. Remarkably, in just one decade, we transitioned from Industry 4.0 to the dawn of Industry 5.0, a testament to the rapid pace of technological advancement and its transformative impact on manufacturing and production.

To continue reading this blog, go to: mou.sr/eit-evolution-industry

Mouser Electronics offers a wide array of industrial automation products, catering to the diverse needs of our customers.

To find out more, go to: mou.sr/automation-solution

RT PRIME INDUSTRIES GROUP LTD.

102-2932 Ed Nixon Terrace Victoria,BC V9B 0B2

Canada

Phone: (250) 590-5297

Email: ian@rtprime.com

Website: rtprime.com

Custom die cast parts, Aluminium heat sinks & Extrusions, injection molded plastic components

SAPA TECHNOLOGIES

3202 Beta Ave

Burnaby, BC V5G 4K4

Canada

Phone: (604) 780-9219

Email: alex@sapatechs.com

Website: sapatechs.com

PCB assembled boards

SCHLEUNIGER

87 Colin Drive Manchester, NH 03103

United States

Phone: (603)668-8117

Email: sales@schleuniger.com

Website: schleuniger.com

Global technology company and innovative solutions supplier to the wire processing and testing industry.

SIMCONA ELECTRONICS

3422 Wonderland Rd S London, ON N6L 1A7

Canada

Phone: (519) 652-1130

Email: vaneecke@simcona.ca

Website: simcona.ca

Passive and electro-mechanical components, wire and cable, and connector products.

SMT INDUSTRIAL SUPPLY INC.

3-200 Memorial Ave Suite 202

Orillia, ON L3V 5X6

Canada

Phone: (416)578-8070

Email: smtindustrial@rogers.com

Website: smtindustrialsupply.com

JBC|Indium Solder wire|Hanwha SMT placement machines

SPLICETRONICS SOLUTIONS INC.

Montréal, Québec, H4A 1G2

Phone: 514-887-9559

Email: sales@splicetronics.com

Website: www.splicetronics.com

Leading edge solutions that improve SMT manufacturing processes

SYNTRONIC INC.

340 Terry Fox Dr #200 Kanata, ON K2K 3A2

Canada

Phone: (613)-277-4815

Email: jaei@syntronic.com

Website: syntronic.com

Development, production and aftermarket services as well as all the related support during the product life cycle.

THE DATA CABLE CO

31 Robb Blvd Orangeville,ON L9W 3L1

Canada

Phone: (519)941-7020

Email: marketing@datacable.ca

Website: datacable.ca

Canadian custom cable assembly manufacturer, connectivity solutions include custom wiring harnesses and electro-mechanical assemblies

TORONTRONICS CIRCUIT TECHNOLOGY INC.

