PACKAGE CONVERTING NOW

DIGITAL

SUPPLEMENT FOR THE AUDIENCE OF CANADIAN PACKAGING

Cascades multiplies the fun with new package designs

SUPPLEMENT FOR THE AUDIENCE OF CANADIAN PACKAGING

Cascades multiplies the fun with new package designs

adorable package design graphics created for its new national brand of household tissues

BY GEORGE GUIDONI, EDIITOR

Standing out in a sea of white is no easy feat when you’re a white product like toilet paper.

But that does not mean one should stop trying, as Canada’s leading paper products Cascades Inc. discovered with last year’s highly successful and high-impact launch of the Cascades Fluff & Tuff brand of super-soft and super-strong bathroom tissues.

Capping off more than a year of intense inhouse product development and expert packaging design work carried out by the Montreal-based branding specialist Bo Branding & , the new toilet paper brand has not only been flying off the retail shelves across Canada, but also garnering serious international accolades for its bold innovation and stunning shelf

In late November last year, the new Cascades brand picked up the Tissue – Innovation Award at the annual Pulp & Paper International Awards gala in Brussels, Belgium, gathering special praise for the product’s market presence and customer satisfaction.

“We launched a line of toilet paper and paper towels that is among the soft est and strongest on the market, while maintaining all of the green properties our products are known for,” says Jean Jobin, president and chief operating officer of Cascades Tissue Group in Kingsey Falls, Que.

“Our objective was simple: to offer consumers the comfort and performance they’re looking for in a product, while also protecting the environment,” says Jobin, reiterating the company’s long-standing firm commitment to make all of its paper products from recycled paper fibers.

Only launched nationally last March, the new brand has enjoyed not only robust sales growth, according to Cascades, but also remarkable brand recogni tion and loyalty from Canadian consumers won over by the brand’s cheerful and wholesome marketing pitch and message.

“We wanted our new and improved products to become the brand of choice for more and more families across the country,” says Jobin, “and we are achiev ing this goal.

“Convincing the industry of the innovative value of our products and win ning over consumers in a matter of months was a considerable but a worth while challenge.”

It’s a challenge that also brought out the best in the Bo Branding creative team, which helped Cascades develop the new brand’s adorable bunny mascots strongly featured on new packaging that is worlds away re moved from the fairly generic and rudimentary package graphics previously used for the branded Cascades tissue products.

As Boucher relates, “We wanted to develop a new connection with our consumers and win their hearts with the two bunnies: the cute and puffy Fluff and strong and confident Tuff.

“The new Cascades Fluff and Tuff packaging evokes softness and strength through the use of mnemonic bunny mascots that mesmerize and attract consumers to their glare,” says Mylène Boucher, director of marketing and innovation at Cascades ULC in Candiac, Que.

“The accompanying colored backgrounds provide the ideal environment for each bunny to stand out,” Boucher adds, “while providing consumers with

“They both generate passion in different ways,” says Boucher, citing the design’s effective use of soothing, comforting blue, green and pink colors to differentiate between the different subbrands, such as Ultra (soft), Strong, Enviro and Absorbent.

“The organic curves in the graphics, combined with the vibrant colors, really help to convey the product benefits,” she notes, while providing consumers with an easy identifiable product segmentation system.

“The color combinations enable a use of subtle tones that emphasize the various product benefits that both Cascades Fluff and Tuff offer,” says Boucher, citing the inherent challenge of achieving impactful product differentiation in highly competitive product category dominated by legacy brand names and limited format flexibility.

“The key challenge in this category is to stand out against the competition,” she says, “which is why the bunny mascots were developed with large, friendly, soft-green eyes that mesmerize and attract consumers with their stare.”

Whereas the previous Cascades branded household tissues had brand equity more closely to that of a privatelabel product than a national brand,

Boucher says the adorable bunny graphics were readily embraced by the targeted consumer audience across Canada—primarily women in the 35- to 54-year-old age group with young families.

