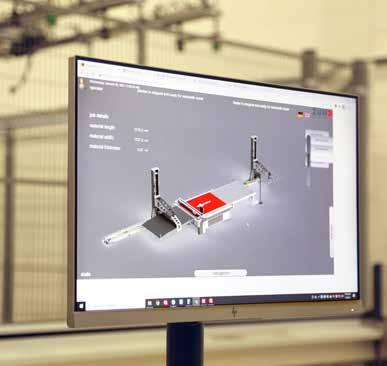

WestRock is your true partner, on the forefront of innovation, providing flexible and scalable solutions for your operation in changing times. Our performance-matched packaging design to automation solutions can help you meet the needs of your operation—today, tomorrow and into the future.

Packaging design to automaton solutions.

westrock.com/automation

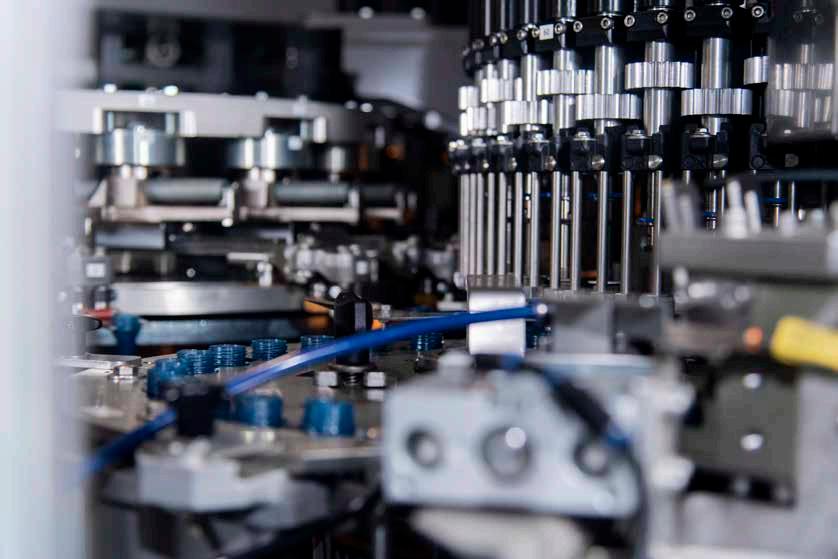

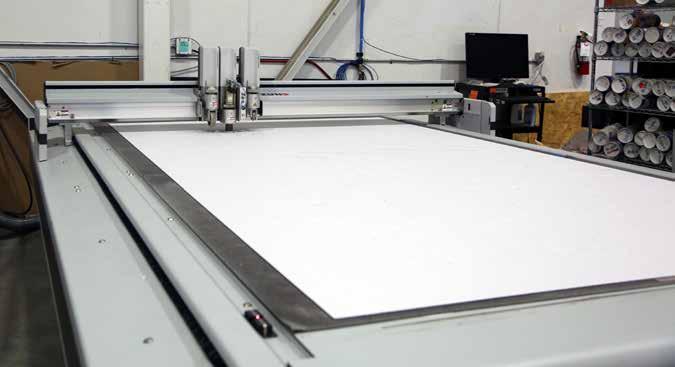

A close-up of the VC999 XtraVac FW600A horizontal flow wrap packaging machine installed at the Les Aliments 2000 production facility. 14 24 37 31

COLUMNS

FROM THE EDITOR

4 George Guidoni No time to waste on sustinability.

CHECKOUT

124 Je May Joe Public speaks out on packaging hits and misses.

ON THE COVER

COVER STORY

Leading Quebec pizza and pastry dough producer optimizes its production line e ciencies and flexibility with state-ofthe-art thermoforming and flow wrapping machinery.

Canadian water bottler showing the way forward in sustainability leadership by refining its closed-loop production capabilities and value chain infrastructure.

Toronto co-packing services provider leverages process automation and digitalization to grow its business in challenging times.

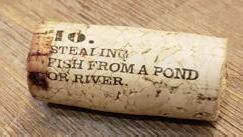

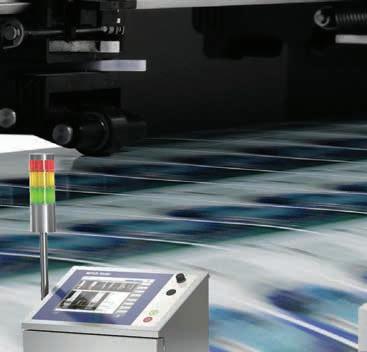

Quebec manufacturer of wooden pallets enhances its brand identity and product traceability with rugged inkjet printing technology.

43 2021 Pa aging

Page-by-page guide to using this one-of-a-kind industry manual.

NEWSPACK

6-7 Packaging news round-up.

NOTES & QUOTES

8-9 Noteworthy industry briefs.

FIRST GLANCE 11-12 New packaging solutions.

ECO-PACK NOW

14 All about packaging sustainability.

imPACt

15 A monthly insight from PAC Packaging Consortium

ANNOUNCEMENTS

120-121 Company brief and updates.

PEOPLE 122-123 Career moves in packaging world.

If there’s one thing that the past decade has taught the global packaging industry, it is that achieving the Holy Grail of truly sustainable packaging will not happen in isolation or through incremental measures.

The share of global greenhouse gas emissions generated by the global food supply chain.

And while the backlash against the science of Climate Change and global warming during the four years of the last U.S. administration has certainly played a role in lulling some business sectors into a sense of smug complacency and apathy about the planet’s environmental woes, it is reassuring to see the new decade start o with some encouraging signs that the world’s leading producers and users of consumer packaging largely remain on the same page in their ongoing e orts to reduce their respective carbon footprints.

In this context, the renowned Swedish-Swiss aseptic packaging products manufacturer Tetra Pak’s approach to making all-inclusive cross-industry collaboration work for greater good is a promising sign that the idea of truly sustainable carbon-neutral packaging is not just an idealistic pipe dream.

Celebrating its 70th anniversary this year, Tetra Pak has been at the forefront of global sustainability movement long before the term sustainable packaging even became widely adopted in industry circles.

With a broad variety of Tetra Pak’s signature paperboard drink cartons used worldwide to package and sell a vast array of liquid and viscous food-and-beverage products as an alternative to conventional metal, glass, plastic packaging—all requiring vast amounts of energy and non-renewable resources to produce—the sincerity of the company’s commitment to environmental responsibility is beyond doubt.

Which is all the more reason to give the company credit for spearheading a new approach to accelerating the development of sustainable packaging through a new “collaborative innovation model” that is no longer based solely on satisfying requirements of the traditional linear supply chain, but rather, “A new partnership ecosystem model, where the entire industry works in close collaboration.”

So far, thisTetra Pak-led initiative has got o to a promising start by drawing the allegiance of global corporate heavyweights such as the Finnish paper product group Stora Enso, leading Brazilian papermaker Klabin and Swedish-based paperboard

packaging producer BillerudKorsnäs, with many others expected to follow suit.

According to UN (United Nations)’s Emission Gaps Report of 2019, the global food system accounts for 26 per cent of global GHG (greenhouse gas) emissions and, to make things worse, a third of that food is either lost or wasted somewhere in that supply chain.

While energy, farming, processing and distribution of food account for the lion’s share of those emissions, packaging does not, nor should it, get a free pass.

For all its lauded virtues, the Tetra Pak carton itself is far from a perfect finished article from a sustainability perspective, as the company readily acknowledges.

“The challenges the industry faces include removing the thin layers of plastic and aluminum [and] replacing them with plant or wood fiber-based materials; developing a renewable alternative to the plastic straw, and improving the recyclability of packages,” says Tetra Pak’s vice-president of development and engineering Laurence Mott .

As Mott points out, there are plenty of opportunities to improve food packaging’s environmental profile through lightweight packaging and e cient design to reduce wasted space during transportation; shifting to renewable energy across all operations; and optimizing processing operations through automation and other e ciencies.

“By taking these steps to reduce GHG emissions, the packaging industry could help limit the global warming to 1.5°C above pre-industrial levels,” Tetra Pak says.

According to the UN, “Limiting global warming to 1.5°C as opposed to 2°C could have significant positive e ects, reducing the number of people exposed to climate-related risks and susceptible to poverty by up to several hundred million by 2050.”

