AUTOMATE NOW Plus

DIGITAL SUPPLEMENT FOR FOOD & DRUG PACKAGERS AND THEIR OEM’S

Broughttoyouby

YOUR AD HERE

11.2” x 7” (TRIM)

6 A KALEIDOSCOPE OF COLORS

Ontario candy and gum manufacturer steps up its production line efficiencies with top-flight equipment designed and built by a Canadian company

13 WITH ALL DUE RESPECT

A mutually respectful partnership with a global automation powerhouse helps Ontario original equipment manufacturer of feeding machines grow its worldwide business base and enrich its design skillset

22 FIRST GLANCE

New packaging solutions and technologies.

23 WHOLE NEW BAG OF TRICKS

Canadian bagging machinery manufacturer finding its feet in the competitive market through thoughtful design innovation and successful strategic partnerships

YOUR AD HERE

Stephen Dean • (416) 510-5198 SDean@canadianpackaging.com

CIRCULATION MANAGER Barbara Adelt • (416)-442-5600 x3546 badelt@annexbizmedia.com VICE PRESIDENT Tim Dimopoulos tdimopoulos@annexbizmedia.com ANNEX BUSINESS MEDIA 80 Valleybrook Drive, North York, ON, M3B 2S9; Tel: (416) 510-5198; Fax (416) 510-5140. November 2016

George Guidoni • (416) 510-5227 GGuidoni@canadianpackaging.com FEATURES EDITOR

Andrew Joseph • (416) 510-5228 AJoseph@canadianpackaging.com ART

Kathy Smith • (416) 442-5600 x 3215 ksmith@annexbizmedia.com

PRODUCTION MANAGER

Barb Vowles • (416) 510-5103 BVowles@annexbizmedia.com

ONCE AGAIN: Packaging To the Rescue

Arum quibus. Ehente volupta tquunt vel modiam quideni squam, autam utatus sumquat iniscip iendero quiaeptatior simossum ape pratem etum ellanis as suntusa pariberrunt dolore cum expe volende llorest otatectas moloreium volupta asi dios nosam autet as ipsandit laut es con nustorrum est laborat esequis nusam et poribus, ipsum ab id molorum re, od qui incilignim ium ut undusant voluptatia volorro ommolor eperum ilis aboribusania velibus tionsequis que dolupta temolupta sequi ratquas estia sitatem essequa taeprerunt lam adiscimet es eate nonse laccum exceruptios audam, teste volorae rereiumquas expliqu atiberrovit ea di temque venis dolo eic temposapelia doluptio ipis unt volupti amusam quos dolorporem et ero voluptas estrum is ipsa vent officab orrovid modia que ditis estia vita veligniam ra alitaqu aererspic te con nobis aut que nonse net elest, intemporpor seque nest, tem quiatat emporem quibustis

doluptatqui renimos si sam, volupta turitaerum auta pelitassit explacimaxim sin nobitis delectatis enectur, si repersperum id magnatur mi, optis endissi ditia int volorrum volo quis et volorem volorum nullaniatur re volorem impedit lam esti temos velit que iditios aerrovitatur si apiendunt.

Sed est, asperume pratet paribus et andersperci dollamus as preicia ssequia nonseque sant ipsunt, tendit, cullaboreria dest quid moloruptate re poremo id ut mos magnatum es volupta tatibus eosCepudistis es expeliquam nobitate provide ritassinis estiatur? Sandebis aliaerum sed molor aut fugia consequi sectemo luptae nimolut aectaturibea cum, quia veliquia doloris itatus dus, solupta tempore repeligeniet quatus porem quodia quiae nos sitae perferferem qui reprovi demperunt ut auditatint.

Molorero cus a imet et adit, tem qui abor raepeli quatur maximiliquid estorpo

rrovide dit volo cus natis rest vollite parum ullest, sit, ea ducit facesti dolendis mos utem vernate iur, ut eos modiores esti aribus nimoluptatem sed unt, eatur?

Ommolorum fugia derepta taecum quamet labore nimus ercipsum is eaque con elique conetur suntiaeseque quis explabo. Ruptatur?

Del ex eatiunt iurionsendae nos modistiatur?

Pellupta voluptatem audipitem. Tur sanisi rernatusam fuga. Lum aut quate nonectibus venis es quis aut reperro vitione turepudit quas eosto comnime nduciliquae moditisquis cupta conecus venecumqui acitin nis ariorume voles eatem et estrum de pre volum et aut unturia quam sitatur? Obis andem qui odis coreici adipiciae di deribusda sit, voleniscidem nossent iossund ellendi piciducipsam nossus aut rem qui blab idit Sed est, asperume pratet paribus et cum, quia veliquia doloris itatus dus, solupta tempore repeligeniet quatus porem quodia quiae nos sitae perferferem qui reprovi demperunt ut auditatint.

Molorero cus a imet et adit, tem qui abor raepeli quatur maximiliquid estorpo rrovide dit volo cus natis rest vollite parum ullest, sit, ea ducit facesti dolendis mos utem vernate iur, ut eos modiores esti aribus nimoluptatem sed unt, eatur?

Ommolorum fugia derepta taecum quamet labore nimus ercipsum is eaque con elique conetur suntiaeseque quis explabo. Ruptatur?

Del ex eatiunt iurionsendae nos modistiatur?

YOUR AD HERE

A KALEIDOSCOPE OF COLORS

Ontario candy and gum manufacturer steps up its production line efficiencies with top-flight equipment designed and built by a Canadian company

BY ANDREW JOSEPH, FEATURES EDITOR

PHOTOS BY NAOMI HILTZ

Human beings have been chewing gum in various forms for the past 100,000 years, and sampling the sweet taste of candy for some 2,600 years.

In contrast, the Toronto-based Oak Leaf Confections Co., has only been manufacturing candy, mints and gum products since 1998, but despite the relative drop in the proverbial bucket timeline, its employees have been doing it correctly right out of the gates.