“Since their launch, our rabbits have become so popular that we get thousands of requests week after week from consumers wanting to buy not only our products, but also a stuffed animal version of Fluff and Tuff,” she chuckles.

According to vice-president of marketing and innovation Thierry Trudel, the success of the Fluff & Tuff launch was underpinned “by our diligent development and marketing efforts.”

Says Trudel: “Our teams worked closely together for over two years reviewing each step in the manufacturing process in order to provide the superior quality that Cascades Fluff and Cascades Tuff products deliver.

“We undertook multiple consumer studies: both qualitative and quantitative in nature,”

“No detail was ignored to improve the products for the families, beginning with the manufacturing formula for the paper all the way through to its embossing and packaging,” he says.

“This [PPI] award definitely brings value to everything that we’ve accomplished,” Trudel declares, also noting the new brand picked up a 2017 Davey Award from the Academy of Interactive and Visual Arts (AIVA) for its in-store marketing campaign. Also selected as a finalist in the annual innova-

tion awards of the Innovation contest of L’Association des Détaillants en alimentation du Québec (ADAC) and the upcoming 2018 PAC Global Leadership Awards competition of PAC Packaging Consortium, the new Cascades

Fluff & Tuff brand was also a big winner where it really counts the most—at the store-shelves.

“We are currently on track for 55-percent sales growth compared to a year ago, which is actually four times our initial objective,” beams Boucher.

“We also gained important new distribution among our existing retail customers,” she confides, “while obtaining completely new listings because our trade customers believed in our new image and its shelf impact.

“Our main goal was, of course, to sell more, but also to be positioned where we belong in consumers’ minds, among national brands.

“And after only three months in the market, the Cascades Fluff brand had reached 86-percent awareness among our target consumers,” says Boucher, noting Bo Branding made full use of its creative licence to completely revamp the packs.

“The packaging design was completely remodeled,” she asserts. “In fact, we have nothing left from the previous one, except for the Cascades name that remains our company brand.

“As it existed before, the Cascades household tissue brand was mainly focused on ‘green’ consumers looking for green products,” Boucher explains.

“With this relaunch, we re-engineered

the whole product line to answer different needs, while staying true to our sustainable roots, by rebranding everything under the new Cascades Fluff and Cascades Tuff umbrella.

“In doing so, we went from an austere package appealing to a very small group of the population to a fun and engaging image able to reach the vast majority of Canadian consumers,” she says, citing extensive back-and-forth consumer research conducted by Cascades for over a year leading up to the March 2017 launch.

“We undertook multiple consumer studies: both qualitative and quantitative in nature,” Boucher recounts. “We started with a completely different set of ideas and adjusted to consumer feedback along the way, making this an interactive process.

“While this added time to our product development,” she acknowledges, “it ultimately ensured success in the market.”

Says Boucher: “One of the key things we learned from this project is that consumers want to see the actual product: the whiteness of the paper, the design of the embossed pattern and the overall quality of the product.

“They spoke, we listened, and in the end we delivered bright and colorful packaging with the essential transparent zones to achieve remarkably strong market presence and shelf impact.”

Feisty flexible packaging converter ready to strut its stuff on bigger stage with proud legacy of continuous process improvement and product innovation

BY GEORGE GUIDONI, EDITOR

PHOTOS BY PIERRE LONGTIN

Sometimes you get an offer that you just can’t refuse— for all the good reasons.

And while they took their time to say yes, Flexipak Industries Inc. founder Charles Boustany and his son Karl clearly saw many good things coming their way upon being first approached by TC Transcontinental Packaging to join its growing roster of ambitious and progressive flexible package converting companies nearly two years ago.

“We never actually put ourselves

up for sale because Flexipak was a very successful family-owned company with double-digit growth and good profitability, but it came down to making a choice of how fast and how far we wanted to grow the business,” recalls Karl Boustany, now serving as general manager of the recently renamed Transcontinental Flexipak in Montreal.

