FLOUR POWER

Packaging finesse key ingredient in specialty baker’s brisk rise up the food chain in the fast-growing flat breads market segment Story on page 12

Page 23

Yuhana Kizilbash, Vice-President, TWI Foods Inc.

Our tankless melters fill themselves. Our SureBead® applicators unclog themselves.

Our Spectra® pattern controls troubleshoot themselves. Our training programs and product manuals are available in a growing variety of languages.

But sometimes bad things happen to good equipment. That’s why we have a global network of customer service support available around the clock, 365 days a year. Our large inventory of ready-to-ship replacement parts are housed in a growing network of warehouses around the world, meaning they can be shipped to your plant quickly – keeping downtime to a minimum.

nVest for Success

Get the complete package with the lowest total cost of ownership. To learn more, contact your Nordson representative, or call (800) 463-3200.

www.nordson.com/hotmelt

/NordsonAdhesiveSystems

/Nordson_HotMelt

/NordsonAdhesiveSyst

Videojet customers depend on innovative marking and coding solutions for reliable performance. For over 40 years, Videojet has set new standards for quality, productivity, service and training.

Videojet customers depend on innovative marking and coding solutions for reliable performance. For over 40 years, Videojet has set new standards for quality, productivity, service and training.

www.videojet.com

www.videojet.com

Videojet customers depend on innovative marking and coding solutions for reliable performance. For over 40 years, Videojet has set new standards for quality, productivity, service and training.

OCTOBER

2015 VOLUME 68, NO. 10

SENIOR PUBLISHER

Stephen Dean • (416) 510-5198

SDean@canadianpackaging.com

EDITOR

George Guidoni • (416) 510-5227

GGuidoni@canadianpackaging.com

FEATURES EDITOR

Andrew Joseph • (416) 510-5228

AJoseph@canadianpackaging.com

ART DIRECTOR

Mark Ryan • (416) 442-5600 x3541 mryan@annexnewcom.ca

PRODUCTION MANAGER

Barb Vowles • (416) 510-5103

BVowles@annexnewcom.ca

CIRCULATION MANAGER

Anita Madden • 442-5600 x3596 AMadden@annexnewcom.ca

ANNEX PUBLISHING & PRINTING INC.

Vice-President Annex Business Media East Tim Dimpoloulos tdimopoulos@canadianmanufacturing.com

President & CEO • Mike Fredericks mfredericks@annexweb.com

HOW TO REACH US: Canadian Packaging, established 1947, is published monthly by Annex Publishing & Printing Inc.

80 Valleybrook Drive, North York, ON, M3B 2S9; Tel: (416) 510-5198; Fax (416) 510-5140.

EDITORIAL AND ADVERTISING OFFICES:

80 Valleybrook Drive, North York, ON, M3B 2S9; Tel: (416) 442-5600; Fax (416) 510-5140.

SUBSCRIBER SERVICES: To subscribe, renew your subscription or to change your address or information, contact us at 416-442-5600 or 1-800-387-0273 ext. 3555.

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE): Canada $72.95 per year, Outside Canada $118.95 US per year, Single Copy Canada $10.00, Outside Canada $27.10. Canadian Packaging is published 11 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

©Contents of this publication are protected by copyright and must not be reprinted in whole or in part without permission of the publisher.

DISCLAIMER: This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice. You should not act on information contained in this publication without seeking specific advice from qualified engineering professionals. Canadian Packaging accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. Canadian Packaging receives unsolicited materials, (including letters to the editor, press releases, promotional items and images) from time to time. Canadian Packaging, its affiliates and assignees may use, reproduce, publish, republish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

PRIVACY NOTICE: From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us via one of the following methods:

Phone: 1-800-668-2374 Fax: 416-442-2191 Email: vmoore@annexnewcom.ca

Mail to: Privacy Office, 80 Valleybrook Drive, North York, ON M3B 2S9

PRINTED IN CANADA

PUBLICATIONS MAIL AGREEMENT NO. 40065710, ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

We acknowledge the financial support of the Government of Canada through the Canada Periodical Fund of the Department of Canadian Heritage for our publishing activities. Canadian Packaging is indexed in the Canadian Magazine Index by Micromedia Limited. Back copies are available in microform from Macromedia Ltd., 158 Pearl St., Toronto, ON M5H 1L3

UPFRONT

PACKAGING SENSES WORKING OVERTIME

Modern consumers expect a lot from their product packaging these days, and rightly so. Being an integral part of a consumer product’s cost structure and premium, it is not unreasonable for people paying good money for that product to anticipate something more than just rudimentary product protection and helpful guidance on the store-shelf.

In today’s social media-obsessed consumer marketplace, the relentless quest for instant gratification and peer approval is driving insatiable demand for packaging as the product’s focal talking point, rather than merely a protective container.

While this new reality naturally presents an epic challenge for many packaging designers and suppliers mandated to keep the price of packaging in line with the consumers’ willingness to pay for it, it also offers a game-changing opportunity to elevate modern packaging to its next natural higher level of superior consumer engagement, education and, wherever possible, entertainment.

The key to doing that successfully lies in leveraging today’s widely available communication technologies across all the five basic tactile senses comprising the full packaging experience: sight, sound, touch, smell and taste.

According to recent market research complied by leading global beverage packaging manufacturer Crown Holdings, Inc. of Pennsylvania, Pa., each of the five sensory experiences can be vastly enhanced with correct application of smart-phone and other wireless communication technologies to leave a long-lasting impression on the consumer, helping to nurture priceless brand loyalty and recognition that ultimately outlasts and outweighs the initial costs of making it happen.

• Sight. With the widespread use of holographic foils and high-definition printing to create

dazzling visual effect to draw consumer’s attention now becoming so ‘me-too’ commonplace, packaging designers would do themselves no harm by exploring the opportunities enabled by augmented reality to get an extra edge over the competition.

“The use of AR to show what’s inside the package, mobile applications to educate consumers, and OLEDs that light up or change color could all bring new visuals to packaging, according to Crown’s recently-published marketing think-piece aptly titled Creating the Sixth Sense of Packaging

• Sound. Traditional reliance on the popping sounds of jars and beverage cans being opened to convey product freshness and package integrity is also largely a 20th Century experience that, according to Crown, could be vastly enhanced with “the employment of micro-speakers to allow brands to create new sound effects in response to a consumer’s interaction with the package.”

• Touch. Likewise, today’s use of convenience enhancements like easy-open ends, tactile finishes and ergonomic shaping should be a prelude to widespread use of “technologies that warm products inside the container or vibrate the package to elevate consumer interaction,” according to Crown.

• Smell. Product opening features that unleash the product’s aroma into the consumer’s nostrils could also be taken up a notch, Crown suggests, through “the adoption of fragrant finishes and new scent technologies on the packaging itself to emphasize product flavors.”

• Taste. Barriers to light and oxygen to maintain product flavor are fine and well, but they’re really a given in today’s marketplace. Imagine, on the other hand, “The engagement of unique sensors that can ‘taste’ a product’s freshness to advise a consumer whether the product is still fit to consume.”

Sound advice, no pun intended. Let’s now see what we can do with it.

Continuous capital equipment investments help Toronto-based processor grab a larger slice of the international market with its expanded line-up of diverse highquality baked ethnic foods. Cover photography by John Packman

FEATURES

Pre-show callout for Canadian Packaging’s own Top 50 Packaging Ideas tabletop expo 2015 21 FINDING ONE’S BEARINGS By Ian Rubin

A primer on machinery bearings and the lubricating greases to keep thei ndsutry’s wheels turning at optimal speed.

23 HIGH ROAD TO FOLLOW By Andrew Joseph Energetic tomato processor and co-packer steps in to fill the economic void left behind by Heinz Canada’s heartbreaking departure.

28 ACTIONS SPEAK LOUDEST By Andrew Joseph

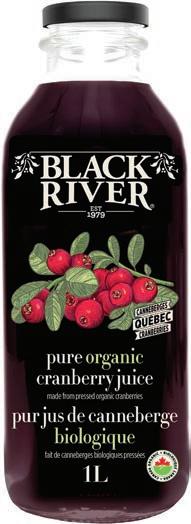

Upstart label and shrinksleeve manufacturer helps beverage producer to make a big splash in the fiercely competitive market segment.