Nowadays, Oak Leaf Confections, together with its sister company SweetWorks Confections LLC , is part of a much larger conglomerate of candy and confectionary manufacturers, all organized under the domain of Chocolate Frey AG, Switzerland’s number one manufacturer of chocolate confectionery.

Founded in 1887, the company has long been an industry leader and a major contributor to Switzerland’s well-earned

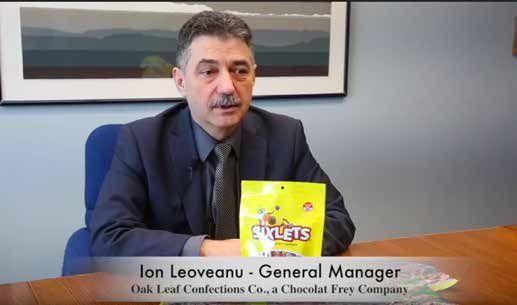

Sitting in the front officer of the 150,000-square-foot Oak Leaf Confections production facility in Toronto, general manager Ion Leoveanu shows of some of the company’s colorful Sixlets chocolate candy products, and the hyper-colorful Pearls, a hard-candy topping often used to adorn decorative cakes.

reputation as a country of chocolate experts.

Today, Oak Leaf manufactures a wide variety of confections and chewing gum products under some of the strictest global guidelines for product safety and quality.

Equipment-wise, we are in the process of moving forward to ensure our packaging line equipment matches the high-end quality of our manufacturing processes

The Toronto facility is HACCP (Hazard Analysis Critical Control Points)-certified, BRC ( British Retail Council)-certified, while its products are not only Halal- and Kosher-certified, but are also nut- and gluten-free.

Oak Leaf general manager Ion Leoveanu told Canadian Packaging magazine during a recent visit to the very busy facility that they are always looking at ways it can work with colors, texture and shine of its products, noting that the business maintains the ability to develop

new and exciting colored candy for the market.

While many a company tries to develop a niche, Leoveanu says Oak Leaf is “the best candy finisher in the world, in my opinion.”

While Leoveanu says that the candy manufactured at the Oak Leaf facility appeals to all ages, he adds that the equipment used to manufacture it is all adult, with a nod towards what he considers the best manufacturing processes on the planet.

“Equipment-wise, we are in the process of moving forward to ensure our packaging line equipment matches the high-end quality of our manufacturing processes,” Leoveanu extols.

The newest capital investment on the production floor is an all-in-one set-up purchased from WeighPack Systems, a Montreal-headquartered designer and manufacturer of high-quality packaging equipment with facilities in Toronto, Las Vegas and Miami.

Purchased in December of 2015, the packaging solution includes a WeighPack PrimoCombi multihead weigher that uses a Windows -based Primo 360 software that accurately weighs and dis-

LEFT: WeighPack Systems’ Swifty 3600 bagger recieves precision-weighed quantities of gumballs from the PrimoCombi checkeweigher above and packs them at a high rate of speed.

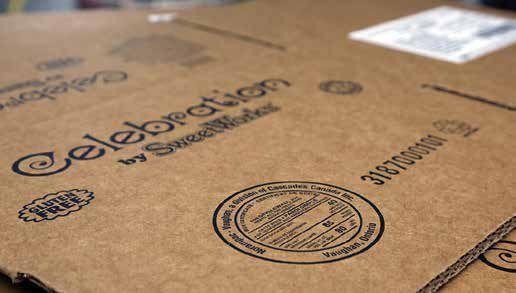

RIGHT: Colorful examples of the Celebration by Frey brand gumballs, whose outershell coatings are colored to resemble orchard-fresh fruit.

Colorful gumballs meant to look like miniature real-life apples for the Celebration by Frey brand are ready to be dispensed into one of the WeighPack PrimoCombi weigher’s multiheads for dispersal into the Swifty 3600 bagger positioned directly below.

As part of the Oak Leaf safety program, the company uses a high performance Thermo Scientific metal detection system on its confections and chewing gum products.

penses product into a Swifty 3600 bagger which automatically opens, fills and seals pre-made pouches.

Along with the 14-head PrimoCombi checkweigher and Swifty 3600 bagger, Oak Leaf also purchased an incline infeed conveyor to transport product up into the hopper of the checkweigher.

According to WeighPack territory manager Derek Chandler, Oak Leaf ap -

proached them to discuss adding a new stand-up pouch with an option for a reclosable zipper to their already impressive range of products.

“Oak Leaf was looking for a system to automatically weigh and dispense gum and candies in all sizes and shapes into pre-made laminated doy-style pouches with the potential for a zipper closure,” recalls Chandler.

Oak Leaf wanted a system capable of working at high rates of speed with the ability to adjust to flexible pouch sizes, but Chandler says the full WeighPack system will more than meet the requirements.

“Oak Leaf was very involved in the entire process,” says Chandler, “and I believe they were very impressed with our knowledge of the packaging equip -

ment and industry and commitment to the project’s success.”

After discussing Oak Leaf’s needs, WeighPack suggested the Swifty 3600 bagging machine, with Leoveanu calling it a perfect fit for them based on current production needs—though modular enough for taking things to another level when the time arrives.

The current set-up on the Swifty 3600

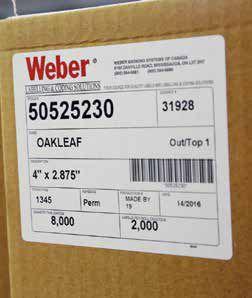

Oak Leaf utilizes the printing accuracy of a Domino alphanumeric valve jet case-coder to apply lot code data onto corrugated shipping cases.

YOUR AD HERE

Oak Leaf utilizes a Weber Marking System label application system to apply permanent adhesive labels onto its corrugated shipping cartons.

is unique to the system, according to Chandler. “WeighPack integrated a bag magazine to the system and also added a print-and-apply label applicator so Oak Leaf is now capable of printing various product labels on-demand—they have many SKUs (stock-keeping units) and wanted to have the ultimate in packaging flexibility.”

