Steam Whistle Brewing lifting the lid on its prolific Midas packaging touch Story on page 37

Hailing the winners of the 2019 PAC Leadership Awards competition Special supplement begins opposite page 12

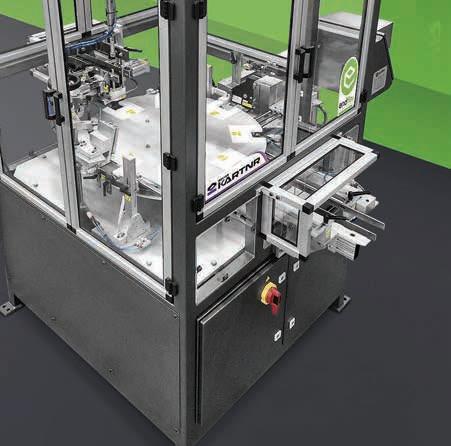

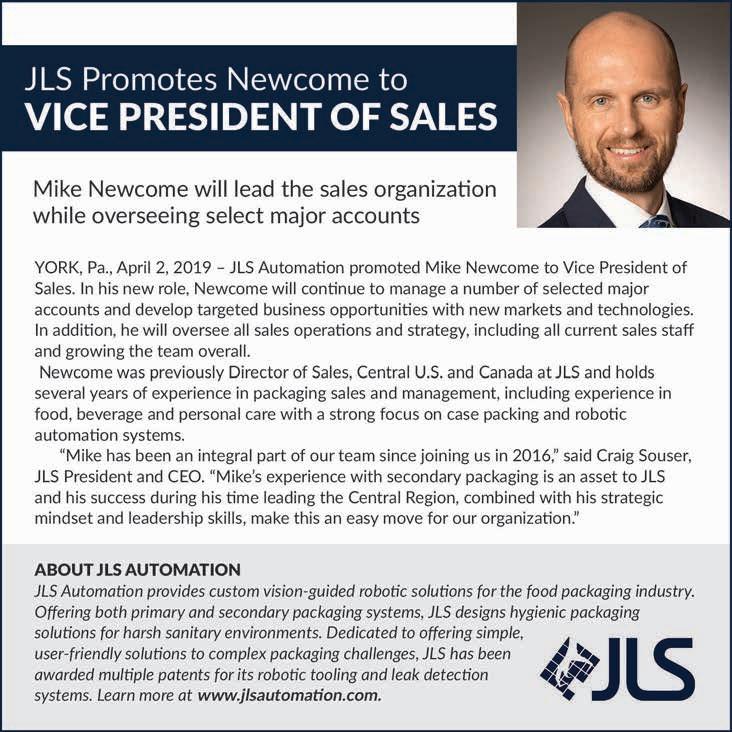

The Boxxer Kartnr™ automatic carton forming machine is engineered to vertically form chip board cartons.

Compact in design, the Boxxer Kartnr™ includes a heavy duty steel frame, PLC, color touch screen, interlocked safety doors and easy to adjust product change over.

Available in three models:

Videojet 1860 Continuous Inkjet Printer

1. True predictability

Industry-first ink build-up sensor provides true predictability and warnings of possibly degrading print quality, even before a fault occurs.

True remote services*

Multiple access options (Ethernet™, WiFi) and secure VPN communication meet highest standards in the industry as part of VideojetConnect™ Remote Service, and help to improve machine uptime and customer experience.

* Subject to availability in your country

True IP rating

Optional IP66 rating for entire cabinet and hygienic design following industry guidelines; easier integration with slanted printhead design.

True scalability

Workflow modules help to customize the printer to perform the exact need required. It is easy to adapt the printer with new capabilities and functionalities, and to meet growing demands.

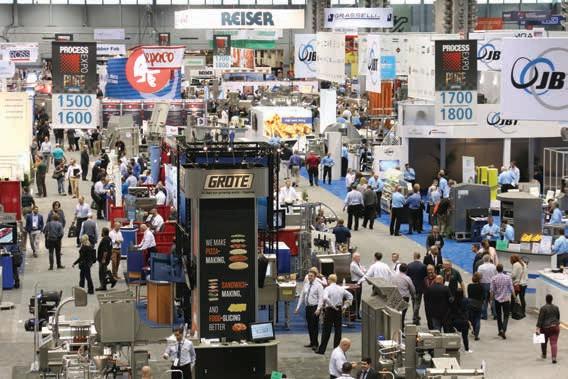

At PROCESS EXPO, you’ll see the latest technology on the show floor to help you find the right fit for your product lines and fill more orders with increased profitability. The full working production lines include examples of machines you can adapt to your operations, and the education program covers critical topics such as recyclable and renewable packaging, filler speeds, package design, and fitments.

Nowhere else will you meet such a large and varied cross-section of the food and beverage industry.

PROCESS it. PACK it. PROFit.

October 8–11, 2019 • McCormick Place • Chicago, IL USA

Register today at www.myprocessexpo.com/packagingstrategies. Use code PS19.

The global food and beverage processing and packaging show.

JUNE 2019

VOLUME 72, NO. 6

SENIOR PUBLISHER

Stephen Dean • (416) 510-5198 SDean@canadianpackaging.com

EDITOR

George Guidoni • (416) 510-5227 GGuidoni@canadianpackaging.com

ASSISTANT EDITOR

Alanna Fairey • (416) 510-5228 afairey@canadianpackaging.com

MEDIA DESIGNER

Brooke Shaw • (519) 428-3471 bshaw@annexbusinessmedia.com

ACCOUNT COORDINATOR

Barb Comer • (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

CIRCULATION MANAGER

Anita Madden • (416) 442-5600 x3596 AMadden@annexbusinessmedia.com

VICE PRESIDENT

Tim Dimopoulos • tdimopoulos@annexbusinessmedia.com

COO Scott Jamieson

ANNEX BUSINESS MEDIA

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

It is often said that people get governments they deserve.

And for the swelling ranks for Ontario residents swept up in a furious backlash against premier Doug Ford’s austerity agenda targeting government spending and institutionalized sacred cows like The Beer Store, for example, it may be wiser to see how things actually play out before rushing to ideologically-driven judgements.

While blaming previous governments for the mess they left behind is a rather cynical time-tested political ploy used by virtually every party in power to justify their more controversial policies, it’s hard to see most Ontarians getting too distraught about Queen’s Park’s decision to end the province’s 10-year agreement with The Beer Store’s co-owners Molson, Labatt and Sleeman signed by the previous Liberal government back in 2015.

For all the respect for the principle of a deal being a deal, some deals are worth revisiting when circumstances warrant a second look, especially a deal structured to maintain the existing status quo of preferential market access for bigger beer brands for a decade.

In some ways, the writing was already on the wall when the Liberals first allowed for the expansion of beer and wine sales at the province’s grocery stores under their watch, so extending that to corner stores and other retail channels as many other Canadian jurisdictions have done long ago is a logical and inevitable outcome that simply reflects the maturity and diversification of Canada’s biggest consumer market.

In doing so, the Ford cabinet is actually expressing a refreshingly libertarian mindset of offering consumers greater freedom of choice, unlike the prohibitionist Nanny State tendencies guiding previous conservative and other governments, which created an uneven playing field for beer and wine industry newcomers.

As the province’s finance minister Vic Fedeli points out, “The current beer distribution system is owned by three global giants who were handed a sweetheart deal by the previous government, and who are more interested in protecting profits than providing convenience or choice for the average people.”

Stinging words, no question, but not without foundation or precedent.

Despite the expected howls of outrage from unionized Beer Store employees predicting thousands of lost jobs, a new report from the Retail Council of Canada (RCC) paints a completely opposite scenario, citing the lower pricing and net job creation experienced in provinces with more liberal rules on beer sales.

Unapologetically titled Alcohol in Ontario: Choice & Convenience Means Jobs & Growth, the report calls the proposed deregulation in Ontario a “win for consumers and a win for Ontario’s economy,” citing Quebec and British Columbia as textbook examples of the benefits of deregulation.

“Currently, Ontario is the most underserviced alcohol market based on retail locations per capita in Canada,” the report notes, “with only 2,702 locations that can retail alcohol [and] net-of-tax beer prices that are higher in Ontario by 8.3 per cent.

“To move to the national average, Ontario would need to increase the number of locations by 4,028,” RCC states, “and by increasing choice and convenience for alcohol to the Canadian average, RCC finds that along with greater choice come 9,100 new jobs and a $3.5-billion increase to the GDP (Gross Domestic Product).”

Only time will tell if such numbers are too good to be true, of course, but we’ll never really know unless we try, even if only just because it is 2019.

George Guidoni, Editor

Alanna Fairey

C anada’s only large-scale rice processor raises its packaging game to stress the company’s rm commitment to environmental responsibility.

New Brunswick seafood processor riding the healthand-wellness market trend with new product creations packed with consumer convenience and environmental awareness.

Our

preview of upcoming PROCESS EXPO 2019 exhibition in Chicago.

Please

out our exclusive special report presenting and celebrating all winning entries in the 2019 PAC

of page 12.

When it comes to sheer size and weight, watermelons are undoubtedly in a league of their own in the world of fresh produce—requiring extraordinarily strong packaging to get these spherical-shaped giants of sweet fruity wholesomeness to market in pristine condition under very tight timelines.

In addition, any such packaging also has to play a critical marketing and branding role for fresh produce distributors such as Mississauga, Ont.based Savco Worldwide Inc. and its H2O brand of seedless watermelons.

Happily for Savco, the folks at Georgia Pacific’s recently-formed Hummingbird digital printing solutions division thrive on answering big challenges with bigger and better solutions enabled by today’s wide-format digital printing technologies.

Measuring 40 by 48 inches and boasting holding capacity of up to 700 pounds, the octagonal bins designed by Hummingbird for Savco were printed on a 110-inch HP PageWide digital corrugated press that offers significant advantages over traditional wide-format printing methods.

“The growing or buying seasons for some produce can be just a few weeks,” says Savco Worldwide president Sav Tsoukalas, “and the HP PageWide digital printing solution gives agility to provide upto-date packaging quickly to farms for shipping to

consumer outlets.”

Tsoukalas says that the bins are shipped straight to the company’s many farmers for speedy farmto-store delivery across Canada and the U.S., while effectively acting as the brand’s moving billboards.

According to Tsoukalas, the digitally printed packaging boosts Savco’s sustainability profile to help meet the environmental stewardship requirements of distributors and to win contracts.

“Another advantage is the easy recyclability of HP PageWide digitally-printed corrugated packaging, which can be collected along with general corrugated materials from stores for recycling,” says Tsoukalas, adding the PageWide packaging also meets the retailers’ requirements for food-grade ink.

According to Hummingbird, the odorless waterbased inks used on the HP PageWide press are free of UV-reactive chemistries—meaning they can be

used across a wide range of primary and secondary packaging applications for food, personal-care and other sensitive products without additional barriers.

