Jnmf sgqdY sdmdc sYqheer eqnl T-R- Oqdrhcdms CnmYkc

Sqtlo gY ud oktmfdc Mnqsg :ldqhbY hmsn Y sqYcd

vYq* vghkd nm Y fYhm* nee Y fYhm mdv kduhdr bnmshmtd

sn drbYkY sd tmbdqsYhmsx- :mc Yr ltbg Yr Ym x nsgdq rdbsnq* BYmYcY r okYrshbr hmctrsq x hr bYtfgs hm sgd

bqnrrehqd-

Ax LZqj Rsdogdm’ dchsnq

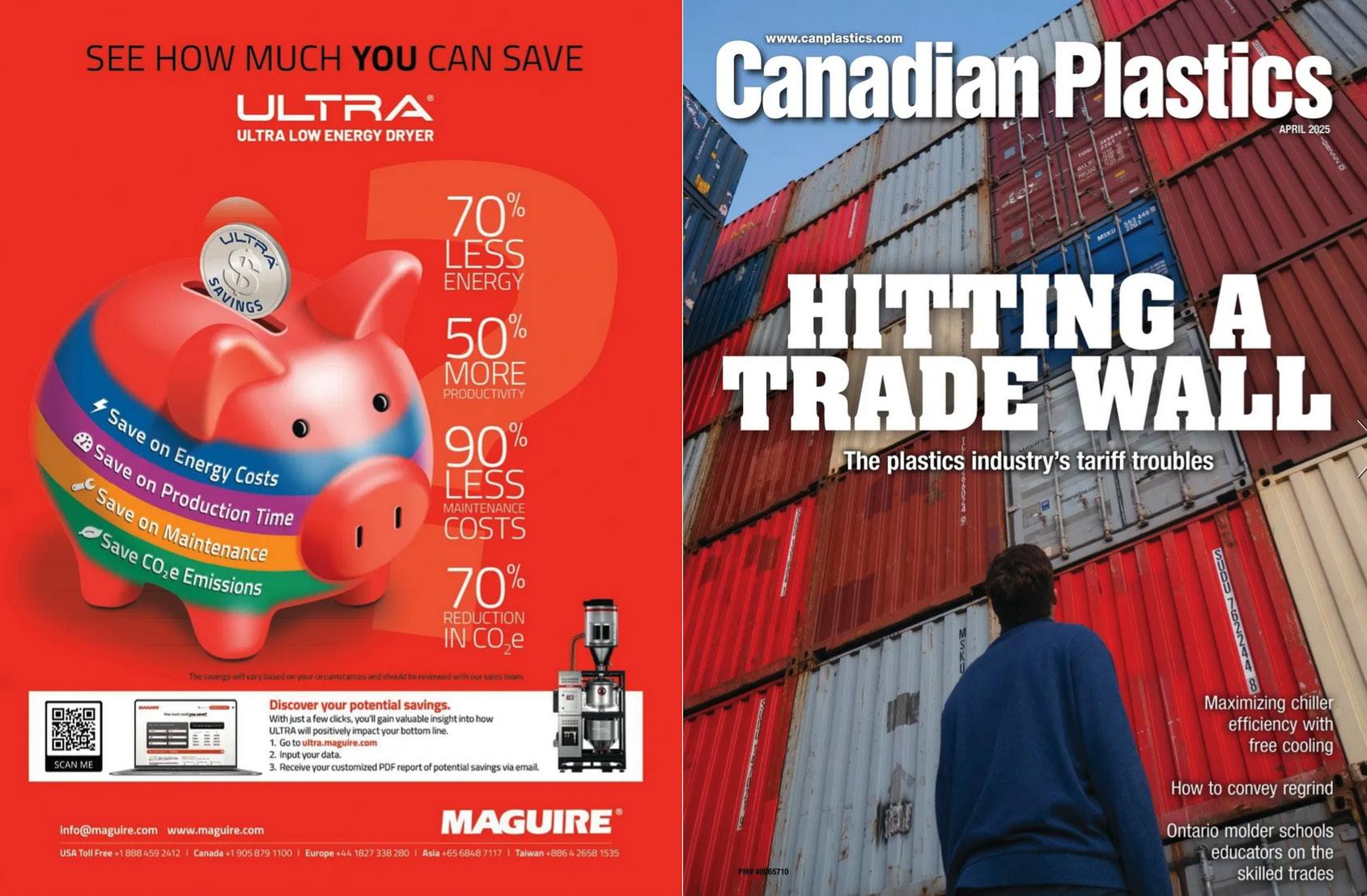

Phere’s a saying that when the U S sneezes, the world catches a cold. So what happens when America undergoes the fullbody dr y heave of building walls around its economy by imposing punishing tariffs on its major trading par tners?

Now that the trade war has begun, that’s the question Canada’s plastics sector is str uggling to answer.

Deter mined to steer the manufacturing of cer tain products back to the U S , President Donald Tr ump is cur rently pursuing a wide range of tariffs, including levies of 25 per cent on Canadian and Mexican impor ts that went into effect on March 4 and new duties on steel, aluminum, semiconductors, and other products slated for the next several weeks. Tr ump has also slapped 20 per cent tariffs on Chinese impor ts across the board The Tr ump administration then quickly paused tariffs on Canadian and Mexican goods that fall under the United States–Mexico – Canada Agreement until April 2, including for the car industr y after pleas from Ford, General Motors, and Stellantis, which have supply chains that stretch across Nor th America

In response, Ottawa imposed 25 per cent counter-tariffs on more than 1, 250 American goods, including a range of items involving plastics: vinyl f looring, siding, windows, trim, and fencing; baths, shower stalls, and toilet seats; home appliances; fur niture; tableware and kitchenware; caps and closures; sacks and bags; and bottled water and other beverages With the pause on Tr ump’s tariffs, however, Canada delayed its second wave of retaliator y tariffs on Can$125 billion wor th of U S impor ts until April 2, but did impose counter-tariffs wor th Can$29 8 billion on steel and aluminum products beginning on March 13.

Meanwhile, Mexico vows to pursue similar counter measures if tariffs come back on, China has imposed tariffs of up to 15 per

cent on a range of American goods, and the European Union plans for a 50 per cent t a x on impor ts of U S -produced whiskey beginning in April.

Tr ump is no stranger to tariffs. He also launched a trade war during his first ter m in office, but has more sweeping plans now. For months, his on-again, off-again tariff th reat has roiled financial markets a nd enveloped ma ny businesses in a n uncer tain atmosphere that has delayed h i r ing, orders, a nd investment Tr ump and officials in his administration say the tariffs will end what they view as unfair trade practices. They’re also using tariffs as leverage to address border secur ity concer ns about uncontrolled im migration and fentanyl trafficking.

T he sit uat ion is f lu id, u npre d ictable, and chaotic, and no one knows how long the cur rent ta riffs will remain in place But we can be sure of one thing: Regardless of how the cur rent situation plays out, the th reat of fur ther rounds of tariffs will hang over the Canadian economy for the duration of Tr ump’s second ter m in office.

Markets don’t like either tariffs or uncertainty, and if the tariffs remain in place for any length of time, economists and other exper ts say it will lead to severe economic disr uption for industries across Canada, shave th ree per cent off the economy as a whole, and have the potential to plunge us into a recession. The Ban k of Canada’s most recent sur vey of consumer expectations finds that 15 3 per cent of Canadians fear losing their job this year – aside from the COVID-19 pandemic, that’s the highest such reading in the ten years of the sur vey

And just to ma ke it more complicated, Canada has a new prime minister, longtime ban ker Mark Car ney, who holds the vir tually unprecedented position of being unelected to Pa rlia ment; and there’s a federal election in the offing

For Canada’s manufacturing sector, it all adds up to ma ke an unprecedented situation “This isn’t like any other economic crisis – not even 9/11 or the pandem ic,” said Ken Brooks, EY Canada strategy and transactions par tner, based

S gd

hlonq sdc eqnl sgd T-R-* hmbktchmf bYor Ymc bknrtqdr-

in Mont rea l. “A nd it’s not li ke du r ing Tr ump’s first ter m, where there were more guardrails in place to contain him. This time around, anything can happen.” And the sta kes of tariffs and a prolonged trade war couldn’t be higher, since deeply integrated supply chains between the U.S., Canada, and Mexico face significant disr uptions, and Canadian businesses that engage i n cross-border t rade wi l l be impacted Those acting as the impor ter of record will face higher operational costs, wh ich ca n squeeze profit ma rgins a nd reduce cash f low; and if increased costs are passed on to Canadians, it may contr ibute to inf lation. For Amer ican purchasers that act as the impor ter of record, meanwhile, higher pr ices could reduce demand for Canadian goods, leading to a decline in expor ts.

