Co-ordinated Services

Concept and Design

Structural Design

Material Purchasing

Packaging and Fulfillment

Off-site Mobile Packaging

Wright Hand Packaging Inc. is a full service contract packaging company providing custom packaging, assembly, logistics, fulfillment and distribution to all sizes of businesses.

Whether you have a definite idea of your packaging needs or are looking for some direction, we can help. Our contract packaging services provide fast, cost-effective solutions, unique to each customer.

We guarantee high quality products at competitive prices

With its breakthrough design, the 9550 applies labels directly onto packs without the need for an applicator, while self-adjusting label placement accommodates varying line speeds, throughput and package sizes. Revolutionary Intelligent Motion™ technology targets zero unscheduled downtime as it precisely and automatically controls the entire system.

See the Videojet 9550 in action at PackExpo 2014 in Chicago.

DECEMBER 2014

VOLUME 67, NO. 12

SENIOR PUBLISHER

Stephen Dean (416) 510-5198

SDean@canadianpackaging.com

EDITOR

George Guidoni (416) 510-5227

GGuidoni@canadianpackaging.com

FEATURES EDITOR

Andrew Joseph • (416) 510-5228

AJoseph@canadianpackaging.com

ART DIRECTOR

Sheila Wilson • (416) 442-5600 x3593 shwilson@bizinfogroup.ca

PRODUCTION MANAGER

Barb Vowles • (416) 510-5103

BVowles@bizinfogroup.ca

CIRCULATION MANAGER

Anita Madden • 442-5600 x3596 AMadden@bizinfogroup.ca

BIG MAGAZINES LP

Vice-President of Canadian Publishing • Alex Papanou

President of Business Information Group • Bruce Creighton

Executive Publisher • Tim Dimopoulos

Editorial Director Lisa Wichmann

HOW TO REACH US: Canadian

SUBSCRIBER

to change your address or information, contact us at 416-442-5600 or 1-800-387-0273 ext. 3555.

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE): Canada $72.95 per year, Outside Canada $118.95 US per year, Single Copy Canada $10.00, Outside Canada $27.10. Canadian Packaging is published 11 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

©Contents of this publication are protected by copyright and must not be reprinted in whole or in part without permission of the publisher.

DISCLAIMER: This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice. You should not act on information contained in this publication without seeking specific advice from qualified engineering professionals. Canadian Packaging accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. Canadian Packaging receives unsolicited materials, (including letters to the editor, press releases, promotional items and images) from time to time. Canadian Packaging, its affiliates and assignees may use, reproduce, publish, republish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

PRIVACY NOTICE: From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us via one of the following methods: Phone: 1-800-668-2374 Fax: 416-442-2191 Email: privacyofficer@businessinformationgroup.ca Mail to: Privacy Office, 80 Valleybrook Drive, North York, ON M3B 2S9

PRINTED IN CANADA

PUBLICATIONS MAIL AGREEMENT NO. 40069240, ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

We acknowledge the financial support of the Government of Canada through the Canada Periodical Fund of the Department of Canadian Heritage for our publishing activities. Canadian Packaging is indexed in the Canadian Magazine Index by Micromedia Limited. Back copies are available in microform from Macromedia Ltd., 158 Pearl St., Toronto, ON M5H 1L3

t’s been brewing for a while, but the ongoing legal tussle between coffee industry stalwarts Club Coffee and Keurig Green Mountain over the licensed use of their respective single-serve pods has really reached a boiling point last month, with Toronto-based Club Coffee filing a formal complaint with Competition Bureau of Canada seeking a federal investigation into Keurig’s allegedly anti-competitive practices.

Coming on the heels of its $600-million lawsuit filed against Keurig earlier in the year, this move considerably raises the stakes for both coffee companies in a North American single-serve coffee market estimated at more than $3 billion.

As inventor of the original K-Cup pod that sparked off whole single-serve coffee pod craze, Keurig may indeed feel genuinely aggrieved by the intense competition from rivals big and small aiming to cash in on the hot market, but knowing full well that its patents for K-Cup technology would expire in 2012, it could have done a better job preparing itself for the competitive onslaught by improving the technology’s environmental profile through innovation, rather than resorting to strong-arm tactics the company now stands accused of, albeit not proven in courts.

As it is, Club Coffee claims to be mere weeks aways from launching the world’s first fullycompostable coffee pod into the marketplace that it alleges has been artificially rigged against it by Keurig-licensed coffee operators under strict orders not to do business with Coffee Club or other companies posing a threat to Keurig’s market dominance.

Whether that market dominance really constitutes a de facto monopoly is something that Competition Bureau of Canada should decide sooner rather than later, with 2015 federal election already being played on in the media making it possible for this issue to become something of a political hot potato, which would be a shame on many levels.

With Keurig admitting that it is still about six years aways for launching its own fully-compostable K-Cup, its enmity towards a competitor claiming to have developed a greener and cheaper alternative does seem self-serving, but that does not necessarily make it illegal.

Nice guys do not always finish first in the cutthroat business world, and for Coffee Club to claim a rightful stake to higher moral ground, making sure its compostable coffee capsule is really as environmentally-friendly as it is claimed will be of paramount importance.

In a perfect world, “Consumers can simply throw the entire pod into their green bin and know that it will break down in the municipal composting system and be converted back into compost and likely used in agriculture, hence closing the loop,” Club Coffee’s senior vice-president of innovation told The Globe and Mail in late summer.

As good as that sounds, the fact that municipalities across Canada all handle discarded coffee pods differently makes this vision more hopeful than likely at the moment, which is why it is important for the Competition Bureau to address this matter in the most expedient and objective way it can before it get mired in a prolonged legal tug-of-war where the only real winners at the end of the day are the lawyers.

12 PROUD WESTERN HERITAGE By Andrew Joseph Canada’s leading perogies manufacturer is pulling out all the stops to make its tasty and nutritional dumpling creations more of a mainstream food staple.

Cover photography by Jason Franson

3 UPFRONT By George Guidoni

4-5 NEWSPACK Packaging news roundup.

6-7 FIRST GLANCE New technologies for packaging applications.

8 ECO-PACK NOW All about packaging sustainability.

10 imPACt Monthly insight from PAC, Packaging Consortium

30 NOTES & QUOTES Industry briefs and company updates.

31 EVENTS Upcoming industry functions.

32 CHECKOUT By Jeff May Joe Public speaks out on packaging hits and misses.

NEXT ISSUE: 2015 PACKAGING MACHINERY SPECIFICATIONS MANUAL

11 THE LUCKY SEVIN By Jim McMahon A multipack makeover makes insecticide brand more weather-proof.

17 THE JOYS OF SKINNY DIPPING Texan salsa producer hits the packaging sweet spot with innovative rigid-plastic technology.

18 OPEN FOR BUSINESS By Andrew Joseph A day in the life of a leading global manufacturer of meat packaging and processing equipment.

22 WRIGHT ON THE MONEY By Andrew Joseph Ontario co-packer provides an evergrowing range of packaging services to solidify its loyal customer base.

27 STRENGTH IN NUMBERS

A preview of next month’s International Production and Processing Expo 2015 in Atlanta, GA.

28 CONVENIENCE IS KING Industry research reveals what busy consumers want and expect from their meat packaging.

Quickly becoming a hot new menu offering at fine restaurants across Canada, the charcuterie platter— combining artisan charcuterie meats with cheese, bread, fruit and spreads—is a timetested mainstay over the holiday season as an appetizer, a finger-food dish, or even a light meal.

And with meat arguably being the key centerpiece of most charcuterie trays, leading independent Ontario meat processor Piller’s Find Foods is helping to make it easier than ever to serve up the perfect charcuterie feast with three new packages of artisan salami and ham slices smoked and cured in accordance to the most authentic

Produced at the company’s hometown processing facility in Waterloo, Ont., the 175-gram portions of Piller’s Charcuterie Alpen and Piller’s Charcuterie Cervelat salami slices—as well as the 125-gram servings of thinly-sliced Piller’s Charcuterie Westphalian Ham —are suitably packaged in high-quality film packs designed by the Cambridge, Ont.-based branding specialists Milestone Integrated Marketing, with the Westphalian Ham packs also containing wax-coated

paper inserts separating all the slices inside for eas ier handling and serving.