“Corrugated boxes are the fastest-growing packaging segment,” says Robert Seay, director for digital business ventures at Georgia Pacific Corrugated LLC in Denton, Tex. “Highvolume digital inkjet printing provides brands with new marketing and supply chain management opportunities for any size job, including versioning and customization.”

For his part, Tsoukalas says that Savco is keen to take advantage of the high-quality graphics and vibrant color of HP’s digital printing to engage customers with its H2O Melon watermelon brand.

“The graphics on the bins are creatively designed to represent clean, clear water—visually attracting shoppers in the store, says Tsoukalas, adding the H2O brand is using nine different designs for this year’s season, compared to three designs last year.

In addition, the H2O bins also feature QR (quick response) codes with geo-location links to connect the watermelon bins to their farms of origin.

“I want to give the farmers credit and the opportunity to publicize their local business and location to the consumers,” Tsoukalas states.

“This makes it a true partnership.”

Knocking back shots of tequila has long been a failproof way to kick any party or festive occasion up a notch or few, but doing so the time-honored way with a dash of salt and a fresh wedge of lemon often requires patience and preparation that some party-goers find too much of a burden or just plain inconvenient.

But thanks to a new RTD (readto-drink) cocktail sensation from London, Ont.-based Black Fly Beverages, tequila fans of all stripes and temperaments can enjoy a flavorful burst of tequila-based pick-me-up in a flash with the company’s new line of Tequila Shaker Shots

Packaged in clear 50-ml test-tube plastic containers that are actually preforms molded into the 400-ml PET (polyethylene terephthalate) used to bottle the company’s fast-growing portfolio of popular RTD cocktails like Black Fly Vodka Cranberry, Tequila Margarita,, Vodka Grapefruit and Long Island Iced Tea, the new tequila ‘poppers’ offer breakthrough convenience and portability to suit virtually any festive occasion.

“Our Mexican-inspired tequila poppers are made Black Fly-style with authentic and premium ingredients, including 17-percent genuine Mexican tequila, real lemon and lime juices, refreshing soda and a hint of salt,” says Black Fly co-founder Rob Kelly.

“I have been wanting to create a unique shot for the past 10 years, but it wasn’t until we moved into our new plant—with all new bells and whistles— that we had the ultimate flexibility to innovate, deliver and produce this exciting innovation and continue to expand our ever-growing line up if spirit mixed drinks all across Canada.”

As Kelly relates, investing into an on-site inline stretch blowmolder to produce its own plastic bottles in 2014 provided a unique opportunity to utilize the company’s proprietary 40-gram preforms as miniature drinking vessels in their own right, topped off with the company’s Fly’s signature 38-ml PCO (plastic continuous thread) tamperevident resealable caps.

“I’ve always thought the preform would make an amazing package for a shot-style drink,” says Kelly, adding the preform are filled on the same filling machine that is to fill the 400-ml widemouth Black Fly plastic bottles.

“We have created the perfect blend of real tequila, soda, and pure lemon and lime juices to deliver an extremely approachable and tasty shot,” says Kelly, complimenting the firm’s packaging

supplier Packaging Technologies Inc. (PTi) of Concord, Ont., for developing a perfect secondary packaging solution to hold the individual poppers securely in place through distribution and retail stages.

“We worked closely with PTi with an objective of reducing packaging to design a minimalist, yet sturdy, corrugated four-pack that holds four shot tubes perfectly upright,”

Kelly states.

“Canadian customers have responded enthusiastically to the bright dynamic packaging,” says Kelly,

crediting graphic designer Travis Stevenson of Oveflow Studios, also of London, for developing the attentiongrabbing images and logos printed on the paperboxes.

“The retailers really appreciate the PTi-designed retail display case that is proving to be a great POS (point-ofsale) asset for retailers displaying and offering these unique Shaker Shots at the cash registers.”

Adds Black Fly Beverages co-founder Cathy SiskindKelly: “The name Shaker Shots is a call to action, to simply shake and enjoy.

“The buzz is already building across the country, and they have only just hit the market.”

Make your machines even more flexible. Easily.

Achieve business excellence with future-ready machine solutions

As a pioneer in smart automation technologies, Schneider Electric makes it easier for you to offer your customers more flexible machines. Our future-ready machine solutions help quickly and easily adapt machines to changing production and operator needs. So you and your customers can meet continuously evolving market expectations. Both today and tomorrow.

How can you improve machine flexibility? Find out, today!

After rising from the ashes of a devastating fire that levelled its production and packaging facility three summers ago, Sanger, Ca.-based Initiative Foods is wasting no time in rebuilding its credentials as one of North America’s leading co-packers of baby foods.

Upon reopening at a new plant in July of 2017, the company worked to regain its marketplace prominence under the leadership of president John Ypma, while also reassessing its overall approach to product packaging.

Ypma wanted to see if it made sense for Initiative Foods to continue packaging its product in glass as before the fire, or to move in another direction.

“We had limited capital after the fire and had to decide

whether to invest in glass again or try something new,” Ypma says.

Although Initiative Foods had previously used basic plastic containers in addition to glass, Ypma understood that customers were expecting more advanced and ontrend designs with plastic packaging.

Taxomatic Hygienic Protection for Cans

n Capable of tax strip and lid labeling 3,000-40,000/cph

n Perfect for small to mid-sized operations

n Applies foil labels at rate of 150-1000/cpm

n Touch screen operation

n Hygienic design helps prevent contamination

n Customizable design for easy conversions and retrofitting

Tino Knoll Krones Machinery

416-627-3595

tino.knoll@krones.ca

Top criteria included having a design that would stand out; allowed for nesting; be aesthetically pleasing as well as functional; and also allow parents to feed their babies in comfort.

Aesthetics aside, the risk of glass breaking during production and falling into the food concerned Ypma, who envisioned a plastic package that would solve those problems and offer greater portability for on-the-go parents.

The containers for Initiative Foods’ veggies and dinners needed to tolerate the high temperatures and pressurized, super-heated water used in the retort process of sterilizing the food.

Ypma turned to TricorBraun, St. Louis, Mo-headquartered designer and manufacturer of rigid plastic packaging products, to come up with a solution.

While glass is adept at withstanding the hot-fill and retort processes, things get trickier with plastics, according to TricorBraun’s design development manager Marco Serrano.

“One of the values TricorBraun brought to this project is that we understand plastic and both its limitations and opportunities,” says Serrano says.

The project grew into a collaborative effort with the client’s other packaging suppliers such as the RPC Group, who supplied the lids and cups.

“There were many intricate measurements in the lid and getting the right snap,” says Ryan Fichuk, TricorBraun’s packaging quality engineer.

TricorBraun and RPC independently checked the parts and data, and then compared results to confirm the lids would perform as expected, so new parents could confidently reseal the package after the initial opening.

With everything clicking into place, Initiative Foods is now using the newly-designed packaging to market is Yummy Organics Line of baby foods available in 16 different varieties.

With the four-ounce cups already retailing in the U.S., the 4.5-ounce version will be introduced to the Canadian market this fall.

As Ypma sums up, “The new plastic containers present themselves as an innovative, differentiated design that offers operational and cost efficiencies, while reducing breakage and meeting consumers’ needs for greater portability and better ergonomics for on-the-go parents.

“While it will be some time before these new containers hit the Canadian store-shelves, responses have been highly positive from early customers, who have found the curvature design to be an attractive, yet practical, alternative to glass.”

nU.K.-headquartered packaging systems supplier Mpac Group plc, parent company of Mississauga, Ont.based machinery manufacturer Mpac Langen (formerly Langen Packaging, Inc.), has completed a nearly $26-million acquisition of Lambert Automation Limited, a prominent U.K. provider of process and packaging automation solutions for medical and consumer healthcare industries employing over 160 people at its main production facility in Tadcaster, Yorkshire. (See Picture) According to Mpac, the acquisition supports the company’s strategy of becoming a market leader in providing full-line packaging solutions for customers in the pharmaceutical,

healthcare and food-and-beverage sectors, with special emphasis on the growing market for “health-and-wellness” products. “Lambert is a high-quality business with proven performance and long-standing embedded relationships with global blue-chip customers,” says Mpac’s chief executive officer Tony Steels. According to Steels, “There are clear synergies in the market, technologies and supply chain that will provide our customers and potential new customers even greater confidence in the delivery of complete turnkey packaging solutions.”

nBerlin Packaging, Chicago-headquartered supplier of glass, plastic and metal containers and closures, has completed the acquisition of Verrerie Calvet, a packaging supplier based in Aimargues, France, specializing in high-end packaging for liquid food products such as wine, spirits, olive oil, gourmet seasonings, marinades and sauces. As part of the transaction, Verrerie Calvet will be will be integrated into Berlin Packaging’s Bruni Glass division, headquartered in Milan, Italy.

Dylan Perrault joins the Videojet Technologies Inc. sales team covering South Western Ontario. Dylan enjoyed ten years in packaging and automation sales with both Domino Amjet and KHS USA, Inc. Recently enjoying time engaged in the legalized cannabis industry and now coming back to packaging and automation.

Dylan Perrault Sales Engineer Videojet Canada Ph: +1-877-225-2241 | Mobile: +1-416-559-2385

|dylan.perrault@videojet.com www.videojet.com

Rugged Ø4, M5, M8, M12, M18 and M30 housings, offering extended ranges up to 22 mm. Easily configured, providing advanced functionalities such as the detection counter (RPM) and the speed controller. Each sensor is fully programmable, providing the means for hundreds of configurations in a single device.

IO-Link Smart Configurator

Configure any IO-Link sensor or actuator via a wireless device that replaces the need to program via a USB IOLink Master connected to a PC or via a network connected master device. The portable Smart Configurator can be used anywhere, as it’s battery powered and equipped with WiFi for IODD files, sync and cloud storage.

Capacitive Sensors with IO-Link

Popular M18 and M30 diameter sensors provide the ideal solution for applications where flexibility or sensing performance needs to be constantly and accurately monitored and logged. IO-Link mode provides added functions such as: QoR (Quality of Run), QoT (Quality of Teach) and Diagnostic Parameters.

Contact us today, and one of our field sales representatives will show you why we are one of the fastest growing automation companies worldwide. We’ll even provide a free evaluation sample to qualified OEMs.

Engineered speci cally for achieving faster throughput in space-limited warehouses and distribution centers, the new Octopus Compact 20/Compact TSi series stretchwrapper from Signode Industrial Group provides a cost-e ective, reduced-footprint solution with a completely new design that provides optimal load containment while optimizing the lm usage, according to the company. Leveraging the Octopus brand’s proprietary design and ring technology, combined with durable aluminum frame construction requires minimal assembly, the new stretchwrapper enables highly e ective bottom-to-top or top-to-bottom automatic rotary ring stretchwrapping, enhanced with minimal maintenance requirements, while offering robust throughput speeds of up to 40 loads per hour.