Canadian industries, the plastics sector among them, are understandably wor ried about these disr uptions, with most manufacturers probably feeling a combination of shock and dismay Canada is the U S ’s largest customer for manufactured goods, with Can$115 billion in trade between Canada and the U S in the chemistr y and plastics sectors In total, the trade volume in the plastics industr y crossing the borders between Canada, the U S , and Mexico in 2023 was nearly US$242 billion

Plastics and chemical industr y groups in all th ree nations – the Chemistr y Industr y Association of Canada (CIAC); the Plastics Industr y Association in the U S ; and Mexico’s national plastics industr y association, Anipac – have been expressing deep concer ns about the tariffs for months

now, and they reiterated those fears in a joi nt Ma rch 5 st atement “A st rong regional trade alliance ensures access to cost-effective materials, enhances supply chain resilience, and boosts global competitiveness,” they said “Without these cr itical trade relationships, the cost of production would rise, limiting economic growth and reducing consumer choice across all industries that are heavily reliant on plastics.”

I n its own st atement on Ma rch 4, CIAC president and CEO Greg Moffatt said tariffs will raise costs and called on the Canadian gover nment to pursue policies that recognize the “changing economic landscape,” including by diversifyi ng its t rade relationsh ips wit h ot her count r ies “W h ile a t a r iff a nd policy response from Canada is war ranted, we must not lose sight of the pressing need to future-proof our economy,” Moffatt said “Increasing our econom ic competitiveness should be the guiding principle for all policy actions in the weeks and months ahead ” CIAC said that “expanding into new markets beyond Nor th America –both east and west – is vital for economic growth and long-ter m prosperity ”

The uncer tainty leading up to March 4 was painful for businesses on all sides of the borders, and it hasn’t gone away just because Tr ump finally pulled the trigger on his tariffs. “The real impact of the tariffs won’t be revealed for some time: how long will they be in place, how will customers react, and what other markets can processors go after and how long will these ta ke to develop?” said Ken Brooks “There’s a lot of manufacturer/customer dep endency for pa r t s t hat ca n’t b e assigned to new molders unless they meet stringent gover nment specifications This inter play will play out over months and years, not days and weeks ”

One thing is clear for manufacturers right now: The effects of the tariffs were felt well before March 4 “There’s been some work placed on hold because our U. S. customers u nderst a nd ably don’t want to release work into Canada without knowing what the r ules are and when the situation could change so quickly,” said M i ke H ick s, d i re ctor of sa les wit h Diemould Ser vice Co (Ca nad a) Ltd

(DMS), in Windsor, Ont. Mike Cyr, president of size reduction equipment ma ker Rotog ra n I nter nationa l I nc , in Bolton, Ont., agrees that the th reat of tariffs has a l ready done da mage. “Ou r A mer ica n customers are apprehensive about ma king any kind of move, and orders are on hold at the moment,” Cyr said. “During the month-long pause, some customers carried on as usual by giving us engineering specs and other infor mation so we could be ready to fill granulator orders – they just didn’t place the orders Now that the ta riffs a re implemented, some of these orders may not go ahead, so we do expect a cer tain loss in U S business ”

In tr uth, the lead-up to the tariffs may not have been all bad. “Some companies act ua l ly benef it ted f rom orders bei ng pushe d t h roug h ea rly b efore t a r i f fs began,” Ken Brooks said. Officials with Ca lga r y, A lt a -based mater ia l suppl ier Nova Chemicals Cor p say their fir m took early steps to pre-place inventor y in the U S beginning when Tr ump signalled his intention to issue tariffs late last year

Ea rly responses f rom indust r y at la rge seem to have coalesced a round two policies: for Ca nada to t rade less with the U S a nd more with other count r ies, a nd to st rengthen the inter nal Ca nadia n economy. T h is is ref lected in some plastics f i r m’s st rategies “We’re al ready actively look ing for more Ca nadia n business a nd ma k ing th is a pr ior ity,” Mi ke Cyr sa id. “T here’s a ‘Buy Ca nadia n’ wave that’s developing a nd we wa nt to r ide it T he key to ou r pla n is to reach out to all gover n ment agencies, to ma ke them awa re that all ou r mach ines a re ma nufact u red 10 0 per cent in Ca nada So when the gover n ment event ually offers stimulus packages a nd other gra nts to stimulate madein- Ca nada ma nufact u r ing, Rotogra n will al ready be on thei r rada r.”

Depending on circumstances, the goal of expanding a customer base within Canada might be easier said than done, however “I nter provincia l t rade ba r r iers in Canada ma ke it a lot easier to go nor th / south than east/west, even with tariffs in place,” Ken Brooks said. “It’s not always cost- ef fective to sh ip wit h i n Ca nad a,

Nms Yqhn Ymc Ptdadb oYq s lnkcdq r sgYs rgho sn : ldqhbYm btr snldq r s xohbYkkx dminx sgd admd ehs ne aYbj gYtk sqtbj hmf sn r Yud sq Ymronq s bnr s r-

especially since most of Canada’s manufact u r i ng operates wit h i n t he Niaga ra Falls/Quebec City cor ridor, and typically these fir ms can use reverse logistics, getting the back haul on com mercial tr ucks retur ning to the U S , so their shipping cost s to go sout h a re sig n i f ica nt ly reduced.”

T he federa l gover n ment is a lso proposing measu res to cush ion the effects of a t rade wa r by launch ing a “rem ission process” that will a llow Ca nadia n businesses to ask for relief f rom the payment of ta r iffs or a ref und of ta r iffs a l ready pa id. A nd some econom ic agencies have t hei r ow n a id packages i n t he work s “Both the BDC [Business Development Ba n k of C a na d a] a nd E D C [ E xp or t Development Ca nada] a re a l ready putting together prog ra ms to provide some relief, but we don’t k now what these will look li ke yet because of a ll the un k nowns: how long the ta r iffs will last, what the cu r rency deva luation will be, a nd what the interest rate envi ron ment will be,” Brooks sa id

Ca nadia n f i r ms with a foot pr int in the U. S. have other options as counter measu res to the ta r iffs “We wa nt to ma xim ize ou r business in Ca nada, of cou rse, but the volumes a ren’t the sa me, so it’s for t unate for us that DMS has a bra nch in Ch icago that we ca n d raw on,” sa id M i ke H icks. “A nd ou r ownersh ip decided du ring the pa ndem ic to pivot into end- ofa r m to ol i ng pro duct s a s a se cond a r y busi ness to prote ct aga i nst over i nvestment in a ny one sector, a nd th is ca n help us du r ing the ta r iff sit uation ” T he CI AC,

as we’ve just seen, suppor ts expa nding into new ma rkets beyond Nor th A mer ica But some indust r y members have doubts about t r ying to d r um up new business in regions li ke Eu rope, for exa mple. “T he Eu ropea n ma rket isn’t a ny bet ter r ight now,” H icks continued “Vol kswagen is shut ting down operations as key regions, including Ger ma ny, have removed or cut incentives for elect r ic veh icles A nd the push to deca rbon ize Eu rope’s economy with g reen ma ndates ma kes it un f r iendly to business ” A nd foreign ma nufact u rers look ing to expa nd into there m ight have a tough ti me for a not her reason. “Eu ropea n competitors a ren’t going to let go of thei r income st rea ms just because Ca nadia n shops need new customers,” Ken Brooks sa id

Other f i r ms a re contemplating put ting down roots either south of the border or nea r it a s a he dge aga i nst f u r t her or d e ep e r t r a d e wa r s Si lc ot e ch No r t h

A mer ica I nc., a l iquid si l icone r ubber molder based in Bolton, Ont , has customers in both Ca nada a nd the U S , a nd compa ny of f icia ls say t hey’ve t a ken a ser ies of steps to prepa re for the cr isis. “We’re actively col laborati ng wit h ou r suppliers to m itigate the negative impacts of ta r iffs, a nd a re consider ing open ing a st rategic ma nufact u r ing location nea r the Ca nada / U S border,” sa id Isolde Boet tger, t he f i r m’s vice president a nd cofou nder “Pla ns a re a lso u nder way to engage with loca l a nd provincia l politicia ns to help suppor t successf ul Ca nadia n businesses in navigating a nd m in im izing ta r iff-related r isks ”

