The homebuilders

Alberta Construction

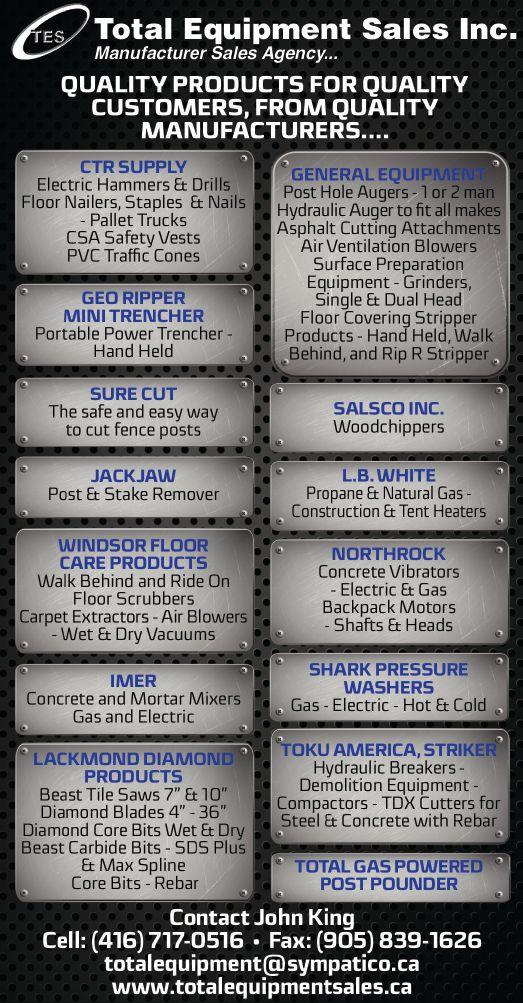

Rentals boasts a strong presence in residential construction

Annex Business Media

P.O. Box 530, Simcoe, Ontario N3Y 4N5

(800) 265-2827 or (519) 429-3966 Fax: (519) 429-3094

EDITOR I Patrick Flannery pflannery@annexweb.com (226) 931-0545

SALES MANAGER I Ed Cosman ecosman@annexweb.com (519) 429-5199, (888) 599-2228, ext 276

ACCOUNT COORDINATOR I Barb Comer bcomer@annexweb.com (519) 429-5176, (888) 599-2228, ext 235

MEDIA DESIGNER I Alison Keba

CIRCULATION MANAGER I Urszula Grzyb ugrzyb@annexbizmedia.com 416-442-5600 ext 3537

GROUP PUBLISHER I Martin McAnulty mmcanulty@annexweb.com

COO I Ted Markle tmarkle@annexweb.com

PRESIDENT & CEO I Mike Fredericks

Publication Mail Agreement #40065710.

Printed in Canada ISSN 0383-7920

email: rthava@annexbizmedia.com Tel: 416-442-5600 ext. 3555

Mail: 80 Valleybrook Drive, Toronto, ON M3B 2S9

Subscription Rates

Canada- 1 Year $42.00 (plus 5% GST - $44.10) U.S.A. - 1 Year $60.00

Occasionally, Canadian Rental Service will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

All rights reserved.

Editorial material is copyrighted. Permission to reprint may be granted on request.

Serving the Canadian rental industry for 41 years.

4

EDITORIAL

We love good deeds, but we don’t always say too much about them.

20

HEAT SMARTS

There are new regulations and training requirements for construction heat that stores should be aware of.

AT YOUR SERVICE

6

INDUSTRY NEWS

Toromont buys Hewitt, Webb joins Norseman, Zelazny retires, Shawmut turns 60... 10 THE

Alberta Construction Rentals specializes in residential construction and finds good business north and south.

The story of how one company went beyond the expected...and earned a fan for life. by Russ Dantu 18

If it makes people or material go up, you’ll find it here.

Your mission is to promote safe habits, not just punish transgressions. by Jeff Thorne

On charity

As I write this at the end of August, Hurricane Harvey continues to sit over south Texas causing devastating floods that are driving thousands of people from their homes in the Houston area. By the time you read this, the stories will have come out in the American media about the Texan rental stores who have moved heaven and earth to respond to the disaster, bringing in extra equipment and working day and night to get life- and property-saving supplies to the people who need them. It’s what our industry does in these situations. There’s even a tie-in to this month’s profile on Alberta Construction Rentals. You see, Warren Carriere, ACR’s president, has expanded into Fort McMurray in part because of the large amount of business available there in the reconstruction efforts following last year’s wildfires. It’s a nice example of business interests meshing with the public good to make everyone’s lives better. With all due respect to our disaster-relief services, I shudder to think what would happen if provision of equipment were left entirely in the hands of public servants. There’s nothing like the energy and expertise of rental professionals who do this for a living.

The rental industry and its suppliers do a lot of good for people in need with charitable donations of equipment and time. You’ll often read about these stories in Canadian Rental Service – but not always. The primary mission of this magazine is to give you information that helps your business. How does hearing about the good deeds of company X help you make money? It really doesn’t, except to the extent that it may give you ideas for similar actions your company can take that might enhance your profile in your local market.

ON THE WEB:

