BY KRISTY NUDDS

The Trans-Pacific Partnership (TPP) finally came to an agreement on Oct. 5, and the supply-managed sectors of Canadian agriculture could be heard breathing a collective sigh of relief.

Since Canada joined the TPP in October 2012 there was much uncertainty regarding the future of supply management. Several TPP member countries, notably the United States and New Zealand, were gunning for increased access to Canada’s dairy and poultry markets. Former prime minister Stephen Harper was steadfast on his desire to remain a part of the TPP, leaving dairy and poultry farmers wondering if their livelihoods would be sacrificed in order to appease demands from member countries.

Although the federal government maintained that it would not surrender supply management in the TPP talks, as talks intensified during the summer it became apparent that the government would have to make some concessions if Canada was to be part of a final deal.

Supply management did not come out of the agreement untouched, yet changes were much less worse than its pundits estimated and the industry feared.

Despite “significant and broad demands” from several of its TPP negotiating partners, the Government of Canada said in a press release “it has only offered limited new access for supply-managed products” — 3.25 per cent for dairy, 2.3 per cent for eggs, 2.1 per cent for chicken, 2 per cent for turkey and 1.5 per cent for broiler hatching eggs.

Although considered a “small fraction” by the federal government, it was nonetheless disappointing to the four national feather boards and the Dairy Farmers of Canada to have to lose domestic share.

However, all of the groups understand the importance of the TPP conclusion to the economy of the country, and to other sectors of agriculture.

TPP member Japan has vowed to cut tariffs over the next several years on wheat for human consumption (by 45 per cent) and on beef exports (these will decrease by nearly 30 per cent), and canola oil (15 per cent). Tariffs will also be reduced on Canadian pork exports. It’s been estimated that exports to Japan alone could triple from the deal.

The Government of Canada had to perform a juggling act for agriculture. Although export commodities seemingly came out on top, the supply management system remains intact and has a stable path for moving forward.

To support supply-managed producers and processors throughout the implementation of the TPP the federal government announced a series of new programs and initiatives that will allow the three pillars of the supply management system to remain intact (see page 22).

Canada’s new Liberal government and the other 11 countries involved still have to ratify the agreement so changes will occur gradually in the coming year or two. In the meantime, the Canadian poultry sector must continue engaging with consumers as to the benefits of the supply management system and its importance to rural Canada. n

DECEMBER 2015 Vol. 102, No.10

Editor

Kristy Nudds – knudds@annexweb.com 519-428-3471 ext 266

Digital Editor – AgAnnex Lianne Appleby – lappleby@annexweb.com 226-971-2133

Sales

Catherine Connolly – cconnolly@annexweb.com 888-599-2228 ext 231 Cell: 289-921-6520

Account Coordinator

Mary Burnie – mburnie@annexweb.com 519-429-5175 • 888-599-2228 ext 234

Media Designer Brooke Shaw

Circulation Manager Anita Madden – amadden@annexbizmedia.com 416-442-5600 ext 3596

VP Production/Group Publisher Diane Kleer – dkleer@annexweb.com

Director of Soul/COO Sue Fredericks

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 1703-2911

Circulation email: blao@annexbizmedia.com Tel: 416-442-5600 ext 3552 Fax: 416-510-5170

Mail: 80 Valleybrook Drive, Toronto, ON M3B 2S9

Subscription Rates

Canada – 1 Year $30.00 per year (with GST $31.50, with HST/QST $33.90) GST – #867172652RT0001

USA – 1 Year $ 66.00 USD Foreign – $75.00 per year

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbizmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2015 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Lubing's EasyLine Nipple Drinking System for turkeys has changed the turkey industry forever. This revolutionary system incorporates a patented pendulum that effectively directs water from the nipple into a self-cleaning drink cup. The low profile cup design allows day-old poults easy access to the water for great starts and has proven to perform with great success delivering water to heavy toms. You too can Live Easy with EasyLine!

Got Lubing? Contact your local Lubing Distributor for more information about EasyLine or visit our website at www.lubingusa.com.

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664.3811

Fax: (519) 664.3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

J. Dean Williamson Ltd.

London, Ontario

Tel: (519) 657.5231

Fax: (519) 657.4092

Eliminates routine cleaning

Provides fresher water supply

Improves litter conditions

Enhances air quality

Improves bird health

Les Equipments Avipor

Cowansville, Quebec

Tel: (450) 263.6222

Fax: (450) 263.9021

Specht-Canada Inc.

Stony Plain, Alberta

Tel: (780) 963.4795

Fax: (780) 963.5034

McDonald’s Canada is moving to remove antibiotics used in humans from its chicken offerings by the end of 2018.

The company’s 1,400 restaurants in Canada, which source all of their chicken from Canadian poultry farmers, says it will work with suppliers to phase out the use of antibiotics that are important to human medicine over the next three years.

chicken farmers will continue to use ionophores, a type of antibiotic that is not used in humans. The international fast-food giant’s American arm made a similar announcement earlier this year.

The company’s direction on chicken raised without the use of antibiotics of human importance is consistent with the overall direction of the Canadian chicken industry and plays a role in advancing Canada’s ongoing, long-term Antimicrobial Use (AMU) Strategy, the Chicken Farmers of Canada said in a release.

reviewing best management practices, ensuring effective controls of AMU in Canada, educating stakeholders, as well as researching and sourcing alternative products.

The biggest concern for producers, said Leech, is that Canadian laws need to be changed to make it easier for farmers to get their hands on alternatives to antibiotics, such as probiotics or specialized enzymes that change the microbial environment of a bird’s stomach to be less hospitable to certain bugs.

McDonald’s Canada will work with its suppliers to phase out use of antibiotics important to humans

“Our guests are telling us that they want these types of changes,’’ said Rob Dick, senior director of McDonald’s Canada’s supply chain.

He also pointed to a McDonald’s Canada announcement last month when the company said it was moving to use eggs from cage-free chickens over the next 10 years.

McDonald’s Canada said

Steve Leech, national program manager at CFC said poultry farms have already banned the application of the most-used human antibiotics (Category 1 antibiotics). The preventive use of Category I antibiotics has not been permitted since May 15, 2014 in the Canadian chicken sector.

Other components of CFC’s AMU strategy include analyzing antimicrobial resistance,

“We need more access to those alternative products in order to be able to successfully supply some of these new markets that are developing,” he said.

Leech noted that in the European Union, which has stricter rules around antibiotic use than Canada, such alternatives are often classified as feed additives, not drugs, and therefore more easy for farmers to put to use.

Agriculture Minister Lyle Stewart has introduced amendments to Saskatchewan’s farm security legislation that clarify who can own farmland in the province.

Pension plans, administrators of pension fund assets and trusts won’t be eligible.

All financing for a farmland purchase will have to be through a financial institution registered to do business in Canada or by a Canadian resident.

The legislation still has to be passed, but the new rules are expected to come into effect by next year.

Almost nine out of every

On October 8 Canada notified the World Organisation for Animal Health (OIE) that Ontario is free of notifiable avian influenza (AI). This declaration is based on the completion of a three-month enhanced surveillance period following the successful eradication of AI and the cleaning and disinfection of all the previously infected premises with no AI detections. At the time of reporting there had been no additional reports of AI elsewhere in Canada.

10 people who responded to a government survey said they didn’t want the province’s farmland to end up in foreign hands.

Eighty-seven per cent of the more than 3,200 respondents said they didn’t support foreign ownership and 75 per cent said they were opposed to allowing investors such as Canadian pension funds to purchase farmland.

The question of who can own farmland in Saskatchewan prompted a spirited debate that was sparked after the Canada Pension Plan Investment Board started buying up farms in 2013. The rules currently don’t allow institutional investors to own Saskatchewan farmland and limit foreign ownership to four hectares, but the investment board’s structure made it eligible.

The B.C. Chicken SquadTM and CREW Marketing Partners were named as finalists for the 2015 BCAMA Marketing Excellence Awards, which took place at the Westin Bayshore Hotel October 21.