Unfortunately, as things stand right now the global warming could rise up by 4.1°C by the end of the century, with catastrophic consequences for humanity and the planet’s well-being.

And that would be a crime of the century for which the current global political and economic elite would forever be held in infamy and contempt by future generations, alas, for all the right reasons.

GEORGE GUIDONI, editor GGuidoni@canadianpackaging.com

JAN/FEB 2021 | VOLUME 74, NO. 1

Reader Service

Print and digital subscription inquires or changes, please contact Anita Madden, Audience Development Manager

Tel: (416) 510-5183

Fax: (416) 510-6875

Email: amadden@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Senior Publisher Stephen Dean | (416) 510-5198 SDean@canadianpackaging.com

Editor George Guidoni | (416) 510-5227 GGuidoni@canadianpackaging.com

Account Coordinator Barb Comer | (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

Media Designer Brooke Shaw | (519) 428-3471 bshaw@annexbusinessmedia.com

COO Scott Jamieson SJamieson@annexbusinessmedia.com

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE: Canada $78.50 per year,USA $179.50 (CDN) per year, Outside Canada $203.50 (CDN) per year, Single Copy Canada $10.00, Outside Canada $27.10.

From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy O icer Privacy@annexbusinessmedia.com Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2020 Annex Publishing & Printing Inc. All rights reserved. This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice. You should not act on information contained in this publication without seeking specific advice from qualified engineering professionals. Canadian Packaging accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. Canadian Packaging receives unsolicited materials, (including letters to the editor, press releases, promotional items and images) from time to time. Canadian Packaging, its a iliates and assignees may use, reproduce, publish, republish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

We acknowledge the [financial] support of the Government of Canada

More than 20 leading Canadian retail and consumer packaged goods (CPG) companies, representing a substantial proportion of the nation’s plastic packaging, are among the first to support new global ‘Golden Design Rules’ to improve plastics recycling and reduce landfill and pollution.

The rules acknowledge the importance of plastic packaging for food quality and safety, while encouraging companies industry-wide to make packaging decisions that better support recycling systems.

In addition to keeping plastic out of landfill and nature, designing packaging to be more recyclable is an important first step in

converting a take-make-waste linear economy into a Circular Economy, where all the ingredients of plastic packaging are captured and reused.

The Golden Design Rules were established and announced last December by members of The Consumer Goods Forum (CGF)’s Plastic Waste Coalition of Action—an alliance of some of the world’s largest retail and consumer brands—based on voluntary 2025 targets and a common vision of a world where no plastic waste ends up in nature, land or sea.

The initial rules focus on two core priorities:

Golden Rule 1.

• Increase value in polyethylene terephthalate (PET) recycling, with PET acknowledged as one of the most commonly used plastic materials;

• Use transparent and uncolored PET (preferred), or transparent blue or green in all PET bottle;

• Ensure material choice, adhesive choice and size of sleeve or label is not problematic for recycling. This rule applies to all PET bottles in food and non-food applications, including beverages, home care products, personal care products, and more.

Golden Rule 2.

Remove problematic elements from packaging including:

• Undetectable carbon black, which frustrates plastics sorting and is sent to landfill;

• PVC or PVDC (polyvinylidene chloride or polyvinylidene dichloride), which are problematic in recycling streams;

• EPS or PS (expanded polystyrene or polystyrene) which have more recyclable alternatives;

• PETG (polyethylene terephthalate glycol) which contaminates batches of otherwise valuable PET recycling;

• Oxo-degradable plastics, which fragment into microplastics.

According to the coalition, many packaging products today include materials that make recycling impossible or very di cult, which is a major reason that more plastic is not being recycled as well as it can be.

Companies supporting the new Golden Rules in Canada already include Amcor, Barilla Group, Coca-Cola Canada, Colgate Palmolive, Danone Canada, Essity, Henkel Canada, Johnson & Johnson Consumer Health, Kraft Heinz Canada, Loblaw Companies, Maple Leaf Foods, Mars Canada, Metro, Mondelez Canada, Nestlé Canada, PepsiCo Canada, RB, Save-On-Foods, SC Johnson Canada, Unilever Canada, and Walmart Canada

According to the coalition, one reason why plastic packaging ends up in nature is due to the complexity of the recycling process, which can be complicated by poor packaging design, the inclusion of problematic materials, and the presence of excess packaging.

“Retailers and consumer product companies represent about on- third of Canada’s plastic waste,” says Galen Weston, executive chairman of Loblaw Companies Limited and a co-sponsor of the global Plastic Waste Coalition of Action, alongside Unilever’s chief executive o cer Alan Jope.

“That means we should be at least a third of the solution, Weston states. “We design, make and sell the products, so by making impactful packaging decisions we can keep plastics in the value chain and out of nature.”

Adds Nestlé Canada president and chief executive o cer Je Hamilton: “Nestlé is pleased to join our industry colleagues in supporting the Golden Rules, which align with our commitment to reducing unnecessary plastics and ensuring all of our packaging is reusable or recyclable by 2025.

“Agreeing to key principles around how to design for recycling is the critical first step in ensuring none of our packaging ends up in nature,” Hamilton says.

According to the coalition—whose worldwide members generate combined revenues over $1 trillion and account for over 10 percent of the global packaging market—most of its members have committed to adopting the Golden Rules wherever possible by 2025. By then, consumers will be able to see the impact of these changes as everyday products like single-use bottles, toiletries, household cleaning supplies, food wrappers and take-away containers will be packaged in materials that can be recycled more easily.

Netpak doubling down on capital investment

Montreal-based paperboard packaging producer Netpak Packaging has completed several capital upgrade projects at its Montreal production plant, estimated at over $2 million, boosting production capacity of the facility’s finishing departments by over 30 per cent.

Allowed to operate during the COVID-19 pandemic as a designated essential business, the privately-owned company has installed a new MasterFold A2 1110 model folder-gluer, equipped with a SpeedWave module, and a new high-performance Spanthera 106-LER die-cutter.

Supplied by the renowned Swiss-based printing press and converting machinery manufacturer Bobst Group, both high-performance machines have been fully integrated with Netpak’s existing ERP (enterprise resource planning), MRP (manufacturing resource planning) and WMS (warehouse management system) operating software to ensure optimal performance and networking benefits.

“Netpak has remained operational as an essential business and at full capacity throughout the pandemic to serve our strategic partners,” says Netpak’s cofounder Carlo Cammalleri.

“Throughout the current circumstances surrounding COVID-19, our incredible dedicated employees have stepped up their e orts,” he states.

“It is thanks to them that we are able to make a series of investments and continue to surpass our objectives year after year.”

Netpak says the new investment underscores its continued commitment to innovation, automation and technology.

As the company explains, the new MasterFold A2 1110 folder-gluer o ers significant performance advantages that include aroundthe-clock speed, automated technology, e ciency, remarkable versatility, and exceptional quality of its straight line boxes, and non-stop production at increased speeds, as well as a high degree of automation.

In addition to its e ciency, the new MasterFold is equipped with a SpeedWave module that has allows Netpak to save a tremendous amount of make-ready or changeover times when needing to set up the machine for other styles of boxes.

According to Netpak, the addition of this machine has enabled a significant production capacity increase in the final stages of production—more than doubling the output of the increasingly popular hymes-bottom (auto-locking) style boxes.

For its part, the Bobst SPanthera 106-LER die-cutter is a remarkably versatile and powerful machine that performs precise cutting, stripping and blanking in one pass at exceptionally high speeds, according to Netpak’s other co-founder Salvatore Novello.

“Since its installation and integration in the plant, it has allowed Netpak to stay ahead of the competition thanks to its remarkable productivity, simplified operation and superior-quality cutting,” Novello relates.

“The competition in the printing and packaging industry is the fiercest it has ever been,” Novello states.

“What sets Netpak apart from competitors is our speed-to-market capabilities, e cient production times, information system and traceability,” says Novello, noting the company will soon be adding Bobst’s automatic Cartonpak case-packing module to the new MasterFold folder-gluer, which will automatically fill shipping boxes with the finished carton blanks.

“Investing in new equipment, has allowed Netpak to remain a leader in the folding-carton industry and to take folding-carton packaging to a new advanced technological level,” says Novello, citing Netpak’s important industry certifications that enabled the company to expand its customer base in the food industry, including the highly-coveted BRCGS (Brand Reputation Compliance Golden Standards) Grade AA certification of the Global Food Safety Initiative (GFSI)

“We are proud to be amongst the first printing and packaging companies in North America to have obtained the BRCGS certification and, more importantly, to have obtained this certification for six consecutive years,” adds Netpak’s chief operating o cer Georges Berbari.

