Quebec chicken processor spreads its wings with top-grade packaging execution

Story on page 28

Quebec chicken processor spreads its wings with top-grade packaging execution

Story on page 28

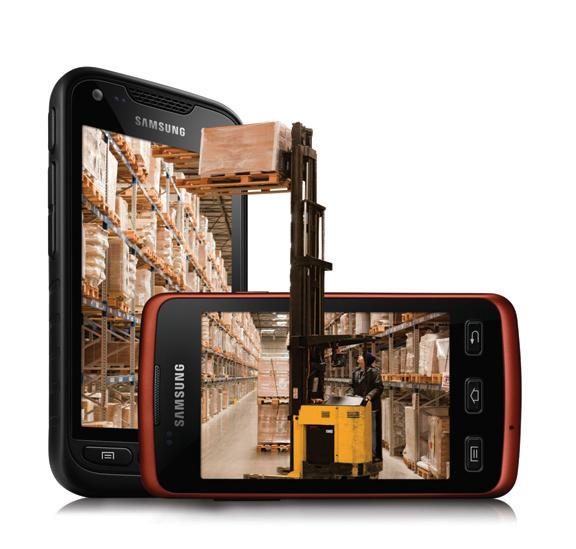

Choose from Samsung’s latest rugged devices. Durable and secure, they’ll stand up to harsh work environments. And on the Bell network, you’ll stay efficient with blazing-fast speeds, Canada’s best Push-to-talk service and 24/7 technical support. With Bell, your business will not only do more, it will make more.

Visit a Bell store • 1 866 BELL-BIZ • bell.ca/MobileBusiness

MARCH 2013 VOLUME 66, NO. 3

SENIOR PUBLISHER

Stephen Dean • (416) 510-5198

SDean@canadianpackaging.com

EDITOR

George Guidoni • (416) 510-5227

GGuidoni@canadianpackaging.com

FEATURES EDITOR

Andrew Joseph • (416) 510-5228

AJoseph@canadianpackaging.com

ART DIRECTOR

Stewart Thomas • (416) 442-5600 x3212

SThomas@bizinfogroup.ca

PRODUCTION MANAGER

Cathy Li • (416) 510-5150

CLi@bizinfogroup.ca

CIRCULATION MANAGER

Diane Rakoff • (416) 510-5216

DRakoff@bizinfogroup.ca

EDITORIAL DIRECTOR

Lisa Wichmann • (416) 442-5600 x5101 LWichmann@canadianmanufacturing.com

EXECUTIVE PUBLISHER

Tim Dimopoulos • (416) 510-5100 TDimopoulos@bizinfogroup.ca

BIG MAGAZINES LP

Vice-President of Canadian Publishing • Alex Papanou President of Business Information Group • Bruce Creighton

HOW TO REACH US: Canadian Packaging, established

Valleybrook Drive, North York, ON, M3B 2S9; Tel: (416) 442-5600; Fax (416) 510-5140.

EDITORIAL AND ADVERTISING OFFICES: 80 Valleybrook Drive, North York, ON, M3B 2S9; Tel: (416) 442-5600; Fax (416) 510-5140.

SUBSCRIBER SERVICES: To subscribe, renew your subscription or to change your address or information, contact us at 416-442-5600 or 1-800-387-0273 ext. 3555.

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE): Canada $72.95 per year, Outside Canada $118.95 US per year, Single Copy Canada $10.00, Outside Canada $27.10. Canadian Packaging is published 11 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

©Contents of this publication are protected by copyright and must not be reprinted in whole or in part without permission of the publisher.

DISCLAIMER: This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice. You should not act on information contained in this publication without seeking speci c advice from quali ed engineering professionals. Canadian Packaging accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. Canadian Packaging receives unsolicited materials, (including letters to the editor, press releases, promotional items and images) from time to time. Canadian Packaging, its af liates and assignees may use, reproduce, publish, republish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

PRIVACY NOTICE: From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us via one of the following methods: Phone: 1-800-668-2374 Fax: 416-442-2191 Email: privacyof cer@businessinformationgroup.ca

For all the good things to have come out, and still yet to come, from economic globalization and international trade liberalization, when things go wrong they can often go wrong in spectacular fashion—the horse-meat scandal spilling across many European countries last month being the latest dramatic reminder of the risks and dangers of overstretching one’s supply chain logistics too far and wide.

Generally presumed to have originated at slaughterhouse operations in Romania, the offending horse-meat managed to find its way in a stunningly diverse range of packaged and fresh foods retailing in 13 European countries, at last count, with high-profile accusations and recriminations across international borders suddenly dominating front-page news and television coverage.

First uncovered in Ireland near the end of last year, the horse-meat scare has already resulted in huge financial losses for many leading European grocery retailers like Tesco, foodservice operators such as Taco Bell, multinational food giant Nestlé and even the iconic Swedish furniture chain Ikea, which discovered traces of horse-meat DNA in the popular Swedish meatballs that the company sells at its store cafeterias.

Considering that no one has died or has even fallen ill from consuming the meat in question, thank goodness, it is tempting to dismiss the whole affair as a passing overreaction to a one-off system failure that has only served to distract European politicians from the real grave economic challenges they should be addressing.

But that would be letting the system off the hook too easily. Safe to eat or not, mislabeling everyday meat products like hamburgers, lasagna, sausages et al is a rightfully punishable offense, and those eventually found responsible should be held accountable for either their actions or the lack thereof, whatever the case.

That said, fixing flaws in the system is a vastly different proposition from advocating its abolishment altogether, as some pundits have been so quick to suggest with zealous vigor.

According to Jon Sorensen, who teaches Critical Animal Studies at Brock University in St. Catharines, Ont., “The discovery of horse-flesh in a number of otherwise-labeled meat products in Europe is an entirely predictable result of industrialized animal exploitation organized according to the values of neoliberal ideology within globalized capitalism.

“All forms of life are transformed into commodities and deregulated industries are allowed to police themselves as they seek to obtain the greatest profits using the cheapest ingredients, which in this case means the corpses of sentient beings,” Sorensen thunders in his thinkpiece on the popular www.rabble.ca website.

While all true to a point, far-left rhetoric notwithstanding, Sorensen’s argument is ultimately undermined by his advice at the end that all “sensible and compassionate people will adopt a vegan diet,” which logically suggests that people who enjoy eating meat are devoid of compassion and sensibility. Sorry, that just doesn’t add up. While the global meat business has had its share of failings that are often of its own making—our very own E.coli outbreak originating at the XL Foods slaughterhouse in Alberta last year a glaringly grim example—there are many incidents of food-borne contamination unfolding on regular basis with fresh and packaged produce, fruits-and-veggies, dairy, baked-goods and many other non-meat items that often go largely unnoticed in the public eye.

While two wrongs never make things right, advocating total consumer boycott of entire categories of foodstuffs on that account is absurd and irresponsible. No one is claiming that the meat industry’s supply chain is perfect, but the mere fact that it is not immune to public scrutiny, accountability and appropriate punishment, when due, is something to build on—not destroy.

Having more or less invented and defined the fast-growing energy-drink segment of the global beverage industry since its 1987 game-changing launch of lightly-carbonated, caffeine-fueled Red Bull drinks, Austrian-headquartered Red Bull GmbH is showing no signs of slowing down its rapid growth in the Canadian market, where it has been a runaway category leader since its initial 2004 product launch.

Following a successful introduction of the calorie-free Red Bull Total Zero version of its flagship brand in Canada last year, the company is hoping to replicate that success in coming months with a widely-anticipated launch of three unique new flavors to give the drink’s Canadian devotees a broader taste choice.

Produced and packaged at the company’s bever-

age production facility in Switzerland, the three new Red Bull Editions —including the sweet-tart cranberry Red Edition; fruity-blueberry Blue Edition; and fresh-lime Silver Edition are expected to be available at grocery stores across the country next month, following well-received limited launches at bars and restaurants throughout Canada earlier this year.

To be retailed in the company’s signature slim 250-ml metal cans decorated with an updated stylized ‘charging bull’ brand mascott, the three new

Produce packages with the same look and feel as a traditional bacon package.

Printed and registered top and bottom films.

