inspiration for our company name: turning thermoforming into an ar t that demands real craftsmanship ”

Aside from IPL, Plastique A r t’s other main customer in the early days was Prevost Car – now known simply as Prevost – a manufacturer of touring coaches and bus shells for high-end motorhomes and specialty conversions, and which is also located in Sainte-Claire “They asked us to make interior plastic par ts for their buses, and this eventually led us to leave the sign and toothbr ush businesses to focus exclusively on thermoforming,” Baillargeon said

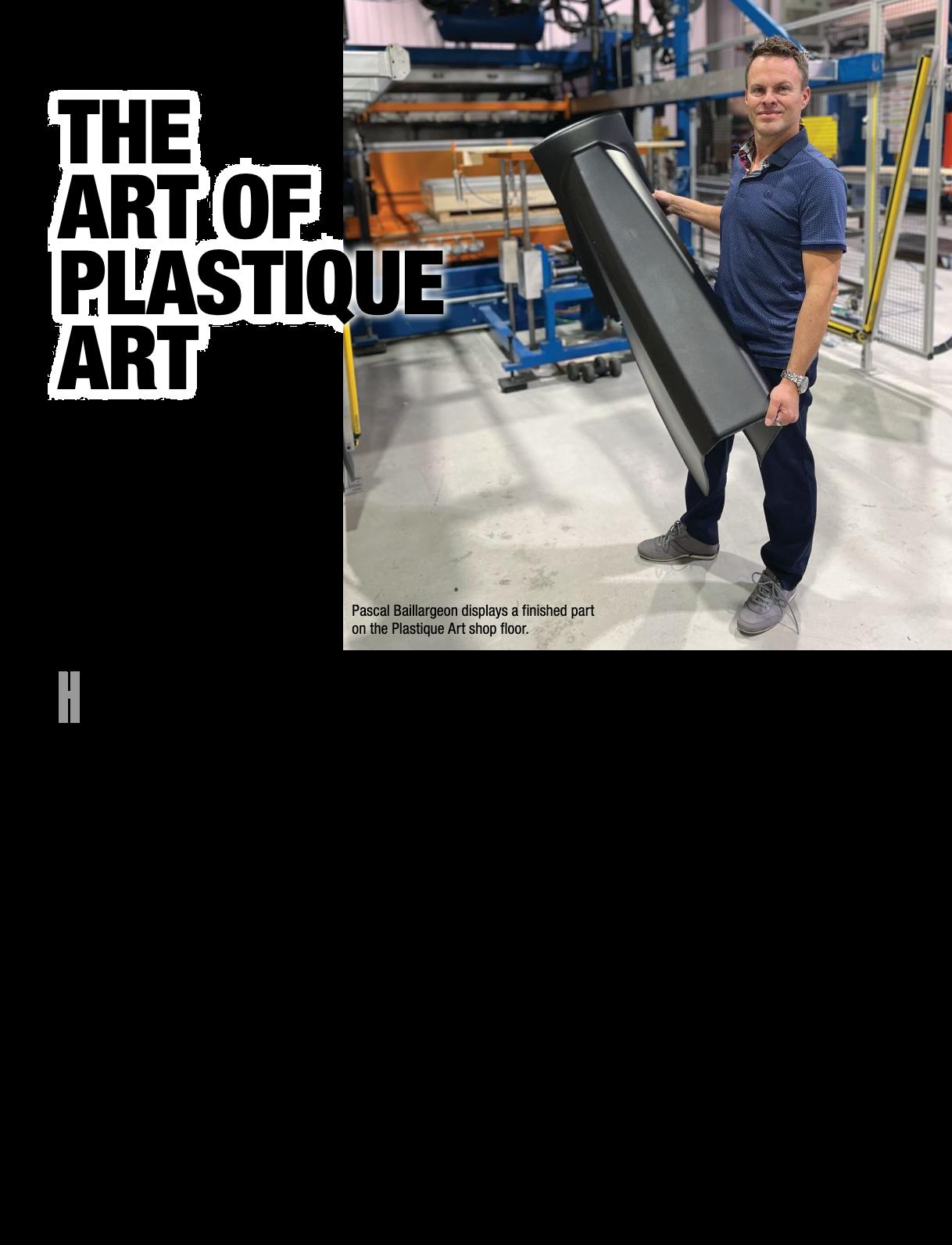

Baillargeon himself joined the company in 1998, and the succession to the third generation was underway “When I was in high school, I worked on the shop f loor during summers, but throughout university I wasn’t sure that I wanted to make it my career,” he said. “But I’ve always been interested in business, and my degree is in business administration, so I joined to become involved on the business side, enjoyed it, and stayed.” In 1999, Baillargeon began buying shares in the company. “By 2010, I was the sole owner, and that was when my father retired,” he said “I’ve been the president and CEO since 2006 ”

Thermoforming is a process that involves heating a plastic sheet and forming it to specific shapes using a vacuum and a mold The shaped plastic then gets cooled down and CNCtrimmed to result in the finished par t. The process can produce a wide range of products, from intricate medical devices to large automotive par ts to tr uly huge plastic projects – unlike most other plastic molding processes, which are limited to smaller items. At the same time, it’s relatively cost-effective due to the minimal waste produced and the low labour and tooling costs i nvolved. “T he g reatest econom ies i n t her mofor m i ng a re achieved at low to moderate volumes, usually 100 to 10,000 units per year depending on the par t size,” Baillargeon said “And the lower par t costs allow thermoforming to compete directly with fibreglass, wood, and metal fabrication while achieving higher production rates ” And nearly all types of resin are suitable for thermoforming, he added, including post-consumer plastics

:S XNTP RDPUHBD

