SMOKING HOT!

Venerable smoked meat brand leverages thermoform packaging to drive retail sales

Story on page 12

RETAIL-READY PACKAGING

FLEXIBLE PACKAGING • CONVEYING

Venerable smoked meat brand leverages thermoform packaging to drive retail sales

Story on page 12

RETAIL-READY PACKAGING

FLEXIBLE PACKAGING • CONVEYING

Videojet 1860 Continuous Inkjet Printer

1. True predictability

Industry-first ink build-up sensor provides true predictability and warnings of possibly degrading print quality, even before a fault occurs.

True remote services*

Multiple access options (Ethernet™, WiFi) and secure VPN communication meet highest standards in the industry as part of VideojetConnect™ Remote Service, and help to improve machine uptime and customer experience.

* Subject to availability in your country

True IP rating

Optional IP66 rating for entire cabinet and hygienic design following industry guidelines; easier integration with slanted printhead design.

True scalability

Workflow modules help to customize the printer to perform the exact need required. It is easy to adapt the printer with new capabilities and functionalities, and to meet growing demands.

SENIOR PUBLISHER

Stephen Dean • (416) 510-5198 SDean@canadianpackaging.com

EDITOR

George Guidoni • (416) 510-5227 GGuidoni@canadianpackaging.com

ASSISTANT EDITOR

Alanna Fairey • (416) 510-5228 afairey@canadianpackaging.com

MEDIA DESIGNER

Brooke Shaw • (519) 428-3471 bshaw@annexbusinessmedia.com

ACCOUNT COORDINATOR

Barb Comer • (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

CIRCULATION MANAGER

Anita Madden • (416) 442-5600 x3596 AMadden@annexbusinessmedia.com

VICE PRESIDENT

Tim Dimopoulos • tdimopoulos@annexbusinessmedia.com

COO Scott Jamieson

ANNEX BUSINESS MEDIA

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA

ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

CIRCULATION

e-mail: rthava@annexbusinessmedia.com

Tel: 416-442-5600 ext. 3555

Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE: Canada $78.50 per year, USA $138.00 US per year, Outside Canada $156.50 US per year, Single Copy Canada $10.00, Outside Canada $27.10. From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer

ANNEX PRIVACY OFFICER

DISCLAIMER:

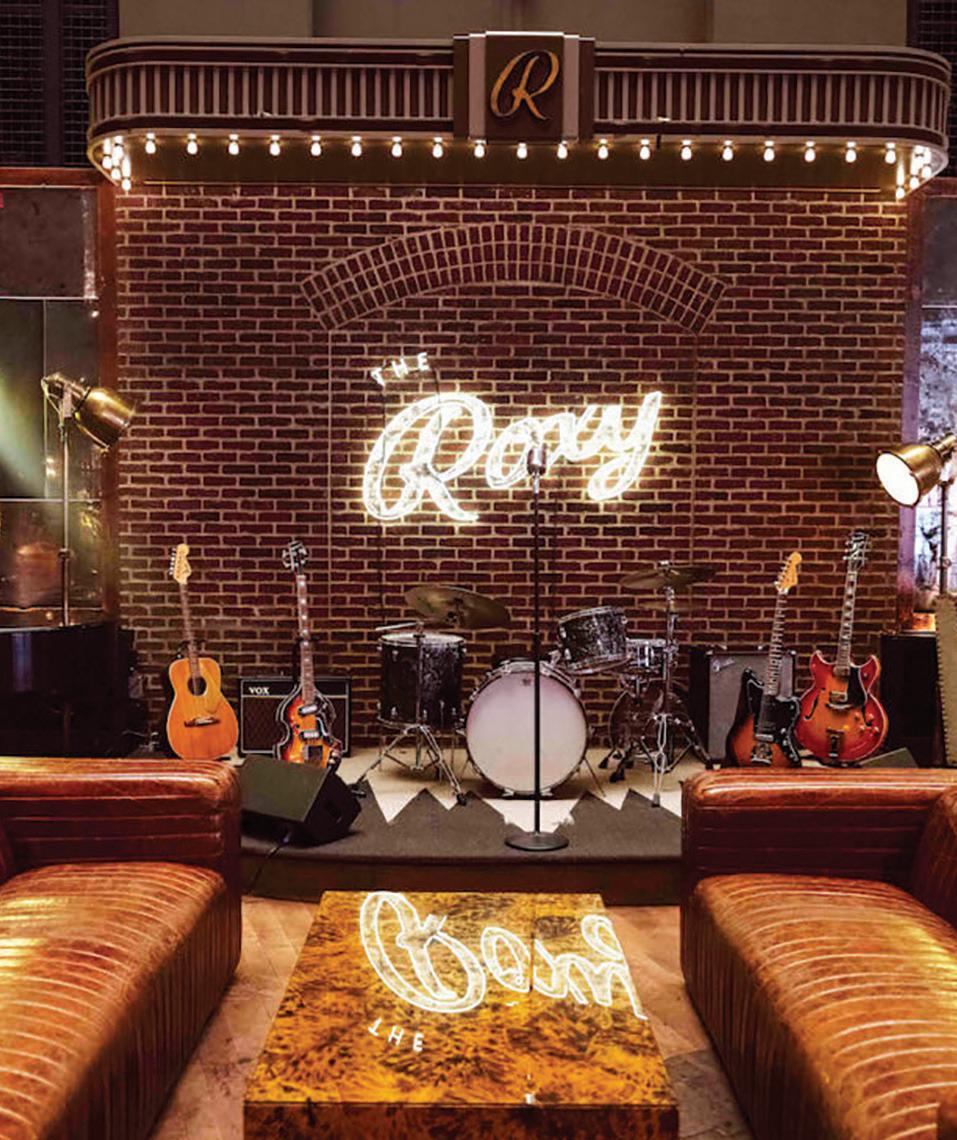

There’s no business like show business in Las Vegas. As the last major global packaging event of this calendar year and, in fact, this past decade, the latest edition of the biennial co-located PACK EXPO Las Vegas and Healthcare Packaging EXPO 2019 exhibitions was a resounding success by all conventional and other measures.

And if a successful trade show is a reflection of a thriving industry, packaging professionals all over North America will find a lot of comfort in knowing that the good times they have enjoyed in the last couple of years are poised to carry on well into the next decade, as long as the industry continues to make meaningful progress on packaging sustainability, food waste and other new challenges posed by shifting demographics and consumer trends—including cannabis and e-commerce packaging.

According to the shows’ owner and organizer PMMI, The Association for Packaging and Processing Technologies, the three–day event in late September continued the show’s proud record of uninterrupted growth in convincing style by smashing a “trifecta” of key indicators in attracting record numbers of visitors (over 31,000 people) and exhibitors (more than 2,000), while covering a record amount of exhibit space (nearly 900,000 square feet).

As impressive as these numbers are, they barely do justice to the high levels of upbeat optimism and inspired innovation pulsating through the Las Vegas Convention Center exhibit halls throughout the highenergy celebration of packaging excellence.

“With the incredible role it now plays for the packaging industry, PACK EXPO Las Vegas and Healthcare Packaging EXPO was the international packaging event of 2019,” beamed PMMI’s president and chief

executive officer Jim Pittas.

“The sheer size and scope of PACK EXPO Las Vegas and Healthcare Packaging EXPO indicates that as our industry continues to prosper it turns to PMMI shows for the solutions and tools to improve their business.”

Boosted by an impressive line-up of live educational sessions led by authoritative industry experts at the show’s overflowing Innovation Stage mini-theaters, the expo also experienced an unprecedented volume of deal-making and equipment tire-kicking to keep both exhibitors and visors alike highly engaged and entertained throughout.

As a senior packaging specialist for Nestlé, Brandon Kelly was pleased to find exhibitors and education sessions that matched the lofty recyclability and reusability goals of the world’s largest food company.

“It gives me a sense of confidence to see that converters, raw material suppliers and other businesses throughout the supply chain are working toward similar sustainability initiatives, as seen in many of this year’s Innovation Stage presentations,” Kelly said.

“The industry has a big challenge to solve when it comes to sustainability,” he noted, “so it’s great to see companies working towards a similar mission.”

With so many of the world’s leading companies having made highly public pledges to achieve significant carbon-footprint reduction milestones by the fastapproaching target dates of 2020, 2025 and 2030, the next decade promises to be one of the most exciting new eras in the history of modern packaging.

Hence ushering it in with the extraordinary aplomb and vibrancy displayed at the Las Vegas event certainly makes it the best time ever to be part of an industry oozing with promise, cofidence and a reassurance of even better things to come.

Ontario

converter opening up exciting new export markets with a lightweight paperboard grade.

Canada’s leading flaxseed processor extends its retail shelf appeal with distinct consumer-friendly flexible packaging.

Garbage bag manufacturer strikes

with a new

line for processing recycled plastic waste.

Packaging

Something sweet is happening just in time for sweater weather and baking season, with Torontobased Redpath Sugar Ltd., the world’s largest refiner of cane sugar, launching its new Redpath Collection product line Redpath Collection

The Canadian heritage brand’s new product line kicked a few weeks ago with the introduction of with distinct sugar products, with plans to add additional unique products in the future.

Packaged in sleek, resealable, stand-up zipper pouches designed by Mississauga, Ont.-based graphic arts and branding specialists Davis Design, the new Redpath Collection sugars—available at leading retailers across the country— provides a premium experience in terms of flavor, presentation and craftsmanship, according to Redpath.

“We want Canadians to enjoy their sugar experiences,” says Redpath Sugar’s brand development manager Nancy Gavin.

“There is something so memorable about connecting your special moments and unique experiences with what’s on your table, and the new Redpath Collection line inspires people to do just that.”

For now, the Redpath Collection line comprises

the Organic Granulated Sugar and Simply Raw Turbinado Sugar varieties.