We’ve packed all the multi-ply strength and versatility you’ve come to expect from Kallima® into a foldable, printable, boxable solution for your packaging, cartons, POP displays… and everything in between. Made right here in North America, with its unique high-bulk, low-density construction, Kallima box™ sets you free to focus on what really matters.

We’ve packed all the multi-ply strength and versatility you’ve come to expect from Kallima® into a foldable, printable, boxable solution for your packaging, cartons, POP displays… and everything in between. Made right here in North America, with its unique high-bulk, low-density construction, Kallima box™ sets you free to focus on what really matters.

We’ve packed all the multi-ply strength and versatility you’ve come to expect from Kallima® into a foldable, printable, boxable solution for your packaging, cartons, POP displays… and everything in between. Made right here in North America, with its unique high-bulk, low-density construction, Kallima box™ sets you free to focus on what really matters.

Jointly developed by MECATHERM and ABI, the Mecabagel line is a complete end-to-end turnkey solution for the production of artisanal-style bagels, from make-up to freezing.

TMG, parent company of leading French industrial baking equipment manufacturer MECATHERM, has acquired a majority stake in ABI Auto-Bake Industries Ltd. (ABI LTD.), a leading Canadian designer, manufacturer and integrator of industrial baking equipment renowned for its expertise in bagel and pretzel production equipment, robotic processing and packaging systems, and automated processing equipment such as rack loading and unloading. According to ABI founder and chief executive o icer Alex Kuperman, “Beyond furthering innovation and enriching our complementary product

From left: Beneco Packaging/ SoOPAK.com vice-president of operations Roy Amm and company president and founder Carol Jiang.

and service o ering, this transaction will greatly benefit the teams of both companies through the sharing of expert know-how and best practices. It will enable ABI LTD to more seamlessly serve large, global customers and o er mid-sized industrial bakeries a wider variety of manufactured solutions.”

Leading global labeling materials and equipment supplier Avery Dennison of Glendale, Ca., has completed a US$87.6-million acquisition of ACPO Ltd., Oak Harbor, Ohio-headquartered manufacturer of pressure-sensitive overlaminate products for label and flexible packaging markets employing

170 people at operations in Atlanta, Ga., Oak Creek, Wis., and Vancouver, Wash. “Our acquisition of ACPO will further strengthen our leadership in core label materials segments,” says Avery Dennison’s chief executive o icer Mitch Butier. “By adding ACPO’s wellregarded and complementary overlaminate producta, we are increasing our product portfolio and adding even more value for our customers.”

Mississauga, Ont.-headquartered folding-carton producer Beneco Packaging/SoOPAK.com has obtained the prestigious International Featured Standard (IFS) certification and Hazard Analysis Critical Control Point (HACCP) certification for food safety, adding to the IFS PACsecure certification the company achieved earlier. “We are very proud of all of the important initiatives and programs we have undertaken for our customers, especially those in the pharmaceutical and food packaging markets,” says Beneco Packaging/ SoOPAK.com president Carol Jiang. “These constant e orts recognize our team’s ability to provide the utmost in safety, transparency and social responsibility, [and] these new

Domino North America is excited to announce the appointment of ikki ohnson as irector of Marketing, bringing an entire new level of depth and understanding to the packaging industry.

For almost three decades now, ikki has cultivated a successful track record of leadership and success in various marketing and sales roles, within the packaging sector. er experience also extends to being an active participant in various industry specific associations, playing a vital role in each, such as MM The Association for ackaging and rocessing and the ontract ackaging Association.

The Executive team here in orth America believe ikki ohnson will support omino orth America in the next chapter of growth and success said Frank Eickenberg, resident of omino orth America. We have been impressed with her track record of success and commitment to the end user, one that is focused on establishing long term

As t e le in business it in omino intin S ien es pl

Domino is an autonomous division within Brother Industries.

oun e in omino s est blis e lob l

eput tion o t e e elopment n m nu tu e o o in m in p intin te nolo ies e m et p o u ts n ustome se i e

certifications and initiatives provide trust in our print process for our clients and the consumer.”

British-based multinational chemicals conglomerate INEOS has competed the acquisition of the global aromatics and acetyls business units of the oil and gas group BP plc in a US$5-billion transaction that includes 15 production sites around the world—comprising five sites in the Americas region, eight in Asia and two in Europe—as well as 10 major joint-venture companies. “We are delighted to have been able to acquire these top-class businesses from BP, extending our position in global petrochemicals and providing good scope for expansion and integration with our existing business,” says INEOS founder and chairman Jim Ratcli e. According to INEOS, the new acquired businesses will be renamed as INEOS Acetyls and INEOS Aromatics, with

partnerships. ikki has consistently delivered growth, and represented adaptability and awareness throughout the constantly evolving phases of the packaging industry in her almost years of experience. With the current economic climate resulting from the pandemic, the level of understanding to support the changes and disruptions experienced by our customers has never been more essential. ikki will be an instrumental part of this evolution in driving the value of our support we bring to our customers going forward.

am honored to represent omino orth America as its next irector of Marketing, and look forward to leading our innovative team ohnson shared. aving been in the packaging industry, and coding and marking specifically, omino has always been perceived as the gold standard of innovative and reliable traceability solutions. To now be a part of that experience o ers tremendous opportunities to continue that legacy of innovation and show the value it brings to our customers in a more impac ul way. We are ust ge ng started.

both units serving a diverse base of manufacturing clients that includes major global producers of plastic packaging products.

Cincinnati, Ohio-headquarteed packaging machinery group ProMach has completed the acquisition of the North American business of KHS Bartelt—a leading provider of packaging systems for flexible packaging applications in the food, confectionery, beverage, home and personal care, pharmaceutical, chemical and tobacco industries. The transaction includes the assets of KHS Kayat and KHS Scandia—also operating out of the Sarasota plant— further expanding ProMach’s product o erings with cartoning, shrinkwrapping, shrinkbundling, case-packing and tray packing systems. Founded in 1941 by Harold and Donald Bartelt in Rockford, Ill., Bartelt is credited with developing numerous pioneering designs and patents for the very first-generation horizontal form-fill-seal (HFFS) technology during the company’s formative years. “Bartelt, Scandia and Kayat expand our product o erings and allow us to bring an even more complete portfolio of solutions to our customers,” says ProMach president and chief executive o icer Mark Anderson. “Together, they bring over 215 combined years of packaging solutions to the marketplace, with a strong and established customer base.”

Cincinnati, Ohio-headquartered flexible packaging product group ProAmpac has completed a series of acquisitions that significantly extends the company’s presence in the Canadian market. The recent acquisitions include the purchase of Rosenbloom Groupe Inc., Montreal-based converter of paper bags; Hymopack Ltd., Toronto-based manufacturer of plastic shopping bags and can liners; and Dyne-A-Pak Inc., manufacturer of food packaging trays based in Laval., Que. According to ProAmpac, the acquisitions will enable the company to expand and broaden its product o ering to customers in the retail grocery and QRS (quick-service restaurant) industries. “With the Rosenbloom, Dyne-A-Pak and Hymopack brands as part of the ProAmpac family, we will deliver even greater value and services to our customers,” says ProAmpac’s chief executive o icer Greg Tucker. Owned by the Pritzker Private Capital investment group, ProAmpac has also acquired the assets of Rapid Action Packaging (RAP), U.K.-based manufacturer of cellulose-based packaging products for fresh prepared

and ready-to-eat foods such as sandwiches, wraps, chicken tenders and salads.

Leading packaging products manufacturing group TricorBraun has entered into an agreement under which the Toronto-based Ontario Teachers’ Pension Plan Board (OTPPB) and global capital investment group Ares Management Corporation will become joint majority owners of the S. Louis, Mo.-headquartered company. Founded in 1902, TricorBraun

employs over 1,100 team members at 50 locations throughout North America, Europe and Asia, generating annual revenues of about US$1.5 billion. “TricorBraun is uniquely positioned to serve the requirements of the packaging industry,” says Karen Frank, administrator of Canada’s largest single-profession pension plan with an estimated $204.7 billion in net assets. “The company has made significant investments in top talent and operations, and we’ll seek to capitalize on those to drive long-term growth in the years ahead.”

