AUTOMATE NOW Plus

DIGITAL SUPPLEMENT FOR FOOD & DRUG PACKAGERS AND THEIR OEM’S

MAKING AUTOMATION AS EASY AS ABB

BY GEORGE GUIDONI

No two packaging trade shows are ever exactly alike, especially when it comes to the highly dynamic and ever-evolving PACK EXPO series of packaging industry showcases produced by the venerable industry group PMMI-The Association for Packaging and Processing Technologies. But if there’s one thing you can safely count on, it’s that you will always see more robots on the latest PACK EXPO show floor than at the previous edition of the event—performing a far more diverse array of tasks than the straight-up carton palletizing or high-speed picking-andplacing of various objects fed into the robotized workcells.

Nothing really says automation without actually saying it as emphatically as a robot going about its business with unerring precision and unwavering dedication,

and seeing hundreds of these marvels of industrial automation drawing hordes of show visitors to the exhibitors’ booths is really a sight to behold. This evolution of robots from their one-time status as packaging oddities and curiosities to packaging necessity did not happen overnight, of course, but it has been greatly accelerated in recent years with the rapid development of new-generation collaborative robots (cobots), whose human-like appearance and movements remove a lot of intimidation from human-machine interaction in the workplace.

Not surprisingly, forward-looking CPG (consumer packaged goods) manufacturers can’t seem to get enough of them these days.

According to PMMI’s timely recent report titled Automation in CPG Companies, cobots are expected to account for

34 per cent of all industrial robotics sales by 2025—representing more than a tenfold jump from their current share of the market.

Although their use in packaging at the moment still lags behind other manufacturing applications, “Of those that are embracing the technology to address workforce and efficiency, an overwhelming 86 per cent report an increase in productivity,” according to the report’s findings.

“Within that 86 per cent, nearly one in five users indicate significantly increased productivity,” PMMI adds. “From an ROI (return-on-investment) point of view, 78 per cent report that whether it be a decrease in labor costs or an increase in output, cobots directly increase their company’s earnings.”

This growing acceptance of cobots in

the workplace is driven primarily by rapid advances in AI (artificial intelligence) technology that frees up robots from tightly enclosed and closely-guarded workcell environments to allow them to work in close proximity to their human counterparts.

“From integrated vision capabilities to mimicking human kinematics, to the utilization of simple teach pendants, today’s cobots are equipped to help CPGs fill labor gaps, maximize a smaller footprint and mitigate worker safety and product contamination risks,” says Jack Uhl of the Consumer Products Group for Yaskawa America, Inc.’s Motoman Robotics Division.

In other worlds, it’s no longer a question of why invest in robots, but rather why not? Yes, the times they are changing indeed, one great show at a time.

THE MANY SILVER LININGS

Canadian cap lining equipment manufacturer using innovative automation technologies to give its specialty machinery an extra cutting edge in the global markets

BY GEORGE GUIDONI

PHOTOS BY PIERRE LONGTIN

With the global market for caps and closures estimated to become a US$58-billion business by the end of next year, companies supplying into this vibrant, fast-growing segment of the global packaging industry owe it to themselves to raise their game in order to take full advantage of that brisk growth.

For companies like the Laval, Que.-based MMC Packaging Equipment Ltd., manufacturer of state-of-the-art cap lining/wadding machines and other postmolding automation systems for the caps and closures industry, anticipating and meeting market needs ahead of the competition has been a key core competency helping the company achieve remarkable success in many of the world’s fastest-growing markets for these essential packaging products and components.

Founded by John McNally in 1968 as a tool-and-dye maker under the origi-

MMC Packaging Equipment technical director and company co-owner Marcel Bélanger strikes a pose in front of a new high-speed slitting and band folding machine being assembled the company’s Laval facility, which will operated at breathtakingly fast speeds of 2,400 caps per hour for the 28-mm tamper-evident enclosure.

nal Montreal Milling Cutter Co. Inc. corporate banner, the company developed its first cap lining/wadding machine in 1978—four years before the infamous “Tylenol Scare” in Chicago shocked pharmaceutical companies worldwide into beginning to insert tamper-evident liners on their products to regain the public’s trust. With this practice quickly being adopted into the foodand-beverage and other CPG (consumer packaged goods) industries, the company quickly built up the manufacturing capabilities to produce more advanced cap lining systems and related systems for an ever-growing array of packaging applications.

So much so, in fact, that in 1991 current president Phillipe McNally, son of the founder, renamed the company to its MMC Packaging moniker to better reflect the company’s growth and a more defined strategic focus on the caps and closures business.

Since moving its new state-of-the-art engineering and manufacturing facility in Laval, the company has steadily diversified its product portfolio with new innovative systems for cap closing, slitting, banding other elated applications, while its 2008 acquisition of machine vision and imaging specialists EOSAI elevated MMC up to a whole new level of technological competence and sophistication.

In 2015, the company reached a major milestone with the installation of its 1,000th machine, according to director of sales and marketing Anthi Balafoutis, who credits the firm’s genuine commitment to innovation and continuous improvement for its excellence in the export markets.

A close-up of the plastic twist-off screw caps used for pharmaceutical products that are lined and wadded with special lining materials on MMC Packaging Equipment’s’ high-performance cap lining machinery for ensuring optimal tamper evidence and product protection.

“Over 90 per cent of our equipment is exported into international markets,” says Balafoutis. “Our primary markets currently are is the U.S. and Mexico, but we would like to focus our future efforts more on Europe, as we see odd growth opportunities there.

“Until recently, we didn’t realize just how many different companies out there are involved in the creation of something as simple as a cap or closure.”

