Vancouver Island craft brewer steps up its packaging game with major canning and labeling upgrades

Story on page 15

Vancouver Island craft brewer steps up its packaging game with major canning and labeling upgrades

Story on page 15

maintains freshness, flavor,

Our automated packaging solutions and performancebased container designs are optimized for speed and productivity. Protecting fragile foods as they travel from your field or greenhouse to the kitchen table, our packaging maintains freshness, flavor, and your place on the shelf.

Providing packaging from field to fork.

westrock.com/produce

FROM THE EDITOR

4 George Guidoni

How high can we grow?

ONE STEP AHEAD

46 Davor Djukic

48 Elena Langlois Joe Public speaks out on packaging hits and misses.

6-8 Packaging news round-up.

FIRST GLANCE

9 New packaging solutions.

imPACt

13 A monthly insight from PAC Packaging Consortium

NOTES & QUOTES

43 Noteworthy industry briefs.

ISSN 1481 9287. Canadian Packaging is published 10 times per year by Annex Business Media. Canada Post

Publications Mail Agreement No. 40065710. Return undeliverable Canadian addresses to: Circulation Department, 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1. No part of the editorial content in this publication may be reprinted without the publisher’s written permission. © 2020 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of this publication. Printed in Canada.

COVER STORY

Victoria craft brewer uses COVID-19 downtime to complete a new canning line installation with shrinksleeve labeling capabilities to diversify its product portfolio.

FEATURES

Acclaimed Niagara wine producer continues to shine in export markets with high-end packaging and labeling excellence.

Canada’s fresh produce sector displays commendable resilience to survive the worst of the COVID-19 shutdowns in the critical hospitality markets.

The inside story on Maple Leaf Foods’ remarkable sustainability journey.

Iconic Austrian chocolate confectionaries producer using packaging automation to keep up with growing global demand for its sweet creations.

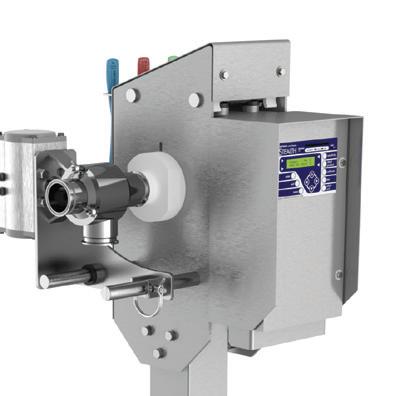

The importance of real-time reporting capabilities in metal detection equipment.

The technological promise and productivity payback of next-generation metal detection technologies.

ON THE COVER

Hoyne Brewing Company founder Sean Hoyne strikes a cheerful pose at his Victoria brewery in front of the Aesus Compact Premier shrink labeling machine installed at the new canning line last year.

Finding economic bright spots in an otherwise moribund economy battered by COVID-19 related shutdowns and closures is for the most part a thankless and largely futile exercise.

posed business lockdowns—particularly in the biggest markets in Ontario and Quebec—and with no export markets to make up for the lack of distribution capabilities, this surge in growth has been nothing short of extraordinary.

MARCH 2021 | VOLUME 74, NO. 3

Reader Service

Print and digital subscription inquires or changes, please contact

Anita Madden, Audience Development

Manager

Tel: (416) 510-5183

Fax: (416) 510-6875

Email: amadden@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Senior Publisher Stephen Dean | (416) 510-5198 SDean@canadianpackaging.com

Editor George Guidoni | (416) 510-5227 GGuidoni@canadianpackaging.com

$2.6 BILLION

Sales of recreational cannabis products in 2020

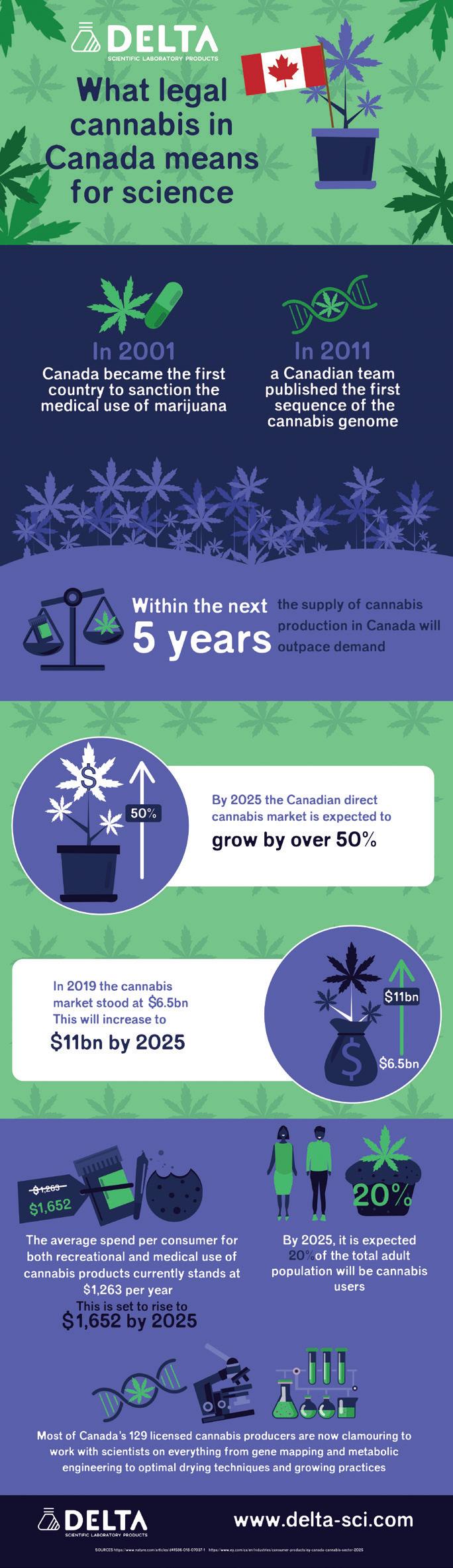

But happily for Canada, the federal government’s decision to legalize recreational marijuana back in 2019 is proving to be a far-sighted masterstroke of entrepreneurial foresight for which the government has yet to receive the full credit it deserves—again, largely due to the fact that the current news cycle is completely dominated by the stubborn COVID-19 crisis and ongoing efforts to vaccinate the population in all-out efforts to lift the economy off the government-funded financial life-support.

Contrasted against this grim backdrop, a 120-percent surge in annual sales recorded by Canada’s fledgling recreational cannabis market between 2019 and 2020 is a stunning validation of Canada’s progressive national drugs policy that could provide the country with an invaluable new source of revenue and value-adding economic activity for many years to come.

According to the national number-cruncher Statistics Canada, sales of recreational cannabis in Canada rose to $2.6 billion in 2020—representing a 120-percent increase in a year when just about every other consumer and retail sector suffered through the worst year on record, in many cases.

Most notably, “Statistics Canada has estimated that legal sales of recreational cannabis overtook illicit sales for the first time during the third quarter of 2020,” according to the federal agency, whose retail trade figures capture sales of regulated adult-use cannabis from licensed brickand-mortar cannabis stores, private-sector online sales in some provinces, and provincially operated online stores in others.

And as much as we don’t like saying “We told you so,” readers of this magazine will recall that we have been steadfast in our pro-legalization stance on this issue ever since it was first brought up in run-up to the last federal election.

Considering that this sales growth as achieved despite the fact that many legal cannabis retail stores in the country failed to obtain the “essential business” designation that would allow them to keep their doors open during the provincially-im-

And the best part is that the best is still to come. According to recent research conducted by Delta Scientific Laboratory Products, manufacturer of laboratory sample containers and equipment used to separate the active chemical ingredient in marijuana in order to extract the non-psychoactive CBD compound widely used in medical cannabis, the domestic cannabis industry still has at least a few years of pent-up demand growth before supply matches market demand in this country, which it expects to happen by 2025.

By then, Delta researchers expect the Canadian direct cannabis market to grow by over 50 per cent to reach $11 billion in total for both recreational and medical cannabis, with the average annual spend per consumer rising from $1,263 to $1,652 per year, with an estimated 20 per cent of the Canadian population expected to be regular cannabis users.

As Delta points out, “Most of Canada’s 129 licensed cannabis producers are now clamoring to work with scientists on everything from gene mapping and metabolic engineering to optimal drying techniques and growing practices,” which should also provide the industry with the veneer of legitimacy and social acceptance to overcome decades of regulatory persecution that still mars the industry’s public image for wide segments of the population.

For Canadian packaging suppliers, all these trends point to a once-in-a-lifetime opportunity to seize the moment by joining the larger scientific community in a common quest to provide Canadians with all the safety and efficacy they should expect from legal made-in-Canada products—available in an ever-growing range of edible, drinkable, topical and other innovative consumable formats—and to nurture Canada’s global leadership position in the still untapped export markets that one day may become an invaluable new engine for the country’s future growth and economic prosperity.

