AUTOMATION DEVICES

SIGNAL TOWERS

Ahearn & Soper Inc.

Arpac Group

Leading Edge Inkjet

Schneider Electric

Siemens Canada

SERVO MOTORS

Ahearn & Soper Inc.

Arpac Group

B&R Industrial Automation

Bosch Rexroth

Capmatic Ltd.

Edson Packaging Machinery

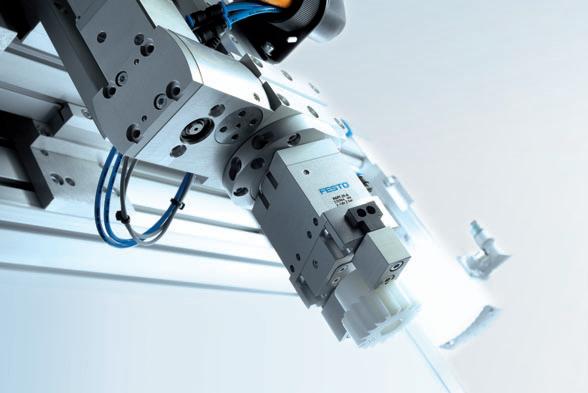

Festo Inc.

Filamatic

General Conveyor Co. Ltd.

Kinecor

Lapp Canada

Leading Edge Inkjet

Lenze Americas

Lenze Americas

North American Laser Systems

Omron Canada Inc.

Rockwell Automation

Schneider Electric

Septimatech Group Inc.

SEW Eurodrive Company Of Canada

Shelley Automation

Sidel (Canada) Inc.

Siemens Canada

Steeltek

Trinamics Incorporated

Zarpac Inc.

Zarpac Inc.

SOFTWARE PROGRAM

Ahearn & Soper Inc.

Arpac Group

B&R Industrial Automation

Capmatic Ltd.

Dematic

Edson Packaging Machinery

Leading Edge Inkjet

North American Laser Systems

Omron Canada Inc.

Schneider Electric

Sensor Products

Shelley Automation

Sidel (Canada) Inc.

Siemens Canada

Zarpac Inc.

ARTY80V Upto75bpm Rollstock,heatsealableOPP andlaminations

Upto7.5in.Wx12in.LAutomaticformfillandseal ARTY130V Upto60bpm Asabove Upto12in.Wx17in.LAsabove

ARTY75H Upto350bpm Asabove Upto8in.Wx24in.LHorizontalflowwrapper

AUTOMATEDPACKAGINGSYSTEMSINC(InCanada:PackProSystems,Inc.Stouffville,ON)

HB-65PaceSetterAutobagto20bpm various 2-11.5"x2-22"L Semi-automatic

AB180Autobag to80bpm various 2-11"Wx2.5-22"LSemitofullyautomatic

AB145Autobag to45bpm various 3.5-11"Wx3.5-22"LSemitofullyautomatic

AutobagAB255WideBaggerto55bpm various 4-16"Wx5-26"L asabove AutobagAB255Horizontal Wide to55bpm various asabove asabove

BOSCHPACKAGINGTECHNOLOGYINCDOBOY(InCanada:CharlesDowner&Co.Ltd.,RichmondHill,ON)

DoboyCBS-DBandSealer350"-750"permin.Allheatsealablepre-madebag film Pre-madebags,tubestyleor gusseted Manualtosemi-auto.

DoboyCBS-DMBandSealerMedical 0"-1000"permin.

Allheatsealablepre-madebag film Pre-madetubestylebagsof anysize Asabove

DoboyB-500BandSealer350"-750"permin.Asabove Asabove Asabove

DoboyB-500MBandSealerMedical 0"-500"permin.

Medicalgradepolyethylene, thinfoil,paper/polyester, Tyvek/Mylarfilms Asabove Asabove

BOSSARUSAINC(InCanada:AbbeyPackagingEquipmentLtd.)

BR2000/2600/330060-90ppm Various;HeatSeal45x45to100x135 Upto90ppmFill/sealpre-made RetortPouches

CAMPACKAGINGSYSTEMS CAM;412 25ppm Polyethylene,polypropylene, laminated,shrink(Polyolefin), Standupwithzipper,3sided seal,recloseable,doypack (standuppouch)

4"x5"upto12"x16";additional sizesuponrequest SemiAutoandAutomatic

BAGPACKAGINGOPENING MAKERANDMODELSPEED TYPESANDMATERIALS ofbags BAGSIZES OPERATION

BOSSARUSAINC(InCanada:AbbeyPackagingEquipmentLtd.) BR2000/2600/330060-90ppm Various;HeatSeal45x45to100x135 Upto90ppmFill/sealpre-made RetortPouches

CAMPACKAGINGSYSTEMS CAM;412 25ppm Polyethylene,polypropylene, laminated,shrink(Polyolefin), 3sidedseal,zipper,Doypack (standuppouch)

FORMOSTFUJICORPORATION

4"x5"upto12"x16";additional sizesuponrequest Semiautoandautomatic

FormostFujiGTSBaggerVaries Poly Varies RJMACHINERYINC PacemakerModel402Bag Blower 30bagsperminuteWicketedPolyBags24"Wx24"Long Blowbagopen&guideproduct intobag REISERCANADACO SupervacGesmbH40/min. All Allsizes SemiAutomatic SEALEDAIRCANADACOCIECRYOVACFOODDIVISION 8189tapedbagloaderHor.Basedoninfeedrate& operatorefficiency CryovacshrinkbagsTo16in.wide Manual BL100SeriesHor. 15ppm CryovacshrinkbagsTo14in.wide Automatic B125Vertical 20ppm Asabove 7-9"wide Automatic B126Vertical 20ppm Asabove 10-14"wide Automatic

STEELNORSYSTEMS(InCanada:AccentPackaging,Surrey,BC;ArtyPacAutomation,Laval,QC;EmpressPackagingInc.,Milton,Ontario;Plan Automation,Orangeville,ON)

SteelNorSUPS-15To15PPM Stand-upPouches 5"x8"-8"x11"StandardAutomatic

SteelNorSUPS-30To28PPM Stand-upPouches 5"x8"-8"x11"StandardAutomatic

SUPERVACGESMBH(InCanada:Reiser(Canada)Ltd.,Burlington,ON) SupervacGesmbH40/min All Allsizes Semiautomatic TOYOJIDOKI(InCanada:TechnoPakPackagingSystemsInc.,Ste-Julie,Quebec)

TOYOJIDOKI 15-250bom Preformedpouches

VC999CANADALTD VC999BL420 20bpm Tapedshrinkbags Various Allautomatic

WEIGHPACKSYSTEMSINC

VSBagger

ZippyBagger

Upto35/min Pre-madewickedbags,zipper bags,bagswithhandles 6"-14"W6"-20"LAutomaticorsemi-automatic

Upto35/min asabove 6"-14"W6"-20"Lasabove

ZippyXL Upto15/min asabove 10"-20"W10"-22"Lasabove

BingoBagger

BingoBaggerXL

Upto25/min Pouches,stand-upbags10"-20"W10"-22"Lasabove

Upto15/min. Pouches,stand-upbags14'-20"W14"-24"Lasabove

FORMOSTFUJICORPORATION

Formostbread,roll,bun& varietybaggers(5models) To90pm Preformedwicketedbags-of PE,nylonorpp To14x24in. Automatic

GOPACKAGING Variousmakesandmodels available HEAT&CONTROLINC(InCanada:HeatandControlCanada,Inc.)

Ishida,Astro SnackFoods 100-330mmW 100-55mmL Upto100bpm

Ishida,Atlas SnackFoods 75-230mmW75-711mmLUpto250pbm

Ishidaflexiblepackaging system SnackFoods Forms,pillows,hemsealflat bottom,gussetedbags

KWIKLOKCORP(InCanada:BritishCanadianImporters(4WesternProvinces);KLR(PQ)) 872 120/min. Polyethelene 2-36in.width Automatic 1002/1003 30/min. Asabove 2-15in.width Semi-automatic MULTIVACCANADA

MultivacChamber&Belted machinemodels 2-4cpm LaminatedbarrierbasUpto1320mmx820mmManual&automatic OPTIMAMACHINERYCORP OptimaMiniBagger10ppm PE/Wicketed Semi-automatic

BagstarIISlant 20ppm PE/wicketed 2x2to6x15 Semi-automatic BagstarIVSpeed 25ppm PE/wicketed 3x8to11x21 Semi-automatic

PACKRITE(InCanada:CiMa-PakCorporation,JamesDawsonEnterprises,FladgatePackaging)

BandRite6000BandSealer250-750 Heatsealablepre-madebagsVarious Semi-automatic PackRiteJawSealers PolyorBarrierBagsvarious manual PEARSONPACKAGINGSYSTEMS(InCanada:AlexE.JonesandAssoc.)

BI18BagInserters 18cpm Polybagrollstock Varied Opens,insertsandcuffs PEMBERTON&ASSOCIATESINC

TipperTiecasing stuffing/clippingsystemModel RS4202 To205-lbpackagespmShirredcasings Various Automatic

TipperTieturretsystemAverage5000lbphFibrouscasing 1to9in.dia. Semi-automatic PLANAUTOMATION MatrixMercury 120bpm Allheatsealablefilms2"-15" Intermittent PLEXPACK

MPS6100,6300,6500,6700500ipm Poly's,waxtypebags,coated papers,moisturebarrierbags, laminatedfoils,multiwalled paper/medicalbags.

Allsizes

CBS-CM,CBS-BBandsealersPE,PVCetc. Continuous Manualorautofeed

COUSINSPACKAGINGINC(InCanada:CousineauPackagingInc.) 8100Series Stretch

PPITECHNOLOGIESGROUP(InCanada:CharlesDowner&Co.,Ltd,RichmondHill,ON;AesusPackagingSystems,PointeClaire,QC) Meurer Polyethylene Both Heat 60%stretch BARCODING&BARCODESCANNINGEQUIPMENT MAKER&MODEL COMPATIBLESYMBOLOGIESOPERATION(Fixed mount,handheld, etc.) FEATURES

AHEARN&SOPERINC AccusortMini-XSeriesII 1D(linear) FixedMount Omnidirectionalbarcodescanner,300sps Windowsbasedconfigurationsoftware. AUTOMATEDPACKAGINGSYSTEMSINC(InCanada:PackProSystems,Inc.Stouffville,ON) AutobagPI412cInlinePrinter Multiple Fixedmount Thermaltransfer,HRtext,graphics& barcodesspeedupto12ips. BARCODEGRAPHICSINC Axicon6015,6515&7015SeriesBarcode Verifiers UPC/EAN,Code128,Code29,Code93, GS1-128,GS1Databar.ITF,ITF-14, Pharmacode HandHeldwithoptional Fixedmounting

ANSI/ISO1DBarcodeTestingand Reporting Axicon12000SeriesBarcodeVerifiersDataMatrix,GS1-Databar,QR&standard 1Dsymbologies Desktop ANSI/ISO1D&2DBarcodeTestingand Reporting TruCheck100&200SeriesBarcode Verifiers UPC/EAN,Code128,Code39,Code93, GS1-128,GS1Databar.ITF,ITF-14, Pharmacode Desktop ANSI/ISO1DBarcodeTestingand Reporting

TruCheck400SeriesBarcodeVerifiersQR,DataMatrix,GS-Databar&standard 1Dsymbologies Desktop

ANSI/ISO1D&2DBarcodeTestingand Reporting TruCheck2DUSB,Omni&TowerBarcode Verifiers QR,DataMatrix,GS1-Databar&standard 1Dsymbologies Desktop ANSI/ISO1D&2DBarcodeTestingand Reporting Datalogic 1D&2DBarcodes Varies BarcodeScanning

HARLUNDINDUSTRIESLTD

IDTech250LPA 1&2D ThermalTransfer

IDTech150/220RFID RFID Microscan asabove Fixedmount RJS asabove Handheld

HitachiPX-260U asabove Inkjet

HitachiPX-460U asabove asabove Foxjet asabove asabove Easyprint asabove Thermaltransfer MATTHEWSMARKINGSYSTEMS

FixedMount

Allsizes Asabove

MPS7100,7500 750ipm Heavydutypolys,multiwalled paperbags Allsizes Asabove MPS14000 1200ipm Poly'swaxtypebags,coated papers;moisturebarrierbags laminatedfoils,multiwalled, paper,medicalbags

PPITECHNOLOGIESGROUP(InCanada:CharlesDowner&Co.,Ltd,RichmondHill,ON;AesusPackagingSystems,PointeClaire,QC)