Employing over 70 full-time specialists, the lively Laval facility is in many ways a model corporate citizen, having been named to the prestigious Deloitte & Touche list of Canada’s Best Managed Companies for the last two years running.

The model LM-270 cap lining machine manufactured by MMC Packaging is the company’s best selling machine, which uses a variety of Beckhoff Automation components and a PC-based control system to enable complete automation of all the machine functions, including feeding, mounting and cutting of the liner, along with inspection and reject confirmation.

As acknowledged by company president McNally, “This award recognizes our ability to adapt to a changing marketplace, comparable to the best companies in the country in terms of product development, business development, and organizational excellence.

“I consider that our success is due to the commitment and efforts of all employees and I am very proud of our team,” McNally says.

“Our constant drive towards recognition as the sector reference and benchmark for product and service quality worldwide is spearheaded by a sharp needs-oriented focus, and the credibility we foster with our partners customers

through the consistency and reliability of both our people and products,” he states.

“In a market that is constantly looking for innovative caps and specialty closures, the dynamic MMC team takes the time needed to understand each individual cap manufacturer’s special machinery requirements,” adds Balafoutis.

“That’s why MMC Packaging is not only a reference point for post-molding automation equipment, but also an authoritative source of expertise in providing services related to the manufacturability of new closure designs.”

With the company’s growing global customer base now extending across food-and-beverage, personal care, pharmaceutical, home-care, and chemical and industrial sectors, MMC Packaging has naturally developed a lot of equipment customization capabilities that enables it to introduce new value-added features on its standard equipment on a regular basis, according to Balafoutis.

“We have acquired a lot of experience when it comes to customization because there really is a lot of difference in the size and the geometry of the caps and closures used in the different sectors,” she states.

“And as one can imagine, there are a lot of very intricate closure designs on the market that require some type of automation to optimize their feasibility.”

To answer those clients’ automation needs, MMC Packaging offers a comprehensive range or equipment comprising:

• Cap lining machines, high-efficiency systems capa-

ble of stamping out and installing liner disks inside the caps at rates of up to 1,200 caps perminute.

• Cap slitting and band folding machines. As Balafoutis explains,“We design and manufacture cap slitting and band folding that score the sidewall of plastic closures either with an arched slitting blade, or a cut-topost technology, for creating tamper-evident closures.

• Cap assembly machines, designed to assemble multipiece closures at high throughput rates.

• Cap closing machines. “This type of equipment is designed to reliably perform and repeat highly efficient and intricate closing functions for closure styles with various hinge and latching features,” Balafoutis explains.

• Vision inspection. “We have a dedicated in-house team of vision specialists and software engineers that design vision systems uses to capture all sorts of closure defects at high processing rates,” according to Balafoutis.

• Because automated machinery is ultimately as good all the components, devices and systems that go into its design and construction, MMC Packaging makes it a point to partner up with the best industrial automation suppliers in the business—such as Germany-headquartered Beckhoff Automation GmbH & Co. KG. With a strong North American presence—underscored by the company’s Beckhoff Automation Canada Ltd. office in Mississauga, Ont. and its parent Beckhoff Automation LLC subsidiary just outside of Minneapolis in Savage, Minn.—the company is a renowned expert in open

MMC Packaging Equipment automation specialist Oliver Turcot refers to the vivid graphic display of the proprietary ICON human-machine interface software running on the custom 18.5-inch control panel terminals manufactured by Beckhoff Automation.

PC-based automation technologies, supplying a broad range of industrial PCs, controllers, control panels, input/ output products, servo drives and motors, and automation software to industrial OEMs (original equipment manufacturers) worldwide.

“Our collaboration with Beckhoff Automation started in 2013, when MMC decided to lead the way of post-molding automation equipment built on PC-based controls system,” Balafoutis relates.

“Ever since, the partnership between MMC and Beckhoff has been growing stronger and stronger.

“As far as we are concerned, PC-based technology offers not only enhanced performance compared to traditional

PLC (programmable logic controller) technology,” Balafoutis states, “but also new capabilities such as remote access and control, integrated multifunctional control and data reporting, and structured text programming that is easier to tailor, deploy and maintain.”

Naturally, such ringing endorsement is sweet music to the ears of Ted Sarazin, Beckhoff Automation’s regional sales manager for Eastern Canada.

“The relationship between MMC and Beckhoff has been extraordinary on every level for many years now,” Sarazin states.

“Their management team are always eager for innovation,” he says, “which is very much in line with the Beckhoff ’s philosophical foundation.

“Moreover, they have a very high skilled engineering team who are always curious for new technology, which is why they have incorporated many of our technologies into their systems.”

Specifically, the Beckhoff automation products deployed on much of the MMC-made equipment include:

• The customized 18.5-inch CP39xx multitouch control panel, with extension pushbuttons, to provide optimal display and functionality for MMC’ proprietary ICON human-machine interface (HMI) software. Designed for both control cabinet and mounting-arm installation options, the panels offer all-around IP 65 level protection, and they can be operated at up to 100 meters away from the industrial PC with Beckhoff ’s

CP-Link 4 one-cable display links.

• The compact and powerful CX2040 four-core CPU (central processing unit) with an i7 processor to connect up to four modules to the scalable PC, with option to add extra PCIe ports for any additional required applications.

• The CX5140 family modular CPUs combining PC technology and modular I/O (input/output) level on a DIN rail unit in the control cabinet to offer a spacesaving solution for various logic and motion control applications. Says Balafoutis: “The Beckhoff I/O is modular and easily adapts to our needs to enable us to connect all the sensors, valves, E-stops and security connections. “It also makes it easier for us to add new sensors without additional wiring just by adding the required communications cards.