“Growing with 50 people is a very different proposition from growing with 900-plus people employed by TC Transcontinental Packaging at its multiple locations,” Boustany says,

Industries founder

says he is proud to pass on the company’s leadership torch to his son Karl Boustany, who is now general manager of Transcontinental Flexipak, the newest operating facility of the fast-growing, Montreal-headquartered TC Transcontinental Packaging flexible packaging business.

“but what really made it all work was the chemistry of the two companies’ similar corporate cultures.

“Because TC Transcontinental places such a high value on family, friendship, relationships and respect, we felt that this was an ideal opportunity to let our employees grow and succeed in this business both personally and professionally,” Boustany told Canadian Packaging in a recent interview.

With both companies also being headquartered in Montreal, the reasons to join the fast-growing TC Transcontinental Packaging division vastly outweighed any potential second-guessing, according to Boustany.

“I felt that it was ultimately the best decision for Flexipak,” says Boustany, adding he has not had any inkling of regret since formally signing off on the acquisition, along with his dad, in the fall of 2017.

“It has been an absolutely positive experience so far,” says Boustany, adding that joining the TC Transcontinental Packaging team—well on-track to reaching its self-defined goal of becoming a North American leader in flexible packaging—is a perfectly fitting way to mark Flexipak’s 20-year anniversary milestone this year.

For its part, the senior management of TC Transcontinental is equally enthused about acquiring an important new strategic asset right in the company’s hometown.

While it is not TC Transcontinental biggest acquisition to date, it certainly adds a lot of momentum and patriotic creed to the company’s ongoing expansion that so far also comprises the purchases and successful integrations of

A close-up view of the bottom gussets of printed rollstock standup pouches being formed inline on the plant’s high-speed pouchmaking machine.

Clinton, Mo.-based Capri Packaging in 2014; Brooklyn, N.Y.-based Ultra Flex in 2015; Lenexa, KS.-based Robbie Manufacturing in 2016; and Flexstar Packaging Inc. of Richmond, B.C. in fall 2016.

As noted by parent company TC Transcontinental’s president and chief executive officer Francois Olivier, “This transaction extends our footprint to eastern Canada by adding a Montreal-based facility equipped with a state-of-the-art platform, and it gives us an opportunity to further develop our existing business relationships with leading retailers in the country.

“Driven by belief in outstanding customer service and innovation, Flexipak has a strong family culture that will naturally blend with ours,” Olivier states.

“We are truly delighted to welcome Flexipak’s employees to TC Transcontinental and look forward to growing our flexible packaging business with them.”

Operations director Alex Grota (back of the table) leading the daily morning meeting with members of the operational, quality control and customer service staff.

Echoing the sentiment, Boustany says TC Transcontinental’s interest and plaudits are a gratifying validation of all the hard work and dedication poured into Flexipak over the years by his father Charles, himself, and the company’s exceptionally loyal staff.

“You could say that I was virtually ‘born’ into this flexible packaging industry,” the 33-year-old Karl Boustany chuckles, recalling the many summers spent at the company’s plant during his school years learning as much as he could about the business.

After earning a trilingual Bachelor of Commerce degree from HEC Montréal (business school of the University of Montreal) in his twenties, Boustany says he was genuinely excited about the opportunity to leverage his university education and acquired knowledge to help make Flexipak a stronger and more influential player in the notoriously competitive flexible packaging business.

As Boustany relates, the Flexipak plant had undergone four building expansions since opening up for business in 1998 to accommodate the growing volumes, which are now pushing the 40,000-square-foot facility to the limits of its manufacturing capacity.

Nowadays processing around 15 million pounds of various plastic stock per year, the Flexipak plant typically runs up to two 10-hour shifts per day, five days a week, to turn out a diverse array of high-quality flexible packaging products ranging from stand-up and three-side-seal pouches to wicket and heavy-duty bags to printed and nonprinted rollstock film.