Printed by flexible packaging manufacturer Winpak Ltd. in Winnipeg using prepress artwork supplied by Optium Graphics of Aurora, Ont., the elegant packages feature stunning product photography displaying the company’s suggested serving ideas—developed in-house by Piller’s corporate chef Graham Kerr—enahbced by seethrough cutout film winnows on the right side of the pack to display the mouth-watering meat slices expertly layered on top of one another inside the easy-open packs outfitted with convenient peel-off closure on the bottom-left corners of the pack.

According to Kerr—better-known to the main stream public as his popular television persona Chef D—one of the most important elements in preparing a standout charcuterie platter is properly matching up the different varieties of meat with the right foods and beverages that “Aged cheddars, three to seven years old, go well with salamis, as do triplecream brie and raw milk goat cheese.” says Kerr, whose television work includes frequent appearances on nationally-televised CTV News at Noon and City TV’s Breakfast Television broadcasts.

While Ontario’s Niagara Region in the province’s southwest has long been knows for producing some of Canada’s best-known wines and ice-wine products, there is a new kid on the local block, thanks to some sining product innovation by Small Talk Vineyards, a family-owned boutique winery located in Niagara-on-the-Lake.

Launched earlier this fall at LCBO (Liquor Control Board of Ontario) retail outlets across the province in fittingly shiny 473-ml aluminum cans manufactured by Ball Corporation, the company’s new Shiny Apple Cider is made exclusively from locally-grow apples to offer Canadian consumers a refreshing, light-tasting alternative to traditional libations, according to the vintner.

“We are extremely excited about our new line of cider,” says Small Talk Vineyards winemaker Angela Kasimos.

“Our Shiny Apple Cider is the perfect drink to sip after a long day at work or at a dinner party with friends,” says Kasimos, adding the gluten-free, vegan-friendly beverage features full apple complexity with notes of pear and caramelized toffee apple that clearly differentiates it from other cider products in the local markets.

“This cider is a fresh, new take on a popular drink and is like nothing you’ve ever tasted before,” she states.

“Niagara is known for having the ideal climate for producing some of the world’s best wine grapes and other delicious fruits,” says Small Talk Vineyards owner Hank Hunse.

“By using 100 per cent natural apple juice made with fresh, hand-picked Ontario apples, we have created an innovative product that everyone can enjoy.”

Capturing Hollywood move-making magic in a box sounds like the stuff of science fiction, but reaching for the stars is all part of the daily toil for folks at California-based Snap Creative Marketing, the creative masterminds behind the Transformers: Age of Extinction home entertainment Bluray/DVD/Digital collector’s set retailing in Canada through Walmart and Target retail outlets, along with online sales via Amazon Featuring faithful toysized replications of some of the hit movie’s main Transformers action heroes—including Optimus and Grimlock—Snap Creative came up with three slightly differing designs to meet specific demands of each of the three Canadian retailers, with the wide-screen limited edition kit created for Walmart Canada (see picture) containing Blu-ray, DVD, Digital HD and three three-inch tall articulated

figures of Optimus Prime, Bumblebee and Stinger transformers standing ready for action in a beautifully windowed, ironically designed box.

For Target, Snap Creative designed an eye-catching Optimus Prime Blu-ray/DVD/Digital set standing over 12 inches tall with four points of articulation—featuring an elaborately detailed Optimus statuette as featured in Age of Extinction, while Amazon’s set features a collectible figure of Optimus riding astride Grimlock with and outstretched sword and shield captured in full battle-ready mode.

To date, Snap Creative has created more than dozen o similar successful marketing and packaging campaigns for some of the world’s largest entertainment companies, including Paramount, Universal, Dreamworks, Sony and Warner Bros

As one of the world’s healthiest foods, beets get sur

of premium, all-natural, ready-to-eat beets now selling in a diverse range of packaging formats at leading North American retailers.

Soon after launching Love Beets to rave reviews in North America in 2010 at the Fancy Food Show exhibition in New York City, the company’s English-born cofounders Guy and Katherine Shropshire moved their family business to Vineland, N.J., using various marinating techniques to help make beets a more appealing veggie option for the increasingly nutrition-savvy mainstream consumers.

Having successfully expanded its retail customer base in Canada to include leading retailers Costco, Sobey’s, Longo’s, Fortinos, Whole Foods and numerous independent grocers, Love Beets recently teamed up with Grand Rapids, Mich.-based branding specialists Display Pack Inc. to further enhance the shelf appeal of the so-called ‘superfood’ tracesing its history back to the ancient Romans, who consumed beets as a form of aphrodisiac.

In addition to containing high amounts of boron—directly related to the production of human sex hormones—beets are also a good natural source of betaine, a relaxing substance often used in other forms to treat depression, and tryptophan, also found in chocolate, which contributes to a sense of well-being.

Incorporating advanced peeland-seal technology to make the packaged beets easier to portion and store mess-free, the new Love Beets flexible packages prominently feature the brand’s signature smiley faces to make the products more approachable for the average consumer, according to the company.

Says Love Beats vice-president George Shropshire: “Love Beets’ aesthetic shines a spotlight on both the brand’s upbeat, cheeky personality to challenges age-old stereotypes around eating this notoriously intimidating vegetable.

“The brand’s logo, vibrant color pallet and signature smiley faces found on the front of its packages make will remind consumers why they should incorporate this trending superfood into their daily diet.

“The creative evolution of Love Beets really brings to life the idea that beets are modern, fun and can be enjoyed by consumers of all ages,” he adds, adding the company’s marinated baby beets, vacuum-packed steamed beets and beet juices are retailing at over 6,500 locations across Canada.

“We’re excited to reveal a whole new look and technology that make beets a hassle-free experience and even easier to snack on whenever and wherever.”

When it comes to packaging ground beef, only Reiser gives you this many choices. We offer a wide range of packaging equipment so that you can choose the best solution for your application. Are you looking for a modified atmosphere package to extend shelf-life? Or perhaps an economical tray with a “fresh, just-packed” appearance? How about a low-cost chub that can be produced at very high speeds? Or maybe a flexible film, semi-rigid, or vacuum package? We have machines that produce all of these packages –and more importantly –we can help determine which one is right for you. Plus, you can test any of these packaging machines for yourself at our Reiser Customer Center. Contact us today and set up a demonstration.

A brief overview of technological innovations making a memorable splash at last month’s PACK EXPO International 2014 exhibition

Things can change a lot in the space of two years, and for producers of last month’s highly successful PACK EXPO International 2014 packaging technologies showcase in Chicago, that change has undoubtedly been all for the better.

According to the show’s organizers PMMI-The Association for Packaging and Processing Technologies, the biennial exhibition drew over 48,000 visitors to the city’s sprawling McCormick Place exhibition grounds over four days—representing a 6.5-percent jump in attendance from the show’s 2012 edition.

“This year’s PACK EXPO International was definitely a success,” said PMMI’s senior vice-president Jim Pittas, also citing a 19-percent increase of exhibitors from two yeas ago—some 2,352 companies in total.

“Exhibitors sold machines right off the show floor and collected high-quality leads from the steady flow of attendees,” Pittas stated, adding many of the exhibitors are already making plans to do it all over again at PMMI’s fast-approaching inaugural PACK EXPO East exhibition in Philadelphia, Pa., Feb. 16-18, 2015.

Covering over 1.2 million net square feet of exhibit space across three fully-packed exhibit halls, the Chicago show certainly delivered on its promise of putting on a dazzling display of packaging innovation and excellence, as reflected by some of the show’s more notable product launches, including:

After years of R&D and representing over a $130-million worth of new product development, product identification technologies powerhouse Domino North America unveiled its new A-series continuous inkjet printers—comprising seven different models featuring marine-grade stainless-steel exterior, a three-stage fluid management system offering the lowest consumable consumption levels in the industry, according to the company, and a remote user interface TouchPanel terminal for intuitive, user-friendly operation. Intended primarily for applications in the food-and-beverage sector, the new model A520i printer pictured here is the industry’s first CIJ printer to incorporate an innovative plenum airflow cooling system, which ensures the printer stays cool whatever the production environment. “The two new key qualities that set this printer aside from the competition are its flexible design and consistent performance,” said James Shippen, the company’s product marketing manager for CIJ technologies. “The ability to integrate the user interface anywhere along the production line is a considerable advantage that will prove beneficial in more complex work environments, while a robust cabinet and the plenum airflow cooling system ensures optimum functionality no matter how challenging the surroundings, whether they are hot, cold, wet or dry.”