31 INDIVIDUAL FREEDOMS

A new industry white paper examines the benefits of tank less adhesive applicatiing systems.

32 THANKS BUT NO TANKS! By Nick Long How tank-free technology can benefit hot-melt adhesive applicating quality and performance.

FLOUR POWER By George Guidoni

KRUGER PLANS A $250-MILLION PAPER MACHINE REBUILD

Montreal-headquartered Kruger Packaging L.P. says it will spend $250 million over the next 20 months to convert the No. 10 newsprint machine (PM10) at its paper mill in Trois-Rivières, Que., to the production of 100-percent recycled, lightweight linerboard with annual capacity of 360,000 metric tonnes.

Backed with a $190-million loan from the Quebec government, which will own a 25-percent stake in the company, the massive modernization project will help secure the 270 jobs at the mill, according to Kruger, which will keep producing

newsprint on the No. 10 machine until two months prior to the end of the conversion in 2017.

Citing “huge growth in North America and around the world, as packaging manufacturers seek to produce increasingly lighter and stronger products,” Kruger plans to sell most of the mill’s linerboard output to the company’s boxmaking facilities in LaSalle, Que., and Brampton, Ont., with remainder to be sold on open markets.

minister for small and medium enterprises Jean-Denis Girard jointly mark announcement of a $250-million capital investment project at Kruger’s Trois-Rivières mill.

After the conversion is complete, the Trois-Rivières mill will continue to produce newsprint on its second PM7 machine, according to Kruger, which currently employs about 800 people at operations across Canada, including 620 in the province of Quebec.

NEW OWNER PLANS MAJOR UPGRADE FOR KITCHENER BOXMAKING FACILITY

Paperboard packaging producer PaperWorks Industries, Inc. says it will spend $11 million in various capital upgrades over the next year to expand production capacity of the Boehmer Box folding-carton manufacturing facility in Kitchener, Ont., which PaperWorks acquired as part of its buyout of the CanAmPac group of Napanee, Ont., this past summer.

According to Paperworks, headquartered in Bala Cynwyd, Pa., the investment will include installation of new sheet-fed lithographic printing presses and related carton-making equipment, as well as upgrading the 340,000 square feet of manufacturing and warehouse space.

“We purchased Boehmer Box because of its demonstrated excellence in operational effectiveness, customer service and quality,” says PaperWorks Industries president and chief executive officer Kevin Kwilinski, noting the expansion will enable the Kitchener plant to increase its output levels by almost 75 per cent.

“We now want to leverage that strong foundation to build a best-in-class site,” Kwilinski states.

“The goal is to deliver even better quality and service to our growing folding-carton customer base—from concept to carton commercialization,” says Kwilinski, adding the upgrade will create about 150 new jobs in all areas of prepress and production over the next year at the Kitchener plant, which

ATLANTIC REACHES OUT INTO THE U.S. MARKETS

Leading independent Canadian corrugated packaging producer Atlantic Packaging Products Ltd. is continuing to expand its reach in the U.S. markets with last month’s acquisition of the Mansfield, Ohio-based SkyBox Packaging

manufactures folding cartons for a diverse range of products in the dry and frozen food, beverage, pharmaceutical, household goods, personal care and institutional foodservice markets.

On a more downbeat note, however, PaperWorks has also announced plans to permanently shut down operations of the 165,000-square-foot, 150-employee folding-carton manufacturing plant in Baie D’Urfé, Que. by the end of 2016.

“We considered many different options across our folding-carton manufacturing footprint in order to improve service levels for our customers, to strengthen our competitiveness, and to our support long-term growth,” Kwilinski says.

“Ultimately, our decision was driven by the desire to position folding carton production closer to geographic areas in which the majority of our customers are located,” says Kwilinski, adding the plant closure will leave PaperWorks with two Canadianbased folding-carton manufacturing operations in Kitchener and Hamilton, Ont., along with seven production facilities located across the U.S.

Says Kwilinski: “Over the next several months, PaperWorks will work with customers serviced by the Baie D’Urfé facility to ensure a smooth transition to other company manufacturing facilities.”

Following up on this year’s earlier formation of BlackHawk Corrugated in Carol Stream, Ill.—a joint venture with the StandFast Group —Toronto-based Atlantic Packaging says the acquisition will significantly enhance its presence in the U.S. markets for mid-sized brands across the industrial, food and consumer end markets, who will be served by the 100,000-square-foot Mansfield facility equipped with advanced flexographic printing, die-cutting and specialty folder/gluer equipment.

“SkyBox is a great company with a leadership team that shares many of the core values we do,” states Atlantic Packaging president Dave Boles.

“The acquisition is a natural fit that acts as a seed investment to grow our manufacturing platform in Ohio,” says Boles. “Mansfield is a terrific location from which to grow thanks to its proximity to multiple key target markets.

“Under the continued leadership of Marc Miller, Marty Rice and the rest of the SkyBox team, we’re confident we will see continued success that will add growth and create jobs,” says Boles. “Our leadership team agreed early on that this would only be possible if our partner was a company that share our values and has a growth plan that views the SkyBox organization and location as a foundation for our continued growth in the future.”

Adds SkyBox president Marc Miller: “Our longterm investment perspective has served SkyBox well over the past 15 years, and last year Marty Rice and I initiated a search for a partner that shares our ambition, operates with an entrepreneurial culture, and brings new capabilities and reach to the table.

“In Atlantic, we found exactly what we were looking for and more,” Miller states. “We’re very excited about the future and the opportunity to be working with Atlantic in the development of their strategic plan.”

NEW ENERGY DRINK FLAVOR ADDING TO THE CELEBRITY HYPE

Revving up your engines with a refreshing energy drink has just gotten a whole lot tastier for Canadian consumers looking for a quick and healthy energy boost to help them stay on top of things through their busy day—thanks to the new Hype Energy Mojito energy drink recently launched in Canada by a beverage brand founded by French car racing legend Bertrand Gachot.

Produced and canned by the Mississauga, Ont.based Cotts Beverages Canada, the new sleek aluminum cans of the carbonated beverage—containing no preservatives or aspartame—were developed specifically to help beat the intense summer heat with a well-balanced mix of mint and lime in an upscale package that is reported to count the notori-

ous celebrity diva Kim Kardashian-West, no less, as one of the brand’s best-known fans.

Loaded with five essential vitamins, taurine and caffeine to deliver a robust pick-me-up, the new Hype flavor currently retails from Ontario east through Newfoundland and Labrador at popular retail and convenience store chains such as Couche-Tard, Sobey’s, Loblaws, Petro Canada, Shell and Winks

Launched in 1984 as one of the first energy drink brands in the global market by Gachot—a former Formula 1 circuit racing driver and 24 Hour Le Mans winner—the Hype brand was launched in the Canadian market in 2004, having evolved into a popular beverage line through active sponsorship of the Montreal Grand Prix Formula 1 race and popular music events such as the Ever After Music Festival in

Kitchener, Ont., and MEG (Electronic Music Festival) in Montreal.

Nowadays available in 45 countries and manufactured at locations in the U.S., Canada, The Netherlands, Austria and Poland—the Hype Energy drinks brand, the official sponsor of the Sahara Force India 2015 Formula 1 team, is now retailed in Canada in five unique flavors and formulations, also including:

• Hype MFP: Classic energy drink flavor that delivers maximum energy;

• Hype MFP Zero: Same taste profile as MFP but with zero calories;

• Hype UP: A mix of berry and cool mint loaded with 10 vitamins.

• Hype Enlite: A sophisticated drink with four vitamins and only 24 calories.

From Left: Québec minister of forests, wildlife and parks Laurent Lessard; Québec premier Philippe Couillard; Kruger Inc. chief executive officer Joseph Kruger II; and Québec

Atlantic Packaging president Dave Boles.

Paperboard production at Boehmer Box plant.

A NEW PAC PARTNERSHIP TO BOOST THE USE OF PRINTABLE ELECTRONICS

Toronto-based industry group PAC, The Packaging Consortium has struck a new strategic partnership with the recently-formed Canadian Printable Electronics Industry Association (CPEIA) to advance the development and adoption of new products and applications enabled with printable, organic and flexible electronics for the global packaging industry.