One pa r t of a two -pronged su r vival st rategy, Ken Brooks sa id, is for Ca nadia n molders to st rategize with thei r U. S. customers on how to lessen a ny da mage “Most Ca nadia n f i r ms tend to focus more on shor t-volume r uns because they ca n’t produce at scale, a nd thei r U S customers value that a nd typically pay a prem ium for it, a nd may be willing to keep doing so,” he sa id “In some cases, if the plastic component is a small pa r t of the overall value of the f inished good, a 25 per cent ta r iff won’t a mount to much, so it m ight be easier to swallow the ta r iff, a big por

tion of wh ich m ight be offset by a devalued cu r rency ”

A second prong, Brooks continued, is to seek lega l a nd ta x advice to m itigate r isk. “T he bigger compa n ies may have i n-house cou nci l, but sma l l a nd m idsized shops should spea k to t hei r t a x account a nt or a n accounting f i r m with deep releva nt U S exper ience, because they ca n give advice on how to set up in the U. S., if that’s on the hor izon. Next, consult a cross-border ta x exper t about what goods will get ta xed a nd at what level.” Nova Chem ica ls has established a cross-f unctiona l r isk ma nagement tea m, compa ny off icia ls sa id, a nd has worked closely wit h it s log ist ics a nd custom s complia nce tea ms “to secu re access to the necessa r y foreign t rade zones ”

D ue to t he ever-sh i f t i ng nat u re of t he t a r i f fs, t h e s t a t u s of t h e t r a d e wa r rema i ns a b ou nci ng fo otba l l G iven h is a d h o c a n d o p p o r t u n i s t ic a p p r o a ch, Tr u m p m ay c a n c el o r sig n i f ic a nt ly re duc e t he t a r i f fs i f ser iously om i nous

r at t les st a r t com i ng f rom t he A mer ica n e conom ic eng i ne, or i nc rea se t hem i n

r e s p o n s e t o r e t a l i a t o r y t a r i f f s A s

Tr u mp sa id, wit h foreshadowi ng, du ri ng a Ma rch 7 press con ferenc e, “ t here w i l l a lways b e ch a nge s a n d a dj u stment s” i n h is t a r i f f p ol icy So it’s no wonder t hat a re c ent CI BC rep or t not e d t hat “ou r st at ist ica l to ols a re i nade quat e for t he t a sk ” of mea su r i ng t he i mpact s of a major t r ade wa r, “lack i ng eit her re c ent pre c e dent s of h ig h t wo -way t a ri f fs to use a s b ench ma rk s, or mo dels t h a t h ave t h e d et a i le d i n du st r y-level d a t a a c r o s s s e c t o r s a n d c o u n t r i e s ne e de d for ac cu r at e si mu lat ions ”

It’s a d i zz yi ng sit u at ion, but Ken Br o ok s suggest s it m ay a lso p r ove inst r uctive “I’m hopef ul that Ca nadia n f i r ms will lea r n not to ta ke the U S ma rket for gra nted,” he sa id. “We occupy a ver y for t unate place in the world, a nd it’s ser ved us well f rom a n access-to -ma rket perspective. But it’s also made us overrelia nt on the U S , a nd the ta r iffs may be

the wa ke-up call to sta nd more f i r m ly on ou r own ”

T he catch is that th is ca n be a costly option that requi res tech nology, sk illed labou r, a nd capital investments; a nd t rade wa rs create uncer ta inty, ma k ing ma nufact u rer s hesit a nt to ma ke la rge -sca le investments that may not pay off once the t rade conf lict ends

T here a re still more un k nowns tha n k nowns at present, but the best possible result now is a ver y shor t t rade wa r “A tempora r y ta r iff would be a shor t-lived shock a nd with a negotiated long-ter m settlement plus policy suppor t, we could get t h roug h wit hout to o much la st i ng d a m age,” t he C I BC rep or t sa id. Fa r worse, t he repor t continued, would be major ta r iffs on Ca nada rema ining until t he Tr u mp t e a m a nd C ong r essiona l Republ ica ns work out a major budget deal, wh ich could ta ke considerable time W hatever the outcome, it’s shaping up to be a n uncer ta in road a head for the Ca nadia n economy B O K

A d oW p r ne SG D B L CH L CD KDE SHN L fnhif rn r g d I 5 G NV 0 !0 2 W i a 5 TD

l cd l Ci nsdan hr nmbd VfVhm oVp smdphmf uhsg KL R7 TDK sn n–dp

V fpnto oVbiVfd enp E rgnu Mb snadp 5 02) 1/14

VD S ID B @D NE DUD@XSGHMF

y 3 R S @) KN C F H M F enp 5 mhfgsr LVpphnss Anknfmd(-

y C H @ DB S EKHF GS R epnl Rnpnmsn.LnmspdVk nm hp AVmVcV-

y 3 C X O R R SN I ) R G NV F T H C D -

y 1 M D S VN @ I H M F C H M M D @ R Vmc CVhkx A T EED S A @ D I E R S-

y KN B K S@ M R O N @ S SH N M -

y O@N ED R R H N M K R R H R S M BD N M R HSD -

y D W S@ 8 M L D BG M F D R KKNV D C to sn 37 g ophnp sn cdoYpstpd

y 2 $ 3 M HF GS O BI F D R U H K A KDkk s ghr enp nmkw ! 3

Enq okYrshb lnkcdqr* qdtrhmf hm gntrd rbqY o hr drrdmshYk enq rY uhmf lnmdx Ymc etkehkkhmf rtrsYhmYahkhsx fnYkr- Ats qdfqhmc fqYmtkdr bYm onrd bnmudxhmf bgYkkdmfdr bnloYqdc sn uhqfhm odkkdsr- Gdqd Yqd rnld jdx onhmsr enq fdsshmf hs qhfgs-