Plastique A r t offers a range of services, beginning with par t design. “We have a team of exper ts that can recommend the best materials, processes, and tools,” Baillargeon said. “From there, our factor y offers vacuum, pressure, and twin-sheet thermoforming capabilities We cur rently have 5 thermoforming machines that can mold par ts up to 80 by 120 inches; and 6 CNC digital machining centres for cutting and trimming Finally, we offer value-added services like gluing, welding, product assembly, paint, and other finishing and decoration processes.”

Plastique A r t’s ther mofor m ing machines come pr ima r ily from one vendor “We selected one brand ten years ago that offered customized machines that we were able to modify for our own needs,” Baillargeon said And while the basic thermoforming process remains the same, he continued, the technology has definitely improved over the years, as the field has seen an infusion of advanced software that brings a new level of precision. “The machines themselves also have more sensors for better

heating and cooling control – giving us more uniform stretching of the sheet – which allows for more complex shapes and more consistent par ts,” he said “Generally, the European machines are more energy-efficient and have more advanced features than the Nor th American brands, but the Nor th American OEMs are star ting to catch up ”

Moreover, automation has been a game changer, including at Plastique A r t. Industr y-wide, some exper ts say, top speeds of thermoformers are being restricted by the ability to handle par ts at those speeds Which is where making the process faster and more consistent by employing robotic arms and automated workf low systems comes in “Twenty-five years ago, all our par ts were trimmed by hand,” Baillargeon said “We were one of the first thermoformers to embrace using CNC – which crossed over from the woodworking industr y – for par t trimming, and now almost 100 per cent of what we trim is CNC-trimmed with automation. Customers are always concerned about the accuracy of the trimming and the placement of any par t holes, and our CNC technology provides this It’s a big boost to our productivity and par t consistency, and it also frees our workers from these repetitive manual tasks, which can be unsafe if not done properly.”