• The AM8000 synchronous servomotors, deigned to provide high power density to achieve precise control of angular position, acceleration and velocity. Featuring small end turns and a fully potted stator to ensure perfect thermal contact between the stator and the motor housing, the high-performance servomotors— available in five sizes and three length dimensions for each size— are engineered for superior durability and robustness, with guaranteed service life of 30,000 hours for the wearing parts such as ball bearings.

The AM8100 series servomotors for OCT (one-cable technology) servo terminal, featuring an integrated absolute

encoder for high-speed digital data transfer—eliminating the need for homing by combining power and feedback within a single cable.

According to Beckhoff, “The high dynamics of these servomotors open up a multitude of possible application in industrial robots for pick-and-place applications, for example, or for general mechanical engineering applications requiring compact design and high positioning accuracy.”

All in all, using Beckhoff automation solutions has enabled MMC to develop better, faster and more flexible caps and closures processing machines for its customers, Balafoutis agrees.

“It helps us execute our vision of being a ‘one-stop shop’ for all post molding-automation solutions—including peripherals, vision and inspection systems—to offer our customers a most comprehensive product offering in the market,” Balafoutis sums up.

“Thanks to our recognized expertise, MMC Packaging is committed to ensuring the complete satisfaction of its customers by offering integrated, automated and innovative products for the post-molding process of the closure industry; by providing an efficient after-sales service; by constantly ensuring the quality and reliability of our solutions, and by distinguishing ourselves with fast and ‘on-time’ leadtimes.”

CHIPPING AWAY

Swiss chip manufacturer implements cutting-edge industrial safety technology to keep its automated process running at full speed

Since its humble beginning in 1957, potato chips manufacturer Zweifel Pomy-Chips AG has worked tirelessly to create a name for itself as one of the most prominent and trusted snack-food brands in Switzerland.

Based in Spreitenbach, a short drive outside of Zurich, the company’s production plant employs about 400 people to produce a popular range of high-quality potato chips comprising the Original, Chilli Paprika, Spicy Tomato and Salt & Vinegar flavor varieties.

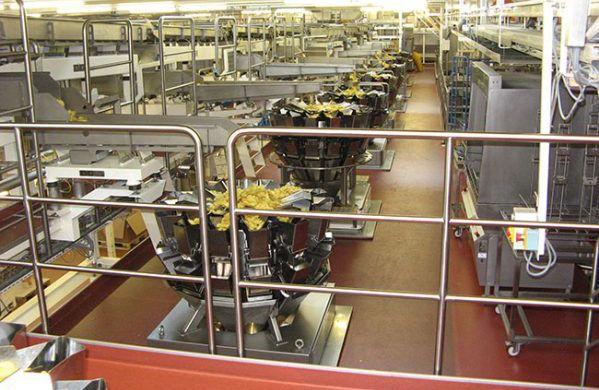

This production takes place over a 200-meter-long production line stretching over two floors of a building filled with and an ever-present aroma of fried potatoes wafting through the air, created by the average of five tonnes of potatoes processed each hour to make and package the product.

Currently in the process of modernizing nine of its packaging lines, Zweifel boasts extensive in-house knowledge and experience in developing and integrating its production equipment and the plant programming associated with running this equipment.

A few years ago, after putting out a tender for new packaging and conveying equipment, the chip producer found itself in need of some specialized knowledge that would enhance the overall safety of its working environment throughout the plant in a consistent and highly reliable way, as specified by the European Union’s Machinery Directive 2006/42/EC standard.

Specifically, the interconnection between the individual plant sections mean that the interfaces and logic connections of the E-STOP functions had to be assessed and transferred into one overall case of compliance with the directive, which mandates that all working machines must be deployed in such a way that man and the environment are sufficiently protected from harm.

With Switzerland agreeing to comply with this directive via several bilateral trade agreements, the manufacturers and marketers of such machinery must provide binding give binding confirmation that their plant meets the minimum safety requirements in through a formal declaration of compliance.

In light of the large number of standards to be considered for such a declaration, being on the safe side required some well-versed specialized expertise in the area of industrial safety.

“It was clear to us that we needed support from a competent partner,” says Gerhard Meier, Zweifel’s team leader of technical services who turned to safety automation specialists Pilz GmbH & Co., to implement the process.

“As we have enjoyed a long-standing partnership with Pilz, we were aware of their expertise in matters regarding risk assessment and development of reliable safety concepts, right through to CE marking”, says Meier.

Based in Ostifildern, Germany, Pilz worked closely with Zweifel to help produce an efficient safety-related control concept, which involved the development of mechanical, electrical and other technical engineering solutions for machine safety, while accounting for all the key considerations of machine availability and productivity.

Essentially, Zweifel was looking for a high-performance safety control system to link and monitor the exchange of safety-related signals—separately and in parallel to the plant control system—incorporating a high-performance device that had to highly network-capable, reliable and simple to program, as well as easy-to-use in an everyday operation.

In this operation, special conveyor grooves are used transport the baked chips to

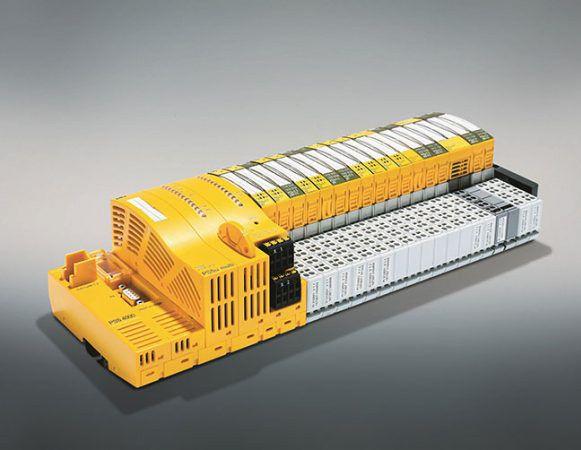

As the central component in the new packaging line, the automation system PSS 4000 for safety and automation closely monitors all of the safety-related functions at Zweifel Pomy-Chips AG.

the new packaging lines, where a pneumatically controlled flap opens up to allow the chips to access the fully-automatic packaging machines, where the chips are sealed in bags in brisk and orderly fashion and packed in standard transport cartons to start making their way to the market.

