SIMPLY DIVINE

Modern cheese processing and packaging technologies help Quebec monastery preserve its righteous way of life Story on Page 12

Delivering Results.

With Heat and Control, you have a partner with the scale to support your success, the innovation to advance your operations, and a commitment to quality that will help you offer better products for consumers.

COMPLETE SNACK PACKAGING SOLUTIONS

• Accumulation

• Horizontal motion conveying

• Incline, belt and bucket conveyors

• Filling and multihead weighing

• Bagmaking and casepacking

• Checkweighing and seal checking

• Foreign object and defect inspection

• Controls and information systems

We are successful when you are successful. That’s why we apply creativity, engineering excellence, and determined perseverance to every project to help our customers get the performance their business demands—whether measured by flavor, efficiencies, sustainability, improvement, or innovation.

Mar. 10-12, 2025 Booth 1108

info@heatandcontrol.com | heatandcontrol.com

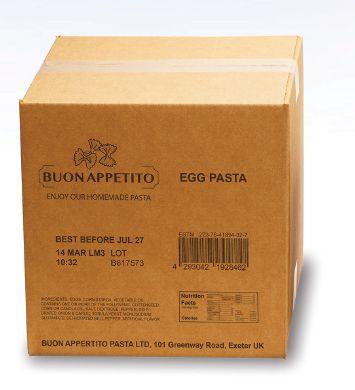

Videojet® 2380 large character printer

Maximize your coding efficiency with the Videojet 2380 inkjet printer. Designed for easy use, it integrates smoothly, requires minimal maintenance, and is operated with simple training. Self-cleaning technology helps ensure crisp, high-resolution text, logos, and barcodes.

NEW: Take advantage of the ability to code on multiple sides of cases and cartons with up to four printheads.

COLUMNS

FROM THE EDITOR

4 By George Guidoni Approaching AI with due caution and diligence.

CHECKOUT

10 By Myles Shane

Joe Public speaks out on packaging hits and misses.

COVER STORY

12 DIVINE INTERVENTION

A boutiques cheese factory operated by a group of Benedictine monks living on the grounds of a historic Quebec monastery installs leading-edge thermoform packaging machinery to keep up with soaring demand for its high-end artisanal creations.

FEATURES

18 Turning New Leaf

Organic lettuce greenhouse operator brings its packaging line efficiencies up to full speed with comprehensive upgrades to its packaging machinery arsenal.

24 Start to Finnish

An inside look into the extraordinary sustainability journey gathering pace at paperboard manufacturing operations of one of Finland’s leading forest product giants.

29 Short and Sweet

Leading Ontario wine producer using disruptive new paper bottle technology to make big waves in in retail markets with an exciting new look and multiple environmental benefits.

35 Paper Trail

Fast-growing Ontario packaging distributor acquires an important competitive edge by helping commercialize new breakthrough paper bottle technology offering dramatic carbon footprint reduction.

ON THE COVER

39 Career moves in the packaging world.

A look at the majestic exterior of the historic Saint-Benoît-du-Lac monastery in rural Quebec, which operates an on-site cheese production facility making high-end, premium-quality cheese products to help fund the monastery’s daily upkeep.

Cover photo by Pierre Longtin.

Caution is the better part of valor for AI integration

For a technology that is arguably still in the early stages of its development and widespread adoption, artificial intelligence (AI) is undoubtedly showing a lot of promise in its potential to be a seismic game-changer for just about every major manufacturing industry out there, including packaging.

That said, it remains to be seen whether the all the hype and buzz surrounding the unfolding AI boom is justified, rather than wishful thinking and conjecture.

A machine-based system that can, for a given set of human-defined objectives, make predictions, recommendations or decisions influencing real or virtual environments. The National Artificial Intelligence Initiative

For all the talk about machines replacing humans across a broad cross-section of manufacturing industries, the vaunted promise of 24/7 lights-out factories run almost exclusively by machines with little or no human intervention is still largely a work-in-progress. And while some of that progress has been truly spectacular, much of it has been achieved through thoughtful deployment of multiple complementary technologies, rather than through one fix-all killer app.

In this light, a new report from PMMI, The Association for Packaging and Processing Technologies, offers a refreshingly objective take on how packaging machine-builders can obtain a competitive edge by integrating AI capabilities into their product offerings.

Titled The AI Advantage in Equipment: Boosting Performance and Bridging Skills Gaps, the timely paper offers invaluable insight into AI’s vast capabilities and obstacles, along with cautionary advice that, “AI is more of an evolution than a revolution.

“The technology is not at the level yet where tasks can be completed solely by AI, and so a human is still required to make final decisions.”

Given that human decision-making is always fraught with the risk of human error, there are already plenty of AI solutions available in the marketplace to help minimize that risk.

This includes the new-generation AI assistants—aka Large Language Models (LLMs)—which employ the same concept used by ChatGPT but are trained on data that is specific to the industry.

“The primary benefit of an AI assistant is to vastly increase the speed in which time-consuming tasks can be completed,” the report notes, “freeing up employees to spend more time performing higher-value, skilled tasks.”

For packaging OEMs, AI assistants are

especially useful at speeding up tasks such as:

• Coding: Helping users generate, optimize, tag, simplify or summarize code, while also being used for bug detection and improving syntax.

• Administration: Increasing the speed of data entry and other time-consuming administrative tasks.

• Customer Service: Inputting machine manuals and previous machine issues and feedback into LLMs to facilitate faster customer service.

• Machine Manual Creation: Speeding up the process of compiling a manual for a specific machine from a generic template.

• Brainstorming: Prompting for ideas during design, marketing, product development, etc.

For operational performance, LLMs can help optimize various functionalities and processes that are essential to running a smoother, faster and more reliable packaging line, including:

• Machine Vision, which uses cameras and other sensors to enable machines to see, analyze and interpret their environment in applications ranging from quality inspection and product sorting/ routing to tamper detection and assembly verification.

• Predictive Maintenance, which is an advanced form of machine or component monitoring to determine when it is likely to fail so that preventive action can be taken to avoid unplanned downtime.

• Digital Twins, which is a virtual representation of a physical process, machine or plant that accurately reflect its real-world counterpart.

• Connected Worker Platforms, generally featuring a Cloud-based management system that operations management or production supervisors can use to create, assign, manage and monitor tasks and workers’ performances by collecting data and linking performance metrics.

All in all, there is no doubt that AI is the future for packaging and many other manufacturing industries striving for excellence in the digitalized world, but for now it is still up to humans to determine where that future takes us.

GEORGE GUIDONI, editor GGuidoni@canadianpackaging.com

NOVEMBER 2024 | VOLUME 77, NO. 9

Reader Service

Print and digital subscription inquires or changes, please contact Angelita Potal, Customer Service Tel: 416-510-5113 apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Senior Publisher Stephen Dean | (416) 510-5198 SDean@canadianpackaging.com

Editor George Guidoni | (416) 510-5227 GGuidoni@canadianpackaging.com

Account Coordinator Barb Comer | (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

Audience Development Manager Barbara Adelt | (416) 510-5184 Fax: (416) 510-6875 badelt@annexbusinessmedia.com

Media Designer Alison Keba | (519) 429-5181 akeba@annexbusinessmedia.com

CEO Scott Jamieson SJamieson@annexbusinessmedia.com

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE: Canada $80.07 per year,USA $183.09 (CDN) per year, Outside Canada $207.57 (CDN) per year, Single Copy Canada $10.00.

From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

Privacy@annexbusinessmedia.com

Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2024 Annex Publishing & Printing Inc. All rights reserved. This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice. You should not act on information contained in this publication without seeking specific advice from qualified engineering professionals. Canadian Packaging accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. Canadian Packaging receives unsolicited materials, (including letters to the editor, press releases, promotional items and images) from time to time. Canadian Packaging, its affiliates and assignees may use, reproduce, publish, republish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

We acknowledge the [financial] support of the Government of Canada

Canadian pastry icon serves up a new frozen treat to share festive joy

Already beloved for its mouthwatering pastries, the popular Canadian restaurant chain BeaverTails is aiming to make the upcoming holidays even sweeter with the launch of new frozen yule logs that are bound to be the talk of the table at any festive gathering.

Launched earlier this month at major grocery stores including Metro, Walmart and Loblaws, new BeaverTails yule logs are available in two comforting flavor combinations to please any palate.

Dessert lovers can choose between Cinnamon Caramel, a rich blend of warm spices and a gooey caramel drizzle, or Chocolate Raspberry, where decadent chocolate meets the tartness of raspberry swirl for a perfect balance of flavors.

Produced in Italy, the ready-to-

eat, ready-to-serve desserts can easily be stored in the freezer and pulled out for any occasion—serving up to 10 people with ease.

Retailing in padded slide-out folding cartons designed by the Montreal-based branding services agency 2.0 Food, the BeaverTails logs are a perfect go-to solution for hosting a festive party, welcoming unexpected guests, or simply satisfying a craving for something sweet.

“Since 1978, BeaverTails has been a beloved Canadian tradition, and we’re thrilled to introduce our festive Christmas Ice Cream Logs,” says Patrick Marcovecchio, director of CPG licensing at BeaverTails Canada Inc.

“This collaboration combines our classic flavors with the spirit of the holiday season, creating a uniquely Canadian treat that captures the warmth and joy of Christmas celebrations with every bite.”

