: ADS SDP V:RGHMF L :BGHMD BNM SPNK O: MDK

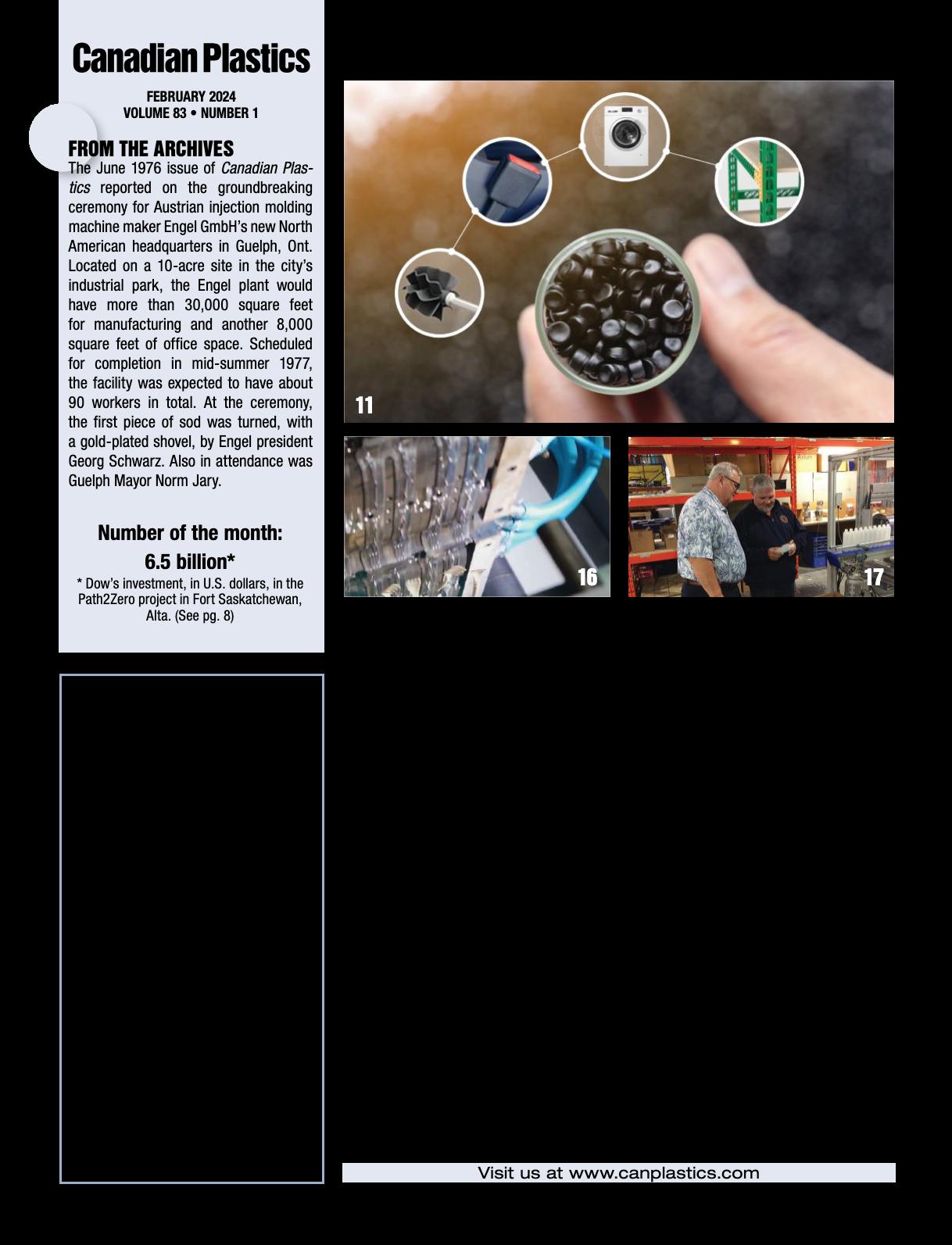

BSH Home Appliances is using light-blocking ABS from Elix Polymers for the control panels of its latest washing machines – and a washing machine’s control panel, if you don’t know, is perhaps the most important part of its design and functionality.

