Premium meat supplier pivots into the grocery E-commerce space to regain lost restaurant sales Story on Page 15

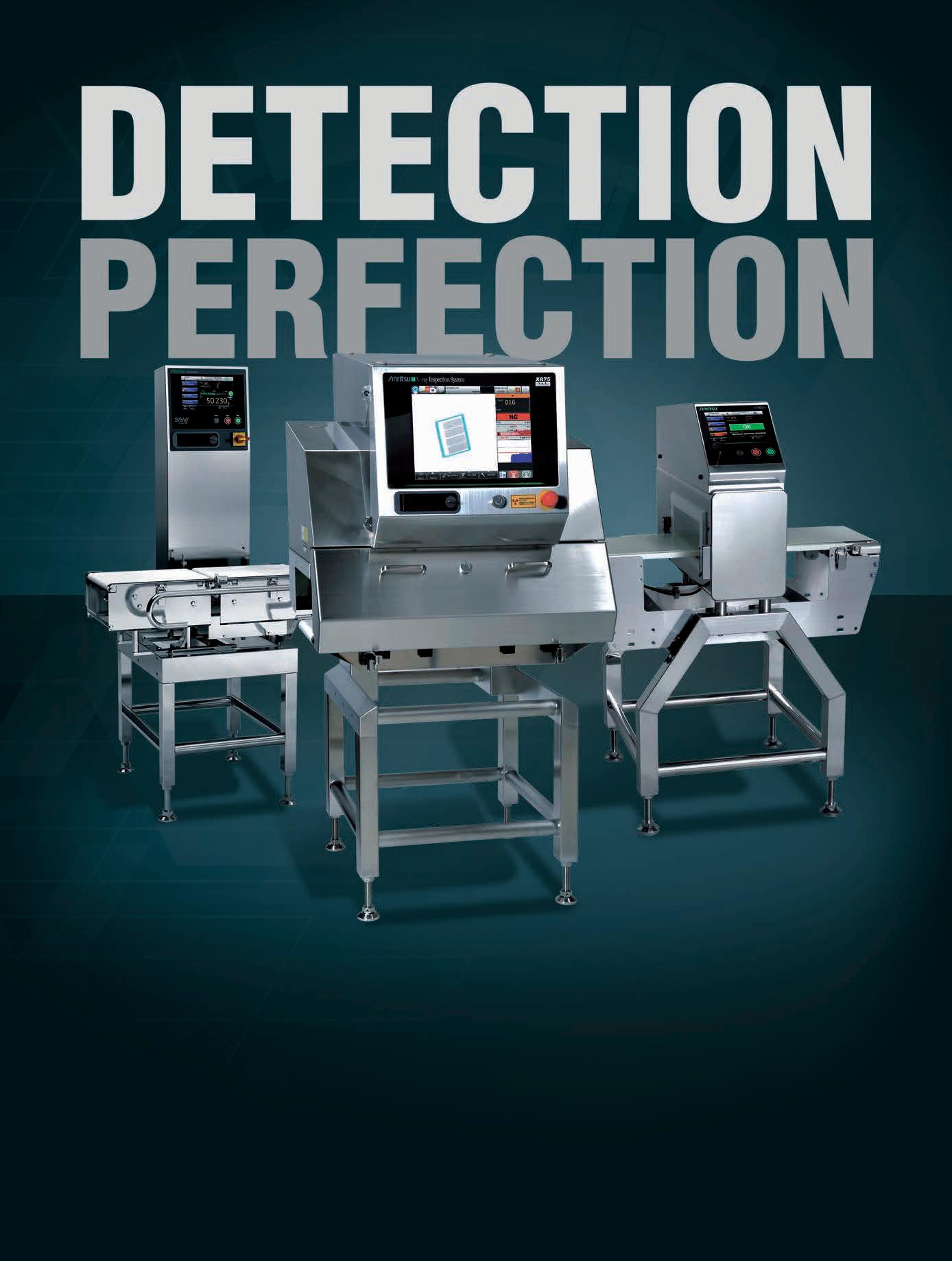

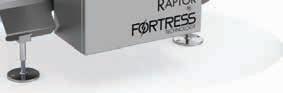

Leading-edge technology trusted worldwide for superior product inspection and contaminant detection. Your brand is on the line, so you need equipment that’s better than good. Anritsu systems deliver performance, reliability and low total cost of ownership. Plus, we back our long-lasting equipment with unparalleled service and support. Contact our exclusive Canadian distributor, Abbey Equipment Solutions at abbeyequipment.com or 905-681-3010

4 George Guidoni

A successful in-person trade show highlights the industry’s resilience.

LIFTING SPIRITS

36 Djavor Dukic

CHECKOUT

40 Naomi Hiltz

Joe Public speaks out on packaging hits and misses.

ISSN 1481 9287. Canadian Packaging is published 10 times per year by Annex Business Media. Canada Post

Publications Mail Agreement No. 40065710. Return undeliverable Canadian addresses to: Circulation Department, 111

Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1. No part of the editorial content in this publication may be reprinted without the publisher’s written permission. © 2021 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of this publication. Printed in Canada.

Premium meats processor successfully pivots into the fast-growing e-commerce channels in wake of restaurant industry lockdowns threatening its very survival.

Dry foods processor using highperformance flexible packaging machinery and materials to keep its business growing during the pandemic.

Thriving midwestern craft beer producer raises a hearty toast to successful installation of robust dry-running conveyor line.

Rapid growth in demand for e-commerce corrugated containers prompts innovative technological developments in adhesive applicating systems.

New advances in case forming machinery reduce human intervention to bare minimum to improve throughput speed and workplace safety.

L Rowe Beef Co. Ltd. co-founder and owner Rod Rowe holding up a pair of premium-quality marbled Wagu Angus striploin steaks sealed in air-tight thermoform packaging perfectly executed on world-class machinery supplied to his processing facility by Reiser (Canada) Co.

Good news has been a preciously rare commodity over the last 20 months or so of living with the dreaded global coronavirus contagion and all its devastating fallouts, so maybe it’s time to celebrate whatever silver linings we can glimpse at right now to acknowledge the impressive resilience and relevance of the global packaging industry we all serve in so many di erent ways.

And there are few organizations out there serving with the remarkable passion, competence and optimism that the venerable PMMI, The Packaging Association for Packaging and Processing Machinery does with resounding aplomb.

At a time when large industry gatherings are still a speculative touch-and-go endeavors for many industries eager to get back to business at full speed ahead, the highly successful PACK EXPO Las Vegas international packaging exhibition at the Las Vegas Convention Center in late September o ered a reassuring reminder of the critical role that the packaging sector plays in our economy and society.

visitors to the PACK EXPO

Las Vegas packaging exhibition in late September

According to PMMI, more than 23,000 visitors passed through the 1,500-plus exhibits during the three-day-event, making it the largest trade show in the U.S. of any kind this year so far.

Giving the background context, it is hardly an exaggeration to call it “perhaps the most important PACK EXPO Las Vegas and Healthcare Packaging EXPO in its history,” as PMMI does in its postshow press release, citing rave reviews from top exhibiting companies about the extraordinary levels of interest in their displays, including spontaneous bidding wars for their show-floor equipment.

“Exhibitors and attendees alike were energized by the number of people who attended and, more importantly, the business conducted from the moment we opened the doors,” says PMMI president and chief executive o cer Jim Pittas, suggesting such displays of pent-up demand for state-of-the-art packaging solutions are only a tip of the iceberg.

According to the State of the Industry U.S. Packaging Machinery Report released by PMMI at the show, 2020 turned out to be a record year for the North American packaging machinery manufacturers, with the total size of the market in the U.S. soaring by 14.4 per cent

to US$12.3 billion, and domestic shipments up 14.7 per cent to US$9.4 billion.

As the PMMI report cheerfully forecasts, U.S. packaging machinery shipments are poised to grow by an average of 5.2 per cent to reach $12.8 billion in 2026, with food, beverage, household/industrial/agricultural chemicals, and pharmaceutical sectors accounting for the lion’s share as usual.

For all that, a rising tide is no guarantee for the lifting of all boats. Ultimately, it is the individual companies who will determine their own fates, which will be defined by how well they come to grips with the prevailing industry trends highlighted in the PMMI report, including:

DEMOGRAPHIC FACTORS

Population growth in the U.S. has slowed to 0.35 per cent in 2020, while millennials have surpassed Baby Boomers as the largest population group and proportion of the U.S workforce. “Product preferences, and subsequently packaging solutions, between these two generations vary significantly, supporting demand for new and flexible machinery,” PMMI states.