In theor y, automating par t handling creates a gap in the inspection process traditionally done by operators In practice, this is augmented at Plastique A r t by using 3D laser scanners to validate the dimensions of the par t

S gd bnloYmx r okYms hm R Yhmsd BkYhqd* vhsg sgd 3* 1 / / rptYqd enns dwoYmrhnm Ys sno qhfgs-

FDS SHMF RL: PS

Another advancement at Plastique A r t is the integration of smar t technologies. “Beginning 10 years ago, we star ted connecting all of our machines so that we can monitor them in real time,” Baillargeon said “We’ve been on the smar t factor y journey for a while, and it’s not finished yet. Before thermoforming machines came with these connected technologies, we added them ourselves in-house ”

A big force driving the automation and smar t technologies trends – not just at Plastique A r t, not just in thermoforming, but across the entire plastics manufacturing sector – is the lack of skilled labour that’s impacting the ability to meet production output and deliver customer orders. And Plastique A r t isn’t immune “Finding skilled labour is tough, and we have training programs to school our new workers in-house,” Baillargeon said. “At a minimum, our new operators need to be good with a bandsaw, and beyond that we’ll train them to become skilled CNC operators With the automation we’ve added, we’ve made the operator’s job easier – nowadays, the engineering knowledge on the operator’s par t comes more from knowing how to use the controls and to set the recipes ”

Other facts on the ground, however, are different for thermoforming companies than for processors of other types of plastic

molding. “Thermoformers make small-scale production r uns of big par ts, which makes the par ts prohibitively expensive to ship over long distances, so there’s not much overseas, or even international, competition,” Baillargeon said. “At Plastique A r t, we’re not competing against China, Europe or the U.S.; our competition is local, mainly in Eastern Canada ” But at least that pool of competitors is stable “There are few, if any, star tups, and because of mergers and acquisitions – especially in the U.S. – there are probably fewer thermoforming shops today, by company name, than 20 years ago,” Baillargeon said

SGD PN: C : GD: C

According to Baillargeon, Plastique A r t’s 3-phase, $3-million investment is par t of the firm’s standardization and modernization strategy. “We want to maintain a machine park that incor porates the latest molding and cutting technologies,” he said “Standardization of the machine park will make it easier to train new employees and optimize working methods.”

The purchase of new equipment, meanwhile, will enable the company to smooth production, reduce deliver y times, and double its production capacity for large par ts up to two metres by three metres And the plant expansion represents an oppor tunity to optimize production f low, improve efficiency, and save storage space. “We’ll receive the new machines in late 2024,” Baillargeon said

Plastique A r t has doubled its revenues since 2021, Baillargeon said, and is now reaching the highest production levels in its histor y, with growing demand for large par ts in par ticular. But the firm still isn’t satisfied “We’re going after new markets and, backed up by our new investment, we think we have a real chance to grow our business – for example, by replacing metal or fibreglass in products like electric vehicle par ts,” he said “In some ways, thermoforming and fibreglass are similar processes, but typical thermoformed par ts may be as much as 30 per cent cheaper, on average, than similar fibreglass par ts, while also being lighter and more recyclable We’re also thinking about expor ting more into the U.S. We’re a third-generation company, but in some ways it feels like we’re just star ting ” B O I

In 2021, during the height of the COVID-19 pandemic, Plastique A r t worked with supply chain par tners to produce a notable ther mofor med application that wound up winning the “Vacuum For ming –Gold” award from the Ther mofor ming Division of the Society of Plastics Engineers

Developed for a customer with an urgent order to supply 10,0 0 0 mechanical ventilators for hospitals across the countr y, Plastique A r t created an enclosure assembly of 8 ther mofor med par ts to house the ventilator. Custom colour sheets made from medica l-g rade ac r yl ic/p oly vi nyl ch lor ide wit h t wo colours were used, and assembly of the enclosure

was designed to minimize the attachment points By ma king the tools in-house and with a staff fully dedicated to the project, Plastique A r t was able to meet the lead time of 10 days for 11 devices ready for cer tification by Health Canada.