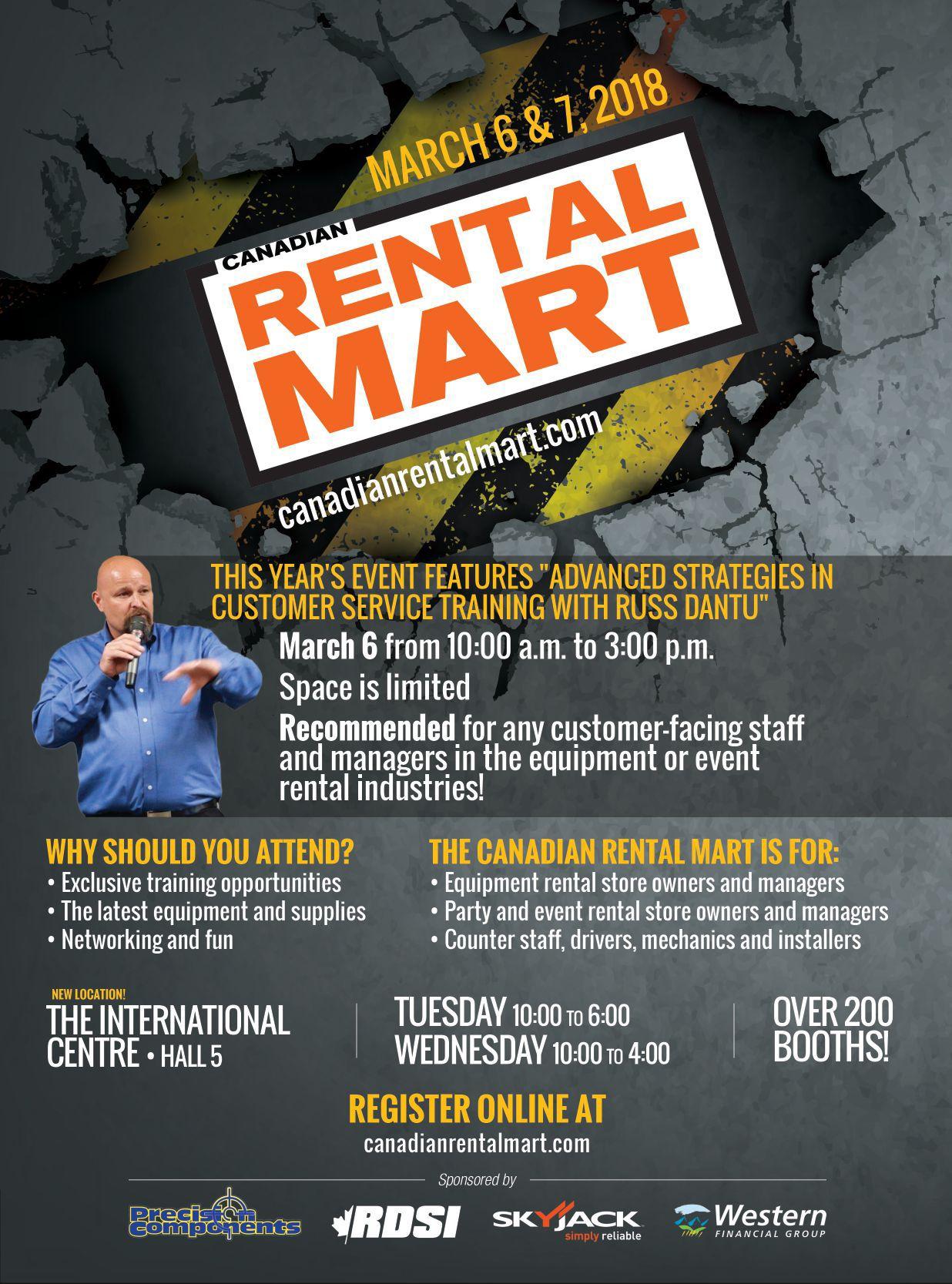

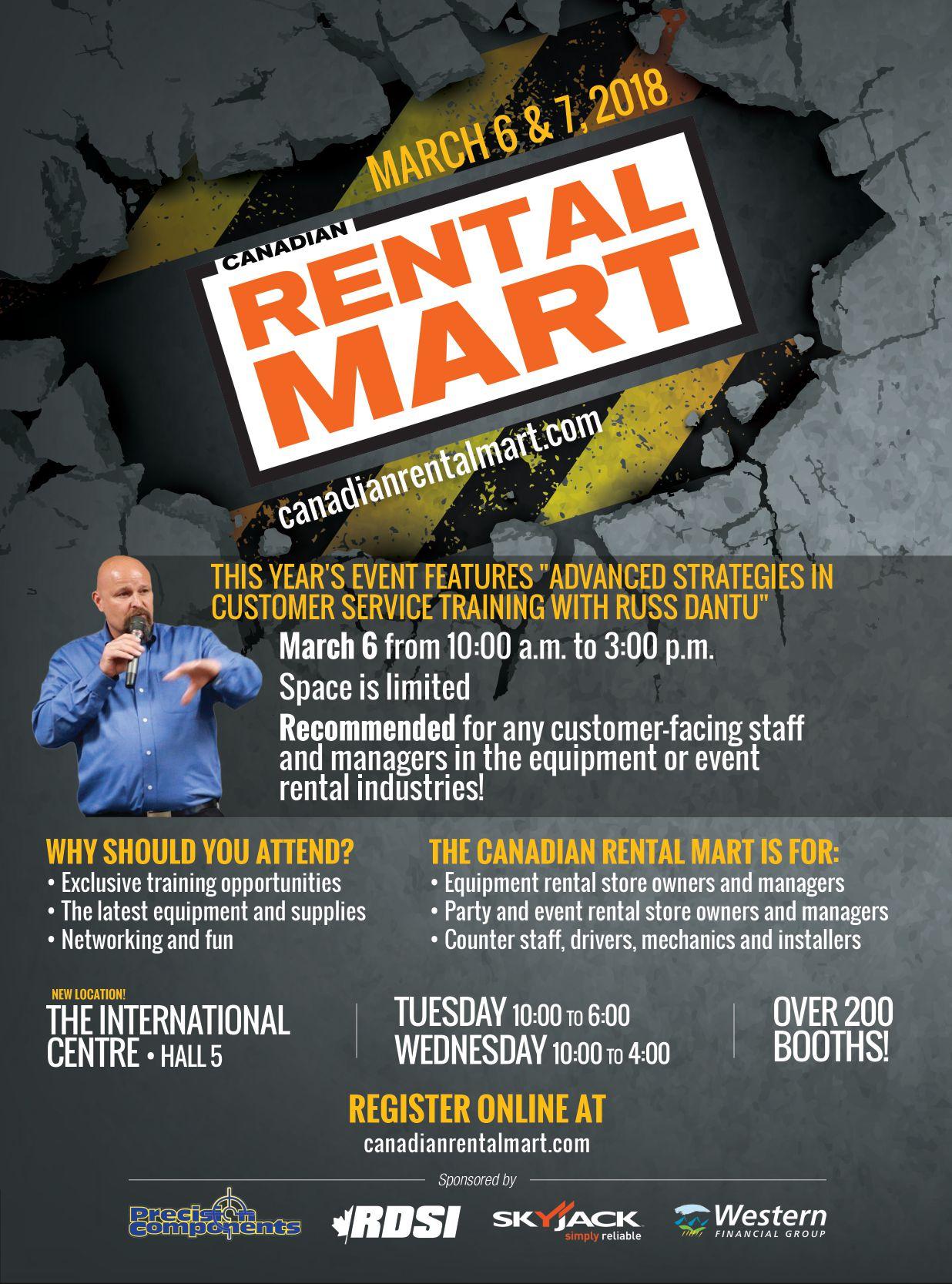

Sign up for exclusive training at the Rental Mart

No matter how good your staff is at pleasing customers, it can always benefit from a day of thinking and talking about customer service. Join Canadian Rental Service columnist and professional customer service consultant Russ Dantu for an energizing session aimed right at the rental industry.

Upgraded job board

We’ve partnered with Indeed to power our job board with positions from right across Canada of interest to anyone in the equipment or event rental industry. Looking for a change? Want to post an opening? Check it out!

by Patrick Flannery

That’s worthwhile and that’s why our coverage tends to focus on novel efforts that take a different approach to charitable giving, such as WestJet’s splashy event last year for the residents of Fort McMurray. I posted a video of that event (which involved local event and equipment rental companies) on our digital channels because of the creativity and magnitude of the effort. At one point, WestJet had gifts for the attendees descending on little parachutes out of the night sky. That was pretty cool and I thought it might get your gears turning as to eye-catching things you could do to attract attention to your business.

Contrast that to the notices that fill up my inbox of corporate donations to such causes as cancer research or children’s hospitals. Worthy causes, for sure. Efforts that should be encouraged and rewarded, absolutely. But this magazine is not in the business of trying to guide or influence corporate behaviour. There’s no social mission here, because I have no moral or intellectual authority to tell you how you should act. If I tried to do so, I’d be the same as those actors and musicians who feel they can lecture us on politics just because they are on TV. So while I might approve of a corporate donor’s actions, I’m not going to take my personal approval as a reason why it should be promoted to you. And editorial coverage in this magazine should never be viewed as any kind of reward for services rendered, whether to the community or anywhere else. It exists to serve you, the reader, and for no other reason. Bottom line, if the purpose of the donation was to help the cause, then the donation itself has served that purpose. If the purpose of the donation was to generate publicity for a particular company, then the appropriate channel for its promotion is advertising. Much as I might approve of a company’s good deeds, it’s not within the scope of this magazine to engineer the behaviour of this industry. We are a conduit for information, not an activist organization. CRS

TOROMONT BUYS HEWITT EQUIPMENT

Toromont Industries has announced it has entered into a definitive agreement to acquire the businesses and net operating assets of the Hewitt Group of companies in exchange for consideration of $917.7 million cash plus the issuance of 2.25 million Toromont shares (nominally $100 million based on 10 day average share price as at signing) for a total consideration of $1.0177 billion.

Hewitt Equipment Limited is the authorized Caterpillar dealer for the province of Quebec, western Labrador and the Maritimes, as well as the Caterpillar lift truck dealer for most of Ontario. Hewitt is also the MaK dealer for Quebec, the Maritimes and the eastern seaboard of the United States, from Maine to Virginia. All amounts are in Canadian currency.

“Acquiring Hewitt marks a very important milestone for Toromont and is beneficial to our customers, employees and shareholders on many levels,” said Scott J. Medhurst, Toromont president and CEO. “We intend to add to its position of strength by investing in people, facilities, technology and rental fleets. Our position will allow us to better capitalize on organic growth opportunities given the recovery of the mining sector that we are currently experiencing and the promise of significant infrastructure investment. We look forward to working with key members of Hewitt’s leadership team.”

Medhurst added, “The acquisition delivers a substantial growth opportunity, allowing us to expand into the significant Quebec, western Labrador and Maritime markets, and strengthens our expertise in the mining, construction, power systems and forestry sectors. We are focused on ensuring a seamless transition for our customers and employees.”

“For more than 65 years, the Hewitt Group has been at the centre of the resource and construction industries in Quebec and the Maritimes, helping to get roads, dams and mines built and running,” said Jim Hewitt, chairman and CEO of Hewitt Equipment. “With the trend towards consolidation taking root in each of the sectors in which Hewitt operates, we are confident that our customers and employees will benefit from working within an even larger organization with access to even more resources and capital.”

Headquartered in Pointe-Claire, Que., Hewitt sells, rents and services the full line of Caterpillar and other products through its six operating business entities: Hewitt Equipment, Atlantic Tractors, Location Hewitt/Hewitt Rentals, Hewitt Material Handling, Montreal Hydraulique and SiteTech QM. Founded in 1952, Hewitt has 45 branches across eastern Canada and employs more than 2,000 people. Hewitt is privately held. In the year ended December 28, 2016, Hewitt generated revenues of over $1 billion, operating profit of $66.4 million and net earnings of $46.6 million.

Upon close of the acquisition, Toromont’s Caterpillar dealership will operate 120 branches in Nunavut, Manitoba, Ontario, Quebec, New Brunswick, Prince Edward Island, Nova Scotia and Newfoundland and Labrador, giving the company one of the largest sales territories in the Caterpillar dealer network. Toromont expects to maintain existing facilities and, under its decentralized business model, regional leadership will continue to run their businesses locally, empowered to make decisions in the best interests of their customers.