The Chicken Squad campaign was built to revolve around a parody action movie featuring real B.C .chicken farmers as the talent. All the creative took on the look and feel of promotions for an upcoming movie release.

“We are honoured to have been selected as BCAMA Award Finalist, and congratulate the winners” said Ms. Cheryl Davie, Manager of Strategic Initiatives at the B.C. Chicken

JANUARY 2016

January 26-28, 2016

International Production and Processing Expo (IPPE), World Congress Center, Atlanta, Georgia. For more information, visit: www.ippexpo.com

January 28-30, 2016

Pacific Agriculture Show, Tradex Exhibition Centre (Abbotsford Airport), Abbotsford, B.C. For more information, visit: www. agricultureshow.net

MARCH 2016

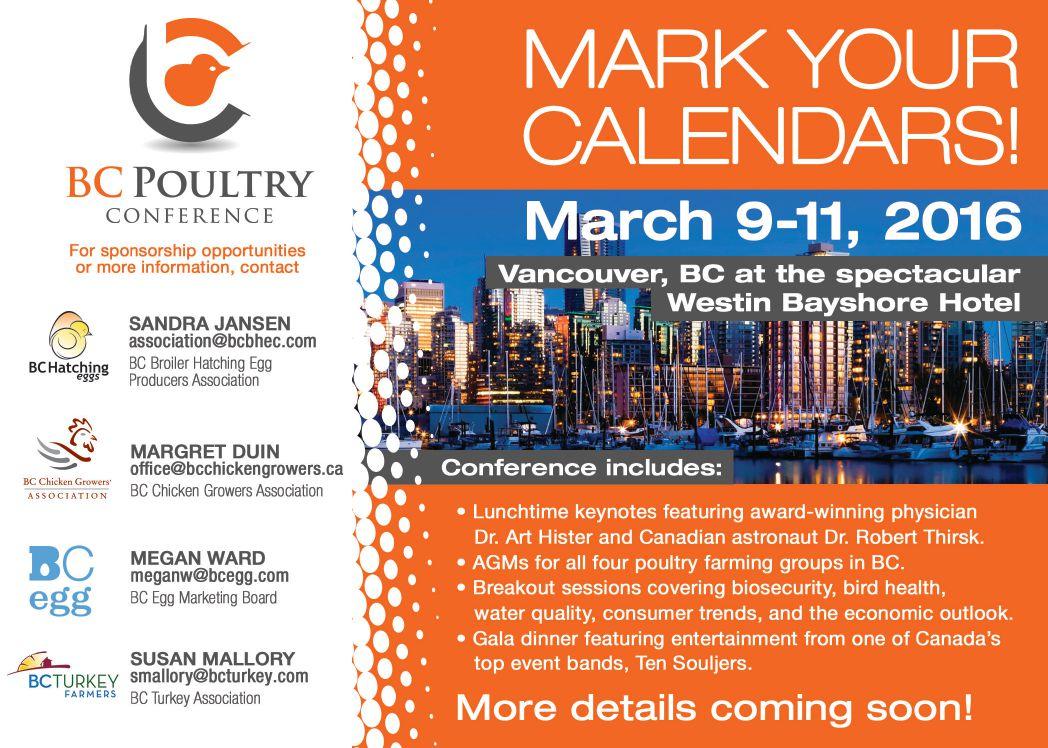

March 9-11, 2016

B.C. Poultry Conference 2016, Westin Bayshore, Vancouver, B.C. The four feather boards in B.C. are hosting a joint conference that will feature breakout sessions, trade exhibits, each commodity’s annual meeting and keynote speakers. For more information, e-mail: office@ bcchickengrowers.ca

Marketing Board. “But we would never have made it to this caliber without the team at Crew Marketing Partners, who so effectively engaged audiences through an action packed, hair-raising story.”

To celebrate the BCAMA’s 60th anniversary, three new recognition awards were added to the line-up, including the public relations and experiential marketing campaign categories which the B.C. Chicken Marketing Board was nominated for.

Funding support for this project was provided, in part, by the B.C. Government’s Buy Local Program; delivered by the Investment Agriculture Foundation of B.C. with funding from the B.C. Ministry of Agriculture.

March 17-19, 2016

Midwest Poultry Federation Convention, Saint Paul RiverCentre, St. Paul, Minn. For more information, visit: www. midwestpoultry.com

We welcome additions to our Coming Events section. To ensure publication at least one month prior to the event, please send your event information at least eight to 12 weeks in advance to: Canadian Poultry, Annex Business Media, P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5; email knudds@ annexweb.com; or fax 519429-3094. Please write ‘Event Submission’ in the subject line.

Subway announced in October that it plans to switch to meat raised without antibiotics over the next several years. The announcement comes after the company was targeted by advocacy groups calling for the change, and a coalition planning to deliver petitions to Subway’s headquarters. The sandwich chain had already said this summer that it would start switching to chicken raised without anti-

biotics important to human medicine by next year. Now, it says it will serve chicken that receive no antibiotics starting in March 2016. It will also make the change to turkey starting sometime next year, with a transition expected to be complete within two to three years.

Pork and beef raised without antibiotics will follow within six years after that, or by 2025, the company says.

niversity of Georgia poultry housing experts have released the state’s first app to help poultry farmers determine how much they should ventilate their houses during cold weather. “CHKMINVENT” (available through Apple’s App Store) allows farmers to enter variables, such as: outside temperature, amount of water consumed, temperature inside the house and size of the fans. It then calculates how long farmers need to run their fans in order to remove excess moisture and keep the chickens at a comfortable temperature.

The programming in the background of the app that

handles the calculations is based on years of research into poultry housing and on a series of spreadsheets that Mike Czarick, a poultry housing engineer at UGA and his fellow UGA Cooperative Extension poultry faculty members Brian Fairchild and John Worley have developed. “The app gives people a starting point as to how much fresh air they need to bring in to control house air quality and litter moisture. It’s not intended to provide a precise minimum ventilation rate. It’s going to take adjusting, but this at least gives a scientifically based place to start,” Czarick said.

Dr. Anangelina Archile has joined Canadian Bio-Systems Inc. as its new Technical Services Manager. She brings a wealth of experience in technical services, including specialized interest and background relevant to agriculture and feed technology. She will help lead analysis and protocols designed to offer the highest in quality assurance and value to CBS Inc. customers, across the company’s complete product portfolio.

Crystal Mackay will be transitioning to the new role of national Chief Executive Officer (CEO) for Farm & Food Care Canada in January 2016. Mackay will continue to manage Farm & Food Care Ontario while the search for her replacement is underway, and through the transition process.

Ruben Bake recently joined Alaso as Chief Financial Officer and is based out of the company’s headquarters in Lakeland, Florida. Before joining Alaso, Mr. Bake worked at Safeworks, LLC, a worldwide manufacturer of industrial equipment.

BY KRISTY NUDDS

The avian influenza outbreak in British Columbia’s Fraser Valley in 2004 was a gamechanger for Canada and how it handles a largescale foreign animal disease outbreak.

Up until that point, Canada’s Foreign Animal Disease emergency plans had been largely unchanged and untested since the Foot and Mouth Disease outbreak in 1952. Consequently, when H7N3 AI hit the Fraser Valley in the spring of 2004, the Canadian Food Inspection Agency (CFIA) and the industry was unprepared, and the virus spread quickly. When the outbreak was finally over, flocks from 42 commercial farms and over 500 backyard flocks had been destroyed.

A 2005 report from Standing Committee on Agriculture and Agri-Food revealed that the CFIA recognized its shortcomings in the handling of the 2004 outbreak and set a path for it to move forward with the development of more effective FAD plans, and most importantly, the recognition that it needs to work with industry stakeholders and provincial governments in order for these plans to be executed successfully.