ENVIRONMENTAL FACTORS

As a result of growing attention to the depletion of natural resources, social, regulatory, and tax pressures are driving increased demand for environmentally friendly solutions.

ECONOMIC FACTORS

“As recovery from the COVID-19 recession is completed, the global economy is moving into the sweet spot of the current expansion,” PMMI states. “As vaccination rates increase and pandemic-related restrictions are lifted, consumer spending is surging.”

AUTOMATION AND ROBOTICS

Look for machine vision and robotics, especially collaborative robots, to become new hot sought-after capabilities in packaging machinery.

IIOT AND WIRELESS CONNECTIVITY

The Industrial Internet of Things (IIoT) will continue to have an impact across the product life-cycle in the packaging industry including design, operation, maintenance, and the supply chain.

E-COMMERCE

It’s here, it’s everywhere, and it will remain at the core of packaging’s New Normal.

NOVEMBER 2021 | VOLUME 74, NO. 11

Reader Service

Print and digital subscription inquiries or changes, please contact: Anita Madden, Audience Development Manager Tel: (416) 510-5183 | Fax: (416) 510-6875 Email: amadden@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Senior Publisher

Stephen Dean | (416) 510-5198 SDean@canadianpackaging.com

Editor George Guidoni | (416) 510-5227 GGuidoni@canadianpackaging.com

Account Coordinator

Barb Comer | (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

Media Designer Brooke Shaw | (519) 428-3471 bshaw@annexbusinessmedia.com

COO Scott Jamieson SJamieson@annexbusinessmedia.com

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE: Canada $78.50 per year,USA $179.50 (CDN) per year, Outside Canada $203.50 (CDN) per year, Single Copy Canada $10.00, Outside Canada $27.10.

From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy O icer Privacy@annexbusinessmedia.com Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2021 Annex Business Media. All rights reserved. This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice. You should not act on information contained in this publication without seeking specific advice from qualified engineering professionals. Canadian Packaging accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. Canadian Packaging receives unsolicited materials, (including letters to the editor, press releases, promotional items and images) from time to time. Canadian Packaging, its a iliates and assignees may use, reproduce, publish, republish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

We acknowledge the [financial] support of the Government of Canada

GEORGE GUIDONI, editor GGuidoni@canadianpackaging.com

World’s biggest co ee brand puts everything on the table with big sustainability goals

As the world’s largest co ee brand accounting for about 10 per cent of all the co ee produced worldwide each year, NESCAFÉ co ee has tremendous influence and clout to

help make the world a better place, which is precisely the point of the far-reaching new Cup of Respect sustainability platform unveiled by its brand-owner Nestlé last month.

Hailed as the most ambitious co ee sustainability plan in the world, the initiative explicitly acknowledges the key role played by the company’s Nestlé Canada subsidiary—operating in this country since 1887—in reducing its global carbon footprint even somewhat ahead of schedule.

Whereas the Cup of Respect plan aims to have all of its global operations sourcing 100-percent sustainable co ee by 2025, NESCAFÉ expects its Canadian business to

achieve this milestone by the end of next year.

“Canadians want to feel good knowing that the co ee they enjoy today contributes to a better tomorrow, and this has been a guiding principle of NESCAFÉ’s work in sustainability innovation for over 10 years,” says Nestlé Canada’s vice-president of marketing Carm DaSilva.

“We’ve come a long way, but the work is far from over and through continuous initiatives under the Cup of Respect, we are making considerable progress building one of the largest and most comprehensive co ee sustainability programs in the world.”

As DaSilva points out, earlier this year NESCAFÉ relaunched its Sweet and Creamy Instant Co ee product line into recyclable glass jars (see picture) and cartons—designed by Mississauga, Ont.-based branding agency Bridgemark—adding that many Canadian consumers surveyed in focus groups keep the attractive signature jars for other storage inside their homes after use.

DaSilva says the reusability attributes of the glass jars are a key component in the brand’s quest to reach its 2025 target of using 100-percent recyclable or reusable packaging.

“NESCAFÉ in Canada is very excited to report the company is on track to achieve 100-percent responsibly sourced co ee by the end of 2022,” says DaSilva, adding that all of the brand’s global plants are working to transition to provide responsibly sourced co ee through the support of the company’s NESCAFÉ Agronomist team, as highlighted in the company’s NESCAFÉ Plan sustainability strategy launched back in 2010.

As part of NESCAFÉ’s sustainability e orts, the company’s agronomists have worked with generations of farmers to teach them how to diversify their income, gain new business skills and support NESCAFÉ’S global sustainability targets.

Partnering with community organizations around the world to secure fair and equitable practices for the future, the NESCAFÉ Plan is based on a variety of unified and actioned commitments to sustainable co ee farming, production and consumption, according to Nestlé.

“While NESCAFÉ is still in the process of making these changes globally,” says DaSilva, “it is proud that nearly all the co ee brought to Canada comes from plants that have completed this transition, with the last sourcing manufacturing site planned to transition mid next year.

To mark the Cup of Respect program launch, NESCAFÉ partnered with Canadian designer Jesson Moen to construct a one-of-a-kind Co ee Co ee Table—made from 30 pounds of NESCAFÉ repurposed co ee grounds—to exemplify sustainable production. (see picture)

“The creation of the Co ee Co ee Table was a unique project that to me had special meaning, because it uses the waste produced by one of the world’s most popular beverages and turns it into a long-lasting conversation piece,” says Moen, co-owner of the Crux Design+Build boutique studio in Toronto.

“This table, inspired by the NESCAFÉ Cup of Respect platform, demonstrates that sustainable living is truly within our grasp,” Moen states.

Pringles doubles down on crossover flavors in updated iconic packaging

They say that lightning never strikes the same place twice, but creative marketing minds at Kellogg Canada Inc. are putting that theory to a serious test with limited-time rollout of the Pringles Wendy’s Spicy Chicken Flavour potato chips— right on the heels of a sensational launch of the Pringles Wendy’s Baconator Flavour chips brand earlier this year.

Mixing the savoury taste of fried chicken with Wendy’s unique, fiery blend of peppers and spices into an iconic snack, this bold recreation of Wendy’s original spicy chicken sandwich satisfies cravings and delivers a mouth-watering combination of flavors found in one of Canada’s most popular sandwiches in every crunchy bite of the signature Pringles chips.

Packaged in the Pringles brand’s iconic tall round canisters holding 156 grams of individually stacked, uniformly saddle-shaped crisps—decorated with lively cross-branding graphics once again created by SGK Inc.—o er “an ideal one-bite, multi-sensorial experience for snack-lovers,” according to Kellogg.

“Following our wildly popular Pringles Wendy’s Baconator chips launched earlier this year, our masters of flavor have captured the unique, fiery spice blend of another Wendy’s classic,” says Christine Jakovcic, vice-president of marketing and nutrition at Kellogg Canada Inc. in Mississauga, Ont.

“Pringles has managed to pack an entire chicken sandwich into a single chip,” Jakovcic says. “We invite everyone to do away with mindless munching and enjoy a moment of ingenious fun instead with this insanely accurate creation.

“Wendy’s Spicy Chicken fans will be amazed.”

Beloved by Canadians, Wendy’s spicy chicken sandwich is an iconic menu item that sparked a pop culture phenomenon.

The world-famous Wendy’s version has become a fan favorite thanks to its juicy, all-white-meat chicken breast marinated and breaded in Wendy’s unique, fiery blend of peppers and spices to deliver more flavor inside and out—all cooled down with crisp lettuce, tomato and mayo.

The Pringles team has cleverly combined these complex taste sensations to create a truly unique snacking experience that begins when

the consumer first opens the pop-top canister to release aromatics of fried chicken, followed by feasting their eyes on the subtle orange hue of the chip with specks of black pepper—reminiscent of the breading on Wendy’s Spicy Chicken patty.

The light and airy texture of the Pringles chip deliver surprising layers of flavor that start o with the notes of juicy, fried chicken, followed by a medley of zesty spices such as black pepper, chili and paprika—generating a zesty heat that gradually builds in intensity.

“Pringles is breaking the chip mold again,” says Liz Geraghty, Wendy’s international chief marketing o cer.

“These masters of mimicry have created a unique flavour experience for the legions of Wendy’s Spicy Chicken lovers across Canada, who can now continue to enjoy Wendy’s great tasting food beyond the restaurant experience,” Geraghty states.

“Both craveable and delicious, this collaboration is a match made in flavor heaven.”