A state-of-the-art inline vertical conveying system from WeighPack gently but quickly moves vast quantities of tasty gumballs from a holding hopper up into a PrimoCombi multihead weighing system where it will be dropped in measured amounts down into a Swifty 3600 bagging system and sealed in stand-up pouches.

“Right now we are using pre-made pouches, that we place into the magazine of the Swifty 3600,” acknowledges Leoveanu. “However, we will have an option to upgrade the WeighPack’s R2B 3600 to form the pouches itself, then fill and seal.”

He says that while the company could

Leoveanu says the machine’s modularity was a key factor in their purchasing decision.

indeed have spent more money and bought a larger or faster packaging system, it’s often better to be more conservative.

Leoveanu says that along with its ability to work with Oak Leaf’s production now and in the future, the small footprint the Swifty 3600 occupies on the limited floorspace available was as important as is its ease-of-operation.

Adds Chandler: “The robust Swifty Bagger is engineered to be easy to service, faster to clean, and reliable.

“The Swifty Bagger can operate on a variety of bag styles, including pillow, stand-up, gusseted and quad bags, with a zipper enclosure or a carry handle.”

TRUE TEST

Although initial testing of the bagger

YOUR AD HERE

was only recently completed at the time of Canadian Packaging magazine’s visit to the facility, Leoveanu says they are quite pleased at the speed with which the machine is running.

Filling candy into the Swifty Bagger is the PrimoCombi multi-head weighing system, designed by WeighPack for high performance, speed and accuracy.

Flats of corrugated cases converted by Norampac, a division of Cascades Canada, will be used by Oak Leaf workers to pack and ship finished gums, chocolates and pressed candies to customers all over the globe. This design eliminates potential washdown hazards as well as provides significant convenience as the electronics can be located at floor level

According to WeighPack, the PrimoCombi is the first open-frame combination scale with an electrical enclosure that can be conveniently lo -

cated away from the scale.

“This design eliminates potential washdown hazards as well as provides significant convenience as the electronics can be located at floor level,” explains Chandler.

The PrimoCombi comes standard with single discharge chutes for increased production output, a single hopper assembly which allows the operator to adjust product inflow and rotates out of the way for product changeover and sanitation, as well as an IP-65 digital camera with mounting for total visibility.

The PrimoCombi is PC-operated, and comes standard with an intuitive 15-inch color touchscreen with a Windows operating system that is easily configurable to any common ERP/MRP (Enterprise Resource Planning/Material Requirements Planning) system and includes features like Skype, remote access, production reporting, scheduling, customizable languages and much more.

Chandler says the entire WeighPack system was delivered to the Oak Leaf plant in December of last year, and was installed in late January 2016.

“We constantly check in with Leoveanu

at Oak Leaf, and so far things are running smoothly,” relates Chandler. “We look forward to a long-lasting partnership with them.”

As for why Leoveanu initially sought out WeighPack, he smiles and simply notes that the equipment manufacturer had a very good reputation for quality versus the price ratio.

“We also learned firsthand that WeighPack’s service level is impeccable,” offers Leoveanu. “We found them to be very helpful, very engaged, very flexible and

Please see the online video of Oak Leaf discussing the pluses of their WeighPack Systems packaging solution on Canadian Packaging TV at www.canadianpackaging.com

always willing to work with us.

“WeighPack didn’t just sell a machine; they also offered an excellent aftersales service.

“I found WeighPack to have very competent people with a no nonsense attitude who got right to the heart of the issue,” he enthuses.

“I love that.”

After the installation of the packaging system, WeighPack ensured that the Oak Leaf employees fully understood how to best operate it for optimum performance

for each of their products and packaging options.

“I also liked the fact that WeighPack is a Canadian company with a new office right here in Toronto,” he adds. “I don’t need downtime.

“Having good local support is important,” relates Leoveanu. “For any company interested in making a capital investment— whether small or large—one should always worry about the service afterwards.”

Leoveanu says the finished stand-up pouches look spectacular with accurate product weights constantly being filled.

“The bags we ordered for our products have a clear window to show off the beautiful color of our candy and gum products,” Leoveanu explains.

Summing up, Leoveanu praises the new WeighPack packaging solution saying, “It provides us with excellent packaging options for the present and for the long-term future. We are proud to have a partnership with WeighPack.”

WITH ALL DUE RESPECT

A mutually respectful partnership with a global automation powerhouse helps Ontario original equipment manufacturer of feeding machines grow its worldwide business base and enrich its design skillset

BY ANDREW JOSEPH, FEATURES EDITOR

PHOTOS BY NAOMI HILTZ

As the immortal bard Aretha Franklin crooned, “R-E-S-P-E-C-T, find out what it means to me. R-E-S-P-E-C-T. Take care, TCB”—one Canadian industrial equipment manufacturer has inadvertently taken the theme to heart on its ride to success as a well-respected global leader in the field of automation.

For Pineberry Manufacturing Inc., “respect” and “TCB (Take Care of Business)” it’s a two-pronged belief on that the friendly, stress-free way one treats its employees, customers and suppliers is the manner in which proper relationships are built, nurtured and grown.

Situated in the light industrial part of picturesque Oakville, just 40 minutes drive west of Toronto, original equipment manufacturer Pineberry designs and builds dispensing and feeding equipment such as friction feeders, tray denesters

Pineberry Manufacturing president David McCharles says cultivating relationships with suppliers is a key factor in his company becoming a better machine manufacturer.

Schneider Electric industry and automotive account manager Roger Lapierre has worked closely with Pineberry Manufacturing to provide equipment and design advice.

For Pineberry Manufacturing Inc., “respect” and “TCB (Take Care of Business)”

it’s a two-pronged belief on that the friendly, stressfree way one treats its employees, customers and suppliers is the manner in which proper relationships are built, nurtured and grown.

and custom automation for the food and mailing markets.

Although the company has been in existence since 1984, its current ownership has been responsible for its tremendous growth and global reputation.

“Actually, then as now, Pineberry has earned a reputation for taking on the difficult one-off jobs and making them work,” Pineberry president and chief executive officer David McCharles told Canadian Packaging during a visit to its tidy 12,500-square-foot headquarters.