T h e A B S m a t e r i a l ensures precise illumination and controlled light with no leakage into neighb o u r i n g c h a m b e r s , E l i x officials said, and BSH was also able to achieve both cost and weight reductions compared to the previously used resin, in particular through very low wall thicknesses of just 0 5 millimeters

Elix’s light-blocking materials can be based on ABS, high-heat ABS, and ABS/PC, and are also used in appliances such as dishwashers and coffee machines, to improve the illumination quality And applications in the automotive sector include light guides, LED reflectors, and button back panels

SNHKDS ANVK APTRG VHSG AK : CDR+ MNS APHRSKDR

If you never thought you’d find a toilet bowl br ush to be interesting, join the club But the new Loowy br ushes from Ger many-based bath room product ma ker Sauba have blades instead of bristles for improved hygiene, and are made from the Dr yf lex Circular range of recycled ther moplastic elastomers (TPEs) from Hexpol AB

Sauba required a TPE that was strong, but with a low hardness to give the required f lexibility and cleaning performance; also, the material had to be easy to process and recyclable in closed-loop systems, with the possibility to rework a ny p ro c ess scrap “We’re working hard to tur n waste into a resource,” said Kathrin Heilmann, a sales manager with Hexpol “We ta ke recycled polymers – in this application, using post-industrial recylate – and incor porate them into the Dr yf lex Circular TPEs, which aligns with Sauba’s goals of producing more resource-efficiently and reducing waste ”

Available in different sizes and colours, the Loowy blades are designed to ma ke the toilet br ush easier to keep clean, and are also easy to replace

RTRS:HM : AKD RD :S ADKS BNU DPR

Vehicle maker Audi has launched cutting-edge plastic covers for seatbelt buckles in its Q8 e-tron models that are partially manufactured from mixed automobile plastic waste using the pyrolysis chemical recycling process

Audi officials say it’s the first time the company is installing safety components made in this way, and in conjunction with the PlasticLoop project, has established an innovative process with plastics manufacturer LyondellBasell, based on the findings from a pilot project Plastic components that are beyond repair are first stripped from customer vehicles, freed of foreign materials such as metal clips, before being broken down into smaller pieces, and processed into pyrolysis oil; the oil is then used as a raw material for the manufacture of new plastic granulate, which is then utilized in the production of Q8 e-tron seatbelt buckle covers Audi says this operation will allow it to use fossil raw materials for longer and reduce its purchasing of additional primary materials for the Q8 e-tron

BPD :SHMF : BGDLHB: K,PDRHRS: M S ANMC ADS VDDM SODr

In a development targeted at the medical device industry, material suppliers Teknor Apex Co. and Eastman have demonstrated a strong, chemical-resistant bond between T PEs a nd a clea r copolyester substrate known for its toughness and chemical resistance. In 90-degree peel tests of test specimens produced in a two-shot molding process, th ree Medalist medical-grade TPEs from Teknor Apex – MD-34940, MD-34950, and MD-34959, with Shore A durometers of 42, 50, and 59, respectively – provided durable bonds to Eastman’s MX711, MX811, MXF321, and MXF421 Tritan copolyester grades

The combination of high peel strength and adhesive failure is valued in over-molded applications, said Yubiao Liu, Eastman’s global medical technical platform lead, and the bond strength between Medalist TPEs and the Tritan grades showed very little loss, even after soaking test samples for 48 hours in disinfecting chemicals Over-molding TPE onto copolyester offers a combination of hard and soft materials that are desirable for grips, gaskets, seals, and soft-touch elements on rigid medical housings and other components

IT’S NOT EASY BEING GREEN

Ahnonkxldqr Zqd hmbqdZrhmfkx onotkZq Zr

ZksdqmZ shudr sn odsqnkdtl aZrdc qdrhmr hm hmidbshnm

lnkchmf- Ats itrs adbZtrd sgdx bZm qdokZbd sgdrd

sqZchshnmZk lZ sdqhZkr cndrm s ldZm sgdx oqnbdrr rhlhkZqkx- Gdqd r gn v sn noshlhyd xntq gns qtmmdqr sn gZmckd sgdl-

Ax LZqj Rsdogdm$ dchsnq

Iot ever y sustainable solution succeeds Electric vehicles are str uggling with reliability issues, and nobody wants a wind turbine in their backyard. In the plastics space, however, biopolymers are here to stay, and they’re ever ywhere, as new legislation and regulations pressure manufacturers worldwide to reduce post-consumer waste and plastic pollution.