The Organic Granulated Sugar is crafted from sugarcane grown on sun-drenched farms committed to sustainable agriculture.

The granulated sugar has a delicate taste and can be used in a number of different ways, including in beverages such as tea and coffee, baking, and sprinkling on hot cereals.

It’s the perfect sugar for anyone who prefers to choose organic products, according to Gavin.

For its part, the Simply Raw Turbinado Sugar is made up of idiosyncratic golden crystals created as a result of the sugar-cane juices evaporating during the refining process.

Touted as a perfect choice for coffee aficionados are looking to duplicate the café experience at home, the Turbinado Sugar provides a delicious mellow caramel flavor to hot beverages, and a pleasing crunch as a topping on baked goods and yogurts.

To celebrate the launch of the brand’s new premium sugar line, Redpath is also giving Canadians the opportunity to win a unique prize pack consisting of a premium espresso maker and a package of each of the two new sugars.

Also accompanying the launch is a series of recipes expertly created to take advantage of the unique properties of each sugar—ranging from beverages to baked goods, including a unique Moroccan Mint Tea with Rose and a stunning Hibiscus White Wine “Celebration” Cake

As a wholly-owned subsidiary part of ASR Group, Redpath Sugar has been crafting sugar in Canada for over 160 years.

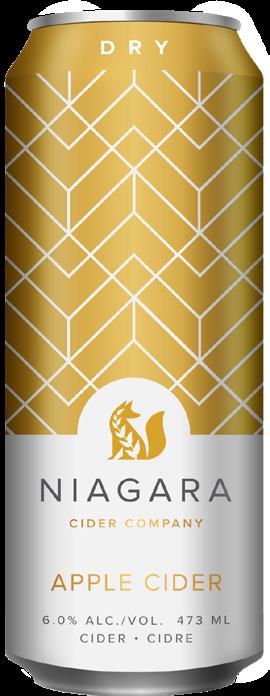

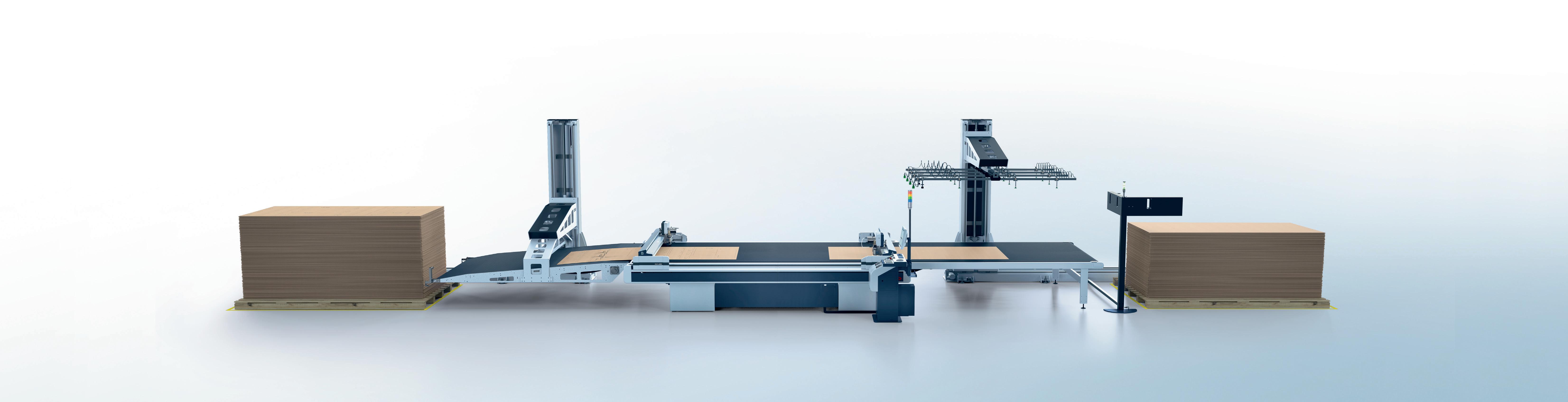

With the tastes of Niagara showing in each sip, Niagara Cider Company’s No. 1 Dry Apple Cider is now available in the LCBO (Liquor Control Board of Ontario)

Hand-crafted with a proprietary blend of apples hand-picked from Niagara orchards, Niagara Cider is an ultra-premium beverage that recently .earned a gold medal at the 2019 Great Lakes International Cider and Perry Competition, the largest and arguably most prestigious cider competition in the world.

“We like to describe our flagship No. 1

Leading Canadian package design specialists PIGEON Brands is hooking up with grocery giant has Metro to offer design students in Ontario and Quebec the opportunity of a life-time with a chance to design packaging for one of Canada’s favorite supermarket chains.

The competition puts selected OCAD University and Collège Salette students to the test by inviting them to create new designs for Metro’s private brand, Irresistibles

Students will be judged based on criteria such as concept rationale, design, creativity, market understanding and viability, as well as overall presentation.

The winning designers will land a paid internship at the Toronto and Montreal Pigeon Brands offices. The second place prize, as well as the Student’s Choice Award decided on by the student faculty, will be presented by Metro separately.

The judging panel will include leading experts from Pigeon, Metro, the participating schools and Christopher Durham, president of My Private Brand and co-founder of the prestigious Vertex Awards competition.

“We’re excited to meet the design leaders of the future, while giving them the chance to gain real-world experience on a project for a massive Canadian retailer,” says Pigeon Brands chief executive officer Thomas Pigeon.

“We want to foster creative minds and help students get familiar with the industry they’re working towards being a part of.”

This joint initiative by Pigeon Metro rapidly gained traction with the partners as it connected two leading schools, expertise from a recognized agency team, and a highly prestigious client.

The winners will be announced by the year-end with an award ceremony at each school celebrating their efforts.

Dry Apple Cider as complex and crushable,” says Rich Houghton, co-founder of the Niagara Cider Company.

“What we have landed on is a true craft cider using local ingredients that is perfectly balanced between sweetness and acidity,”he adds.

Designed by Toronto, Ont.-based Cactus Design, Niagara Cider Company worked with Fast Track Packaging on the decorative shrinksleeves applied onto the 473-ml aluminum cans sourced from Crown Beverage Packaging.

The company started as a hobby project for Houghton, who was seeking a cider that suited his tastes, but was unable to find one on the market.

He joined forces with his hockey buddy Matt Dixon, who has a long history working in Ontario’s beverage alcohol sector, to develop an all-natural style of dry cider that is rare in the current market.

“The unique blend of climate, soils and geography allows Niagara farmers to grow some of the best apples in the world,” says Dixon.

“It was important to us to create a drink that shows off the bounty of Niagara,” he adds. “Using heirloom apples from orchards in our community, we have accomplished just that.”

nPretium Packaging, Chesterfield, Mo.-based A manufacturer of plastic containers and closures for the food, specialty beverage, household, industrial, healthcare and beauty care industries, has completed the acquisition of Toronto-based healthcare packaging sup -

plier Starplex Scientific Inc. from Apotex Corp Starplex Scientific has built up highly-respected product lines that include leak-resistant sterilized containers, biological swabs, and pharmaceutical-grade containers and closures widely used in the clinical, laboratory and drug manufacturing markets in Canada and the U.S. “This acquisition of is another example of Pretium merging independent, well-run companies with strong brand presence, a robust product line and complementary geographic locations into our existing family of companies,” says Pretium’s president and chief executive officer Paul Kayser. “Starplex’s quality systems and medical device knowledge will be welcome additions to our growing healthcare market segment.”

Do you want SUPERIOR flexibility? You’ll love the range of packages that Reiser machines can provide.

Do you want SUPERIOR production? You’ll love the speed.

Do you want SUPERIOR package seals? You’ll love not worrying about leakers and returns. Reiser’s form/fill/seal technology and packaging expertise are the powerful combination you need to produce a SUPERIOR package.

nCrown Beverage Packaging North America, a business unit of Philadelphia, Pa.-headquartered Crown Holdings, Inc., has opened up a new graphics studio in Ambler, Pa., featuring cutting-edge technologies that shorten product development timelines and allow for design mockups in real time. The 14,000-squarefoot facility enables customers to have hands-on involvement alongside onsite experts to produce finished packages that create brand differentiation on the shelf through comprehensive suite of services, ranging from consultation and color and ink recommendations to separation and a preview of the finished product. “Our new graphics studio represents the changing beverage landscape,” says Crown’s director of graphics Paul Fennessy. “Today’s brands are recognizing that in many cases, the can serves as the customer’s first experience with a product, whereby he size, look, feel and, of course, the graphics, create a first and lasting impression in the mind of consumers,” Fennessy adds. “When designed with these factors in mind, cans are able to foster a valuable connection and build brand preference.” As Fennessy points out, the studio also handles production of printing plates for all of the company’s U.S. and Canadian manufacturing plants, including standard computer-to-plate (CTP) plates and high-quality printing (HQP)/direct laser engraving (DLE) plates.

nChicago-headquartered packaging products manufacturing group Berlin Packaging has concluded its fourth acquisition in Europe this year by purchasing the assets of Montilla, Spainbased firm Vidrimon, a supplier of olive oil bottles and other innovative glass packaging for the southern European markets. To be incorporated into Berlin Packaging’s Bruni Glass division, headquartered in Malan, Italy, under the new name of Bruni Glass Iberia, the company’s strong position

in markets for olive oil and custom glass beverage strongly complements Berlin’s growing presence in food, beverage, pharma, personal care, household care, cannabis, and industrial packaging markets. “Adding Vidrimon is another important building block as we become the world’s strongest, broadest, and most customer-centric packaging supplier,” says Bruni Glass chief executive officer Paolo Recrosio. “It only strengthens our expansive European offering, while aligning us with a company that shares our glass packaging expertise, our commitment to quality, and our thrilling customer service.