Signode Industrial Group

The new robotic VC Series case-packer from Delkor Systems combines FANUC’s IR Vision robotics and Delkor’s own linear-servo three-axis gantry to enable high-speed, automated case and carton packing of spouted pouches, tment pouches and other single-serve pouch products. Packing spouted pouches both on-edge and lay- at pack-out with a simple toolless changeover, the VC Series case-packer can run at speed of up to 250 products per minute, using FANUC IR Vision technology to pick pouches from the infeed belt while pouches lay in di erent orientations. The case-packer achives its compact footprint by using three closely spaced FANUC LR-Mate robots and the compact gantry to ensure optimal reach and payload. Delkor Systems

Engineered to package a broad range of range of food, household, personal-care and pharmaceutical products, the new high-barrier AmLite Ultra Recyclable laminate from Amcor can be used to suit a wide variety of formats such as pillow pouches, stand-up and spouted pouches, bags, lidding for trays and containers, stick-packs and other popular formats. Made from Amcor’s proprietary high-barrier polyole n lm introduced about a year ago, the new recyclable material incorporates an ultra-thin, transparent barrier coating to replace aluminum and metallized barriers that previously made a lot of exible packaging exceptionally di cult to recycle.

The new Dual Cell-E robotic palletizer from ESS Technologies Inc. integrates a FANUC M-710iC/50H ve-axis robot with 50-kg payload capacity with custom-designed end-of-arm tooling (EOAT) to create a cost-e ective, e cient, end-of-line solution for palletizing applications in a very small footprint, according to the company. Designed for easy t into existing packaging lines to eliminate manual pallet-loading, the ergonomic pallet cell o ers virtually non-stop operation, whereby the robot automatically begins palletizing the second pallet position after the rst pallet load is complete. Optional light curtains with independent zone controls allow the operator to deactivate the safety sensors and remove the loaded pallet without stopping the robot, while additional system options include Allen-Bradley CompactLogix PLC (programmable logic controller) with Allen-Bradley PanelView Plus color touchscreen HMI (human-machine interface) terminal, deck sheet/tier sheet placement, and a safety guarding upgrade to interlocked polycarbonate panels. ESS Technologies, Inc.

Keeping a country the size of Canada clean is a massive task, so it helps a great deal when consumer product giants like Henkel Canada Corporation, a subsidiary of leading German chemical and consumer products group Henkel AG & Company, KGaA, makes an earnest pledge to keeping its packaging waste out of landfills.

Earlier this spring, the Mississauga, Ont.-based company teamed up with acclaimed international recycling leader TerraCycle, Inc. to create a free cross-country recycling program Canada for Henkel’s bestselling Sunlight and Purex brands of plastic detergent pouches.

By purchasing Sunlight or Purex pouches in Canada and recycling the empty containers through the program, Canadian consumers can earn TerraCycle points redeemable for charity gifts or converted to cash and donated to the non-profit, school or charitable organization of their choice.

“Henkel has been focusing on sustainability in packaging for several decades, and we are pleased to partner with TerraCycle to enable this creative approach to help ensure that Sunlight and Purex product packaging can be recycled after the product has been consumed,” says Henkel Canada’s general manager Mario Altan.

“This partnership is part of our commitment that 100 percent of Henkel’s packaging will be recyclable, reusable or compostable by 2025.”

Under the Sunlight & Purex Recycling Program, consumers signed up on the TerraCyle program page (www.terracycle.ca/en-CA/brigades/sunlightpurex) can send in their empty Sunlight and Purex plastic detergent pouches to be recycled for free by mailing in the packages using a pre-paid shipping

label.

Once collected, the pouches are cleaned and melted into hard plastic that can be remolded to make new recycled products.

“Henkel is giving their customers the unique opportunity to divert waste from landfills by offering them a way to responsibly recycle their plastic detergent pouches,” says TerraCycle founder and chief executive officer Tom Szaky. “The Sunlight & Purex Recycling Program provides consumers a way to keep their laundry clean, while also helping to keep the environment clean.”

In addition to individual consumers, the Sunlight & Purex Recycling Program is open to any interested schools, offices or community organization in Canada.

While this program is new to Canada, Henkel has in fact been partnering with Trenton, N.J.headquartered TerraCycle since 2016, when the company’s Adhesive Technologies business unit launched a similar partnership with TerraCycle in the U.S. to allow its American customers to recycle their used adhesives packaging instead of sending them to a landfill or incinerator.

The joint effort involved dedicated teams from Henkel and TerraCycle working together to develop a new process that deactivates the adhesive—making it easier to remove from the plastic packaging.

This material is then melted and turned into pellets that can be used to manufacture new products—from garbage cans to park benches and outdoor furniture.

According to TerraCycle, Henkel was the first adhesive technologies company to offer this type of a recycling program.

Founded in 1981 under the former Communist regime in Poland, family-owned mushroom processing company Jantex Group has overcome a plethora of serious challenges to its growth along the way of becoming one of the country’s leading mushroom products—today exporting its highquality products across Western Europe and North America. Driven by the company’s self-styled mantra of slogan “Be the first and be the better,” the company has thrived in recent years through relentless product innovation that recently resulted in market launch of a novel convenience food concept: a unique combination of selected mushrooms combined with the nutritional values of rice and buckwheat in fully-recyclable packaging providing outstanding shelf impact and brand differentiation at the POS (point-of-sale) stage.

After a diligent search for a viable packaging solution, the company settled on the Schur Star stand-up bag packaging offered by the globally-operating Schur Star Systems group of companies. Consisting of a Schur Star Packaging Machine and pre-made Schur Star Bags linked together on a unique string to ensure a smooth and flexible packaging process, the Schur Star Concept not only provided Jantex with superior barrier properties to protect the delicate aroma of the mushrooms, but also to act as a home storage container for unused product. Using stand-up pouches constructed of transparent flexor-printed CPP (cast polypropylene) film to achieve the required gloss and stiffness, the single-substrate bags do not require any separation after use—making the fully recyclable in most conventional waste streams. Moreover, the film offers excellent printability and high mechanical strength throughout the the packaging process, according to Schur Star, along with quick changeovers between bag size, bag construction and product variety that require only a few minutes.

Like to minimize the cost of ownership? Ryson can help. Our Spiral Conveyors need less oor space than conventional conveyors and are faster and more reliable than any elevator or lift. All our products are designed for low maintenance and long life and our proprietary modular construction makes future recon guring cost effective.

Quality and service come rst at Ryson. We are the number one spiral manufacturer in the USA. For application assistance or more information, give us a call or visit www.ryson.com

BY ALANNA FAIREY, ASSISTANT EDITOR PHOTOS BY CHASE ROONEY

With Canadian consumers becoming increasingly more educated about proactive sustainable practices whilst seeking out healthier alternatives to their everyday diets, it is not surprising that many progressive CPG (consumer packaged goods) businesses are overhauling their strategies to meet these demands.

Headquartered in Montreal, Canada’s sole rice milling and manufacturing company Les Aliments Dainty Foods Inc. has been quick to recognize these evolving consumer demands with the forthcoming launch of its new Organics line of processed rice in early summer, which will be retailed in fully-recyclable exible packaging manufactured by Tempo Plastics Limited of Innis ll, Ont.

Founded in Montreal way back in 1882 by Robert Reford on the Lachine Canal, the company ran its production operations there for decades under its original Mount Royal Rice Mills banner until a major change to existing tari duties allowed for large-scale importation of raw rice to Canada from the U.S. That landmark change prompted the company to build a new processing facility in the southwestern Ontario border city of Windsor, which would bene t from easy cross-border rail car access to keep the imported rice owing freely.

Completed in 1967, the 130,000-square-foot facility—owned by French multinational foods giant Marbour Group since 2015—nowadays employs about 40 unionized and 24 salaried sta , with the company founder’s descendent Nicola Reford keeping the original family roots alive in her role as the company’s marketing director.

“We want to make consumers life as simple as possible, so we hope to show them that there are easy, tasty ways to prepare rice,” Reford told Canadian Packaging in a recent interview, descibing her company’s products as “healthier food comes out of your own kitchen.”

As Reford relates, the ceri ed gluten-free Windsor facility boasts the coveted internationally-recognized SQF (Safety Quality Food) certi cation, that is consistently maintined and validated by dedicated e ort of the plant’s in-house Quality Assurance Department.

According to Dainty, the company’s dry rices are 100-percent natural product that

contain no arti cal additives or GMOs (geneticallymodi ed organisms), while boasting valid Kosher certi cation across the full product porfolio, along with Organic certi cation for some select products.

Back in 2016, Dainty enlisted the help of leading Canadian branding and design agency Pigeon Brands Inc. to redesign their brand and packaging for an upcoing product relaunch. Pleased with their work, Dainty has continued its partnership with Pigeon Brands.

“Packaging is key to our marketing,” says Reford. “Our packaging is our face to the world, to our consumers and buyers, and it must re ect our conviction of nding the best environmental solutions for all that we do at Dainty,” Reford asserts.

“To date, the packaging evolution has only been held back by availability, and Dainty is ready to evolve.”

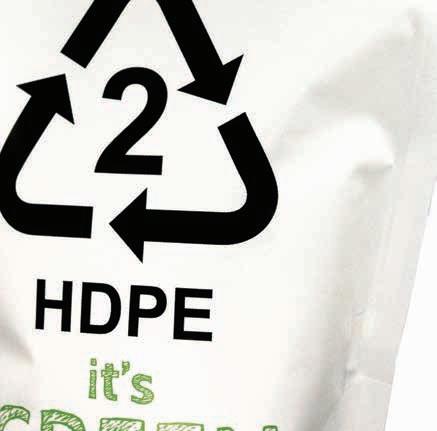

Part of this evolution included nding a lm pouch that was sustainable and fully recyclable, to align with the values of the brand-new Organics line, which will be the company’s rst line that is going to be in this truly recyclable packaging.

“Several years ago, we were printing a lot of di erent SKUs (stock keeping units) and had a number of issues with the printer we were using,” Reford explains.

“We then began interviewing other printers.”

After Dainty discovered the Innis l, Ont.-based Tempo Plastics Limited a few years back, a partnership was born.

“Tempo Plastics has been the key to enabling us to launch an Organics line in a recyclable lm pouch,” Reford extols.

“We are very excited to be the rst in the market to do so and we are already trialing recyclable lm on other packaging lines.”

A leading supplier of exible packaging solutions, such as pouches, rollstock and poly bags, Tempo Plastics makes it their goal to produce environmentally friendly packaging without compromising food safety at their 100,000-square-feet facility.

“We’re working towards better,” Leonardo Giglio, vice-president, marketing & product development of Tempo Plastics, says.

“At Tempo, we are doing our best to minimize waste, and while minimizing waste is nothing new, it’s good business practice and we want to be promoting

that as much as we can.

“We just want to continue down the path of showing di erent solutions to people.”

Sustainability in packaging has become a hot-button topic in the past year.

Thanks to advancements in packaging technology, suppliers like Tempo are able to o er Dainty standup resealable pouches from their new brand, HarmonyPack, which Tempo feels is the future of circular economy packaging.

“We think it’s the perfect harmony of what people have been asking for these last couple of years,” Giglio told Canadian Packaging on a recent visit to the lively 133-employee facility.