Produce packages with or without J, L, or clear bacon carry boards.

High-speed reliable production.

Superior seals significantly reduce leakers.

Packages can withstand HPP.

Take advantage of EZ peel film.

Washdown machine provides better sanitation and hygiene.

Produce standard and custom retail packages, as well as bulk packages, all on the same machine.

Upgrade your retail bacon packaging to a whole new level with the Reiser Bacon Packaging System. Reiser engineers have done it again. This time they’ve developed a packaging solution for retail bacon that sets the new standard. With printed and registered top and bottom films, the ability to run with or without a carry board, superior seals, EZ peel film, and a package that can withstand HPP, the high-speed Reiser form/fill/seal packaging machine brings the newest technology to your bacon packaging line. This is the one machine that does it all. Not only does it easily produce a range of retail and bulk package formats on a single machine, the rugged Bacon Packaging System also eliminates costly maintenance and downtime.

flavors will be easy for shoppers to distinguish thanks to the use of matching can colors to indicate the respective flavor—bright red, blue and sliver/pewter. (See Pictures) According to the company’s Red Bull Canada subsidiary in Toronto, the Canadian Red Bull Editions launch represents the brand’s biggest packaging graphics makeover anywhere in the world to date.

“The can designs of The Red Edition, The Blue Edition and The Silver Edition are intentionally different from the one of the Red Bull Energy Drink because they are intended to highlight the individual flavors with their color at first sight,” Red Bull Canada explains.

“They will address all those fans who love the functionality of the Red Bull Energy Drink but are looking for new tastes,” says the company, adding the new Editions use the same product formulation and feature the same calorie content and nutritional functionality as the core Red Bull brand.

“The Red Bull Editions contain different added colors, as well as fruit-and-vegetable concentrates, which are used as coloring foodstuffs,” Red Bull explains. “All the ingredients are indicated on the can [and] listed on the label.”

While energy-drink brand-owners have come under increased regulatory scrutiny across North America in recent months after some highprofile reports of harmful side-effects linked to excessive energy-drink consumption, Red Bull maintains its products are perfectly safe when consumed in reasonable moderation.

“The consumption of the Red Bull Editions is only limited by its caffeine content,” the company states in its product Fact Sheet press release.

“One 250-ml can of Red Bull Edition contains about the same amount of caffeine as a small cup of coffee, which is 80-mg, so the consumption of Red Bull Energy Drink should therefore correspond to a person’s intake of coffee.”

According to Red Bull Canada, the new Red Bull Editions are best consumed “in times of increased mental and physical exertion, such as on long sleep-inducing motorways, during intensive working days, prior to demanding athletic activities, or before tests and exams.

“It is recommended to drink one can of Red Bull Edition about 30 minutes before the start of a concentration task or the start of a race or game in sports,” says Red Bull. “This is about the time it takes for the ingredients of the Red Bull Editions to become effective in the body.”

If cats really have nine lives, then the adorable little white kittens used as mascots for the ROYALE brand of paper and bathroom tissue produced by the Dieppe, N.B.-headquartered Irivng Tissue group have to be the proverbial “poster child” felines for this popular bit of folklore.

Celebrating its 50th anniversary this year, the beloved ROYALE tissue brand—currently comprising 38 different SKUs (stock-keeping units) produced primarily at Irving’s manufacturing facilities in Dieppe and Toronto—has revamped its packaging in grand style earlier this year “to create a fresh, modern look for the brand while highlighting the natural white of the product,” according to the brand’s director of marketing Gary MacIntosh.

Developed by one of Canada’s leading brand and package design experts Pigeon branding + design of Oakville, Ont., the new packaging incorporates a newly-created “Kitteny Soft” package-flash feature to help increase consumer awareness and excitement for the brand, MacIntosh explains.

Claimed to be Canada’s only consumer household paper brand that markets a full line of high-quality paper products including bathroom tissue, facial tissue, paper towels and napkins, the ROYALE brand currently ranks as the country’s Number One brand of household paper products.

MacIntosh credits the brand’s enduring consumer loyalty in large part to the popular ROYALE television commercials that became one of the longest-running ads in Canadian history.

corner pack-flash. (See Pictures)

“Traditionally, ROYALE packaging has focused on the brand’s signature-blue color,” MacIntosh says, “whereas the new design places a greater emphasis on

the ROYALE kittens, which are the truly iconic part of the brand.

“Not only does the new packaging bring out the personality of kittens, it also showcases a key characteristic of both the kittens and the ROYALE brand, which is softness,” says MacIntosh, adding the company is also planning to create a commemorative book later this year to showcase the brand’s history, growth and the “many milestones it has shared with Canadian consumers over the years.”

production cost | floor space requirements equipment requirements | man hours and labor cost liability & exposure

First airing in 1973, the TV ads features two ultra-white fluffy kittens engaged in playful rolling around with the matching white rolls of bathroom tissue—gently projecting a unique “soft” brand impression that still resonates with Canadian consumers in a big way across all age groups.

It may do so even more this year, MacIntosh relates, on the account of “the Search for the Golden Kittens” cash-prize contest promoted on the newly-updated packaging with the

... productivity | robust equipment | sealing options random case sealing capability | money in your pocket

...when it comes to case sealing. SCHNEIDER S&R has the solution that will cost you less to acquire and ultimately put more money in your pocket at the end of the line.

Whether you’re sealing the same sized cases on a non-stop production line or random sized cases... pressure sensitive tape, hot melt glue, water activated tape... 8-10 hour shifts or 24/7... whatever you’re sealing, SCHNEIDER S&R has the perfect, robust, long life expectancy equipment for the task.

Visit us at all the major packaging shows, check us out online or call us today for more information.

Leading material handling systems manufacturer and integrator Intelligrated has celebrated the formal grand opening of the company’s 122,000-square-foot headquarters expansion in Mason, Ohio, to mark successful completion of a year-long construction project that has boosted the facility’s combined size to 262,000 square feet, according to the company. Partly financed with incentives from the state of Ohio and the

“ FCC is key to our company

city of Mason to support local job growth, the expansion enabled Intelligrated to add more than 160 employees to its Ohio workforce—mostly in engineering and R&D—and 275 new staff company-wide. “This state-of-the-art facility is designed to attract and retain world-class talent,” says Intelligrated’s chief executive officer Chris Cole. “We appreciate the incentives from the state of Ohio and the city of Mason that allowed us to expand our footprint, increase our technical staff, and continue to meet an increasing demand for innovative automated material handling solutions.” Tel. (513) 881-5239

Milacron LLC , Cincinnati, Ohioheadquartered manufacturer of plastics processing technologies and industrial metalworking fluids, has reached a deal to acquire Mold-Masters Limited, Georgetown, Ont.-based manufacturer

of hot-runner systems, temperature controllers and auxiliary equipment, for an estimated US$975 million. Under the terms of the deal—expected to close in the first half of 2013 pending regulatory approvals—Mold-Masters will operate as one of five Milacron strategic business units, with current company president Bill Barker continuing to head the hot-runner business. According to Milacron’s chief executive officer Tom Goeke, “Mold-Masters’ expertise in the high-growth hot-runner market is second to none, and we are excited by the unique customer value proposition and numerous opportunities for growth that will result from this combination.” Founded in 1963, Mold-Masters owns over 900 granted and pending patents for numerous technological breakthroughs in the plastics molding field—currently operating manufacturing facilities throughout North and South Americas, Europe and Asia.