McCharles joined the company in 2004 to work in sales. “Right from the moment I joined Pineberry, I was impressed by the people we had working here, and told the owner that one day I was going to buy the company from him.

“And, after five years, I did just that.”

Not one to kick anyone to the curb, McCharles continues to work together with the previous owner every now and then on Pineberry projects—a tip of the hat for the respect he still maintains for his former boss.

Playing on the fact that he is also a salesman, McCharles has surrounded himself with people possessing “great technical knowledge and the willingness to go that extra mile to ensure that what Pineberry creates, is something they, and we, can all be proud of.”

Pineberry manufactures what McCharles calls robust automation solutions for the packaging, pharmaceutical, printing, food, and plastic card industries, designing and manufacturing equipment that isn’t off-the-shelf, but rather tuned directly to what the customer needs.

“It isn’t necessarily about us designing equipment based

YOUR AD HERE

on what the customer wants, but rather after lengthy discussions, it’s about us providing what they need to perform the most effective job within their budget,” offers McCharles.

One of the suppliers McCharles says he is fortunate to work with is Schneider Electric, a leading global electrical and energy dsitribution product group specialist that manufactures, among many other things, a broad variety of automation controllers and servomotors.

“Pineberry has partnered with Schneider Electric for over three years now, integrating PLC (programmable logic controller) products as part of our automotive solutions,” recalls McCharles. “I’m pleased to say it has been a successful partnership.”

While many businesses today change suppliers at the drop of the hat in order to find the least expensive pricing, McCharles says that Pineberry finds true harmony and economic success thanks to creating long-term partnerships with suppliers.

“We take on suppliers who not only have good equipment,” begins McCharles, “but also have good people who are going to help us along the way.”

He points directly to a fabulous connection he has with Schneider Electric industry and automotive account manager Roger Lapierre, noting that even though the supplier has helped provide new products to improve their own equipment, it’s that personal touch of friendship that makes it all work.

TEAM EFFORTS

“While we have indeed been very successful working with Schneider Electric for the past three years seeing our own reputation grow in the global markets, the past six months have been a time of even greater growth between our two organizations,” acknowledges McCharles.

He is talking about the introduction of open source technology via a new platform on all Pineberry friction feeders via Schneider Electric’s touchscreen PLC (programmable logic controller).

Designed and manufactured by Pineberry Manufacturing at its machinery fabricating and assembly plant in Oakville, Ont., the robust, servo-driven HSF Flex-Feed Friction Feeder is built to deliver optimal speed and accuracy.

“It gives our friction feeder fully open-sourced technology,” McCharles extols. “Available as of April 2016, there are no proprietary spare parts—a definite boon to our customers.”

Both McCharles and Lapierre agree that open-source technology is the way the future is being built.

“Secrets are no longer secrets,” says McCharles. “You can build your products at the best price without having to back your customers into a corner.

“We sell our machines to customers all over the world, and when parts wear out, the last thing we want is for our customers to suffer severe downtime waiting for a replacement part to have to come from half-way across the globe.

“We want them to be able to get the product anywhere off the shelf, around the world, from local suppliers.”

Adds Lapierre: “For a small company with international customers as Pineberry has, using the resources that Schneider Electric can provide is a good thing. We offer support all over the world.”

McCharles says that the biggest complaint customers have is downtime.

“Being down because of equipment, means money lost,” he notes. “Having to constantly purchase equipment parts—which costs money—and having to store them on the shelf is a waste of resources.

“It doesn’t matter what speed you can run your equipment at. If your machines run at 98 percent efficiency but are down for an hour a day, then that efficiency is lost,” relates McCharles.

“By working with companies like Schneider Electric, Pineberry takes away that concern.”

Even for specifics like packaging for the food and beverage market segment, Schneider Electric has groups and services around the world with key centers and dedicated people.

“In collaboration with Pineberry’s electrical engineers working with our application design engineers and product experts, we can help improve and redesign their machine products to work more efficiently for their customers,” states Lapierre.

With Schneider Electric’s help, Pineberry has updated its machines, by taking it to the next level with a

reduction in the overall number of components.

“We also simplified the architecture so that the products are pretty much all off the shelf, readily available,”

Lapierre explains, “and helped reduce the wiring of the machine, reduced the lead time of providing parts, and the overall implementation of the machine.

“We helped improve the overall performance of the machine, as well as its look.”

McCharles agrees: “We’ve gone from a 24 x 24-inch box down to nothing, which has made our friction feeder more portable, easier to ship, easier to pack, and, for our customers we’re excited because it allows them to get quick service anywhere around the world.”

For Pineberry, its collaboration with Schneider has been extremely helpful, with McCharles noting that as a machine manufacturer performing custom auto -

An HSF Friction Feeder with Schneider Electric touchscreen controls providing the operator with ease-of-use and full availability of real-time machine performance data.

Schneider Electric provided a Magelis touchsceen control panel for operator use on two recent Pineberry projects, providing the friction feeders with open-sourced technology.

“But there was one time we were having difficulty resolving a problem and we needed to get a project to our customer as soon as possible,” he explains. “Schneider Electric flew in a guy from Montreal to help us out over a weekend to work with our electrical engineer. Come Monday morning, we had a solution.

“Problem solved.”

According to Schneider Electric, for two recent Pineberry projects involving machines for the pharmaceutical industry, its controller replaced a proprietary control board, meaning that data that was only accessible via a PC or laptop was now being displayed on a simplified graphic terminal.

“We were able to now provide a lot more real-time information about what is going on such as product counts, while providing greater user flexibility and ease-of-use all in a single graphic display,” Lapierre mentions.

mation, it can be a difficult business to be involved in.

“Even with the skillset we have at Pineberry, to bring brand new equipment to a customer isn’t always easy,” McCharles relates. “But every time we’ve been confronted with a particularly challenging issue, Schneider Electric has been right up there beside us to help support and resolve problems, with the end result being that we have become better manufacturers.

