At Paxiom®, we deliver automated packaging solutions for the demands of today and tomorrow while never losing focus that our customers come first. We are driven by solving problems, providing exceptional value and taking turnkey responsibility.

At Paxiom®, we deliver automated packaging solutions for the demands of today and tomorrow while never losing focus that our customers come first. We are driven by solving problems, providing exceptional value and taking turnkey responsibility.

Videojet 1860 Continuous Inkjet Printer

True predictability

Industry-first ink build-up sensor provides true predictability and warnings of possibly degrading print quality, even before a fault occurs.

True remote services*

Multiple access options (Ethernet™, WiFi) and secure VPN communication meet highest standards in the industry as part of VideojetConnect™ Remote Service, and help to improve machine uptime and customer experience.

* Subject to availability in your country

True IP rating

Optional IP66 rating for entire cabinet and hygienic design following industry guidelines; easier integration with slanted printhead design.

True scalability

Workflow modules help to customize the printer to perform the exact need required. It is easy to adapt the printer with new capabilities and functionalities, and to meet growing demands.

The C anadian mar ket is char ac ter ize d by small- size d packa ge s that facilitate ea sy handling C onsumers are also lo oking for novel and premium pro duc ts that c ome in luxur ious packa ging In addition, c onsumer awarene s s of the environment c ontinue s to dr ive grow th of e c o -fr iendly packa ge s Finally, but imp or tantly, with up c oming laws and regulations, new industr y re quirements will emerge, which will lead to unc onventional c a se de signs

B os c h c a s e pa c ke r s fo r eve r y n e e d

B osch c a se packers r ange from e c onomy level machine s up to high - end solutions. A dvanc e d te chnolog y guar ante e s ef fi cient and gentle pro duc t handling , re sulting in increa se d output .

A nother cr iter ion of the sophistic ate d C anadian packa ging industr y is fl exibilit y and br anding O ur shelf-ready packa ging de signs ensure exc ellent pro duc t pre sentation, and in order to re sp ond to the late st mar ket trends, our unr ivalle d exp er tise in c a se packing means our machine s c an r un a var iet y of c a se st yle s

O ur mo dular str ateg y for c a se packers acc ommo date s multiple pack st yle s but is also adaptable to future re quirements for any t yp e of c a se de sign

O ur mo dular str ateg y for c a se packers acc ommo date s multiple pack st yle s but is also adaptable to future re quirements for any t yp e of c a se de sign

To ensure easy oper ation, B osch c ase packers are designed for tool-less, fast and easy changeovers to ma ximize production ef ficienc y, helped fur ther by the machines’ ver tic al restar t The open but compact machine design ensures excellent accessibilit y, for ease of cleaning and maintenance

H i g h av aila b ilit y th roughou t th e m a c hin e life c yc le

C onnec tivit y is imp or tant in the C anadian packa ging wor ld.

W ith B osch ’s Digital Shop fl o or S olutions, we c an integr ate de cisive par ameters to improve the qualit y, pro duc tivit y and ef fi cienc y of the whole machine life c ycle.

Par tner ing with B osch means you are wor king with a single - sourc e solution supplier We are plea se d to of fer you our ex tensive exp er ienc e and c onsultation c apabilitie s O ur lo c al ser vic e supp or ts you in C anada , from c oa st to c oa st , throughout the machine life c ycle

O u r c o m mitm e nt i s yo u r s u cc e s s ful fu tu re :

C onstant innovation in packa ging solutions me ets your exp ec tations

Ea sy change overs and ver tic al re star t ensure s the c omp etitive e dge

Digital Shop fl o or S olutions supp or t your demands for c ost ef fec tivenes s

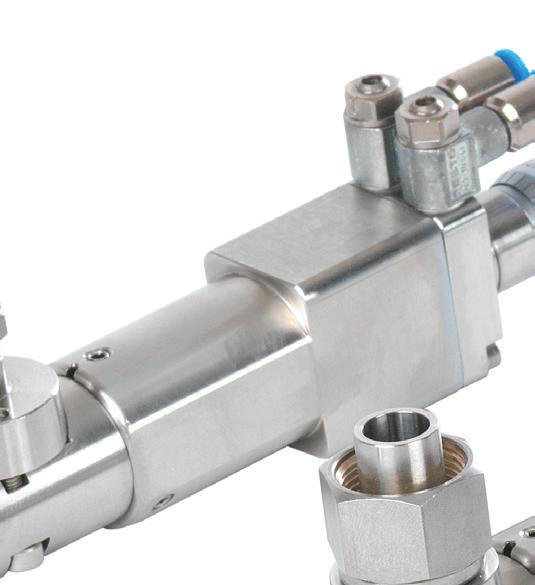

2BRP

Pneumatic

CBD/THC Oils

Distillates and Tinctures

Essential Oils

Vape Cartridge

Dropper Bottles

Custom Built Specialty Equipment

Vac/Fill Applications

Automated Packaging Equipment

Hazardous Location Filling Equipment

Automated Assembly and Feeding Systems

High Speed Assembly Equipment Robotic Filling

JANUARY/FEBRUARY 2019

VOLUME 72, NO. 1&2

SENIOR PUBLISHER

Stephen Dean • (416) 510-5198 SDean@canadianpackaging.com

EDITOR

George Guidoni • (416) 510-5227 GGuidoni@canadianpackaging.com

ASSISTANT EDITOR

Alanna Fairey • (416) 510-5228 afairey@canadianpackaging.com

MEDIA DESIGNER

Brooke Shaw • (519) 428-3471 bshaw@annexbusinessmedia.com

ACCOUNT COORDINATOR

Barb Comer • (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

CIRCULATION MANAGER

Anita Madden • (416) 442-5600 x3596 AMadden@annexbusinessmedia.com

VICE PRESIDENT

Tim Dimopoulos • tdimopoulos@annexbusinessmedia.com

PRESIDENT & CEO Mike Fredericks

ANNEX BUSINESS MEDIA

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA

ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

CIRCULATION

e-mail: rthava@annexbusinessmedia.com

Tel: 416-442-5600 ext. 3555

Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE): Canada $78.50 per year, USA $138.00 US per year, Outside Canada $156.50 US per year, Single Copy Canada $10.00, Outside Canada $27.10. From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

ANNEX PRIVACY OFFICER

Privacy@annexbusinessmedia.com

Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may

If we truly are what we eat, Canada’s health czars are adamant to turn Canadians into a very unadventurous humdrum bunch of grain-fed creatures consuming an assortment of plain ‘good for you’ plants, legumes and nuts that, according to the new Canada’s Food Guide, are the missing link to our collective health and well-being.

Look, no one is denying that Canada has its share of serious dietrelated health issues such as obesity, diabetes, heart disease and other nasty ailments related to overeating and lack of sufficient exercise, but if the revamped 2019 Food Guide is intended to be an inspirational rallying cry for Canadians to embrace a new wave of alternative proteins and other meat and dairy substitutes, one has to wonder about the point of the whole exercise.

Considering the Canada Food Guide was last updated back in 2017, it’s hard to take issue with the fact that Health Canada has belatedly made the time to bring Canadians up to speed on healthy eating, but the resounding ‘meh ’ execution of this well-intended initiative leaves a rather hollow feeling inside.

In all fairness, it is just too much work to get excited about the rather bland, if varied, offering of finger-sized tidbits depicted on Health Canada’s pictogram of what a well-balanced meal should look like. (See Graphic) Whatever little loose bits of meat and fish you

can spot in the upper-right corner of the plate are dwarfed by the heaps of beans, nuts and chickpeas, while the suggested serving of carbs directly below resembles something closer to birdseed feed than a reasonable facsimile of a proper side-dish.

For its part, the left side of the plate is a medley of mostly fresh-cut chunks of sliced fruit and veggies that, despite providing a few splashes of color to the graphic, look like they should be served as salad garnishes rather than a substantive source of nourishment.

But it’s really what the new Food Guide doesn’t show on its graphic plate—cheese, milk, a broader meat variety—that makes it such a joyless buzzkill.

If this ensemble were actually a graphic package design for a brand, the product would never stand a chance on a store-shelf!

Demonizing meat and dairy products is not a new phenomenon, but in the last few years it has become more fashionable, as evidenced by the latest global scare campaigns linking meat production and consumption directly to global warming, no less, on account of fairly stretched factual evidence.

Like everyone else, vegetarians and animal welfare activists are all entitled to their opinions, but politicizing those opinions under the guise of public health policy is something Health Canada should have no part of.

Unfortunately, the latest Canada Food Guide appears to imply too much pandering to the meatfree crowd to suggest that sound science was the one true driving force guiding its development and execution. And that’s a pity for all of us.

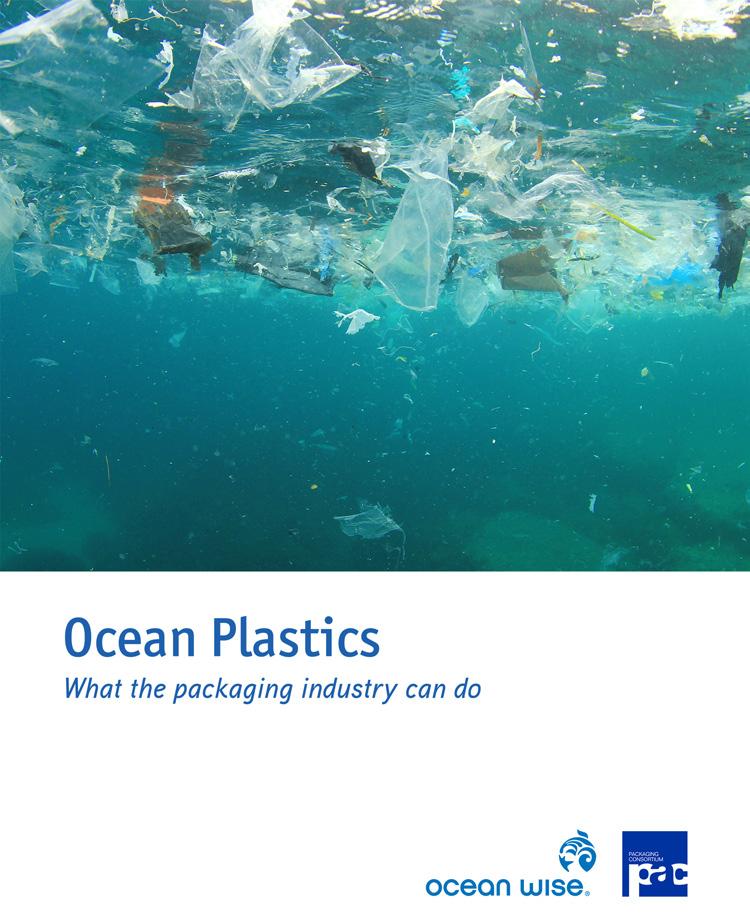

Exploring the brave new world of cannabis packaging.

report from

Packaging Consortium

in-depth look at some of major challenges facing today’s fast-evolving packaging industry.

Despite being one of the modern society’s most wrongly maligned plants, industrial help was actually one the world’s first plants to be spun into usable fabric by early humans 10,000 years ago, and today can be refined into a plethora of useful commercial products such as paper, textiles, clothing, biodegradable plastics, paint, animal feeds, insulation, biofuel and food.