When you talk financing with FCC, we’ll listen

Ready to expand? We learn how you want to grow, then create a financing package that helps you do it. Work with the leading lender to agriculture, agribusiness and agri-food in Canada. Let’s talk business. www.fcc financing.ca

Guelph, Ont.-headquartered Guelph Food Technology Centre (GFTC), Canada’s leading food industry research institute providing numerous food safety training, certification, quality assurance and technical services to the country’s food-and-beverage producers, has merged with NSF International, a leading independent global organization mandated to develop universal standards, testing criteria, and auditing and certification services for the food, water and other consumer goods industries previously based in Ann Arbor, Mich. Now operating out of Guelph under the new NSFGFTC banner, the merged entity offers more than 180 training courses focusing on various food safety, regulatory and HACCP (Hazard Analysis and Critical Control Points) compliance to support its designation as a Licensed Training Center for the SQF (Safe Quality Food) institute and the Approved Training Establishment status for the U.K.-based BRC (British Retail Consortium) group. “The globalization of the supply chain creates a need for global solutions [and] adding GFTC’s food safety expertise to our global food division will enable us to expand services to Canadian and multinational companies to help strengthen their food safety practices and stay competitive,” says NSF International president Kevan Lawlor. Proceeds from the merger will be used to establish GFTC Legacy Inc., an affiliate organization with a mandate to provide University of Guelph undergraduate students with scholarship, co-op programs and internship opportunities, according to NSF-GFTC, as well as to help develop new programs that will stimulate greater innovation among food-processing companies across all the key supply chain sectors—from agriculture, produce, dairy and seafood to processing, distribution, retailing, and foodservice and restaurant operations.

The new PimoLinear C-Series linear scale from WeighPack Systems Inc. is designed specifically for weighing, filling and transferring sticky, wet, delicate and other difficult-to-handle products with conveyors— rather than the traditional vibratory feed pans—to ensure more effective and efficient product transfer, according to the company. Capable of handling a very broad product weight range from five grams up to 100 pounds—including fresh fruit and vegetables, cheese, noodles, fresh poultry, confectioneries, cookies, etc.—the scale is offered in one- to four-lane configurations to suit specific application requirements, enhanced with a user-friendly design to facilitate tool-less disassembly of conveyors, hopper, weigh bucket and funnel for efficient sanitation and speedy product changeover.

WeighPack Systems Inc.

deliver exceptional 2,400- dpi (dots per inch) print resolution at speeds of up to 16.25 feet (five meters) per minute to produce professional-grade, prediecut labels in run quantities from as little as 50 up to 5,000 labels.

Primera Technology, Inc.

401

The new model SBG-50 (Servo Bag Gripper) system from SAS Automation, LLC features adjustable width capabilities to enable cost-effective, simultaneous high-speed palletizing of multiple bag widths with a single robot in two-in/two-out rotation, or used with a single infeed conveyor with multiple bag sizes. Equipped with stainless-steel fingers to withstand harsh palletizing environments to handle bags weighing up to 50 kilograms, the system’s innovative programmable servo drive provides on-the-fly bag-width adjustment from 265- to 500mm, along with an additional manual adjustment to reduce the width further to 165-mm to accommodate very narrow bags. The gripper’s robust belt and pulley system—combined with linear rails for smooth and quiet motion—are enhanced with specially-designed, independent decker plates to ensure highly accurate and repeatable bag drop placement, according to the company.

SAS Automation, LLC

402

Designed to enable smaller and mid-sized manufacturers to bring their products to market quicker with inhouse production of affordable top-quality product labels, the new CX1200 digital color label printer from Primera Technology, Inc. is capable of printing on virtually any laser-compatible label material—including pressure-sensitive plain papers, white and clear polyesters, etc.—to

403

Offered on a caster-mounted frame that can be maneuvered through narrow aisles and around corners, Flexicon Corporation’s new Sanitary Tilt-Down Flexible Screw Conveyor is designed to allow many types of bulk materials and ingredients—from sub-micron powders to large pellets—to flow from the hopper into an adapter that charges the conveyor to facilitate gentle rolling action of the material being conveyed. Configured for dust-tight connection to the outlet of upstream equipment, the conveyor’s surge hopper includes an air displacement vent with a special cartridge

filter that is equipped with a reverse pulse cleaning system for dislodging any dust build-up with short bursts of compressed air—returning the dust to the hopper on a timed cycle to maintain full operating efficiency, according to the company. With the hopper, support boom and conveyor assembly tilted down, the unit fits through standard doorways and orients the conveyor tube horizontally— allowing the flexible screw to be easily removed for thorough cleaning and inspection. Driven only at the discharge end, the flexible screw—self-centered within the fully-enclosed tube to provide ample clearance between the screw and tube wall in order to eliminate or minimize grinding—does not require any bearings or seals within the product contact area.

Flexicon Corporation

from Eriez features multilane inspection capabilities; a compact, 60-inch-long lowprofile design; and ‘auto-learn’ features to facilitate superior performance in identifying contaminants, scanning for missing or broken products, and performing accurate mass inspection to ensure optimal product and packaging integrity, along with inline verification of product count, seal integrity, weight and shape accuracy, item positioning, and item presence or absence. Er

The heavy-duty System Plast 2508 and 2630 Series belts from Emerson Industrial Automation boast extremely durable and rugged construction for use across a full range of high-weight unit material handling applications, with the 2508 Series belting—made in standard LFG (lubricated food-grade) material—boasting impressive load capacity of 5,480 pounds per square foot. Also available in PPLG (plastic paint light grey) and other materials, the belts are fully-compatible with the extensive range of System Plast conveyor components like guide-rails and clamps, rail brackets, halters, supports and various custom-made accessories.

Emerson Industrial Automation 406

40 4

Designed for inspecting virtually any continuous product stream for unwanted foreign objects such as metal, stone, glass, bone and some plastics, the new E-Z Tec XR-Bulk X-Ray inspection system

The new AR-200 Series robotic case-packer from Premier Tech Systems is designed to provide an optimal solution for high-speed packing of packing bags, bottles, cases, cans, bundles, etc., into boxes or any other rigid container without the use of any flap holders, according to the company, thanks to the system’s robotic motion. Featuring fully-integrated machine vision capabilities, the AR-200 Series casepacker can easily pick up different kinds of products in multipick mode, as well as randomly-oriented items, before packing them into cases or any other rigid containers, with stored program recipes helping to facilitate quick product changeover.

Premier Tech Systems 407

Heightened public awareness of packaging sustainability and recyclability will help the U.S. demand for PCR (post-consumer recycled) plastic to grow by 6.5 per cent annually to reach 3.5 billion pounds by 2016, according to a new study from the Cleveland, Ohio-based market researchers The Freedonia Group, Inc.

“Gains will be driven by a number of factors, including a growing emphasis on sustainability among packaging and consumer product manufacturers, advancements in processing and sorting technologies allowing a wider variety of plastic to be recycled into-high quality resins, and an improved collection infrastructure which raises the plastic recycling rate,” says the recently-published Recycled Plastic report, noting that packaging will remain the largest single PCR market in the U.S. through 2016.

“Continued support by federal, state, and local

Source: The Freedonia Group, Inc.

governments for recycling efforts will also provide a significant boost to recycled plastic collection, processing and demand,” states the report, adding that recycled bottles will account for over half of all collected PCR plastic in 2016.

For all that, PCR demand will still account for less than seven per cent of the total demand for plastic for the forecast period, says the study, citing “a number of challenges” to more robust growth in PCR demand.

“The overall rate of plastic recycling in the US will remain relatively low,” the Freedonia report says.

“Recycling is minimal in several major plastic markets, including construction products, motor vehicles (other than batteries), and packaging film due to a lack of collection capability or economical processing.”

While PET (polyethylene terephthalate) and HDPE (high-density polyethylene) accounted for over 70 per cent of PCR demand in 2011 (see table), demand growth for HDPE is expected to drop to below average in the forecast period, accord-

ing to The Freedonia Group.

“While PET will see above-average gains in demand, fueled by rising recycled content in beverage bottles and thermoformed containers, subpar increases in HDPE collection will limit the availability of recycled resin,” the study states.

“The most rapid growth is forecast for recycled low-density polyethylene, which will benefit from a rebound in the construction market.

“Recycled polypropylene will also see healthy gains in demand as collection volumes increase and processing techniques improve the quality of the resin ... [and] rapid growth is expected for smaller-volume resins such as nylon and polystyrene—fueled by rising collection of products such as carpets, plastic foam, and consumer electronics for recycling.”

Full copies of the 236-page Recycled Plastic report may be purchased for US$5,100 by contacting The Freedonia Group, Inc. at (440) 684-9600 or online at www.freedoniagroup.com

Despite being largely invisible in a finished package, hot-melt adhesives can play a large role in determining the overall environmental profile of the package they help keep intact.