Washington, Ky.-based Material Handling Systems, Inc. (MHS) has reached a definitive agreement to acquire the Norton Shores, Mich.based conveyor manufacturing assets of TGW Logistics Group of Marchtrenk, Austria, for an undisclosed amount. According to MHS chief executive o icer Scott McReynolds, “TGW’s conveyor material handling business in North America looks back on an impressive growth history of more than 50 years [and] it is fantastic addition to our portfolio that expands our existing capabilities.”

Leading Canadian manufacturer of thermal inkjet (IIJ) printers MapleJet Co. is making designing barcodes easier through an IP-based simple message editor that can be accessed using any smart device, incorporating this innovative technology into its compact, rugged, Wi-Fi-capable industrial inkjet printer. According to the company, production line integration for its Hx Nitro TIJ is easier than for other traditional inkjet printers because it does not require extra parts to be installed in the production line, aside from the printhead. As a result, there are no bulky touchscreen controllers and additional wirings that limit the printer’s flexibility during operation. The optimized combination of being a small-footprint system and the ability to be controlled using any devices allows for the Hx Nitro TIJ printer to be positioned anywhere in the packaging line, while allowing operators to remotely control and design messages such as barcodes and date codes using a tablet, computer, or any smartphone device. The Hx Nitro printer’s simple message editor can be accessed using direct Wi-Fi to the printer without using an Internet connection or dedicated access point. MapleJet Co.

Developed as a child-resistant closure for cannabis-infused beverages, the new PakLock cap from PakTech is designed to provide a safe, secure, and simple solution to allow responsible adults to enjoy their THC beverages without children being able to access them, according to the company. “As

cannabis became more readily available in the recreational market, both in Canada and state-by-state in the U.S., we started to receive inquiries about whether we had any child-resistant or tamper-evident packaging,” says PakTech director of sales Lloyd McGri . “That was when we realized we could leverage our experience from our PakTech can carriers to meet this new market need.” Like the company’s patented can carriers, the PakLock closures are made from 100-percent recycled and 100-percent recyclable HDPE #2 plastic, and features an easy-to-apply design to provide a snug fit on all standard 202 to 260 aluminum can formats.

PakTech

The new Delta series vertical form-fill-seal (V/F/F/S) bagger from Triangle Package Machinery Company is designed for easy operation and fast changeovers of forming tubes, film rolls, and sealing jaws. Capable of running at speeds of up to 100 bags per minute—including pillow, gusseted, flat bottom, and EZ Stand bags—the new bagging machine features a rugged, sanitary design with a solid stainless-steel frame and a pivoting control box that allows access from all sides, making washdown and maintenance simple and e icient.

Operated by Rockwell Automation’s CompactLogix PLC (programmable logic controller) using PLC recipes to control sensors and actuators for easy and consistent set-up, the intermittent-motion Delta bagger can be easily integrated with a combination weigher, auger, cup filler or liquid pump to provide a turnkey bagging solution, according to the company.

Triangle Package Machinery Co.

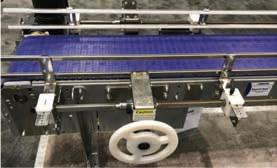

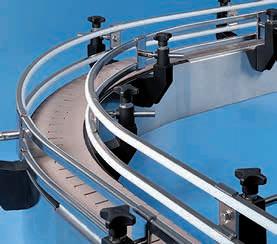

Featuring an adjustable rail system to accommodate multiple bottle sizes, the Pharmafill series conveyors from Deitz Co. allow for quick changes to the height, width and shape with no tools to accommodate di erent bottle heights and/or diameters and speed

changeovers. Included as standard equipment on the sanitary conveyors, the adjustable rail system sets dual, upper and lower guide-rails on both sides of the raised belt conveyor to keep bottles centered without tipping or sliding as they move downstream, whether empty or filled. A single knob on the proprietary rail-gripping bracket may be loosened to raise or lower the rail height, widen or narrow the width, or straighten or curve the shape, and then tightened to resume operation. Developed for pharmaceutical, nutrition and contract packaging companies as a versatile companion for filling and packaging machinery, the conveyors integrate smooth, plastic inserts within the aluminum guide-rails for safe, sanitary product contact—all set on a stainles- steel conveyor body.

Deitz Co.

Distributed by Heat and Control Inc., the three new CEIA metal detection systems for pharmaceutical industry application include the THS/FBB for plastic tubes and sanitary packages inspection; the THS/FBB model for e ervescent tablets inspection; and the THS/MBB for vertically oriented products. According to the manufacturer, all three new models have high sensitivity to all metals, integrated controls for line speed and rejection, digitally adjusted belt speed, and high immunity to environmental interference—delivering superior inline inspection for contaminating metals , including ferrous, non-ferrous and stainless-steel particles.

Heat and Control Inc.

Designed to identify invisible product defects and di erentiate foods by moisture content in sorting applications, the new allPIXA SWIR (shortwave infrared) line scan cameras from Chromasens are capable of picking out defects not visible to the human eye in the 950- to 1,700-nm spectral range to provide superior detection capabilities in packaging inspection, semiconductor fabrication, solar panel manufacturing, along with exceptionally accurate sorting of raw minerals, foods, and recycling products on fast-moving conveyor belts. Featuring an uncooled 1K InGaAs sensor in a compact rugged IP40 housing, the allPIXA SWIR camera can identify water and fat within foods, detect fill levels through non-transparent containers, monitor plant moisture to prevent over/under watering, identify chemicals, and aid in anti-counterfeiting e orts, according t the company, while its standard interface options ensure simple integration with standard industrial software suites in existing systems.

Chromasens

Developed for food and chocolate production applications, the new vacuum-based piSOFTGRIP50-2 pinch gripper from Piab can grip sensitive and lightweight oblong objects with odd geometries or with unusual surfaces by utilizing its two gripping fingers and a sealed vacuum cavity contained in simple and robust one-piece design. Made from silicone and approved for direct contact with food products, the piSOFTGRIP50-2 is not sensitive to dust, and its the gripping force is easily adjusted and controlled by the applied vacuum level. Designed for gentle handling of delicate products, according to Piab, the gripper can easily be put in rows (multiple mode) to enable the picking of multiple objects. Piab

Suitable for a broad range of industrial gas monitoring applications, the new

ProLine t-mass F/I 300/500 flowmeter from Endress+Hauser provide additional benefits of bidrectional measurement and reverse flow detection to ensure superior precision and accuracy in critical process control, quantity measurement, leak detection, cost allocation and energy management operations. Boasting a robust, low-maintenance design and innovative monitoring and alarm functions for detecting condensate, pulsating flow, flow direction or reverse flow, the Proline t-mass 300/500 flowmeter’s measuring system comes with a standard Gas

Engine software model that o ers 22 gases to choose from, with corresponding gas mixtures with up to eight components. According to Endress+Hauser, this software model o er users advantages of an exact measurement of pure gases and gas mixtures, as well as the ability to calculate additional process variables such as flow velocity, reference density, corrected volume and energy flow. Endress+Hauser

The new PLANETA Q continuous-motion capsule filling machine from MG2

boasts an ergonomic design that allows total accessibility to the machine to carry out routine operations—either in actual production or during maintenance programs—including a reduction in edgy parts, gull-wing-shaped safety guards, and an SR/I empty capsule selector integrated into the machine. The machine’s mobile control panel— equipped with a 21-inch touchscreen HMI (human-machine interface)— can be rotated around the PLANETA Q at up to 180 degrees for optimal user-friendly operation. Moreover, the system’s VPN connection allows faster remote access to ask for online technical assistance, according to the company, along with enhanced connectivity enabled by innovative networking features designed for full integration with the end-users’ corporate network systems.

MG2

Engineered to provide a high-end, eye-catching finish for FMCG (fast-moving consumer goods) packaged products, Penn Color’s new penne ex line of color and finish e ects for monolayer and multilayer PET packaging o ers a virtually unlimited array of product customization options with variations that include matte, brushed metal, frost, metallic, luster and bubbles—o ering brand-owners in the home care, personal care, food-and-beverage and other industries many creative product di erentiation opportunities. “The penne ex line sets consumer goods products apart from other items on the shelf by pushing the limits of product packaging design to achieve colors and e ects not yet seen on the market today,” says PennColor industry manager for packaging Simon Clarke. Penn Color

PROCESS EXPO is your best opportunity to showcase your latest products and technology first-hand, to grow your industry presence and connect with customers. Display your newest equipment and advancements to thousands of decision makers looking for solutions in the food and beverage packaging market!

