PACKAGE CONVERTING NOW

DIGITAL SUPPLEMENT FOR THE AUDIENCE OF CANADIAN PACKAGING

X-RITE AND FLINT GROUP ANNOUNCE GLOBAL PARTNERSHIP

Partnership will benefit Flint Group’s customer base of printers around the world

With an increasing demand for color equity across ever wider geographies and packaging substrates, it is essential that every provider—from brand owner specifier, to print and packaging supplier—contribute to establish a consistent and robust color communication workflow.

Flint Group’s Paper & Board business has entered into an exciting new partnership with X-Rite Incorporated, a global leader in color science and technology, to deliver a color solution that leverages the X-Rite eXact and NetProfiler to reliably meet the color management needs of each stakeholder in the package print value and supply chain.

VIVO Colour Solutions is a dynamic color communication and service platform supported by Flint Group’s centralized color service provider, the Global Colour Centre (GCC). VIVO ColourCloud utilities the eXact device to provide a central webbased self-service digital color repository, containing thousands of approved and tested colors. Customers benefit from the ability to easily search and download CxF files, DigiSwatches, and ink recipes.

Ray Cheydleur, printing and imaging product portfolio manager for X-Rite, comments, “This partnership will benefit Flint Group’s customer base of printers around the world. Utilizing X-Rite’s NetProfiler software for verifying device performance,

along with the award-winning eXact handheld spectrophotometer, will provide ultimate agreement of measured colors amongst Flint Group and their printing and

converter clientele. When paired with VIVO Colour Solutions, this technology will provide the basis for converter confidence in their ink supply, and a competitive advantage to deliver consistent color packaging.”

Stuart Duffy, Flint Group director, Professional Services Paper & Board says, “We are excited to have reached agreement on this unique partnership with X-Rite, the leader in color measurement equipment.”

Duffy continues: “Following rigorous beta testing at a number of corrugated sites, our initial expectations have been surpassed.The sites conducted hundreds of searches from VIVO ColourCloud with every download achieving 100% ‘Right First Time.’ This level of performance can only be delivered through a consistent and managed digital workflow along with the support of X-Rite’s eXact spectrophotometer. This results in an effective end-to-end color management process that fits the needs of prepress, printing, and packaging companies of all sizes while reducing variability and improving efficiencies. I have no doubt VIVO Colour Solutions, in combination with X-Rite equipment, can become an industry benchmark.”

Stay tuned for the planned releases of Flint Group’s new VIVO Colour Solutions modules as the company establishes a NEW NORMAL in digital color management.

Visit the Flint Group website, Flint Group’s YouTube channel, or social media channels to see a short video related to VIVO Colour Solutions.

For more information, please contact Deanna Klemesrud via e-mail at Deanna.klemesrud@ flintgrp.com.

ABOUT X-RITE

Founded in 1958, X-Rite Incorporated is a global leader in the science and tech-

nology of color and appearance. With Pantone, X-Rite employs more than 800 people in 11 countries. The company’s corporate headquarters are located in Grand Rapids, Mich., with regional headquarters in Europe and Asia and service centers across Europe, the Middle East, Asia, and the Americas. X-Rite offers a full range of solutions used by manufacturers, retailers, printers, photographers and graphic design houses to achieve precise management and communication of color and appearance throughout their processes. X-Rite products and services are recognized standards in the printing, packaging, photography, graphic design, video, automotive, paints, plastics, textiles and medical industries. For further information, visit www.xrite.com.

ABOUT FLINT GROUP

Flint Group is dedicated to serving the global printing and packaging industry. The company develops, manufactures and markets an extensive portfolio of printing consumables, including: a vast range of conventional and energy curable inks and coatings for most offset, flexographic and gravure applications; pressroom chemicals, printing blankets and sleeves for offset printing; photopolymer printing plates and sleeves, plate-making equipment and flexographic sleeve systems; pigments and additives for use in inks and other colorant applications. With a strong customer focus, unmatched service and support, and superior products, Flint Group strives to provide exceptional value, consistent quality and continuous innovation to customers around the world. Headquartered in Luxembourg, Flint Group employs some 7,900 people. Revenues for 2016 were €2.3 billion (~CDN $3.6. billion). On a worldwide basis, the company is the number one or number two supplier in every major market segment it serves. For more information, visit www.flintgrp.com.