The chips metaphorically fell into place when Pilz introduced Zweifel to their perfect match—namely the PSS 4000 automation system.

“We had been following the development and launch of the PSS 4000 automation system with interest for some time,” says Meier, noting that Zweifel had previously used Pilz’s PNOZmulti configurable control system with considerable success.

But as the plant became bigger and the production requirements more complex, the case for upgrading to a more efficient modular system such as the PSS 4000 automation system—offering the option of combining and merging safety with automation—became more compelling.

The E-STOP pushbuttons positioned along the packaging line are monitored using the automation system. The company attached great importance to the formation of four autonomous safety circuits, as it must be possible to clean one section of the plant without entirely halting the whole plant production process in its entirety.

According to Pilz, the PSS 4000 automation system is designed to allow for optimal interaction between hardware and software components, network devices and the real-time Ethernet—thereby enabling a wide range of projects to be implemented more easily and with greater flexibility than with conventional solutions.

A pneumatically controlled flap opens up when the machine is in operation, allowing the different kinds of chips to access the fully automatic packaging machines prior to being packaged.

“Following an internal cost and benefit analysis of both systems, we came to the conclusion that it was the right time to use the PSS 4000,” says Meier.

As the central component in the new packaging line, the PSS 4000 automation system monitors all the safety-related functions such as the packaging line and safety gates via an advanced intelligent access concept.

The gates are fitted with PSENmag magnetic safety switches and the coded PSENcode safety switches from Pilz. The latter is then used to monitor the position of guards in accordance with the EN 60947-5-3 standard, and also for simple position monitoring.

The pneumatic cylinders are thoroughly monitored. In order to avoid an increased risk of injury to the operators, the flaps must be safely locked during the cleaning process.

Rather than having a centralized control system, a modular user program is made available within a centralized project, which allows for standardized and simple handling.

With its ability to undertake safety and automation tasks, the automation system has already proven itself in numerous applications in the widest range of industry sectors, according to Pilz.

After reviewing the PSS 4000 automation system and learning how it functions and operates, the decision to employ it was a no-brainer for Zweifel.

“When selecting the PSS 4000 automation system, the deciding factors for us were the simplicity, the drastically reduced cabling work, clear communication, clear responsibilities and, ultimately, the excellent price-performance ratio,” Meier states.

Meier adds another factoring decision in choosing the

automation system was the ability of the PAS4000 software platform and its Graphics Editor functionality to link into the existing structure of the PNOZmulti Configurator, meaning that the parameter setting remains transparent and simple into the future.

Since implementing the PSS 4000 automation system, the working relationship between Zweifel and Pilz has been smooth sailing, as the partnership has resulted in excellent prospects for other future prospects for the chip manufacturing company.

“As usual, our collaboration with Pilz was conducted in the full spirit of partnership,” Meier concludes.

“Pilz not only supplied us with outstanding products, but also provided competent support in word and deed before, during and after commissioning.”

A centralized standard automation control system monitors the machine and processes all the signals, while the automation system PSS 4000 allows for the consistent distribution of various control functions at a time.

BY GEORGE GUIDONI

HAPPY ENDINGS

Stretchwrapping equipment manufacturer and integrator spares no effort to grow its business through formidable technical competencies and customization capabilities

Being squeezed out of a job by forces way beyond one’s control can be a crushing and deflating experience for many. But it can also be the proverbial opportunity in disguise for ambitious and energetic entrepreneurial types like Stéphane Côté, founder and president of Solutech Packaging Systems in Richmond, Que., a one-hour drive northeast of Montreal.

Once a long-time employee and shareholder of a thriving family-owned stretchwrapping equipment manufacturer Wulftec International, Côté thought the time was right to to expand his professional horizons after Wulftec was acquired by a big overseas packaging machinery conglomerate M.J. Maillis Group back in 2002.

After another few years working at the North American subsidiary of Italian stretchwrapping equipment manufacturer Robopac, Côté’s entrepreneurial instincts steered him to the inevitable decision of starting his own company—specializing in the aforementioned stretchwrapping machinery, palletizing equipment, and related end-of-line material handling systems and equipment.

But rather than bing just another ‘me too’ packaging machine manucaturer and fabricator, the startup company decided early on to hone its system integration skills

Solutech Packaging Systems founder and president Stéphane Côté (left) and Gaétan Larivière, local sales representative for the ASCO/Numatics division of Emerson Automation Solutions, hold up the high-quality pneumatic components from ASCO incorporated inside Solutech’s high-performance stretchwrapping machinery manufactured in Richmond, Que.

PHOTOS BY PIERRE LONGTIN

in order to be able to offer its customers turnkey end-ofline solutions incorporating all three types of equipment it would make and market.

With Solutech celebrating its 10th anniversary this year, it’s safe to say that Côté’s entrepreneurial drive and instincts have been aptly rewarded in the highly competitive marketplace for end-of-line packaging machinery.

Today employing 25 full-time staff at two side-by-side plants totaling up to about 24,000 square feet of production space, the company has expertly executed hundreds of successful machine installations in its primary bread-andbutter food-and-beverage markets across North America.