The fall-out from the 2004 AI outbreak and lessons learned has been beneficial for the Canadian poultry industry to be able to effectively contain subsequent AI incidents, and this was obvious during the H5N2 AI outbreak in North America in late 2014 and the spring of 2015.

H5N2 came to North America last year in a highly-pathogenic form (HPAI), rather than mutating into a HPAI from a low-pathogenic AI (LPAI), as happened in the 2004 B.C. outbreak.

Biosecurity is still key to preventing avian influenza from infecting commercial flocks, but we are still learning how to best manage outbreaks

The virus breached 11 farms in B.C. in December 2014 before it was contained, and three farms in Ontario in April 2015.

The U.S., however, did not fare as well. By July 2015, over 200 farms in 15 states had been infected and 49 million birds were dead or destroyed. The United States Department of Agriculture (USDA) was admittedly overwhelmed and has been doing its own analysis on what went wrong and how it can move forward. Considering the magnitude of the U.S. outbreak, how did Canada fare so well?

“The U.S. had never had a dress rehearsal,” says Dr. Sandra Stephens, a Veterinary Program Specialist with the CFIA, who spoke at the recent Poultry Service Industry Workshop (PSIW) in Banff. “It helps to have had to live through [an outbreak].” As Canada did in 2004, she says the U.S. underestimated the virus.

In an initial “lessons learned” meeting after the virus was contained, the USDA recognized that emergency response planning is critical and that communications are critical at all levels, and appropriate contacts must be established prior to any organized response.

Since 2004, Stephens says the CFIA has had a mandate to actively engage with all stakeholders. It’s adapted an Incident Command system to coordinate emergency response, and it’s paid off.

The B.C. poultry industry noted a much improved working relationship with the CFIA as compared to 2004, which further helped to contain the outbreak to only 11 farms.

Edward Malek, CFIA Ontario Operational Specialist – Animal Health told attendees of the Poultry Industry Council’s Health Day that having a

CFIA Incident Command, in addition to the Feather Board Command Centre (a centralized emergency response for the Ontario feather boards), was instrumental in helping Ontario minimize the effects of HPAI.

However, despite having made much improvement in responding to AI outbreaks since 2004, there is still much to be learned from each subsequent outbreak.

One of the biggest challenges revealed from the Ontario outbreak, says Malek, is data sharing, says. “So much electronic data is not transportable, shareable, or moveable.” Nearly every stakeholder involved was using a different data system, and firewalls also presented challenges, he says.

Despite this, Malek says the CFIA had a commitment from the feather boards that if it needed information, they would provide it. Considering the first infected farm was identified on Easter weekend, “this is what got us through the process very quickly,” he says.

However, Malek says the data sharing process needs to be more streamlined. The data on farm locations, for example, needs to be analyzed and is used by the CFIA to determine which farms are within a quarantine zone. In several instances the CFIA was given incorrect information, and properties they thought were within the five kilometre quarantine zone were actually within a 20 kilometre zone and not under quarantine. This was not discovered until CFIA staff drove out to the farms. “This is part of validation process, and it takes time,” he says.

Data also needs to be updated frequently, he says. Its important that the CFIA knows what products are coming in or leaving the farms in real time.

Document control was also identified by Malek as an area that needs improvement. During an outbreak, numerous documents are circulated amongst stakeholders, and yet often it was found that not everyone was working with the same version of a document at the same time. Malek says a document number system

needs to be in place so that “everyone is on the same page.”

Malek also suggests the development of templates, particularly for license applications to move products. He says there has been discussion post-outbreak of developing a multiple application process, so that each sector fills out one application to apply for multiple licenses.

It’s helpful that the marketing boards have written procedures for enhanced biosecurity situations, but Malek says that they must be effective and followed. “There is no use having written procedures if only half of your producers know what it is and can understand it,” says Malek.

According to Malek, “much more work” needs to be done with regards to cleaning and disinfecting (C&D). In Ontario, it only took four weeks to perform disposal and destruction, but seven to eight weeks to do C&D. The biggest

hurdle to C&D, says Malek, is that no one wants to go in and do the cleaning. “Well guess what? The whole industry suffers when it takes another three to four weeks to get back to business.”

Ontario was able to limit the outbreak to three farms for a multitude of reasons, but that doesn’t mean if HPAI strikes again the province will fare as well, says Malek. “We got lucky,” he says.

A lot of it had to do with self-declaration. “We had really great farmers that called when they noticed their birds were not right,” he says. The virus also struck in a low-density poultry area of the province, and examination of the flight patterns of migratory waterfowl revealed that the majority of these birds had already left the area by the time the first premise tested positive.

Ontario, like B.C., also has a “topnotch” animal health laboratory that expedited testing of samples, he says.

Fortunately for the Ontario poultry industry, no hatchery, processing plant, or breeder/pullet farms was within the avian influenza control zones, but it has forced the industry to consider a lot of “what ifs”, says Malek. “There are so many.”

For example, the Ontario poultry industry needs to be able to answer questions such as what the implication would be if a feed mill, hatchery, or poultry processor were in a restricted zone, and how, or if they would be able to supply customers.

A question that’s never had to be asked before, says Malek, is how to move product and import product if the U.S. experiences another massive AI outbreak. This past spring, the number of mid-western U.S. states with restricted zones was so vast Western Canadian provinces were forced to transport breeder chicks from U.S. hatcheries via Ontario. Fortunately, the hatcheries were located in states

unaffected or minimally affected by the outbreak, but plans need to be in place in case this is not the reality in a future outbreak. Mexico is not a viable option, as AI has been endemic there for the past four years.

Under NAFTA, Canada is obligated to bring in a certain about of table eggs, yet the AI outbreak caused a shortage in the U.S. leading to elevated prices. “When we found eggs, we couldn’t afford them,” says Malek.

Having plans is important, says Malek, and the industry has had, and is continuing to have the necessary conversations to address the “what ifs.” “The key is we have to keep working on this, and thinking of how we can do better.”

As Dr. Stephens told attendees at the PSIW, preventing AI from hitting a farm

in the first place or spreading from farm to farm is “really about biosecurity, biosecurity, biosecurity.” In her opinion, the B.C. poultry industry demonstrated this well during the 2014 outbreak. “Producers took it seriously. They really upped their game.”

She says that there also needs to be “recognition that there is no such thing as enhanced biosecurity. You must be at superenhanced biosecurity”, because, she says, we don’t fully know where the virus is coming from. “It’s dropping from the sky.”

Keeping accurate, up-to-date premises log is essential for helping understand where the virus may have come from, and where it may go. It allows the CFIA to do traceback and becomes “a critical component in determining what our next steps will be,” says Stephens. “I can never overstate how important premises logs are,” she says. n

The “perfect” holiday Les fêtes «parfaites»

It’s time with family that really counts. Season’s greetings from the Egg Farmers of Canada. eggfarmers.ca

Les moments en famille sont les plus précieux. Les Producteurs d’œufs du Canada vous souhaitent de joyeuses fêtes. producteursdoeufs.ca

Like broilers, it is probable that daylength has an impact on both productivity and welfare in turkeys and therefore it is economically relevant to understand its consequences. Welfare issues seen in broiler research may be more pronounced in turkey production where age and bird size at market have changed considerably over the last decade. These changes likely mean new challenges for modern strains as previous research was performed some time ago on birds that did not grow as quickly or reach the same market body weights. The challenges include both bird productivity and welfare. However, research and literature are lacking on the effects of lighting programs on modern commercial turkeys.

affect the welfare of turkeys and optimize productivity in Canadian flocks.

M.Sc. student, Catherine Vermette, Dr. Hank Classen and the research team at the University of Saskatchewan aimed to determine the effect of graded levels of daylength on the welfare and productivity of modern commercial turkeys. A more complete understanding of lighting effects can be achieved by using graded levels of daylength to allow prediction of response criteria associated with productivity and welfare.