Medhurst added, “The acquisition is the largest in our 56-year history and is only possible because of the strength of our balance sheet and proven track record as a disciplined operator focused on generating steady growth across each of our core markets. We are confident in the opportunities and bright future this transaction will bring to all of our key stakeholders: employees, customers, suppliers, shareholders and the communities we serve. We are very proud of our partnership with Caterpillar and appreciative of this opportunity. “

COMING EVENTS

Oct. 3

ICUEE Demo Expo Louisville, Kty. icuee.com

2018

Jan. 9 - 11

Landscape Ontario Congress Toronto, Ont. locongress.com

Jan. 19 - 20

B.C. Regional Trade Show Langley, B.C. crarental.org

Feb. 9 - 10

Atlantic Regional Trade Show Moncton, N.B crarental.org

Feb. 19 - 21

The ARA Rental Show New Orleans, La. therentalshow.com

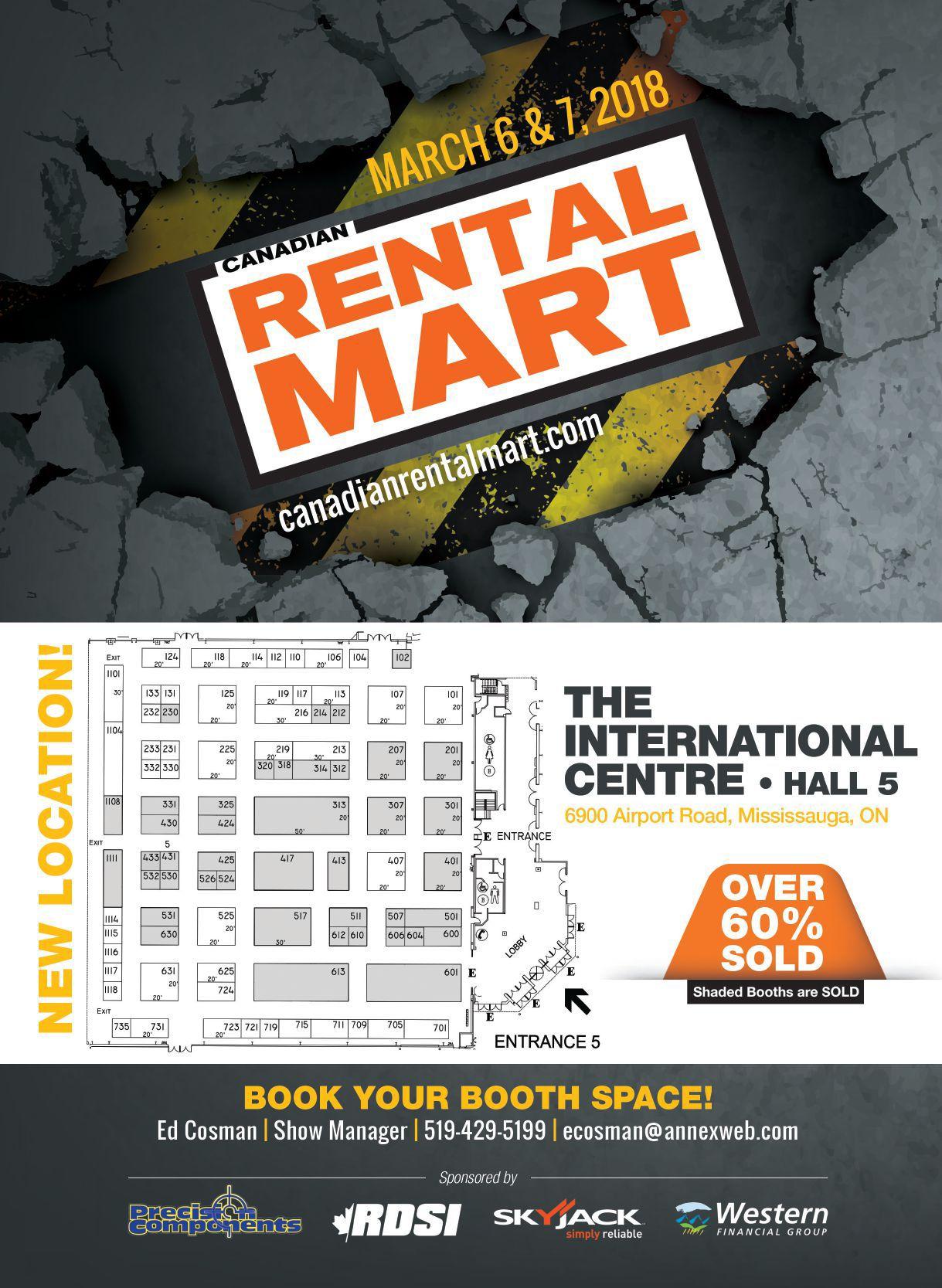

March 6 - 7

Canadian Rental Mart Mississauga, Ont. canadianrentalmart.com

March 9 - 10

Prairie Regional Trade Show Edmonton, Alta. crarental.org

March 26 - 28

Quebexpo Drummondville, Que. crarental.org

June 12 - 14

Global Petroleum Show Calgary, Alta. globalpetroleumshow.com

June 20 - 22

Canada’s Farm Progress Show Regina, Sask. myfarmshow.com

Photo credit: The Suburban

ARA PROJECTING ACCELERATING RENTAL GROWTH IN CANADA

In Canada, the latest five-year forecast from the American Rental Association continues to call for accelerating revenue growth each year, starting with a 2.7 per cent increase in 2017 to reach $5.12 billion (all figures in U.S. dollars). Total rental revenue in Canada is expected to grow another 3.2 per cent in 2018, 4.7 per cent in 2019, 5.1 per cent in 2020 and 5.6 per cent in 2021 to reach $6.14 billion. The new forecast projects U.S. equipment rental revenue to reach $49.3 billion in 2017, up 4.3 per cent over last year.

“What is interesting to note is that the U.S. equipment rental industry continues to post strong performance numbers that nearly double the growth of the economy and we expect this trend to continue for the foreseeable future,” said John McClelland, ARA’s vice-president for government affairs and chief economist.

PERSONNEL MOVES AT GENIE

Genie has announced the appointments of Dave Hubbell as vice-president of national accounts, as well as the promotions of Paul Smith, Casey Brabham, Joe Broughton and Mitch Carlson to roles as national accounts managers. These gentlemen will support all Genie products and services for the company’s national accounts customers. As vicepresident of national accounts, Hubbell will align and lead the Genie national accounts teams with the objective of increasing the company’s market share in North America. The unification of the national accounts customers under Hubbell aligns with the company’s strategy to strengthen its commercial presence through more effective pipeline management and account management efforts, as well as increasing opportunities for customer-facing interactions. Smith takes on the role of national accounts manager of the Cat team; Brabham is now the national accounts manager of Blueline Rentals; Broughton has been promoted to national account manager of HERC; and Carlson is now the national account manager of Sunstate Equipment and Pape Rents.

“In these new roles, Dave, Paul, Casey, Joe and Mitch are well-positioned to help Genie continue to meet the needs of the rental industry and aerial market,” finishes Saxelby

In other Genie news, Genie has hired four new field service representatives in North America to represent the company:

Victoria Bergsma, William Halfhill, Cory Baiz and Bart Fongers. Twenty-six Genie product support field technicians are now strategically located throughout the United States and Canada. Victoria Bergsma has joined the team to cover the Ontario territory. She is an experienced veteran of the aerial equipment business having served in roles as a shop and field technician, shop/ service manager and branch management. “Victoria’s variety of experience in the aerial and equipment industry will be a benefit to quickly assist our customers,” said Bob Bartley, senior director of product support and service solutions for Terex AWP.

WEBB JOINS NORSEMAN

Norseman has introduced Gary Webb as its new national sales manager for the U.S. Webb will be responsible for growing Norseman’s construction and ventilation product sales within the U.S. market. He comes to Norseman with over 23 years of experience in the industrial and construction products market in North America and Europe. Most recently, Webb worked as a national sales manager for an international manufacturer of industrial heaters where he led a team of over 70 sales professionals across more than 20 sales agencies and master distributors. Prior to this, he worked in the construction and industrial rental industry in key positions. He brings to the role extensive industry experience, knowledge and respect throughout the industry. Norseman supplies and manufactures industrial fabric and foam products.

ZELAZNY RETIRES FROM GENERAL PIPE CLEANERS

After 40 years of company service, Andy Zelazny, national sales manager for General Pipe Cleaners, announced his retirement at the end of September. Named national sales manager in 2001 after his predecessor, Bob Gelman, passed away, Zelazny helped fuel General’s growth by developing a strong, knowledgeable sales representative force and by forging a company-wide commitment to training efforts. He joined General as a customer service representative in 1977.

Assistant sales manager Dave Dunbar, a 20-year veteran of General, has succeeded Zelazny as national sales manager.

Gary Webb

Dave Hubbell

Victoria Bergsma

Andy Zelazny

DAHL TO LEAD SALES AT GENERAL EQUIPMENT

General Equipment Company has announced that Randy Dahl has joined the company as vice-president of sales where he will have responsibility for the development and coordination of sales and marketing for national and independent accounts. He will also oversee long-term sales strategy development as well as General Equipment’s sales representative organizations for North America.