GEORGE GUIDONI, editor GGuidoni@canadianpackaging.com

Account Coordinator Barb Comer | (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

Media Designer Brooke Shaw | (519) 428-3471 bshaw@annexbusinessmedia.com

COO Scott Jamieson SJamieson@annexbusinessmedia.com

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE: Canada $78.50 per year,USA $179.50 (CDN) per year, Outside Canada $203.50 (CDN) per year, Single Copy Canada $10.00, Outside Canada $27.10.

From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer Privacy@annexbusinessmedia.com Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2020 Annex Publishing & Printing Inc. All rights reserved. This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice. You should not act on information contained in this publication without seeking specific advice from qualified engineering professionals. Canadian Packaging accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. Canadian Packaging receives unsolicited materials, (including letters to the editor, press releases, promotional items and images) from time to time. Canadian Packaging, its affiliates and assignees may use, reproduce, publish, republish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

We acknowledge the [financial] support of the Government of Canada

You can rely on Anritsu product inspection and contaminant detection solutions to provide high performance, reliability, and return on investment. Our industry-leading equipment will safeguard the quality of your cannabis products — ensuring they contain everything promised, and nothing more. Let our experts partner with you to configure the system that is best for your operation.

To learn more, contact our exclusive Canadian distributor, Abbey Equipment Solutions at abbeyequipment.com or 905-681-3010.

Iconic waffle treat rolls out Into the supermarket cereal aisles

First introduced in Canada in 1971, the iconic Eggo pastry massively disrupted the breakfast scene back then with its frozen toaster-sized waffles featuring a great-tasting “secret formula” that made serving a hot breakfast both easy and delicious.

The beloved brand quickly became a breakfast staple, and the unforgettable ‘L’Eggo my Eggo’ slogan introduced in

brand’s advertisements the following year still endures in everyday chit-chat.

To this day, the majority of Canadians can properly complete this famous catchphrase, according to the Eggo brand-owner Kellogg Canada Inc., which is marking the brand’s 50th anniversary with the launch of the Eggo Chocolate Flavour Cereal

Packaged in 320-gram cereal boxes adorned with bright and vibrant graphics created by package design experts at SGK Inc. in Mississauga, the new Eggo brand is intended to remain a permanent flavor in the cereal aisles, according to Kellogg.

“We’re excited to have chocolate lovers and Eggo fans experience this delicious new cereal,” says Christine Jakovcic, vice-president marketing and nutrition at Kellogg

Canada in Mississauga.

Made with whole grains and containing no artificial flavors or colors, the new Eggo Chocolate Flavour Cereal features mini chocolate-flavured waffle-shaped cereal pieces, dusted with a decadent chocolaty coating, that remain crisp in the bowl of milk right through breakfast.

“Canadians are pleasantly surprised to find Eggo in the cereal category,” Jakovcic points out, citing the highly successful launch of the first-ever Eggo cereal, Eggo Maple Syrup Flavour Cereal, last year.

“It’s a whole new way to enjoy the famous Eggo we love!”

While imported fruits and vegetables tend to dominate the produce aisles at Canadian grocery outlets during the cold winter months, an enterprising greenhouse operator is helping more Ontario consumers get their hands on fresh locally-grown leafy baby greens and microgreens packed with nutrients and flavor.

Grown at the state-of-the-art indoor vertical farm operated by GreenLeaf Farms in Guelph, Ont., the leafy microgreens and baby greens can elevate any dish to a whole new level of freshness, according to the company.

“They are ideal in salads, as a topping for burgers or sandwiches, or to add a punch of nutrients to a smoothie,” says GreenLeaf Farms account manager Jacquie Needham.

First launched at the Fortino’s and Zher’s outlets operated by the Loblaw Companies in 2019, the GoodLeaf brand can now be also found in the produce sections of the popular Longo’s and Whole Foods Market stores across Ontario—retailing in transparent, fully-recyclable plastic clamshells produced by Shepherd Thermoforming in Brampton, Ont.

“It’s exciting for us to make more Ontario-grown food available to Ontario consumers through Loblaw Companies, Longo’s and Whole Foods Market stores,” Needham states. “Local food is fresher, packed with nutrients, and tastes better.”

As Needham explains, microgreens are young plants harvested in the primary stage of plant growth just after the first set of true leaves has appeared.

“At this young age, the greens are packed with up to 40 times the nutrients of their mature counterparts,” says Needham says, adding that the GoodLeaf Spicy Mustard Medley, Asian Blend, Micro Arugula and Pea Shoots microgreen mixes are typically harvested within two weeks of planting.

For their part, baby greens like GoodLeaf’s Ontario Baby Kale and Arugula mixes are allowed to grow a little bit longer than microgreens, but are still harvested before they are fully mature, typically between 18 and 20 days from planting.

As Needham relates, the FDA-approved Pentafood Rigid APET material used to make the plastic food-grade clamshells does not contain any ozone-depleting substances or BPA material.

“These clamshells are completely recyclable,” she says, “and they are excellent from a shelf-life perspective.”

Medical cannabis producer lanches new CBD products for fast-growing market

While most retail sectors across Canada have been hard-hit with huge sales declines last year due to the raging COVID-19 pandemic that shut down many of their brick-and-mortar operations, sales in the country’s budding recreational cannabis market soared to $2.6 billion last year—representing a massive 120-percent increase from 2019.

According to Statistics Canada, every Canadian jurisdiction except for Saskatchewan has seen double-digit sales growth for recreational cannabis products, as stressed-out Canadian are increasingly turning to cannabis to deal with economic and social anxieties unleashed by the pandemic crisis.

Combined with an estimated

$1.8 billion in sales of medical marijuana products, the country’s fast-growing cannabis market offers tremendous growth opportunities for companies like MediPharm Labs Corp., a global leader in specialized, research-driven pharmaceutical-quality cannabis extraction, distillation and derivative products.

Founded in 2015 in Barrie, Ont., MediPharm Labs produces its purified, pharmaceutical quality cannabis oil, concentrates and other advanced derivative products at a GMP (Good Manufacturing Practices)-certified certified facility with ISO standards-compliant cleanrooms.

According to the company, MediPharm Labs has invested in an expert, research-driven team, state-of-the-art technology, downstream purification methodologies, and purpose-built facilities with five primary extraction lines for delivery of pure, trusted and precision-dosed cannabis products for its customers.

A few months ago, the company launched its MediPharm Labs brand of products to deliver high

quality, innovative offerings to consumers in the medical and adult-use markets across Canada.

The products are targeted for distribution across multiple patient and adult use channels to serve an estimated 1.1 million Canadians currently using marijuana for medicinal purposes, according to Statistics Canada.

The company’s first branded product, MediPharm Labs CBD Regular Formula 25, is a 25:1 high-CBD, low-THC regular-strength oil containing approximately 25 mg/ml of CBD to 1-mg of THC.

Made using full spectrum cannabis concentrate processed at MediPharm Labs’ GMP-certified facility under strict manufacturing standards, the product has a unique flavor profile achieved through inclusion of the coconut/

palm-based MCT carrier oil, which has been carefully chosen for its sustainable practices from plantation through manufacturing.

“We are thrilled to be launching MediPharm Labs’ first branded products, answering the call from consumers and retailers for more choice of high-quality, innovative cannabis products,” says Pat McCutcheon, chief executive officer of MediPharm Labs.

“True to our pharma roots, based on a foundation of quality, our first branded product is a high-concentration CBD oil, created by our expert pharmaceutical team specifically for medical and wellness purposes,” McCutcheon states.

“We believe our focus on purity, potency and price will make MediPharm Labs CBD Regular Formula 25 Canada’s preferred choice,” says McCutcheon, adding the company plans to introduce many more MediPharm Labs branded products in coming months, providing market-leading innovation through cannabinoid formulations, varied potencies and product formats.

According to MediPharm, the company’s ability to introduce new products to the Canadian market has received a tremendous regulatory boost last month by obtaining the vaunted Cannabis Drug Licence (CDL licence) from Health Canada—a critical licence required in the qualification for MediPharm Labs to manufacture and supply drugs that contain cannabis.

These products include pharmaceutical prescription drugs that have been classified as drugs with a Drug Identification Number (DIN).

“With a growing interest in pharmaceutical products containing cannabis and

thousands of active trials occurring globally, MediPharm has positioned itself as an essential part of the pharmaceutical industry supply chain,” says company president Keith Strachan.

“The groundwork required for a CDL licence began many years ago as we embarked on our journey to become a GMP-certified platform,” Strachan relates, citing pending introduction of other innovative cannabis products such as gel-caps and topicals.

“This CDL licence enhances our opportunity with our existing pharma customers, while also opening the door to working with additional large and smaller pharma companies, to produce existing approved cannabis drugs, or to develop and manufacture new and innovative drugs through later-stage clinical trials.”

Obtaining the CDL licence also allows MediPharm to supply cannabis-based pharmaceutical drugs and active pharmaceutical ingredients to other CDL licence holders and clinical research trials for novel drug discovery.