“Like the old adage says,‘What gets measured gets done,’

Over the years, Flexipak built a solid team of dedicated individuals who worked tirelessly to bring the industry’s ficiencies with a manufacturing process geared specifically

Karl Boustany strikes a proud pose in front the Flexipak facility’s state-of-the-art Bobst 20SIX CI central impression press that has enabled the plant to streamline its operations from three different printing presses down to a single machine, while handling far more volume of work for a growing range of prominent clients in the North American food and beverage industries.

substrates used for flexible packaging, while handling all run lengths with equal efficiency.

“We actually used to have more printing presses at the plant,” Boustany relates, “but with the mindset of achieving operational excellency, coupled with state-of-the-art printing technology, we were able to divest ourselves of the older presses.”

Boustany reiterates that regardless of how modern or high-tech machines are, meaningful results are achieved by measuring.

With that mindset, Flexipak allowed the management team in place to flourish and implement industry best tions director Alex Grota insists on having daily meetings with the entire Operational Team, QC (quality control) and Customer Service staff to make sure that everything gets measured and interpreted, so that any detected problems are resolved immediately or addressed with a clear plan to remedy them—enabling for quality products to be expedited on time.

Nothing is left to chance, with every pending item closed after being carefully reviewed.

As Boustany points out, “If you are good at small- and medium-run printing, you are pretty much guaranteed to be good at managing long runs, but if you’re only good at managing large runs, you will find it very hard to succeed

Certified to the stringent GFSI BRC AA standards for food contact safety for flexible packaging products, the high-output Montreal facility is home to a high-speed, made-in-Canada Fen Tech wicket bagmaking machine above. with smaller runs.

“We deliberately decided to focus on small-run production early on because we could see the market moving in the direction of rapid SKU (stock-keeping unit) proliferation by brand-owners, which required us to become a very flexible and agile operator, with an emphasis on very quick changeovers.”

Currently executing an average of six to seven product changeovers on the press per shift, according to Boustany, Flexipak

The digital smartGPS impression and registration setting system integrated into the the 20SIX CI flexographic printing press allows the press to quickly accelerate right up to production speed by performing the whole set-up offline at the plate-mounting stage.

press operators have all been extensively cross-trained to optimize all of the press’s performance attributes—often completing changeovers as quickly as 30 minutes.

“This is a core competence that we are specially proud of,” says Boustany, likening the plant’s changeover routine to a

Formula One pit crew getting its race driver back onto the track in the quickest possible manner.

“We have experienced double-digit growth in our revenues in the past five

years,” he proclaims.

Boustany says the company also made a major investment in operator skill-training because he believes after all that regardless of the business, it’s all about the people.

A truly unique and breakthrough technology at the time of the purchase, the digital off-press smartGPS impression and registration setting system integrated into the press was designed to inform press operators of all the required print

adjustments and impression parameters in advance of loading the job onto the press, thereby allowing the press to be accelerated to production speed right after the first kiss contact.

Unlike the traditional manual adjustment techniques and automatic opticalbased systems that perform the set-up process in the press whilst the machine is running, smartGPS does the job off-line at the plate mounting stage to deliver the necessary set-up parameters whilst the

machine is idle.

The result is a dramatic reduction of waste—from substrates and inks/solvents used during the set-up, to the energy used to run the press—and exceptionally fast changeovers, according to Bobst.

Moreover, smartGPS also serves as a highly reliable quality control instrument for printing hardware and plate mounting because all new sleeves or intermedi-

The Flexipak plant produces a broad range of high-impact flexible packaging in both rollstock form and as premade bags ready for filling.

ate bridging sleeves/mandrels, as well as the anilox, can be precisely measured for diameter, length (end to end), and TIR (concentricity) on the same plate mounting machine.

Best of all, the system works on any substrate—including metalized films— and any substrate thickness or type, such as corrugated linerboard.