Productivity and welfare parameters assessed included growth, mortality, meat yield, behaviour, bird mobility and leg abnormalities, skin lesions and ocular measures. Productivity parameters assessed were not only economically relevant, but applicable to welfare when behaviour and bird health measures were incorporated. These measures together provide a description of welfare in turkeys. Results will provide scientific evidence for recommendations on lighting programs that are known to positively

Four graded levels of daylength (14, 17, 20, and 23 hours) were used to raise male and female turkeys to 18 weeks of age. The research included two trials with two replications per trial. Each trial consisted of 4 lighting treatments with two room replications for each lighting program. Productivity and welfare parameters were assessed at regular intervals during the course of the trials.

males. Similarly, the incidence of breast blisters increased with increasing daylength, only in males.

This study’s findings show that daylength affected turkey productivity in an age and gender dependent manner and use of longer daylength during the production cycle of males and female turkeys also affected a number of other measures indicative of reduced welfare.

At young ages, growth rate increased with increasing daylength, although this was reversed in older birds, sooner in males than females. In terms of mortality, shorter daylength treatments had beneficial effects on older birds and had a more pronounced effect on males. Carcass characteristics were affected by daylength in an age, but not gender dependent manner. Furthermore, the incidence of culling was increased with 23 hour daylength regardless of gender or age.

In general, longer daylengths had negative welfare implications in regards to turkey health and behaviour for both genders, but with a more pronounced effect in males. Mobility decreased with longer daylength for both genders, but the proportion of birds with poorer mobility associated with pain was only evident in

Lighting program recommendations derived from this research for meat turkeys are dependent on gender and the age at which birds are marketed. For both genders regardless of age beyond early brooding, 23 hours of daylength was found unacceptable due to reduced welfare, with birds experiencing poorer mobility, increased ocular size and increased mortality. In addition, for toms and older hens, the rationale for not recommending 23 hours daylength includes reduced growth rate.

For hens marketed at a younger age, a maximum of 20 hours of daylength is recommended, while the recommendation for older hens and toms is between 14-17 hours of daylength.

This research was funded by the Poultry Industry Council, Lilydale Inc., Charison’s Turkey Hatchery Ltd, and CPRC.

For more details on any CPRC activities, please contact The Canadian Poultry Research Council, 350 Sparks Street, Suite 1007, Ottawa, Ontario K1R 7S8, phone: (613) 566-5916, fax: (613) 241-5999, email: info@cp-rc.ca, or visit us at www. cp-rc.ca. n

The membership of the CPRC consists of Chicken Farmers of Canada, Canadian Hatching Egg Producers, Turkey Farmers of Canada, Egg Farmers of Canada and the Canadian Poultry and Egg Processors’ Council. CPRC’s mission is to address its members’ needs through dynamic leadership in the creation and implementation of programs for poultry research in Canada, which may also include societal concerns.

International Symposium strengthens networking, fills gaps for systems to manage mass animal mortalities

BY PENN STATE EXTENSION

The 5th International Symposium on Managing Animal Mortalities, Products, By-Products and Associated Health Risks

was held Sept. 28 – Oct. 1, 2015 in Lancaster, Pa. Through presentations, tours, hands-on activities and networking opportunities, participants were able to discuss effective plans and methods aimed at protecting animal health, human health, economies, communities and our environment during routine and emergency animal mortality management. Symposium participants also were encouraged to strengthen new and existing networks in order to identify current gaps or capability challenges in animal mortality management and work together to develop solutions.

“We wanted our participants to think about creating systems that work effectively and quickly to manage mass animal mortality events,” said Dale Rozeboom, Ph.D., Michigan State University professor and extension specialist and Symposium Chair. “Gaps can exist in many areas –from depopulation, disposal and decontamination to administration of response, funding availability and communication between national, state and local government agencies.”

Keynote speaker Tim Goldsmith, DVM, MPH, DACVPM, University of Minnesota College of Veterinary Medicine assistant professor and co-director of the Veterinary Public Health and Preventative Medicine Residency Program, explained the

Two Symposium participants inspect a recently-turned compost windrow during a tour on Monday, Sept. 28, 2015. Compost windrows are turned to redistribute moisture and oxygen throughout the mixture in order to maintain a consistent temperature.

importance of understanding risk in planning for and responding to catastrophic animal disease and how meetings like the Symposium are crucial for providing the tools needed to manage risk.

“Risks associated with catastrophic animal disease go beyond the health of the animal – it affects people, communities, and industries,” Goldsmith said. “Zero risk is not possible and we shouldn’t strive for zero, but, we need to look at the risk management possibilities out there for activities with significant risk in order to lower those risks to an acceptable level for all stakeholders involved in the management of a disease event.”

Tim Rueter, Ph.D., Livestock Research Branch of Alberta Agriculture and Forestry,

spoke about managing high-risk pathogens through composting. Another plenary speaker, Patrick Webb, DVM, director of swine health programs at the National Pork Board, explained lessons learned in the swine industry and its recent experience with an outbreak of Porcine Epidemic Diarrhea Virus. Webb described response strategies and methods used for managing mortality and morbidity during an emerging disease outbreak significantly impacting swine production and the effects of the disease on U.S. pork producers.

The Symposium began with a day-long tour of Pennsylvania’s diverse agriculture industry – including dairy, beef, poultry and swine operations. Participants were able to see biosecurity procedures, routine

composting, anaerobic digestion and invessel mortality composting at different local farms. Tour locations also included livestock truck wash sanitation stations that are vital to biosecurity and the health of people and animals involved in the farm’s operations.

Attendees also visited the Southeast Agricultural Research and Extension Center in Landisville, Pennsylvania. Demonstrations were hosted by experts and showed emergency windrow composting, carcass reduction, portable vehicle wash systems, wastewater treatment systems and humane euthanasia methods for livestock and poultry. The demonstration of techniques and challenges of foam euthanasia of poultry was particularly relevant, as many of the participants have been actively involved in response to the recent Highly Pathogenic Avian Influenza (HPAI) outbreak in the U.S. flock.

HPAI was further explored through a producer’s viewpoint with plenary speaker Mark Van Oort, complex manager for the Center Fresh Egg Farm – one of America’s leading egg producers. Van Oort guided Center Fresh Egg Farm through the 2015 outbreak of HPAI with a response that included large-scale euthanasia, carcass disposal, manure disposal and virus education through composting, control of a quarantine zone to control virus spread, and large scale cleaning and disinfecting.

“Immediately, I had planned to compost the birds,” Van Oort said. “We had dabbled in composting a bit before but not with 7.3 million birds – more like seven. We had to develop a cookbook and become resourceful . . . There were many lessons learned throughout this crisis and it’s certainly something that we hope to not have to deal with again.”

In order to understand the issues and

to apply research opportunities and lessons learned from the 2015 HPAI outbreak response, the Symposium’s emergency exercise focused on response to a notional HPAI outbreak. Through breakout sessions and participating in facilitated scenario discussions, participants analyzed the notional outbreak on multiple levels (single farm, multiple farms, state, nationally and internationally) and identified issues and research opportunities related to depopulation, disposal, cleaning and decontamination and business continuity plans for the management of realistic issues that may occur during an outbreak.

Symposium planning committee members Edward Malek, Ontario Operational Specialist for Animal Health, Canadian Food Inspection Agency, and Duncan Worsfold, Statewide Specialist in Animal Emergency Preparedness, Agriculture Services and Biosecurity for the Department

WE GO WAY BACK.

100 years. That’s a good long time to prove our values, our innovations, our service and our breeders.

Thank you for being the major part of our success.

of Economic Development, Jobs, Transport & Resources of Echuca, Victoria, Australia, served as moderators for the exercise. The two envisioned that this emergency exercise would not only allow the participants to understand lessons learned, but also better prepare attendees to gather information and concepts for the development of collaborative discussions that may apply should an outbreak like this happen in their area in the future.