PSGLEE 80 Laminate 4"to14"W

PSGABT 120 Laminate 6"to10"W Premade RJMACHINERYINC PacemakerModel624Drop Sealer 30bagsperminuteWicketedPolyBags24"Wx24"Long

PacemakerModel402Bag Blower 30bagsperminuteWicketedPolyBags24"Wx24"Long Blowbagopen&guideproduct intobag REISERCANADACO SupervacGesmbHVarious All Allsizes Manualandauto. SEALEDAIRCANADACOCIECRYOVACFOODDIVISION

To20ppm Asabove To14in.wide

8800-E14E To15pp, Asabove To14in.wide Automatic STEELNORSYSTEMS(InCanada:AccentPackaging,Surrey,BC;ArtyPacAutomation,Laval,QC;EmpressPackagingInc.,Milton,Ontario;Plan Automation,Orangeville,ON)

SteelNorSS85T 25-475IPM MostfilmsandLaminatesSmallbags,pouches,ect.8"Manualfeed,continuous SS850-SSC440 25-475IPM MostfilmsandLaminatesBags,pouches,sidegusset19"Manualfeed,continuous SS1500T-SSC545 25-1100IPM MostfilmsandLaminatesAsaboveto30" Manualfeed,continuous SS1510T-SSC545 25-1100IPM MostfilmsandLaminatesAsabove,forthickerfilmsManualfeed,continuous STEELTEKADIVISIONOF877418ONTLTD(InCanada:ImpactSales;R-JMachineryInc;RossPackagingServices;PaxiomGroup,W-P-LMachinery Sales;MDPackagingInc)

SteeltekST-80 Fixed590ipm MostheatsealablematerialsAllsizes Manualfeed,portable SteeltekST-80VS Variableto590ipmMostheatsealablematerialAllsizes Manualfeed SUPERVACGESMBH(InCanada:Reiser(Canada)Ltd.,Burlington,ON) SupervacGesmbHVarious All Allsizes Manualandauto. TNANORTHAMERICAINC tnarobag3ci 250onsingletube OPP/BOPP 2-1/2to16-1/2in.WVFFS TRIANGLEPACKAGEMACHINERYCO(InCanada:M&MPackagingAssoc.;AnypackPackagingMachineryInc.) TriangleB108 140/min. Poly&Supported Upto8"Wx14"L Intermittent TriangleB12 110/min. Asabove Upto12"Wx14"LIntermittent TriangleB32 110/min. Asabove Upto12"Wx20"L Intermittent TriangleB35 90/min. Asabove Upto15"Wx20"L Intermittent WEIGHPACKSYSTEMSINC XpdiusElite1200VFSUpto120/min RollStock 3"-12"W2"-16"LAutomaticorSemi-Automatic SwiftyBagger1200,3600to25/min-1200 to40/min-3600 Pre-made,non-jacketedbags, allstyles 1200-6"-12"W,8"-18"L; 3600-3.3"-8"W,6"-11"L Asabove BingoBagger upto25/minwithoutgasflushPouches,stand-upbags6"-14"W6"-20"LAsabove BingoBaggerXL upto15/min Pouches,stand-upbags14"-20"W14"-24"L

VertekJR Upto70cpm RollStock 1"-5.5"W2"-8"LAutomaticorsemi-automatic

Upto40cpm RollStock 2.5"-11.5"W4"-18"LAutomaticorsemi-automatic Vertek1600 Upto30cpm RollStock 10"-16"W6"-18"LAutomaticorsemi-automatic Vertek2400 Upto20cpm RollStock 16"-24"W9"-36"LAutomaticorsemi-automatic VSBagger Upto35/min Pre-madewickedbags,zipper bags,bagswithhandles 6"-14"W-6"-20"LAutomaticorsemi-automatic ZippyBagger Upto35/min

MatthewsViacodeT-Series ITF,ITF-14,Code39,EAN8,EAN13, UPC-A,PDF147,Code128,GS1-128A&B, SCC14DatamatrixQRCode

FixedMount

Highresolutioninkjetcasecoding.Upto4" messageperhead.Remoteconnectivity andeffortlessintegrationwithERP/MRPor WMSsystems.Replaceadhesivelabelsor pre-printedcartons.Brandondemand. MatthewsCoditherm EAN-13,EAN8,EAN-128,UPC-A Interleaved,Code39,Code128(A,C), ITF-14,Paraf,HIBC43,Binary,2Dmatrix, PDF417

NORDSONCANADALIMITED(InCanada:Timeco-Marten,Calgary,AB;Edmonton,AB;Winnipeg,MB)

Digitalthermaltransferprintingofvariable dataontorigidmaterials.Barcodes, graphics,serialization,date,time,lot numbers,batchnumbers.Upto600dpi.

BC5100BarCodeReaderLogiComm ControlSystem Coabar,Code39,Interleaved2of5,Code 93,Code128,UPC/EAN,Pharmacode, BobstCode Console&ScannerScans,verifiesbarcodesatupto 425m/min.easyinstallation,installon parentmachines

PPITECHNOLOGIESGROUP(InCanada:CharlesDowner&Co.,Ltd,RichmondHill,ON;AesusPackagingSystems,PointeClaire,QC) PSG Yes All Checkallitems

SAMUELSTRAPPINGSYSTEMS ToshibaTEC

operationand maintenance.

PET/HeatSetPETupto3liter 36,000bph

ConfiformFlexWaveBeverages-8cavityonlyPETmicrowave technology,multiple colors

ContiformC3highSpeedBeverages PET 2250cph(cavity/hour)

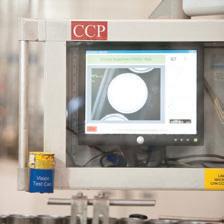

PET-ViewInspection CamerainspectionofPET containersfordefects tosuitspecificblowmolder application buildtosuit IntegratedatBlowmolder dischargestarwheel.

PreformCheckAirWizard

InspectionofPET Preformsfordefects tosuitspecificblowmolder application buildtosuitcontiformIntegratedatpreform infeedrailrecoveryoflow andhighpressureairfor reuse.

Contipure beverages Sterilizationofpreformsin theblowmolder tolog3or4 buildtosuitContiform

PETBottle-to-Bottle RecyclingPlant TurnkeysystemCompactBottle-to-Bottle RecyclingLinesfor ConvertersandBottlers.

SIDELCANADAINC SBOUNIVERSAL

PostconsumerPET Bottles

Outputrangeof500kg/h or1,000kg/h

Outputrangeof500kg/h or1,000kg/h

Includesbottlesorting (colourandon conformancematerials) thrutocleanPETflake material.

SBOUniversalisarotarymachine,usingthebi-orientationblowmoldingprinciple.Thismachinehasbeendesignedtodelivertop-qualityplasticpackagesat highspeeds. Mainfeatures:Output:10,800to54,000bottles/h.Bottlesize:0.25Lto3L.Suitableforstillandcarbonatedwater,softdrinks,juice,tea,isotonicbeverages,milk anddairyproducts,beer,oilandsaucesandHPCproducts.AvailableinaCombiconfiguration

technologydevelopedforSidelCombimachinesisaunique,sustainabledrydecontaminationprocessforpreformsandcaps.

BOTTLECAPPING,SEALING

500ml

CapmaticRoadRunner 180-4-6-8 60-200bpm Alltypes 80mm 120mm Continuousmovement motion

CapmaticRoadRunner 300M-4-6-8-10-12 60-300bpm Alltypes 120mm 230mm Asabove

CapmaticRoadRunner Pharma Aluminumseal32mm 10mm Continuousmotion

CapmaticBeltstarIn-lineUpto350bpmCap&retorquer

DJSENTERPRISES(InCanada:Hanli;Cadmac;SkySoftgelMachinery)

DJS6SplindleCapper100pbm Screwcaps 8mm-89mm

Conveyorendcapfeeder

ENERCONINDUSTRIESCORP(InCanada:MDPackaging,ON,QC;ThomasMackay&Sons,BC) AutoJr. Semiautomatic Upto89mm Benchmounted,easyto use

SuperSealJr.Manual Upto120mm Portable,easytouse

FEEDSYSTEMSINC(InCanada:NewmapakLtd)

ModelA6 to300pbm 13mto120mmalltypesto120mm to2.5gals Nochangeparts AM-250 upto600bpm13mmto120mmall types to120mm upto2.5galsNochangeparts

FERRUM(InCanada:ChisholmMachinerySalesLimited,NiagaraFalls,ON)

FerrumF403 to270cpm RoundCans 200-401

102to714HtFood/Bev/CanMfg

FerrumF404-T1to360cpm RoundCans 200-401 102to714HtFood/Bev/CanMfg

FerrumF404-T2to360cpm RoundCans 401-603

FerrumF405 to500cpm RoundCans 200-404

102to914HtFood/Bev/CanMfg

102to714HtFood/Bev/CanMfg

FerrumF406 to600cpm RoundCans 200-401 102to714HtFood/Bev/CanMfg

FerrumF408 to800cpm RoundCans 200-401

FerrumF410 to1,000cpm RoundCans 200-401

FerrumF412 to1,200cpm RoundCans 200-307

FILAMATIC(InCanada:Bellatrx,Pointe-Claire,QC)

102to914HtFood/Bev/CanMfg

102to914HtFood/Bev/CanMfg

102to914HtFood/Bev/CanMfg

Filamatic Upto50cpmscrewcaps,plugs, stoppers 65mm gals Servotorquingadj. gripperchuck

KAPSALLPACKAGINGSYSTEMSINC(InCanada:NewmapakLtd) Kaps-All 1-400 CT,disctop,yorkeretc.120mm

SPEEDWAYPACKAGINGMACHINERYINC

BOTTLECLEANERS

MAKERANDMODELPRODUCTS OPERATION SPEED FEATURES CAPMATICLTD CleanStarSS VacuumaspiratorwithHEPA filter

DESCONCONVEYORSYSTEMS

LowlevelgripperrinserPET,Glass,Metal FullyAutomatic 50-1200bpm Cleandesign,fullyautomatic operation,quickchangeover

FEEDSYSTEMSINC(InCanada:NewmapakLtd)

ModelAC-35 Alltypes Straightlinecontinuous motions upto150bpm nochangeparts,inonizing, invertingandpositive vacuuming

KAPSALLPACKAGINGSYSTEMSINC(InCanada:NewmapakLtd) Kaps-All Plastic,Glass,CorrigatedAirRinsing KRONESMACHINERYCOLTD Variojetrinser rinsermediawithair,water and/oralternatives rotarymachineprincipleactionupto2000bpm positivebottlerinsingviarotary machinedesignwithnozzle

Spiragrip returnablePETbottlecleaningBottlesubmersionand subsequentmediajetting inquire LavatecKE returnableglassbottlecleaningBottlesubmersionand subsequentmediajetting upto2000bpm

MCBRADYENGINEERINGINC

Model100 AnyRidgedcontainerAutomatic 100bpm 25in.linespacerequired OMEGADESIGNCORP(InCanada:TrilliumMachineryGroupInc) ILARInLineAirRinserGlassorplastic Inline Upto150 Usesionizedair RARRotaryAirRinserGlassorplastic Rotary Upto300

PAXTONPRODUCTS(InCanada:EckertMachines,3841PortageRd.,NiagaraFalls,Ontario,L2J2L1) Compact,Oil-freeBlowers,Air Knives&AirKnifeDrying Systems

Highspeeddrying.Airflowsto 2400cfm,airpressuresto130" H2O(g) Any Advanced,energyefficient design,FDAcompliant

REMORRISONEQUIPMENTINC AdamarkAirKnifeCleaning Systems Cans,bottlesairrinserBlowerdrivenairknifewith staticelimination Asrequired Oil-freewarmdryHEPAquality air,compactblower

SBC(InCanada:NewmapakLtd.) Bottling&Caning Water/aircleaners Rotary Upto800bpm StandaloneorMonobloc

SEPTIMATECHGROUPINC RXNTChangeParts,Standard OEMChangeParts,Feed Screws,StockParts BOTTLEDRYING

MAKER&MODELPRODUCTS OPERATION SPEED FEATURES

ECKERTMACHINESINC PaxtonProductsvarious modelsavailabletosuit application.