This includes Canada’s largest pharmacy chain Shopper’s Drug

Mart, who will utilize MediPharm Labs’proprietary pharmaceutical-quality manufacturing platform, methodologies and scientific data to provide the Medical Cannabis by Shoppers private-label brand with a wide range of concentrate-based products, starting with MediPharm Labs CBD Regular Formula 25

According to a 2019 Hill & Knowlton study analyzing cannabis consumer attitudes and behaviors, 87 per cent of regular cannabis consumers reported that medical wellness was a factor in their use.

“Whether Cannabis is consumed for prescribed medicinal or wellness reasons, patients and consumers want to feel they can trust their product choices and

know they are receiving pure, tested products that are properly dosed for a predictable, consistent experience,” McCutcheon states.

“As a pharmaceutical-quality manufacturer, MediPharm Labs will continue to live up to our brand promise,” says McCutcheon,.

Following legalization of Cannabis 2.0 products (all concentrate-based) in October of 2019, MediPharm Labs continued to evolve by delivering its first white label products, conducting sensory tests, process, and packageing and distributing cannabis derivative products for others, including CPG companies and direct-to-consumer brands.

According to MediPharm, the newly authorized Cannabis 2.0 product cohort has been slow to roll out—leaving consumers with limited product choice.

This has provided MediPharm Labs with a lucrative opportunity to leverage its in-house product development and manufacturing expertise, along with its knowledge of consumer and patient categories, to launch new products in targeted segments, continue to sell

wholesale cannabis inputs, and to provide contract manufacturing and white-label service for other producers.

“Since inception, our focus has been to establish a strong foundation so that we could remain agile to quickly adapt in the ever-evolving cannabis landscape,” McCutcheon states.

“We’ve seized opportunities available to us in Canada while continuing to build a multi-jurisdictional foundation to become a leader in emerging global medical cannabis markets,” he notes.

According to the Hill & Knowlton survey, the non-psychotropic CBD product category was found to show the most promise with occasional/rare consumer types (30 per cent) and non-users (38 per cent) being significantly more likely to try these non-intoxicating products.

According to StatsCan, Canada’s four largest cannabis markets—Ontario, Alberta, Quebec and British Columbia— accounted for more than 84 per cent of the country’s legal recreational marijuana sales in December of 2020.

n Fully automatic Ross IN inline tray sealer

n High-speed production of lid-only and modified atmosphere packages.

n Reliable, high-quality seals virtually eliminate leakers, extending product freshness and shelf life.

n Uses preformed trays of almost any size or shape.

n Fast, highly flexible, and extremely easy to operate.

n Contact us for sample packages.

Compressed air is a key utility supporting the packaging industry in Canada. Compressed air must be contaminant-free to ensure the protection of the products processed in each facility. There are tens of thousands of facilities using compressed air for blow-off applications; cleaning containers prior to filling; and sorting, cutting, shaping and conveying packaging systems.

Many sensitive packaging applications, such as food and beverage, require compressed air free of contaminants.

Depending on how compressed air is used in your facility will determine how to specify a safe and efficient compressed air system. The U.K. Code of Practice for Food Grade Air sets the bar on compressed air systems in the food and beverage industry with three identified systems: contact; non-contact high-risk; and non-contact low-risk.

“Contact” is defined as the process where compressed air is used as a part of the production and processing including packaging and transportation of safe food production. In other words, if compressed air comes into direct contact with food products.

In this type of “Contact System,” a -40 F (-40 C) pressure dewpoint is recommended, accomplished with desiccant air dryers located in the compressor room.

Non-Contact is defined as the process where compressed air is exhausted into the local atmosphere of the food preparation, production, processing, packaging or storage. Within this section there is High-Risk and Low-Risk. A Non-Contact High-Risk situation may be where compressed air is used in a blow-molding process to create a package – and then product is introduced into the package later in

the day. Many food processors and have their own in-house production lines to create their own packaging. Without proper air treatment, it is possible oil, moisture and particulates (bacteria) could be present on the packaging – the packaging waiting for the food product!

“Non-Contact High-Risk” compressed air systems should establish the same compressed air purity specifications as “Contact” systems.

In “Non-Contact Low-Risk” systems, a +37 F (+3 C) pressure dewpoint is recommended. This can be accomplished with refrigerated type compressed air dryers located in the compressor room.

Defining a Non-Contact Low-Risk system is equally important to define because it is common to see food industry systems “over-protect” their compressed air systems. Most plants have significant portions (over 50%) of their compressed air going to “plant air” applications. These “plant air” applications do not have contact with food products or food-packaging machinery. It is important to understand this relationship and design your system accordingly. We often see desiccant air dryers used to dry all the compressed air in the facility to a -40 F (-40 C) dewpoint – when only 40% of the compressed air needs this dewpoint.

Conclusion

Compressed air efficiently supports the food and beverage industry if care is taken to remove contaminants from the system. Industry professionals should define how compressed air is used in their facility and define a specification for compressed air purity based upon the three system types defined by the U.K. Code of Practice for FoodGrade Air. As always, consult with your local compressed air expert to find the optimal solution for your production.

The PAC Canadian Awards celebrates the intersection of greatness. We recognize the journey. The diversity of talent. The disruptors. The collaborators. The forward thinkers. The innovators.

Brewing Company founder and brewmaster Sean

has dedicated his entire adult life to the craft brewing industry, using his extensive acquired knowledge of the business to make Hoyne Brewing one of the five largest craft brewers in British Columbia in just 10 years.

West Coast craft brewer invests in canning line and rollstock shrinksleeve labeling technology to foster market share growth

By Andrew Snook

To call the craft beer market in British Columbia competitive would be a serious understatement for a province that is home to about 190 operating microbreweries, second only to Ontario.

In this light, becoming one of the province’s five largest craft brewers in the space of 10 years is an exceptional feat by Victoria-based Hoyne Brewing Company and its hardworking founder and brewmaster Sean Hoyne, who has dedicated his life to producing high-quality beers.

“I’ve got a long history in the craft beer world,” Hoyne says. “I started out back in 1989, where I learnt my craft under the tutelage of Brewmaster Frank Appleton at Buckerfields Brewery.

“In 1998, I assembled and ran the brewery at Canoe Brewpub for a dozen years

and, finally, in 2011 I branched out and decided to start up my own company.

“It’s been doing really well, and it’s been growing ever since it opened,” Honey states. “Basically, I’ve been brewing beer my whole adult life.”

Hoyne says the craft brewery market has changed a great deal since his early days in the business.

“I was in this at a time when there were very few people in it,”Hoyne told the Canadian Packaging magazine in a recent interview.

“As Malcolm Gladwell would say, we were one of the ‘early adopters.’

“Back then we’d stand up on our soapboxes to tell everyone how great craft brewing is,” says Hoyne, “but it’s become commonplace now.

“Everyone is now aware that craft brewing is here to stay, as we continue to take

market share from the big monolithic breweries that have been out there for a long time.

“I am super stoked to know that I’ve been part of that whole movement,” Hoyne proclaims.

When he started up Hoyne Brewing in 2011, Hoyne told himself that the brewery would stay true to many time-honored traditions for making great beer.

“At Hoyne Brewing we hold those same ideals: integrity, getting the best ingredients you can get your hands on, and no use of chemicals,” Hoyne says.

The brewery’s current product portfolio consists of:

• Seven core beers that include Dark Matter, Hoyne Pilsner, Hoyne IPA, Helios Dortmunder, Appleton’s Finest British Ale, Vienna Amber Lager and Down Easy Pale Ale;

• Four limited-release brews comprising Wolf Vine Wet Hopped Pale Ale, Voltage Espresso Stout, Gratitude Winter Ale and High Voltage Espresso Stout;

• Three seasonal brews including Finnegans Irish Stout, Summer

•

Labels are pre-cut within the machine and then applied to cans in continuous motion on the way to the Aesus-patented heat

(Bottom Left) Filled cans of beer making their way to the DMM packaging case-packing system along a food-grade plastic conveyor belt.

of

at Hoyne

comprising Carte Blanche BelgianWhite IPA, Terra Firma Saison and Weizenbock

As much as time-honored traditional brewing methods have been a key to Hoyne’s success, he has not shied away from embracing the latest packaging technologies to enhance his business.

Until recently, Hoyne Brewing Company’s beers were only available in 650-ml and 354-ml bottles and draft.

Having recently reached maximum annual capacity to produce 25,000 hectoliters of beer—a hectoliter is a rough equivalent of about 18 24-bottle cases—Hoyne started making plans to install a new canning line at the plant to enhance his packaging operations and the variety of product offerings.

But as the COVID-19 pandemic started spreading across Canada just over a year ago, and Hoyne was faced with some difficult decisions to make.

“Just prior to the pandemic, I had made the decision we were

“At Hoyne Brewing we hold those same ideals: integrity, getting the best ingredients you can get your hands on, and no use of chemicals.”

going to put our beer into cans, so we designed a canning line and I put deposits down on quite a few pieces of the equipment,” he recalls.

“Then the pandemic hit and I had a decision to make, whether to proceed ahead with the canning line—and burn through a lot of capital to do so—or hold off and wait for the pandemic to recede and weather out the storm.”