Domino North America 4 01

Sealed Air Corporation’s expansive exhibit featured the North American debut of the Cryovac Modified Atmosphere Packaging (MAP) for Bakery barrier film. Developed by the company’s Food Care Division to enhance product freshness and shelf-life extension premium and specialty baked goods— including preservative-free, whole-grain, glutenfree and other high-end, specialty bakery products that are often susceptible to mold—the new film can extend these product’s shelf-life from the standard one to two weeks to more than 40 days, according to the company. “As more specialty bakery items enter the market, there is a growing need for packaging solutions to accommodate these high-value, specialty goods,” said Kari Dawson-Ekeland, director of marketing for center-of-store products. “The trad itionally short shelf-life of specialty baked goods, along with the elevated costs for raw materials and ingredients, make it especially critical for bakeries and retailers to reduce waste and keep products on shelves, and Cryovac MAP for Bakery alleviates these challenges by preserving freshness, while enabling wider distribution ranges and extending product shelf-life.” The high-performance package combines the company’s Cryovac Freshness Plus active barrier films with gas-flush processing to deter oxygen ingress and prevent mold growth— thereby preserving freshness and quality while also extending sales time for retailers and consumption windows for consumers. As an efficient alternative to cold chain packaging technologies that can impede quality, Cryovac MAP for Bakery enables processors to extend their distribution ranges without losing peak freshness time in transit, effectively preserving the products smell and taste to offer customers an improved sensory experience.

is fully compatible for use with the highly durable Trident ProSeries 384 and ProSeries 768 jet printheads that can last as long as 10 years of service. FoxJet (in Canada: Harlund Industries Ltd.) 4 03

For sheer originality, label manufacturer Avery Dennison set a high benchmark with its one-of-akind, smooth real-wood veneer material. Boasting a unique surface that provides the texture of genuine wood, but is also smooth enough for printing and label converting, the Fasson Cherry Wood material was recently-used with great aplomb by U.S. microbrewer AC Golden Brewing Company for its Belgian-style Framboise Noir ale that is actually aged in oak wine barrels with blackberries. According to AC Golden president Glenn Knippenberg, the limited run of 750-ml bottles boasting this label sold out within hours in the local Denver market.

“Just as the wood bar rels add complexity and illuminates the flavors in the beer, the wood label illuminates the most intriguing points of our brand story,” said Knippenberg. “The label reflects our product’s barrel aging process and also signals to craft beer drinkers that our product is handcrafted for a unique experience.” Printed on flexographic and UV digital inkjet presses, featuring Fasson AT20N all-temperature adhesive and a PET liner, the wood veneer’s unique sensory experience is optimally enhanced by crisp visual detail to really engage consumers at the shelf level.

Avery Dennison 4 04

Sealed Air Corporation 4 02

Coding and labeling systems manufacturer FoxJet (available in Canada via Harlund Industries) used the show for a global launch of its new Marksman Matrix controller for inkjet printing system loaded with value-added features such as a 10-inch touchscreen terminal for live on-floor editing of printed codes and a userfriendly interface that enables it to control as many as four printheads on two production lines. Ideally suited for use in systems that print alphanumerics, graphics and barcodes onto porous packaging substrates like corrugated boxes in a broad range of food, beverage, personal-care and medical applications, the system

For Plastic Technologies, Inc. (PTI), the show was an opportune time for the North American debut of the company’s innovative new foamed polyethylene terephthalate (PET) bottle technology that can provides extraordinarily powerful new physical and visual attributes for carbonated beverages, wine, spirits, cosmetics, personal care and many other high-end products that were previously unattainable with a monolayer PET bottle. Developed by Toyo Seikan Co. Ltd. in Japan—where it has already been commercialized for a popular line of coffee drinks—the Fi-Cell (fine cellular) foamed PET bottle is made via a proprietary process that ensures a smooth inner and outer wall surface, unlike other foamed bottle technologies requiring an overmolded bottle to achieve a similar result. According to PTI, this is particularly significant for carbonated bev-

erage applications that require a smooth inner wall for an accurate fill, since a rough interior surface can cause CO 2 to come out of the liquid and turn into gas or froth and result in underfilled containers. “Using Fi-Cell foamed PET bottle technology offers an exciting way for companies to create strong shelf impact for their brand,” said PTI president Scott Steele, pointing out that the Fi-Cell process produces a visually-exciting metallic finish without the use of expensive metallic colorants.

Plastic Technologies, Inc. 4 05

Although it was first introduced to the North American market last year, the NextGuard X-Ray detection systems from Thermo Fisher Scientific Inc. had been significantly enhanced in time for the show with new, customizable vision software that enables it to inspect packaged products for flaws such as missing pieces or components. The NextGuard product verification software allows customers to use a pull down menu to quickly select and sequence a range of image processing and analysis algorithms, enabling a wide range of size, shape, angle, count and position-based inspections in minutes. “The new product verification option allows users to execute a wide range of size, position and count inspections

without relying on the X-ray vendor to create new software for each application,” said Bob Ries, the company’s lead product manager for metal detection and X-ray inspection technologies. “We anticipate that this feature will reduce time/cost for the customer, enabling them to quickly and easily experiment with different inspection algorithms on their own.” Some of the new algorithms provided by the software specifically target the detection of less dense contaminants such as glass or rocks in complex, textured products such as nuts or tea bag boxes, while its optional mass estimation software is designed to utilize the density information in the X-ray image to estimate weight and detect under- and overfilled products. Thermo Fisher Scientific Inc. 406

Mondi North America launched the innovative Pinch Pro largeformat industrial bag designed for packing powdered and granulated products such as pet food, sugar,

bakery ingredients and specialty chemicals. Boasting a patent-pending inner heat seal on the bag ends that requires only a hot air-sealer to create a seal when the ends are folded over during closure, the Pinch Pro bag eliminates the need for sewing or hot melt equipment for the bag closure. At the same time, the bags are very easy to open for the consumers, who simply lift up on the bag’s sealed end closure and then peel apart the front and back sides of the bag to the desired opening size. “The Pinch Pro bag enables packagers to achieve a higher quality, more reliable bag seal with better productivity than is possible with bag sewing and other closure methods,” said Bill Flynn, senior market development manager for Mondi North America’s indus-

trial bags business. “With the ‘easy open’ feature, Pinch Pro bags also enhance the end-user experience.” In addition to superior material strength, Pinch Pro woven polypropylene bags provide packagers with an array of printing possibilities, including eight-color reverse or surface printing via flexography, rotogravure and offset lithography, along with a choice of gloss, matte and differential gloss printing options. According to Mondi, consumer goods packagers can utilize “billboard” branding on one or both ends of a Pinch Pro bag to attract the shopper’s eye on the retail shelf, with the bag ends providing an ideal space for marketers to feature their product names, logos and images.

Used takeout food containers are notoriously hard to recycle or keep out of landfill for a multitude of reasons, but a breakthrough innovation from Canada’s leading forest products group Cascades Inc. of Kingsey Falls, Que., is showing much promise in helping the fast-food industry to reduce its carbon footprint in a more meaningful way.

Launched earlier this year as an eco-friendly alternative to traditional nonrecyclable polycoated paper packaging products, the widelylauded Respak food containers incorporate a proprietary water-based barrier coating that provides the same effective water-, grease- and oilrepelling performance attributes of polycoated containers, while being fully-recyclable and compostable.

Manufactured from 50-percent recycled fibers at the company’s Norampac boxboard plant in Jonquière, Que., the Respak containers have just been awarded the highly prestigious EnviroLys Award of the Conseil des entreprises en technologies environnementales du Québec (CETEQ) for innovation and environmental protection, which recognize Quebec-based companies in the environmental services industry for their innovative approach, new services, new

From Left: Benoît de Villiers, chief executive officer of RECYC-QUÉBEC; Serge Desbiens, Cascades director of logistics, purchasing and transportation; Carl Blanchet, Cascades corporate director of innovation and sustainable development; David Heurtel, Quebec’s provincial minister of sustainable development and environment, at last month’s EnviroLys Award gala in Saint-Leonard, Que.

It may seem like just the proverbial drop in the ocean, but a new brand of spring water sourced from the remote True North Springs in Newfoundland’s Notre Dame Bay provides a telling reminder about the virtue of sustainability when it comes to one of Mother Nature’s most precious gifts.

Launched across the U.S. this fall by Water Resources Group pany’s Icebox Water brand is packaged right at the source in shelf-stable, 500-ml beverage gabletop cartons— manufactured by Norwegian-based liquid packaging products group Elopak—claimed to provide a con siderably more sustainable packaging alternative to the commonly-used PET (polyethylene terephthalate) plastic water bottles.