While the recycling of packaging waste is much more than a game, putting a little fun into serious endeavors to address serious issues seems like a sound way to build a bigger audience.

Developed by renowned international recycling leader TerraCycle , the innovative new ReZound kit is an easy-to-use contraption that attaches to recycling bins and encourages recycling through positive audible feedback.

to compliment the users for doing their part in the recycling movement, which can be anything from a music clip to a pre-recorded ‘Thank You!’ message or some other fun audible signal.

Every time a recyclable item is placed inside the bin, ReZound will play music, a fun sound e ect, or encouraging words to make recycling an interactive and a rewarding personal experience.

Once the device is attached to the bin, every recyclable object that is put into that bin, like a bottle or a can, will trigger the device’s sensor to produce a positive audible signal

Designed for quick installation in nearly any recycling bin, the ReZound device comes pre-loaded with 20 recycling-themed sound clips to activate what TerraCycle calls “gamified” interaction with the consumer.

With a weather- and tamper-resistant design and the option for a solar-powered charging function, ReZound devices are functional anywhere, allowing recycling bins to be placed outdoors with little requiredmmaintenance or supervision.

The ReZound device can also be customized with sounds to bring excitement to recycling in a variety of public locations like offices; stadiums; parks and recreational centers; schools and college campuses; music venues and event centers; theme parks and

Corporate milestones come in di erent shapes and sizes, but sometimes the sheer size of the accomplishment is an overwhelming confirmation of extraordinary success.

For Swiss-based aseptic beverage cartons manufacturer SIG, selling more than 150 million SIGNATURE brand aseptic cartons in just three years is a remarkable feat for the company and a giant step in accelerated progress in the development of sustainable packaging solutions.

Launched in 2017, SIG’s innovative SIGNATURE packaging material links the polymers used to 100-percent forest-based renewable materials via an independently certified mass balance system.

By selecting tall oil—a residue extracted from wood in the papermaking process—as the forest-based feedstock, SIG is working with a byproduct from another industry rather than an agricultural crop requiring land and resources that could be used to produce food.

Compared to other competing drink boxes out in the market, the SIGNATURE cartons also use dramatically less aluminum in their closures to provide the required barrier protection from oxygen.

The aluminum-free SIGNATURE 100 packs for dairy products is the world’s first aseptic carton

zoos.

“At TerraCycle, we are constantly innovating new ways to drive our mission to ‘Eliminate the Idea of Waste’,” says TerraCycle founder and chief executive o cer Tom Szaky. “ReZound offers a fun, engaging way to educate and motivate more people to recycle and reduce waste in their communities.”

SIG has now sold over 150 million packs of its award-winning SIGNATURE, the world’s first aseptic carton packaging material linked up to 100-percent renewable materials.

packaging material linked to 100-percent forest-based renewable material, while the SIGNATURE Full Barrier packs come with an ultra-thin layer of aluminum, certified under the Aluminum Stewardship Initiative (ASI) standards,

to protect products like orange juice, which are more sensitive to light and oxygen.

Made with around 75-percent renewable paperboard from FSC (Forest Stewardship Council)-certified sustainable sources, paperboard beverage cartons already o er a significantly better environmental performance than alternative types of packaging, according to SIG, boasting 70-perecent lower carbon footprint than plastic or glass bottles.

But by virtually doing away with

aluminum content, the SIGNATURE packs reduce the carbon footprint of carton packs by another 45 to 58 per cent, according to SIG, depending on the selected option.

“SIG’s ground-breaking SIGNATURE is a great success, with over 150 million packs sold,” says Alina Theissen Hageresch, SIG’s European marketing manager for sustainability and responsibility.

“Increased uptake shows that its strong environmental credentials o er customers an answer to consumers wanting more sustainable packaging alternatives as they seek to do their part for a low-carbon future,” she says, citing notable early CPG (consumer packaged goods) adopters of SIGNATURE cartons such as Unilever’s B-Better brand in Belgium; Candia in France; nutpods in the U.S.; and Water Cubed in the U.K.

“B-Better water was launched with strong brand values: help consumers to be good to themselves and do better for the planet,” said Hélène Esser, B-Better brand co-founder and marketing manager for refreshments at Unilever.

“SIGNATURE’s unmatched environmental credentials, combined with SIG’s unique bottle-shaped combidome carton, align perfectly with our strapline: ‘It’s a start for less plastic and a better planet’.”

Lead by industry thought leaders, webinars feature timely packaging related topics including innovation and trends, sustainability, insights and new industry developments. Webinars are free for PAC members.

More Information pac.ca/events

visit www.pac.ca

A virtual event held to inspire the packaging industry to challenge the status quo by thinking beyond the package in order to foster creative and innovative business solutions. PAC Global Leadership Award winners will be announced and celebrated at this event!

More Information pac-awards.com/oneof100

Education courses including Packaging Circularity (March 22-23), Packaging Essentials (April 13-15); Complete Plastics Packaging (May 18-20) and Paper Packaging Plus (September 14-16).

More Information pac.ca/paced

Hardworking dough producer gets a big bang for the buck with leading-edge packaging machinery to achieve optimal production line efficiencies

By Andrew Snook

It often takes money to make more money, and for hardworking 40-yearold dough manufacturer Les Aliments 2000, the company’s significant recent investment in its packaging operations is happily proving to be the proverbial money in the bank.

Located in Saint-Augustin-de-Desmaures, a small city lying about 25 kilometers southwest of Québec City in central Quebec, the company has made many great strides since starting out back in 1980 as a producer of pizza dough.

In 1990, Les Aliments 2000 success-

Company president and general manager Denis

and his

Giroux, vice-president of sales and marketing, cheerfully display some of the company’s bestselling Pâte 2000 brand dough products at the plant’s reception area.

fully added the production of pie crusts to its repertoire, following that up in 1999 with another significant product portfolio expansion by commencing production of a broad variety of tart bases.

This growth prompted a 2002 move to a new production facility located in an industrial park in Saint-Augustin-deDesmaures, where the company continued to refine its dough-making knowhow and expertise—making it a major regional player in the segment.

Today, Les Aliments 2000 supplies millions of units of pie dough, frozen pizza dough, and pressed and baked

pizza doughs to some of the largest grocery chains operating in the province—including Walmart , Sobeys , Loblaws, Costco and Metro—as well as a multitude of restaurants.

While Quebec accounts for the lion’s share of the company’s sales, it also ships some of its output to customers in Ontario and parts of the U.S.

“There are a lot of other big companies operating in the frozen pizza business, so it is very competitive,” says Les Aliments 2000 president and general manager Denis Giroux.

“But when it comes to pie dough, and pie shells and plates, we are the main producer in Quebec,” says Giroux, adding the company has enjoyed significant and consistent growth in demand for its products since the turn of the century.

So much so, in fact, that in 2017 it invested $4.5 million in a new 35,000-square-foot production plant equipped with a variety of state-of-theart automated food processing equipment.

But even with this investment, the 50-employee operation was still struggling to keep pace with customer demand, according to Giroux, due to its packaging equipment being unable to keep up with the pace of production on the processing side.

This imbalance often resulted in frustrating operational bottlenecks that kept the plant from achieving its full potential.

To address these bottleneck issues, Les Aliments 2000 recently invested in a high-performance VC999 RS 520 rollstock thermoform packaging system manufactured by the renowned Swissbased food packaging equipment specialists VC999 Packaging Systems, Inc.

According to Giroux, this investment has enabled Les Aliments 2000 to significantly improve its production capabilities, along with the environmental footprint of its packaging.

“Before this machine arrived, we were putting foam trays into our packaging,” Giroux relates. “Now that we have this thermoformer and a flow wrapper in place, we no longer require the use of foam trays, which is much better for the environment.

“We also increased our packaging speed to match our production levels, while also being able to produce more product with less employees.

“It’s really di erent from before, when we had an employee take a Styrofoam plate and put each ball of pizza dough and pie dough onto the plate.

“Now the pie dough is going directly in the machine automatically, with no Styrofoam.”