Packaging machinery manufacturer Paxiom Group has announced its pending move to a new 50,000-square-foot manufacturing facility located near the McCarran International Airport in Las Vegas, Nev., which will provide the company with additional space to accommodate new sta , while also housing all the system integration, warehousing and local fabrication activities. “This expansion comes at a time of significant growth for our businesses and will provide us the necessary space for the foreseeable future, while ensuring we continue to deliver to our customers on time and on budget,” says Paxiom’s vice-president Nicholas Taraborelli, “We expect construction build-outs to be completed within the month of November and anticipate occupancy for December 1, 2021.”

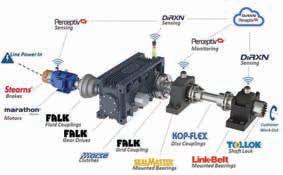

Regal Beloit Corporation, Beloit, Wis.-based manufacturer of electric motors and controls, power generation products and power transmission components, has completed its merger with Rexnord Process and Motion Control (PPMC) to become Regal Rexnord Corporation. With combined sales of over US$4 billion, the newly-merged company comprises four distinct business segments— Motion Control Solutions, Climate Solutions, Commercial Systems and Industrial Systems—employing approximately 29,000 people at manufacturing locations across five continents. “For over 125 years, Regal has consistently provided our customers with reliable, high-quality powertrain products and solutions,” says Regal Rexnord’s chief executive o icer Louis Pinkham. “With the addition of Rexnord PMC, we are

taking a tremendous positive step forward in Regal’s ongoing transformation, positioning the new Regal Rexnord company to create significant value for all our customers. By providing more energy-e icient solutions developed with greater intention, especially when it comes to leveraging voice of the customer, Regal Rexnord is also now in a better position to fulfill our business purpose: creating a better tomorrow by energy-e iciently converting power into motion.”

Electromate Inc., Toronto-based distributor of precision robotic and mechatronic solutions, has formed a partnership Mecademic, Montreal-based manufacturer of compact miniature industrial robots designed to excel in the precise and repetitive manipulation of small parts and tools in a variety of industries. Designed as plug-and-work automation compon-

ents that integrate with any PC or PLC, Mecademic’s robotic arms don’t require a proprietary programming language, and are compatible with virtually any other automation component. Designed to maximize space-e iciency and minimize deployment time in labs and factories, Mecademic’s robots can be employed in a broad range of pick-and-place, dispensing, testing, inspection, machine tending and other industrial applications. Tel. (877) 737-8698.

Leading flexible packaging products manufacturer TC Transcontinental Packaging has commenced operations company’s new ASTRA (The Art, Science, and Technology Research and Applications) facility. Based in Menasha, Wis., the

12,000-square-foot building will house more than 20 engineers tasked with innovating and identifying sustainable packaging solutions for the company’s customers. “The ASTRA Center is at the core of our operations to drive growth and innovation and to be the sustainability partner to our customers,” says Alex Hayden, senior vice-president for R&D, innovation and sustainability. “The many tests, instruments, and technology available to us provide enhanced product development knowledge through the entire process of flexible plastic packaging design—allowing the development of innovative films for sustainability, e-commerce, and more.” Built and equipped over several months, ASTRA houses four di erent state-of-the-art R&D labs sta ed by dedicated teams of sustainability gurus to o er brand-owners deep expertise in compostable, recyclable, and recycled content packaging:

• The Analytical and Testing Services Lab performs physical testing to simulate real life use of the package from filling to transportation and distribution.

• The Applications and Packaging Development La b is a dedicated lab equipped with a nine-layer blown extrusion line, which allows designed experiments and optimization of film formulations, and various form-fill-seal packaging machinery to perform production-scale customer prototypes.

• The Advanced Compost Lab , said to be the first of its kind to operated in-house by a packaging manufacturer, is fully integrated the R&D team’s expertise and knowledge to develop the next generation of packaging, and improve the turnaround time and cost for certifying compostable packaging.

• The Recycling Technology Lab will measure each aspect of a package designed for industry-accepted criteria to ensure that it is truly recycling-compatible, as per the latest design guidelines available in the industry.

Leading Canadian food producer George Weston Limited has signed an agreement to sell its Weston Foods fresh and frozen bakery businesses to FGF Brands , a family-owned bakery based in Toronto, for an estimated $1.2 billion. “The Weston Foods business has been the foundation for the Weston Group in Canada since its establishment in 1882 and the decision to sell it was a di icult one,” says chief executive o icer and company chairman Galen Weston. “However, we are pleased that the purchaser of the fresh and frozen businesses is FGF, another long-standing family business with a strong presence in bakery and a significant footprint in Canada. With FGF as the new owner, the business will be in good hands.” Adds FGF Brands co-founder Tejus Ajmera: “We are thrilled to be acquiring the fresh and frozen businesses of Weston Foods, a Canadian company with over 100 years of baking experience, and we look forward to building on that legacy by investing in people, facilities and innovation across our entire operations.” George Weston first announced in March that it planned to sell its bakery segment—accounting for 75 per cent of total revenues—to focus on its retail and real estate businesses.

Abbey Equipment Solutions has the expertise to deliver highly flexible packaging solutions that are efficient, reliable, and innovative.

Whether you are looking for a Vertical Flow packaging solution, Baggers, Wrappers, or Pouch machines, we have you covered. Our goal is to deliver our clients with the best solution that meets their production objectives, streamlines their process, and provides them with high-quality machinery.

Delivering Results.

With Heat and Control, you have a partner with the scale to support your success, the innovation to advance your operations, and a commitment to quality that will help you offer better products for consumers.

• Accumulation

• Horizontal motion conveying

• Incline, belt and bucket conveyors

• Filling and multihead weighing

• Bagmaking and casepacking

• Checkweighing and seal checking

• Foreign object and defect inspection

• Controls and information systems

We are successful when you are successful. That’s why we apply creativity, engineering excellence, and determined perseverance to every project to help our customers get the performance their business demands—whether measured by flavor, efficiencies, sustainability, improvement, or innovation. COMPLETE

info@heatandcontrol.com |

Leading conveyor system designer and manufacturer mk North America has added two new conveyor models to its VersaFlex flat top chain conveyor system—a highly modular, flexible system that is ideal for complex layouts and o ers fast and simple configuration and commissioning possibilities. Both the A17 and A29 models boast added length and width capabilities to enable larger products, or those requiring extra support, to make their way through the conveyor line. The VersaFlex A17 has a chain width of 175-mm and a system width of 182-mm, allowing it to convey a product width from 70-mm to 400-mm at speed of 50 meters per minute—while the VersaFlex A29 has a chain width of 295-mm and a system width of 300-mm. The VersaFlex conveyor system features di erent chain widths and track designs for e icient transporting of primary and secondary packaged products, as well as workpieces for assembly lines. One the greatest competitive advantages of VersaFlex is that it can adapt to elevation changes, curves and straight sections, according to the company, while being driven by a single motor. mk North America

The new Robot S7 model portable stretchwrapping robot from Robopac USA o ers an e ective, economical and highly portable means for businesses to stretchwrap mixedload pallets without the expense and space requirements of dedicated stretchwrapping cells, whereby the user simply brings the robot

to the load, after which the robot proceeds to wrap any width or length pallet load to any desired weigh. Available with an optional rechargeable lithium battery for quick recharging throughout the day, the Robot S7 portable stretchwrappers provide enhanced operational safety by emitting a powerful blue light on the floor a few feet ahead in the direction of travel of the machine—warning anyone around the machine that the Robot S7 is approaching—while an easily accessible emergency button makes the machine easy to stop. The machine rudder with inclined knobs prevents dangerous objects from getting caught, while new LED lighting at the top of the mast indicates machine status—letting everyone know that the machine is operational. The film carriage features a closing door to protect the operator from rotating parts inside, and the automatic cycle start is automatically deactivated if the film carriage door is left open.

Robopac USA

Designed for optimal performance, the new TraceServer software from Eagle Product Inspection (distributed in Canada by PLAN Automation) can connect up to 32 X-Ray inspection machines at once, while capturing and recording production data at every pass to consolidate information and images into an easily accessible centralized database. Featuring an intuitive dashboard with machine status indictors, along with the ability to print and export informa-

tion from a centralized source, the TraceServer software was developed to unlock vital information that can help and di erentiate a manufacturer in an increasingly competitive and regulated marketplace, according to the company. “Through this intelligent software, manufacturers can increase their due-diligence capabilities for greater product traceability and overall quality assurance. In today’s operating environment, those goals are more crucial than ever,” says Eagle Product Inspection marketing manager Christy Draus. Scalable to meet an operator’s unique needs and easily installed on a network server or a stand-alone PC, the TraceServer software powers a wide range of Eagle X-Ray inspection systems to provide reliable product tracing through every stage of production—helping food companies enhance product treaceability and overall quality assurance.