Founded in 1978, BeaverTails specializes in making delicious Canadian artisanal pastries that have nurtured a loyal consumer following across Canada and

abroad with a diverse product portfolio filled with virtually infinite flavor combinations to satisfy everyone’s appetite.

Today, the company operates 195 active franchise establishments in Canada and the U.S., well as international distribution licenses in countries such as France and Qatar.

Beverage innovator lands a big Costco deal

That investment in now paying off in a big way with rapid market penetration of the Oatbox Barista oat drink.

Developed by professional baristas and micro-roasters, the high-quality beverage has already been embraced by nearly 1,000 points of sale, including over 400 independent cafés, across Canada.

Montral-based beverage innovator Oatbox continues to make big waves in the market by obtaining a listing at 20 Costco retail locations across Canada for the company’s flagship plant-based Barista oat beverage brand.

Established in November 2014, Oatbox is already a leader in in Canadian oat-based food products, having invested nearly $10 million to build its own liquid oat extraction plant—ensuring it offers the highest-quality beverages with the lowest possible environmental impact.

With its creamy micro-foam, perfect for creating lattes and other beverages inspired by the best specialty coffee-based drinks, Oatbox’s Barista beverage appears to be well on its way to setting the standard for oat-based beverages.

According to the company, Oatbox uses only high-quality local ingredients in its Barista oat beverage, using only the specifically-selected oats grown in Canada without GMOs or glyphosate.

“This is important for consumers who care about their health and the environment,” the company states.

“This ethical and responsible approach fully aligns with the company’s mission to provide products that are good for its customers and the planet.”

24_010892_Canadian_Packaging_NOV_CN Mod: October 8, 2024 9:20 AM Print: 10/09/24 page 1 v2.5

Email:

Phone:

BEST CASE SCENARIO

Designed for seamless integration, the new PROFLEX case-packing machine from Propack provides superior versatility, speed and reliability for today’s fast-moving industries, enhanced with a unified control system for user-friendly training,

operation and maintenance. With adjustable internal settings letting users to configure it for different packaging formats, shapes and sizes, the high-performance system employs a high-speed delta robot, powered by three advanced servos, to ensure speed and precision in every action for rapid, secure and efficient packing of items ranging from fragile goods to heavy products. With compact and robust design, the PROFLEX is built to fit seamlessly into existing lines for communication with upstream and downstream equipment. Propack

PLUG-AND-PLAY PALLETIZING

The new TOMA product line from Premier Tech leverages FANUC’s cobot technology to provide a user-friendly palletizing solution combining robustness, reliability and performance with optimal agility and autonomy. Designed as an out-of-the-box, plug-and-play solution that can be integrated with the existing packaging lines within minutes, the system’s user-friendly MOVN software allows virtually anyone to operate it from its touchscreen HMI (human-machine interface) terminal by simply entering the selected case dimensions and pallet patterns. Notably, the system’s integrated FANUC CRX-30iA robot arm can easily handle payloads of up to 55 pounds at rates of eight pick per minute in the collaborative mode.

Premier Tech

Clear On-Hol With Suspect Foreign Materia

STRETCHING THE LIMITS

The new Flex HPD (High-Profile Deluxe) turntable pallet wrapping system from Orion is designed to deliver high-throughput stretchwrapping for any application in one modular design, while providing compatibility with various paper-based protective wrap materials. Offering optimal flexibility in terms of conveyor sizes and the height of the rotary arm, the Flex HPD can be easily tailored or even retrofitted to grow with end-users’ changing application requirements for excelling in unique challenging applications involving heavy, light or unstable loads.

Orion (Div. of ProMach)

NEW CODES OF CONDUCT

Markem-Imaje has unveiled a whole new range of innovative to 2D solutions to help food facilitate implementation of the FDA’s strict traceability requirements for a host of fresh and frozen foods, entering into force in January 2026. According to the company, the new technology combines the assets of its continuous inkjet (CIJ) and Drop-on Demand (DoD) hardware and software to provide full traceability information, with the capability to produce high-quality serialized 2D barcodes in at high-speed on complex 3D surfaces. The new hardware can produce scannable, GS-1 compliant 2D codes, like QRs, as small as 5-mm (0.2-inches) in height, and it can also mark the new eco-friendlier and thinner monomaterial film structures. For its part, the Markem-Imaje CoLOS software—compatible with almost all commonly-used ERP and MES systems, including SAP to record and encode the detailed traceability data required for the pending new FSMA (Food Safety Modernization Act) traceability regulations.

Markem-Imaje

THE COMPOST ALTERNATIVE

How compostable packaging can give Canadian produce growers a green competitive edge

By Rodrigo Castaneda

Canada produces over three million tonnes of plastic waste each year, with only nine per cent of it being recycled. The rest contributes to environmental damage by accumulating in landfills, waste-toenergy plants, and polluting ecosystems vital to the agricultural sector, including rivers, lakes and oceans.

For Canadian produce growers, who rely on the health of these natural resources, plastic pollution presents a critical challenge—but also a unique opportunity.

With 72 per cent of Canadians actively seeking ways to reduce their environmental footprint, and 41 per cent specifically choosing products with environmentally-friendly packaging, transitioning to alternative sustainable packaging, including compostable options, is not only a practical solution but also a strategic move for Canadian produce growers.

It enables them to actively reduce their environmental impact and help preserve the ecosystems they depend on while also aligning with increasing consumer demands for eco-friendly solutions.

Compostable packaging is engineered to fully decompose in a composting environment, returning to the earth as nutrient-rich soil without leaving any harmful residues behind.

With access to local production of compostable packaging expanding throughout North America, the benefits for growers and retailers are also increasing.

Among these are faster turnarounds, extended the shelf-life of produce, and enhanced brand commitment to circular business practices.

For example, research has shown

that compostable films can preserve the freshness of fruits and vegetables for longer periods compared to traditional plastic packaging. This is particularly advantageous for growers who need to ensure that their produce remains fresh during long distribution cycles or when displayed on store-shelves.

By reducing spoilage and extending shelf-life, compostable packaging helps growers maximize the value of their crops while minimizing waste—benefiting both their bottom line and the environment. In an industry where margins can be slim, these benefits are invaluable.

In addition to its environmental and shelf-life benefits, compostable packaging offers a significant advantage in terms of waste management.

Traditional plastic packaging often requires separate disposal processes, with consumers needing to sort out recyclable materials from non-recyclable ones.

Compostable packaging simplifies this process by allowing the entire package to be composted alongside food scraps. This reduces the need for sorting and ensures that all packaging waste is disposed of in an environmentally friendly manner.

The shift to compostable packaging is not only more convenient for consumers, but it also aligns with Canada’s ambitious plastic reduction goals. With the federal government’s target of achieving zero plastic waste by 2030 and recent bans on harmful single-use plastics, Canadian growers have a unique opportunity to support national efforts while meeting the expectations of environmentally conscious consumers.

Offering produce in compostable packaging can help growers tap into the 41 per cent of Canadians who prioritize eco-friendly packaging. This can help them stand out in a crowded market and present their products as part of the solution to plastic waste.

This move can not only help attract eco-conscious customers but also enhance brand loyalty, as consumers increasingly seek out and support companies that prioritize sustainability.

While compostable packaging production was commonly conducted and imported from abroad until recently, a growing number of conventional plastic packaging

Compostable packaging can play an important role in helping Canada alleviate its plastic pollution crisis.

factories now offer eco-friendly alternatives to traditional plastic that can be manufactured using existing machinery. This capability allows growers to establish more resilient and flexible supply chains—reducing dependence on

foreign manufacturers.

Local production also enables quicker response times to market demands, changing consumer preferences, and new regulatory requirements.

Ultimately, the adoption of a local compostable packaging supply chain represents a forward-thinking approach to packaging that aligns with modern consumer values and environmental imperatives.

By choosing compostable packaging, growers can not only help protect the environment by reducing plastic waste, but also enhance the freshness and marketability of their products.

RODRIGO CASTANEDA is general manager and vice-president for North America at TIPA, manufacturer of compostable packaging solutions headquartered in Israel.

Kris Bulmer to service Eastern Ontario Area

Shawpak Systems, a leading distributor and equipment representative for product inspection, packaging, and industrial hygiene equipment, is pleased to announce the appointment of Kris Bulmer as Technical Sales Associate. In this role, Kris will serve customers in Eastern Ontario with our complete line of Shawpak products and will be responsible for expanding our hygiene in the United States. Kris brings a wealth of experience to this position. Most recently, he served as the Canadian General Manager for another X-ray manufacturer. He also spent 15 years at Mettler Toledo Canada in various roles, gaining extensive technical expertise in the food, pharmaceutical, and beverage industries.

SHAWPAK SYSTEMS ADDS NEW

Shawpak Systems, a leading distributor and equipment representative for product inspection, packaging, and industrial hygiene equipment, is pleased to announce the appointment of Kris Bulmer as Technical Sales Associate. In this role, Kris will serve customers in Eastern Ontario with our complete line of Shawpak products and will be responsible for expanding our hygiene in the United States. Kris brings a wealth of experience to this position. Most recently, he served as the Canadian General Manager for another X-ray manufacturer. He also spent 15 years at Mettler Toledo Canada in various roles, gaining extensive technical expertise in the food, pharmaceutical, and beverage industries.