According to Daniel Gardner, sales director for VC999 Canada Ltd . in Saint-Germain-de-Grantham, Que., the

(from top) Machine operator preloads flattened squares of fresh pizza dough into the film-lined cavities of the VC999 RS520 rollstock thermoformer prior to packaging and sealing.

Vice-president of sales and marketing Sébastien Giroux holds up the finished 580-gram, four-piece package of pizza dough coming o the VC999 RS520 rollstock thermoforming system.

A close-up of a stack of flattened pizza dough squares being placed on top the bottom film layers positioned inside the VC999 RS520 pocket chambers.

• 2 exposition dates – March 16 & June 16

• Visit virtual exhibits for packaging materials, containers, machinery & services.

• Experience virtual chats, screen sharing, live demos and new product displays.

Pick the Best of the Top 50 Packaging Ideas, and be entered in the draw for Amazon Gift Cards.

Marquee speaker: Jordan Fengel, Tetra Pak Sustainability Manager for U.S. and Canada

Second speaker: Jorge Izquierdo Vice President, Market Development, PMMI

Exhibitors: Take a booth for just $995 CAD net or $799 US net.

Contact: Stephen Dean 416-510-5198

sdean@canadianpackaging.com

vacuum-operated machine makes its own deep-draw packages from the rolls of film feeding it.

Once the products are placed inside the formed pockets, the thermoformer quickly seals them under vacuum, or with MAP (modified atmosphere packaging) gas flushing.

As Gardner explains, this direct approach eliminates the need to print and apply extra labels to the package.

“Now they can use top- and bottomprinted film to show all the required nutrition information, with no need to print out a separate label and, moreover, the final package looks much nicer.”

With its straightforward single-track design concept, the high-speed machine is very easy to add and integrate with

peripheral equipment such as dosing, filling (multihead weigher dosing and filling system), printing (inkjet printer with X+Y movement) and coding to provide a turnkey solution, according to VC999.

The system’s film gripper chain design has a mechanical clamping mechanism, which locks the film tighter when more weight is applied, and the machine is also equipped with an innovative CIP (Clean-in-Place) power wash system for transport chain to ensure minimal maintenance downtime.

Moreover, the RS520 system can make di erent-shaped packages from the same roll of film, thereby significantly reducing material storage and inventory costs.

“We no longer have production bottlenecks at packaging stage since the equipment was installed.”

The production of the baked pizza dough at Les Aliments 2000 begins with the mix used to create the dough, which is then left to rise. Afterwards, the dough is pressed into the required shape and baked in a stone oven.

The baked pizza dough is then sent via conveyor through a cooling tunnel and then packaged on the VC999 RS520 rollstock thermoformer, which inserts MAP gas mixture into the package to ensure that the product remains fresh on a grocery retail shelf at room temperature for 90 days.

“We have round and square dough we package on this machine,” Giroux says, also citing the benefit of not having to print and apply extra product labels to the packaging.

“All the product and nutritional information is already pre-printed on the rollstock film, so there is no need for product labels.

“We now only have one person working in this area at a time,” Giroux extols.

“Basically, their job is to take the finished packs of pizza dough from the end of the production line and to place it inside cases.

Say Giroux: “We no longer have production bottlenecks at packaging stage

(clockwise)

A colorful array of impeccably sealed retail packages produced on high-quality VC999 packaging equipment.

Supplied by Reiser Canada, the VEMAG HPE vacuum filler provides precise portioning of soft and sti mixtures, along with steady product feeding.

The VEMAG HPE vacuum filler’s control panel enables easy on-the-fly recipe changes with its intuitive and user-friendly graphic control functions.

since the VC999 equipment was installed.

“Moreover, we are running the product 40 per cent faster than we were before.”

As Gardner relates, Les Aliments 2000’s relationship with VC999 began a few years ago on the floor of the popular SIAL Canada food industry trade show in Toronto, when Giroux approached the VC999 exhibit to relate his plant’s bottleneck issues.

“They already had a rollstock machine in place, but they weren’t really happy with it,” Gardner recalls.

“So we came up with a di erent kind of tooling for them for the rollstock machine,” says Gardner, who eventually

convinced Giroux that the ultimate solution for his needs would be investing in a new machine altogether.

Before long Giroux bought into the idea, and a brand new VC999 RS520 machine was installed at the Saint-Augustinde-Desmaures factory in June of 2018.

“The machine was also a bit shorter and more compact than what they had before,” Gardner says, “which they really liked because they didn’t have that much floorspace.”

A little over a year later, Giroux approached VC999 Canada again—this time looking for a solution to improve the e ciency of the plant’s pie dough production line.

(top left)

Integrated with Reiser’s VEMAG HPE rotary filler (background), the VC999 XtraVac flow wrapping machine can easily achieve robust throughput rates of up to 250 packages per minute.

(top right)

All finished packages of dough coming o the XtraVac flow wrapper immediately pass through the Loma IQ2 metal detector to ensure contaminant-free product.

(bottom left)

Pre-cut one-kilogram balls of freshly made dough arriving at the XtraVac horizontal flow wrapping machine to be packaged inside pre-printed rollstock film.

Not only was Giroux satisfied with the performance of the VC999 RS520 system, he was also impressed with the after-sales service and technical support that followed the installation.

“We have access to their technicians whenever we need help,” Giroux says, explaining his decision to acquire more VC999 technology.

To help Giroux get his pie dough production more up to speed, Gardner’s team supplied the plant with a VC999 XtraVac FW600A horizontal flow wrapper.

According to VC999, the XtraVac horizontal flow wrapper can reach production speeds of up to 250 packs per minute, while o ering many value-added performance and safety features that

include a large user-friendly interface control; stainless-steel frame and surfaces; memory function for flexible packaging operations; and an overload-sensing function for each of the machine’s three AC servomotors.

Equipped with a 1,000-W heater for the center sealer and a 1,200-W heater for the end sealer, the versatile machine can handle a wide range of bag sizes with bag lengths of 50- to 700-mm and widths of 110- to 270mm, while accommodating product height of up to 120-mm.

Other notable performance feature and attributes include:

• Large user-friendly interface control for convenient operations;

• Stainless-steel frame and surfaces for maximum hygiene and durability;

• Memory function makes the machine ideal for flexible packaging operations;

• Overload-sensing function for each servo motor to prevent parts and product from being damaged;

• An auto-splicer option for higher-speed operation;

• Adjustable forming box to facilitate flexible production;

• A self-diagnostics function for easy troubleshooting;

• Durable low-noise servomotors.

After the pie dough has been properly mixed and prepared at the Les Aliments 2000 plant, it is transferred into an inline portioning/dosing machine that forms the pie dough ball in one- and two-kilogram sizes.

These are then conveyed into the VC999 XtraVac horizontal flow wrapper that automatically wraps and seals the product, which is then whisked away for case-packing in smooth and continuous cooperation.

By taking care of all the obstacles that used to hamper the plant’s production e ciency,

Abbey Equipment Solutions is a Canadian based company with 30 years’ experience in the Food & Beverage and Cannabis industry. We have strategically sourced manufacturing partners of high-quality and reliable equipment to best serve our customers needs. With Abbey Equipment’s mixture of options from packaging, inspection, and processing equipment to our integrated mechanical solutions, we’ve got you covered. We can provide you with standalone equipment options to fully integrated turnkey project solutions all supported by our local service team.

the VC999 equipment has allowed Giroux and his team to concentrate on new product development, which is a critical core competency in this segment of the baked goods industry.

“Our customers always want to have new products made available to them,” Giroux states, “and we have to respond to their demands to keep their business.

“We need to o er new products every year to remain competitive,” Giroux states, “so investing in new equipment is vitally important for us to stay competitive.

“Fortunately, the development of new products is one of our biggest strengths,” Giroux asserts, while acknowledging the dedication and hard-working ethos of his sta .

“We have a very good team of employees here,” Giroux says, crediting their contribution to enabling the plant to achieve vital industry certifications food safety that include HACCP (Hazard Analysis Critical Control Points) certification (2005), FSSC 22000 certification (2011) and, more recently, the internationally recognized GFSI (Global Food Safety Initiative) certification.

As with the vast majority of Canadian businesses across numerous industries, the outbreak of the COVID-19 epidemic unleashed last March had seriously tested the company’s ability to be agile and respond to unprecedented new challenges

on-the-fly.