And thanks to a hearty new line of hemp-based granola mix developed by Manitoba Harvest Hemp Foods, mainstream Canadian consumers can enjoy the natural

‘superfood’ goodness of shelled hemp seeds as part of a healthy breakfast or nourishing one-the-go snacking.

Packaged in elegant resealable standup pouches designed by Austin, Tex.based graphic design agency PTMK, the 283-gram packs of Hemp Yeah! Honey & Oats, Hemp Yeah! Blueberry and Hemp Yeah! Dark Chocolate granola blends offer a crunchy, chewy and tasty snack densely packed with protein and nutrients, including:

• Ten grams of plant-based, non-soy protein with 10 grams

of sugar or less;

• A healthy helping of Omega 3, Omega 6, iron, zinc, fiber, magnesium and other essential nutrients in a 55-gram serving.

• High-quality, organic, non-GMO ingredients like shelled hemp seeds, quinoa, chia and natural sweeteners.

According to company founder Mike Fata, the hemp seed is an overlooked “nutritional powerhouse” that contains twice the protein, 10 times the amino acids, 25 per cent more Omega 3 and Omega 6, and 70 per cent more iron than chia or flax seed per 30-gram serving.

Although hemp comes from the same Cannabis Stevia plant species as its more notorious distant cousin marijuana, it contains only negligible traces of the psychoactive ingredient THC (less than 0.003 per cent), so there is no chance whatsoever of getting high from the product.

According to Fata, a long-time user of different hemp products for health and nutritional reasons, Manitoba Harvest is the world’s largest manufacturer to grow, make and sell its own lone of hemp food products.

“At Manitoba Harvest we take a seedto-shelf approach,” he states.

“We are pat of an entire process that includes working with Canadian farmers on what hemp seeds get planted, to controlling how the products are manufactured, packaged and distributed in store.

“By manufacturing the highestquality hemp foods, we aim to educate consumers on the nutritional and environmental benefits of hemp.”

Providing one-year product shelf-life, the Hemp Yeah! pouches incorporate a sturdy, user-friend PTC “press-toclose” releasable closures to keep the product fresh after opening.

“The resealable closure is important to us because it maintains our product freshness and integrity,” Fata states.

“Since more than 10 per cent of our product is hemp, and since we don’t use any preservatives, it’s important that we limit the amount of oxygen that goes into the bag to maintain the freshness.”

Fata notes he is very happy with PTMK designers for creating outstanding package design that incorporates a generous see-through window in the front panel of the pouch to let consumers examine the product up-close, along with the “different bright, bold colors that tell what flavor the product is to evaluate.”

Adds Fata: “Our consumer will also appreciate seeing the ingredients highlighted on the back panel to show why ingredients were chosen and what nutritional value they brought.”

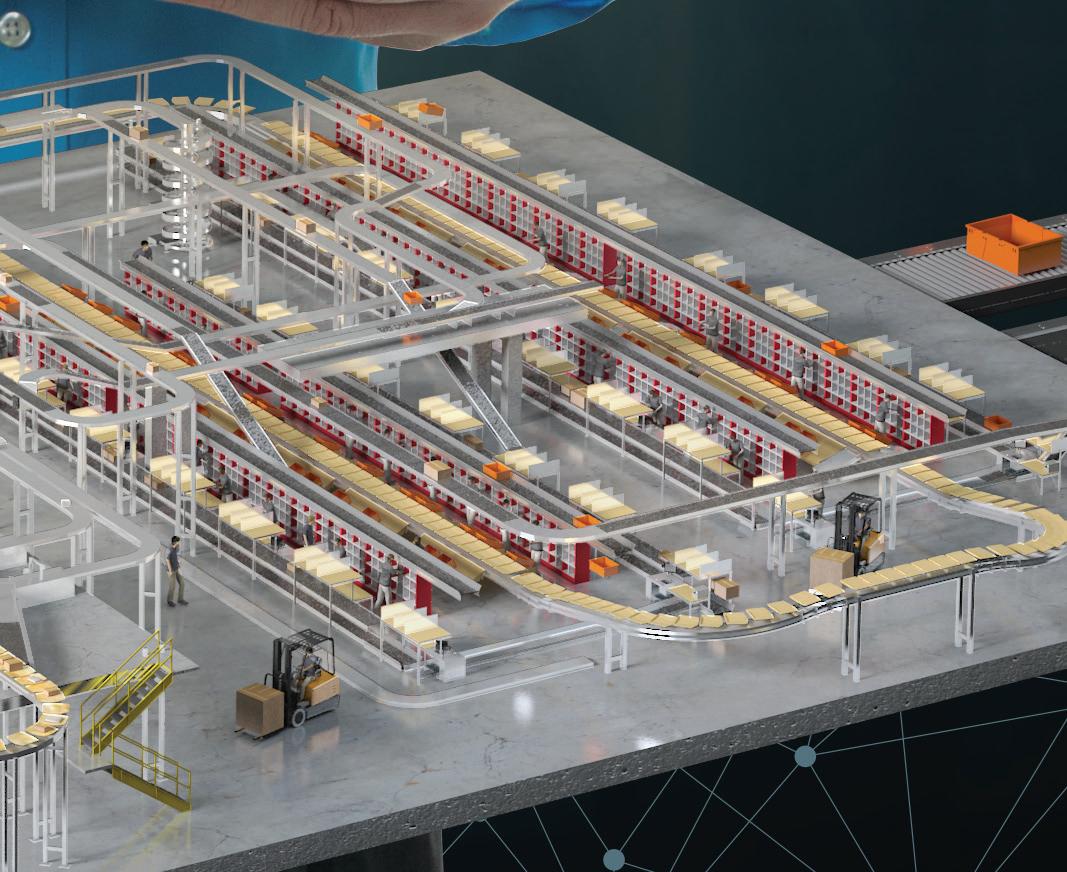

Complete motion control solutions - from Mechatronics, Conveyance, Assembly Handling, and Tightening Systems, to Linear and Electric Drives and Controls Technology

Rely on Bosch Rexroth, the world leader in drive and motion control technologies that power today’s most advanced manufacturing systems. You can rely on our local manufacturing, applications engineering, and commissioning expertise as well as our complete local support services.

Our automation solutions drive your manufacturing performance with fast throughput, precision, repeatable efficient motion control for maximum uptime. We’re set to help you achieve smarter, more productive automation solutions for your factory of the future today.

Because the Factory of the Future begins Now. develops Next. and goes Beyond.

Visit Bosch Rexroth booth #1213 at ADM/PACKEX Toronto, June 4-6, 2019.

Order your free Factory Automation Resource Kit: www.boschrexroth.ca/factoryautokit

For expert advice call 1-855-REXROTH (739-7684) or email us at info@boschrexroth.ca