According to PAC, the newly-launched IntelliPACK initiative—also supported by the National Research Council of Canada and The Netherlands-based Intelligent Packaging Industry Association (AIPIA) —will work “to assemble the ecosystem required to bring new PE

NEW U.S. PLANT A GREEN SHOWCASE

Canadian paper products giant Cascades Inc. has officially unveiled the state-of-the-art Greenpac Mill LLC linerboard plant in Niagara Falls, N.Y., with annual capacity to produce over 540,000 short tons of lightweight linerboard from 100-percent recycled fibers.

Built and operated by Cascades’ Norampac corrugated division since July of 2013, the Greenfield site employs 135 staff and many advanced papermaking technologies to produce the new Greenpac XP brand of recycled linerboard said to offer strength and print quality, while maintaining a lower basis weight than traditional linerboards.

“This investment is the tangible result of the deployment of our strategic plan aiming to position Cascades as a leader in the packaging industry in terms of both productivity and profitability,” says Mario Plourde, president and chief executive officer of the Kingsey Falls, Que.-headquartered Cascades, noting the innovative manufacturing process for producing Greenpac XP requires significantly less fibers.

Lauded as the company’s “most ambitious project in 50 years,” the Greenpac Mill facility boasts the automation of numerous operations traditionally performed manually, a state-of-the-art water treatment system, high-performance drying equipment, and the reuse of process water, according to Cascades.

(printable electronics)-enabled packaging solutions to market through webinars, workshops and conference participation” via a collaborative research, development and commercialization effort.

Says PAC president and chief executive officer

James Downham: “IntelliPACK represents the leadership, collaboration and knowledge sharing we believe is crucial to drive progress throughout the entire packaging supply chain.

“Intelligent packaging enabled by PE could dramatically reduce food waste during transport, retailing and at the consumer end, while brand-owners will be able to engage with the consumers like never before through everyday products that are capable of

wireless communication.”

The Ottawa-based CPEIA says the current lack of available wireless communication that can be produced in vast quantities at low cost and consume little power—while being disposable, flexible and even stretchable, have held back the advancement of PE technology for packaging applications so far.

Says CPEIA president and chief executive officer

Peter Kallai: “Our focus is to foster collaboration between the creators and integrators of PE technologies, with end-users in key market verticals where we believe PE offers a compelling competitive advantage.”

Beer without Borders – Parallel 49 team breaks the rules to create break-through brews

The 49th parallel marks the border between Canada and the U.S., but it’s no barrier for Vancouver-based Parallel 49 Brewing Company, who plans to share its zany band of more than 30 beers with neighbors to the south. Its flagship brand, Gypsy Tears red ale, hints at the brewer’s wanderlust. Other creations allude to the fun that is a pivotal part of the brewery’s brand: Hoparazzi lager, Old Boy brown ale, Seed Spitter wheat beer, Filthy Dirty India pale ale, and Tricycle grapefruit shandy - to name just a few.

A “work of art” crafting the best beers

Starting out as a brew pub in 2008, Parallel 49 outgrew its startup Chinese Monobloc and replaced it with a krones/kosme Monobloc comprised of a Sensicol labeler, a Jetclean rinser and a Barifill filler (its first “authentic” filler) along with a Checkmat F-HF to ensure an exact fill.

The attraction of the new Monobloc? The small footprint belies its utility and speed: It runs at up to 10,000 bottles per hour and changeover can be done during a lunch break, so there’s little standstill on the line. Plus, Parallel 49 has found krones service to be “incomparable.” It’s an unbeatable combination for the best of beers.

To make the best of your brew, contact krones today.

Cascades officials and local dignitaries cut the ribbon on the Greenpac facility.

PAC president Jim Downham.

RADIO WAVES

FIRST GLANCE

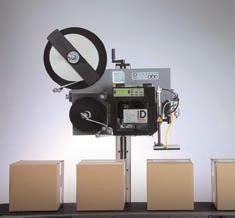

FOX IV Technologies, Inc. offers a broad line-up of fullyautomated RFID (radio frequency identification) systems to provide CPG brand-owners and manufacturers with powerful and highly accurate track-and-trace capabilities across the full range of product identification, item-level tracking, inventory management, pallet tracking, WIP (work-in-progress), compliance labeling and other supply chain management applications. Powered by high-quality Zebra, Datamax-O’Neil, SATO, Printronix and Avery-Dennison print engines, the all-in-one RFID printer-applicator can write, verify, print and apply fully-integrated RFID compliance encoding solutions at high throughput speeds, with models available to print and encode HF (high-frequency) tags as well as most commonly used UHF (ultra high-frequency) tags such as the UHF EPC Gen 2. Boasting modular design, short pitch encoding, auto-calibration, and highly accurate tag placement and application, the company’s proprietary Tag Handling System technology enables any ‘out-of-spec’ tags to remain on the label liner and out of the production process to facilitate uninterrupted system operation.

FOX IV Technologies, Inc. 4 02

BLOCK PARTY

capacity magazine holding 3,000 blanks—to ensure optimal productive machine uptime, as well as quick product changeovers.

Standard-Knapp

Weber Packaging Solutions is pleased to announce the appointment of Michael J. Brown to Executive Vice-President of North America.

Bringing over 20 years of executive leadership experience developing and managing highperformance teams within the industrial/printing category in North America, Michael was named Vice President and General Manager of Weber Marking Systems – Canada in January of this year.

The newly-patented BLOCK-BUSTER hydraulic bulk bag conditioner from Flexicon Corporation employs hydraulically-actuated rams that automatically adjust in height during conditioning cycles to accommodate a broad range of bag sizes from short to extra-tall. As well as providing about two meters of vertical travel—roughly doubling the range of most conditioners employing scissor lifts to raise the bag—the system’s fixed-height turntable also reduces loading deck height by about a half, according to the company. Ideal for loosening bulk materials that cannot be loosened by pneumatically-actuated flow promotion devices integral to bulk bag dischargers, the BLOCK-BUSTER can be easily programmed by the user to select single or multiple heights at which the rams condition the bag; the amount of pressure applied by the rams’ contoured end plates; the frequency of ram actuations; and the number of 90-degree rotations of the turntable to ensure optimal loosening of solidified materials throughout the bag for optimal discharge through the bag spout.

With his years of experience, leadership and proven performance, his abilities and success in the NA marketplace make him a key member of the Weber Executive Team as we continue to grow our position as a leader in the industry.

A leading innovator in the design, engineering, manufacture and supply of high-performance pressure-sensitive labels and labelling systems, Weber has been bringing innovative products to our customers for over 80 years.

Flexicon Corporation 4 03

SETTING THE STANDARD

Standard-Knapp’s new 298 Tritium tray-shrink packer is a highly versatile and reliable system designed for high-speed processing of tray, pad and unsupported pack styles. Featuring an innovative proprietary Robo-Wand wrapping module that makes it capable of running up to 120 trays per minute and providing a consistent tight, wrinklefree wrap—while also offering multi-axis control for limitless packing possibilities without the need for change parts. The highthroughput machine comes with a standard magazine capable holding 1,500 blanks, or an extended-

404

VIAL INTENT

Designed for high-speed, high-precision filling and capping of micro-vials and small bottles in critical pharmaceutical packaging applications, the new model MB 25 Monoblock filler/capper from ESS Technologies employs a series of strategically-positioned, highly-sensitive no-bottle/co-cap/ no-fill sensors to prevent filling in case of a missed microvial, and it can also be ordered with the net weigh filling option—with the microvial being weighed before and after it is filled—to ensure extremely precise amounts of product. Once the filling is complete, a two-stage servo-driven capping system first picks and places a cap onto the vial and applies a slight amount of pre-torque to seat it, after which the system’s starwheel indexes the microvial to the final torque station for application of the final, pre-programmed amount of torque to seal the cap securely into place.

ESS Technologies

4 05

CLEAR ADVANTAGES

Clear Lam Packaging, Inc. has launched an innovative new flexible, stackable PrimaPak sixsided package with a reclosable feature made from a single roll of flexible packaging film on the model XYT15 vertical form-fill-seal (VFFS) bagging machine manufactured by Triangle Packaging Machinery Co. as part of the two companies’ recently-signed global licensing agreement. Designed as a flexible lightweight alternative to rigid cans, bottles, jars and trays in applications such as snack products, cereal, coffee, detergent pods, pet food, cheese and produce, the PrimaPak is said to retain its shape even when empty—providing superior merchandising compared to stand-up pouches and similar packaging that may fall over—with Triangle’s model XYT15 bagger capable of churning out up to 100 PrimaPak packages per minute.