Ax LZqj Rsdogdm’ dchsnq

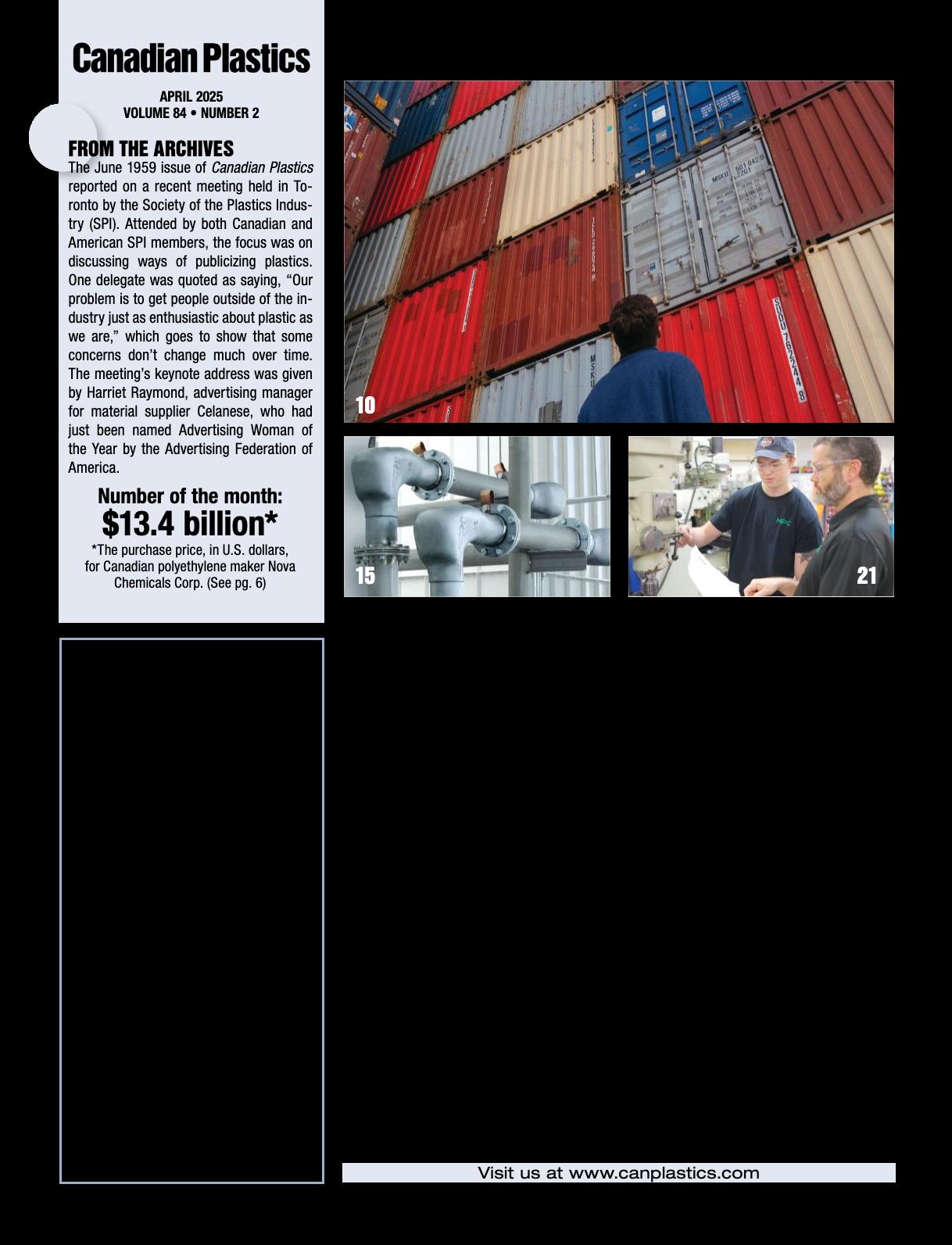

Phe ancient Greek philosopher Heraclitus wrote that the only constant is change And this definitely applies to resin conveying Historically, most plastics processors specia lized in molding st a nda rd vi rgin resin pellets, so that’s what they conveyed th rough enclosed, air tight pipelines. But times have changed, a nd nowad ays pro c essor s a re usi ng regrind in their products whenever possible as a cost-cutting measure. One way to do this is by implementing in-house recycling, which allows the molder to contribute to the circular economy in an easy manner: by reusing the plastic residual waste off-spec par ts, spr ues, r unners, and more from their injection molding mach i nes a nd ext r uder s. E conom ics aside, it’s not always a choice, as more customers demand that regrind be used in end products.

W hich means the regrind has to be collected, sh redded, a nd – cr ucia lly –conveyed f rom a storage a rea to t he machine th roat. Typically, for material in bags, d r ums or boxes, th is involves a pneumatic conveying system that utilizes vacuum suction to transpor t the material th rough pipes, often combined with a dust filtration system to maintain clean air in t he production a rea. A nd sp ecia l ized feeders can be added to ensure consistent f low a nd precise m i x i ng wit h vi rgi n material, depending on the application.

But as with so many things, the devil is in the details Compared to virgin pellets,

regrind from traditional consumer par ts can present conveying challenges due to its lower bu l k densit y ( Bot tle f la ke regrind from polyethylene terephthalate [PET] bottles is a whole other animal, and won’t be considered in this ar ticle ) Simply put, as you i ncrease t he ratio of regrind, and all other things remain equal, you’re moving less material th rough your system Added to that, dusty, f la ky regrind can clog mesh filters, resulting in maintenance headaches.

But these are speed bumps, not real hurdles We spoke with some of the system suppliers about how to convey inhouse regrind efficiently

Flowability is key to good material conveying As a r ule, typical virgin resin pellets are clean, unifor mly sized, spherical, and lightweight, which ma kes them fairly easy to convey, with lit tle to no dust, a lt hough moder n mater ia ls li ke glassf i l led nylons ca n be h igh ly abrasive. Regrind is different, although a big benefit of in-house scrap is that it’s a known quantity – unlike regrind bought from a third-par ty vender, which can be cobbled together from multiple industrial sources and contain foreign contamination. “Typica lly, heavier i n-house reg r i nds made from thick-walled par ts are better f lowing a nd wi l l convey more l i ke pel letized material than lighter regrind from thinwalled or ther mofor m par ts,” said Nick

Paradiso, senior director, sales operations with Conair Group.

But this heavier in-house regrind is still a mixed bag of differing thicknesses and sizes, most of which is actually larger than typical pellets due to the hole sizes in the granulator screens And this lack of unifor mity is what you want to minimize as much as possible before conveying, since regrind granules need to be unifor m to assure that virgin /regrind blends are consist ent du r i ng repro cessi ng. “ T he quality of the regrind is a function of the style, configuration, setup, and condition of the granulator,” said Rob Miller, president of Wittmann Battenfeld Canada “In a t y pica l i nje ct ion /p rof i le ext r usion regrind process, the regrind component should be as close as possible to the same bulk density as the virgin pellet component. This is done by having granulation equipment that’s sized and configured to meet the requirements of the application ”

P rocessors wit h ex isti ng conveyi ng systems – which is most of them – will have either pressure or vacuum conveying, and either dilute phase or dense phase W hen it comes to conveyi ng reg r i nd, Miller said, solutions should be application-specific “The typical application of loading regrind into a primar y processing machine doesn’t require a pressure system – vacuum would definitely be the standard,” he said. “If the application requires conveying a 10 0 per cent regrind stream into an outdoor silo at a high rate from a

la rge g ra nulator, t hen pressu re is a n option And anytime pressure is used for conveying, whatever the product or process – regrind included – filtration at the destination always needs to be considered, as the pressure air needs to be exhausted from the destination vessel in an environmentally safe way.”

And dense phase isn’t really an option, Miller continued, period “We’ve never been asked to even consider dense phase as a met hod of conveyi ng p el lets or reg r ind,” he sa id “I n ou r exper ience, dense phase is more of a powder application and rarely used in plastics.”

To foster greater precision, vir tually ever y capacity in plastics processing equipment is rated in ter ms of pounds per hour based on pelletized materials. “But conveying regrind th rows a wrench into these ratings, because lighter bulk density material has the effect of changing equipment and system capacity,” Nick Paradiso said To maintain the th roughput that you’re used to having with virgin pellets, therefore, you’ll have to move more regrind more often This can be done in several ways, the OEMs say, including by r unning more frequent fill cycles to keep existing receivers topped off, subdividing existing conveying system capacity into smaller subsystems that each ser ve a lower number of receivers, and expanding conveying line size and pump capacity to handle higher volumes with similar loading times.

Depending on how many of these steps are ta ken, any remaining differences in bulk density can be either a handicap or a benefit. “Because regrind is usually ir regularly shaped, the processor is conveying more air with slightly reduced bulk densit y, wh ich they don’t wa nt,” sa id Ja n R ickenbach, appl ication ma nager wit h Mot a n “But t he i r reg ula r shap es of regrind can create a better grip from the air, so you may lose some bulk density with regrind but still convey it better than spherical virgin pellets.”

Also for regrind, the conveying system may require lower micron filtration, but this is deter mined by the regrind itself. “Depending on the regrind quality and t he a mount of dust, t he system could

Odkkdsqnm r Odkkanv rodbhYk ohod admcr bnmudx ansg uhqfhm odkkds r Ymc qdfqhmc* vhsg vdYq qdrhr s Ymbd sgYs dwbddcr sq YchshnmYk dkanvr-

require the same filter elements as with powder in special cases, but could in most cases use f lat screen filters and la rger discharges,” Rickenbach said. In addition, some OEMs recom mend using filterless receivers because dusty, f la ky regrind can clog mesh filters. The caveat is that filterless receivers work wel l wit h coa rse regrind – which has comparatively significant bulk density – but are less effective for lighter, lower bulk density materials, some of which m ight escape back th rough the vacuum header to the central dust collecting system.

A ra nge of tools ex ist for feedi ng regrind for reprocessing, and selecting the right ones depend on the precision desired in the material mix “W hen the virgin / regrind mix ratio isn’t critical to product quality, a simple ratio valve may do the job, providing a steady stream of regrind to the mach ine th roat,” Nick Pa radiso said. “W hen ratio accuracy is more critica l, a n auger- d r iven feed of mater ia ls either to the blender or to the machine th roat is the right answer.”