“I think we have a serious contender for a solution on the end life side, which has always been the biggest challenge for exible packaging.”

As part of Tempo’s Guilt-Free Packaging line, the HarmonyPack pouch solutions are made from number two polyethylene and also o er full HD Graphics and barrier if needed for shelf-stable products.

In addition, HarmonyPack is certi ed to use the esteemed how2recycle logo, a standardized labeling system that visibly communicates recycling instructions to the public to o er reliable and transparent on-package recycling information to customers in North America.

Impressed by Tempo’s commitment to sustainability and progressive mindset, Dainty Foods hopes to use the HarmonyPack material for all of their brands.

“We’re hoping to get all of our product into this kind of lm by the end of the year,” Reford explains.

“We are trialling some of the Tempo lm on some of our block bottom bag machines, and it’s really important that we produce as little waste as possible.”

For Giglio, the creation of the HarmonyPack pouches serve as a way for Tempo Plastics to educate consumers about what their options are with the package they are using at the time of disposal.

“We started showing people this year and so far there’s been a lot of interest, a lot more activity and we expect that to continue,” Giglio says with an exuberant smile.

“All we can do is design things better, give opportunities to people to use it at the end and hope that the innovation will follow with more recycling options.

Adds Giglio: “If we wait for the recycling innovation to be here, we’re never going to have anything, so why don’t we start making alternatives today?”

Prior to production, Tempo and Dainty collaborate together on the format that they would like to bring to market, with Dainty providing Tempo with the size and weight that they want for the stand-up resealable pouches.

Once the sizing exercises are complete, Pigeon designs according to Dainty specs and then Tempo produces colour proofs.

Once nal, Giglio’s team then creates print plates with the approved colors, fonts and logos.

The specialty lm is co-extruded together to form a homogenous material, thus beginning its transformative evolution into the HarmonyPack pouches.

After it completes the nal stage on the Totani pouchmaking machine, Tempo then ships the HarmonyPack pouches to Dainty’s Windsor facility, where the rice is waiting to ll after being processed through rigorous cleaning and/or milling steps.

The rice is then guided to the ll hoppers for speci c packaging machines and packaging will run at varying ll speeds, depending on the machine and the size of the package.

The packaged rice is then conveyed to cases, a palletizer and nally rests in its place in Dainty’s on-site warehouse before it is shipped for retail distribution.

Deep commitment to sustainable packaging aside, both Giglio and Reford agree that the working relationship between Dainty and Tempo has been smooth sailing thanks to a collaborative e ort on both sides.

“It has been a great synergy between the two businesses and I’m excited that they are one of the early adopters for this fully recyclable material,” Giglio praises.

“We are focused on high-end printing and Dainty sees that as the value in a supplier and they want their brand to look and resonate a certain way and we do our best to make sure that we have their message come true on shelves.”

Reford recalled several occasions where sales representatives from Tempo made the long drive to Windsor to hand deliver the nished pouches, which indicates Tempo going far above the ordinary to match client expectations and values.

“We are a small Canadian company and so is Tempo,” Reford re ects.

“I think in that sense we make good partners, because there is no hierarchy—everybody works together, and I hope this will be a long partnership.”

Moving forward, both Tempo and Dainty will continue to educate customers about fully recyclable packaging through their continued e orts and everyday practices.

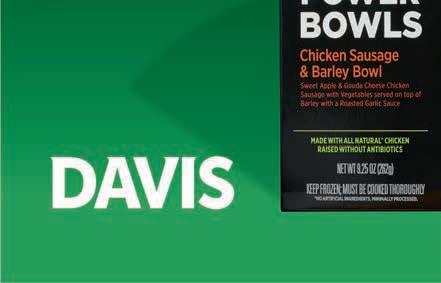

“We are the David, not the Goliath of the Flexible Packaging industry––our ability to adapt quickly will continue to be one of our strengths,” Giglio elucidates.

“We want to really push the envelope and see how far can we take this.”

Concludes Reford: “Part of the issue is education— If we can do our little part in helping people make greener decisions, then that is a big accomplishment for us.”

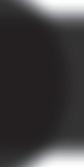

GREATNESS COMES IN ALL SHAPES AND SIZES. Congratulations to our 2019 PAC Canadian Leadership awardwinning clients that we are privileged to collaborate with.

We are Pigeon. For the past four decades, we’ve been collaborating with award-winning Canadian and International brands to build their stories from the ground up. We do it by bringing key attributes to light and weaving them throughout the entire brand – from the packaging right through to the entire communications eco-system. At Pigeon, we understand that IDEAS THAT TRAVEL are ideas that ensure your brand’s growth and success in the marketplace.

Chairman Brent Heist, Global Packaging Sustainability Procter & Gamble, Inc.

First Vice-Chairman

James Davidson, Director, Commercial Excellence, Marketing & Value Plus Amcor Flexibles Americas

Second Vice-Chairman Leon Hall, Sales WestRock

DIRECTORS AT LARGE

Rebecca Casey, Senior Director, Marketing T.C. Transcontinental

James D. Downham, President & CEO PAC Packaging Consortium

Sheldon Gouthro, Vice-President & Chief Operating Of cer Maritime Paper Products Ltd.

Jennifer Hottinger-Sloan, Director of Packaging Coca-Cola Ltd.

Louis Lemaire, Vice-President, Sales and Marketing Graphic Packaging International Canada

Paul McCarthy, Country Manager HP Canada Co.

Linda McGregor, Vice-President & Account Director Davis

Al Metauro, Executive Vice-President Cascades Recovery

Richard Pileski, Corporate Development Jones Packaging

Jon Pyper, North American Associate Director, Sustainability & Advocacy, Packaging & Specialty Plastics The Dow Chemical Co.

Dan Reshef, Manager of Steward Relations & Sustainability Canada Fibres - Urban Resource Group

Mike Richmond, Principal PTIS

Seanna Rishor, Vice-President, Private Label Sobeys

Amy Tomasek, Senior Manager, Packaging & R&D Molson Coors Brewing Company

Laura Studwell, Industry Marketing Manager OMRON Automation & Safety

Denis Vachon, Sales Manager O-I Canada Corp.

Publisher: Stephen Dean

Editor: George Guidoni

Features Editor: Alanna Fairey

Art Director: Brooke Shaw

Production Manager: Barb Comer

Rich in history and leadership, the PAC Leadership Awards competition is marking its 66th year in style by continuing to attract some of the most in uential and innovative packaging entries from across the globe.

In 2019, we continue to see an evolution in all categories. The competition entries continue to impress with clear focus on trends we see emerge in the marketplace: solutions for a circular economy; reinventing the package for e-commerce strategies; using technology to produce more connected packaging that allows brands to connect the physical and virtual world; and overall dedication and focus from all value chain stakeholders to reducing plastic waste.

Earlier this year, we were proud to welcome 25 dedicated industry professional experts who came together to grade and weigh in on each entry in person, while our ve sustainability and in-store marketing experts performed their package evaluations online.

I wish to extend my gratitude to all judges for their participation in this long-running PAC competition, as well as for ensuring that all the entries received objective and expert scoring and evaluation.

Our committee this year continued to adapt to the rapidly changing packaging landscape, while ensuring the integrity and legacy of our awards competition and gala will live on.

We are most grateful for their enduring commitment to overseeing such a dynamic competition and for bringing the fun and energetic awards gala to life.

As such, we are delighted to extend special gratitude to the following committee members: Joseph Campbell of Acorn Packaging; Tony

Corsillo of Atlantic Packaging; Elsie Cross of Nestle; Steve Murphy of Canadian Tire; Thomas Pigeon of Pigeon Brands; Brandon Quinn of Molson Coors; Shaun Ramrattan of The Central Group; and Stuart Werle of Werle Design

We would also like to extend our thanks to the Canadian Packaging magazine of Annex Business Media—our long-standing media partner and sponsor of the competition’s Consumer’s Voice Award—for its continued steadfast support for both the PAC community and the packaging industry at large.

Also, a very special thank you to Pigeon Brands for their creative direction and design work in designing this magazine cover and giving the awards presentations a fresh new look and feel.

This year we are presenting three Best-of Showawards, including the Brand Marketing Award; Packaging Innovation Award; Proudly Canadian Award; and the Consumer’s Voice Award, sponsored by the Canadian Packaging magazine.

Congratulations to our 2019 competition winners for their brilliant packaging submissions and leadership in the industry!

Drop by the PAC booth at the PACKEX Toronto exhibition, June 4-6, 2019, to take an intimate close-up look at all of the competition entries and winners. You will be glad you did!

Sincerely,

James D. Downham President & CEO, PAC, Packaging Consortium

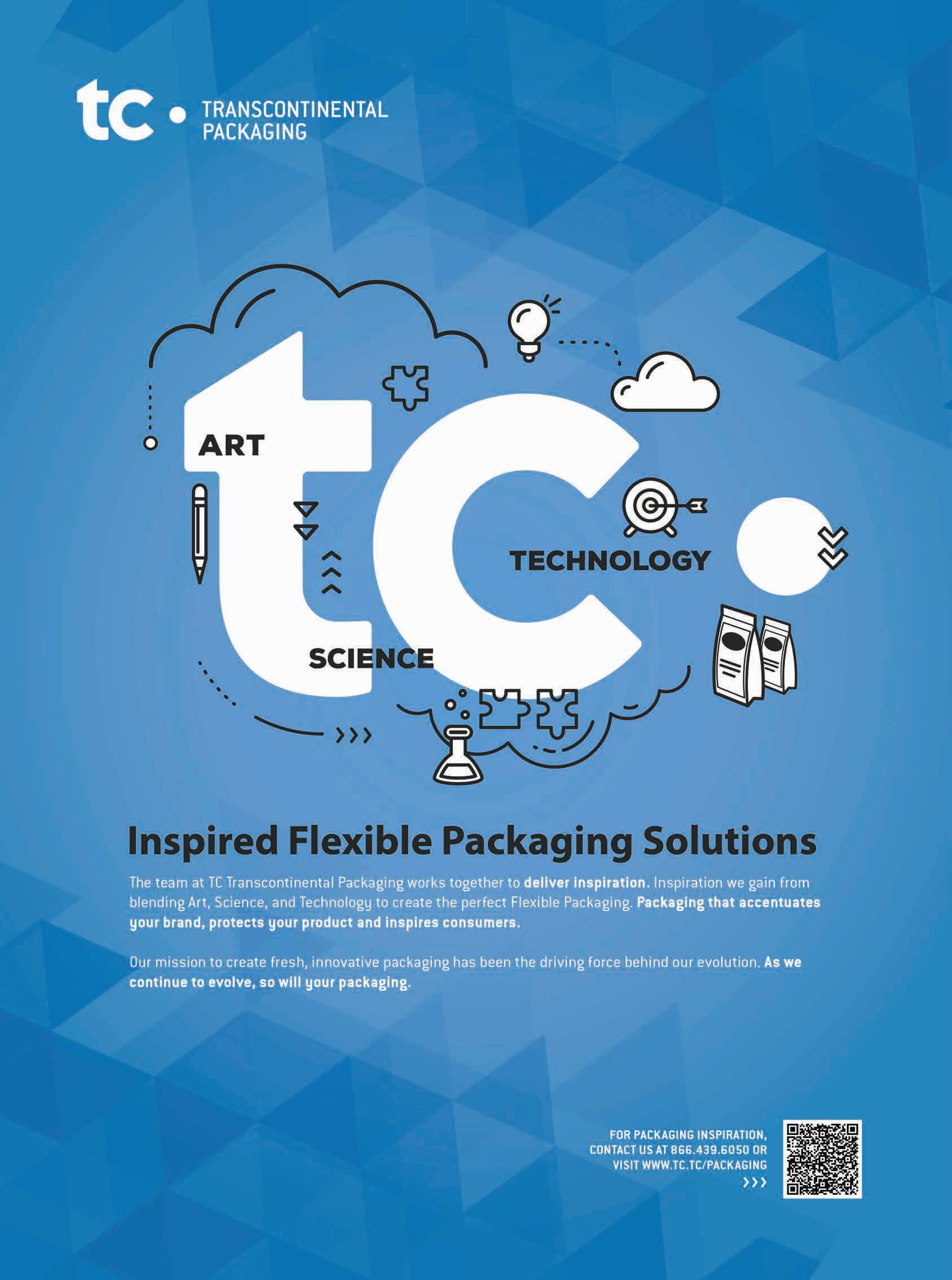

for your packaging inks and coatings requirements

We supply consistent and highly performant inks and coatings, for all kinds of packaging printing applications.