After taking a hard look at his goals for the brewery, Hoyne’s mind was quickly made up.

“We had two key goals with the company: to keep everyone safe and keep everyone employed,” he states.

“So, I decided we would proceed ahead with the canning operation,” he says. “Although we burned through a lot of our financial resources, assembling our canning line has kept our guys working.”

Hoyne took advantage of his decades of experience in the industry to select the best equipment he could get his hands on from around the globe, including:

• A state-of-the-art filling machine from CFT Group in Italy;

• An automatic can depalletizer from U.S.-based SKA Fab;

• A made-in-Germany X-Ray inspection machine manufactured by HEUFT Systemtechnik GmbH

As for Canadian packaging OEMs (original equipment manufacturers), Hoyne turned to the renowned Montreal-based labeling systems manufacturer Aesus Packaging Systems, Inc., who supplied the brewery with the Compact Premier model shrinksleeve labeler and its patented Hybrid shrink tunnel.

Installation of the canning line was trickier than expected, since none of the technicians that would normally accompany these pieces of equipment were available for travel due to the pandemic.

“What this forced us to do is figure out how to piece this whole thing together and commission it,” Hoyne says. “With the help of Zoom, far-away technicians and a bunch of guys here, me included, we built the canning line right from the nuts-and-bolts and pieces that arrived in big containers.”

The process to go from receiving the equipment to installation and commissioning of the canning line took about two months to complete.

For some of the final assembly and commissioning work, Hoyne was able to turn to BevCo, a manufacturer of conveyors and other equipment for the food and beverage industry based in Vancouver.

(Above clockwise)

The quality of shrinksleeves applied to the cans by Aesus labeling equipment rivals those of high-end direct-printed cans.

The Aesus Compact Premier Shrink labeler can accommodate a broad range of aluminum can sizes and diameters.

State-of-the-art can filling and seaming system manufactured in Italy by CFT Group.

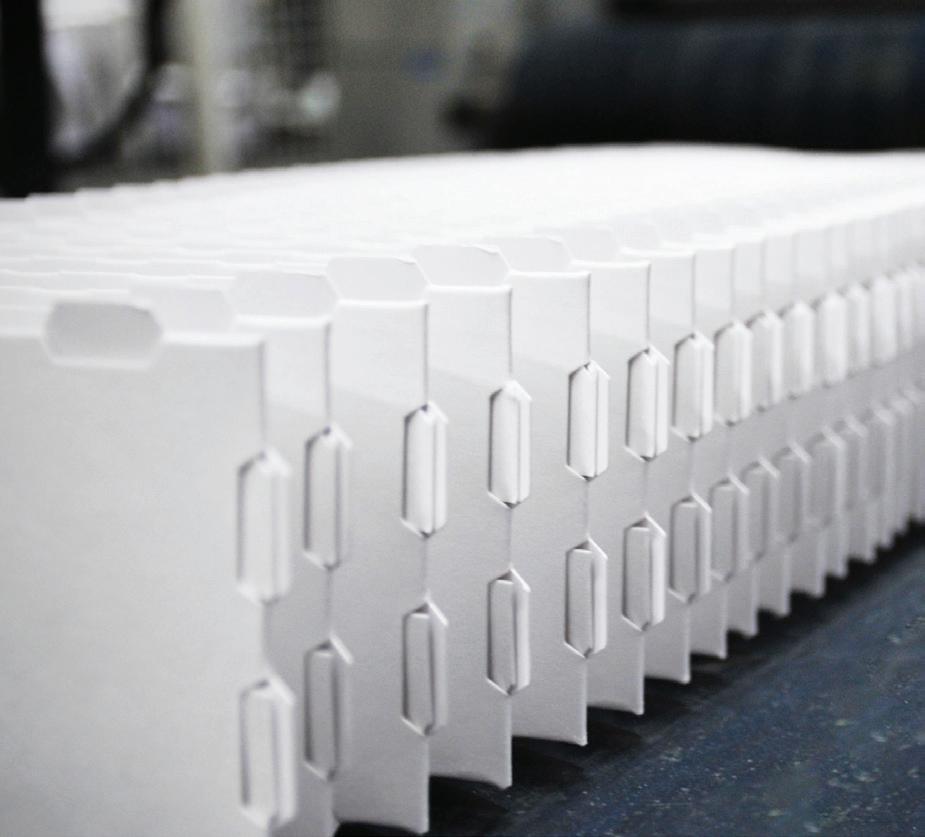

A close-up look inside the feeding magazine of the cartoning system linked up to the DMM Packaging case-packer.

“They came by and fine-tuned everything, making sure all the motors were working at the right speed,” Hoyne says.

“We got it up-and-running and it’s been running ever since—keeping us all employed,” he extols. “We haven’t had to lay a single person off and, knock on wood, nobody has gotten sick.”

The new canning line uses an ionized air twist rinser in place of using water to remove any dust or particles from the cans before the filling begins.

From there, the cans go through the Aesus Compact Premier shrink labeler to have the rollstock pre-printed sleeves applied around each can’s curvature.

Hoyne says he opted for the sleeving machine instead of using printed cans due to the increased flexibility it offers him to market his lesser-known brews, which would not justify the minimum quantities of printed cans he would have had to purchase.

“In the case of craft brewers where they’re doing 5,000 cans here, 10,000 cans there, or seasonal brews, it is an ideal solution,” explains Steve Mons, vice-president of sales at Aesus Packaging.

As Hoyne relates, “The sleeves have really allowed us to become diversified in the marketplace.

“A lot of small breweries get someone else to sleeve the cans, but we decided to do that ourselves to have more control over the process and it saved us money.”

The Aesus Compact Premier shrink labeler is equipped with a rotary blade system with an indexing wheel/feedscrew, and the sleever machine can handle a height range of 25-mm to 304-mm, with the diameter range from 16.5-mm up to 123-mm.

“Sean was comfortable with the allowance of space to run at 100 to 150 cans per minute, which fell beautifully into this line,” Mons relates.

“The Aesus Compact Premier shrink labeler has a speed capability of up to 150 cans per minute, empty or full, while offering a very small footprint and continuous motion.”

After being sleeved, the cans then move through the Aesus Hybrid shrink tunnel.

“The small-footprint heat tunnel generates two forms of heat: infrared through bulbs and a small steam generator we have integrated on our heat tunnels,” Mons explains.

“This results in a final look that rivals the big brands that have their cans printed directly in terms of the ‘Wow’ factor.”

After the cans are labeled, they move along conveyors to the CFT filling machine, which fills and seams the cans at a speed of about 100 cans per minute with extremely low dissolved oxygen.

“It’s state-of-the-art for the size of the machine; a really well-made piece of equipment,” Hoyne says.

After the cans are filled and seamed, they go through a Markem Imaje date coder and are scanned by a HEUFT X-Ray Inspector for fill heights.

“If the fill height is slightly lower than spec, then it automatically kicks the can out of the line,” Hoyne notes.

Afterwards, the cans proceed along a large collection conveyor toward a DMM Packaging case-packing system that swiftly erects the boxes, stuffs the cans into those boxes, and glues the cases shut as they come out. The finished cases are then placed onto the pallets by hand.

According to Hoyne, staying operational through the pandemic comes down the brewer’s time-tested agility and flexibility.

“We’ve always prided ourselves on being quite nimble,” Hoyne states. “Having the ability to pivot and change direction really quickly has been critical during this pandemic.

“Our sales team, which has been more or less sidelined during this pandemic, has turned to home deliveries for people who don’t want to go out to the liquor store,” he relates.

“We’ve also pivoted towards more retail outlets with our packaged beer instead of focusing on draft,” quickly extending credit to the brewery’s highly dedicated staff of highly motivated and competent 40 employees.

“We have a fantastic team here and we very much value their input,” Hoyne states, “who get rewarded for being creative and innovative.”

Going forward, Hoyne plans to continue to remain agile throughout the pandemic and look for any opportunity to get his delicious brews in the hands of as many beerlovers as possible.

“Running a craft brewery is a lot of hard work and it’s a long, slow growth.You have to love it, like I do,” he says.

“We are already available almost entirely across British Columbi,” Hoyne points out, “but we recently started moving a small percentage of our beer output into Alberta as well.”

“We have long-term ambition to become a nationwide brand,” Hoyne concludes, “but we intend to grow organically, patiently, and in a sustainable manner.”

Aesus Packaging Systems, Inc.