PAXTONPRODUCTS(InCanada:EckertMachines,3841PortageRd.,NiagaraFalls,Ontario,L2J2L1) Compact,Oil-freeBlowers,Air Knives&AirKnifeDrying Systems Highspeeddrying,airflowsto 2400cfm,airpressuresto130" H2O(g)

REMORRISONEQUIPMENTINC

RepublicBlowerSystemsCans,bottles,foodpacksAirknifedryingsystemCansupto1,400pm;bottlesto 680pm;foodtraysto60pm Energysavings,turnkey system,compact,lownoise AdamarkAirKnifeDryingCanbottlescomplete conveyorizedstandaloneunit Model301completedryer packagewithenclosure FoodPackage/Pouchdryer BrandModel302 Shrinktunnelexitdryerof packages/pouches

Continuousencloseddrying unit asrequired Selfcontainedconveyorized systemwithVFDbeltdrive blowerenclosurebaseairknife enclosedwithdrippan

SEPTIMATECHGROUPINC RXNTChangeParts,Standard OEMChangeParts,Feed Screws,StockParts, STANMECHTECHNOLOGIESINC UnheatedAirKnifeDrying Systems Allapplications Allspeeds Energyefficient,costeffective

CARTONING

MAKERAND MODEL TYPEOPERATION*STYLECARTONSIZESPEEDFILLINGFEATURES

BIVANSCORPORATION 50SeriesHorizorVertF,O,CCont 7/8x3/8x1-1/4 to5x3-1/2x12 60 ManualCartonerector, portable,easy changeover BLUEPRINTAUTOMATIONINC(InCanada:Flexi-PackMachinerySolutions;TechnoPak) RemoteCase Erectro(RCE) In-lineor right-angle varied 15cpm(erectand tapeseal) Std.Auto changeover, double-stripping fromotherblanks BOSCHPACKAGINGSYSTEMSAGPAAL(InCanada:CharlesDowner&Co.Ltd.,RichmondHill,ON) Elematic1000HorizontalIndexing6,9&12 70-260mmLto90/min Quiet,gentle operaton HC-CBICartoner inchvers.hotmelt ortuck-in 40-130mmW 110-350mmH Touchscreen

BOSCHPACKAGINGSYSTEMSAGSIGPACK(InCanada:CharlesDownerCo.Ltd.,RichmondHill,ON)

7420(dualhead)Pic-Lock,Hor.F

CARTONING

MAKERAND MODEL TYPEOPERATION*STYLECARTONSIZESPEEDFILLINGFEATURES

ECONOCORPINC(InCanada:ArpakPackaging;MarpakPackagingSystems&Flexi-PackMachinerySolutions)

MiniMonosealFlapGluerC,S Cartonflaps1x1in.to12x4 in. OperatordictatedManualSimple&portable

E-System2000HorizontalF,I,C,SEnd-load1x3/4x2-1/2to 12x4x12in. 25cpmManualorauto load Stainlesssteel

EconosealSpartanHorizontalF,I,C,SFolding& corrugated 2x1x5to10x4x12 in. 40cpmAutoloadMechanically driven,stainless

PegasusHorizontalFlexibleF,O,I,C,SEndload2x3/4x5to8x3x12 in. 120cpmAutoorManual

ELLIOTTMFGCOINC(InCanada:ChisholmMachinerySalesLimited)

ElliottIH2,CH2, CH3 O,In,Fi,L,C,S, Seal Fullend1"Lx1/2"WMin To300cpm Allmechanical drive,splindshaft drive,elevated.

ILAPAKINC Cayenne KRONESMACHINERYCOLTD

VariocartC-40RSCcorrugated cartons

VariocartC-50RSCcorrugated cartons

VariocartCM-40RSCcorrugated carton

inquire8-40cartons/min

inquire15-50cartons/min

inquire8-40cartons/min

Variocolcartonlid sealer RSCcorrugated cartons inquire60-120packs/min

LANGENPACKAGINGINC

C-1000AutoloadHor.F,O,In,C,Sendload 180cpm opendesign, cartonpre-break, varietyofinfeeds.

ChinookAutoloadHor.F,O,In,C,Sendload 500cpm Stainlesssteel, continuousmotion, rotarycarton, feederservodriven B1M ManualHor.F,O,C,Sendload 120cpm Continuous intermittentmotion, tuckorglue,rotary cartonfeederl

MASSMANAUTOMATIONDESIGNSLLC MassmanPSA NORDENPACKAGINGCO

NordenPac700, 1400,2002,3002 series Horizontal, continuousmotion O,I,Fi,L,C,SReverse,straight tuck,glue 60-350pm Microprocessor controls 5002(new) 25-500pm PEMBERTON&ASSOCIATESINC Futura F,O,In,L,C,S PINEBERRYMANUFACTURINGINC

Boxxer3424

Boxxer4235

Boxxer4839 Min.20"Lx18"WX10"D Max.26"Lx22"WX17"D

20/min. Automatic

BoxxerAutoLockMin.10"Lx6"Wx9"DMax20"Lx12"Wx16"D KnockDown-Min.16"LX 12"W-Max.20"LX12"W X16"D-Knockdown:28"W x32"D

BoxxerFOL

Min.10"Lx6"Wx8"D Max.15.5"Lx7.5"Wx11"D 18/min Automatic

BoxxerT-12 Min.11"Lx7.5"Wx6"D Max24"Lx15.75"x19"D 12/min Automatic

BoxxerT-4036

Min.11"Lx9"WX6"D Max.24"Lx16"wX20"D 18/min Automatic

Erectingcorrugatedcasewithglue;Heavy duty,weldedsteelframe;Quicksizechange overpackage;Mechanicalchaindrive; interlockedsafetygatesordoors;Easyaccess panelsaroundthemachine

Erectingcorrugatedcasewithglue;Heavy duty,weldedsteelframe;Quicksizechange overpackage;Mechanicalchaindrive; interlockedsafetygatesordoors;Easyaccess panelsaroundthemachine

Erectingcorrugatedcasewithglue;Heavy duty,weldedsteelframe;Quicksizechange overpackage;Mechanicalchaindrive; interlockedsafetygatesordoors;Easyaccess panelsaroundthemachine

Erectingcorrugatedcasewithglue;Heavy duty,weldedsteelframe;Quicksizechange overpackage;Mechanicalchaindrive; interlockedsafetygatesordoors;Easyaccess panelsaroundthemachine

Erectingcorrugatedcasesself-locking,fold& tuckstyles-noglue/notape;quicksize change-over,Heavyduty,weldedsteelframe; Interlockedsafetygatesordoors;Low maintenancemechanicaldrive

Erectingcorrugatedcasewithglue;Heavy duty,weldedsteelframe;Quicksizechange overpackage;Mechanicalchaindrive; interlockedsafetygatesordoors

Erectingcorrugatedcasewithtape;Quick change-over;Interlockedsafetygatesordoors; lowmaintenancemechancialdrive;Venturi vacuumusedincaseerection;Smallfootprint

Erectingcorrugatedcasewithtape;Heavy duty,weldedsteelframe;Quicksizechange overpackage;Mechanicalchaindrive; Interlockedsafetygatesordoors;Easyaccess panelsaroundthemachine

PoplokTSF Widerangeofsizes15/min Automatic Tuckstyles-noglue/notape;2,4ormulti-fold &tuckavailable;Formlargeorsmalltrayswith orwithoutalid;Quicksizeadjustment-no mandrelrequired;topsheetfeed

Poplok Widerangeofsizes20/min. Automatic Tuckstyles-noglue/notape;2,4ormulti-fold &tuckavailable;Formlargeorsmalltrayswith orwithoutalid;Quicksizeadjustment-no mandrelrequired;Quickchange-over

Vassoyo3029

Vassoyo3934

TishmaVertical& horizontal Cartoners Semi&Fully Automated systems TuckGlue,Cable& Flip-tops,etc. AllsizesUpto1000cpmVolumetricscales, roboticsetc. SSconst.

TRIANGLEPACKAGEMACHINERYCO(InCanada:M&MPackagingAssoc.;AnypackPackagingMachineryInc.) TriangleFlex1HorizontalBag-In Box Intermittent Upto9"Lx7"W x13"D 100cpmbeltloadSmallfootprint

TRINAMICSINCORPORATED TR2000ML,AL, ALX HorizontalCartonerO,I,C,SKnockeddownvariousto120cpmManual&autoload cartoner Powerful,safe coding,gluing UpgradabletoA/L Shaftdriven

TR2000SWSleeverF,C,S W/AroundVarious120/min Bowls,foiltopcups

UHLMANNPACKAGINGSYSTEMSLP

T2060 ToploaderF,O,In,L,C,STopload250x210x15mm max 80cpmAutomaticcGMPcompliant

WEPACKIT2009INC

250CEQuicklockerectorO Variousto25cpm CASEPACKAGING

MAKER&MODELCASESIZERANGESPEED OPERATIONFEATURES

3MCANADAINC

a20 6"-nolimitLx6"-21.5"W x4.75"-21.5"HWx21.5"H max Upto30cpm

a70 6"-nolimitLx6"-21.5"Wx 4.75"-21.5"H upto30cpm

Semi-Automatic,AdjustableBottombeltdrive;2"AccuGlideII+taping heads

Semi-Automatic,AdjustableUpper&Lowerbeltdrive;2"AccuGlideII+ tapingheads

r70 6"-nolimitLx6"-21.5"Wx 4.75"-21.5"H upto15cpm FullyRandom Upper&Lowerbeltdrive;2"AccuGlideII+ tapingheads

a80 6"-nolimitLx6"-21.5"Wx 4.75"-21.5"H upto30

a80-b 6"-nolimitLx6"-21.5"Wx 4.75"-21.5"H upto30

200a 6"-nolimitLx6"-21.5"Wx 4.75"-28.5"H upto40cpm

Semi-Automatic,AdjustableSidebeltdrive;2"&3"AccuGlideII+taping Heads

Semi-Automatic,AdjustableBottomsealonly;sidebeltdrive;2"AccuGlide II+tapingheads

Semi-Automatic,AdjustableBottombeltdrive;2"&3"AccuGlide3taping heads

700a 6"-nolimitLx6"-21.5"Wx 3.5"-28.5"H upto40cpm Semi-Automatic,AdjustableUpper&Lowerbeltdrive;2"&3"AccuGlide3 tapingheads

700a-S 6"-nolimitLx6"-21.5"Wx 3.5"-28.5"H upto30cpm Semi-Automatic,AdjustableStainlessSteel;Upper&Lowerbeltdrive;2"& 3"AccuGlideII+tapingheads

700aks 6"-nolimitLx7"-25.5"Wx 4"-36"H upto40cpm Semi-Automatic,AdjustableLargeCases;Upper&Lowerbeltdrive;2",3"& 6"AccuGlide3tapingheads

ABBINCBUSINESSUNITROBOTICS

IRB260 Materialhandling,case packaging,pickandplace 30kgpayload,1.50mreach,IP67protection IRB360 Asabove 3kgpayload,15600mmworkingarea,IP69 protection

BELCORINDUSTRIESINC(InCanada:MDPackaging)

BEL150 Min.8x5.5x3.5in.;max. unlimitedx24+x31in. 30cpm Semi-automaticuniform casetaper Heavydutytaperwithuni-drive

BEL270 Min.8x8.5x5.25in.;max. 20x15x14.25in 25cpm Fullyautomatictop& bottomhotmeltcasegluer Softcompression"No-Gap"closuresystem

BIZERBACANADAINC

CPSCP201 450X450mm 140ppm Horizontal Fullyintegratedsolutions CPS Various GravityorVacuumQuickchange-over

CPSCLP 600X500X500mm120ppm Horizontal Availableformetaldetection,checkweighing, caselabelling

BLUEPRINTAUTOMATIONINC(InCanada:Flexi-PackMachinerySolutions;TechnoPak)

RoboticTopLoaderVaried Upto100ppm;upto300 ppmwithBPASmart-Trak Collation Toploadingofsecondary containers Easilyadaptedtolargechangesinpackage andcontainerstyles.Higherspeedswithless maintenance.

BOSCHPACKAGINGSYSTEMSAGPAAL(InCanada:CharlesDowner&Co.Ltd.,RichmondHill,ON)

Elematic1000SLCase packer 150-400mmL150-500mm W50-350mmH to25/min. Servodrives,modernIPC control,mostcomponents automated,lowblankmag. height,designedfor24/7 operation

Largeblankmagazineasastandard (profeeder).Blankdimensions:min. 200x300mmmax.1100x700mm

Elematic2000Series60-250mmL150-600mm W60-240mmH 15-50/min WraparoundverticalPackaging,Flexibility,idealforRRP,Wrap aroundortraywithllid

BOSCHPACKAGINGSYSTEMSAGSIGPACK(InCanada:CharlesDownerCo.Ltd.,RichmondHill,ON) TBL Toploading,case packaging,RSC 30cpm

F38CaseErectorCustomdesignto requirement 40cases/min. Erectcorrugatedcase (RSC,HSC) 5min,toolesschangeover99%efficiency

Min.9"Lx7"WX1.5"D Max22"LX21"WX6"D 40/min. Automatic

Min.14"Lx6"WX 1.5"D Max32"Lx28"WX8"D 40/min. Automatic

VassoyoClamshellMin.12"Lx8"WX2"D Max18"Lx12"WX6"D 30/min.

