2025 PACKAGING MACHINERY SPECIFICATIONS MANUAL

Delivering Results.

With Heat and Control, you have a partner with the scale to support your success, the innovation to advance your operations, and a commitment to quality that will help you offer better products for consumers.

COMPLETE SNACK PACKAGING SOLUTIONS

• Accumulation

• Horizontal motion conveying

• Incline, belt and bucket conveyors

• Filling and multihead weighing

• Bagmaking and casepacking

• Checkweighing and seal checking

• Foreign object and defect inspection

• Controls and information systems

We are successful when you are successful. That’s why we apply creativity, engineering excellence, and determined perseverance to every project to help our customers get the performance their business demands—whether measured by flavor, efficiencies, sustainability, improvement, or innovation.

Mar. 10-12, 2025

Booth 1108

Georgia

info@heatandcontrol.com |

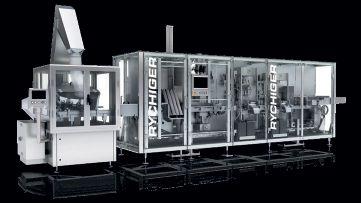

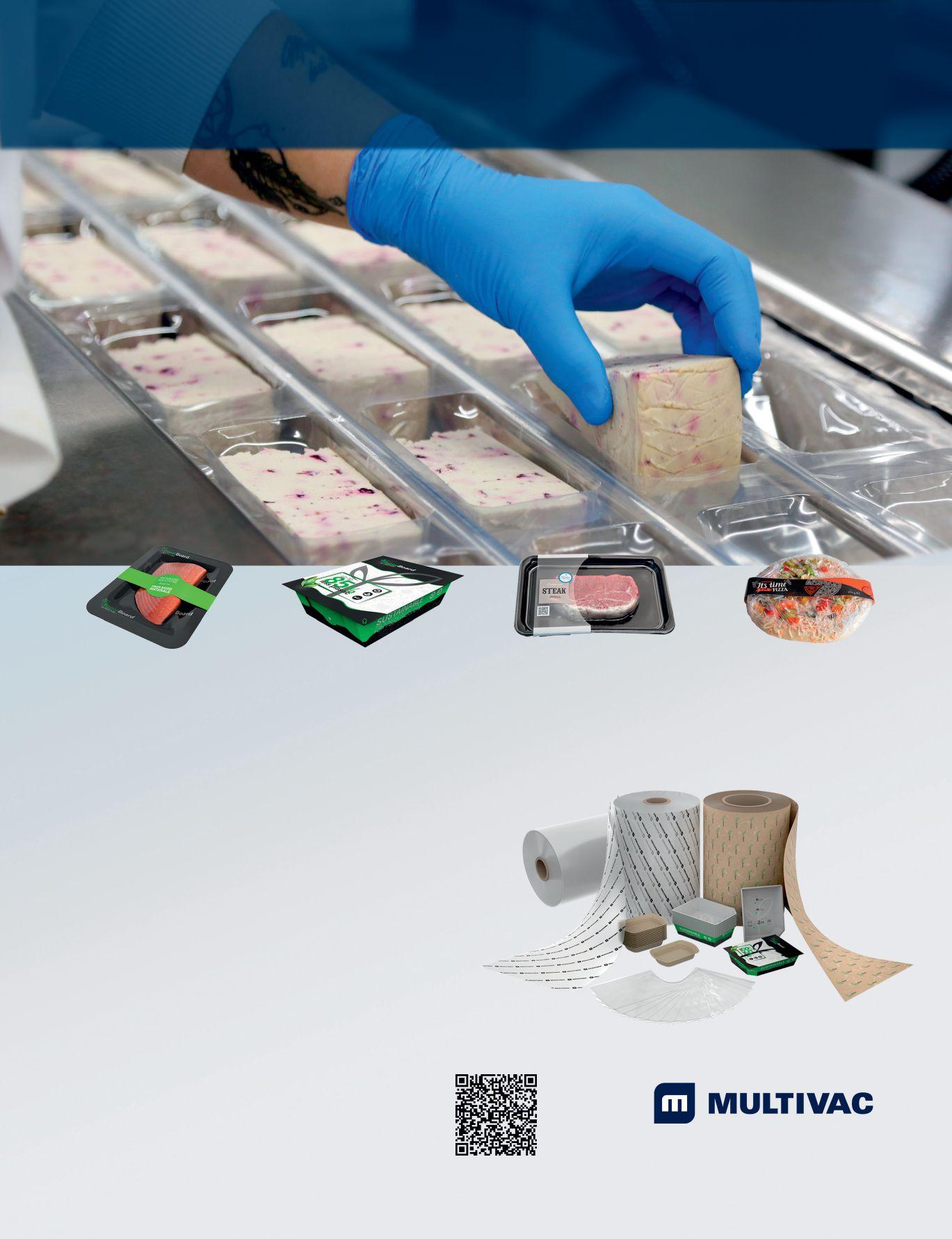

n Flexible system produces

n Fully automatic, high-speed

n Uses preformed trays of almost any

n Superior package seals eliminate leakers and returns

15 For Safety’s Sake

Leading Canadian manufacturer of pharmaceutical packaging machinery leaves nothing to chance by incorporating leading-edge safety automation technologies into its machine design.

20 License to Print

Fast-growing Quebec folding carton manufacturer and printer poised to expand its market reach and footprint after a comprehensive upgrade of its printing and converting machinery.

25 Safety in Numbers

Leading Ontario producer of Halal processed meats doubles down on product safety and quality by beefing up its metal detection capabilities.

29 Catch the Wave!

Brief preview of the upcoming Seafood Expo North America/ Seafood Processing North America exhibition in Boston next month.

30 Joint Endeavors

A new cross-Atlantic partnership aims to address the labor shortage dilemma in the North American food packaging industry with cutting-edge packaging automation.

32 Meeting of Minds

Consumer

The high-speed gummies packaging line at the Herbaland Nutritionals nutraceuticals production facility in Richmond, B.C., installed by Paxiom Group of the ATS Packaging and Food Technology.

Two Canadian family-owned flexible packaging producers orchestrate a friendly merger to build up coast-tocoast distribution reach for their innovative packaging products.

All

is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or

advertised. Publisher reserves the right to refuse advertising that does not meet the standards of this publication. Printed in Canada.

Page-by-page guide to using this one-of-a-kind industry manual.

U.S. trade tariffs would pose existential threat

The booing and jeering of the U.S. national anthem at hockey and basketball matches is a sadly immature and disrespectful expression of the current national sentiment in respect to the fierce economic pressure unleashed on our country by the new U.S. administration since taking over the White House last month.

$3.6 BILLION

Estimated value of goods and services crossing the U.S.-Canada border daily

That said, imposing economically crippling 25-per cent tariffs on all Canadian goods exported to the U.S., as the U.S. briefly tried to do at the start of February, before having a last-minute change of mind, was never going to go down well north of the world’s largest undefended border.

With a wobbly economy and a lameduck federal government, the imposition of a 25-percent duty on Canadian exports to the U.S. would have a devastating and long-lasting impact on the Canadian economy—possibly resulting in a nasty recession that the country is ill-equipped to cope with.

It would also be prelude to a nasty titfor-tat trade war with very few beneficiaries but plenty of misery for both Canadian and U.S. consumers in terms of even higher consumer inflation than what we have had since coming out of the COVID-19 pandemic.

For a U.S. president that made lower food prices one of his key election promises, casually using tariffs as a primary foreign policy tactic against its closest allies and biggest trade partners seems as illogical as will be counterproductive, but that’s where we are.

While the announced one-month delay in imposing tariffs on Canadian goods may seem promising at the moment, it would be naive to thank that the threat is over—at least for the next four years.

As most Canadians are now well aware: the stakes for could not be higher for the country’s economy and its general socio-political well-being.

With the cross-border trade estimated at $3.6 billion in goods and services per day, an estimated 2.7 million Canadian jobs could be a serious risk in the event of a sharp decline in that trade traffic.

According to the Bank of Canada, the loss of business caused by these tariffs could shrink the Canadian GDP by 2.6 percent—essentially pushing the economy into recession territory—with Canadian households seeing their living costs

rising by an average of $1,900 per year.

With its heavy reliance on the automotive sector, Ontario’s manufacturing industry could be at the risk of losing up to 675,000 direct export-related jobs, which would be a massive body blow to the country’s biggest provincial economy.

In Quebec, some 359,000 export-related jobs would be put in jeopardy, with another 219,000 jobs in British Columbia.