”

nSwiss-based manufacturer of package converting machinery and equipment manufacturer Bobst has been awarded a gold medal Sustainability Award in the machinery category during the recent PackBox Forum conference at the Fachpack 2019 international packaging exhibition in Nuremberg, Germany. Selected from among 25 finalists, Bobst was picked as the category winner in recognition of company’s innovative, Ink-on-Demand (IoD) and DigiColor solutions offering converters distinct sustainability advantages. For example, the revolutionary IoD system eliminates ink trays and chambered doctor blades and only requires 30 grams of ink in the print unit to operate, while the complementary DigiColor color matching technology enables ‘on-the-fly’ job changes of color Delta E at any speed and on any substrate. “We understand the combined pressures of modern packaging supply chains in

today’s environmental and legislative space,” says Matteo Cardinotti, head of Bobst’s narrow- and mid-web multi-process and converting product line. “Converters today want to be assured they’re investing in solutions that not only deliver consistently high quality, but also make best use of resources. Continually driving innovations to meet this need is important to us, and so to receive this award is a great honor.”

n Cincinnati, Ohio-headquartered ProMach has completed the acquisition of Grip-Pak , a turnkey provider of multipack handle solutions for beverage companies packaging their products in cans or bottles, as well as retailers and wholesale distributors looking to repack their SKUs (stock-keeping units). “The craft beverage marketplace is exploding with new products—not just beer, but wine, spirits, energy drinks and more,” says Doug Stambaugh, president of ProMach’s Global Filler & Integrated Solutions business. “Through our Roberts PolyPro product brand, ProMach already had one of the widest line-ups of bottle and can handle solutions with both sheet-extruded and injection-molded handles that use significantly less plastic. With the addition of Grip-Pak’s LDPE handle solutions, we now have the broadest portfolio of handle solutions in the marketplace, all available from a single source, help companies of all types grow their business.”

Next-generation leadership performance

Hitachi’s UX Series continuous inkjet printers represent the pinnacle of innovation in marking and coding technology, all while showcasing Hitachi’s reputation for Reliability, Efficiency, and Ease of Use. sales@harlund.com

Developed for easy adaptation to the today’s dynamic manufacturing environment, the new-generation ProBlue Flex melter with BBconn Controls from Nordson Corporation is an advanced modular, scalable and intelligent adhesive applicating technology that provides users with more flexibility, improved precision, better connectivity, and complete machine

integration. Built on the trusted, long-standing legacy of the company’s renowned ProBlue series melters, the ProBlue Flex series features the new BBconn Controls platform to provide easy connectivity, remote accessibility, and the data users need to meet their continuous improvement goals. A fullyoutfitted ProBlue Flex melter comes with a built-in integrated Adhesive Tracking System (ATS) for accurate measuring and monitoring of adhesive volumes, while the system’s intuitive user interface can save up to 100 recipes that can be easily

recalled as needed. Moreover, all the settings and recipes can be accessed or updated remotely through the main machine’s PLC (programmable logic controller) control panel, eliminating the need for operators to access the machine for changeover. Using the optional electronic pressure regulator, changes to adhesive add-ons can be password-protected or set remotely via the PLC, enabling users to set up pressure limits that will trigger an alert notification if the system pressure goes out of bounds. In addition, the system’s electronic pressure run-up allows the pressure to ramp up with the line speeds—enabling the same amount of adhesive to be dispensed for each product.

Nordson Corporation

Designed as a reliable and economical solution for wrapping pallets, Signode’s compact C Series automatic rotary ring stretchwrapper features virtually silent operation and plenty of versatility to handle a multitude of applications with the ability to wrap up to 45 loads per hour. Outfitted with color touchscreen controls, Octopus C provides plenty of flexibility in creating the optimal wrap pattern to solve specific stretch packaging challenges, with ptional features includeing:

Gravity load stabilizer to ensure unstable loads remain intact;

A roping device to reinforcement the bottom of the film for load stability. A pallet lifting device to raise the load above the conveyor, allowing it to be wrapped to the pallet more securely.

Signode

The new automatic Z.ZAG palletizing machine from EndFlex LLC uses vacuum generators to pick up cases one at a time and place them on a pallet from above, with its ample suction capacity is capable of lifting 40-pound boxes at speeds up to 360 boxes per hour. Once the position of each case is calculated automatically according to the desired pattern and the dimensions of the case, the Z.ZAG palletizer locates all cases on one pallet and, upon completion, starts filling the next pallet as the first pallet is replaced. According to EndFlex, placing this end-of-line application at the end of each production line is less costly than using conveyors to transport cases to an expensive high-speed palletizer. EndFlex LLC

Leading global packaging and paper group Mondi, chemicals giant BASF and Dutch produce processor Coroos have recently collaborated on a state-of-the-art pilot project to produce a food-grade stand-up pouch that is partly made with raw material derived from chemically recycled plastic.

Until now, recycling plastic has chiefly been a mechanical process, limiting the scope of plastics that can be recycled and limiting the number of products that can be created with recycled material, due to potential impurities and other flaws that can occur in the plastic layers.

To overcome these drawbacks, Mondi partnered with BASF to process virgin-grade ChemCycled plastic material into a multilayer laminate for food packaging for Coroos’ privatelabel products and its own flagship-brand Servero brand of fruit spreads and preserves.

In the manufacturing process, 100 per cent of the fossil feedstock was replaced by pyrolysis oil derived from mixed recycled material— allocated via a certified mass balance approach— for one of the inner layers. In total, 12-percent of the packaging weight is made of ChemCycled material.

According to Mondi Consumer Packaging’s sustainability manager Graeme Smith, food packaging should be sustainable by design—using paper where possible, and plastic when useful. For food protection and shelf-life extension, plastic is often the best option because of its barrier properties.

“It is important to show proof of concept when establishing breakthrough developments,” Smith says, “and chemical recycling is an essential part of the roadmap to commercializing this process in the future.”

Adds BASF’s director of polyamide business Christoph Gahn: “BASF is working on advancing the chemical recycling of plastic waste, because this will make it possible to process and reuse plastics that are currently difficult to recycle such as mixed plastics.”

As for Coroos, “We are partnering in this project because we care about sustainability and are looking into different options to improve our footprint by using packaging from recycled materials, as well as for packaging materials that are recyclable or reusable,” says marketing manager Elke Schroevers. “This development paves the way for plastic waste to become a new resource for flexible packaging.”

As part of its continuing packaging sustainability journey, famed Danish beermaker Carlsberg Group has created the world’s first ‘paper’ beer bottle, made from sustainably-sourced wood fibres, that is both 100-percent bio-based and fully recyclable.

While it’s not quite ready for full-scale commercialization, the two new prototypes of the Green Fibre Bottle unveiled so far pride plenty of credibility to Carlsberg’s commitment to its Together Towards ZERO program, which includes achieving zero carbon emissions at Carlsberg’s breweries and a 30-percent carbon-footprint reduction in its full value chain.

The two new research prototypes are made from sustainably sourced wood fibre, are fully recyclable and have an inner barrier to allow the bottles to contain beer. One prototype uses a thin recycled PET polymer film barrier, and the other a 100-percent bio-based PEF polymer film barrier.

These prototypes will be used to test the barrier technology as Carlsberg seeks a solution to achieve their ultimate ambition of a 100-percent bio-based bottle without polymers.

“As we continue to innovate across all our packaging formats, we are pleased with the progress we’ve made on the Green Fibre Bottle so far,” says Myriam Shingleton, vice-president of group development at Carlsberg Group.

“While we are not completely there yet, the two prototypes are an important step towards realizing our ultimate ambition of bringing this breakthrough to market,”Shingleton states.

“Innovation takes time and we will continue to collaborate with leading experts in order to overcome remaining technical challenges, just as we did with our plastic-reducing Snap Pack.”

Carlsberg kicked off the project to develop a bottle

made from sustainably sourced wood fibres, the ‘Green Fibre Bottle,’ in 2015 alongside innovation experts ecoXpac, packaging company BillerudKorsnäs, and postdoctoral researchers from the Danish Technical University, supported by the Innovation Fund Denmark agency. These combined efforts have resulted in the formation of Paboco, a joint-venture company specializing in the development of paper bottles.

Carlsberg will now join The Coca-Cola Company, The Absolut Company and L’Oréal in an international paper bottle community. that unites leading global companies and experts with the vision of advancing sustainable packaging by offering high-quality products while reducing their environmental impact.

“The work with our partners since 2015 on the Green Fibre Bottle illustrates that this kind of innovation can happen when we work together,” Shingleton says.

“We’re delighted that other like-minded companies have now joined us as part of Paboco’s paper bottle community. Partnerships such as these, ones that are united by a desire to create sustainable innovations, are the best way to bring about real change.

“We’re driven by our constant pursuit of creating more sustainable packaging solutions that help people to live more sustainable lives,” Shingleton proclaims.

“Sometimes that means completely rethinking how things are done—pushing the boundaries of existing technologies and overcoming technical challenges as they present themselves.”

Gittan Schiöld, interim chief executive officer of Paboco, adds: “We are collaborating across the value chain, sharing the risks and remaining united in our vision that the paper bottle will become a reality that fundamentally change this industry for the better.”

This one-day summit offers guests the perfect mix of education and connection opportunities alongside fresh, bold and current industry trends.

Hosted in a beautiful theatre setting, it is sure to impress.

Storyteller topics will cover sustainability and trends in the circular economy, mindful entrepreneurship, women design trailblazers, CBD & cannabis in the wild west, the power of personalization, and more. Sponsorship

Winners of the PAC Global Leadership Awards will be celebrated at the event, showcasing some of the best in brand packaging and innovation.