VassoyoAir Showcase

Min.23"Lx15"Wx4"D Max.23"Lx15"X11"D 22/min. Automatic

VassoyoAir Min.14"Lx10"Wx2"D Max.32"x28"Wx8"D 22/min. Automatic

Erectingcorrugatedtraywithglue;Quicksize change-over;Compactfootprint;HighSpeedupto40traysminute;Mechanicallow maintenancedrive:largetraysizerange.

Erectingcorrugatedtraywithglue;Quicksize change-over;Compactfootprint:HigSpeedupto40traysminute;Mechanicallow maintenancedrive:largetraysizerange.

Erectingcorrugatedtraywithglue;Quicksize change-over;Compactfootprint:HigSpeedupto40traysminute;Mechanicallow maintenancedrive:largetraysizerange.

Erectingcorrugatedtraywithglue;retractable mandrels;Quicksizechange-over;compact footprint;largetraysizerange-runlargeor smalltrays

Erectingcorrugatedtraywithglue;Qucksize change-over;Compactfootprint;largesize range-runlargeorsmalltrays,withorwithout lids

EDSONPACKAGINGMACHINERYLTDInCanada:AlexEJones&Associates 1000 3"-36" 3-5cpm Semi-AutomaticPneumaticorservo 3200

ELLIOTTMFGCOINC(InCanada:ChisholmMachinerySalesLimited)

ElliottModel9110 Servopacpickandplace casepacker Min:8"Lx6"Wx5"H;Max: 23"Lx16"Wx16"H Upto30cpm Topload Servodriven,fullyprogrammable,gentle producthandling.

FANUCROBOTICSCANADALTD(InCanada:FanucRobotiqueduCanada,Ltee)

LRMateSeriesupto6kgpayload

Picking,Packingand Assembly 5or6degreesoffreedom,+/-0.04mm repeatability,tabletopsize

M6iB upto6kgpayload PickingandPacking0.08 mmrepeatability,large workenvelope 6degreesoffreedom,+/M16iB upto20kgpayloadTo520°/sec PickingandPackingAsabove

HARTNESSINTERNATIONAL(InCanada:AlexE.Jones&Assoc.)

30cpm Bottles&cans Airtransfer

835Packers

ModelD-1000DecaserFullrange 30cpm Auto Positivehandling,allsizesandshapes, minimalspaceneeded

GlobalPack3500widerange 60+ Continuous

KRONESMACHINERYCOLTD

Modulpac inquire 10-25Outputpacksper min. continuousmotion

VariopacPro inquire 30-100packs/mincontinuousmotionhandleswraparound,trays,pads,UBoard, bundles

VariolinePackerinquire 30-80pack/minIntermittentmotionplacescans,containersintopaperboardor corrugatedpacks

RobotSeries inquire inquire Intermittentmotion

Contipac inquire inquire continuousmotionpacker

LinapacII inquire inquire IntermittentmotionServomotorcontrolled

Blitzpac inquire inquire IntermittentmotionCamcontrolled

KUKAROBOTICSCANADALTD KR5

ContactKUKARoboticsfor afreecycletimeanalysis withyourproduct

Casepacking,material handling 6-axis,5kgpayload,1412mmreach

KR6 Asabove Casepacking,material handling 6-axis,6kgpayload,1611mm

LANGENPACKAGINGINC LRC-500 Variable 200-600pm Toploadroboticpackaging (trays,cases) Collisionguard,pathoptimization,varietyof opt.Add-onfeaturesincl.Palletizingopt. (LRC700)

MARQPACKAGINGSYSTEMSINC(InCanada:AbbeyPackagingEquipment)

MARQSeries erector/sealer220

6X5.25X3.5to27X18.5X18Upto1200cphAutomatic 230VAC,setsupcasesondemand MARQHPAtop&bottom casesealer 8x8x5to22x22x20in.Upto1800cphAutomatic Runson110/220VAC,60or102in.length, tapeorhotmeltglue

MARQ(HPE)high performancecaseerector bottomsealer 10x8x6to20x19x15in.Upto1200cphAutomatic Tapeorhotmeltgluesealing.Heavyduty construction

MARQProduct Settler/Sealers

8x8x6 24x20x20 Upto1200cphAutomatic Toponly-Top&bottomtapeorhotmelt4-6" overpack

MASSMANAUTOMATIONDESIGNSLLC SE/M 8x5x3to30x24x24in.To17cpm Fullyautomaticbottom loader MildsteelorStainlesssteelconstruction.Very compactframe,servodrivenmotions InlineIL-20 8x5x5to18x12x12in.To20cpm Asabove MildsteelorStainlesssteelconstruction,fast changeover WACP To30cpm Asabove A-BPLC,PVHMI,Servos,Robustdesign Continuous To60cpm Asabove A-BPLC,PVHMI,Servos,Robustdesign

METTLERTOLEDOINC(InCanada:MDPackaging) Robocaster MOTOMAN(InCanada:YaskawaMotomanCanada) HP20,HP50HP50-356axis High Upto50kgpayload Upto2,525mmreach PEARSONPACKAGINGSYSTEMS(InCanada:AlexE.JonesandAssoc.) MP35Multipacker21"Lx17"W 35cpm Loadsfour6-packcarriers, six4-packcarriers,orthree 8-packcarriersinto trays/cases In-lineorcrossflowfeedofcarriers&cases

MP50Multipacker14.25-15.5L,8.75-11.3W, 15"opendepthmax 50cpm Highspeedmultipackerfor beverage&brewing PLANAUTOMATION DouglasMachine4"x18" Upto60cpm IntermittentandcontinuousAllServo

PPITECHNOLOGIESGROUP(InCanada:CharlesDowner&Co.,Ltd,RichmondHill,ON;AesusPackagingSystems,PointeClaire,QC) Meurer All 50cpm Fillandload Endofline

PREMIERTECHSYSTEMS PremierTechSystems RoboticCasePacker Upto20picks/minute -simpleoperation;noflapholderneeded thankstoroboticmotion-designedtomeetthe moststringentsafetystandardscurrentlyon themarket-simultaneoushandlingofdifferent products-Multipickavailable-Flexible,gentle handling

ROBOPACSA(InCanada:CartierPackaging,Saint-Césaire,QC) SuperBoxCaseErectorL250mm-600mm W170mm-410mm H90mm-500mm AutomaticCardboard CaseErector StandardFeedStorageUnitCapacity:50/60 Standardtape

SATURNPACKAGINGEQUIPMENT Case-It 20'-20" to25cpm Various

When it comes to forming corrugated or paperboard cartons, Delkor Trayfecta Formers are specifically engineered for maximum flexibility to accommodate a broad range of package formats. Trayfecta Formers enable our customers to quickly address the changing needs of the marketplace with one machine.

CHECKWEIGHING

MAKERAND MODEL SPEED CAPACITY ACCURACY TOLERANCE WEIGHT CAPACITY REJECT MECHANISM RECORD

ANRITSUINDUSTRIALSOLUTIONSINC(InCanada:AbbeyPackagingEquipmentLtd.)

SVhHighAccuracy Series 600ppm+/-0.01g0.5g-3kgVariousYes

SViWashdown Series 280ppm+/-0.01g6g-15kgVariousYes

SVfEconomySeries400ppm+/-0.05g6g-3.5kgVariousYes

BIZERBACANADAINC BizerbaCWMSeries250ppm0.1g-20g750g-60kgAirBlow

MatrixScales

EAGLEPIFORMERLYSMITHDETECTION(InCanada:PlanAutomation,Orangeville,ON) EaglePISystemsUpto120mpm and1500ppm Check-Weighing downto+/0.5%. Contamination inspectiondown to0.2mmforFE, Non-FEandSS, 0.8mmGlass, 1.25mm Ceramic,1.5mm CalcifiedBones, etc.

0-150lbAirKnife,Piston Arm,DropNose, Etc. EagleTrace Server,SQF, CVS,etc. Standard Ethernetand USB Connectivity

CODINGMARKING,IMPRINTING

MAKERAND

LinxSL50150Wattnoncontactlaser printing. 12/33mpsor2425 fpm 139x135mmunlimitedIdealforhighspeedapplications,designedfor brewingandbeverageindustries.Standalone mobilecabinetwithIP65rating.Nofactoryair requiredandnocoolingliquidsrequiredforthe lasertube.

HEAT&CONTROLCANADAINC

IshidaDACS-Gto440ppmto+/-0.1g600-1500g multi-range 3000-6000g multi-range

PackagedorRawProduct Inspection:Automaticproduct inspectionandrejectionfor: contaminants,check-weighing anddefects.PatentedMDX DualEnergyX-rayfor unparalleleddetectionof low-densitycontaminantssuch as:plastic,rubber,bones, stones,glass,etc.EagleTrace TraceabilitySoftware.Can inspectrandomlyin-feedcases frommultiplelines simultaneouslyusinga barcodereader.Unmatched Canadianserviceandparts supportfromPLAN Automation.

Various Versatile,multi-rangeweighing capacity;digitalhigh-output loadcellforfaster,more accurateweighing;allstainless steelIP-30andIP-69K waterproofconstruction.

IshidaDACS-2to600wpmto+/-0.2g600-3000gVarious

KRONESMACHINERYCOLTD Checkmatinquireperapplication softpush, continuous motionorcase divider. Designedtosuit application

LOCKINSPECTIONSYSTEMSINC

CK100 100cpm+/-1g1000gVariousYes

CK200 200cpm+/-2g200gVariousYes

CK2500 300cpm+/-1-2g25kgVariousYes

CK6000 80cpm+/-2-4g6kg VariousYes

CK50HW50cpm+/-10-20g50kgVariousYes

LOMASYSTEMSINC(InB.C.&Alta.:RossPackaging)

FullyAutomated, RecipeDriven, PushButtonand under10 seconds

LinxIJ355Highresolutionprinting ontocorrugateand secondarypackaging. 550m/sor2.1ipsupto53mminheightunlimitedTouchscreeninterface,automaticinkrecycling toreducewaste,USBportformessageback up.Simpleinkrefillwithuninterruptedprinter operation.Standarddatabaseinterfaceand imagestitchingfeatures.

LinxIJ375Highresolutionprinting ontocorrugateand secondarypackaging. sameasIJ355upto70mminheightunlimitedSameasIJ355withanincreasedprintarea.

LinxTT5/10Thermaltransferover printer.

DIAGRAPH(InQuebec:VisuascanInc.)

DiagraphPELHigh ResolutionInkJet Non-contactinkjet printing

V/700InkJet Printer Asabove

Changebelts,conveyors withoutusingtools,easy cleaning,100productmemory.

systemdesignedtosuit customerapplication touchscreen

Variablespeed,Servo Feedback,RS232

Seconds,40 products

Variablespeed,Servo Feedback,RS232 Seconds,40 products

Variablespeed,Servo Feedback,RS232 Seconds,40 products

Variablespeed,Servo Feedback,RS232 Seconds,40 products

Variablespeed,Servo Feedback,RS232 Seconds,40 products

LCW3000,6000,& heavyweight 350/450ppm 300ppm +0.6g300gr6000grtosuitEnet&OPC washdown Productmemory,PCbased touchscreen,AllenBradley Controls

METTLERTOLEDOINC(InCanada:MDPackaging) CM6000seriesfor cartons 400ppm1g 5ozto50lbFullrangeof options Fullrangeof digital& computing controls Widerangereporting& recordingdevices,Allen BradleyPLCinterfaceoption Allmodels1min. orless

CornerstoneSeries900ppm1g 50gto15lbFullrangeof rejectoroptions AsaboveAsabove Asabove SSeries 400ppm50-150mgto40000g AsaboveColordisplay Asabove

NALBACHENGINEERINGCOMPANYINC

WeighRightIQ-1EUpto14pmTo1gram10lbs.n/a n/a 5-10mins

PPITECHNOLOGIESGROUP(InCanada:CharlesDowner&Co.,Ltd,RichmondHill,ON;AesusPackagingSystems,PointeClaire,QC) PPINOW50 +/-0.01%1lb

Servomotor-controlledfeed gate

ESeriesNetWeigh Scales Upto20 weighments/min (simplex configuration)

+0.5to3.5oz10lbto110lb Gravity,belt,gravity-vibratory, screw,orvibratoryfeeder

E955Series BlendingScales Upto12 weighments/min (simplex configuration) +0.5to3.5oz10lbto110lb Gravity-vibratoryfeeder

CheckweighersCW10 upto250 packs/min +/-.5to1g dependingon application upto10lbsper package Airjet,swing gate, pusher/bopper, alarmhorn,drop belt,orcustom configuration

Alpha CheckweighersHP14

upto800mm/sec107mmx200mmunlimitedCanuseribbonwith1000minlength,Colour touchscreen,3levelpasswordprotection, onboarddiagnostics.Printersadapttoexisting bracketsforretrofittingontoproductionline.