Clear Lam Packaging, Inc.

4 06

BAG RECYCLING PROGRAM GIVES PET OWNERS A CLEAR GREEN CHOICE

Caring for the environment comes rather naturally to animal lovers, and with a helping hand from the world’s leading waste recycling specialists TerraCycle, displaying their affection for both their pets and Mother Nature has just gotten a whole lot easier.

Starting last month, Canadian consumer who purchase the new TruFood line of grain-free, raw-inspired dog and cat food products produced by Wellness Natural Pet Food of Tewksbury, Mass.—retailing across Canada at PetSmart and numerous independent retailers—can have the brand’s packaging recycled after use through TerraCycle’s Wellness Pet Food Brigade program, which collects discarded TruFood bags for use in the manufacture of new consumers products such as park benches, bike racks and pet food bowls, among many others.

By registering for the program online at www. TerraCycle.ca, consumers can collect redeemable ‘points’ for every shipment of TruFood bags weigh-

ing at least two pounds, using those points to make a donation to their chosen favorite school, charity or non-profit organization.

“Until now, almost all pet food packaging has ended up in landfills,” says Leslie Tan, general manager of TerraCycle Canada in Toronto.

“We’re thrilled to have the support of Wellness as we aim to effect positive change in this industry and give pet owners a more sustainable option,” says Tan, noting that participating in the program is entirely free, including shipping.

“Individuals can start collecting their TruFood bags by placing them into any standard cardboard box, and when they have collected two pounds, they can log into their account, print

TALE OF THE TAPE’S HAPPY ENDING

Leading life sconce and industrial product conglomerate 3M Company says it has achieved a nearly solvent-free manufacturing process in the production of the company’s bestselling 3M Scotch Box Sealing Tapes at its manufacturing facility in Greenville, S.C.

According to the St. Paul, Minn.-headquartered 3M, the plant’s “virtually free of organic solvents” manufacturing process will yield GHG (greenhouse gas) emission savings of about 100 metric tonnes per year, without any impact on the tapes’ quality or performance.

Having manufactured the adhesive side of Scotch Box Sealing Tape without solvents since 1975, the Greenville plant has developed a new way to make the release coating (non-sticky) side of the tape without the addition of solvents in a cost-effective way that will not affect the product’s pricing, 3M says.

“At 3M, nothing is more important to us than improving lives and enriching the communities in which we live and work,” says 3M’s Industrial Adhesives & Tapes Division manager of sustainability Teresa Borzcik.

“We take responsibility to establish sustainable practices and continually improve our products and processes,” says Borzcik, adding the Greenville facility is now formally recognized as a Responsible Tape Manufacturer by the Pressure Sensitive Tape Council organization.

“By eliminating volatile organic compounds from the manufacturing process of our Scotch Box Sealing Tapes, we continue to invest not only in the superior quality of our products, but also in our customers and communities.”

15_0855 CANPackaging_OCT_AK02 Mod: August 4, 2015 2:05 PM Print: 08/11/15 11:41:57 AM page 1 v7

out a free UPS shipping label, and then either drop the boxes off at a UPS store or call in a request for a free next-day pickup,” Tan explains.

“There are big changes happening in the pet food industry, with a lot of effort being made to ensure that pet ownership is more sustainable, and we’re excited to be part of this,” Tan adds.

Adds Wellness senior manager of marketing communications Chanda Leary-Coutu: ” We are very excited for our partnership with TerraCycle,

“Many of our consumers embrace a green lifestyle,” Leary-Coutu points out, “and we are happy to offer an easy way for them to recycle their pet food packaging, which we know is important to them.”

COMPOSTABLE FILM A GREEN EVOLUTION

With sound nutrition being an integral part of children’s growth and development, South African-based cereals and dried-fruit snacks producer KiddieKix is also doing its bit to ensure those children have a clean and healthy world to grow up in by switching its packaging to the biodegradable NatureFlex flexible plastic packaging film made from a renewable resource.

Produced by the U.K.-based packaging films group Innovia Films Ltd, the NatureFlex brand film—independently certified to meet the North American ASTM D6400 and European EN13432 standards for compostable packaging—is helping to reinforce the KiddieKix product philosophy or sourcing only the highest-quality ingredients that are also free from any additives or preservatives, says the company’s founder Alison McDowell.

“Our main aim is take care of our children’s future, which means creating an entirely eco-sustainable product, including the packaging,” says McDowell. “We sampled many compostable materials for our inner packaging and nothing compared to NatureFlex.

“In terms of feel, quality, strength, durability and barrier protection, NatureFlex came out streets ahead of any other product.”

According to Innovia, all NatureFlex brand films begin their life as an allnatural product—namely wood sourced from certi fied plantations operating in strict compliance with leading recognized sustainable forestry standards and principles.

One Size Doesn’t Fit All

Squid Ink’s new family of CoPilot Printing Systems offers 3 different print heights for your different applications.

Squid Ink’s CoPilot 128 is a proven choice for printing small character codes or barcodes on egg cartons, PVC pipe, corrugate cases or more. The CoPilot 382 is ideal for replacing costly print and apply labels or printing GS1 barcodes on the side of a box. The CoPilot 256 fits right in between, making Squid Ink’s CoPilot family the ideal solution for your specific coding and marking applications.

For more information visit www.squidink.com or call 1-800-877-5658 for your local Authorized Squid Ink Distributor today.

Labe L Converting that turns on a dime…

In today’s markets characterised by big market swings and last minute orders, you need a label converter who can respond quickly and at the right price.

If you’re not getting the service you need from your current label supplier, give us a call. We’ve made all the right investments in label printing and converting technology. Take for example our new Nilpeter flexographic press. It has all you need to produce the labels and shrink sleeves demanded by today’s new labeling trends. We

BREAKING BREAD

Ontario bakery turns up the heat in the Canadian baked-goods industry with a diverse product portfolio and cutting-edge packaging competence

BY GEORGE GUIDONI, EDITOR

PHOTOS BY JOHN PACKMAN

As home to one of the most multiculturally diverse population mixes in the world, the so-called GTA (Greater Toronto Area) region offers plenty of opportunities to specialty ethnic food producers to not only make a decent living

by introducing Canadians to exiting new tastes and flavors of the world cuisine, but also make their products an indelible part of the mainstream local food retail landscape.

Which is exactly what the Toronto -based TWI Foods Inc. has done remarkably swiftly with great style and much aplomb since appearing on the scene in 1997 as a fledgling specialty bread, pastries and baked goods producer aiming to serve the growing

South Asian ethnic segment in Ontario and, as it happily turned out, well beyond.

Founded by the husband-and-wife team of company president Ali Kizilbash and vice-president Yuhana Kizilbash, TWI Foods nowadays employs about 250 people at two busy, state-of-the-art production facilities in Toronto and Mississauga.

Over the years, the family-owned commercial bakery has achieved resounding success not just filling a void in the local ethnic markets for fresh-made South Asian- and Middle Eastern-style breads and pastries, but also riding the wave of the Canadian consumers’ growing appetites for more adventurous and exotic world cuisine offerings to the point of having to run its production and packaging operations virtually flat-out to keep up with soaring demand.

Already operating a total of eight lines at the two plants in multishift rotation that often swings into a 24/7 production mode at peak demand periods, the company’s growing diverse product range comprises three main product lines—marketed under Crispy, Sunrize and Crispy St. brand labels—distributed to customers in the retail, foodservice, and private-label markets in more than 200 different SKUs (stock-keeping units).

And not just within Canada, mind you, but also in the U.S. and other growing offshore export markets in the U.K., Germany, Australia, Middle East and Singapore, with Japan expected to follow suit soon.

Little wonder, then, that TWI Foods was a 2013

Produced and packaged at TWI Foods’ state-of-the-art production facilities in Toronto and Mississauga, Ont., the company’s diverse product range comprises a wide variety of authentically-made flat breads and an expansive dessert offering of various types of cookies, biscuits, loafcakes, poundcakes, shortbreads and other high-quality sweet indulgences.

A roll of pre-printed plastic film wound through its places along the Multivac R 245 machine just prior to packing.