Meat processing company invests in flexible thermoform packaging technology to leverage packaging sustainability and ensure extended product shelf-life

BY ALANNA FAIREY, ASSISTANT EDITOR

BY PIERRE LONGTIN

There are many companies and products that claim to be the best thing since sliced bread, but for Boisbriand, Que.-based Salaisons Desco Inc., being the proverbial best thing in the processed meats industry is the company’s true calling.

Originally founded in 1980 by president Guy Chevalier, Desco began as a 50,000-square-foot facility that exclusively operated as a ham business, before making the shift to smoked Montreal meat back in 2000.

Today, Desco has greatly expanded in square footage and has acquired the globally recognized HACCP (Hazard Analysis and Critical Control Points) and GFSI (Global Food Safety Initiative) certifications and houses approximately 135 employees typically operating two shifts dedicated to production and sanitation.

Desco’s Aliments Delstar Foods and Virginia

brand has been sold all across Canada, and can be found in Loblaws and foodservice accounts like Sysco and

Joe Ambrosino, director of Desco, credits Desco’s 35-year success not just to their high quality products, but also to their deep commitment to giving customers an authentic deli experience from the comfort of their own home.

“We are very efficient and very knowledgeable about our products and that gives us an advantage,” Ambrosino told Canadian Packaging in a recent interview.

“We’re able to turn on a dime, so that gives us an advantage on the open market.

Adds Ambrosino: “It’s always with the idea of trying to recreate the deli experience at home for the consumer ”

In recent years, Desco began to supply their smoked meat and brisket products to the venerable Schwartz brand, inspired by the revered Saint-Laurent, Que.based restaurant of the same.

Ambrosino shares that although the smoked meat bears the Schwartz brand name, the making of the smoked meat products is much different.

“The brands that we make are Schwartz-at-home, which is different than the restaurant,” Ambrosino relates.

“We’ve come up with a product that is based off of their formula and their recipes.

“But our smoked meat is more conducent to being sold in a grocery chain.”

For grocery chains to stock their merchandise, Desco needs to ensure that their

deli meat products have optimal shelf-life thanks to high quality packaging.

When it came to purchasing, Ambrosino and his team did not have to look much further than the Saint-Germain-de-Grantham, Que.-headquartered VC999 Canada Ltd., a leading supplier of packaging machinery.

Like the old saying goes, Desco and VC999 go way back, having been previously impressed by their experience of providing them with equipment to ensure top shelf-life and high quality packaging on their smoked meat products.

“We bought our first machine from VC999 sometime in the early 2000s and then another machine about eight years ago,” Ambrosino explains.

“The reason why we continue to do business with them is that we found that the product itself is reliable, we have also good service and the quality that you get for the price point is also very good.”

Through the guidance and expertise of VC999’s seasoned sales representatives, Desco purchased two full model RS420 thermoforming machines

In the past, Desco’s other investments in high-performance VC999 equipment comprised of:

• A single RS420c thermoforming machines;

• Two Xtravac 860 automatic chamber machines;

• And a single Xtravac 800 semi-automatic chamber machine.

Desco also purchased XtraPlast Kostex films from VC999, which are designed to be boilable in an effort to keep moisture in the meat as well as preserve the flavourful taste.

According to Ambrosino, the move to sustainable options has become a necessary means of doing business.

“Sustainability in our industry is basically survival, so you have to be able to continue to do things right for your customers,” Ambrosino says.

“Our point is always just to keep the end-user happy and giving them a product that they enjoy and will keep enjoying for a long time.”

Ambrosino says Desco acquired the RS420 thermoformer to achive optimal packaging performance, citing its robust output of 10-12 cycles per minute.

“It runs at a quick pace,” Ambrosino says, “actually faster than we’re able to produce!”

Ideal for portion adequate industrial packaging of fresh food and product innovations, the RS420 seemed like a natural choice for Ambrosino.

From the coveted R-Series, the RS420 thermoformer offers Desco marginal packaging and material storage cost, as the packaging comes in various shapes and can be made off the same rolls of film, which in turn helps Desco to minimize their carbon footprint.

Equipped with a steadfast PLC platform, the RS420 thermoformer has also helped to reduce operating costs for Desco, as the machine necessitates fewer workers to operate.

“I like the RS420 thermoformer’s flexibility,” extols Ambrosino.

“It’s fairly rapid and, overall, the machine is reliable.”

Sourcing their fresh meat from companies in the likes of Cargill, facility workers then begin the process of trimming, marinating and tumbling the meat to lock in the flavour.

Operators then slow roast the meat in smoking ovens, and then typically chill the meat before it is

taken to the slicing department.

Leading slicing equipment manufacturer Weber, Inc. supplied Desco with two Weber Slicer 902 slicing machines that slice large cuts of meat into extremely thin slices for the portioned products with remarkable precision and consistency.

“We have had great results with our Weber slicers, which play a very important role on our production lines,” Ambrosino remarks.

“They have been very reliable and god knows we work them pretty hard,” he states, adding that Desco has recenly purchased a new Weber Slicer 405 model slicer to further beef up its throughput.

Once sliced, the meat is then promptly moved along to the RS420 Thermoformer, where it forms a pocket so that workers can fit Desco’s individual pouches of 125- or 175-gram varieties into the pocket.

Once in the pocket, the RS420 thermoformer then applies the forming web and the XtraPlast Kostex film goes on top of the forming web and it is then vacuum-sealed, so that the product has an extended shelf-life of a minimum of 65 days.

After it is packaged, the meat is pasteurized in pasteurization equipment from Lutetia Eduipment.

Once the meat has been pasteurized, the meat is promptly run through the Loma IQ2 Metal Detector, supplied by Loma Systems, to ensure that no possible contaminants inadvertently made their way into the package.

Once successfully run through the metal detector, the finished sliced smoked meat product comes out the other end, and is then packaged into individual boxes of either the four or six per box varieties. Once packaged, the smoked meat is deemed ready to be distributed for retail sale.

Once again, Ambrosino is pleased with the overall experience purchasing from VC999, who made themselves available to them whenever they were having trouble with the RS420

“Whenever we have needed service, VC999 has always been quick to respond,” Ambrosino shares. “They are always there to partner up with us and getting the machine going with the least amount of downtime.”

Asked if Desco would consider purchasing from VC999 again, Ambrosino responds with a resounding, “Yes, definitely.”

As Ambrosino relates, the ultimate goal for Desco is to bring the iconic Canadian Schwartz brand and Montreal smoked meat product to the U.S. market.

While there several other food producers offering similar products, Ambrosino is not unduly worried.

“There’s no more than three or four businesses in the industry that can do exactly the same thing that we do,” Ambrosino proclaims. “We’re probably one of the biggest in the industry as far as the sliced pouches and smoked meat is concerned.”

As he concludes, “Right now, we think that Desco is trying to be on the cutting edge of technology to repond to the consumer demand as we know it.”

Family-owned boxmaker runs up the score on packaging sustainability with lightweight new paperboard offering customers a more earth-friendly packaging solution

BY GEORGE GUIDONI, EDITOR

PHOTOS BY NAOMI HILTZ

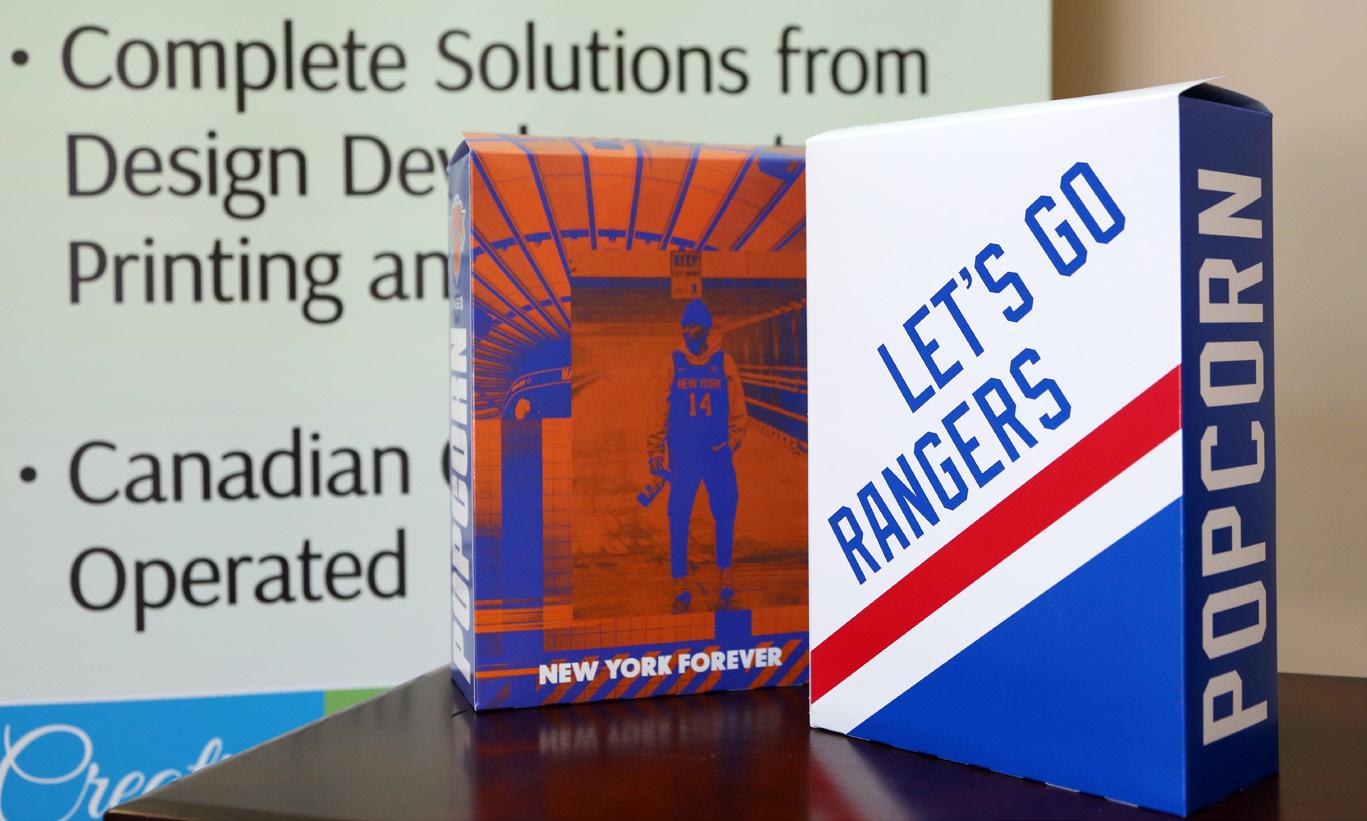

The bright lights of New York City are often at their brightest during an NHL or NBA game at the city’s storied Madison Square Garden sports arena.