According to the Cold Spring Harbor, N.Y.-based company, the reclosable capped cartons— stylishly designed by Communications of Santa Barbara, Ca.—are both fully-recyc lable and compostable, while boast ing a 74-percent smaller carbon footprint than comparable plastic containers.

Featuring a unique construc tion with 74-percent cardboard and pressed paper content—its spout and cap are made from 100-percent polypropylene (PP) material and all-aluminum inside lining—the BPA (Bisphenol A) -free cartons are made compost-ready with a simple removal of the spout from the box, which can then biodegrade in an

industrial composting facility in as little as two months after having its aluminum lining separated at the recycling mill.

Moreover, the cartons only use vegetable-based inks—containing no wax or solvents—to print the graphics on the box, whose exterior is protected with a thin layer of specially-formulated coating to provide an adequate moisture barrier and to protect the graphics, according to the company, which plans to introduce a 250-ml single-serve carton in early 2015.

Boasting a neutral (soft) pH level of 7.4 that ensures optimal hydration properties, “Icebox Water is bottled at source far from the effects of industry and contamination in a pristine environment that sparkles under the Northern Lights, with towering icebergs floating off the coast, and evergreens flourishing in the dense forests that grow along the rugged coastline,” the company

“Open a box of Icebox and you can almost smell the fresh breeze with the scents of the fresh wilderness.”

Currently retailing in the U.S. at Whole Foods, Mother’s Market, and Gristedes outIcebox Water brand is part One Per Cent for the Planet group of companies whose members voluntarily donate at least one per cent of their annual sales to various environmental causes—generating an estimated US$100 million in total “environmental preservation” contributions in 2012.

processes or a new technology that has a positive impact on the environment.

“We are pleased that Cascades’ ongoing efforts to ‘green up’ the industry have once again been recognized,” says Cascades director of innovation Carl Blanchet, adding the revolutionary material was developed in collaboration with the company’s Research Centre in Kingsey Falls.

“The development of Respak goes hand-inhand with the company’s values of respect for the environment and innovation that have made Cascades a leader in eco-friendly packaging for 50 years,” says Blanchet.

According to results of a company-conducted LCA (life-cycle analysis) study, the Respak paperboard has demonstrated 50-percent less environmental footprint impact than the conventional polycoated cardboard boxes widely used in the foodservice industry.

Boasting both FSC (Forest Stewardship Council) and ECG (elemental chlorine-free) ecolabel certifications, the Respak paperboard fully complies with all the main food safety standards—including those established by the U.S. Food and Drug Administration (FDA) —for packaging that comes in contact with dry, aqueous and fatty foods.

Doing the right thing for the planet has its own rewards, but a new collection program launched last month across Canada by waste upcyclers TerraCycle, Inc. will make those rewards sweeter with some cash prizes.

As part of the industry-first Air and Home Care Brigade project—aimed at diverting packaging waste associated with home cleaning products from landfill—Canadians who collect and ship used Febreze air-fresheners and Swiffer homecare detergents made by Procter & Gamble Inc., will be eligible for $5,000 in prize money they can donate to a charity or school of their choice.

Under the Febreze Fall Frenzy Contest rules, the top collector will receive a $3,000 cash prize, while two other randomly-selected participants will receive $1,000 each to donate to their selected cause.

According to TerraCycle, air and home-care packaging waste presents a number of challenges to conventional recycling collection streams. Although technically recyclable, the high cost of handling and processing these mixed plastics means that not every municipality in Canada has the infrastructure to handle all the leftover packaging components like plug-in refills, trigger heads, pumps and caps, etc., which then end up in landfills. Instead, TerraCycle will process this waste to make new plastic materials that can be used to manufacturer new watering cans, lamp shades (see picture), garden benches, garbage bins and other products typically made from virgin plastic.

f rom fa S t movin G con Sumer

G ood S to indu S trial product S

from traceability to brand protection worldwide...

from GS1 compliance to late S ta G e cu S tomization...

▶ product codin G

Inkjet, laser and thermal transfer

▶ ca S e codin G

Inkjet, valvejet, print & apply

▶ pallet codin G

Print & apply

▶ S oftware S olution S

Design, networking and traceability software

Markem-imaje has built its market knowledge and consultative approach by implementing globally a wide array of well-targeted coding solutions for numerous industries. We are capable of adapting our offer to your specific needs. We deliver the right insights, technologies and worldwide support to solve your next coding challenge.

1.866.263.4644

Make an investment in a greater future. Visit us at www.markem-imaje.com

BY JIM McMAHON

The Sevin brand of garden insecticide products has long been a popular fixture on the shelves of thousands of nurseries, lawnand-garden centers, and Big Box retailers around the U.S. for many years and for many good reasons. Over time, the patented dust formulation has proved to be an especially effective line of defense against more than 65 varieties of nuisance garden pest such as ants, ticks, Japanese beetles and worms preying on vegetables, fruits, ornamental shrubs, flowers and lawns.

Marketed and distributed by the Central Garden & Pet Company of Walnut Creek, Ca., the brand’s flagship Sevin 5 Ready-to-Use 5% Dust product line—a one-pound dust formulation developed specifically for application onto edible fruits and vegetables—has recently undergone a fairly major packaging makeover aimed at giving it greater shelf-space in secondary displays in the outside edible plants section at nurseries and lawn-and-garden centers.

To make the product packaging more weather-resistant for outside presenta tion, the company redesigned the con tainer to a plastic bottle format, incor porating a water-resistant plastic lid design and that would repel water, and fade-resistant label coding.

However, the company was still chal lenged to come up with an effective multipack format that would withstand whatever harsh elements it must endure outdoors.

However, this information was easily impaired whenever the shrinkwrapped three packs were left outside in the rain.

“Consequently, the company wanted to do away with the tray altogether,” says David Nettles, strategic account manager with the Atlanta, Ga.-based packaging systems integrator Associated Packaging, which was contacted by Central Garden & Pet in early 2012 to develop a more practical solution.

“They were interested in printing the product information on the film instead of the tray,” recalls Nettles, relating that he suggested a switch to the high-performance shrinkwrap film manufactured by prominent flexible packaging products supplier Clysar, LLC of Clinton, Iowa.

“However, the company’s existing horizontal shrinkwrapper proved to be ineffective in applying the required product information onto this film,” says Nettles.

While Sevin dust was already retailing in a convenient three-pack option for some time—featuring three containers set inside a shrinkwrapped corrugated tray—this option only proved effective as long as it stayed indoors.

When placed outside, the shrinkwrapping film was not able to stop water from reaching the corrugated tray—causing it to deteriorate, lose its structural integrity, and degrade the product’s overall appearance.

Moreover, in order to comply with federal regulations on insecticides requiring that consumer must be able to easily read all the about product content, usage and contamination risks, the obstruction caused by the mere presence of the corrugated tray made this information difficult to read on individual containers—making it necessary to print it on the bottom of the tray itself.

The company’s prior horizontal wrapper required that the containers be manually laid down on their sides on a conveyor, after filling, and the carrier tray be manually put into position to hold the containers together, horizontally, during infeed.

With the vertical wrapper, however, the Sevin product containers go directly from the filler to the shrink infeed standing upright, where they are manually rotated into the proper position for input into the wrapper.

“The seal is not interfering with readability at all,” says Central Garden & Pet’s senior brand manager Daphne Huey.

“It is located so that the words and images fit around it, so we do not have to worry about the shrink drawing together at a certain point and making the information, graphics or UPC unreadable.

“Using horizontal wrappers always bring seal and other aesthetic issues to vertical product packaging, which is why we recommended they switch over to a vertical shrinkwrapping system.”

Specifically, Associated Packaging recommended the use of the model 914 OVS (Orbital Vertical System) —manufactured by the Washington, Mo.-based packaging machine-builder Texwrap Packaging Systems —which does not require a carrier tray to hold product in place while wrapping and, more importantly, can use pre-printed film to wrap the multipack.

“The wrapper trims the film underneath the package, where it is hidden from view,” Nettles explains. “This offers many more packaging opportunities for the Sevin product, without compromising product presentation.

“The wrapper has a mechanism that cuts and trims away the film in one action to create a fullbottom trim-seal to enclose the product, instead of the traditional lap-seal with horizontal shrinkwrappers,” Nettles points out, “which makes for a very secure and attractive package.”