After final approval of the device – and just 142 days since the star t of the project – mass production was under way, and Plastique A r t made the 10,0 0 0 devices in under 16 weeks, using multi-cavity, temperature controlled aluminum molds for all par ts (For perspective, the average time for a medical device to go from conception to production, under nor mal conditions, is at least 18 months )

process by using feedback a nd feedforwa rd mecha n isms, such as neu ra l networks, f uzzy logic, a nd rein forcement lea r n ing,” sa id Kaveh Ka kaei Nezhad, a n A I sof t wa re develop er wit h Rega l Pet rochem ica l “A I ca n a lso help optim ize the design a nd con f igu ration of the ext r uder, such as the screw geomet r y, ba r rel length, a nd die shape, to ach ieve the desi red product cha racter istics ” A nd by st rea m lin ing a nd ma inta in ing tight cont rol over the enti re production process, A I cont r ibutes to shor tened timeto -ma rket for new products, wh ich is pa r ticula rly cr ucia l in indust r ies where rapid in novation a nd quick responses to ma rket dema nds a re pa ra mount.

Second, A I-powered qua lit y cont rol systems offer a proactive approach to identif ying defects in rea l time by spott i ng t h e mom ent a p r o c e ss st r ays, expla i n i ng why, a nd of fer i ng si mple step -by-step inst r uctions for put ting it back. “A I ca n help adjust the process pa ra meters in rea l time according to the cha nges in the mater ia l proper ties, product sp e ci f icat ions, a nd envi ron ment a l c ond it ion s,” Nez ha d c ont i nue d. T h is mea ns t hat problems ca n be recti f ied b efore t hey esca lat e, m i n i m i z i ng t he ne e d for cost ly rework a nd ensu r i ng h igher qua lity out puts, wh ile a lso m in im izing mater ia l wastage A nd these savings a ren’t just theoretica l. “One of ou r customers has reduced its scrap by 23 per cent, down to less tha n 1 per cent, by using A I- d r iven insights,” sa id Da n Ba rlow, sen ior product ma nager, cont rols with M ilacron A nd K raussMa ffei’s new processSuppor t tech nology, pa r t of its socia l P roduction plat for m, uses A I to help identi f y deviations i n production p ro c esses a nd c om mu n icat e t hem to operators. K raussMa ffei off icia ls say the compa ny has developed its own complex a lgor it h m for ea rly detection of t hese deviat ions, wit h t he goa l of re duci ng scrap A nd reducing scrap a lso mea ns r e duc i ng u n ne c essa r y ene rg y usage, wh ich cont r ibutes to susta inabilit y goa ls a nd results in substa ntia l cost savings over the long ter m

T h i rd, a nd related, A I’s dat a collection capabilities – including dat a a na lysis f rom sensors embedded in mach in-

Ax kdudpIfhmf .B Im dwsptrhnm opnbdrrnp bIm ehmd,stmd opnctbshnm oIpIldsdpr khid sdlodpIstpd opdrrtpd roddc Imc eddc pIsd hm pdIk shld sn noshlhyd pdrntpbd IkknbIshnm Imc dmgImbd nudpIkk opnctbshuhs x-

er y, combi ne d wit h h istor ica l re cords – ca n be used for predictive ma intena nce by sp ot t i ng a nom a l ies t hat i nd icat e potentia l equipment fa ilu res before they happen, a llowing the ext r uder to schedu le m a i nt ena nc e p roa ct ively “ T hes e forecasting capabilities ca n keep ext r usion lines up a nd r un n ing, preventing exp ensive u npla n ne d downt i me,” Ba rlow sa id “For exa mple, there’s a n A I comp onent to M i lac ron’s M-Powere d, ou r I ndust r ia l I nter net of T h ings digita l plat for m for pre d ict ive a na ly t ics, t hat p r ov id e s p e r fo r m a n c e i m p r ove m e nt insights ” Even bet ter, the ext r uder ca n usua lly t roubleshoot with a n A I solution f rom a nywhere in the world.

As to how much of an extr uder’s operation the processor wants to hand off to AI, well, that’s up to each shop. “A lot depends on your organization’s comfor t level, but in general, AI is extremely valuable when decisions involve more data or variables than humans can manage,” Barlow continued “For example, it can be configured to war n an operator when an unsafe condition is detected or perfor m an emergency shutdown on its own Each organization sets its own parameters ”

Vi r t u a l ly a l l new ext r ud er s c ome with A I capabilities, a nd older mach ines ca n of ten be ret rof it ted with m in ima l in f rast r uct u res, a lthough it depends on severa l pa ra meters. “A I requi res a lot more computing power because it’s ha ndl i ng exponentia l ly la rger a mounts of data,” Ba rlow sa id. “T he mach ine’s processor speed, CPU, memor y, a nd other related factors will t ypica lly deter m ine its suitability for a n A I upg rade.”