And while it’s clearly the players showing off their athletic prowess to thousands of adoring New York Rangers and New York Knicks fans that are the center of attention, many of those fans may soon also develop a fondness for the new popcorn boxes making their debut at the venue’s concession stands this season.

And many of them would be surprised to learn that the crisply-printed lightweight boxes—elegantly decorated with the official full-color team logos, graphics and slogans for both sports franchises—have in fact been shipped from an unassuming, 30,000-square-foot

in

Ont., by the

Manufactured in Japan by the Komori Corporation, the Lithrone 40 sheetfed six-color printing press with inline aqueous coating is the Vaughan facility’s primary workhorse handling all of its printing jobs with reliable consistency and high-quality finishing across a broad range of paperboard grades and thicknesses.

Founded in 1982 by Charles Parlagreco, a recent arrival to Canada from his native Italy with little more than an electrical engineering college diploma and the clothes on his back, the words “humble beginning” are arguably an understatement when talking about the 37-year-old company’s early days.

“When I arrived in Canada at the age of 20, I hardly spoke a word of English,” recalls Parlagreco, who began his new life by working for a Toronto Paper Bag Manufacturing company owned by his future father-in-law.

After doing that for over four years, Parlagreco went to work for Toronto Hydro, putting his college education to good practical use.

But after five years of desk work at the utility company, Parlagreco got restless.

“I just could not see myself doing it for another 20 years,” he relates, “so after consulting with my family and obtaining a startup loan from my father-in-law, I invested in my first used letterpress, a two-cylinder machine with zinc plates, and began printing paper cartons in a corner of his shop.”

After his father-in-law introduced Parlagreco to his first customer, a once-popular Open Window Bakery in north Toronto, Parlagreco upgraded his letterpress to start using rubber printing plates to obtain the desired print quality, while learning as much as he could about die-cutting from a local die-maker.

“I was doing all this while still working full-time at Hydro for the first three years,” he recalls, “learning everything about the print business from scratch.”

Parlagreco says that working a staggered shift schedule at Hydro allowed him the flexibility to find time for his budding new business venture—albeit at a considerable personal sacrifice.

“I was getting about eight hours of sleep a week,” he recounts, “but being in my

20s and having a strong ambition to succeed, helped me manage to get through it all.”

Once his fledgling operation got too big for his borrowed workspace, Parlagreco rented a space next door to the paperbag facility and installed his first lithographic printing press—laying foundations for what is now a highly respected supplier of a versatile range of high-quality paperboard packaging to the Canadian food processing and grocery retail industries.

Says Parlagreco: “From the outset, Astro has always tried to set itself apart from the competition by providing the best service possible to our customers, with the quickest turnaround times.

“We thrive on finding ways to improve customer packaging so that it’s more environmentally-friendly, runs better on their production line, or is easier for their employees to handle,” he states.

“We pride ourselves on product development, loving nothing more than designing entire product lines from the ground up.

“Hearing our customers call us ‘problem-solvers’ is the highest compliment we can get.”

As a family-owned and operated business, Parlagreco says he is immensely proud to see two of his three daughters join the company’s management team, with vicepresident of administration Daniela Parlagreco coming on-board in 2007 and vicepresident of operations Laura Parlagreco following suit in 2010.

“We run the company with family values in mind,” Charles Parlagreco told Canadian Packaging on a recent visit to the Vaughan facility, housing Astro Box since 2010.

“We treat our employees, customers and suppliers alike with the highest respect,” he says, adding that some of the plant’s 30 full-time employees have been with the

Manufactured by Rayonier Advanced Materials at the company’s paper mill in Temiscaming, Que., the lightweight Kallima box brand of paperboard provides significant sustainability advantages over thicker board grades while providing all the required strength and rigidity.

company for over 30 years.

During that time, many of them have played key roles in enabling Astro Box to evolve into a full-service paperboard packaging supplier operating in a clean, safe and fully HACCP (Hazard Analysis Critical Control Points)-compliant environment meeting all the relevant GMP (Good Manufacturing Practice) standards and requirements.

“We work very hard to maintain a clean, safe and efficient plant that protects both our employees and our customers,” states Laura Parlagreco.

“We run our plant in much the same way as a food processing plant would, tailored to our Food Safety Enhancement Program (FSEP) and GMPs.

“Our facility is very bright, clean and well-maintained,” she says, citing the average 99-percent approval rating from the annual third-party audits of the plant’s HACCP/ Preventative Control Plan program implementations.

With annual capacity to convert 4,000 metric tons of boxboard, the plant employs a state-of-the-art, sheetfed Lithrone 40 six-color lithographic printing press with inline AQ (aqueous coating) to print a broad range of paperboard grades, utilizing highquality ink purchased from Sun Chemical Corporation

Manufactured in Japan by Komori Corporation, the Lithrone 40 sheetfed press at Astro Box runs at speeds of up to 15,000 sheets per hour to produce vibrant and colorful images on paperboard up to 40 inches in width and 28 inches in height.

“It has been a real workhorse for us ever since we purchased and installed it back in 2001,” says Laura Parlagreco, adding that the multimillion-dollar press remains the company’s biggest ever single capital investment to date.

Over the last few months, the Komori Lithrone 40 press has been increasingly used to process a new lightweight grade of paperboard manufactured in the province of Quebec by Rayonier Advanced Materials

Headquartered in Jacksonville, Florida, RayonierAM is a global manufacturer of high-purity cellulose, paperboard, lumber, newsprint and high-yield pulp.

Two years ago, RayonierAM completed the acquisition of Quebec-based forestry firm Tembec—opening another new chapter for the company by significantly increasing its presence in the paper and paperboard markets.

Marketed under the Kallima box™ brand name, the FSC® (Forest Stewardship Council®)-certified paperboard (FSC® C017431) is a three-ply FBB (folding boxboard) produced in Temiscaming, Que. Now available in 14 pt., 16 pt. and 18 pt. thicknesses, the low-density multi-ply construction offers significant weight savings, compared to thicker board grades.

At the same time, the thicker 18 pt. grade that Charles Parlagreco calls the “bull’s-eye of the folding-carton market today” enables converters to achieve exceptionally high print quality on cartons, shelf displays, POP (pointof-purchase) displays, etc.

As RayonierAM’s Vice President of Sales and Marketing Martin Lavoie relates, “Our customers from the commercial print markets have come to appreciate the main

benefits of Kallima—such as its lower basis weight and its North American footprint.”

“We are now pleased to offer this unique combination of advantages to packaging converters,” says Lavoie, noting the lightweight board’s impressive strength, impact resistance, versatility and machinability on a diverse range of printing and packaging equipment.

For his part, Charles Parlagreco is exceptionally pleased with being able to source the innovative Kallima box board from a Canadian-based manufacturer.

“Most of everything we buy for our business is priced in U.S. currency,” he points out. This naturally puts us under a lot of pressure when the Canadian dollar is as weak as it is now.

“That’s why buying this board from a Canadian company in Canadian dollars makes it an attractive option for us,” says Parlagreco, noting that Kallima box paperboard now accounts for nearly 10 per cent of all the grades that Astro Box processes at the facility.

“In the long run, using this board will help us increase our share of the U.S. export markets,” he says, citing the aforementioned New York Rangers and New York Knicks popcorn boxes that Astro Box now ships to Madison Square Garden, along with other new work that the company has been able to obtain by highlighting the environmental advantages of the FDA-approved (dry food contact) Kallima box to its client base.

“In addition to the basis weight advantage,” says Parlagreco, “it also has great printability, stiffness and smooth runnability.

“It provides an ideal surface for high ink coverage to enable us to execute complex print jobs,” Parlagreco extols, “and the material runs well through all stages of production: from printing and die-cutting to windowing and gluing.”

According to Parlagreco, the feedback from his customers to date has been overwhelmingly positive.

“Many of our customers have conducted tests and switched their entire product lines to Kallima because it runs well on their automated production lines,” he states.

“Many have seen improved efficiencies on their own lines,” he says, “and

they also like the high-quality printing we are able to achieve with Kallima box.”

Adds Laura Parlagreco: “Astro has always had a customer-centric vision. Our customers know that we’ll do whatever it takes to solve problems and meet deadlines,” she says, “and this hasn’t changed in 37 years of business.

“We work closely with our customers to develop solutions,” she expands.

“Whether it’s through prototyping and experimenting or spending time at their production facility to better understand their needs, we fully immerse ourselves when it comes to problem-solving, because seeing something first-hand is the best way to understand.

“We also understand that market conditions change

quickly, so we don’t ask twice when our customers need a lightning-fast turnaround,” Parlagreco adds.