One of two high-performance Multivac R 245 packaging machines working side-by-side at the Mississauga plant.

and 2014 finalist in the Ontario Food Exporter Awards competition, with two consecutive annual rankings on the Canada’s 500 Fastest Growing Companies list of the Profit magazine and the finalist award from the financial services giant Deloitte in its annual Canada’s Best Managed Companies rankings.

Coming during some very challenging times for the baked goods industry in general, such fast growth provides compelling testament to the company’s core values of impeccably high product quality, exemplary customer service, keen product innovation, and continuous investment in automated processing and packaging equipment to retain a key competitive edge.

“We work in a very tough and extremely pricesensitive industry,” production manager Hyder Hasan told Canadian Packaging on a recent visit to the company’s smaller, 36,000-square-foot Mississauga facility dedicated exclusively to the production of the round-shaped naan and roti/wrap flat breads, each offered in several different flavor varieties and ingredient formulations.

“It is quite difficult to survive in this industry,” Ali Kizilbash expands, “and since we bake a lot of different varieties of bread, pastries, cookies and so on, we have a lot of serious competitors out there.

“However, we have been able to sustain our growth in the market in large part because our efficient buying practices and continuous improvement,” Kizilbash reveals.

“The biggest challenge in the food industry nowadays is to maintain affordable prices and to maintain high quality standards, which can only be done by efficient management of resources and achieving favorable economies of scale.”

According to Kizilbash, TWI Foods spares no ex-

pense and effort “to deliver our promise of quality to all our customers.”

Says Kizilbash: “We provide comprehensive firsthand quality assurance trainings for our employees, and our in-house laboratory is equipped with stateof-the-art testing equipment and run by a dedicated staff of qualified and fully-trained professionals 24/7.

“We strongly believe in, and have implemented, root cause analysis of QC (quality control) data for

continuous improvement,” Kizilbash reveals, citing the company’s internationally-recognized SQF Level II certification for food safety and implementation of HACCP (Hazardous Analysis Critical Control Points)based quality assurance system in line with the recently-unveiled Food Safety Modernization Act (FSMA).

“We take all customer complaints were seriously, with our higher management personally takingcharge of all the complaints to make sure we fully address the issue and ensure that any repetition of

Inline zipper applicators place press-to-close resealable closures at top of every bag. The film strip above the zipper easily peels off to expose the resealable bag closure.

Mississauga plant’s packaging room employees in full protective clothing placing freshly-made naan flat breads inside the cavities of the Multivac R 245 thermoform packaging machine to be packaged in high-barrier plastic film bags.

such things happening again is optimally mitigated,” Kizilbash states, stressing the importance of keeping all customers happy at all times.

“Our customers love our product and for the most

“We have been able to retain our customer base over the years primarily because of the quality assurance systems we put in place and by delivering consistent high-quality product to them over and over again.” This core competence is continually reinforced

SEW-StaffTeaserManny4x7.pdf 1 8/5/2014 12:24:03 PM

and fine-tuned with the company’s proactive capital investment strategy, according to Kizilbash, with its emphasis on automating as much of the more tedious and manual production and processing functions as possible.

Maximizing Freshness

Chedworth Way, Mississauga, Ontario L5R 0A2 Phone 1-888-256-7359, Fax 1-877-262-8955 www.lindecanada.com, www.shop.lindecanada.com

A row of freshly-prepared naan breads making its way out of the cooking ovens inside the packaging room.

Balls of mixed and blended dough are placed onto food-grade conveyor belting and transferred to be pressed flat into shape before being sent on through the ovens for baking and ultimately into the adjacent packaging room for bagging.

“We work with a very ‘lean’ production process by eliminating any unnecessary steps and optimizing all of our lines,” says Hasan, noting that one of the company’s cookie lines at its much bigger, 145,000-square-foot Toronto facility is capable of processing one ton of cookies per hour when running at full capacity.

“Automation is a given, considering our emphasis on keeping labor costs to a minimum,” says Kizilbash, “so we make it a priority to continue to invest in new machinery that increases our throughputs and overall capabilities on the production and packaging lines.”

At the Mississauga facility, this proactive capital investment activity is emphatically underscored with the recent arrival of two state-of-the-art, high-performance Multivac R 245 thermoform packaging machines built by renowned German packaging equipment manufacturer Multivac Sepp Haggenmüller GmbH & Co. KG.

Installed virtually side-by-side in the Mississauga plant’s highly sanitized and ultra-clean packaging room, one of the two Multivac R 245 systems is dedicated to high-speed packaging of the Crispy 100% Roti brand ultra-thin wraps 10 to a bag, with the second unit used to bag the more lumpy, pita-style Crispy brand naan bread, which is packed five to six pieces to a bag, depending on the flavor and recipe.

Each of the Multivac machines has been customfitted with the application-specific tooling, gasflushing options and inline zipper applicators to create perfectly-filled and zippered doy pack bags of product boasting six- to seven-week shelf-life, with the resealable PTC (press-to-close) zippers helping to keep the product’s freshness and aroma in the bag well after it’s been opened.

Filling the bags at robust steady rates of six cycles per minute, the two rollstock Multivac machines offer superior hygienic design with full washdown capability inside and out, with easy-access side panels offering plenty of space to perform the required maintenance and cleaning.

Controlled and monitored via an operator-friendly, intuitive touchsreen control panel, the fullyautomatic, stainless-steel R 245 thermoformers are also easily integrated with all the peripheral product coding, labeling, weighing and product inspection systems to provide a highly reliable turnkey bagging solution for the Mississauga operation.

“The addition of Multivac equipment on the

naan and roti/wrap lines side has done wonders for us with both local and export customers,” Kizilbash extols.

“Both products are doing extremely well in the market, and the main Big Box chains just can’t seem to get enough of it—keeping our operation busy week-in and week-out.”

Kizilbash says he’s highly impressed by the quality, appearance and shelf impact of the doy pack bags processed by the two R 245 machines.

“Packaging plays a very vital role in selling our product,” says Kizilbash, praising the quality of resealable zippers applied to the plastic film bags inline.

“In terms of packaging, we are always focusing on what the consumer wants and how they want it, and convenience is always on the top of our list because of the consumers’ increasingly busy lifestyle.

“All of our investments in packaging are based on responding to the changing trends in the market,” he

adds, “and resealability is a big part of the convenience today’s consumers expect from their packaging.”

Kizilbash notes that the outstanding packaging results the plant has achieved with its new Multivac workhorses has prompted further investments in zipper applicating and FFS (form/fill/seal) technologies for the Toronto facility, which is gearing up for installation of new production lines in the near future.

“We have recently relaunched our poundcake with new, more upbeat packaging and overall look that has been received very well by our customers and consumers,” Kizilbash relates, “and we have some very exciting new initiatives in the works.” With its stringent hygienic demands and uncompromising stance on product quality excellence, Hasan says TWI Foods only works with well-vetted and trusted suppliers of packaging machinery and materials both in Canada and globally.

Touchscreen panel of the Videojet 1610 inkjet coder used to apply variable product information onto the bags.

Intuitive touchscreen control panels help to ensure userfriendly operation of the Multivac R 245 machines.

Stacks of freshly-baked flat bread manually inserted into their proper spots on the Multivac R 245 thermoformer before wrapping and sealing.

A heavy-duty SEW-Eurodrive electric motor is a common feature on the Mississauga plant’s production machinery.

Manufactured by the Toronto-based Fortress Technologies Inc., the Phantom series metal detector plays a central role in helping the Mississauga packaging lines meet their stringent quality assurance standards.

“We have a full system for vendor approval in which the vendor’s capabilities, certifications, quality, service and technical assistance is carefully measured prior to the approval,” he states.

“Only vendors who qualify the vigorous screening process are awarded our business,” Kizilbash points out, “which is to say that we typically work with the biggest and the best around the world.”

Some of the other packaging machinery and technologies helping the Mutivac packaging lines at the Mississauga facility keep humming at top performance include:

• Videojet 1610 continuous inkjet (CIJ) printer from Videojet Technologies Inc., used to apply the product codes, graphics and key variable product information onto the rollstock film web, as well as a Videojet Unicorn II case-coder for large-character printing onto the corrugated shipping boxes;

t he c anadian corrugated and containerboard industry develops creative packaging solutions that are cost effective, versatile, environmentally sound and food safe. o ur boxes are designed with high impact graphics that communicate your brand. we focus on what matters: what’s inside the box. Visit us at www.cccabox.org to learn more.

