There are many things to consider when creating quality space for your flock, such as proper ventilation, a fresh and even supply of feed and water, quality litter, perch space, and nest placement... just to name a few. We focus on providing quality space for your flock so they can thrive and have a healthy and highly productive life.

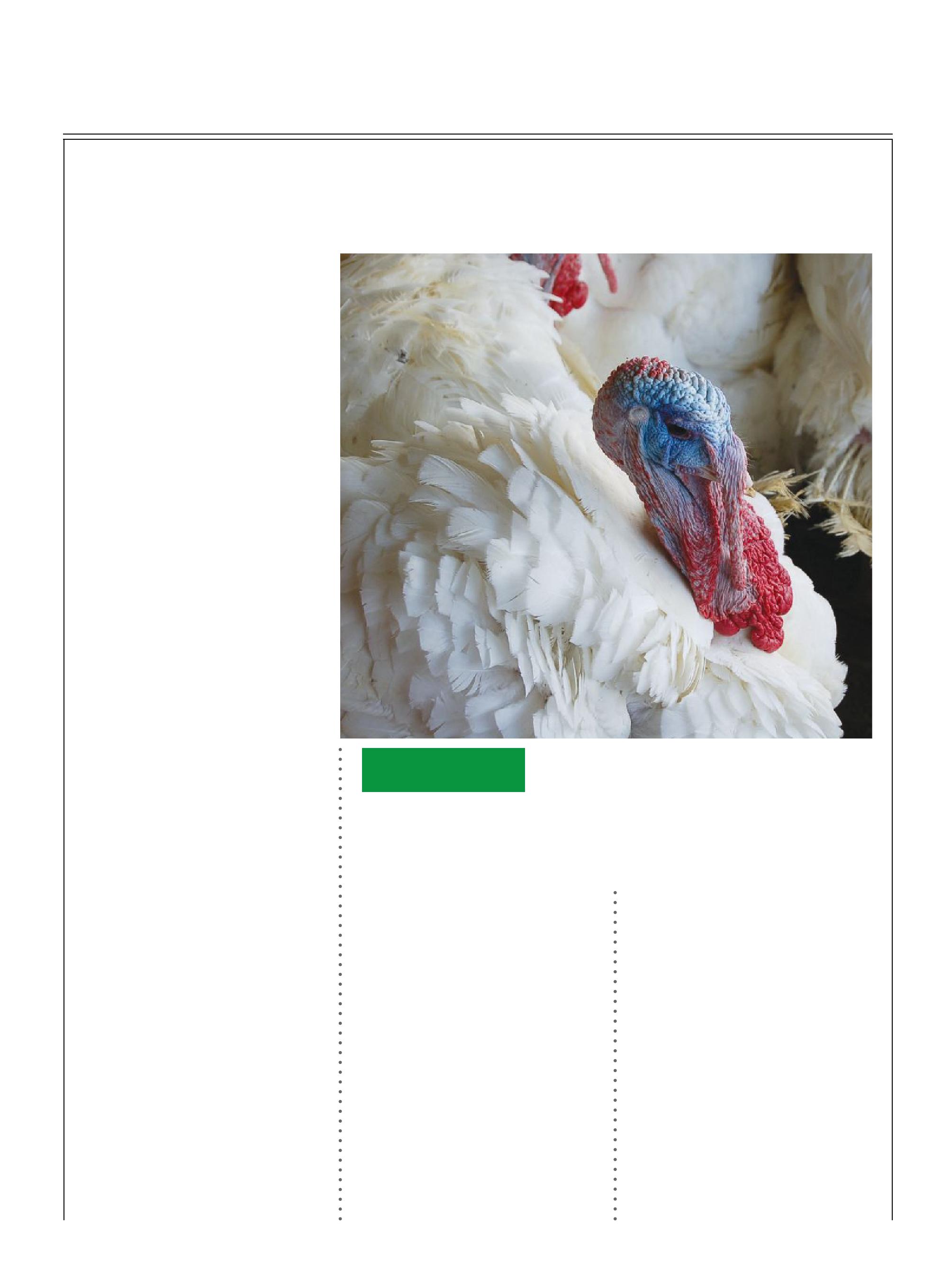

INDUSTRY: TFC Celebrates 40 Years

A look back at the history of turkey production and the development of the Turkey Farmers of Canada

By Nick Van Allen

HEALTH: Foot Pad Dermatitis in Turkeys

How to manage the barn environment to minimize the development of lesions

By Dr. Jim Blackman, PhD, Nutritionist, and Megan DeVisser, M.Sc. Candidate, Monogastric Nutrition Associate, New Life Mills

FEED: Feeding What Comes Naturally

A Canadian company is looking to produce livestock feed from insect larvae

By Leslie Ballentine

MARKETING: A Uniform Approach

A new branding campaign from the Chicken Farmers of Canada hopes to boost public awareness — and chicken sales

By Treena Hein

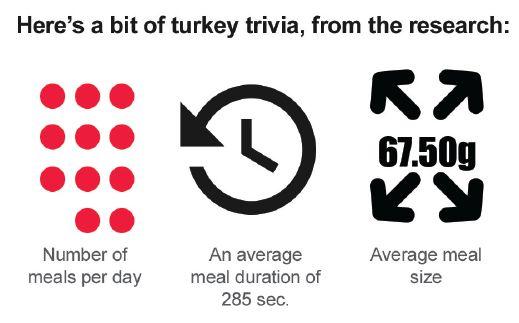

BEAKER: Tracking Turkey Feeding Behaviour

A UofG researcher has found a way to measure efficiency in a group setting

By Karen Dallimore

A raid by activists led Butterball LLC to implement changes to its animal care policies

By Karen Dallimore

BY KRISTY NUDDS

While I was putting this issue together I couldn’t help but wonder what the founders of the Canadian Poultry industry would think about how far the industry has come in terms of production efficiency and organized marketing.

Even if you’re not a turkey farmer, I encourage you to read our cover story (page 11) as it’s an excellent reminder to all producers and those working in the industry just how advancements in scientific knowledge and technology have allowed the industry to progress from a “sideline” to the success it is today — not only in terms of production efficiencies, but also with its popularity with consumers and, most importantly, its development into a stable market for farmers.

Our cover story also provides readership with a little “refresher” course on the history of supply management, something I feel everyone involved in supply-managed commodities needs to be reminded of from time to time. As Eugene Whalen, esteemed former federal agriculture minister, famously said, “supply management is always under attack.” Indeed, as I write this, U.S. trade representative Michael Froman and four cabinet secretaries, including Secretary of State John Kerry, are travelling across Canada telling audiences that Canada’s (and Japan’s) farm protections, are “a remaining hurdle to a major trade deal,” referencing the desire of the U.S. to complete the Trans-Pacific Partnership (TPP), and, indirectly, access our market.

Mr. Whalen is correct; history has shown that the poultry industry needs to constantly be on watch for threats to the supply management system. But like its fellow supplymanaged and non supply-managed commodities, the greatest attacks at the moment

are not those based on trade deals, but those based on trying to affect public opinion on how food is produced.

I’m not overly concerned that tactics by animal rights activists are going to persuade a significant number of consumers into vegetarians or vegans, but I’ve been with this magazine long enough now to see a definite trend in how much more media-savvy and educated these groups are getting.

A decade ago, activist groups, for the most part, were using shock tactics and graphic images to try and get their messages in the faces of consumers. But then, for example, the Humane Society of the United States began utilizing the democratic system to evoke change (think of Proposition 2). Although not a new tactic, Mercy for Animals has been utilizing undercover videos to its advantage. The difference is the group has been working with national media groups to disseminate the videos, which helps to sensationalize and has a much further reach (and unfortunately credibility) than it could on its own.

The result is that companies that produce food and buy from farmers are under the microscope. No one wants to be portrayed in a negative light and in some cases the videos have made companies re-visit existing animal care policies or implement new ones — that is never a bad thing (see page 38).

But the worry is that producers and companies will face a myriad of rules and regulations set by retailers out of fear of losing consumers, and that is a bad thing.

I bet having farming practices questioned was not something that even crossed our ancestors’ minds. Looking after animals was just good practice and farmers and their neighbours alike were just happy to have food on the table. ■

DECEMBER 2014

Vol. 101, No. 10

Editor

Kristy Nudds – knudds@annexweb.com 519-428-3471 ext 266

Digital Editor – AgAnnex Lianne Appleby – lappleby@annexweb.com 226-971-2133

Publisher/Sales Manager

Marilyn White – mwhite@annexweb.com 519-400-2424

888-599-2228 ext 237 • fax: 888-404-1129

Account Coordinator

Mary Burnie – mburnie@annexweb.com 519-429-5175 • 888-599-2228 ext 234

Media Designer

Brooke Shaw

Group Publisher

Diane Kleer – dkleer@annexweb.com

President Mike Fredericks – mfredericks@annexweb.com

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

Publication Mail Agreement #40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPT., P.O. BOX 530, SIMCOE, ON N3Y 4N5.

email: subscribe@canadianpoultrymag.com.