“We have been able to get our ink consumptions requirements down to a science,” says Boustany, citing over 20-percent cost-savings in ink purchases since going live with smartGPS, despite the growing volumes.

“We now buy only the exact amount of ink required to do the job,.

For all that, Boustany estimates that Flexipak is currently at 55-percent capacity—meaning that it still has plenty of room to help the plant grow its business further.

A lot of that growth will be driven by Transcontinental Flexipak’s keen focus on new product development and innovation, according to Boustany.

The ink stations are always kept in clean condition to enable press operators to perform extremely quick product changeovers required by the plant’s short-run and medium-run production requirement that often necessitate six changeovers per shift.

add real value to their organization.

“We are strongly focused on producing high-value-added niche products for our customers,” he says,“because that is where the future market growth lies both for us and TC Transcontinental Packaging.”

Says Boustany: “I am very encouraged by the fact that TC Transcontinental acquired us because we are both dynamic, second-generation businesses run by very dedicated individuals who have worked tirelessly to build a successful and highly efficient packaging enterprise that will

In addition, Boustany says the company is also looking to capitalize on the emerging hot trend of SPS (spouted stand-up pouches) for an ever-growing variety of food and beverage products.

“We are certainly not the first or the only packaging company that they looked at to extend their market reach in Eastern Canada,” he concludes, “so their decision to partner with us says a lot about all the good things we have done over the years to get to this point.

“I am really looking forward to getting bigger, better and even more successful in the coming years in light of their genuine commitment to help us become the best that we can be in our chosen markets.”

MONTREAL—TC Transcontinental Packaging is pleased to announce that it has won the Gold award for Sustainability with its compostable peanut bag at the 2018 Flexible Packaging Achievement Awards Competition.

This award celebrates TC Transcontinental Packaging’s commitment to sustainability, especially to ecodesign, as it strives to design products that take into consideration the environmental impacts of the product during its entire life-cycle.

Developed internally at Transcontinental Ultra Flex, the new flexible peanut bag (see image at right) was designed using certified compostable materials to support arenas and stadiums’ green initiatives and help sports teams, venues, and leagues achieve the next level of landfill waste diversion.

“The chief benefit of the new bag is that it reduces the amount of labor previously devoted to the manual sorting of materials collected during clean-up after games.The economic benefit is the lowering of overall waste management costs for the venue and the environmental benefits of this package center around the use of renewable resources and its easy inclusion into the venue managed composting program,” says TC Transcon-

tinental Packaging vice-president of business development Todd Addison.“It is a great honor to be recognized by the industry for setting a new bar for packaging sustainability. Our customers can count on us to always look for new materials, new technologies and new techniques to create brilliant packaging that meets today’s consumer needs.”

The new compostable peanut bag replaces the current laminated polypropylene bag which has become steadily barred from stadiums, thereby eliminating a classic game-day menu offering. TC Transcontinental Packaging now offers an alternative made of two-layer adhesive lamination consisting of certified compostable materials.