SIZE MATTERS

In addition, Solutech has also performed several highly one-off system installations at massive industrial and commercial facilities operated by paper product giants Domtar and Cascades, roofing products manufacturer Soprema Group and the Government of Québec, among others.

“Since starting out in my own garage 10 years ago, I had to move the company four times to keep up with the growth,” says Côté, saying he had full confidence in Solutech’s ability to succeed, despite formidable competition from the industry’s more established players.

“We now have machines installed all over Canada and the U.S., along with a few in Mexico,” Côté told Canadian Packaging in a recent interview.

“Having been around strethchwrappers for about 20

years before starting up Solutech, I always felt there was a gap in the marketplace for turnkey end-of-line solutions,” says Côté, “and filling that gap is what I thought would enable Solutech to carve itself a piece of the market pie.

“There were a lot of people manufacturing just stretchwrappers and a lot of people manufacturing just palletizers,” Côté explains, “but there were not many companies providing one-stop-shop solutions to the marketplace.

“That’s where I thought that Solutech had a real market opportunity to exploit,” he reflects, “and in hindsight I am very happy to have been proven right.”

Considering that 10 years is a relatively brief period in any traditional industry, let alone the packaging machinery market dominated by venerable multinational heavyweights, the company’s scope of equipment offerings is truly remarkable—ranging from basic stand-alone semi-automatic wrappers to sophisticated, fully-automatic rotary-arm and orbital configurations capable of handling large truck tires, giant paper rolls, oversized wood panels and all other manner of bulky or awkward product loads.

“We do it all,” says Côté, “but where we really shine is in customizing end-of-line solutions specifically for our customers’ application needs.”

Côté says the Solutech equipment compares very well in price and performance against all of its main competitors, while offering some unique value-added features not found elsewhere.

“We equip all our semi-automatic machines with Allen-Bradley control panels as on our semi-automatic ma-

chines as a standard feature,” Côté points out, “whereas other manufacturers only offer it as an option, with all the extra costs that entails.”

With stretchwrapping equipment accounting for about 70 per cent of Solutech’s total business, the company’s stretchwrapping portfolio comprises:

The semi-automatic INTELLI-WRAP portable stretchwrapping system with throughout capacity to wrap 15 to 20 loads per hour.

Designed as a cost-effective solution for busy distribution centers, the battery-operated system can provide up to 12 hours of completely autonomous operation from an eight-hour charge, according to Solutech, with its 20-inch film carriage capable of making light work of oversized loads.

While the use of similar independently operating stretchwrappers has been gaining momentum in recent years thanks to their portability and extremely compact footprint, “To the best of my knowledge we are the only North American manufactures of these types of systems,” Côté asserts.

“All the other ones are imported from Europe, where such systems were originally designed and commercialized,” he states.

“I originally imported them myself but I found little success in marketing them,” he relates,“so about four years ago I decided to start making them myself.

“I have sold about 50 of them since then,” Côté states, saying the user-friendly machine—looking more like a

home appliance than an industrial equipment—stole the show at this year’s SIAL Canada 2018 food industry exhibition in Montreal.

“Show visitors just couldn’t get enough of seeing the INTELLI-WRAP in action casually going about its business of circling around a pallet and stretchwrapping the stacks of product all on its own, load after load.

“I got more solid sales leads from that show for this machine than I do at many of the packaging industry shows we exhibit at,” he chuckles.

SERIAL SUCCESS

Other notable stretchwrapping equipment lines manufactured by Solutech include:

• The SLP series semi-automatic turntable stretchwrappers, equipped with a pre-stretch film carriage installed on the side of the machine to provide optimal working ergonomics for the operators, while ensuring optimal film pre-stretch to maximize film usage.

• The SHP series high-profile stretchwrapping machines, designed to be loaded only by forklift.

• The SRT series stretchwrappers in-

A fully-integrated end-of-line packaging system assembled by Solutech Packaging Solutions makes light work of preparing giant truck tires for a perfectly safe and secure shipment to customer.

corporating a rotary tower attached to a 20-inch powered pre-stretch carriage, which rotates around a stationary pallet load on the floor to optimize film usage.

• The automatic SLPA series low-profile turntable stretchwrappers and the SHPA series high-profile turntable stretchwrappers—both designed to allow the operator to start the system without getting off the forklift.

According to Solutech, “The system automatically attaches the stretch film at the

beginning of the cycle and cuts and wipes the film at the end of the cycle—enhancing ergonomics and workplace safety.”

• The automatic SCTA series stetchwrappers integrated with fivefoot-long infeed and outfeed conveyors. “This fully automated systems requires simply loading and unloading of conveyors with pallet loads,” according to Solutech, “with the complete wrapping cycle performed automatically.”

• The SRTA series rotary tower

stetchwrappers. Also designed to allow the operator to start the system without getting off the forklift, the system automatically attaches the stretch film at the beginning of the cycle and cuts and wipes the film at the end of the cycle lowering the risk of injury for the operator and optimizing the wrapping cycle time.

• The automatic SCRTA series rotary tower system that can be inserted into an existing conveyor line, or installed as a stand-alone system. According to Solutech, the high-speed system is designed to index the pallet load automatically, securely wrap the load at optimal pre-stretch, and cut and wipe the film at the end of the cycle without any operator intervention.

As Côté relates: “I am exremely proud of what our team has developed and brought to the market.

“The latest integration of the new features, such as multilingual touchscreen technology, the use of only nonproprietary parts, and custom-made robotics integration enable us to go beyond our customers’ expectations,” he enthuses, “offering custom-made applications to fill any need

and requirement.