Printed in Canada ISSN 1703-2911

Circulation email: subscribe@canadianpoultrymag.com Tel: 866-790-6070 ext 201 Fax: 877-624-1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

Subscription Rates

Canada – 1 Year $30.00 per year (with GST $31.50, with HST/QST $33.90)

GST – #867172652RT0001

USA – 1 Year $ 66.00 USD Foreign – $75.00 per year

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2014 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Lubing's EasyLine Nipple Drinking System for turkeys has changed the turkey industry forever. This revolutionary system incorporates a patented pendulum that effectively directs water from the nipple into a self-cleaning drink cup. The low profile cup design allows day-old poults easy access to the water for great starts and has proven to perform with great success delivering water to heavy toms. You too can Live Easy with EasyLine!

Got Lubing? Contact your local Lubing Distributor for more information about EasyLine or visit our website at www.lubingusa.com.

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664.3811

Fax: (519) 664.3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

J. Dean Williamson Ltd.

London, Ontario

Tel: (519) 657.5231

Fax: (519) 657.4092

Eliminates routine cleaning

Provides fresher water supply

Improves litter conditions

Enhances air quality

Improves bird health

Les Equipments Avipor

Cowansville, Quebec

Tel: (450) 263.6222

Fax: (450) 263.9021

Specht-Canada Inc.

Stony Plain, Alberta

Tel: (780) 963.4795

Fax: (780) 963.5034

The federal government is spending $7.5 million to develop, implement and operate a centralized traceability service.

Agriculture Minister Gerry Ritz said in a release, having a national database for tracing livestock will help improve food safety and bolster trade.

Canadian Agri-Traceability Services is a new not-for-profit corporation that brings together the combined experience of the Canadian Cattle Identification Agency (CCIA) and AgriTracabilité Quebec (ATQ).

Plans are to use information from industry groups to build a comprehensive database by 2016.

Ritz said food safety is the main goal and the national traceability database will collect, maintain and manage information in accordance with national standards, federal and provincial regula-

tions, and the specific needs and requirements of industry. The project is divided into two phases. The first phase will look at the development and implementation of the traceability database. The second phase will involve seeing it into operation.

The government said the database will reduce red tape and complement the work the Canadian Food Inspection Agency is doing through the Traceability National Information Portal, one of 90 department-specific reforms under the Government’s Red Tape Reduction Action Plan. Streamlining regulations and cutting red tape will help to spur innovation and productivity in agriculture, as well as increase Canadian competitiveness and free business to innovate, invest, grow and create jobs, it said.

Terry Kremeniuk, chairman of Canadian Agri-Traceability Services, said when the system is completed it will have a comprehensive list of livestock

in the beef, dairy, pork, sheep, bison, goat, equine and poultry industries.

He said consumers place a high value on knowing that authorities can trace back where their food comes from. “It will be invaluable in responding to unfortunate events such as a disease outbreak or national disaster,’’ Kremeniuk said. Quick responses to these events can help mitigate animal and market losses that can result in financial disasters for producers and the industry.’’

Ritz said the project will reinforce Canada’s reputation as a world leader when it comes to traceability and will be a selling point as agricultural producers work to improve their market share around the world.

“Of course when you have discerning trade partners like Korea, Japan, the European Union now — they’re requesting this for their consumers and we’re able to deliver it,’’ he said. “No one else can at this point.’’

The Canadian Press, AAFC

Olymel is investing over $10 million in an expansion and modernization of its poultry processing plant at Ste-Rosalie in St-Hyacinthe. The investment is intended to increase the production capacity of the cooked products facility in order to meet a growing demand on the Quebec and Canadian markets for this category of product. The construction work required by the expansion project began in

October and will add 15,000 square feet of work and storage space to the facility. The work, which should be completed in April next year, includes installation of a third cooking line, construction of a spice warehouse, the addition of two loading docks and redevelopment of the individually quick frozen (IQF) section.

The Ste-Rosalie processing facility employs more than 420 persons. In addition to its boning operation, the facility fabricates cooked and

breaded chicken products such as wings, breast morsels and breast strips to serve its own brands, mainly Flamingo, as well as for private labels. The plant in Ste-Rosalie sources its fresh products from Olymel’s poultry slaughter facilities.

Ste-Rosalie plant manager Claude Chapdelaine said in a release that once construction is completed, operations can be reduced by seven days to five while still retaining all staff, and production volume will increase by nearly 40 per cent.

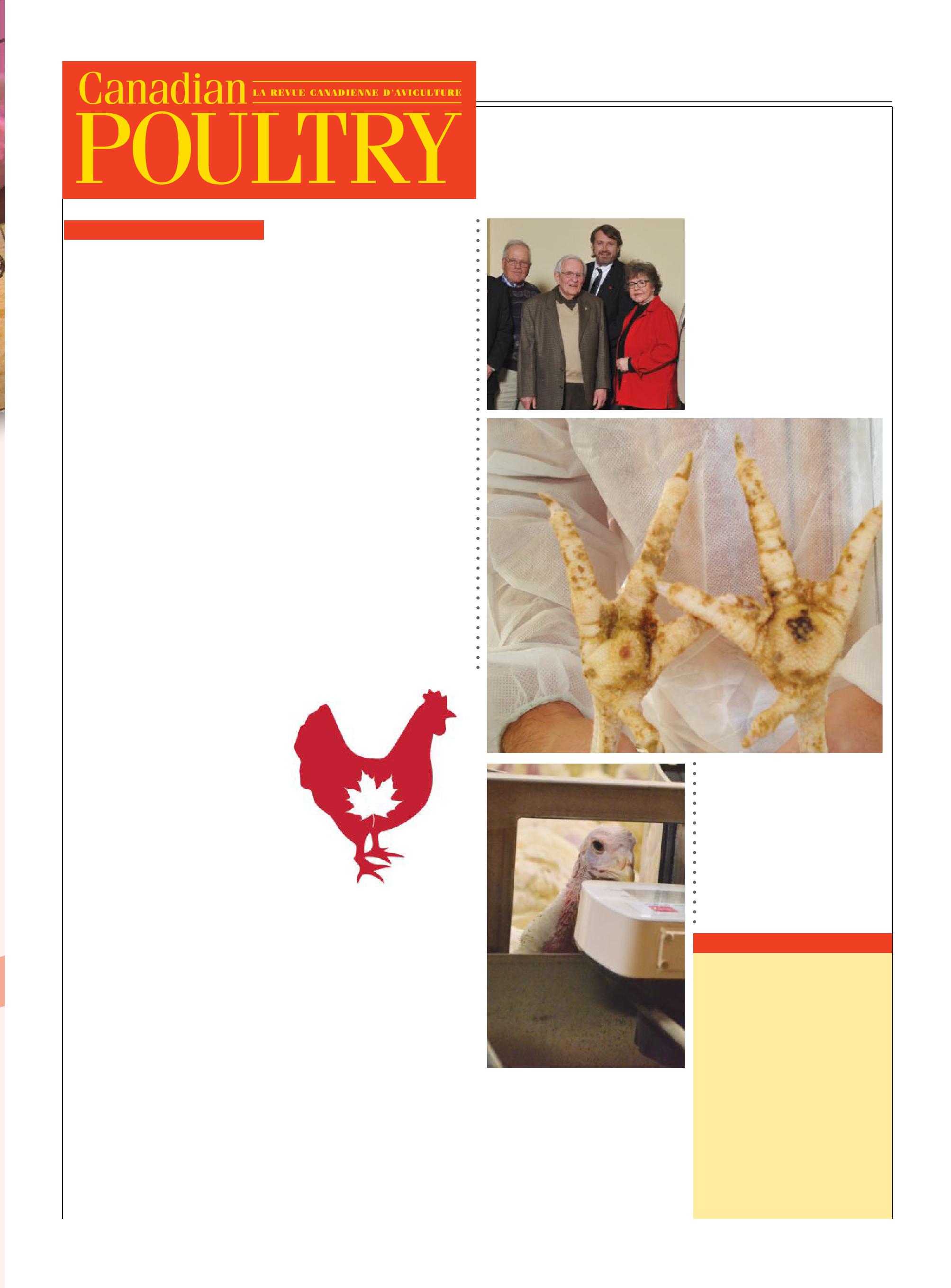

Dr. Bill Cox from British Columbia was named Poultry Serviceman of the Year at the recent Poultry Service Industry Workshop, held in Banff, Alta.

The annual award is presented to an individual who has proven to provide consistent, outstanding service to the poultry industry in Western Canada.

Stephanie Nelson, general manager of the B.C. Hatching Egg Commission, presented the award to Dr. Cox during the PSIW banquet. Cox is the Poultry Health Veterinarian with the B.C. Ministry of Agriculture.

Nelson said that Cox’s list of accomplishments “would have you all sitting here listening to me for the rest of the night.” She highlighted his involvement in the development of the B.C. Biosecurity Program, the SE Project and the province’s Antimicrobial Useage project.

“He is a key leader in the

DR. BILL COX IS THE 2014 POULTRY SERVICEMAN OF THE YEAR. STEPHANIE NELSON, GENERAL MANAGER OF THE B.C. HATCHING EGG COMMISSION PRESENTED THE AWARD.

B.C. Poultry Industry and has earned the trust of the farmers, a task that this room can appreciate is difficult,” she said.

When interviewing Cox’s collegues in both government and industry, Nelson said words such as “wonderful,” “advocate,” “passionate” and “genuine” were used. She concluded, “he inspires the next generation of poultry

vets, technicians and commodity boards to do better and be better. He is a tactful leader, a passionate advocate, and a steadfast problem solver. He is a supporter, a forward thinker, and a proactive planner. He works with everyone and anyone. He is the hands on trusted ally to our farms and so worthy of the recognition of this award.”

