Ontario craft brewer steps up to COVID-19 front lines Story on page 15

Backed by more than 40 years of continuous inkjet expertise, the latest Videojet CIJ printer is designed for uptime peace of mind and errorproof operation. The 1580 features the SIMPLICiTY™ user interface, CleanFlow™ technology, Dynamic Calibration, SmartCell™ components and optional VideojetConnect™ Remote Service to drive significant printer improvements through everyday operations.

As an essential business in the retail supply chain, our network of manufacturing and fulfillment sites remain fully operational and productive, with available capacity to accommodate the rapidly evolving demands at retail.

Our skilled workforce and world-class automation allow us to meet the changing needs of our customers and their retail partners.

Menasha continues to implement proactive and controlled measures to combat the spread of COVID-19. The safety, health and wellbeing of our employees, their families, our suppliers, customers, and communities remains our number one priority. Partnering with your business as we

Our continued focus is to provide a clean, healthy, and safe work environment to ensure the seamless flow of products our customers and communities are counting on us to deliver.

Together we will ensure your business continuity by protecting, moving and promoting your products better than anyone else in these uncertain times. For further information please contact us at Menasha.Canada.Solutions@menasha.com

SENIOR PUBLISHER

Stephen Dean • (416) 510-5198 SDean@canadianpackaging.com

EDITOR

George Guidoni • (416) 510-5227 GGuidoni@canadianpackaging.com

MEDIA DESIGNER

Brooke Shaw • (519) 428-3471 bshaw@annexbusinessmedia.com

ACCOUNT COORDINATOR

Barb Comer • (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER

Anita Madden • (416) 510-5183 AMadden@annexbusinessmedia.com

VICE PRESIDENT

Tim Dimopoulos • tdimopoulos@annexbusinessmedia.com

COO Scott Jamieson

ANNEX BUSINESS MEDIA

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA

ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

CIRCULATION

Tel: 416-442-5600

Fax: 416-510-6875

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE: Canada $78.50 per year, USA $138.00 US per year, Outside Canada $156.50 US per year, Single Copy Canada $10.00, Outside Canada $27.10. From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

ANNEX PRIVACY OFFICER

Privacy@annexbusinessmedia.com

Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2020 Annex Publishing & Printing Inc. All rights reserved. This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice.

Getting one’s head wrapped around the idea of accepting change is not an easy proposition, lockdown or not. Here in Toronto, the sight of thousands of people congregating in an impromptu block party a few weeks ago at a popular downtown park on a sunny weekend afternoon was a shocking and sobering revelation that people’s willingness to accept the social distancing realities of the new normal public behavior just cannot be taken for granted—despite endless pleas by government officials and health experts to stay at home while the deadly COVID-19 pandemic continues to add significant numbers of fatalities and new infections to its grim and growing total.

Appalling as it seemed at the time, the widely publicized display of collective public amnesia and lack of personal responsibility is a reminder that the more things change in life, the more they tend to stay the same in the long term on some deep subconscious level.

As the celebrated American organizational systems scientist Peter Senge once famously opined: “People don’t resist change, they resist being changed.”

Although such instinctive resistance can be an honorable trait when it comes to defending righteous causes and principles, it can also be a monumental obstacle to further socioeconomic progress for mankind at large, and for thousands of business organization currently contemplating life after the COVID-19 lockdown.

For the relatively few businesses granted exemption from shutting down their doors to the public, some parts of that future working environment are already in place on what may well turn out to be permanent basis—plastic shields and fiberglass dividers at checkout lines at grocery stores being just a hint of how many other businesses will operate going forward.

And as the growing number of professional sports leagues around the world are cautiously revealing

We

their plans for salvaging their suspended seasons without any fans being allowed inside the sporting venues, it’s increasingly hard to accept the anticipated disruptive organizational changes as becoming standard operating procedures.

Hard, but not necessarily impossible.

As noted management consultant Andrea Belk Olson, chief executive officer of business strategy development firm Pragmatic, writes in her recent blog, “There’s a portion of the organization that wants to maintain the status quo and another portion that’s ready and willing to change.

“So leaders often take a variety of approaches to get the other half on board, whether it be taking a hard line, amplifying communications, or reinforcing the logic of the decision.

“Yet, the problem isn’t the approach, but the change itself,” Olson states, noting that business leaders must consider the size, scope and impact of change on their employees in order to earn the required level of acceptance, however begrudgingly.

“We tend to roll out big changes and of course, there’s some appeal in the approach of taking the whole, well-described package and implementing it across an organization,” Olson writes.

“However, organizations don’t take into consideration—or prepare their teams for—the impact of the transition,” she adds.

“Right after a change, employees can struggle to get used to new processes or shifts in job responsibilities that might make them feel less accomplished in their roles.

“Even if these growing pains lead to great skill advancements and process improvements, that temporary space of feeling clumsy around the office doesn’t feel good. And that’s what people resist—giving up that sense of expertise, even if it’s temporary.”

than doubles its production throughput with cutting-edge packaging automation.

South American PepsiCo bottler closes in on

efficiency perfection with a

A little automation delivers big payback for

Hard work and quick customer service have always gone hand-in-hand at Toronto-based Plexpack Corp.—ever since the packaging machine-builder entered the market over 50 years ago.

And in the last couple of months, these qualities have been tested to the limit, as the family-owned business worked around-the-clock to assemble and supply 36 packaging machines to various manufacturers who had to retool their operations in order to supply the much-needed medical supplies and devices needed to combat the spread of the COVID-19 virus.

According to Plexpack, these customers include producers of medical supplies such as kits and swabs, customers in packaged, prepared and frozen food markets, and other businesses in essential supply chains.

To manage both the high-demand and urgent-need for packaging systems, Plexpack offered customers immediate shipments of on-hand inventory and for priority production to COVID19-related orders.

One such customer was an automotive company in Detroit, Mich., that had retooled its operations to produce face masks. This customer ordered seven machines and requested the machines to be on-site within a week.

Even though at the time Plexpack had reduced operations for the safety of their staff and community, they successfully delivered.

While experiencing an overall increase in demand by 60 per cent since March compared to the same period a year ago, Plexpack had to pivot its operations to

accommodate both these urgent-need orders from essential businesses, as well as the standard orders.

“Plexpack has successfully navigated this increase in demand and continues to provide for all their customers,” says Plexpack’s business and marketing administrator Natalie Irvine.

“Every department in the company has been affected in some way by the COVID crisis,” adds Plexpack sales manager Adrian Hermosillo. “From a sales perspective, the face-to-face interaction with customers and channel partners has been lost, but we have adapted with the use of virtual communication technology.

“Our decades of history in this business, with the variety of industries that we attend to very well, has protected us during this time and kept us very busy, and we thank our customers and distributors for their continued trust in our solutions.”

With global installation base comprising over 5,000 customers worldwide, Plexpack typically employs 50 people to produce over 500 machines per year at its modern manufacturing facility in east-end Toronto. (See Pictures)

Some of the company’s better-known machine brands include the highperformance Damark line of shrinkwrapping and bundling equipment; the Emplex range of automatic bag and pouch sealing systems; and the Vacpack family of bag sealers for vacuum and MAP (modified atmosphere packaging) applications in the food industry.

Our goal is, and still remains, to provide continued support to Canada’s critical supply chains throughout this uncertain time. A huge thanks to our service and production team for their service and following COVID-19 protocols.

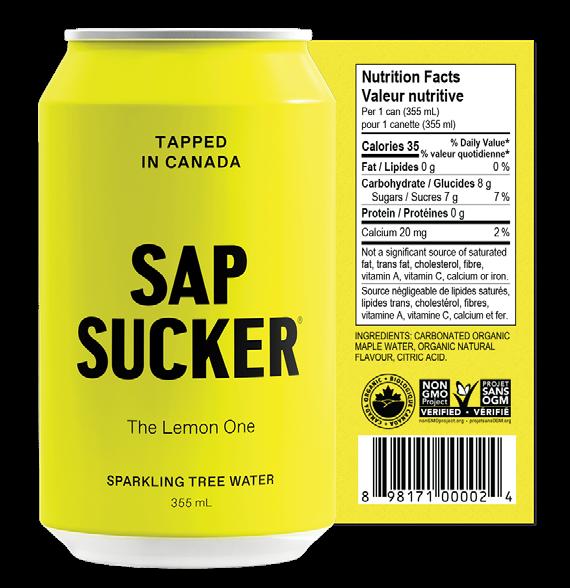

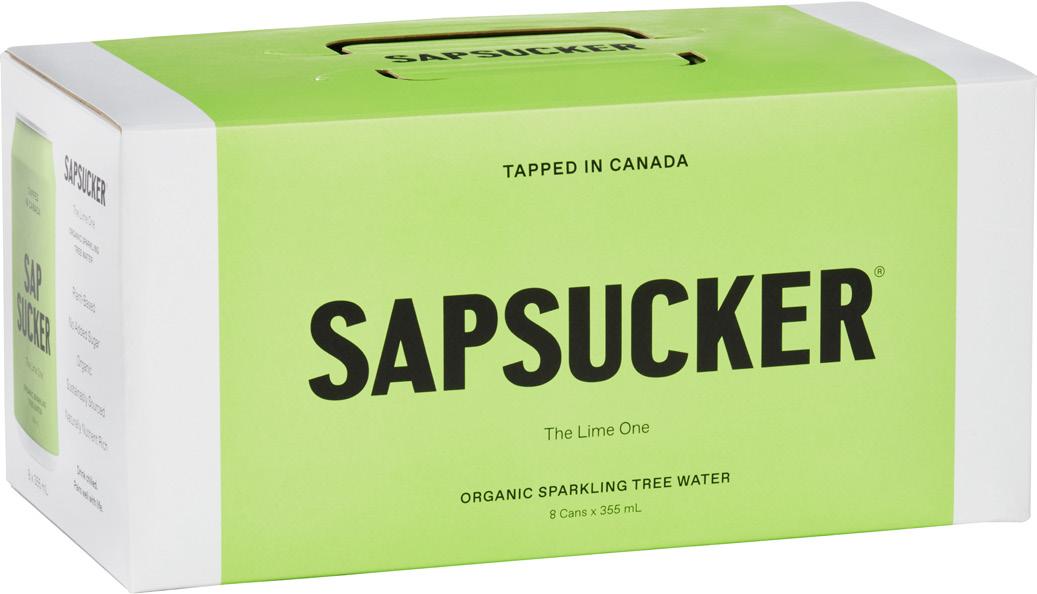

While it may not yet enjoy the worldwide fame and acclaim of Canadian-made maple syrup, maple tree water has everything going for it to succeed as a whole new beverage category, thanks to innovative new products like the Sapsucker brand of organic, sparkling tree water.