We offer a large basket of inks and coatings with “green” properties, for e.g. Cradle-2-Cradle certifiable packaging print products.

Our inks and coatings provide excellent mileage for maximizing the input / output yield.

USA:

For the expanding packaging industry we hold pervasive presence for a worldwide available basket.

The fastest response for technical challenges is just good enough to support our business partners.

As a pioneer of low-migration print consumables, we offer the broadest range of safe inks and coatings to the packaging printing industry.

Visit our website for the full range of commercial printing inks and coatings info.us@hubergroup.com • Phone: 877-642-7640 Toll-Free Customer Service CANADA: ca.info@hubergroup.com • Phone: 905-671-0750 (Main Office)

hubergroup USA Inc., 2850 Festival Drive, Kankakee, IL 60901

hubergroup Canada Limited, 2150A Drew Road, Mississauga, ON L5S 1B1 Your printing ink partner www.hubergroup.net

We provide our products with broad documentation and additional valuable information, thanks to our industry experts. Excellence

Objective driven alliances are our role model for doing business. Your goals matter and we are used to deliver more than just ink!

ACTIVIA DRINK

Brand Owner: Danone Wave Canada

Entering Company Name: Pigeon Brands

Brand Agency/Graphic Designer: Pigeon Brands

Pre-press/Structural Designer: SGS

Package Converter/Printer/Raw Materials: Westrock and American Fuji Seal

COMPASS ORGANIC APRICOTS

Brand Owner: Compass Foods Sales Company

Entering Company Name: Pigeon Brands

Brand Agency/Graphic Designer: Pigeon Brands

Pre-press/Structural Designer: Tempo Plastics Limited

Package Converter/Printer/Raw Materials: Tempo Plastics Limited COMTE DE GRASSE

Brand Owner: Comte de Grasse

Entering Company Name: forceMAJEURE Design in Partnership with CHIC Agency

Brand Agency/Graphic Designer: forceMAJEURE Design in Partnership with CHIC Agency

COOLWAY

Brand Owner: Coolwhey Inc.

Entering Company Name: Bo Branding & Design Agency Ltd.

Brand Agency/Graphic Designer: Bo Branding & Design Agency Ltd.

Pre-press/Structural Designer: Stanpac

Package Converter/Printer/Raw Materials: Stanpac

CRAVE

Brand Owner: Kraft Heinz Canada

Entering Company Name: Shikatani Lacroix Design

Brand Agency/Graphic Designer: Shikatani Lacroix Design

Pre-press/Structural Designer: SGS

Package Converter/Printer/Raw Materials: GPI

OCEAN GO WILD ARGENTINIAN SHRIMP

Brand Owner: Tree of Life Canada

Entering Company Name: Rayment & Collins

Brand Agency/Graphic Designer: Rayment & Collins

Pre-press/Structural Designer: Rayment & Collins

Package Converter/Printer/Raw Materials: BAO BÌ DUY NHÂT

HÄAGEN-DAZS EXTRÄAZ

Brand Owner: Nestlé

Entering Company Name: Bridgemark

Brand Agency/Graphic Designer: Bridgemark

Pre-press/Structural Designer: SGS HERSHEY’S GOLD

Brand Owner: The Hershey Company

Entering Company Name: Pigeon Brands

Brand Agency/Graphic Designer: Pigeon Brands

Pre-press/Structural Designer: SGS

Package Converter/Printer/Raw Materials: Bemis

IRRESISTIBLES NATURALIA

Brand Owner: Metro

Entering Company Name: St. Joseph Communications

Brand Agency/Graphic Designer: St. Joseph Communications

Pre-press/Structural Designer: SGS

Package Converter/Printer/Raw Materials: Various

Brand Owner: Metro Brands

Entering Company Name: Pigeon Brands

Brand Agency/Graphic Designer: Pigeon Brands

Pre-press/Structural Designer: SGS

Package Converter/Printer/Raw Materials: SSK Graphics / Asaya

GOOD PASTA

Brand Owner: It’s Good Pasta | National Pasta

Entering Company Name: Rayment & Collins

Brand Agency/Graphic Designer: Rayment & Collins / Tryan Servinis

Pre-press/Structural Designer: Rayment & Collins

Package Converter/Printer/Raw Materials: Rayment & Collins

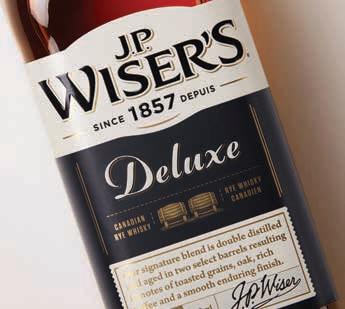

Entering Company Name: Anthem Worldwide

Brand Agency/Graphic Designer: Anthem Worldwide Pre-press/Structural Designer: Schawk Package Converter/Printer/Raw Materials: MediaWorks Inc. & Transcontinental Flexstar Inc.

Brand Owner: Metro Brands

Entering Company Name: Pigeon Brands

Brand Agency/Graphic Designer: Pigeon Brands Pre-press/Structural Designer: Multiple prepress Package Converter/Printer/Raw Materials: Multiple printers

Entering Company Name: ProAmpac

Designer: Schawk

Converter/Printer/Raw Materials: ProAmpac

Brand Owner: Coca-Cola Company

Entering Company Name: Werle Design Associates Brand Agency/Graphic Designer: Werle Design Associates Pre-press/Structural Designer: Sonoco-Trident Package Converter/Printer/Raw Materials: Fort Dearborn Company

Entering Company Name: Bridgemark

Agency/Graphic Designer: Bridgemark Pre-press/Structural Designer: Paperworks

Pre-press/Structural Designer: Sonoco-Trident

Converter/Printer/Raw Materials: Ball Packaging

Entering Company Name: Pigeon Brands

Agency/Graphic Designer: Pigeon

Package Converter/Printer/Raw Materials: Papier & Passion

WestRock’s Automated Packaging Systems performance matches our equipment with our innovative corrugated designs to provide an optimized solution that works with your processes, speeds up your operations, and lowers your costs regardless of production scale. From a single case erector to a fully integrated line design, we have the expertise to propose e ciencies that can positively impact your bottom line.

westrock.com/aps aps@westrock.com

PAC is pleased to introduce the Proudly Canadian bestof-show award, reserved exclusively for products that are created, packaged and manufactured in Canada.

This Lovibles packaging was created and designed to attract attention, tell stories and connect with the intended customer. When placed on the shelf, it creates a strong brand presence and becomes a billboard for the brand.

The project team created consistency across all packaging using a bright and colorful approach, to differentiate the brand and product against the competition.

The product can be kept in the original packaging even after opening, while its outstanding product-to-package ratio and the material used provide the lightest weight possible in packaging compared to rigid alternatives.

Eat These Foods Inc.

Eat These is a premium, hand-crafted, artisanal line of products sold in upscale butcher shops, food markets and other boutique retailers. Visually, the packaging is contemporary in style and stands out from the existing and traditional competitors in the category.

The size of the label enables consumers to immediately see the quality and appeal of the product within the jar. Targeting adults over 20, the Eat These brand was introduced as an upscale product with a price point comparable to that of similar products typically sold at farmers’ markets.

The Eat These product team recognized that adult consumers (35 plus) that frequent upscale butchers and markets have a ‘taste’ for unique food experiences. Although the target is for those with a discernible palate, the Eat These products continue to be a hit with children of all ages.

While they look great in your fridge, they can also be elevated as a unique hostess gift!

The team worked together to take advantage of extended gamut printing— leveraging an opportunity to produce a higher number of colors and gradients with a reduced number of printing plates.

Lavo

Selected by regular contributors to the Checkout product review column of the Canadian Packaging magazine, the attractive and lavish visual effect created by La Parisienne product range makes one want to try each one. The engaging color palette—vibrant for detergents and soft for fabric softeners—makes it easy to browse the product, while inviting shoppers to discover more.

The block effect is created by the unique La Parisienne vibrant green bottle for detergents and the soft beige bottle for softeners, whereby the used colors and illustrations creates ‘visual disruption’ from big brands at shelf level to make the new positioning clearly understandable for consumers.

The structural aspect of the bottle was revamped in order to re ect the round and organic side of the design, while maximizing its impact with a shape that stands out.

The La Parisienne brand is a rare treat for all the senses:

• Smell, with scents that are both delicate and tart;

• Touch, with a range of detergents and fabric softeners that respect the ber of fabrics;

• Sight, thanks to a set of organic and inviting illustrations.

The YUNI brand is passionate about its sustainability effort; hence the project was approached with both beauty and sustainability in mind.

The soft graphic design with satin nishing provides an eye-catching appeal in the busy aisles of cosmetic merchandising. The cartons are recyclable, and have been produced with soy-based inks on FSC-certi ed board to re ect sustainable forest management.

Using NFC technologies, the packaging offers the shopper information about the enclosed products prior to purchase. Using this technology allows YUNI the opportunity to update this information without a packaging change—allowing the brand to keep content fresh and adjust promotions to drive purchasing.

The NFC tags consist of polymer, metals and silicon very similar to EAS tags for anti-theft purposes, which are removed from the recycling stream in the repulping process.

The overall design of the product family was created to elicit the message of a soft, organic and healthy lifestyle brand.

Brand

Entering Company Name: Pigeon Brands

Brand Agency/Graphic Designer: Pigeon Brands

Brand

Entering Company Name: Invok Brands

Brand

Brand Owner: Left Field Foods

Entering Company Name: Anthem Worldwide

Brand Agency/Graphic Designer: Anthem Worldwide

Pre-press/Structural Designer: Schawk Inc.