DECEMBER 2014

December 10, 2014

Prairie Livestock Expo (formerly Hog and Poultry Days), Victoria Inn Hotel & Convention Centre, Winnipeg, Man. For more information, visit: www.prairielivestockexpo. ca or email: info@ prairielivestockexpo.ca

JANUARY 2015

January 27-29, 2015

International Production and Processing Expo (IPPE), World Congress Center, Atlanta, Georgia. For more information, visit: www.ippexpo.com

January 29-31, 2015 Pacific Agriculture Show, Tradex Exhibition Centre (Abbotsford Airport), Abbotsford, B.C. For more information, visit: www.agricultureshow.net

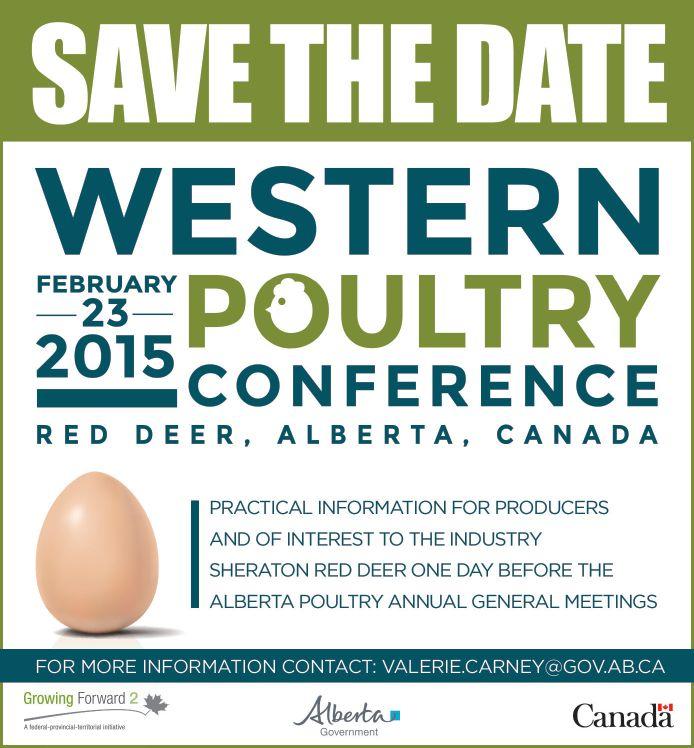

FEBRUARY 2015

February 11-13, 2015 Atlantic Poultry Conference, Old Orchard Inn, Greenwich, N.S. For more information, visit: www. atlanticpoultryconference. com

February 23, 2015 Western Poultry Conference, Capri Hotel and Convention Centre. For more information, email: valerie.carney@gov. ab.ca

Hybrid Turkeys (Hybrid) recently announced that it has signed a letter of intent to enter into proposed agreements in which Ag Forte/ Willmar Poultry Company (Ag Forte) would produce commercial eggs and poults under contract to Hybrid, which will allow Hybrid to begin selling commercial eggs and poults in the U.S. and abroad. Hybrid will also take responsibility and ownership of Ag Forte’s U.S. Hybrid

Grandparent operations.

Under the proposed terms of the agreement, Hybrid will begin selling commercial eggs and poults to existing Ag Forte customers. Hybrid will lead in all aspects of customer relationships including sales, service and customer satisfaction.

The parties expect to finalize the agreement by December 31, 2014, and will begin the immediate process of planning with prospective customers.

Three young poultry farmers from Canada recently visited Aviagen’s world headquarters to get a first-hand look at one of the most advanced poultry breeding operations in the world.

Selected from the Canadian Broiler hatching Egg Producers Association’s (CBHEPA) young farmer’s program, the farmers spent a week at Aviagen facilities in Huntsville, Alabama, and the surrounding areas. This year’s program participants are Kurt Barkman and Melissa Wiens Barkman, both of Bredenbury, Saskatchawan,

and Marianne Bonner from Chilliwack, British Columbia.

The visit allowed the Barkmans and Bonner to tour an Aviagen farm and hatchery, in addition to the company’s product development facility. In their tours and meetings the Barkmans and Bonner gained in-depth knowledge of the U.S. poultry industry, biosecurity practices, production planning, shipping and export processes, Ross® brand broiler/breeder traits and development, and Aviagen’s commitment to sustainability and animal welfare.

APRIL 2015

April 22-23, 2015

London Poultry Show, Agriplex (*note: new building location), Western Fair District, London, Ont. For more information, visit: www.westernfairdistrict.com

2015

May 6, 2015

PIC Research Day, Guelph, Ont. For more information, visit: www. poultryindustrycouncil.ca

2015

July 27-30, 2015

Poultry Science Association annual meeting, Galt House Hotel,Louisville, Ky. For more information, visit: www.poultryscience.org/ psa15

We welcome additions to our Coming Events section. To ensure publication at least one month prior to the event, please send your event information at least eight to 12 weeks in advance to: Canadian Poultry, Annex Business Media, P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5; email knudds@annexweb.com; or fax 519-429-3094. Please write ‘Event Submission’ in the subject line.

A look back at the history of turkey production and the development of the Turkey

BY NICK VAN ALLEN

On March 20th, 2014, in the halls of Ottawa’s Chateau Laurier Hotel, a gathering took place. Members of the Turkey Farmers of Canada (TFC – formerly the Canadian Turkey Marketing Agency –CTMA) enjoyed a luncheon and speeches to mark the 40th anniversary of the TFC. At the assembly were past TFC chairs Brent Montgomery, Eike Futter, and others. Mark Davies, the current chair, also recognized former chairs not in attendance, some posthumously. Here we take a look back at the origins of the TFC, its present and its future.

Turkey farming was once a sideline activity for farm families. In the eighteenth and early nineteenth centuries, according to British historian John Martin, turkey production was a seasonal activity undertaken “often as an adjunct to farming.”1 Many small-scale producers in Canada, Britain, and the U.S. kept flocks in order to make extra cash that was essential to family incomes. Farm women, who did the majority of the work, found that turkey rearing was an activity that fit well with their daily tasks. Since turkeys often wandered about poultry yards kept near farmhouses and

Numerous past chairs were able to participate in TFC’s 40th annual meeting in Ottawa

fed upon “insects, mast, and other food on their own,” the women could complete other chores while rearing the birds, or instruct children to care for them.2

Soon, farming men and women became captivated by the possibilities that the turkey offered. Agriculturalists worked on better breeding and raising methods, enhancing quality and quantity. In the United States, by 1890, American farms housed 11 million turkeys, showing the popularity of the product among progressive farmers. However, as of 1910, less than a third of them remained. According to environmental historian Neil Pendergast, the decline was owing to the high levels of production that “courted disease;” blackhead had made its way through American farmland, from the east coast to the midwest, reducing producers’ flocks. Agricultural scien-

tists investigated solutions to the disease, and in doing so carried turkey farming out of the hands of small-scale farmers and into that of larger agribusiness. Over the next two decades farmers even developed turkey ranches, putting the “production of domestic turkeys on a new scale.”3

During the Great Depression, many Canadian farmers could barely put food on the table, but national concern for turkey production wasn’t far off. According to former Canada Poutlryman editor Fred Beeson, in the 1930s “it was enough” that producers “could scrape up sufficient food” to feed their families so poultry production remained small scale through-

out the provinces. However, as Jim Knisley stated in a 2013 issue of Canadian Poultry, “when the war happened, it all changed.” Canadian farmers rushed to the service of the British cause — poultry production was a part of that effort. By 1945, for example, The Canadian Yearbook cited nearly 3.4 million turkeys produced on Canadian farms, whereas in 1927 the number had been only 1.9 million – farmers had doubled their turkey production in less than two decades.4 Canadian governments and farmers organized controls and systems to encourage such production, bringing poultry farming into centre stage.

Following the war, Knisely said, “no one was certain what would come next.” Neo-liberal economists and other businessmen called for a return to the free enterprise system and the removal of government influence. Many poultry farmers enjoyed the stability that wartime agricultural management brought them, but Canada remained non-committed to the idea of an official national production system in the face of such calls for a return to laissez-faire economics. Even though Australia was able to establish an egg board in 1949, Canadian farmers went without such representation until the “Chicken and Egg Wars” arrived in the early 1970s and producers and governments alike realized that they could ignore the question no longer.

Twentieth-century agricultural science, put simply, worked almost too well for Canadian poultry producers. By the 1960s, electrification, better barns, lighting, feed and ventilation systems raised production to new levels. Now, though, the problem was the overproduction of poultry. In 1961, for example, B.C. broilers shipped their surpluses to other provinces, drastically affecting prices at destination points. And in 1970, when Ontario and Manitoba egg producers shipped large quantities of eggs into Quebec, a fire was sparked that became known as the “Chicken and Egg War.” Quebec responded to Ontario and Manitoba producers by restricting future imports, and in retaliation the provinces sought to prevent the import of Quebec-originated chicken. While the battle was eventually taken care of by the Manitoba Court of Appeal, the Canadian poultry trade was, in essence, cracking under the pressure.