Trade with the U.S. accounts for nearly 40 per cent of Saskatchewan’s annual GDP and for 38 per cent of Alberta’s economic output, and 35 per cent for New Brunswick.

No wonder so many Canadians are outraged by the threat of U.S. tariffs: this is the most existential explicit threat to the country’s economic fortunes in the nation’s history.

If there’s any silver lining to be found in this dark chapter of U.S.-Canada relations, it may be that the common threat finally unites the federal and provincial governments in a concerted effort to remove the hundreds of artificial interprovincial trade barriers that have held back Canada's economic growth for decades, while attracting only scant attention from time to time, with little end result.

According to the Canadian Federation of Independent Business (CFIB), removing internal trade barriers would boost the annual Canadian GDP by about $200 billion, while a 2019 study by IMF (International Monetary Fund) calculated the total cost of interprovincial trade barriers as the equivalent of a 21-percent tariff. Clearly, removing these barriers would go a long way to taking the sting out of the 25-percent tariff threated by the U.S. right now.

The problem is time, of course, or rather the lack of it. Sorting out and removing interprovincial trade barriers could be a very lengthy undertaking, whereas U.S. tariffs can be introduced at virtually any time with minimal advance notice, as we are all finding out the hard way.

It’s a lousy state of affairs, to be sure, but if it’s true that every crisis carries a whiff of opportunity, it would be foolish to wilfully ignore it.

GEORGE GUIDONI, editor GGuidoni@canadianpackaging.com

January/February 2025 | VOLUME 78, NO. 1

Reader Service

Print and digital subscription inquires or changes, please contact Angelita Potal, Customer Service Tel: 416-510-5113 apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Senior Publisher Stephen Dean | (416) 510-5198 SDean@canadianpackaging.com

Editor George Guidoni | (416) 510-5227 GGuidoni@canadianpackaging.com

Account Coordinator Barb Comer | (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

Audience Development Manager Barbara Adelt | (416) 510-5184 Fax: (416) 510-6875 badelt@annexbusinessmedia.com

Media Designer Brooke Shaw | (519) 428-3471 bshaw@annexbusinessmedia.com

CEO Scott Jamieson SJamieson@annexbusinessmedia.com

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE: Canada $80.07 per year,USA $183.09 (CDN) per year, Outside Canada $207.57 (CDN) per year, Single Copy Canada $10.00. From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

Privacy@annexbusinessmedia.com Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2025 Annex Publishing & Printing Inc. All rights reserved. This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice. You should not act on information contained in this publication without seeking specific advice from qualified engineering professionals. Canadian Packaging accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. Canadian Packaging receives unsolicited materials, (including letters to the editor, press releases, promotional items and images) from time to time. Canadian Packaging, its affiliates and assignees may use, reproduce, publish, republish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

We acknowledge the [financial] support of the Government of Canada

CFT GROUP

IWK GROUP

Packaging machinery sector poised for sustained robust growth over next three years

After two years of underwhelming growth, the North American packaging machinery market is expected to pick up rapid pace in the next three years, according to an upbeat new report from PMMI, The Association for Packaging and Processing Technologies.

exhibition in Chicago, PMMI cites substantial announced investments in new plants and line upgrades in many industry segments, lower interest rates, and changes in consumer preferences as key growth drivers that will fuel the U.S. packaging machinery to new heights with annual growth of eight per cent by 2027, surpassing US$13 billion in total sales.

While that pace of growth will not match

Material X-Ray Detection

X-Ray On-Hold Finished Goods

PMMI vice-president of market development Jorge Izquierdo shares key findings of the association’s State of the Industry report at a press briefing during the recent PACK EXPO International exhibition in Chicago.

2022, it will still represent a significant improvement from the “softened demand” experienced during 2023 and most of last year, according to PMMI.

As the report points out, much of the growth in the last two years was driven primarily by the clearing up of order backlogs amassed during the pandemic, thereby dampening growth in orders for new equipment and machinery.

“The lighter demand experienced in the back half of 2023 continued into 2024,” PMMI notes.

“Resultingly, the packaging machinery sector is expected to experience its slowest growth year [in 2024] compared to the last three years in the industry.”

While the market for U.S.-made packaging machinery grew by 5.8 per cent in 2023—reaching US$10.9 billion—PMMI expects the final numbers for 2024 to show a more modest increase of 2.5 per cent.

Despite the statistically notable drop-off s, the U.S. market for packaging machinery remains fundamentally sound, according to PMMI, and is expected to enjoy accelerated demand growth in the next three years.

“Despite this general slowdown in 2023 and 2024, the packaging industry is in a unique position,” PMMI explains. “This industry rarely experiences negative growth because sectors can adapt to consumer

“For instance, during the pandemic there was a shift towards single-packaged items to meet increased demand for convenience and safety,” the report notes, “but as more people returned to restaurants, there was a shift towards packaging solutions like kegs.

“Additionally, packaging companies can easily adjust to offer smaller sizes to cater to consumers who prefer not to purchase larger quantities of a product.

“This flexibility allows the packaging industry to continuously meet evolving market demands.

While PMMI conducts comprehensive survey of the industry’s well-being on annual basis, this report marks the first time

Industrial

Protection

that PMMI has gathered comprehensive revenue and volume statistics for the Canadian packaging machinery sector—reflecting the growing presence and influence of Canadian companies in the tightly integrated North American landscape of the packaging machinery business.

In fact, many of leading Canadian manufactures already operate major manufacturing and distribution facilities south of the U.S.-Canada border, with many more planning to follow suit to avoid possible trade sanctions down the road.

“The value of packaging machinery sold in Canada in 2023 was estimated to be US$921 million” the report says, citing persistent labor issues, stringent regulations governing the use of single-use plastics, and generally higher operating cost as primary factors for the slower growth for Canadian packaging OEMs.

“In 2024, new sales are expected to remain relatively flat with a year-over-year growth rate of 1.3 per cent,” PMMI says, although

growth is expected to pick up significantly in coming years— mirroring that of the U.S. market rebound.

According to PMMI, the association’s upbeat forecast is based on expectations of continued growth right across all of the packaging machinery sector’s major end-user sectors:

• FOOD. “The food sector remains robust and ever-growing, driven by the constant demand for food products,” PMMI says.

“Whether consumers are buying groceries or dining out, the need for food packaging remains steady

“This sector’s resilience is due to its essential nature, and

machinery equipment adapts to consumer preferences regardless of the economic state,” says PMMI, citing 11 announcements by major industry players regarding plans for new facilities and upgrades in coming years, totalling over US$838 million.

• BEVERAGES. “This highly resilient sector is also poised to enjoy accelerated growth thanks to “a steady demand for drinks of all kinds,” PMMI states, citing diversification of drink sizes and the growing popularity of non-alcoholic drinks.

“A significant trend to watch is the shift in packaging materials, with glass and cans gaining

popularity as the industry seeks more alternatives to plastic.”

In 2023 alone, the beverage industry’s major players announced eight new large capital investment plans, amounting to over US$686 million.

• CHEMICALS. After a fairly sluggish 2023, the chemical sector is expected to pick up pace in coming years after a significant number of new investment plans unveiled over the course of last year, totalling over US$1.6 billion.

• PHARMACEUTICALS.

Having posted the highest growth rate of nine per cent in 2023, the highest of all end-use sectors, the pharmaceutical industry will remain on a fast-growth track over the next three years, having announced six massive investment projects worth over US$2.3 billion.

• PERSONAL CARE. The industry’s unfolding switch from plastic packaging to carton-based solutions is expected to continue in the near future, according to PMMI, citing seven announcement for new investment projects totalling over U.S.$1 billion. 24_012000_Canadian_Packaging_JAN_FEB_CN Mod: October 22, 2024 5:46 PM Print: 11/06/24 page 1 v2.5

HYGIENE PRODUCTS FOR THE FOOD INDUSTRY

Shawpak Passion For Hygiene

HYGIENIC ENTRANCE WITH SOLE CLEANING AND HAND DISINFECTION

When the hands are inserted into the cylinders, sensors activate the dispensing of disinfectant or soap. After this, the turnstile is released and the user can proceed to the next step in the hygienic process

WALKTHROUGH SOLE AND SHAFT CLEANER

Upon entering the unit, sensors automatically activate the rotation of the brushes and your soles and shafts are cleaned. This installation is ideally suited for the cleaning and disinfection of heavily soiled boots

CHEMICAL DISPENSER WITH TURNSTILE

When the hands are inserted into the cylinders, sensors activate the dispensing of disinfectant or soap. After this, the turnstile is released and the user can proceed to the next step in the hygienic process

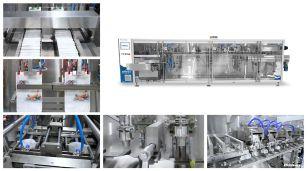

INDUSTRIAL WASHING SYSTEMS FOR AL YOUR LOAD CARRIERS

Our industrial washing systems clean load carriers, crates, pallets or boxes. The systems are thrifty with water, energy and cleaning agents, without making concessions to the cleaning itself. Our systems utilize a precisely tailored combination of temperature, chemical agents, time, and mechanical force, ensuring optimal cleaning results are always achieved.