“That’s why we keep an open mind when it comes to scheduling and try to accommodate all our customers’ needs,” she states.“If our customers are happy, so are we.”

While Charles Parlagreco says he expects the plant’s Komori Lithrone 40 press to provide at least another five years of good service, he says the company is also benefitting from various capital investments it has made in the last five years, including the installation of two highspeed Bobst folder-gluers; an Iberica blanker and additional windowing machines.

“These additional investments have improved efficiencies, increased our throughput, and allowed greater schedule flexibility,” says Laura Parlagreco, while also drawing attention to the high degree of process automation implemented throughout all Astro Box operations.

“The beating heart of our operation is our ERP (Enterprise Resource Planning) system, a boutique system that is tailored to the folding carton industry. The ERP system encompasses daily tasks from estimating to inventory control, shop floor data collection, shipping and everything in-between,” she relates.

“Our shop floor capabilities include computerized make-readies, inline quality control with glue and window detection, and real-time data from the shop floor, which provides immediate feedback to management.

“Also, our Cloud-based customer portal links directly to our automated CTP and workflow,” she notes,“making prepress a breeze.”

As Daniela Parlagreco happily adds, “Bringing the next generation into the business has provided Astro with a smooth succession plan for achieving our goal to grow the business, while maintaining high customer satisfaction levels.

“Given the worldwide attention and concern over pollution and climate change issues, there’s no doubt the focus has shifted towards more sustainable packaging solutions,” she states, “which is exactly what folding cartons offer.

“We feel that more and more business owners will continue to gravitate towards folding cartons,” she concludes, “requiring manufacturers like Astro to come up with creative solutions for their needs. Since this is how we’ve grown our business, we’re eager to rise to the challenge.”

VC999 Packaging Systems, a division of the Swiss-based Inauen Group, is excited to announce that our own Daniel Gardner has assumed the role of Vice President in charge of VC999 Canada Operations.

Daniel has been with VC999 Canada Ltd. since 2006 as Sales Manager for Quebec. He has an extended background in the meat industry, spanning more than a quarter-century. Mr. Gardner’s knowledge reaches across purchasing, packaging, & processing equipment as well as plant management in Ontario and Quebec for Olymel SEC.

VC999 is a growing company that believes in strong ties both internally and externally with processing and packaging operations all over the world. Originally founded in Switzerland a half-century ago, VC999 continues to innovate offerings and make our customers’ businesses grow. Daniel Gardner will oversee thirty-plus years of putting customers first, producing top-quality products, and striving to add value to your bottom line.

one source took you further?

The inventor of cam followers has provided industry leading solutions in the food and beverage processing and packaging industries for over 40 years. Let McGill® bearings experts help you select the right cam follower for your application, or design a highly engineered custom solution designed for your machines!

Take advantage of innovative features unique to McGill bearings, which provide significant operational life compared to standard cam followers. With extensive unmounted bearing product offerings and customized solutions, optimal performance can be maximized across your entire canning plant!

Trust the inventor – trust McGill bearings.

regalbeloit.com/McGill Creating a better tomorrow™...

Saskatchewan flaxseed processor using high-quality flexible packaging to make its products shine on the retail shelf and in growing global markets

BY GEORGE GUIDONI, EDITOR

As an established member of the growing family of so-called functional ‘superfoods’ targeting today’s health-minded consumers, flaxseed may not always get the widespread praise and recognition it duly deserves for all its nutritional attributes.

But that may well change in the not-so-distant future thanks to relentless efforts of companies like the Regina-based CanMar Foods Ltd. to increase consumer awareness of this long-cultivated food and fiber crop thriving in the world’s cooler regions, with Canada, Saskatchewan in particular, providing an ideal growing environment for this hearty and versatile plant.

In fact, Canada currently ranks as the world’s second-largest producer of flaxseed just behind Russia, accounting for 579,000 tonnes of the total global flaxseed output of 2.7 million tonnes in 2016, according to the United Nations (UN)’s Food and Agriculture Organization

Brought to Canada by European settlers about 400

years ago, flax is in fact considered to be one of the one of the first domesticated plants and, as such, a foundation crop of modern civilization.

These days, food-grade flax is also the key foundation underpinning the considerable commercial success of CanMar Foods on the global stage as a leading supplier of high-quality food-grade flaxseed to consumers, baking goods producers, and pet-food manufacturers in more than 20 countries worldwide.

Founded in 2004, “We are the largest food-grade processor of flax in Canada,” says company president Myles Hamilton.

“We have the Number One flax brand in Canada, sold under the CanMar brand name, and we also produce a growing range of private-label flax products,” says Hamilton, adding the company employs a proprietary patented process it developed for evenly roasting flaxseed to a consistent taste and identical color.

“Today we produce over 30 different SKUs (stockkeeping units) in a variety of packages—from 340gram pouches all the way up to 900-kilogram totes,” Hamilton relates.

“Our product is used by consumers primarily for breakfast or baking,” Hamilton continues, “and it is also sold as an ingredient for bakery and pet-food products.”

As Myles explains, the company’s flagship CanMar brands of Milled Golden Roasted Flax, Whole Seed Golden Roasted Flax, and Cold Milled Golden Roasted Flaxseed are all processed at its state-of-theart roasting facility in Regina, which runs a busy seven-days-a-week production schedule on year-round basis.

“The consumption of flax over the course of the year is fairly consistent,” Hamilton notes, “so there is not a big number of peak and valleys with our business.”

Such seasonal consistency is in itself a testament to flaxseed’s remarkable versatility as a nutritionally rich and healthy food supplement and ingredient offering a broad array of serving choices.

As CanMar’s website proudly proclaims, “It is easy to incorporate golden roasted flaxseed in the daily diet and in existing meals or dishes.

“Golden roasted flaxseed is an ideal meal compo-

nent can be added to all kinds of food items and meal ideas, like adding it to your hot or cold cereals in the morning, or mixing it into yogurts and smoothies,” CanMar suggests.

“Furthermore, you can bake and cook with golden roasted flaxseed or sprinkle it over salads, vegetables, desserts and ice cream, or incorporate some roasted flaxseed in breading for fish and chicken for an extra crunchy coating.

“The possibilities are endless.”

Such cooking versatility is fittingly matched by flaxseed’s remarkably healthy nutritional profile and benefits, including high concentrations of “good for you” nutrients such as:

• The Omega-3 fatty acids, which play a key balancing role in the body to promote better cardiovascular health.

• Fiber, both soluble and nonsoluble, to help lower blood cholesterol levels and moderate blood sugar, while also moving stool through the colon more quickly to help bowel movements and improve laxation.

• Lignans, phytoestrogenic compounds that have been shown in studies of animals, and in early human clinical trials, to help protect against certain kinds of cancer, notably breast and colon, by blocking tumour formation.

In 2014, Health Canada formally approved a health claim linking eating ground whole flaxseed to blood cholesterol lowering—a major risk factor for heart disease—along with 10 other claims related to flaxseed’s evident benefits in controlling diabetes, obesity and heart disease.

The best part of all, according to Hamilton, is that roasted flaxseeds actually taste really good.

“Our flax is roasted to give it a nuttier flavor and nice a aroma which consumers prefer, with a taste profile that is truly unique to CanMar flax,’ he says.

“So while many consumers initially consume flaxseed for its nutritional value, they increasingly choose our golden roasted flaxseed for its taste and aroma!”

Naturally, product quality and safety are always on the mind for a company like CanMar Foods, and Hamilton says that being a vertically-integrated operation that runs its own farms—comprising 20,000 acres for conventional and 3,000 acres for organic farming—offers substantial competitive advantages.

“Because we control all the agronomics on our farm, we start with and manage the crop rotations in a way that allows us to get as clean flax as possible coming off the farm,” Hamilton explains.

“We also manage the entire storage, so that our product is not intermingled in large elevator opera tions, unlike our competitors.

“Our flax is shipped directly to our own stateof-the-art cleaning facility where we achieve a 99.99-percent-plus purity level, which is the highest in the industry.

“After roasting, the product is ei ther prepared, whole-seed or milled, and then packaged accordingly based on our customers’ specific needs.”

To get its retail packaging right, CanMar makes extensive use of the innovative box-pouch flexible packaging manufactured by TC Transcontinental Packaging, one of North America’s leading flexible packaging manufacturers headquartered in Montreal.

“The box-pouch is unique in that it is in the shape of a box: it has a flat bottom so that it stands up very nicely,” says Ro berto Travaglini, account manger for business development with TC

Transcontinental Packaging.

“Since it is a box-pouch, it also takes up less store shelf-space by being more compact and rectangular—allowing CanMar to place more pouches in a display and thus increasing the number of packs that can be placed on a shipping skid,” Travaglini explains.

“In the long run, shipping more pouches per skid and using less skids to ship a bigger quantity equates to having less trucks on the road to deliver the product, thereby reducing carbon-dioxide emissions.”

As Travaglini relates, the box-pouches are made at his company’s TC Ultraflex facility in Brooklyn, N.Y., on state-of-the-art Totani box-pouch machines designed specifically for high-speed pro-

duction of the so-called ‘quad pouches’ featuring flat bottoms and sides.

“These sophisticated machines are very precise during the manufacturing process,” he says, “ensuring that the finished pouches are perfectly hermetic.

“It is extremely important to have excellent seals on these pouches to prevent any ‘leakers’ that would allow oxygen to enter the packaging.”

Says Travaglini: “Since CanMar roasts its flaxseeds in a proprietary way, the seeds need to be protected from oxygen, as the product can become rancid if it is not protected from the elements.

“The very high EVOH (ethylene vinyl alcohol) barrier that TC Ultraflex uses in the construction of this pouch gives the flaxseeds the oxygen barrier protection that it needs to ensure the minimum

18-month product shelf-life.