Even in the face of such a situation, “consumers groups, some economists, and many corporate interests” remained firmly against price and production controls, often seeing agricultural policy as being co-opted into a system of social welfare for farmers.5 However, with steep financial losses in the poultry production sector worrying politicians, and many farmers calling for some type of national planning, governments finally acted. After Bill C-176 was passed, egg farmers of Canada came first, establishing the Canadian egg Marketing Agency (CEMA) in 1972. Turkey farmers followed this step shortly thereafter. In 1974 producers founded the CTMA, and John Tanchak took the reins as the group’s first chair. Coming a long way since a few birds wandered about farmhouse poultry yards, turkey production became a fully nationalized and institutionalized system that year, and CTMA sought to give producers the representation and stability they would need going forth.

In a 2003 interview, former agriculture minister Eugene Whalen said that supply management was intended to fix the chaotic system that existed in Canadian agriculture before the mid-1970s, “especially for perishable products. The principle was to provide some kind of stability to the overall economic situation.” While battles still had to be fought after 1974, the group’s next four decades brought stability to the industry, in turn encouraging innovation and public service.

Between 1974 and 2013, turkey production in Canada boomed. While the total number of producers actually declined (from 602 to 527), according the 2013 Turkey Factbook, cash receipts increased from $121 million in 1974 to $400 million in 2013. The changes represent the consolidation of turkey production into the hands of successful producers, made possible by supply management.

A quick look at the TFC timeline, published in 2014 to celebrate the 40th anniversary, shows what the group did for turkey

producers over the past forty years. Just three years after the group was established, CTMA practices encouraged a pricing increase of 25 per cent — from the 1964 price of just 77 cents, to $1.00 per kilo in 1977. Farmers could make that price work for them and their families. And in 1984, under chair William Chrismas, “signatories

to the Federal-Provincial Agreement” agreed to allow “provincial Commodity Boards to enter into and execute a Promotion Agreement containing a monetary penalty for overproduction,” further discouraging the practice that had contributed to low prices in the early 1970s. Nearly ten years later, CTMA was also present during the

www.hybridturkeys.com

Our commitment and dedication to the Canadian turkey industry has spanned the last 60 years. Today, the lasting relationships we have developed, ongoing investments in research and the performance of our products are assurances that Canadian turkey farmers will continue to benef ifit from the advantages Hybrid Turkeys has to offer:

> a network of trusted Canadian distributors

> aff iliations with agricultural research institutions

> a team of global technical experts

Partnering for your success.

NAFTA and GATT negotiations and the group helped ensure that the “long-term visibility of the Canadian turkey industry” remained on the minds of negotiators (keeping a drumstick on the table, soto-speak). With the CTMA at the helm, turkey farmers experienced a business environment they could operate in, expanding and improving their practices in a stable and relatively certain climate.

While the Canadian urban public often thinks of farmers as ultramontane or conservative, the CTMA and its members were actually quite innovative and willing to adapt to change. In 1987, for example, the group established the CTMA research committee, and in order to enhance humane livestock handling and biosecurity in the turkey production industry, the CTMA sought the publication of the Recommended Code of Practice for the Care and Handling of Poultry from Hatchery to Processing Plant in 1988/1989, and the Best Management Practices for Turkey Production in 1996. In terms of biosecurity, the CTMA was present when avian influenza arrived in 2004 on a B.C. turkey farm and resulted “in a major culling program.” Turkey farmers benefitted from having standardized recommendations and a representative group constantly reflecting on the health and vitality of the industry, preventing and responding to disasters mild and severe.

The CTMA, however, was not just about service directly to turkey farmers. The organization has also worked to ensure consumers are aware of turkey as a consumptive product. In this sense, public service is also a key mission for the group. As early as 1976 the CTMA published its first turkey cookbook, Talking Turkey, which was distributed across member provinces. And to ensure that consumers didn’t just think about turkey at Christmas, Easter or Thanksgiving, by 1984 the CTMA looked at motivating Canadians to have “turkey anytime,” a mission that was further encouraged after 1996 when the CTMA website Canadianturkey.ca was established. The digital effort expanded into the 1996 Turkeytuesday.ca website, the 2009 creation of a Twitter account (under the new name Turkey Farmers of Canada), and the 2011 Facebook page and YouTube channel.

According to Mark Davies, the goal was to make turkey an “everyday choice” for consumers, and it worked.4

Increased purchases of non-whole turkey depicts the success of these campaigns. In fact, the 2013 Turkey Factbook shows that across Canada sales of “parts” tripled, from 2,325,000 kilos to 5,682,000, and “processed” increased even more substantially, from 579,000 to 11,695,000 kilos, between 1983 and 2013. The campaigns clearly gave turkey producers a bigger share of the market and allowed the products to find their way onto consumers’ tables. CMTA/ TFC’s efforts continue to pay dividends to this day.

Even though the CTMA/TFC has shown itself as a benefit to both consumers and producers, it is not without its critics.

Indeed, anti-supply management attacks have been part-and-parcel of the SM experience since the beginning, often popping up when opportunity strikes. As Canada has recently weighed the costs of entry into the Trans-Pacific Partnership (TPP), for example, the C.D. Howe Institute released a number of reports critical of SM controls, and even former Liberal leadership hopeful Martha Hall Findlay, now at the Calgary school of public policy, and National Post columnist Andrew Coyne chimed in. A 2013 C.D. Howe paper (commentary 382 – written by Robert Mysicka and Marty McKendry) referred to SM controls as “anticompetitive regulations” creating government-sponsored “cartels.” And Findlay, in her 2012 paper, said the TPP trade negotiations are a welcomed surprise as they offer Canada an opportune moment in which to abandon the “supply management regime,” similarly using the term “cartel” to label SM boards and agencies.

According to Eugene Whalen in 2013, “supply management is always under attack.” And, in typical blunt fashion, Whalen said that SM critics often “don’t know a thing about agriculture.”7 The only issue farmers should concern themselves with is “the fact that self-destruction is possible.” Those producers, turkey farmers among them, who have supported and prospered under SM controls, in other words, need to “continue to defend the system and continue to explain it.” Since such public service and educative efforts have been a part of the CTMA/ TFC since its inception, and the group has proved itself adept at working with the public and policy makers, it is likely that in the future the group will have to dedicate itself to ensuring that the Canadian public understands agricultural systems and the benefits that SM controls brought producers and consumers — forty years of them, to be exact.

Mark Davies, commenting in the TFC Annual Report 2013, said that “in 1974, when Turkey Farmers of Canada was established under the federal Farm Products Agencies Act...staff members were tasked with the responsibility of administering national quota policy.” This was no easy task, but CTMA/TFC did it in spades. Working with farmers, politicians, negotiators and the Canadian public, the group proved itself capable of making the system work and it brought forty years of turkey successes and innovations. The advances experienced and the long- and short-term profitability of the TFC, Davies said, are “the ultimate confirmation of the supply management system and confirmation of what...individual farmers, leaders and business owners can accomplish when we work together.”

What the future has in store for turkey can never be known, of course, but the TFC will surely have an important role to play for consumers and producers alike. But, this year, let’s take a break and celebrate the 40th anniversary of the TFC which, as Phil Boyd says, “is a big deal.” Congratulations to the Turkey Farmers of Canada. ■

References available on our website www.canadianpoultrymag.com or by request

Together, we can make a difference this holiday season.

This Thanksgiving, Turkey Farmers of Canada challenged Canadians to #BOGOTurkey - Buy One turkey for their own Thanksgiving meal and Give One to a local food bank to help others in their community.

Now, in the spirit of the holidays, we’re going to BOGO all over again.

Please join us this December by donating a turkey to your own local food bank. Then join the conversation online and help spread the word using #BOGOTurkey

Together, we can help make the holidays happier for Canadian families!