• Phantom series metal detection system, manufactured by the Toronto-based Fortress Technologies, Inc., to provide high-speed, high-sensitivity final inspection of all finished packages prior to being placed into the corrugated shipping cases;

• Semi-automatic Fox C1 plus model turntable stretchwrapper from Fox Packaging Services, along with a fully-automatic stretchwarpping machine from Orion Packaging Systems, LLC for securing the faster-moving full pallets of 40 shipping cartons;

• A high-performance, fullyautomatic boxformer from the iPak Machinery division of Pro Mach, Inc., to shape corrugated blanks into ready-to-load shipping carriers to be loaded with the 500-gram bags of bread, 18 bags to a box, and placed onto the pallets, which are whisked away for stretchwrapping via Blue Giant powered lift-trucks.

All in all, Kizilbash says that the plant’s vastly enhanced packaging capabilities achieved with the Mulitvac equipment installation will help TWI Foods attract additional business well into the future.

“We definitely see many Big Box stores focusing more and more on ethnic food products to draw more consumers to their stores, so we see good future growth ahead of us,” Kizilbash sums up.

“In addition to that, we are also working with developing key strategic partnerships that will help us grow our business even further.”

Packed 10 wraps to a bag, the Crispy brand roti breads have become a popular sandwich option for many Canadians.

TOP 50 PACKAGING IDEAS

TABLETOP TRADE SHOW 2015

November 4, 2015

9 a.m. - 3 p.m.

Mississauga Convention Centre 75 Derry Road West Mississauga, Ont.

Admission and parking FREE! Register at: www.top50packagingideas.com

For exhibitor information contact: Stephen Dean

Email: sdean@canadianpackaging.com

Tel: 416-510-5198

Official show sponsors: SEW-Eurodrive | QuickLabel Systems

Samuel Packaging Group

is one of North America’s leading specialty packaging equipment and consumable supply companies for food and non-food, primary packaging requirements.

With an excellent reputation for providing innovative packaging solutions and creating exceptional value to a wide variety of customers and markets, Samuel Packaging Group possesses unique experience that allows us to deliver industry leading solutions for all types of packaging requirements.

These products combined with Ahearn & Soper’s

Advances in technology are revolutionizing the role of marking and printing. In partnership with our customers, Markem-Imaje is leading the way...

We offer a complete range of innovative inkjet, thermal transfer, laser, digital, print & apply systems, software, consumables and services to help you…

Verify code accuracy

Manage any recalls

Assure full compliance

Reduce product rework

Minimize line downtime

With breakthrough technology and state-of-the-art software for any need, Markem-Imaje is redefining what’s possible so you can maximize your production and lead the way in your own market.

ATOP 50 PACKAGING IDEAS

JUST IN CASE!

A bright shelf-ready packaging idea moves flexible stand-up pouches closer to the forefront of the fast-changing grocery retailing landscape

bright new idea is never out of fashion or demand in packaging or any other industry. But as the famed American humorist Arnold Glasow once so deftly deadpanned for the ages, “An idea not coupled with action will never get any bigger than the brain cell it occupies.”

No such dilemma for folks at the Minneapolis, Minn.-based end-of-line-packaging systems manufacturer Delkor Systems Inc., whose recently-launched Delkor Cabrio Case shelf-ready corrugated tray/hood package is catching fire in the North American food retail markets at a stunning rate of growth.

“The growth has been just off the charts,” Delkor’s marketing director Rick Gessler told Canadian Packaging during a booth visit at last month’s PACK EXPO Las Vegas 2015 packaging technologies exhibition.

“In less than 12 months, we have gone from not having a single Cabrio Case in the market, just an idea, to having installed enough Cabrio Case systems to produce over 50 million Cabrio cases per year for all kinds of food companies selling their products in flexible stand-up pouches,” Gessler extols.

“We have never seen such rates of growth for any Delkor product offerings before,” says Gessler, proudly citing the 2015 AmeriStar Package-of-theYear honors Cabrio picked up in the competition’s Refrigerated Foods category.

STAR ATTRACTION

Making it first Canadian public appearance at the upcoming Top 50 Packaging Ideas tabletop trade show at the Mississauga Convention Centre, Nov. 4, 2015, the Cabrio cases have recently enabled retail giant Walmart to transform the way its Great Value store brand cheese products are retailed at its U.S. locations—delivering huge savings in shelf-stocking labor costs and a vastly simplified, better organized, more stable, and a much more eye-pleasing of displaying the brand on the shelf.

“The reason it is so popular lies in its simplicity,” says Gessler, describing the patent-pending process that turns on a single piece of flat corrugated blank into a durable, hooded corrugated tray featuring a pre-die-cut perforation that enables the store employee to tear off the hood with one simple motion—leaving behind a stable, low-profile square base tray to display the pre-loaded stand-up pouches of product to the passing shoppers.

“Retailers love it because it is so dead simple,” says Gessler, effortlessly removing the hood from a finished Cabrio Case in less than a second to demonstrate the point.

“It is also very cost-effective compared to a twopiece tray-and-hood construction, so you also get very good material savings,” he expands, citing the package’s pre-cut tray front and four smooth-finished corners, whereby all the jagged edges formed by the tearaway of the hood are cleverly positioned at the back of the tray, completely unnoticed by consumers.

Gessler explains that the Cabrio cases are designed

primarily for use by manufacturers and brand-owners of frozen, refrigerated, snack-food and dressing/ sauce products packaged in flexible stand-up pouches, which are showing no let-up in demand growth among grocery suppliers and retailers.

“Stand-up pouches are red-hot right now, with an incredible rate of conversion from boxes and other types of packaging,” Gessler points out, “and it’s easy to see why.

“They provide plenty of real estate for great branding graphics, they are relatively low-cost, and they offer great functionality in terms of application of resealable zippers, screw-top closures, and all other types of innovative consumer convenience options.

“We see many manufacturers of ketchup condiments, cereals, snack-foods going that way, with yogurt cups being replaced by screw-top pouches, for example, or canisters of nuts being converted to resealable pouches of nuts.

“And as they change their filling and primary packaging equipment upstream to accommodate the conversion, why not also change the downstream packaging to a system that will also provide a great-looking, shelf-ready display to compliment the brand right where it really counts at the point of purchase?”

For now, the Cabrio Case trays/hoods are offered in three basic versions:

• A standard single-facing design accommodating up to eight 24-ounce pouches, as Walmart has done for its Great Value cheese brand (see picture);

• A wider double-facing tray/hood that displays two rows of product side-by-side;

• An even wider triple-facing tray/hood design for triple-row shelf display;

• Customized narrow designs to accommodate specialty stand-up pouches with screw-caps.

“For all intents and purposes, the Cabrio Case design is essentially application-customized,” Gessler reveals, “whereby we meet with the customer to understand what size of pouch they want to use for the product, how many pouches they want displayed on the shelf at any one time and so on, after which we proceed to design the right Cabrio Case system for their specific needs.

“We can accommodate pretty much anything from two-ounce mini-pouches to 24-ounce pouches for dry foods, but we can also go up to 160-ounce pouches of powdered material and liquid pouches of up to one-gallon, which can come into play for the innovative milk producers out there.”

Because many of Delkor’s potential customers in the food business are at different stages of conversion to the flexible stand-up pouch format, Delkor

offers several different machine options for creating the finished Cabrio Case packages, Gessler notes.

“For companies just getting started with shelfready packaging, or people who already have their own pouch loader in place, we can supply a Delkor Trayfecta series tray-former that will form the case from a single-piece blank, along with a Kapstone closer to seal it,” Gessler relates.

“It can be positioned either right before or after their existing case-packing machine, or be filled with pouches manually.”

FULL SPEED AHEAD

For the more advanced standard applications running between 110 and 120 pouches per minute, Delkor’s MSP series automatic case-formers can handle speeds of up to 150 pouches (30 cases) per minute, with the fully-automatic modular machine version—comprising an integrated former, robotic loader and case-closer—providing even faster throughput speed range of 150 to 200 pouches per minute.

“And for really high-speed applications, our HSP series machines—featuring a linear servo-collator, can handle up to 300 pouches, or 60 cases, per minute,” Gessler states.

“With all these options available, we can really fit the production needs of food producers of any size or capacity—from the highest-volume operators to someone who has just entered the market.”