Kris may be reached at 647-334-7734 or via e-mail at Kris@shawpak com

Kris may be reached at 647-334-9892 or via e-mail at Kris@shawpak.com

Please welcome Kris to the Shawpak Team

Please welcome Kris to the Shawpak Team shawpak.com

Kris Bulmer to service Eastern Ontario Area

Transforming the Packaging Industry through Sustainable, Inclusive and Accessible Best Practices

Trusted ADVISORS, INNOVATORS and EDUCATORS to Global Packaging Leaders

Virtual Gateway to Global Packaging Innovation, Knowledge and Leaders

Get connected to our virtual network of global packaging industry leaders; sustainable, inclusive, and accessible solutions and library of best practices.

Packaging Education and Professional Development

We offer comprehensive virtual educational, in-class programs, webinars, summits, and facility tours. Designed for those new to the industry and executives.

We are thrilled to unveil a remarkable opportunity: the publication of The Power of Packaging

Contact Jim Downham at jdd@leaderlinx.com for more info.

Leverage Sustainable Design and Circular Economy Principles

Join our experts and working groups to collaborate in search of next-life packaging innovations and solutions. Consulting services available.

PAC Global Awards: Celebrating Global Excellence in Packaging Design

Join us in New York City this February 4, 2025.

rt .

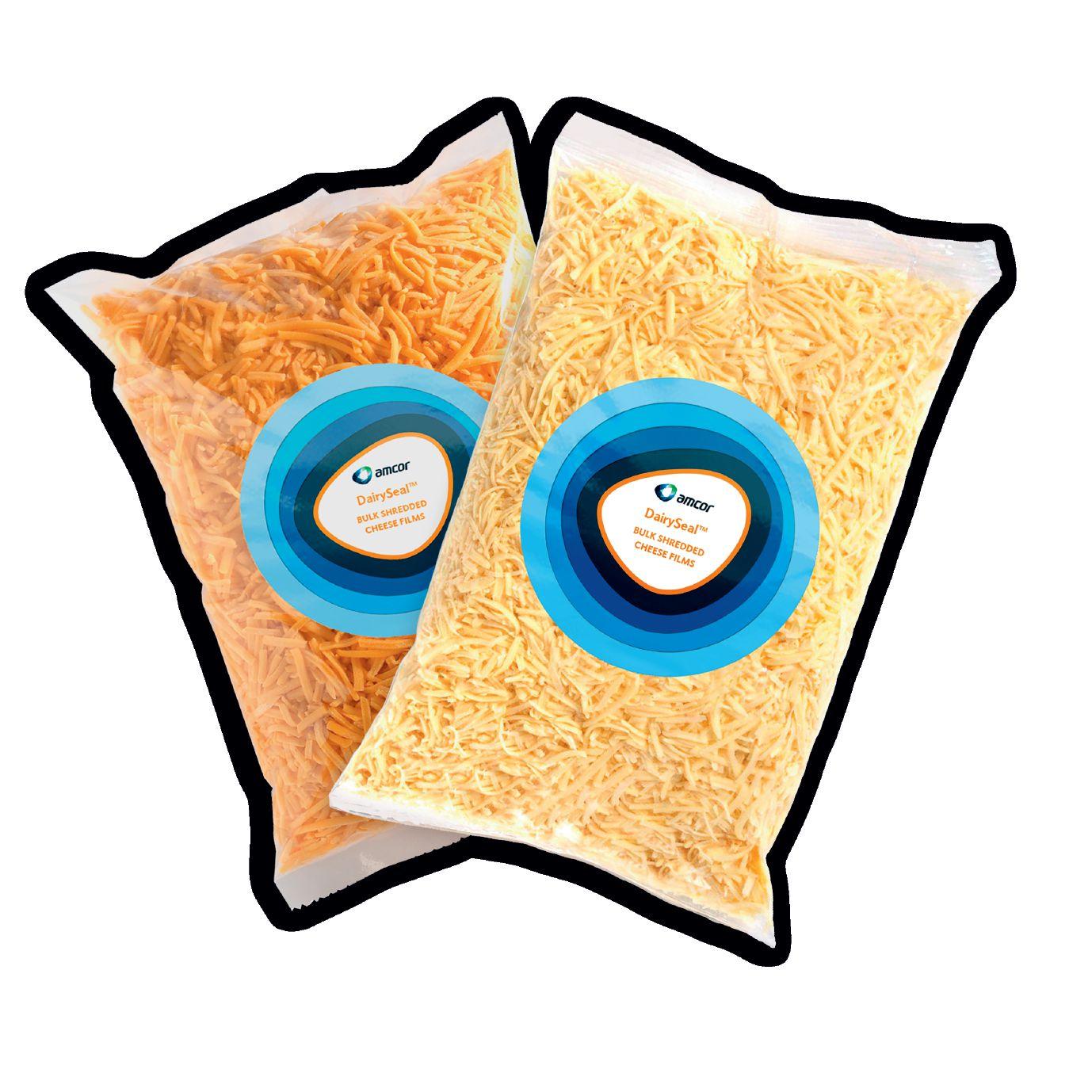

DELIVER S SUPER B MACHI NA BILITY AND EXCE LL ENT SEALING PROPERTIES

ID EA L FOR SMAL L TO LARGE FOOD SERVICE P OU C HE S ( 2 - 14 KILOGRAMS )

SEAL S AT LOWER TEMPERATURES

BARRIER AND NO N- BARRIER OPTIONS TO PROTECT FRE SHN ESS AND FLAVOR

OUTSTANDING ABUSE, ABRASION AND PUNCTUR E RESISTANCE THR OU GHOUT DISTRIBUTION

Abbaye-de-SaintBenoît-du-Lac’s communications

director David Morel joins production manager Alex Lachapelle and Reiser Canada’s sales representative Jean Collette inside the landmark abbey to show off thermoformed packages of the premium quality cheese products hand-crafted a the monastery’s on-site cheese factory.

DIVINE INSPIRATION

New thermoform packaging machine helping Benedictine monks keep up with growing production volumes at their on-site boutique cheese factory

By Andrew Snook

Photos by Pierre Longtin

The province of Quebec is synonymous with cheese production. But while Canada’s largest cheese-making jurisdiction is home to thousands of very capable cheese producers, there may arguably be none more unique than Abbaye-de-SaintBenoît-du-Lac

Built in 1912, the operating abbey in Saint-Benoît-du-Lac, Que., is home to 25 monks who continue to live a monastic life only a two-hour drive east of Montreal. Times were tough for the abbey in its early years, as it struggled to find a market for its dairy farm products.

“Back in the ’30s and ’40s, the monks already had a big dairy farm, but they couldn’t find a way to develop the sale of

the milk,” explains David Morel, communications coordinator for Abbaye-deSaint-Benoît-du-Lac.

Realizing that there were no cheese factories operating in the nearby region, the abbey decided to start up cheese production using its own milk production in 1943. Also relying on the milk supplied by other small, local dairy farms, it started with a single blue cheeses product.

“It was the first blue cheese produced in Quebec and in Canada,” according to Morel. “This cheese factory helped to finance all the operations here.

“It was the first stable source of income for the monastery,” Morel points out, “and it is still the most important one for their living.”

The original blue cheese was the only product the factory produced for its first 10 years of operation, before adding

From Left

Gruyère to its production in the mid-1950s.

From 1960 to 1965, the abbey stopped the production of blue cheese and focused on developing new types of Gruyère.

The decision to halt production of blue cheese was fuelled by a combination of low market prices and increased competition from Europe, according to Morel.

However, the 1960s were an important time for the growth of the cheese factory, because this was the time that the abbey decided to try and market its products in the U.S.

“The development of the American market was the rebirth of the cheese factory, a new beginning to give a kick to the production process,” Morel says.

“It helped a lot because people from Quebec found their cheese in the U.S., and it helped them to develop the market here in Quebec.”

By the early 1970s, the abbey was producing three different types of Gruyère, Morel says.

When the cheese factory first started in 1943, it was producing about 16,000 kilograms of cheese annually

In the 1960s, annual production grew to approximately 100,000 kilograms of cheese, and increased again in the 1970s to about 150,000 kilograms during the 1970s.

But the most significant growth took place in the 1980s, when the cheese factory benefited from a newfound corporate partnership.

“During the early ’80s, they developed a partnership with Kraft, which provided the opening for the cheese factory to enter into all the main groceries in Quebec,” Morel says.

Fast-forward to present day, and the cheese factory has an annual production of 300,000 kilograms.

While the abbey has developed a wide variety of cheeses over its 80-plus years of operation, one of its Gruyère cheeses remains its most popular product today: the Mount Saint-Benoît brand.

The abbey currently produces 11 different types of cheeses in total, including:

• Benedictine Blue;

• Extra Strong Blue;

• Smoky Blue;

• Hermit;

• Fontina;

• Smoked Fontina;

• Brother Jacques;

• Cheese Curds;

• The Monk;

• The Moutier;

• Mount Saint-Benoît.

Several of the plant’s cheeses have won prestigious awards for their quality, including 2024 First Prize for its Smoked Fontina at the Sélection Caseus competition, which recognizes the excellence of Quebec cheesemakers; and a Bronze Medal at the World Cheese Awards

“The development of the American market was the rebirth of the cheese factory, a new beginning to give a kick to the production process.”