Package Converter/Printer/Raw Materials: GenPak, LLC

COUNTRY HARVEST

Brand Owner: Weston Foods

Entering Company Name: Davis

Brand Agency/Graphic Designer: Davis

DEMPSTER’S DELUXE

Brand Owner: Bimbo Canada

Entering Company Name: Pigeon Brands

Brand Agency/Graphic Designer: Pigeon Brands

Pre-press/Structural Designer: SGS

Package Converter/Printer/Raw Materials: Allied Halo

DIAMOND BRAND SHELLED WALNUTS

Brand Owner: Diamond of California

Entering Company Name: TC Transcontinental Packaging

Brand Agency/Graphic Designer: Diamond of California In-house

Package Converter/Printer/Raw Materials:

TC Transcontinental Packaging

VEGGIE CUISINE

Brand Owner: Hain Celestial

Entering Company Name: Corporate Visuals Inc. Brand Agency/Graphic Designer: Corporate Visuals Inc.

Converter/Printer/Raw Materials: Glenmore

EARTH’S OWN

Brand Owner: Earth’s Own

Entering Company Name: Davis

Brand Agency/Graphic Designer: Davis

Package Converter/Printer/Raw Materials: Evergreen Packaging and Tetra Pak

JIF PEANUT BUTTER

Brand Owner: Smucker Foods of Canada Corp.

Entering Company Name: Corporate Visuals Inc.

Brand Agency/Graphic Designer: Corporate Visuals Inc.

Pre-press/Structural Designer:

Smucker Foods of Canada Corp.

Package Converter/Printer/Raw Materials: Walle Corporation

PARIS PÂTÉ

Brand Owner: Aliments Ouimet-Cordon Bleu Inc.

Entering Company Name: Bo Branding & Design Agency Ltd.

Brand Agency/Graphic Designer:

Bo Branding & Design Agency Ltd.

Pre-press/Structural Designer: Domiberia S.L.U.

Package Converter/Printer/Raw Materials: Domiberia S.L.U

TIM HORTONS FALL HOCKEY PROMOTIONAL CUPS 2018

Brand Owner: Restaurant Brands International

Entering Company Name: Pigeon Brands

Brand Agency/Graphic Designer: Pigeon Brands

Package Converter/Printer/Raw Materials: Pactiv, Dart, Georgia Pacific

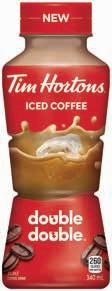

TIM HORTONS ICED CAPPS, AND TIM HORTONS ICED COFFEES

Brand Owner: Coca-Cola Ltd

Entering Company Name: Coca-Cola Ltd

Brand Agency/Graphic Designer: Perennial

Pre-press/Structural Designer: Schawk

Brand Owner: Restaurant Brands International

Entering Company Name: Pigeon Brands

Brand Agency/Graphic Designer: Pigeon Brands

Pre-press/Structural Designer: Illustrator: Laura Mensinga

Package Converter/Printer/Raw Materials: Letica

WESTERN FAMILY SPARKLING WATER

Brand Owner: Save-On-Foods

Package Converter/Printer/Raw Materials: American Fujiseal TIM HORTONS US HOLIDAY CUPS 2017

Entering Company Name: RKW Communications Inc.

Brand Agency/Graphic Designer: RKW Communications Inc. WHOLE HOG

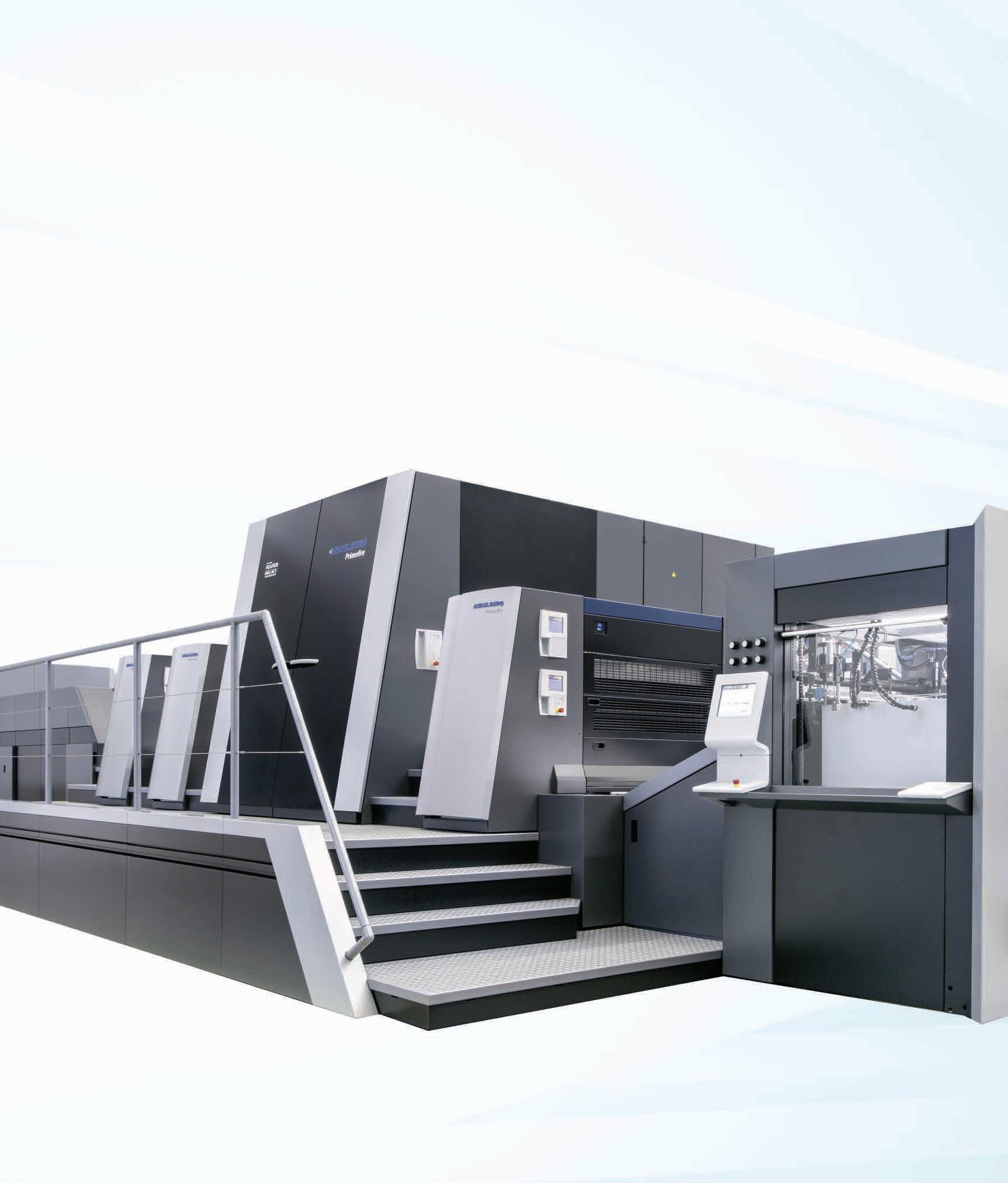

Recipient of the 2018 Intertech™ Technology Award, the Primefire 106 is changing the future of printing. The first commercially available industrial inkjet press in the 70 x 100 format, the Primefire 106 impresses with 1,200 x 1,200 dpi resolution. Based on the platform of the Speedmaster XL 106, the machine gives packaging printers the confidence of over 80% available uptime while also seamlessly integrating into offset environments. Raise the bar with Primefire’s direct-to-sheet 7-color imaging registration by incorporating variable content as well as unique security features for anti-counterfeiting designs. Learn more at http://news.heidelbergusa.com/digital

Brand Owner: Theory Wellness

Entering Company Name: Duallok

Brand Agency/Graphic Designer: HIPPO Premium Packaging

Pre-press/Structural Designer: Duallok

Package Converter/Printer/Raw Materials: Duallok

YUNI

Brand Owner: YUNI

Entering Company Name: Jones Packaging Inc.

Brand Agency/Graphic Designer: Kelsey Chung Design

Pre-press/Structural Designer: Jones Packaging Inc.

Package Converter/Printer/Raw Materials:

KITKAT SENSES COLLECTION

Brand Owner: Nestlé Canada Inc.

Entering Company Name: Jones Packaging Inc

Brand Agency/Graphic Designer: sgsco

Entering

Brand Owner: Metro Brands

Entering Company Name: Pigeon Brands

Brand Agency/Graphic Designer: Pigeon Brands

Pre-press/Structural Designer:

Package Converter/Printer/Raw Materials:

Pre-press/Structural Designer: sgsco /Jones Packaging Inc.

Package Converter/Printer/Raw Materials: Jones Packaging Inc.

PARIS HILTON

Brand Owner: Paris Hilton/Parlux Fragrances

Entering Company Name: SupremeX Inc

Brand Agency/Graphic Designer: Parlux Fragrances

Pre-press/Structural Designer: SupremeX Inc

Package Converter/Printer/Raw Materials: SupremeX Inc

BRAND

Brand Owner: Coca-Cola Ltd

Entering Company Name: Coca-Cola Ltd

Pre-press/Structural

Pre-press/Structural

BRAND MARKETING JUDGES

Wendy Kufeldt, Anthem

Alicia Mulak, CVI Group Inc.

Carla Tulli, Southern Graphic Systems

Dennis Benoit, St. Joseph Communications Content

Lisa Olay, Davis

Marc Beauregard, Bo Branding & Design

Gary Oakley, Shikatani Lacroix Design

Michael Lawrence, Canadian Tire

Kat Dean, Coca Cola Ltd.

Charlene Codner, FISH Agency

Bri-Anne Kitka, Bridgemark

Mike Luciani, Sobeys Inc.

Bob Boutilier, Pigeon Brands

Afsana Mansoor, McDonald’s Restaurants of Canada

Kim Fearon, ASL Print FX

David Haslam, DFH Consultants

PAPER PACKAGING JUDGES

Joel Porter, Coca-Cola Ltd.

Jeff Mills, Cascades Containerboard Packaging

James Lee, Jones Packaging

Mike Millard, Ellis Packaging

FLEXIBLE & RIGID PACKAGING JUDGES

Leonardo Giglio, Tempo Plastics

Diana Courtepatte, TC Transcontinental Packaging

Neil Strickland, Amcor

Guy Lanoue, ProAmpac

Wally Petrac, Strategica

CONSUMER’S VOICE JUDGES

(online judging only)

Alanna Fairey, Canadian Packaging

George Guidoni, Canadian Packaging (panel chair)

Rhea Gordon

Shannon Kupp

Elena Langlois

Jeff May

Megan Moffat

Paul Pethick

Julie Saunders

Alan Blake, Alan Blake Consulting

David Faris-Yousif, The Continuous Improvement Fund

Dan Lantz, Crow’s Nest Environmental

Mike Richmond, PTIS

Claire Sand, Packaging Technology & Research

Tabletop Label Printers & Label Mini-Presses suited for all your packaging needs

QL-120

Industry-leading Print Quality, Reliability, and Performance for Prime Label Printing

QL-300

World’s First CMYK + hite Toner-Based Desktop Label Printer

T2-C

World’s Smallest Label Press

T-4

Label Printing & Finishing System in a Compact Footprint

Contact us for a free consultation to help determine the best combination of printers and materials for your application

A smart solution for your labeling needs – maximize production by efficiently printing short to mid-size runs up to 24/7 production with user-friendly, just-in-time labeling solutions. AstroNova’s expertise in on-demand labeling will set your brand apart with vibrant, high-resolution labels allowing for fast, high-quality, full-color labeling solutions spanning from desktop to narrow-web press applications.