The sealing is done with a servo orbital-motion head, which eliminates the need for the head to move with the product while the seal is made.

The head moves in an ellipse, without the backand-forth motion of typical sealing heads, which reduces vibration, improves registration, and increases the throughput speed of the wrapper.

Another critical advantage is the ease of handling for infeed into the wrapper, according to Nettles.

“We still have the UPC on the original containers, but we have them covered up by graphics on the shrinkwrap so that the barcodes on the containers do not read through,” she says.

“This is just a much more consumerfriendly package because we have the entire shrink printed, front to back, to create a very attractive package.”

Although the vertical shrink line has a throughput capacity of 120 multipacks per minute, the line speed is set by the speed of filling, which is currently operating at 25 multipacks per minute. For safety reasons, the filling area is kept in a separate room, and 50 feet from the shrink wrapping system, because of excessive dust.

From the shrinkwrapper, the containers are put through a dual-chamber shrink tunnel to provide a highly-controlled shrink—critical for achieving the precise placement of copy, graphics and UPC on the multipack—and moved on to cartoning and shipping.

In a addition to creating the weather-resistant multipacks, the installation of the Texwrap vertical wrapping line has brought into play several other key efficiency improvements.

“With the elimination of the corrugated tray, the company has realized a 45-percent reduction in packaging material costs,” says Nettles, “while end-of-line packaging labor hours have also been reduced by 35 per cent.

“And with the corrugated now gone, so is the space that it occupied, one-half inch on each side, which amounts to 15 per cent more Sevin dust multipacks being loaded onto a pallet.”

Huey concurs: “Not only has the cut-down on the expense of our multipack shrink wrapping for the Sevin dust line been very significant, it has also significantly expanded our merchandising options.”

Jim McMahon is a U.S.-based freelancer specializing in packaging automation.

Leading Canadian perogies manufacturer leverages product authenticity and technological competence to remain on its fast-growth trajectory

ANDREW JOSEPH, FEATURES EDITOR PHOTOS BY JASON FRANSON

Stuffing a dough with various delicious ing redients before cooking seems to be a global phenomenon: from Chinese dumplings, gyoza in Japan, ghoogra in India, to ravioli in Italy and maultaschen in Germany, to name just a few examples.

But despite our familiarity with such foods that have long cultural heritages, in North America, at least, such tasty food fare is still in its relative infancy, becoming exposed to the general nonethnic population only about 40 years ago in the form of the eastern European style perogy.

Essentially a semi circular dumpling that is first boiled and then either fried in butter and onions or baked, this staple of eastern European cuisine is traditionally stuffed with potato filling, sauerkraut, ground meat, cheese and spices or, in the case of dessert perogies, filled with fruit.

Whatever the stuffing, one Canadian manufacturer can perhaps be considered a true culinary pioneer in bringing perogies to the general population of the country, even though it is about 200 kilometers away from the world’s largest perogy— a nearly 25 foot high statue and roadside attraction in the village of Glendon, Alta.

Founded in 1972 by Walter Makowecki, Heritage Frozen Foods Ltd. is headquartered in Edmonton in a stateoftheart 80,000 squarefoot facility with 85 to 100 employees capable of creating some three million perogies a day, perhaps proving that size in sales matters more than the size of a tourist attraction.

Better k nown to consumers via its CHEEMO brand name, the perogies manufactured by Heritage Frozen Foods are all pre cooked and flashf rozen to lock in the flavor for each of the brand’s 12 different flavor varieties.

Walter Makowecki’s parents emigrated from the Ukraine to Canada, and thanks to his cultural heritage, perogies were a staple on the dinner table, usually made by hand by his mother.

“When my father was looking for a business venture back in the early 1970s, he noticed that women were beginning to enter the workforce in greater numbers, which he surmised to also mean there was now less time for meal preparation,” current Heritage Frozen Foods president and chief executive officer Joe Makowecki told the Canadian Packaging magazine in a recent interview.

“My father saw this as an opportunity to provide perogies as a quick and convenient value priced

meal option for busy families,” recalls Makowecki.

The problem that Walter Makowecki and his family had, however, was how to introduce the noni mmigrant families to perogies.

“In the early years of the business, the whole Makowecki family would load up the family car and drive to numerous fairs and rodeos throughout the Canadian prairies, providing taste samples and selling the perogies in places where prior to their arrival had never seen or even heard of perogies, let alone tasted one,” Makowecki relates.

“But my father knew that all he had to do was to

get people to taste it—one taste and the company had a new customer.”

Right from the beginning, Walter Makowecki had branded his perogies as CHEEMO, an Inuit greeting that means ‘We are friendly.’ As well, the term ‘cheemo’ was still being used as an exclusive Canadian greeting, helping to celebrate the 100 th birthday of the nation in 1967.

As Makowecki explains, when his father chose CHEEMO as a brand name, he believed he would ‘Canadianize’ the perogy, and one would be hardpressed to say he didn’t.

The company’s first major retail sale was to a Woodward’s store in Edmonton, where over a one week period the retailer sold almost an entire trailer load of perogies.

“Needless to say, other grocery retailers took notice of the consumer’s huge interest in CHEEMO perogies,” relates Makowecki, “and soon enough our perogies were available throughout the city of Edmonton.”

Nowadays, CHEEMO brand products can be found in most grocery stores and food departments of major national retailers right across Canada, though the company also manufactures perogies for both the foodservice and privatelabel markets, such as copacking the Compliments brand on behalf of Sobeys

Heritage Frozen Foods boasts some 108 SKUs (stockkeeping units), featuring its top selling CHEEMO Potato & Cheddar Cheese available in 907 g ram packs and the two k ilogram family sizes. And, along with the standard size perogy, Heritage Frozen Foods also offers a 907 g ram pack of Bite Size featuring the Number One selling perogy flavor.

Other perogy recipes produced by Heritage Frozen Foods include: Potato, Bacon & Romano Cheese ; Potato & Cottage Cheese ; Potato & Onion; Three Cheese - White Cheddar, Mozzarella & Swiss; Potato, Spinach & Feta Cheese ; Potato, Sour Cream & Chives; Country Mushroom; and Ukrainian Style Roasted Garlic

“All of those brands contain zero transfats, are low in cholesterol, and taste just like homemade,” says Makowecki, quickly adding: “My family’s home m ade.”

Under the CHEEMO brand the company also offers its Heritage Perogies featuring: Harvest Potatoes with Aged White Cheddar Cheese ; and Harvest Potatoes with Farm Style Cream Cheese and Savoury Dill

Thanks to the efforts of Walter Makowecki

and Heritage Frozen Foods, the humble eastern European perogies are now part of the Canadian dinner table, with CHEEMO perogies having been selected by readers of Canadian Family magazine as their Number One choice of frozen food entrées for an impressive four years in a row.

The process for making perogies is essentially the same as it has always been—mixing wheat flour to make dough, mixing raw materials and ingredients, extruding dough and ingredients into form.

However, Makowecki says it’s the care his company takes in only using the best and freshest ingredients that is the real key to the company’s continued success amongst the consumers.

Given the company’s moniker, it is not one to forget its own cultural heritage, but according to Makowecki, the company’s Canadian roots are also part of that cultural landscape, as evidenced by Heritage Frozen Foods support for Canadian farmers.

Says Makowecki: “We are quite proud that CHEEMO perogies are made using natural ingredients such as fresh potatoes, quality cheeses, tangy onions and other garden vegetables—all from Canada.

“Our family truly appreciates the work of the farmers and our suppliers that goes into supplying us with the high quality ingredients we need to make our perogies.

“You can’t have a great tasting product without greatt asting ingredients,” Makowecki proclaims.

Heritage Frozen Foods has also taken to proudly waving the maple leaf in its packaging operation with multiple machines purchased from Harlund Industries Ltd., a 100 percent Canadian owned company specializing in the supply of coding and identification systems.

Incorporated in Edmonton in 1983 by Mert Eklund and current company president Bruce Hartfelder, Harlund Industries with its amalgamated moniker is wellk nown for bringing some of the very first CIJ (continuous inkjet) printers into Canada.