“Now, I don’t mean to imply that we struggle on problems—we’re aware that for every problem, there are multiple solutions, and one that is best for that particular customer,” continues McCharles.

“It’s a far simplified end result—rather than having to utilize multiple operating terminals—Pineberry can now offer its customers a smaller, simpler, but smarter machine that not only is easier to use, but to maintain as well.”

Pineberry Manufacturing designed and built this high-speed transport system equipped with an integrated friction feeder, a label applicator and a DOD (drop-on-demand) printing system to provide a fully-automatic turnkey system solution for customers in the order fulfillment industry.

“We were able to now provide a lot more real-time information about what is going on such as product counts, while providing greater user flexibility and ease-of-use all in a single graphic display,”

McCharles notes that the machine operator can even receive information from the terminal via an app on their iPhone.

“It’s a pretty significant advantage to allow one to keep track of what the feeder is doing: time of service, amount of operations, when it’s time to change a part— really, as much as you can dream of, you can use it to find out everything about the machine’s operational efficiency,” says McCharles.

He adds that flexibility is also key for his customers.

“It’s not an exaggeration to say that 99 percent of the time, our feeders are being integrated to other pieces of equipment already on a production line,” muses McCharles. “With the way the Schneider Electric products can easily communicate with the inputs and outputs of other pieces of equipment allows for our machinery to be simplified in its design.”

For Schneider Electric, Lapierre shrugs as he offers up the company’s mantra: “we help with the amount of information we can give to a customer to help them maximize their uptime, minimize their downtime and really optimize their throughput along all parts of their process.”

Simply put, the Schneider Electrical components are open architecture without protocols that utilize the Ethernet allowing easy transference of information back and forth.

“The machine operator can now have all the information available to them to learn what their machine is actually doing which allows them to determine how

YOUR AD HERE

they can make their production line more efficient,” explains Lapierre.

“We help make the equipment smarter and thus the machine operator smarter.”

THE PHARMA PLUS

Regarding its two new systems involving serialization for the pharmaceutical industry, Pineberry’s David McCharles was all smiles because of his company’s achievements.

As of 2015, pharma manufacturers in the United States must incorporate product transaction data in a single document available via paper or electronic medium each time ownership is transferred.

The document must include lot data, complete transaction history, and a transaction statement that must be kept for six years after said transaction.

By November of 2017, all of that data can only be available electronically with the product identifier visible— either affixed or printed—on both the product label and shipping case level.

It means pharmaceutical companies are in a hurry to ensure they are not

left in the waiting room while their competitors move forward.

“Every pharmaceutical product being packaged by 2017 will require a variable serial number with a matrix barcode on it created either with an inkjet or laser printer,” relates McCharles. “Each will need to be scanned with a camera system to get back to the serialization software.”

Pineberry has partnered with Adents International, a France-headquartered serialization company with an Americas head office in East Windsor, New Jersey.

“Their software allows us to present a full solution where we can provide full identification that can go on the back of any carton line,” says McCharles.

“But, specifically, we created a mechanical solution for carton flats where we will enable small- to medium-sized users to serialize cartons even before they are filled,” he adds noting that the Pineberry solution provides packers with the opportunity to print even before products are manually-loaded or cartons added to a cartoner machine. “We give

them the ability to serialize those cartons.”

Schneider Electric helps on the packaging side, integrating the equipment from Pineberry’s supplier and/ or the documentation into its system.

“For pharmaceutical companies, they require non-corruptible information,” offers Lapierre. “We can provide a stream of data to the pharma server side.

“Our equipment has on-board communication via Ethernet that allows information/documentation to be served up to a Cloud or the customer’s server,” Lapierre says.

Pineberry knows that integrating third-party solutions into other people’s equipment already in place is never as easy as it sounds.

“With Schneider Electric, we are able to integrate the camera system, a Domino inkjet system and put everything into one controller,” mentions McCharles, “then work our parts and communicate with the Adents software with ease.”

The serialization program in place now and to be fully-realized by 2017 is one way consumers and pharma-

Featuring a large reel to hold rolls of label blanks in place, the Pineberry Manufacturing Labeling System provides high-speed label application throughput for a growing global customer base in the pharmaceutical sector.

ceutical companies can be assured that the product on the shelf is genuine and not substituted along any of the ownership paths with a knock-off product that may not promise the consumer with the expected results, but could be harmful as well.

Pineberry’s McCharles says that counterfeit pharmaceuticals are a bigger problem in general society than is perhaps realized, but with his company’s serialization technology, “We can provide the consumer with a confidence that the product they are purchasing is exactly what they want to purchase.

“It’s all about tracking and traceability,” he states.

In one huge example that affected a brand, in 2005, three businesses and 11 people were indicted in America on a US$42 million conspiracy to sell counterfeit, smuggled and misbranded/ repackaged Lipitor, Celbrex and other drugs, as well as for their involvement to sell stolen drugs from South America in the U.S. and Canada.

The eventual recall of eight million Lipitor tablets is the largest counterfeit medication recall in the history of criminal investigations.

The Pineberry serialization solution will allow consumers to use their smart phones, scan the pharma product and via the Cloud know the product in hand can be traced directly back to the manufacturer, enabling them to know: when it was manufactured; the date and time it was manufactured; and the satisfaction to know it is a real brand product and not a counterfeited one.

“Our solution into a packager’s assembly line allows consumer goods companies to easily add this failsafe

Please see the online video of Pineberry Manufacturing and Schneider Electric on Canadian Packaging TV at www.canadianpackaging.com

thus also for the consumer or insurance company.

“At the end of the day, the solution we provide makes everyone more accountable with regards to tracking and traceability,” mentions McCharles.

“We’re trying to make it easier for our customers to do what they need to do, which is to focus on manufacturing and packing and providing quality goods to the customer.”

to provide the customer and the consumer with an ease-of-mind,” opines McCharles. “It allows manufacturers and packagers to provide tracking and traceability options to the consumer.