Produced by the Lower Valley Beverage Company of Flesherton, Ont., the plant-based, nutrient-rich, easy-to-drink beverage is powered by 46 naturally occurring minerals, vitamins and antioxidants sourced from sustainablymanaged maple trees in Ontario’s great outdoors.

Boasting subtle bubble and the slightest hint of natural sweetness to create a truly unique and refreshing beverage experience, the Sapsucker beverages are sustainably harvested, according to the company, to support local tree farmers and forest management.

Offered in three flavour varieties—including The Original One, The Lime One and The Lemon One Sapsucker is packaged in 335- ml aluminum cans, supplied by BSG Canada, and decorated with catchy, bold-and-simple ‘clean label’ graphics deigned by Toronto-based graphic arts agency Vanderbrand

Currently sold online (www.well.ca) and at Whole Foods Market, the three Sapsucker flavors are also available in custom eight-pack paperboard carriers made from 100-percent recycled materials by Zebra Paper Converters in Mississauga, Ont.

According to Lower Valley, “Our custom eight-pack foldable carrier package is developed with minimal adhesive use, making it more recyclable than the average beverage carrier.”

While drinking tree sap is not a new phenomenon in itself—with birch tree sap being a long-time favorite across Nordic folk cultures in Eastern Europe— mainly in Russia, Estonia, Lithuania, Poland and Latvia—tapping maple trees

Next-generation leadership performance

Hitachi’s UX Series continuous inkjet printers represent the pinnacle of innovation in marking and coding technology, all while showcasing Hitachi’s reputation for Reliability, Efficiency, and Ease of Use. sales@harlund.com

to make sparkling beverages is certainly an exciting new development in the Canadian beverage marketplace.

The sap is made with water tapped from Ontario and Québec maple trees that draw moisture up through their roots and trunk, acting as a natural filter, to collects nutrients that are stored in the tree all winter long to provide the hydration and nourishment that enables the trees’ growth and rejuvenation in the spring.

At spring time, the tree water is harvested by tapping the trees and then infusing the water with organic, natural lime or lemon, along with some light carbonation.

According to Lower Valley, “Tapping trees is both ethical and sustainable.

“The harvest process does not harm trees and lets them continue to produce throughout their natural lives, allowing us to make a healthy, plant-based beverage boasting minerals, antioxidants, amino acids, vitamins and prebiotics aplenty.”

Keep your products and your customers safe with Reiser’s wide range of packaging solutions.

Fabbri stretch wrap packaging from Reiser offers the ultimate in food safety by eliminating in-store handling of loose products while providing a tamper evident package for consumers. Fabbri Automatic Stretch Wrappers produce highly attractive packages that make food products look fresh and “just packed”. Fabbri Stretch Wrappers use stretch film to package fresh produce, meat, poultry and seafood products in preformed trays to provide an in-store wrapped appearance. Fabbri Stretch Wrappers employ four-way stretch technology to produce tight, over-the-flange, wrinklefree packages with securely sealed bottoms and a superb case presentation.

Reiser horizontal form/fill/seal packaging systems produce vacuum, modified atmosphere and vacuum skin packages from flexible and semi-rigid materials. Compact configurations are available for lower production requirements, as well as high-performance machines capable of the industry’s fastest production speeds.

Ross tray sealers produce modified atmosphere and vacuum skin packages from preformed trays. They package fresh, refrigerated and frozen food products at a full range of output rates. Ross tray sealers produce attractive packages with superior seal integrity and extended shelf life. Ross tray sealers are designed to allow rapid tool changeover between tray sizes, reducing downtime and maximizing production efficiency.

Supervac is the technology leader in automatic belt vacuum chamber packaging machines, shrink tanks, chill tanks and dryers. Supervac machines feature a Double Biactive highpressure sealing system that provides two superior seals to every bag. Heat and pressure are applied from above and below the packaging material to produce two superior seals, virtually eliminating leakers.

Keep your products and customers safe. Talk with our team of Reiser Packaging Specialists to determine which package format makes the most sense for your business.

Be it AT home or abroad, in person or online, leading Canadian package design and branding agency Pigeon Brands Inc. just can’t help itself but keep winning one award after another in recognition of its stellar world-class package design work.

Last month, Pigeon distinguished itself once again at the Dieline Awards by winning Gold in the Savory Snacks category for its design of the new Puffs snacks from GoGo Quinoa

“Winning at the Dieline Awards is a bit like winning an Oscar,” says Élyse Boulet, senior vice-president and managing director of Pigeon Brands.

“It was great to see us squared up against the best of the best design agencies in the world—from Sweden, the U.S., U.K, Italy, Australia, Hong Kong and more.”

For the past 10 years, the Dieline Awards competition has been formally recognized the absolute best in consumer product packaging design worldwide, highlighting the impactful trends and bringing awareness to the immense value that lies in well-designed brand packaging.

Every submission to Dieline , said to be the most visited packaging design website, is reviewed by an esteemed jury of branding, structural packaging, design and consumer product experts with regards to five key elements: creativity, marketability, innovation, execution, and on-pack branding.

The ceremony, which was supposed to be held in Boston this year, has been replaced by a virtual acknowledgment to all winners.

Designed to attract a young consumer, GoGo Quinoa Puffs is a bold, healthy and fun brand of plant-based snacks with a short list of healthy, organic and gluten-free ingredients.

“We had a good product and a credible brand. We therefore had an opportunity to convey good storytelling and bring meaningfulness, differentiation and emotion to the natural food aisles/categories,” says Pigeon Brands creative director Olivier Chevillot.

“For this product, aimed at Millennials and Gen Z, we wanted the design to evoke the goodness inside with a modern, optimistic and uplifting approach to create a fun, inventive and inspiring product experience for this nourishing snack, which goes beyond the functional attributes we know about healthier products.”

As Chevillot explains, the traditional functional packaging design cues

With our modular safety gate system you can build an individual safety gate solution optimally tailored to your application!

• Configurable safety controller PNOZmulti 2: Modular and compact solution as flexible as your application

• Safety gate system PSENslock: Safe position monitoring with process guarding in one system

• Pushbutton unit PITgatebox: Simple operation of your safety gate system

• Safety gate system PSENmlock: Safe interlock and guard-locking in one product with optional escape release

Modular safety gate system: Your gate. Our system. Your safety.

are left behind to inject some humanity and dynamism to the design, while the brand’s trio of flavors is illustrated by characters as colorful as the flavors they represent. Whether the high hair or the long beard, this imagery is rooted in the shape of the product itself way to show that the product is different, with the unique characters virtually popping out of the package while holding a quinoa puff in their hands.

“The bold colors of the characters on the black background create a very strong shelf and online impact,” says Chevillot. “It brings a good dose of dynamism, eases product recognition, and shows taste appeal in a different manner, because it is a snack after all!

“But more importantly, it is another proof that strategic design is an incredible tool to boost sales,” Chevillot adds.

“The collaboration with the Pigeon team and this innovative design helped the sales team not only achieve but exceed their business goals,” says GoGo Quinoa president Martin Bilodeau. “After the products were launched instore the week of October 28, 2019, sales went through the roof in just three weeks, selling out the stock exceeding sales objectives by 200 per cent.”

PMMI Business Drivers equip the makers of packaging and processing technologies to succeed in a competitive global marketplace. pmmi.org

PMMI is a leading global resource for packaging and processing. Our core purpose is to unite the industry across the manufacturing supply chain. For more information go to pmmi.org

PACK EXPO Portfolio of Trade Shows unites the world of packaging and processing to advance industries. packexpo.com

PMMI Media Group connects manufacturers year-round to the latest solutions, trends and innovations in packaging and processing. pmmimediagroup.com

Designed for optimal cleaning efficiency in highcare industrial environments, the new RUN-WET IQ4 metal detector with conveyor from Loma Systems incorporates an open frame that uses multi-angled surfaces and minimal welds, as well as quickly removable covers, to reduce excess water and cleaning chemicals that typically pool on machine surfaces. In addition to reducing the risk of corrosion and accumulation of bacteria that could potentially contaminate foods, the system also virtually eliminates the need for drying time after cleaning, thereby significantly reducing production downtime in fast-paced environments. The system’s newly-designed, easy-to-clean reject bin comes with a raised window to provide easy viewing, along a lower grid base with drainage holes for quick draining following washdown cleaning. Moreover, the system’s height-adjustable feet have been designed to eliminate exposed screw threads, thereby helping to remove the risk of bacterial accumulation points and food debris traps within the system, while the use of metal cable hoops removes the need for cable ties and allows for thorough cleaning. In addition, the system uses blue plastic components—including pushers, guides, wear strips and PEC mounts— throughout the design of the machine to allow for easy visible inspection.