A nd for reg r i nd wit h pa r t icu la rly rough or inconsistent cuts, additional system accessories may be required to help get the material moving or prevent bridging or ratholing Indeed, the OEMs stress, the pick up point where the reg r ind is introduced into the conveying system is cr ucial for getting good results “Pickup points, along with discharge points, are areas that you really have to focus on,” Paradiso said Vacuum systems for pellets can just pick up from the bottom of bins, but not so for regrind, where the lighter bulk density could ma ke it difficult to pick up, thereby star ving the downstream

machine. “I recom mend keeping regrind in surge bins instead of gaylords,” Jan Rickenbach said “Surge bins have cone configurations available for the hoppers, depending on the material they’ll be storing – hoppers for pellet storage usually have a 45° cone bottom and hoppers for hard-to-f low materials have a 60° cone bottom It’s a small detail, but it means the operator doesn’t have to waste time at the gaylord with a pickup wand.”

Another challenge in moving regrind is that rotar y valves can lock when used for conveying or discharging the material. Pelletron offers a special rotar y valve, the GR M-RG, which has a combination of feat u res – i nclud i ng a n a nt i-shea r i ng device that works in combination with V-shape rotors – designed to prevent locking of the valve

An issue when conveying any material –especially glass-filled polymers – is abrasion to the interior pipe surface over the long ter m due to the constant friction, but conveying regrind as opposed to virgin pellets shouldn’t ma ke this problem any worse “In-house regrind is the same polymer as its virgin counter par t – it’s not any harder, just ir regularly shaped,” Rickenbach sa id “Most conveyi ng syst em s offered by most OEMs have aluminum straights and stainless-steel elbows, which are tough enough for most regrind materials ” In extreme cases, Rickenbach continued, glass elbows may be required, but these will already be in place for conveyi ng t he glass-f i l le d vi rg i n mat er ia ls “Depending on the situation, we m ight a lso r e c om mend sp e cia l ly d esig ne d elbows such as the Pelletron Pellbow to help m inim ize fr iction, heat, and abrasion,” said Nick Paradiso.

Another advantage to adjusting the size reduction parameters is that the closer the regrind is to a pellet as far as being clean and unifor mly shaped, the better the odds that a standard pellet conveying system can move it without difficulty. “In a typical application, we’re not going to adjust air volumes or pump horsepower or most other conveying parameters just because it’s regrind, because regrind typically is a small par t of the virgin /regrind mix, so

therefore the conveying demands aren’t as high as for the virgin component,” said Rob Miller “We might get a slightly different rate of conveyi ng wit h reg r i nd because the par ticles won’t f low as well th rough the airstream as round pellets, but otherwise there’s no real difference ”

The diameter of the tubing nor mally is deter mined by the rate and distance In the case of regrind with square par ticles, la rge pa r ticles, ir regula r shapes or soft materials, the tube size may need to be larger to prevent clogging “If the regrind is in question, we may increase the size of the inlet pipe to prevent this jam m ing condition,” Miller said

As noted, in-house regr ind is also dusty, and what to do about this dust is an ea rly – and key – consideration First, you’ll want to limit the amount of that dust, which means knowing how it’s generated “D ust y i n-house reg r i nd is a g r inder issue, not a conveying issue,” Miller said. “If a customer is using a quality beside-the-press granulator or central grinding area and the knives are shar p, they’ll get quality regrind.” Beyond keeping a granulator in good working trim, it’s impor tant to select a screen size that balances the size and bulk density of the material while minimizing dust generation, the OEMs said Finally, they suggest, processing regrind in an enclosed grinding area helps to eliminate much of the mess from the molding f loor

Other conveying equipment can also help. D esig ne d for bot h p el lets a nd regr ind, the XSL vacuum loader f rom Novatec, available in Canada from Magui re P roducts Ca nada, feat u res a h ighintensity micro-burst blowback that provides an air blast to the filter to remove dust and fines

A fundamental question for processors is whether they even want to completely remove dust from their regrind “Dust is a valuable raw material that most molders will want to put back into ma king new par ts – the challenge is to prevent it from clogging filters and reducing conveying eff iciency,” Ja n R ickenbach sa id “But dust par ticles melt differently than pellets – creating black specks, for example – and if this is a processing problem, then you’ll want to remove as much dust as possible

with a dedusting device.”

M nuYsdb r W R J knYcdq ne edq r de ehbhdms odkkds Ymc qdfqhmc sq Ymr edq-

Given regr ind’s lack of consistency, processors t hat wa nt to move la rger amounts of it may need to ma ke some retrofits to their existing conveying system “It’s often a good idea to add f low enhancing features such as conveying airlocks wit h mecha n ica l feeds; modula r distribution boxes with inter nal agitators that keep material moving toward conveying ta keoffs; bins with augers or mechanical ‘clump brea kers;’ and additional filtration upstream of the vacuum pump, such as a cyclone dust collector combined with a traditional dust collector,” Nick Paradiso said But your existing control package should be fine, however. “Typically, standa rd softwa re is totally acceptable for conveyi ng reg r i nd,” sa id Rob M i l ler “Even when blending virgin and regrind, most conveying software packages allow for ‘propor tioning’ options to mix them in each vacuum cycle ”

In a standard conveying system, a regular maintenance schedule prevents potential equipment disr uption or failure The same holds tr ue for systems conveying regrind, but with a twist. “Regrind contains more impurities, dust, and fines than virgin pellets, so more frequent filter maintenance on receivers, dust f ilters, a nd vacuum pumps is recom mended,” Nick Paradiso said “And it helps the conveying to perfor m regular maintenance of granulator cut t i ng k n ives, t o m i n i m i z e dust y regrind ”

As with standard pellet conveying systems, signs of operational trouble in systems that convey regrind include the usual susp e ct s: i nc rea se d t h roug hput t i me; drops in dosing or in dispensing volume accuracy; lea ks in the joints, connections, lines, and tubes; and an increase in oper-

ating pressure or vacuum levels.

The goal of giving in-house regrind a second life th rough reuse in new par ts is universal among molders these days. But regrind itself isn’t universal – it’s not all equal from a conveying perspective So to recom mend the right conveying system for reg r i nd, t he system suppl ier must know what the regrind is and where it’s coming from W hich ma kes it critical that the customer and supplier have good communication about the customer’s needs from the outset “Injection molded par t regrind is ver y different from spr ues and r un ners, wh ich is ver y different f rom extr usion profile, which is ver y different from tabs and tails,” Rob Miller said. “It’s a l most i mpossible for t he suppl ier to deter mine what’s required mechanically without specifically knowing the process and, most impor tantly, the configuration of the regrind in all aspects We can quote a system for tops and tails in a blow molding application, but if the customer star ts dumping in large quantities of bottles the condition and processability of the regrind will ta ke a ver y large left tur n.” Resin conveying is the lifeblood of a plastics processing facility, and that won’t change. W hat will change is the amount, and quality, of regrind being blended with vi rgi n p el lets W h ich ma kes eff icient regrind conveying an increasingly important par t of your business. BOK

B nmWhp F p nto ’BqYmadqq x Snvmrgho) OY-(: v v v-bnmYhqfqnto-bnl ;t whokWr s Gmb- ’ UYqdmmdr) Ptd-(: v v v-YtwhokYrs-bnl

Chdp Gms dp mWs hnmWk OkWr s hb r Gmb’ T mhnmuhkkd) Nms-(: v v v-chdqhmsdqmYshnmYk-bnl

Stp mdp F p nto Gmb- ’ R dYs skd) VYrg-(: v v v-stqmdqfqnto-mds

Ln s Wm Gmb- ’ OkYhmvdkk) Lhbg-(: v v v-lns Ym bnknq sqnmhb-bnl

C Btad ’ L nmsqdYk (: v v v-cbtad-b Y

M nuWs d b Gmb- . LWfthp d Op nctb s r BWmWcW Gmb’ UYtfgYm) Nms-(: v v v-mnuYsdb-bnl

Odkkd s p nm B np o- ’ I Ymb Yrsdq) OY-(: v v v-odkkdsqnmbnq o-bnl

V hs s lWmm AWs s dme dkc BWmWcW Gmb’ Q hbglnmc G hkk) Nms-(: v v v-vhs slYmm fqnto-bnl

cooling systems we install are central.” Beside-the-press chillers can also utilize free cooling, depending on their configuration. “Water- cooled por t able ch illers connected to a central cooling system can have an inter nal free cooling valve that diver ts water from the inter nal condenser directly to the process, for independent free cooling at the machine level,” Mario Coletti said “Air-cooled por table chillers

require an additional condenser for free cooling, but if the air-cooled chiller is installed inside the facility, free cooling becomes less effective due to the higher indoor temperature compared to the outside environment ”

Key considerations to satisfy before using free cooling include, first, having the available space “Plant layout plays a key role in deter mining the type of plant-

wide f ree cooling system t hat ca n be installed,” Coletti said “Available f loor space, ceiling height, and outdoor areas impact whether dr y coolers, cooling towers, or heat exchangers can be accom modated Piping distances and system integ r at ion a lso a f fe ct ef f ic iency a nd feasibility.”