Above

Completed in 1912, the landmark Abbaye-de-SaintBenoît-du-Lac monastery is home to 25 Benedictine monks who operate an on-site cheese production facility to help cover the building’s upkeep and maintenance expenses.

Below

A selection of the premium quality cheese wedges packaged on the cheese plant’s new Reiser VARIOVAC Primus 50 rollstock thermoforming machine installed by Reiser Canada to help the operation keep up with the brisk market demand for its boutique products.

In addition to cheese, the abbey also produces craft compotes, sparkling ciders and apple butters.

As well as to servicing big and small retailers, the landmark abbey is also a major tourist attraction in the region, drawing approximately 200,000 visitors every year.

To this day, all of the abbey’s cheeses are produced using 100-percent natural dairy products without any additives. This means that having top-notch pack-

Machine operator placing cheese wedges inside the film-lined cavities to prepare the VARIOVAC Primus 50 thermoform packaging machine for the next production cycle inside the Abbaye-de-SaintBenoît-du-Lac’s on-site cheese factory.

aging is paramount to factory’s success.

“The absence of additives in our cheese demands a high-quality packaging to ensure we can deliver a quality product to the consumer,” says Alex Lachapelle, production manager for the cheese factory at Abbaye-de-Saint-Benoît-du-Lac.

“A very important aspect of cheese making is the aging process,” he says. “For us, that happens in the packaging.”

For the past 20 years, the Abbaye-deSaint-Benoît-du-Lac cheese factory has

relied on a Dixie Union 2001 model packaging machine to package its cheese wedges.

But in 2023, the abbey decided to it needed to upgrade its machinery to keep up with growing demand.

“The Dixie Union machine has been a real workhorse for us,” Lachapelle relates. “But with the production levels being the way they are, we saw the need to upgrade.”

When deciding on a new packaging line, the abbey immediately reached out

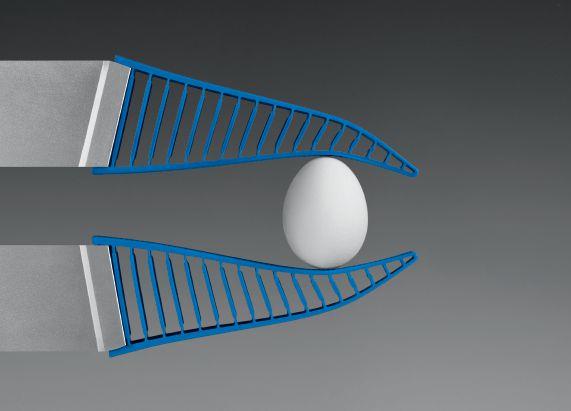

Left: The new Reiser VARIOVAC Primus 50 rollstock thermoform packaging machine installed by Reiser Canada enables the Abbaye-de-Saint-Benoît-duLac plant to produce up 64 high-quality airtight packs per minute.

Right: Close-up of the VARIOVAC Primus 50 thermoform packaging machine’s HMI (human-machine interface) terminal displaying all of the key operating parameters and critical production data in real time.

to Burlington, Ont.-based food processing and packaging machinery distributor Reiser Canada, which had been servicing the Dixie Union equipment for 20 years.

“There was proven reliability with the old machine,” says Jean Collette, sales representative for Reiser Canada. “Even though it was an older model, it showed the quality of our builds.

“The other machine was still running well,” he points out, “but as their production increased, they needed something faster to remove [packaging line] bottlenecks.”

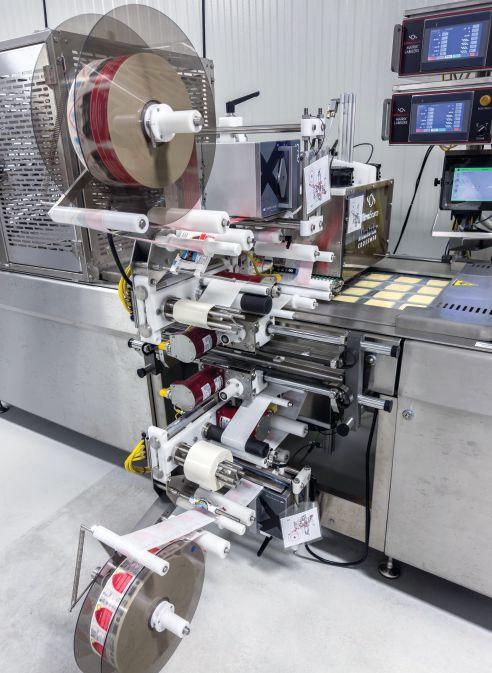

To meet current and future targets, the abbey invested in a Reiser VARIOVAC Primus 50 rollstock thermoformer, which offers significant improvements in packaging speed and ease of changeovers.

“With this machine we’ve increased throughput by three times,” Lachapelle states. “We’re now packaging 64 pieces a minute, and we still haven’t realized the full potential of the machine.”

Among many new performance benefits, Lachapelle cites VARIOVAC’s user-friendly HMI (human-machine interface) terminal as one of the system’s most important standout features.

“All of our operators have no trouble operating the machine, and they all find that the HMI interface is very user-friendly,” Lachapelle says.

The HMI’s home screen makes all aspects of the VARIOVAC Primus 50 rollstock thermoformer easily accessible to users. This includes the ability to enable or disable

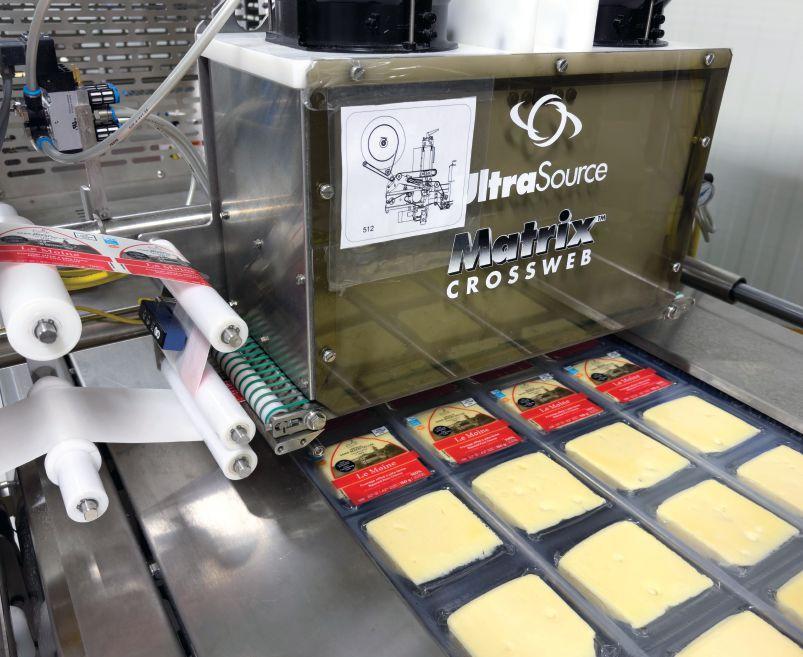

The Matrix Crossweb automatic film labeler manufactured by UltraSource integrated into the Reiser VARIOVAC Primus 50 thermoform packaging machine to apply pressure-sensitive labels at high speedsonto the top panels of finished packs processed on the high-performance system.

“We track our cheese from start to finish using the inventory management software that was developed by one of the very monks that lives here.”

the unit’s two labelers and cross-cutting knife, as well as to increase or decrease the speed of the machine.

After the cheese wedges are placed inside the unit and run through the sealing station, they travel through the labelling station, where the products are labeled by a top web labeler, before have a best-before date and lot number applied to the package by a bottom web labeler.

The cheese then enters the cross-cutting station to be cut into individual packages, with any excess plastic film automatically collected and removed.

“The VARIOVAC Primus 50 is a very rugged high-capacity packaging machine,” Collette says. “The four-point lifting mechanism, along with the rapid air system, ensures very high-quality packages with very reliable seals.”

Moreover, the VARIOVAC Primus 50 rollstock thermoformer is equipped with a rollaway forming die-top, which makes for very quick and easy die changeovers that generally take about 15 minutes to

Above left

complete.

Additional features of Reiser’s VARIOVAC Primus series models include:

• Frame lengths of five to 12 meters;

• Bottom film strengths up to 550 μ;

• Advance lengths of 100- to 700-mm;

• Packaging depth up to 135-mm;

• High-performance control IPC, swivel-mounted 12.1-touchscreen;

• Packaging output up to 20 cycles/min.;

• Handling a variety of packaging operations, including sealing, vacuum-packing, MAP (modified-atmosphere packaging), skinning, steaming and shrinkwrapping;

• Cooling integrated heat exchangers without consumption of water. The unit’s stainless-steel design offers a hygienic design, which is extremely im-

Finished thremoformed packs of cheese wedges being conveyed through the Bizerba weigh price labeler after emerging from the Reiser VARIOVAC Primus 50 machine, prior to being packed for shipping and distribution.

Above right

A big roll of pressure-sensitive pre-printed product labels going through the rollers of the Matrix Crossweb labeler positioned on top of the VARIOVAC Primus 50 machine.

portant to Abbaye-de-Saint-Benoît-duLac for food safety as per its global FSC 22000 food safety certification.