The Symposium’s focus extended beyond the U.S. borders through an international panel of experts who convened to discuss their perspectives and experiences on animal mortality management. This session included a plenary address from Heekwon Ahn, Ph.D., associate professor in the Department of Animal Biosystems Science at Chungnam National University in South Korea, who discussed his experiences and the response of the South Korean government during the 2011 South Korea Foot and Mouth Disease outbreak. The panel included representatives from: Vietnam, the Republic of Georgia, Australia, South Korea, Tunisia, the United Kingdom, Canada and Nigeria.

Technical presentations explored new and emerging technologies for euthanasia, carcass treatment and disinfection, carcass management, federal and state planning, disease mitigation strategies, depopulation and disposal and all hazards. The Symposium also included exhibits and software demonstrations.

Though the Symposium has concluded, the group’s work continues. Over the next year, the planning committee will produce a white paper for the U.S. Department of Homeland Security (DHS) and continue to collaborate with participants in order to advance the preparedness of the industry for a mass animal mortality event. n

The Symposium was hosted by Penn State Extension. To learn more about the Symposium, go to http://animalmortmgmt.org.

Warmest Greetings of the Holiday Season and Best Wishes for the New Year from the

BY KRISTY NUDDS

On October 5, 2015 an agreement amongst the 12 countries involved in the TransPacific Partnership (TPP) was finally reached.

The supply-managed agricultural sectors in Canada had been concerned since Canada joined the TPP in October 2012 that demands to gain increased access to these sectors from participating countries would pose a significant threat to the supply management system.

Not so, says the federal government, who stated in a press release “despite significant and broad demands from several of our TPP negotiating partners, Canada has offered only limited new access for supply-managed products.” This access, which it says will be granted through quotas phased in over five years, amounts to a “small fraction” of Canada’s current annual production: 3.25 per cent for dairy, 2.3 per cent for eggs, 2.1 per cent for chicken, 2 per cent for turkey and 1.5 per cent for broiler hatching eggs.

To support supply-managed producers and processors throughout the implementation of the TPP and the Canada-EU Trade Agreement (CETA), the Government of Canada announced a series of new programs and initiatives that will allow the three pillars of the supply management system to remain protected under

The Government of Canada has announced a series of new programs and initiatives for supply-managed producers and processors to support them throughout the implementation of the Trans-Pacific Partnership (TPP)

both systems. These initiatives have been approved by Cabinet.

According to the federal government, the TPP will secure new market access opportunities for Canadian dairy, poultry and egg exports and that dairy, poultry and egg producers and processors will benefit over time from increased duty-free access to the United States and all other TPP countries.

To off-set the concessions it made to sign a TPP agreement, the Government of Canada said it will be providing new programs for dairy, chicken, turkey, egg and hatching egg producers as the implementation of the TPP proceeds.

Although when the TPP will come into effect is unknown at this time, Agriculture

and Agri-Food Canada (AAFC) will be working with the Farm Products Council of Canada to ensure that these programs are delivered to producers “in an effective and efficient manner.”

According to AAFC, this program will keep producers “whole” by providing 100 per cent income protection for 10 years. Income support assistance will continue on a tapered basis for an additional five years, for a total of 15 years. $2.4 billion is available for this program. Annual payments will be directly linked to the amount of quota a producer holds.

The Income Guarantee Program transfers with the sale of the quota, meaning that if the quota is sold at any point in the 15-year period, the remaining direct payments linked to that quota will transfer to the new quota holder. Annual payments will begin when TPP comes into force. The income guarantee payments will be calculated based on expected domestic production levels under conditions with TPP and the Canada-EU Trade Agreement in place. A model will be used that takes into account detailed historic economic and farm level data, projected into the future.

The Quota Value Guarantee will come into effect once TPP comes into force. AAFC says this program will protect producers against reduction in quota value when the

quota is sold following the implementation of TPP, and $1.5 billion has been set aside for this demand-driven program that will be in place for 10 years.

In addition to producer programs, the Government of Canada has also developed two programs to assist food processors within the supply-managed sectors. These programs have been approved by Cabinet and will be phased in starting fiscal year 2015/16.

This seven-year $450-million program will provide processors with support to increase competitiveness through capital investments and technical and management capacity. For-profit agri-food cooperatives and processors in the supply-managed sectors,including small and medium-sized

enterprises (SMEs) are eligible to apply for this program.

The following activities are eligible for financial support: purchase and installation of new equipment; construction, renovation and expansion of facilities; hiring of required expertise to complete the project; development of new products/ product lines; improvement of manufacturing processes; and collaborative partnerships for research.

The Market Development Initiative provides new funding over five years to the AgriMarketing Program to help the supply-managed sector to maintain, develop and expand their Canadian and international market share. The Initiative will add $15 million of new funding to the

Merry Christmas and a very Happy New Year from Chicken Farmers of Canada

Joyeux Noël et une très heureuse nouvelle année des Producteurs de poulet du Canada

AgriMarketing Program.

Not-for-profit organizations working on behalf of supply-managed producers and processors, as well as small and mediumsized enterprises in the supply-managed sector are eligible to apply for funding. The following activities are eligible: additional promotional campaigns and activities that position and differentiate Canadian supply-managed products; and marketing materials, events (e.g., attendance at trade shows) and research that supports the sale of Canadian supply-managed products. Eligible activities will be cost-shared on a 50/50 basis with industry.

While the Chicken Farmers of Canada (CFC), Turkey Farmers of Canada (TFC), Egg Farmers of Canada (EFC), the Canadian Hatching Egg Producers (CHEP) and the Canadian Poultry and Egg Processors Council (CPEPC) expressed disappointment that additional access to

the Canadian poultry market was granted in the TPP, all national groups recognized the economic importance of the trade deal to other agricultural sectors and industries and thanked the federal government for its support.

In addition to program funding (worth $4.3-billion), the federal government stated that it will “intensify on-going anticircumvention measures that will enhance border controls.” These measures include requiring certification for spent fowl, preventing importers from circumventing import quotas by adding sauce packets to chicken products, and excluding supplymanaged products from the Government of Canada’s Duties Relief Program.

This is welcome news for CFC in particular. CFC Chair Dave Janzen said in a

release that fraudulent import practices have plagued the industry for over five years that have cost the chicken industry thousands of jobs, millions of kilograms in production, millions of dollars in revenues and millions of dollars in GDP contributions to the Canadian economy.

“We are counting on the government to cease the practice of regularly issuing supplementary import allocations,” he said.

All of the national poultry associations have stated they will need additional time and analysis to fully understand the potential future impact of the TPP on their farms and the entire value chain, and that they will work with AAFC on the details of the agreement to ensure that the provisions agreed to do not jeopardize the Canadian Government’s commitment to maintain the integrity of the import control pillar of the supply management system. n

BY NERINE T. JOSEPH PH.D., LIVESTOCK RESEARCH INNOVATION CORPORATION ON BEHALF OF THE POULTRY INDUSTRY COUNCIL

Despite routine utilization of standard vaccination protocols in broiler breeder and broiler flocks, outbreaks of diseases in broiler flocks still occur. However, limited data on pathogen prevalence and associated risk factors among commercial broiler flocks in Canada are available.

Dr. Michele Guerin, a Poultry Epidemiologist from the University of Guelph recently completed a comprehen

industry. The study included the associations of exposure to the pathogens with management and biosecurity practices, flock mortality, and condemnations.

“As a contribution to disease control initiatives, this study will enable producers to adopt better strategies to reduce the incidence of these pathogens within their flocks,” said Dr. Guerin in an interview.

Guerin’s team investigated 231 randomly selected Ontario broiler flocks and results

cecorum, and no exposure to, or low prevalence of, AEV, IBV, ILTV, NDV, Brachyspira spp., and Clostridium difficile. Beyond prevalence, the genotypes of several of these pathogens were determined.

“Potentially pathogenic genotypes of FAdV, IBDV, and IBV were identified that can guide vaccine development and disease control efforts in Ontario,” she explains.