A second prerequisite is having a facility and process equipment capable of suppor ting a glycol/water process f luid, and of reducing the water temperature sufficiently to be usable

Additionally, the outdoor temperature must be low enough – which won’t be a problem during the cooler months in Canada. Beyond that, the specific location matters – la kes, rivers, or wells can be efficient water sources for free cooling but require environmental considerations and local/provincial per mits, which might ma ke them difficult to implement

But even in instances when the f luid cooler can’t meet the full cooling requirement, such as when the ambient temperature isn’t low enough, it can still remove at least par t of the heat load. “Finally, the process water temperature must be sufficiently reduced for use in t he pla nt,” Coletti added.

The good news is, depending on the existing system design and climate conditions, most chillers can be retrofitted for free cooling fairly easily. “A processor will need the right controls that monitor the outside temperature and activate free cooling whenever possible,” Jon Gunderson said “Beyond that, retrofitting is a straightforward process that usually only involves adding a few components – such as a free cooling coil or a heat exchanger – and plumbing pipes A typical retrofit only requires a few days of shutdown or less, and the retur n on investment from energy savings can be achieved in as little as six to 12 months ”

As a technology, free cooling has been around for a while, as mentioned, but it continues to evolve to improve reliability, energy efficiency, a nd d r ive down life cycle cost s. “ Te ch nolog ica l adva ncements, especially in automation and cont rols, have sign if ica ntly en ha nced f ree

ODFGRSO:SGNM GMBJTCDR5

y otmbg

y 07 gnkdr ne fnke Umc bUos

y Sun cohmi shbidsr

y tffds chmmdo

25,$ bgdlhm Fdbkdob$ :gdffnoc$ Ptdadb

D:OJU AGOC O:SD !ADENOD ITMD 0(5

y Entornld8 7,,

y :hmfkd8 11, y Chmmdo nmkw8 63

cooling capabilities,” Mario Co “Moder n systems can now fully the process, optim izing energ and efficiency even more.” And connectivity between systems operational efficiencies by enab d ict ive ma i nt ena nc e a nd op uptime – monitor ing package live data from compressed air an equipment to give clear insigh t i me, g iv i ng pla st ics m a nu im mediate access to data about uptime, energy efficiency, and the health of their complete insta llation. Additiona lly, the development of more advanced materials with improved heat transfer proper ties has bet ter enabled f re e cool i ng met hods. Finally, some chillers even feature energy recover y technologies

And some OEMs are introducing what t hey descr ibe as hybr id systems t hat i ncor porate bot h a ch iller a nd a f ree cooler in a single package, allowing the system to switch between free cooling and compressor-driven cooling, depending on ambient conditions “In a hybrid chiller, t he f re e co ol i ng mo de is t y pica l ly achieved by using a th ree-way valve that diver ts the process f luid th rough the free cooling coil when the outdoor temperature is lower than the process temperature setpoint,” said Rick Holzhauer “W hen the outdoor temperature rises above that setpoint, the valve switches back to the mechanical cooling mode and the chiller compressor is tur ned on to provide additional cooling.” According to Holzhauer, hybrid chillers are often used in applicat ions where t he cool i ng load va r ies th roughout the day or year, such as industrial processes with inter mittent cooling requirements

Delta T Systems is cur rently developing a new line of hybrid chillers scheduled for market-release by the end of 2025 “It combines the free cooler with a traditional chiller with mechanical refrigeration and uses va r iable-speed compressors, so it star ts slow, with the free cooler ta king most of the load; and as the ambient temperature goes up, the chiller will increase its speed,” Holzhauer said “We’re also using round coils instead of f lat coils, which provide more heat exchange area for the footprint, so the new hybrid chill-

Eqdd bnnkhmf bghkkdq r eqnl

Cdks Y S R xr sdlr ne edq lnqd sgYm

2 . odq bdms enns oqhms qdctb shnm sgqntfg Y qntmc bnhk cdrhfm-

ers will be smaller units And because it’s all packaged in one unit, there’s less water circulating and less piping, so there’s less potential for lea ks.”

W hile hybrid chillers share many of the same components as traditional electrical chillers, they also include additional elements such as control valves, temperat u re sensors, a nd a n expa nded cont rol system to optimize the transition between cooling modes “Hybrid chillers are an advancement in chiller technology rather than an entirely different categor y,” said Ryan Matthews, product manager, dr ying a nd heat t ra nsfer wit h Cona i r G roup “They incor porate both free cooling and me cha n ica l ref r iger at ion to i mprove energy efficiency and operational f lexibility. W hile they still rely on traditional vapou r compression ref r igeration, t he added free cooling functionality distinguishes them from conventional electrical chillers. And they’re available as central systems, ser ving multiple process cooling loads across a facility ”

Several years ago, Berg Chilling Systems installed a hybrid unit that combined a chiller and an air-blast f luid cooler at an unnamed major plastics facility in Quebec. “The customer’s initial requirement called for most of the load to be chilled water-type cooling, as the temperature requirement was stated to be within the range of 7° to 25°C,” said Adam Zyskowsk i, sa les ma nager, ma nufact u r ing “We reviewed the customer’s process and suggested that most of the load could successfully operate at higher supply temperatures. They agreed, made a few small – and no-charge – modifications, and the result was that most of the load was satisfied with ambient-produced free cooling rather than high-horsepower mechanical cooling Only 22 per cent of the load now

requires a chiller supplying mechanical cooling at 7°C while the balance is satisf ied wit h cooling at 30° to 35°C, for extraordinar y water and energy savings.”

As with all other assets, regular maintenance ensures chiller efficiency, since an un reliable process cooling system puts ever ything that needs temperature control at r isk. A proper ch iller ma i ntena nce che ck l ist i ncludes reg u la rly applyi ng lubrication to bearings, motors, fans, and other moving components; cleaning key components such as the condenser and evaporator coils; testing refrigerant levels a nd topping them up when necessa r y; testing the water quality; inspecting the insulation and seals; checking wiring; and perfor ming vibration analysis on motors, compressors, and other rotating equipment “The free cooling components in a hybr id ch iller, such as additiona l heat excha nger s a nd cont rol va lves, may require additional attention, such as seasona l clea n i ng a nd i nsp ection,” Rya n Matthews added.

Effective process cooling is vital for par t molding, but attaining it doesn’t have to brea k the ban k. Ta king advantage of free cooling to reduce a chiller’s operating hours will ta ke a big bite out of your plant’s energy bill BOK

O C RLTO C I ER S

;c uWms Wfd Dmfhmd dphmf Gmb- ’F qddmvn nc) Hmc-(: v v v-Yc uYms Yfddmfhmddqhmf-bnl

Bghkkdp r Gmb- ’ M dvlYq jds) Nms-(: v v v-bghkkdqrhmb-bnl

Adp f Bghkkhmf R xr s dl r Gmb- ’ Snqnmsn(: v v v-adqf fqnto-bnl

B nmWhp F p nto ’BqYmadqq x Snvmrgho) OY-(: v v v-bnmYhqfqnto-bnl ;t whokWr s Gmb- ’ UYqdmmdr) Ptd-(: v v v-YtwhokYrs-bnl

Chdp Gms dp mWs hnmWk OkWr s hb r Gmb’ T mhnmuhkkd) Nms-(: v v v-chdqhmsdqmYshnmYk-bnl

Stp mdp F p nto Gmb- ’ R dYs skd) VYrg-(: v v v-stqmdqfqnto-mds

Cdks W S R xr s dl r Gmb- ’ Q hbgehdkc) V hr-(: v v v-cdks Ys rxr-bnl

Ephfdk M np s g ; l dphbW ’ D Yrs Ctmcdd) Hkk-(: v v v-eqhfdk-bnl

Gmid b s hnm Cdon s F p nto ’ L Yq j gYl) Nms-(: v v v-hmidbshnmcdons-b Y

Nmd vYx sn gdko rnkud sgd kYantq rgnqsY fd hr sn fhud sgd rjhkkdc sqYcdr lnqd Y ssdmshnm hm ghfg rbgnnkr Ymc

bnkkdfdr- NmsYqhn hmidbshnm lnkcdq Lnkcdc Oqdbhrhnm Bnlonmdmsr hr kdYchmf sgd bgYqfd-