LANDAAL PACKAGING SYSTEMS ADDS DESIGN CAPACITY THANKS TO ESKO

Using the Esko WebCenter QuickStart for Corrugated,

Landaal not only adds design capacity, but gains

efficiency and serves customers more proactively

GHENT, Belgium—It does not have to take long to implement a system that manages packaging specification, approval and project life cycle. After installing Esko’s WebCenter QuickStart for Corrugated in just five days, Landaal Packaging Systems added designer capacity, could track projects, manage process efficiencies, and reduce errors. A third-generation family-owned and family-operated packaging company headquartered in Flint with two other facilities in Michigan, U.S., Laandal Packaging Systems has been a leading packaging manufacturer since 1959. The company specializes in corrugated shipping boxes, POP (point-of-purchase) displays and protective packaging, pro-

viding personalized innovative packaging and shipping strategies.

Product diversification with four core product offerings (corrugated, contract packaging, sustainable packaging, and POP) is critical to Landaal’s success, taking them away from being a commodity business.

“We also separate ourselves from the marketplace by pitching our strengths as a smaller, nimbler and family-owned business with the expertise to deliver an innovative supply chain, offering logistics from shipping to warehouse and distribution; we are not only manufacturing packaging but also co-packing or assisting a packaging department,” explains Mark Landaal, vice-president of Landaal’s In-Store Division.

(From left): Terry Choate, Marketing Manager; Matt Krupka, Packaging and POP Specialist, and; Mark Landaal, vice-president of Landaal’s In-Store Division.

A STREAMLINED WORKFLOW WITH FULL TRANSPARENCY BETWEEN DEPARTMENTS

Originally, Landaal’s prepress was typically driven manually and fragmented between digital, direct to print, and traditional printing—flexo, offset, and litho.

“We had different people siloed on these different print and prep methods. This was primarily because they were conducted in different manufacturing facilities. Our graphic design team took customer-provided artwork or our own designs and created one-up art proofs that were sent for approval manually via email,” recalls Landaal. “For the most part we relied on Adobe Illustrator and our RIP software for our digital prepress. We would manually prep them for multiple layouts for flexo and offset.”

At the time, Landaal had three pain points. One was a strong desire to have project transparency from the design to quote process. They also wanted to control and manage their structural and graphic artwork content in a secure and manageable way—to make certain that the right design went from customer approval to the shop floor. The third challenge was to create additional capacity for their ‘design to quote’ pipeline and to streamline and automate mundane tasks.

“We wanted to automate and streamline repetitive tasks using a solution that had a user-friendly interface—internally and externally,” explains Landaal. “We also needed a project management tool that was driven off our design tool. We had been using ArtiosCAD (by Esko) for a long time and needed something that made the design to quote process more efficient. Finally, we wanted to partner with a vendor that offered excellent service that could help us grow beyond implementation. And we needed a constant partner who could help us after implementation to grow beyond today.”

A NEW, COMPLETE WORKFLOW IN JUST FIVE DAYS

Landaal selected WebCenter QuickStart for Corrugated , providing a single source to keep all active jobs, allowing a cross-functional team to visit, access, and really know project status.

“The implementation was a very pleasant and efficient process. The Esko team of project managers and support specialists helped to configure WebCenter QuickStart for Corrugated based on our goals,” relates Landaal. “It was quite a difference advancing in five days from email and Excel and Word documents, to a web-based platform for RFQs (request for quotations) and the ability to track projects to collect the right information in real time. We also installed Esko’s Automation Engine to help streamline and automate our workflow beyond the quote process. Ultimately, we hope to oversee prepress from art design to manufacturing spec reports to production—and integrate it into our ERP (enterprise resource planning).”

Landaal has been using WebCenter QuickStart for Corrugated live for about four months.

“Previously, we were using a spreadsheet to track projects. Now we have one access point for all data. With WebCenter, all the final customer project data is shared in one place and via visual dashboards. The sales development team has learned how to track and manage projects to prioritize jobs,” says Landaal director of business development and marketing Terry Choate.

“From my perspective, it gives us great transparency through all our projects,” adds Landaal marketing specialist Nichole Salzano. “Now, everybody is accountable for their tasks and responsible for deadlines. We can also look at a project and easily track it back to its origin to help calculate ROI (return on investment) on our marketing initiatives.”