Although no specific management or biosecurity practice was identified as a predictor of all pathogens investi

15HY010-HybridDramaticAds_1/4page(4)_CanadianPoultry_vf_3.pdf 1 2015-07-28 11:23 AM

Of interest, a high proportion of Clostridium perfringens isolates were found to be resistant to antimicrobials commonly used in feed, and use of these antimicrobials was a risk factor in the development of resistance.

“Finding alternatives to the use of antimicrobials in the feed to prevent necrotic enteritis should continue to be a priority for the industry,” Dr. Guerin asserted.

Dr. Michele Guerin, a Poultry Epidemiologist from the University of Guelph recently completed a comprehensive project that investigated the prevalence of nine viruses and four bacteria of health significance for the Ontario broiler industry

environmental conditions, hatchery, manure disposal, and antimicrobial use).

“Geographic and seasonal variation in the prevalence of a number of pathogens was evident,” Dr. Guerin indicated. “However no one district or season stood out as being a hotspot or time period of high prevalence for all pathogens investigated.”

Dr. Guerin highlights that of all the pathogens surveyed, only Clostridium difficile poses a potential risk of infection for humans via the food chain, and despite the fact that toxigenic strains were found among the isolates, the proportion of positive flocks was low.

This research was funded by the Animal Health Laboratory’s AHSI, Poultry Industry Council, OMAFRA- U of G Partnership, and Chicken Farmers of Ontario. n

*Avian adeno-associated virus (AAAV), Avian encephalomyelitis virus (AEV), Avian reovirus (ARV), Chicken anemia virus (CAV), Fowl adenovirus (FAdV), Infectious bronchitis virus (IBV), Infectious bursal disease virus (IBDV), Infectious laryngotracheitis virus (ILTV), Newcastle disease virus (NDV)

BY KAREN DALLIMORE

Ontario now has a research study underway that will generate baseline information about the main pathogens – viruses, bacteria and parasites - present in noncommercial poultry flocks in the province.

Starting the first of October 2015 until the end of September 2017, small flock (non-quota, non-commercial) owners of chickens, turkeys, game fowl, geese and ducks, are encouraged to submit sick or dead birds to the Animal Health Laboratory in Guelph or Kemptville for post-mortem examination and diagnostic testing. Submissions must be made through a veterinarian, who will do the initial screening of submissions. While there will be some veterinary fees involved at the farm level the lab testing itself will be done at a substantially discounted cost of $25 per submission. The tests would normally cost over $500.

“In general, there is not a lot of data,” said Leonardo Susta, DVM. “The number of small poultry flocks has markedly increased over the past few years in Ontario, however, there is a void of knowledge regarding the type and number of diseases that affect this segment of the poultry sector.”

Susta, who works out of the Department of Pathobiology at the Ontario Veterinary College, is leading this effort and is providing some of his own research funding to hire a graduate student for this project. Funding for the tests is provided by the Animal Health Laboratory (AHL) within the framework of the Ontario Animal Health Network within the Disease Surveillance Program.

Susta said there isn’t a lower limit on

Through a brief questionnaire, researchers will gather information about common husbandry and biosecurity practices used by non-commercial flock owners. Data collected may help to identify diseases that are specific to the non-commercial poultry population

the size of the flock, with the upper limit of less than 50 turkeys, less than 300 broilers, less than 100 layers or 300 or fewer ducks, geese and game birds. Pigeons and doves are excluded from this study.

Through a brief questionnaire, researchers will gather information about common husbandry and biosecurity practices used by non-commercial flock owners. The data collected may help to identify diseases that are specific to the non-commercial poultry population, while helping vets better understand the needs of these flocks and producers. The results will be also tied with current surveillance studies at the Ontario Veterinary College (see page XX).

“We want vets to know and encourage owners (to submit birds),” Susta told a

meeting of the Poultry Industry Council in August. He will also be advertising the program through the distribution of flyers at shows and through hatcheries.

Partners in the study include the Ontario Ministry of Agriculture and Food, the University of Guelph, the Animal Health Laboratory and the Ontario Animal Health Network (Disease Surveillance Program). n

For more information, visit:

• phrn.net/dis-surveillance-dr-susta-lab/

• www.guelphlabservices.com/AHL/Poultry_ Flock_Disease.aspx

• or contact Dr. Leonardo Susta at 519-8244120 x54323, email: lsusta@uoguelph.ca

• or Dr. Marina Brash at 519-824-4120 x54550, email: mbrash@uoguelph.ca

BY TREENA HEIN

MEALsource, the only non-profit health care purchasing group in the province (perhaps even in the country) is working hard to get more Ontario-grown food into hospitals, long-term care and other health care facilities. The agency, based in Brantford, Ontario and part of the St. Joseph’s Health System, has an active and ongoing goal to educate processors – and everyone else in agriculture – about health care institution contracts and help bidders prepare for the Request for Proposals (RFP) process.

bidding for turkey contracts,” notes MEALsource contract specialist Wendy Smith. “And they are successful. The turkey folks have a good understanding of how we do business and they want a piece of it.” Smith notes that all the raw egg MEALsource contracts are currently served by Ontario companies and that there’s regular Ontario participation for cooked egg items.

ince, but mostly the U.S.” (See sidebar for details on 2015 poultry meat contracts. These contracts are for two years, so the next round of bidding will begin January 1st 2017. However, some fullycooked entre contracts which include poultry meat will be up for bidding in 2016.)

15HY010-HybridDramaticAds_1/4page(4)_CanadianPoultry_vf_3.pdf 2 2015-07-28 11:23 AM

“There are always Ontario companies

However, Smith says “We are not getting nearly enough Ontario bids for raw and cooked chicken. There were no Ontario-based bids for this year’s chicken contracts at all. The only Ontario companies we have ever had bids from are Pinty’s and DND Poultry. So that means it’s coming from the U.S. or out of prov-

MEALsource staff spend a lot of time making local connections at food shows and trade shows and giving presentations before the RFP process for a contract begins (once the RFP is posted, they can have contact with no one). “Typically a food broker or supplier will call us in, and we’ll present on the contract specifications, the reasons why they exists, the process we

follow and more,” Smith says. “We’ve gone to Local Niagara, FoodShare, Greenbelt, anywhere we’re asked to go, we will go. We haven’t had any requests from a poultry company to give a presentation.”

THE WELCOME MAT

In addition to this ongoing work with industry and food groups, MEALsource has changed RFP’s to make the playing field more level. “It started in 2010 that food origin became a concern, a legitimate concern with regard to where tax dollars are going,” Smith explains. “We were invited to participate with the Greenbelt in a project to look at the origin of MEALsource contract food products in five categories: eggs, dairy, sliced whole meats and poultry (‘protein cooked’), cheese, and ‘other refrigerated products.’ We discovered a fair bit was local, but there could be a lot more.” Over the course of the 15-month project, $670 000 of contracts were moved to local companies through finding local vendors and inviting them to participate, equating to a 15 per cent local swing in all categories.

“In 2011, we changed the RFP so that food origin must be stated,” Smith adds, “and so that in the case of a tie, the contract goes to the local vendor. The Broader Public Sector (BPS) Procurement Directive [a provincial directive put in place around that time] also requires all BPS institutions and/or their representatives running a contract process to offer the option of a debrief for bidders, where they can get feedback on the process and find out why their bids failed.” Before and after bids, MEALsource educates as much as it can. “We can’t give anyone an edge, but we can educate,” says Smith. “The international firms are very savvy, with almost an assumption that they will be successful in all their bids. It’s great to see new faces bidding. We would be happy to talk to chicken processors.”

The Ontario Independent Meat Processors (OIMP) does not have an active relationship with MEALsource, says media relations lead Heather Mahachowitz, but supports more Ontario chicken going into Ontario health care institutions. “We communicate opportunities to our members if presented to us, and they will respond directly if interested,” she explains, clarifying that OIMP members are smaller independent operations. “We do not represent companies like Maple Leaf and Lilydale, who may have better resources to respond to RFP’s.” She adds that some MEALsource contract requirements may occlude OIMP members off the bat because of things like volume, delivery or HAACCP requirements. “That said, we would still like to share the opportunity and hopefully foster some connections between our members and MEALsource,” Mahachowitz notes. “[In addition], we would be happy to run/host an information session here at our Guelph office.” Smith says she is certain that MEALsource reps have met OIMP reps at many local food events over the past four years, and that she would be

happy to meet with any and all interested vendors.