Loma Systems

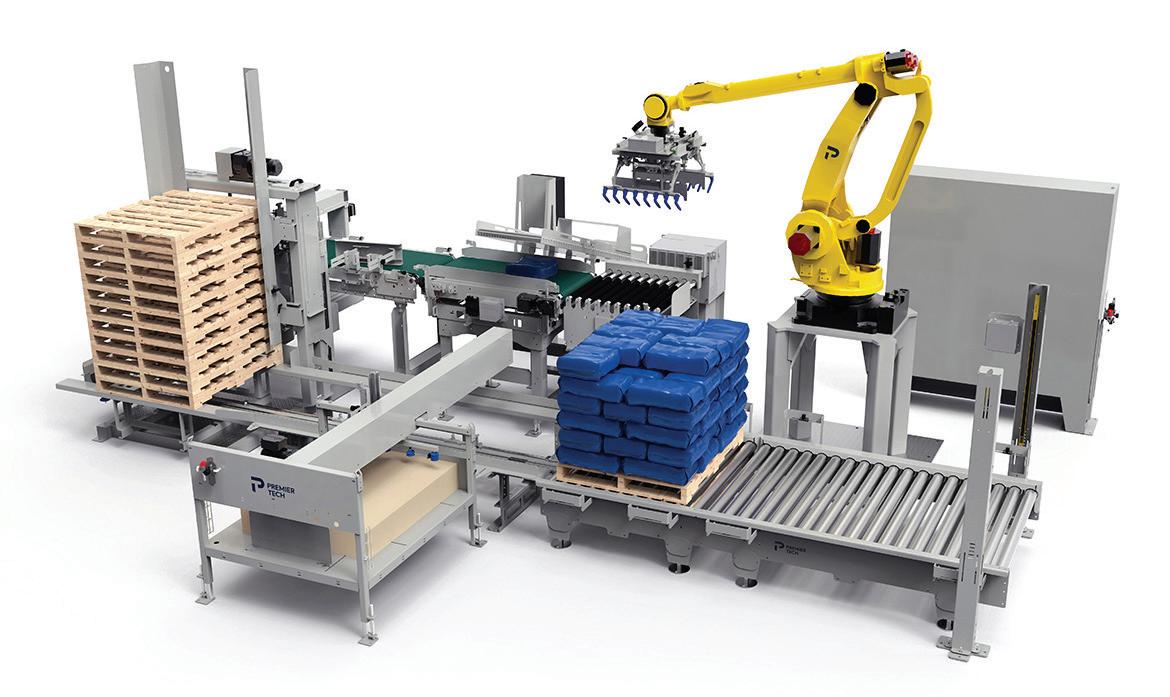

The new high-speed model AR-225 robotic bag palletizer from Premier Tech can palletize up to 25 bags per minute, while its pallet magazine and dispenser offer optimal versatility by being able to handle pallets of different sizes with minimal changeover downtime. Also capable of handling bales and bundles of different sizes, the system’s robot can be programmed to pick the slip and top sheets from a bin and place them on the pallet for applications requiring their use. Designed for low maintenance requirements, the fully-automatic AR-225 system incorporates the intuitive and user-friendly Pattern Expert interface—available in several languages—to allows users to easily modify existing palletizing patterns and to create new ones with highly accurate bag positioning.

Premier Tech

Capable of wraparound or two-sided operation, the new model 362E labeler from HERMA US Inc. is a flexible, high-throughput labeling machine designed for high-speed application of front-and-back or wraparound labels onto a broad variety of products, including disinfectants, cleaning agents, shampoos, shower gels and roll-on deodorants. Outfitted with two HERMA 500 applicators for two-side labeling—with the option for integrating a third applicator, or hot-foil printers and thermal transfer printers—the 362E system can label up to 200 products per minute on both front and back, handling an extensive range of products sizes, shapes and dimensions on both two-sided and wraparound operations.

HERMA US Inc.

Offering intelligent and simple operation, the new sturdy ASL300 shrink labeler from AMAC Technologies can apply heat shrink labels and tamper-evident bands at speeds up to 300 containers per minute, while handling a broad range of bottles, cans and canisters that are made from glass, plastic, tin or aluminum. Boasting a compact, cantilevered design for easy installation and changeover, the sturdy ASL-300 labeler incorporates a powerful servo motor and a dual-roll film unwind and feed system to allow for continuous operation with only brief splicing stops, with the label feeding mechanism featuring multiple tension-control dancers for jam-free feeding. Providing remarkable versatility that enables it to work with a broad range of containers shapes and sizes—round, oval, oblong or square, ranging in size from a few ounces to multiple gallons—the ASL300 can also bundle two-for-one promo packs or apply tamper-evident seals and other kinds of neck bands, as well as shrink labels with perforation that fully extend over the top of the container. Optional custom features include a cradle belt stopper to allows labels to be applied to the middle of containers; vertical and T perforation units for add perforation to labels, such as for temper-evident bands; a label tamp-down device to ensure the label is properly

pressed down against the container for shrinking; a dual timing screw assembly to hold non-round containers in place during labeling; and motorized height adjustment to ensure faster, simpler and more accurate height changes during the container changeover.

AMAC Technologies

Developed to provide an economical solution for e -commerce packaging applications, the new OmniPack family of stock PET (polyethylene terephthalate) plastic bottles from Amcor features the same diameter with the same finish for all bottles, requiring only height changes to accommodate the varying fill volumes for the packaged liquids. Available in eight-, 10-, and 12-ounce sizes with a 38-mm finish that accepts continuous-thread or beverage-style closures, the OmniPack containers can help reduce or eliminate the need for secondary packaging, according to Amcor, while offering a lightweight, shatterproof, reclosable, resealable, reusable and recyclable packaging solution that also meets all of Amazon’s PFP (Prep-Free Packaging) requirements for shipping.

Amcor

Product coding and marking systems supplier Squid Ink Manufacturing, Inc., has developed a new food-grade red ink for use with the company’s Streamline 5 and JetStream series CIJ (continuous inkjet) printers. Designed for printing quality codes directly onto eggs, cheese and other edible products, the FDA -compliant SI-CIJ9351 food-grade red ink is also well-suited for applications where the food package may not create an effective barrier against ink migration, according to the company. The new food-grade ink utilizes the same simple quick-change cartridges as all other existing Squid Ink CIJ fluids, whereby clean cartridges of ink and make-up can be replaced in seconds without having to stop production.

Squid Ink Manufacturing, Inc.

(Div. of Engage Technologies Corporation)

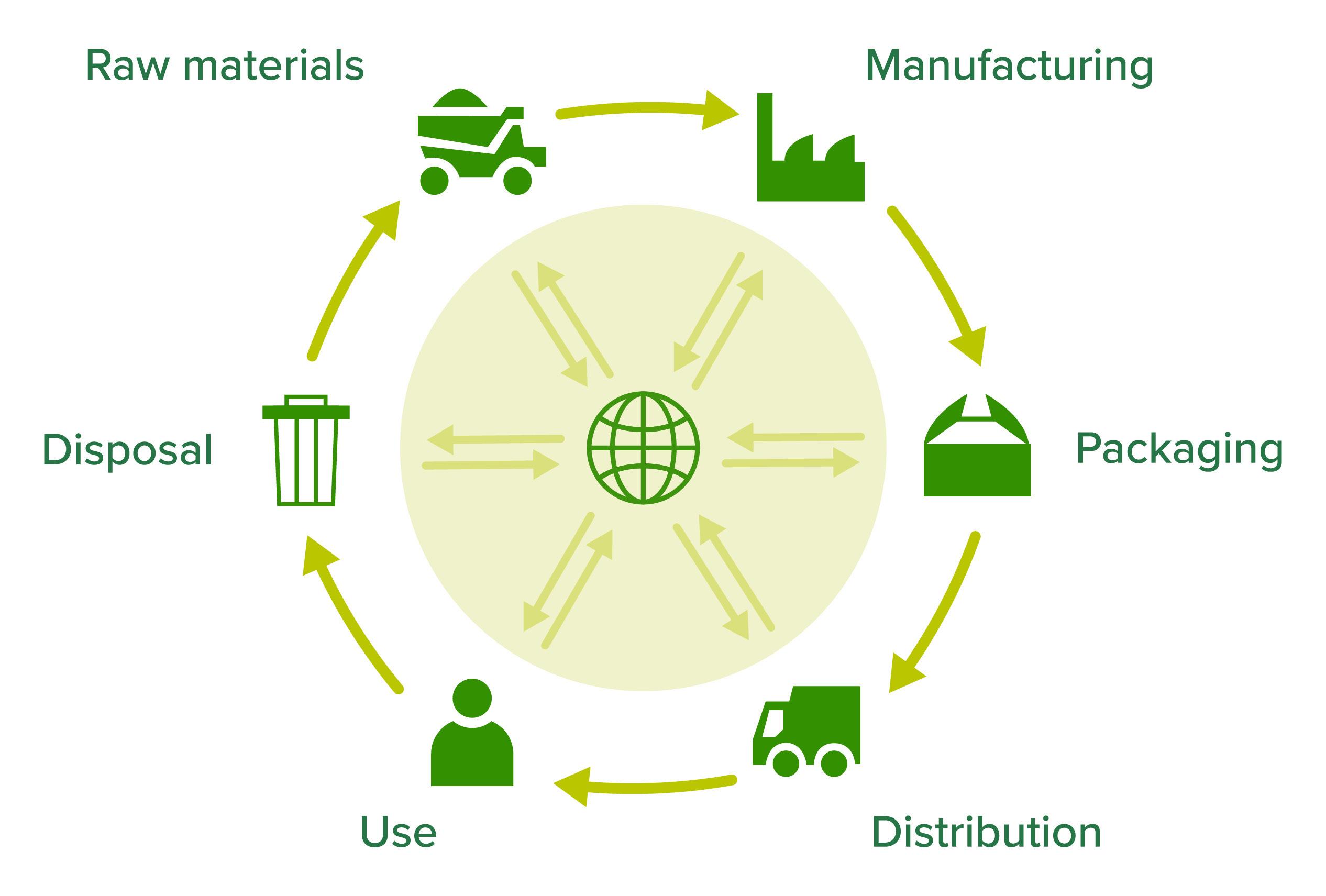

Why Circular Economy and Bio-Economy are really two sides of the same coin

BY IAN LIFSHITZ

Think about the last item you purchased and threw away: did you consider where the said product would end up once in the trash?

In our age of mass consumption we are producing waste at alarming rates. Although this trend has been slowly changing at last, consumer desire is radically shifting to more sustainable practices.

Consumers more than ever are vocalizing how they expect the companies they engage with, including the brands they patronize, to collaborate and provide products and services that help promote an eco-friendly way of life and contribute to the emerging Circular Economy business model.

When considering a sustainable path forward, organizations and decision-makers would be remiss not to consider the role suppliers play driving sustainable production.

Ultimately, the supply chain economy is part of one interconnected ecosystem, where end products have longer life-spans and the ability to re-enter the cycle for reuse.

With this in mind, sustainable supply chain development requires holistic strategy to achieve meaningful results.

Many companies are working to blend the Circular Economy with the BioEconomy to ensure that a sustainable closed system forms the key of their operations.

The combined approach examines how a sustainable product process can leverage compostable and recycled materials, resulting in less waste production and smarter use of renewable materials.

Alignment with the Circular Bio-Economy encourages industrial symbiosis and a clear move away from the take-make-waste approach to manufacturing. It means finding opportunities to change how we do things while maintaining the benefits we derive from ecosystems.

Supporting a green supply chain from start to finish can make a big difference in developing sustainability initiatives.