“Traceability is also very important to us,” Lachapelle states. “We track our cheese from start to finish using the inventory management software that was developed by one of the very monks that lives here.”

As Lachapelle relates, Reiser’s dedication to offering quality service during the upkeep of the old Dixie Union machine never wavered in the slightest, and this commitment to customer service excellence has continued since the VARIOVAC Primus 50 installation.

“The installation went very well,” Lachapelle says. “When we experienced a scheduling delay with the installation of our printer, Reiser really came through to make sure we were up-and-running in time.”

With the abbey’s plans for significant growth in the coming years, the VARIOVAC Primus 50 was the perfect fit to meet their packaging needs, he adds.

“In the coming years, our plan is to increase our production by 50 per cent,” Lachapelle concludes. “I’m glad we have Reiser on our side when it comes to the packaging.”

REDUCED WEIGHT VS. CONVENTIONAL ALTERNATIVES

MetsäBoard Pro FBB Bright is up to 35% lighter than conventional paperboards, while retaining the same quality and rigidity.

MORE THAN YOUR AVERAGE PAPERBOARD

metsagroup.com/metsaboard

TURNING A NEW LEAF

Organic greenhouse operator leverages leading-edge packaging line automation to ensure a smooth-running production process

By Andrew Snook

Packaging automation is finding its way into all industries, and the agricultural sector is no exception.

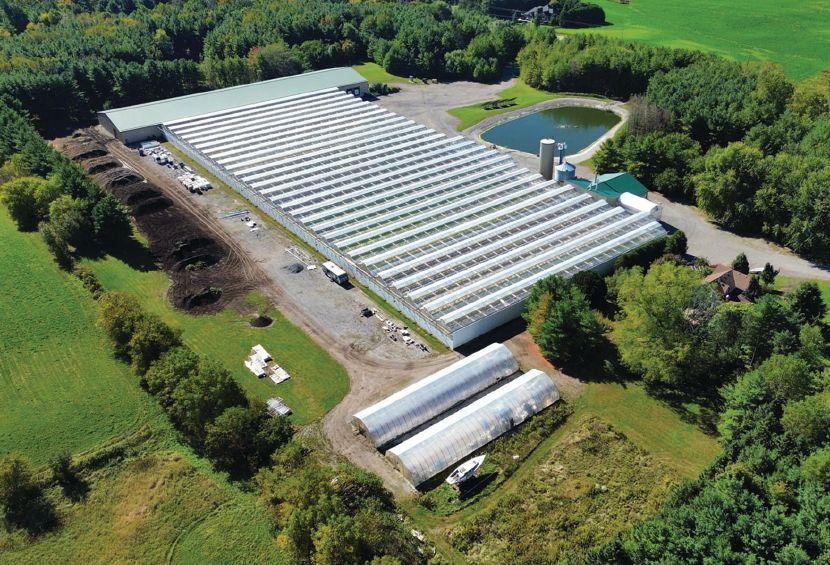

Greenbelt Greenhouse, an organic farming operation based in Lynden, Ont., recently invested in a stateof-the-art processing and packaging lines for its popular lines of leafy greens.

The farmer-owned and operated company was founded by Ian Adamson, who grew up in Ontario and the Yukon surrounded by plants his entire life, with Adamson dedicating more than 15 years of his life growing salad greens.

The company’s four main products branded under the Greenbelt Organic Greens label comprise Ontario Super Crunch (a mix of lettuce, arugula, mustard and pea shoots); Ontario Arugula; and Ontario Spring Mix (lettuces).

These popular lines of leafy greens can be found at a variety of major retailers including Loblaws, Fortinos, Zehrs, Sobeys, Metro and Foodland.

Recently, Greenbelt partnered with major fresh produce wholesale distributor Fresh Advancements to convert an existing greenhouse into an organic salad production facility.

In essence, they used the facility’s existing table system to develop a new system that allows the company to treat each table like a miniature farmer’s field.

There are approximately 1,800 tables in use in the growing operation, and Greenbelt utilizes an LED lighting system that allows it to grow 52 weeks of the year.

One of the key differences that makes Greenbelt stand out against the competition is the organic soil that the company creates itself, which is used for growing its products.

“We create a tremendous amount of flavor in our product because of the nutrition that we build into the soil,” Adamson says. “We are literally the only certified organic local brand in Ontario on the shelf.”

Growing with organic soil comes with its own set of production challenges, according to Adamson.

While the average hydroponic grower using chemical-based fertilizers can generate anywhere from 65 to 85 kilograms per square meter annually, Greenbelt is able to achieve 25 to 30 kilograms per square meter, Adamson acknowledges.

“But one of the reasons our product lasts so long and has so much flavor is because it’s grown in organic soil,” Andersen points out.

“We get comments from our customers all the time on our website about how crunchy and how flavorful it is,” Adamson adds. “Some people have commented they didn’t even realize that lettuce had taste.”

As Adamson relates, Greenbelt is a CanadaGAP-certified facility that is audited to ensure it is conforming to all the standards to be labeled a certified organic facility.

The greenhouse also recycles 100 per cent of its media back into its growing operations.

“We produce 150 cubic meters of soil per week at the facility,” he says, “and 80 per cent of that is our compost that we

An aerial view of the vast Greenbelt Greenhouse indoor growing operation located near Lynden, Ont., which houses approximately 1,800 mobile tables used to grow the company’s organic lettuce on a year-round basis.

have composted over a three- to fourmonth period.

“It is reutilized within the facility, substantially reducing our imports of peat moss,” Adamson explains.“Otherwise, we would consume five tractor-trailer loads of peat moss per month, whereas now we only consume one.”

Greenbelt also works extensively with the University of Guelph on various research projects to continuously improve its composting processes.

While planning out the automation of its packaging lines recently, Greenbelt reached out to Abbey Equipment Solutions in Burlington, Ont., who helped design the entire line layout, comprising a bagging line and a clamshell line.

Adamson says the knowledge of automation and packaging technologies showcased by Erik Van Coppenolle, technical sales representative for Abbey Equipment Solutions, was a major factor in the decision to work with them.

“I’ve seen Abbey at many trade shows,” Adamson relates, “and we’ve had many conversations.

“Their level of expertise and knowledge in regard to packing salad greens was the best that I came across in Ontario,” Adamson states.

Each of the greenhouse’s 1,800 growing tables is connected to a rail system that transports them to the pack house, where the greens are harvested using an automated saw system and then sent for sort-

ing, sanitizing, cooling, weighing and packaging.

“Our process, from when the product heads to the pack house from the harvester to being put in the box, ready for shipment, is four minutes flat,” Adamson says.

“We’ve invested substantial time, money and effort into automating the processes to keep our production costs as low as possible.”

Once harvested, the various leafy greens are sorted and conveyed via a

Turatti C-Force knocking belt conveying system, distributed by Abbey Equipment.

The mesh belt of the conveyor vibrates up and down to shake the product, whereby small holes in the belt allow for the small fines to be removed from the flow of good product and conveyed via a second belt to another area for collection.

“Essentially, we are cleaning the product,” Abbey’s Van Coppenolle explains.

“Were keeping the good leaves and getting rid of all the small fines.”

“We’ve invested substantial time, money and effort into automating our processes to keep our production costs as low as possible.”

After removing the fines, the leaves are conveyed through a Clean Works Clean Flow tunnel, which uses a combination of UV light, hydrogen peroxide and ozone to kill bacteria and sanitize the leafy greens instead of washing them with water.

“One of the reasons we get such good product shelf-life is because we do not wash our product,” Adamson says.

Before purchasing the system, Greenbelt had its products tested using a Clean Works system at the University of Guelph lab, which verified successful results.

“The Clean Works technology is critical to the food safety of our operation,” Adamson relates. “Erik was in charge of making sure that system integrated seamlessly into the Turatti conveyor belts and the rest of the line.”

The Clean Works system offers significant competitive advantages over other washing options that utilize large amounts of chlorine, Adamson points out.

“That (chlorine) actually shortens the shelf-life of the product, whereas this process kills any bacteria without damaging the product in any way, shape or form,” Adamson says.

After moving through the Clean Works tunnel, the product needs to be cooled

from top

The growing tables are mounted onto rollers and connected to a specially designed rail system that guide that transports fresh lettuce to the packhouse.

Loose lettuce being conveyed via the incline Turatti conveyor on the left to Liftvrac elevator conveyor that gently transport them to the weighscales up on the mezzanine level.

Manufactured by Clean Work in St. Catharines, Ont., the Clean Flow tunnel thoroughly sanitizes the leafy greens without water by utilizing UV light, hydrogen peroxide and ozone to kill off the bacteria.

Clockwise

automatic weighscales located on the upper mezzanine level.

before the packaging process can begin.

With the greenhouse temperature maintained at about 25°C, and the leaves needing to be cooled down to 4°C, the product is conveyed over to a Turatti cooling tunnel.

“The entire line runs continuously—no stoppages, and no people needed,” Van Coppenolle remarks.

After being cooled, the leaves are discharged on to a Turatti bi-directional belt, where the product moves in two directions.

It will either transfer to a bulk packaging station, where it is bagged manually in large bags for customers in the food service industry, or sent to one of two of the main packaging lines, where the leafy greens are placed into clamshells on one side or to the second bagging line on the other side.