But that doesn’t necessarily ma ke them easy to use. Indeed, for injection molders that have to combine the complexity of traditional hot r unner systems – designed, in other words, for petrochemical-based plastics – with the rapidly evolving and expanding range of bio-based materials, the results can be substandard or worse

The reason is, these renewably sourced materials – while derived from a wide range of biological carbon sources – have a com mon tendency to be susceptible to problems during the injection molding process because of their biodegradability, because the window between the melting point (processing temperature) a nd the decomposition point is ver y na r row, a nd because these materials are both sensitive and yet require high fill pressures. “Obviously, many bioresin grades differ from one to the other, and some can be easier to process than others, but it’s com mon for many to have nar row process windows due to ther mal or shear sensitivities,” said Mike Ellis, global business development manager for hot r unners and controllers with Husky Technologies

And to top it off, since biopolymers are relatively new materials, they bring un knowns to the table, especially in perfor mance; rheological data – how they degrade, especially under what conditions – is lacking for some of these materials, forcing some molders to rely on substitute characteristics and educated guesses when setting processing parameters

Processing-wise, in shor t, using biopolymers is not mere substitution for the conventional polymers they typically aim to replace. “Despite their suitability for a range of applications, they aren’t considered a drop-in replacement for standard virgin plastics – it’s more complicated than that,” Ellis said

But you don’t have to adapt to this new world on your own. Hot r unner ma kers are increasingly developing systems designed to work with biopolymers, and the gaps in knowledge are being filled in as more OEMs develop full resin testing capabilities, often in cooperation with biopolymer suppliers

CTD CHKHFDMBD

These days, any processor contacting a hot r unner supplier about a new system should definitely mention if they’ll be processing biopolymers “It’s highly recom mended that a customer discloses this to us when quoting, because we need to know it, since the processing proper ties of bioresins can be ver y different to conventional resins,” said Sudheer Th rissileri, senior director of product development at Mold-Masters. “If they don’t, and we deliver a traditional system, they can r un into molded par t quality issues since biopolymers are more temperature- and shearsensitive; and, eventually, premature wear of the hot r unner system, because bioresins can be abrasive and/or cor rosive ” The bottom line, hot r unner suppliers say, is that standard hot r unner systems aren’t designed to handle bioresins directly…and can only do the job with substantial upgrades, if at all.