Max.400fpm1/8-2in.charactersVariesDate&timecoding,alpha-numerictext,special charactersandlogos

Max:250fpm1/8-2in.charactersVaries$1595U.S.Dollars-upgradefromcontact coding.

Series1Inkjet System Asabove Max650fpm3/8to2in. VariesSuitableforcartoncoding

DOMINONORTHAMERICA A100Plus 4000fpm1-2lineswithavarietyof printformats

A200PlusAsabove AsaboveUpto4lineswitha varietyofprintformats

UnlimitedProvenA-Seriesreliabilityethernetport enablingprinterstobenetworkedbuiltinweb servertoallowremotemessageselectionand statusmonitoring:allrastersandprintformats onboardallowingthemachinetobe configuredfromtheuserinterfaceorvia networkedPC.

AsaboveSameasA100PlusAbilitytoset printer-generatedemail/SMSalerts;optional touchscreencontrol

A300PlusAsabove AsaboveUpto4lineswitha varietyofprintformats AsaboveSameasA200PlusIP55ratedcabinetforwet anddustyenvironments

A-SeriesFood Grade Environmentallyfriendly1500fpm1-4linesmixedUnlimitedDesignedfordirectfoodcontact,enhancedink system

A-SeriesOpaqueWire&cableapplications1500fpm1-3lnesmixedUnlimitedUserfriendly,completewithautostart/stop, enhancedinksystem

A400 Compactdesignfor rackable/stackaleoptions 1500fpm1-4linesmixedUnlimitedUserfriendly,designedfortightspacesand multipleheadappl.Enhancedinksys.

S100PlusSealedCo2laser(500 ft/min) Upto152m/minof 0.8-50mm (0.03-1.97") Max.printheightUnlimitedProvenS-Seriesreliability;highqualitycodes, colourtouchscreeninterfacewithfamiliar functionkeysforquickcodeset-upandediting.

S200B Sealedlaserwithblue tube Upto20ft/min30x50mm UnlimitedHighlyvisibleindeliblecodes;doesn'tmarkas deepasSTDlaser

S300PlusSealedCo2LaserUpto305m/min (1,000ft/min) (0.03-3.0")

Max.printheightof 0.8-76mm

UnlimitedSameasS200Plus

DDC3DualHeadAsabove 1,300fpm1-2lines/headAsaboveAsabove

DSLplusScribinglaserfor complex,highspeed applications Upto400m/pm 1212fpm Upto180x180mmUnlimitedLargermarkingfield;Greaterrangeofspot sizes&focallengths.

DataMatrixMachinescanablecoding solutions

400fpmMixedcode&textUnlimitedAutomationsolutionforsecure machine-readablecodes

C7-Large CharacterPrinter IndustrialCoding Applications 35m/minMaxCharacterHeight 17mm

C100High ResolutionLarge CharacterPrinter

C1000Plus-High ResolutionLarge CharacterPrinter

C3000Plus-High ResolutionLarge CharacterPrinter

C6000Plus-High ResolutionLarge CharacterPrinter

PrintsMultiplelinetext, on-linegraphicsandall majorbarcodesonuter cartons

Upto80m/mm;300 dotsperinch MaxPrintHeightof 17mm

Printsmultiplelinetext, on-linegraphicsandall majorbarcodesonouter cases,tray,andsacks.

Printsmultiplelinetext, on-linegraphicsandall majorbarcodesonouter cases,trays,andsacks.

Printsmultiplelinetext, on-linegraphicsandall majorbarcodesonouter cases,trays,andsacks.

Upto80m/mm;263 ft/min

Upto80m/mm:263 ft/min

Upto800m/mm; 263ft/min

Max.printheightof 17.5mm(0.67")

Max.pringheightof 35mm(1.38")

Max.printheightof 70mm(2.76")

UnlimitedMemorycapacityfor50messages;40 charactersperline

UnlimitedMessagestorage:50x4linemessagesupto 100charactersperline

UnlimitedSameasC3000Plus

UnlimitedSameasC6000Plus

UnlimitedMessagestorage:100x8linemessagesupto 200charactersperline;provenC-Series reliability.

D100+Scribing Laser 10Wscribingandrange ofsurfacesatlowto med.sized 198m/minAsmanylinesas desired. UnlimitedSeparatecontrollercanbeeasilymountedor stackedtosizeofmarkingfieldand/orstored forspacelimitations.

D-300+Scribling Laser Robust30W 396m/min.1500 characters/sec. Asmanylinesas desired. UnlimitedBuiltinwebserver.

DataacquisitionFillerFeedbackDoveTail chainsforsmalldia.Bottle transfer

packs/min +/0.100grams dependingon application Upto5lbsper package AsaboveDataacquisitionDraftCover,fillerfeedback

DataacquisitionFillerFeedback

CheckweighersHW15 upto50 packs/min +/-0.25g dependingon application upto100lbsper package swinggate, pusheralarm horn,dropbelt, orcustom configuration

Alpha CheckweighersMW16 upto125 packs/min +/-2grams dependingon application upto35lbsper package AsaboveDataacquisitionFillerFeedback

DataacquisitionDraftcover,Fillerfeedback

pusher MinimalLowprofile100k

K100 Dropondemandprint technology Upto984fpmUpto71.5mmUnlimitedDigitalprinter;in-lineprintingplasticcards K200 Dropondemandprint technology Upto9950fpm61mm UnlimitedDigitalprinter;offersfullpageorweb personalization

V-100 Thermaltransfer overcoding 500mm/sec53mmx106mmUnlimitedComprehensiverangeofhigh-speedthermal transferprintersfointermittentandcontinuous motionverticalandhorizontalpackaging machinery.

A320iInkjetInkJetcodingdesigned toreducecostand simplifytheproduction line.

A420InkjetIdealforBeverage, CanningandPEP applications

D120/D320iCompact,scribingLaser codersidealforcoding onawidevarietyof materialsatlowtohigh linespeeds.

D620i Idealforhighspeed beveragepackagingor serialisation requirements,both humanreadableand2D datamatrixcoding.

V120i

Thesmartupgradeto digitalcoding-andthe mostcosteffective solutionforflexible packaginginitsclass.

V220i Forflexiblefilmsand labels,theV220idelivers thecodingperformance youexpect,withoutthe costs.

V320i

witharesolutionof

TheV320iprintslarge area,highresolution codes,textandimages onflexiblefoils,filmsand labels.

max325m/minupto4linesofprint;255 charactersperline

max325m/minupto4linesofprint;255 charactersperline

D120-800 charactersper second;200m/min; 650ft/min-D320i 1500charactersper second;400m/min; 1300ft/min

2000charactersper second;600m/min; 1970ft/min

Intermittemnt400mm/s; Continuous10 mm/s-750mm/s

For52mmMode: Intermittent53mm/s; Continuous10 mm/s-750mm/s

50x50upto180x180 mm(characterheight from0.6mmtosizeof markfield)

50x50upto180x180 mm(characterheight from0.6mmtosizeof markfield)

Intermittent-32mmx 55mm;Continuous 32mmx500mm

Intermittent-53mmx 55mm;Continuous 53mmx500mm

UnlimitedDomino'sA320iinkjetprinteroffesaservice freeprinterplus:(1)Theoperatorinterfaceis easytouse-justenterthejobandgoontothe nexttask.(2)Simplifieddisplayquicklyputs theprinterinaction.(3)Itsprintheadstaysclear ofresidualink-you'llseelowerinkcosts.

UnlimitedTheA420i'sincreasedinkcapability complementsthegeneralrangeofi-Techinks, withaversatilerangeofSpecialistandCustom inkofferings,suchasspecialistthermochromic inkforcanning.

UnlimitedThekeytotheD-Seriesflexibilityisasmaller i-Techscanhead,connectedtothelasertube onamulti-positionmount.Theheadcanbe rotatedthrough90degreestepstoallowfor manymountingpositions,andbecauseitisso muchsmaller,itcaneasilyfitwherebigger laserscannot.

UnlimitedIncreasedpowerandspeed,combinedwithan optionalIP65-ratedversion,resultintheD620i laser,thatisequaltothemostdemanding applicationsandenvironments.RapidScan makesourlasers20%fasterforhigh-speed applicationsthanotherscribinglasers.

UnlimitedDomino'si-TechRibbonDriveoffers4ribbon savesettingsincluding'EconomyMode'which allowsyoutouseupto60%lessribbonper print-withoutaffectingprintquality.

UnlimitedUnlikeotherthermaltransfercoders,theV220i usesintelligentTechnologytomeetallyour generalpurposecodingneedswhilekeeping yourcostsaslowaspossible.Itscompactsize allowssimpleretrofitintoexistingbrackets. 650mribbonrolls.

Intermittment700mm/s; Continuous10 mm/s-1400mm/s (1)53mmVersion: Intermittent-53mmx 115mm;Continuous 53mmx2700mmand(2) 128mmVersion: Intermittent-128mmx 115mm;Continuous 128mmx1000mm

UnlimitedWiththelargestribbonrollsintheindustryand uniqueribbonsavefeatures,theV320ialso deliversthelowestcostofownershipofall thermaltransferprinters.

animatedgraphicsforsimpleoperation.Hasa builtinphotosensor. AT400SeriesThisseriesofprinteris idealforprinting ingredientsontounit boxesandcartoncoding. Suitedforvariousprimary andsecondaryproduct marking.

Linx4900Designedforavarietyof noncontactprinting applicationsontoprimary products.

CJ400 Noncontactinkjet printingfortraceability information.

LinxCJ400Carton Coder Noncontactinkjet printingfortraceability informationidealforprint ontotraysandcartons.

Linx7900NonContactinkjet printingfortraceability information.

Linx7900 Spectrum NonContactinkjet printingfortraceability information.

Upto480fpm4headedmodelupto2 incheshighand40 incheslong. unlimitedStainlesssteelhousingandisnetworkready. Capableofseveralbarcodesymbologies.

7.28m/sor1430 fpm 2.1to8.8mmunlimitedUpto2linesofprintwithsinglebuttonstartup andshutdown,mistakeproofinkandsolvent replenishment,autopowerdownwithprint headandconduitflushandonscreen diagnostics.

2.6m/sor510fpmupto3linesofprintor 8.8mminheight

unlimitedTouchscreenprogramming,easychange servicemodule,lightweightandcarryhandles forportability.

.5m/sor98fpm1lineofprint20mmin height unlimitedEasychangeservice

8.41m/sor1650 fpm upto5linesofprintor 13.8mminheight

7.28m/sor1430 fpm upto5linesofprintor 13.8mminheight

unlimitedLinx"Insight"remotemonitoringfromsmart phoneaswellasmessagedownloadingfrom PC,Messagechangeusingbarcodescanner option,USBportmaybeusedtotransferof messagebetweenprinters.

unlimitedDesignedforpigmentedinksforhighcontrast coding.HasallthesamefeaturesastheLinx 7900

LinxSL10110Wattnoncontactlaser printing. 1.83mpsor360 fpm 295x407mmunlimitedTubelifeof45000hours,nofactoryair required,idealforglassmarkingusing VisiCodetechnology,fastandeasycode changeswithoptionofusingbarcodescanner.

LinxSL30130Wattnoncontactlaser printing.

5m/sor980fpm295x407mmunlimitedSameasSL101withmorepower.HasanIP55 modelavailable.

G-SeriesIndustrialthermalinkjet priters

300m/min(984 ft/min)dpi dependentor60 m/min@300dpi

G100Model-25.4 mm/1"(2x12.7mm); G200Model-50.8mm/2" (4x12.7mm);G300Model -50.8mm/2"(4x12.7mm)

C6000PlusHighresolutionLarge characterinkjetforouter cases,traysandsacks upto800m/mm; 263ft/min Maxprintheightof70mm (2.76")

K600i DigitalinkjetDesigned forsheetorweb-printing ontolabels,tags,tickets, forms,securityproducts anddirectmail.

75m/m(246ft/min)Printwidthsrangefroma singleprintmodule, printinganimageareaof 108mm(4.25¿)upto 782mm(30.79¿).