: I I : ANT S C:S:

At the hea r t of A I lies dat a, wh ich is the f uel that powers a lgor ith ms, t ra ins models, a nd d r ives insights “Good data is

the foundation that a ll A I systems a re built on,” sa id Derek Moeller, the founder a nd president of Cogn itionWorks, a compa ny that designs nat u ra l la nguage A I systems for ma nufact u rers. “H igh- qua lit y, releva nt, a nd wel l- orga n i z e d d at a enables A I a lgor ith ms to lea r n pat ter ns, ma ke predictions, a nd generate va luable i nsights wit h accu racy a nd precision ” Without good data, A I systems ca n produce un reliable results, leading to f lawed de cisions a nd sub opt i ma l out comes –a nd if there’s a lim itation at present as to how much improvement A I ca n ma ke to a n ext r usion ap pl icat ion, it r evolves a round data ava ilability a nd qua lity “A I requi res a la rge a mount of data to lea r n a nd i mprove it s p er for ma nc e, but t he data may not be ava ilable or reliable due to the lack of sensors, com mun ication, a nd stor age syst em s i n t he ext r uder,” Kaveh Ka kaei Nezhad sa id “T he data may a lso be noisy, incomplete, or inconsistent due to the va r iability a nd uncerta inty of the ext r usion process ” T hese a reas a re works in prog ress, a nd it’s the reason why a n ext r uder ca n’t simply plug a ny indust r ia l A I model into its applications “T he A I solution has to be t ra ined by a tea m of h igh ly qua l i f ie d hu ma n exper ts who k now the process inside a nd out,” sa id Da n Ba rlow

A key to get ting th is good dat a – a nd a lso to understa nding how A I ca n benef it ext r usion in genera l – involves ta k ing a deeper dive into two specia lized classes of A I, both of wh ich represent the newest a nd most h igh ly dyna m ic doma ins with in t he A I f ield: la rge la ng u age mo d els ( LLMs) a nd generative A I. T he key difference between LLMs a nd generative A I lies in thei r scope LLMs constit ute a specif ic categor y of A I models with a specia lized focus on text-based data, by having been fed enough exa mples to be able to recogn ize a nd inter pret huma n la ng uage. Ma ny LLMs a re t ra i ned on data that’s been gathered f rom the I nternet huge sets of data consisting of t hou sa nd s or m i l l ion s of g iga by t es’ wor t h of t ext, henc e t he na m eword “la rge” – a nd they excel at predicting what comes next in a given sequence of word s or gener at i ng t ext ba se d on a p r om p t G e n e r a t ive A I, m e a nwh i le,

1. Narrow or Weak AI:

Nar row AI is designed to perfor m a specific task or a set of closely related tasks. It excels in its predefined domain but lacks the ability to generalize its intelligence beyond that scope Examples include vir tual personal assistants like Siri or Alexa, which are adept at understanding and responding to specific voice com mands.

2. General or Strong AI:

General AI represents a level of intelligence where machines possess the ability to understand, lear n, and apply knowledge across a wide range of tasks, a kin to human intelligence Achieving general AI remains a significant challenge, and cur rent AI systems are mostly categorized under nar row AI.

3. Machine Learning:

Machine lear ning is a subset of AI that focuses on enabling machines to lear n from data without explicit program ming. Machine lear ning algorithms use patter ns and statistical techniques to improve their perfor mance over time This is the technology behind recom mendation systems and natural language processing

4. Deep Learning:

Deep lear ning is a specialized for m of machine lear ning that involves neural networks with multiple layers (deep neural networks). Mimicking the str ucture of the human brain, deep lear ning excels in tasks like image and speech recognition. It has fueled advancements in facial recognition technology, autonomous vehicles, and more

5. Reinforcement Learning:

Reinforcement lear ning involves training machines to ma ke sequences of decisions by rewarding desired behaviours and penalizing undesirable ones This type of AI is often used in gaming, robotics, and optimization problems, allowing machines to lear n th rough trial and er ror

6. Natural Language Processing (NLP):

N LP enables machines to understand, inter pret, and generate human language Applications include language translation, sentiment analysis, and chatbots N LP is integral to ma king AI systems more accessible and interactive for users.