Landaal’s goal is to stay a step ahead of the competition.

“One of the best ways is to be the first to the customer with a design and a

quote. WebCenter QuickStart for Corrugated has all the supporting tools to help us get there, easily,” exclaims Landaal. “With simple job requests using an ArtiosCAD standard design, we can return with a quote within hours. Those requests with some structural design take about 15 to 20 percent less time than before WebCenter QuickStart for Corrugated because there is no longer a ‘back and forth’ between our designers and estimators. It also helps us to make sure that the first quote is the correct quote.”

ADDING DESIGN CAPACITY BY ELIMINATING MANUAL ADMINISTRATIVE TASKS

WebCenter QuickStart for Corrugated has allowed Landaal to streamline the output of the structural design team, allowing them to spend their time on designing and drawing and understanding customer needs and thinking innovatively—rather than on administrative details. They don’t have to access their server to organize files and create, save, export, manage or email them. They also don’t have to manually create spec reports.

“During the past four months, our data shows that our three structural designers have gained close to 1.5 hours of additional workflow capacity each day. We can accept an additional 20 percent capacity before we have to think about hiring another designer,” notes Landaal. “And we have improved quality by catching small errors that would previously have been caught on press.”

Before, Landaal would send a lot of printed samples. Now, with Esko Studio Visualizer, they can send realistic graphic designs more cost effectively at the concept stage and let the customer make early decisions. They have seen the difference and it’s now much faster for Landaal to get an approved design and be ready for quote.

“WebCenter QuickStart for Corrugated has been the most important investment our company has made in the past year because it’s given us the ability to organize ourselves internally, and to professionalize ourselves to the outside world with so-

phisticated software that can manage and control the process from start to finish,” concludes Landaal. “We have gained efficiency and can handle customers more proactively. We have really seen how we can grow in a scalable manner with Esko tools. It enables us to manage the complexity of print.”

ABOUT LANDAAL PACKAGING SYSTEMS

Landaal Packaging Systems’ mission is to be the best full-service provider of packaging products, supplies and services. Since 1959, they have helped customers solve their packaging problems with innovative ideas, uncompromising product quality and on-time delivery. As a family-owned business, they offer a tradition of consistent, reliable service to companies in the manufacturing and retail industries. Company information at www.landaal.com.

ABOUT ESKO

Esko helps its customers to make the best packaging for billions of consumers. The Esko product portfolio supports and manages the packaging and print processes for brand owners, retailers, designers, premedia and trade shops, packaging manufacturers, and converters. For nine out of 10 retail packages, Esko solutions are used in packaging management, asset management, artwork creation, structural design, prepress, 3D visualization, flexo plate making, workflow automation, quality assurance, sample-making, palletization, supply chain collaboration and/or the production of signage and displays. The Esko solutions consist of an extensive suite of software and two hardware product lines: CDI flexo computer-to-plate imagers and exposure units as well as Kongsberg digital cutting systems, complemented with professional services, training and consultancy.

Esko employs about 1,500 people worldwide. Headquartered in Gent (Belgium), its sales and service organization is in daily contact with customers all over the globe. Company information at www.esko.com.

RESOLUTE TO INVEST OVER $52 MILLION IN ITS SAINT-FÉLICIEN PULP MILL IN QUEBEC

The investment will increase daily capacity while reducing greenhouse gas emissions

SAINT-FÉLICIEN, Que.—On

May 14, 2018, Resolute Forest Products Inc. announced

a $52.3 million strategic investment plan for its Saint-Félicien pulp mill, located in the Lac-Saint-Jean region of Quebec.The announcement was made at a press conference attended by Quebec Premier Philippe Couillard, and many dignitaries and company employees.

“The significant investments at SaintFélicien are expected to improve several areas of the operation, increasing the average daily production capacity by 76 metric tons and reducing greenhouse gas

emissions from the use of fossil fuels by 20 percent,” says Resolute Forest Products president and chief executive officer Yves Laflamme.

On April 30, 2018, Resolute announced a $13 million investment in its La Doré (Quebec) wood products facilities, also located in Lac-Saint-Jean. In 2016, the company inaugurated Toundra Greenhouse, located adjacent to the Saint-Félicien pulp mill, a $100 million joint venture project with local investors.