“Our robust machines are built last for years with total peace-of-mind,” says Côté, citing superior structural strength and integrity of all machine parts fabricated by Solutech.

“The thickness of the steel we use on our turntables makes Solutech equipment one of the most hardworking machines on the market, period,” he extols, crediting the company’s expert staff, boasting a wealth of combined mechanical and electrical engineering knowledge, for helping Solutech establish a stellar industry reputation.

“One of our greatest strength it is our talented, committed and passionate employees,” Côté states.

“The before and after sales service is a direct Solutech service done by Solutech employees, so that if a distributor or end-user ever has any issue with any of our equipment, the same team that developed the equipment will also be the same team addressing those inquiries.”

Côté also credits the company’s various business partners for helping it succeed—reserving special praise for the ASCO/Numatics division of Emerson Automation Solutions in Saint-Laurent, Que.

Says Côté: “ASCO/Numatics has been our choice for pneumatic components since Solutech started up 10 years ago, and their support has been instrumental helping us realize our vision of what top-quality stretchwrapping equipment should look and work like.

“They have been a tremendous partners.”

The sentiment is resoundingly mutual, according to

Gaétan Larivière, Emerson’s technical sales specialist for fluid and motion control products.

“We are proud of our partnership with Solutech Packaging Systems,” Larivière told Canadian Packaging.

“We have been partners for many years now, and I’d like to think that we have played a part in helping Solutech achieve their impressive growth in both size and reputation.

“By using real world-class components made ASCO/ Numatics, they have been able to raise their technology to a much higher standard, while also adding a lot of value to their product portfolio,” says Larivière, praising the high level of collaboration between the two companies on all new projects initiated by Solutech.

CLOSE & PERSONAL

“We work closely with all their departments: from purchasing to engineering,” he states. “We help them with purchasing on day-to-day basis, keeping track of the orders and make sure that we are always on top of the game when it comes to price and delivery.

“We also help their engineering with creating the 3D drawing for their designs, assisting them in conceptualizing new designs, or bringing additional information for their new product development,” he adds.

“It’s all about keeping Solutech completely up-to-date on all new technologies available, so that they continue to improved their product offering by building more efficiency into their machinery—thereby and get the best

possible return on investment.”

Some of the key high-quality pneumatic components supplied by ASCO/Numatics to Solutech include:

• The 651/652 Series air filtration line featuring modular construction with body-to-body clamps and end plates, which offers mounting versatility and enables quick product replacement, while leaving piping in place.

• The stainless-steel M Series pneumatics cylinder line, engineered to exceed all light-duty cylinder application requirements. According to ASCO/ Numatics, “This reliable cylinder is reliable and is designed and built to maximize performance with a multitude of standard value-added features such as stainless-steel piston rods, roll-formed threads at both ends of the piston rod, and pre-lubed installation for lubrication-free service life.

• The Solenoid Pilot Valve-Manifold with a highflow rate 11-mm pneumatic valve. Designed to save mounting space requirements and troubleshooting time, the four-way solenoid air pilot actuate valve is available in manifold with Fieldbus and is compatible with all leading industrial Ethernet protocols.

BY JACK UHL

THE SMART SOLUTION

PHOTOS COURTESY CSI PALLETIZING

Palletizing can often be an afterthought when considering complete packaging line automation. In fact, it is not uncommon to see a company, especially with lowvolume production, experience an uptick in production output based on primary and secondary robotic process automation alone. The major issue with this conservative approach is the unavoidable truth that successful implementation of robotic automation increases productivity, enabling businesses to thrive and grow. Most likely, end users that fail to address end-of-line palletizing requirements will be forced to “catch up” at some point. No matter a company’s production volume or the success level, today’s market challenges will impact operations in some way. At the end of the day, it is how manufacturers embrace and utilize the vast array of robots and technologies available to tackle tough situations that matters.

THE GROWING CASE FOR END-OF-LINE PALLETIZING

Traditionally, manual labour has been used to facilitate end-of-line process needs; however, a growing number of challenges are forcing manufacturers to recognize the difference that automated palletizing can make in packaging operations. All too often, decision makers are saying:

• “I can’t find or keep adequate manual labour for end-of-line palletizing.”

• “My end customers keep adding or changing patterns on the pallet, and even pal-

let types/sizes, which are hard to maintain and control.”

• “Since my shipments go to a distribution center, the customers want the bar code labels shown on all four sides of the pallet. My staff finds this difficult.”

• “My company wants to control all production setup and production information management in a real-time software method, instead of depending on individuals and manual methods on the plant floor.”

These examples reflect a portion of current conditions manufacturers face daily, and with the ultra-competitive market in Consumer Products manufacturing, keeping every customer satisfied is of upmost importance.

It has become increasingly difficult for manufacturers, especially food processors, to maintain a high level of efficiency in managing end-of-line palletizing, and pallet shipment or movement into storage, using conventional methods. Combine this need for high throughput efficiency with stricter safety regulations and rising labour costs, and the case for end-of-line robotic automation gets stronger.

THE IDEAL PALLETIZING COMBINATION

While having the proper hardware to facilitate application needs is important, having a complete packaging solution – equipped with comprehensive, user-friendly palletizing software to streamline the process – is equally important to enable fast development and deployment of palletizing workcells.

From single-line to complex multi-line palletizing operations, it is ideal for companies to be able to achieve the upmost efficiency. This is why Yaskawa Motoman listened to customer feedback prior to radically re-engineering the palletizing software, known as PalletSolver:

• Offline, PC-based software component permits layer patterns to be “built” in the simplest way:

• Easy 3D model of the case and pallet, via a drag/drop/snap command method

• Use of over 70 templates from the Layer Pattern Library for minor modification

• Importation of electronic files from leading, third party software providers, CAPE & TOPS

*Since these tasks are performed offline, there is no downtime of the cell to perform these changes.