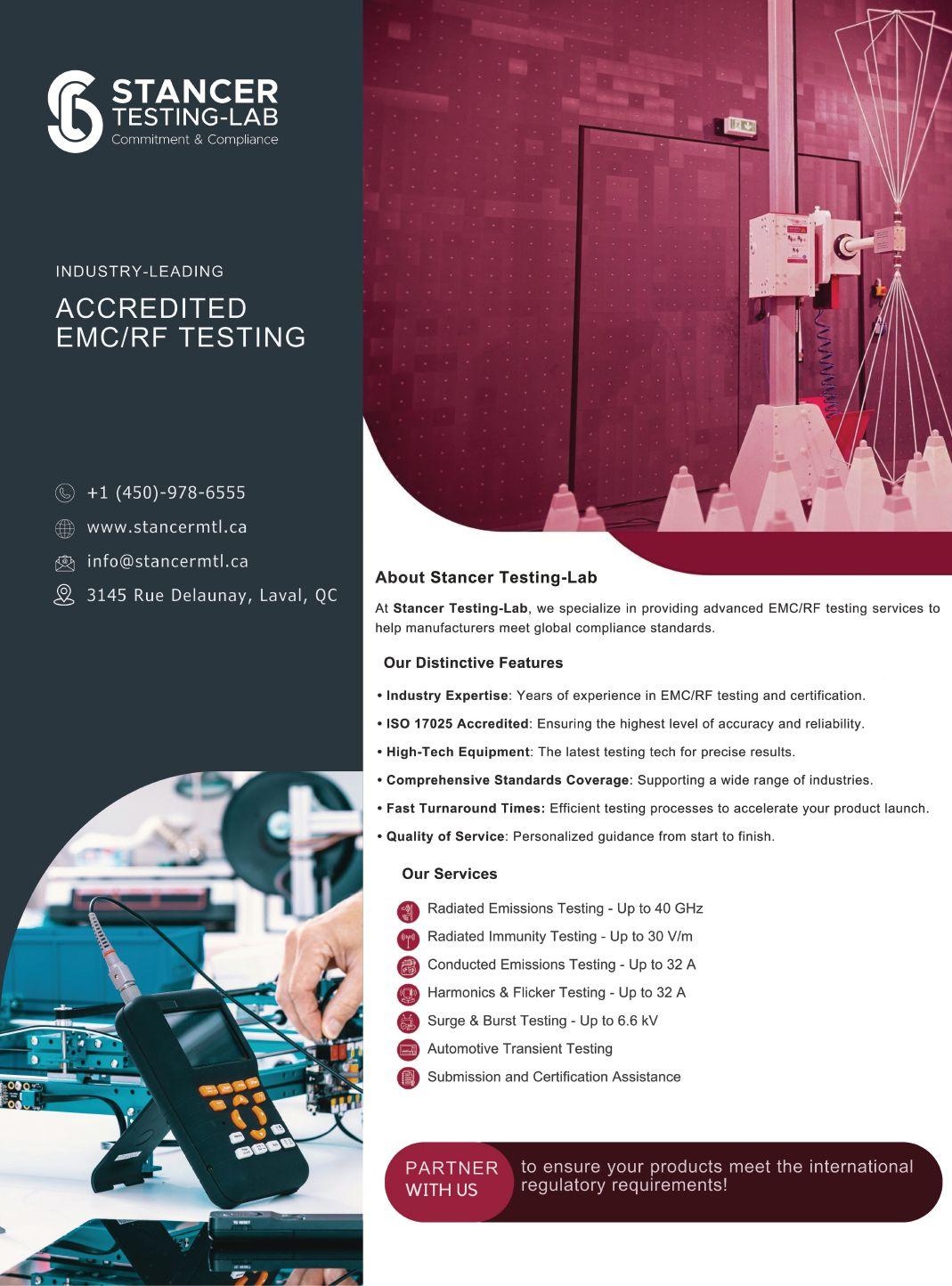

STANCER TESTING-LAB

3145 Rue Delaunay, Laval,QC H7L 5A4

Canada

Phone: (514)318-0247

Email: ksheshyekani@stancermtl.ca

Website: stancermtl.ca

Top-tier accredited EMC/RF Testing and Certification Laboratory, Top-notch technology for high quality testing with fastest turnaround, One-stop shop for EMC testing for Canadian automotive industry

110 Ironside Crescent, Unit 20 Toronto,ON M1X 1M2

Canada

Phone: (416)291-1117

Email: info@torontronics.com

Website: torontronics.com

Printed Circuit Boards

More than 75 000 connector combinations

The modular design of LEMO products provides more than 75 000 different combinations of connectors with a large choice of contact configurations:

• High and low voltage

• Coaxial and triaxial

• Quadrax

• Thermocouple

• Fibre optic

• Fluidic and pneumatic

• Hybrid

• Custom cable

Cable assembly service

Expand the quality of your connector to the cable assembly with LEMO one-stop shop value-added cable assembly services.