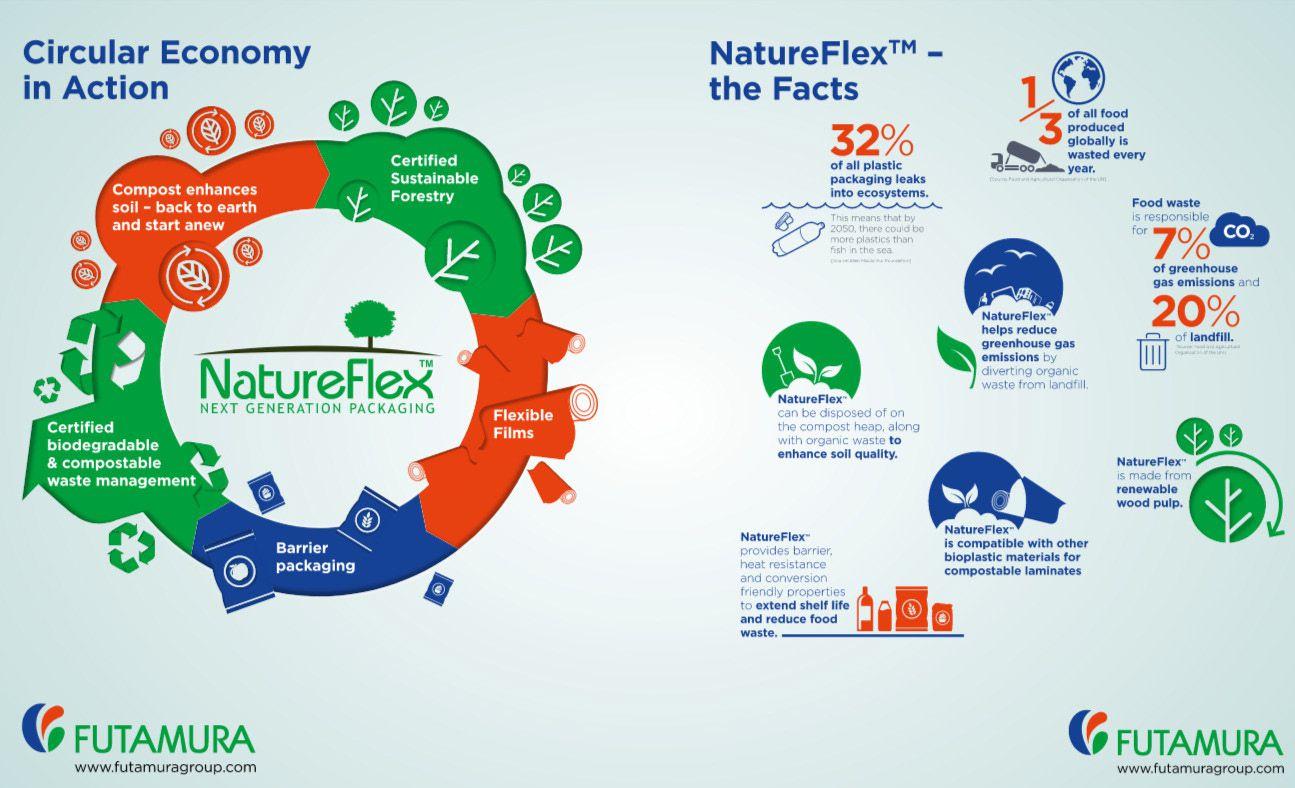

The print and barrier layer is NatureFlex, a cellulose-based product from Futamura USA and the heat-seal layer is composed of ecovio, a compostable biopolymer from BASF.

One of the challenges of this structure was in the adhesive lamination of the two plies which was overcome with the Epotal product line, also from BASF, a compostable water-based adhesive that allows the packaging to pass the ASTM International standards it needs to be considered compostable.

The inks are fully tested for ecotoxicity and the graphics are reverse-printed using standard flexographic printing technology. Finally, the bag shows printed verbiage to help consumers understand that it is compostable as part of the venue composting program.

To date, the introduction of this package is through specific Aramark venues where its composter has verified the compostability of the package. The packaging is shipped to filling plants in rollstock for vertical form-fill-seal machines.

TC Transcontinental Packaging has formalized its commitment to sustainability by developing a social responsibility strategy based on three pillars: creative collaboration, product responsibility and ecodesign. It commits to collaborating towards finding long term solutions with its stakeholders, providing its customers and the community with safe and performant packaging as well as designing products which consider the environmental impacts of a product during its entire life-cycle.

Because TC Transcontinental is determined to build a company that can adapt and transform itself, this strategy allows the Packaging division to always integrate best practices in sustainable development as part of its activities, processes and execution.

The annual Flexible Packaging Achievement Awards Competition is conducted by the Flexible Packaging Association and showcases the industry’s innovation and the advances that have changed packaging.