GREYDONINC(InCanada:GreydonCanada,Montréal,Québec) FlexographicHPPrinting AllApplication Specific ThermalTransferInkJet AllApplication Specific ContactWetInkTraversingSystemAllApplication Specific

HARLUNDINDUSTRIESLTD

UnlimitedWhetheryourlineissimpleorcomplex,the G-Seriesrangehasthecapabilitytointegrate easily,withuptofourprintheadsmanagedby asinglecontroller.

UnlimitedPrintsmultiplelinetext,on-linegraphicsandall majorbarcodes,includingGS1compatible codes.Storageof100x8linemessagesupto 200charactersperline;Connectivity: centralizedprintingcontrol.

UnlimitedPrintingontoawiderangeofuncoatedand coated,aswellasplasticmedia,theK600i combinesproductivitywith600dpiprintquality. TheK600i,configuredtotheprintwidth required,canbeintegratedintoanexisting handlingsystemfordigitalimprintingorcanbe intheformatofamonochromedigitalpress.

HitachiPB-260USmallcharacterprintingcall call all Lowfluiduse HitachiPX-260UHighspeedsmall character call call all Low fluid use,touchscreen,ip55-2lineof hi-speedtext HitachiPX-460Uasabove call call all asabove,4linestext

LittleDavid Microjets LargecharacterDODcall call all Compact

LittleDavid Versajet LargecharDODcall call all Compact Foxjet Highres. call call all WindowsOS,networkcontrollers,pigmented ink

EasyprintElectronicfoilprintingcall call all Many

CODINGMARKING,IMPRINTING

MAKERAND MODEL APPLICATIONSPEEDPRINTAREAPACKAGE SIZE FEATURES

KWIKLOKCORP(InCanada:BritishCanadianImporters(4WesternProvinces);KLR(PQ))

883SmartDate ThermalPrinter Printingonclosures100/min.1,2,or3linesN/A Thermalprinter,SmartDate

894SquidInk TurboPrinter Asabove 120/min.Asabove N/A Ink(nonsmear)

Model1011EAsabove 120/min.Asabove N/A Coldfoil

LABELAIREINC(InCanada:Ahearn&Soper) HotstampcoderPrintinglabels&tags400lpm4x4in.

LEADINGEDGEINKJETLTD

Large&small character Porous&Nonporousupto4m/s3mm&up 3mm&up

LEIBINGERNUMBERINGLP Jet2 Inkjettext,graphicsUpto1300fpmUpto20mmH

Exclusivesealednozzledesignthateliminates clogging.Lesscleaning SmarjetTwolineprintingUpto1050fpm Asabove,sameruggedhydraulicsystemused onJet2model

LINXPRINTINGTECHNOLOGIESLTD(InCanada:CodingProductsofCanadaLtd.,Flamborough,ON,Visuascan,Montréal,QC)

Linx4900Noncontactinkjet printingfortraceability information

LinxCJ400Noncontactinkjet printingfortraceability information

LinxCJ400Carton coder Noncontactinkjet printingfortraceability informationidealfortray packsandcartons

Linx7900Noncontactinkjet printingfortraceability information

Linx7900 Spectrum Noncontactinkjet printingfortraceability information

Linx7900SolverNoncontactinkjet printingfortraceability information

LinxSL10110wattnoncontactlaser printing

LinxSL50150wattnoncontactlaser printer

LinxIJ355/375highresolutionnon contactcartoncoder

MARKEMIMAJEINC

Imaje9000Continuousink-jet printing

Imaje7000Laserprinter

7.28m/sor1430 fpm upto2linesofprintor 8.8mminheight

2.6m/sor510fpmupto3linesofprintor 8.8mminheight

0.5m/sor98fpm1lineofprint20mmin height

8.41m/sor1650 fpm upto5linesofprintor 13.8mminheight

7.28m/sor1430 fpm upto5linesofprintor 13.8mminheight

8.41m/sor1650 fpm upto5linesofprintor12 mminheight

variableSinglebuttonstartupandshutdown,mistake proofinkandsolventreplenishment,auto powerdownwithprintheadandconduitflush andonscreendiagnostics

variableTouchscreenprogramming,easychange servicemodule,lightweightwithcarryhandles forportability

variableEasychangeservice

variableSinglebuttonstartupandshutdown,mistake prookinkandsolventreplenishment,auto powerdownwithprintheadandconduitflush.

variableTheSpectrumprinterwasdesignedtorun pigmentedinksandhasthesamefeaturesas theLink7900.

variableSameastheLinx7900withupto40%savings insolventconsumptionreducingoperating costs.

1.83mpsor360 fpm 295x407mmvariableTubelifeof45000hours,nofactoryair required,idealforglassmarkingusing VisiCodetechnology,fastandeasycode changeswithoptionofusinbarcodescanner.

12.33mpsor2425 fpm 139x135

Series1520Asabove Upto914ft/minUpto5lines Variable12,000hourrunlife;Make-upconsumptionas lowas2.4ml/hr

Series1620Asabove Upto960fpmUpto5lines Variable14,000hourcorelife;noplantairrequired;dust protection

Series1710Asabove Upto888fpmUpto5lines VariableModularcoredesign;easymaintenance; advancedprintheadcleaningforpigmented inks

Series2300(3 models) HiReslargecharacterBarcoder:1-108 fpm;Text:upto433 fpm Upto2.7" AllcartonsReplacepre-printedboxes/labelswithhir-res text,barcordes&logos.Microplugingforhigh pointqualityandcleanoperation

WEBERMARKINGSYSTEMSOFCANADA Zebra105SLThermalTransferto8ips to4.09"Wx106"Lvaries203/300dpi

Zebra110XIIIIplusasabove to10ipsto4.09"Wx39"Lasabove203/300/600dpi

Zebra140XIIIIplusasabove to12ipsto5.5"W asabove203dpi

Zebra170XIIIIplusasabove to8ips to7.1"W asabove300dpi

Zebra220XIIIplusasabove to10ipsto8.8"W asabove203dpi

SatoM84Pro Series DirectThermal/Thermal TransferPrinter 10ips 0.87"to5" Varies203/305/609dpi.

Sato CL408e/CL412e Asabove 6ips 1"to5.1" Varies203/305dpi.

DatamaxI-Class ThermalLabel Printer DirectThermal/Thermal TransferPrinter 4-12ips 1"to4.16" Varies203/300/406/600dpi.

WIEDENBACH(InCanada:LeadingEdgePackaging)

WiedenbachCS 407(Pigmented) Smallcharacter continousinkjetprinter 800m/mVariable VariablePrintsupto4lines,integratedkeypad,auto self-flushinghead

WiedenbachCS 405(Dyebased) asabove 800m/masabove asabovePrints1,2or3lines,softwarecontrolled, automaticselfflushinghead,1or2printheads Printsupto4lines

COLDGLUEAPPLICATORS

MAKER&MODELADHESIVE USES PATTERN/SIZEOPERATION

ITWDYNATEC(InCanada:HMASystems(Brampton,ON),Servi-CentreLtee(Montreal,QC)) Dynacold Coldresin Highspeedcartonseam, envelope Contactandnon-contact extrusion Automatic,longlifesealsand cyclelife

NORDSONCANADALIMITED(InCanada:Timeco-Marten,Calgary,AB;Edmonton,AB;Winnipeg,MB)

LASeriesLiquidAdhesive Pumps Lowtohighviscosityadhesives andsealants Foldingcarton,corrugatedbag &sack,envelopemfrg. ExtrusiongunpressurePistonpump

Rhino5Gal55Gal BulkDeliverySystem Highviscosityadhesives, sealant,mastics,varnishes Manual,automated applications. Extrusiongun,pressurePistonpump

variableIdealforhighspeedapplicationsdesignedfor brewingandbeverageindustries.Standalone mobilecabinetwithIP65rating.Nofactoryair requiredandnocoolingliquidsrequiredforthe lasertube.

550mm/sor21in/supto70mminheightvariableTouchscreeninterface,automaticinkrecycling toreducewaste,USBportformessageback up.Simpleinkrefillwithuninterruptedprinter operation.

1080fpm1-20mm

980fpm6inchwide

NolimitCompact,to8linesofcode,ethernet,auto flush

NolimitModulardesign,thirdgeneraion,economical, touchscreen,to890fpm Markem-Imaje Smartdate thermaltransferonline1200fpmprint& apply upto128mmNolimitFast,ribbonto1100m,largeprintarea,ribbon savings

Markhem-Imaje 2200 Print&Apply80cases/min6"x12"

Markhem-Imjae 5000 HighResolutionCase coder

NolimitModular,compactmanyapplicators,easeof integration

300fpm2.5"perheadNolimitHotmeltinstantdryinks,GS1compatible, cleannobleed

MARSHCO(InCanada:VideojetTechnologiesCanada)

LCPSymbolJetBarcodeprinter60fpm Code12of5, Code 39-42characters DirecttocartonUPCsymbologies

LCP/ML8Ink-jetcoder

200fpmperline, max8lines 24-hrclockcalendar;largecharacters; bar-coding

LCPDLiAsabove AsaboveAsabove,max.2lines Printslogos,largeordoublelines

MarshUnicornAsabove 1line Countinglogic

Mini-MarkAsabove 20-250fpm 3/32in.7x7matrixor1/16in.5/5matrix

Hi-Res Asabove 250fpm40in. 3/16to1in.

OvertureLT, OvertureLX Ink-jetcoder 250fpmMaxlengthformessage 40in. VariousHighresolutionprinting,barcodes&graphics

OvertureESInk-jetcoder 200fpmMaxmessage40in.VariousHi-resprinting,barcodes&logos,lowcost

ML8,PatrionHi-Res 250fpm Hi-resgraphics,barcoding

P5000A,P2500ALabelling LabelApplications

MARTINFRANDOMARKETING&SHIPPINGSUPPLIESLTD

SMRMicroSpray Marker

Dotsorline

IndustrialMarking Inks Lumbermarkinginks,stencilinks,Eddy Currentweldseamidentificationinks,porous andnonporousinks,colourmatchingavailable

UniversalConveyor Coder 1"-4"

MATTHEWSMARKINGSYSTEMS

ContinuousInkjetPrimarypackagecodingover1000fpmUpto5lines/.05"-61" Characters Easytouseinterface

HighResolution Inkjet Secondary(casecoding)276fpm4"fromeach head/unlimitedstitching Highres.graphicsandbarcodes Laser Primarypackagecoding Upto200mmx200mm Highspeedpermanentcoding Drop-On-DemandSecondarycoding780fpm3/32"-5"charactersizes Rugged,reliableprintheads PLANAUTOMATION

MarkemImajeInk-jet,Laser,P&Aupto800ppmvariable variable

RESOLUTIONTECHNOLOGIESCORP

EconomizerDigitalcartonprinter20cpm 11"x32" 40"x40"Manualfeed,PCbasedlabeldesign,200dpi resolution Optimizerasabove 60cpm 11"x32" 36"x36"Automaticfeed,PCbasedlabeldesign,200 dpi

SAMUELSTRAPPINGSYSTEMS

HSAutomaticsHi-definition 1000'/minUnlimited All Xaar&HPtechnology CitronicsCIJ 1000'/min1/2"high All CIJ

Rea-JetDOD 800'/minUnlimited All DOD

Variable24-hourclock,Juliandate,counter,lotcounter, dotsizeadjustment,printdelay,character widthadjustment,photocellon/off,invertprint, reverseprint,purgeroutine. SQ/2ScorpionLargeCharacter200ft/min.25"to.75"

VariableCounter,lotcounter,24-hourclock,shiftcode, Juliandate,3-lettermonthname,3-letter weekdayname,expirationdate,expiration month,expirationday,expirationyear, expirationJulian. VectorXIILargeCharacter200ft/min.25"to1.75"

VariableCounter,lotcounter,24-hourclock,shiftcode, Juliandate,3-lettermonthname,3-letter weekdayname,expirationdate,expiration month,expirationday,expirationyear, expirationJulian.

ROBATECHCANADA

RobatechEquipmentPVA,acrylicscoldglueHighspeed Useonfoldergluers

SORTPRODUCTIONPRODUCTSLTD Vansco VALCOMELTON QuiktakExtrusion

Coldresins&dextrinesCaseandcartonsealer, laminating,palletizing 1/8in.to12ftperextrusion valve Gluevalvesforpositioncut-off ofgluepattern Flexoseal Asabove Corrugatedboxesfolding cartons,bags Singleupto3inpervalveVariablespeedapplication, capableofhighandlow operatingpressure MicroSeal ColdResin Envelopes,folders presentations Various,contactornon-contactVariablespeedapplication utilizingcompactdispensing VANSCOPRODUCTSINC(InCanada:SortProductionProductsLtd.)