Green supply chains must support a global industry with responsible business practices by protecting forests, peatlands and biodiversity, and working in harmony with local communities.

Companies across the globe have undertaken this new consumer demand, radically transforming their business practices to becomes industry leaders in their respective fields.

From the implementation of satellite technology to track logging operations to the development of new packaging systems not reliant upon harmful plastics, companies are now more than ever heeding the call to action.

Businesses are always looking into innovations that’s could play an integral role in the sustainability mandates.

For example, since 2016 APP has been engaged in a strategic partnership with MDA , a Canadian company that forefronts such an innovation.

MDA’s aim is to help businesses leverage technology to provide transparency and customer assurance that their products are produced sustainably right from the forest level, the first part of the Circular Economy.

To that end, MDA’s space-borne RADARSAT-2 radar imaging sensor images through clouds to enable proactive and persistent monitor of forest cover loss in conservations areas through their Forest Alert Service (FAS), which could stem from planned jobs, natural loss stemming from disasters, and illegal encroachment on conservation land.

Industries across the board are also looking for ways to directly reduce their carbon footprints.

From reducing the amount of water they use, to reducing their actual greenhouse gas emissions, many companies are moving in the right direction.

The pulp and paper industry have seen such changes over the past 10 years. For example, from 2013 to 2018 APP reduced their water consumption rate by 24 percent and their greenhouse gas emissions by 18 per cent.

Companies are also investing vast resources to ensure their power consumption comes from renewable energy sources, some even going as far as using their own byproducts as fuel itself.

By using byproducts that include palm shell, biogas and sludge waste, and by implementing other progressive practices, APP has been able to shift 54 per cent of their energy consumption to renewable sources.

Everyone knows that he food takeout industry has been exponentially growing over the past 10 years, in the process creating a substantial amount of waste.

With more food deliveries comes more packaging, and the need to ensure that businesses and consumers are able to get serviced with sustainable options.

As consumer demand for sustainable products continues to rise, businesses are adapting their supply chains and processes to ensure that they provide sustainable, recyclable and fully compostable solutions.

Responding to this increase in demand, APP developed the Bio Natura Foopak line of products (picture above) to replace plastic and foam packaging with a fully sustainable and compostable product made from lightweight virgin paper alternatives.

Further innovations along these lines will allow the food industry to continue to meet demand, while appeasing consumer’s growing appetite for sustainability through sustainable investment and strategic business partnerships.

Ian Lifshitz is vice-president of sustainability & stakeholder relations at Asia Pulp & Paper Canada (APP Canada) in Brampton, Ont.

From food to pharmaceuticals, Heat and Control® supports you with ef cient and reliable equipment for weighing, container lling, conveying, packaging, and inspection. With more technicians in more locations, we also offer the industry’s most responsive technical support.

info@heatandcontrol.com

Helping customers adapt to changing flexible packaging needs has been at the core of our business for over 50 years. When our customers responding to COVID-19 needed us, we acted—fast—by shipping on-hand inventories immediately and expediting priority orders. Our dedicated team then increased output 60% to meet urgent needs from essential industries. We’re proud of our team, customers and partners supporting the health, safety and well being of people around the world.

Be certain. Let our team support yours today.

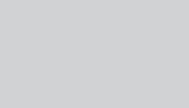

Hometown craft brewer giving it all it got in the tank to help keep the COVID-19 pandemic at bay by using its distilling expertise to produce much-needed hand sanitizer

BY GEORGE GUIDONI, EDITOR

PHOTOS BY NAOMI HILTZ

If home is where the heart is, then residents of the southwestern Ontario city of Oshawa can rest assured that the industrious young entrepreneurs behind the recent start-up of the city’s first real microbrewery have their heart in the right place.

For All or Nothing Brewing & Distillery cofounding brothers Jeff and Eric Dornan, who started out in the craft beer industry in 2014 using various co-packers to bring their brand to market, a chance to realize their vision of running a thriving microbrewery where they both grew up and went to school was the proverbial no-brainer from the moment the opportunity came knocking on their door.

As Jeff Dornan fondly recalls, it was initially all about location, location, and location.

“Although Oshawa has lived in the shadow of the big General Motors plant here for many years, there is a lot going on in Oshawa that people outside the city may not know about,” says Dornan, who graduated from the local Durham College & Ontario Tech University before joining their father’s sales and service business in the early 2010s.

“My brother and me both view Oshawa as a fantastic city: a city which has its own port, an airport a big downtown core, a large sports arena and countless other big-city amenities all within the city limits,” Dornan extols.

“And despite what has been going on with the GM plant in recent years, Oshawa is very much a booming city,” says Dornan, recounting the momentous decision a couple of years ago to acquire an abandoned but historic downtown Oshawa building that had been used as The Beer Store retail outlet since the 1950s.

After spending a couple of years operating All or Nothing in Oakville, Ont., where Dornan brothers purchased a small brewing and distilling facility in June of 2016, “the idea of bringing our business back to where we started was really exciting for us,” Dornan recalls.

Situated on Ritson Road South in close vicinity to the GM automotive plant that employed nearly 30,000 workers back in its glory days, the

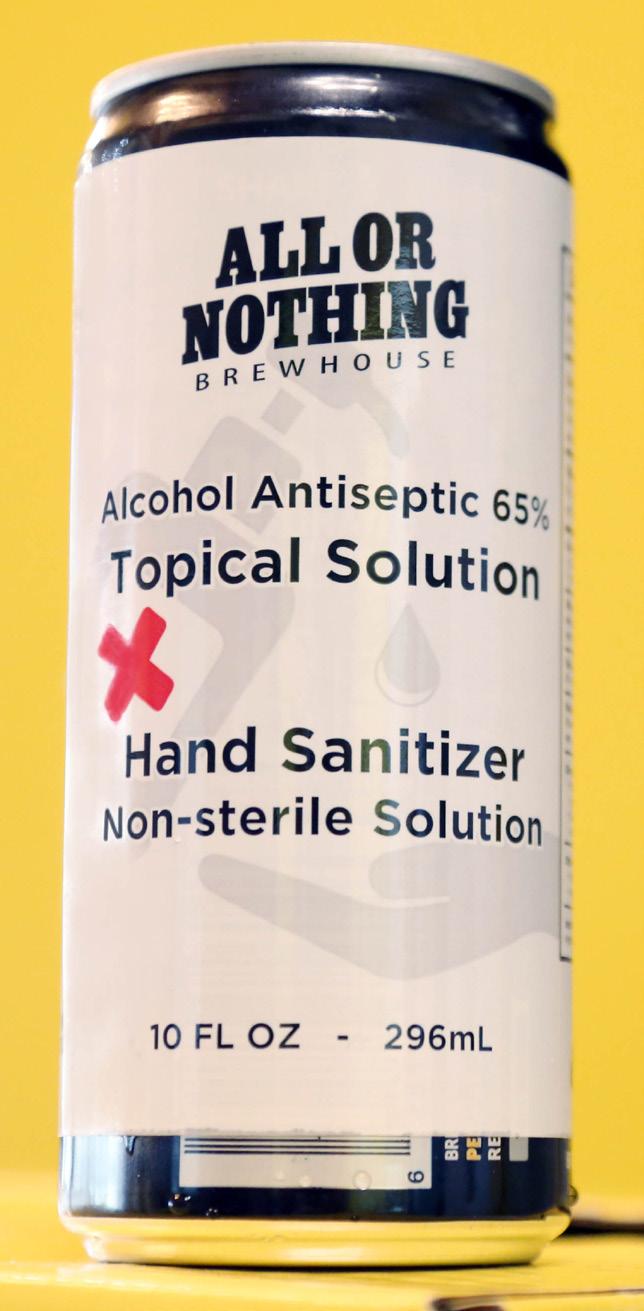

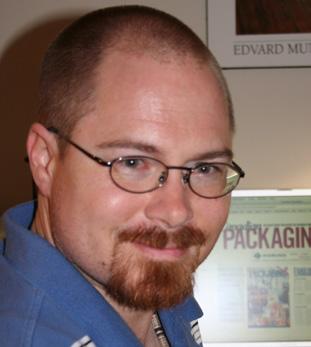

All or Nothing co-founder and owner Jeff Dornan (right) proudly displays samples of the non-sterile hand sanitizing solution that the company has been producing at its new Oshawa facility since early March to help alleviate the desperate shortage of hand sanitizing solutions in the marketplace caused by the sudden outbreak and spread of the coronavirus.

25,000-square-foot facility was at one time one of the busiest beer stores in Ontario, but changing fortunes saw it sit idle for about eight years before the Dornan brothers proceed to acquire it in 2018.

“We had to do a lot of heavy renovations, electrical work, plumbing, painting and a tonne of other repairs to get the place up-and-running,” Dornan recalls, “but we were so passionate about bringing the building back to life that the time flew by really fast.”

Aside from renovation and reinstallation of all the key brewing and production equipment relocated from Oakville, All or Nothing also installed a sleek and modern storefront to sell its beer and brand merchandise, along with a welcoming outside patio area for customers to enjoy some of their purchase on-site.

“We are very proud of what we have done with the place,” says Dornan, who actually resides a short eight-minute drive away from what is now once again an elegant and contemporary commercial landmark with welcoming exterior and storefront area.

But while the facility’s festive grand opening to the public last June was filled with promise of glorious days ahead, the sudden global outbreak of the deadly COVID-19 virus this past winter has naturally put the early expectations of continued brisk growth on hold for the time being.

“We were having some very good early success before COVID-19 came around,” Dornan recounts, “but like everyone else, we had to adjust our thinking.”

But rather than merely accept the new reality of social distancing and retail lockdowns as a de facto new normal, All or Nothing decided to do its part in the collective pushback against the pandemic’s spread by retooling a substantial part of its production capabilities to manufacture non-sterile hand sanitizing solution that quickly became one of the most sought-after essential commodities in combatting the virus.

“We heard about people hoarding sanitizer at the start of the outbreak,” Dornan recalls, “and because we used to produce alcoholic coolers and spirits back in Oakville, we had the knowledge, and the equipment and supplies, to switch over to the production of sanitizer pretty swiftly.

“So we temporarily halted the production of beer altogether to make as much tank space available for converting sugar and water into alcohol, which would be distilled into the ethanol.