Which is why German-owned adhesives manufacturer Henkel is leading the way in the commercialization of a new generation of hotmelt adhesives based on the proprietary breakthrough biopolymer technologies pioneered by the life science products developer DaniMer Scientific, LLC of Bainbridge, Ga.

“A large number of our customers in the consumer packaging industry have publicized pro-

jects to drive sustainability initiatives, such as reducing carbon footprint of packaging materials, delivering on consumer-driven environmental initiatives, and diversifying supply chains for packaging materials,” says Gary Raykovitz, senior vice-president of product development for Henkel Adhesive Technologies

“Working together with DaniMer to solve these issues is yet another confirmation that we will consistently deliver genuinely innovative technologies that enhance our customers’ efforts to

achieve their sustainability goals.”

According to DaniMer, the company’s patented biopolymers are largely derived from nonfood renewable resources.

“The renewably sourced feedstocks that we use to produce these specific hot-melt adhesives are not derived from any direct food chain resources,” says DaniMer Scientific’s chief executive officer Daniel Carraway.

Videojet Technologies Canada Announces New Headquarters And Extended Logistics Hours

Videojet Technologies, a leading manufacturer of coding and marking equipment and fluids, has recently completed the relocation of its Canadian headquarters. The company is now located in a state-of-the-art facility, next to sister company Beckman-Coulter, at 7075 Financial Drive, Mississauga, Ontario L5N 6V8.

In addition to the new headquarters location, Videojet Technologies Canada is pleased to announce its enhanced logistics hours. Available between the hours of 7:00 AM and 7:00 PM Central, the new logistics operation will enable better same day shipping and longer pick-up window hours.

Videojet constantly endeavors to provide its customers with best-in-class service. Videojet Canada can be reached at 877-225-2241 or via website www.videojet.ca

“They are also unique in that we have enabled the use of recycled renewable content in certain adhesive grades,” Carraway adds, “which allows us to further diversify our supply chain.”

According to Carraway, the new technology platform was specifically formulated to meet all the pertinent health and safety requirements for the use of these materials in packaging applications.

Initially targeting the global consumer packaging market, including end-of-line packaging and labeling applications, the two companies expect their new bio-based hot-melts to be launched commercially in the first half of 2013.

“We believe that this technology, along with a range of other technologies Henkel is currently working on, will play a big role in assisting customers in reducing their dependence on petroleum-based materials in their packaging operations,” states John Rye, vice-president for the Consumer Packaging Group division of Henkel Adhesive Technologies

Experience the new SmartLase C series. Re-engineered for your industry giving you ultimate control of your coding quality and production costs at the speed you need whatever the rate, size or substrate. the new SmartLase C Series Power up your packaging line.

A top-level vew of the newly-installed Krones Modul ll ller and capping system putting Steam Whistle’s signature-green bottles throught their paces at high speeds wtih clockwork precision.

New state-of-the-art bottling line equipment helping popular Toronto beermaker boost its output while raising the bar for product quality and shelf-life

History, heritage and culture often play a huge role in the fiercely competitive world of beer brewing and marketing, and Steam Whistle Brewing has all those angles wellcovered at its one-of-a-kind home premises inside Toronto’s last remaining railroad roundhouse.

Located a short foot stroll away from the city’s signature landmarks such as the Rogers Centre— the world’s first domed stadium with a retractable rooftop—and the one-time word’s tallest free-standing structure CN Tower, the historically-designated historic John Street Roundhouse was built in 1931 for servicing steam and diesel-powered locomotives operated by the Canadian Pacific Railway

Once housing up to 32 locomotives at a time during its post World War II heydays, the 42,000-square-foot facility serves a much different purpose today—providing home to one of Ontario’s most successful independent craft brewers determined to write its own history with a relentless and open-ended pursuit of brewing perfection.

Owned by a group of private investors comprised mostly of employees, family and friends, Steam Whistle Brewing may seem like an odd choice of tenant in a building literally from another long-gone era—lovingly restored to its former architectural glory with original materials like Douglas Fir wooden beams, 30-foot ceilings and old-school multipanel windows—but defying standard industry wisdom and convention is an integral part of the company’s genuinely unique approach to the marketplace at large.

out any intent to add to its brisk-selling flagship Steam Whistle Pilsner label any time soon, if ever.

“Our motto is to ‘Do one thing really, really well,’ which is why it has been a conscious decision on our part to only brew a pilsner beer,” the brewer’s head of communications Sybil Taylor told Canadian Packaging on a recent visit to the busy brewhouse and bottling facility churning out approximately 90,000 bottles of its premium pilsner product daily.

Originating in the historic Czech city of Pilzen back in the 19th century, pilsner is widely touted by many industry experts to be the word’s most popular type of beer— owing to its smooth and easygoing taste profile and eye-pleasing light color.

But with the Canadian market

already well-supplied with a multitude of renowned and acclaimed pilsner brands produced by some of the world’s largest beermakers, making its product stand out in a big crowd was always going to be a serious challenge for a company that only commenced full-on commercial beer production in 2000.

And it’s a challenge that Steam Whistle has addressed better than anyone in the industry would have expected at the time, according to Taylor, a Steam Whistle employee from Day One.

“Because Steam Whistle believes in staying true to the pilsner brewing tradition, instead of heat pasteurizing the beer, we prefer to use a three-step filtration process that preserves the quality and taste consistently in every batch we brew,” says Taylor, explaining that the company takes between 28 and 31 day for the beer to brew, ferment and age to its optimal state before packaging and shipping it to customers.

In similar vein, the company has also taken it time in building domestic client base in a gradual

Not only does the brewer produce only one style of beer, a Czech-style pilsner, it purposefully manufactures only one beer brand period—with-

Reducing water usage is an important goal for the Beverage Industry around the world. Eliminating water and lubrication from conveyor systems is a proven method of achieving this goal!

System Plast’s unique NG™ material chain is capable of running with no lubrication, creates less noise than acetal materials, consumes less power, and is available in both side-flexing and straight running configurations.

and patient manner, according to Taylor.

Today retailing all across Ontario, Alberta, British Columbia and Manitoba—along with accommodating special orders from fans of Steam Whistle Pilsner in Saskatchewan Yukon and Northwest territories—the brand’s steady and unwavering rise through the domestic industry’s ranks is a compelling validation of the company’s well-measured, unhurried approach to growth and expansion.

With its beer available in bottles, cans and kegs all across Ontario, Alberta, British Columbia and more recently Manitoba—with some orders delivered to the Yukon, Northwest Territories, and Saskatchewan—the brewer respects and maintains historical traditions by utilizing ‘suitcase’-style 12-pack cartons and green glass bottles which pay homage to the industry standard beer bottle from the so called ‘Golden Era’, of the 1950s.

While brewers do agree that there is a difference in beer protection in respect to the particular color

of glass, Taylor says that Steam Whistle’s efficient and quick packing of bottles into fully-enclosed beer cases minimizes the effects of UV light on the beverage, providing an important step in ensuring a quality end product.

While the actual percentages vary depending on the season, Taylor reveals that “bottles account for approximately 50 per cent of Steam Whistle’s production, with the remainder made up of kegs at 30 per cent, and cans at 20 per cent.”

Taylor relates that Steam Whistle has been growing at double-digit rates over its 13-year history, in large part by investing in additional brewing and packaging equipment annually to meet rising demand. But this continuous investment hasn’t been without its challenges for a company operating within the confined space of a national heritage site.

“Thanks to the popularity of our beer, we needed to install a new equipment package that would help us achieve our ongoing goal of increasing our sales, while also taking advantage of technological advancements in the packaging industry,” notes Taylor.

To that extent, Steam Whistle recently looked towards the extensive expertise of brewing systems manufacturer Krones AG to help take it to the next level, working with its Canadian subsidiary in Mississauga, Ont. when installing a new filler for its canning line several years ago.

Late last spring, Steam Whistle also purchased three key machines built by Krones for its production line: a Lavatec E2 bottle washer; a Modulfil filler and capper; and a Steinecker TFS filtration system.

According to Steam Whistle assistant brewmaster Colin Banting, “The capital expenditures weren’t made so much to increase efficiencies, as it was about meeting our growing demand without compromising on quality.”