Endress+Hauser, Swiss-headquartered manufacturer of measurement, instrumentation and testing technologies for industrial process engineering has entered into a new strategic partnership with SICK AG, a leading Germans supplier of industrial sensors, making SICK’s advanced gas analysis and flow measurement technology an integral part of Endress+Hauser’s comprehensive instrumentation portfolio. As part of the deal, about 800 SICK sales and service employees are being transferred to Endress+Hauser’s global network across 42 countries, including Canada, with the production and further development of gas analyzers and brought together under the umbrella of the newly-formed joint-venture company Endress+Hauser SICK GmbH+Co.

KG, with each partner owing an equal 50-percent stake. The new entity will employ around 730 people at several German sites, who will collaborate closely with Endress+Hauser’s product centers to drive product innovation and meet evolving market demands. “This partnership is a perfect match because it creates new opportunities for growth and development, particularly in the sustainable transformation of the process industry,” says Endress+Hauser Group’s chief executive officer Peter Selders.

Global beverage packaging systems manufacturer Sidel has announced that launch of the Aseptic Knowledge Center, an online resource sharing the company’s in-depth expertise with sensitive liquid food and drink manufacturers. Accessible on the company’s website (www. sidel.com/aseptic), the Aseptic Knowledge Center is dedicated to helping manufacturers meet the challenges of the growing market for healthy and nutritious long shelf-life drinks, such as juices, isotonics, ready-to-drinks, teas and liquid dairy

products. According to Sidel, using this online resource will enable manufacturers to discover Sidel’s line safety and performance credentials and explore how its innovative solutions help ensure the highest levels of safety and product integrity. “Food safety and extending product shelf-life are top priorities for the aseptic packaging industry,” says Damien Fournier, Sidel’s vice-president for sensitive portfolio. “With the Aseptic Knowledge Centre, Sidel’s extensive experience positions us as the ‘go-to’ partner for manufacturers seeking to enhance operational efficiency in the aseptic market.”

INX Group Limited, a subsidiary of Osaka, Japan-headquartered Sakata INX Corporation, has completed the acquisition of Coatings & Adhesives Corporation (C&A), a leading supplier of specialty inks in Leland, N.C., to create a new entity, INX International Coatings and Adhesives

According to INX, the merger will allow both companies to elevate the industry by enhancing customer satisfaction and operational excellence. “Our commitment to innovation, quality and service aligns perfectly with C&A’s legacy,” says INX International president Bryce Kristo. “We are not merely merging companies; we are creating new possibilities and a new standard for excellence in the packaging market.”

CASCADES APPOINTS MR. JEAN-DAVID TARDIF AS EXECUTIVE VICE-PRESIDENT, PACKAGING

To support its strategic growth, Cascades Inc (TSX: CAS) is proud to announce the appointment of Mr. Jean-David Tardif as Executive Vice-President, Packaging.

Mr. Tardif was, until last November, President and Chief Operating Officer of Cascades Tissue Group. Jean-David Tardif holds a bachelor’s degree in mechanical engineering and an MBA. He has worked in each of Cascades’ three groups since joining the Company in 1997. From 2013 to 2017 he was Vice-President, Consumer Products of the Tissue Papers business. He subsequently served as Vice-President, Operations, for the Company’s Containerboard Packaging segment from 2017 to 2019. Mr. Tardif returned to the Tissue Papers business in 2019 and has served as the Group’s President and Chief Operating Officer since then.

“Jean-David has played a key role in restoring our Tissue Group’s competitive positioning and profitability. In so doing, he demonstrated the full extent of his leadership capabilities and talent for fostering the full potential of a high-performance team and improving customer service. I am convinced he has what it takes to succeed in this new challenge,” said Cascades President and Chief Executive Officer Hugues Simon.

About Cascades

Founded in 1964, Cascades offers sustainable, innovative and value-added solutions for packaging, hygiene and recovery needs. The company employs 10,000 women and men, who work in a network of nearly 70 production units in North America. Driven by its management philosophy, half a century of experience in recycling, and continuous research and development efforts, Cascades continues to provide innovative products that customers have come to rely on, while contributing to the well-being of people, communities and the entire planet. Cascades’ shares trade on the Toronto Stock Exchange under the ticker symbol CAS.

STRAP AND GO!

Launched at the PACK EXPO International 2024 exhibition in Chicago last November, the new BXT4 battery hand tool for plastic strapping from Signode features the innovative EasyTrigger technology for enhanced user operation, performance and durability. According to Signode, the EasyTrigger simplifies the mobile strapping process by allowing uses to operate the ergonomically-designed tool with minimal manual force to reduce workplace fatigue and improve efficiency, whereby a single click quickly opens the tensioning unit with built-in motor support, making it easier than ever to handle strapping tasks demanding environments. In addition, the EasyTrigger technology also enables controlled release of strap tension at any point before the welding process, offering enhanced flexibility and operational performance. Additional features include an optimized center of gravity for more balanced use, a rubberized handle for a more comfortable grip, and a new full-color display that offers intuitive visual guidance for strapping operations and real-time feedback, while its motor-assisted strap insertion and tensioning enable high-speed, efficient strapping. Moreover, the tool’s robust construction includes a wear-resistant base plate and impact-resistant display for long-lasting durability and reliability, even under harsh conditions.

Signode

SUPER SWIFT

Designed to maximize productivity, flexibility and ease-of-use, the new Swifty Bagger S-3600 Duplex Servo from WeighPack Systems is capable of opening, filling and sealing up to 70 pre-made pouches per minute, or

4,200 pouches per hour, with its unique straight-line design allowing operators full visibility of the bag opening, filling and sealing processes. Equipped with twin pouch infeed conveyors and dual fill stations, this advanced bagger seamlessly handles liquids, solids, and powders with high speed and optimal precision, according to WeighPack. Well-suited for high-speed pouching of snacks, confectionery, seafood, meats, gummies, coffee, tobacco, flour, chemicals or pet treats, the versatile Swifty Bagger S-3600 Duplex Servo handls a broad range of pouch styles like stand-up, pillow, gusseted, carry-handle, and three- and four-sided sealed pouches.

WeighPack Systems (Div. of Paxiom Group)

GO WITH THE FLOW

Designed for the rigorous demands of high-speed modified-atmosphere packaging (MAP) for fresh food applications, the FM400 flow-wrap packaging machine from Harpak-ULMA is capable of producing up to 150 packs per minute, while setting new bench marks for sanitation and versatility. As a central feature of the flow-wrapper’s design, its sealing head features an advanced orbital movement mechanism that delivers impeccable hermetic seals at exceptional speeds, while the machine’s modular design extends through multiple configuration options, including top reel, bottom reel, and side seal versions. Meeting strict sanitation standards, the FM400 boasts a stainless-steel body and vertical plate construction to allow for rigorous cleaning with hot water and chemicals, while its external electronic components provide superior water and dust protection for long-term durability in challenging environments.

Harpak-ULMA

Our folding grade Kallima is the only 3-ply FBB made right here in North America. Its unique high-bulk, low-density construction brings a host of benefits to every project.

Local construction provides supply peaceof-mind, a lower basis weight gives you a significant yield advantage, and our renewable manufacturing energy source means a low carbon footprint.

3-PLY PEACE-OFMIND IN EVERY BOX

Compostable coffee pods take aim at waste

For all their consumer convenience and enjoyment, single-serve coffee capsules have earned an unenviable reputation for their allegedly detrimental environmental impact due to the sheer amount of landfill waste the plastic pods generate after use.

However, recent collaborative efforts by Austrian-based companies like Greiner Packaging and Constantia Flexibles are showing

great promise in rehabilitating that much-tarnished reputation by introducing an innovative, fully home compostable coffee capsule solution.