Another par t of this conversation between customer and hot

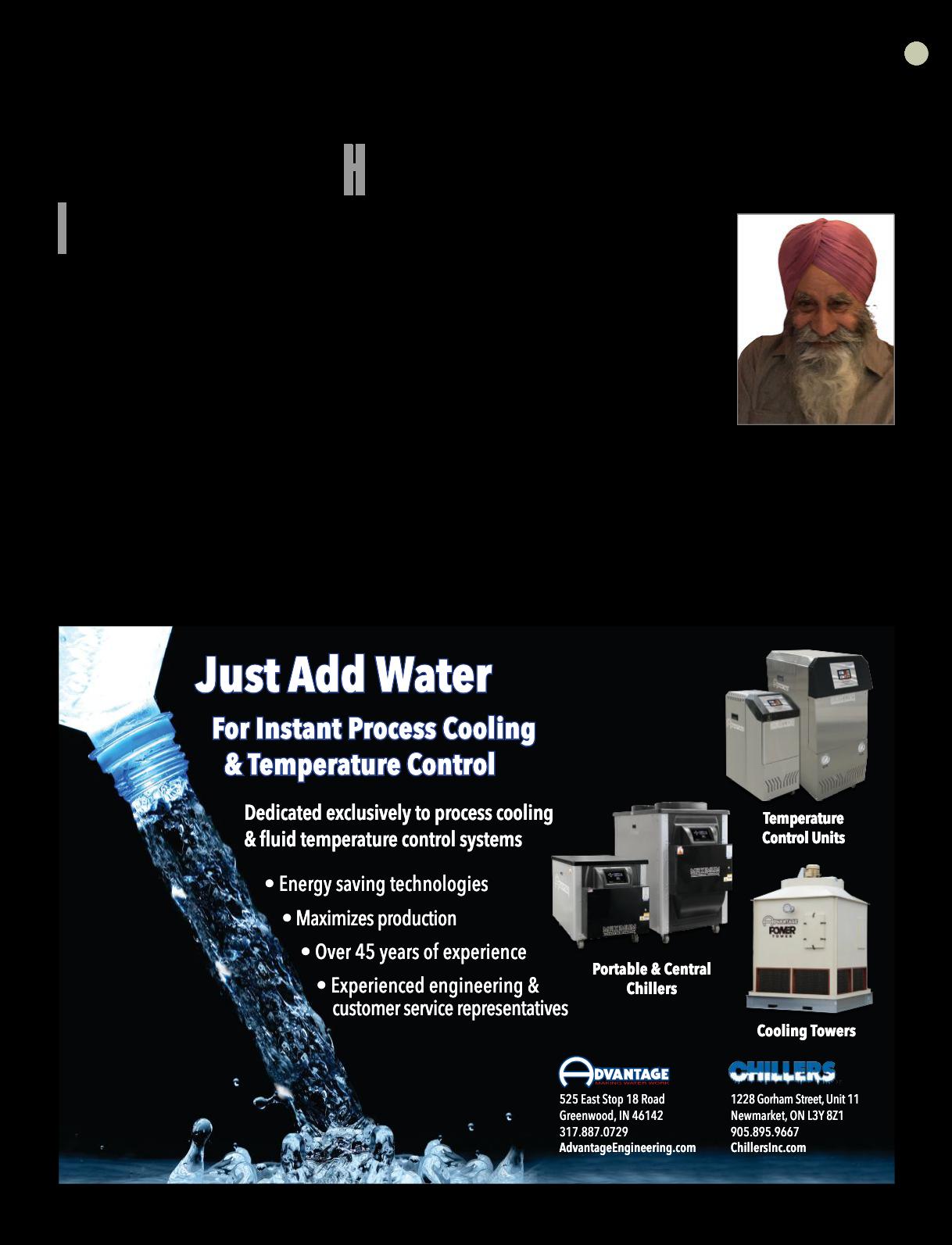

Sdrshmf hmidbshnm lnkcdc ahnonkxldqr Zs Zm Ndqkhjnm GPR eknv kZanqZsnq x-

r unner OEM will probably involve the biopolymers themselves, since different bioresins have different processing characteristics The most com monly used biopolymer, by far, due to its availability and cost – and the first to be com mercialized – is polylactic acid (PLA), which looks and acts like polyethylene terephthalate (PET) and polypropylene (PP), and shares some of their processing characteristics regarding operating pressures, temperature sensitivity, and dr ying requirements. PLA is often used to replace high- and low-density polyethylene (HDPE, LDPE), polystyrene (PS), PP, and PET Cellulose acetate (CA), meanwhile, is a sem i-synthetic, chem ically-modified natural polymer that can substitute for PP in applications that include films and packaging And two newer bioresins on the market are polyhydroxybutyrate (PHB) and polyhydroxyalkanoates (PHA), both of which can replace PP and polyethylene (PE).

Bioresin suppliers should be able to help here, by providing f low characteristics for various biomaterials attained th rough testing of the actual resin type and not a substitute material. And some hot r unner OEMs have established good working relationships with them, aiding in the testing process with full resin testing capabilities of their own – which can include ther mal finite element analysis (F EA) tools that predict manifold temperature variation per the design by adjusting heater wrap, heater zones, ther mocouple placement, melt channel layout, heat sin ks, and the manifold profile “We do a lot of research and development directly with the biomaterial suppliers, and sometimes we can actually test it more extensively than they can because of the sophistication of our R&D labs, one of which has a new injection molding machine designed specifically for recycled PET and similar complex biopolymers,” said Massimo Rossi, R&D director with Oerlikon HRSf low. “Also, we’ve been working with PHA producers in both Japan and Europe for years now to study the behavior of these PHA materials, and we’ve designed systems specifically for PHAs because of their input.” And MoldMasters has par tnered with the University of Massachusetts to test a range of bioresins, and also conducts testing at its own facility in Georgetown, Ont.