Prior to installing the new Krones Steinecker filtration system, Banting acknowledges that there were capacity issues on their single shift, as the old system

A showcase of famed German engineering prowess, the Lavatec E2 washer has twice the bottle soak time than Steam Whistle’s previous washer, but still maintains the brewery’s output rates thanks to its larger capacity.

could only handle processing 35 hectolitres (3,500 liters or 10,264 bottles) of Steam Whistle Pilsner per hour.

But with the new Krones filtration system installed, the ‘little-brewery-that-could’ is now able to process 50 hectolitres (14,663 bottles) per hour, giving Steam Whistle ample room for growth merely beyond scheduling additional shifts.

“I think the degree of automation in the Krones Steinecker filtration system is like night-and-day compared to what we had previously,” suggests Banting. “For example, the in-line turbidity meter is worth its weight to us.”

Banting describes beer turbidity as a measurement of haze, whereby too much of it—depending on the type of beer brewed—is an undesirable factor.

“This filtration system will place the beer in recirculation mode until the situation—the turbidity—resolves itself,” says Banting.

“Turbidity is usually high when we start up a filtration run, but this system won’t let the equipment actually start production until the turbidity comes into specification.”

Banting also notes that the filtration system also contains a dissolved oxygen meter, which he says gives the brewery a tighter control on the shelf life of the beer.

Along with its iconic green bottles, Steam Whistle Brewery tries to do it best in being a ‘green’ manufacturer, incorporating sustainable practices into its entire operations.

The brewer’s new Krones Lavatec E2 bottle washer certainly helps the brewery do its part by reusing rinsing water over the course of the bottle wash-cycle.

“Conserving water is desireable initself, but it also saves us money,” says Banting.

“The industry is subject to surcharges from the City of Toronto for any waste water being put back into the system and since introducing the Lavatec we have seen significant wastewater quality improvements.”

Like most Canadian breweries, Steam Whistle reuses its glass bottles, and Banting says that because its bottles are a bit heavier than most, a bottle might come back to be refilled some 45 times or so—about three times that of the industry-standard brown bottle.

Because space is always at a premium at the Steam Whistle brewhouse, the Lavatec E2 is a perfect fit for the brewery, which is why the bottles enter and exit the washer from the same end, though on different levels.

Referring to the direction of a bottle in the rinser, Banting explains: “Bottles enter and are rinsed, bathed and soaked by scores of spray jets, rinsed again and are ejected.”

According to Krones, the system’s fingers pick up the bottles from the conveyor and move them gently and precisely into a bottle carrier within the washer. When exiting the Lavatec E2, special discharge fingers transport the clean bottles carefully onto another conveyor, without allowing them to tip and fall as they head to the filling equipment.

Banting explains that when it comes the initial application of the water, it enters the rinser from the opposite end of where the bottles enter.

The way the Lavatec E2 is set up at Steam Whistle, the purest water is used for the final rinse of the bottles at the end of the cycle, after which it is collected and filtered before being recirculated to the preceding rinse stage—through six full rinse stages. The rinse water is then recovered and ultimately used as the pre-rinse of the bottles as they first enter the washer.

When washing the bottles, a light food-grade caustic detergent is used to thoroughly clean them. According to Krones general manager and vice-president of Canadian sales Sebastian Delgado, the single-end Lavatec E2 washer works so well in a compact space because the washer guides the bottles through its interior along a horizontal loop, ensuring the bottles remain

in the caustic just long enough to make them perfectly clean.

“The pre-cleaning system heats the bottles and removes the coarser contaminants,” explains Delgado, adding that after subsequent runs through the caustic bath in horizontal loops, the bottles emerge perfectly clean.

“And before the bottles leave the machine, they are cooled in the post-treatment zones with a small quantity of fresh clean water—the initial place where water enters the rinser—to remove the last traces of the caustic cleaner.”

Banting says that although the new washer is only slightly larger than the one it replaced, it provides a far longer soak time for the bottles helping to ensure quality.

“The actual residence of each bottle inside the rinser is about 30 minutes, which is about double the old one,” he notes.

“And despite the longer soak time, the rinser still maintains our production efficiency, as the Krones Lavatec E2 has a greater number of lanes. Having 26 lanes essentially means that it cleans a case of beer every couple of seconds or at speeds up to 2,600 bottles per hour.”

Banting says that in addition to the Modulfill filler’s lightning-fast filling rate of up to 12,000 bottles per hour, he is also highly impressed with the improvements of the Modulfill ’s dissolved oxygen control capabilities.

“Dissolved oxygen is problem Number One in

After lling and capping, each signature green Steam Whistle Pilsner glass bottle moves past an EBS-6200 single-head industrial inkjet printer, manufactured by EBS Ink-Jet Systeme, for application of lling and lot code data (inset) onto the shoulder of each container.

breweries, and getting a low oxygen content in our beer is very important,” Banting explains.

“Generally, our bottles contain dissolved oxygen levels under 30 parts per billion with oxygen pick-up during filling that is nearly undetectable,” he states.

The Modulfill utilizes a double pre-evacuation system just prior to the golden beverage being added to the bottle, whereby the empty bottle is flushed with carbon-dioxide (CO 2 ) and drawn out by a vacuum, and then flushed again with CO 2 and drawn out by vacuum once more.

This is done to ensure there is no air in the bottle, says Banting, explaining that CO2 is a natural element of beer. The bottle is then filled with beer under a counter-pressure to prevent foaming as well as to also keep the beer within the bottle during filling.

Immediately after filling, the Modulfill performs a fobbing process by shooting a sterile, hot-water jet into each bottle to agitate the contents and to expel all the air from within the beer, causing a small level of beer foam to come up as the air is pushed out.

A capper then crimps a cap down onto the bottle to preserve the tasty pilsner inside.

“The Modulfill has been specifically designed for bottling in a hygienic environment, as the free-

standing Montec transfer starwheels have less exterior surface than on conventional filling systems,” explains Delgado. “As well, the fill quantity is measured precisely by an inductive flow meter, ensuring each bottle contains the same amount of beer.”

The Modulfill also came with a crown (cap) and hopper system that Banting says has also enhanced production line efficiency.

“Our old crown hopper was ‘very aggressive’ in

the way it worked,” admits Banting. “It used to create a bit of crown dust which would often lead to a stuck chute where the caps would come down for crimping.

“But the new system is very gentle and has greatly reduced the stoppages.”

Because the brewery also often lends itself out for parties and weddings, Steam Whistle had to ensure that when it moved out the older equipment and brought in the new, it had to move quickly between long-scheduled events.

Not only did operations have to be shut down for five weeks to accommodate the installation, but Steam Whistle had to carefully dismantle a large section of the building’s inner brick wall and glass windows to get the equipment into its location on the production floor, and then painstakingly rebuild the wall to maintain the heritage look and feel of the facility.

“There was literally less than an inch of space between the huge bottle washer and our freshlymade hole in the wall,” says the brewery’s plant engineer Sergei Mikhniouk, “but we did it with a tremendous coordinated effort.”

Along with the tight squeeze, there were also the technical issues of electrically wiring all of the components.

Gord Hannah, Steam Whistle’s automation and electrical manager, had the difficult task of installing literally hundreds of feet of wiring to a bank of remote electrical panels associated with the equipment installs settling on a remote corridor as the best place for the panel placement. Hannah received numerous rolls of electrical wires that were each paintstakingly labeled by Krones technicians in Germany to facilitate a seamless installation.

“A brewmaster can be incredibly skilled at creating a recipe and brewing with quality ingredients and methods, but if the packaging equipment isn’t top quality, beer drinkers will never taste the beer the way the brewmaster intended,” explains Steam Whistle’s co-founder Cam Heaps.

“If we can help keep our Pilsner brewery-fresh by using the most sophisticated packaging technology available, Steam Whistle will be that much better,” Heaps asserts.

Adds Delgado: “Steam Whistle Brewing is definitely considered a brewer of distinction by its industry peers, and Krones is honored to partner with a company of its caliber. The Roundhouse Brewery location is a superlative showcase in North America for both companies to demonstrate the art of excellence, whereby a great beer is combined with precision machine technology,” he says describing the brewery as the North American showcase craft brewery for Krones technology.