Typically, this type of packaging would require two separate lines. But to save money, Abbey Equipment offered a flexible solution, whereby a mobile weigher on rails is positioned above two different

types of packaging lines below.

To further simplify the product delivery from the cooler to the mobile weigher, a Liftvrac elevator was mounted onto an anchored post—enabling the unit to pivot with the scale to reach the two weigher positions on the mezzanine.

“This eliminated the need for two scales and two elevators, which added up to a lot of savings,” Van Coppenolle says.

Abbey Equipment designed this section of the line so that the scale position ed on the top of a mezzanine is equipped with wheels and rails to move with whichever type of product is being packaged at the time.

“While you’re delivering product on one side and packaging in one way, you obviously cannot produce on the other side,” Van Coppenolle notes, “so you have to coordinate your production accordingly.”

Since leafy greens are a fragile product, it is critical that the conveying solution used is extremely gentle.

“Liftvrac has a really interesting solu-

Manufactured in Germany by Multipond and distributed in Canada by Abbey Equipment Solutions, the model MP-14-3800 scaling system (top) is equipped with a high-performance

Argus 3D camera vision system (middle) that displays everything that happens up on the mezzanine level on the system’s HMI (human-machine interface) terminal panel below in real time.

tion that elevates the product to the scale without the use of flights, which can potentially cause product damage,” Van Coppenolle says.

“It use a flexible flat-belt system, which wraps itself around the product and transfers the product up to the Multipond scale, where it opens up again at the discharge.”

Also distributed by Abbey Equipment, the Liftvrac is equipped with sensors that read the amount of product being conveyed to the intake of the unit.

If too much product is being fed into the Liftvrac’s infeed hopper, the bi-directional belt will reverse direction and act as a buffer until the Liftvrac releases the product and the belt carries it to the infeed again, Van Coppenolle explains.

The process is entirely automated, so there is no need for employees to monitor this part of the line, he adds.

As for the line’s Multipond MP-143800 scaling system, Van Coppenolle relates that Multipond has patented a stepped profile design of the stainless-steel surface that effectively prevent product from sticking to the scale.

Above Top: The Turatti C-Force conveyor features a patented dual vibrating belt design to facilitate the removal of foreign bodies from the product stream.

Above Bottom: The Liftvrac elevator conveyor depositing leafy lettuce into the Multipond

Clockwise from top

An Argus 3D camera vision system is mounted directly above the Multipond weighscales.

A FANUC robotic arm incorporated into the Robotic Case Packer system from Consolidated Technologies.

Stacks of corrugated cases from Atlantic Packaging Products used to ship Greenbelt lettuce to market.

Erected corrugated cases being loaded with filled clamshells inside the Robotic Case Packer.

The Robotic Case Packer can pack and seal up to 20 shipping cases per minute.

Clear plastic clamshells making their way onto the filling line.

The system is also equipped with Multipond’s high-performance Argus 3D camera vision system.

“This allows the scale to see where the product is located on each of the scale’s vibrating feeding trays and adjust the infeed amplitude of each tray accordingly,” Adamson says.

“This results in an even flow dispersion of the product into the weigh hoppers.”

Typically, a staff member would be standing on top of the scale throughout an entire shift, distributing the product evenly across the surface of the scale to maintain the scale’s accuracy and speed. This is no longer necessary with the Argus 3D camera system.

“I don’t have to have anyone on top of our scale maintaining product flow; it does this automatically,” Adamson says.

“Down below the mezzanine, there’s a screen where you can see whether there are any jams on top of the scale,” he says.“It makes my staff quite happy.”

The Argus 3D camera system is fitted above the Multipond scale to scans each vibrating pan of that scale, identifying the

location of all the leafy greens on the scale.

After scanning the location of product, it will decide which pan to vibrate in order to disperse the product in an even flow.

After the portions are weighed, the product moves through a tamping system that deposits the pre-determined portions into the clamshells.

Once the system has placed the portion

into a clamshell, the operator then visually inspects each package to ensure there is no product sticking out before the lids are sealed.

The clamshells are then conveyed to a packaging station, where the clamshells are sealed and labeled using a Weber Marking Systems labeler.

The product is then scanned using

package up to 20 cases per minute, which are fully erected, loaded, sealed and labeled in a small-footprint—offering significant room for growth.

A Weber Marking Systems labeler applying product labels onto the passing clamshells.

A finished clamshell passing through the Anritsu metal detector to ensure it’s free of any metal particles.

A Videojet case coding system applying the required variable product information and barcodes onto a box panel.

Anritsu’s SSV/M6 Combo checkweigher and metal detector.

“This piece of equipment is all integrated into one unit with its own reject system,” Van Coppenolle points out.

“The solution for rejecting product in this case is quite simple,” he says, describing how all Rejected product is moved via a flipper reject system and conveyed in one of two directions.

“On one side, we have contaminants going into a locked bin,” he says. “On the other side, we have rejected underweights and overweights.”

Finally, the approved product is then conveyed from the packaging area over to the case-packing room housing a Robotic Case Packer Unicel-20R machine from Consolidated Technologies.

The unit is equipped with a robotic arm and oversees the entire case-packing process: from loading the blank cases to opening the cases, presenting them to the robot arm, loading products into the cases, closing the cases, gluing or taping them, and finally labeling them.

An employee then moves the skids of product cases away and replaces the skid for the next pallet load.

While the new packaging line typically handles up to 2,400 clamshells per hour, the system has the capacity to

Adamson says is extremely impressed with the technical knowledge and expertise that Abbey Equipment showcased in helping him find a solution for his packaging and processing needs.

“We have a very complex line, with a lot of integration between Turatti, Liftvrac, Multipond, Anritsu and Consolidated Technologies,” Adamson sums up.

“Integrating all those systems and the technical expertise provided by the Abbey team has been an incredible experience.”

The HMI touchscreen panel of the Anritsu checkweigher displaying the packaged product’s precise net weight.

From left

Above Left: Abbey Equipment Solutions technical sales rep Erik Van Coppenolle (left) joins Greenbelt head grower Alice Farris near the packhouse’s shipping dock.

Above Right: Greenbelt Greenhouse founder Ian Adamson enjoying a light moment.

FROM START TO FINNISH

Finland’s leading paperboard producer aims to expand its ambitious sustainability blueprint far and wide through determined efforts to grow its North American client base

By George Guidoni, Editor

Photos by Lewis Stiefel

Overused terminology is often fraught with the risk of being dismissed as a mere trendy buzzwords.

But there is nothing remotely trendy or faddish about the bold and ambitious efforts by Finland’s leading paperboard producer Metsä Board to continue setting new global benchmarks for sustainable production of high-quality paperboard packaging materials to accelerate inevitable emergence of the new Circular Economy business model.

Formed under its current corporate moniker in 1986, the Helsinki-headquartered company is an operating division of one of the country’s largest forest products conglomerate Metsä Group, whose other core business include tissue and cooking papers ( Metsä Tissue ), pulp (Metsä Fibre), and wood products ( Metsä Wood ), as well as wood trade and forestry services ( Metsä Forest) division.

While the publicly-traded parent company currently ranks as the world’s 23-largest producer of pulp and paper products, its Metsä Board division, also listed on the Nasdaq Helsinki stock exchange, is a dominant player in the global paperboard industry’s pecking order.

As a widely acknowledged leader in

the production of folding boxboards and white kraftliners in Europe, as well as the world’s largest producer of coated white kraftliners, the company sells its fresh-fiber paperboards—comprising folding boxboards, foodservice board and white kfraftliners—to over 100 countries worldwide, enjoying a stellar and well-earned reputation for high product quality and customer service excellence.

Employing about 2,300 people and generating annual revenues of over US$2.1 billion, Metsä Board has the capacity to produce 2.5 million tonnes of paperboard—along with 2.87 million tonnes of chemical pulp and BCTMP (bleached chemi-thermomechanical pulp—per year.

This impressive output total is generated at the company’s seven modern and highly efficient production sites in Finland (Kyro, Tako, Simpele, Äänekoski, Kemi, Joutseno and Kaskinen) and one in Sweden (Husum).

While Metsä Board is not yet the household name it is in the North American CPG (consumer packaged goods) industries as it is in the European markets, that may well change in coming years, with the company having set sights on North America for a major expansion of its global operating footprint.

As part of this strategic marketing focus shift, the company has recently

Metsä Board’s vertically-integrated Äänekoski paperboard mill has the capacity to produce 260,000 tonnes of flying boxboard and 140,000 tonnes of sheeting per year, while generating enough surplu fossil-free energy during the production process to help heat homes in nearby communities.

organized a press tour for leading North American-based trade media—including the Canadian Packaging magazine—involving visits to its Nemus Futurum forest visitor center; the Äänekoski paperboard mill in central Finland; and the newly-opened nearby Excellence Center, the company’s newly-opened R&D and paperboard/ packaging innovation and packaging design lab.

Featuring highly-informative daily presentations by the company’s senior management executives and sustainability experts, the three-day tour revealed not only the company’s worldclass manufacturing competencies and technological expertise, but also its deep-rooted commitment to advancing

packaging sustainability and achieving carbon neutrality by 2030.

In light of the company’s already impressive list of environmental and CSR (corporate social responsibility) milestones achieved to date—including certification to five different global ISO standards related to responsible environmental practices, along with FSC and PEFC —there is little reason to question the company’s ability of meeting all the major sustainability targets by its self-imposed 2030 deadline.