“We are thrilled to have Randy join our team,” said Dennis Von Ruden, General Equipment president. “Randy has a rich history of contributing to the strategic direction and overall growth of every organization he has worked for in the past.”

Dahl has more than 20 years’ experience driving the profitability of industrial, global organizations with respect to strategic planning, business development, sales, operations and finance. Prior to joining General Equipment, he served as vicepresident of sales and marketing for Poly-Tex, a manufacturer of building structures, retail fixtures and shade systems for the retail industry. Prior to Poly-Tex he worked for Door Engineering as vice-president of sales and marketing for three business units. Dahl has an MBA in marketing/finance from Columbia University.

In his spare time, he enjoys hunting, fishing, gardening and cooking. His many hobbies and interests also include snowmobiling, classic cars and riding motorcycles.

SHAWMUT CELEBRATES 60 YEARS

Shawmut Equipment has been a leading equipment distributor bringing quality products to its customers since 1957. This year marks 60 years of continued success in the industry. Shawmut represents the Manitowoc Crane Group’s range of construction cranes, including Manitowoc crawler cranes, Grove rough terrain cranes, Grove GMK all-terrain cranes, Grove hydraulic crawler cranes, Grove Yard Boss industrial cranes, National boom trucks and Potain self-erecting cranes, as well as a variety of utility equipment. Shawmut is a full-service company, with three facilities offering sales, rentals, parts and service located in Manchester, Conn., South Easton, Mass., and Saint John, N.B. Shawmut was founded in 1957 by George O’Connell and is still to this day run by the O’Connell family. David O’Connell, George’s son, joined the company in the 1960s and took over in 1978 as president. David’s sons, Brian O’Connell and Kevin O’Connell, joined the business in the early 2000s, as well as David’s nephew, Joe Vergoni. Today, all three of them act as vicepresidents and sales representatives of the company.

Shawmut expanded its international presence in 2008 when it was awarded the territory of the Atlantic provinces of Canada. Shawmut Equipment of Canada, a full subsidiary of Shawmut Equipment Company, was created and opened the doors of its facility in Saint John, N.B. Shawmut Equipment now also serves customers in the Atlantic provinces of Canada, including New Brunswick, Nova Scotia, Prince Edward Island, and Newfoundland and Labradour. Demand for sales and service in Canada has been growing at a steady rate, requiring another location to better serve its customers. A new facility is in the process of being built in Elmsdale, N.S. This location will serve as the headquarters for the Maritime provinces of Canada and will increase access to a larger geographic area and more remote jobsite locations.

President of Shawmut Equipment of Canada, Joe Vergoni, comments, “This opportunity expanded Shawmut’s territory, customer base and markets served. The timing was very good for Shawmut. As the U.S. economy slowed in 2008 and 2009 we were growing our business in Canada where the economy was still strong. Our new territory is due east of our traditional territory of New England. Culturally, New England and Atlantic Canada are very similar, which made the transition very smooth.”

NEW TOOL BRAND LAUNCHED

Ficodis has announced the launch of Cromson, a range of top-quality tools with optimized ergonomics to help companies be more efficient and reduce production costs. Cromson is now available to all manufacturing and machining companies in the automotive, aerospace, construction and transportation sectors.

“As a partner of choice, and with 12 points of sales in Quebec and Ontario, we’ve become much closer to our end-users who rely on us for the solutions we bring as well as our deep understanding of the challenges faced by industrial companies in Canada,” says Christophe Bevillard, president of Ficodis. “Cromson, our new line of tools, was created in Quebec, to help companies become more productive, while reducing costs.”

Cromson includes more than 160 tools and industrial solutions, including pliers, grinding wheels and bits. Products are available with both metric and imperial measurements. Featured tools include combination pliers, vise grips, abrasive cutting wheels and toolboxes.

WESTERNONE ANNOUNCES DEPARTURE OF DAY

WesternOne has announced that Stockwell Day has resigned as a director of WesternOne Inc. in order to pursue other interests.

“On behalf of the board of directors, I would like to thank Stockwell for his leadership and contributions to WesternOne since he joined our board in September 2013 and we wish him well with his new endeavours,” stated Robert King, WesternOne’s chairman. Day is the former leader of the Canadian Alliance federal political party and served in subsequent Stephen Harper cabinets as Minister of Public Safety, Minister of International Trade and president of the Treasury Board.

Randy Dahl

THE HOMEBUILDERS

ACR helps Albertans when they build homes and after.

According to Warren Carriere, once you get rentals in your blood, it’s really tough to change industries. Despite starting out on a career path in social work, Carriere found himself bitten by the rental bug more than 14 years ago.

by LINDSEY MCCAFFREY

Alberta Construction Rentals is a relatively new venture, having started in 2015. Warren Carriere, president, likes the different daily challenges and close relationships with customers and employees. He left rentals for a while, but the industry keeps sucking him back in.

“I was a trucker and dispatcher for the party rental business with four days on, four days off,” he recalls. “Then, I left it all and went into sales…but I got drawn back into construction rentals later on, and later ran an independent rentals shop for almost nine years.”

More than a decade later, Carriere is now president of Alberta Construction Rentals (which he opened in January, 2015), as well as president of the Alberta chapter of the Canadian Rental Association. And he’s loving every minute of it.

“This industry kind of traps you, but in a good way,” he explains. “For the most part, if you do rentals right and run your business efficiently, it’s profitable and you can make a good living out of it. No two days are alike. There is no redundancy because things are

changing every day, like new equipment, new issues or new challenges. It really keeps the heart pumping.”

ESTABLISHING A NEW BUSINESS

Three years ago, Carriere decided to start up his own construction rental company. He partnered with a local residential developer who also happened to be looking to do the same thing.

“I already had a business proposal put together and here he was,” Carriere explains. “It was like ‘You’re looking for me just as I was looking for you.’ It turned out to be a really neat coincidence.”

From there, Alberta Construction Rentals (ACR) was formed. Headquartered in Calgary, the company started off supporting Carriere’s partner’s project. “It was a great customer to

start with because it was a very strong account. We were supplying heat and lights to a large residential tower being built in downtown Calgary and we’ve been growing ever since.”

The creation of ACR occurred at the beginning of the provincial economic downturn, this one coming on the heels of the 2008-09 recession.

“Starting the company at the start of the downturn was a double-edged sword,” says Carriere. “We were really, really cautious at the time. We didn’t

over-purchase inventory, and we made and still continue to make sure that what we buy is going out. We had projected some pretty good numbers but haven’t met any of our initial budgetary forecasts.”

Despite this, adds Carriere, “We’ve been able to acquire some customers from my history who are really strong and loyal, and I’ve got a great team that hasn’t had to stress as much as other people with regards to their security in their workplace.”

MEET THE NEW KING OF CAPACITY.

SERVICES AND SUCCESS

Carriere describes Alberta Construction Rentals as a temporary power company for single and multi-family residential construction, as well as small commercial clients. Customers who turn to ACR are often building single homes upwards of 2,000 square feet with attached garages; condos up to 20 storeys; or smaller commercial buildings like assisted-living facilities, strip malls and warehouse spaces.

See how the new Genie XTRA

“Basically, we bring in temporary power so construction workers can run things like fans and lights as they’re getting their work done,” he says. “We’ll even put a diesel generator in front of a site so workers can use their tools with help from it. And we can also help heat up a building in the colder winter months.”

While many rental companies provide heat and power support, one major differentiator of ACR is that it also does its own refuelling. “All rental companies have pretty much the same equipment, but this is the one thing that makes us stand out,” Carriere explains.

ACR has a wide range of equipment to support heat and power including small electric space heaters all the way up to units producing 2 million BTUs. The generator fleet starts from 3,000 watts and runs up to 235 kilowatts. Pumps and dehumidifiers are also a big part of the business.

While Carriere refers to heat and power as ACR’s “meat and potatoes,” the company also rents out equipment including Bobcats and mini Bobcats, as well as lawn and garden supplies such as rotor tillers, aerators, power rakes, augers and jackhammers.

“That’s my favourite thing to rent out: the lawn and garden stuff,” says Carriere. “You get to talk to homeowners about their projects and you get to see what they’re really excited about. That’s the fun part for me. They may not quite know what they want and our team can assist and troubleshoot with them to give them what they need. And customers are always pretty appreciative of that.”