BY DR. JIM BLACKMAN, PhD, NUTRITIONIST, AND MEGAN DEVISSER, M.SC. CANDIDATE, MONOGASTRIC

NUTRITION

ASSOCIATE, NEW LIFE MILLS, A DIVISION OF PARRISH & HEIMBECKER, LIMITED

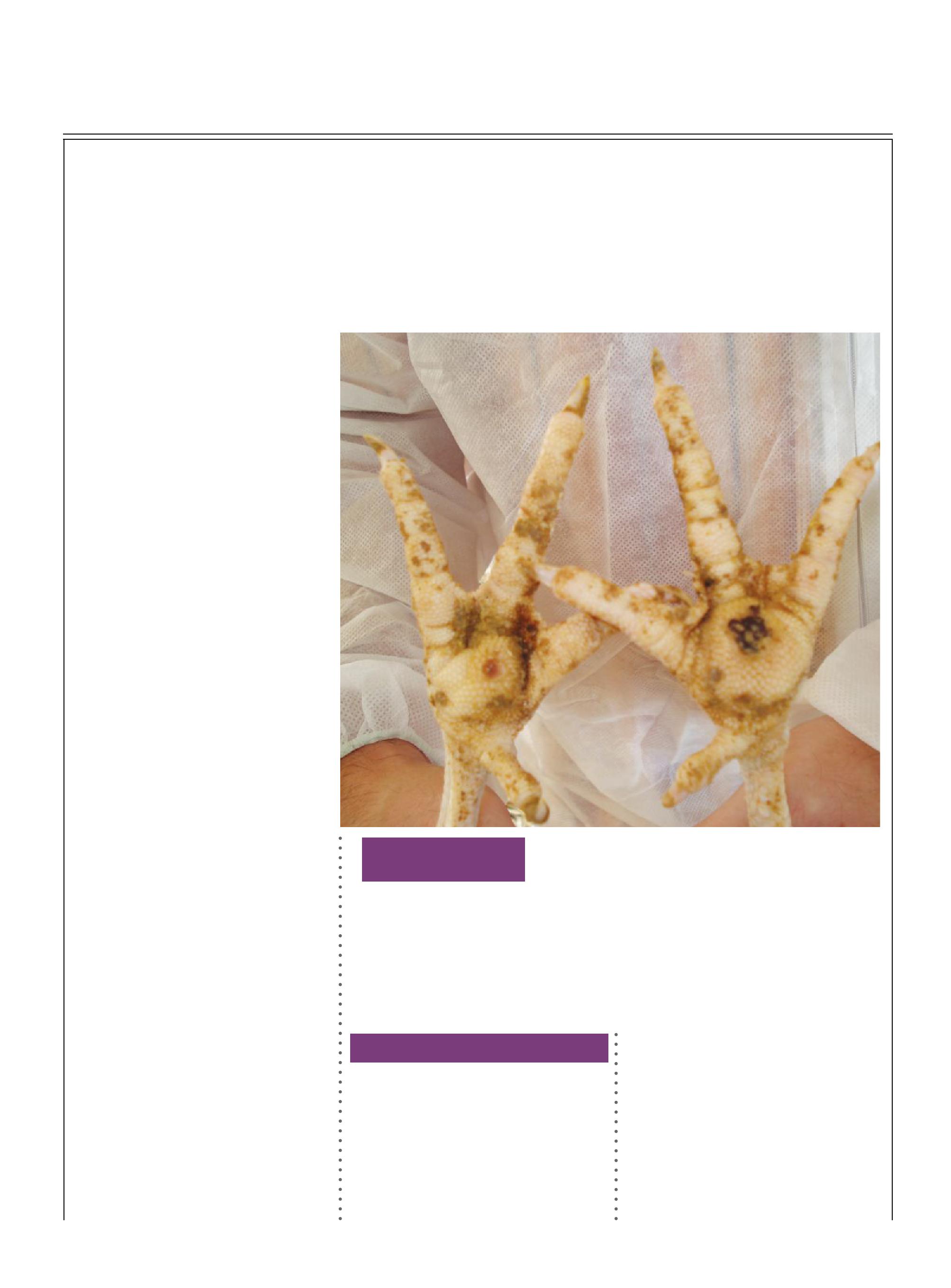

Foot pad dermatitis is a condition characterized by lesions on the foot pad of turkeys, which, when severe, lead to the erosion of the skin layers and cause pain when weight is put on the foot. Scoring scales used at the processing plant to determine the severity of the lesions can be used as an indication of welfare of a flock, due to the pain associated with this condition, making it a management aspect which should be monitored very closely. Additionally, the pain caused by foot pad dermatitis leads to decreased mobility which may cause a decrease in eating and drinking, as it is too painful to walk to the feed and water lines. Many factors, including management and nutrition, may contribute to the development and severity of foot pad dermatitis and can be manipulated to reduce the incidence of foot pad dermatitis in a flock. It is important to be aware of all factors contributing to foot pad dermatitis and manage the barn to ensure these risk factors are being minimized before any lesions appear on the foot pad of the bird.

The effect of litter material, ventilation and humidity, water line management, bird health, and nutrition on foot pad dermatitis needs to be well understood by producers to minimize the risk of this disease developing within their flock of turkeys

The moisture of the litter used for bedding in a turkey barn is the most important contributor to foot pad dermatitis in turkey flocks. This is because increased litter moisture facilitates the softening of the foot pad, making it more susceptible to bacterial invasion. This bacterial invasion leads to the production of a lesion on the

foot pad. In general, other factors involved in the development of foot pad dermatitis are simply related to the way in which they contribute to increased litter moisture. This includes the litter material being used. Understanding the ability of that material to hold water and keep it away from the foot pad of the turkey, thereby decreasing the moisture of the litter in contact with the foot pad, is important as making the

decision on litter material and depth is an important aspect of barn management. The litter material may also induce the development of a lesion based on the physical properties of the material, as an abrasive material may cause irritation to the foot pad.

The barn environment is influenced by a variety of management factors including humidity, ventilation, and temperature. Ensuring the humidity is low enough to reduce the litter moisture helps prevent

the development of foot pad dermatitis in the turkeys, while still keeping the humidity high enough to prevent the barn from become dusty. Managing ventilation in such a way that relative humidity levels are maintained between 50 and 70 per cent is a key component of managing to reduce the incidence of foot pad dermatitis in the flock. This is particularly difficult in the winter, as adding heat is expensive which may cause a producer to decrease ventilation rates to save on heating costs. Lowering the ventilation in the winter allows for the buildup of moisture within the barn and promotes wet litter, making the flock more susceptible to the development of foot pad dermatitis. A too high ventilation rate can also have negative effects as this will increase the heating cost to unnecessarily high levels during the winter months. Higher stocking density will put more pressure on litter management due to increased excreta output per

square metre. Finding the balance in ventilation that allows for a sufficient quantity of fresh air and removal of moisture from the barn, while keeping heating costs as low as possible, is required to manage the barn and the flock to their potential.

The management of the water lines in the barn can contribute to the development of foot pad dermatitis in a turkey flock by contributing to increased litter moisture. Regularly checking water lines for leaks, ensuring they are set to the correct pressure, and maintaining water sanitation in the barn helps to minimize water spillage. Additionally, ensuring the water lines are at the right height such that the turkeys are not stretching or bending down to drink decreases the amount of water being wasted during drinking and contributes to keeping the litter dry.

Bird health plays a very important role in the development of foot pad dermatitis. Disease challenges, such as coccidiosis and enteritis, are associated with malabsorption in the gut, leading to loose excreta and increased litter moisture. Watery, foamy droppings are often the first indication of a disease challenge. Enteric diseases lead to a decrease in feed and water intake, which results in marginal intake of nutrients critical to health, including energy, amino acids, vitamins and trace minerals. Unless quickly addressed, litter conditions will deteriorate and birds will develop dirty feathering and lethargy. The combination of these factors results in impaired immune response, increasing the turkey’s susceptibility to foot pad dermatitis. Closely monitoring flock health and mortality for the duration of the growing period is very important and

should be done in consultation with your flock veterinarian.

Components of the ingredients provided in the feed can contribute to foot pad dermatitis. Ingredients containing difficult to digest carbohydrates, such as soybean meal, corn distillers grains with solubles, barley and wheat, are associated with sticky droppings due to their ability to retain water in the excreta. These sticky droppings are concerning as they increase the contact time of the foot pad with the excreta, as well as increasing the water contained in the excreta. This challenge can be overcome with enzyme supplementation in the diet. Another nutritional component is the quality and balance of protein being supplied in the diet. A diet that is poorly balanced in terms of protein leads to increased excretion of water into the litter, contributing to an increase in

Addition of fats or oils rich in polyunsaturated fatty acids in poultry diets is a straightforward approach to enrich poultry products with polyunsaturated fatty acids.Consequently, there has been a great interest in using different types of fats, oils or oil seeds as feed additives in poultry nutrition.

The purpose of this book is to educate the readers on the role of dietary fats in poultry on: production aspects, health effects, growth and product quality.

In addition, the role of poultry food products in meeting the human requirement of much needed functional nutrients such as omega-3 fatty acids is discussed.

litter moisture. The presence of mycotoxins in the feed can also contribute to the development of foot pad dermatitis. The Fusarium mycotoxin deoxynivalenol (vomitoxin), has been shown to disrupt the intestinal mucosa structure, leading to impaired nutrient absorption and contributing to the development of malabsorption and increased excreta moisture. The risk from mycotoxins can be mitigated by stringent screening of feedstuffs and nutritional support to minimize their negative effects. Another dietary factor is sodium intake from both feed and water as it impacts electrolyte balance. Sodium intake in excess of nutritional requirements can contribute to the development of foot pad dermatitis through increased excreta moisture. Maintaining moderate, but adequate, levels of sodium in the diet, with adjustment for the contribution from drinking water, is a necessary step in foot pad dermatitis prevention. Proper nutrition and feed formulation can address many of the factors involved with foot pad health in turkeys. Developing a nutritional strategy to prevent the development of foot pad dermatitis in your flock should be done in consultation with your flock nutritionist.

Old OrChArd INN & SPA Greenwich, Nova Scotia in the heart of Annapolis Valley February 11 - 13, 2015

Come enjoy the Atlantic Poultry Conference and the tranquil atmosphere of the beautiful Annapolis Valley, Nova Scotia

Bruce Rathgeber

Email: brathgeber@dal.ca

Telephone: 902-893-6654

Fax: 902-895-6734

The effect of litter material, ventilation and humidity, water line management, bird health, and nutrition on foot pad dermatitis needs to be well understood by producers to minimize the risk of this disease developing within their flock of turkeys. Understanding how these factors work both independently, as well as the way they interact, to induce and increase severity of foot pad dermatitis in a turkey flock gives producers the opportunity to manage their barns to reduce the risk factors present to the turkeys, from day-old poults through to market age. Barn and flock management that focuses on the reduction of foot pad dermatitis risk factors, particularly by monitoring litter moisture, will contribute significantly to producing a high performing, healthy flock of turkeys. ■

BY LESLIE BALLENTINE

Insects as a sustainable human food source have received a good deal of attention and investment over the last several years. Less visible are efforts here and abroad to use insects as a sustainable animal feed source. One such initiative is taking place in a commercial sized facility in Vancouver.