“It takes about three to five days to ferment the sugar water into alcohol, and then about an eight-hour shift to distil and dilute that into the final 65-percent ethanol solution,” Dornan relates. “So we would go through 4,000 liters of sugar water to turn out about 500 liters of ethanol that we would then dilute, mix and blend to the exact specifications.”

As for packaging the final product, Dornan had to look no further than the significant leftover inventory of unused 296-ml aluminum cans, manufactured by Crown Beverage Packaging, that All or Nothing also brought in from the former Oakville location.

“After I found out there was a big market shortage of spray-pump type dispensing containers typically used to package sanitizer and soap products, using our inventory of 296- ml cans, previously used to package coolers and some limited-run products, seemed like a perfect solution.”

Since commencing sanitizer production in early March, the brewery has produced well over 100,000 cans of the All or Nothing Hand Sanitizer brand solution—distributing them a diverse list of healthcare, industrial and commercial facilities caught offguard by soaring demand for sanitizing and disinfecting solutions essential to containing the COVID-19 spread.

“Now that there’s been more and more sanitizer products coming to the market, things have calmed down a little bit,” says Dornan, grateful for the opportunity to return some of the plant’s capacity back to its original purpose of making beer.

“It is possible for us to produce both products for the time-being,” says Dornan, naturally eager to focus on ramping up beer production for the upcoming summer season, while also making make up for the lost downtime.

While the company plans to use up the reminder of the slim 296-ml cans it currently has in stock for the sanitizing solution if necessary, about 80 per cent of all beer produced at the Oshawa facility to date has been

Manual case-packing can be a time-consuming joyless chore, with inconsistent results, whenever you have to apply glue or tape to each box by hand to close it shut.

But for smaller-sized companies without an automatic case-packing system in place, the answer to greater secondary packaging efficiency often lies in the box itself.

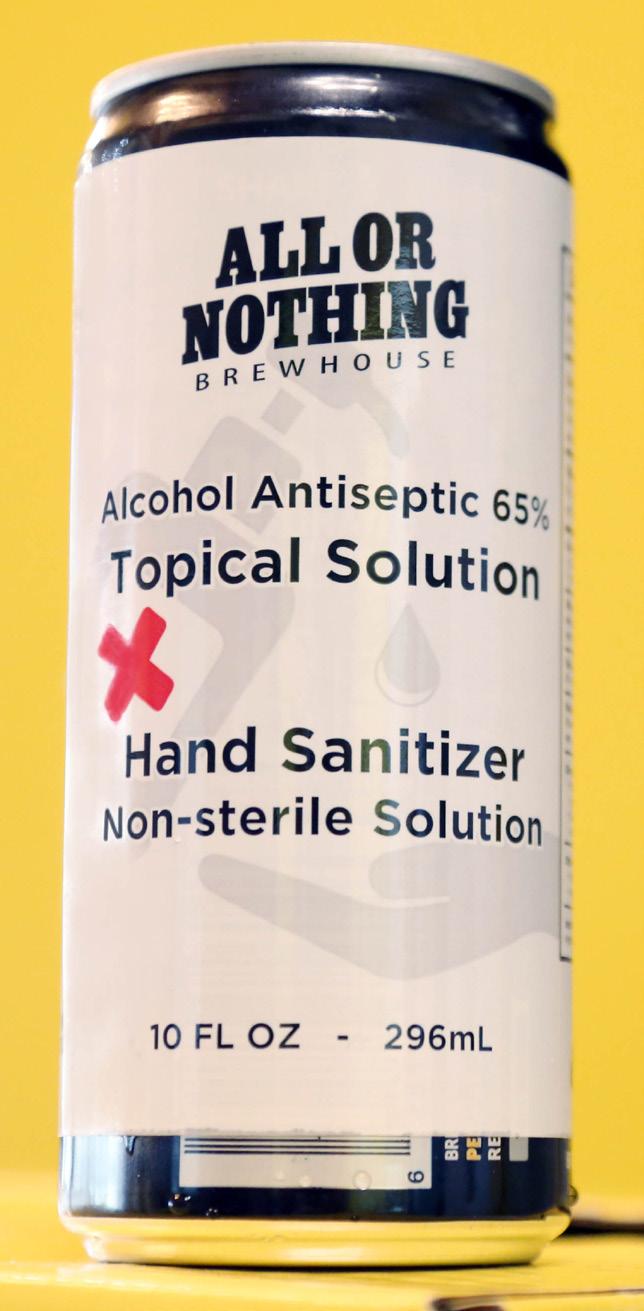

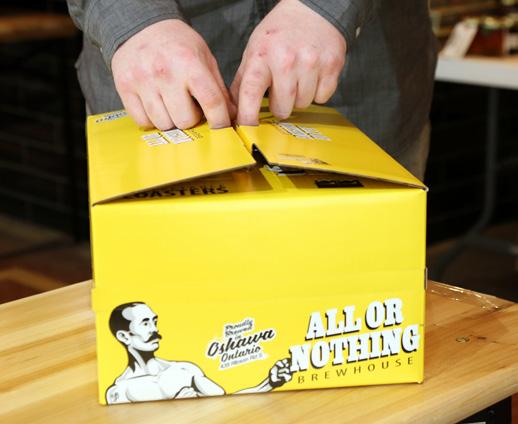

For Oshawa, Ont.-based craft brewer All or Nothing Brewhouse, shipping 24-packs of its canned beer to LCBO (Liquor Control Board of Ontario) outlets and other retail customers has been a fairly smooth ride— thanks to the use of special auto-lock bottom boxes produced by the IMGN retail and branded product division of Cascades Containerboard Packaging in Toronto.

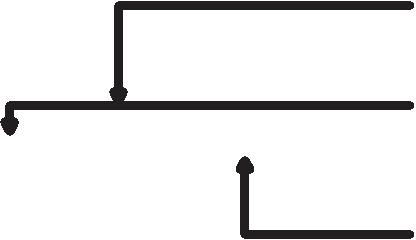

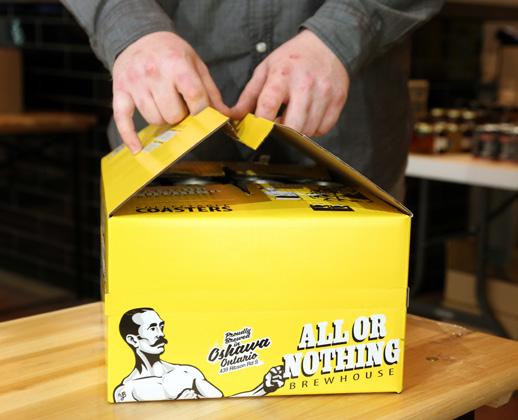

Featuring a fully-automatic bottom and product entry from the top of the box, the tuck-style Hymes bottom corrugated boxes are folded in seconds by gently manipulating the corners in a swift sequence to erect the box, while creating a secure, high-strength bottom. (See below)

The bottom structure of the box includes four bottom panels connected to four side panels, respectively, whereby each of the side panels is connected to an adjacent side panel along first folding lines, while the bottom panels are connected to the side panels along second folding lines.

All or Nothing owner Jeff Dornan has nothing but praise for the quality and sturdiness of litho-printed B-flute auto-lock bottom boxes printed on a KBA sheetfed printing press in a two-color process to create strong shelf presence with vibrant, cartoonish black-and-yellow graphics created by his brother Eric Dornan and a local graphic artist Matt Dyck.

“We worked closely with Cascades to design all the die-cut lines and folds to make this box not only easy to fold into place, but also to be easy to open with a friction top that releases our brand mascot cutouts to literally ‘pop out’ of the box when opened,” Dornan says. (See bottom of page)

“It’s a very unique box that way, something that we have not seen other craft beer companies do, he adds.”

“Cascades has been a fantastic partner for us to work with,” says Dornan, “and they have done a great job for us in helping us express our creativity to consumers through attention-grabbing packaging.

“When we worked with Cascades on the initial box design, it was important for us to remove the need for glue-lined case tops, and with this box design, which they did with the tuck-in top panels that hold the artwork in place until popping out of the box when opened.”

As Cascades’ IMGN division Accounts Manager Dave Cawthorne recalls: “I first met the Dornan brothers at a craft beer festival in Toronto six years ago when they were first starting out, and they have been a real dream client to work with.

“Using the auto-lock bottom box to package beer is still a rather novel approach to packaging in the craft beer business,” Cawthorne notes, “but it has worked really well for them by eliminating the need for all the extra steps and equipment required for taping or gluing boxes together after filling them.

“We worked closely with All or Nothing to develop their combination shipping/retail-ready case to incorporate easy-tear perforations around the box that enable their retail customers to remove the top layer of the box with virtually no effort,” Cawthorne adds.

“The end result is an engaging shelf display solution for selling their cans individually, straight out of the box, that still packs a lot of great graphic appeal,” he states.

“The craft beer section of the LCBO stores can sometimes overwhelm the consumer with all the different colors and SKUs (stock-keeping units) screaming out for attention,” he says, “but the All or Nothing boxes’ bold and straightforward yellow color-block scheme really cuts through the clutter to command the consumers’ attention.

“We are really happy to have enjoyed such a mutually respectful professional relationship with All or Nothing over the years,” Cawthorne sums up, “and we are looking forward to continuing it as they continue to grow their business further at their fabulous new brewhouse in Oshawa.”

packaged in the industry-standard 473-ml Tallboystyle cans, also supplied by Crown.

This includes the company’s three leading beer brands, comprising: Think Big’Ger Cream Ale; Hustle Over Hype Pale Wheat; and the Snooze You Lose Brown Ale

Dornan says the company’s ale products were largely inspired by some of the Old World Englishstyle beers, while the wheat brand beer was developed according to timeless wheat beer recipes originating in Germany centuries ago.

In addition to this core year-round product lineup, Dornan says he is proud of the cult-like status

in the craft-beer market enjoyed by the company’s innovative Mind Over Matter Mead Braggot beer infused with fermented honey, the main ingredient in alcoholic mead beverages.

With a hearty seven-percent alcohol content per volume, Mind Over Matter is still packaged in the slimmer 296-ml cans that, according to Dornan, “give it a unique personality and shelf presence at the retail level.”

Dornan explains: “It’s a very balanced mixture of barley and fermented honey with a very subtle profile and aftertaste that makes it truly unique, hence we package it in 296-ml cans that are also unique to

us in the marketplace.