Representing a major step forward for providing a new, sustainable option for coffee suppliers focused on convenience, Greiner Packaging supplied the body of the capsule—made from biodegradable plastic—while Constantia Flexibles provided the compostable EcoPressoLid

Process improvement is like skydiving. With a dependable partner, you can reach the next level.

Just as skydivers rely on their jumping partners, we know that partnering with our customers brings the same level of support and dependability in the area of manufacturing productivity. Together, we can overcome challenges and achieve a shared goal, optimizing processes with regards to economic efficiency, safety, and environmental protection. Let’s improve together.

lidding to create an effective end-of-life solution with minimal environmental impact.

Developed by Greiner. the capsule body preserves the freshness of the coffee and is compatible with conventional coffee capsule machines. For its part, the paper-based EcoPressoLid can be used to seal both the top and bottom of the capsules, with both components having received the OK Compost Home certification from TÜV Austria together as a system.

According to the companies, this innovative solution offers consumers a more sustainable option without compromising on quality or convenience, while supporting the Circular Economy by reducing waste and minimizing environmental impact.

“We are committed to pushing the boundaries of sustainable packaging solutions,” states Taner Ertan, global business development manager at Greiner Packaging. “Our collaboration with Constantia Flexibles on the home compostable coffee capsule embodies our shared vision for a greener future.

“This innovative product not only meets the high expectations of eco-conscious consumers but also sets a new standard in the industry,” says Ertan. “We are proud to contribute to a solution that balances convenience and environmental responsibility.”

According to Constantia Flexibles, the paper-based EcoPressoLid boasts several impressive characteristics: including providing a high barrier to oxygen, excellent sealing, and exceptional coffee brewing performance.

Moreover, it is compatible with commonly used capsule filling and sealing machines on the market.

“The EcoPressoLid capsule liner is a significant step towards more sustainable coffee consumption,” says Peter Wallach, head of the processed meat and beverages segment at Constantia Flexibles. “We are especially proud of our partnership with Greiner Packaging, as it allows us to offer a complete, TÜV Austria-certified solution to our customers.”

FOR SAFETY’S SAKE

Leading Quebec packaging OEM leaves nothing to chance with high-precision safety relays installed on its world-class monobloc machinery

By George Guidoni, Editor

To borrow a line from former U.S. Secretary of the Treasury Paul O’Neill, safety is not just a priority for companies like Capmatic Ltd.—it’s a precondition.

Founded in 1964, the Montreal-based packaging machine-builder is the leading Canadian manufacturer of high-performance, multifunctional monobloc packaging systems for precision liquid filling applications in the pharmaceutical, life sciences, food-and-beverage, cosmetics, personal-care and chemical industries.

With an estimated installation base of over 5,000 machines to its credit, the privately-owned company has worked tirelessly over the last 60 years to establish itself as a highly respected and renowned leader in the liquid filling space

through strict adherence to its business philosophy built on the four core pillars of innovation, passion, integrity and trust.

With deep-rooted commitment to continuous innovation and world-class craftsmanship, the company’s highly-skilled engineering and technical teams are constantly looking for ways to push the technological envelope of existing packaging solutions to produce ever-faster, more efficient and reliable packaging solutions to the market year after year.

It’s no different this year, as the company prepares to hit the market in style with two new high-performance machines combining world-class performance and productivity attributes, along with impeccable safety features enabled by advanced relay technology developed by leading global automation and safety

Capmatic’s director of project management Michael Rossi strike s a pose in front of the new Galaxy series monobloc machine.

Above

A fully-finished Galaxy monobloc machine, designed for high-speed scientific research applications, offers highprecision liquid dispensing and swift and gentle handling of PCR plates and auto injectors.

Left

Michael Rossi displays some of the Pilz safety relays deployed on Capmatic-made packaging machinery to ensure completely safe machine operation.

“These machines represent our strong capabilities in producing hiqh-quality, complex products for various industries.”

experts Pilz GmbH & Co. KG

Designed and built at the Capmatic America manufacturing facility in Cypress, Ca., the brand new California Soldier is a multi-station monobloc machine draws upon the legacy of Capmatic’s core machine series—including the Bambino and Patriot brands—by combining proven mechanics with cutting-edge servo motor technology to offer a best-in-class automation solution for laboratory automation across a broad range of scientific research applications requiring high-speed, accurate and hygienic filling and capping operations.

As Capmatic’s director of project management Mike Rossi explains, “California Soldier epitomizes simplicity and versatility within a compact footprint, requiring just one operator for seamless operation.

“It excels in speed, achieving up to 60 bpm (bottle per minute) with exceptional volumetric piston filling, dropper insertion, and cap placement.

“The design facilitates quick format changes, making it perfect for dynamic production environments where adaptability is key,” Rossi adds.

“With its robust, compact structure, California Soldier is the ideal solution to meet the complex demands of modern filling operations, ensuring reliability and precision for every task.”

For its part, the new Galaxy series machine is “designed to elevate precision and efficiency in scientific research,” according to Rossi.

“Engineered for meticulous handling of PCR (polymerase chain reaction) plates and auto-injectors, Galaxy offers high-precision liquid dispensing that guarantees accurate and consistent results,” Rossi explains.

“Its automated functionalities streamline tasks such as plate transportation and liquid handling, significantly boosting productivity while adhering to uncompromising quality standards.”

Designed as an Industry 4.0-ready solution, the new Galaxy is equipped with advanced AI (artificial intelligence) vision systems to ensure 100-percent in-process inspections for all components and assemblies to ensure rigorous quality control, according to Rossi, while integrating real-time data tracking and analytics for optimized operations.

“Designed with flexibility in mind, Galaxy boasts customizable workflows and adaptable programming capabilities to accommodate diverse projects,” Rossi says, “while its IPC

(Inline Process Control) feature accurately verifies the weight of unidose powder nasal spray devices to maintain strict fill accuracy.”

As Rossi proclaims, “Both Galaxy and California Soldier represent the cutting edge of laboratory technology—showcasing innovations that drive efficiency and excellence in scientific and manufacturing processes.

“These machines represent Capmatic’s commitment to advanced manufacturing technologies and our strong capabilities in producing high-quality, complex products for various industries,” Rossi states.

To ensure completely safe operation of its high-speed automated machinery, Capmatic spares no effort or expense in equipping its machines with the best-in-class safety relays and devices manufactured in Germany by Pilz and marketed in Canada through its Canadian subsidiary Pilz Automation Safety Canada L.P.

Based in Mississauga, Ont., Pilz Canada works various reputed distributors across Canada to supply major industrial equipment end-users with a broad portfolio of high-quality Pilz automation safety solutions, ranging from safety switches, E-stops and light curtains to safety relays, PLC controllers and brake control devices, among others.

In Quebec, the distribution of Pilz automation and safety technologies is capably handled by Jacmar, a prominent supplier of industrial automation and control products that has just celebrated its 30th anniversary last year.

Based in Montreal, the company employs about 60 people at its three locations in Victoriaville, Quebec City and Mascouche (Montreal suburb) to serve its expansive industrial client base—including over 200 packaging OEMs (original equipment manufacturers)—across the province.

“I think the best way to describe us would be a value-added distributor,” says Jacmar vice-president and co-owner JeanPierre Godin, one of four business partners who purchased the company from its previous owners back in 2006.

As Godin explains, Jacmar’s steady growth and marketplace success since the ownership change—culminating in a major expansion of its 27,000-square-foot distribution center in Mascouche last year—can be traced directly to the high quality of its workforce and the overwhelmingly positive reputation of the product brands and manufacturers that the company represents, including Pilz.

“The brands that we carry are known worldwide,” Godin says, “and so is our commitment to invest in in the company with more manpower and more technologies to better serve our clients.

“We went from 30 people in 2015 to a staff of 60 today because we wanted to create new opportunities for our product managers and support our salespeople in the field with real practical knowledge of the particular technology they are trying to sell,” Godin explains.

“So in addition to distributing the products, we can also offer engineering services, assist companies with their project management needs, build custom electrical enclosure cabinets for them, and do all kinds of other things that many of our competitors cannot offer,” Godin states.

“It gives our customers a great deal of confidence to know that they’re working with people who really know what they are talking about.”

As Godin relates, Jacmar has been working with Capmatic on various projects for nearly 20 years, but it was about eight years ago that Jacmar introduced Capmatic to the Pilz brand of safety devices, which have since then become an integral part of all new Capmatic-made monobloc machinery.

Says Godin: “Whenever something happens on the machine, it’s very important to know where exactly in the machine it happened and why it happened, which is not the easiest thing to pinpoint right away on a 40-foot-long machine.