“It was really di erent for us, because we had to change our ways from how we used to do many things we did before,” Giroux recalls.

In addition to making it mandatory for all employees to wear masks and visors, and supplying all areas of the plant with hand sanitizer, the company also purchased a special machine— installed at the facility’s front entrance—for taking the employees’ temperatures.

“We have also hired a dedicated employee that performs the regular disinfection of all of the surfaces in the plant,” Giroux says. “We had to put a lot of new procedures in place.”

Fortunately for Les Aliments 2000, some of those costs were o set by the fact that the demand for its dough products has soared during the pandemic months.

“With so many people now cooking at home,” says VC999 Canada’s Gardner, “they (Les Aliments 2000) are very pleased about getting our machines because they pack so fast; they never would have been able to keep up with the demand surge otherwise.”

Giroux agrees: “We are very happy with the productivity improvements that the VC999 equipment has enabled us to achieve.

“And although we do not have any major new investments planned right at this moment,” he concludes, “when we see something that is right for us, we will definitely go for it.”

VC999 Canada, Ltd.

Reiser (Canada) Ltd.

Loma Systems (Canada) Inc.

Denis Giroux holding up a finished package of Pâte 2000 tart dough coming o the VC999 XtraVac horizontal flow wrapper.

“All the product and nutritional information is already pre-printed on the rollstock film, so there is no need for product labels.”

Ryson makes a full line of spiral conveyors that can satisfy most vertical conveying needs. Ryson Spirals need less floor space than conventional conveyors and are faster and more reliable than any elevator or lift.

Ryson makes a full line of spiral conveyors that can satisfy most vertical conveying needs. Ryson Spirals need less floor space than conventional conveyors and are faster and more reliable than any elevator or lift.

Unit Load Spirals convey cases, totes and packaged goods smoothly on our slat style belts and come in 9 standard slat widths ranging from 6” to 30”. Available in powder coated carbon steel, stainless steel, washdown and freezer versions

Unit Load Spirals convey cases, totes and packaged goods smoothly on our slat style belts and come in 9 standard slat widths ranging from 6” to 30”. Available in powder coated carbon steel, stainless steel, washdown and freezer versions

Mass Flow Spirals handle full and empty bottles, cans and jars in mass up to 2000 units per minute. Available in 4 different slat widths ranging from 6” to 20”.

Mass Flow Spirals handle full and empty bottles, cans and jars in mass up to 2000 units per minute. Available in 4 different slat widths ranging from 6” to 20”.

Narrow Trak Spirals are super compact and designed to handle your smaller loads. Our new 6” and 9” wide nesting slats can endtransfer small cartons and packages or side-transfer small bottles and containers in a single file or in mass at speeds in excess of 200 FPM.

Narrow Trak Spirals are super compact and designed to handle your smaller loads. Our new 6” and 9” wide nesting slats can endtransfer small cartons and packages or side-transfer small bottles and containers in a single file or in mass at speeds in excess of 200 FPM.

High Capacity Spirals are in response to our customers need to go higher and handle more weight. They can handle double the weight capacity of our regular spirals at speeds up to 200 FPM. The new WT Model comes in a slat width of 30” and 36” and can provide an elevation change of up to 35 feet with only one drive.

High Capacity Spirals are in response to our customers need to go higher and handle more weight. They can handle double the weight capacity of our regular spirals at speeds up to 200 FPM. The new WT Model comes in a slat width of 30” and 36” and can provide an elevation change of up to 35 feet with only one drive.

Multiple Entry and Exit Spirals allow loads to enter or exit the High Capacity Spirals at intermediate elevations. New special induction and divert conveyors have individually adjustable conveying surfaces to match the spiral pitch, assuring a smooth and reliable operation.

Multiple Entry and Exit Spirals allow loads to enter or exit the High Capacity Spirals at intermediate elevations. New special induction and divert conveyors have individually adjustable conveying surfaces to match the spiral pitch, assuring a smooth and reliable operation.

Quality and service come first at Ryson. We are the number one spiral manufacturer in the USA. For application assistance or more information, give us a call or visit www.ryson.com.

Quality and service come first at Ryson. We are the number one spiral manufacturer in the USA. For application assistance or more information, give us a call or visit www.ryson.com

300 Newsome Drive • Yorktown, VA 23692

Phone: (757) 898 -1530 • Fax: (757) 898 -1580

Canadian water bottler shifting gears to respond to many new challenges and realities of the emerging Circular Economy

By Andrew Snook

The sustainability of products and packaging are becoming an increasingly hot topic as the push to reduce waste and greenhouse gas emissions become evermore pressing issues for governments and consumers worldwide.

While plastic packaging has recently drawn negative attention from environmentalists and governments around the globe, Shelburne, Ont.-headquartered water bottler Ice River Sustainable Solutions o ers a compelling example of how some companies in the water bottling industry are buckling the trend to ostracize

an entire industry by developing progressive recycling strategies to provide truly sustainable products for Canadian consumers.

“We’ve devoted ourselves to developing a Circular Economy model by thinking about how we can ensure our products can be turned back into the same product at end-of-life.

“This is recycling at its best,” says Crystal Howe, says Ice River’s sustainability manager Crystal Howe.

As part of the company’s source protection plan, it organically farms about 3,000 acres of land.

But the family-owned company, which started up in 1995, has had its roots

grounded in sustainable practices for far longer, running farming operations including field crops, poultry and aquaculture, in the area for multiple generations.

To support the growing market for bottled water more e ciently, Ice River has built facilities across Canada to supply local markets and reduce transportation.

Currently operating six bottled water plants in Canada—three in Ontario and one apiece in Quebec, Alberta and British Columbia—Ice River also owns a bottled-water facility in Miami, Fla.

In addition to manufacturing private-label bottled water products for a wide variety of large retailers throughout North America, the company is also wellknown for its own brand of Ice River Green Bottle Co. water, which retails in containers made from recycled ‘green’ plastic.

According to Howe, the company’s hands-on involvement in the recycling aspect of its operations first came into focus in 2007.

“That’s when we started to really think about the plastics and how to recover and reuse them,” How told Canadian Packaging in a recent interview.

“Having that farming background always made the environmental impact front-and-center for us,” Howe states.

As Howe relates, the company tried a variety of packaging types in e orts to reduce its carbon footprint before arriving at the right packaging—including polyactic acid (PLA) plastic and packaging the water in cartons.

“We tried PLA but found the shelf-life was very short, and that the water would take on the flavor of the PLA itself,” Howe recalls.

“We tried packaging our water in cartons,” she says, “but we ultimately determined that as much as people thought it was more sustainable, because there’s not nearly as much plastic in it, it is not an easy packaging to recycle—being a mixed material containing paper, aluminum and plastic together in one structure.”

Undeterred, Ice River continued to search for the proper sustainable pack-

“Having that farming background always made the environmental impact front-andcenter for us.”

aging solution, which it ultimately found in the form of recycled polyethylene terephthalate (rPET) plastic.

At first, Ice River started out on this path by sourcing its rPET resins from outside suppliers, Howe relates, but it was far from an ideal solution.

“Each batch of rPET resin was a little di erent,” she says, “which made it hard to set consistent recipes for the preforms and bottles.

“So we decided to make our own rPET resin,” says Howe, describing the 2010 formation of the Blue Mountain Plastics Recycling (BMP Recycling) sister company.

“We were the first beverage company in North America to build our own recycling plant and create a closed-loop system,” Howe points out.

Built right next to Ice River’s original bottling plant in Shelburne, the BMP Recycling facility purchases approximately 80 per cent of all the PET plastic bottles and packaging collected via Ontario’s Blue Box curbside recycling program, which it then sorts, shreds down into flake form, sorts it again, and finally transfers the flakes to a nearby facility in Feversham, Ont., where the bulk flakes are trans-

formed into food-grade rPET resin.

After that the resin is blowmolded into bottles, which are quickly filled, capped and shipped out into the marketplace.

After the product has been consumed, the process begins all over again once consumers put the empty bottles inside their Blue Box bins.

By using recycled-content instead of virgin resin, Ice River has been able to reduce its greenhouse gas emissions by an estimated 76 per cent, while also slashing its energy use requirements by 78 per cent and water consumption by 99 per cent, and keeping millions of pounds of plastic in the value chain, instead of going to landfill our simply being discarded into the environment.