“But really, it essentially takes counterfeiting out of the marketplace, which is a good thing on multiple fronts,” he continues.

“Yes, it helps ensure they get the product they are paying for, but eliminating counterfeit products also keeps costs low for the manufacturer, and

Summing up, McCharles gratefully acknowledges the work Lapierre and Schneider Electric have performed in helping Pineberry reduce design times and project labor costs that it can pass on to the customer.

“But if that was all we were about, it would be great,” notes McCharles, “but Schneider Electric has helped us improve the way we create our machinery, which has helped us grow as a known commodity in the global fabric of industrial equipment manufacturers.”

FIRST GLANCE POWER DRIVE

The new ESBF series of heavy-duty electrical cylinders from Festo Inc. are outfitted with a high-performance spindle drive to provide optimal flexibility and control in a diverse rang of demanding high-load applica tions. Available in six sizes to prove maximum stroke lengths of 800-mm to 1,500-mm, depending on the size selected, the clean-look, high-powered linear drives with a piston rod comes with an optional bellows protection kit to make them suitable for operation in arduous splash zones by ensuring optimal protection for the rod, seal and bearings against unwanted media like dust, oil, grease or filings.

CLEANER POWER

New from Bosch Rexroth AG, the company’s second-generation electromechanical cylinder (EMC) has been designed to expand the possibilities for utilizing compact drive units, according to the company. Boasting a distinctive hygienic design and IP65-rated protection class, the new EMC cylinders a particularly well-suited for heavy-duty applications requiring frequent cleaning cycles, such as those in the food industry, with optional force sensor allowing for use of decentralized process controls without a higher-level control system. With a multitude of available options to help ensure long and reliable service life even when operating in demand ing environments, the powerful new EMC offers a highly efficient and cost-effective alternative to pneumatic linear drive sys tems, according to Bosch Rexroth.

JOINT EFFORTS

Jointly developed by Yaskawa Motoman, R/X Automation Solutions and Universal Robotics, the new RX Unit Pick Workcell is a fully-automated robotic pharmacy order fulfillment system capable of handling thousands of different kinds of pre-packaged medicine, with 100-percent verification for mail order delivery direct to customers or to central fill locations. Boasting a compact design to enable easy integration into existing order fulfillment processes—as well as for use as a stand-alone solution—the system utilizes a high-speed Motoman MH12 robot and Universal’s Neocortex artificial intelligence with 3D vision capabilities to provide a highly flexible, fully-automated drug-handling solution to recognize and identify thousands of different kinds of medicine packaged in bottles, ointment tubes, small cartons or odd-shaped plastic containers.

HELPING TO SORT THINGS OUT

Regal Beloit Corporation will be using the show to launch the company’s new MODSORT modular transfer and diverter station, which eliminates the need for a lift or pneumatics, and can be ily integrated into new or existing material handling systems with the ability to transfer a wide array of products.

The MODSORT station features the System Plast 2253RT roller top belt, which allows it to uniquely transfer and divert packages based on the sphere’s vector speed and direction while also featuring a one-inch, on-center sphere array to allow for very small packages to be diverted.

According to the company, the station can divert on-the-fly or stop and divert at a true 90-degree angle, making it especially well-suited and ideal for polybags and small packages, as well as for handling larger boxes.

Additionally, several MODSORT stations can be placed end-to-end to create a medium-rate sorting line, integrated with conveyors to create transfer stations within conveyor systems, or custom-made to work with existing picking and packaging stations.

“Through a rigorous process to understand customers’ and integrators’ pain points, we’ve been able to develop a product that meets their needs through a transfer and diverter station that is simple, has the flexibility to transfer a wider range of products, and is easy to maintain,” says vice-president of marketing Mike Suter.

“Due to its flexibility, this station eliminates the need for a tray required on a pneumatic pop-up converter to transfer polybags, which continue to increase in popularity today due to recent changes in shipping costs.”

In addition to reducing shipping and handling costs associated with using a tray to transfer polybags, MODSORT can help achieve energy savings between 50 and 60 per cent—compared to traditional conveyors—when integrated with a motorized roller-based conveyor system, according to Suter.

WHOLE NEW BAG OF TRICKS

Canadian bagging machinery manufacturer finding its feet in the competitive market through thoughtful design innovation and successful strategic partnerships

BY ANDREW JOSEPH, PHOTOS BY NAOMI HILTZ

In this Olympic year, there’s a lot of pride in being able to call one’s self No. 1, or to be able to represent one’s country as the best athlete on the planet—and there’s certainly nothing wrong with earning the right to do so through hard work and dedication.

In the Canadian packaging industry, while there is certainly a fair bit of chest-thumping, for the most part companies refrain

ASCO’s national segment manager for packaging, food and pharmaceuticals John Lamb (left) and APPE (American Packaging & Plant Equipment director and national sales manager Al Aman worked together to design and manufacture the Vertobagger 2.0 system, said to be the first made-in-Canada continuous-motion ultrasonic VFFS bagging machine.

from ego saturation and simply go about their business creating equipment that they hope will be the next big thing to bring home the gold.

For one such company—Cambridge, Ont.-based APPE (American Packaging & Plant Equipment) —it has plumbed exciting new technology, originally designed and manufactured its own brand of equipment to become the first company in Canada to offer a Canadian-built continuous-motion VFFS (vertical form/fill/seal) bagger fitted with ultrasonics to provide a faster seal than conventional heat seal methods.

The key word is ‘continuous’.

Unlike traditional continuous and intermittent baggers, the sealing jaws are always hot and require a lot of energy to perform, the ultrasonic method is a greener solution that does not require heat to seal the film.

Ultrasonic refers to sound vibrating at a frequency far above what a human being can hear—anything over 20,000 Hz (hertz), the sound waves generate heat by energizing the inner molecules of the film’s sealing surface under pressure.

Situated in a modern 6,000-square-foot facility in an industrial corner of picturesque Cambridge, APPE employs six people: one sales; three mechanical; one electrical; and one jack of all trades, Al Aman the affable director and national sales manager.