Above

High-speed Capmatic machinery makes extensive use of Kinova pick-andplace robots , manufactured in Quebec, to ensure high-speed precision and accuracy of its monobloc packaging machinery.

Right

Close-up of one of the Pilz PSENslock magnetic safety interlocks installed inside the new Galaxy series machine to ensure that machine doors cannot be opened until the machine is in a safe state.

“And that's exactly what the Pilz safety devices were able to bring to the table—the ability to know where to look for a problem and why it has occurred,” Godin elaborates, “be it a machine malfunction or a safety issue.

“There are a lot of companies out there making safety devices,” he notes, but Pilz really is the ‘golden standard’ for these types of products.

“So when potential customers looks at your machinery and see the Pilz safety devices deployed on it, it immediately communicates the high quality and technical excellence that machine has to offer,” he says.

“It’s like buying a BMW or a Mercedes Benz rather than an ordinary car model.”

For Capmatic’s new California Soldier and Galaxy series machines, Jacmar provides three main Pilz technologies incorporated into the machine design, including:

• The PNOZsigma (E-STOP relay/ emergency stop relay PNOZsigmaPilz CA) safety relay with time delay function.

• According to Pilz, this relay provides flexibility being able to be used with most standard safety functions, as well as being able to set time delays when required by the application.

• The PSENcode (PSENcode – Coded safety switch – Pilz DE - Pilz CA) RFID-coded door sensors with a 30-newton magnet—ensuring that the machine doors close without needing extra mechanical mounting.

• The PSENslock (Safety locking device PSENslock / PSENslock 2 - Pilz CA) magnetic interlock, which prvides a robust safety gate locking without any moving parts.

According to Capmatic’s Rossi, the

Galaxy is equipped with six PSEN magnetic safety switches—boasting IP69 rating and thermal tolerance of -25°C to 70°C—while the California Soldier deploys six Pilz magnetic switches. .

“The Pilz safety components, such as safety PLCs and sensors, help us ensure safe operation by monitoring machine status, detecting potential hazards, and triggering emergency stops if necessary,” says Rossi, lauding the cutting-edge technology, such as RFID codes, incorporated into the Pilz devices.

As Rossi points out, “Pilz’s focus on innovation ensures that our machines are future-ready.

“As the industry evolves, Pilz’s advanced technologies enable us to adapt to new challenges and opportunities.

“By leveraging Pilz’s expertise, we can develop machines that are capable of handling complex production scenarios—meeting the demands of Industry 4.0, and addressing the evolving needs of our customers,” Rossi states.

“Our partnership with Pilz and Jacmar is a testament to our commitment to delivering world-class capping and filling machines,” Rossi concludes.

“By combining our expertise in ma-

Left

Full and partial views of the new California Soldier machine built by Capmatic USA for a broad range of laboratory automation applications in scientific research.

Above Close-up view of one of the high-quality Robotiq brand robots incorporated into the California Solider machine design.

chine design and Pilz’s leadership in safety automation, we are able to provide solutions that empower our customers to achieve operational excellence.”

SUPPLIERS

Capmatic Ltd.

Pilz Automation Safety Canada Jacmar

LICENSE TO PRINT

Quebec paperboard converter keeping up with the times through proactive capital investment and staying tuned to the evolving market needs

By Andrew Snook

Photos by Pierre Longtin

With a razorsharp focus on the printing and design of innovative packaging products,

LMi Packaging (LMi) has always kept a close eye on packaging trends to meet the needs of its manufacturing clients.

Originally founded as Litho MilleIles, Inc. in 1977, the company found success as a commercial printing company, operating out of Terrebonne, Que. It operated this way until the 1990s, when the company changed gears and became a printer of CDs and DVDs.

“That was the main market for the company at the time,” recalls LMi co-

owner Gerry Bonneau.

Around that same time, LMi hired two key employees, Josée Debien (1991) and Bonneau (1993), who would go on to lead the company into the future.

The two became co-owners of the company in 2006, the same year it began to transition away from CD and DVDs to focus on packaging for the cosmetics industry and general folding carton production.

One year later, Bonneau and Debien purchased the company’s two printing facilities.

Fast-forward to present day and LMi has continued to grow to fill a variety of needs within the printing and packaging sectors.

In addition to cosmetics, the company services the frozen foods sector for major grocery retailers such as Costco,

LMi Packaging co-owners Gerry Bonneau (left) and Josée Debien at the company’s production facility located in Saint-Eustache, Que.

IGA, and Super C, as well as clients in pharmaceutical and other sectors.

“We service everything now, and we do it all in-house,” Bonneau says.

LMi’s most active market is currently the frozen food sector in Quebec, Ontario and the U.S.

To keep up with clients’ needs, the company sold its two original production facilities in the fall of 2023 and bought a new 54,000-square-foot facility in 2024, located within the Albatros St. Eustache Eco Park in Saint-Eustache, Que.

The new plant is equipped with the latest packaging technologies, including a recently purchased Komori Lithrone GLX Advance six-color press (sold by Komcan Komori) that has the capability to produce up to 18,000 sheets per hour at sizes upwards of 29.5x42-inches.

“It’s a high-speed machine for the packaging industry,” says John Chisca, general manager at LMi.

LMi’s decision to invest in the Komori Lithrone GLX Advance six-color press was re-affirmed as a sound busi-

“We’re always working on the bottom line towards becoming more efficient, while working on improving our environmental practices at the same time.”

ness decision when the leadership team attended the Drupa 2024 global printing industry exhibition in Düsseldorf, Germany, where they found their machine as one of the main technologies being showcased at the global trade show.

“We were really proud about that,” Bonneau says. “We were going there to see what the future of printing presses would be, and discovered that we had actually bought that future press.”

The Komori Lithrone GLX Advance press is equipped with the innovative Smart Colour technology, allowing LMi to produce a wide variety of options for customers.

“We’re capable to reproduce 90 per cent of the Pantone book with six colors,” Chisca says.

As an H-UV printing press, the Komori Lithrone GLX Advance consumes 18 per cent less energy than a UV printing press, he adds.

In addition to the new printing press, LMi invested in:

LMi co-owner Gerry Bonneau stands next to the six-color Lithrone GX40 Adnce printing press from Komori Corporation, which boasts imprssive throughput capacity to print up to 19,000 sheets per hour.

• A BOBST VISIONCUT 106 die-cutter, capable of die cutting 9,000 sheets per hour;

• A BOBST Masterfoil hot-foil stamper for embossing, debossing and other hot-stamp finishing applications;

• A BOBST VISIONFOLD 106 folder-gluer, capable of high-speed gluing of four and six corners, and equipped with advanced box inspection and rejection technologies;

• A new window patching machine.

The combination of these new technologies has significantly increased the company’s production speeds and capacities, according to Bonneau.

“We’re able to do stocking programs. We’re able to do justin-time (JIT) printing of folding boxes, and we’re able to do jobs in seven days,” Bonneau says. “That’s rare in our industry.”

Bonneau notes that it is becoming more common for companies to purchase their boxes using JIT printing purchasing strategies.

“JIT brings down the cost for clients, so they don’t have to keep big quantities in stock,” he explains. “It’s good for everybody’s cash flows.”

the new production line, according to Bonneau, while helping the plant to become a highly sustainable operation.

“Since 2006, our main goal at LMi Packaging was to be a 100-percent sustainable plant,” Bonneau says. “Everything is recyclable in the plant, not just the products.

“Every machine is sustainable, and we even recycle our varnishes.”

Bonneau relates that LMi is currently in the process of obtaining the vaunted the new BRCGS food safety certification of the Global Food Safety Initiative (GFSI), having already earned the environmental FSC certification of the Forest Stewardship Council

Bonneau says that creating a fully sustainable operation has been a long work-in-progress for the company, but also a rewarding one.

“We’ve been working on this since 2006,” Bonneau says. “We’ve always got our eyes open for the next best thing out there,” he says.

Below A BOBST

VISIONFOLD 106 folder-gluer (left) and a BOBST

VISIONCUT 106 die-cutter in action at the LMi production facility.

Thanks to careful planning, the installation of the new equipment went seamlessly and LMi didn’t lose any production time.

“Everything went well because before we let go of the other buildings, we made sure we were fully up-and-running here first,” Debien explains.

“So we ran all buildings for a few months before closing the older ones down.”

Overall, productivity at LMi has increased 20 per cent with

“Industry trade shows in Germany are still quite good for learning about the latest technologies, which is why Josee, John and I have been going to Drupa every four years since the 1990s.