“Blue Mountain Plastics recycles about 50 million pounds of plastic per year,” Howe proclaims.

“Across our family of companies, we recycle about 65 million pounds of plastic each year, says Howe, citing the company’s recent acquisition of Toronto-based Urban Polymers, “which will add significant additional capacity to our PET recycling.”

To create the finished product, the company uses ErgoBloc L wet section blocks supplied by Krones Machinery,

With output capacity of up to 81,000 containers per hour, the ErgoBloc L wet section from Krones requires 70 per cent less floorspace than conventional bottling lines.

Inc., Franklin, Wis.-based subsidiary of leading German beverage processing and packaging line equipment manufacturer Krones AG

The most recent installation of this Krones equipment took place at the company’s Shelburne facility, where Ice River now has a recycling plant, a film extrusion plant, and a bottling facility operating in the same compound.

Says Howe: “Installing a Krones line in this facility was the final step in creating a showcase location in Shelburne, where visitors can see the entire process from recycling to production—the entire Ice River story.”

As Howe relates, Ice River has enjoyed a very beneficial business relationship with Krones Machinery since installing its first Krones bottling equipment back in 2013.

“It’s all high-end equipment, very ecient and very environmentally-friendly, with low scrap rates.

“It’s also very water-e cient and energy-e cient,” Howe adds.

“All of our high-speed 500-ml bottle production lines come from Krones,” she relates, “and we also recently purchased a four-liter line from Krones.

“It’s very detailed equipment that can be di cult to learn, but once you learn it,

there’s nothing that can beat it,” Howe states.

“Now that we have that expertise in our plant, we can replicate that across all of our facilities.”

The bottle manufacturing process begins with the recycled rPET preforms being fed into the ErgoBloc L via a hopper, where they are heated in the oven before being sent to the blowmolder.

At this stage, the water bottles are blown into shape using an electromagnetic stretching system, with each blowing station keeping the process running at a fast pace with robust output capacity of up to 2,750 containers per hour.

The high-performance line features an integrated quick-change system for the molds; an energy-e cient infrared linear oven with ceramic reflectors; and actively controlled transfer grippers.

The bottles are then sent through a cooler, where the container base is cooled down using blown air.The bottles are then sent to a labeling station, equipped with built-in gap detection.

The bottles are labeled before being filled to ensure the optimal label positioning, since full bottles can have varying internal pressures that can potentially impact the label placement during application.

The highly flexible Solomodul labeler can handle cold glue, hot-melt and selfadhesive applications, with its modular design even enabling a combination of di erent labeling techniques on a single container.

The Modufill VFJ is a hygienic filler for PET containers is designed to ensure precise fill quantities, with exceptional output rates of up to 81,000 containers per hour.

The fully-automatic, flexible and modular Variopac Pro case-packer easily adapts to all packaging needs to handle packaging with pads, inside trays, and wraparound cartons with or without shrinkwrap film.

“A robotic palletizer takes the packs andwrapped and labeled,” Howe explains, adding that all of the equipment through the production process (post cooled down

The bottles are then sent to a labelingtion. The bottles are labeled before beingternal pressures that can potentially impact

The bottles are then transferred to the filling station, where a swirl insert in the fill valve activates a low-foam filling process,

using a high-precision flowmeter to ensure accurate fill levels.

The bottles are then capped and sent through a vision system to ensure the caps, labels and fill levels are all within the specs, after which the approved products are transferred on to the case-packer, where they are typically packed in groups of 24 bottles.

“We make our own case-packing film at our BMP Extrusion next door, an the Krones case-packer wraps 24 bottles into the shrink film and sends it into the oven, which selects a very specific heating profile to shrink the film and secure the pack.

“A robotic palletizer then takes the packs and fits them onto a pallet, which is stretchwrapped and labeled,” Howe explains, adding that all of the equipment through the production process (post preform) is supplied by Krones Machinery.

Howe recalls watching the robotic palletizer work for an hour the first time she saw it in action, thinking back to how much her family’s operation has changed over the years.

“When we started in 1995 at Ice River, it was a manual line,” she recalls.

“I remember running the second-hand equipment, putting the labels on by hand, holding bottles under a filler, and capping them by hand.

“We built the boxes and hand-piled them on the pallet,” Howe recounts. “It’s quite amazing to see how far we have come.”

As it happened, the installation of the Krones ErgoBloc L wet section at the Shelburne facility was scheduled to take place right about the time that the devastating COVID-19 pandemic spread to Canada last March.

Due to the ensuing to international travelling restrictions, things had to be done a little di erently than usual.

“The start of the pandemic created (from top)

more conversations with the customer and installation team than we normally would have,” says Adam Gores, regional sales manager for Krones Machinery.

“The ErgoBloc installation team comes from our Guatemala division, so it was a challenge to keep the project on task.”

Fortunately, Ice River had a lot of prior experience working with Krones Machinery on the installation of this type of equipment.

“IRSS has its own installation team, who felt that with Krones’ support they had the background and enough experience to get these machines uncrated and on the ground to start laying them out mechanically,” Gores says.

“We started with that, and after we understood how to bring in colleagues from other parts of the world, we were able to bring in more technicians to help.

“We were still able to achieve the production runs when needed.

“It was a big collaboration,” Gores recalls. “Hats o to their installation team, because they really know how to take on a problem and find solutions.

“Not completing something is not an option to them,” Gores states. “It’s nice to work with people like that.

“It was quite an interesting installation.”

Running a business supplying one of the most price-sensitive commodities in

The robots of the Modulpal Pro series palletizer provide a wide array of options for loading and unloading of pallets, including returnable crates, cartons, filmwrapped packs and multipacks, with a maximum output of 650 layers per hour.

the world is not an easy way to make a living, according to Howe.

“It’s a very competitive market and water is a commodity product,” she points out.

“People rely on it, and being a low-margin business requires that production costs must be controlled,” she says.

“Moving to 100-percent recycled content meant we had to be even more ecient in order for our product to compete in price against companies who use virgin PET.

“If it was easy to switch,” Howe states, “everyone would do it.

“We were told we would never achieve a 100-percent recycled-content bottle,” she points out, “but we did it within a year.”

Howe adds that being a family-run operation allows the company to be agile and adapt to any challenges that come its way in with timely response.

“That’s the nice thing about having a family-run business,” she extols. “We don’t have a ‘corporate feel’ here, and we don’t have a board of directors or shareholders to answer to.

“We just need to agree as an executive team to make a change,” she says, “and then we do it.”

As Howe relates, Ice River’s supply chain wasn’t really a ected by the COVID-19 pandemic, since recycling

operations that the company depends on were deemed essential, remaining active throughout Ontario’s municipalities.

To help out during the pandemic, Ice River also repurposed some of its bottle production output to supply bottles to breweries, distilleries, and cosmetic companies who began producing hand sanitizer.

“Some companies were trying to supply hand sanitizer for front line workers but weren’t able to get bottles because of international supply issues,” recalls Howe.

“We were able to step in and to supply recycled PET bottles to those companies right here at home in Ontario, and even one in Nova Scotia,” Howe says.

“We were also able to help by donating bottled water to shelters and organizations feeding the homeless across Canada,” says Howe, stressing the family-owned company feels very proud about being able to combine its environmentally responsible production practices with genuine social conscience.

As Howe sums up, “We are Canadian through and through, and our team felt good knowing we could help our communities, while continuing to lead the way in responsible manufacturing.”

SUPPLIERS

Krones Machinery, Inc.

Toronto co-packer embraces digital technologies and process automation to pave the path for prosperous future

By George Guidoni, Editor

Photos by Naomi Hiltz

Longevity and staying power in the highly competitive co-packing business are largely defined by a company’s ability to reinvent itself to meet its customers’ ever-evolving needs and requirements to succeed in the markets they serve.

And if the last 35 years are any indication, Toronto-based Promotional Print & Packaging Inc. (PPP) has mastered the art of self-reinvention down to science—in many ways thanks to its willingness and ability not only to embrace change, but to use it as a catalyst for continued growth and success.

Founded in 1985 by a husband-andwife team of Brad and Sherry Townsend, the family-owned company enjoys a proud and extensive track record of providing its demanding CPG (consumer packaged goods) customers with the

essential product packaging, display and distribution services to help brandowners reach and entice their target customers to purchase their products.