During the latest press conference, Laflamme thanked local employees, government officials, as well as regional aca-

demic and economic development organizations for their continued support and advocacy.

Resolute employs close to 240 workers at the pulp mill, and more than 2,000 in the Saguenay–Lac-Saint-Jean region.

The upgrades are expected to be completed by the end of 2019.

ABOUT RESOLUTE FOREST PRODUCTS

Resolute Forest Products is a global leader in the forest products industry with a diverse range of products, including market pulp, tissue, wood products, newsprint

and specialty papers, which are marketed in close to 70 countries. The company owns or operates some 40 manufacturing facilities, as well as power generation assets, in the U.S. and Canada. Resolute has third-party certified 100 percent of its managed woodlands to internationally recognized sustainable forest management standards.

Resolute has received regional, North American and global recognition for its leadership in corporate social responsibility and sustainable development, as well as for its business practices. More information available at www.resolutefp.com.

SILVERY OR GOLDEN SURFACE NO PROBLEM FOR HP INDIGO 12000 SERIES

No brush off here: new Colgate toothbrush packaging gets royal send-off thanks to Iggesund, HP Indigo

and The Print House

When Iggesund

Paperboard asked Print House AS in Oslo, Norway to do the certification testing of its new silvery metallized PET (Polyethylene terephthalate) film-laminated paperboard Metalprint Digital, custom-designed for the HP Indigo 12000 series of digital printing presses, the Swedish company also gained an exciting benchmark example of Metalprint Digital’s performance ability. The printers had simultaneously been asked to develop an exclusive packaging for the launch of Colgate’s gold toothbrush, the Gold 360⁰.

From the sheets left over from the certification testing, the printers created a packaging for Colgate in the form of a gold bar—unusually, even before the paperboard was on the market.

“Colgate wanted a gold finish and so we tried printing yellow onto Metalprint Digital’s silvery surface to achieve the gold

Colgate’s gold toothbrush, the Gold 360º, was launched in Norway in packaging in the form of a gold bar. The packaging is printed on Invercote Metalprint Digital 300 g/m² + 29 g/m², 420 µm, 16.5 pt. The printers, Print House, playfully developed the combination of printing a gold effect onto Iggesund’s new Metalprint Digital paperboard, certified for the HP Indigo 12000 series.

“The possibilities of starting with packaging that has been digitally printed on a small scale is a strong driver behind the expansion

of our business,” says Steven Widlic, project manager at Print House in Oslo.

effect. It was a great success,” explains Print House project manager Steven Widlic.

A couple of years ago, Metalprint, which is based on Invercote G, attracted great interest in digital print circles, but it had one limitation—it could only be used in the biggest presses with the equipment to apply a primer.

However, along with HP Indigo, Iggesund Paperboard has now developed another version—the Metalprint Digital, which is customized and certified for HP Indigo’s 12000 presses.

“The certification test runs exceeded expectations and we’re impressed by how well Metalprint Digital functioned in our press,”Widlic continues.

“It works so well because Invercote is fundamentally stable with good quality and a fine surface. When the metallized film is then applied by using a forgiving method, the result is the mirror-smooth finish that is an ideal prerequisite for a superb print result.”

Print House is one of the pioneering digital printers in Norway. Until the beginning of 2018 it had about 20 employees before merging with a considerably larger group of printing companies, 07 Media.

“Here at Print House we’ve been able to follow the exciting developments in digital printing,” Widlic says. “The growth in the packaging segment has been particularly impressive and still has a lot of potential.”

The ability to produce small series of packaging involving complex printing opens up new possibilities for small companies. Packaging printed with traditional technology involves relatively high start-up costs, which are an obstacle for companies that want to limit their print runs for cost reasons.

“That factor is what’s driving the expansion of our packaging business, as well as the advantages that digital technology offers when you have to make many versions of a basic packaging design,”Widlic concludes.

“The possibilities of starting with packaging that has been digitally

printed on a small scale is a strong driver behind the expansion of our business,” says Steven Widlic, project manager at Print House in Oslo.

ABOUT IGGESUND

Iggesund Paperboard is part of the Swedish forest industry group Holmen Group, one of the world’s 100 most sustainable companies listed on the United Nations Global Compact Index. Iggesund’s turnover is just over €500 million (~ CDN $764 million) and its flagship product Invercote is sold in more than 100 countries. The company has two brand families, Invercote and Incada, both positioned at the high end of their respective segments. Since 2010 Iggesund has invested more than €380 million (~CDN $580.7 million) to increase its energy efficiency and reduce the fossil emissions from its production.