Designed for printing superior quality high-resolution characters on porous or non-porous surfaces, the new CoPilot Max 512i Turbo printing system from Squid Ink Manufacturing, Inc. features an innovative design that allows the user to tilt or rotate the printhead in any direction without making height adjustments to the ink supply. Available as an oil-based system for printing on porous substrates like uncoated corrugated, or as a solvent-based system for printing on a variety of non-porous substrates, the new CoPilot Max 512i Turbo system prints high-resolution characters, razorsharp text, scannable barcodes, and great-looking logos up to 2.8-inches-high at up to 180-dpi resolution at speeds of up to 480 feet per minute, while the system’s large 500-ml snap-in cartridge allows users the ability to swap ink cartridges in a matter of seconds. Utilizing the same active ink system found in Squid Ink’s CoPilot and CoPilot Max printing systems, the CoPilot Max 512i Turbo features a 4.3-inch full-color touchscreen that allows users to access the system’s internal messages and print functions, while creating and editing new messages on the user-friendly Orion PC

software and transferring them via USB, Ethernet, wireless or an optional Windows tablet for users who need the message creation and editing functionality right on the production floor.

Squid Ink Manufacturing, Inc.

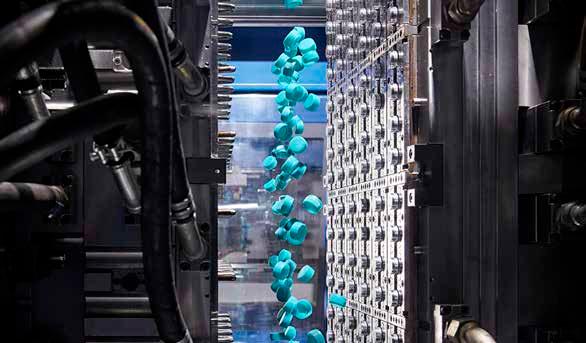

Integrated with Yaskawa Motoman HC10 and HC20 collaborative robots to provide greater efficiency and automation for blowmolded bottle manufacturing lines, the new Pakman case-packer from Proco Machinery Inc. features a robust collating and indexing accumulation system to accumulate complete layers of bottles inside the cell. The accumulation table stages the layer of bottles so they can be picked up by Proco’s end-of-arm (EOA) tooling and placed inside the box. Featuring Proco’s Integrated Rotary Inverting Technology for rotating a layer of bottles to neck-down orientation in a layer formation, the Pakman has many advanced features to help users pack bottles in neck-down orientation in a layer formation, including a six-axis collaborative robotic arm, an infeed conveyor, and a box conveyormounted onto a common sub-frame

outfitted with levelers andcaster wheels.

Proco Machinery Inc.

The new e-Pack series shrink wrapper and shrink tunnel from Texwrap, a ProMach division specializing in shrinkwarpping systems technologies, is designed for mid- to high-volume e-commerce applications requiring ready-to-ship packaging without having to packg the products inside shipping cases. Developed as an e icient alternative for e-tailers still using cases or boxes to ship their products, the e-Pack series system uses product dimensions to create a perfectly sized flexible package every time—significantly reducing shipping costs, labor and time. The system’s Smart Scan technology detects if a package is removed from the sequence after scanning, and automatically stops the machine to ensure product is not shipped to the wrong customer. Texwrap

Designed for e icient filling of bulk bags and drums in low-headroom

areas, the new low-profile combination bulk bag/drum filler from Flexicon Corporation uses full-length forklifting tubes integral to the rear-post fill head to allow incremental height adjustments, secured with hitch pins to accommodate bags of all popular sizes. Equipped with an inflatable bag spout seal, a feed chute dust vent, and a low-profile densification deck, the filler can can be switched to drum-filling mode in several seconds by positioning the swing-arm-mounted drum-filling chute under the fill head discharge port.

Flexicon Corporation

The new Diversity range of waterbased flexo coatings from DataLase are formulated to facilitate the application of laser-imageable text, date and lot codes, and graphics on various packaging substrates in direct food-contact applications in the pharmaceutical and food-and-beverage industries, while o ering the benefits of a lower carbon footprint compared to print-and-apply labeling. DataLase

With the federal ban on a variety of single-use plastic packaging and utensils drawing closer with each passing day, leading Canadian fruit beverage producer A. Lassonde Inc. is accelerating the company’s e orts to replace all plastic straws in its single-serve product portfolio with fully-recyclable paper straws.

Less than two years after puchasing Kelowna, B.C.-based SunRype Products Ltd. in a $89.3-million acquisition, Lassonde is replacing plastic straws on all the SunRype branded 200- ml single-serve Tetra Pak juice boxes sold across Canada, including the 100-percent juice and 60-percent less sugar juice products.

“We plan on incorporating recyclable packaging for all of our products, and the launch of paper straws on our single-serve juice products is another step in the right direction,” says A. Lassonde president Claire Bara. “We know that our customers place a lot of importance on finding products that meet today’s environmental challenges, and these SunRype juice containers with new bendable paper straws are now available at Canadian grocery retailers—just in time for back-to-school

lunch boxes.”

As Bara points out, all packaging on SunRype’s 200-ml multilayered Tetra Pak drink cartons is fully recyclable, and the new paper straws are made exclusively from FSC-certified paper.

“In 2020, Lassonde was the first company in Canada to manufacture and commercialize the 200-ml bendable paper straw under the Kiju organic brand, as well as our water brands Simple Drop and Fruit Drop,” Bara points out.

“We are pleased to provide our customers with this environmentally responsible paper straw on all 200ml beverage containers of our iconic SunRype brand,” she says, adding the switch is in line with the com-

pany’s concerted e orts to meet ambitious sustainability targets for all its brands.

“We are on track to meet our sustainable development objectives by 2025,” says Bara, adding that SunRype is also aiming to achieve 25-percent PCR (post-consumer recycled) content in its PET plastic bottles by 2023, along with full recylability for all its brands.

Earlier this year, Lassonde has switched several of the company’s stalwart flagship brands—including Oasis , Allen’s , Fairlee and Fruité —to new 300- ml plastic bottles containing 25-percent post-consumer recycled plastic (rPET) made from food-grade polyethylene terephthalate (PET)

resin from post-consumer bottles.

Lassonde says it is aiming to be using 50-percent (PCR) % content in all its PET packaging by 2025.

Among its other environmental initiatives, Lassonde has made sustained e orts to reduce the weight of its packaging and decrease the amount of water used in its cooling and sanitization processes, according to Bara.

Headquartered in Rougement, Que., Lassonde is the largest producer of fruit juices and drinks in Canada and one of the two largest producers of store brand shelfstable fruit juices and drinks in the U.S., employing more than 2,700 people at 17 plants across Canada and the U.S.

An event inspired by the PAC IOU vision to create an inclusive packaging world.

Be moved by an international panel of industry leaders highlighting the value of embedding inclusivity and accessibility in all facets of packaging design and innovation.

Feb. 8 & 9, 2022 Virtual pac.global/events

The 2022 PAC Global Awards winners to be announced and celebrated at the ONEOF100 Summit.

FLAGSHIP SPONSORS

SPEAKERS

Rowe Beef co-founder and owner Rod Rowe holds up a shipping box filled with premium cuts of beef processed and packaged on various Reiser-supplied machines at the company’s Mississauga meat factory.

Premium meat processor recoups market share lost to COVID-19 indoor dining restrictions with swift transition to the grocery e-commerce channels

By George Guidoni, Editor

Photos by Naomi Hiltz

Life in the meat business is never a walk in the park at best of times, and it’s been downright rotten for countless processors and suppliers of premium meat products to fine restaurants, hotels, golf clubs, banquet halls and other ‘white table’ dining establishments struggling to outlast the nasty COVID-19 pandemic that has shuttered their businesses with strict widespread bans on indoor dining.

For Rod Rowe, co-founder and owner of L Rowe Beef Co. Ltd. in Mississauga, Ont., the curve ball thrown his way by the coronavirus outbreak in March of 2019 was fundamentally more devastating than anything he had faced in his baseball-playing days with the NewYork Mets organization back in the 1980s, with potentially far graver consequences.

“I suddenly had $4 million worth of meat inventory on my hands for which I had no customers,” says Rowe, a 48-year-

old native of Toronto who played college ball on a scholarship at the Texas A&M University Texarkana prior to being drafted by the Mets and assigned to the team’s minor league a liate in Rochester, N.Y.