CFT Group

SKA Fab

HEUFT Systemtechnik GmbH

Markem Imaje

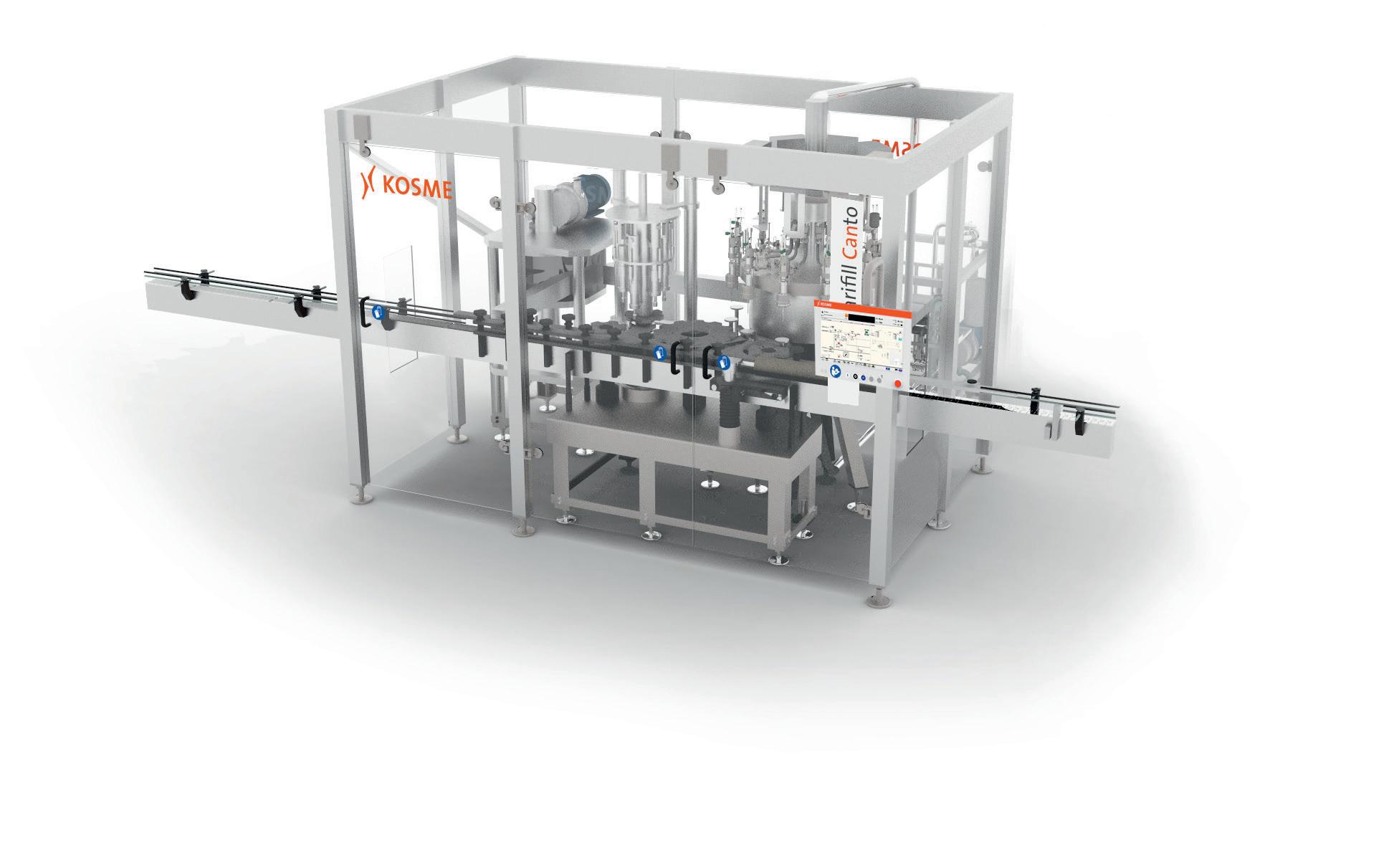

Barifill Canto

Can and Bottle Filler:

■

A filling machine suitable for both bottles and cans with no valve change over needed. This new generation of compact beverage fillers exemplifies KOSME’s flexibility and ease of use, and a guarantee of top quality in all conditions.

Highly reliable, new pneumatically actuated filling valves allow fast, accurate and non-foaming processing while the product quality is preserved.

Roberto Anselmi Krones, Inc.

414-207-1188

roberto.anselmi@kronesusa.com www.kosme.com

Features:

Simple operation, convenient access and easy manual cleaning

Minimal maintenance requirements

No greasing necessary due to a complete closed loop oil lubrication system

High availability due to the use of well-proven technology

Long life due to the use of stainless steel and other corrosion-free materials

Metal labels and classy bottles key part of export success for the acclaimed Niagara ice wine producer

By Andrew Snook

Ontario’s Niagara Region is home to many of Canada’s top wineries. But not all of them have a story as unique as that of Pillitteri Estates Winery in Niagara-On-TheLake.

Although the winery was established in 1993, the roots of the Pillitteri family business stem much farther back in the province’s prime romantic destination.

The winery’s founder, Gary Pillitteri, first immigrated to Canada from Italy with his father in 1948, settling in the Niagara Region. Nine years later, Gary met Lena Agro (now Lena Pillitteri), who by chance also immigrated to Canada from the same Italian town as Gary’s family—Racalmuto in the Province of Agrigento in the Region of Sicily.

In 1960 the couple got married, and in 1965 they purchased a small fruit farm in the Niagara Region, where they grew vegetables and a variety of fruits including peaches, cherries, pears, plums, prunes, apples and, above all, grapes.

“They originally bought this as a farm in the 1960s and were fruit farmers,” says Jeff Letvenuk, marketing and media manager for

Pillitteri Estates Winery.

“In the 80s, Gary started growing grape vines. Being from Italy [and having a farming background], he had experience back home growing them.”

Several years later in 1973, the couple decided to open Gary’s Fruit Market, which still operates within the grounds of Pillitteri Estates Winery.

Fifteen years later, Gary began experimenting with creating small batches of Vidal Icewine. He found success with the wine fairly quickly, winning a gold medal at a prestigious wine competition.

This victory was the extra push Gary needed to pursue opening his own winery in the Niagara Region, which was becoming well-known as an area for producing quality wines.

Gary spent the next five years converting his property into a winery and opened up Pillitteri Estates Winery on June 5, 1993.

When the winery opened, it had the production capacity to produce 16,000 cases. Fast-forward to present day, and it is now producing 160,000 cases per year, half of which, are ice wines, with a customer base that now stretches around the globe.

In addition to the winery’s popular ice wines,

they make a special wine with a deep connection to Gary and Lena’s Italian heritage.

“We also produce some traditional Amarone-style wines,” Letvenuk explains. “We actually have fruittaios, which are drying rooms that we will put our grapes in, that dry the water out of them so when they’re pressed, they’re intensely flavored and have higher sugars.

“It is a traditional process in Italy for making Amarone.”

Says Letvenuk : “We have the only plantings of the traditional varieties that make the wine—corvina, rondinella and molinara. We can’t call it Amarone, because it’s geographic-specific, but we make an appassimento wine using the traditional Italian grapes.

“It’s a very popular high-end wine,” Letvenuk says, also citing the popularity of other varietals like Cabernet Franc, Cabernet Sauvignon and Merlot for reds, and Gewürztraminer, Riesling, Pino Grigio and Viognier for whites.

For all that, Letvenuk says the winery is still best-known for its award-winning ice wines.

“We’ve produced over 13 different styles of ice wines, focusing on our four core varietals of Riesling, Vidal, Cabernet Franc and Cabernet Sauvignon,” Letvenuk says.

“We make a number of different quality levels of ice wines to suit different market needs,” he explains. “Everything from entrylevel ice wines that are focused on price point for larger retailers in places like Europe all the way up to ultra-premium ice wines for

niche wine shops focusing on unique and rare things, to high-end ice wines sold in wine bars and restaurants in places like Shanghai or Hong Kong.”

With so many different types of wine in demand from so many different parts of the world, Pillitteri needs to supply a wide variety of bottles, gift boxes, labels and packaging, according to Letvenuk.

“Because we export so broadly, each unique market in each country has its own unique brand image they want to portray, and you have to meet their packaging requirements and labelling laws,” he explains.

To handle a remarkably diverse set of labelling needs, the winery decided to invest in making many of its own labels in-house.

“We use a Primera CX1200 digital label press to produce labels so we can do back labels, regulatory labels, stickers and print them in real time for our export orders.

“They get applied through a standardized label applicator that we purchased from Criveller Company in Niagara Falls,” Letvenuk says, adding that Criveller also oversees all the maintenance for the bottling operations at the winery.

As for the bottles, Pillitteri sources them from all over the world.

“We find that Italian glass is some of the best glass in the world,” Letvenuk says, “and we source a lot of it through Jane’s Packaging [in Toronto].

“But we use many suppliers for our glass, because we like to do unique packages, and glass is one of the unique things about packaging when it comes to wine,” Letvenuk says.

One way the winery uses glass for its marketing is by using different-shaped bottles for some of its high-end wine, combined with top-quality metallic labels.

As Letvenuk explains, “The different-shaped bottles each have a different product: one has Merlot in it, one has Cabernet Blanc and one has Cabernet Sauvignon in it, but the labels are identical.

“It’s a different kind of marketing approach: it’s very high-end packaging,” says Letvenuk, adding the winery also applies metallic labels onto the specialty glass bottles used for the Amaronestyled wines.