Operating sales and service facilities in Toronto, Montreal, Vancouver and head office in Edmonton, Harlund Industries supplies a complete line of packaging technology including coders, printandapply labeling systems, and caseerectors from a host of strategic partners, including FoxJet, WEXXAR/ Bel, Hitachi, ID Technology, Little David, EASYPRINT A/S and MicroScan

“We’ve actually been involved with Harlund Industries for over 20 years,” explains Heritage Frozen Foods operations manager Casey Marchand, who is directly involved in capital expenditures. “Their knowledge and expertise in their field has provided good counsel for our packaging and case coding solutions.

“We find them to be a good Canadian company focused on helping Canadian manufacturers.”

Over the years, Harlund Industries has sold equipment to Heritage Frozen Foods including:

• Three LS6000 print a nd apply case labeling sys

tems manufactured by FoxJet , acquired in 2011;

• Four Wexxar WF-20T caseerectors, the last one purchased in 2013;

• Four PXR-D260w continuous ink jet printers providing two lines of code with 65 m icron nozPX-D260u inkjet printer—all manu

According to Marchand, PXR- D260w coders remain part of the company’s daily produc

“The service that we have received and continue to receive from Harlund Industries is excellent,” hand. “They keep a good assortment of spare parts on the shelf and are always quick to service

Heritage Frozen Foods runs its production line fiveoursper

day nonstop, and as such relies quite heavily on the equipment supplied to them via Harlund.

“We code in excess of 100,000 packages per day and case erect in excess of 10,000 cases per day,” points out Marchand. “The equipment we purchased from Harlund Industries has, quite frankly, exceeded our expectations.”

The Hitachi PXR series of inkjet printers can provide standard, small and large character type, and is described as user f riendly, with an easytooperate TFT (thinf ilm transistor) liquid crystal touch screen display with full on screen guidance.

The PXR-D260w Hitachi printers utilize an ecological ink system that minimizes vapor emissions and offers a wide range of adjustment possibilities to ensure that no matter the job, highquality print is always achieved.

The unique ink circulation system of the Hitachi industrial PXR series continuous inkjet printers also reduces typical fluid usage by 50 per cent, contributing to lower solvent emissions.

According to Harlund’s Hartfelder, “The unique ink return system on these machines helps to reduce solvent evaporation, which minimizes the mixing of air and ink. Combined with the viscosity and density

control to reduce solvent consumption, there’s still the highquality printing capabilities it provides.”

Besides minimizing the fluid wastes, these continuous inkjet printers offer higher component reliability and MTBFR (mean time between failure rates), which essential means owners will realize a better ROI (return on investment).

“The print quality we have been able to get from our PXD260w Hitachi printers has been wonderful,” says Marchand. “It’s a high quality print output that helps our packaged products maintain the high quality of the perogies inside them.”

Another set of equipment purchased from Harlund Industries are the complete FoxJet label systems.

“Because we run 24 hours a d ay, fivedays aweek, we don’t need bottlenecks resulting from one part of the production line running less efficiently than another, and we certainly don’t want equipment breaking down,” says Marchand. “But the three LS6000 FoxJet print a nd apply caselabelers are not only robust, but are also very fast.”

According to FoxJet, an ITW Company, the LS6000 are capable of running at speeds up to 110 units per minute.

“At Heritage Frozen Foods, we use the LS6000 to print labels and apply them with a corner w rap applications,” explains Marchand, noting that a pivoting pad on the system allows it to conform and apply to irregular surfaces as well.

According to Harlund, the industrial LS6000 systems are allelectric units with no

pneumatic adjustments, and feature a rugged design constructed with high quality, longlife components.

“We’re quite happy with the FoxJet print a ndapply label systems,” relates Marchand. “Even with the corner wrap application, there is no label corner sticking up. It’s just a nice, tight label on a corrugated case that we are sure will be there when it reaches its next destination.”

For the operator, the LS6000 features a rotating three color LCD (liquid crystal display) touchscreen interface, that Marchand says is not only easy to use, but is also easy to learn.

“We’ve also had excellent response from the four Wexxar case erectors purchased from Harlund Industries.

The Wexxar WF-20T is a fully automatic case

• Increase the flexibility of your robots by adding the ability to use more than one end-effector in an application.

• Production line tooling changed in seconds for maximum flexibility.

• Change tools in seconds for maintenance and repair.

• Increase operator safety by changing tools automatically.

• Million-cycle tested for reliability.

that changeover can be achieved in less than five minutes.

The WF-20T can erect and construct cases at a rate of 20 units per minute, ranging in size from: seven to 22 i nches in length; six to 17i nches in width; and six to 34 i nches in height.

The WF-20T are built fullyguarded from infeed to outfeed, with interlocked safety guarding throughout the machine, with easy to reach emergency palm switches located on both sides of the machine.

Other equipment utilized by Heritage Frozen Foods includes:

• An RS-214W-S/30-PB Ishida multihead scale and dispersal system manufactured by Heat and Control placed atop an XM15PR vertical form/fill/seal bagger from Triangle Package Machinery;

• A Vegatronic 2000/400P ILAPAK flexible film bagger;

BluePrint Automation case packer; floor level palletizer manufactured by adhesive tape case sealers from 3M

onveyors powered by AC motors manufacBaldor Electric Company ; machine vision systems placed near label printer applicators to ensure the labels are placed perfectly on the car

The Heritage Frozen Foods facility is BRC British Retail Consortium) audited for rade certification, a fact that keeps the company on its toes looking for ways to continually

A few years ago, the company purchased sevheeled, electrical personal

• Comparative category machine performance listings.

• OEM addresses, contact information.

• Distributor, agent coordinates.

• Automation control/motor listings.

• Integrator service listings and contacts.

• Feature articles on some of Canada’s top rated performance packaging lines.

i f you sell packaging machinery in canada, you should run your besT adverTising message in The January/ february packaging machinery s pecificaTions manual.

With all due respect to fashion beauty icon Kate Moss, who famously observed that “nothing tastes as good as skinny feels,” it is possible to enjoy a little of both when you put the right packaging to good use—like Texas-based Ana’s Foods is doing with its popular Ana’s Salsa range of fresh-made salsas.

Manufactured and copacked under the Ana’s Salsa brand name at the Fresh from Texas processing plant in San Antonio and by the Round Rock-based co-packer TexFrance, the company’s innovative salsa recipes have enjoyed widespread popularity among many local Tex-Mex food lovers since the company’s beginnings in 1997, when its husband-and-wife ownership team of Jim Ullrich and Anna Olvera-Ullrich started selling jars of home-made salsa to their neighbors, friends and co-workers.

for a diverse range of customers in the retail, bulk packaging, and material handling industries.

Widely respected in industry circles for continuous innovation, IPL suggested changing the packaging of the Ana’s Restaurant Style Salsa brand to the novel new SkinnyPack brand of new poly-

“Food companies looking for something innovative can really find the sweet spot with the SkinnyPack packaging,” Sergerie enthuses. “Specific market segments such as salsa, dips, deli and snacks are especially well-suited—given the price-points and the lack of commoditized packaging.”

propylene (PP) containers that use significantly less plastic materials in their construction.

Made from a unique blend of cilantro and serrano peppers—rather than the widely-used jalapeños— the fresh-tasting salsa picante has quickly built up a loyal cult following among local foodies drawn to the fact that this authentic Mexican salsa was made the traditional way: blended but never cooked.

Packed immediately after blending to retain maximum product freshness and taste, the tangy salsa uses just a miniscule amount of preservatives—namely sodium benzoate and potassium sorbate— to achieve a 90-day shelf-life.

“The primary appeal of our salsas is the fact they are fresh, refrigerated products that have never been cooked, meaning they taste like they were just made,” says Jim Ullrich, the company’s chief operating officer.

“People who are more used to consuming the jarred, shelf-stable salsas out in the marketplace can immediately appreciate how much better our salsas taste,” Ullrich recently told Canadian Packaging

“None of our products are bland: They all have great flavors and at least a little spiciness to them.”

As the multiple award-winning Ana’s Salsa brand continues to gain market share, the company recently decided to update its retail packaging from the somewhat outdated round, clear-plastic deli-style tubs decorated with only stick-on labels.

“They didn’t look very good and they leaked a little,” relates Ullrich, whose search for a more effective packaging option led him to hook up with Canadian-based rigid-plastic packaging specialists IPL, Inc.

Headquartered in Saint-Damien, Que., IPL is one of North America’s elite manufacturers of injection-molded plastic products and solutions

According to IPL’s product manager Joel Sergerie, SkinnyPack was originally developed in Europe about four years ago by Internova Pack , but the new design remained largely in its concept stage until IPL joined in on the effort.