Ax LZqj Rsdogdm’ dchsnq

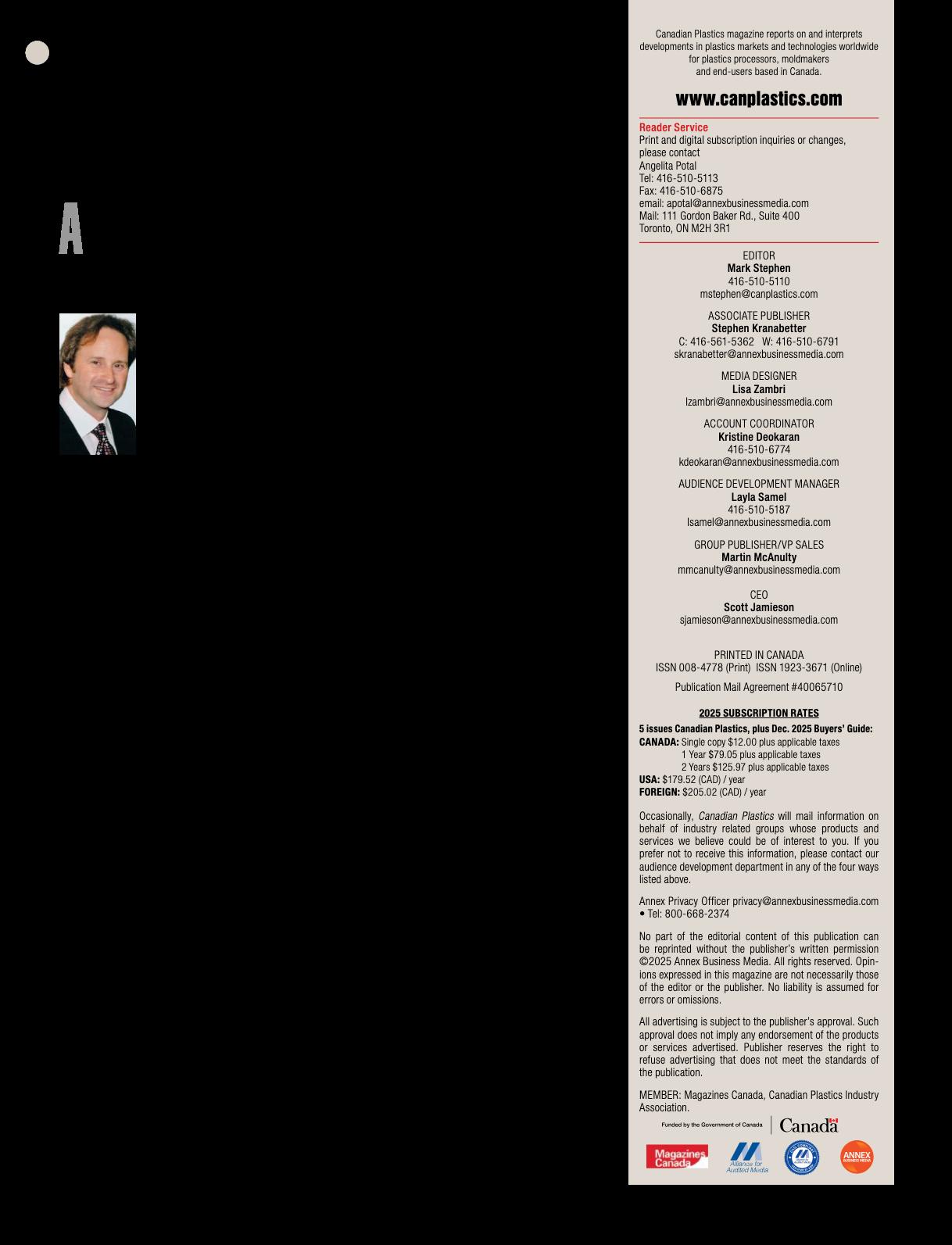

Phe labou r shor tage is a bit li ke the weat her: ever yone c ompla i ns, but nobody ever seems to do a ny th ing about it. I n recent yea rs, the sk ills shor tage i n C a na d ia n m a nu fa ct u r i ng ha s become acute I n 2022, Statistics Ca nada repor ted 47 4 per cent of Ca nadia n ma nufact u rers st r uggled to f ind sk illed workers, compa red to 39 per cent in 2016; a nd 85 p e r c ent r ep or t e d u nd e r st a f f i ng

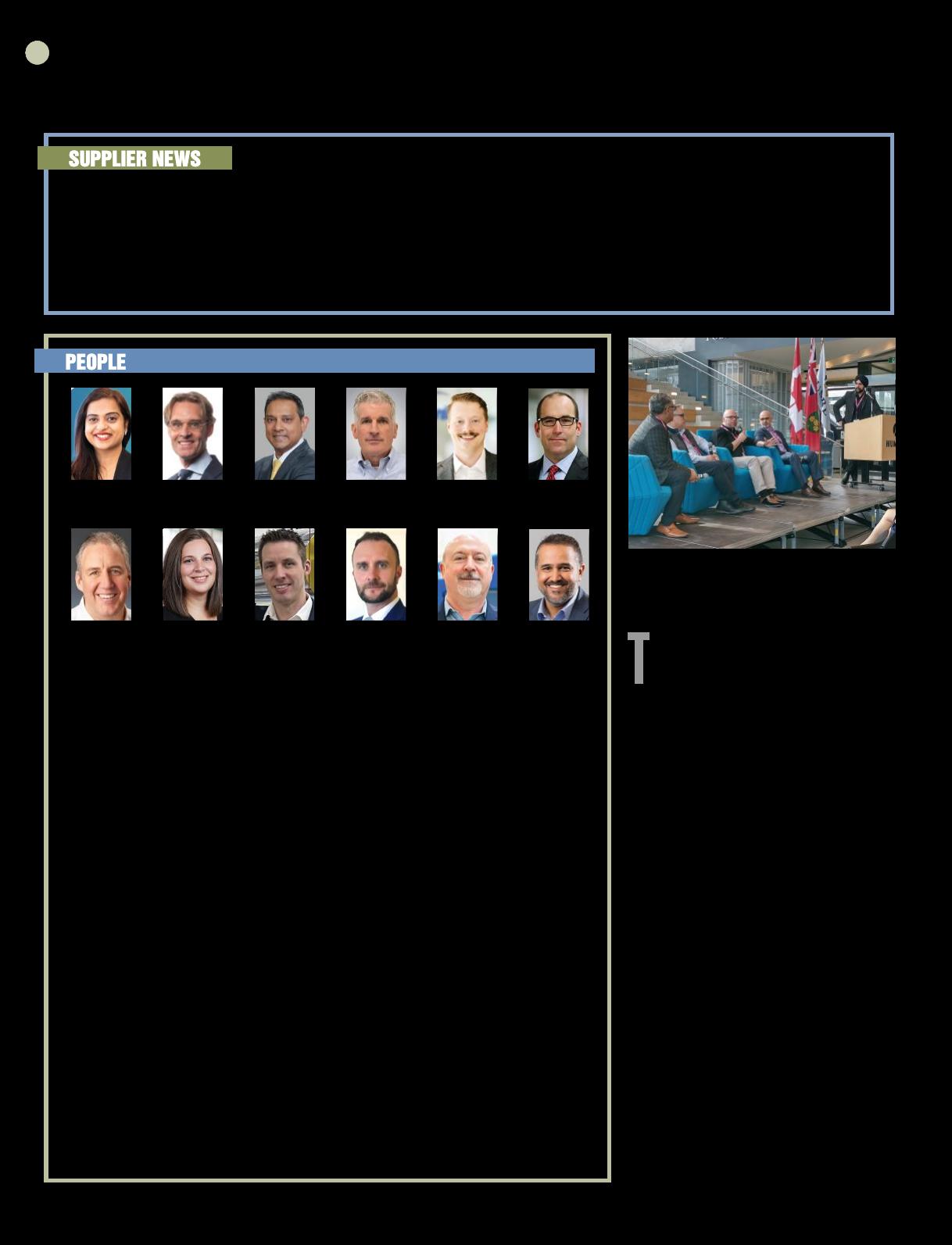

According to a Deloit te st udy, access to sk illed ta lent now out ra n ks factors li ke t a xes a nd access to mater ia ls when it comes to a compa ny’s competitive edge. It’s sad reading, but it’s not new – the plastics ma nufact u r ing indust r y has been d e a l i ng w it h st a f f i ng sho r t a ge s fo r decades. One good way to f ix th is is by br idging the gap between education a nd i ndust r y, a nd O nt a r io -ba se d i nje ct ion molder Molded P recision Components ( M PC) is explor ing th is th rough st rategic pa r t nersh ips, educationa l out reach, a nd work force development in itiatives.