“It’s a very heavy-weighted glass that can age for a very long period of time without cracking or breaking or becoming brittle,” he extols.

The metal labels for the high-end Merlot, Cabernet Blanc and Cabernet Sauvignon are applied on the production line automatically, while the metal labels for the Amarone-styled wines have their own unique process.

“Our really high-end labels are all manually applied,” he says.

“There’s a mold that you place the bottle in, and then you use a device that lines it up, and then you manually put the label on.

“Because those are ultra-premium wines, we put them all on manually,” he says. “That label is designed to match the curve of

(Above)

Charlie Pillitteri, chief executive officer and president of sales at Pillitteri Estates Winery, inspecting state-of-the-art red wine fermenting tanks that are part of the company’s massive tank farm (right) supplied by Criveller Company to the vintner’s brand new production facility, completed in 2019.

(Below)

All Pillitteri products bear the Sustainable Winemaking Ontario Certified accreditation.

the bottle, and it is a very rigid label that does not flex or bend at all during application.

“It’s actually about half-a-centimeter-thick,” he points out. “We produce each of those labels to match the specific curve of each specific bottle in that exact location,” says Letvenuk says.

The winery’s packaging department operates two labeling lines and one bottling line, Letvenuk relates, while also housing a manual wax dispenser for the premium-priced products.

“They are basically heat guns that dispense an allotment of wax onto the top to seal the corks, which is another type of process we do here,” Letvenuk says.

The labels for the remaining wines are supplied by Toronto-based converter A1 Label and are applied using an automatic machine made in Italy by Newtec Labelling Srl

“They (A1 Label) supply us with all of our bulk labels and

they do fantastic work for us,” Letvenuk relates, adding Pillitteri uses its in-house label printers go make back labels and import/ regulatory stickers, while A1 Label takes care of all the frontlabel work involving a lot of high-end finishing work for special embellishment, foil-stamping, gloss varnishing, etc.”

This collaborative arrangement provides Pilletteri with good cost-savings and invaluable operational flexibility, according to Letvenuk.

“We get good volume label purchasing from them for our export labels, which must be customized from market to market,” he explains. “If we’re producing 20,000 bottles of a Vidal ice wine, for example, there will be 3,000 going to the U.K., 4,000 to Germany, 2,000 to Brazil and 1,000 are going to China or Japan, all with different regulatory requirements for labeling.

“So we have to be very adaptable in how we can produce those labels to fit into the market, while projecting a similar high-quality brand image on each of the labels.”

The winery also recently invested in retrofitting its operations with an entirely new set of vats and other core equipment for its production lines, also supplied by Criveller Company.

“We now use state-of-the-art, stainless-steel fermenters that hold the wine and produce the wine very efficiently to make the highest-quality wines we’ve ever produced,” Letvenuk says.

“We’re trying to use as much new technology as possible, but while maintaining a connection to our heritage,” he adds. “That’s very important to us.”

The business is very much a family affair, with three generations of the Pillitteri family working at the winery in different daily functions of the business, including Gary and Lena’s three children—Connie, Lucy and Charlie— who all grew up working on the farm.

(From Top)

The winery uses an automatic Newtec label applicator to apply the more conventional wine bottle labels, many of them designed in-house.

A harvester in the vineyard collecting ice wine grapes at temperatures as low as -10°C or colder.

Assistant winemaker Chris Thompson preparing the tank for filling at harvest time.

“The family stepped in altogether and have worked together to grow the farm,” Letvenuk relates. “They’ve continued to do that now for 28 years and the winery has continued to grow.

“It’s certainly a point of pride that Gary and Lena, who are now in their 80s, are continuing to foster that sense of importance of family in the business,” Letvenuk says, citing the three siblings’ roles as chief executive officer (Charlie); chief financial officer (Connie); and chief marketing officer (Lucy).

“They all have backgrounds in different avenues of the business and operations,” Letvenuk says, “and some of their children have also gone into the family business to continue that legacy.

“It is still a family-owned and operated enterprise, and it is one of the largest producers of ice wine producers in the world.

“We’re very proud of that fact.”

As Letvenuk confides, the COVID-19 pandemic has brought the local tourism industry down to a halt to make life very hard for many of the region’s independent wine producers who rely on tourist spending for a large part of their sales.

“The export market has not been as seriously impacted as we thought it might be, but we also rely on restaurants and frontdoor tourism, along with the duty-free shopping channel” he says. “Obviously, COVID-19 has had a significant impact on all of that.”

To recoup come of those losses, the winery has increased its options for the direct-to-consumer market.

“When our customers couldn’t come to our front door, we started offering curbside pickup,” says Letvenuk, “and a lot of customers are taking us up on that.

“I’s like to think we’ll be able to do some outdoor tourist wine-tasting this year, he adds. “We’re adapting like everybody else—finding good ways to stay safe and expand our business opportunities.”

Criveller Company

Jane’s Packaging

Primera Technology, Inc.

A1 Label

Newtec Labelling Srl.

When expanding your canning or bottling operations, there is much to consider. It can take many months to plan and procure new equipment prior to installation. Plus, it can take several months to get to producing saleable cans after you’ve installed new equipment. You know beer, we know conveyors –we can assist with design, consultation, installation, service and support during and after run-in. From conveying components, guide rail, speed reduces and bearings to Perceptiv™ diagnostic services, we can help you get new conveyors running smoothly and make the complex simple. For more information, contact 800-626-2093 or PTSAppEng@regalbeloit.com regalbeloit.com/Beverage Creating a better tomorrow™...

As one of the vital engines of economic growth and prosperity in Canada, the fresh produce sector is hoping for a quick rebound in domestic market demand that has been hit hard by prolonged lockdowns and work stoppages in key segments of the Canadian hospitality industry .

Canada’s fresh produce industry eagerly looking forward to first signs of post-pandemic recovery to get back to daily business

By George Guidoni, Editor

Like most other segments of the Canadian food industry, the country’s fresh produce sector has suffered through unprecedented economic pain and loss caused by the global COVD-19 pandemic over the last year.

And with many hospitality, dining, entertainment and leisure industries across the country still effectively shut down to stop the stubborn virus spreading further, the country’s growers, distributors, processors and retailers of fresh fruit and vegetables are still not out of the woods by any stretch.

In fact, the worst may still be yet to come for many independent, small and medium-sized operators who are only barely clinging to life by extending their credit financing beyond their ability to service their debt in the future.

“We could well see increased bankruptcies and insolvency models come into play in the second and third quarter of the year, as there are many zombie com-

panies out there that are leveraging credit, but not able to pay back even their interest amounts,” says Ron Lemaire, president of the fresh produce industry’s leading trade group CPMA (Canadian Produce Marketing Association)

“They’ve been using government’s wage subsidies and other tools to get by and leverage their businesses, but unless there’s a real recovery plan for the foodservice industry in place, they are going to have a real challenge in reopening effectively once all the subsidies dry up.”

On the bright side, the fresh produce sector as a whole has held up reasonably well to avoid a full-blown collapse, says Lemaire, citing the industry’s perennial challenge of hiring enough migrant filed workers during the last summer harvest season due to COVID-related travel restrictions.

Coupled with highly publicized coronavirus outbreaks at some Canadian farm and greenhouse operations, the industry was only able to hire about 85 per cent of seasonal migrant workers last year

CPMA president Ron Lemaire says that while the country’s fresh produce sector has survived the painful economic fallout of the COVID-19 pandemic better than many other industries, he is concerned that many smaller operators will go out of business soon unless there is a meaningful reopening of the vital restaurant sector that accounts for a large portion of their cashflow and income.

of the estimated 55,000 it did in 2019, according to Lemaire.

Prior to the pandemic, the industry was actually planning to boost its TFW (temporary foreign worker) hiring by 20 per cent from 2019, Lemaire notes, to harvest its products.

According to Statistics Canada , TFWs accounted 31.2 per cent of all agricultural jobs in Ontario in 2019, followed by 26.2 per cent in Quebec and 21.4 per cent in British Columbia—three provinces recording the highest numbers of COVID-19 cases.

Labor shortages aside, the produce industry also had to do a lot of on-the-fly pivoting and adjusting to fast-changing market demand conditions, exacerbated by lengthy lockdowns in the restaurant sector.

“After experiencing hoarding at the very front end of the pandemic there were suddenly challenges with container availability to export produce to international markets—with many ships and cargo planes grounded by bans on international travel,” Lemaire reflects.

“So just as producers began repositioning to focus more on domestic markets, they saw a massive sharp drop in their

foodservice business because of restaurant closures,” he laments.

“And then you have provincial fragmentation of jurisdictions, whereby one market in Vancouver may open up but then Alberta shuts down, Ontario shuts down, Alberta reopens, and so on,” Lemaire adds.

“So there is a continuous ebb-and-flow at the retail and foodservice levels related to changing rules to address COVID among the different jurisdictions,” he states, “and that is a real challenge for many of our member-companies.