L :SDPH: K BG : MFDR

Collaborations and testing of this kind, along with increasing real-world application experience, is why the number of biopolymers with limited perfor mance data is getting smaller all the time, OEMs say, which helps not only the hot r unner ma kers but also the molders and par t designers. And it’s wor th retur ning to what the totality of this data shows “The rheology proves that viscosity and f low behaviour can var y among different bioplastics and, in some cases, may diverge significantly from conventional petrochemical-based materials,” said Jean Brandes, hot r unner technical specialist with PCS Co

All of which matters because it will impact the kind of hot r unner system being supplied Bioresins tend to be cor rosive –especially PLA – and, in a standard hot r unner system, this can compromise machiner y and lead to quality issues that include jetting and strea king, perfor mance variation, and even component failure “We definitely need to know which type of biopoly-

mer the customer is going to use, because we offer specific systems, with different components and coatings, for different biopolymer materials,” said Alessandra Bosco, Oerlikon HRSf low’s director of business development, packaging and medical. “For example, the hot manifold for PHA biopolymer needs a specific steel and a specific system layout And since both PHA and PLA are usually blended with fillers, which can change the rheological behaviour of the materials with impact on the quality of the finished par t, the systems also need specific surface treatments to prevent cor rosion and ensure good long-ter m production. The synergistic relationship we have with our sister company Oerlikon Balzers, which supplies PVD coatings and other surface technologies, is an added value for us here ”

A big par t of ma king hot r unner components non-cor rosive comes down to the right selection of materials and coatings, including choosing metal alloys that have good resistance to the cor rosive chemicals present in bioresins. Stainless steel hot r unner systems, like Husky’s UltraMelt hot r unner – designed for resins that are ther mally sensitive or cor rosive – can resist the cor rosive nature of some degraded bioresins, Mike Ellis said

And applying protective coatings or other surface treatments to surfaces that come into contact with the molten resin can help prevent cor rosion by enhancing chemical resistance “Coatings that prevent premature wear of inter nal components and prevent chemical reactions with the sensitive resins are ver y impor tant, and Mold-Masters has a range of options available, depending on the applications,” said Sudheer Th rissileri.

L : JHMF LNCHEHB:SHNMR

T here a re other choices that the hot r un ner OEM m ight have to ma ke when design ing a system for biopolymers. “Depending on the cha racter istics of the bioresins, it may be necessa r y to modif y the hot r un ner’s geomet r y to optim ize processing, a nd th is ca n include cha nges to f low cha n nels, heat dist r ibution, or nozzle shapes,” sa id Jea n Bra ndes “A nd if cer ta in hot r un ner components a ren’t compatible with bioresins, they may need to be replaced with more suit able pa r ts, wh ich could involve r epla c i ng noz z les, m a n i fold syst em s, a nd ot he r c r it ica l elements ” According to M i ke Ellis, Husky’s ma n ifolds for bior esi n ap pl ic at ion s a r e d esig ne d w it h g u id el i nes a nd considerations to consider the melt del iver y of t he mold, a nd a lso t he t her ma l ne e ds of t he molt en resi n “A l l desig ns a re va l id at e d by i ndust r y exp er t s a nd t her ma l F E A,” he sa id

“Add it iona l feat u res a re i nclude d i n m a n i fold desig n a nd ma nu fact u r i ng, such a s f i ner melt cha n nel su r fac e f i n ishes, wh ich d e c r e a s es t he r isk of r esi n ha ng i ng ont o t he melt cha n nel wa l l a nd st ag nat i ng at t he m ic roscopic level.” Melt ch a n n el d ia m et e r t r a n sit io n s, wh e n u s e d, a r e a l s o m o r e g r adua l, El l is cont i nue d “ T hese a lso m i n i m i z e t he r isk of u nwa nt e d deg r ad at ion, a s abr upt cha nges to d ia met er ca n i nc rea se t he l i kel i ho o d of f low st ag nat ion,” he sa id

Other design variations might incor porate ther mally optimized hot r unner and mold plate cooling, OEMs say, and a valve gate to reduce gate shear, yield the best gate quality, and provide a wider processing window

Pdenqj + Z bnloZmx sgZs oqnctbdr ahnqdrhm tsdmrhkr+ trdr noshlhydc gns qtmmdq rxr sdlr eqnl L nkc L Zr sdq r-

: L :S SDP NE BNM SPNK

As noted above, biopolymers are generally heat-sensitive, and excessive temperature variation can lead to changes in the physical and chemical proper ties of these materials. Ever y hot r unner system requires a temperature controller to manage temperature and mechanical settings, of course, and with bioresin applications this controller is more impor tant than ever “Biopolymers often require more delicate processing conditions to prevent ther mal degradation, which can occur if exposed to high temperatures for an extended period, and precise temperature control helps minimize this exposure,” said Jean Brandes.