CUSTOMER SERVICE PHILOSOPHY

When it comes to customer service, ACR abides by two unofficial mottos. First, they are committed to supporting other

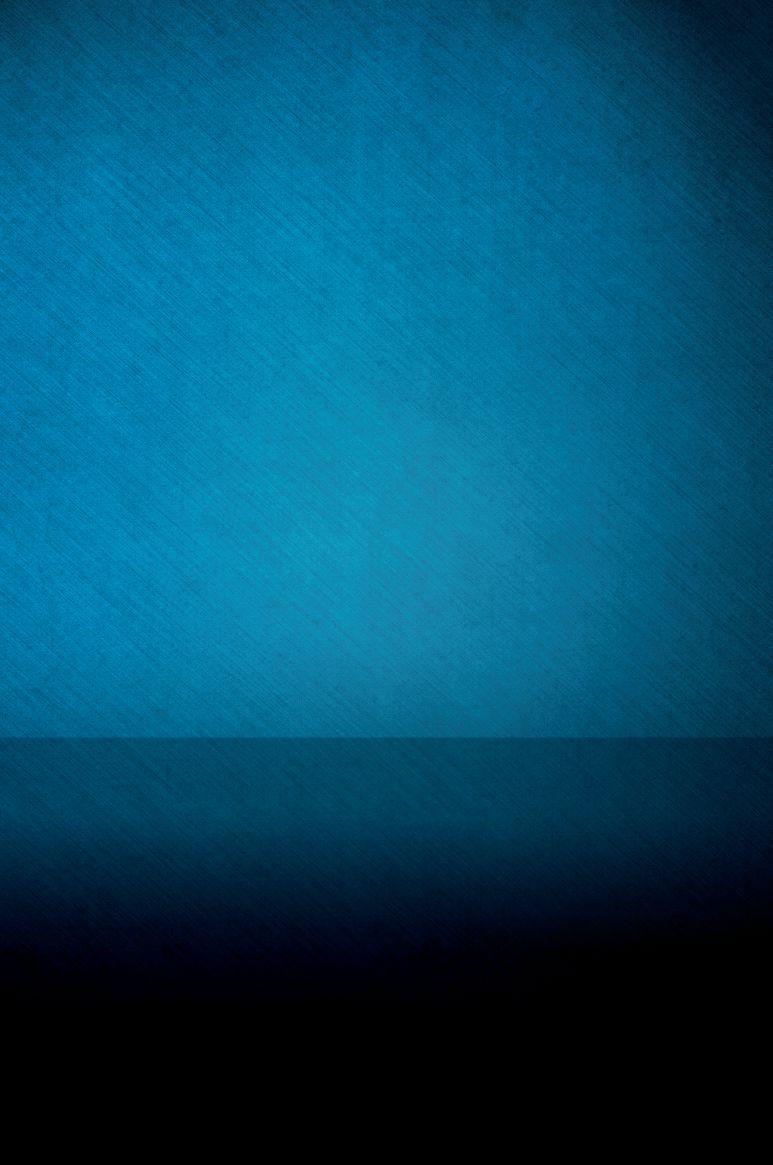

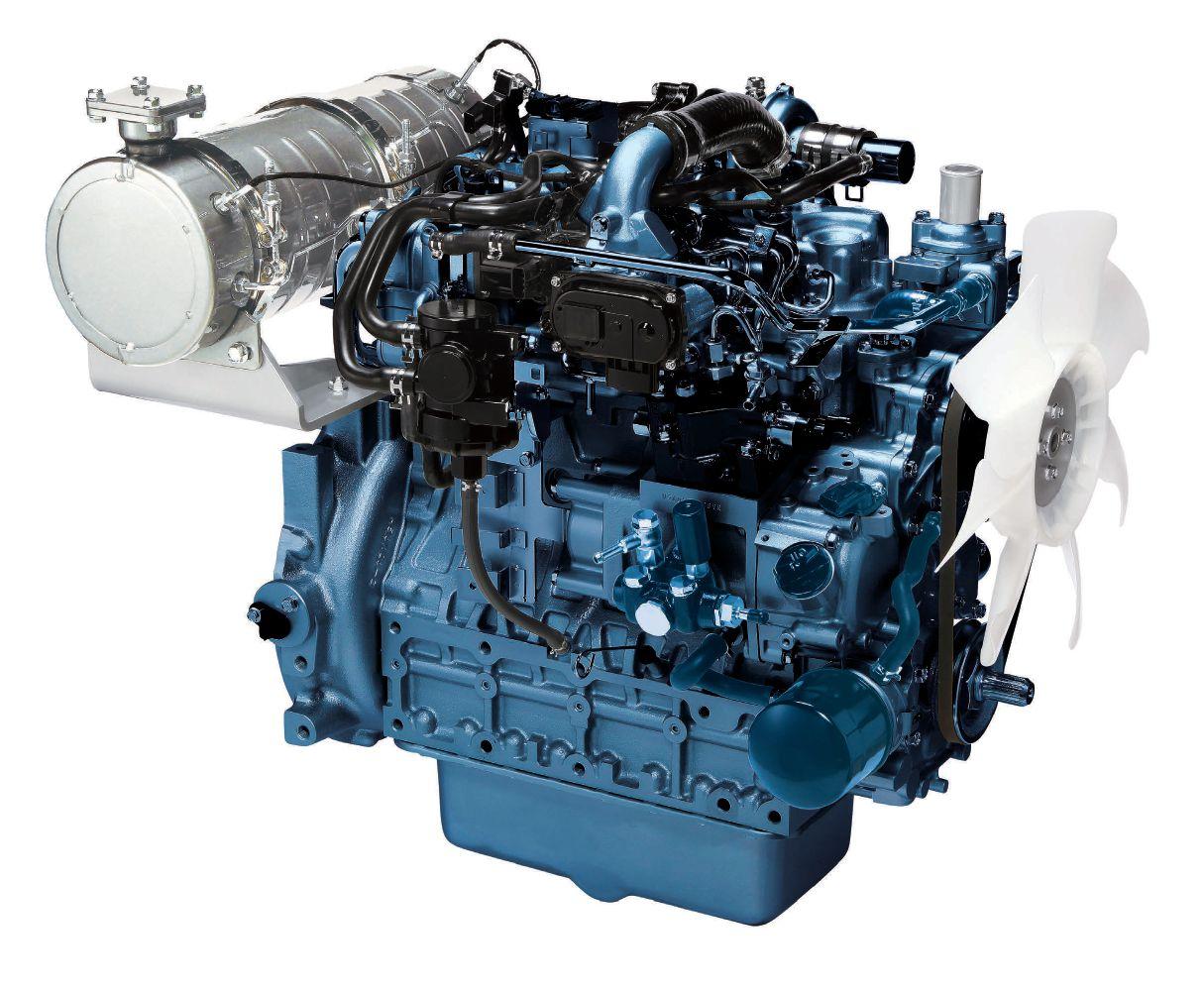

THE ENGINE OF YOUR SUCCESS

Looking for a strategy you can bank on? Select the ultimate in reliability, ease of maintenance and parts availability for all of your equipment under 115 horsepower. Run your fleet and power your business success with Kubota engines.

in this role. I’ve volunteered for other different committees and boards of directors and I really enjoy being right in the heart of things.”

OPENING IN FORT MCMURRAY

Just this summer, ACR opened up a second location in Fort McMurray. Only a bit more than one year ago, the community of “Fort Mac” was ravaged by wildfires, forcing more than 88,000 people from their homes and destroying approximately 2,400 homes and buildings. According to Wikipedia, the fire spread across more than 1.5 million acres before it was declared under control in early July, 2016.

“We chose to open up a location in Fort McMurray for a couple of reasons,” says Carriere. “Right now, the city has a very large need for rebuilding in regards to the residential areas, and that’s what

we specialize in. They’re going to have some nice growth in the upcoming years, and we want to participate in that. Plus, the properties have become a bit more affordable at the moment and so has equipment, mainly because of the economic downturn the province has

been experiencing.”

Opening up in Fort McMurray was not part of ACR’s original plan. “We weren’t going to look at expansion until we’d been in business for about five years,” says Carriere. “However, it just seemed like the right time to do it. And opening up there hasn’t really been difficult because there are many people looking for work with equipment to be had and lots of work to get done.”

At the moment, the new location has two employees on site and is geared primarily toward a customer base that includes homeowners and homebuilders.

FUTURE PLANS

As for the future, ACR is in the process of becoming core-safety certified. Carriere says he is also looking at more opportunities for expansion.

“We named this business Alberta Construction Rentals for a reason. We never expected to be restricted to just one part of the province. And we’ve got some great partnerships with some companies that allow us to have equipment throughout the province. So keep your eyes out for us because we plan to keep growing.”

CRS

Above and beyond

by Russ Dantu

Iam in the middle of writing a book on customer service (hoping to have this available before the end of 2017) and one of the chapters I am writing is called “Above and Beyond.” It’s strictly about companies that go above and beyond to make their customers extra happy when opportunities arise. This is what makes the difference between good companies and great companies, in my humble opinion. It’s why you and I as consumers become raving fans and always promote that company when we hear someone saying they need a specific product or service that it sells.

In the story below, this company didn’t have to do what it did and no one would have thought any worse about it if it hadn’t, but by going above and beyond it made a huge impact on its customers. An impact that will pay dividends for years to come.

The story is from Canwest Productions. It is the producer of many consumer shows such as the Woman’s Show, the Tattoo and Arts Festival, The Wedding Fair, and several others in multiple cities (check them out at canwestproductions. com/CWP-Our-Shows). Canwest has been a customer of mine for several years and I have known its shows for many more as I spent a lot of years in the trade show industry. I actually was emceeing their main stage at the show where this story took place and its actions were so heartwarming to see. The story below is from one of the owners, Terra Connors.