As fate would have it, an unfortunate injury ultimately put an end to Rowe’s dream of making it to the major leagues, but that setback only strengthened his resolve to succeed in his next career phase as one of the top-performing salespeople for a leading Toronto-area meat distributor Derma Meat Co.

After Derma was eventually acquired by global food distribution giant Sysco Corporation, Rowe and a like-minded industry acquaintance William Leavoy teamed up to launch their own fine meats distribution business under the Leavoy Rowe Beef Co. Ltd. banner in 2006, with Rowe eventually buying out his partner about two years ago to become the sole owner.

Quickly building up a loyal client base

in the foodservice industry by leveraging superior product quality, outstanding customer service and a diverse product portfolio comprising high-quality fresh beef, veal, lamb, poultry and various game meats, the new business venture enjoyed brisk growth over the years— moving from its original 5,000-squarefoot meat shop five years ago to a bigger, 21,000-square-foot meat processing and

packing facility boasting all the relevant Health Canada and CFIA (Canadian Food Inspection Agency) accreditations required for a federally-approved meat processing operation.

Painstakingly refurbished and rebuilt on the inside virtually from scratch over 16 weeks, the HACCP-certified, temperature-controlled facility currently processes and ships about 10,000 kilograms

Close-up pictures of the Seydelmann AE-130/3 automatic meat grinder used for processing large chunks of raw beef into ground meat at the Rowe Beef plant in Mississauga.

“We had to diversify and change things around to be able to execute all this different packaging for all these different customers.”

of premium-quality fresh meat products per week, sourcing its meat from the most reputable and prestigious farm operators located in Ontario and a select few cattle ranches in the U.S.

According to Rowe, beef products account for about 60 per cent of the Halal-certified plant’s output—with products ranging from mouth-watering T-bone steaks and prime rib to hamburger patties and deli sausage meats—with poultry accounting for about 30 per cent and the remainder split among lamb, veal and game meat specialties like venison, wild boar and bison.

Operating its own multi-vehicle fleet of refrigerated trucks to ensure flawless customer service and on-time delivery, the thriving meat shop employs 65 fulltime sta over a two -shift, five-day-week schedule to serve a sizeable geographic region stretching from Sarnia, Ont., in the southwest of the province to Ottawa in the eastern part.

For all that growth and success, however, the sudden outbreak of COVID-19 two years ago and the ensuing restrictions on indoor dining, particularly at fine dining establishments, threatened to undo all the hard work and heavy lifting Rowe did over the years to make the company succeed in a highly competitive segment of the Canadian meat industry. But rather than pack it in, Rowe pro-

ceeded to turn a looming crisis into an unprecedented opportunity by successfully pivoting the operation to tailor to the unique new requirements of the burgeoning e -commerce grocery marketplace spearhead by a new breed of grocery e-tailers like Butcher Box, truLOCAL and Goodfood, among others.

While this sudden turnaround in corporate strategy was driven largely by necessity and desperation, Rowe says that in retrospect he is glad to have discovered a lucrative new business segment with outstanding opportunities for future growth that he may have had overlooked or underestimated otherwise.

“Our business is up by 50 per cent since two years ago,” Rowe told the Canadian Packaging magazine on a recent visit to the busy and lively Mississauga plant typically operating at about 2°C throughout the year.

“We never did anything with the home delivery business prior to that,” Rowe relates, “and obviously we had to make some changes to our operation, especially on the packaging side of things.

“The packaging requirements for e-commerce are very di erent from shipping to restaurants,” Rowe explains.

“When a restaurant gets our order, they open the box right away.

“When a consumer gets theirs at home, they will often take a package out of the

Above

The compact Vemag Lucky Linker meat stu er at the facility is used exclusively for production of Italian sausages.

Right

Thick 260-gram ground beef patties coming out of the Vemag FM-250 former, connected to the Vemag HP-20E stu er, are neatly placed by hand onto plastic trays in rows of four prior to being transferred towards packaging.

delivery box and put it in the fridge, so there is no room for defects like a leaky package, or any signs of animal blood on the packaging … you can’t a ord to have any issues with packaging in this business segment.”

To get the packaging right for all of the company’s diverse product lines and SKU (stock-keeping units) selection, Rowe turned to a long-time business acquaintance Terry Rees, regional sales manager for south-central Ontario at Reiser (Canada) Co.

Based in Burlington, Ont., the company is a Canadian subsidiary of the renowned food processing and packaging systems group Robert Reiser Inc. , Canton, Mass.-headquartered supplier of automatic food processing and packaging machinery for the sausage, meat, poultry, seafood, prepared food, bakery, cheese and pet food industries.

Established in 1959, Reiser had risen

to keen industry prominence over the years by supplying the global markets with renowned machinery brands such as Ross tray-sealers for case-ready and MAP (modified atmosphere packaging) applications; Repak and Variovac brands of HFFS (horizontal form/fill/ seal) packaging machinery; Supervac automatic vacuum chamber packaging machines; and Vemag meat processing systems, among others.

Having already benefitted from Reiser’s equipment expertise during his company’s formative years, Rowe was confident that Rees and his Reiser colleagues would provide the right solutions for his new product packaging needs and heightened customer expectations.

“It just made total sense to deal with one company that has both the processing and the packaging equipment we would use to pivot into the new markets,” Rowe states.

“I’ve been buying from Reiser through Terry for nearly 14 years, and they have always been very good to me.

“Not only do they have the best machines out there,” Rowe states, “but they also keep me on top of all the important changes in the industry I should know about.

“We are a Reiser facility from stem to stern,” says Rowe, who purchased his first machine from Reiser—a Reman Dixie DP 100 skin-packaging machine— back in 2008.

After the business expanded and moved to newer premises, Rowe turned to Reiser to purchase a Repak RE20/4 horizontal FFS machine in 2015 to speed up its vacuum-packing and skin-packaging operations, which worked out so well that Rowe placed an order for yet another Repak RE20/4 machine two years later.

While these machines have remained at the core of Rowe’s Beef’s packaging capabilities to this day, they were not

“It goes without saying that I need to have the best quality equipment to take proper care of this kind of quality product.”

enough on their own to help Rowe make a smooth and swift transition to fulfilling the challenging e-commerce packaging standards and requirements dictated by his new client base in the home delivery business, as well as the important new retail customers such as Costco, Longo’s and Farm Boy.

“We had to diversify and change things around in a major way to be able to execute all this di erent packaging for all these di erent customers,” Rowe explains.

“What I had in place was already a pretty significant investment for a company our size,” he remarks, “but it was not adequate for the kind of a major pivot that we needed to implement.

“So I called Reiser again to help us bring all the equipment we needed under our roof,” says Rowe, who invested $1.7 million in the last year to purchase and install 13 di erent Reiser-supplied packaging and processing machines to raise the plant’s production and packaging capabilities to a whole new level of excellence.

Between April of 2020 and October 2021, the Mississauga facility had evolved into a living showcase of the latest food processing and packaging technologies o ered by Reiser, which supplied Rowe Beef with a comprehensive range of stateof-the-art equipment comprising:

• Vemag HP- 20E stu er, an FM-250 former and a PPI stacker/interleaver;

• SuperVac GK-501B vacuum-pack-

One of two Reiser-supplied Repak RE20/4 horizontal form-fill-seal machines used to pack premium chicken breasts features special four-point lifting systems on the forming and sealing dies to generate exceptionally strong closing pressure for producing airtight packages with the rapid air forming method that helps create perfectly sealed packages with minimal film consumption.

ing machine with a SuperVac AT-8E hot-water shrink tank;

• Variovac Optimus 55 Easy Skin thermoformer and skin-packaging machine;

• Vemag Lucky Linker sausage meat stu er;

• Seydelmann AE-130/3 automatic meat grinder;

• Holac Sectomat 230 TC portion cutting machine;

• AMFEC model 510 meat mixer/ blender with a model 2-3K2 column loader;

• RotoClaw II frozen meat breaker;

As a supplier of premium-quality meats aged to tender perfection and meticulously portioned and prepared to customers’ specifications, Rowe Beef simply can’t a ord the risk of letting poor packaging execution to mar the company’s hard-earned reputation for quality, Rowe points out.

“Our products are all high-value products,” says Rowe, citing the company’s own Wellington County brand of Canada AAA and Canada Prime grades of beef; the Est.8Angus brand of black angus beef striploin harvested from a select breed of Iowa-raised cattle; and the

Snake River Farms brand of American Kobe (Wagu) Angus beef, sourced from a proprietary herd in eastern Idaho.