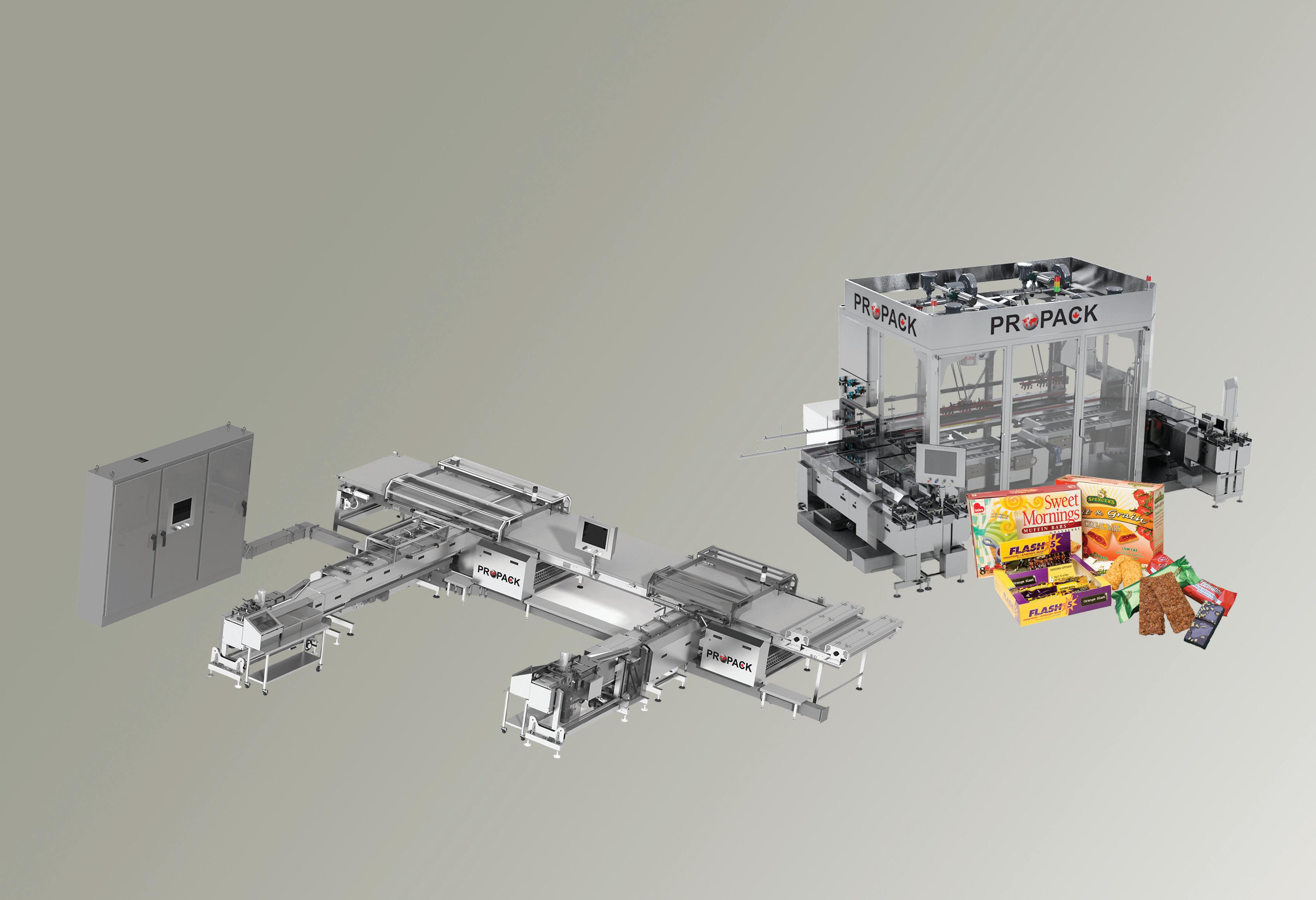

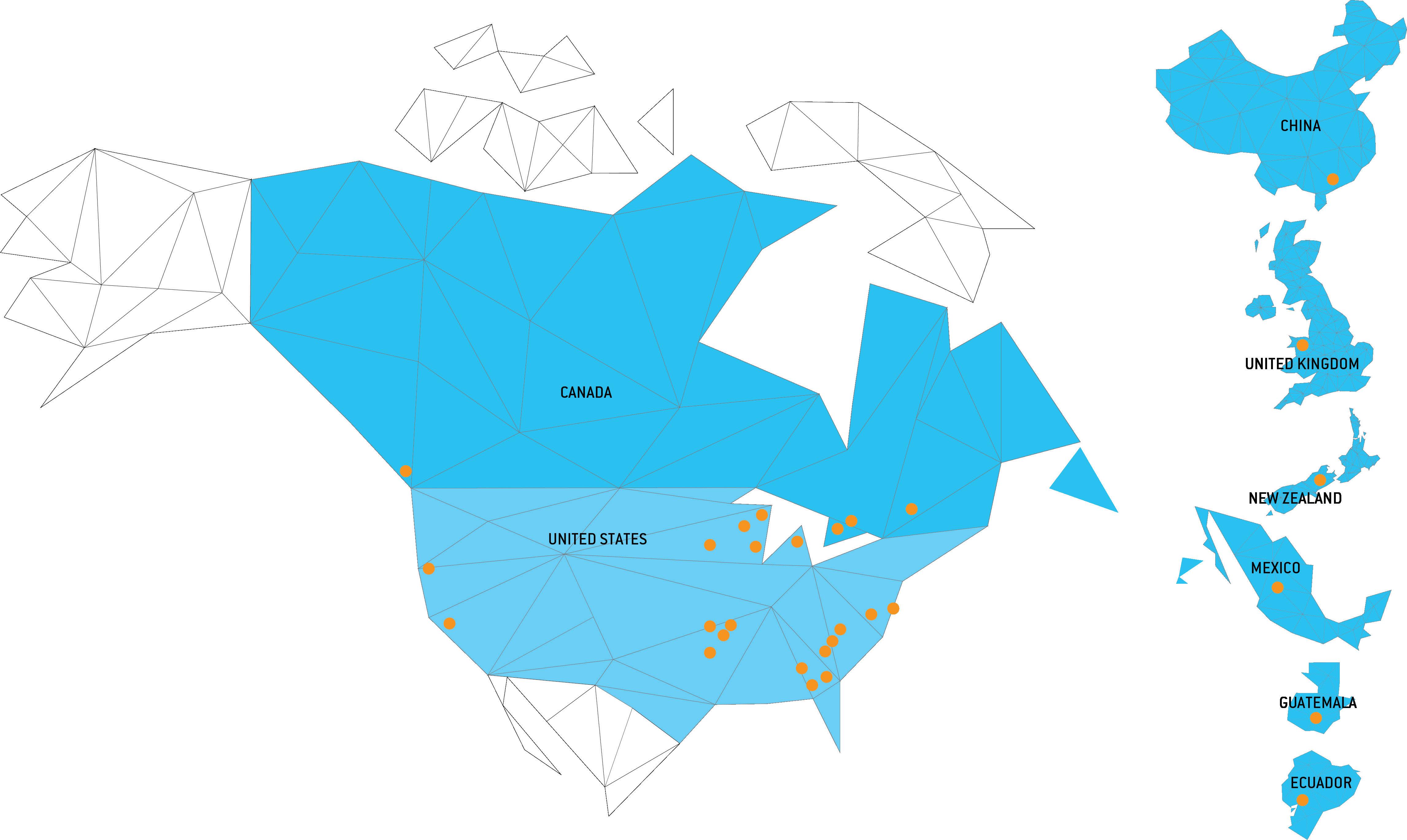

n Montreal-headquartered packaging machinery manufacturer Paxiom Group Inc. has formed a strategic partnership with an established Italian machine-builder ValTara, whereby ValTara will focus on further product development of Paxiom’s proprietary SleekWrapper brand of flowwrapping machinery, along with other end-of-line container handling and automatic case-loading systems. Operating out of a new, wholly-owned 20,000-square-foot manufacturing facility in Schio, Italy, ValTara has already completed several key local strategic acquisitions that it says will further complement Paxiom’s already robust product line, while also providing Paxiom with a strategic operating base for expanding its business growth in the European, Russian, Middle Eastern and African markets.

nToshiharu Kageyama, mechanical engineer at the research-and-development department of Japanese packaging machinery manufacturer Ishida Co., Ltd., has been awarded the 62nd Kyoto Inventors Award for the innovative new oval-shaped 18-head multihead weigher that Kageyama invented to overcome some traditional limitations in the operation of high-speed vertical form–fill-seal (VFFS) packaging machinery. (See Picture) According to Heat and Control, Inc., which is the exclusive distributor of

Ishida industrial weighing, packaging and inspection systems across North America and Latin America, as well as Australia and New Zealand, the new multihead weigher provides highly accurate and consistent weighing on high-speed VFFS machines to support the bagmaking process executed by these machines at exceptionally high speeds—performing up to 280 weight measurements per minute. Patented in Japan, the new technology has already been installed at more than 350 snack-food, baked-goods and vegetable processing plants worldwide. “I am honored to receive this historical award, it is a great pleasure that the product created from my ideas are satisfying customers needs throughout the world,” says Kageyama, who is currently involved in the development of next-generation Ishida multihead weigh scales that will incorporate artificial intelligence (AI) technology for even higher performance levels.

nMP Solutions (JMP), London, Ont.-based industrial automation systems integrator, has completed the acquisition of Alfacon Solutions, manufacturer o custom-built material handling solutions operating in Milton, Ont., for the last 35 years. According to JMP, Alfacon’s existing customer base will significantly benefit from the infusion of JMP’s extensive expertise in the fields of robotics, AGVs (automated guided vehicles), control systems and MES (manu-

facturing execution system) technologies. “I could not be more thrilled to have our team become part of JMP Solutions,” says John Murdoch, Alfacon’s former chief executive officer now serving as managing director of JMP’s Material Handling Division. “We can now offer our customers improved execution capabilities, long-term stability, broader turnkey solutions, more control system flexibility and better system-wide implementation, coupled with worldclass project management capabilities to reduce project risk and improve returns for our customers.”

nChesterfield, Mo.-based Pretium Packaging has won two high-profile international Worldstar awards of the World Packaging Organisation (WPO) for its new SureHandle polyethylene terephthalate (PET) container featuring an integrated handle. Using proprietary OneBottle technology developed by Houston, Tex.-based Practically Impossible Labs, the SureHandle container—currently available in 64-ounce and two-liter sizes—was recognized as a true “on-of-a-kind” bottle because it comes out of the injection mold with the handle already in place, integrated into the sidewall. According to Pretium, “This new technology creates new possibilities for many products—including beverages, foods and household and industrial chemicals—that could benefit from a monolayer PET container with an ergonomic handle-ware solution.”

The Power of Performance... means that our vast experience and expertise is concentrated in the areas that directly offer the most value to our customers.

• Integrating Complete Packaging & Processing Solutions

• High Speed Automation

• System Project Management

• Motion Control and Robotics

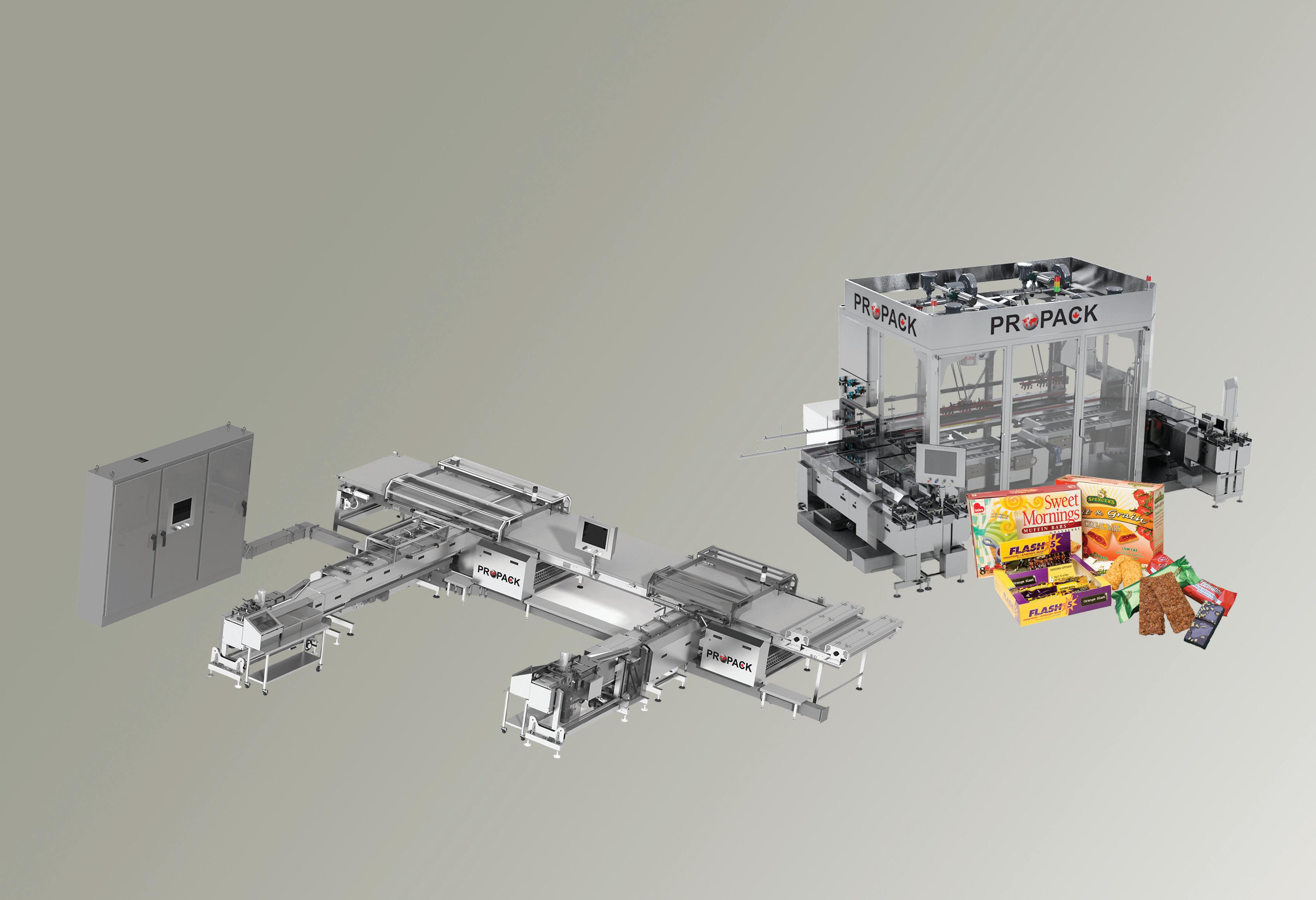

Row Distribution System

The unrelenting pace of commerce is forcing manufacturing and fulfillment centers to process higher order volumes at speeds once considered unimaginable. To stay competitive and protect profits, companies can no longer settle for fragmented oversight of their operations.

The Connected Distribution Center provides end-to-end connectivity of workers, systems and processes to increase reliability, improve utilization and maximize productivity.