“It’s important to see the machines live.”

The company currently employs a team of 50 people working on day, evening and weekend shifts.

While many printers and packagers currently face challenges with getting the necessary labor for their operations, Debien says LMi does not really have this issue.

Above from left LMi press operators checking out the print quality of sheets being printed on the high-speed, six-color H-UV Komori printing press.

Close-up of the high-quality folding cartons produced on the Komir press.

“It’s not hard for us to get people,” Debien says.

“Half of our staff has over 10 years of experience with the company.

“We treat our people well,” Debien points out. “We have a family-oriented vision, and we are really interested in the well-being of each employee.”

According to Debien, having a fairly young workforce is in itself an important competitive advantage.

“Almost all of us are under 50 years old,” Debien says.

While LMi’s customer base is split between Quebec, Ontario and the U.S.—with the majority of its clients based in Quebec—Bonneau says the company has firm plans to expand its business in Ontario.

To that end, LMi is currently weighing its options for a partnership with an Ontario-based sales agency to represent them there.

“We want to expand in Ontario and we’re open to speak with companies that want to enquire about representing us in Toronto,” Bonneau says.

“We used to be present in the Toronto market quite heavily when we printed CDs and DVDs,” Bonneau relates,“so it’s fairly easy for us to work in Ontario again.

“We just want to find the best agency to work with us.”

Left

A Kongsberg X digital cutting table inside the LMi plant’s prepress room.

A sampling of high-quality folding cartons produced at the LMi paperboard printing and converting facility.

According to the company’s management, LMi’s success to date comes from its ability to adapt to changing trends and needs within the packaging sector, along with competitive pricing and a hands-on approach at the production plant.

“Our success came from being in the plant, working handson in the facility, and also working with the clients being present in our shop,” Debien says.

“We’re always challenging ourselves to be more efficient, finding ways to waste less to save costs,” Debien adds.

“We’re always working on the bottom line towards becoming more efficient, while working on improving our environmental practices at the same time.”

Strong customer service has also been a vital component of the company’s success over the years.

“One of our services is we do mock-ups internally at no charge: it’s a quick service,” Bonneau says

“We’re also always open to working with clients as a contingency partner,” he adds.

“We often quickly become their main printer because we work with our customers,” Bonneau concludes.

“If they sell, we sell.”

Check out LMi at the upcoming SIAL Canada 2025 food industry trade show taking place April 29 to May 1, 2025, in Montreal, or at the Halal Show in Mississauga, Ont., May 27-28, 2025.

Packaging Circularity Course

*This course can be taken in full or register for individual modules*

Content, Alternative Materials | June 3

Measuring Sustainability: Managing Trade-offs & Making Decisions | June 17

Paper Packaging Plus

Paperboard and Folding Cartons, Corrugated Fibreboard, Box Compression Strength, Distribution Packaging, Glass Containers, Aerosols, Metal and Packaging Machinery.

March 4, 5, 6

Packaging Essentials

Introduction to Packaging, Food Preservation, Packaging Development, Prepress Processes, Print Processes, Graphic Design.

May 6, 7, 8

Complete Plastics Packaging Course

Introduction to Polymers, Rigid & Semi-Rigid Plastics, Flexible Packaging, Plastics and Circulary Economy, Design Basics for Plastics.

September 23, 24, 25

Delivered by industry experts, the PAC Global Packaging Certificate Program has been designed to meet the needs of international professionals in the packaging value chain, whether new to industry or tenured.

SAFETY IN NUMBERS

Fast-growing Halal meats producer beefs up its food safety credentials and capabilities with addition of inline metal detection

As one of the largest halal meat processors in Canada, supplying more than 75 different products to Canadian retail outlets and restaurants, Solmaz Foods never undervalues the importance of food safety and providing consumers with peace of mind.

Specializing in Turkish-style meats, Montreal-style turkey breast, halal pepperoni, deli cuts and fan-favorite sujuk sausage, Solmaz Foods was founded in 2001 when father-and-son duo Tahsin and Mehmet Solmaz opened a small butcher shop in east-end Toronto.

Over the next several years, the company’s fast-growing reputation for high quality, taste and freshness—along with establishing national distribution—

quickly made Solmaz virtually a household name in the Canadian Halal maet business.

Today, the company operates a 20,000-square-foot processing facility that process about 135,000 pounds of the finest halal meat monthly, sharing the building with a roomy on-site storefront housing counters of mouthwatering Halal deli meats, sausage and freshly-butchered, ready-to-cook meat products neatly arranged by type and species behind glass.

Oozing with extraordinary product diversity, elegant presentation and attractive packaging, the Solmaz storefront has become a true magnet for the nearby Canadian Muslim community, as well as for many other meat-lovers in general.

“Our retail store doubles as a ‘Taste Lab for us,” says company president

From left Solmaz Foods founder and president Mehmet Solmaz and Eric Garr, regional sales manager for Toronto-based metal detection technologies experts Fortress Technology Inc.

Mehmet Solmaz. “This is where we test all our finished products, all our new products, and get a great chance to observe our customers and learn their thoughts about our product.

“We only process Halal-certified meat products,” says Solmaz, “meaning products that comply with the Islamic dietary law, ensuring they are permissible and pure according to the standards.”

Solmaz explains that this strict compliance helped the company establish a stellar reputation for product integrity and authenticity, opening up new market opportunities outside of Ontario.

“We now cover the entire Canadian market east to west,” Solmaz relates, “selling our products in national chain stores and practically in all independently-owned ethnic stores catering to the Middle Eastern, South Asian and the Mediterranean communities.

“And recently we even started to export to the U.S. as well,” he proclaims.

The company’s splendid market growth has been brilliantly supported by continuous investment in top-quality processing and packaging systems over the years—enabling Solmaz to produce a broad variety of packaging formats for its leading flagship product brands.

This proactive investment has boosted the company’s total annual processing output to 850 tons, according to Solmaz, noting he is aiming to raise that output to

1.5 million tons in a couple of years.

To keep pace with growing production volumes, the Solmaz plant deploys several high-performance packaging and product inspection machines, the latter supplied in stages by the Toronto-based metal detection technologies manufacturer Fortress Technology Inc.

With a warm business relationship that goes back about seven years, Solmaz had no hesitation in turning to Fortress again recently to install a new inline Fortress Stealth pipeline metal detector, ensuring optimal quality control upstream right at the earliest processing stages next to the giant stuffers/grinders grounding primary cuts of meat shipped to the plant into ground meat.

With this purchase, the Solmaz plant now has four Fortress metal detectors strategically positioned along the production line from start to finish.

“When you’re producing 1.85 million pounds of product, food safety becomes a paramount issue for both our customers and us,” Solmaz asserts. “It’s a fundamental part of our operation and a non-negotiable priority for us.

As Solmaz relates, “We partner with Fortress Technology because we highly respect their innovative and reliable solutions, as well as our shared commitment to safety.

“We have worked with them for over seven years,” Solmaz point out, “and their experience has been instrumental in maintaining our food safety standards.

“In addition to excellent equipment, the service and technical support they provide for us is exemplary,” says Solmaz, clearly happy with the new equipment’s performance so far.

“Bringing in the two new inline Stealth detectors—an inline and a conveyor model—has enabled us to control the food safety, starting with the raw processing part and continuing all the way through to cooking and on to the packaging.”

Positioned right next to the stainless-steel meat suffers and grinders, the new Fortress Stealth pipeline metal detector has been doing a masterful job of inspecting the ground meat before it is stuffed, cooked, smoked, sliced and eventually packaged.

As Solmaz reasons, having double inspections doubles the probability that potential contaminants are not going undetected, thereby potentially undermining the brand image and reputation.

Since installing the new in-line pipe metal Stealth detector at the raw meat processing stage, while adding the new conveyor unit to the slicing and packaging area, Solmaz credits the new machines for helping the plant reduce its labor, processing and product waste costs by about 50 per cent.

“That 50 per cent basically represent the combined time and labor savings,” Solmaz says, “plus risk reduction.

“Our inline detector eliminates a lot of waste because the moment this system detects any material in the meat, it automatically discharges that part of the batch, and we can still process the rest of it,” he explains.

“So, this gives us two control systems in place,” he notes, “whereas before we only had one on the packaging line.”

According to Solmaz, having the combination of both upstream pipeline and end-of-line conveyor metal detectors gives the company a strong competitive edge.

Now we have a control point where we can identify if a product has any metal pieces or other materials inside earlier in our production,” Solmaz says. “That gives us better control and peace of mind that our products are safe.”