• Simple, visual command identifies label location on cases and if they need to remain visible on all four sides of the pallet:

• All step-by-step robot commands are automatically generated

*The process is completely automated.

• Multi-size or -style capability manages various pallet types:

• Popular pallet types (i.e.: GMA, CHEP, PECO, etc.)

*Multiple pallets can be used and managed with ease, meeting ever-changing market demand.

• Easy programming facilitates changes:

• Quick changes can be made to layer patterns, case sizes and confirmations by an operator.

*Operator does not need to understand how to program a robot to utilize software.

Robotic automation is a direct solution for many challenges, including labour availability, and pallet type or size changes.While some manufacturers (i.e.: food manufacturers) may feel more pressure to automate all aspects of packaging operations, the need for preparing and transporting end-of-line pallet loads efficiently with proper product tracking and minimal product damage is crucial for all companies to maintain a competitive edge.

As businesses grow and evolve, so must the equipment being used to fulfill orders. end-of-line palletizing equipment and pallet transport systems should be flexible and durable to meet demands.When companies recognize the need for end-of-line automation and invest in the innovative equipment and software available, substantial benefits can be achieved.

Jack UHl, Sales Manager – CPG (Consumer Products Group) for Yaskawa America, Inc.’s Motoman Robotics Division.

TEAM GAME

Collaborative robots redefining man-machine workplace dynamics

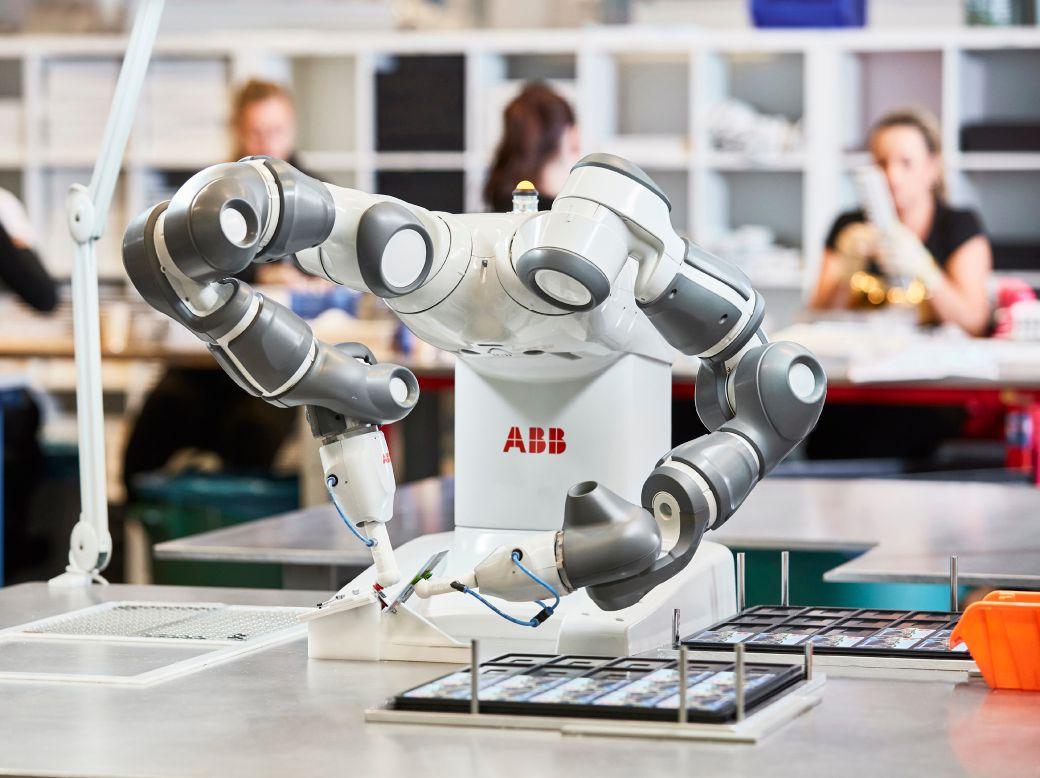

The hottest topic in robotics right now seems to be collaborative robots, and few people are better qualified to talk about their impact on the modern manufacturing workplace than Phil Crowther, global product manager for small robots at ABB Inc.

What industries do you see having the most practical applications for collaborative robots and in which applications might they replace traditional industrial robots? Small parts assembly is the biggest current market for collaborative robotics. The electronics industry, in particular, has seen demand skyrocket past the supply of skilled labor. As conventional assembly methods diminish in value, manufacturers are finding it strategically and economically imperative to invest in new

solutions, like that offered with the newly emerging collaborative robotics technology.

YuMi, the world’s first truly collaborative robot, is about combining the strengths of both man and machine into an optimal solution. YuMi, in fact, means “you” and “me”, working together to create endless possibilities.

Industrial robots are ideally suited to perform the dull, dirty, delicate and dangerous tasks so often associated with manufacturing. They provide humans the freedom to concentrate on cognitive tasks.

How will these types of smart robots transform manufacturing and assembly in the near future?

The rapid rise of smart electronics has increased the demand for highly skilled production workers capable of consistent precision. This impacts every industry that incorporates small, sensitive parts into its end products.

For manufacturers, the market has changed the rules in ways that can be addressed effectively only by automation. The “new norm” of small parts assembly is higher product volumes, shorter product life-cycles, shorter-lead times and a growing trend to customize goods—particularly electronics—close to final markets.