Vancouver-based Enterra Feed Corporation is not only unique to Canada; it is attempting to resolve two problems with a single solution by using food waste to create feed protein derived from insects. They describe it as upcycling.

By using a food source that is naturally eaten by poultry, Enterra is tackling two major, global problems – wasted food and a growing demand for affordable protein sources.

According to recent reports, more than 30 per cent of the world’s food supply never makes it to the consumer and ends up as disposed waste or compost. In Canada, over 50 per cent of food waste occurs at the consumer level but 29 per cent occurs at the processing and retail levels amounting to about $7.8 billion a year.

The sharp increase in pre-consumer food waste over the last 50 years is due in large part to increasing consumption of perishable fruits and vegetables and stricter food quality requirements. This is happening at the same time as fish stocks and crop lands are shrinking and as

Vancouver-based Enterra Corporation is looking to produce animal feed from larvae of the black soldier fly

demand for soy and other plant proteins is growing, creating volatile feed supplies and prices for poultry farmers.

The farm and food sector is continuously seeking ways to make their practices more environmentally and economically sustainable. This is where insect-feed fits in.

According to the company website,

Enterra’s patent-pending hatchery process uses a local beneficial insect to recover nutrients from traceable feedstock. “We operate an organic, zerowaste system to provide a sustainable supply of high quality nutrients for food production at a stable price, and that also reduces food waste disposal costs for businesses and municipalities.”

Raising youR flock’s peRfoRmance with the Right suppoRt team,technical seRvices and the name you can tRust:

Talk to your veterinarian to find out more.

This is the way it works.

Enterra takes fruit and vegetable waste from grocers and food processors — including Overwaitea Food Group and Sun Processing — combines it with a small amount of fish trim and waste bread and feeds it to the larvae of the black soldier fly. This common and benign fly is

used because it is not a vector for disease and because the female flies are prolificproducing up to 900 larvae eggs during their seven day lifespan.

Known for their voracious appetite, the larvae consume each feeding in just a few hours, so the waste food never has time to decompose and breed pathogens.

The largely automated, enclosed hatching facility can take in 100 tonnes of pre-consumer food waste per day or 36,500 tonnes per year.

This produces approximately 5,400 tonnes of larvae, 2,700 tonnes of fertilizer and can recover nearly 20,000 tonnes per year of clean water from the fruit and vegetable feedstock.

After two weeks when they are at their prime, the larvae are cleaned, cooked, dried and ground into meal. The meal is about 60 per cent protein, comparable to soy feed, and, according to the company, suitable for both fish or poultry feed. The larvae castings and spent brood flies are being used as fertilizer by local farmers.

The company calls it “Renewable Food for Animals and Plants™”.

Breeding trials conducted by the EU initiative PROteINSECT have found that one hectare of land could produce at least 150 tons of insect protein per year. By comparison, soy planted over the same area yielded just under a ton of protein and is more resource intensive to grow. And a 2013 report by the Food and Agriculture Organization of the UN suggests that feeding trials with fish and poultry showed that the animals fed insect-feed outperformed those raised on traditional diets.

In September, Enterra announced that it had received additional investor funding to help complete its 56,000-square-foot commercial pilot facility in Langley B.C., expand production and begin selling feed on a commercial scale. This makes Enterra the only large scale commercial producer in Canada although there are many in the research, pilot and start-up stages here in Canada and globally.

Company CEO Brad Marchant says “we have been testing our products with poultry for about two years now — both in Canada and the U.S. The most recent field testing is being conducted at the University of Saskatchewan as well as an organic poultry farm in Oregon, with very encouraging results and positive response from the farm operators.”

As the company prepares to ramp up commercial production, it has filed for Canadian Food Inspection Agency (CFIA) approval to sell its feed products in Canada and is awaiting organic certification for its fertilizer product in Canada. Marchant reports that Enterra has “been working with CFIA for about two and half years now, to register the product as a novel feed ingredient for poultry and aquaculture.” Adding, “We understand that this is a normal timeline for approval of a novel feed ingredient.”

Currently, the products are being sold in Washington, Oregon and Idaho where the firm has received product approvals. The company is awaiting approval in several other U.S. states. At the same time, Enterra is working on FDA registration so they can sell to all of the U.S. market rather than just certain states.

When it comes to price, Marchant says it is price competitive with common protein sources such as soy and fish meals. “Based on the nutritional content and digestibility we are priced between premium fish meal and poultry meal. In some cases, where the advantages of local, consistent supply of a natural protein product are desired, there is a premium paid.”

The company is receiving inquiries from poultry producers and Marchant says, “there seems to be pent up demand for the product as insect larvae are a natural feed source for poultry, and our larvae are grown from traceable feedstock sources. It is really more a case of regulations catching up with product demand.”

If all goes according to plan the company may open hatcheries in Toronto, Seattle or San Francisco.

Although 1/3 of the world’s population eats insects as a regular food source it will be a challenge to get North Americans to adopt an insect diet. The next best thing is to use those insects to feed animals we will readily eat. And that poultry will too. ■

“On this farm, we’re the experts.”

Sean Gorrill – FCC Customer

More of Canada’s farm experts choose to do business with FCC Together, we’ll create the financing plan that works for you. We get to know you, your farm and how you want to grow. If you’re ready to get down to business, talk to one of our farm business experts.

fcc.ca/Expert2Expert 1-800-387-3232

BY TREENA HEIN

Canadian chicken farmers are trustworthy, responsible and they really care about their flocks, the environment and producing quality products. That’s the message of a new branding campaign just launched by the Chicken Farmers of Canada (CFC).

The campaign is called “Raised by a Canadian Farmer,” and CFC says it will “showcase the commitment of Canada’s chicken farmers to providing families with nutritious chicken raised to the highest standards of care, quality, and freshness.”

One push for the initiative comes from the fact that there are already many store and processor brands in the marketplace that are attempting to identify products as Canadian, but consumers don’t know which of them they should rely on. CFC research has shown that the majority of Canadians would trust a national brand if it came from a farmer group as opposed to a retailer or processor. Therefore, CFC believes that because it both represents Canada’s 2700 chicken farmers and administers the On-Farm Food Safety and Animal Care programs to which they must adhere, it made sense for CFC to spearhead a national branding campaign.

“Raised by a Canadian Farmer” got off the ground in 2011, when CFC Directors approved its creation as part of the organization’s annual strategic planning process. “This kind of program takes a long time –particularly since it’s integral that as many partners are consulted as possible,” notes CFC’s Manager of Communications Lisa

“Raised by a Canadian Farmer” logo is now being used by retailers and will also be used by restaurants

Bishop-Spencer. In 2012, CFC engaged a firm called “Brand Matters” to develop the campaign. This involved conducting many extensive and in-depth interviews among CFC member organizations, which represent an extensive portion of the chicken value chain. The firm also conducted many extensive interviews with representatives from major Canadian grocery retailers and primary processors.

Meanwhile, CFC also did research

through its “Usage & Attitude” surveys. These questionnaires are used on an ongoing basis to track Canadian consumer trends and concerns like food safety and animal care. The survey work found that it’s increasingly important to shoppers that the products they buy come from Canada. More specifically, over 85 per cent of respondents felt that it’s important that the chicken they buy be Canadian and not imported. They were also inclined to feel

that their expectations for food safety and animal care are met when the chicken is raised in Canada. Throughout 2012, all of these elements were integrated in a cohesive branding strategy. “Effectively,” says Bishop-Spencer, “it cleared the path to capitalize on Canadians’ already positive view of Canadian chicken, Canadian chicken farmers, as well as on the importance of a Canadian identity.”

During 2013, CFC approached several major grocery retailers to determine their willingness to participate in the campaign, and find out what would be needed to ensure the successful launch of branded fresh Canadian chicken in stores. CFC is currently negotiating with a variety of retailers and restaurant chains, big and small, to try to make the brand as widely available as possible. “At this time, we are not working with foodservice, as this is a program meant predominantly for fresh chicken at retail, although we do have a couple of frozen products that will be ‘on-brand’ soon,” says Bishop-Spencer. “So, the program is launching at retail right now, but we’re receiving a big influx of interest from restaurants across the country — which points to the possibility that this will be a next step in the brand’s evolution.”

Bishop-Spencer says that the processors and retailers coming into the program are very enthusiastic and are making longerterm plans to incorporate it. “We currently have two retailers and one processor ‘on brand’ and other contracts are currently in negotiation,” she notes. “What’s really interesting is that we’re seeing a greater level of attention being paid to the matter of demonstrating when chicken is Canadian. We’ve brought a great deal of awareness throughout the industry to the importance of this issue…It looks like people are listening when we tell them that the vast majority of Canadians would be likely to buy chicken if it has a label showing it is from Canada.”

While Bishop-Spencer says a uniform approach in marketing to the public — one that allows individual retailers or processors to market their products, but also include the message that their product has been raised to a strict set of national standards endorsed by farmers — is one she believes consumers will feel is stronger than any alternative. Every retailer or restaurant will likely reach shoppers or diners with package labelling and menu highlighting, but signage and other avenues could also be used. “We do see it as being on package, that’s for sure, but we’re hearing more and more interest in placing the brand within flyers, at point of sale,” Bishop-Spenser says. “Most interestingly, there’s interest in incorporating the use of our mark within CFC’s expansive digital strategy, which is an established means of getting directly to those people who actually buy our chicken.” CFC’s digital strategy includes things like Twitter, Facebook, mobile apps and Pinterest. Once a retailer or processor comes “on brand,” discussions are initiated about how they can work with CFC to share these avenues. “There may be later opportunities for them to partner with us in traditional print and television marketing as well,” says BishopSpencer.