These include:

• 100-percent fossil-free total energy consumption, which is currently estimated at 90 per cent;

• Fossil-free mills with zero-fossil carbon-dioxide emissions, both from its own production and all purchased energy.

• Fossil-free product portfolio by the end of 2030.

• 35-percent reduction in process water use per tonne of product, along with 10-percent improvement in energy efficiency by the end of 2030;

• Achieving at least a 90-percent share of certified wood out of all sourced wood material.

As challenging as these targets are, Metsä Board’s sustainability mission is also impacted by the complexity of the organizational structure of its forest lands, whereby the lion’s share of its raw fiber sources originates at more than 90,000 different Finnish forestland-owners that make up the Metsäliitto Cooperative , the Metsä Group’s parent company.

That said, Metsä Board’s executives insist that all of its key suppliers are on the same page in terms of a collective pursuit of its environmental goals and objectives.

This unity of purpose is strongly underscored by the company’s unique forestry management practices based on core principles of the so-called Regenerative Forestry, which is a polar opposite of the commonplace, industrial-scale tree plantation forestry practiced by most of Metsä’s major competitors.

Whereas plantation forestry focuses of producing the highest volume of wood in the shortest period of time— usually by planting one type of tree to create a monoculture forest—regenerative forestry is all about nurturing and increasing species biodiversity for both the trees and the forest inhabitants living among them—plants, animals and insects alike.

According to Metsä, “Our goal is to strengthen the value of natural capital together with the economic value generated by forests, as in addition to trees, commercial forests produce numerous vital natural benefits for both people and the environment.

“Our goal is to strengthen the value of natural capital together with the economic value generated by forests, as in addition to trees, commercial forests produce numerous vital natural benefits for both people and the environment.”

These environmental benefits include clean water, propagation of pollinators, promoting the growth of vari-

Above Äänekoski paperboard mill’s manager Timo Tallinen (second from left) joins traveling media for a group photo in front of the gigantic Voith paperboard making machine started up in 1966.

Above right

Metsä Group’s leading nature expert Timo Lehesvirta explaining the company’s commitment to Regenerative Forestry forest management practices.

Bottom right

Metsä Group’s vice-president of climate and circular economy

Maija Pohjakallio delivers an informative presentation on the company’s broad-ranging sustainability efforts.

ous pollinators, berries and mushrooms, enabling more enjoyable recreational use for the public, and creating effective new carbon sinks, among others.

Naturally, optimizing these laudable benefits takes a lot of hard work and dedication, requiring virtually daily execution of various specific science-based actions such as:

• Utilizing native tree species;

• Diversification of tree species and structural (age) features;

• Adding old trees and varied decayed wood;

• Protection of valuable habitats.

Despite all the required extra work and effort, “Metsä Group is committed to the principles of regenerative forestry,” according to the company.

“Regenerative forestry is carried out every day in Finnish forests, and we are constantly improving our forest management services.

“We want to leave forests for future generations in a better condition than we have received them ourselves—more vibrant, diverse and climate-resilient.”

The company’s noble goals and conservation efforts are not exclusively altruistic: there are also many business good business reasons for using regenerative forestry to secure a reliable source of fiber to sustain future business growth and continuous innovation.

Whereas plantation forestry typically produces fiber derived from one tree species, Metsä Board’s fiber supply comprises fiber from four different native species—pine, spruce, birch and aspen—to provide a key competitive

advantage of having a varied supply of raw material to work with.

With each different species’ fiber boasting its own unique profile in terms of physical properties and attributes— strength, density, porosity, etc.—the company’s production sites have a lot more choice and flexibility to innovate and experiment with different blends to achieve superior product quality across all the different end product they make, while helping he company continue to to diversify its product portfolio to grow its customer base.

“With forestry being the base for all out business units, they have all committed to the principles of regenerative forestry,” Metsä Group’s vice-president of climate and circular economy Maija Pohjakallio noted in her welcoming presentation.

“Collaboration and partnerships are really key assets in our operations,” she noted, “and we believe that collaboration is the way for us to go forward on a strategic level.”

Because a product’s carbon footprint is only one of 16 different “impact factors” scrutinized in a typical LCA (lifecycle analysis) evaluation, Pohjakallio says it is essential to collaborate with the company’s suppliers, land and sea transportation providers, energy producers, and other key business partners to pursue a more “holistic approach to sustainability” that is ultimately reflected in a more favorable LCA evaluation.

“There are other impact factors like water quality, nutrient levels, toxicity,

Leaving tree stems in place after harvesting is an integral part of the Regenerative Forestry forest management practices that naturally stimulate the growth of mushrooms, berries and other native fauna to maintain healthy species biodiversity in the forestlands that supply Metsä’s manufacturing sites with high-quality wood fiber stock.

ozone depletion, etc., which we can’t control directly,” she said.

Nevertheless, Metsä Board is continuously working on how to make more end-products with less resources—primarily through aggressive lightweighting—without compromising on their functionality, performance or recyclability.

Said Pohjakallio: “If were to convert our total 2.6-tonne paperboard capacity into finished boxes, we’d be producing the equivalent of 200 million 19-gram boxes a day.

“But if we were to make those boxes just one per cent lighter, we’d be able to produce two million more packages per day,” she said, “without using any additional natural resources.

“So even a little lightweighting can make a big difference.”

As Pohjakallio pointed out, “Making paperboard is actually a very high-tech process.

“It is not just about taking the pulp, draining the water from it, and pressing it into sheets,” she said.

“It’s more about optimizing the use of fiber by combining different paper layers made from different pulp into the final paper construction,” she summed up, “which requires a lot of high-end technology and scientific knowledge to do it right.”

This high-tech process is continuously performed and refined at the company’s Äänekoski mill in central Finland, which produces coated bleached paperboard for high-performance packaging and graphic end-use applications.

Originally started up back in 1899, the mill boast annual capacity to produce 260,000 tonnes of premium-quality folding boxboards, along with about 140,000 tonnes of sheeting.

Employing about 200 people, the mill is home to a gigantic Voith papermaking machine that has undergone numerous major upgrades since it started up in 1966, virtually running like brand new at speeds of up to 800 meters per minute.

The primary product produced on the machine is the proprietary Pro FBB Bright brand of fully-coated bleached

paperboards with white back lining.

The board’s three-layer structure — comprising two layers of chemical pulp with a layer of high-yield pulp sandwiched in between—is coated on both sides to provide superior printability and high brightness, creating an ideal base for special finishing effects and embellishments, along with excellent sensory properties for sensitive premium products.

“The three-layer structure we produce here is very light, but it has very good strength properties,” said the mill’s manager and vice-president Timo Tallinen. “It is actually a very high-tech product.”

Approved for direct food contact as per the food industry’s ISO/FSSC 22000 food safety management systems certification, the Pro BBB Bright folding boxboard’s lightweight but stiff construction make it a popular choice for producers of chocolate, confectioneries, food and pharma products, personal care and beauty items, wines and spirits, consumer electronics, graphic applications and point-of-sale materials.

As Tallinen explains, 90 per cent of the wood fibers used at the mill—derived primarily from softwood and birch sourced from Finnish forests—is fully certified and traceable.

According to Tallinen, the mill consumes roughly 6.5 million cubic meters of wood per year, receiving an average of 240 truck-loads and 70 fully-load ed railcars full of wood to the mill’s gates each day.

“At the beginning of the pulping process, the wood is debarked in debarking drums, after which it is dried and forwarded to for gasification to be converted into product gas for the mill’s

lime kiln,” Tallinen said.

“This renewable gas is used to replace around 45,000 cubic meters of heavy fuel oil per year,” Tallinen pointrd out.

“The debarked wood is chipped, and the wood chips are forwarded to huge chip piles just outside the mill,” Tallinen continues, adding it takes about 15 hours for the fresh chips to be turned into pulp.

“There are three piles of chips—pine, birch combined with spruce, and purchased chips—which are unloaded according to the species of the trees need ed for a particular process.

“The chips are then forwarded to the digester, where they are mixed with processed chemicals to produce pulp fiber during the cooking phase,” he says, “whereby the fibers are separated from each other.

“The chips are cooked in a chemical called ‘white liqueur,’ which turns into black liqueur during the cooking process. The black liqueur passes through the evaporation plant into the chemical processing cycle.

“After the pulp is bleached, it is sprayed onto the wire in the drying department, where most of the water is removed by suction and pressing,” Tallinen relatef.

“After all the remaining water is evaporated with the blast of hot air on one of our mill’s three cutting machines, which are layered in into big stacks and taken away for warehousing.”

Tallinen pointed out that the mill’s highly-efficient recovery process produce 2.4 more energy than it needs for its operation, enabling it to supply excesses energy to heat homes in nearby communities.

As he summed up, “All of the wood,

raw material and production side streams are used to produce specialty bio-products and energy, so not even a single stick of wood is wasted at the mill.”

This zero-waste production process is an integral part of Metsä Board’s ongoing sustainability journey that the company hopes to leverage in coming years to accelerate its growth in North American markets.

With the U.S. already accounting for a 27-percent share of the company’s paperboard exports, the market presents a unique opportunity for Metsä Board to cement its credentials as a leading global paperboard manufacturing powerhouse with impeccable sustainability credentials and commitment.