Source: RJG Inc S X ODR NE : H9 : ADFHMMDP&R FTHCD

i ntel lect ua l prop er t y t hef t, comprom isi ng t he comp et it ive edge of ma nu fact u ri ng busi nesses W h ich is why it’s i mport a nt to choose t he r ight A I model, wit h d at a secu r it y i n place, before goi ng down t he A I road To begi n, avoid usi ng ChatGP T – t he A I model t hat’s most fa m i l ia r to most p eople – i n a ma nu fact u r i ng sett i ng A nd not just be cause cybercr i m ina ls const a ntly se ek to exploit v ul nerab i l it ie s i n C h a t G P T a n d o t h e r A I chatbots i n order to ga i n u naut hor ized access to sensit ive i n for mat ion, but a lso because a ny t h i ng put i nto t he ChatGP T plat for m r u ns t he r isk of be com i ng publ ic a nd could be used to t ra i n its A I –wh ich is why ele ct ron ics gia nt Sa msu ng, for one, cla mp ed down on use of t he chatbot ea rl ier t h is yea r “ T he r isk is t hat, u n less t here’s a n A I a lter nat ive, a you ng work force wi l l use ChatGP T as a default because t hat’s what t hey’re used to,” D erek Mo el ler sa id “A bet ter opt ion, because it removes t h is tempt at ion, is for a n ext r usion compa ny to for mulate its own generat ive A I st rateg y a nd br i ng i n a tool where its i n for mat ion is se cu re a nd seg mente d, wit h no possibi l it y of i n for m a t ion b ei ng sh a r e d, or le a ke d, exter na l ly.” A nd t he good news is t hat d a t a s e cu r it y a nd p r iva cy a r e m o r e secu re now t ha n even a few shor t yea rs a go “ C u r r e n t d a t a p r o t e c t io n h a s become fa r more robust,” sa id Da n Ba rlow

T here’s a lso some concer n about a lack of t ra nspa rency, since some A I a lgor ith ms – pa r ticula rly deep lea r n ing models – a re opaque in thei r decision-ma k ing processes. T h is lack of t ra nspa rency ca n ma ke it diff icult to understa nd how A I systems a r r ive at thei r conclusions, some exper ts say, potentia lly leading to dist r ust a mong workers a nd sta keholders.

S GD MD V MNP L : I

T he A I mo dels for ma nu fact u r i ng a re developi ng fa st, a nd it’s ha rd to pre d ict where t he t e ch nolog y wi l l go But you ca n b et t hat so - ca l le d A I agent s wi l l have a role Autonomous i nt el l igent syst em s desig ne d to p er for m sp e ci f ic t a sk s wit hout hu ma n i nt er vent ion, A I agent s a re p owere d by mach i ne lea r n i ng a nd rea l-t i me d at a a na ly t ics to f u nct ion a s

vi r t ua l a ssist a nt s a nd – i n a ma nu fact u ri ng set t i ng – cou ld b e even more ef fe ct ive t ha n cu r rent A I t e ch nolog ies at such t a sk s a s opt i m i z i ng pro duct ion sche du l e s, e n h a n c i n g q u a l it y c o n t r ol by d e t e c t i ng d efe c t s e a rly, st r e a m l i n i ng pro c esses to re duc e op er at iona l cost s, a nd ident i f yi ng e qu ipment brea kdow ns b efo r e t h ey o c cu r “O n e of t h e c o r e st reng t hs of A I agent s is t hei r ad apt ive nat u re a nd cont i nuous i mprovement –by lever ag i ng L L Ms, A I agent s ref i ne t hei r capabi l it ies t h roug h ongoi ng i nt era c t i o n s, g r a d u a l ly b e c o m i n g m o r e s o p h i s t i c a t e d a n d ef fe c t ive,” D e r e k Mo el ler sa id “A I agent s wi l l b e much more comprehensive a nd complet e t ha n t h e A I m o d el s ava i l a ble t o d ay, a n d t hey’l l b e come pro duct i z e d i n 2 025 ”