Iggesund and the Holmen Group report all their fossil carbon emissions to the Carbon Disclosure Project. The environmental data form an integral part of an annual report that complies with the Global Reporting Initiative’s highest level of sustainability reporting. Iggesund was founded as an iron mill in 1685, but has been making paperboard for more than 50 years.The two mills, in northern Sweden and northern England employ 1,500 people. Company information available at https://www.iggesund.com/ en/.

ABOUT HP INDIGO

HP Indigo Division is a division of hp’s Graphic Arts business. It was founded in 1977 as the Israeli company Indigo Digital Press and bought by Hewlett-Packard in 2001. It develops, manufactures and markets digital printing solutions, including printing presses, proprietary consumables and workflow. More information available at http://www8.hp.com/ us/en/commercial-printers/indigo-presses/products.html.

SOFT TISSUES—TOUGH EQUIPMENT

Irving Consumer Products to use integrated power systems from Rockwell Automation in new Georgia plant

MILWAUKEE, Wisconsin—Irving Consumer

Products Limited, a Canadian-based manufacturer of household and store-brand paper and personal care products, recently broke ground on a new, US$400 million state-of-the-art tissue production plant in Macon, Georgia.

The new plant will produce ultra-premium quality household paper products including soft bath tissue and high quality paper towel that is both strong and absorbent.

Multiple production lines are planned for this plant, the first of which will have Allen-Bradley PowerFlex 7000 and PowerFlex 755T integrated power systems from Rockwell Automation Inc.

The integrated system will help control speed, torque, direction and power to the motors that run the machines on the production line, as well as aggregate data to manage energy usage.

“The new, fully-integrated motor control system will help to support our company’s focus on managing and maximizing our energy usage, reducing environmental impacts and achieving our vision of having an Irving consumer product in every North American household by 2020.We are confident that working with Rockwell Automation will help to make this and future projects a success,” states David Dennis, vice president of

manufacturing, Irving Consumer Products.

“We take pride in our long-standing business relationship with Irving Consumer Products and look forward to helping them with this connected enterprise implementation for their new plant,” states Mike Laszkiewicz, vice-president and general manager, power control business, Rockwell Automation.

The scope of the project also includes low- and medium-voltage motors as well as a complete portfolio of integral services and support throughout the duration of the project, which is expected to be complete in 2019.

ABOUT IRVING CONSUMER PRODUCTS

Irving Consumer Products is one of North America’s leading manufacturers of household paper and baby diaper products. Irving Consumer Products companies include Irving Tissue and Irving Personal Care. Irving Tissue produces premium household store brand paper products for many of North America’s top retailers, in addition to some of the topselling tissue brands in the marketplace. Irving Personal Care is the only manufacturer of baby diapers and training pants in Canada. Using stateof-the-art equipment and technology, they produce premium quality private label products for major North American customers. Learn more at www.irvingconsumerproducts.com.

ABOUT ROCKWELL AUTOMATION

Rockwell Automation Inc., the world’s largest company dedicated to industrial automation and information, makes its customers more productive and the world more sustainable. Headquartered in Milwaukee, Wisconsin, Rockwell Automation employs approximately 22,000 people serving customers in more than 80 countries. Company information available at www.rockwellautomation.com.

CORNER BROOK PULP & PAPER MAKES ITS LARGEST SHIPMENT OF NEWSPRINT

India to receive 4,000 tons-plus of high-quality newsprint

More than 4,000 tons of highquality newsprint is being shipped from Corner Brook Pulp and Paper Limited of Newfoundland to India.

While this is not its first dealings with the sub-continent market, shipping newsprint to India, this is Corner Brook Pulp & Paper’s biggest one-time shipment ever of newsprint. Usually, the shipments to India have involved it being transported to another location for shipment, but this endeavor is the first-time Corner Brook Pulp & Paper is shipping a load direct to the customer destination.