Mahachowitz asks whether some institutions will only purchase from federally-inspected plants, which puts provincially-licensed plants at a competitive disadvantage. The answer from Smith is no. She says MEALsource has looked into this, and that there are no issues with bids from provinciallyinspected plants. “It is a common misperception though,” she notes, “and worth addressing.”

The Association of Ontario Chicken Processors (AOCP) does not get involved in the marketing and sale of chicken, says Mike Tertstra, AOCP Executive Director. “That function is left to each individual processor,” he explains, adding however that “AOCP members purchase approximately 95 per cent of the chicken grown by Ontario farmers and welcome opportunities to provide local chicken to Ontario consumers.” Tertstra did not say whether or not he had been in contact with MEALsource in the past when asked, but stated that “If you have information that I can give to members, I would be happy to do so.”

Overall, there could be many reasons why processors in Ontario aren’t

Turkey Farmers of Ontario (TFO) has worked with some healthcare facilities in the province by promoting the nutritional benefits of turkey and its versatility with a variety of turkey menu features being offered. “In addition to the menu items, says TFO General Manager Janet Schlitt, “past program activities have included posters, consumer contests, on-site staff to discuss the nutritional facts of turkey, and giveaways of promotional items and recipe booklets.”

Egg Farmers of Ontario reaches out to more than 1,100 food service operators annually through personal visits to independent restaurants, meetings at restaurant chain head offices, contact at trade shows and mailings. “EFO generated 85 customized egg promotions in 264 locations last year for food service operators,” says Public Affairs Manager Bill Mitchell. “Over 100 restaurants used our point-of-purchase materials, such as table cards, posters, balloons and buttons. EFO operates an online portal Egg Chef that provides enhancements to operators participating in EFO’s food service program, while reducing production costs of the program. Operators can use the password-protected site to create customizable menus and point-of-sale material to be printed and shipped directly to their restaurants.”

Chicken Famers of Ontario is focused on meeting all Ontario chicken markets, notes CFO Director of Communications and Government Relations Michael Edmonds. “CFO has developed and launched programs to encourage farmers and processors of all sizes to seek out and support currently underserved or emerging markets,” he adds. “CFO’s recently announced ‘Artisanal Chicken’ and ‘Local Niche Market Programs’ will supplement our traditional chicken and Specialty Breeds markets and will help provide additional opportunities for those looking to grow the Ontario market for locally-grown chicken.”

they are focused on other markets, don’t have the resources to look into this sales avenue, or don’t feel it would be worth-

inside or outside Ontario with comments on the topic, please contact us. In addition, if there is a similar agency to

15HY010-HybridDramaticAds_1/4page(4)_CanadianPoultry_vf_3.pdf 3 2015-07-28 11:23 AM

One of the purposes of practical housing and equipment is to provide for the biological, economic and welfare needs of the birds.

Fortunately, the scientific literature contains a great deal of information on these needs, so that a recommended approach to practical problems is to start with an appraisal of the requirements and responses of the birds. Then, designers and engineers can provide for these needs.

This book provides information on the needs and responses of poultry to aspects of the climatic environment, by means of reviews of the scientific literature. Biological responses to environmental factors are discussed, as well as some principles of the movement of air through and within buildings.

Many of the principles apply to both indoor production and to the housing attached to free range systems.

BY LESLIE BALLENTINE

When we look abroad we can see there are many moves afoot to deal with some of the issues that impact on poultry production. Europe is arguably the leader on animal welfare research, and we in Canada have benefitted from some of this research. At the 2015 International Egg Commission business conference in Lisbon, one of the main focuses was on beak-trimming.

Much of the information on reducing the risk of feather pecking has come from research conducted in Europe where beak trimming has been or will be prohibited in certain countries in upcoming years. Research has being going on for decades to identify alternatives to beak trimming

that are effective, practical, and affordable. Research is also on-going to refine current methods of beak-trimming.

Research over the years has found that there are large differences in strains for feather pecking and cannibalism. This knowledge may prove useful for developing commercial strains that require no beak-trimming or less invasive trimming.

There is potential for reducing feather pecking and cannibalism if low fear strains are selected, according to Dutch researchers at Wageningen University and Lelystad Animal Sciences Group. The results of one project,showed selective breeding of chickens may reduce flock mortality by as much as two-thirds, resulting in mortality rates comparable to those when using beak-trimming.

15HY010-HybridDramaticAds_1/4page(4)_CanadianPoultry_vf_3.pdf 4 2015-07-28 11:23 AM

Alternative options to beak trimming include both genetic and management methods. Selective breeding research is underway in an effort to produce strains that have lower tendencies to feather peck and are not cannibalistic. In addition, a number of nutritional, management and environmental strategies are being researched or promoted as an alternative to beak trimming. According to numerous researchers conducting such research, the alternatives have some potential to be effective in various management situations, but none of these alternatives give guarantees that cannibalism and feather pecking will be prevented.

Selection against feather pecking behavior has not been implement-

ed in commercial breeding programs so far, according to a report at the 2015 Australian Poultry Symposium. However, there exist several experimental lines which differ in their propensity for feather pecking and cannibalism. These lines are now being used for genomic studies. In the interim, Dutch

researchers report that, “Just as egg layer primary breeders have been placing their genetic lines in a variety of housing systems to make sure they are selecting for birds that are adaptive to many environments, they are also housing some birds without beak treatment to inform selection decisions.”

Some think you can establish specific column pressure settings that work for all brands and models of poultry drinkers.

See a video at poultrywatering.com that shows how the same water column pressure can result in wet litter under one drinker model and potentially too little water discharge with another drinker model. The take away is that column pressure settings cannot be standardized across all brands and models. Each model requires it own unique column pressure settings throughout the production cycle to ensure ample water discharge without creating wet litter.

For a complete understanding of important concepts in poultry watering watch all the videos at poultrywatering.com

A service of www.PoultryWatering.com

• How-to videos

• Poultry Watering U news

• Management downloads

A variety of research has determined that nutritional deficiencies may affect feather pecking activity. Amino acids, animal proteins, calcium and B12 along with high fibre diets and adequate feed intake have all shown to have benefits in reducing incidents of feather pecking. Much of this research has been conducted in the UK and the Netherlands over the past 25 years, and continues today.

Feather pecking occurs regardless of the housing system. Dutch researcher, Dr. Elske de Haas found that housing and litter conditions are influencing factors. She has said: “These results are important for designing measures to prevent the development of Severe Feather Pecking (SFP), which may require a different approach in brown and white flocks.”

However, for both brown and white hybrids her research has found that large group housing, floor or aviary housing may provide risks during both the growing and laying phase. Meanwhile, she reports that she has found incorporating variable pecking options and fear reducing measures (i.e. radio, introduction of roosters, human interaction) can reduce SFP.

ENVIRONMENTAL ENRICHMENT

Environmental enrichment is defined as increasing environmental complexity to encourage birds to interact with their environment. The objective is to increase desirable behaviours and reduce harmful ones.

Research has been conducted using a wide range of objects fitted to cages to enrich the environment for poultry and divert them from feather picking behavior. Various “toys” have been developed based on European and Australian research and are marketed around the world. Designed to attract pecking these devices have been found to reduce aggression and mortality in caged hens as well as among broiler and turkey breeders.