Adds Steam Whistle co-founder Greg Taylor: “At Steam Whistle, we understand that there are no shortcuts on the way to quality.

“Our commitment to using only the highest quality ingredients and time-honored brewing traditions is made that much stronger with our use of the best equipment in the industry. These are steps we gladly take to deliver our premium craft Pilsner to Canadians.”

ANDREW JOSEPH, FEATURES EDITOR PHOTOS BY COLE GARSIDE

An apple a day may or may not be one of the most enduringly brilliant health-and-wellness advices ever known to mankind, but it’s certainly a recipe that has done many wonders over the years for Martin’s Family Fruit Farm Ltd. in Waterloo, Ont.

Established in 1971 by a prominent local farming family with nearly two centuries of cross-generational experience in pig farming, the family-owned business actually got turned onto apple farming by chance—after company founder Leighton Martin heard a visiting farm worker from the formerYugoslavia extol the virtues of apple growing as a righteous and rewarding way of making a living from one of Mother Nature’s finest creations.

Indeed, if all the different popular fruits out there could be likened to celebrities, the apple would undoubtedly be one of its biggest superstars—in a league of its own.

A key aspect of the Christian world’s culture and civilization, as well as an integral part of ancient Greek and even Norse traditions, apples have been bred for thousands of years to create a virtually unrivaled variety of tastes, textures and culinary uses—including sauces, pies, jams, juices, ciders and fresh eating, of course—with more than 7,500 varieties reported to be known in existence.

With more than 69 million tonnes of apples produced globally in 2010, according to most recent available industry statistics, this eminently versatile fruit has rightfully earned its ages-old reputation as an effective way to staunch both hunger and thirst with a quick boost of energy.

Providing a healthy mix of carbohydrates, sugars, dietary fiber, fat, protein and water that are critical elements to just about everyone’s daily food intake, the fruit also contains an array of essential vitamins and minerals such as vitamins A, B1, B2, B3, B6, B9 and C , calcium, iron, magnesium, phosphorus, potassium and zinc.

So in retrospect, the idea of getting into the act of harvesting Mother Nature’s quintessential multivitamins was not all that far-fetched after all, according to the company’s plant manager Brian Stubbs.

“A bit of product diversification is always a good thing,” Stubbs told Canadian Packaging on a recent visit to its new 17,000-square-foot processing facility in Elmira, that works in conjunction with the nearby 70,000-square-foot fresh fruit facility in Waterloo that is known as a thriving southwestern Ontario community and one of Canada’s leading high-tech hubs and research centers.

Stubbs relates that soon after acquiring and planting 100 apple trees on a one-acre parcel of land that is nowadays called Martin’s Orchard, the Martin family patriarch realized he was onto something special after selling his first four-and-a-half bushels of apples (each bushel weighing about 42 pounds) at the nearby Waterloo Farmer’s Market—proceeding to acquire many other nearby apple farms.

“Today we own some 700 acres of orchards ourselves, and we also market apples shipped in from over 1,600 acres in total, including our own and those from other growers,” says Stubbs.

“We are, however, ultimately responsible for deciding as to what apples are acceptable for us to sell into the marketplace.”

These days led by a second-generation team of Martin’s sons that includes company president Kevin, retail store manager Steve, and operations manager Ken—the company also sells some varieties of locally-sourced berries and other types of produce.

According to Stubbs, having a few other products on the go enables the company to absorb the occasional shock weather-related setbacks, such as an unexpected sudden drop in temperature after an early warming in March of 2012 that devastated large parts of the fruit industry in parts of Ontario and Quebec, as well as in the neighboring U.S. states of Michigan and New York.

“It completely froze off the buds,” Stubbs recalls. “Whereas normally an average apple tree might

don’t sell yourself short with the wrong container

today’s consumers expect more. They want the whole picture. They need answers for their important questions:

“Who is the producer?”

“Where was it packaged?”

“What are the contents?”

“Why should I buy this?”

Colourful, fully-interactive corrugated packaging delivers “the

”

Contact

Displaying a highly detailed image of dehydrated apple rings packaged inside a sealed exible pouch on the control panel (inset above), the high-speed Pack 240 Pro X-Ray inspection system manufactured by Eagle Product inspection and installed at the Martin’s plant by PLAN Automation provides the plant with highperformance detection capabilities to ensure optimal product safety, quality and purity.

have 500 apples on it, some trees had zero apples.

“Overall, it has been estimated that there was an 80-percent crop loss for the season.”

Taking it all remarkably well in stride, the company nevertheless proceeded to expand —breaking ground on the new 17,000-square-foot sister plant in the nearby town of Elmira in July of 2012 and commencing production there early this year.

“In fact, we have the capability to potentially add up to 45,000 more square feet of production space because we own three full acres on this Elmira lot,” says Stubbs, who also plays a key role in the company’s new product development efforts and initiatives that are in reality not nearly as simple as they may appear.

“While finding traditional uses for apples may not be complicated, finding new uses for a novel product made from apples is a rather challenging proposition,” says Stubbs, who played a key role in the development of the company’s recentlylaunched brand of Crispy Apple Chips made from 100-percent dehydrated apples.

While there are a handful of companies who already have similar type of apple-based snacks out in the market, Stubbs insists that his company’s all-natural

product content makes them a truly unique offering.

“The only ingredient in every bag of Crispy Apple Chips is the apple: just as it says on the bag’s list of ingredients,” Stubbs enthuses. “When you have made something as good as it can be, there’s really very little that needs to be added to it.

“This company is proud to be pioneering a new way to enjoy the wholesome deliciousness of an apple that we hope will resonate well with consumers—and early indications are that it will.

“We are very proud of our Crispy Apple Chips product line,” proclaims Stubbs.

“Not only are our chips completely gluten-free, but they contain no fat, no preservatives, and no sugar added—the product achieves its sweet flavor naturally,” Stubbs points out.

“And unlike other similar brands out there, Martin’s Crispy Apple Crisps are not deep-fried.”

While the manufacture of individual chips is a fairly straightforward and simple operation, Stubbs insists that the exacting process employed by Martin’s for its chips make them superior to those produced by competitors.

Stubbs relates that the Martin’s plant employs the facility’s only existing production line to run the product on a continuous 24-hours-a-day, threedays-a-week schedule to ensure optimal product consistency and integrity.

“Although we only have this one single line,” Stubbs acknowledges, “it is quite a versatile line that easily enables us to shift from producing fresh slice to making the dehydrated product.”

Plucked fresh from the orchards, the apples are cored and sliced into ring shapes by a PDS/R apple peeler—manufactured in Italy by ABL S.r.l. and featuring a Kernel sistemi PLC (programmable logic controller)—which can both peel the apples as well as slice them into wedges.

“Our 22-gram snack bags each contain about 10 chips,” says Stubbs. “If that sounds like too few, consider that we use one apple to produce seven crispy apple chips, so there’s actually a lot of goodness in each bag.”

Stubbs says the company is currently engaged in discussions with several large food distributors and grocers across Canada in regards to bringing the product to market nationally in the near future.

“Right now, we are only producing two SKUs (stock-keeping units) in 22-gram and 103-gram bags,” he notes, “but we also have plans for additional formats, such as multipacks for kid’s lunches and a larger-sized bulk bags.”

After slicing, the apple rings head to a huge dryer—manufactured by global thermal processing leader Bühler Aeroglide —which has been custom-set, after much trial-and-error, to achieve

the

the perfect balance of drying time and temperature to enable the dehydrated apples to maintain a flavorful, fresh-tasting apple crispy crunch.

From the dryer, the apples are conveyed along a series of Ever-Kleen incline conveyors built and installed by the Elmira-based Tri-Mach Group, which also installed the upper-level mezzanine platform in the packaging room equipped with a high-precision weighscale and FastBack oscillating conveyor systems.

Stubbs explains: “The apples are first conveyed vertically 16 feet up from the dryer room at a rate of about 40 feet per minute, and after that they are conveyed an additional 20 feet across our packaging room.

“It’s quite impressive to see,” says Stubbs, complimenting the reliable performance to date provided by the stainless-steel conveyors with their HDPE (high-density polyethylene) belting.