“It goes without saying that I need to have the best quality equipment to take proper care of this kind of quality product,” says Rowe, “and Reiser equipment is absolutely top-notch.

“I would recommend them to anyone in the meat industry because they have the best equipment,” Rowe reiterates.

“That’s why I never left them,” says Rowe, indicating there is probably more Reiser equipment to install down the line after Rowe Beef completes its pending move to a new 50,000-square-foot meat processing facility in Mississauga later

this year, which will o er a lot more elbow room for both the machinery and the plant’s highly loyal and dedicated production sta .

“At the end of the day it is the people who ultimately make the di erence,” Rowe acknowledges, “and having good people working on best available equipment is a strong core competency for us.”

As Rowe relates, the company’s uncompromising approach to product quality and customer service excellence have also greatly contributed to its outstanding industry reputation—backed up by the vast insider knowledge base about the meat business he started to acquire early in life from his father, who was a

The Canadian corrugated and containerboard industry develops creative packaging solutions that are cost effective, versatile, environmentally sound and food safe. Our boxes are designed with high impact graphics that communicate your brand. We focus on what matters: what’s inside the box.

www.cccabox.org

Of all the machines Rod Rowe has purchased from Reiser, he is especially fond of the Variovac Optimus 55 Easy Skin thermoformer and skin-packaging machine, which he has named “Sexy Beast,” primarily used for skin-packaging of flattened premium chickens encased in clear plastic trays to create a perfectly transparent and “sexy” package in a series of automated steps (see sequence on the right) performed at remarkably high through speeds.

Leading Canadian corrugated packaging producer Cascades Continerboard supplies the Rowe Beef plant attractive blackand-white shipping containers used to transport the premium meat products to both e-commerce and retail customers.

professional butcher operating his own meat company decades ago.

“I believe what sets us apart is the consistency of our product, which is aged far longer than the minimum retail requirements, and that the meat is cut and portioned to perfect specs as required by our customers.

“Our customers always come back because they know they will be getting consistently high-quality product, backed up by service that I believe is second to none in our industry,” Rowe asserts.

“If some customer is in a pinch for a box of bacon that they need right always, I will drive that box over myself if none of our

Manufactured by METTLER TOLEDO and installed by Oakville, Ont.-based integrators Shawpak Systems, the Safeline PowerPhase PRO metal detector provides a solid additional layer of product quality and safety assurance for the Rowe Beef facility.

trucks are available at the moment,” he states.

Not surprisingly, Rowe is quick to cite superior customer service as one of Reiser Canada’s value-add attributes that he appreciates as much as the leading-edge machinery that the company distributes.

“I have an amazing relationship with Terry and the whole Reiser crew,” Rowe states.

“Whenever I need something, or if a machine breaks down and I need a special part in a hurry, somebody from their crew will be here in the afternoon or the first thing next morning.

“For me, service is everything,” Rowe asserts, adding that he’s eagerly anticipating the easing of current restrictions on indoor dining to herald the return of his former restaurant and foodservice industry clients.

“We managed to get through the whole COVID crisis without shutting down production or laying anyone one o ,” Rowe reflects, “thanks to our ability to pivot quickly when many of our key customers had to shut down.

“Now that the golf courses have reopened and the restaurants are getting closer to allowing more customers to dine indoors,” he concludes, “I have good reasons to feel good about the future—serving our growing customer base from a brand new facility equipped with the best processing and packaging systems you will find anywhere.”

Reiser (Canada) Co.

Cascades Containerboard

METTLER TOLEDO/Shawpak Systems Ltd.

Please see a video of the Reiser-supplied packaging machinery in action at the Rowe Beef meat processing plant in Mississauga, Ont., on Canadian Packaging TV at: www.canadianpackaging.com

Fabbri Automatic Stretch Wrappers produce low-cost, highly attractive packages that make your products look fresh and “just packed”.

■ Uses stretch film to overwrap fresh food products in preformed trays.

■ Produces tight, over-the-flange, wrinkle-free packages with securely sealed bottoms.

■ Handles a wide range of tray sizes with no changeovers to reduce downtime and increase production.

■ Up to 75 packs per minute.

www.reiserexperts.com

Reiser Canada • Burlington, ON • (905) 631-6611 Reiser • Canton, MA • (781) 821-1290

UK • Milton Keynes, Bucks • (01908) 585300

Shah Trading vice-president of business development Sanjeev Shah poses in the Scarborough plant’s reception area alongside a selection of the company’s private-label products packaged in high-quality plastic bags supplied by its long-time packaging partner Tempo Plastics Limited.

Canadian dry foods distributor soldiers on in uncertain times with strong packaging competencies and relentless focus on line efficiencies and product quality

By Andrew Snook

The success story of Shah Trading Company is one built on humble beginnings. What started out as a small business operating out of the Shah family’s home in the mid-1970s has grown to become Canada’s largest ethnic food distributor of rice and grains, beans, peas and lentils, spices and herbs, nuts and dried fruits and other specialty Items.

“The company was started in 1974 by my dad and his brothers,” says Sanjeev

Shah, vice-president of business development and second-generation family member of the Shah Trading Company.

“It started o from the garage of our house, selling at the time to the small Indian community in Montreal. There was a growing population in Toronto, so we started catering to that market—importing some food items that were special to the Indian market. We were more of distributors at that point.”

With time, the Shah family realized very quickly that they had the potential to grow beyond serving a single market.

“We saw that the Indian market wasn’t big enough and that a lot of the stu we carried was something that was in demand in other communities in other ethnic markets,” Shah says. “So we started selling to those markets as well.

“Within about three to four years, my uncle moved to Toronto to oversee the Toronto market and we grew from there.”

The Shah Trading plant in Scarborough makes extensive use of the Hayssen brand of vertical form-fillseal machinery manufactured by BW Flexible Systems and distributed in Canada by Alex E Jones & Associates, who have installed several VFFS packaging machines at the facility over the years to enable Shah Trading establish itself as one of the country’s leading private-label manufacturers of dry foodstu s.

Fast-forward to 2021 and Shah Trading Company has grown exponentially. Headquartered in Toronto’s eastern suburb of Scarborough, the company now operates three locations in Ontario and one in Montreal, employing approximately 200 people.

“We have a huge product line. If you look at what we do with all the beans, peas, lentils, rice, nuts and dried fruits, I would say we have about 1,000 active SKUs (stock-keeping units), maybe more,” Shah says.

No company grows this quickly and successfully without the ability to build strong, lasting relationships throughout its supply chain.

One of those relationships that were forged by the first generation of the Shah family was with Tempo Plastics Limited, Innisfil, Ont.-based manufacturer of a wide variety of flexible packaging solutions including monolayer and laminated multilayer pouches, bags, and rollstock film with high-quality process printed graphics.

“We have a very long history with Shah, over 20 years, so I would call it a partnership,” says Tempo Plastics chief executive o cer Leonardo Giglio who, like Sanjeev, is the second-generation of his family to operate his family’s business.

Giglio says the two companies have enjoyed a great deal of success together and that there is a strong alignment between the two businesses.

“When it comes to packaging technologies over the past 20 years, almost all our capabilities have been utilized to service Shah—rollstock, polybags, laminated pouches and films.

“Everything we’ve had capability for, we’ve done for them. It’s great that they’ve utilized our entire portfolio of flexible packaging solutions,” Giglio says.

One area where Tempo Plastics and Shah Trading have worked together extensively on many projects is in the private-label market.

“Even though Shah is our customer, we have a joint customer when we do the private label business,” Giglio relates.

“Because we have certain obligations as a preferred printer, and also certain obligations as the vendor, we need to work together to bring a solution to the shelf.

“Not only are Shah Trading using a lot of flexible packaging solutions, but they fit in the private label space for executing private label brands.

“And that’s a whole di erent kettle of fish,” says Giglio, adding that companies

Sanjeev Shah provides a handson demonstration of the resealability feature of the Tempo stand-up pouches enabled by inline application of Ziploc reclosable zippers applied inline on the high-speed Hayssen flexible packaging machinery manufactured by BW Flexible Systems.

operating in that space need to be extremely agile.

“You have to be able to handle multiple SKUs, manage a lot a lot of di erent artwork, and then execute that whole supply-chain process for a retailer.

“That’s really been our bread-and-butter and Tempo’s core competency, and that’s the space that Shah lives in,” Giglio says.

“They’re a leader in that space, both in Canada and throughout all of North America.”

One thing that separates Tempo Plastics from many of its competitors is the company’s versatility.

“Not all packaging suppliers are vertically integrated like we are, and being able to o er so many di erent packaging solutions,” Giglio says.