Providing free run layers with sufficient

Our entire team — researchers, technicians , distributors, operations and global development — focuses all our skills on making your relationship with us the most productive and rewarding t hat it can possibly be.

perch space, adequate drinkers, and high quality litter has been found to result in less feather pecking by Dutch researchers. For free range hens, which account for a growing production method in the UK, some European countries and Australia, encouraging more frequent and more

even use of hen runs has been found by Australian research to reduce feather pecking. Researchers at the Poultry Cooperative Research Centres (CRC) argue that, “birds do not feel safe in an open unroofed run area. When the range has cover, trees or hedges, birds are more evenly distributed

and risk of feather pecking is reduced.” Australian research is being conducted to identify potential repellants that can be used to train birds to avoid blood or feathers and therefore prevent cannibalism. Non-toxic repellants based on smell or nausea associated with ingestion are being tested. Two German experiments have found that severe and gentle feather pecking decreased when feathers were made distasteful. According to the researchers, the findings may be useful in the development of spraying devices to prevent feather pecking when other management tools fail.

Beak trimming remains the predominant method to deal with feather pecking and cannibalism in most of the world. According to industry statistics, between 2002-2009 infrared (IR) beak trimming was used on 2.4 billion turkeys, 596 million layers and broiler breeders. Uptake of infrared technology continues to grow. UK research suggests that IR trimming of day old chicks does not result in chronic adverse consequences for sensory function. Nor does it demonstrate evidence of chronic pain associated with the procedure, according to the study by the University of Glasgow. Studies conducted in Germany by scientists at the Specialty Center for Poultry and Small Animal Farming in Kitzingen, concluded that infrared beak trimming was more beneficial at both the growing phase and subsequent egg production phase compared to conventional hot-blade trimming. These findings have been corroborated by US and by Australian researchers. Effects of different infrared beak trimming procedures on chicken welfare and physiology each show that IR technology is superior to traditional hot-blade beak trimming in comparative studies. The results from these studies suggest that productivity as well as animal well-being can be optimized by refining infrared procedures. For example, research has shown that bird welfare can be improved by applying beak trimming earlier and by removing less of the beak to minimize pain.

Additional, yet to be released, research on beak trimming is ongoing. Canadian producers stand to benefit from the findings. n

BY NERINE T. JOSEPH PH.D., LIVESTOCK RESEARCH INNOVATION CORPORATION ON BEHALF OF THE POULTRY INDUSTRY COUNCIL

Broilers have been genetically selected for increased growth rates, which is associated with increased appetite. Feed restriction is the management strategy used commercially to prevent breeder hens from expressing their genetic potential for growth. Uniformity of flocks remains a key challenge encountered by hatching egg producers as poor body weight uniformity results in low reproductive success. Feed restriction does not match nutrient supply to nutrient requirement in non-uniform flocks. This problem is exacerbated during puberty and after peak egg production when feed allocations must be reduced to control body weight, but be sufficient to maximize chick production.

Dr. Martin Zuidhof and his research team from the University of Alberta have recently completed a study to develop, and validate a Precision Broiler Breeder Feeding System (PBBFS). This unique feeding system accurately distributes feed to individual birds when their body weight is lower than their target weight. Following results obtained from pilot studies, a beta prototype of the PBBFS was developed.*

This article focuses on a production study performed with this prototype to determine if flock uniformity and body weight control was improved by precision feeding (PF) compared to conventional feeding (CF) restriction regimes. The study was performed using 10-week old Ross 308 broiler breeder pullets with five individual PF target body weight profiles versus the skip-a-day CF restriction regimes. Additionally, Dr. Zuidhof and his team

The Precision Broiler Breeder Feeding system (prototype is behind chick eating from hand) is proving that it results in more uniform birds

investigated the effects of the PBBFS on feed efficiency, birds’ available metabolizable energy for growth and maintenance, behavioural traits, and water consumption.

Overall, the findings show that PF birds matched the target body weights within two per cent variation and flock uniformity reached 100 per cent. Feed efficiency was improved, maintenance metabolizable energy requirements were lowered, cumulative feed conversion rate was reduced, and no difference was observed in water consumption. Behaviourally, the birds were less active, performed more sitting and laying, and less feather pecking and foraging compared to CF birds.

As Dr. Zuidhof continues to optimize this PBBFS, he anticipates that improvements will be made to overcome limitations identified in this trial. Currently the

research team is determining the impact of stocking pressure on birds transitioning to PF and developing standard operating and remedial protocols to ensure all birds are fed by the PF system. The researchers aim to facilitate the implementation of this PBBFS for large commercial flocks of free run broiler breeders.

This project was funded by the Poultry Industry Council, OBCHEPA.

Alberta Meat and Livestock Agency, Agriculture and Food Council of Alberta, Alberta Innovates Bio Solutions, Danisco, Alberta Hatching Egg Producers, Canadian Hatching Egg Producers, Alberta Chicken Producers, Maple Leaf Poultry and OBHECC. n

Initial pilot study results were published in the October 2014 issue of Canadian Poultry Magazine.

When it comes to controversial topics about food production — GMOs, hormones, antibiotics, food ingredients and pesticide use, for example — online conversations can get nasty, and fast.

In fact, heated dialogue around any topic is more likely to happen online because of the anonymity of it all. Most likely, the hostile responders could be states or countries away and don’t have to face the person they’re attacking at the office water cooler or at the next family gathering.

So how do you respond when an online conversation takes a turn for the worse? Enlist the Simple 7 of Social Media Posts:

• What is the issue and what values are being expressed?

• Dissect the post. What’s the underlying area of concern in the person’s comment and what does that person value? Is it food safety, animal well-being, care for the environment, family or community? Where do your values lie when it comes to the issue at hand?

• Determine if it is worth a response.

• By the tone of the comment, do you feel there’s an opportunity for a productive dialogue? If so, continue a conversation by sharing your values about the issue and relevant information in a timely manner. Sometimes it’s worth it to respond no matter what. While you may not be able to persuade the attacker, others are watching the dialogue unfold and may be impacted by your words.

• Engage with values.

• Engage others to comment on the issue.

• Consider enlisting allies who would be willing to join in the conversation with support.

• Take your conversation offline.

• Acknowledge the responder’s concerns and offer to connect offline via email or a phone call. Most often, you won’t hear from that person again, but you have demonstrated that you’re open and transparent.

• Agree to disagree.

• After a few exchanges, you may be able to determine that this person doesn’t recognize your right to be involved in agriculture and food production. If that’s the case, agree to disagree and end the conversation.

One way to protect yourself when it comes to hostile posts on a blog or Facebook page is to have a comment policy that outlines what is acceptable and unacceptable. It’s not intended to put a damper on dialogue with those who have differing viewpoints. A comment policy simply assures your readers that you’ve created a positive and civil environment where they’re encouraged to comment in constructive ways and engage in productive conversations.

Arguing will get you nowhere. It only deepens the divide as both sides hunker down for battle.

• The goal with any conversation is to help the person understand where your values align — that there are goals you share. Research from The Center for Food Integrity shows that engaging with values — demonstrating why you do what you do — is three-to-five times more important to building trust than simply providing facts or demonstrating your technical expertise.

• Never argue.

• Arguing will get you nowhere. It only deepens the divide as both sides hunker down for battle.

More resources like the “Simple 7” are available from the Center for Food Integrity’s Engage Resource Center (www. cfiengage.com). This website equips those in agriculture and the food industry with the tools to both respond with values to uses gaining traction and service as a voice of reason. The Engage program enables those in the industry to serve as a “voice of reason” for situations that call for more balance.

Resources are available to help with addressing consumer concerns via social media, hosting community events and writing letters to the editor. Information on hot topics, including animal well-being; chemicals; the environment; GMOs; farm size; food security, processing, safety and production; organic production; obesity; sustainability; and use of antibiotics and hormones in food production is also available. n

These are some of the products eligible for the Vetoquinol Club points program. Sign up today at vetoquinolclub.ca and reap the benefits. club

• Low or no wax formulations

• Grains and food grade oils ingredients

• Greater acceptance for better results

• Different actives for rotation

GIVE THEM BAITS THAT THEY WILL LIKE!