VISCOTEC AMERICA

221 Glenholme Ave

Hamilton,ON L8K 3L9

Canada

Phone: (905)616-7557

Email: James.Blight@viscotec-america.com

Website: viscotec.com

Preeflow by ViscoTec, Progressive Cavity Pumps for Volumetric Dispensing Systems

WAGO CORPORATION

Phone: (262)525-9723

Email: meghan.anderson@wago.com

Website: wago.com/ca Power Supplies, UPS and ECBs

12 A/F., Hangdu Bldg., No.1006 Handu Road Shenzhen, 518000

China

Phone: (867) 558-3957

Email: public09@win-source.net

Website: win-source.net

Sourcing hard-to-find and obsolete electronic components, as well as secure genuine and commonly used parts at competitive prices.

WÜRTH ELEKTRONIK

Phone: (605)886-4385

Email: missy.hansen@we-online.com

Website: we-online.com/en/products/ components/overview

Passive Components, Electromechanical Components, LEDs

As Canada aims to strengthen its position in the global semiconductor value chain, the Canada’s Semiconductor Council (CSC) has unveiled an ambitious initiative: the Automotive and New Mobility Power Electronic Consortium. This proposal invites stakeholders from across the Canadian electronics industry to collaborate in shaping the future of power electronics for next-gen solutions in these sectors.

The proposed Automotive and New Mobility Power Electronics Consortium aims to foster collaboration across the automotive and semiconductor industries to facilitate a strategic transition towards EVs. The consortium’s goals align with Canada’s broader semiconductor strategy by promoting strategic investments, R&D, and commercialization, and integrating semiconductor manufacturing into local industries. These efforts aim to position Canada as a

leader in EV and power electronics innovation.

The consortium will facilitate collaboration between industry and academia through a structured partnership framework. Industry will lead governance, ensuring research aligns with automotive needs. Industry stakeholders will play a central role in defining the consortium’s agenda, providing financial support, and guiding its direction to maximize the relevance and impact of research outcomes. A core research team of academic experts will contribute specialized knowledge, with industry partners leading research topics to ensure practical solutions. The consortium will be housed at a major university R&D hub with a strong focus on automotive electrification, such as the McMaster Automotive Resource Centre (MARC) at McMaster Innovation Park.

To attract potential industry

partners, the consortium offers several compelling incentives:

• Strategic Collaboration: Access to a network of academic experts, R&D infrastructure, and collaborative opportunities with other leading companies.

• Innovation Leadership: Involvement in shaping the future of EV technology and automotive semiconductors, ensuring early access to innovations.

• Government Matching Funds: Industry contributions will help to generate matching or supplementary government funding, maximizing the return on their investment.

• Talent Development: Access to a pipeline of highly skilled researchers and engineers trained through consortium projects, strengthening Canada’s talent ecosystem in automotive electronics.

Interested parties can contact CSC for more information. www.canadassemiconductorcouncil.com/

“We appreciate the trust our customers have placed in us and look forward to providing an even more comprehensive range of services, Our expanded presence in Vancouver will allow us to serve our clients more efficiently and effectively.”

Vancouver, BC – March 3, 2025 – RT Prime Industries Group Ltd. is pleased to announce the successful acquisition of Leister Blake Enterprises Ltd. (LBE), a highly regarded company with 35 years of industry expertise. This strategic acquisition marks a major milestone in RT Prime’s growth, strengthening its service offerings and expanding its footprint with a new office and warehouse in Vancouver.

“This acquisition reinforces our commitment to delivering top-tier manufacturing, engineering, and supply chain solutions,” said Ray Cao, President at RT Prime. “LBE has built a strong reputation over the past three decades, and we are excited to integrate its expertise into our operations, ensuring continuity for existing customers while offering enhanced capabilities.”RT Prime remains dedicated to upholding the high standards and reliability that customers expect from both LBE and RT Prime.