If you’re ready to achieve day-to-day flexibility, future-proof scalability and the intelligence to make informed decisions, let us show you how the Connected Distribution Center can transform your operations.

please

Generating 900W of X-Ray power, the new Xpert Heavy Duty (HD) X-ray inspection system from Thermo Fisher Scientific is designed to enable food manufacturers to obtain easy detection of a wide range of physical contaminants in large packages and dense, heavy products like cheese blocks, cases of spice, and boxes

containing various meat products. Distributed in Canada by MD Packaging Inc., it features a large aperture width and height to accommodate big cases, boxes, bags and trays. Morover, the Xpert HD system incorporates a trapezoidal, top-down 770-mm-wide X-Ray beam at the belt, which narrows to 525-mm-wide at the 300-mm aperture height, as well as an enhanced mechanical design to stand up to daily washdowns and a water-cooled ceramic X-ray tube for long service life.

Delivering high penetration of food products in difficult applications to support the highest level of food safety, the Xpert HD offers:

• Three inspection widths to optimize price and system size;

• External water chiller for cooling the X-Ray tube;

• The same easy-to-use software available on all Thermo Fisher Scientific Xpert conveyor models. Thermo Fisher Scientific In Canada: MD Packaging Inc.

The new FHV7 series smart camera from Omron Automation Americas features an all-new multicolor light and a high-resolution image sensor for advanced vision inspections on high-mix production lines. Designed to address the inspection needs of manufacturers running different products in different colors, shapes and sizes on a single production line, the FHV7 series smart camera’s multicolor light and an autofocus lens enables it to respond flexibly to any changes in the color and size of objects to be inspected. This eliminates the need for multiple cameras or manual lens adjustments, while ensuring compatibility with wideranging inspection criteria on lines producing many different types of products in varying quantities. According to Omron, the system’s high-speed image compression algorithm compresses data at double the typical speed—enabling for all image data to be saved while simultaneously inspecting a second image to facilitate complete traceability. Some of the new smart camera’s other notable value-added features include:

• Autofocus lens that covers a focal distance between 59-mm and 2,000-mm, so that even when differently sized products are running on the line, the focal range can be easily changed by altering parameters rather than moving the camera;

• Modular structure that allows the user to freely combine the lens and lighting variants available for use with the camera;

• Dual-core CPU that provides the fastest image processing speed among smart cameras (four times faster than the previous generation), according to Omron.

Omron Automation Americas

Designed for measuring metallic coatings on both the finish and body regions of glass containers, the new Combined Coating Measurement System

(CCMS) from Agr International, Inc. is designed to provide operators with a one-stop, single operation testing station for measuring tin oxide coatings applied to a container during the production process. In order to achieve maximum precision on finish and body measurements, the CCMS incorporates dedicated measurement heads for each of the finish and body regions. According to the company, one head is optimized to operate with the precision necessary for the limited area of the finish region, while the second head is configured for body measurements where larger areas and heavier coatings are typically encountered. The advanced electronics of the system, in conjunction with dedicated measurement heads for finish and body, make it possible to precisely identify the presence of very small amounts of coating in the finish region while measuring heavier coating levels applied to the body of the container—all in one operation. The CCMS device is designed for fully automated operation, whereby the positioning of measurement heads— including vertical height location, container rotation and capture of measurement data—is performed in a single progression, without the need for operator intervention during the testing sequence.

Agr International, Inc.

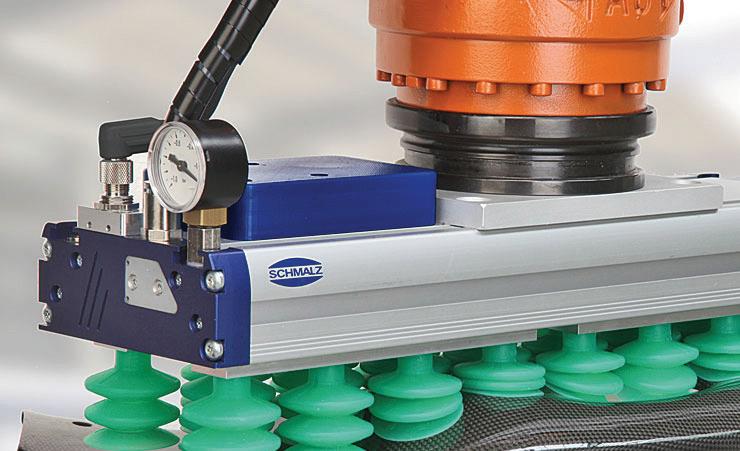

Incorporating three FANUC LR Mate 200iD robots with custom-designed end-of-arm tooling (EOAT) for gentle handling of fragile, pre-filled glass syringes, the new robotic tray-loading system from ESS Technologies is designed to automate the loading fivecount thermoformed trays at rates of up to 25 trays per minute. After the operator manually loads thermoformed trays into dual-powered, high-capacity tray magazines, the syringes enter the starwheel infeed via an infeed track that connects to the syringe filling equipment at a rate of 125 syringes per minute. At this point, the starwheel picks syringes and lays them in carriers on the infeed conveyor. From there, the first FANUC robot uses vacuum EOAT to pick a tray and, with the help of line tracking, places it on the lugged tray transport conveyor. A second robot, also equipped with line tracking, will then pick five syringes from the syringe infeed conveyor, load three in the tray, and rotate the remaining two syringes 180 degrees before pla -

cing them to complete the tray. Any missed syringes fall into a soft discharge bin to be manually re-introduced into the robotic tray-loading cell. At the discharge point, the third FANUC robot uses a hybrid vacuum/gripper EOAT to rotate a tray and stack it on the next tray that follows, after which it then picks both trays and places them on a discharge conveyor for downstream inspection and cartoning.

ESS Technologies

Designed for the specialty beverage markets, the new 64-ounce SureHandle polyethylene terephthal -

ate (PET) container from Pretium Packaging features an integrated handle for user-friendly handling,

along with shatter-resistant construction and full recyclability. Inspired by the ‘growler’ glass containers used in the craft brewing industry, the SureHandle jug weighs only 84 grams and costs a fraction of the original glass version, while providing an ideal vessel for larger quantities of beverages—from beer to juice and ice-brewed coffee—that are either consumed over time or by multiple people at home gatherings.

Pretium Packaging

Make your machines even more flexible. Easily.

As a pioneer in smart automation technologies, Schneider Electric makes it easier for you to offer your customers more flexible machines. Our future-ready machine solutions help quickly and easily adapt machines to changing production and operator needs. So you and your customers can meet continuously evolving market expectations. Both today and tomorrow.

How can you improve machine flexibility? Find out, today!

Vancouver-based flexible packaging converter Transcontinental Flexstar has completed the installation of a high-capacity RTO (Regenerative Thermal Oxidizer) pollution abatement system that will reduce its Richmond plants’ air-borne emission by more than 90 per cent, according to the company.

Boasting capacity of 50,000 standard cubic feet per minute, the $2-million investment will help the operation capture VOCs (volatile organic compounds) emitted from the two neighboring facilities’ various exhaust streams originating at the printing presses, laminators, and ink room operations.

Installed in a collaborative effort with Long Beach, Ca.-based pollution abatement specialists Ship & Shore Environmental, Inc., the new RTO swill allow Transcontinental Flexstar—a wholly-owned subsidiary of Montreal-headquartered flexible packaging group TC Transcontinental Packaging—to significantly improve air quality both indoors and outdoors.

“As part of TC Transcontinental Packaging’s commitment towards compliance and social responsibility, our plant was looking to control and capture VOCs,” explains Transcontinental Flexstar’s general manager Marc Bray, “and the installation of this regenerative thermal oxidizer significantly reduces our plant’s emissions.

Transcontinental Flexstar general manager Mike Bray (fourth from left) and a team of project collaborators pose to commemorate the startup of a high-capacity regenerative thermal oxidizer (top) that will help the company reduce its air emissions by over 90 per cent.

“We are proud to be the first flexible packaging company in British Columbia’s Lower Mainland to have a system of this caliber.”

Originally started up in 2005, Flexstar Transcontinental is said to be the most

vertically integrated flexible packaging operation in North America, specializing in blown extrusion, printing, lamination and converting, including pouchmaking and bidirectional laser scoring, for the cereal, confectionery and snack markets.

Employing 135 people, the company’s Richmond operations comprise a state-of-the-art 61,000-square-foot film extrusion facility and a next-door 30,000-square-foot converting facility housing all the slitting, bagmaking and radial laser scoring equipment.

Both facilities operate on a busy 24/7 schedule throughout most of the year to produce a broad range of high-quality flexible packaging products, both in rollstock and pre-made bags.

According to Bray, who co-founded Flexstar back in 2005, progressive environmental practise have always been at the forefront of the company’s agenda from the outset, as evidenced by the BC Export Award for sustainability it earned in 2008.

TC Transcontinental Packaging president Brian Reid says the company always strives to work with its internal and external stakeholders in a concerted manner to conduct its business responsibly.

“One of our goals is to reduce the environmental footprint of our activities, namely by fostering a forward-thinking culture within our business units,” Reid explains. “Air quality is a top concern, and we are always aiming to limit and control air pollutants, both at the source by choosing new products, and through the exhaust systems of our plants, by capturing VOCs.

“Hence we are very are pleased with the completion of this project at Transcontinental Flexstar.”

With plastic drinking straws recently emerging as a serious contributor to the world’s growing marine pollution crisis, progressive companies like Stora Enso and Sulapac are quickly off to the races to develop an eco-friendly solution that will still allow consumers to enjoy the sheer convenience of this vitally handy utensil.

Demonstrated at the recent Slush 2018 global exhibition for technology startups in Helsinki, Finland, the new range of sustainable drinking straws are made from a specialty biocomposite material— comprising wood and natural binders—that can be recycled via industrial composting and will also biodegrade in marine environments.

In May of 2018, the two Finnish companies signed a joint development agreement that allows Stora Enso, one of Europe’s leading forest product groups, to license Sulapac’s innovative materials and technology, which drew highly positive feedback from over 20,000 visitors to Slush 2018

“This is an important step for Stora Enso and it showcases our long-term commitment to gradually replacing fossil-based materials with renewable solutions,” says Annica Bresky, executive vice-president for the company’s Consumer Board Division.

“Our collaboration with Sulapac is a great example of what we can achieve through partnership in terms of driving innovation to create sustainable solutions within the bioeconomy,” states Bresky, noting the company is making plans to commence production of the renewable straws on industrial scale in the near future.

“Eco-awareness is a strong driver for consumer demand, and our customers want help in replacing non-renewable materials,” adds Hannu Kasurinen, senior vice-president for Stora Enso’s liquid packaging and carton board products.

“Different biocomposite solutions, such as renewable caps and closures and straws, will be add-ons and a complement to our own consumer board portfolio, while bringing additional value to our customers.”

Noting that Sulapac’s material works well with most existing extrusion lines, Kasurinen says Stora Enso expects the renewable straws to be available commercially in the second quarter of 2019.

“This straw has the potential to be a true game-changer,” says Sulapac’s founder and chief executive officer Suvi Haimi. “Being recyclable, microplastic-free and marine-biodegradable straw, this is the world’s most sustainable straw that can be produced on an industrial scale to provide an alternative to the billions of plastic straws are produced, used and discarded every week.”

folding-carton producer moves into the higher gear of production capacity and product quality with a new plant and state-of-the-art package converting machinery

BY ALANNA FAIREY, ASSISTANT EDITOR

PHOTOS BY NAOMI HILTZ

Ms. Carol Jiang, president and founder of Beneco Packaging and subsidiary company SoOPAK.com, has come a long way since a pair of $2 chairs from a yard sale became her first assets when starting her business back in 2004.