Adds Fortress Technology’s regional sales representative Eric Garr: “I love their product as a consumer, but as a supplier I dearly love their commitment to food safety and improving their product and process quality.

“They deserve a lot of credit for realizing the efficiencies they can achieve by deploying metal detection upstream in the process,” Garr says, “where you can remove the metal more efficiently.

“Using the inline metal detector to detect and keep unwanted particulates away from the product at the early stage definitely saves a lot of time and labor and the product wastage.”

In addition to citing exceptional hygienic design features—including seamless sanitary pipe—Garr also singles out the system’s easy-disassembly for maintenance and cleaning, as well as the powerful patented Halo testing technology incorporated into the Stealth units.

“Our Halo auto test system is designed to replicate the performance verifications that must have in place when you

The Variovac Optimus thermoform packaging machine from Reiser used to package processed Halal deli meats at Solmaz Foods.

have metal detection systems,” Garr explains, “and it does it all on-the-fly, thereby automating all the record-keeping.”

As Garr notes, “Pipeline systems can be notoriously difficult to test properly inline, but we’re able to replicate the exact disturbances caused by different metal types, sizes and speeds going through the system.”

In addition to boosting superb sensitivity, accuracy and user-friendliness, “The inline Stealth is designed as a potable turnkey solution that can be easily roll up to any vacuum filler and easily connected,” Garr points out.

“It has fully-adjustable wheels to cope with sloped floors found at many meat production facilities,” Garr notes, “and it also features an electric lift to protect operators and those setting up the equipment.

“Once the meat is then pumped from the vacuum filler through the piping, any contamination will then trigger the ball valve to divert rejected product downwards,” Garr explains.

“The Stealth metal detector also stores all the performance data on-board, which can be simply stored on a USB,” says Garr. “It will log every event on the metal detector, so that you can easily recall exactly what might have happened, who’s re-

Above

Finished packages of Solmaz brand

Halal bacon-style meat strips going through the Stealth metal detector for one last quality check to make sure there are not metal contaminants in the final product before it’s packed for shipment.

sponsible, and how to prevent it from ever happening again.”

Solmaz concurs: “Fortress has a lot of experience in the food business with many global brands, as well as local players in Canada like us.

“That gives us a nice comfort zone: We know they have the experience and experts in place that have faced similar situations that we face in our operation.”

As Solmaz points out, “The Fortress team not only showed the processing staff how to operate the equipment, but explained how the machines can best be used in specific detection scenarios during production.

“We now have the total peace of mind that whenever we make a certain amount of product,” he concludes, “and that whatever product was not discharged by the detectors is perfectly safe to eat.”

It’s important that your machine can stand the test of time and adapt to your packaging needs as your goals and strategies change. With Harpak-ULMA, you can experience the many faces of flexibility in packaging.

World-class customer service and support

• Reliable support

• In-house specialized technicians

• 24/7 customer service

• Extensive network of field technicians

Augmented reality can be an operation game changer for remote support, training and maintenance.

• Address issues immediately

• Shorten learning curves for your staff

• Perform maintenance tasks on your own

CATCH THE WAVE!

Upcoming Boston

exhibition shaping up to be a landmark event for the North American seafood industry

With the North American seafood market projected to surpass US$47 billion this year, according to global market intelligence researchers Statista, it’s safe to say that the upcoming Seafood Expo North America/Seafood Processing North America exhibition in Boston, Ma., is a must-attend event for any Canadian company aiming to benefit from that robust and remarkable growth.

Running at the Boston Convention and Exhibition Center from March 16 to March 18, 2025, the annual event—organized by the Portland, Me.-based Diversified events and media group, provides the opportunity for suppliers from around the world to build relationships, display their latest seafood products, equipment and services and conduct business with North American buyers.

These buyers include restaurants, supermarkets, catering firms, seafood markets, hotels, airlines and cruise lines, importers, wholesalers and distributors, as well as buyers of processing equipment, machinery, packaging and service solutions.

According to Diversified, attendees will be also able to engage in the conference program, where they can listen to insights from experts addressing the most important and timely issues relevant to today’s seafood industry.

This year, the show will kick off in style with an insightful keynote address to be delivered by Dr. Prins, PhD, a renowned macro-economist, geopolitical financial expert and best-selling author.

Titled Riding the Waves: Navigating Economic, Energy, and Trade Policies Impacting the Seafood Industry in 2025 , the presentation (March 16, 11:15 am EST, Room 153 CB) ) will provide an updated economic outlook for the seafood industry and a

tailored discussion around topics including tariff policies and regulations and its impacts on the North American and global supply chain, energy prices, sustainability, AI, traceability and more

“Dr. Prins’ background as a Wall Street executive and successful author with a deep knowledge of finance, economics and politics makes her a great addition to our event as keynote speaker,” says Wynter Courmont, vice-president of seafood at Diversified.

“Dr. Prins is highly effective in tailoring her discussions for diverse audiences and we are thrilled to have her unique viewpoint on the complex topics impacting the seafood industry,” Courmont adds.

An author of seven books and countless articles published across major media outlets, Dr. Prins has held key positions on Wall Street including as a managing director at Goldman Sachs, a senior managing director at Bear Stearns in London, a strategist at Lehman Brothers, and an analyst at the Chase Manhattan Bank

Special on-site events will include:

• Seafood Excellence North America Awards. Established to recognize and celebrate the best new seafood products in the North American seafood market, the long-running competition will split contestants to compete in two prestigious award categories, including Best New Retail Product and Best New Foodservice Product.

Taking place next month at the beautiful Boston Convention and Exhibition Center, the Seafood Expo North America exhibition is expected to draw about 20,000 seafood professionals from around the world to the event, running concurrently with the Seafood Processing North America exhibition that will host exhibitors from over 50 countries.

To select the winners, three seafood industry experts judge the new products based on appropriateness to the market, taste profile, packaging, market potential, convenience, nutritional value and originality.

• Oyster Shucking Competition. Sponsored by the government of New Brunswick, this popular feature will pit contestants to compete against each other and the clock to shuck oysters as fast as they can.

• Conference Program. The 2025 conference program will feature more than 30 educational sessions, covering the most important and timely issues relevant to today’s seafood business environment, including:

• Consumer trends and the impact on consumer purchase behavior in the seafood industry;

• Artificial intelligence (AI) as it relates to quality and food safety inspection in the seafood business;

• Traceability-based import control programs across the global seafood supply chain;

• The future of aquaculture;

• The economics of sustainability and responsibility of seafood;

• How the seafood industry is addressing marine plastic debris;

• Policy trends and regulatory issues;

• Forced labor and human rights standards across the supply chain.

To register for the show, please go to: .seafoodexpo.com/north-america

Joint Endeavors

Food packaging machinery leaders combine their knowledge and expertise to deliver next-generation packaging solutions

By George Guidoni, Editor

Grand announcements deserve a big stage for maximum impact, and for the North American packaging industry, the stage does not get much bigger than the biennial PACK EXPO International packaging and processing technologies exhibition in Chicago.

Coincidence or not, but with last show edition’s dates (Nov. 3-6, 2024) overlapping with the historic U.S. presidential election, the city’s sprawling McCormick Place fairgrounds was briefly transformed into a buoyant hotbed of drama, energy and excitement to rival any pre-election rally.

Expertly produced and conducted by the show’s management team at PMMI (The Association for Packaging and Processing Technologies) , North America’s packaging event of the year was a resounding success by any measure— smashing all previous records for attendance, exhibit space and the ever-growing breadth of exciting new packaging technologies entering the market.

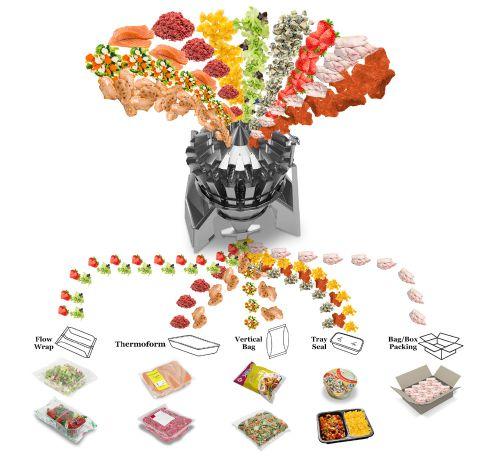

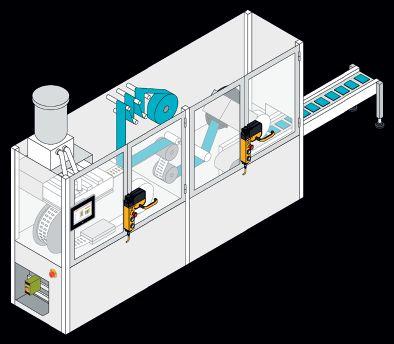

For Taunton, Ma.-based packaging line equipment distributor and integrator Harpak-ULMA, the four-day event was a perfect occasion to showcase the state-of-the-art fixed-weight packaging solutions manufactured in Denmark by Cabinplant A/S, a well-know European food packaging and processing OEM now aiming to grow its North American presence through a new distribution partnership with Harpak-ULMA.