ABOUT CORNER BROOK PULP AND PAPER

Corner Brook Pulp and Paper Limited is a vital force in the economy of western Newfoundland. Construction of the mill began in 1923 with the first paper produced in 1925. It was then incorporated in 1927 as the International Paper Company of Newfoundland Limited and was acquired by Bowater Corporation in 1938. The company became part of the Kruger organization in December of 1984, at which time it adopted its present name. Company information available at www.cbppl.com.

TC TRANSCONTINENTAL PACKAGING WINS BIG AT THE 2018 EXCELLENCE IN FLEXOGRAPHY AWARDS

As part of the 2018 Excellence in Flexography Awards by the FTA, TC Transcontinental won a total of eight awards, including the prestigious “Best of Show” award in the Web/Process/Film category for Transcontinental

Robbie’s Post Fruity Pebbles / Cocoa Pebbles packages

MONTREAL—

TC Transcontinental Packaging has swept the Wide Web/Process/Film category at the 2018 Excellence in Flexography Awards of the Flexographic Technical Association ( FTA ) by winning a Bronze, Silver and Gold award. Additionally, TC Transcontinental Packaging was the recipient of the coveted “ Best of Show ” award, for Transcontinental Robbie ’s Post Fruity Pebbles / Cocoa Pebbles packages, while also winning a Silver award in the Wide Web/Line/ Film category as well as in the Wide Web/Screen/Film category, a Bronze in the Wide Web/Screen/Coated Paper category, and a Self-Promotion award for its Inspire NexGen 240 bag.

For the second year in a row, TC Transcontinental Packaging has been recognized with the prestigious “Best of Show” for its printing performance and execution. These back-to-back awards are further proof that TC Transcontinental Packaging is creating some of North America’s finest and most innovative flexible packaging; each carefully tailored and printed to meet the specific need of its customers.

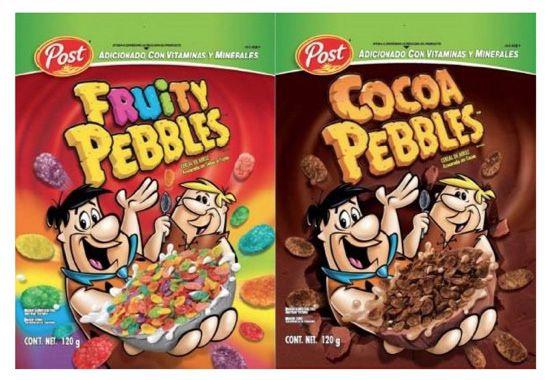

“It is very rewarding to win FTA’s back-to-back Best of Show award and to be recognized by the industry,” says Transcontinental Robbie general manager Pepper Stokes. “The challenge in printing this particular project was the two different SKU’s on the web which are on totally opposite ends of the tonal range.

“The Fruity Pebbles is largely high-key, bright colors and the Cocoa Pebbles is

largely low key dark colors. At the same time, within each of these items we have solid/near solids of the process colors on the same plate as highlights, so we are hitting almost 100 percent of the tonal range on each. Both represented very busy designs with a lot of individual elements requiring great detail to be produced. Together with leading edge technology in prepress, plate materials, and world class press room execution, we were able to show what flexography printing can accomplish,” notes Stokes.

The Wide Web category is the only category to continue the upward trend in awards seen over the past five years with one judge noting “this year was probably the best for execution.” “Printers understand it is not just the look, but also the technical details that make their samples stand out.”

More than 500 entries from around the world set the stage this year and 114 coveted awards, plus six best of show recipients were revealed in Indiana, on May 6, 2018. The judging panel, comprised of industry members who have an eye for detail, evaluated each print for their degree of difficulty and level of execution. This year, no longer were

THE AWARD-WINNING PACKAGES

Post Fruity Pebbles/Cocoa Pebbles printed by

Transcontinental Robbie

• Gold and “Best of Show” award

• Wide Web/Process/Film category

“The image pops off the web! Highlight dots are clean, crisp and solid. Register is perfect.” – Judges’ comment

Tantillo Basil Pesto/Garlic Oregano Premium Croutons printed by Transcontinental Robbie

• Silver award

• Wide Web/Process/Film category

“Near-perfect highlight dots without donuts; nothing is misshapen. Great image with near perfect register.” – Judges’ comment