And while such extreme penny-pinching may no longer be required, Jiang’s knack for fiscal discipline and cost control has enabled her paperboard converting business to achieve many impressive milestones over the years.

By any measure, the startup of Beneco’s second manufacturing facility just over a years in Toronto’s east-end is a just reward for a hardworking ‘lean’ manufacturing enterprise operating in one of the packaging industry’s most fiercely competitive market segments.

Coming online in early January of 2018, the new 43,000-square-foot plant in the city’s suburb of Scarborough is a confident statement of the company’s intent to continue scaling new heights in the Canadian folding-carton industry.

Equipped with some state-of-the-art printing press and converting equipment manufactured by the famed leading German printing press technologies experts Heidelberger Druckmaschinen AG, the new Beneco plant is a testament to Jiang’s indomitable entrepreneurial spirit and sharp business acumen.

Along with Beneco’s original 45,000-square-foot plant in Mississauga, Ont., the company now employs 60 full-time staff over a two-shift, six-days-a-week schedule at the two locations— producing a diverse range of high-quality folding cartons for clients in a multitude of industries, with a strong focus on the food-andbeverage sector.

“For a company that started with almost nothing, we have grown very well indeed,” Jiang told Canadian Packaging on a recent visit to the new Scarborough location.

“It has been about 15 years now, and having done well enough to grow the business by expanding from one to two manufacturing locations will enable us to increase our capacity dramatically,” Jiang states.

Having already won an impressive number of prestigious awards in the past— including the 2018 Best Custom Medical Product Packaging Award from Global Health & Pharma (GHP)—the company is currently working on obtaining the vaunted GFSI (Global Food Safety Initiative) food safety certification to grow its client base in the food industry.

As one of the relatively few independent folding carton manufacturers in the North American market, Beneco and its SoOPAK.com subsidiary—a strictly online service for small-batch and short-run production of specialty packaging such as food boxes, soap boxes, wedding gift boxes and other custom-printed packaging—must leverage flexibility and customer service as key competitive core strengths.

Based on the growing order volumes, they have been able to get it all down to a science so far.

“I have a lot of customers that come up to me and say, ‘I heard that you’re the only few companies with good delivery in town at this moment,’ so we do whatever we need to do to meet our customers delivery requirement,” Jiang says.

“If my customers need their order in a rush, and I can make sure that they always get their products on time—that’s called flexibility.

“We offer high-quality packaging solutions designed to meet your turn-around time and specific needs—while keeping our customers’ costs down.

“Whether our customers require a small text run for a limited market or a large national rollout we have the expertise you need to meet your unique packaging goals in a cost effective way,” adds Jiang, a firm believer in the merits of JIT (justin-time) approach to order fulfillment and inventory control.

Stressing that equipment should always be waiting for an order rather than an order waiting for equipment, the standard delivery time from Beneco Packaging and SoOPAK.com is around three weeks, but they also provide five- and ten-day delivery options.

Beneco’s printing and finishing services include structural and graphic design, prepress, offset printing, UV Printing, embossing, die cutting, window patching, folding, gluing and other services.

Jiang’s point is clearly demonstrated beyond doubt with the massive capital investment the company made in new Heidelberg equipment installed at the new Scarborough location, including:

• a state-of-the-art Heidelberg Speedmaster CX 102-6+L printing press;

• a Heidelberg MK Promatrix 106 CS die-cutter;

• a Heidelberg MK Diana Easy folder gluer.

While Jiang says she evaluated other suppliers’ equipment, she was ultimately swayed by Heidelberg’s global reputation as a gold standard for printing and converting machinery, as well as the exceptional service and support offered by the company’s Heidelberg Canada subsidiary nearby in Mississauga.

“Heidelberg manufactures the best printing machines worldwide,” Jiang states, “and their Canadian team have been very professional in assessing and looking after our facility’s needs.

That’s why we chose Heidelberg.”

With lighting-fast printing speeds of 16,500 impressions per hour, the Heidelberg Speedmaster CX 102-6+L is equipped to handle both short runs with quick turnaround and longer-run work, while offering exceptionally short changeover and make-ready times.

With the Heidelberg Speedmaster CX 102-6+L renowned for its user-friendly interfaces—including a PressCenter XL 2 operating system with the Wallscreen XL—jobs are pre-defined as they are output from prepress, which helps to reduce time on job transfer and loading.

Once at the press, the job data concurrently activate a “job change” sequence which may include blanket and roller washes, automatic plate loading with AutoPlate Pro, and spectral color measurement with Prinect AxisControl

Using top-quality printing inks supplied by Hubergroup Canada Ltd., the Speedmaster press excels at executing many special value-added finishes, flourishes and other special effects during the printing process, according to Jiang.

“We do run a lot of the UV (ultraviolet) projects and the printing press allows us to do UV, gloss and matte, along with many special effects printed onto the package surfaces,” Jiang extols.

“The machine is so good,” she adds, “that it really brings up our printing quality standard to a much higher level.”

An equivalently significant machine at Beneco is the Heidelberg MK Promatrix 106 CS die-cutter, which has also gathered much praise from many Heidelberg customers as being the finest die-cutting machine in North America.

Boasting output capacity of 8,000 sheets per hour, the MK Promatrix 106 CS diecutter is a highly reliable, fully-automated workhorse outfitted with many highperformance features such as a non-stop feeder; a belt table with suction tapes and central roller and brush adjustment; precision register system up to the stripping station; quick-lock chase and cutting plate fine adjustment in the cutting station; and a quick lock frame with fine adjustment in the stripping station to facilitate short set-up times.

According to Heidelberg, motorized cutting pressure adjustment and non-stop delivery with rolling carpet facilitate a very smooth and comfortable operation to provide the machine operator additional time for production monitoring and quality control.

For its part, the Heidelberg MK Diana folder-gluer is engineered to facilitate user-friendly operation and fast and easy changeover processes, while achieving robust throughput speeds of 300 meters across a broad range of paperboard grades and weights, up to an E-flute of corrugated material, with maximum product lengths of 600-mm.

According to Jiang, all the Heidelberg machines have performed as well as advertised since coming online at the Scarborough plant.

“Our printing quality is a lot better and our production efficiencies have become very good,” she relates.

“These machines really open up our capacity because they are all stateof-the-art, and they are all highly automated and, moreover, it’s all very user-friendly equipment.”

Jiang adds she has been very impressed by the professionalism and expertise of Heidelberg’s Canadian staff, especially with their quick response time during the few instances when the machines were acting up a little.

“At Beneco, we recognize the fact that packaging plays a key role in the overall marketing process. We take the time to clearly understand your brand, and then work with you from start to finish to select the packaging options that bring out your product’s attributes and help to bolster sales.

“And because we are famous for fast turnaround and on time delivery, you can always be sure that even your tightest deadlines will be met.”

While Jiang acknowledges that there are not a bountiful amount of female entrepreneurs running their own businesses in the package printing industry, she sees no reason why this imbalance may not be corrected in the future.

Having made Beneco and SoOPAK.com highly successful enterprises, Jiang hopes that she may inspire many more young female entrepreneurs to take charge of their own fates in the future—in any industry for that matter.

“No matter what you do, you have to work hard and to be able to fight for your work almost everyday,” Jiang advises.

As for her own plans, Jiang says she has her mind set on making Beneco and SoOPAK.com reach their full potential.

“I think that the company is moving in the right direction,” she says, “and while I think there are a lot of things that we need to continuously improve, our goal is very clear.

“We want to be a just-in-time supplier; we want to have more machin-

ery; and we want to be able to deliver our packaging to customer within two weeks of getting the order,” Jiang proclaims.

“As more and more people are continuing to switch away from plastic to paperboard packaging,” she concludes, “we will continue to have a bright future in which Beneco will continue to grow, no doubt about it.”

Heidelberger Druckmaschinen AG Hubergroup Canada Ltd. Spicers Canada ULC

Product inspection experts start up a hands-on training curriculum to put production line operators at ease with the critical and complex food safety technology

BY GEORGE GUIDONI, EDITOR

BY NAOMI HILTZ

An investment in knowledge is a must for companies in any line of work in today’s knowledge-based economy. And it’s fair to say that there is no such thing as too much knowledge when it comes to food safety and consumer health and welfare.

But while food manufacturers have never been as spoilt for choice as today in terms of having access to powerful product inspection technologies such as metal detectors and X-Ray inspection systems, there is often a disconnect between what the technologies can deliver and the actual results, according to Larry Swift, co-owner and vice-president of Oakville, Ont.-based product inspection and hygiene systems distributor Shawpak Systems Ltd.