The Woman’s Show has had a long history in Calgary, in fact we have been around for 35 years. Over that time we have been fortunate to have many loyal attendees, coming back year after year, and many we greet by name with a friendly hug and quick chat. Last fall, one of our attendees, Anne, – a very spry senior – came to the show on her own to visit her favourite Young and the Restless star, Peter Bergman. Unfortunately, while walking though the show, Anne tripped and fell on the concrete floor resulting in a nasty gash on her chin. She refused to go anywhere for treatment for fear of missing Peter on our main stage.

Thinking quickly, a member of our staff ran over to our EMS booth and asked one of the paramedics

to come visit Anne at the main stage while another one of us grabbed her some water and a chair to compose herself. After some quick patchwork, the paramedic insisted Anne visit the hospital as a precautionary measure. But again Anne refused to leave, so we sat with her and chatted with her, passing the time for over an hour while waiting for Peter to arrive. Once Peter did arrive, we asked him to make a special exception and meet with Anne personally, to sit and chat with her before his appearance and to give her his autograph and take a picture. Thrilled, Anne immediately removed her bandage and asked us to help spruce her up!

Then we were finally able to convince Anne to visit the urgent care centre, and were able to secure her a ride via EMS, who also made a special trip to take her home. After the show, we made sure to print Anne’s picture with Peter and sent it with a handwritten card, wishing her a speedy recovery and telling her how much we appreciate her loyalty, as she is a part of our Woman’s Show family.

Considering there are tens of thousands of visitors to this particular show, taking this extra care of a hurt senior to make her dream come true really does show them going above and beyond. Did they have to? No, they had to make sure she was safe and taken to the hospital to be checked out. It’s this kind of forward thinking that takes a company from good to great in the eyes of their customers. Peter Bergman even made a special mention of Anne when I was interviewing him on the main stage shortly after his visit with her, which had her and the whole audience glowing from ear to ear.

What stories do you have about going above and beyond for your customers?

Are you standing out from your competitors because you do more for your customers?

Will you empower your staff to go above and beyond when there is an opportunity?

If you have a great story to share that I can use in my upcoming book or a future newsletter, please email me at russ@russdantu.com

Take care of yourselves…and your customers! CRS

Russ Dantu is a customer service consultant based in Calgary, Alta. russdantu.com

CLASS LEADING 85’ (25.91 m) PLATFORM HEIGHT

DUAL CAPACITY RATING OF 750/500LBS (227/340 kg)

SJ85AJ LAUNCH READY!

34’ (10.36 m) UP AND OVER CLEARANCE

Launching the newest addition to its growing boom lineup, the SJ85AJ Articulating Boom fills out Skyjack’s offering in the core 40’, 60’ and 80’ boom classes. Like all Skyjack booms, the new SJ85AJ is engineered with simple reliability in mind.

FOR MORE INFORMATION VISIT WWW.SKYJACK.COM

HEAT SMARTS

Training and compliance go hand-in-hand.

Many of you in the rental business are readying your construction heater equipment for winter rental duty. There is much to do and know. More than ever before, rental companies and their customers are faced with a plethora of choices of construction heater models that offer a varying range of BTU-per-hour output. Luckily, we have some great and well-established made-in-Canada innovative brands.

by GEORGE OLAH

Today’s heaters come with a number of safety features that represent a vast improvement over older designs. This unit from Flagro produces 200,000 BTUs per hour and is thermostatically controlled with a 2,600 CFM recirculating fanshown here with Hitex ducting.

Some of the new energy-saving heating equipment can not only blow heat but also circulate air simultaneously. New heat ducting material is now available and it is more durable and sweeter-smelling than the old canvas ducts. Heaters are diesel-powered, others operate on electricity, and yet more are fuelled by propane or natural gas. Certainly, each fuel type has its benefit. I must admit I am partial to the operational portability and clean-combusting economic attributes of propane-fuelled construction heaters.

Whatever heater fuel model you choose, it must be approved for use in Canada. It is your responsibility to ensure the equipment you rent meets all safety compliance requirements of both federal and provincial regulatory authorities. If you are unsure if any of the equipment is non-compliant, ask your favourite professional equipment sales people to show you the compliance certification that came with the equipment. Equipment approv-

als can always be verified by calling the equipment manufacturer to confirm their product has certification for use in Canada. And that certification is not just for heaters but for hoses, couplings, ducting, propane fuel cylinders and electrical cords.

Don’t neglect to keep the manufacturer’s instruction book and parts list supplied with your equipment. They are UL-approved and come with the equipment for a reason: safety. Keep these documents with each model you rent. Equipment instruction documentation provides important, basic, how-to-operate instructions, including the manufacturer’s contact information in case anyone has questions about safely operating its product. Make it available to everyone renting your equipment so they understand that the radiant heater they rented is designed for providing temporary space heat and is not a pizza oven for reheating lunches. If you are missing these documents for older equipment, or equipment obtained at an

auction, contact the manufacturer or visit its website and obtain the instruction manuals originally shipped with the product.

As someone who has worked on both the equipment manufacturer and rental company sides of the business, I cannot stress how important training is. First and foremost, training is a compliance requirement when using any rental equipment. And it is the responsibility of the rental company to ensure that whoever is renting its equipment knows how to use it. For example, in Ontario, training can be verified by ensuring the renter has an appropriate and acceptable Record of Training (ROT) certificate corresponding to the BTU-per-hour size of the propane-fuelled equipment they are renting. Remember to check the date on ROTs — they are valid for only three years. Those who rent equipment and are properly trained reduce the possibility of accidents, are less likely to ruin rental equipment and decrease the amount of nuisance calls, such as, “Where is the reset switch?”

Rental companies usually have certified trainers on staff providing these courses. If your company does not have such staff, you can always contact professional trainers recommended by your equipment suppliers. In the case of propane equipment, the Canadian Propane Association’s Propane Training Institute offers a national network of some 1,200 trainers who teach approved training courses satisfying the needs of the rental industry. I know – I am one of them.

Take note that many recent national code and regulatory changes have propelled updates to training requirements. Early this summer, Transport Canada issued new requirements for the transportation of dangerous goods. All hydrocarbon-based fuels are considered dangerous goods. So, if you are transporting diesel, propane or gasoline, it’s important you have the most up-to-date training. Knowing how to placard and document properly, as well as handle fuels safely, is critical to rental operations. Neither your insurance company nor safety inspectors appreciate non-compliant workers. I recently updated the PTI’s Transportation of Dangerous Goods Propane/LPG-specific course and there are new key changes to be aware of, so get trained to stay safe, compliant and avoid needless fines.

One of the disappointing things I often see on construction sites are heaters that are oversized or undersized for the job. This demonstrates that no one knew how to “size” a heater; they were just renting heaters in stock or came across a “good deal.” Proper training will help you make informed decisions on how to select the correct size and the type of heater for the jobsite and save costs.

Electric heaters are typically good for smaller jobs, when electricity is readily available, but most bigger job sites, including high-rise buildings or big box stores, have little electricity to spare. Selecting more practical solutions requiring oil-fired, natural gas or (my favourite) propane-fuelled heaters makes much more sense to rent. Heater portability gives increased site options and jobsite flexibility for the contractor.

Today, most modern indirect heaters with built-in venting and re-circulating air capability are rapidly becoming the heaters of rental choice. Venerable direct-fired heaters still offer a value per dollar spent per BTU-per-hour that is difficult to beat. Whatever type of heater you choose or recommend, ensure customers and workers alike know that you need fresh air to not only provide good heater performance but to also prevent a dangerous buildup

of carbon monoxide (CO).

CO on a worksite is usually the result of incomplete combustion or lack of adequate air for safe heater operation. CO is a colourless, odourless gas that mixes readily with the air around us. In higher concentrations, CO can be deadly to workers. The simplest way of preventing unnecessary CO while providing heat is good ventilation.

When using direct-fired, hydrocarbon-fuelled heater equipment, ensure there is a minimum of one square inch of fresh air available for every 1,000 BTUsper-hour output. For instance, a typical direct-fired 150,000 BTU-per-hour propane-fuelled construction heater would need a tarp or window opening of at least 150 square inches for fresh air ventilation. The placement of CO detectors on larger enclosed worksites for peace of mind is recommended.

Another simple way to reduce jobsite CO buildup is to properly service and tune heaters prior to rental. Well-trained heater mechanics in rental shops are a must. Completing the PTI 400-02 course can help ensure your heater mechanic’s training is up-to-date. Tuning up lawn mowers and maintaining construction heaters are two distinctly different streams of knowledge and training. Also, know how to properly apply a Canadian Rental Association R2GO tag. Remember, you are certifying that you have checked that the equipment will work properly on the job site. Your customers are depending on you for equipment that works safely.