This year, 66 packages were submitted in the competition, for a total of 164 entries. Twenty packages were

honored with 31 Achievement Awards in five categories:

Expanding the Use of Flexible Packaging, Technical Innovation, Sustainability, Printing and Shelf Impact as well as Packaging Excellence. All entries were judged by an independent panel of experts.

TC Transcontinental Packaging, which has close to 1,000 employees in the U.S. and Canada, is a key supplier of flexible packaging in North America. Its coast-to-coast platform comprises one premedia studio and seven pro-

duction plants specializing in flexographic printing, lamination of plastic films, and converting, including bags and pouches. The division offers an array of innovative solutions for a variety of industries, including dairy, coffee, pet food, bakery, snacks and confectionery, supermarket fresh perimeter, frozen foods, and cigars.

TC Transcontinental Packaging is a division of Transcontinental Inc., which has close to 6,500 employees in Canada and the U.S., and revenues of CDN$2-billion in 2017.

Company information available at www.tc.tc.

Granular level of redundancy vastly minimizes risk for labeling customers

Edmonton,Alberta—Jet Label & Packaging Ltd., one of the largest Canadian producers of labels and printed tape for a broad range of industries, has announced commitment to

total platform redundancy at its primary manufacturing facility in Edmonton.

Acquiring duplicates of critical machinery and components brings speed and economic benefits for customers, and minimizes risk by diminishing delay due to scheduled or sudden machinery downtime. The redundancy is necessary to maintain customer satisfaction while growing double digits annually.

At its Edmonton production plant, Jet Label has doubled up on all equipment—including the twin HP Indigo digital presses and Delta diecutters. Other couplings include a pair of wide presses, eight-color flexo presses, and rewinders for each press width.

The company also is moving toward complete redundancy at its Coquitlam, British Columbia facility, which it secured by acquiring United Label Company in 2017.

With proper preventive maintenance, today’s flexo and digital machines remain robust and rarely experience unforeseen mechanical breakdown.

“Although ‘outliers’ rarely occur, we don’t want to jeopardize our customers,” says Jet Label president and chief executive officer Darrell Friesen. “Our customers do not worry about having all their eggs in one basket.”

For printing industry manufacturers like Jet Label, commitment to total redundancy is a calculated risk. Despite obvious benefits of production consistency and customer reassurance, manufacturers typically make infrastructure investments based on anticipated business needs.

“Our decisions in adding redundant equipment has been realized across platforms, with causes like unexpected downtime, unexpected operator availability to unexpected growth,” states Friesen.

“Part of our commitment to total redundancy is an expectation of continued growth,” continues Friesen.

“We’re willing to put the pieces in place as a landing zone for new business, a proactive approach that lends

itself to in-person appraisals by prospective customers or, increasingly, cyber-tours.”

With manufacturing facilities in Edmonton and Vancouver, Jet Label produces labels and printed tape efficiently and cost-effectively for a diverse portfolio of customers, including grocery stores such as Safeway and Sobeys, international forest product companies such as Canfor and West Fraser, consumer product companies such as Bee Maid Honey and Arc-

tic Chiller, industrial application companies such as Acklands Grainger, Gregg Distributors, and All Weather Windows.

Jet Label also supplies parking and boarding passes and baggage tags to the Toronto, Calgary, and Edmonton international airports. The Edmonton Police Service has also been a long standing customer. In addition to Edmonton and Vancouver, Jet has sales and distribution operations in Calgary, Prince George, Kelowna, Surrey, Saskatoon and Winnipeg.

For more information, visit www.jet-label.com.

UPM Raflatac’s new Premium Gloss UVI product produces stunning print definition on Mark Andy Digital Series hybrid press.

MILLS RIVER, North Carolina—UPM Raflatac’s recently-launched Premium Gloss UVI product is now the highest quality premium-gloss paper labelstock for UV (ultraviolet) ink-jet printing on the market.