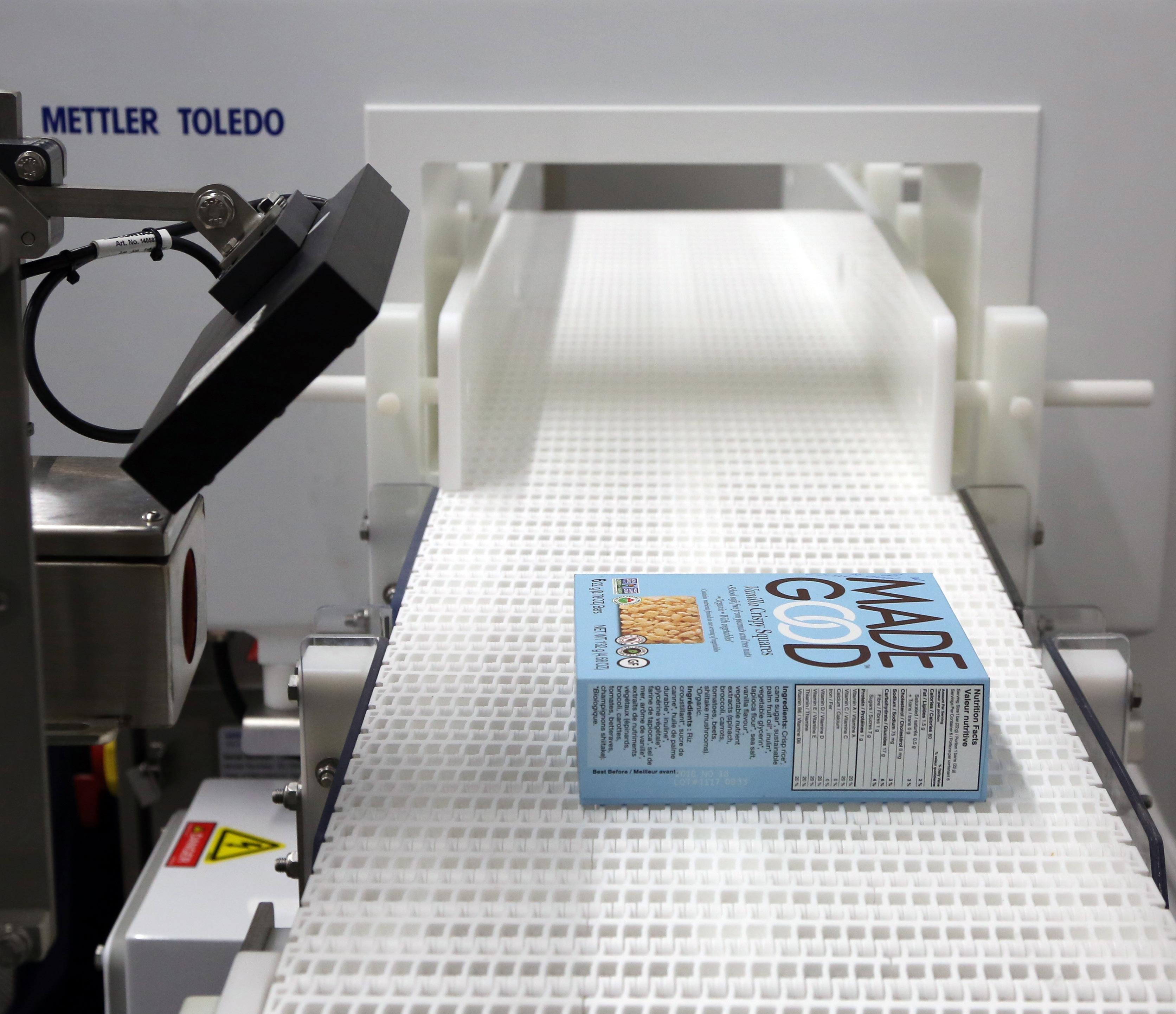

“We have found that many operators in the food business don’t fully understand product inspection technology,” says Swift, whose company is the exclusive Canadian agent for METTLER TOLEDO Product Inspection, the world’s leading manufacturer of metal detection, X-Ray inspection and vision technologies for the global food industries.

“Typically a plant engineer would purchase the inspection system, sign off on it, and move on to the next project—leaving people on the production floor to work with it,” says Swift, who has built up a vast knowledge of the subject during his 20-plus years of experience in product inspection systems manufacturing and integration.

“They may receive about two to four hours to learn it all when a technician starts it up after installation,” Swift says, “but that is typically all they get.

“So there is often frustration on the plant floor and people losing faith in the equipment,” Swift states, “which all comes down to not having a complete un-

Shawpak Systems co-owner and vice-president Larry Swift (above left) and the company’s certified trainer Brent Wilkins strike a cheerful pose inside Shawpak’s brand new Centre of Excellence training facility in Oakville, Ont., where the company intends to conduct informative hands-on training session on product inspection and hygiene technologies for critical plant personnel operating such systems at their workplaces.

derstanding the technology and its full functionality.”

To address this knowledge deficit head on, Shawpak Systems has just launched a new series of training programs conducted at the company’s newly-built Centre of Excellence training and demonstration facility in Oakville, offering hands-on training and expert classroom instruction to plant personnel and other end-users of product inspection and hygiene systems.

“We are very passionate about training here at Shawpak,” Swift told Canadian Packaging on a recent visit to the 2,200-square-foot facility equipped with a comprehensive range of advanced METTLER TOLEDO product inspection systems and automatic hygiene equipment ready to perform a broad range of tests and process simulations encountered by front-line plant personnel on daily basis.

“We teach Product Inspection 101, which includes metal-detection, X-Ray, checkweighing and vision technologies,” says Swift, adding all courses are custom-tailored to address the visitors’ specific application requirements.

“We focus on how the technology works, how it detects and why it rejects things, and so on.”

Says Swift: “Educating clients on the fundamental principles of the product inspection equipment and processes is key for food producers to create and maintain a strong food safety program in their facilities.

“Once they obtain that understanding, they will start to see a real change in performance and start realizing ROI (return-on-investment) almost immediately through less downtime and not having to experience the frustration of high false-rejects counts,” says Swift,” citing the company’s authoritative credentials as a certified trainer issued and validated by PMMI-The Association for Packaging and Processing Technologies

“Many people think that an X-Ray unit is a magic ‘Black Box’ that will detect anything and everything,” Swift relates, “but that’s just not the case.

“It is fundamental to understand the principles of the technology’s operation and the equipment’s limitations,” Swift asserts “which very from one application to the next.”

As Swift explains, the company’s Center of Excellence training and demo facility is designed to put the trained personnel at ease by removing them from the pressurecooker environment of busy production lines in order to absorb the acquired knowledge and information better.

“Before we would typically go to customers’ plants to do the training,” he recalls, “but we often found that there is a problem with the attention span whenever you pull people away from their production line at their work—they just don’t absorb the training as well.

“Here we can give people an opportunity to step away from the production environment and have a hands-on learning experience, without the distraction of what’s going on at their plant, so that they can really focus on understanding the technology from ground up.”

According to Shawpak Systems’ principal trainer Brent Wilkins, a typical training session would last from four to five hours of instruction and product testing for groups of four to six people in a “more intimate and confortable environment so that the

people being trained so can absorb the information better.

“We typically focus on maintenance and quality control personnel,” he says, “and we can customize and tailor a training course specifically to suit their requirements, whether they want to focus solely on X-Ray technology, or if they want to learn about all the different food safety standard levels and how they relate to product inspection … we can tailor to all that.

“We find that once they understand that core knowledge of the technology,” says Wilkins, “they will be able to structure their quality control programs at their facility more effectively.

“Naturally, we are also willing to do any follow-up the may require at their facilities as well.”

Says Wilkins:“Having been in this industry for a long time enables us to be dynamic in our approach.”

This dynamic approach has certainly paid dividends with the Centre of Excellence facility’s first trainee.

Paul Canacas, global market segment manager for food and conveyance with Quadrant Engineering Plastic Products, as well as market segment manager for food and packaging with Quadrant Plastic Composites, says the training he received at the facility in late 2018 was “real eye-opener” for him and his company, which is currently developing a range of metal-detectable plastics that can be used to replace metal parts across a broad range of processing and packaging equipment used in the food industries.

Nowadays operating as a wholly-owned subsidiary of the Mitsubishi Plastics business of Mitsubishi Chemical Corporation, Reading, Pa.-headquartered Quadrant group of companies is one of the world’s leading manufacturers of engineering plastics for a broad range of industries—from aerospace and automotive to industrial equipment and food and beverage.

As Canacas explains, the emerging trend among food processing and packaging machinery manufacturers to incorporate more plastic component into the design of their equipment has created demand for a new range of metal-detectable plastics that can be detected in trace amounts by existing metal detection and X-Ray inspection technology.

According to Canacas, many OEMs (original equipment manufacturers) and their clients increasingly prefer engineered plastics to metal due to the inherent benefits of their lighter weight, which results in reduced energy consumption and the associated reduction in carbon footprint; superior chemical resistance; higher processing speeds; and self-lubricating properties that reduce the risk of dirt accumulation and dust build-up.

“We believe that detectable plastics are the future for global food safety, in terms of both total system performance and overall consumer protection,” says Canacas, citing fast-growing use of plastic equipment components in the food industry, including scrapers, conveyor guide rails, gears wheels, sprockets, grippers, paddles, former plates and other machine parts coming into direct contact with food product.

“Although it’s not mandatory right now, trends in industry regulations indicate a focus on addressing concerns that can be solved best with food-grade plastics for food

handling and conveyance applications,” says Canacas, noting that Quadrant actually supplies METTLER TOLEDO with the plastic parts used in its metal detection systems.

As Canacas relates, making plastics detectable by metal detectors and X-Ray systems is a “complex” scientific endeavour requiring highly precise application and dispersion of various specialty ferrous or nonferrous powdered additives in a perfectly measured and balanced way that “fully respects mechanical properties of the plastic material and the integrity of the machinery.

“Different materials and different resins will accept different amounts of these additives and must therefore be expertly formulated and manufactured to achieve success in the field,” Canacas says.

“It’s critical to consider the big picture, the total system. At Quadrant, we develop materials to solve or prevent issues, so while a material might perform well on paper, we also go to the next step of field-testing it to ensure, let’s say, tht there is no crystallization, which can result in brittleness and cause premature component fatigue.

“This is especially important in busy high line-speed food plants with frequent washdown requirements and other extreme conditions.”

Says Canacas: “It is vitally important for Quadrant to understand the markets to which it is selling its product, and the food business is definitely a high-growth market for us.

“As the population continues to grow and the amount of food being produced to feed it grows accordingly, we are seeing the parameters of machinery being pushed to the limit with faster production speeds, with a higher chance of components fatigues and, consequently, plastic particles getting into the product.”

Adds Swift: “The challenge for Qaudrant is to produce a product that can be detected to avoid complaints from customers about plastic contamination of their food product.

“Hence they have to add special chemical component to the plastic so that the radiation embedded in the product inspection systems can detect it.

“As a rule, plastics are very hard to detect because they don’t have the conductive characteristics to enable reliable and repeatable detection,” Swift says, adding he is proud to count Quadrant as the Center of Excellence’s first full-fledged training client.

As Canacas concurs, the feeling is mutual.

“It was tremendous to see the complexity and continual advancement of the technology,” he states.

“All the variations involved lead to a better understanding in how we can best knowledge share to further optimize the detectability of the materials, adapting to the unique processing requirements, different food densities and so on.

“It was tremendous eye-opener for me to see the complexity of the technology and all the variations involved in understanding how we can make the materials detectable, and how they behave differently with the different kinds of food, different densities and so on.

“It really was an incredible learning experience and a very informative discussion forum,” he adds. “The Shawpak staff are very knowledgeable in this technology and they are always very accessible, a real pleasure to work with.”

In fact, Canacas says he has already enrolled himself to attend a more detailed and advanced training session at METTLER TOLEDO Product Inspection’s international headquarters in Tampa Bay, Fla., this year to expand his knowledge of product inspection further.

“Knowledge is eternal,” he quips, “and I’m eager to take this partnership to the next level.

“A superior understanding of the science of material detection in the food industry is what will continue to keep Quadrant customers optimized, protected and up and running,” Canacas states.

Naturally, such ringing endorsement is music to the ears of Swift, who takes immense pride in being able to complement Shawapak Systems’ vast technical experience to its client base with state-of-the-art METTLER TOLEDO inspection systems, backed up by extensive coast-to-coast technical support offered by the Mississauga, Ont.-headquartered METTLER TOLEDO Canada Inc.

Says Swift: “With food safety initiatives increasingly being strengthened by governments through regulations such as Safe Food for Canadians Regulations and the FSMA (Food Suppliers Modernization Act), it is critical that food production facilities take complete ownership of their product inspection systems.

“But having a machine in place is only one part of the puzzle,” Swift concludes.

“It is essential to control the whole process, and with a weak understanding of the technology and all the equipment features, you can’t perform the job correctly.”

entrepreneurs turning ice cream world on its head one scoop at a time with low-calorie recipe and cool packaging execution

BY GEORGE GUIDONI, EDITOR

If being cool means standing in a sea of conformity, then the three Montreal-based entrepreneurial bright minds behind Canada’s first national brand of low-calorie ice cream are true masters of the big chill.