The answer to whether some of the rationale for the branding program is a firmer establishment of Canadian chicken sales (in case, for example, more chicken imports occur in future) is yes. “Certainly, there are elements of this program that, no doubt, are about keeping and growing the market for Canadian chicken,” says Bishop-Spencer. “Imports are always an issue — and so is spent fowl. As importantly, though, the program is about delivering on consumer expectations. As an industry, we have a responsibility to be straightforward with consumers and let them know what they’re buying and where it’s from and to not just let them make assumptions. That’s a risk we can’t afford. We spend a great deal of time, as a part of our ongoing strategic planning, surveying and learning about what our consumers want – and Canadians want Canadian chicken.” ■

Season’s greetings to you and your loved ones, and a very happy New Year from all of us at Egg Farmers of Canada.

This joyous season gives us the opportunity to say thank you to our partners who work tirelessly to help us produce fresh, local, high-quality eggs.

Les Producteurs d’œufs du Canada vous souhaitent, ainsi qu’aux membres de votre famille, un très bon temps des Fêtes et une bonne et heureuse année.

Ce joyeux temps de l’année nous permet de dire merci à nos partenaires qui travaillent sans relâche pour nous aider à produire des œufs frais, de production locale et de haute qualité.

A University of Guelph researcher has found a way to measure efficiency in a group

BY KAREN DALLIMORE

One of the challenges with poultry research is that the birds may not respond the same in trial conditions as they do in a commercial setting. So how do we find the turkey that is most efficient under group housing conditions?

Owen Willems, a PhD candidate at the University of Guelph, working under the supervision of Dr. Ben Wood and Dr. Andy Robinson in the Centre for Genetic Improvement of Livestock is trying to do just that.

His area of research is focused primarily on the genetics of feed efficiency and feed behaviour in group-housed turkeys, looking at the correlations between feed efficiency and time spent feeding, number of meals, feeding rate, and daily feed intake. As a geneticist, Willems is ultimately in search of the most efficient turkey, housed in the same large group conditions as it will be raised commercially.

Seventy per cent of the total production costs is feed, said Willems, with most primary breeders selecting for feed conversion values. Under conventional feed trial research, data would have to be gathered on individual birds — weigh the bird, weigh the feed in and weigh the feed out — but that data would not

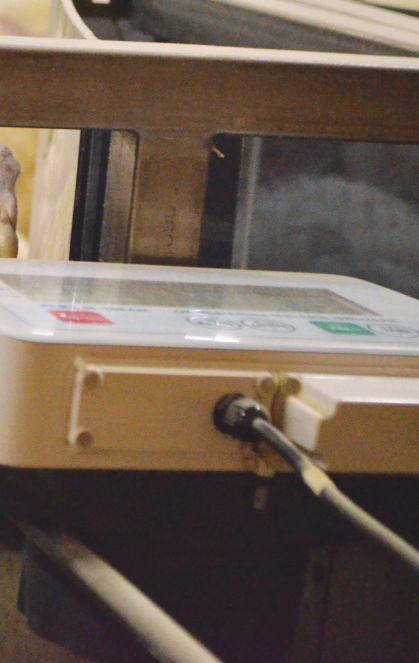

The difficulty of measuring feeding behaviour in a large group is overcome with the use of electronic feeding stations.

always reflect the behavioural aspects involved with group housing in a commercial environment. In a commercial setting the bird would face competition from other birds for feed and water, while in an individual research pen, a meek bird that would do poorly in a group could still be considered as a good

performer.

But how do you keep track of feeding behaviour in a large group? As far as Willems was concerned, other livestock industries, beef, swine and dairy, were using auto feed measurement systems, so why not turkeys?

Picture 320 turkeys in one big pen

PH: 604-798-9750 * TF: 1-1877573276

website: http://www.flokstragroup.com email: info@flokstragroup.com

This book is fully referenced and covers the science that underpins the lighting of poultry, with chapters describing the physics of light, the physiology and mechanisms by which poultry react to light, and the responses of all classes of poultry to conventional and unconventional photoperiods, light intensity, light colour, light source and the pathological consequences of extremes of illumination.

with 32 electronically monitored feed intake stations, ten birds per station. The birds are all “Large White” toms, from 15 to 19 weeks of age. Attached to the wing web of each bird is a generic RFID tag, similar to those used in the dairy industry. The tags weigh 5.6 grams and cost around two dollars each but the information they provide is priceless.

The birds would enter feeders that are mounted on scales, providing data about their feed intake, duration of feeding and the

number of times they fed every day. Willems describes the data collected as “vast.” Some birds preferred the central feeders; some preferred the ones on the sides of the pen. “The system records data from each scale every second and the turkeys are active around 14 hours a day,” said Willems, “giving us the capacity to record about 1.6 million data points a day.”

His data is already being used for both research and commercial purposes. In future, it will provide a large dataset for mining and analysis by subsequent graduate students. For example, Willems suggested that someone could now use the data to look at behavioural and animal welfare considerations, while the commercial application is really about improving the breeding candidates that will then become future generations at the commercial level.

The Poultry Industry Council of Ontario, the University of Guelph and industry partner Hybrid Turkeys provided funding for the project. ■

built to survive

Flexible, shock-absorbing stem prevents breakage.

300 Series stainless steel is corrosion resistant.

After years of field research and fine tuning Ziggity has created the robust T-Max turkey drinker using the same proven principles as our poult drinkers. Finishing turkeys requires birds to get ample hygienic water. Turkeys have poor eye-beak coordination, so we created a large target that they can’t miss. With each drinking action T-Max dispenses a small amount of fresh water, while minimizing spillage. Birds grow big. Litter stays dryer, reducing ammonia release for healthier flocks.

Tel: + 1 574.825.5849 www.ziggity.com

Big, healthy male and female turkeys. Self-cleaning. Built-to-survive. T-Max drinkers from Ziggity, the most trusted name in poultry watering. Visit www.ziggity.com/turkey for a demonstration.

BY KAREN DALLIMORE

No company or farm wants undercover employees infiltrating their barns, videos demonizing their operations, and search warrants being executed on their property.

But that’s what happened to Butterball LLC, when a hidden-camera video showing turkeys being abused was released by animal rights activist group Mercy for Animals, prompting law enforcement to obtain a warrant to search Butterball’s Shannon, N.C. facility. The two-day raid in 2011 closed down their barns while investigators examined and took photos of 1,800 turkeys, one bird at a time.

“Activists and law enforcement barged right in,” said Dr. Becky Tilley, veterinarian with Butterball Turkeys in Goldsboro, North Carolina.

Tilley told delegates at the 2014 Farm and Food Care Annual Conference in Milton, Ontario, that all other employees were told to leave the area while she watched barn biosecurity being breached. Eventually she persuaded them to at least put on hair covers and personal protection equipment.

Butterball has long held a zero-tolerance policy for animal abuse and notes that any employee found to have violated its animal care and well-being guidelines or witnesses abuse and fails to report it will be terminated. Faced with a need to act immediately and decisively in the face of serious allegations, the first step was to investigate and suspend the six employees “exposed” in the undercover video.

“We want no undercover videos and no

abuse,” said Tilley.

When a two-day raid in 2011 closed down a Butterball turkey facility, law enforcement examined and took photos of 1800 individual birds

Butterball then reviewed all of its current programs, making sure they were science-based, with enhanced documentation. The resulting enhanced Animal Care and Well-Being Program consists of four elements: a newly created Animal Care and Well-Being Advisory Council, enhanced employee training, American Humane Association certification and operational enhancements.

The Animal Care and Well Being Advisory Council is an independent panel of industry experts that has been set up to review operations at Butterball and make recommendations. Council members include Temple Grandin, Professor

of Animal Science at Colorado State University; Joy Mench, Professor of Animal Science at the University of CaliforniaDavis; Yvonne Thaxton, from the Centre for Animal Well-Being at the University of Arkansas; Jesse Grimes, Poultry Science Extension Specialist at North Carolina State University; and Michael Martin, Professor of Poultry Health Management at North Carolina State University. Each serves a two-year term, contributing to an open dialogue related to best practices and new developments in turkey production.

Butterball has also enhanced its regular training offerings. Both new and tenured employees now receive mandatory training and participate in ongo-

ing training sessions to target continual improvement at their specific job. There has always been a zero tolerance for any employee mistreating turkeys or failing to report mistreatment. Tilley says they have set up a Butterball hotline, where animal care concerns can be reported anonymously with immediate followup.

Butterball also voluntarily participates in the American Humane Association’s (AHA) Humane Heartland Program. Beginning in 2013, the AHA started an on-going audit process of all Butterball facilities that interact with live birds. This program provides independent thirdparty oversight and certification and Butterball is the first national turkey producer to become an American Humane Certified producer, meeting some 200 rigorous, scientifically-based standards.