“That’s why our Totani machines are tested regularly by our quality control operators to make sure that they meet the strict standards that this pouch requires.”

As Hamilton concurs, such meticulous attention to detail and customer service make TC Transcontinental Packaging a highly valued packaging partner.

“We have been very well-serviced by Roberto Travaglini, who has also been instrumental in helping us to further enhance our packaging design through the different types of materials and finishing options,” Hamilton states.

“Naturally, we really appreciate the quality and consistency of the packaging.

“It’s very easy to save a few cents per bag by or-

dering your packaging from Asia,” says Hamilton, “but when your production facility is out of bags and you’re waiting for late deliveries, the value equation diminishes very quickly.

“Production and packaging efficiency are very important to us,” Hamilton proclaims, “and we know when we open a box received from Transcontinental Packaging that we are getting exactly what we ordered, at that it will run perfectly on our machine.”

Citing the Regina facility’s internationally recognized SQF Level 2 certification for food safety from the Safe Quality Food Institute (SQFI), Hamilton says he is proud to be heading a company providing Canadian and global consumers with gluten-free, non-GMO, nut-free, egg-free and overall allergenfree product with a tremendous healthy upside.

“We have never had a recall,” says Hamilton, extending full credit to the Regina plant’s 31 loyal and dedicated full-time employees.

“Many of our employees have over 10 years of experience with the company,” he says, “and we have very little turnover.

“I think we’ve got a great culture and a highly skilled work group that are passionate about producing the highest-quality flax not only in Canada,” Hamilton stresses, “but around the world.”

Says Hamilton: “The flax industry is as competitive as many other industries.

“We are selling a commodity, and so as a company you have to provide a value-added product in order to ‘de-commoditize’ your product.

“I believe we have done that through our fully integrated operation from field to spoon and our stateof-the art production facility,” he concludes, “along with great consumer-friendly packaging supplied to us by Transcontinental Packaging.

“Nothing is more gratifying than getting letters from consumers telling us that our flax is different, how much they love the roasted flavor, and how happy they are to consume our products every day.” TC

BY ALANNA FAIREY, ASSISTANT EDITOR

PHOTOS BY PIERRE LONGTIN

They say that one man’s trash is another man’s treasure, but for Saint-Laurent, Que.based Polykar, garbage bags just happen to be their bread and butter.

Founded back in 1987 by Elyse Damdjee and Aziz Karim, the family-owned business focused solely on the production of high-quality garbage bags for the ICI sector across Canada.

Fast forward to the present day, and the founders’ son Amir Karim has taken up the mantle as president and chief executive where Polykar diversified its products to include compostable bags, food-approved poly bags and multi-layered film for convertors from 2014 onwards.

Polykar’s product diversification coincided with Karim’s desire to position the company to help educate the public on sustainability in the plastics industry, plastic end of life processes, and the environmental impact of plastics.

When the company was first launched over 30 years ago, Polykar made the decision to make garbage bags from recycled materials. As early as then, the company pushed the advantages of a recycled garbage bag and the positive environmental footprint they hoped they could advance in the industry. Coupled with the reduced cost compared to using virgin material, this win-win situation helped Polykar become more competitive.

As Polykar took off and dove further into the business of recycling plastics, Polykar was at the forefront of a sustainability movement within the industry before the general public had recognized it.

“Way before it became fashionable to talk about the environment or about sustainability, we were using as much recycled material as possible,” Karim told Canadian Packaging in a recent interview.

“My family and the company never saw a conflict between being more sustainable and being competitive.”

Adds Karim: “the two went hand-in-hand.”

To further accentuate the company’s commitment to environmental practices, Polykar’s manufacturing facility bears the internationally recognized LEED (Leadership in Energy and Environmental Design) silver certification, which verifies that Polykar identifies and implements sensible and considerable green building design, construction, operations and maintenance solutions.

Even though all of Polykar’s products are either recyclable or compostable, there is no denying that the plastics industry as a whole has been feeling the pressure of what Karim calls the issues of post-use life of packaging.

There have been significant developments in the industry over the years , as most plastic products are made today with higher performance resins, have much lower environmental footprint than in previous years, and are made with more recycled content.

will prevail over subjective opinions.”

When Polykar entered the converter film market back in 2014, Karim admits that they had no experience in dealing with this segment, but knew that they wanted to remain true to their high quality and sustainable values.

While Polykar had an excellent reputation for the quality and consistency of their products, Karim felt it was important to have the credibility of being a viable supplier in the polyethylene film market.

“The family did not come from a plastics background and knew little about plastic,” Karim says of the experience looking for reliable state-of-the-art machines.

“So the strategy was to use the best equipment in the world or available in the market so that we can come out with the best product,” Karim says.

It did not take long for Polykar to enlist the help of Lincoln, Rhode Island headquartered Windmoeller & Hoelscher Corporation (W&H), a leading supplier of machinery and systems for the manufacturing and converting of flexible packaging.

“W&H is basically the Rolls Royce of the extrusion equipment market,” Karim extols.

“We opted to buy the Rolls Royce because it would help to give Polykar instant credibility in this marketplace.

Karim believes that there is a tsunami of negative news about the impact of plastic in the environment, which not only results in an improper use of facts, but a need for better education surrounding plastic.

“I think there is a lot of miscommunication about the benefits, the use and the afterlife of plastics,” Karim elucidates.

“It’s not because there’s not enough information––I think there’s plenty of information.

“The recyclability of some of the materials has significantly improved and there are a lot of good things that are happening to our industry which are making plastics more recyclable.”

Karim concludes: “I’m very confident that at the end of the day, science and facts

“The combination of the Polykar brand and reputation of the W&H equipment meant that nobody would doubt our ability to service them, and that allowed us to get into this business in an effective way.”

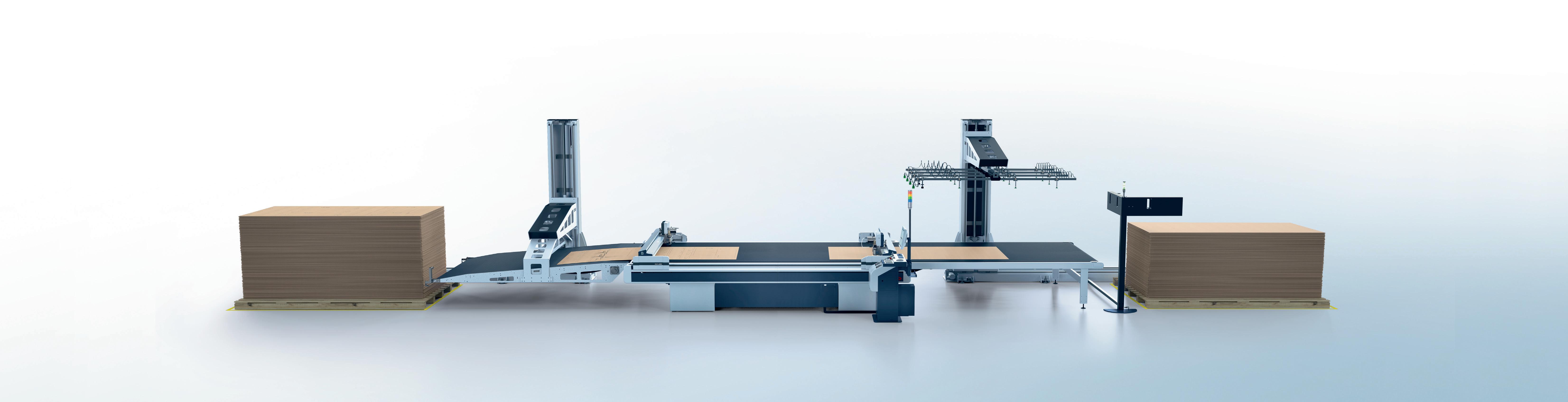

From W&H, Polykar purchased an Optimex extruder, which was promptly installed at the 105,000-square-foot, 110-employee operation some time back in 2014.

Within three months of installation, Polykar saw an increase in their production.

Impressed with the level of automation, Karim’s favourite feature of the extruder is the ease of use that comes along with it.

“For example, when you run a particular recipe or size of film, you can actually save the settings,” Karim explains, “for the next time you get a repeat order from the customer, the configuration is already there.”

“The higher level of automation allows you to maintain a certain level of consistency in your product that our film customers have now come to expect.”

In addition, a multi-layer extrusion line allows us to easily build multiple structures that give the different characteristics that are needed, in each layer.

According to Karim, the addition of the extruder has further helped Polykar to stay true to their values as a sustainable business.

“The fact that we’re now making multi-layer packaging, allows us to embed recycled content in the film structures,” Karim relates.

“Whether its to create a plan or structure that is a purely compostable package or whether we use a plan that in some layers you put more biobased materials.”

Impressed with the overall quality and consistency that the extrusion line has offered thus far, Polykar has added two more extrusion lines from W&H, including their third Optimex line installed at the facility last month.

With each installation of W&H equipment, Polykar continues to see a positive impact on their business and overall quality of their products.

“Overall, the W&H extruders enabled us to enter this new market of polyethylene film and it allowed us to extend our reputation for quality and consistency.”

Looking ahead, the future of Polykar looks busy, yet prosperous and fulfilling.

While production capacity has been maximized, it was recently announced that a second manufacturing facility based out in Edmonton is expected to be fully operational sometime in early 2021.

In an industry that will continue to change and evolve with the times, Karim firmly believes that Polykar will continue to strive to be the voice of expertise and educate the public with help of industry colleagues to provide thought and manufacturing leadership advancing environmental sustainability in plastics.

“Those companies in our field that are not in tune with this new reality of making more sustainable packaging will start to decline, there is no doubt about it,” says Karim.

“But those that have been concerned about the post-use life of plastics and their environmental impact will continue to flourish.