OVER AUTOMATEDPACKAGINGSYSTEMSINC(InCanada:PackProSystems,Inc.Stouffville,ON) AutobagLinearto45bpmn/a 8lbs 1-4heads Availableinstainlesssteel.Fully automatic n/a COMBISCALELLC

CS5L Upto70/min Upto55lbs

CS1.5LUpto120/min Upto7lbs

CS2.5LUpto120/min Upto18lbs PrimoWeigher200+/min Upto7lbs

PrimoWeigher200+/min Upto18lbs PrimoWeigherUpto80/min Upto55lbs HEAT&CONTROLCANADAINC

IshidaCCW-Rto400wpmvariousvarious10,14,15,18,24,28headModelsforallapplications:dry, washdown,USDA

IshidaCCW-R RH/VH to95wpmtoò.5g800g 10-30headsUSDADairy-AcceptedDigital metering.Preprogrammedpreset changehighspeedprecise accuracy.

IshidaCCW-R-GS gentleslope multiheadweigher to60wpmtog to2000or4000g Gentlehandlingforfragileproducts; quickchangeoverswith200 productpresets;IP66waterproof construction;allproductcontact partsareremovedwithoutusing tools,simplecontrols.

Ishida

CCW-R-218WB-O V to280wmpò.5g-1g400-800gdoubleweigherOptimizedfortwin-bagmaker interfacesavesfloorspace,200 productpresets

Ishida CCW-R-218/224/2 28-WB to120wmpò.5-1gto400gproductmix-weighingHighspeeds,gentlehandling products 200presets

IshidaCCW-RSto180wpmvariousvarious14,16head Affordable Asabove

Ishida-CCW-SEto85wpmvariousvarious10,14,20head

IshidaCCW-RVto210wpmtog to8,000g14 Self-drainsurfaces;IP66,6T&69K waterproof;autoset-up;wireless control

IshidaCCW-R LinearWeigher to12wpmtog to500g6to12linearweigh heads Superioraccuracyforultra-low targetweights.Highspeedshort dropheight,dryorwashdown models. Notools

MULTIPONDAMERICAINC(InCanada:AbbeyPackagingEquipmentLtd.) 01Series450wpm<0.1g1.6kg/3.21Various QuietFast,HighAccuracy, Multipointdistribution Tool-less 01S5Series800wpm<0.1g1.6kg/3.21Various QuietFast,HighAcuracy, Multipointdistribution

28-400/400A450+wpm<0.1g1g-200gVarious QuietFast,HighAccuracy, Multipointdistribution

PZPilotHi-Resolution200ft/min.06"-.7"

PZPilotProHi-Resolution167ft/min.06"-2.1"

AutoPilotHi-Resolution135ft/min.06"-.7"

VariableBarcodes,logos,text,lotcodes,shiftcodes, time&date,repeatprint,reverseprint.

VariableTime&Date,Item,ShiftCodes,BarCodes, Fonts,AutoConfiguration,Numberof Messages-2GBflashmemory,Graphics, Languages-UserselectablebetweenEnglish, Spanish,andChinese.

VariableTime&DateAMorPM,ShiftCodes,Bar Codes,VarietyofFonts,Logos1GBstorage, LanguagesEnglish,Spanish,andChinese versionsavailable.

STERLINGMARKINGPRODUCTSINC M-15 Reciprocatingimprinter225impressionspmVaries NolimitCanprintontop,bottom&sidesofproductas wellasprintonwebmaterial RapideReciprocatingimprinter usinghotinkrolls AsaboveAsabove AsaboveAsabove

VIDEOJETTECHNOLOGIES

43S,1220CIJ Upto800fpm.08to.4

VariableAirles,patentselfclean,nomess,nowaste,IP 54 1520,1620CIJ Upto1,066fpmAsabove AsaboveAsabove 1720 CIJ-PigmentAsabove.08to.5

AsaboveAirlesspatentselfclean,nomess,nowaste, IP66 3120 Laser 10wattsVaries AsaboveHighresolutionpermanentcodes S320 Laser 30watt AsAbove AsaboveAsabove AlltechSmartsAsabove 60watt Asabove AsaboveAsabove

50watt Asabove AsaboveAsabove

Varies AsaboveHighquality-4lines

2400/S5Series200wpm<0.2g1.5-3kgVarious QuietFast,HighAccuracy, Multipointdistribution,Stainless Hoppers,HighSpeedApplications Tool-less 3800Series200wpm<0.5gto5kg Various QuietFast,HighAccuracy, Multipointdistribution,Stainless Hoppers,HighSpeedApplicatoins Tool-less 71ooSeries140wpm<0.5gto7.5kgVarious QuietFast,HighAccuracy, Multipointdistribution,Stainless Hopers,HighSpeedApplications. Tool-less 9600Series120wpm<1.0gto100kgVarious QuietFast,HighAccuracy, Multipointdistribution,Stainless Hoppers,HighSpeedApplications Tool-less

YAMATOCORPORATION Omega200 weighments/min

Alpha 120 weighments/min

Sigma 360 weighments/min

CONTROLLERS-LOGIC

Singleandmulti-point discharge IP-67washdown,loadcellscan withstand150kgofforce,tapered bodydesign,polygonal-shaped weighbuckets

SingleandtwindischargeDigitalfiltering,spring-lessbuckets

Singleandmulti-point discharge Highspeedandfragilehandling modifications,multi-pointdischarge configurationsfortrays.

MAKER&MODELCAPABILITYSPEED FEATURES

BOSCHREXROTH

RexrothMLCControllersHighPerformance5microsecondsper1,000 instructions

NORDSONCANADALIMITED(InCanada:Timeco-Marten,Calgary,AB;Edmonton,AB;Winnipeg,MB)

EclipseSeriesPattern Controls Preciseadhesiveplacement& real-timepatternadjustment capability

LogCommPatternControl andVerificationSystem accuracyviatouchscreen

EPC30:300m/min(984ft/min) EPC15:150m/min(500ft/min)

Programpatternsandverify adhesivepattern/placement 1200m/min (3937ft/min)

SelectEPC15fortime-basedprogramforconstantlinespeedsor EPC30fordistance-basedprogramforconstantorvariableline

Multipleguncontrolandtriggerinputs,productionreporting,detect &verifybarcodes,cellophanewindows,securitytagsetc.

EcoBeadPatternGenerator forOptiBondSolutions Easilyconfiguresbeadsize andpatterns 5msminimumontime40presetprogramswith30-40-50-60%adhesivesavings

UNITRONICS

UnitronicsVison1210òx2122Upto100010points9secper1Koftypical application

UnitronicsVision 1040òx2122 Upto100010points9secper1Koftypical

12.1"ColortouchHMI,BuiltinAlarms,Auto-TunedPID(upto24 independentLoops),MicroSDCard,2IsolatedRS232/RS485 ports,Ethernet(optional)andmore

10.4"ColortouchHMI,BuiltinAlarms,Auto-TunedPID(upto24 independentLoops),MicroSDCard,2IsolatedRS232/RS485 ports,Ethernet(optional)andmore

Designedtobagclosinglinerequirements

Comprehensiverangeofconveyorchains.

Varies Bottles,cans,boxes S.S.,derlinchain

Varies Cartons,packoff S.S.construction,unscrambling,round container DEMATICLIMITED

ConveyorsMoreLoadTypes,Excellent CartonControl,UniversalSideFrameforall Models,EasytoRe-ConfigureLayout,Eastto ChangeFunctions,CommonPartsReduces partsInventory,AC&SCDriveMotor.

CONVEYORS

MAKER&MODEL SIZEOPERATION FEATURES

PoweredBelt:HorizontalMBC-Modular PlasticBeltConv. Various DurableTechno-PolymerBelting

PositiveCOnveyanceofunstableandfragile loads

HD-HBC-HeavyDutyBeltConv. Various Ruggedconstruction Providescontinuous,smoothloadsupport

PoweredRoller:HeadyDuty HD-BDLR-HeavyDutyBeltDrivenVarious RugedwidecentralbeltdrivedesignEconomicalsolutionfortransportationof heavyloads

CFC-BDLR-HeavyDutyZero-PressureVarious PneumaticairbagpressurerolleroperatedDurable,LowMaintenanceZeroLine Pressureavailable.Economicalaccumulation solutionforheavyloads.

CDLR:ChainDrivenLiveRoller Various RollertoRollerChainDrivenUprightand inverteddrive EasyintegratedwithChainTransferandturn tablePositiveDrive

CFC-CDLR-ZeroPressureChainDrivenVarious AirClutch/BrakeOperated PositiveDrive.Durable.LowMaintenance. ZeroLinePressureavailable

ST:SlatConveyor Various Discretesupportforaspecificloadshape

CT:ChainTransferConveyor Various DblePitchC2060orC2080conveyorchain Uhmx"Chanex"Wearstrips.Centralorend drivetype Positiveconveyanceofloads.Quiet Operation

CDLR-TT:Motorizedturntable Various EveryRollerDrivenincl.VariablelengthrollerEasyintegrationwithothertypeofpallet conveyor

Descon Varies Full&emptycase/carton/shell

EDSONPACKAGINGMACHINERYLTDInCanada:AlexEJones&Associates

Edson 1-X,1-2,2-4,2-5Laner

Air,highspeedsinglefiling/deceleration, accumulation,servo,merging/indexing, vacuum,vertical,incline/decline,bucket.

Conveyingoftheproduct

FLEXLINKSYSTEMSCANADA(InCanada:ABFSystèmesInc.Boucherville,QC;PharmaCosMachineryIncSaint-Laurent,QC)

FlexLinktabletopconveyor,UCIndustries beltconveyor,Hitrolcaseconveyorand sortation

FRAZIER&SON(InCanada:ChisholmMachinerySalesLimited,NiagaraFalls,ON)

Frazier&SonBucketConveyors/Elevators4"x8"

Frazier&SonBucketConveyors/Elevators6"x10"

GARVEYCORPORATION

InfinitySeries Varies

90-120cu.ft./hr

180-240cu.ft./hr

Quietcleanstainlesssteel

9000Series Varies Modular

3600Series Varies asabove

InfinitySeriesFIFO Varies First-in,firstout

InfinitySeries3D Varies

GESCOFAB(ByPremierTechSystems)

Assembly-AutomationConveyingSystemVarious

ConveyorRepair&Installation Various

Accumulates,orients&dischargesflow wrappedpackages,bags,trays&cartons

Self-integratedlogicorPCLcontrolled Modularconfig.allowseveraltypesandtech modulestobeintegrated,includingID recognitionlikebarcodereaders,toprovidea completehandlingsolution

Wideexperienceinpreventivemaintenance, overhaul,emergencysupport;Annual maintenanceplansavailable

Conveyors,Cases,Parcels,Totes Automatic&Semi-Auto

PoweredBelt:HorizontalHBC-horizontalbelt conveyor Various

IBC-inclinebeltconveyor Various

RollerorSliderBed

Single/multipledischarges,various configurations,bucketmaterials&washdown designs

Single/multipledischarges,various configurations,bucketmaterials&washdown designs

UHMWPEtracksprovidesmoothquietride withfullcleanability

Stainlesssteel,tabletopchain

Paintedcoldrolledsteel

Tablefillsinsideoutwithnobackpressure

Accumulationbetweenupstream& downstreammachineswithnobackpressure.

Completesolutionfromauniquepartner, includingeverythingfrompre-engineeredto engineered-to-orderdevicesifrequired,to control,toinstallation,andproject management

Troublefreemaintenancebyareliable partner,allowingyouroperationpeopleto focusonproduction

Pre-EngineeredLineUniversalFrameDesign HighPerformance,durabilityandreliability

VidelyVaryingLoadSizes:Rugged.Versatile

Adjustableanglefrom0to30degrees

TBC-trashbeltconveyor Various Ruggedconstructionandreliableoperation

PoweredRoller-MediumDutyBDLR-Belt DriveLiveRoller Various SpecialCamPressureAdj. Economical,Quiet,LowMaintenance

CFC-BDLR-Zeropressureaccum.Various Pheunaticairbagpressureroleroperated. VariousProductDischargeModesavailable. Widecentralbeltforlongerlife.

LRLS-LiveRollerLineShaft Various VariablePressureAccum.Straights,curves, junctionassemblies,rightangletransfer, pop-upwheeldivertersandgatescanbeall poweredwithonedrive.

MDR-MotorDrivenRoller24VDC Various Straights,curves,junctionassemblies,right angletran.,pop-upwheeldiverters.Speed, Compactaccumulationandreleaselogiccan besetindependentlyperzone.Network communicationpossible.

QuietatHigh&LowSpeed.DurableatAll Speeds.HandlesmanyProductSizes.Low Maintenance.ZeroLinePressure.