Canada’s premier craft brewer raises its packaging game to new heights with inline foil lid labeling capabilities for maximum shelf impact and pristine product purity

BY GEORGE GUIDONI, EDITOR

PHOTOS BY COLE GARSIDE

Blowing one’s horn may not seem like the epitome of modesty. But for the self-styled ‘Good Beer Folks’ at the Toronto-based Steam Whistle Brewing, the recent launch of the company’s new Von Bugle brand of Munich-style lager is a ttingly symbolic validation of 20 years of brewing and packaging excellence that have entrenched the hardworking beermaker rmly at the very top of Canada’s burgeoning craft beer business.

And getting there almost entirely on the strength of just one sole brand—the company’s signature agship Steam Whistle Pilsner—makes that accomplishment seem all the more unique and satisfying for everyone taking part in this remarkable transformational journey.

Twenty years ago, Steam Whistle Brewing was just an idea without a home, started up by co-founders Cam Heaps and Greg Taylor around the premise of producing a single beer product, but doing it exceptionally well.

Upon nding home in downtown Toronto at a former locomotive repair facility called The Roundhouse, Stream Whistle founders proceeded to realize their vision with relentless drive, enthusiasm and dedication to the art and tradition of European brewing craftsmanship that quickly established their Czech-style pilsner as the rising star of Ontario’s then- edgling craft-brewing scene.

And while the Steam Whistle Pilsner brand still remains the company’s most instantly recognizable calling card to this day, it may have to share some of its marketplace acclaim going forward with the newly-launched Von Bugle Munich Lager—produced and packaged at the company’s second new $19-million brewing facility located in the west-end Toronto suburb of Etobicoke.

Started up only a few months ago, the 55,000-square-foot brewery now houses all of the

Packaging supervisor Lawrence Rench (left) and brand manager Jeff Deegan raising a toast with Steam Whistle Brewing’s new Von Bugle brand of Munich-style lager, which is currently shipped to LCBO (Liquor Control Board of Ontario) outlets and other Ontario-based retailers in pre-printed corrugated cases (inset) supplied to the company’s new 55,000-square-foot brewhouse in west-end Toronto by the brewer’s long-time packaging partner Packaging Technologies Inc. of Concord, Ont.

company’s canning and bottling operations—freeing up The Roundhouse site to concentrate on kegging, which accounts for a very respectable 30-percent share of Steam Whistle’s steadfastly growing output volumes.

“We always knew that we were going to outgrow The Roundhouse one day, when would simply not be able to produce enough beer for nationwide distribution,” says Je Deegan, Steam Whistle’s brand manager for the Von Bugle label.

“So opening up a second facility was always in the cards,” Deegan told Canadian Packaging on a recent visit to the Evans Avenue brewhouse, a former print shop completely refurbished and modernized to house all the critical bottling and canning equipment once virtually ghting for open space at The Roundhouse facility’s con ned quarters.

“And as the move to a new facility came closer to reality,” Deegan recalls, “we thought it would be a good idea to bring out a second beer brand at the new facility—something that would complement and live alongside Steam Whistle Pilsner, while staying true to our European lagering heritage.”

Because launching a second brand would mark a complete break with the company’s original ‘one beer company’ mantra, Steam Whistle spared no e ort to ensure that the new brew would live up to the lofty standards and consumer expectations raised by stellar marketplace success of the original pilsner brand.

“We even brought back our former brewmaster Marek Mikunda out of retirement in his native Czech Republic to help us develop the new recipe and brand,” says Deegan.

“For the Von Bugle brand, we wanted to replicate the European tradition of producing a darker beer that would o er incredible full-body avour, but would

not sacri ce the drinkability and sessionability associated with traditional European lager,” Deegan says, calling the Van Bugle ‘the most sessionable dark beer’ in the Canadian market.

Distinguished with a beautiful rich amber color and a refreshing crispness associated with cold fermenting techniques, Von Bugle is made with a complex blend of traditional and grains and specialty hops—including the newly-bred Kazbek nishing hop sourced exclusively by Steam Whistle from the Czech Republic— to achieve a robust and bold taste pro le that creates a smooth balance between gentle bitterness and malt sweetness.

Primarily targeting wheat Deegan calls “mature craft beer drinkers,” the new lager o ers a “reliable avorful beer that is also drinkable and easy-going enough to be enjoyed over the length of a sporting event on TV or the course of a summer barbecue,” Deegan opines.

As for the brand name, Steam Whistle borrowed a page from its own playbook by associating it with the loud sounds generated by a bugle horn to signal the start of nish of a workday or other scheduled activities—much in the same way that stem whistles were used back in the golden age of steam-powered rail locomotives.

“The bugle would have been one of the earliest musical instruments the early European settlers would have brought with them to Canada,” Deegan explains.

“It would have been widely used to bring the local community together for special events and celebrations,” he says, “and so it made a very suitable point of reference to our company’s nod to the European brewing heritage.”

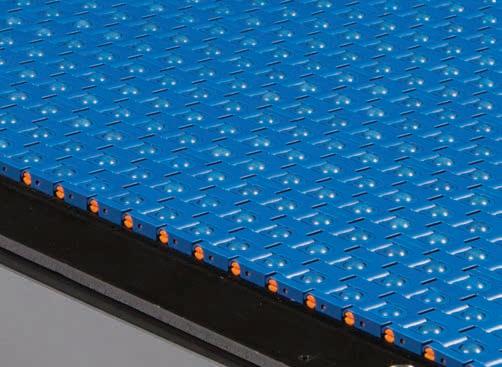

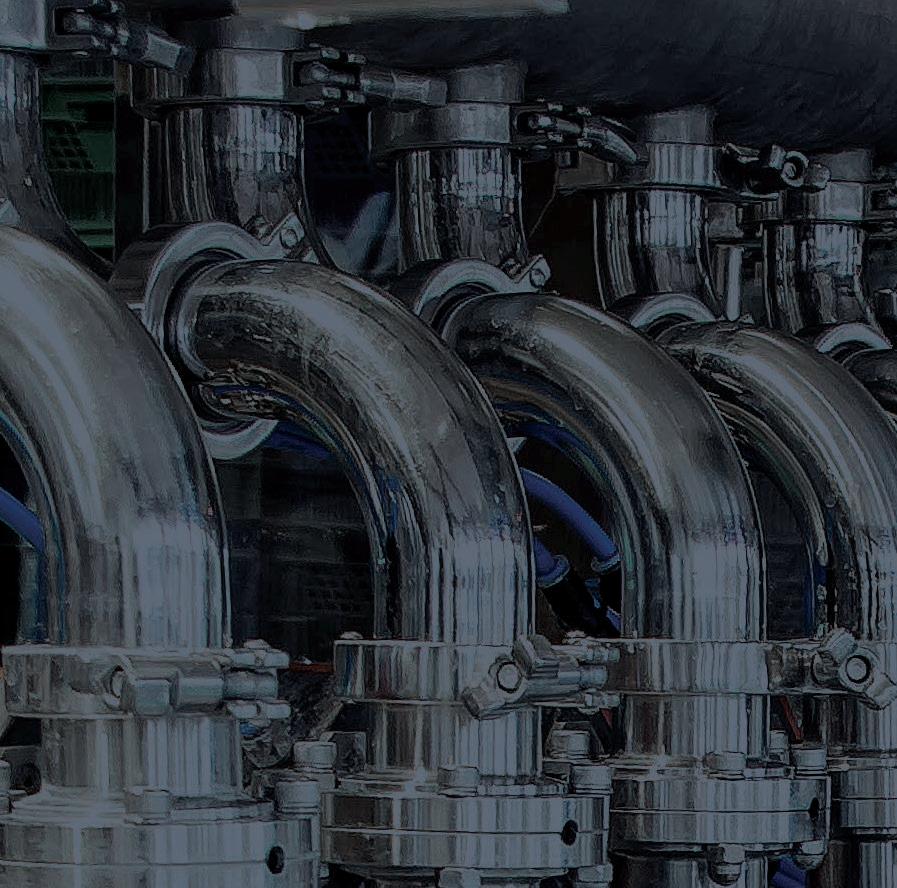

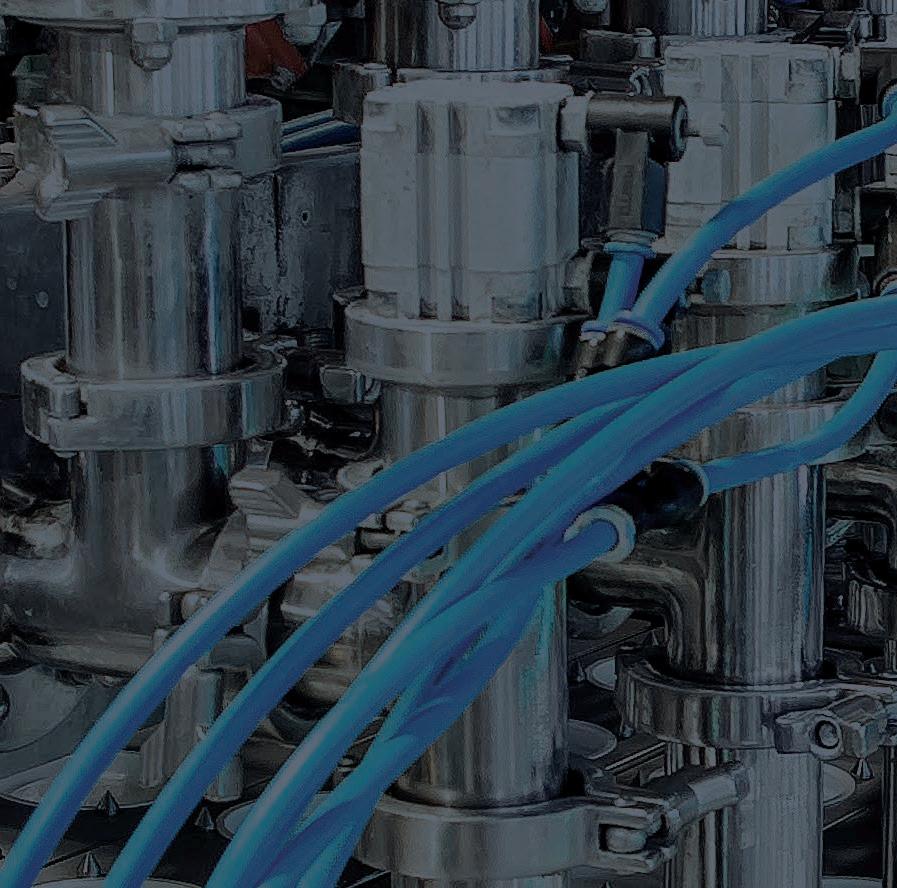

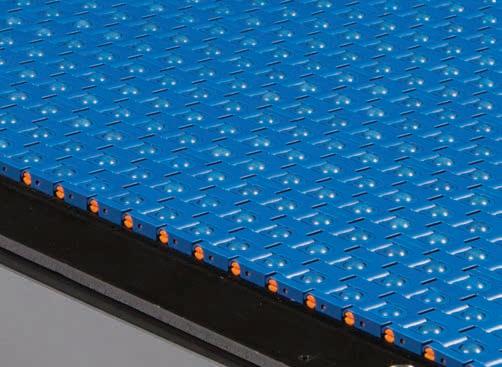

And while the new beer’s elaborate, regal blue-and-gold brand graphics represent a colorful departure from the more laid-back green-and-white color palette used to market the pilsner product, the two beers share a unique branding and packaging commonality buy virtue of having the cans of both brands being topped o with an additional thin layer of branded foil lidding—applied onto the can ends inline just after seaming via the brand new Taxomatic lid labeling machine installed at the new facility’s canning line earlier this year.