“They will have to adapt to this new reality to continue to prosper and grow,” Karim concludes, “and Polykar hopes to be one of them.”

Yes, we can solve that too.

WestRock Automated Packaging Systems’ innovative shelf- and retail-ready packaging design to automation solutions reduce the need for third party repackaging and the associated packaging and freight redundancies. Efficiently run one- and two-piece structures in-house while satisfying multiple retailer requirements and increasing your sales lift.

westrock.com/automation aps@westrock.com

hoever said “It’s what’s inside that counts” did not work in the retail-ready packaging space.

With the e-commerce market seemingly exploding on a global scale, big consumer brands owe it to themselves to reinforce consumer engagement at the traditional brick-and-mortar retail level with shelf-ready displays that make it easier for retailers to showcase their products, while catching the consumers’ attention.

Thanks to trade shows like this year’s enormously successful PACK EXPO

Displayed at the recent PACK EXPO Las Vegas exhibition, the Pak On Demand Pouch System is the latest retailready innovation from WestRock

With brands requiring more innovative automation solutions that have the capability to deliver increased productivity and improved sustainability, the Pak on Demand is an ideal choice.

Thanks to its 3D scanning products placed on the conveyor system, the Pak on Demand in turn can produce custom, right-sized pouches and then promptly seals the package for delivery.

Because it is able to create a package that is custom to the size of the product, the Pak On Demand Pouch System helps to eliminate superfluous void fill and shipping charges, increases pack efficiency and, ultimately, decreases labour costs.

By using the Pak On Demand, the end result for customers is an exceedingly protective package that is also abundantly curbside recyclable. WestRock

Las Vegas exhibition, an increasing number of packaging machinery manufacturers are using these events as a launching pad for showcasing their latest stateof-the-art retail-ready packaging machines for the first time.

To make the search for the next best-in-class retail-ready packaging machinery just a little bit easier , Canadian Packaging scouted some of the latest stateof-the-art packaging machines in the retail-ready packaging segment that CPG (consumer packaged goods) companies and their co-packing partners would be wise to check out for themselves.

Designed to streamline operations and get to market quicker, the new Meta Duo from WestRock is their latest automation technology.

Utilizing WestRock’s unique Meta Systems precision forming technology, retail cases are formed around a stationary mandrel, minimizing case skew and maximizing structural integrity.

This results in cases that outperform comparable standard cases, RCSs (regular slotted cartons) in production efficiency (higher run speeds) and stacking strength.

Additionally, the Meta Duo also has the capability to efficiently transition between four-sided, eight-sided, HSCs (Half Slotted Container), a one and two-piece SRP (Shelf-Ready Packaging) designs and SIOCs (Ships in Own Container).

This feature allows users to meet a number of retailer and e-tailer requirements, as the Meta Duo is a single and small footprint machine. WestRock

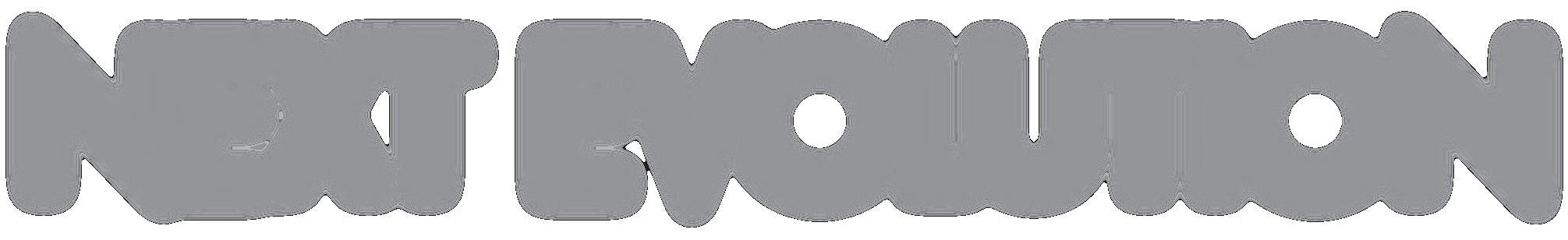

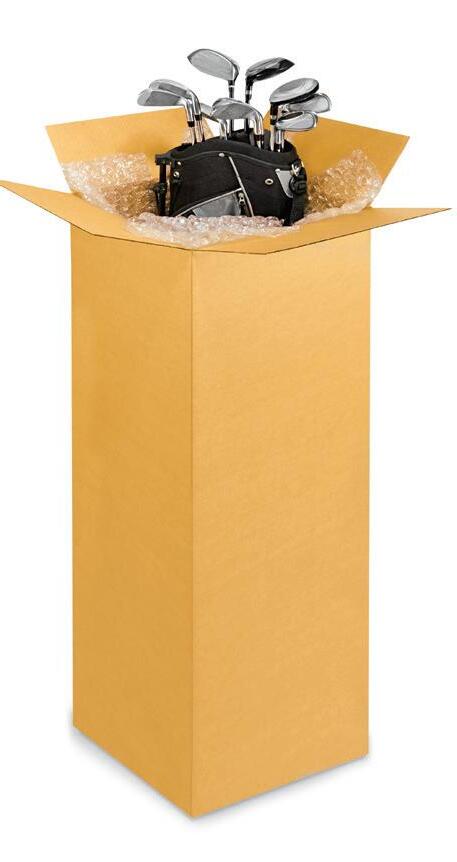

Keeping sustainable practices in mind, WestRock’s multiawardwinning BoxSizer has become a top contender for the job.

The BoxSizer has been recognized as being one of the only stand-alone e-commerce packaging machines that has the ability to continuously reduce multiple footprint box sizes.

The BoxSizer achieves this enthusiastically on-demand without ever stopping for changeover, making it an ideal for B2B (business-to-business) and B2C (business-to-consumers) applications.

By guaranteeing optimum DIM (dimensional) weight, the BoxSizer platform can help to lower total carbon footprint and improve sustainability.

Furthermore, right-sized packages keep products secure and neat while making the packaging easier to open for end customers.

The BoxSizer was designed by WestRock to be effortlessly amalgamated into existing production lines, or a tailored turnkey solution can be created.

Release your packaging from the ordinary with brighter ideas from Sun Chemical. Get your customers’ attention quickly and outshine the competition with packaging that bursts with potential. Sun Chemical is a true packaging solutions partner who can innovate and inspire your brand from concept to consumer.

Download your Brighter Ideas for Packaging Guides at www.sunchemical.com/brighterideas or contact us at 1-708-236-3798 working for you.

SOMIC America plans to extend its market reach when the new SOMIC ReadyPack end-of-line packaging machine.

Making its debut at last month’s PACK EXPO Las Vegas, ReadyPack is a customized solution for shelfready packages that offers a reduced footprint, excellent automation and greater affordability.

An ideal fit for retail, food and beverage and consumer goods manufacturers, ReadyPack assembles, groups and bundles products in trays and a plethora of open, wraparound, display and folding cases.

As well, pre-packed products like stand-up pouches, flow packs and glass jars are fed separately and grouped as case contents before the grouping is positioned onto the flat case blank.

The product is then folded around the entire grouping and held together with hot glue.

As a wraparound model, the cover is then folded and closed.

“ReadyPack is a solid, entry-level case packing system with unique benefits and plenty of flexibility,” explains Peter Fox, senior vice-president of sales for SOMIC America.

“While our last two machines have proven to be popular with our customers, we learned there is room in the marketplace for a machine like ReadyPack.

“It collates, cartons and closes like the others, and it is equipped with Rockwell Automation controls.

Adds Fox: “It does operate at a slower pace and we have reduced lead times, two things that potential customers had expressed interest in.”

Depending on the product, ReadyPack has a collating capacity of 160 products per minute.

As a tray packer, the ReadyPack has the capability to case up to 18 packaging units per minute, while the wraparound model dispenses 12 units per minute.

SOMIC America

Who knew that just a few inches could make all the difference?

It may not seem like a lot, but for employees packaging cheese on a tray line at Monroe, Wis.-based Alpine Slicing & Cheese Conversion, those few inches were noticeable from the repetitive motion of reaching out and grabbing packaged cheese trays.

When it came time to expand its contract packaging services by adding a second tray line, the company was looking for new ideas to improve upon this process and they found the solution through an adjustable sanitary conveyor system from Dorner.

Providing consistent, reliable service, combined with this country’s insatiable appetite for cheese helped grow Alpine Slicing & Cheese Conversion’s business since its founding in 2006.

Being located in the heart of America’s ‘Dairyland,’ the company’s ownership team boasts more than a combined 100 years of experience within the cheese producing and packing industry.

Today, its 100-employees creates retail, foodservice and specialty packaging of up to 700 SKUs for more than 30 private-label brands.

The original tray line is functional as it moves packaged cheese trays to the pack out station for shipping, but it could have been designed better.

“The height on the tray line isn’t exactly where we want it to be,” says Alpine Slicing & Cheese Conversion manager Jim Natzke. “For some of our employees they were hunched over a bit. Just that little bit of extra reaching adds up, and people can get sore backs.

Adds Natzke: “Our goal with the new line was to eliminate that condition and make things more ergonomically correct for our employees.”

As the need for a second tray line became clear to leadership, the task of heading up that project fell to Natzke.

“Knowing the limitations of our original tray line, we thought for this new one let’s just approach it differently and see if we can do it better,” he said.

On the original tray line, cheese is sliced, packaged and placed onto a conveyor, which passes product through a metal detection unit.

Then, the conveyor deposits the cheese onto a large rotating lazy Susan-type round table, which is used to accumulate cheese as the two employees grab the packages and load them into packing boxes in preparation for shipment.

The main issue with this line is the height of the conveyor and position of the rotating table, both of which are a few inches lower than Natzke would like.