Economical,flexible,quiet,safe,low maintenance

Modulardesignimproveslayout.Runon demand/lessnoise,wear,&Energy.Compact lowprofile/multi-levelusage.Reversible/less hardwarerequired.Higherflexibilityprovides improvedsystemfunctionality.

VBDLR-:V:BeltDrivenLiveRollerVarious Compace,sidedrivebelt.BeltguardsEconomical,simplemain,reversible

CDLR-ChainDrivenLiveRoller

Various RollertoRollerChainDriveUprightand inverteddrive PositiveDrive,durable,lowmaintence.Zero linepressureavailable Conveyors,Pallet,Drum,HeavyLoads

CDLR-PUCT:RightAnglePop-uptransferVarious Airbagliftingmechanism.Speciallinkagefor smoothlifting PositiveTransferenceofwidevarietyofloads. Minimalmaintenancerequirement.Easy integrationwithothertpyeofpalletconveyor

T/CAR:TransferCar Various Dumagroller5000#cap.Fullyautomatic. Integratedencoderforpositioningorlaser positioning.Upto380feetperminute. Motorizedfollerconveyororchainconveyor available.Cable

Positivetransferenceofwidevarietyofloads. Transferarearemainclearwitheasyaccess foroperationandmaintenancepersonnel.

GravityConveyor:Light,Medium,HeavyDutyVarious 2"rollerswithspacingasrequiredVeryeconomical

GOPACKAGING PrimeConveyor Various GravityorFullyautomatic

HARTNESSINTERNATIONAL(InCanada:AlexE.Jones&Assoc.)

Dynac6100

150-225linearfat. helicaldesign Singlefile,FIFOaccumulatingconveyorFullyautomatic,pressurelessaccumulation, diverse,flexibleproducthandling

Dynac6200 Variablelengthfloor level Asabove Asabove

Dynac7000

HEAT&CONTROLCANADAINC

180-540linearfat. 2-6levels,helical design Massflow,FIFOaccumulatingconveyorAsabove

FastbackBlendingConveyor Various Horizontalmotion Loadcellsaccuratelymeterdifferent ingredients,gentleblending,easycleaning

Fastbacksizing/separatingconveyorVarious Horizontalmotion Sizesortandremovefines,gentlehandling, easycleaning

FastbackuphillConveyor Various Horizontalmotion Moveproductonslopesupto8degrees, easycleaning,quietcomfort

FastbackSwitchBackaccumulationVarious Horizontalmotion InlineShort-termaccumulationforfrozenand dry,fragileproducts,compact,gentleeasy cleaning.

Varilift

Inclinebelt

Vibratory

WeighBackweighconveyor

INTELLIGRATED IntelliQ

Modular,tosuitVertical,sanitarybuckets No-spillconveying,easy-to-clean,multiple infeed&dischargepoints

Modular,tosuitVariablespeed Pivotingsideguides,easycleaning,wide varietyofbelts

Vibratory Direct,indirectorelectro-magneticdrives, variouspan,screening,laningconfigurations, easycleaning

PleasecallforsizesBelt-driven,zeropresureAccumulationVarybyapplication,callfordetails Accuglide

MotorDrivenRoller(MDR)

v-BeltDrivenLiveRoller

E-ZSetConveyor

Chain-driven,zeropressureAccumulation, availablepallethandling

Advancedtransportation,zerocontactand pressureaccumulation

Maximumflexibilityforsystemlayouts

Positiveconveyanceinincline,declineor horizontalapplications

Accumat Rollerlessplastic-beltedzeropressure accumulation

ChainDrivenLiveRollerPalletConveyor

PalmatPalletConveyor

KRONESMACHINERYCOLTD

CaseConveyor

Containerconveyors

Palletconveyors

Airveyor

Builttosuit application

Builttosuit application

Builttosuit application

Lowmaintenance,positiveconveyanceof widerangeofproducts

Full-widthtransportationconveyorwitha modularplasticbeltforpositiveload conveyance

Touchscreenoperationandchangeoverstainlesssteelconstruction-lowback pressuredesign-lowenergyconsumption

Touchscreenoperationandchangeoverstainlesssteelconstruction-lowback pressuredesign-lowenergyconsumption

TouchscreenoperationandchangeoverSoftstartVFDoperation-stainlesssteel construction-lowenergyconsumption

Accucase

Builttosuit application

Builttosuit application

Touchscreenoperationandchangeoverstainlesssteelconstruction-lowback pressuredesign-lowenergyconsumption gentlecontainerhandling,automaticguiderail adjustment

firstinfirstoutcaseaccumulationsystemLowfloorspacerequirement

Accutable Builttosuit application firstinfirstoutcontaineraccumulationsystemLowfloorspacerequirement

Accuflow

Accutower

Acculink

Builttosuit application

Builttosuit application

firstinfirstoutcontaineraccumulationsystemLowfloorspacerequirement

firstinfirstoutcontaineraccumulationsystemLowfloorspacerequirement

Builttosuit application firstinfirstout-nolowpressurePET accumulationsystem Lowfloorspacerequirement

LOMASYSTEMSINC(InB.C.&Alta.:RossPackaging)

LomaSystems Various RejectDesignCapabilities

METTLERTOLEDOINC(InCanada:MDPackaging)

MagnaSwitchlineconvergers

MagnaSwitchServoMerge

NEWMAPAKLTD

From2'Wx4'Lto 4'Wx8'L Convergesproductflowfrommultiplelinesto 1line

Patentedjam-free,magneticswitching.Solid statecontrol.AlsoavailablewithPLCcontrol

3x6.5,4x8Convergersrandomlyspacedproductinto evenlyspacedlaneusingservomotors Twostagesmartbeltsystem.High performanceservomotors.Handleswide varietyofpackagetypesandsizes

Tabletopconveyor,caseswitch Pressureless Sanitarydesign,heavy-duty,modular

PREMIERTECHSYSTEMS

GescofabBeltConveyor Various Bottles,cans,cartons,bags,etc.applications varyfrommanufacturingtodistribution operations

BeltDrivenLiveRoller Various Mediumtoheavycartons,applicationsvary frommanufacturingtodistributionoperations

LiveRollerLineShaft

Various Bottles,cans,cartons,bags,etc.applications varyfrommanufacturingtodistribution operations

"V"BeltDrivenLiveRollerConveyorVarious Bottles,cans,cartons,bags,etc.applications varyfrommanufacturingtodistribution operations

Differentconfigurationsforspecific applicationsareavailable

Variousconfigurationsareavailablefrom straightconveyor,self-poweredcurves,slave drivencurvesandself-poweredspurs.The systemisalsoavailableaszeropressure accumulationwithelectronicsensors.

Rollesaredrivenbyindividualelastomeric beltsfromacommondriveshaft.Thesystem isalsoavailableaszeropressure accumulationwithelectronicsensors

Variousconfigurationsareavailablefrom straightconveyor,self-poweredcurves,slave drivencurvesandself-poweredspurs

Heavy-DutyBeltDrivenLiveRollerConveyorVarious Applicationsvaryfrommanufacturingto distributionoperations

Thesystemisalsoavailableaszeropressure accumulationwithelectronicsensors ChainDrivenLiveRollerConveyorVarious Forhigherloadcapabilitiessuchasloaded palletsanddrums.Chaindrivenrollersmake itidealforconveyingoilypartsinbottlingand steelindustries

RJMACHINERYINC

Brinerlineconveyors

3to12in.widthPlasticmesh,openchain

Singlestrandandroller-to-roller configurationsareavailabletomeetspecific requirements.Thesystemisalsoavailableas zeropressureaccumulationwithelectronic sensors.

Stainlesssteelpanels&driptrays

Tabletopconveyors AsaboveDCpowered,plasticslats OnepieceSSpanels,sanitarydesign, inboardbearings

Efficiencyline AsaboveConveyorintegratedontoSStableTablewillsupportfiller-capper-labeler

REISERCANADACO

SupervacGesmbH Various Automatic RILEYPRODUCTHANDLING(InCanada:CharlesDowner&Co.Ltd.)

VibratoryTracks Accumulation&pressurecontrol Side&bottomrejects,landdumping,product turning V-BeltAccumulatingConveyors Pressurelessaccumulation

BeltConveyors Longitudinalpitching Simplerowreduction

LaneDiversionmatrices Diversion

ROTZINGERAG(InCanada:CharlesDowner&Co.Ltd.,RichmondHill,ON)

CrossFeedingStations Various Asrequired Highspeedcrossfeeding,gagclosing,cont.

BufferSystems Various First-In,First-Out Compace,dentle,permanentlyoptimized

RYSONINTERNATIONALINC

Spiralconveyors MadetoorderVerticalconveying

CONVEYORS

MAKER&MODEL SIZEOPERATION FEATURES

SIDELCANADAINC

SIDELCONVEYORAUTOMATION

SIDELautomationenhanceslineefficiencybyapplyingbalancedlineflowprinciple.Meetclientspecifications.Userfriendlyprogramming

SIDELAIRCONVEYORS AirConveyingofemptycontainerinsinglefile.Lightweightbottlebelow10gr.Automaticservodrivenguiderail.Highspeedswitchgate.ThreeairfiltrationgradesuptoHepa. Tabletopconveyors Conveyingofbottlescansjarsandcontainersinsinglefileormass.Stainlesssteelorpaintedfinish.Sanitarycleandesign ALS Automaticadjustableguides.Diversifiedproductionmeansalargenumberofformatchangeovers,whichhavetobequick,inlessthenaminuteandreliable.ThesimplicityoftheALSguidemeansthatitcanbe reliablyadaptedtothemajorityofcontainersandconveyorsonthemarket.Itacceptsanunlimitednumberofformats.

SIDELPRESSURELESSCOMBINER Pioneerinpressurelesscombinersautomatedtechnology.Operatingupto2,000cpm

SPEEDWAYPACKAGINGMACHINERYINC

SpeedwayModularPlasticBelt Custom

Modulardesign. STORCANLTD

StorcanTableTop&CaseConveyors,ICS/RIONDEbulk

ISP IntegratedServoPump Hopper

e.dot+ElectricGuns Electric,highspeed,accuratedot placementforlabelling,coupons, pharma,specialtypackaging

E-400ElectricGuns Electric,highspeedsuperior accuracyandrepeatability

MiniBlueIIGuns PneumaticHighspeed,longlife

PatternJetPlus Pneumatic,highspeedapplications requiringflexibilitytochange patterns,labeling

SolidBlueHotMeltDispensingGunsPneumaticAO/ACandAO/SCstyles

SureBeadReducedCavityHotMelt

DispensingGuns PneumaticAO/ACandAO/SCstyles

SureSealNon-ContactSiftProof Gun Electric.Eliminateproductlossat seams;singleordualgunsystems

1.8msminimumontimewith viscosityrangeof1,000to5,000cps

msminimumontimewithviscosity rangeof1,000to10,000cps

2msminimumontimewithviscosity rangeof500to5,000cps

Compact,high-speed,quiet operation,exceptionalservicelife

Beadanddotpatterns,high-speed, superioraccuracyandrepeatablity

Industryfastest,longestlife

15msminimumontimewithviscosity rangeof500to15,000cps

Intermittentpatterns,contactor non-contactnozzles

15msminimumontimewithviscocity rangeof,000to5,000cps

Myritexsealsforlonglife,EasyOn modulemounting

15msminimumontimewithviscocity rangeof ,000to5,000cps

Self-cleaning,reducedcavity, changeablenozzles

Over450cartons/min

InstallseasilywithIntegratedslotted, gunmountingbracketquickchange nozzleplates SPEEDWAYPACKAGINGMACHINERYINC

Glass,cans,cartons To60cpm Infinitevariation Single-headautomaticauger, conveyorized,automatic BD-600 Bags,cartons,rigidcontainers50cpm 4ozto50lb Weight-auger,bulk&dribble

TORNADO600 Bags,cans,cartons Upto80cpm 1gto50kg

ROTOR40 Asabove Upto60cpm 10gto10kg

Automaticandsemi-autoaugerfillerwith Vectormotiondrivesystem

Automaticandsemi-autovolumetriccup filler,singleandmultipledump ROTOR60 Asabove Upto80cpm Asabove Asabove

BOSCHPACKAGINGSYSTEMSAGSIGPACK(InCanada:CharlesDownerCo.Ltd.,RichmondHill,ON) StickPackMachine(multilane)RAStickPacks 100cpm 150mg-50g PLC

VerticalFlatPouchMachineRXSachets 125cpm Asabove Asabove

BOSSARUSAINC(InCanada:AbbeyPackagingEquipmentLtd.)