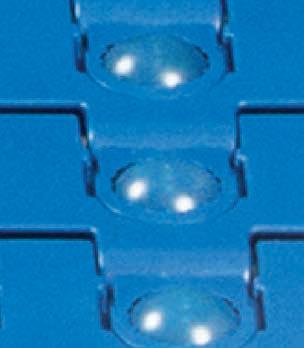

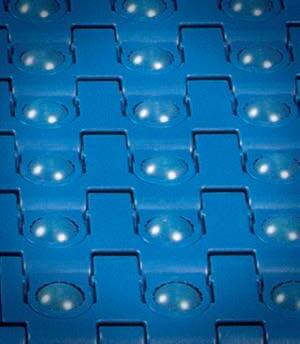

Manufactured in Germany by Krones AG, the Taxomatic machine was integrated into the plant’s Krones Volumetric VOC can lling line, combined with a Ferrum seamer, to top o the 473-ml direct-printed aluminum cans with pre-cut foils that serve as an added layer of hygienic protection for the lids, while providing another layer of packaging real estate to advertise and market the brand.

Mounted vertically above the infeed starwheel, the Taxomatic labeling station transfers the pre-cut round foils onto the passing containers from above, which are automatically cold-glued and pressed into place at a blink of an eye with unerring precision and repeatability at a brisk pace of 225 cans per minute.

Said to be the rst Krones Taxomatic machine to be installed at any brewery in Canada, the half-million-dollar system is quickly proving to have been worth every penny in terms of immediate shelf impact and rand di erentiation, according to Deegan.

“We take a lot of e ort in producing a pure product free of additives, corn syrup, arti cial foam enhancers and so on,” Deegan says, “and having this foiling capability helps us ensure tat the consumer holding this beer in their hands will have the

beer experience possible.

Mostly comprised of high-performance equipment manufactured by leading German beverage processing and packaging systems group Krones AG, the highly automated canning line typically requires only eight operators to oversee the smooth-running packaging process.

“A lot of people who have tried our foil-lidded beer have told me that they now think about it every time they see a ‘naked’ can of beer, and make sure that they give it a wipe before opening.

“The truth is that once the cans of beer leave the warehouse, there is no telling what they my have gone through before ending up on the store-shelf,” Deegan points out, “so this layer of foil gives consumers a real peace-of-mind, as well as another good reason to choose our product.”

Deegan adds he’s also very happy about the subtle subliminal brand connection made at the shelf level between the two brands despite the considerable di erences in the graphic designs featured on the canned products.

The packaging graphics for both of the company’s brands were created by Steam Whistle’s talented in-house graphic designers, including the logo graphics for the fully-recyclable pre-cut foils printed in Germany by Multi-Color Corporation and shipped to the plant in ready-to-load stacks to be inserted into the Taxomatic unit’s magazine.

The application process uses specially-formulated glue, also supplied by Krones, to make the labels adhere to the cans’ surface area to cover the top and a bit around the sides, after which the foil is crimped into place to remain sealed right up to the moment of consumption, with consumer simply pulling on a little tab on the label’s edge for quick and easy removal.

According to Steam Whistle’s national planning and procurement manager Glenn Truelove, integrating this extra packaging step into the process has had no adverse impact of the production line’s speeds whatsoever.

“We did not need to compromise any line e ciencies to accommodate this new value-added capability,” says Truelove, praising Krones for coming up with a perfect solution to Steam Whistle’s insistence on 100-percent recyclability of all its packaging.

“The glue supplied by Krones is actually a vegan formulation that does not impede recyclability at all,” Truelove relates.

As for the extra costs of the so-called Purity Seal materials, Truelove says they are virtually negligible—adding up to less than the costs of applying a standard paper label.

“It’s a wonderful billboard for our new product,” Truelove extols, “whereby the sparkling gold background with blue lettering and logo creates incredible shelf presence.”

According to Truelove, the new facility currently has annual capacity to produce 85,000 hectoliters of Steam Whistle Pilsner and 3,000-hectoliters of Von Bugle—for now distributed only in Ontario—as well as accommodate co-packing requirements for the Fat Tire beer band of New Belgium Brewing Company, a Colorado-based beermaker ranking as the fourth-largest craft beer producer in the U.S.

With canned beer nowadays accounting for about 40 per cent of the company’s output volumes, the Von Bugle plant makes extensive use of its fully-automatic bulk depalletizer—manufactured by Alliance Industrial Corporation—to unload the endless stream of towering palletloads of direct-printed aluminum cans supplied to the plant by a Crown Cork & Seal plant in Batesville, Miss.

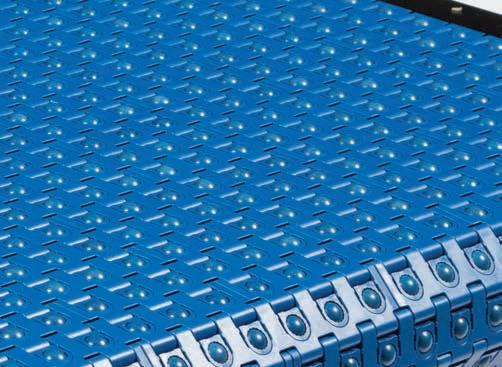

The unloaded cans are quickly transferred towards the canning line along a highly synchronized network of food-grade conveyors—including System Plast

NGE belting from Regal Beloit and product transfer conveyors from Gebo Cermex—to pass through strategicallypositioned Krones rinsing, drying and UV light-curing stations, before entering the Volumetric VOC ller in a single le for high-precision lling and seaming.

After the lling process is done and the Purity Seal foil lids are applied, the cans are date-coded by a small-character EBS-6200 inkjet printer—manufactured in Germany by EBS Ink-Jet Systeme GmbH—and conveyed down the line for case-packing.

Upon entering the Dimac Blue Star case-packer, the cans are grouped into four- or six-packs, which are immediately heat-sealed in plastic stretch lm, or loaded 24 at a time in-

Do you want SUPERIOR flexibility? You’ll love the range of packages that Reiser machines can provide.

Do you want SUPERIOR production? You’ll love the speed.

Do you want SUPERIOR package seals? You’ll love not worrying about leakers and returns.

Reiser’s form/fill/seal technology and packaging expertise are the powerful combination you need to produce a SUPERIOR package.

side pre-printed corrugated trays—supplied by the brewer’s long-time packaging partner Packaging Technologies Inc. (PTi) of Concord, Ont.—to be sold as individual single-serve cans.

From there, the nished packs make their way onto a Ryson vertical spiral conveyor to be moved inside the fullyautomatic Columbia HL2000 palletizer, which stacks them onto the shipping pallets seven-layers-high.

Once done, the palletized loads are whisked by forklift to the semi-automatic model A-Arm turntable stretchwrapping machine—manufactured by Cousins Packaging Inc.—which applies a layer of protective stretchwrap lm around the load.

The stretchwrapped loads are then swiftly moved inside the plant’s onsite cooler warehouse to await customer delivery, which is primarily handled via the brewer’s own eet of delivery trucks and vehicles decorated with large-format Steam Whistle or Von Bugle brand graphics.

The highly automated canning line process typically requires only eight people per shift to operate from start to nish, according to Truelove, who is quick to compliment Krones for the quality and reliability of its equipment, as well as unfailing customer service.

“The Taxomatic machine, for example, took just one day to install, a couple of more days to all the wiring hookups, and then we were ready to go,” say Truelove, noting that the user-friendly system has not experienced any unscheduled downtime since then.

To give credit where it’s due, Truelove is also highly complimentary about the machine installation work for most of the plant’s equipment performed by Toronto-based Pivot Systems Limited, along with the line design expertise provided by Linetec Solutions Inc. of Mississauga, Ont.

“We are getting about 75-percent line e ciency in our canning operations right now,” Truelove relates, “which is pretty good in this industry. “I would like to see it closer to 80 per cent,” he adds, “but I am sure we will get there by the end of the year.

“Being Canada’s Number One craft brewer means everyone else is out to catch up to you,” Truelove concludes, “but with the new facility and an exciting new product in place, we are more than ready for whatever the future holds.”

waves in retail markets with bold product innovation and stunning package design masterclass

BY GEORGE GUIDONI, EDITOR

PHOTOS BY RUBIN MARTINEZ

For a country blessed with the longest coastline in the world, it’s only tting that some of the world’s top seafood producers call Canada their home, with Black’s Harbour, N.B.headquartered Cooke Aquaculture Inc. o ering a particularly compelling proof of this gravitational a nity.

Founded in 1985 as a small salmon farming business with a single marine site, the family-owned company has grown at a breathtaking pace over the years through an aggressive acquisition and diversi cation strategy that

enabled it to evolve into the Largest North American seafood producer, according to the industry’s leading database SeafoodSource.

Nowadays employing over 9,400 people at operations in Atlantic Canada, U.S., Chile, Scotland, Spain, Uruguay, Honduras and Nicaragua, the vertically-integrated seafood farming corporation ships well over a billion pounds of seafood products to over 65 countries annually, generating revenues in excess of $2.5 billion.

Despite its proli c international success and presence—including 25 processing facilities and operations

established in 10 countries—the company remains closely tied to its New Brunswick roots, employing about 1,500 people across the province.

“We are very mindful of our economic impact here at home in Atlantic Canada, and we also appreciate the support that we receive in return from local businesses,” says Jill Cronk, director of marketing for Cooke Aquaculture’s True North Seafood Company branded products business.

“The local communities where we operate are very important to us,” Cronk told Canadian Packaging in a