Leister Blake Enterprises wants, first of all, to reassure all our customers they will enjoy the same level of service they have come to expect from Leister Blake Enterprises over the years.” I will be staying on in an advisory role with RT Prime for the foreseeable future to ensure as seamless a transition as possible. I have really enjoyed my time with our customers and will continue to do my utmost to ensure RT Prime’s success with our valuable customers.” said Rob Blake, President of LBE.

Customers of LBE will experience no disruption to their current services and will now benefit from RT Prime’s broader capabilities, including:

• Injection molding

• Metal casting

• CNC machining

• Full assembly solutions

• Mechanical & tooling design

• ISO 9001: 2015 Quality Assurance

• Warehousing services in Greater Vancouver

Crafting Quality, Accelerating Potential.

TIt’s never easy for technology start-ups. There are so many landmines to navigate – particularly once the tech innovation or device has been commercialized and poised to take the world by storm. With heightened attention being given to semiconductor development in Canada, we thought it would timely to hear from trade experts as it relates to Canadian-based firms interested in expanding globally.

For this article, EP&T sits down with Waqas Yousafzai, an Ontario Trade Commissioner, based in Toronto, who works with Global Affairs Canada, where he specializes in promoting and fostering global trade opportunities within the semiconductor, cybersecurity and enterprise software sectors.

The Trade Commissioner Service (TCS), part of Global Affairs Canada, has been helping Canadian companies, including those in electronics and semiconductors, expand globally for over 125 years. TCS provides tailored market insights, business connections and support for navigating foreign markets. We help identify export opportunities, foster partnerships, and overcome trade barriers.

TCS helps with market entry and expansion by providing tailored market intelligence, identifying opportunities, and connecting OEMs with potential partners that help drive business results (sales, R&D, etc.) The on-the-ground expertise also assists in navigating local and regional regulatory requirements and developing effective market entry strategies to venture into and succeed in global markets. TCS’ extensive network of global offices supports Canada’s hardware and electronics companies in building business relationships and addressing challenges, ensuring a smoother entry into new markets.

TCS organizes trade missions, B2B matchmaking events, webinars & information sessions, and physical presence at international trade shows like Hannover Messe, Electronica and Mobile

World Congress. These help companies network, showcase products, and build relationships with local customers and partners. Additionally, we provide logistical and export assistance to eligible clients, that helps guide them through documentation, customs regulations, supply chain challenges, packaging requirements, and other market-specific idiosyncrasies.

TCS provides guidance on tariffs, duties, and trade agreements, helping Canadian businesses understand and navigate barriers like quotas or trade restrictions. Global trade commissioners can assist firm in understanding foreign regulations, licensing, and import/ export requirements, and help advocate for regulatory changes when necessary.

TCS services are free, but eligibility criteria must be met to receive support from a Trade Commissioner. To understand your options, contact the Trade Commissioner in your province or territory. Ontario businesses should reach out to the regional office in their area.

For Canadian knowledge workers, understanding your unique value proposition (UVP) is crucial to standing out in the global marketplace. By leveraging specialized skills, deep expertise, or innovative approaches, you can differentiate yourself and add significant value. This might include a unique methodology, in-depth knowledge of a specific field, cost competitiveness, or the ability to effectively leverage intellectual property. Identifying your UVP and aligning it with a gap or business challenge in your target market is a recipe for success. Positioning your solutions to address specific needs, or offering more efficient, sustainable, or cost-effective alternatives, can help you quickly unlock new markets. It’s equally important to be able to clearly communicate your vision and UVP to a Trade Commissioner, so they can recognize opportunities within their networks. International trade is a collaborative effort, and the clearer your UVP is the more effective you will be in your international business development efforts.

Are you Export Ready? A Quiz: www.tradecommissioner.gc.ca/quiz.aspx?lang=eng

The semiconductor industry is the backbone of modern electronics, but managing product lifecycles in this fast-evolving sector is no small feat. From ensuring long-term availability to addressing supply chain disruptions, the challenges are as diverse as they are critical.