Significantly, end-users of Delkor machinery are not limited to producing just the Cabrio Cases exclusively, Gessler points out.

“All our machines that can run the Cabrio Cases can also work with the standard corrugated shipping cases, as well as most other shelf-ready packaging already out in the market,” he states. “It just takes a simple 10-minute changeover to facilitate a shift from a standard 12-pound shipper to a sixpound Cabrio Case, which can then be transformed into an effective, shelf-ready merchandising display literally with an effortless sleight-of-hand.”

Delkor’s marketing director Rick Gessler showing off the shelf-ready Cabrio Case packaging.

FINDING ONE’S BEARINGS

Dispelling the common lubrication myths to keep the industry’s wheels turning

By IAN RUBIN

The wheels of industry turn on bearings, so why do these wheels so often vibrate, clatter, squeak, drag and overheat? There are many reasons.

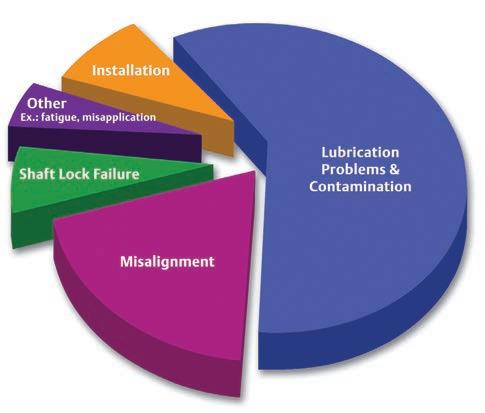

Most bearing failures (see chart) are related to lubrication and contamination, but myths and misconceptions handed from one generation of maintenance engineers to the next help perpetuate many easily avoidable problems.

These myths fall into three general areas of bearing use: installation, misapplication and lubrication.

Installation myth #1: It’s okay to hammer a bearing into position if needed – FALSE

Never strike a direct blow to bearing. The rolling elements and raceway are hardened, but can still be damaged. A hammer blow can leave dents in the raceway that can cause noise and dramatically reduce bearing life. If installation is difficult, first check the shaft diameter and look for burrs, dirt or corrosion on the shaft. If needed, use a press to slide the bearing on. Apply pressure equally on the face of the inner ring to avoid damaging the raceways and rolling elements.

Installation myth #2: (Turned, Ground & Polished) shafting is the best option – FALSE It’s much more important to know the shaft’s tolerance range to be sure it meets your bearing manu facturer’s specs for diam eter and roundness. Review the bearing manufacturer’s recom mendations and measure/specify the correct shaft diameter.

purge excess grease through the seals, the bearings return to steady-state temperatures.

Application myth #2: Bigger bearings are always better – FALSE

Bigger bearings with a higher load capacity may show a higher fatigue life, but if the load does not achieve the minimum requirements, the rolling elements can skid along the raceway instead of rolling—causing high temperatures, excessive wear, lubrication breakdown and bearing failure.

Application myth #3: Sealed/Lubed-for-Life bearings will last forever – FALSE

Bearing life depends on grease life, which is affected by the operating conditions (speed and load) and environment (temperature and contamination). Grease life can be improved with enhanced seals, along with proper installation and grease selection. Ultimately, the best bearing is the properly lubricated bearing.

Lubrication myth #1: Relubrication once a year is sufficient – FALSE

Before lubricating a bearing, the grease fitting must be clean to avoid introducing contamination into the bearing during relubrication.

Installation myth #3: It’s fine to hand-tighten setscrews one at a time – FALSE

Setscrews should be tightened to the manufacturer’s recommend torque. Under-tightening can allow the bearing to slip on the shaft, while over-tightening can distort the raceway or crack the inner ring. Use the “half-full/full” rule for tightening setscrews, whereby you tighten the first setscrew to half the recommended torque, the second setscrew to the full torque, and then go back to the first setscrew and apply full torque.

Application myth #1: Bearings should not be hot to the touch – FALSE

Normal bearing operating temperatures can range from 80°F to 150°F, but certain applications may run higher or lower. Most bearings are rated for -20°F to 220°F, but can be supplied with special grease, seals or heat stabilizing processes that allow them to operate at higher temperatures. Bearings normally run hotter at startup or right after relubrication because excess grease increases drag and friction in the bearing. Spikes up to 50°F are normal at startup and up to 30°F after relubrication. As the rolling elements

Start by reviewing the bearing manufacturer’s lubrication recommendations. These will give amounts and intervals as suggested starting points, but in reality the actual lubrication intervals may vary quite a bit, depending on load, speed, temperature, or environmental conditions. Applications with higher speeds, temperatures, or heavy contamination sometimes require frequent relubrication, possibly weekly or daily. By contrast, a mounted ball bearing in a lightly loaded, low-speed, clean environment may do fine with relubrication at 12- to 24-month intervals.

Relubrication replenishes grease when the current grease breaks down or deteriorates because the base oil breaks down due to temperature. Without this, the lubricating property is gone and the result is metal-to-metal contact. Relubricating the bearing replenishes the oil, maintaining the proper film. Pumping new grease into a bearing also helps flush away contamination. Many mounted bearings are designed to allow grease to enter the bearing cavity as close to the rolling elements as possible. As more grease is added, the old grease is pushed out of the seals (if the seals are purgeable) to . carry out con taminants and to keep dirt away from the seals.

Lubrication myth #2: Always add grease until it purges from the seal – FALSE

If you pump grease into the bearing until it purges out the seal, you probably have completely filled the bearing cavity. Excess grease

can increase operating temperature and may create enough pressure to blow the seal out. In low-speed or dirty conditions, where contamination may easily enter the seals, filling a bearing with grease may help improve performance. Application experience will dictate when the entire bearing cavity should be filled.

Lubrication myth #3: If a bearing makes noise, grease should be added – FALSE

If a bearing is making noise, internal damage has likely occurred and will likely increase over time, creating potential for catastrophic failure. Adding grease may provide temporary relief, but a noisy bearing should be closely monitored and replaced at the first opportunity. The root of the failure should also be investigated either with independent or manufacturer failure analysis, which requires removal of the bearing as soon as possible to aid in a more accurate diagnosis of the problem.

Lubrication myth #4: Any grease will do – FALSE Greases do differ. Some may be incompatible because of the different thickeners (soaps) used. When two incompatible greases are mixed, they may either thicken and harden or become thin and leak out of the bearing. For example, many electric motors use a polyurea thickener, while some mounted ball bearings use lithium-complex thickeners.

These greases are borderline compatible, and depending on the actual make-up, may not work together. Grease types can also be incompatible based on the viscosity or type of oil in the grease, so consulting a lubrication supplier is always highly recommended.

Lubrication myth #5: Just shoot grease through the fitting – FALSE

Always clean grease fittings and the grease gun tip. It’s good practice to put the grease gun tip in an oil bath or wrap it with a plastic cover to protect it.

Your plant’s uptime and OEE (overall equipment effectiveness) may “turn” on your bearings’ good health. If you are not achieving the desired operational life for some of them, a bearing manufacturer can assist you with proper selection and troubleshooting.

Ian Rubin is the director of marketing for mounted bearings at the Regal Power Transmission Solutions division of Regal Beloit America, Inc.

Surface smearing, peeling and skidding are forms of adhesive wear that occur when operating with insufficient oil film thickness with sliding between the rolling elements and raceways causing surface deformation, cold wielding and/or material transfer.

A chart showing sources of bearing wear or failures.

LABELING

HIGH ROAD TO FOLLOW

Upstart food processor is well at ease with having big shoes to fill after ketchup giant’s exit from a landmark Leamington factory

ANDREW JOSEPH, FEATURES EDITOR

PHOTOS BY JOHN PACKMAN

In any discussion about tomatoes, wrapping one’s head about the notion of a tomato being a fruit, rather than a vegetable, is a good starting point. And growing tomatoes for a living has, for decades, provided a fruitful existence to thousands of folks living in and around Leamington, Ont.—until recently the undisputed “Tomato Capital of Canada” by virtue of being home to the giant Heinz Canada tomato harvesting, processing and packaging facility that was one of southwestern Ontario’s biggest and most important manufacturing employers.

At least until last year, when the Pittsburgh, Pa.headquartered parent company H.J. Heinz Company decided to pull the plug on its 100-year-plus Canadian manufacturing operations as part of a widespread global corporate restructuring.