Nestled nor t h of Ba r r ie in r u ra l O roMedonte, M P C is a f ul l-ser vice engineer ing, product development, a nd precision molding facility Founded in 1980 under the or igina l na me Molded Plastic Consult a nts, t he f i r m was r un for the next qua r ter cent u r y as a simple protot y p e mold i ng shop w it h just a few mach ines, but was reinvented in 20 06 when plastics i ndust r y vetera ns David Ye a m a n a nd T hom a s Wo eger er pu rchased M PC’s assets with the goa l of t u r n i ng it i nto a ver t ica l ly-i nt eg r at e d engineer ing a nd cont ract injection molding pa r tner. M PC cu r rently utilizes its i n-house tool i ng op erat ion to produce

Eqnl kde s9 : m Yooqdmshbd vnqjr vhsg CYqq xk F q Ysqhw nm sgd L O B rgno eknnq-

upwa rds of 70 m i l l ion h ig h-pre cision plastic pa r ts each yea r, f rom la rge automot ive comp onent s to m ic ro pa r t s as sma ll as 0 3 g ra ms But despite its cutting- edge tech nology a nd robust g row th, sta ff ing rema ins a cha llenge. “I n 2022, we expa nd e d i nt o a s e c ond fa ci l it y, wh ich increased ou r production capacity by 4 0 per cent,” sa id tooling ma nager Da r r yl G rat r ix. “But to ma xim ize that capacit y, we need sk illed t radespeople, a nd they’re not easy to f ind ”

Rather tha n wa iting for solutions to m ag ic a l ly em e rge, M P C is a c t ively work ing to cultivate a new generation of sk illed t rades professiona ls. T he compa ny has long suppor ted apprenticesh ip prog ra ms, typica lly employing at least o n e m old m a k i ng a n d o n e ge n e r a l mach in ist apprentice at a ny given time. However, given the sca le of the labou r

gap, more needs to be done, a nd G rat r ix ha s t a ken a lea d i ng role i n out rea ch effor ts, focusing on cha nging perceptions about sk illed t rades a mong educators a nd st udents “Ma ny teachers a nd guida nce counselors default to steer ing undecided st udents towa rds a r ts prog ra ms because t hat’s what t hey k now,” G r at r i x sa id “But a genera l BA deg ree won’t necessa r ily lead to a stable ca reer. We wa nt h igh school a nd college adm in ist rators to recogn ize sk illed t rades as a viable a nd rewa rding option.”

To th is end, M PC has st rengthened its engagem ent w it h t he O nt a r io Yout h Apprenticesh ip P rog ra m (OYA P), wh ich enables h igh school st udents to b egi n t ra in ing in sk illed t rades wh ile ea r n ing thei r diploma. G rat r ix is a member of the advisor y com m it tee for OYA P’s precision meta lwork ing sk ills sector, a nd has

facilitated pla nt tou rs of M PC for guida nce counselors a nd educators “W hen they see ou r adva nced automation a nd h ightech envi ron ment, thei r perspective cha nges,” he sa id. “T hey rea lize that ma nufact u r ing isn’t the da rk, outdated indust r y they assumed it was ” M PC has a lso been added to Simcoe County’s list for h igh school f ield t r ips, so that st udents ca n see a moder n plastics ma nufact u r ing pla nt f i rstha nd a nd ta l k to the sta ff Additiona lly, G rat r ix regula rly spea ks at schools, giving st udents h is di rect insights into ca reers in toolma k ing a nd mach in ing.

M PC’s effor ts extend beyond seconda r y schools T he compa ny has a long-sta nding relationsh ip with Georgia n College in Ba r r ie, with more tha n 20 Georgia n a lum n i – including G rat r ix h imself – now employed at M PC. I n 2020, M PC collaborated with Georgia n st udents to develop a n automated robot cell for one of its cube molding mach ines, a nd M PC a ims to deepen th is pa r tnersh ip going for wa rd. T he compa ny is actively involved in the implementation of Georgia n’s Peter B Moore Adva nced Ma nufact u r ing Cent re, a hub for tech nologica l in novation a nd indust r y engagement. M PC is a lso a sponsor of the Sa ndbox Cent re in Ba r r ie, a network ing a nd mentor ing space for ent repreneu rs; a nd of the Cyber Gnomes, a tea m of loca l h igh school st udents competing in the a n nua l F I RST Robotics L eague competition

EqtrsqYsdc vhsg oqn–sr adhmf knrs sn tmmdbdrr Yqw rbqYo bnrsr3 Lhmhlhyd vYrsd vhsg CwmY Otqfd sgd lnrs deedb shud bnlldqbhYk otqfhmf bnlontmc hm sgd hmctrsqw- Uhsg nudq 0. wdYqr ne hmmnuYshnm CwmY Otqfd oqnuhcdr tmdptYkdc oqnctb s Ymc sdbgmhbYk rtoonqsNtq btrsnldqr dminw ntsrsYmchmf btrsnldq rdq uhbd Ymc qdkhYakd qdrtksr- RsYqs qdctbhmf rbqYo bnrsr Ymc hmbqd Yrhmf oqn–sr sncYwPdptdrs R eqdd r Rloid ne 8wmR Dtqfd Rmc rdd enq wntqrdie8hranudq sgd 8heedqdmad744 4.6 7630 vvv-cwmRotqfd-anl

Eqnl kde s9

G rat r ix ack nowledges that expa nding tech n ica l education isn’t wit hout cha l lenges, pa r ticula rly when it comes to f undi ng “Sk illed t rades prog ra ms a re expensive to r un, a nd schools a nd col leges of ten face budget const ra i nts,” he sa id “But t hat doesn’t mea n they need to spend more Sometimes it’s about rea llocating resou rces effectively, a nd pr ior itizing h igh- dema nd t rades prog ra ms li ke moldma k ing would ma ke a sign if ica nt impact ”

M PC’s advocacy effor ts a lso extend to the provincia l level. I n 2023, Onta r io M in ister of E ducation Jill Dun lop visited M PC’s facility to discuss st rategies for increasing sk illed t rades exp osu re i n scho ols “We t a l ke d about t he i mp or t a nc e of ha nds- on lea r n ing a nd of closing the gap between education a nd indust r y,” G rat r ix sa id “She understa nds the u rgency, a nd we’re hopef ul that rea l cha nge will come ”

A nd look ing a head, M PC is consider ing launch ing its own in-house apprenticesh ip prog ra m, with st r uct u red t ra in ing for both moldma k ing a nd mold set up “T h is is someth ing we’re ser ious about,” G rat r ix sa id. “We have tea m members f rom Eu rope who’ve gone th rough world- class Eu ropea n apprenticesh ip systems, a nd they’re eager to sha re thei r exper tise ”

U ltimately, M PC’s m ission is la rger tha n just f illing its own job vaca ncies: it’s about t ra nsfor m ing how sk illed t rades a re perceived by st udents in thei r for mative yea rs “Ma nufact u r ing today is h igh-tech, automated, a nd offers i ncredible ca reer oppor t un ities,” G rat r ix sa id. “H igh schools a nd colleges have a vit a l role to play in solving the sk illed t rades shor tage, but they need to reth in k how they guide st udents P rog ra ms li ke OYA P a re g reat for st udents who k now they wa nt to get into the sk illed t rades, but we wa nt to cast a wider net to reach the k ids who don’t k now what they wa nt to do, to ma ke them awa re that the t rades a re a good oppor t un ity. I f we ca n cha nge the na r rative begin n ing in seconda r y school, we ca n help secu re the f ut u re of ou r indust r y ”