“While there has been a slight rebound with the quickservice restaurant curbside pick-ups and home meal deliveries,” Lemaire acknowledges, “that still represents only 15 to 30 per cent of what the foodservice business was before the pandemic, so it’s not recovering quickly enough with this ebb-and-flow of restrictions, recovery, restrictions, recovery, and so on.

“And even when the restaurant do reopen,” he suggests, “any recovery will be initially be constrained by only being allowed to service 20 customers in the evening, for example, rather than 80 tables like they used to prior to pandemic.”

“Overall, the pandemic has shown us that we still have a strong domestic demand for locally-grown produce.”

For all that, the latest statistics gathered by the federal department Agriculture and Agri-Food Canada (AFAC) suggest that the industry as a whole has managed to navigate its way through the worst of the COVID 19-inflictedharships.

According to AFAC, the total sales of fruits and vegetables in Canada last year stood at $2.5 billion—down only by 0.8 per cent from 2019—while total harvest area was down by 1.4 per cent to 180,815 hectares.

While the sales of vegetables actually rose by 2.5 per cent last year to $1.3 billion, much of that increase was driven by higher farm-gate prices rather that volume, according to AFAC, with higher sales of cabbage (+9.6 per cent), sweet corn (+7.4 per cent) and tomatoes (+6.4 per cent) leading the way.

Conversely, the sales of fresh fruit last years dropped by 4.3 per cent from 2019 to $1.3 billion, with inclement weather in many parts of the country significantly hampering farm harvesting and production.

But while last year may be the one to forget for many vital economic sectors across Canada, Lemaire says he is encouraged by the produce industry’s general resilience and adaptability to fastchanging market conditions.

“Overall, the pandemic has shown us that we have still a strong domestic demand for locally-grown produce,” says Lemaire, estimating the produce sector’s direct economic contribution to the country’s food supply chain at about $26 billion—including all the further value-added processing—while supporting about 249,000 jobs within that value chain.

“Our greenhouse industry has remained very strong during the pandemic to drive our vegetable exports,” Lemaire states, “and our fruit imports have also remained very strong, which indicates strong underlying domestic demand for year-round consumption of fresh produce.”

According to Lemaire, boosted immigration levels, an increasingly diverse multicultural consumer base, and growing emphasis on healthy eating and nutrition have made the Canadian market an attractive destination for many produce growers around the world, worth an estimated $12 billion in annual imports of fruits and vegetables.

“This represents compounded annual growth of 213 per cent over the last 20 years,” says Lemaire, “which is quite amazing for any mature industry.

“It’s a real testament to the Canadians’ willingness to try new things, domestic and global,” he says, “which translates

While the total sales of fresh fruit and vegetables were down by 0.8 per cent last year to $2.5 billion, higher prices for some core commodity products helped to make up for the more pronounced declines in shipping volumes.

into a vibrant domestic market under normal conditions.”

While waiting for those normal conditions to return, however, the CPMA also had to do some serious pivoting itself in regards to its flagship annual trade show and convention that until last year used to alternate its home venues between Toronto, Montreal and Vancouver.

After being forced to cancel its 2020 trade show in Toronto last spring due to COVID-19, the 96-year-old trade group will have to hold this year’s event online next month, with CPMA staff doing everything they can to make sure the virtual event will be a memorable success, given the circumstances.

Running from April 12 to April 16, the CPMA Fresh Week 2021 will feature a comprehensive line-up of educational sessions, workshops, virtual tours and exhibits, roundtable panels, award presentations, networking opportunities and other popular show features that usually draw up to 5,000 industry professionals to the live annual conventions, which CPMA is aiming to resume next year in Montreal. (April 5-7, 2022)

Offering free registration to the public (www.convention.cpma.ca/register), this year’s online event will have “multiple education modules that will allow the audience to listen in on a broad range of topics, from sustainability to industry best practices and trade statistics, that many people will find extremely interesting and informative,” Lemaire states.

One of the subjects that will come under close scrutiny at next month’s virtual show will inevitably be the use of

“Right now we have a diversity of approaches across the country at provincial levels, with fragmented modeling on collection and recycling across Canada,” Lemaire points out.

“This effectively prevents any growth in demand for recycling resins that can be part of creating a Circular Economy.

“What we need to do is address that gap in the system,” he says, “but we need to do it properly.

plastic packaging in the produce sector, which has become a prominent cause célèbre for the association in the last couple of years.

With the federal government recently legislating a ban on some single-use plastic packaging products by the end of the year—including drinking straws, grocery bags, stir sticks and cutlery— Lemaire says he is concerned about the government’s inclination to enforce sweeping legislation without fully understanding its impact on the industry, thereby putting political expediency above scientific research and evidence.

“In an ideal world,” Lemaire argues, “the federal government should have taken the time to develop legislative framework that could have effectively addressed the single-use plastic issue, which is evolving and changing very quickly.

“We have the science to identify the certain resins in the market that we should not be using,” Lemaire acknowledges, “but there is a wide range of plastics in the market that have a [recycling] channel or may have a potential channel for post-use.

“What the government is doing is leveraging a loud voice of the consumer to deal with the issue quickly,” he says, “which is not necessarily the right thing to do.

“We have to use sound science when making such far-reaching decisions, and it is our job as an industry to provide them with the information they need to address the challenges of unnecessary problematic plastics and to develop appropriate solutions for it,” Lemaire states.

“Many plastics used in the fresh produce supply chain are an important part of the industry’s ecosystem,” Lemaire notes, “and we need to be careful not to eliminate current packaging efficiencies that enable us to move the product to market quickly, without increasing the risk of food insecurity, big price increases, and more food waste.”

“So there’s a whole bunch of work that has to go in to managing the use of the right resin for the right material, to meet the right demand and to perform,” says Lemaire, citing CPMA’s own position paper, A Landscape Review of Plastics in the Canadian Fresh Produce Sector, released in 2019, as validation of the industry’s willingness to embrace “science-based sustainability.”

That said, Lemaire believes the Canadian fresh produce industry is well-positioned to bounce back from the economic and human suffering caused by the COVID-19 crisis to help drive the rest of the Canadian economy back to full health, both domestically and in export markets.

“I’m not sure exactly where we rank statistically in terms of overall influence in the world markets,” Lemaire sums up, “but I know that what we grow, what we produce, and what we process for our export markets is all world-class product with excellent reputation.

“Canadian companies are known and respected for their innovation, they’re known for their quality, and they are increasingly known for their efficiency in getting their product to customer,” Lemaire concludes.

For FREE registration to the CPMA Fresh Week 2021 virtual convention and trade show next month, please go to: www.convention.cpma.ca/register

Delivering Results.

With Heat and Control, you have a partner with the scale to support your success, the innovation to advance your operations, and a commitment to quality that will help you offer better products for consumers.

• Accumulation

• Horizontal motion conveying

• Incline, belt and bucket conveyors

• Filling and multihead weighing

• Bagmaking and casepacking

• Checkweighing and seal checking

• Foreign object and defect inspection

• Controls and information systems

We are successful when you are successful. That’s why we apply creativity, engineering excellence, and determined perseverance to every project to help our customers get the performance their business demands—whether measured by flavor, efficiencies, sustainability, improvement, or innovation. COMPLETE

info@heatandcontrol.com |

Canada’s leading meat processor setting the blueprint for sustainable protein products manufacturing

As the global meat industry continues to come under fire from all sides of the public debate on combating climate change and global warming, leading Canadian meat processor Maple Leaf Foods is wasting no time in separating itself from the herd by embarking on a sweeping sustainability journey to minimize its global carbon footprint.

In addition to becoming a carbon-neutral enterprise in late 2019, the Mississauga, Ont.-headquartered company is also shaking up its vast product portfolio of traditional pork and poultry products with significant investment in the production of plant-based proteins— targeting $3 billion in annual sales of plant protein products by 2009.

As Canada’s largest prepared meats and poultry producer—generating $3.9 billion in revenues and employing over 13,000 people at nearly 30 manufacturing operations in Canada and the U.S.— the company appears to have both the means and the will to help transform Canada’s domestic meat industry into a global showcase of environmental excellence by setting new industry benchmarks for sustainable manufacturing and packaging practices.

To find out on what’s driving the company’s relentless focus on environmental sustainability, the Canadian Packaging magazine has recently caught up with Tim Faveri, Maple Leaf Foods vice-president of sustainability and shared value, to explain his company’s green transformation process.

Congratulations to Maple Leaf Foods for celebrating one-year anniversary as a carbon-neutral company last year. How long did it take to achieve this distinction, and what is its significance?

Maple Leaf Foods embarked on its sustainability journey in 2013 and remains committed to being a leader in sustaina-

bility by taking necessary action to address the urgent threat of climate change and protect the environment.

Achieving carbon neutrality in 2019 was the result of a company-wide initiative to review every aspect of the business, ensuring that sustainability is prioritized in everything Maple Leaf Foods does and makes.

Our recent second-place ranking in the 2020 Coller FAIRR Protein Producer Index , an award-winning environmental, social, and governance (ESG) ranking of the world’s 60 largest publicly-traded protein producers, is due in large part to our leadership in plant protein.