While the ensuing shock and hardship caused by the sudden loss of nearly 750 well-paid manufacturing jobs is still being widely felt throughout the local economy, there may be a good chance the landmark facility’s days are not numbered just yet—thanks to the efforts of an energetic upstart company made up of a swathe of ex-Heinz personnel armed with a highly feasible business plan and priceless combined experience and expertise in the produce business.

While still far from a finished slam-dunk commercial success, the recently-formed Highbury Canco Corp., is already firing on a lot of cylinders after purchasing the 2.1-million-square-foot facility and a 46-acre plot of land from Heinz.

Having hired back 325 of the former Heinz employees on full-time basis, along with another 120 part-timers to help it process tomato juice and tomato paste as a niche third-party contractor for one of the world’s bestselling brands, the company is doing many things right to resurrect the facility to its former glories.

“We Canadians tend not to miss things until they are gone,” Highbury president and chief executive officer Sam Diab told Canadian Packaging magazine during a recent visit to the bustling facility.

“So when the opportunity arose for us to purchase the assets of the Canadian operation of Heinz, we just went for it.

“So far, all of our expectations have been exceeded,” says Diab, noting that there was very little downtime between the closing of the Heinz business and Highbury getting its feet wet.

“Heinz closed its doors on July 27, 2014, and Highbury took over on July 1, with 50 truckloads of product leaving our doors on July 2,” he recalls.

“It was stressful, but it was also quite the rush,” Diab relates.

“What it did was quickly establish the Highbury identity in the wake of the closing of the Heinz Canada facility,” he states.

While naturally still providing co-packing and third-party logistics services for branded Heinz products sold in Canada, Highbury is also free to

pursue other major opportunities in the privatelabel businesses, Diab acknowledges.

“Tomato juice and tomato paste are two of our fresh packed products that we manufacture here,” relates Diab, “and despite what you might think, tomato paste is actually by far the larger of the two products we manufacture here.

“People tend to forget that tomato paste is used in a lot more products than simply as a stand-alone paste-in-a-can product,” he points out, citing the enduring popularity of products like canned pasta lunches and baked beans, which both use tomato paste in their recipes.

“All in all, we produce about 120 SKUs (stockkeeping units) of products,” Diab says, “but we also distribute hundreds of SKUs across Canada.

“While Highbury can easily co-pack for large CPG (consumer packaged goods) brand and private-label businesses, we can also set up boutique lines for smaller companies that might have smaller volumes,” Diab relates, “whereby they can utilize our expertise to help them grow in their markets as well.”

Diab says Highbury’s strength is the fact that it isn’t actually a large conglomeration, and that it has a focus on being a co-packer staffed with top-caliber food professionals.

A third-generation Heinz Canada employee, Highbury Canco president and chief executive officer Sam Diab and several other partners purchased the land, facility and equipment from Heinz using its knowledge of the tomato industry to become a third-party contractor counting Heinz as one of its chief customers for Canadian-made products.

The fully-automatic Canmatic labeling machine from Krones applies wraparound labels with hotmelt adhesive.

LABELING

“I think our size, along with the tremendous capacity we carry, enables us to operate our asset management better,” says Diab, himself a thirdgeneration Heinz employee.

Diab says that Highbury has found many ways to create a truly ‘lean’ manufacturing base to ensure his company has the chance to be profitable, insisting that proper utilization of automated technologies assembled will help its production lines run at optimal efficiency.

In terms of its current physical assets, the Highbury plant currently houses production lines, 30 loading docks; a semi-automated distribution center with robotic product picking and palletizing; 800,000 square feet of storage space; and an active R&D (research-and-development) department that Diab says has the capacity to handle large integrated processing projects for various food-and beverage product segments.

Along with tomatoes, Highbury also has the manufacturing capabilities to process and pack beans, pasta, soup, dips and sauces, emulsifications, mayonnaise, barbeque sauces, steak sauces, “or just about anything one could want to put into a can or a bottle,” Diab asserts.

In terms of packaging formats, Highbury can offer its customers a fairly broad product mix, including:

• 11 aluminum can options;

• four Cryovac flexible packaging choices;

• two Volpak alternatives;

• multiple formats of glass jars and bottles;

• various styles of plastic bottles;

• and stand-up resealable pouches.

“It almost seems cliché to say, but we take food safety very seriously here at Highbury,” relates Diab. “We have quite the experienced team of professionals who monitor all facets of the product preparation 24-hours-a-day,” explains Diab. “We have processes in place from the receipt of the raw tomatoes and ingredients all the way through to when we send the finished product out to our customers—it is imperative that our food consistently exceed standard food safety requirements.”

Diab says that Highbury is a CFIA (Canadian Food Inspection Agency) -registered processor and uses the principles of HACCP (Hazard Analysis and Critical Control Points) protocol to meet strict food safety standards.

“We also maintain accurate record-keeping of all ingredients, packaging and finished products shipped,” he adds.

Highbury receives and inspects tomatoes—samples from each load are taken for testing—from local farms within a 100-kilometer area before separating them via an outdoor washdown series of conveyor elevators to the further processing departments contained within the facility. These separate elevators are used for fruit destined for juicing and those to be processed into paste.

Because of the specific harvest time of the locally-

grown tomatoes, these elevators are only used for about six weeks of the year.

“During the month of September, Highbury just focuses on juice and paste,” Diab notes, “with the remaining calendar days used to process everything from baked beans, soups, pizza sauces, canned pastes, condiments, sauces, dressings, as well as infant cereal.”

Owing to the large quantities of water required to remove soil from the fruit, Highbury utilizes re-circulated water during this initial washing process—re-circulated from a chlorinated water mixture further down the production chain that adds a better cleaning to the product before inspection.

The next level of product inspection is undertaken by human eye to remove foreign objects, rotten or possibly blighted fruits, before it moves through equipment that effectively smashes and grinds the tomato while removing the skin and seeds.

“The seeds and skins are not used in any Highbury-created products, so we remove it to a holding area where it is shipped to an outside company for further processing into animal feed,” Diab reveals.

Immediately after the tomatoes are chopped, Diab says that it undergoes a heating process to deactivate enzymes that could cause the fruit to deteriorate in color.

The heating also helps remove the appropriate amount of moisture content to create tomato juice and even more heating to create the tomato paste products.

Highbury uses a Yaskawa Motoman HP500 robot with a LayerPicker Flex-R pallet builder from Qubiqa.

Purchased in November of 2014, the Krones Canmatic labeling system is capable of running at a production speed of 39,600 units per hour (also see inset ), and is one of four such systems at the Highbury 2.1-million-square-foot facility.

LABELING

“We actually have a pair of jet engines on our premises, that we use to generate electricity for the facility, with the heat gathered from the working of the jet engines used to heat the tomato products,” mentions Diab. “After filling, cans of product ranging in production run sizes from 5.5 to 19-ounces are conveyed through a Krones Canmatic labeler— Highbury has four of the machines, but purchased and installed its latest in November of 2014.

According to Krones, the labeler can run at a speed of 39,600 cans/hour. Notes Diab, “It labels so quickly for us, that we are now looking to purchase a new tray and shrink case packer.”

The fully-automatic Canmatic labeling machine applies wraparound labels with hotmelt adhesive, and is capable of handling a variety of different container types.

Designed to handle pre-cut paper labels, the label is applied directly to the container and sealed via adhesive.

“It’s a pretty good machine,” extols Diab. “We receive consistent precision labeling on every unit.”

The Krones Canmatic is a continuous-motion machine that automatically adjusts to the inflow and outflow of the containers.

As containers move in via an infeed conveyor and taken up by the infeed worm, it is spaced to pitch so it can then be quickly taken up by the infeed starwheel and transferred to the container table, where it is positioned between container plates and centering bells to ensure perfect alignment.

When applying labels, the Canmatic uses two independent hotmelt labeling stations from Nord-

Domino’s A520i continuous inkjet coder works well in difficult production environments.

Not only does Highbury utilize a lot of CHEP skids for transport of product, it is also a hub for the pallet distributor.

Depending on the production run, Highbury utilizes a Mettler Toledo Safeline X-Ray inspection system for product integrity and safety.

Powerful SEW-Eurodrive motors such as the one pictured above, help provide the smooth operational power to the input/output conveying solutions on Highbury Canco’s Krones Canmatic labelers at the Leamington, Ont. facility.