With an exceptionally diverse product portfolio—ranging from multihead weighers and fillers to vibratory feeders and product distribution systems—adding Cabinplant to Harpak-ULMA’s own

expansive repertoire seems like a sure win-win proposition for both partners.

According to Harpak-ULMA’s president and chief executive officer Kevin Roach, the agreement significantly increases the range of automation and packaging combinations available to the company’s customers in the food, medical, bakery, and industrial markets in both the U.S. and Canada.

“We are thrilled to welcome Cabinplant to our family of packaging platforms and automation solutions: it’s a value-add play for both existing and prospective customers.,” Roach says.

“We are particularly excited by the variety of feeding and weighing configuration options they create for our tray seal, thermoformer, vertical form/fill/ seal, flow-wrap and carton solutions.

“That kind of customizable, modular packaging approach is very much in line with how we see the market evolving across every one of the industries we serve,” Roach states.

“We believe that the ability to deliver highly accurate, automated portioning is very much in demand, not only in caseready applications, but in fresh or frozen prepared foods and packaged meats or seafood,” he adds.

“The fact that their accuracy is so good as to all but eliminate product giveaway will turn a lot of heads.”

Founded in 1969, Cabinplant has enjoyed considerable success in the

From left Cabinplant’s chief executive officer Lars Ryholl and R&D director Henning Ingemann Hansen are joined by Harpak-ULMA president and chief executive officer Kevin Roach in front of the expansive Harpak-ULMA exhibit at the PACK EXPO International exhibition in Chicago last November.

European markets for decades, building up a loyal customer base in the fish and seafood, fruits and vegetables, meat and poultry, dairy and convenience food markets,while earning strong brand recognition and sparkling reputation for the high quality and craftsmanship of its equipment.

Cabinplant’s multihead food processing and weighing systems offer precise portioning and accurate weighing of a wide variety of naturally variable food products, including fresh, frozen, and delicate items.

These systems integrate seamlessly with different types of packaging solutions, such as trays, bags, or cartons, ensuring efficient product handling and reducing food waste, while maintaining high-speed production with minimal overfill.

This versatility supports diverse packaging needs in the food industry, promoting sustainability and operational efficiency, according to Cabinplant.

And while the company is still a relative newcomer the North American markets—with only about 100 machine installations to date—being acquired by the U.S.-based Berkshire Hathaway subsidiary CTB, Inc. in 2016 has prompted the company to find ways to expand its overseas markets, particularly in North America.

According to Cabinplast’s chief executive officer Lars Ryholl, the new partnership with Harpak-ULMA checks of

all the boxes for accelerating its growth in North America.

Ryholl says he expects Cabinplant’s proven technology and expertise in multihead weighing systems to appeal to a large untapped base of meat processors looking to automate their operations in face of ongoing labor market pressures.

As he explains, the value of multihead weighing is derived from a combination of automated pre-packaging product processing, distribution and feeding, highly accurate portioning, and dramatically lower manual labor costs.

“Delivering food products at a fixed weight without automation poses significant challenges due to the natural variability in product size and yield management complexities,” Ryholl explains. “Traditional manually-intensive packaging processes are notoriously inefficient and costly, both in terms of labor and product ‘giveaway,’ which can run up to five to six per cent of the packaging yield.

“Cabinplant’s solutions are designed to ensure the lowest giveaway on the market for our customers,” Ryholl states, “which is substantial in terms of profit optimization, not to mention the significant labor savings.”

Adds Roach: “The equipment these guys produce is really world-class by any measure—hygienic design, quality build, speed and precision, flexibility, all the attributes the food processors are looking for today.”

As he points out, Cabinplant’s highly efficient and tailored food processing solutions are capable of managing the entire pre-packaging process: from initial bulk product distribution to product feeding and highly accurate portioning and weighing for fresh, frozen or processed meat, poultry, dairy, seafood, fruits, vegetables, convenience foods, and pet food products.

“Their innovative patented technologies allow them to cover all stages of the

Left The state-of-theart multihead weighing systems manufactured by Cabinplant provide exceptional portioning accuracy and high-speed throughput for a wide variety of food products.

Right

A sampling of the broad range of high-performance food packaging machinery distributed across North America by Harpak-ULMA.

process, from sorting the raw material and doing all the product distribution to moving it to the multihead weighers, making the precisely-weighed portions, and putting it into the package,” Roach says.

Notably, Cabinplant machines have proven to be highly compatible for being integrated with many of the other secondary and tertiary packaging equipment supplied by Harpak-ULMA—including ULMA brand primary packaging machines and G. Mondini tray sealers, among others (pictures above) —allowing Harpak-ULMA to deliver full-line, end-to-end packaging solutions to its customers.

As Roach points out, “A single, automated pre-integrated solution reduces the risk and time typically associated with patching together technology from multiple vendors.

“Moreover, it also eliminates on-site testing iterations, improves machine performance, simplifies diagnostics, and streamlines the entire planning, installation and start-up process to deliver optimized production sooner,” Roach asserts.

“That translates into faster time to market, better ROI, and faster payback than more complex, multi-vendor solutions by implementing more efficient and accurate fixed-weight packaging automation.”

According to Roach, combining Cabinplant’s capabilities with Harpak-ULMA’s existing slate of smart, connected packaging platforms provides Harpak-ULMA with one of the most comprehensive, modular portfolios of integrated, automated food packaging solutions available from a single vendor in North America.

“Expanding our solutions footprint to embrace more units of production for a customer makes a lot of sense because it lifts the burden of interoperability from the buyer,” says Roach, adding that

Cabinplant’s existing North American customers will also benefit from access to Harpak-ULMA’s extended service offerings such as package design, training, OEE monitoring, and an extensive North American support services and parts supply operation.

In keeping with Harpak-ULMA’s philosophy of delivering smart, connected packaging solutions, Cabinplant’s solutions can be easily pre-integrated to allow for seamless plug-and-play connectivity with the company’s existing automation and packaging platforms.

This includes maintaining a consistent digital thread across production to enable real-time packaging visibility—exposing key information to advanced manufacturing software applications designed to drive production performance improvements.

According to Roach, this perfectly fits into Harpak-ULMA’s customer-centric philosophy focused on delivering complete solutions: from package and automation design through commissioning and support of the entire automated packaging line.

“Food producers and co-packers who have pivoted their product strategy to diversify into the high-speed, high-volume food packaging are turning to Harpak-ULMA because of our deep knowledge and turnkey approach,” he states.

“Our most successful customers are accessing new and growing markets, enjoying better total cost of ownership, and raising productivity by leveraging innovative emerging digital technologies,” Roach says.

“But the real secret sauce behind our success is building our culture around customer-centricity,” Roach asserts.

“That means finding new ways to help them grow and expand their business,” he concludes, “and our new partnership with Cabinplant is a powerful testament to this mindset.”

MEETING OF MINDS

Merger of family-run flexible packaging producers paves the way for continuous nationwide market growth from coast to coast

By Andrew Snook

When two companies consider a merger, it is common for leadership on both sides

to look for synergies that will boost efficiencies and improve operations.

These synergies were the main drivers for the merger between family-run businesses Duropac and Foodpak in 2024.

Founded in 1993 by Yvon Tremblay and purchased by Jean-Francois and Olivier Bourdeau in 2015, Duropac has grown to become a leading provider of flexible packaging solutions for the

Canadian food industry across Eastern Canada.

Based in Candiac, Que., Jean-Francois leads the company alongside his son, Olivier, co-owner of Duropac who manages overall sales and procurement.

The company has been successful in growing its market share from Ontario eastward into the Maritimes but was looking to expand into Western Canada to better serve its customers in the region and grow its market share.

“We’re established in Quebec with strong business in Quebec and Ontario,” Jean-Francois says.

“We wanted to go west in order to grow our organization and to support our national customers who were asking for products for their manufacturing plants out west.”