“It’s a product that has some real historical merit to it,” Dornan says, “so we treat it like a special side project especially close to our heart.”

As Dornan relates, the ability to express oneself creatively through new product development is one of the craft beer industry’s more compelling reasons for getting into the business, which has been growing at double-digit rates through most of the last decade.

“When we first started out six-and-a-half years ago, there was only about 40 microbreweries in all of Ontario,” says Dornan, who also serves as chairman of the industry’s leading trade association Ontario Craft Brewers (OCB)

“Today there are over 300 brick-and-mortar microbrewing facilities across the province,” Dornan states, “so we picked a good time to catch the earlier wave of this tremendous craft beer renaissance of the craft brewing business.”

With current annual production capacity of 5,000 hectoliters, Dornan says the company is “somewhere in the middle of the pack” of Ontario craft brewers in terms of volume, but he quickly points out that boosting capacity strictly for the sake of raising volume was never the company’s goal to begin with.

As Dornan explains, the company’s steady success in the market to date—with All or Nothing brands now sold at well over 200 LCBO (Liquor Control Board of Ontario) outlets—has been achieved by focusing on a few selected beer styles that it has identified as its most promising segments, through both experience and continuous R&D (research and development).

“Once we focus on something, we go all out wholeheartedly,” he says, citing “obsessive personalities” driving both Dornan brothers’ shared ambition and drive to succeed.

Currently employing eight people to keep the new Oshawa operation running over a one-shift,

Monday-to-Friday production schedule, Dornan is confident that the significant capital investment poured into the new Oshawa brewery will help the company achieve for a whole new level of growth in coming years.

“Like any other new business, we’ve had our peaks and valleys in the past six years,” Dornan says, “but overall our business is up significantly from our early days.”

According to Dornan, All or Nothing already enjoys a lot of local goodwill and brand loyalty by virtue of being a locally-founded company, and he says the company has big plans for making the brewery a prominent local event venue and a social gathering point after the pandemic crisis subsides.

“We definitely have some great capabilities at our facility with all the extra square footage,” Dornan proclaims, “and all the tools we need to succeed.

“While we spent a lot of time literally filling holes in the ground to bring this building to life, we have also been busy identifying key areas for process improvement, like grain handling for example, and focus on fixing them.

“There is a lot of science involved in the beer making process that we had to learn,” Dornan recalls, “along with understanding all the many inputs in the production process: from the mineral content of the source water to all the different fermenting techniques, the supply logistics, the production line layout, process documentation … thousands of decisions that need to be made to ensure consistent product quality going forward.

“It’s something that we have always done in the past to build the business up block by block,” he says, “and with this great new facility, we feel like we are really ready to make a strong statement in the marketplace.”

Says Dornan: “What attracted us to the craft beer business from the start was an opportunity to offer Ontario consumers a locally sourced product and the opportunity to be really creative about making and marketing such a product.

“We just love the whole story of the craft beer industry, the whole David versus Goliath angle,” he states.

“While we may be just a fraction the size of the major brewers, we believe that our strengths in creativity, speed-to-market, and being nimble and flexible will enable us to compete with anyone out there.”

This fighting spirit is boldly captured on the vibrant and punchy packaging cartoon graphics—featuring a slim bare-knuckled street brawler named Cornelius raising fists against a large monster foe—created by his brother

All or Nothing co-founder and owner Jeff Dornan strikes a cheerful pose outside the Oshawa brewery alongside the refurbished vintage model Mighty Moonshine 3800 series one-tonne truck originally produced at the Oshawa General Motors plant’s old truck line back in the 1950s.

The beginning of a new labeling era

n Modular, flexible labeling technology

n New open design

n Automatic docking

n Available in six table diameters and seven labeling station types

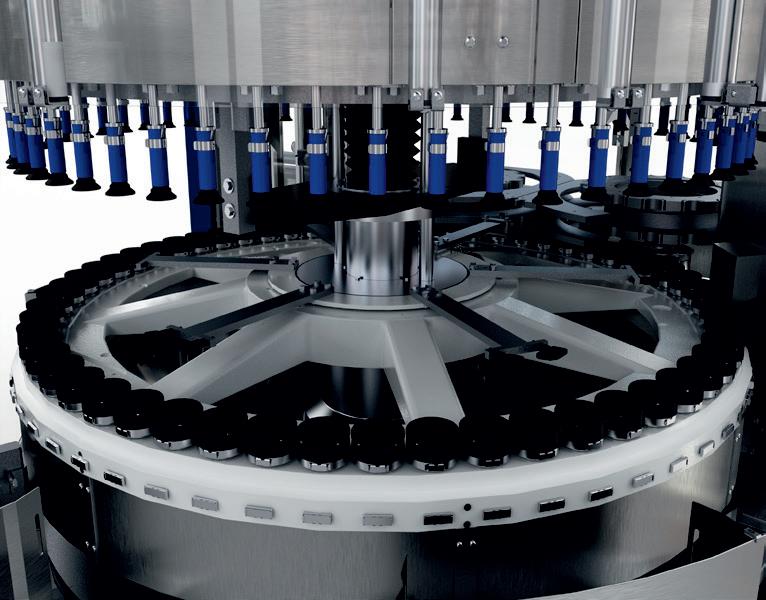

n Speeds up to 81,000 containers per hour

Michael Soloway Krones, Inc. (414) 207-1612

michael.soloway@kronesusa.com

Eric and local graphic artist Matt Dyck.

“It’s all about projecting a confident image that All or Nothing is not afraid of anyone out there,” says Jeff Dornan, “and is always giving it all we got in everything we do.”

Printed in bold back against a high-gloss yellow background, the instantly likeable Cornelius mascot makes numerous appearances not only on the cans of beer themselves, but also on the surface and the inside of the distinct black-and-yellow 24-pack corrugated cartons used to ship the All or Nothing beer brands to LCBO stores and other retail customers.

Expertly manufactured by Cascades Containerboard Packaging at the company’s IMGN retail and branded products division plant in Toronto, the two-color litho-printed cartons were designed as combination shipping/retail-ready cartons featuring an innovative auto-locking bottom feature that enables the brewery staff to assemble and load the case manually in seconds without using any tape or glue. (See Sidebar)

“That is a really big thing for us,” says Dornan, praising Cascades for the sturdy construction and strength of the single-wall B-flute cartons, along with easy-tear die-cut perforations for removing the top of the boxes.

As the tops are removed, the cutout inserts of the brand mascot Cornelius pops out from the inside on one side or the case, squaring off against its much larger opponent Lennox, also popping up in a ready-to-go pre-fight stance.

“Our customers seem to have as much fun with these characters as we had developing them,” says Dornan, adding each 24-pack case also comes with a couple of branded coasters pressed against a sidewall inside.

“Cascades really did a fantastic job for us with these boxes,” says Dornan, citing warm feedback for the box design from the LCBO staff and individual consumers, some of them actually taking time to make humorous media postings of the brand mascots ending up in unlikely places.

“It’s been a little secret of ours that we think helps us make a positive long-lasting impression on the Ontario consumers,” says Dornan.

“I think it really captures the essence of our company’s spirit and culture of giving it all we got when it comes to producing highquality beer for the people of Ontario to enjoy and have fun with,” Dornan concludes.

“Hopefully, we’ll be doing much more of this in the weeks and months to come.”

Since electricity powers the wide majority of industrial and infrastructure equipment, it is becoming more important to ensure that this incoming power does not damage the equipment it’s meant to power. Besides monitoring DC signals, one-phase AC signals, or the three-phase AC mains voltage entering into a building or a room, monitoring of the equipment or machinery within the building is just as important.

Machine and equipment monitoring devices detect abnormalities in the incoming power, and permit preventative actions to be taken to protect equipment before any serious damage can occur.

Here are nine helpful tips on selecting the proper monitoring device for your machinery.

Machinery monitoring devices and relays provide a multitude of preventative options. You’ll want to select a relay or device that is capable of monitoring the most critical aspects of the supplied power for your application.

Monitoring relays are designed for voltage, current, frequency, three-phase power, power factor, or temperature. For each relay type, you’ll want a clear delineation of the acceptable tolerances and measurement parameters for your application.

Many types of heavy industrial equipment rely on 3-phase power. Inconsistencies or anomalies in this power quality can cause disastrous damage to machinery or equipment.

Inconsistencies in the three-phase power can include phase loss, improper phase sequence, and/or an imbalance between the three phases.

Many of these situations can be averted through the use of a three-phase monitoring relay. If a motor operating on three-phase power were to suddenly receive two phases out of sequence, it will reverse direction. This not only poses a threat of damage to the motor, but it could also pose a safety risk in applications such as elevators, moving walkways or conveying equipment.

Losing one of the three phases of incoming power can render a motor unable to operate, or force it to operate at a lower efficiency rating. In addition to decreased performance, the latter mentioned consequence can lead to heat generation within the motor, which shortens component life. A similar result can occur if all phases are present, but one or more of the phases is underpowered because one-phase loads are drawing power unequally on one or more of the three phases.

Powering devices, such as motors, on a voltage that is lower than specified causes the load to draw more current.This then leads to inefficiencies and excessive

heat that will lead to shortened component life.

Overvoltage can also cause component stress, resulting to permanent damage of some parts.Voltage monitoring relays can handle anywhere from a low millivolt range up to several hundred volts. There are, however, versions that monitor under and/or overvoltage, some offering adjustable hysteresis and time delays.

Voltage relays for DC voltage are often used to monitor back-up battery status, such as those found on generator sets or solar power systems.

Relays designed for one-phase AC work well for motors, which could possibly be used in a variety of countries, where different supply voltages are present and/or in areas where voltage fluctuates, causing brownouts and/or voltage surges.

Current can be used as an indication of proper machine function. Equipment that suddenly starts drawing more current might be experiencing a voltage imbalance, an impending bearing failure, or a number of other issues. Current monitoring relays help detect these variances, allowing for action to be taken before equipment damage occurs.

Low-current AC or DC inputs can be directly connected to most monitoring relays, and AC currents up to 100 A can be monitored by some modules directly. However, higher currents need to be monitored through a shunt or current transformer.

Power monitoring relays can also detect variations in the power consumption of various loads. Depending on the relay, you can detect and react to load excess or absence, motor load variation, and motor direction.

In addition to DIN rail mount or plug-in monitoring relays, some manufacturers of these protective devices have integrated monitoring relays with current transformers, creating an all-in-one solution.