Based on the evidence presented during the aforementioned media tour of the company’s expansive asset base, there is no doubt that Metsä Board has everything it needs to make it happen.

Package design specialists working at Metsä Board’s new state-of-the-art Excellence Center facility make extensive use of simulation software, virtual reality and other leading-edge technologies to produce virtually market-ready packaging prototypes (see below) for a broad range of CPG and foodservice industry customers.

A sampling of packaging prototypes produced at Metsä Board’s newly-opened Excellence Center innovation hub located a short walking distance from the Äänekoski paperboard mill.

Packaging made with nature available through Spicers

Our future depends on respecting nature.

That is why Metsä Board sources raw material – pure fresh wood fibre – from sustainably managed northern forests. Together with its partners, Metsä Board plants over 30 million trees every year to ensure that forests grow more than they are used. Lightweight paperboards help reduce the carbon footprint of packaging.

Naturally pure, fresh fibre paperboards are safe for even the most demanding end-uses such as food, pharma and luxury packaging. All the way from the forest to the consumers and with easy recyclability, Metsä Board’s premium paperboards are the natural choice for sustainable packaging.

Count on Spicers’ Custom Sheeting Capabilities.

At Spicers, we prioritize your production efficiency by stocking a comprehensive local roll inventory, ensuring that customers never face downtime.

With our commitment to speed and fast delivery, we streamline client operations, providing the market with sustainable solutions exactly when our clients need them. Count on hassle-free service that enhances your productivity and keeps your business running smoothly.

Together, we make the perfect package.

Call your local Spicers Sales Consultant for more information. 877-790-2335

MESSAGE ON A BOTTLE

Groundbreaking technology enables Ontario vintner to make a big splash in the marketplace with one-of-a-kind paper bottle

By George Guidoni,

Editor

Putting old wine in new bottles is a rudimentary daily task at commercial wineries all over the world. But thanks to recent groundbreaking advances in liquid packaging technology, a prominent Ontario winemaker is making a big splash in the marketplace with the launch of proprietary new paper bottles that are unlike anything the wine industry has seen up to now.

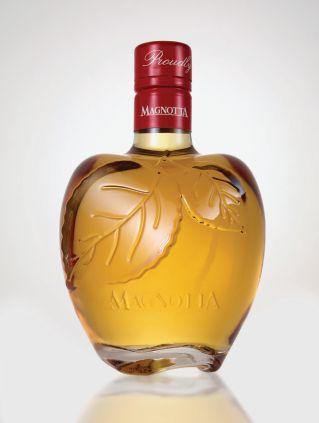

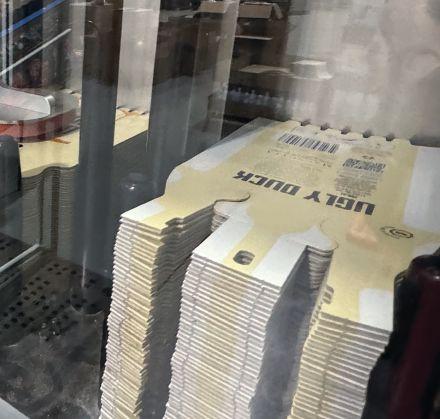

Called KB Bottle, the innovative container was launched at select LCBO (Liquor Control Board of Ontario) retail outlets earlier this year as part of a rollout of the Ugly Duck wine brand produced by Magnotta Winery , Ontario’s third-largest winemaker.

Founded in 1990 by Gabe and Rossana Magnotta, the company operates two beverage production facilities located in Beamsville—right in the midst of the Niagara Peninsula’s winemaking heartland in southwestern Ontario—and the city of Vaughan, a fast-growing suburban community a short drive north of Toronto, as well as two craft breweries and a craft distillery.

Between them, the two state-of-the-art plants and other production facilities produce over 180 different wines to suit just about every dining or entertaining occasion, as well as a multitude of craft beer, distilled spirits and a variety of alcoholic and non-alcoholic beverages distributed under Magnotta’s own brand labels and those of its co-packing customers.

“Our wines, beers and spirits stand out due to our innovative approach to product creation,” says Magnotta’s senior marketing manager Kimara Oram.

“We pride ourselves on our craftsmanship and dedication to quality, as demonstrated by our award-winning icewines and the Sparkling Ice brand icewine, which was the first of its kind in the world.

“Additionally, we introduced Enotrium, Canada’s first Amarone-inspired red wine,” Oram relates, “while our craft beers, like True North and Grand River Brewing, are also recognized for their quality.

“Additionally, our distillery produces unique spirits such as our trademarked Ice Grappa, which is made from our icewine grapes and offers a product experience unlike any other.”

As Oram points out, “Magnotta Winery is steeped in innovative winemaking and local history,” citing over 5,000 prestigious industry awards that the family-owned company has won at numerous domestic and international competitions over the years.”

Adds Magnotta’s vice-president of operations Marco Finolio: “We grow grapes from our 180 acres of family-owned and operated vineyards in the heart of the Niagara Peninsula, one of the finest wine regions in the world, to create our award-winning, 100-percent Ontario vintages.

Above

An eye-catching point-of-purchase display of the Ugly Duck wine brand products packaged in paperboard KB Bottle containers makes a cheerful statement inside the company’s retail store in Vaughan, one of Magnotta’s 14 retail outlets located across Ontario.

Right

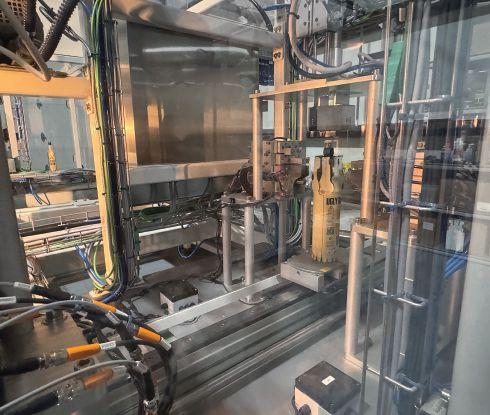

Close-up of the KB Bottle filling process at one of Magnotta Winery’s state-of-the-art production facilities located in Vaughan, Ont.

“For additional grapes, we support the agricultural growth of the province by partnering with local independent grape growers,” Finolio relates.

“From grape to bottle to the table, we are there every step of the way to handcraft our wines,” he proclaims.

“The entire winemaking process—harvesting, crushing, fermentation, vinification and bottling—is managed exclusively by our winemakers and production teams at our expansive facilities.”

Finolio says that over the years Magnotta has established solid relationships with several important packaging suppliers to maintain a premium attractive look for all of its major brands.

These include the Cambridge, Ont.-based sustainable packaging specialists Kinsbrae Packaging, who in fact make and supply the fully-recyclable KB Bottle paper continers for the Ugly Duck line of red and white wine blends.

The containers’ exterior is made from 100-percent recycled paperboard blanks formed around the metallized plastic bladders, which inserted inside the paper bottles as they are being formed into shape on a Frugalpac machine said to be the only machine of its kind anywhere in the world at the moment, according to Kinsbrae.

“It is very new technology, and we are very excited to be the first ones to use it to make these highly sustainable bottles made from 100-percent recyclable components,” says Kinsbrae founder and president Shawn Bonnick.

Offering a multitude of performance and sustainability benefits, the novel lightweight containers are virtually unbreakable during production and distribution, while offering a dramatically lower carbon footprint—up to six times less—

compared to traditional glass bottles.

These attributes quickly convinced Magnotta Winery to adopt the bottles for their newly-developed Ugly Duck wine brand that is specifically targeted at the younger demographic who are firmly committed to environmental protection and sustainable products and packaging.

“In a category often seen as traditional, the paper bottle offers a refreshing and novel approach, sparking curiosity and conversations around innovation,” Oram explains.

“We’re hoping that the packaging will encourage trial and adoption from wine drinkers looking for environmentally-conscious solutions,” she states.

“The Ugly duck Paper bottle wines are aimed primarily at millennials and Gen Z consumers, who are socially and environmentally conscious and who appreciate convenience and functionality, as the lightweight, shatterproof paper bottle will appeal to their on-the-go lifestyles.”

Says Oram: “The Ugly Duck wines encourage consumers to ‘Embrace Your Inner Duck’ by celebrating individuality and the unique qualities that make each wine drinker special.

“This messaging highlights that, like the Ugly Duck, we all have something to offer—whether it’s the way we approach life or the choices we make, including opting for eco-friendly products.”

As Finolio relates, the introduction of KB Bottles required some equipment modification to the existing line to enable the product to run at commercial-level speeds, but working closely with Kinsbrae enabled Magnotta to overcome all the technical challenges encountered along the way.

“Due to the specific requirements and lack of equipment available in North America, we partnered with Asset Care & Management (AC&M) Inc., who designed a filler specific to the paper bottle,” says Finolio.

“So far, it has been working well,” he notes. “The biggest difference is in the way Frugalpac bottle is designed and produced.

“The bottle requires a volumetric filler—less widely used in

Above

Close-up of the unique precision capping process and equipment deployed on the Ugly Duck bottling line at Magnotta Winery’s Vaughan production facility.

Left Magnotta Winery’s senior marketing manager Kimara Oram (left) and vice-president of operations Marco Finolio at the Vaughan plant’s expansive tank farm used to ferment and distill a variety of wines and other craft beverages.