“They had the right idea but could not master the manufacturing, so over the last four years IPL has partnered with Internova Pack to bring SkinnyPack from a concept to a container technology that can be commercially produced and mastered,” Sergerie relates.

“We introduced Ana’s Foods to the new packaging in June of 2014, and they immediately liked the uniqueness of the container, as well as all the sustainability advantages that using SkinnyPack represents,” he recalls. “At first they were looking for a new 12-ounce container, but seeing the opportunity offered by this technology, they also decided to switch their 16-ounce containers to SkinnyPack.”

In addition to being fully compatible with the high-impact IML (in-mold labeling) process to enable greater shelf appeal by grabbing consumers attention, the lighter weight and stackability of the SkinnyPack containers also facilitates cost reductions in shipping and stocking.

Ullrich agrees: “We had to find something different and the SkinnyPack is the best food packaging idea to come out in a long time.”

Having already launched the Restaurant Style Salsa recipe in 12-ounce SkinnyPack containers in October, Ana’s Foods is looking forward to converting its Original Salsas to the 16-ounce tubs by the end of the year, according to Ullrich.

“We are moving our whole line to the SkinnyPacks because of their visual appeal and customer impact on the shelves,” Ullrich states. “They stand out because they look different than any other container and they literally make customers want to pick up the product and look at it.

“That is half the battle of getting a consumer to buy our salsa,” says Ullrich, while also noting the significant environmental benefits this packaging makeover is expected to yield.

“The 12-ounce SkinnyPack tubs for our Restaurant Style salsa uses 5.7 per cent less plastic than the deli tubs, while the 16-ounce SkinnyPack tubs for our Original salsa uses 54.8 per cent less plastic,” Ullrich points out. “So once our whole line of salsas has moved to the SkinnyPacks, Ana’s Foods will be using 60.5 per cent less plastic.

“The left panel of the tubs highlights this fact by stating ‘Tub made with less plastic for a greener world,’ and we definitely expect that our sales will increase when the SkinnyPacks hit our major outlets.”

Sergerie concurs: “The SkinnyPack is the first container on the market that combines the advantages of rigid packaging, such as strength and resistance to impact, to the flexibility of film.

“We believe that the market is at a stage where new technologies and innovations are becoming increasingly high in demand, and given that this is a new technology, we are working hard on making SkinnyPack not only a commercial success, but above all a technology and innovation reference in the packaging world.”

“Not only is there less plastic used in the production process, but being a mono-material construction also makes it 100-percent recyclable and ‘crushable’ in order to take less space during the recycling process,” he points out.

ANDREW JOSEPH, FEATURES EDITOR PHOTOS BY COLE GARSIDE

For the 30 visitors to the 28,000-square-foot Multivac Canada Inc. facility in Brampton, Ont., about a 30-minute drive northwest of Toronto, it was an opportunity to grow their knowledge of packaging equipment. For many of them, this became their first exposure to such high-tech machinery, made possible by Multivac played host to members of the Ontario Independent Meat Processors (OIMP) association in late October, providing a timely opportunity to discuss packaging technology and innovation.

Headquartered in Guelph, the not-for-profit OIMP is the representative voice of the independent meat and poultry processor in Ontario, working closely with agricultural and commodity organizations and various levels of government for over 30 years.

With over 300 members, the OIMP’s vision is to provide leadership for Ontario’s meat and poultry industry, by fostering innovation, promoting food safety and integrity and recognizing excellence.

“Our objective is to ensure the continued growth of the meat industry through communications, education, training, promotion and government

support,” OIMP technical director Daphne NuysHall told Canadian Packaging during the Meat Innovation Academy event hosted and presented by Multivac.

“The Meat Innovation Academy is part of that education aspect we provide.”

Multivac Canada, whose parent company is headquartered in Wolfertschwenden, Germany, is the Canadian arm of a privately-held global group of companies with 65 locations worldwide that sells, services and supports a wide range of vacuum-packing technol ogy, and other machin ery, including: rollstock machines for automatic packaging from rolls of thermoformable plastic materials; tray-sealers for use with pre-made trays; and chamber machines for packaging in pre formed pouches.

“It was back in 2006 when Multivac recog nized that the Canadian

market would be best served by a dedicated company,” said Multivac Canada president Nestor Plawiuk. “Multivac Canada opened its doors in February of 2007 in a 7,000-square-foot facility in Woodbridge just north of Toronto, with seven customer care, sales and administration employees.

“Since then, we have grown and moved into

and now employ 50 staff deployed across Canada focusing on the current and emerging packaging machinery, systems and packaging materials needs of our Canadian customers,” he noted, adding that there are plans to open additional service centers in Quebec and in western Canada in the near future.

The Brampton facility is the head office for all Multivac sales, service, distribution and manufacturing activities for Canada, but also boasts an impressive 5,000-square-foot Packaging Technology Centre—the live demonstration room for its impressive line of packaging machines.

According to Plawiuk, the purposes and uses of the Packaging Technology Centre are multifold:

• a f acility where customers and partners can develop and evaluate new packaging concepts, applications and materials on state-of-the-art equipment;

• a training center for Multivac’s customers and partners;

• a center for learning where Multivac can facilitate and present seminars and learning events for customers, industry associations and more;

• a f acility where Multivac can demonstrate and showcase the various packaging machines and platforms and technologies it produces.

After Multivac had opened the Brampton facility in 2013, Plawiuk contacted the OIMP offering the association the use of its Packaging Technology Centre for training and workshops for its members.

“Last year we met with the OIMP to discuss ways in which our organizations might collaborate,” explained Plawiuk. “We made our Technology Centre available to all OIMP members for machine testing, training and learning seminars.

“The Meat Academy evolved from those discussions.”

According to Nuys-Hall, the focus of the event was to introduce new and innovative packaging concepts to the small- to medium-sized poultry and meat processors.

“The Multivac showroom has a wide range of packaging equipment, which afforded the attending OIMP members the opportunity to see the equipment and packaging in action,” explained Nuys-Hall.

The focus of the Meat Innovation Academy was to allow the processors to envision for themselves how the different packaging technologies could enhance their current packaging

“Our members were afforded the opportunity of being able to see where they are today, and envision where they want to be tomorrow.”

For equipment manufacturers like Multivac, they are only all too aware that for companies or people not exposed to excessive automation in their meat farming processes, taking that next step can be quite daunting.

“We know that for anyone, whether experienced or new to the game, any capital purchase is difficult,” Plawiuk said.

“A capital expenditure can’t be an emotional choice: It has to be based on facts,” he said. “At events like this open house with the OIMP, we try to help with that to allay any fears or concerns, to let them trust that expanding one’s automation base need not be a scary proposition.”

Multivac personnel involved in the presentations to the OIMP included: director of sales Wayne Bryant; key account sales manager Paul Marsden; regional sales managers Chris Salmon and Nick Tate; marketing and packaging innovation specialist Sonia Tarantini; and Henley Parsons, who served double-duty as Multivac expert and event cook, cooking steaks and roasts for everyone’s lunch.

The frank discussion and working demonstration of Multivac’s machinery began with its entry-level Tray Sealer T 200, a simple yet versatile machine with a small footprint and price tag that still offers efficient tray packaging.

The semi-automatic tray-sealer, however, still provides the same function as other tray-sealers from Multivac, with the key difference being speed and size of package offered.

After meat is placed into a tray, the atmosphere is withdrawn from the tray, it is then gas-flushed with a modified atmosphere gas mixture via an electronic limiter that controls the amount of gas released, before a film is sealed on top of the package.

In keeping with its inexpensive set-up, the T 200 also runs on the industry standard #3 plastic tray, and yet Multivac was adamant that the machine was not going to short-change anyone in performance. To illustrate the point, a Multivac employee stood on top of a sealed—and empty tray—proving to the visiting OIMP members it wouldn’t crush.

“It runs at a rate of three cycles per minute with gas-flushing—faster if you opt to not gas-flush,” said Multivac Canada marketing and packaging innovation specialist Sonia Tarantini, adding that the T 200 can also perform skin-form packaging.

As part of its overall packaging education,

Multivac informed the enthralled crowd how the colors of the meat products are maintained with better packaging, and how the type of gas used will affect the product color, along with the decay rate.

“Without gas-flushing in packaging, a processor will just get the same sort of safety rate as an overwrapped package,” explained Bryant. “But with gas-flushing, a processor can get several weeks of shelf-life. This is an important factor retailers will consider, as it provides a greater opportunity for a product to be purchased before eventual spoilage and other safety concerns become a reality.”