Launched a little less than a year ago, the aptly named CoolWay range of ice cream is nothing less than a dream come true for countless Canadian consumers who love the taste of high-quality ice cream but dread the high calorie count and fat intake associated with one of the world’s most popular and universally beloved desserts.

Developed as a “guilt-free” alternative to conventional ice cream products by long-time buddies Benjamine Outmezguine, Noah Bernett and Dino Vassiliou, CoolWay ice-cream is actually a triumphant remake of the trio’s earlier creation called CoolWhey, which was high-protein frozen dairy treat intended for sale at fitness centers, health clubs and vitamin stores as a post-workout supplement.

While that product received a fair bit of media attention and notoriety with the founders’ appearance on the popular Dragon’s Den television series of the Canadian Broadcasting Corporation (CBC), the costs and logistics of making in it widely available in its intended frozen format at limited points-of-sale put breaks on further market development.

Undaunted, the three company founders turned the initial setback into an opportunity by reformulating their product to appeal to a far larger mainstream audience, while retaining the product’s high protein

content.

“But we quickly realized through in-store demos that the mainstream market was mostly interested in the low-calorie aspect of our products,” CoolWay co-founder Benjamine Outmezguine told Canadian Packaging in a recent interview.

“That’s when we asked Richard, our product developer and partner, to go back in the kitchen and come up with the best-tasting low-calorie ice cream he could possibly make,” says Outmezguine, noting it took about nine months of intense product development to obtain the right texture and taste profile,

along with remarkably low calorie count.

“We have removed most of the calories, fat and sugar from traditional ice cream while keeping that premium and rich taste,” he says, “so that anyone who want to indulge a bit without all the guilt can do so any time they wish.”

Already retailing across Canada in seven different flavors, the CoolWay brand contains only 280 to 360 calories per a full 500-ml “pint” tub—a stunningly low total that is proudly displayed as a primary graphic on each of the brand’s different flavors in the center of the cylindrical tubs.

Produced in strict accordance to CoolWay’s safeguarded recipe, the novel ice-cream also packs 28 grams of protein and a healthy helping of fiber in each 500-ml tub, while containing 50 per cent less sugar than most established ice cream brands in the market.

Offering one-year shelf-life, the CoolWay brand has been quickly picked up by leading national grocers such as in Walmart, Metro, IGA and Whole Foods, among others, where its cheerful light-blue package design adorned with playful graphics of ice cream scoops floating in mid-air has made a huge impact with the consumers.

“The ice cream category is a very competitive space where big companies spend big bucks to remain on the shelves, as well as on advertising Outmezguine states.

“To compete against them, you absolutely need to have the better product, a better story, and better packaging.”

Says Outmezguine: “Before launching the CoolWay brand, we knew that we were onto something special and that we needed very strong packaging to communicate the right messages to consumers.

To get the packaging and story-telling just right, CoolWay approached Montreal-based packaged deign and branding services specialists Bo Branding & Design Ltd., which has built up an impressive body of work over the years for multiple clients in the dairy and other CPG (consumer packaged goods) industries.

“After looking at Bo Branding’s impressive portfolio, we knew that they were the right partner to create something truly special for us,” Outmezguine relates.

As he recalls, the three CoolWay founders were keen to retain the original light-blue background from the original CoolWhey packaging as a key common branding template for all flavor varieties, while playing up the product’s health attributes in light-hearted style with clean, engaging graphics and fonts.

“The keywords that we used at the start of the project were ‘indulgent,’ ‘calorie-focused,’ and ‘blue,’ which was the legacy colour from our previous brand,” Outmezguine explains.

“We went with our legacy blue (Pantone 3115 C for life) from our previous CoolWhey brand because it’s friendly, approachable, and also one of our trademarks,” he states. “It also has this pastel nostalgic feel to it.

“We also wanted to go with modern, clear and professional fonts that would represent us as a brand,” Outmezguine elaborates, “and we wanted to include fun elements like falling ice cream scoops and spoons to add to the ‘funness’ of our packaging.”

Over about five months, Bo Branding patiently proceeded nearly 40 different prototypes of the new packaging graphics, Outmezguine relates, before nailing the ultimate packaging “sweet spot.”

As he recalls, “The consumers and our clients loved CoolWay’s packaging from the first day we announced it!

“It is blue, it is approachable and, above all, it is fun,” Outmezguine extols, while also crediting the company’s packaging supplier Stanpac of Smithville, Ont., for exemplary service in supplying the sturdy, fully-recyclable paperboard pint tubs and plastic lidding incorporating tamper-evident safety seals.

All in all, Outmezguine says he was highly impressed with Bo Branding’s professionalism and creativity that are aptly reflected in the final packaging execution.

“It’s never easy to create new packaging in Canada,” he says, “due to the unique challenges that we face because of the two-language (English and French) requirements.

“But with Bo being a local [Montreal-based] agency, they are very familiar with the process and all the best practices.

“Thanks to that knowledge, we were able to fit everything on our front panel in a nice and functional way, while still having room for a second ‘benefits’

section.”

Says Outmezguine: “Bo Branding handled our packaging from A to Z and they did an amazing job … we could not be happier with the result.

“The entire process was a pleasure—they always listened well to our feedback, acted quickly to respond, and they have great taste and,” he quips.

“If I had to rate their success, I’d give them a solid 10 out of 10,” says Outmezguine, adding that CoolWay has also recently engaged Bo Branding to develop packaging for the new range of CoolWay ice cream bars that the company plans to launch in Canada later this year, along with seven new flavor varieties.

“They did a fantastic adaptation of our pint design for our new ice cream bars,” he confides, “and we were also very pleased with the limited-edition packaging that they created with us for the [past Christmas] holidays.

As Outmezguine sums up, “When you compete in the CPG space, your product is everything: taste first and packaging second.

“In this light, the packaging created for us by Bo Branding is a big contributor to our success to date,” he states, “and I think it has successfully set the tone for our branding going forward.

“We plan to use this structure for all CoolWay’s future products and innovations,” he says, “because it really stands out in the freezer and it’s great at creating brand uniqueness and loyalty.

“We don’t go plan to go for the conservative corporate look simply because that is not who we are,” Outmezguine concludes.

“We are part of the new generation of ‘better-foryou’ foods made by real people who have a real story to share.”

High-speed digital label printer ignites steady production for innovative cannabis production plant

BY ALANNA FAIREY, ASSISTANT EDITOR PHOTOS BY NAOMI HILTZ

Since its legalization back in October, the demand for cannabis in the market has been at an all-time high.

While legalizing cannabis has opened the door for a number of different markets, Peterborough, Ont.-based Canveda aims to make a prominent name for itself in the medicinal marijuana sector.

“I think in every business you have to find a niche that can separate yourself from your competition and focus on your niche to become the best in that,” Michael Arnkvarn, executive vice-president and chief operating officer of MPXI Canada and Canveda, says.

“Medicinal cannabis is the niche that we’re going to have for this facility.”

Bought by MPX Bioceutical Corporation back in June 2018, Canveda, with approval from the CRA (Canada Revenue Agency) and Health Canada, is currently starting production and will be producing about 30 different strains.

“Obviously you want to have different strains to try and differentiate yourself as a cannabis producer versus your competitors,” Arnkvarn explains.

“Our philosophy is to focus more on producing finished products, in addition to

ABOVE: The 12,000-square-foot production facility in Peterborough, Ont.,

marijuana as part a partnership with Spartan Wellness, a group dedicated to helping veterans who are suffering from PTSD (Post-traumatic stress disorder).

producing specialized products.

“Canveda has a joint venture with the largest cannabis Pharmafarm producer in the world from Israel, Panaxia and we’ll be producing products with them together. Says Arnkvarn: “We’re really going to keep a very medical approach.”

While this facility produces only flower, Arnkvarn says that this will not be the way that the Canadian cannabis market will continue in, as there will be a demand for other specialized cannabis products in the likes of oils and edibles, which will be allowed to sell in Oct. 2019.

“If we look at the history of the cannabis markets in the U.S., typically when a new market starts, it’s almost 80 per cent flower, and very few derivatives,” Arnkvarn told Canadian Packaging on a recent plant visit.

“As the market matures, the cannabis market will see that flower consumption will go way down and the other products are going to go up.”

Whether packaging flower or edibles, all cannabis products must be packaged in the same way.

According to a lengthy report from Health Canada, all cannabis products must abide by a number of strict packaging and labeling laws since marijuana became legal.

The report states that the packaged cannabis requires a long list of information about the product, which include the name and contact information of the processor, product description, THC (Tetrahydrocannabinol) and CBD (Cannabidiol) content in a distinct red color, potential allergens and the statement “Keep out of reach of children.”

Packaging would also have to include a “universal symbol” denoting that it is a cannabis product, as well as a health-warning message inside a yellow box printed in the largest font on the label.

priority is to serve struggling veterans and to further develop that niche for producing medical marijuana to those suffering from PTSD and other illnesses.

In a similar fashion to cigarettes boxes, the warning messages on the cannabis products alternate between phrases such as “Cannabis smoke is harmful,” “Do not use if pregnant or breastfeeding” or “Regular use of cannabis can increase the risk of psychosis and schizophrenia.”

With a background in natural food health and producing lots of products, Arnkvarn’s instinctual train of thought was to get a color printer and have the labels made promptly, in-house.

After being reminded about the precise regulations surrounding packaging and labeling cannabis, Arnkvarn had to look no further than his influx of unread emails.

“Timing is everything in life,” Arnkvarn enlightens. “I get hundreds of emails a day from people trying to sell me different products.”

One of those fated unread emails came from data visualization technology specialists AstroNova Inc., who were pitching their Kiaro! QL-120 professional tabletop digital label printer from their QuickLabel subsidiary.

After responding to the email, Arnkvarn was able to address what his facility needed in terms of label printing and a sales rep quickly made a visit to the facility and presented the label printer to Arnkvarn and his team. They were immediately convinced that this was the printer for Canveda.

“It’s an essential item, you cannot package and you cannot function without it.

“Emails do pay off,” Arnkvarn adds with a laugh. With its original launch back in 2018, the QL-120

has already made a positive impression on customers in a number of different sectors.

Having been applauded for its network-friendly printer operations and a compact design, the QL-120 manufactures premium 1200 x 1200 dpi (dots per inch) color labels in a timely and cost-effective method.

Offering flexible print widths that are unmatched in the industry, the QL-120 enables Arnkvarn and his team to print labels as narrow as 0.5” or as wide as 4.2” on the same device.

Thanks to a function-rich Windows operating interface, completely integral utility and status monitoring software, the QL-120 helps users to straightforwardly and tenuously manage printer setup and operation.

In addition, the QL-120 also features self-maintenance during the printing process, which has resulted in the highest quality printed labels with little to no user intervention.

Having had the QL-120 installed at the plant for a little over a month, a professional graphic artist is in charge of designing the labels to the government’s strict requirements.

Arnkvarn also shares that Canveda benefits from the label printer’s welladapted settings and ability to provide them with different label sizes.

“When you’re doing labels or you’re doing even any printing mate-

rials, they become out of date every quickly,” Arnkvarn explains.

“The QL-120 gives us the flexibility and the ability to change the information as needed.”