They typically provide a relay, transistor, or analog output, with some even requiring no supply voltage. The current monitoring device with integrated current transformer is an innovative concept which allows you to run the wire carrying the AC current right through the device’s through-hole, therefore simplifying installation and minimizing wire connections.

Knowing the temperature of your equipment can help prevent equipment downtime or even fire. Temperature monitoring relays use PTC thermistors, mounted in motors, whose resistance increases with rising motor temperature. They are capable of monitoring the temperature of up to six motors or motor windings simultaneously, and can be used to shut down motors during overheating, thereby preventing damage to the motor.

With monitoring relays, you can set up the device to immediately interrupt power to the equipment, similar to the operation of a fuse.

More commonly, the monitoring relay signals a shutdown relay that is applied to safely power down the equipment. If minor variations of voltage, current, or frequency are tolerable, you can utilize a monitoring relay with adjustable hysteresis and time delays.

These types of relays can prevent nuisance tripping in the instance of occasional sags or spikes in the incoming power, but the choice is ultimately up to you.

Many design engineers look at machine monitoring relays like an insurance policy. Some higher efficiency industrial motors can cost thousands of dollars, whereas monitoring relays typically cost from a few hundred dollars, usually one-tenth of the equipment cost.

When considering the initial cost, remember that machine monitoring relays can protect machinery and help reduce the cost of both downtime and damaged products, which in turn provides immediate payback. To get that extra peace of mind, always specify and select relays with approvals like UL or CE appropriate for your application.

For more help in selecting machine monitoring relays, turn to automation experts such as Carlo Gavazzi, who have extensive product literature and selector guides on their websites to help you get the right product. They also have international distribution and experienced personnel who can assist you by email, phone, Skype or in person.

For more information on machine monitoring relays, please go to www.gavazzionline.com

BY MATT REYNOLDS

Ideal for breakfast, on-the-go snacking, children’s lunches, or even large receptions, a diminutively sized pastry called Micro Croissant has been a big hit for a well-known Canadian baked products manufacturer La Petite Bretonne in Blainville, Que. Big enough, in fact, to make the 54-year-old, family-owned bakery to make plans to become capable of produce as many as 1.2 million micro croissants per day, in different flavor varieties like Danish and mini chocolate croissants.

While some percentage of this high-volume product—alongside multiple SKUs (stock-keeping units) of cookies, madeleines, and more traditionally sized croissants—are sold under the company’s flagship La Petite Bretonne brand, most of the croissants are produced for store brand, in-store retail, private-label and foodservice applications throughout North America.

It may sound like a lot of croissants, but La Petite Bretonne is uniquely comfortable with this kind of volume.That’s because, since the inception of the business, founder and chief executive officer Serge Bohec has pioneered pastry and croissant automation.

While such products had been traditionally limited to small batches that were baked in artisan shops, continuous investment in automation over the years has enabled the bakery is now capable to achieve that artisan quality at a high-volume scale.

In fact, Bohec and La Petite Bretonne were so ahead of the game with automation that they had to wait for consumers—particularly French Canadians with a discerning eye for pastry—to come around to the idea of croissants as a pre-packaged food on a shelf or in a carton.

As Bohec confides, the initial rollout of a pain au chocolate [chocolate croissant] product in 2010 didn’t pan out because consumers just weren’t used to seeing croissants in a flowwrapped package.

But these days, after a decade’s worth of trends like on-the-go snacking, single-serving sizes and convenience, the consumers have warmed up to the idea of Danishes and croissants being produced at an industrial scale.

“Consumers of these croissants want fresh products, but they also don’t want to have to rewrap the products at home for their kids’ or their own lunches.

“They want something that is easy,” says Audrey Laurin, La Petite Bretonne’s chief financial officer.

“They are stressed, and often there are two working parents feeding themselves and their kids, so they do not have as much time as previous generations had.

“These individually wrapped products keep longer, as well,” Laurin adds.

As the flowwrapped chocolate croissants and Danishes took off, Bohec recognized that sophisticated equipment was in order.

But any new pick-and-place and flowwrapping sys-

tem that Bohec might select would need to accommodate several different products on a single line, specifically Danish pastries and chocolate-filled croissants, both in two sizes. Moreover, these delicate, heat-sensitive products require exceptionally gentle handling.

With those obstacles in mind, Bohec set about to automate.

As he recalls, he first got a look at fully-automatic, high-speed lightline Flowpacker system, manufactured in Germany by Gerhard Schubert Gmbh, at the PACK EXPO International 2018 global packaging technologies and materials trade show in Chicago.

At that point, Bohec was already a bit of a Schubert connoisseur, having had collaborated with the reputable machine builder for more than a decade after becoming convinced that the industry’s future would lie in “employing” robotics, instead of humans, for executing simple, repetitive tasks such as picking and placing products on a conveyor.

Ever since, Bohec had been strengthening his company’s supply chain process automation. When he was sizing up that lightline Flowpacker at PACK EXPO 2018, he already owned several Schubert machines at two manufacturing sites, both for end-of-line automation and for individual pick-and-place and flowwrapping applications.

Fittingly, a year later at PACK EXPO Las Vegas

machine that was on display at the Schubert booth.

The Las Vegas show was in fact just a brief pit stop between the factory and the SAT (site acceptance testing), installation, and commissioning in Quebec.

Equipped with a Flowmodul flowwrapper, four pick-and-place robots, and a 3D vision system for detection and inspection, the now-up-and-running system operates currently employs four delta-style pickand-place robotic arms, but can expand modularly in case of increased volume or speed.

Bohec says he was particularly attracted to attracted to the lightline Flowpacker system’s new flowwrapping component, the Flowmodul, that can be seamlessly integrated into a pick-and-place line without interrupting the process flow.

Equipped with Schubert’s latest robotic innovation—the flying cross-sealing unit combined with ultrasonic longitudinal sealing—the Flowmodul enables La Petite Bretonne to not only integrate several processes into a single system, but to also the flexibly flowwrap heat-sensitive products.

According to Schubert, the Flowmodul’s exceptionally compact footprint, about 70-percent smaller than single mechanical flowwrapping lines, offers the bakery considerably more space to accommodate future

installations.

The flowwrapping process is fully integrated into the top-load machine (TLM) system and offers a slim, compact layout, whereby Schubert’s T4 pick-andplace robots gently feed the Flowmodul’s infeed system within a tight space. Compared to infeed conveyors in conventional lines, this solution avoids product abrasion and breakage by eliminating long infeed paths.

Moreover, the Flowmodul is also equipped with innovative new sealing technology for heat-sensitive products, whereby the flowwrap’s longitudinal seam is sealed first using an ultrasonic sealing unit, followed by Schubert’s patented flying cross-sealing unit.

Importantly, the flying cross-sealing unit adapts to the upstream pick-and-place robots without damaging the product or the film.

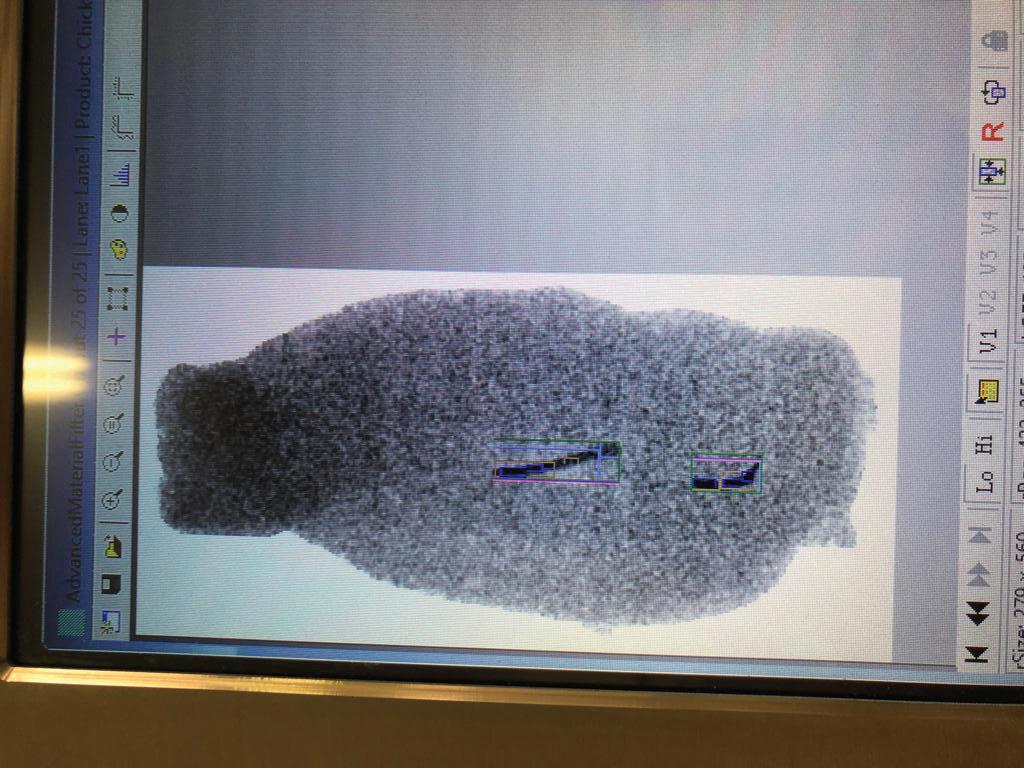

Using advanced image recognition, the Schubert 3D vision system checks each product’s position, shape, volume, orientation and color, and only allows flawless products to be processed.

“The sealing system means you don’t scrap the film or packaging materials,” Bohec says.

“An imperfect product will never be placed onto the infeed chain, so we never waste materials on it, and the seals are perfect, so they never cause scrap.

“The machine also checks the packaging’s seal quality,” adds Bohec. “When one roll of film is finished, another roll is swapped in automatically, without stopping. And with film being expensive, we avoid ever scrapping film.”

As the film is dispensed from the roll and travels to a die to wrap the product and eventually be sealed, a continuous inkjet coding system codes each individual product with best-by dates or lot coding.

The machine at La Petite Bretonne takes advantage of what Schubert calls the counterflow principle to efficiently produce flowwrapped Danishes and croissants.

To apply this principle, a conveyor carries loose, random product into the enclosed frame of the machine’s first module. As it travels into this frame, it

passes to the left of a parallel Flowmodul flowwrapping station, all within the same frame.