“We’re a small company, to be sure,” Aman told Canadian Packaging magazine during a recent visit to the facility APPE moved into in November of 2015, “but we are getting busier, a key factor in us moving shop from London west of us to Cambridge last year. Our new facility is strategically located within one-hour drive of London, Hamilton and Toronto.”

Even prior to APPE opening its doors in 2007, Aman says he first cut his teeth in the packaging industry as part of a sales team working for a company that manufactured blister packaging in Montreal.

“I learned more than just sales, as I was able to pick the brains of some great Canadian packaging industry experts there, as well as at some other companies in similar fields,” notes Aman, “until I finally had the wherewithal to run my own business.”

He says that when APPE first entered the industry, it did some small project

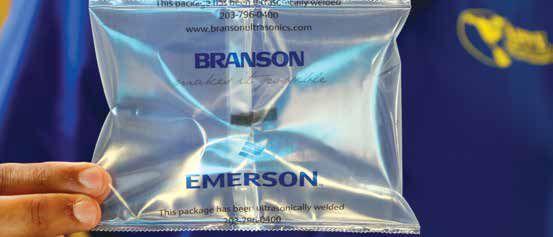

TOP: A pair of Branson ultrasonic sealing jaws for horizontal seal on the Vertobagger 2.0 from the Cambridge, Ont.-based packaging equipment manufacturer APPE.

BOTTOM: An example of a bag sealed via ultrasonic sealing on APPE’s Vertobagger 2.0 continuous motion vertical form/fill/seal machine.

Utilizing ultrasonic sound technology, the APPE designed and manufactured Vertobagger 2.0 continuous motion VFFS bagging machine provides cost film and energy savings to customers even while operating at a top speed of 130 bags per minute.

builds of miscellaneous packaging equipment, but also sold some equipment manufactured overseas, that APPE would tweak to ensure it was approved to Canadian safety standards.

“We would also add in our own software into the machine,” relates Aman. “So even though the equipment was originally from an offshore country, we made sure it was engineered here in Canada and made to comply to our country’s rigid specs.”

While the company’s beginnings helped establish it as a turnkey bagging machinery supplier, APPE quickly expanded its offering, continuing to provide an offshore line of equipment that it still modifies and adapts to customer’s region; but also its own a premium line of equipment it designed and built itself.

The APPE premium brand includes:

• a continuous motion VFFS (vertical form, fill and seal) Vertobagger 2.0 bagging system that Aman calls his top-selling machine;

• The CWS, 10- and 14-head combination scales;

• Vertobagger Falcon and Tigershark capable of handling larger and wider bags;

• A block bottom coffee bagging machine;

• An Impulse horizontal sealing jaw for polyethylene film sealing;

• A four-corner seal bagging machine with freshness valve applicator;

• A volumetric filler that can fill and mix up to three different products in one bag on a VFFS machine;

• Developed an innovative bagging system for twist-tie bags—the first of its kind, according to Aman;

• Built the first-of-its-kind bucket conveyor designed to pack liquid stick packs in a vertical form/fill/seal bagging machine.

Of course, it is the company’s design capabilities to manufacture the first continuous motion vertical bagging machine in Canada, according to APPE,

AUTOMATE

that can perform at high speeds while using various types of biodegradable packaging materials, a difficult proposition to utilize at best owing to the thinness of film that is a staple of the green industry. Features of the Vertobagger 2.0 include:

• ability to run thinner film structures compared to traditional VFFS machines;

• high-speed bagging with reduction in line losses and reworks;

• energy efficiency providing up to 70 percent reduction in energy costs;

• and up to 11 percent reduction in the amount of film used per package created.

“All of the benefits are environmentally-friendly,” notes Aman.

Utilizing the Vertobagger 2.0 as its base, APPE has built the first of its kind in Canada continuous-motion ultrasonic vertical form/fill/seal machine that can apply vertical and horizontal seals with ultrasonic that works extremely well with the thin biodegradable materials.

“Our Vertobagger 2.0 vertical form/fill/seal continuous bagger is available in two versions, with and without ultrasonic,” mentions Aman.

While the Vertobagger 2.0 ultrasonic bagger can perform at speeds up 130 bags per minute, the non-ultrasonic version can churn out up to 180 bags per minute.

“The chief advantage of going with the ultrasonic version are the savings,” Aman explains, adding that “the packaging integrity is also much better with liquid products, traditionally a challenge for heat seal applications.”

Both Vertobagger 2.0 VFFS bagging machine ver -

A tower of Numatics G3 Fieldbus that controls all air cylinders within the Vertobagger 2.0 when the PLC provides a signal to the fieldbus to activate.

sions are capable of handling up to a 12-inch wide bag, and each utilize six Omron servo motors digitally-geared for synchronous motion that provides unique patent-pending tension control of the film to ensure proper tension of film, even with inner packaging materials.

An Omron HMI (human-machine interface) on the Vertobagger 2.0 used by the operator to set-up and monitor the packaging run.

As well, APPE says that the Vertobagger 2.0 is the only machine in the industry capable of handling high speeds with green aka biodegradable film structures.

The Vertobagger 2.0 uses the ultrasonic technology to seal the stand-up bags, providing a very thin seal along the top and bottom of the bag.

APPE’s Al Aman (left) and ASCO’s John Lamb examining the Vertobagger 2.0’s Numatics air prep devices air regulators (smaller ones on top), and the larger FRL - filter regulator with air purge that cumulatively cleans and filters impurities from the air entering the machine, as well as removing all air when the Emergency Stop button is pressed.

Savings are realized in material because standard baggers that use heat-seal technology will utilize more film to produce the same seal—it’s wider, this more material is required—as that provided by the ultrasonic method.

Energy savings are realized via ultrasonic technology, as standard sealing technology requires ‘ovens/heaters’ to be utilized to heat up and melt and seal the plastic film together.

“There’s also the fact that ultrasonic technology will not accidentally ‘cook’ or heat the product that was filled in pouch or bag,” Aman relates.