For this innovative product development, UPM Raflatac collaborated with a number of industryleading printing press manufacturers to ensure it would achieve excellent print quality on their machines, including Mark Andy Inc.’s Digital Series hybrid press.

“UPM Raflatac’s new Premium Gloss UVI has incredible print definition and fine details using our UV ink-jet Digital Series hybrid press,” says Mark Andy digital product manager Nat Davis. “It’s a great addition to our extensive qualified and recommended substrates.

“Congratulations to UPM Raflatac for bringing

this solution to market; we are very happy to have been able to collaborate on its development.”

Kirit Naik PhD, research and development director, Americas, UPM Raflatac says: “With our new Premium Gloss UVI, we have solved the industry-wide challenge for semi-gloss paper on UV ink-jet presses.

“We could not have developed this innovative, never-before-seen solution without the valuable help from OEMs (original equipment manufacturers) like Mark Andy, who let us perform a number of print trials on their equipment.”

For more information about UPM Raflatac’s new Premium Gloss UVI paper for UV ink-jet printing, click HERE.

UPM Raflatac is labeling a smarter future by developing innovative and sustainable labeling solutions complemented with world-class service.

As one of the world’s leading producers of self-adhesive label materials, it supplies high-quality paper and film label stock for consumer product and industrial labeling through a global network of factories, distribution terminals and sales offices.

UPM Raflatac employs around 3,000 people and made sales of €1.5 billion (CDN $2.42 billion) in

2017. It is part of UPM – The Biofore Company. Find out more at www.upmraflatac.com.

(CDN $16.1 billion). Company information is available at www.upm.com.

UPM leads the forest-based bioindustry into a sustainable, innovation-driven and exciting future across six business areas: UPM Biorefining, UPM Energy, UPM Raflatac, UPM Specialty Papers, UPM Paper ENA and UPM Plywood. UPM provides sustainable and safe solutions to the growing global consumer demand. Products are made of renewable and recyclable materials.

The group employs around 19,100 people worldwide and its annual sales are approximately €10 billion

Mark Andy Inc. is a total solutions partner to the label and packaging industry with a mission to be ‘the supplier of choice with high quality innovative solutions that drive customer profitability. The company responds to business needs by offering the broadest portfolio of equipment, the largest consumables distribution and the most robust service infrastructure to better support printers and converters around the world. For more information, visit www. markandy.com.

OKLAHOMA CITY, Oklahoma—Maxcess International, a global leader in innovative products and services for web handling applications, has acquired Componex.

Headquartered in Edgerton, Wisconsin, Componex will join Menges Roller, Valley Roller, Webex, Fife, Tidland and MAGPOWR under the Maxcess International umbrella of companies.

“The acquisition of an innovative brand like Componex adds tremendous value to our family of web handling companies, specifically our Precision Rolls Group,” says Maxcess chief executive officer Greg Jehlik. “Being deeply focused on expansion through organic growth, product development and acquisitions, Componex is a perfect example of a category leader and an addition that will add significant capabilities at other Maxcess facilities around the world moving forward.”

As the fifth acquisition in four years,

Componex will add its patented WINertia line of dead shaft idlers to Maxcess’ roll product offering from Menges Roller,Valley Roller and Webex to expand its onestop-shop strategy.

“Maxcess can take Componex to the next level by introducing our WINertia technology to markets outside of North America,” says Componex president Cal Couillard. “Its size and scope provided a

logical landing spot for the company that we worked so hard to build over the past 20 years.”

Maxcess helps its customers maximize productivity through innovative products and services worldwide. By combining more than 320 years of global service and support across the storied brands of Menges Roller,Valley Roller, Webex, Fife, Tidland and MAGPOWR, Maxcess offers an unrivaled network of application experts. More at www.maxcessintl.com.

Componex is the worldwide component expert leading the web handling industry with clear-cut, differentiated, value. Componex provides innovative precision products at competitive prices with the shortest lead time in the industry. For more information, visit www.componex.net.