The product then travels into the frame of a second module, this one containing the 3D vision system for inspection and quality control. The product then enters a third frame, where it is carried past the four camera-guided delta-style T4 robots.

Here, the product is picked and placed onto a parallel infeed chain traveling 180 degrees in the opposite direction, back toward the first machine frame and the Flowmodul the product had already passed.

The product travels in a U-shape under the counterflow principle, whereby the raw product enters, and the flowwrapped product leaves the system from the same window in the machine enclosure.

Defective products, recognized in the second frame by the vision system, are never picked by the robots and end up discarded into a bin at the end of the infeed conveyor as it exits the third frame.

For their part, format changeovers are fast thanks to the Flowmodul’s integrated, fully automatic conversion feature that automatically adapts to different product lengths and shapes.

As is the case with most baked products, a significant amount of cooling must occur prior to packaging, especially when the primary package is made from film.

In this Danish line at La Petite Bretonne, product may travel 8,000 meters during a 98-minute travel through spiral conveyors, but to the lightline Flowpacker’s flexibility, no accumulation is required.

Bohec explains: “With this machine, you don’t need to have someone keeping an eye on production speed, because the machine automatically adapts to whatever the speed of production is.

“When it’s slow, the machine runs slow. When you have a lot of production, the machine goes fast automatically. It even stops automatically.

“And when you change the product, the robot changes the die in the flowwrapper.”

With its new system, La Petite Bretonne has been

able to significantly reduce the number of operators.

“For the speed we need, you would need six or eight people easily to keep up manually, and labor has been hard to find,” Bohec says.

Furthermore, the new system satisfies a larger, company-wide directive to simultaneously improve employee morale and deal with an ever-shrinking workforce.

“One consideration that we also had choosing this equipment is that we are trying to reduce the number of employees working on back-breaking manual tasks,” Laurin states. “Instead, we want to have fewer employees with better jobs and better pay, doing something less difficult.

“Operating equipment is a lot of responsibility, but it is not as hard physically as packaging by hand, counting by hand, or executing repetitive movements that can cause injuries.

“This is something that we are very aware of whenever we buy new equipment. Instead of lots of employees working in harsh conditions, we want a smaller roster of employees that, collectively, enjoy better working conditions.”

With the Schubert system in place, La Petite Bretonne now packages 183 Danishes per minute; 220 chocolatine croissants per minute; and 280 Mini-Chocolatines per minute.

As Bohec sums up: “For a high-output production line, this is the best machine in the world.”

This article was reproduced with permission of the Packaging World magazine, a PMMI (The Association of Packaging and Processing Technologies) publication based in Chicago.

production capabilities

Rotkäppchen and Mumm are two brands that practically all Germans are very familiar with. Since 1984, the brand with the red cap that lends it its name (Red Hood in English) has stood for sparkling wine from the town of Freyburg, located in the Saale-Unstrut wine-growing region of what was once called East Germany.

In 2002, with Rotkäppchen by then a national market leader, the company took rival brands Mumm and MM, made by Matheus Müller in Eltville in Germany’s Rheingau wine region further to the west, significantly expanding its fast-growing product portfolio.

Comprising various other sparkling wines such as Jules Mumm or Geldermann, branded spirits Chantré, Mariacron, Nordhäuser or Eckes Edelkirsch; and wines like Blanchet, these products which are produced, filled and packaged in countless variations at seven facilities in Germany and one in Italy.

The range of different packaging required is thus also sizeable, proving something of a challenge for production.

“Up until now we needed a separate packaging machine for each format,” explains Lars Grebe, head of the sparkling wine business at the Rotkäppchen-Mumm Enology Competence Center in Eltville, where product like Mumm, MM Extra and Rotkäppchen fruit secco are filled into 750-ml bottles, as well the 200-ml Piccolo beverage containers.

“Our production site is in the middle of a residential area bordered on one side by the River Rhine—therefore there’s no room to expand,” recalls Grebe.

“As we only have a very limited space at our disposal, it’s imperative that we make efficient use of it.”

Naturally, Rotkäppchen-Mumm was limited by this reality when it began looking for a specialist who could make its packaging area more powerful and flexible in order to satisfy growing market and marketing requirements.

Following a long phase of orientation and planning the contract was awarded to the Dortmund-headquartered beverage line equipment specialists KHS GmbH, which for its part teamed up with the Crailsheimbased cartoning machinery experts Gerhard Schubert GmbH to develop a perfect solution for the mammoth undertaking, using just one machine.

Installed in September of 2018, the combined 33-meter-long Innopack TLM packaging system comprises 13 integrated submachines working in perfectly integrated unison to provide exceptional levels of performance, quality and operational flexibility.

“Compared to our previous standard we’ve doubled the line capacity for our gift packs of one and two bottles, and can now package up to 33,000 bottles an hour,” reports Grebe, who thus far has run the machine in two-shift operation.

Even so, speed is not everything, as Grebe is keen to emphasize.

“While a shipping carton of 24 can let you get away with the odd tiny flaw, we want 100-percent quality for our gift-packs, so there’s practically no leeway here.

“After all, the person receiving the gift should have fun unpacking it, for we all know that beautiful wrapping makes a gift all the more enjoyable.”

The most important criterion for Grebe and his colleagues, however, was flexibility.

Whereas on placement of the order there were nine packaging formats listed in the requirement specifications, during commissioning a few more were added, with the machine now processing 11 different types of cardboard packaging.

This is by no means the end of the story,.

“I’m convinced that we’ll be able to meet future demands from the retail trade with our new technology,” Grebe says.

“One prospective option could be the packaging of 750-ml wine bottles, for instance, and also new format sizes, such as packs of three or five.”

Another major aspect of the machine’s flexibility is that it has been designed so that only a few format changeovers are necessary, and the tools can be switched over relatively quickly.

“We convert the machinery a maximum of four times a week,” Grebe notes.

“Depending on whether we’re making a hard change from fruit secco to sparkling wine, where we have to change over several transmodule plates, or just switching the heads on the KHS pick-and-place packer, this only takes 30 to 90 minutes,” Grebe happily remarks.

The high-speed, fullyautomatic KHS Innopack PPZ pick-and-pace casepacker gently placing filled bottles of sparkling wine inside the decorative shipping cases that are formed from blanks at rates of up to 550 cartons per minute.

Finished pallet loads of cases of the Sagre Mini brand of sparkling wine stacked up in the plant’s storage area await their turn to be loaded onto trucks for delivery to customers.

In order to understand how complex the packaging tasks are at RotkäppchenMumm, consider the individual steps involved when the machine packs individual bottles into gift packs and then shipping cartons, for example.

Here, no fewer than 10 of the 13 sub-machines are used.

On the first two, up to 550 cardboard blanks per minute are extracted from the magazines, after which robots grip the individual packs that are arranged in a row, erect them and place them on a transmodule, which travels through the machine to the next steps in the process.

The flaps are glued before the underside is sealed in the next sub-machine, and

The Rotkäppchen-Mumm Enology Competence Center facility in Eltville uses its new Innopack TLM packaging line to process up to 11 different packaging formats for its brands.

the gift pack is turned upright and placed on a second transmodule segment in rows of two.

At the next station, the bottles are picked up by the KHS Innopack PPZ pickand-place packer and carefully placed in the gift packs, which are open at the top.

The top side of the cartons is then also sealed, and then pre-grouped on one of two further transmodules so that they can be packaged for shipping.

The last part of the packaging process prepares the goods for shipping.

As with the individual packs, the blanks are also destacked from the magazines for the secondary packaging, erected, glued and placed on their own transmodule segment.

In the penultimate sub-machine, the sealed gift packs are lifted into the secondary packaging in groups of four by six products at a rate of up to 23 times a minute.

At the final station, the top of the shipping carton is also sealed shut.

The various sub-machines are linked by Schubert’s patented transmodules.Thanks to their inductive energy supply and wireless transfer of data and signals, they glide back and forth on their rails along the entire line without interfaces.

Maximum availability and the best possible efficiency are ensured by a considerable reduction in the number of mechanical parts.

One can imagine that the planning, installation and commissioning of such a complex machine was a huge challenge for all involved.

“The time slot for installation was extremely ambitious,” recalls Max Schwaiger, the man responsible for packaging product support at KHS.

“Thanks to our good project management we were able to keep to the deadlines. This wasn’t just a matter of course as the growth in the number of formats during the process resulted in a certain level of complexity.”

Owing to the limited space at the final place of installation in Eltville, the system had to be completely dismantled and brought into the building horizontally.

With the help of 3D simulation, all calculations were also made with one-millimeter accuracy as to how much space the machine column on the pick-and-place packer would need during erection of the machinery. In a work of absolute precision, the ceiling grid only had to be dismantled and cut out at this point.

Lars Grebe is delighted with the cooperation between KHS and Schubert.

“They made a really strong team. We’d never have come up with the idea of Schubert and its transmodules on our own ,as we associate these with totally different branches of industry – from pharmaceuticals to candies.

“Only in conjunction with KHS’ expertise in the beverage sector and particularly in the handling of bottles have we found the perfect solution.”

For Rotkäppchen-Mumm one big success factor was also that there was only one point of contact in KHS’ system of project management.

In the meantime the new technology also has the system operators convinced.

“Over the years our colleagues of course built up a kind of emotional bond with their old machines, which could be ‘knocked back into shape’ with a hammer if need be,” Grebe notes. “But the overall function and look of the new machine are so fascinating and convincing, that any initial scepticism has long given way to total enthusiasm.”

Operating in Argentina for over 130 years, beverage producer Quilmes first started out in the beer business by opening its first brewery in the city of Quilmes, about 20 kilometers southeast of the capital, Buenos Aires.

Over the years, Quilmes have expanded across a growing number og beverage categories by acquiring a carbonated soft-drink business.

“This happened about 20 years ago, with PepsiCo’s exclusive franchise for production, distribution and marketing of the brand’s full line of beverages in Argentina,” explains Quilmes plant manager Juan José Ferrer.

The company is also active in the water business through the Eco de los Andes SA joint-venture company co-owned by global water bottling giant Nestlé Waters

“The company’s objective is to provide consumers with quality beverages and to take care of the environment,” says Ferrer, decribing the company’s recent decision to invest in a new bottling line supplied by leading global beverage production machinery group Sidel