“It’s very typical for some suppliers just to be doing laminated pouches, with some just doing rollstock and some just doing polybags.

“Because Tempo does it all under its portfolio, we try to o er a very simple one-stop-shop type of approach for a partner like Shah, so they can work with

Since 1976, Alex E. Jones & Associates remains the name you can trust for your packaging machinery needs. Committed to providing superior sales and customer service, the team at Alex E. Jones ensures product, quality, price competitiveness & promptness in delivery for your packaging needs.

Talk to the packaging & automation experts Let’s work together to find the right solution to your packaging needs. It is the best way to set you up for success.

Ontario & Western Canada | +1 905-847-0166

Quebec & The Maritimes | +1 514-731-7747

us to execute whatever their customers are looking for without having to source multiple suppliers.”

Not surprisingly, Shah Trading and Tempo Plastics are also very much aligned when it comes to sustainable packaging.

“Tempo has an emphasis on sustainable packaging,” Giglio says. “Shah has already moved into that space with some of our brand partners and started to utilize some of the recycle-ready technologies behind the scenes.

“They’re not getting a lot of credit for it,” he notes, “but these things are happening.

“They are also an early adopter and leader in that space,” Giglio asserts, “and we are very proud to work with a company that also values moving forward towards Circular Economy packaging solutions.”

After all the years the two companies have been working together, they have built a remarkable level of mutual trust and respect.

“It’s a unique relationship we have with Shah,” Giglio says. “It’s not often a second generation [company] gets to

Packaging success in the following industries:

Pharmaceutical Chemical & Household Products

Meat, Poultry & Proteins

Pet Food & Pet Care

Personal Care

Seafood & Fish

IQF Cereal, Grains, Beans, Spices

E.

Website:

Email:

Phone:

work with another second generation [company], and I think that’s kind of cool.

“It’s great that these two companies are still around and carrying on some traditions, because I think tradition is important.”

Naturally, Tempo Plastics isn’t the only supplier Shah Trading has relied on to keep its production growing and moving e ciently over the years.

The company has also invested in many Hayssen flexible packaging machines—a renowned equipment brand owned and operated by BarryWehmiller Flexible Systems since 1997.

“Shah Trading purchased its first Hayssen VFFS (vertical form-fill-seal machine) in 2003 and then, about every two years after that, they purchased the next four or five machines,” recalls Gerry Cellucci of Alex E Jones & Associates, Canadian sales representative for BW Flexible Systems.

“They now have eight Barry-Wehmiller flexible systems, including the Hayssen Ultima SVJ vertical FFS machine, all coupled with volumetric cup fillers.”

Cellucci says the Hayssen machines combine the ruggedness of machines

designed many years ago with the hightech electronics of today.

“Shah Trading have had these machines for so many years, they know this machinery very well,” he says. “They’re really happy with their investment decisions, which is why they keep buying from us.”

The bagging machines acquired by Shah Trading o er an extensive range of bag weight capacities—from 100 grams up to 11 kilograms—in the production of pillow-bags, tucked bags, and block-bottom bags, running both laminated and polyethylene films.

The Hayssen equipment can also add carrying handles to the larger-sized bags meant to hold from eight to 11 kilograms of product.

“When bags start to get really big, it’s very convenient to add a carrying handle,” says Cellucci, noting that the user-friendly Ultima SVJ’s servo-driven system incorporates o -the-shelf Allen-Bradley series controls manufactured by Rockwell Automation

“When the film is pulled o the roll, the film travels through a set of rollers, which are all servo-driven,” Cellucci explains.

“This allows us to pull the film fast, which helps with film tracking. Then

Clockwise from top Free-flowing bulk rice grains are measured in desired pre-determined quantities in the multihead precision weighscales dispensing the product below into the PSG LEE automatic bagger manufactured by Leepak and supplied to the plant by Charles Downer & Co.

A close-up view of the Eastey tape-applicating machine used for closing the corrugated shipping containers leaving the Scarborough plant filled with product.

there are the pull belts, used to pull the film over the forming tube, which require little pressure and little torque—improving the film tracking characteristics.

“When you run a wide variety of films like Shah Trading does, this is quite important,” Cellucci notes, “because they can use a wide variety of films and not worry about film tracking.”

As Cellucci points out, all the Hayssen machines are designed to facilitate easy maintenance.

“It has an open-framed architecture, so it is very easy for maintenance people to work on the machines,” Cellucci says.

“Customers keep asking for lower- cost machinery and so you have some manufacturers that are designing machines that are purpose-built and have small footprints.

“Servicing those machines is a nightmare: they’ve compressed things so much that you have to rip half of it apart,” says Cellucci.

“When Hayssen designs its machines, they are designed with open architecture, so you have access from all four sides of the machine for maintenance and cleaning.”

The Hayssen machines have also been

designed for retrofitting in the future, Cellucci says, to enable integration of additional technologies to incorporate additional value-add inline capabilities, like creating a form at the bottom of the bags and adding zipper attachments for reselability.

“Not being purpose-built machines, their flexibility makes them future-proof,” Cellucci says. “These machines have served Shah Trading well.”

Over their years of growth, Shah Trading have added several other types of packaging technologies to their facilities, including the PSG LEE baggers—manufactured in Korea by Leepak and supplied through its Canadian distributor Charles Downer & Co. of Richmond Hill, Ont.—for the company’s rice plant in Toronto.

“It provides us with a stand-up Ziploc bagger at a reasonable cost,” Shah says. That machine takes a ready-made bag, and fills it and seals it with total precision.”

To ensure rigorous quality control and uncompromising product safety, Shah Trading also purchased an Eagle Tall PRO X X-ray inspection system—supplied by Orangeville, Ont.-based system integrators PLAN Automation—for the

company’s canning line.

“In 2014 we started our own canning line to make canned beans,” Shah recalls.

“Before that, we were getting someone to manufacture the canned beans for us, whereby we would send them the beans and they would return it back to us canned.

“Now we’re in the business of our own canned products,” says Shah, adding the Eagle Tall PRO X typically scans about 220 cans per minute on the canning line, with plenty of built-in capacity to run a lot faster if need be.

“Our constraint in canning is the cookers; they are the pinch point,” Shah explains. “We can’t fill faster than we cook.”

Mat Bédard, vice-president and chief operating o cer at PLAN Automation, says that the Tall PRO X X-ray system has the capability to run up to 1,500 containers per minute and 425 feet per minute.

“The big advantage with the X-ray system is it has the ability to see metal inside a metal product, like a can,” Bédard says.

As Bédard recalls, Shah Trading also wanted to be able to run detection for other types of hard-to-find contaminants like small stones, which the Eagle Tall

PRO X X-ray inspection system can detect with great e ciency.

Moreover, the Eagle Tall PRO X X-ray machine’s side view detection coverage provides full inspection of a range of container sizes and can carry out multiple inspections at line rates in excess of 1,500-ppm (products per minute.)

Additional features include:

• advanced image analysis with proprietary SimulTask software for automatic detection and rejection;

• capability to adjust to variable line speeds;

• easy installation over existing conveyor lines for seamless integration;

• on-board CAT 3 (EN 954), PLC (EN 13849 ) safety system with embedded self-diagnostics;

• a built-in modem and Ethernet card for remote technical support;

• HAACP-ready hygienic design;

• full event and contaminant logging;

• Standard A/C cooling on all models

Being an essential supplier of muchneed food items, Shah Trading had to be extremely agile to keep its plants running e ciently during the COVID-19 pandemic.

“We had to do a lot reconfiguring of our

Designed to provide reliable X-Ray inspection of tall metal cans, glass jars and other upright rigid packing, the Tall PRO X -ray inspection system manufactured by Eagle Product Inspection and supplied by PLAN Automation provides the Scarborough facility E with a highly e ective method of quality assurance and food safety validation.

lines to give people the proper social distancing: that was our main issue,” Shah relates.

“We had to plan ways to schedule lunch breaks on a staggered basis, so that the teams would not be filling up lunchrooms at the same time.”

Labor shortages have also posed a serious challenge for the operation, according to Shah.

“We had to increase wages many times to attract new workers,” Shah relates, “and because you can’t hire new people at a higher cost than what you’ve been paying your existing workers, the whole cost structure goes up,” Shah explains.

One of the biggest current challenges facing the company is navigating the new global supplying chain constraints, with Shah noting that the shipping costs in the agricultural importing business have skyrocketed.

“Freight costs from Asia have risen devastatingly high,” he says, “and because of that it doesn’t make sense to bring in certain products at this moment.

“The freight rates are now eight times what they should be,” Shah states, “and that just makes the cost

not worth it.”