But for ext r uders, t he t a keaway f rom LLMs, generat ive A I, A I agents – a nd ot her developments t hat no one ca n se e com i ng – is t hat t he A I gen ie is t r uly out of t he bot tle, a nd you ig nore it at you r compa ny’s p er i l “A I is a t ra nsfor mat ive, fou nd at iona l new te ch nolog y – just l i ke t he I nter net was 30 yea rs ago – a nd a lot of p eople a re st i l l g rappl i ng wit h it, a nd w it h t h e id e a t h a t we’ve c r e a t e d a mach i ne t hat ca n out p er for m hu ma ns on some cog n it ive levels, wh ich has never b e en ava i la ble b efor e,” Mo el le r sa id “But it’s not somet h i ng you buy just to che ck t he ‘A I’ box a nd t hen forget about; it’s a new way of r u n n i ng a busi ness, where you have hu ma n-level cog n it ion ava i lable at a ny t i me. Even t hough t he i ndust r y hasn’t had much t i me yet to f igu re out how to use it f ul ly, t he ext r usion compa n ies t hat a re A I-for wa rd have a good cha nce of pul l i ng a head, a nd t hose t hat wa it 10 yea rs for t he dust to set tle wi l l get lef t beh i nd ”

A I isn’t just com ing, it’s a l ready here, a nd it’s on ly going to become a bigger forc e i n ext r usion goi ng for wa rd O n offer is the ability of mach ines to automate t asks with no huma n inter vention wh en m a nu fa c t u r i ng la b ou r c a n b e exceedingly ha rd to f ind, t ra in, a nd keep; when mach ine uptime a nd optim ization is more c r ucia l t ha n ever; a nd where pro duct qua l it y a nd consist ency is a n absolute must. It a lso gives businesses the agilit y to quick ly revise production pla ns

or i m m e d iat ely a djust m at er ia l f low based on schedule or product cha nges

A nd t h is is on ly t h e b eg i n n i ng

W hereas the cu r rent tech nology sees A I being utilized on discrete pieces of ext r usion equipment, it’s not too fa r-fetched to envision A I- endowed ext r uders as pa r t of a n intercon nected pla nt that sequences a nd cont rols multiple mach ines

A ny ta kers?

B O I

Mdawaihmf lRaghmdr sdagmninfhdr Rmc chfhsRi rnitshnmr epnl AMAE. fhud oiRrsha R mdv ihed, :wbid Tesdq bwbid. Tmnsgdq ihed- Fgdw sqTmrenql yvTrsdfi hmsn T uTitTaid qdrntqbd- Cmdqfw rTuhmf de“bhdms Tmc rlTqs- Eqnl vTrsd sn uTitd- Eqnl sqTrg sn sqdTrtqd- Enq qdbwbidc odiidsr ne rsTaid Tmc qdihTaid ptTihsw- Enq T bhqbtiTq dbnmnlw sgTs hr rtrsThmTaid Tmc. oqn“sTaid enq wnt-

O C RLTO C I ER S

I q Zt r r,LZe e dh B nq o- ’ E knqdmbd+ Ix-(: v v v-j qYtrrlYe edh-bnl: 7 4 8 17 2 / 1 / /

LhkZbq nm K KB ’ A Ys YuhY+ Nghn(: v v v-lhkYbqnm-bnl: 402 4 2 5 1 /62

PdfZk Od s q nbgdlhbZk B n- ’ L YgrgYgq+ I gtydrs Ym+ HqYm(: v v v-qdfYkodsqn-bnl: )8 7 ’20( 2 5 2 / 4 7 40