With 51 per cent of Canadians looking to add more plant-based protein into their diets, we responded directly by expanding our plant-based offerings. In fact, we are the only company to achieve a 100-percent score in the alternative protein category in the 2020 Coller FAIRR Index, and the only company to have set a target to achieve $3 billion in plant protein sales by 2029.

This is the direction the protein industry is heading in, and we are proud to be leaders in a more sustainable food system.

What are some of the notable milestones and benchmarks that helped you achieve this high ranking?

In addition to being the world’s first major carbon-neutral food company, Maple Leaf Foods is the only protein company in Canada to have set science-based targets that are aligned with the goals of the Paris Agreement on

Tim Faveri, Vice-President, Sustainability & Shared Value, Maple Leaf Foods

Climate Change.

In order to meet our ambitious sustainability goals, we have aggressively reduced our emissions wherever possible in our plants and supply chain, and we have invested heavily in a variety of high-impact environmental projects across Canada and the United States— from supporting forestry and renewable energy initiatives to waste diversion projects —in order to offset our emissions.

The safety of our food and our people are key pillars of our company-wide approach to sustainability. In 2019, Maple Leaf Foods exceeded its performance goals in both its Food Safety Incident Rate (by 53 per cent) and its Quality Incident Rate (by 15 per cent). These results reflect the dedication and commitment to our Food Safety Promise from our manufacturing facilities.

Waste diversion and renewable energy project financially supported by Maple Leaf Foods include:

• Foam Blowing Agent Project

• Van Steyn Dairy Digester

• Maple Hill Landfill Gas

What is the importance of such achievements to the Maple Leaf Foods’ customers and everyday consumers?

Canadians expect corporations to do their part to protect the environment and reduce carbon emissions. According to a national survey conducted buy Angus Reid, 72 percent say they prefer sustainably made food products for themselves and their loved ones.

This clearly demonstrates that sustainability is top-of-mind for Canadians, who are looking for ways to make sustainable food choices.

Maple Leaf Foods’ customers include many of North America’s most loved restaurant and QSR (quick-service restaurant) brands, including KFC and Harvey’s.

These companies recognize the importance of having sustainable suppliers to meet the growing consumer demand for sustainably produced food.

Achieving carbon neutrality was just one step on our mission; Maple Leaf Foods is on a purposeful journey to become the most sustainable protein company on earth.

To achieve this, we are committed to reducing our environmental footprint and food waste by 50 per cent by 2025.

To maintain our carbon neutrality, and further reduce our emissions, we are working towards 30-percent absolute reduction for Scope 1 & 2 emissions and 30-percent intensity reduction (per 1,000 kilograms of product produced) for Scope 3 emissions, from a 2014 baseline.

The global meat industry is facing severe pressure and criticism over

• Rochelle Municipal Landfill Gas

• HFC Emissions Reduction

• Carbon Neutral Technology Project

• St. Joseph Wind Energy

• St. Leon Wind Energy

• Brady Wind I

• University Energy Efficiency and Renewable Energy Projects

• AIM Environmental Waste Diversion Project

• Massachusetts Tri-City Forestry

Organizations interested in joining the Maple Leaf Foods sustainability commitment can contact the company at media.hotline@mapleleaf.com. To learn more about the Science Based Targets initiative, go to: www.sciencebasedtargets.org

its massive carbon footprint. What can the global industry, and companies like Maple Leaf, do to improve the industry’s unfavorable image?

We are very proud of the progress we have made, but our mission is far from over. Canadians have made it clear that climate change is a priority for them, and they expect companies to do their part to protect the environment.

The protein industry is a significant emitter of greenhouse gases, and there is a lot of work to be done to make the industry more sustainable.

This is evident in the fact that Maple Leaf Foods was one of only three “lowrisk investments” out of 60 global protein companies in the Coller FAIRR 2020 Protein Producer Index, and the only Canadian company on the list. This should serve as a call to action for protein companies to step up and take action, now.

There is a real demand for companies to prioritize sustainability, and there is enormous opportunity within the food sector to do this.

We recently co-signed an Open Letter with fellow Canadian Science Based Targets initiative (SBTi) members, CN and Celestica Inc., committing to four strategic actions in accordance with the Paris Climate Accords.

Thee include reducing carbon emissions; setting science-based targets; resource stewardship; and sustainability reporting.

The time for climate action is now,

to what the latest climate science deems necessary to limit global warming to below 2°C above pre-industrial levels.

Maple Leaf Foods is the only protein company in Canada to set science-based targets that are aligned with the goals of the Paris Agreement on Climate Change.

We aim to achieve these targets by continually seeking opportunities to reduce waste and

Maple Leaf Foods is committed to prioritizing sustainability in everything we do and make— from farm to table. We are working now to ensure a healthy planet and sustainable future for generations to come.

We believe that real meaningful change requires strategic action, and to meet our goals we have studied every aspect of our company— from the way we route our trucks to the light

sustainable action every day, and 74 per cent of them say they would prioritize recyclable products where possible to positively contribute to the environment. We recognize this, and packaging is a major focus area of our sustainability initiatives.

As part of our Scope 3 greenhouse gas emissions reductions targets for our supply chain, we work closely with our suppliers to focus on

material reduction, post-consumer recycled content, and alternative materials.

Please provide some concrete examples of this commitment to more sustainable packaging formats, materials and designs?

In January of 2021, Maple Leaf Foods proudly joined the Canada Plastics Pact in an effort to end plastic waste and pollution.

We are rethinking the way we design, use and reuse plastics, and we are actively working towards ambitious 2025 targets to make packaging waste a thing of the past.

Maple Leaf Foods has implemented a sustainable packing strategy with the goal of shifting to fully recyclable materials over time.

This includes reducing packaging materials used where possible and sourcing materials with high recycled content.

We have begun rolling out more recyclable packaging for our protein products, including our new Maple Leaf 50/50 product range, and will be introducing new family lunch kits with 100-percent recyclable trays in 2021.

To help Canadians better identify sustainably made food products, Maple Leaf Foods has introduced a new Carbon Zero logo on the packaging of

many of our leading brands, including Maple Leaf , Greenfield Natural Meat Co., Lightlife and Field Roast Grain Meat Co. This whole initiative is based on making it easier than ever for Canadians to identify sustainable options for themselves, their families and the planet.

Please provide some examples of the GHG reductions that your company has achieved through more sustainable packaging design and practices?

We are proud of the advancements we have made in our waste diversion efforts to date: our 2019 diversion rate is 90.7 per cent.

However, there is always room for improvement. Maple Leaf Foods is always looking for ways to reduce our solid waste across our facilities and our focus in 2019 was on sustainable packaging.

We worked towards material education, post-consumer recycled content, alternative materials and consumer education to drive packaging innovation. Packaging makes up eight per cent out of the 78.4 per cent of our Scope 3 emissions.

To reduce waste in our supply chain, we have partnered with CHEP to provides us with reusable pallets that are built from 99.7-certified lumber (PEFC and FSC certifications). Every time we use one of CHEP’s reusable pallets, rather than one-way packaging, we eliminate waste and improve efficiency. Over 10 years, we have reduced substantial environmental impacts, including 513,601 kilograms of solid waste and 388 tonnes of carbon-dioxide.

Where do you see the biggest opportunities for more packaging innovation and improved sustainability?

Maple Leaf Foods is extremely proud of our leadership in packaging innovation. Last year, we launched our Maple Leaf 50/50 fusion protein product with 100-percent recyclable packaging, including the packaging for the meat itself and not just the outer sleeve, which is usually the case. We believe it’s innovations like this that will set the standard and drive the industry forward.

Many packaging products today still include materials that make recycling impossible or very difficult. The two rules outlined in the ‘Golden Design Rules’ framework—to switch to using transparent and uncolored PET in all bottles to boost recycling, and to remove all problematic elements from plastic packaging—are both strong starting points for other companies looking to reduce their environmental footprint through packaging innovation.

Iconic sweets and innovative packaging making beautiful music on the legendary candy factory’s high-speed production line

Created to provide magical little indulgent moments for chocolate connoisseurs all over the world, the Echte Reber Mozart Kugeln chocolate delights are as popular and famous today as their namesake—the great Austrian composer Wolfgang Amadeus Mozart.

Produced in Bad Reichenhall, Germany, in accordance to Reber’s closely guarded family recipe and with timeless tradition of craftsmanship and quality that have made the Reber a household name for over 150 years, the Mozart Kugeln

confectionery pastries and confectionery chocolate are beloved worldwide for their unique filling—made from the finest nougat and fine marzipan with almonds and fresh pistachios—double-coated in alpine milk and dark chocolate.

About half a million Mozart Kugeln creations leave the factory every day and are exported to more than 50 countries, including the U.S., China and Russia.

As Reber’s operations manager Reinhold Kaiser acknowledges, this turnover would not be possible without highly efficient processes, excellent quality control and agile, completely reliable packaging equipment in place.

And when the company recently need-