Additional supply chain issues Shah Trading has had to navigate have included shortages of card board corrugate for boxes, and shortages of glue for labelling its canned products.

Despite all these challenges, Shah Trading has largely held up well through the pandemic, according to Shah.

“We had a really good year last year,” Shah says. “The initial surge in demand for packaged food staples in the early pandemic days certinaly helped us grow our business.

“It has dropped o a bit,” he con cludes, “but for the most part our sales growth has been sustained.”

Tempo Plastic Limited

BW Flexible Systems (Div. of BarryWehmiller Companies)

Alex E Jones & Associates

Leepak

Charles Downer & Co.

Eagle Product Inspection

PLAN Automation

Technical Adhesives Limited

Eastey Enterprises Inc. (Div. of Engage Technologies Corp.)

el on our brand new eti auro 33 large ormat in et printer to reate ibrant print on a wide range o rigid and flexible media up to 3.3 m wide. and ull automati .

When expanding your canning or bottling operations, there is much to consider. It can take many months to plan and procure new equipment prior to installation. Plus, it can take several months to get to producing saleable cans after you’ve installed new equipment. You know beer, we know conveyors – we can assist with design, consultation, installation, service and support during and after run-in. From conveying components, guide rail, speed reduces and bearings to Perceptiv™ diagnostic services, we can help you get new conveyors running smoothly and make the complex simple.

For more information, contact 800-626-2093 or PTSAppEng@regalrexnord.com. regalrexnord.com/RunDry Creating a better tomorrow™...

An overhead view of the dry-running conveying line installed at the new Mad Tree Brewing facility in Cincinnati by conveying systems experts from the Beloit Rexnord Corporation, enabling the craft brewer to boost its canning line output up to 250 cans per minute.

Thriving midwestern craft brewer keeping the taps running at full speed with custom-designed, dry-running canning line

Like most North American craft brewers, Cincinnati, Ohio-based MadTree Brewing started out pretty small back in 2013, with its original canning line’s running speed of 24 cans per minute hardly a contender for breaking any speed records in the industry.

However, the speed with which the privately-owned brewer became one of the most popular and celebrated beer producers in the so-called Tri-State region in America’s mid-west is a compelling testament to the company’s remarkable natural knack for producing high-quality craft beer.

With brisk growth in consumer demand vastly outpacing the original canning line’s capacity to keep up, MadTree quickly found itself in need of a new home to package its popular canned beer brands such as PSA Proper Session Ale, Lift, Psychopathy and Happy Amber

With the help of local commercial real estate developer Al. Neyer, LLC, MadTree found what it was looking for just a couple of miles from its original location at a historic site once operated by former paper packaging products manufacturer RockTenn. As Al. Neyer proceeded to reconstruct the old paper mill site to suit the needs of the expanding brewery—including construction of a 10,000-square-foot outdoor beer garden, two private event spaces, a 64-tap taproom, and an on-site Catch-AFire Pizza café—MadTree knew it would also need to install a modern, high-performance canning line worthy of the renovated grand 50,000-square-foot facility.

To get this done in the most e cient and expedient manner, MadTree contacted conveying systems specialists Regal Rexnord Corporation, having heard a lot of positive things about the company’s many system installations in the craft beer business from several other

Clockwise Quirky names and dazzling graphics are big part of the comumer appeal for Mad Tree brands; MadTree’s new packaging line conveyors utilize run dry (no lubrication) premium materials such as NGE modular belts, and Nolu-S components; a close-up of Leeson motor and Hera gearbox powering the conveyor line; filling station within the new conveyor layout can run at speeds of 250 cans per minute.

successful craft beermakers.

A year before start-up of the expansion, Regal assisted in equipment selection, conveyor/component design, layout simplification, OEM “Final Acceptance Testing,” and on-site installation support, which continued through start-up and run-in.

Headed by conveyor e ciency expert Jim Kullman, the Regal team assembled a thoughtfully selected bundle of key parts and components manufactured by Regal, including System Plast NGE modular belts and Nolu-S wear strips, Sealmaster bearings, Hub City Hera gearboxes, and LEESON motors.

“At Regal, we like to get personally involved,” Kullman recalls. “I began working with MadTree a year before start-up and remained with them throughout the project.

“I essentially worked as a consultant and integrator on behalf of MadTree to ensure they met their overall goals regarding lowest total cost-of-ownership and line e ectiveness.

“Because Regal manufactures all of the products we needed in our parts bundle, we made it easy for MadTree to get all they needed from one source,” Kullman relates.

“All the products we selected played a key role in products optimizing production e ciency—ultimately resulting in a 100-percent dry-running conveyor line

that provides many e ciency and sustainability benefits.”

As Kullman recounts, one of the project’s highlights involved developing a streamlined transition from packaging line conveyors to a key piece of equipment by designing, building and integrating a System Plast custom side-transfer module into the equipment.

“This created a really smooth product transfer—eliminating jamming and downed cans,” he recalls.

“Another key component during the install was a punch list to identify potential installation issues and recommended corrective actions before start-up,” Kullman adds, “saving significant time during run-in.”

Says Kullman: “The Regal team made a complex undertaking simple for the MadTree brewery, who now have an ecient, smooth-running packaging line— running 250 cans per minute—that will also be relatively maintenance-free for the long term.

“By providing much higher yields and faster throughput, the new line allows them to conduct business in a sustainable and environmentally-friendly way.”

Adds MadTree Brewery founder Kenny McNutt: “We decided to go with Jim Kullman and the Regal team as our packaging line advisors based on their hands-on approach and positive feedback from other brewers who worked

with them, and we couldn’t be happier with this decision—it really paid o for us in the end.

“It’s common for new packaging lines to have a run-in period of several months, before even producing one saleable can, which can be a costly and unpredictable burden,” McNutt says.

“But with the support of the team at Regal, we significantly compressed the initial conveyor run-in time, and we were selling cases of canned beer much sooner than we expected.

“Developing an optimal layout was not an easy task,” McNutt points out. “It took several iterations.

“But Jim’s experience with brewery conveying helped me to design a layout to take the best advantage of our equipment features for optimal product flow.”

Says McNutt: “Jim Kullman and the Regal team focused on what was important to us, while at the same time sharing their conveyor knowledge and experience.

“With them by our side throughout the process, we got the best packaging line for our specific needs,” Kullman concludes.

“For anyone contemplating expanding or upgrading their brewery’s packaging line, I would strongly recommend that they contact Regal.”

Regal Rexnord Corporation

The new hot-melt system from Baumer hhs provides a highly e ective solution for producing e-commerce boxes and other delivery packaging with pressure-sensitive adhesive closures.

Adhesive applicating strips provide extra layer of protection for e-commerce distribution

The COVID-19 pandemic has rapidly driven up demand around the globe for e-commerce boxes and other delivery packaging sealed with pressure-sensitive adhesives.

Boxes containing purchased items are typically sealed with adhesive strips that are applied by hot-melt systems and then covered with silicone tape. These pressure-sensitive adhesive closures securely seal the packaging.

As market leader for these applications, adhesive applicating systems manufacturer Baumer hhs GmbH is working hard to further improve its already very successful and highly productive systesm, simplify operation and increase process reliability.

The e-commerce market imposes increasing demands on the quality of pressure-sensitive adhesive application, according to Andreas Schneiders, corrugated business development man-

ager at Baumer hhs in Krefeld, Germany.

“These days, systems that apply adhesive strips are expected to deposit perfect, uniform layer thicknesses and accurately cover them with silicone tape, even when dispensing high quantities at high production speeds,” Schneiders explains.

“The more homogeneous the contact surface, the more reliably and securely the boxes can be sealed.

“In addition, homogeneous contact surfaces facilitate the work of employees in shipping, who no longer have to manually smooth over the closures to firmly seal them,” says Schneiders, citing introduction of a new and improved Baumer hhs hot-melt system for applying pressure-sensitive adhesive on corrugated and cardboard surfaces that achieves consistent application quality and a high melt rate.

As Schneiders explains, “It supports the production of premium quality e-commerce boxes and delivery packaging with pressure-sensitive adhesive

Power of Sustainable Packaging. Today’s consumers are more environmentally conscious than ever — that’s why we’re committed to innovative folding carton packaging solutions that are good for the environment and the bottom line. At Sun Chemical, helping you meet your sustainability goals just comes naturally.

Request your copy of Sun Chemical’s Guide to Sustainable Packaging at sunchemical.com/ poweroffoldingcartonpackaging. who can give their

working for you.

closures that will dramatically increase the reliability of the shipping process in online trade.”