When heating party tents remember to inform your customers to allow for proper ventilation. Don’t confuse direct-fired tent

heaters with indirect-fired tent heaters that safely exhaust products of combustion through their own vents. Both are often painted white and look very similar. If you are unsure, ask your rental supplier or read the heater’s equipment manual.

When supplying a construction heater, don’t neglect to determine whether electricity is required to power the heater. Most larger-capacity heaters need power for ignition circuits and burners. One of the major operating issues on site is consistent electricity supply. The other is the length and proper rating of extension cords. Whenever practical, recommend heaters with lower voltage requirements, as well as built-in digital voltage management so the heater doesn’t shut down unexpectedly.

Select heaters and fuel types providing the greatest worksite flexibility for the best value. The portability of propaneand oil-fuelled heaters gives you that choice. In my opinion at least, propane is a cleaner-combusting fuel and more environmentally friendly because even in the event of a propane fuel leak, the propane quickly dissipates without contaminating the ground like an oil leak. Good training will help reduce the potential for any type of fuel leak or spill.

Great rental service requires up-to-date training to be compliant. Rather than trolling equipment auction sites for old equipment bargains, invest in newer and more efficient made-in-Canada equipment to stay competitive, profitable and safe.

CRS

George A. Olah is advisor for business development and training programs with the Canadian Propane Association.

At events, appearance can be important. This quiet, gleaming white indirect-fired unit can act as a heater or air recirculator at the touch of a button.

There’s more innovation in lift technology than in any other part of the rental industry. Here’s the latest.

LIFT AND ACCESS SHOWCASE

NO BELLS OR WHISTLES

8skyjack.com

Skyjack’s SJ1256 THS telehandler is a true Skyjack product. It has no bells or whistles and is a simply reliable product focusing on features operators need for moving materials to height. Ideal for heavy-duty applications, the SJ1256 THS brings Skyjack’s load chart performance to the 12,000pound lifting capacity market and moves Skyjack one step closer to being a full-line telehandlers manufacturer.

The SJ1256 THS follows the success of Skyjack’s 6,000-, 8 and 10K telehandlers. Based heavily on the SJ1056 TH, the SJ1256 THS can lift 12,000 pounds to 35 feet, while most telehandlers in this class can only reach around 20 feet. Additionally, it can lift 1,000 pounds at its maximum forward reach of 42.6 feet without deploying outriggers, whereas most similar machines can only lift up to 500 pounds, or no load at all. The SJ1256 THS features

12,000 pounds maximum lift capacity, a 56.3-foot maximum lift height, a 6,000-pound lift capacity at maximum lift height without deploying outriggers and a 7,000-pound lift capacity at maximum lift height with outriggers deployed. Like other models, the SJ1256 THS retains all the unique features found on prior Skyjack telehandlers: the SkyCoded control system, the FlexCab easy cab conversion system, and the ReadyHook yoke-mounted rigging hook for effective handling of suspended loads. The SJ1256 THS shares the same control systems, mechanical, electrical and hydraulic layout as the rest of the TH range, ensuring instant familiarity for operators of other TH units.

PURPOSE-BUILT FOR RENTAL 8jlg.com

The JLG 1932R electric scissor lift is purpose-built for rental. The machine offers a platform height of 19 feet and platform capacity of 550 pounds as well as compact dimensions. It is 32 inches wide with a stowed height of six feet, seven inches. Designed with low total cost of ownership in mind, the 1932R offers serviceability, reliability, and durability. Serviceability is improved through the

1932R’s service access via allsteel, swing-out component trays. It offers a layout that provides technicians with plenty of room to inspect and work effectively on accessible components. Serviceable platform and ground controls provide technicians the ability to repair these components rather than replace them. The 1932R also has a battery charger with a fault code display panel and a USB port, allowing an owner to download the battery charge history. An optional multifunctional digital indicator display on the ground control panel produces fault codes, which saves time diagnosing issues and allows a technician to get right to work fixing the problem.

The 1932R features a lowmaintenance active pothole protection system with fewer moving parts. A new platform extension is designed to shed debris, keeping deployment smooth and effective throughout the life of the

machine. Meanwhile, the machine’s all-steel platform, steel component doors and thick rubber tires help provide durability. Additionally, a recessed panel protects ground controls from damage during operation. Lift and tie-down points on the frame are strategically located so the transport chains don’t damage the tires while traveling between sites, helping extend tire life.

DESIGNED TO MEET NEW REGULATIONS

8 genielift.com

Continuing to offer versatility in the self-propelled large articulated boom market, at 120 feet to 135 feet, the Genie ZX-135/70 articulating boom has been updated to offer customers the latest advancements in engineering design and technology. This new generation of the Genie ZX-135/70 includes the new Genie mini-XChassis axle design, a platform loadsensing system and a simple

LIFT AND ACCESS TECHNOLOGY

two-point calibration process to set up the primary boom, secondary boom and jib bell crank in as little as 15 minutes. Designed with transportability in mind, the new Genie miniXChassis axle design extends and retracts the axles to and from the stowed position with a more compact footprint –eight feet, two inches by 13 feet, six inches retracted or 12 feet 11 inches by 13 feet, six inches extended – to provide both stability on the job and a narrow profile for transport. Similar in design to the fullsize XChassis expanding axle on the previous generations of this machine, the miniXChassis system boasts twothirds the footprint of the fullsize version for excellent manoeuverability on and around confined jobsites without disturbing people or traffic. This boom has also been

engineered to meet the overload restriction guidelines in the proposed ANSI A92 and CSA B354 industry standards in North America, as well as the current European EN280 and Australian AS 1418.10 standards. To comply, all new Genie ZX-135/70 booms come standard with new lowmaintenance load sense cell technology that monitors the weight in the platform and disables drive, steer and certain boom functions if the load exceeds the platform load limit.

PACKED WITH FEATURES

8 snorkellifts.com

Built to handle the toughest job sites, the compact Snorkel S3219E electric scissor lift delivers a working height of 25 feet and a lift capacity of up to 550 pounds. Designed with a focus on low total

• 2-way splitter

• Honda GX engines

• Compact & towable • Safe, low maintenance

ownership costs, this lift can be driven through a standard doorway and can be used outdoors by one person. The Snorkel S3219E is packed with features that benefit both the owner and operator. A dual shear scissor stack and upsized pins provide rigidity and the all-steel construction is robust and durable for a long working life. High-quality components increase machine reliability and upsized kingpins minimize the risk of damage on-site. A fixed upper control box reduces the risk of theft or damage and includes an integrated power outlet for hand tools. Saloon-door-style entry gates are fitted as standard for easy access into the platform, even when carrying tools. Snorkel’s smooth, proportional operating system gives the operator precise control and deep-cycle batteries ensure a long working life. Sharing the same features, the smaller Snorkel S3215E offers a working height of 21 feet and a lift capacity of up to 600 pounds, while the higher capacity S3220E offers a working height of 26 feet and a lift height of up to 900 pounds. All Snorkel products come with a five-year structural warranty, plus a two-year warranty for parts and labour.

NO SLAVE CYLINDERS

8 gopettibone.com Pettibone has introduced

a 74-horsepower engine option for its Extendo 944B telehandler, giving end users and rental operators another material-handling solution to fit their needs. The 74-horsepower Cummins QSF 3.8 Tier 4 Final diesel engine features a DOC muffler and requires no diesel exhaust fluid (DEF). This simplified exhaust system is more compact and eliminates the need for the MD3 after-treatment display found on the standard 944B model. Drivetrain and axles have been optimized with the 74-horsepower engine to provide greater tractive effort with minimal tradeoff on top end speed. Delivering a maximum load capacity of 9,000 pounds, the 944B provides forward reach up to 30 feet, three inches, and a maximum lift height of 44 feet, four inches. Single-joystick, pilotoperated controls allow for smooth control of all the Extendo’s boom and auxiliary hydraulics. For operation in tight areas, the 944B offers four-wheel, two-wheel and crab steering modes. The robust design of the Extendo features two wide-stance, heavy-duty lift cylinders with innovative automatic fork and load leveling that eliminates the need for slave cylinders. To further improve load stability, the 944B offers 24 degrees of frame sway (12 degrees left and right of center) and is equipped with a rear axle stabilization system.

AUTOMATIC ADJUSTMENT

8ca.wackerneuson.com

Wacker Neuson has expanded its telehandler line with the addition of the TH627. The TH627 is a unique groundengaging telehandler that uses a versatile three-in-one machine concept. Designed with a hydraulic universal attachment plate, the TH627 can be used with groundengaging attachments and work like a wheel loader to dig and carry, a skid steer with a compact footprint capable of using multiple attachments, and a telehandler with a lift height of 18-feet, seven-inches and 5,500-pound lifting capacity. The TH627 features a load-management system that maximizes performance and minimizes tipping situations by automatically adjusting the position of the load. The bucket mode is used for loading and unloading materials with a bucket and operating in more open areas. When raising the load in bucket mode, the boom functions are controlled manually by the operator. When the boom is lowered, the LMS automatically retracts the telescopic arm to keep the load as close to the front axle as possible. In stacking/ fork mode, when raising the load, the boom raises and telescopes at the same time, keeping the load on a vertical plane. The operator does not need to self-adjust the load in a tight situation. When lowering the load in stacking/ fork mode, the LMS retracts and lowers the boom at the same time, to keep the load on a vertical plane. Wacker Neuson’s newest telehandler is powered by a Tier 4 Final,

74-horsepower Kohler engine with diesel oxidation catalyst (DOC) after-treatment with no diesel particulate filter, no regeneration and no maintenance. The TH627 features excellent service and maintenance access, reducing downtime and significantly shortening daily maintenance checks.