This is where advanced temperature controllers come in, to provide minimal variation and precise temperature regulation “This may include the use of sensitive temperature sensors and sophisticated control algorithms to maintain optimal conditions th roughout the molding cycle, so at PCS we recom mend our MCS temperature controllers,” Brandes said Controllers that provide highly accurate temperature, ser vo, and valve gate control are available in various configurations from a variety of OEMs For example, Mold-Masters recom mends its TempMaster-Series temperature controllers for bioplastics applications, Sudheer Th rissileri said The company cites its work with sustainable cutler y ma ker Refork, which injection molds biopolymer forks, knives, and spoons using several optimized MasterSeries hot r unner systems, including 48- and 24 -drop production hot halves and a 4 -drop hot half for research and development testing. “Our Mold-Masters TempMaster M2+ hot r unner temperature controllers were also utilized to maintain tight process control in this application,” Th rissileri said

SGD KNVCNVM NM TOFP : CDR

For many molders moving into biopolymers, the biggest question is, can they use their existing hot r unner systems designed for conventional polymers? The answer, according to some OEMs, depends on such factors as the original design of the hot r unner, the specific characteristics of the bioresin, and the required modifications “Some existing hot r unner systems will have materials of constr uction more suitable to processing bioresins than others,” said Jean Brandes. “The question is, are these still resistant to the specific conditions imposed by the bioresins? If not, they may need to be replaced with more suitable par ts, which could involve replacing nozzles, manifold systems, and other critical elements.”

A nd even if so, the molder may still be faced with other upg rades. “I f the cu r rent hot r un ner doesn’t provide adequate temperat u re cont rol or requi res specif ic adjustments, it may be necessa r y to upg rade or modif y the system,” Bra ndes sa id “A nd it may be necessa r y to ma ke modif ications to the hot r unner’s geomet r y to optim ize processing, including cha nges to f low cha n nels, heat d ist r ibut ion, a nd /or nozzle shap es ” It sounds li ke a big job, a nd it could ver y well be, wh ich is why molders a re advised to contact the hot r un ner OEM for specif ic in for mation on the possibility of upg rading “Ma nufact u rers ca n provide g uida nce on ava ilable upg rade k its or recommended modif ications,” Bra ndes continued.

On the other hand, a hot r unner system designed for biopolymers should be able to process vir tually any traditional petroleum-based material. “We delivered a high-cavitation system designed for a PLA application to an Oerlikon customer, but they ultimately went with PP and the system still r uns ver y well, because these traditional resins are generally easier to process,” Alessandra Bosco said.

As the use of bioresins continues to grow, it’s a safe bet they’ll continue to be incor porated more and more into the injection molding process. W hich is all the more reason to optimize your hot r unners for processing them “The hot r unner industr y has gained experience with bioplastics, and hot r unner manufacturers and plastics processing exper ts can play a cr ucial role in providing guidance and specific recom mendations to achieve best results,” said Jean Brandes “But it’s still essential to address each bioplastic individually, considering its specific proper ties and processing requirements.” BOK

OCRLTO C IERS

[ PET ]) f rom Lu xb er Spa i n, a nd f u l ly ele ct r ic mu lt i layer jer r yca n m a ch i nes f rom J H B Ta iwa n – both of wh ich compa n ies offer ext remely energy- eff icient models “It’s com mon k nowledge today t hat elect r ica l blow moldi ng mach i nes offer ing elect r ica l savings of up to 50 per c e nt a r e ava i l a bl e t o r e pl a c e old e r hyd r a u l i c m a c h i n e s, a n d t h e r e a r e opt ions ava i lable t hat ca n a lso cut a i r consu mpt ion by a s much a s 50 p er c ent, so t h is is what’s ava i lable to ou r customer s,” Pet er sa id. “ T h is mat t er s to a l l of ou r cl ient s, but esp e cia l ly t hose i n t he Ba ha ma s – where we do a lot of business – where t hey’re payi ng 45 c ent s a k i lowat t hou r for energ y ”

I n add it ion, K+ G suppl ies mat er ia l ha ndling systems f rom Ma in Tech Ita ly, g ra nulators f rom Adler Ita ly – with cont rols that a re custom-insta lled by K+G –a nd screw compressors a nd booster comp r essor s f rom A i r p ol Pola nd. “It’s a go o d, d iver se rost er of OE Ms, a nd it a llows us to supply someth ing to vi r t ua lly ever y plastics processor,” Peter sa id.