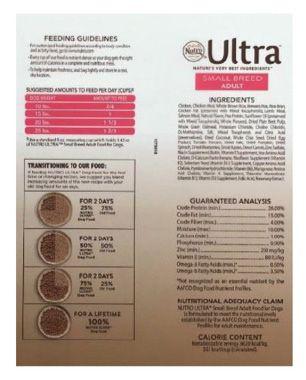

Nutro Ultra Small Breed Adult Dog Food, printed by Coveris Americas, now part of TC Transcontinental Packaging

• Silver award

• Wide Web/Screen/Film category

“Impressive gradient, ink coverage and laydown. Sharp text.Very clean.” – Judges’ comment

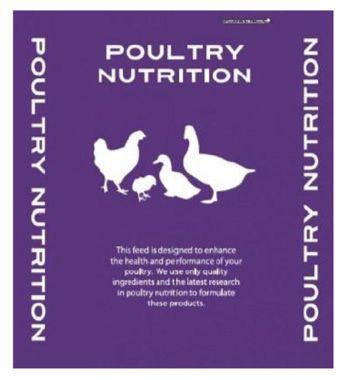

Alltech Poultry Nutrition printed by Coveris Americas, now part of TC Transcontinental Packaging

• Silver award

• Wide Web/Line/Film category

“This has even coverage with no ghosting or chatter. It’s a challenging larger repeat.” – Judges’ comment

tight registrations adequate; they had to be tighter. An image couldn’t just be sharp; it had to be sharper. Judges huddled and debated, until the winners were chosen.

ABOUT TC TRANSCONTINENTAL PACKAGING

TC Transcontinental Packaging positions itself as leader in flexible packaging in North America, with operations in Mexico, Guatemala, Ecuador, United Kingdom, China and New Zealand. The division has over 4,000 employees, the majority of which are based in the U.S. Its platform is comprised of one premedia studio and 28 production plants specializing in extrusion, lamination, printing and converting. TC Transcontinental Packaging offers a variety of flexible plastic and paper products, including rollstock, bags and pouches, coextruded films, shrink films and coatings. The division services a variety of industries, including dairy, coffee, proteins, pet food, agriculture, confectionery, supermarket fresh perimeter and frozen foods. TC Transcontinental Packaging is a division of Transcontinental Inc., which has over 9,000 employees, the majority of which are based in Canada, the U.S. and Latin America. Following the transformational acquisition of Coveris Americas, TC Transcontinental’s consolidated pro forma revenues are estimated at CDN$3.3 billion for fiscal 2017. For more information, visit TC Transcontinental’s website at www.tc.tc.

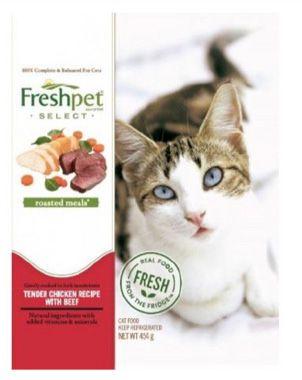

Freshpet Select Roasted Meats

Tender Chicken Recipe with Beef Cat Food printed by Transcontinental Ultra Flex

• Bronze award

• Wide Web/Process/Film category

“High level of detail, especially in the highlight area of the cat. Low dot gain – great minimum dot.” – Judges’ comments

THE AWARD-WINNING PACKAGES

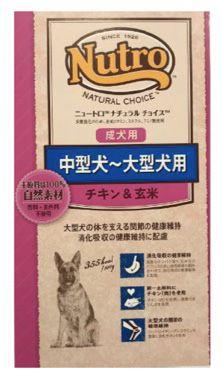

Nutro Natural Choice Dog Food Bag printed by Coveris Americas, now part of TC Transcontinental Packaging

• Bronze award

• Wide Web/Screen/Coated paper category

“Registration is well done, with crisp positive and reverses. Nice ink coverage.”

– Judges’ comments

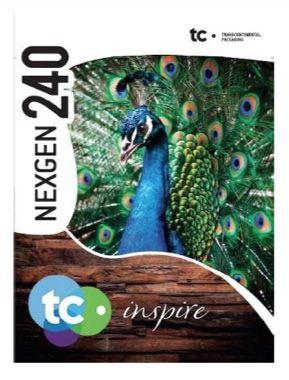

Inspire NEXGEN 240 Bag printed by Transcontinental Robbie

• Award for Self-Promotion

“Register of reverse panels was good.” –Judges’ comment