The solution needs to be easily portable and redeployable, as well as being able to fit into existing workspaces designed for humans.

collaborative robots, are there still safety concerns that remain when humans and robots work side-by-side?

casing wrapped in soft padding. This arrangement absorbs the force of any unexpected impacts to a very high degree.

With all of the advanced sensing, force-feedback, and machine vision technologies incorporated in industrial and

Not with the new wave of collaborative robots. Much like a human arm has a skeleton covered with muscles that provide padding; YuMi, for example, has a lightweight yet rigid magnesium skeleton covered with a floating plastic

Like the human arm, they have no pinch points so that sensitive ancillary parts cannot be crushed between two opposing surfaces as the axes open and close.

If an unexpected impact occurs, such as a collision with

a coworker, YuMi can pause its motion within milliseconds, and the motion can be restarted again as easily as pressing play on a remote control.

Is programming still a large pain point for facilities incorporating robots in their processes?

In order to address programming complexity issues, collaborative robots like ABB’s YuMi employ innovative programming methods, so intuitive to use anyone can do it without special training. It has senses and motor control comparable to humans. One of YuMi’s unique features is its “inherently safe” design, allowing it to work alongside humans while reducing risks to acceptable safety levels.

At first glance, processes on manual assembly lines might seem relatively simple to automate, but in reality it is not so easy to replicate human abilities. Humans have touch and motor control, which allows us to handle delicate things with dexterity and precision, as well as judge how much force to use on a given component so that we do not break it. Humans can see where an item is, easily pick it up, and are able to handle an incredibly diverse variety of parts without pausing. Humans also have spatial awareness, which allows us to interact closely and in harmony with our coworkers.

In designing collaborative robots, the challenge is to determine how to replicate all of these human attributes in a way that is cost effective, essentially recreating the minimum number of senses and abilities necessary to be at least as safe as humans, yet still able to provide the substantial benefits of automation.

Through purpose-built design that is much more than just the robot, a truly collaborative robot must be an inherently safe system of components that delivers the precision, ease-of-use, speed, flexibility and return-on- investment required for the future of small parts assembly.

How do you address concerns about the cost of robot integration into an existing facility?

What advantages does robot integration present that support a customer’s ROI?

While conventional robotic systems will still be needed for a long time to come and have several key advantages over current collaborative technology (e.g. higher payloads,

much faster cycle times and stronger protection from harsh environments such as foundries), collaborative robots are far less resource-intensive in terms of system design, installation, commissioning and operation when compared to conventional industrial robots.

As the robotics market continues to exhibit explosive growth, collaborative humanrobot workplaces will be a large driver of that growth, thanks to increased ease of deployment and operation, as well as the automation of many industries that were previously considered impossible to automate effectively.

ABOUT ABB’S YUMI

What motivated ABB to develop this robot?

The meteoric rise of smart technologies such as smartphones and wearable technologies (Fitbits, watches, etc.) has led to a demand for automated assembly lines. ABB rec-

ognized this need within the small parts assembly arena, early on where the desire for better quality and a rapid ROI are key drivers.

Additionally, customers in this arena wanted an automated solution that was safe and would allow people to concentrate on more cognitive tasks rather than the dull, dirty and dangerous job so often associated with manual assembly.

How is YuMi different from similar robots on the market today?

YuMi is the world’ first truly collaborative robot, able to work side-by-side on the same tasks as humans while still ensuring the safety of those around it.

Capable of handling anything from a watch to a tablet PC and with the level of accuracy that could thread a needle, YuMi will radically change the way we think about assembly automation.

With regards to safety, YuMi’s provides an inherently safe design with lightweight, padded arms, and limited power. This sets it aside from other collaborative robots.

What problems needed to be addressed during the development process?

YuMi’s design is extremely compact and when technology is miniaturized there are often technical issues, or barriers, that must be addressed. Some examples include, but are not limited to, cabling for small radius areas, motors and gears and the encapsulation of controller technologies into the robot body.

How long did it take from conception to ultimate production?

The concept for YuMi was developed nearly a decade ago. ABB only recently decided, based on favorable market conditions, to enter the collaborative robot market. Once the

decision was made to productize YuMi, and move forward, the final development was rather fast.

What effect did cost factors have in changing the final design of this product?

When going from a prototype to product the primary design factor to consider is product lifetime. In other words, quality and reliability are the most important things to take into consideration. Product lifetime testing is very stringent at ABB and we set very high goals and milestones before we introduce a new product to the market.

Who is your target audience to be and what benefits will they achieve from using this product?

YuMi is specifically designed to address the needs of Small Parts Assembly, especially in the consumer electronics sector. A key differentiator is that it is part of a total Small Parts Assembly solution that includes adaptable hands, flexible parts feeders, force control sensing, vision guidance, in addition to state-of-the-art control and software.

It can collaborate, side-by-side, with humans in a normal manufacturing environment enabling companies to get the best out of both humans and robots, together.

YuMi meets the demands of a consumer market that is driving a need for greater flexibility in automated manufacturing head-on. For manufacturers, the market has changed the rules in ways that can be addressed effectively only by automation. The “new norm” of Small Parts Assembly is higher product volumes, shorter product lifecycles, shorter lead times and a growing trend to customize goods – particularly electronics – close to final markets.

Do you have any other interesting information you would like to add?

We are extremely keen to talk with customers about their needs and to learn and understand what kinds of applications YuMi is best suited for. In this way, we will continue to find ways to allow people to concentrate on more cognitive tasks rather than the dull, dirty and dangerous job so often associated with manual assembly.

Phil Crowther, global product manager for small robots at ABB Inc.