Butterball is also currently implementing several pilot projects to verify

that their turkeys are receiving proper care, such as video auditing and refining internal and third party audits. In order to evaluate and monitor transportation procedures, a series of three video cameras now record handling in the barn, chute and loading. Through video monitoring they can see potential areas for review and provide re-training to an employee where necessary.

Euthanasia methods are being reviewed, looking at approved alternatives to blunt force trauma. Tilley described an on-farm euthanasia decision tree that they have developed, which consists of questions pertaining to a bird’s health status to allow employees to make consistent, objective decisions on whether or not a bird should be euthanized.

For the truck loading itself, Butterball is evaluating the use of a tongue loader, where birds are put inside a coop which

then moves on a belt to the truck. Tilley says this could alleviate some potential handling problems. They will also be evaluating processing methods, comparing controlled atmosphere use of CO2 stunning on the trucks versus a shackling and stunning procedure.

Butterball has packaged its animal care platform as part of its new Traditions with Purpose program, unveiling the commitment in a September 2014 press release. Beyond the basic commitment to continual improvement of animal care, the corporation has also outlined commitment to people, the planet, and philanthropy. “It is our responsibility to make positive impacts throughout our business,” said Butterball President and CEO, Kerry Doughty. “Our new corporate citizenship platform helps define this important role, particularly our signature commitment to animal care and wellbeing.” ■

BY LESLIE BALLENTINE

Kevin, a twenty-something former manager for a commercial fitness centre, arrived at my front door one day this summer offering a free sample of beef in exchange for letting him tell me about the home-delivered natural meat he was selling. I was about to do the “sorry, I’m making dinner” response. But, when Kevin launched into his pitch about how his company’s “chicken, beef and pork don’t contain all the toxic chemicals, GMOs and antibiotics and hormones like regular meat,” I knew I wanted to hear more. Keeping in mind that Kevin has, by his own admission, only ever been on one farm — the beef farm that supplies his company — and that he has only worked for the company for six-months, my first questions were about the farms that supply his company.

What he told me was that all three Ontario farms that supply the chicken, beef and pork respectively are free range small family farms. When I asked how three farms could produce enough to supply families in cities stretching from London to Ottawa he really couldn’t provide a convincing answer other than these three “small natural farms” were big enough to supply 3,500 families with meat packages starting at 190 lbs.

He did encourage me to check out the three farm profile videos that are featured on the company site.

The chicken farmer was his favourite. Having recently met him, but not having been on his farm, Kevin explained that these chickens were free range in the barn. “The chicken farmer goes above and beyond,” Kevin informed me, “like he doubles the airflow to bring in healthy fresh air and no one else does that.” The 72-day-old capons raised with no drugs or hormones are also given double the space that is required for free range chicken, I was told. The grain fed birds receive no animal by-products and Kevin said the farmer “only purchases really high quality feed not the cheap stuff that contains high calories and no nutrients.”

20 per cent to shrink when you go to cook it.” Describing a video he saw of the facility, Kevin said he was really impressed; “it is super clean with everyone dressed in white, the air chill room shows all the chickens being hung properly, and there are three plant inspectors there 24 hours a day. So not only is it safe, it tastes amazing.” Adding emphatically, “I can’t say enough about the quality because you just don’t get this anywhere.”

And then we got to the sales clincher: kids and their health.

Kevin truly believes he is helping families. “Kids really like our food because kids have a better sense for healthy food, he explained, and that, most of all, is what is so rewarding to me.”

Kevin blames his health problems on the food he ate growing up. Food in the grocery store is a big health problem in the long term with all the sugar and salt and chemicals, he said. And, according to this former fitness centre manager, traditional meat is a big cause of health problems in kids.

Until agriculture can get ahead of the marketers in educating the public, the public will continue to be unfairly misled

“You are obviously smarter and more interested in the farms and quality than most,” he said to me, “so I talk to families in a different way than I am talking to you. But what I say to families is this. Do you know what is in your meat? Do you know that every single piece of meat that Loblaws sells, unless it says otherwise, is grown with antibiotics? These are sick and inflamed animals and the only reason they are alive is because they are fed sub-therapeutic antibiotics and you’re feeding this to your kids for only two bucks a pound less than what you would spend with us? It’s just not worth it.”

The farm also does the processing onsite and, according to Kevin, does no processing with water it is only chilled in cold air, unlike other processors who say it is air chilled but still use water. “So unlike the air chilled chicken you buy at Loblaws, even though ours is a bit more expensive, you aren’t losing

He also tells potential customers, “People complain that we are so much more expensive than No Frills but you are also losing 20 per cent of your meat when you buy there and it’s not air chilled, it’s not free range, it’s full of drugs, it’s full of antibiotics, it’s fed the cheapest stuff imaginable and you’re going to feed that to your kids and then they are going to be a statistic.”

No wonder he gets 40 per cent of families to sign on.

Here’s the point: Until agriculture can get ahead of the marketers in educating the public, the public will continue to be unfairly misled. ■

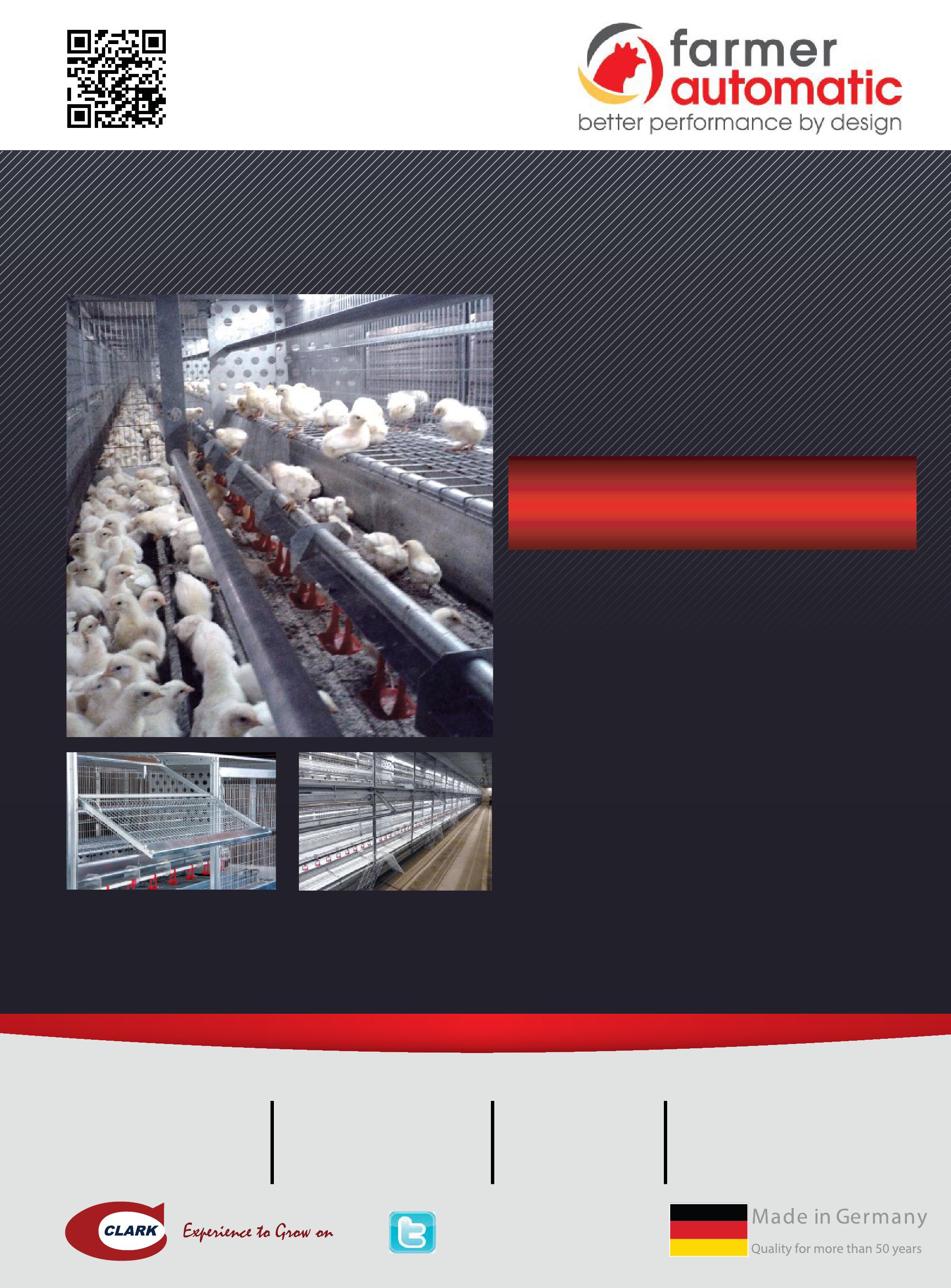

The Farmer Automatic Combi Pullet is a flexible rearing system for pullets. The special feature of this combination system is that birds can be reared for either conventional enriched or aviary housing systems.

• ZINAL 5 or plastic coated flooring

• Optional LED system lighting

• Flexible use - aviary or closed

• Muliple perch diameters & heights

• Reliable V-Link feeding system

• Hot-dip galvanized components

• Optimum utilization of floor space

• Low system height for ease of management

“We chose the Farmer Automatic Combi Pullet system because of the feed chain capability - it is unbelievable how it moves everything seamlessly. The second reason I chose this system is that it also features flexible use of aviary or closed systems for pullet rearing.“ Philip Kleinsasser, Rose Valley Farms, SK