In this Q&A, we sit down with Rochester Electronics, a global leader in semiconductor lifecycle solutions, to explore their insights on navigating the complexities of the product lifecycle.

As silicon fabrication technology advances, older processes are phased out. Due to limited equipment and expertise, producing legacy components is challenging. The shift to advanced silicon fabrication reduces the availability of raw materials and equipment, causing suppliers to phase out older materials and machinery.

These changes accelerate component obsolescence. Thus, manufacturers seeking efficiency and reliability often adopt new processes that are incompatible with older components like PLCC and PQFP.

Innovations can render legacy components obsolete, as new materials provide improved performance, such as higher thermal stability and enhanced conductivity. This shift may result in the discontinuation of older materials, complicating production and support for legacy components.

Component manufacturers often discontinue unprofitable parts as demand shifts to newer technologies, focusing on in-demand parts with better profit margins.

Producing small quantities of obsolete items can be cost-prohibitive. Obsolete components can disrupt supply chains, affecting production schedules and complicating sourcing authentic, quality replacements.

Due to their reliability, legacy systems in industries like aerospace, automotive, and healthcare must be preserved. Replacing them with untested systems can pose risks, lead to regulatory issues, and cause costly failures, including high expenses for new equipment and training.

Component obsolescence challenges designers by threatening legacy systems with outdated parts. They must balance finding obsolete components and integrating modern technologies. Proactively addressing component obsolescence is crucial for smooth operations. Tools like Z2Data and Accuris can track component lifecycles and end-of-life dates, helping organizations forecast and manage obsolescence-related costs effectively.

Component obsolescence and requests for ‘LastTime-Buys’ (LTB) require customers to predict future equipment sales, but these forecasts can be unreliable

due to unforeseen market changes.

Successful long-term system companies balance their designs by anticipating semiconductor changes. They maintain communication with aftermarket manufacturers and providers to prepare for shifts before LTB notices.

Product lifecycles can outlast the availability of semiconductor components, making lifecycle status essential in the new product introduction (NPI) process. If critical components reach end-of-life (EOL) before the product matures, a reliable long-term supply chain for semiconductor lifecycle solutions is necessary.

When the original component manufacturer (OCM) discontinues a product, they often offer a ‘Last-Time Buy.’ However, customers might struggle with the cost, volume requirements, or storage for future needs.

Unprepared companies face risks of counterfeits and quality issues. Authorized distribution players can provide a dependable source with storage solutions. Partnering with a licensed semiconductor maker can reduce the risks of component EOL

by enabling the production of discontinued devices.

Key elements to obsolescence strategy

It begins at the design and product definition phases. We’ve all heard stories of products launched with obsolete components, especially affecting customers with long development cycles. Some key points to consider include: What is the component’s lifecycle status during the application’s lifetime? Are the design’s key components fully documented? Can true design files be archived for rebuilding if needed? And, does the design include proprietary intellectual property? If your equipment has extended qualification, production, or in-service lives, you will face component obsolescence. Organizations should devote skilled, multi-disciplinary workers to obsolescence management. Preventive planning can reduce or eliminate costs and risks.

It is imperative to identify Product Discontinuation Notices (PDNs) that may affect your business. Proactively monitoring component lifecycles is essential for anticipating issues. Reliable commercial tools track lifecycle stages, lead times, and specification changes and provide alerts for PDNs. Some key questions to ask yourself include: Will your sub-tier suppliers share their BOMs; and do they have adequate obsolescence management processes? While many component electronics manufacturers offer proactive component lifecycle management as a service, others are entirely reactive.

■ Your Direct Parts Source from the Origin

■ Get Obsolete Components with Ease

■ Smart BOM Sourcing Tool

■ API Integration for Real-Time Inventory

■ Substantial Cost Reductions

■ Sell Your Excess Inventory