The Tri-Mach conveyors eventually transfer the apples onto a pair of Fastback conveyors—manufactured by Heat and Control, Inc.—which serve as accumulators and also help separate and position the product more accurately towards the 14-head Ishida weighscale, also supplied by Heat and Control.

“The Fastback systems ensure that we are never starving or overfeeding the weighscale,” explains Stubbs, calling the Ishida weighscale “a really great product for ensuring optimal accuracy.

“We certainly didn’t want to have issues with our scale—we wanted the most accurate and dependable weighscale out there,” says Stubbs.

Once the pre-set weights of apple rings are achieved, the product is released from the right combination of weighscale heads into a VertoBagger Tomcat vertical bag filler—supplied by the Mississauga, Ont.-based American Packaging & Plant Equipment —capable of filling rates of up to 45 bags per minute.

Prior to filling, the VertoBagger applies a hot date stamp onto the film before it is formed into its pillow pouch.

Located in the packaging room, Schneider Electric’s Magelis HMI (human-machine interface) terminal provides operator-friendly control over the plant’s conveyors, dryer, carton sealer and all other automated packaging functions.

To obtain optimal shelf-life for its apple chips, Martin’s first opted to utilize a metallized PET (Polyethylene terephthalate) film for the bags— with mixed results, Stubbs recounts.

“Initially we thought about getting a three-month shelf-life, after which the chips would not spoil, but could lose some of their crispiness.”

Despite positive early feedback, Martin’s decided to increase product shelf-life earlier this year by switching to a different high-barrier film—sourced by Kitchener, Ont.-based Tri Pac Inc.—and gas-flushing the bags with a 99.5-percent nitrogen mixture that the company produces itself on the premises.

To ensure optimal product integrity and purity, Martin’s also installed a high-performance Pack 240 Pro X-Ray inspection system, manufactured by the Tampa, Fla.-based Eagle Product Inspection and distributed in Canada exclusively by the Orangeville, Ont.-based automated packaging systems integrators PLAN Automation

Because of metal content in the bags used to package the apple chips, standard metal detection was not deemed a good-enough means of ensuring failproof product inspection, according to Stubbs.

“Metal detection systems typically don’t work very well with metallized PET or foilfilm products, but our Eagle 240 Pro X-Ray inspection system sure does,” states Stubbs.

“Even though we no longer use a metallized

A pair of vibrating Fastback conveyors from Heat and Control (background) help to untangle and separate bulk apple rings from each other before they make their way into the top of the 14-head Ishida weighscale.

PET foil film, our new high-barrier film actually contains more metal in it, so using the Eagle Pack 240 Pro is even more important for us now than before,” he explains.

“But because the food safety programs we cater to recommends that product be inspected after it has been fully sealed, it means inspecting both the packaging and the product,” Stubbs explains.

“Given our choice of packaging, X-Ray inspection was the only way for us to go.”

PLAN Automation’s X-Ray inspection specialist Mat Bédard agrees, noting that new food safety initiatives such as the GFSI (Global Food Safety

The Bel 5252 carton-sealer taping the loaded cartons of product shut after automatically folding the aps inwards.

Initiative) are demanding producer accountability at unprecedented levels.

“The need for better food safety has forced all food-and-beverage manufacturers to reevaluate and rethink their food safety programs and initiatives,” Bédard says.

“As such, X-Ray inspection systems are increasingly used for inspection of food and beverage products, validating product safety by detecting contaminants and ensuring product integrity by performing a wide range of in-line quality checks such as checkweighing and defect inspection,” says Bédard, citing the technology’s unrivaled ability to detect even the tiniest dense objects such as hard plastic, glass, or bone, and stainless steel at high-speed of up to 120 meters per minute, with up to a 240-mm range of detection coverage.

After passing through the X-Ray inspection system, the finished bags are hand-packed into pre-printed corrugated cartons, manufactured by Rock-Tenn Company, which are then placed onto a Wexxar model Bel 5252 carton sealer that folds the carton’s flaps and adds a tape strip to seal them shut.

The entire line operation—including start and stop controls, conveyor speed, dryer discharge and the carton sealer—is controlled via Schneider Electric‘s operator-friendly Magelis brand HMI (human-machine interface) terminal supplied by TriElectric, a division of the Tri-Mach Group.

While the recent influx of automated packaging equipment has certainly meant a learning curve for the Martin’s staff, Stubbs says he’s very happy with how everything fell into place without causing any major disruptions to the company’s core business.

“Despite our foray into new ventures and obtaining wonderful hightechnical equipment like the Eagle Pack 240 Pro X-Ray inspection system, we are not leaving our roots,” he sums up.

“We are still farmers: still rustic at heart,” Stubbs concludes. “We just happen to be doing something a little different with our apples.”

For More Information:

New cutting-edge packaging technologies and competencies help thriving Quebec chicken farmer keep going from strength to strength in the cutthroat marketplace

ANDREW JOSEPH, FEATURES EDITOR PHOTOS BY FRANÇOIS PINARD

There are many good reasons why chicken consumption in Canada has remained on a remarkably steady upwards growth curve since the early 1970s.

Many of the industry’s insiders will point to the keen and effective advertising campaigns stressing the healthy and dietary qualities of poultry meat, compared to red-meat protein alternatives, while others are quick to cite the modern consumer’s natural preference for food products that save them precious time by being easy to prepare and increasingly—thanks to the wonders of 21st Century retailing and foodservicing—ready to eat.

Whatever the underlying reasons, the well-documented facts and figures themselves paint a compelling picture of a lively and buoyant meat market segment, as well as that of a widely-accepted de rigour of most Canadian consumers making a trip to the local grocery store or supermarket.

With the average Canadian is estimated to consume over 90 kilograms of chicken meat per year, the overall big market picture for the domestic chicken industry—estimated by Statistics Canada at nearly 639

million birds with a total market value of $2.26 billion in 2001—is just about as bright as it gets in today’s increasingly globalized and competitive marketplace, despite the statistical ups-and-downs of the last five years rooted more in the generally sluggish economic growth throughout North America.

But larger macroeconomic challenges aside, the chicken business has held up quite well throughout Canada—often at the expense of beef and pork producers—and especially well in the province of Quebec, where some 170.9 million chickens were processed during the course of 2011, according to StatsCan.

And while the tide of a booming economy often tends to lift all boats, to borrow an old metaphor, it should come as little surprise that it is the more well-established regional chicken industry players—such as the Ferme des Voltigeurs Inc. (Voltigeurs Farm) of Drummondville, Que.— that have managed to thrive and shine even during the bleakest and weakest periods of underperforming economy of recent years.

Getting its start in 1958, Voltigeurs Farm has admittedly benefited from being one of the Quebec chicken industry’s early birds, in a manner of speaking, but given its humble beginnings— mostly confined to selling freshly-slaughtered chickens at local farmer’s markets—the company has more than earned the right to take genuine pride in its growth and accomplishments to date.

Nowadays operating out of a state-of-the-art,

25,000-square-foot processing plant on a one-shift, five-days-a-week production schedule, the roughly 100-employee operation currently processes about 8.5 million kilograms of chickens per year for a broad range of customers in eastern and central Canada—ranging from smaller butcher shops to the giant Sobeys and Metro supermarket chains, primarily in Quebec and parts of Ontario.

As a vertically-integrated producer, the company raises, slaughters, processes and packages its own chickens from start to finish—providing it with optimal production flexibility as well as full control of marketing of its own flagship Ferme des Voltigeurs brand of high-quality chicken products.

According to production director Georges Martel, the processing of fresh chicken products— as opposed to frozen chicken—accounts for 99 percent of the company’s output, with 90 per cent of that volume dedicated primarily to the Ferme des Voltigeurs brand products.

Son of the company’s original founders Georges Martel Sr. and Denise Turcotte says that operating its own slaughterhouses and all the downstream processing and packaging operations enables the company—deriving its name from the Voltigeurs light infantry unit that came to historical prominence during the War of 1812—to maintain full control of its own destiny in terms of quality control and product safety compliance.