Next up, the tour took in the powerful T 800 machine, a powerful, high-performance tray-sealer designed for high-volume industrial production.

“The T 800 works in a manner quite similar to the entry-level T 200,” said Bryant, “except the T 800 can process five trays at once up to 96 trays per minute.”

Featuring a hygienic design with full wash-down capability inside and out, the T 800 ’s conveyor belts can be removed for better accessibility.

Other key operational features include:

• Stainless-steel construction;

• Quick-change tooling;

• User-friendly IPC control system that stores up to 200 programs in 40 different languages;

• Film trim rewinder;

• PIN-protected control panel.

The T 800 also has an infeed conveyor belt and automatic tray denester, as well as an automatic shut-down in the event it is opened while in use.

Multivac also demonstrated a pair of chamber machines—the “backpack” and the C 550 double chamber.

Product that can be placed within a plastic film pouch are hermetically sealed with a seam—single seam, double seam or top/bottom single seam seal—by the equipment’s high-quality anodized aluminum seal bars.

According to Bryant, the chamber machines can provide double duty, performing gas-flushing and vacuum-packing.

“The backpack, despite its diminutive size, per-

of-use, and of course, the ability to pack product quickly and effectively.

With speeds of up to 23 cycles per minute, the unroller pulls and forms pockets or trays, allowing the product to be handplaced inside before a second film is placed over for heat sealing.

“While processors can use regular plastic film or a biodegradable version, one can also opt to use a cook ing film—a mylar-based plastic—so that after label ing is removed, the entire pack can be cooked with out it having to be opened; a boon to the consumer,” said Bryant, noting that the event’s lunch was all

place), and can be configured to meet specific processor requirements; not to mention it is suitable

for modular expansion and integration into automated packaging lines.

The last machine demonstrated on the tour was the Thermoformer R 175 CD, a small, compact machine with all the standard Multivac hygienic features but designed for lower- to medium-range vacuum skin packaging (VSP) applications.

For freezing—and this is perhaps something the consumer should be aware of—a small an aperture of space between the product and the film is ideal to avoid ice crystal build-up, with the innovative VSP option the best choice.

While originally setup to create the Darfresh skin-packs with Cryovac, Multivac has decided to go it alone, now offering its as MultiFresh brand of film.

The MultiFresh VSP process uses special films that gently surround the product and seal over the entire surface of the pack like a second skin,

preserving shape, texture and product integrity for a premium retail presentation allowing greater retail shelf visibility for high-quality food products like prime cuts of meat, pastries, fish fillets, seafood, poultry, and cheese.

It was an impressive showing, according to OIMP member and Apolstolos Poultry owner Steven Apostolos. As owner of 50 acres in Niagara Falls who sells 150,000 chickens a year to a major Canadian chicken processor, he was curious to see if that was something he could do himself.

“My family farm has been at the farm level of the chicken industry for 50 years as of 2015 and I want to see if it is viable for me to do further processing myself,” related Apolstolos. “I want to do a horizontal move from farm to plate.

“I have expanded my knowledge tremendously on the whole business of meats processing since I joined the OIMP, and with today’s events, the

Multivac equipment has further opened my eyes to the possibilities for both my farm and myself.”

For the OIMP, the day’s visit to Multivac was a resounding success, a sentiment enthusiastically endorsed by Multivac Canada.

“Our facility is unique,” summed up Plawiuk. “No other facility in Canada offers the size or breadth of capabilities.

“We hope we can build on that and together find ways the Packaging Technology Centre can be utilized for the benefit of all OIMP members and anyone else looking to take that next step forward in process automation.”

Full-service contract packager helps brand-name manufacturers get their products to market faster by letting them focus solely on what they do best

ANDREW JOSEPH, FEATURES EDITOR PHOTOS BY COLE GARSIDE

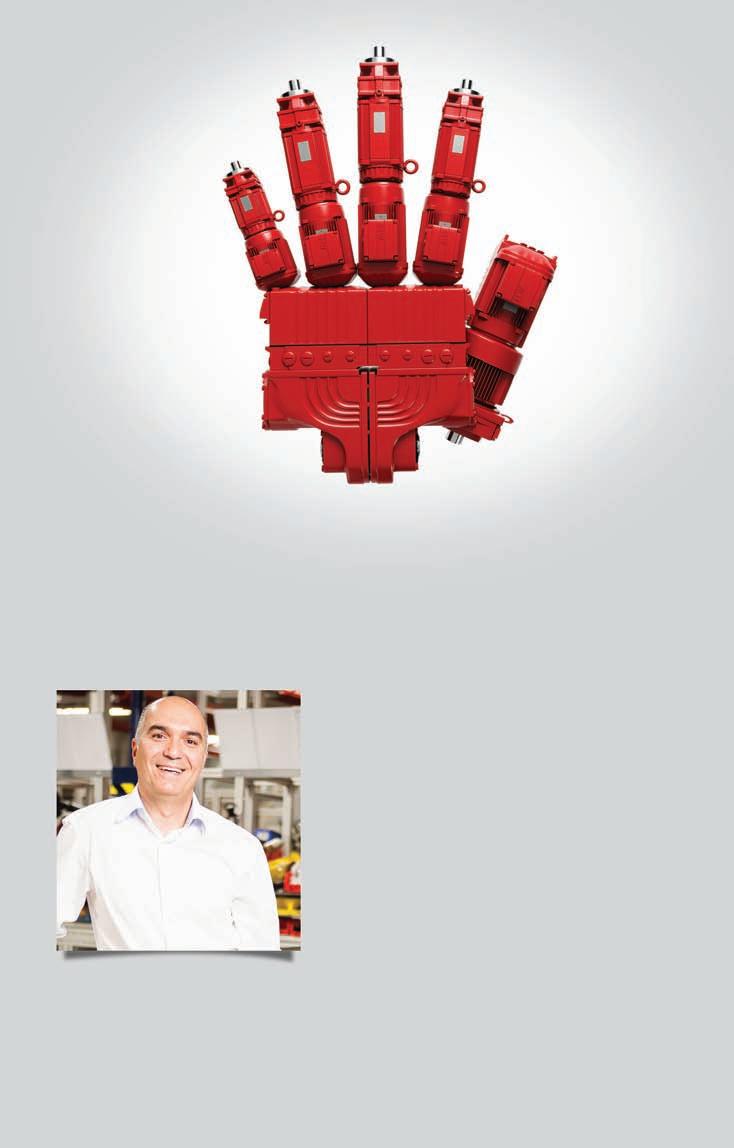

Sometimes in the world of packaging you just need a hand in getting the job done, which is how one Oakville, Ont.-based company has been successful in filling a niche segment of the packaging industry.

Known as a contract packager, Wright Hand Packaging Inc. has made its mark in the packaging industry for the past 25 years providing a high level of service to companies that simply do not have the sufficient time, space, equipment or even the labor force to complete their own production needs in order to get their product ready for the retail shelf.

Essentially, such companies provide Wright Hand Packaging with products or materials that need to be shelf-ready, having the co-packer look after assembly of the product packaging as an extension of the customer’s manufacturing process.

Wright Hand Packaging founder, owner and president Lynn Wright told Canadian Packaging magazine, who recently visited the 14,000-square-foot facility, that “the company is named after my surname and I wanted to create a play-on-words with it.

“When we first started up the business in 1989, we did not provide any services that included automation—hence the ‘hand’ packaging.”

According to Wright, in the 1980s she was working in purchasing at Alberto Culver, an American corporation with international sales manufacturing hair and skin beauty care products under such well-known brands as Alberto VO5, St. Ives, TRESemmé and Nexxus, with the company looking for a contract packaging company to take on some of its packaging overflow.

“There weren’t that many companies out there that offered these types of services, so I decided that this seemed like the type of opportunity I couldn’t pass up,” says Wright.

The company started with just herself and three other staff in a small 3,000-square-foot building— but six months later, the company had tripled in size, tripling again a few years later in 2004. Nowadays, Wright Hand Packaging employs anywhere from 20 to 50 staff, depending on production requirements.

“It was after our second expansion, that I realized that Wright Hand Packaging was on its way to becoming a recognized contract packager within the Toronto area.”

Wright describes her company to be a mediumsized contract packager, usually running on a oneto two-shift schedule, but with the capabilities to add a third shift if tight deadlines demand it.