Asked if they would consider buying from AstroNova in the future, Arnkvarn says with a smile, “When you find suppliers that you’re happy with, you don’t change.”

While he does not want to change his supplier, one thing that Arnkvarn would like to change is the public’s perception on PTSD (Post-traumatic stress disorder) seen in veterans. With their lead grower a veteran, the cause is near and dear to Canveda.

“When we talk about PTSD and other mental illnesses, PTSD is more people perceive that as a psychological fallout from somebody in the army, but that’s not really true.”

Canveda supports and promotes a group called Spartan Wellness, which is a network comprised of veterans, physicians, specialists and other support teams that work to help other veterans recover from opioid addictions and the often-tragic repercussions of PTSD.

A fundamental element of the program includes converting the struggling veterans away from opioids and towards medicinal cannabis, which Canveda provides them.

PRODUCTS,

FOOD,

GAMES, ICE MELTERS, POT-LINERS, PLASTER PRODUCTS, NOVELTY ITEMS, AND MORE.

We help make running your business easier. From sourcing packaging and material components to formulating and filling, assembling kits and point of sale displays, our experienced management team makes your company’s unique packaging decisionmaking process easy and hassle-free.

as a result of their opioid addictions and mental health, Arnkvarn says that introducing cannabis conversion therapy to the veterans has been promising.

“Ever since they have been able to convert the veterans to cannabis, Spartan Wellness has had great success in reducing opioid addiction,” Arnkvarn extols.

“Medicinal cannabis allows the veterans to function in society and become functioning human be-

ings again so it’s really cool and with that, we’re going to initiate different studies on PTSD and the effects of cannabis.”

While Canveda stands at a mere 12,000-square-feet with plans to add a number of trimmers and machines, there are no immediate plans to expand the facility.

Arnkvarn explains that the focus of Canveda as a business is not to compete with big name cannabis production corporations, but instead to focus on the needs and the accommodations of the veterans in the Spartan program.

After the tragic bus crash in Ottawa at the beginning of the year, Canveda would like to expand the Spartan Wellness group not just to veterans, but also to first responders and police officers who are also experiencing PTSD. Arnkvarn says that the goal is to have medical cannabis become much more mainstream.

“We’re really just going to use this facility to fulfill the needs of our veteran group,” Arnkvarn says.

“We really want to stress that this is veteran grown for veterans, and by veterans.”

Veritiv® offers a variety of packaging solutions, including cannabis specialty packaging items. Such solutions include custom jars, trays, bottles, paperboard, tins, folding cartons, bags and safety requirement labels. Additionally, we provide automation equipment, such as bottling, labeling and molding, for peak efficiency. Other solutions include child resistant, senior friendly and re-closable containers, point of purchase (POP) displays, and retail-ready packaging (graphical and structural design).

We combine the best ideas, optimum materials, cutting-edge equipment, proven processes and original designs to provide the right mix of specialty packaging products to meet your ever-changing needs. No matter what packaging products you need, we ensure you have a continuous supply of them.

By understanding your business inside and out, Veritiv can identify opportunities across the scope of your entire packaging supply chain.Then we help you implement them into innovative, cost effective solutions to achieve powerful advantages. The result? Improved visual and physical design of your packaging, greater efficiencies in your supply chain logistics, and a packaging process that reduces steps and saves time.

Veritiv® is a leading North American business-to-business distributor of Packaging, Facility Solutions, Print and Publishing, and Print Management; and also a provider of logistics and supply chain management services.

Visit veritivcorp.com/cannabispackaging to request to be contacted by a Veritiv Packaging representative.

Toronto-based Nuspark Inc. has come a long way from their humble beginnings way back in 1999.

With an already impressive packaging portfolio in sectors such as pharmaceutical, food & beverage, and consumer goods, Nuspark is ready to move into the cannabis market with the help of their leading compact cartoners.

Offered in horizontal and vertical loading configurations, Nuspark cartoners have the ability to quickly move from a manual packaging operation to an effusively automated single or multi machine solutions.

Such solutions include: full product QC and integrity tracking through on-demand label application, printing, scanning, complete database integration, third party equipment integration, in addition to boasting a industry 4.0 support.

Nuspark has a proven need for speed, as their cartoners have an impressive range from 10 cartons per minute, up to 80 cartons a minute.

In an effort to significantly save materials, the cartoners allow glue to replace tuck and auto bottom closure.

Due to Health Canada’s strict laws and regulations in regards to cannabis packaging, cartoners are able to adapt to be configured to accommodate current packaging

requests, such as airplane or reverse tuck cartons, glue closure, and auto-bottom cartons.

In addition, the multi-station indexing turret allows for several integrated options, such as leaflet insertion, labeling, printing, scanning, open flap detection, product detection, check weighing, and automatic reject for simple, and efficient QC within a single machine.

Nuspark

Packaging powerhouse Cannamation Corporation has produced a brand spanking new resolution that cannabis suppliers are currently lining up for.

The impressive Cannamation LM-W150-ETAX with Container Orientation is designed specifically for applying wrap labels and pressure sensitive excise tax stamps.

The LM-W150-ETAX had been purposefully made so that it can be incorporated with an automated line or alternatively can be proposed as a self-supporting

system with a self contained conveyor.

Noted for its simple and user-friendly design, the LM-W150-ETAX offers a low-cost solution for the application of pressure sensitive labels and excise tax stamps.

After the container has a wrap label applied, it is oriented prior to the excise tax stamp application to ensure stamps are accurately applied to the target area. Manufactured from high-quality stainless steel and anodized aluminum, the LM-W150-ETAX has been guaranteed to show strength and endurance in a fastpaced cannabis production environment.

AE Jones

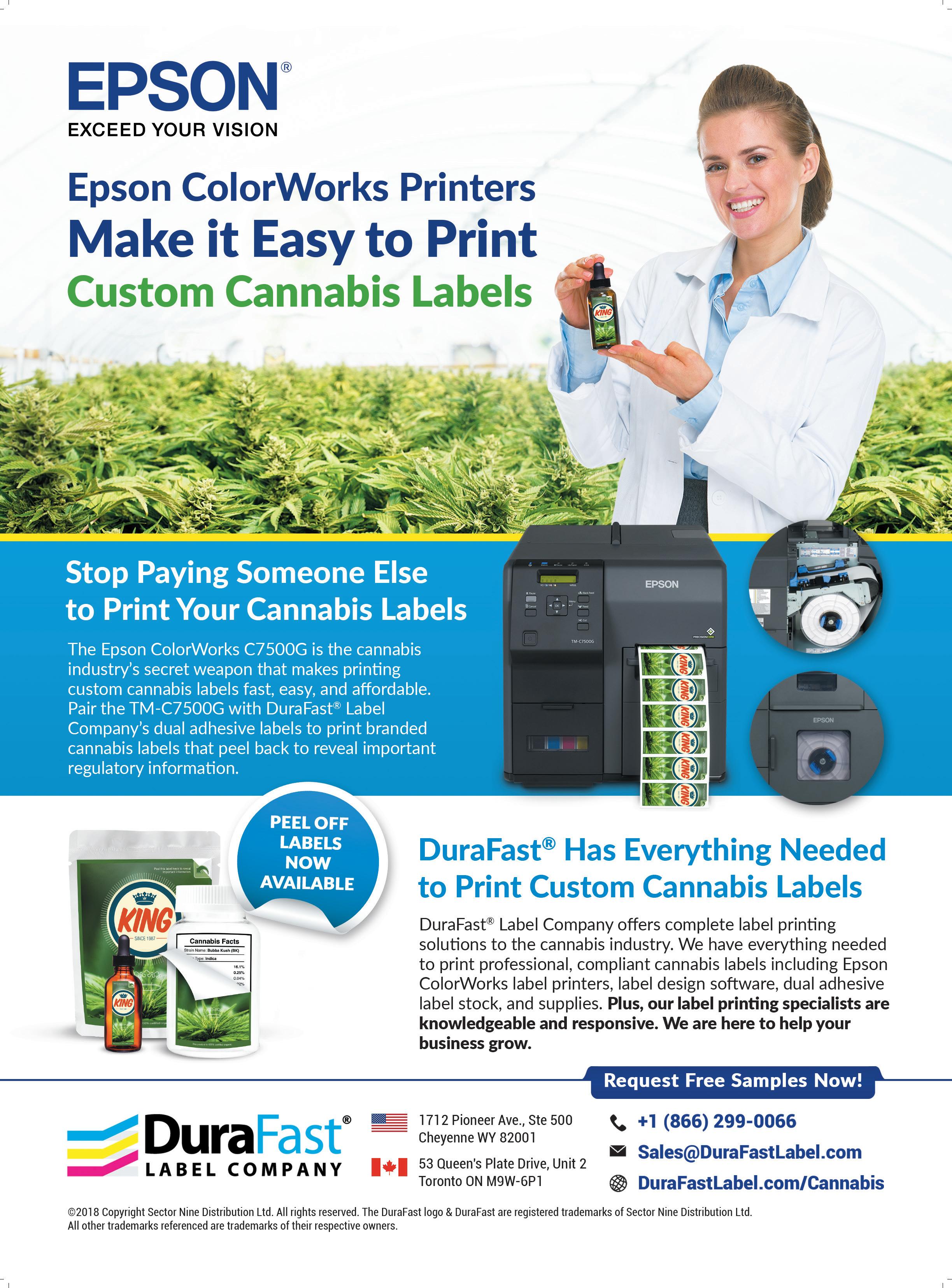

Legal cannabis is not the only thing now available in Canada.

Instead of buying labels and packaging from a third party, Epson’s Canadian agent DuraFast Label Company will bring the production in-house thanks to the Epson SurePress L-4533AW digital label press, ensured to give customers control over their products while also

dispensing low label production cost.

Praised as an inexpensive turnkey solution the Epson SurePress L-4533 can print on virtually any type of material including uncoated, gloss, and semi-gloss paper, film, and vinyl, making it extremely versatile.

Powered by MicroPiezo inkjet technology, the Epson SurePress L-4533 uses a 7-color ink set of durable, water-based pigment inks including white, orange, and green.

The digital label press also offers a wide color gamut for producing prime labels and packaging.

In compliance with cannabis packaging and labeling regulations, the Epson SurePress L-4533 has incomparable data support that allows for serialization for text, graphics, and barcodes.

Customers have vaster control over print jobs thanks to the aggregated Wasatch RIP software.

In addition to the Wasatch RIP software, the Epson SurePress L-4533 also includes: the label press, a photospectrometer, training, and inks.

The Epson SurePress L-4533AW supports large rolls ranging from 3.15 inches wide to 13 inches wide. Substrates can be as thin as 0.00213 inches, making it an ideal piece of technology in high volume production environments.

Manufactured by Epson and contains all-Epson components, the Epson SurePress L-4533AW furnishes automated printing for unattended operation, while a single

operator can effortlessly run several units concurrently. With an outpour of positive feedback on its output, reliability and reasonable cost, the Epson SurePress L4533AW is an easy choice for suppliers in the cannabis market.

Epson/DuraFast Label Company

The legalization of recreational marijuana has not only resulted in a prominent spike in product demand for suppliers, but also the need to stay ahead in a fresh but competitive industry.