THINKING OF EVERYTHING

8haulotte.com

The HA26 range of articulating booms from Haulotte builds on the same design, architecture and performance levels that drove the success of the HA16 and HA20 ranges. It has been designed to meet the expectations of operators in terms of performance and ensure a cost-effective investment for rental companies. The HA26 is suitable for multiple applications, including construction, finishing, maintenance, industrial operations, demolition and landscaping. To simplify loading and unloading, Haulotte has added a high-performance lighting system located at several points around the machine. The lighting illuminates the controls and the area around the boom. To prevent crushing risks and protect operators the HA26 range is equipped with the Haulotte ActiveShield Bar 2.0 fully incorporated into the upper control protection cover to guarantee better ergonomics and strength. The bar uses a “push forward” principle that provides a safety gap to prevent crushing without

compromising productivity. The boom is designed for smooth and flexible movement with enhanced boom rigidity, regulated boom kinematics and automatic damping of the ramp motion when approaching full extension. For better visibility while driving, the jib can be raised to a vertical position even when the machine is moving at full speed. Working height is 26.4 meters with an up-and-over clearance of 9.3 meters and horizontal reach of 17.5 meters. The dual loadcapacity modes take 250 or 350 kilograms depending on the mode selected. Oscillating axles provide superior ground adhesion and the hydraulic differential wheel lock effectively distributes power with higher ground clearance and a small turning radius. Gradeability is 45 per cent.

NO OUTRIGGERS NEEDED 8jcb.com

JCB has launched the 510-42 Loadall, a telescopic handler with a 10,000-pound maximum lift capacity and a 42-foot lift height that requires no outriggers. The 510-42

is available with a JCB EcoMAX 109-horsepower engine requiring no diesel particulate filter, or a 74 horsepower engine requiring no diesel particulate filter and no diesel engine fluid. The new 510-42 Loadall is unique in its capability, capacity and efficiency, designed to move loads up to 10,000 pounds while adding efficiency and productivity gains by not having to deploy stabilizers. It features 500-hour extended service intervals and simplified maintenance procedures with all daily checks performed at ground level. Maintenance planning is enhanced by JCB’s available LiveLink telematics system, which provides machine status information to remote devices. With a one-piece, fully welded chassis and JCB’s U-profile boom that has been proven on more than 200,000 machines, the 510-42 delivers the strength and reliability necessary to complete any work site application.

LITERATURE REVIEW

Readers may request the literature item featured in this review.

Simply contact the

Simply contact the company directly using the phone number indicated to request their latest brochure(s).

the phone number indicated to request their latest brochure(s).

DANUSER MEGA MIXER

Readers may request the literature item featured in this review.

Danuser Mega Mixer can scoop, mix, and dispense a wide variety of materials from concrete to livestock feed. The built-in cutting edges and robust design make it well-suited for scooping from piles. With skid steer mounting brackets and pallet fork tine slots on both sides. Includes chute storage, klik pin holders, easy-to-read yardage markers, an 8” diameter auger coupled directly to a heavy-duty, low-speed, high-torque motor capable of dispensing 3/4 yard of 2” materials in 35 seconds.

4 models advance and retrieve cable with the push of a lever. Cable guides keep hands off rotating cable for added safety. Open cages allow quick cable inspection and cleaning. More

4 models advance and retrieve cable with the push of a lever. Cable guides keep hands off rotating cable for added safety. Open cages allow quick cable inspection and cleaning. More user-friendly for contractors and homeowners. Model RF cleans 3” – 6” dia. lines up to 100 ft. Model Z5-AF cleans 1” – 3” dia. lines up to

Simply contact the company directly using the phone number indicated to request their latest brochure(s).

Tel: 519-763-2400 • www.easternfarmmachinery.com

globe. The Allen product lineup includes: compaction equipment, mixers, power buggies, screeds, concrete vibrators, power trowels and more. Each piece of equipment is designed to maximize contractor usability and dependability, and they each come with a two

This catalog is a complete guide to the entire line of Allen products.

ALLEN ENGINEERING • Toll Free: 800.643.0095 Email: customerservice@alleneng.com Website: www.alleneng.com

NEW RENTAL CATALOG

SHOCKER POSITIVE AIR SHUTOFF SYSTEM

Petroleum industry safety standards are changing. RPM controlled positive air shutoff systems will soon be required on any diesel engine at most petroleum industry sites.

We offer a fully automatic system which is operator-proof yet can be easily tested when requested by site safety supervisor.

We have systems to fit all diesel engines and can take engine speed signal from a variety of sources. Don’t wait until your equipment is barred from a work site for non-compliance.

Tel: 1-844-304-7277 • headwindsolutions.ca

www.drainbrain.com 800-245-6300

A new catalog of drain cleaning tools designed for the rental industry is available from General Pipe Cleaners. The catalog illustrates both rental tough power drain cleaners and professional drain cleaning equipment with automatic feeds to clear clogged drains from 1-1/4” to 10” in diameter. General manufactures a full line of drain cleaning equipment, high pressure water jets, video pipe inspection and location equipment, and pipe thawing machines.

Five steps to safer behaviour

by Jeff Thorne

The goal is to change habits before they lead to incidents.

Behaviour is one of the most common denominators for every organizational performance issue. It certainly is when it comes to safety. So often we see repeatedly poor safety performance and there is no sustainable change in behaviour because the focus is on the action and not the behaviour that led to the action. To curb the non-compliant behaviour we discipline without ever realizing what led to the behaviour. This makes it difficult to achieve desired changes in safety performance.

For the implementation of a behaviour-based safety program to be successful, there are five key things that need to occur.

1. Identify the objectives and outcomes of a behaviour-based program. The main objective of a behaviour-based safety program focuses on making safe behaviour a habit. Many incidents arise from the repeated at-risk behaviour of the worker. The worker has worked unsafely for years and avoided injury, so assumes there is no need to change their behaviour. A major objective of your program is to replace unsafe behaviours with automatic safe work habits. To do this, all parties must be able to understand and apply basic principles of behaviour change effectively so everyone is working towards the same goal.

2. Application of positive reinforcement. We’ve all done it, we’ve all taken risks. Often we take risks because there is a positive result. Risk-taking may result in saved time, effort, and resources. The unsafe behaviour that we exhibit occurs and is maintained because of the perceived positive results that follow. Therefore, management needs to focus on positively reinforcing safe work habits to replace unsafe habits. A little training in how to effectively apply positive reinforcement goes a long way.

3. Applying the program to everyone in the company, not just the front-line workers. All too often these programs are targeted at yard staff, mechanics and drivers only and they may grow to feel like they are the ones putting in

all the effort to make the process work. For change to be sustained, the program must apply to management and office staff. Workers’ safe behaviour must be reinforced, as should the managers and supervisors for supporting and reinforcing the workers’ safe behaviour.

4. Training – just do it. Provide the same type of training to everyone. All parties – managers, supervisors and workers – should be trained in core behaviour principles and the objectives and outcomes of the behaviour-based safety program. Desired behaviours and roles and responsibilities should all be clearly defined so that everyone can accept their role within the program. The training must focus on safe behaviour, not the process.

5. Create a program that fits the needs of the organization. Many organizations take the same approach where their behaviour-based safety program focuses on a specific action sequence: meetings about what to observe, detailed observation, data collection and review, and more meetings, with very little focus on changing the behaviour. A well-planned and designed program does not require significant amounts of time offline to complete training, complete paperwork, perform observations and attend meetings. The program should not affect key performance indicators such as service and production.

If you’re implementing a behaviour–based safety program, it should be custom-tailored to fit your needs. Keep observations short, no longer than five minutes. Focus on two or three behaviours, not an extensive list, and be prepared to implement changes quickly.

Behaviour-based safety is more than observation. It’s about understanding how and why people do the things they do. When we have an understanding of how to change behaviours and properly reinforce desired safety behaviours, safety performance will improve. CRS

Jeff Thorne is training manager for Occupational Safety Group.

JCB telehandlers are your no-hassle solution

JCB is the first to offer telescopic handlers with 10,000 lb lift capacity that meet Tier 4 Final standards with no DEF, no DPF and no engine aftertreatment. JCB is also the only manufacturer to build its entire telehandler drivetrain; from the JCB EcoMax engine with clean-burn technology, to the transmission and hydraulics, all systems work in harmony for unrivaled performance, efficiency and productivity.

Learn more about the world’s most popular telehandlers at www.jcb.com