“Before the first hen house was built in 1966,” he recalls, “the chickens would come in from other producers, but my parents felt it was important to ensure

that all the chickens we processed were all of the same consistent quality, and that they were all being fed and cared for in the most humane manner.”

“We added a second slaughterhouse in 1974, and by 1979 the company was licensed to sell its chickens throughout the Province of Quebec,” Martel told Canadian Packaging in a recent interview.

“In 2006, our installation was licensed as a federally-inspected facility by the CFIA (Canada Food Inspection Agency) as operating in full compliance with the strict slaughter standards specified by our HACCP (Hazard Analysis Critical Control Points) certification.”

Obtaining this certification was critical for the company, Martel explains, because it made a strategic decision in 2005 to diversify its product line with innovative new retail products by setting up its own kitchen facility and an on-site Voltigeurs Farm retail store.

“Moving into this market segment was quite a successful venture for us,” Martel relates. “So much so, that thanks to the success of our delicious meals and ancillary products, Voltigeurs Farm built another [third] store and expanded our kitchen facilities, so that our employees have more and better means to create new products from our tasty chickens.”

Voltigeurs Farm adopted quite the rigorous process to define each step involved in the production of vegetable grain-fed chicken with no animal by-products.

Martel explains: “We firmly believe that by providing a healthy and nutritious feed for our chickens, it can only help provide a great tasting and nutritious bird.”

Martel points out that consumers throughout Quebec and Ontario continue to find the birds from Voltigeurs Farm “to have an exceptional flavor,” making it a popular choice among food lovers

and health-conscious consumers.

Martel says that feeding a healthy grain-fed diet with high protein content to the chickens ensures a tasty, more flavorful and nutritionally superior bird with less fat than regular chicken.

“For us, Voltigeurs Farm believes it is worth spending a few extra cents per kilogram of feed,” says Martel.

“Because it’s less fatty, not only is the taste superior, but the meat quality is better with no shrinkage during cooking, which means the consumer will recover more meat in comparison with the regular chicken sold on the market.

“Moreover, your family receives a nutritionally healthy meal,” he states.

Voltigeurs uses independent third-party BNQ (Bureau de normalisation du Quebec) to verify the Agro-com audit program, which confirms that Voltigeurs Farm chickens have all been raised on an all-vegetable feed with no animal byproducts.

Since 2009 Voltigeurs Farms also began offering consumers a line of organic chickens.

“There are several steps that must be followed before the organic chicken label can be applied on our packaging,” explains Martel adding that Ecocert provides the certification.

“Chickens must be raised under natural conditions, including having natural lighting, and must have access to perches and the outdoors, where they can roam freely.

“Food also matters,” he continues. “Our chickens are fed 100-percent organic vegetable grain and pure water.

“Voltigeurs Farms organic chicken meets all of these criteria and complies with Ecocert Canada standards, which is why the Ecocert Canada logo—recognized by the entire industry—can be proudly displayed on our label,” says Martel, adding he expects the company to achieve its GFSI (Global Food Safety Initiative) certification some time in 2013.

Although the chicken processing industry tends

to utilize two different methods to retain a chicken’s freshness before packaging—water chilling and air-chilling—Martel says his company prefers to rely solely on air-chilling.

According to Martel, this method helps the chicken better retain its freshness, flavor and color.

“Another significant advantage is that the airchilled method ensures our chickens contain five to eight per cent less water than water-chilled birds,” he points out.

“Our plump chickens don’t just look plump— they are naturally plump.”

Along with the most demanding food safety protocols, Martel says Voltigeurs Farm has also become very proficient at using various types of packaging equipment.

“We use vacuum-packing for our fresh chicken products and a MAP (modified atmosphere packaging) gas-flush line for our ready-to-eat meals,” Martel reveals.

“For our breasts, legs and other cuts, we find that the vacuum-packing method gives our products its unique freshness, not to mention a longer shelflife,” says Martel, while complimenting the helpful folks at VC999 Packaging Systems for suppling a plethora of its top-of-the-line equipment to the Voltigeurs Farm plant.

Operating service centers throughout the world, VC999 is a Switzerland-based company that designs and builds a wide range of vacuum-packing solutions, including vacuum chamber machines, rollstock thermoformers and tray-sealing equipment, as well as shrink bags, pouches, films and trays.

Roll with It

Installed in 2010, Voltigeurs Farms uses its model RS420c rollstock thermoformer—the ‘c’ stands for compact—designed as a high-performance solution for fresh-food packaging applications with large volumes of similarly-shaped products.

Capable of processing MAP, skin-pack, flexible or rigid seal packaging, Voltigeurs Farms says it uses its new RS420c thermoformer only for vacuum-packing, as it provides a best solution for an extended shelf life for refrigerated items.

Says Martel, “After utilizing the new RS420c from VC999, we found that our fresh products were, on average, achieving an additional six days of shelf life over the previous method—and that is outstanding!”

Although the RS420c only takes up a fairly small footprint on the shop floor—a mere 12 feet in length—it is undoubtably a high-output machine, as VC999 Canada vice-president Remi Boudot explains.

“Even with a high vacuum, the RS420 thermoformer machine can reach a speed of six to seven cycles per minute,” says Boudot.

“But, if the vacuum level required is less, pack speed can increase to eight or nine cycles per minute.

“Of course, the cycles per minute actually mean a different number when considering the actual number of packs sealed,” says Boudot.

While multiple tooling helps the RS420c achieve high cycle speeds, VC999 says that Voltigeurs Farm has found the flexibility of its new thermoformer to be a necessity.

“We designed the machine so that it can easily handle different configurations of package sizes and depths,” reveals Boudot, “so that it easily works with a large single package or four smaller ones during a single cycle.”

Adds Boudot: “By providing a modular machine—

and knowing that Voltigeurs Farm is a progressive company—VC999 can design further configurations as their packaging needs change, as well as create a new package format to meet their demands.

“We feel that VC999’s design of the stainless steel and easy-to-clean RS420 is superb, in that with its flexibility it can be easily retrofitted with new designs and new options as the situation requires to provide dating, printing, coding, cutting, loading and more at a very competitive cost.

“All of our designs, in fact, are done in such a way that any customer can grow with their VC999 machine and not have to be stuck with a singletype application,” continues Boudot.

Martel agrees that the vacuum pack thermoformer has provided a tremendous performance upside.

“For us it was extremely important that our fresh products achieve an excellent vacuum pack that would help provide a better shelf life,” admits Martel.

“We also were interested in getting away from having to use foam trays—in fact, we have found that for customers that want to freeze the product, the vacuum-pack solution is much better than a tray-pack.”

While Martel is reluctant to share exact speeds to run the thermoformer at, he says that right now it is more than adequate for packing its fresh boneless breasts, legs and drumsticks.

“Our employees hand-place product into the

basket of film in the RS420c, and then add a foodsafe paperboard cover,” says Martel.

“After the product moves through the thermoformer, it vacuum-packs it with such an excellent seal that it provides us with an extended shelf-life, which is something grocers and consumers find appealing.”

According to Boudot, VC999 supplies all the film to Voltigeurs via its Xtraplast supply division—both clear and pre-printed—while the black paperboard is obtained via another supplier.

“The film VC999 uses does indeed have special properties that are specific to Voltigeur’s needs,” notes Boudot, “and while I cannot get into any specific details, I can state that the film was developed based on a target shelf-life, product coloration, display counter conditions, light exposure, and plastic strength.

“However, since the chief product being vacuum-packed by the RS420c is fresh chicken,” Boudot reveals, “it contains little bones that are very sharp and easily able to perforate film, we had to determine and develop the ideal right film thickness that could still meet Voltigeurs’ OTR (oxygen transmission rate).”

Along with the fact that VC999 has a Canadian office located a mere 10 minutes away from the Voltigeurs Farm facility, Martel explains that in deciding to work with each other, that it is the respect VC999 garners within the food-processing industry for providing a quality machine—along with adaptability—that helped make choosing the machine manufacturer easy.

The respect is mutual, according to Boudot: “In general Voltigeurs Farm is a good example of what we can bring to the customer—a full and complete packaging solution sized to their needs.

“We handled the project from start to finish, and I know we can develop the line further as their production changes and increases.