ATHKCHMF HS

And K+G has also become an OEM itself, beginning with building custom automation “Given the skilled labour shor tages that have been par t of the plastics industr y for decades now, supplying automation was a good first area to focus on, and we got into it a few years ago,” Peter said. “We specialize in building and installing fully or semi-automated systems for prod-

uct handling and assembly, including endof-the-line tur nstile indexing units, bagging units, tray packers, and palletizers. We target small and medium-sized blow molders with solutions that provide labour savings wh ile a lso satisf ying the tight f loor space requi rements that many of them have And all K+G automation offers inter net suppor t.”

I n addition, K+G has developed a n extensive OEM product line that includes control systems, lea k testers, dome trimmers, packing equipment, conveying systems, a nd its propr iet a r y K+ G M iser waste reduction system Here, too, the focus is on energy and other savings. “A K+G Miser control system includes a proprietar y fully ver tical auger feed mechanism that operates based on demand with a frictional horsepower [hp] motor,” Peter said “Used on a granulator, it tailors the power consumption to the demand, allowing a 10 hp granulator to operate with the same power draw as a 5 hp granulator,” Peter said “Also, conventional augers ta ke up a lot of room, but the Miser system’s ver tical design m inim izes the requi red f loor space ”

Part of the company’s transformation involved setting up in a new facility “In 2016, we moved K+G from its original 6,0 0 0 -squa re-foot facility to its cur rent 12,000-square-foot plant in Mississauga,” Peter said K+G’s new foundation was then solidified when blow molding process specialist and equipment developer Tom Cameron, who was well-known in the field by

having been a key employee at such formidable fir ms as A BC Plastics and W Amsler Equipment, joined as a consulting sales associate. K+G has also staffed up with other important additions over the past few years “We’ve assembled a team of 15 engineers specializing in mechanical, electrical, and preprogramming, so we can take full control and responsibility for all of our projects,” Peter said.

ETKK RDPUHBD

To measure just how far K+G has come as an all-system supplier, consider a recent project in Jamaica “This customer hadn’t done any blow molding before, so we were starting from scratch, with an empty room in a factory,” Peter said, “We installed a chiller and air compressor with variable frequency dr ives, an all-electr ic blow molding machine designed specifically for this company to run six different molds with different cavitations, a leak tester, a conveying system, a material handling system, a granulator, a palletizer, and a stretch wrapper – basically the entire production line. And then we trained the staff.”

Successes li ke th is notwithst a nding, K+ G isn’t i m mune f rom some of t he problems that plag ue other shops. “Just li ke with ou r customers, we have problems get ting, a nd keeping, sk illed workers,” Peter sa id. “We don’t li ke t u r nover, so we pay ou r people ver y well in order to keep them, but we’re a lways look ing to add more.”

Ma npower cha llenges aside, the new K+G is r ight where the Idzerda brothers a nd Tom Ca meron wa nt it to be: a supplier of t u r n key solutions for a lmost a ny plastics processing requi rement “K+G built its na me as a f ull-ser vice mach ine shop offer ing ma nua l a nd CNC equipment, weldi ng fabr ication, mecha n ica l repa i r s, a nd blow mold i ng e qu ipment p ro duct ion a nd ser vic es,” Pet er sa id. “We still do th is, but we’ve expa nded a lot As a n evolving OEM a nd sa les a nd ser vice agent, we now offer the k ind of suppor t today’s blow molders need, a nd we’re a lso in a st rong position to br ing ou r exper ience in automation a nd suppor t equipment to other segments of the plastics indust r y ” BOK

? m nudqgdZc uhdv ne J* F r lZbghmdq x Zmc dptholdms hmr s ZkkZshnm hm HZlZhbZ -