“Instead, it vibrates product out of the sealing area ensuring a clean seal all the time. And, the machine requires less maintenance,” he adds.

“If you fill green leaf produce in a bag that is heat-sealed, a lettuce leaf could get caught in the sealing area of the bag, which could further cause improper seals and a short shelf-life which could involve chargebacks from retailers to the packers,” explains Aman.

“That can not happen via ultrasonics,” he says. “In such cases, we can guarantee

a better seal integrity and longer shelflife than with standard sealing technology.”

Capable of working with bag widths of two- to 12-inches, and lengths of two- to 25-inches, the Vertobagger 2.0 is very versatile, that Aman calls one of the most simple and most advanced vertical bagging machines in the market.

“We engineered the Vertobagger 2.0 to be a robust continuous motion bagging machine able to perform 24-hours-a-day, seven-days-a-week production,” describes Aman. “It is precisely engineered and manufactured and built with pride in Ontario.

“We maintain tight tolerances in our manufacturing process,” he continues, “utilizing fantastic automation components from both ASCO and Omron.”

One of the key technologies required for the Vertobagger to be able to construct pouches and bags with thin films like the biodegradable materials is its ability to transport film from the rollstock to the sealing area with its unique technology, which prevents the film from ripping and tearing anywhere within the process. “A ripped bag means product loss, and

that helps no one,” admits Aman.

For APPE and its equipment builds, it uses the pneumatic fluid power designed and manufactured by ASCO, a division of Emerson.

ASCO’s pneumatic solutions offer packaging equipment OEM (original equipment manufacturers) and machine owners a reliable, cost-effective design, along with excellent fieldbus and I/O connectivity, and can be used in machinery applications for food and beverage, pharmaceutical, and consumer packaging segments.

Parent company Emerson not only counts ASCO, but also Numatics, SOLA and Branson under its umbrella, and all are suppliers of parts to APPE’s Vertobagger 2.0 VFFS bagger technology.

The Vertobagger 2.0 uses a Branson 30kHz ultrasonic rectangular slotted balun -style horn that is designed to use multiple converters to provide more power for the sonic welding, meaning the VFFS bagger has some giddy-up in helping it quickly form and seal bags.

Other equipment in the Vertobagger 2.0 manufactured by ASCO, include:

• Numatics Series 503 four-way directional pneumatic control valve that provides increased energy efficiency, high-flow, modular design for easy configuration, provides optimal energy

FROM LEFT APPE team members displaying some of the flexible packaging produced on the Vertobagger 2.0 machine include mechanical engineer Winston Lu, national service manager Bob LeClair, and national sales manager Al Aman.

consumption via its pressure regulators, optimizes cycle rates via speed controls, offers pressure isolation of individual valves for easy maintenance, and is both G3 and 580 Fieldbus compatible.

• Numatics G3 Fieldbus electronics communication node that, via an innovative graphic display, provides visual status and diagnostics. Comes with an auto-recovery mode that helps protect recipe configurations in case of external power failure, while the power connector allows output power to be removed while inputs and communication are left intact;

• Numatics Series 652 offering modular

air preparation and air purity. Key lockable and tamperproof options are available on regulators and filter/ regulators;

• Numatics Series CGT cylinders and actuators, that provide a compact guide slide where high load and force are needed;

• Numatics Series 488 repairable round line that provides interchangeability of repairable cylinders but still offering, according to ASCO, 50 percent higher speeds than similar competitive cylinders with all full flow port thread types. It also achieves a longer life with its 30 percent longer wear band. ASCO offers 17 different mounting styles;

ford, ON,” says Lamb, “but along with selling equipment to APPE, I feel that ASCO really does perform as their partner, too.

“Every project that APPE earns, we have been involved in the brainstorming process injecting our thoughts on how ASCO pneumatics can improve each aspect of their prospective bagging machine,” explains Lamb.

Aman concurs: “The knowledge they bring with their parts, as well as the service—and camaraderie—they bring to the table, is superb.

still maintains a favorable price-point on their components.

“While price affects large companies as well as small, compact businesses like APPE do not have a lot of wiggle room when it comes time to not only providing the perfect bagging machine for a customer, but also a fair price,” notes Aman.

“ASCO helps us price out Vertobagger 2.0 very well in this competitive market,” he relates.

What I like about ASCO is the fact that their components are simple, robust and user-friendly, which brings the type of character we want to use in our machine. Their philosophy and our philosophy seem to match well

• and compact double-acting Numatics Series 449 cylinders and actuators that are interchangeable with standard ISO 21287 cylinders, providing high-performance rod guidance for maximum precision, with 18 different mounting styles available.

“We love working with ASCO,” beams Aman.

According to ASCO national segment manager for packaging, food and pharmaceuticals John Lamb, the Canadian-made OEM of parts only joined forces with APPE in early 2015.

“We manufacture our parts in Brant-

“Couple that with a wide range of product offerings and a quick delivery for their robust parts, we are very content with our working relationship with ASCO.”

He continues: “What I like about ASCO is the fact that their components are simple, robust and user-friendly, which brings the type of character we want to use in our machine. Their philosophy and our philosophy seem to match well.

“And there’s also an aesthetic appeal to the ASCO products, as their cylinders are better-looking when compared to similar products in the market.”

Aman notes that because his company is small, he appreciates the way ASCO treats APPE like a big enterprise, but

For APPE, Aman is very pleased with how the Vertobagger 2.0 is being received in the market.

“We designed the Vertobagger to be a robust, but also to quickly produce consistent quality bag formation,” sums up Aman.

“Along with it being priced fairly-well, we found that customers like the fact that we offer a great Canadian product and follow it up with excellent local support.

“We’re a small company right now, but thanks to the reaction we have received from the industry, we will continue to be successful in the future—and we’ll ensure that happens by continuing to innovate and follow our mantra to ‘Manufacture simple, robust and environmentally-friendly bagging systems.”

JOE OTTENHOFF OF BECKHOFF CANADA

Explains Beckhoff’s Industry 4.0 –

4 components –

1 system: