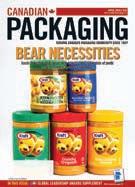

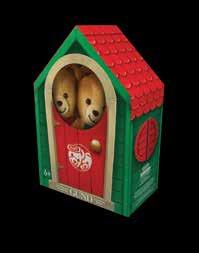

BEAR NECESSITIES

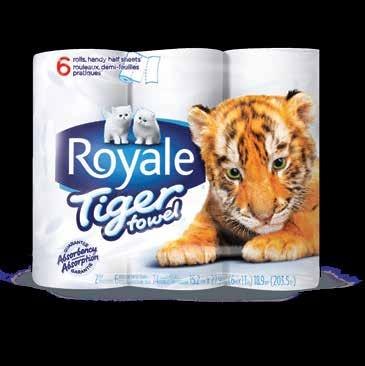

Iconic Canadian Kraft brand taps into the eternal fountain of youth with an inspired packaging redesign Story on page 40

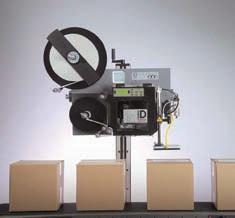

With its breakthrough design, the 9550 applies labels directly onto packs without the need for an applicator, while self-adjusting label placement accommodates varying line speeds, throughput and package sizes. Revolutionary Intelligent Motion™ technology targets zero unscheduled downtime as it precisely and automatically controls the entire system.

APRIL 2015

VOLUME 68, NO. 4

SENIOR PUBLISHER

Stephen Dean • (416) 510-5198

SDean@canadianpackaging.com

EDITOR

George Guidoni • (416) 510-5227

GGuidoni@canadianpackaging.com

FEATURES EDITOR

Andrew Joseph • (416) 510-5228

AJoseph@canadianpackaging.com

ART DIRECTOR

Sheila Wilson • (416) 442-5600 x3593 shwilson@annexnewcom.ca

PRODUCTION MANAGER

Barb Vowles • (416) 510-5103 BVowles@annexnewcom.ca

CIRCULATION MANAGER

Anita Madden • 442-5600 x3596 AMadden@annexnewcom.ca

ANNEX PUBLISHING & PRINTING INC.

Vice-President Annex Business Media East Tim Dimpoloulos tdimopoulos@canadianmanufacturing.com

President & CEO • Mike Fredericks mfredericks@annexweb.com

THE APPLE OF THEIR EYES

ust as an over ripe apple rarely falls far off from its tree, best pack aging ideas sometimes quietly lie in plain view right in front of one’s eyes—literally begging to be un veiled from an existing packaging structure through a moment of sheer ingenuity, creative inspiration, or just plain old good luck.

Whatever the case, the recentlylaunched new plastic stand-up pouches used to pack the Red Prince brand apples grown by the Thornbury, Ont.-based grower Binkley Apples Ltd. provide a compelling proof to the notion that packaging innovation does not always have to come in epic, gamechanging breakthroughs: sometimes, a simple packaging sleight-of-hand can be just as effective in compelling consumers to look at their everyday

business of St. Joseph Communications did with its superficially average polybag to convince the Canadian Packaging judging panel to select it as the winner of the magazine’s Consumer’s Voice award in this year’s PAC Global Leadership Awards competition of the Torontoheadquartered PAC, Packaging Consortium (Please see all the competition winners in a special supplement starting opposite of page 14)

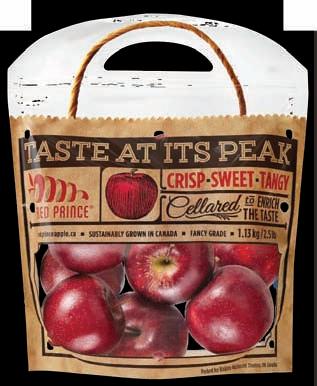

Cleverly using the see-through poly material as the transparent backdrop canvas for a life-size flexo-printed craft paper bag with a weaved-rope carrying handle that’s not actually there (see picture), the daring simplicity of this packaging optical illusion is counterbalanced by incorporation of very real functional benefits of a high-quality PTC (press-to-close) resealable closure running along the top of the bag and the stand-up footprint of its bottom layer. Neither of these value-added functionalities is immediately apparent until one actually picks up the bag by its virtual handle to have a closer look, but that is exactly the “gotcha” moment that made this package such a hit with the judges.

By hook or by crook, getting a consumer to give the package more than a cursory passing glance and nod is what all effective packages must aim to do for the product they contain. And doing so while virtually winking at consumers picking up the 2.5-pound faux bags of Red Prince apples at the produce aisles of their grocery stores is a timely testament to the virtues of mixing fun with work and using a little sense of humor for a common good and cheer, without spending a princely ransom to make it happen.

DEPARTMENTS & COLUMNS

FEATURES

13

By Andrew Joseph Hardworking Quebec meat processor answers the calls of duty with cuttingedge thermoforming equipment.

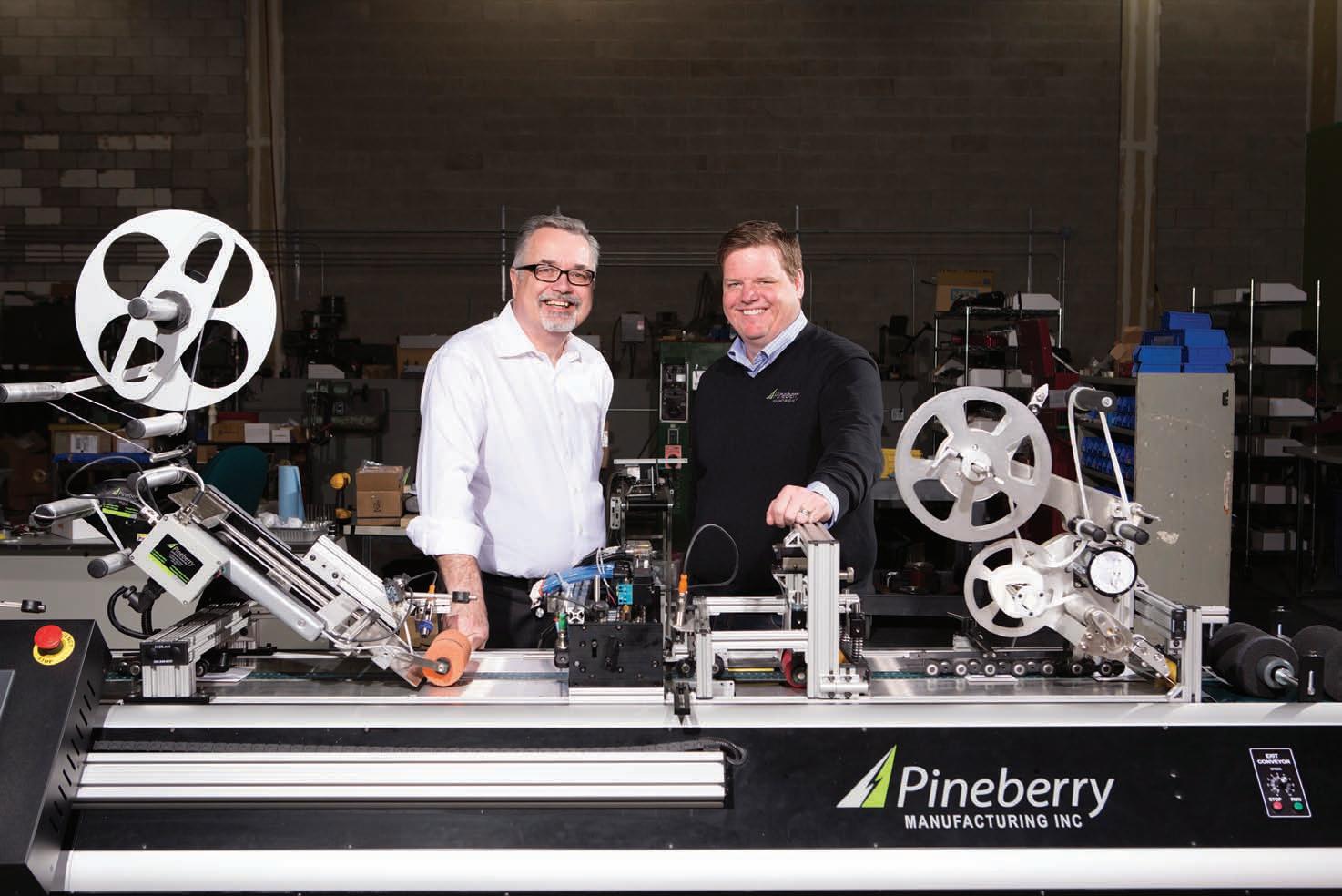

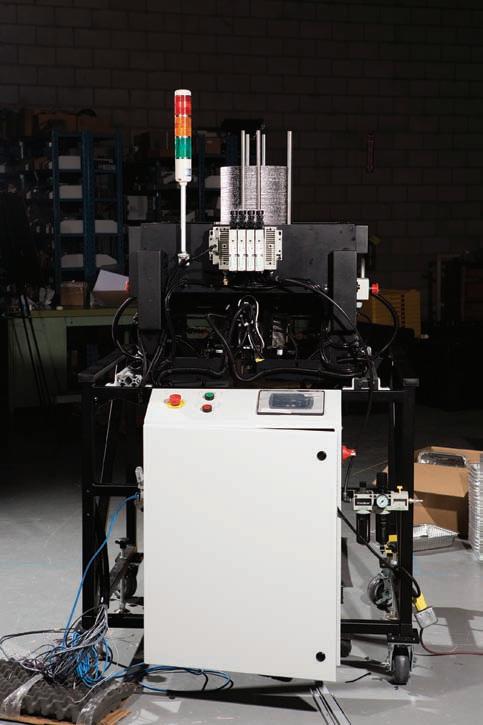

By George Guidoni Canadian branding services provider leverages technological savvy and know-how to expand its fast-growing client base. 48

By Andrew Joseph Canadian manufacturer of feeder equipment feeds off its automation partners to build better and faster machines.

NEWSPACK

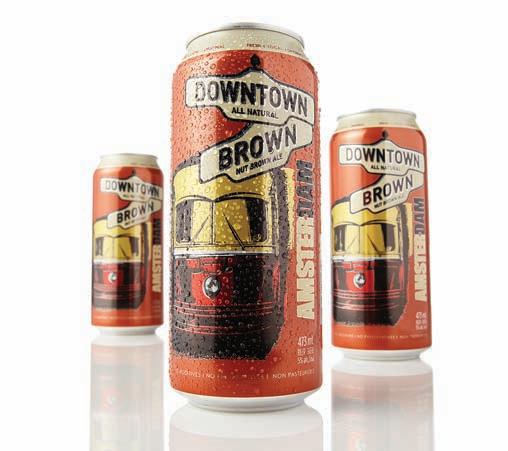

TORONTO CRAFT BREWER SERVES UP AN AWARD-WINNING PACKAGING KEEPSAKE

Last year’s Oktoberfest may now be just a fleeting hazy memory for some, but not for the Ontario beer-lovers with the foresight to have picked up a commemorative two-pack of Steam Whistle Pilsner cans packed with a collectible, ceramic one-liter drinking stein paying homage to the world-renowned celebration.

Selected as Gold Winner in the Corrugated Containers (Structural Design) category of the PAC Global Leadership Awards competition of PAC, Packaging Consortium , the eye-catching giftpack was produced by the Concord, Ont.-based corrugated converter Packaging Technologies Inc. (PTI) to coincide with the annual Oktoberfest celebrations last fall.

Used as part of the Toronto-based Steam Whistle Brewing’s successful Keep the Stein promotional campaign—also involving free stein

giveaways to restaurant patrons ordering a liter of the brewer’s popular flagship brand—the keepsake branded steins were inspired by the world-famous Munich Oktoberfest celebrations taking place in Bavaria’s capital city in late September each year and enthusiastically replicated worldwide—notably in soutwestern Ontario, with its rich German cultural heritage.

“There are not many gift-pack options available in the LCBO (Liquor Control Board of Ontario) in September and October, and we saw an opportunity to respond to this need,” explains Steam Whistle’s marketing director Bromlyn Bethune.

“The Oktoberfest Gift Pack with its collectible ceramic stein honors a timeless tradition and provides the perfect way to bring the Oktoberfest experience home.”

The limited-edition cases feature high-impact graphics—created by the brewer’s former in-house graphics designer Elton Clemente—that are lithoprinted on a clay-coated stock, laminated onto the E -flute linerboard, and formed into a well-made pack designed to withstand handling, transportation and the weight of the stein and the two aluminum beer cans without compromising the attractiveness of the pack, according to PTI.

“The packaging beautifully showcases the limited-edition Steam Whistle ceramic stein and the two 500-ml cans of premium Pilsner to tell the story of Oktoberfest through custom-designed graphics embodying the camaraderie, folk culture and pageantry of the renowned German festival,” says PTI account manager Ian Page, pointing out that the handle of the stein inside the case cleverly pops out of the back of the carton to serve as the giftpack’s carrying handle.

“By integrating the custombuilt dividers into the packaging to secure the products in place, we were able to create an open, clean and premium aesthetic without leaving the packaging susceptible to tinkering.”

UNTAPPING SPARKLING INNOVATION

Just as water is one of Mother Nature’s greatest gifts to mankind, Nestlé Waters Canada (NWC) is a gift that just keeps on giving to Canadian consumers in the form of healthy beverages packed in planetfriendly containers.

Early last month, the Puslinsch, Ont.-basedbottler added four new flavors to its bestselling Nestlé Pure Life Sparkling Water brand of flavored waters—retailing in a choice of fullyrecyclable 500- ml and one-liter plastic bottles, as well as in 100-percent recyclable, 355- ml aluminum cans sold in 12-pack cases. Sold at leading retailers across Canada, the zero-calorie, zero-sugar flavors include Original, Black Cherry, LemonLime, Mango-Peach-Pineapple and Raspberry-Lime variations to provide a suitable, healthy hydrations choice for just about every taste and occasion, according to NWC, a subsidiary of the Nestlé Waters North America of Stamford, Conn.

NOTES & QUOTES

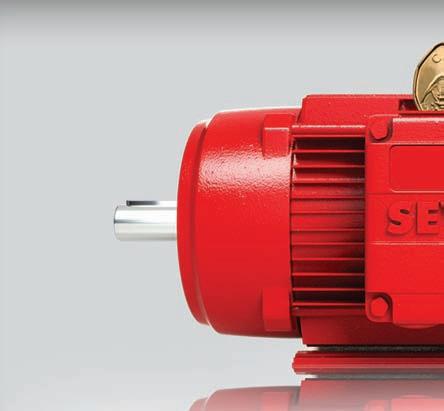

Weber Packaging Solutions has been appointed as a Canadian distributor for the full range

Michael Brown, vice-president and general manager of Weber Marking Systems – Canada in

Packaging Produce?

MULTIVAC produces a wide range of fresh produce packaging formats for retail, foodservice and wholesale products. Our packaging is suitable for: prepared fruit, soft fruit, vegetables, fresh produce, leafy greens and fresh salads.

FreshSAFE, MULTIVAC’s innovative packaging process for fresh produce, ensures that through a combination of MAP and EMAP packaging the shelf life of these products can be significantly enhanced. Many of these pack formats can also be designed with easy open features, portion control or in convenient multipack layouts.

Challenge MULTIVAC to produce your better packaging.

tions,” says Greg Kughn, sales development director

French manufacturer of capping has Fowler of Athens, Ga., to be its exclusive value-added services distributor in Canada, while appointing Alex E. Jones as Canadian sales agent for new Zalkin capping equipwidely used in the food-and-beverage, household products, personal-care and pharmaceutical industries. Like Fowler Products, Zalkin is part of the globally-operating group of companies, headquartered in Loveland, Ohio. Under the announced partnership, Alex E. Jones will supply Zalkin machinery across Canada from its Oakville, Montreal and Edmonton operating locations.

Toronto-based metal detectors manufacturer Fortress Technology Inc. has moved its Brazilian operations to a larger 33,000-square-foot production and office facility near São Paulo in Vila Rosina, Caieiras, to keep up with company’s fast growth in local markets. “We are very pleased about the unprecedented growth we’ve achieved in such a short time and the support from our customers, and the new plant will dramatically increase the manufacturing capacity in response to customer demand and the growth their clients are experiencing in the region,” says Pierre DiGirolamo, executive director of Brazilian operations.

Sitting from left: Berry Plastics sales development director Greg Kughn and executive vice-president Keith Brechtelsbauer joined by vice-president of sales development Joe Marinacci (standing left) and Klöckner’s director of strategic business development Jeffrey Best.

REALITY CHECK

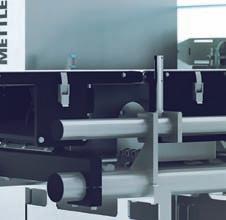

The new C3000 system from the Product Inspection business of Mettler-Toledo International Inc. is a highly versatile next-generation checkweigher covering an extensive weighing range of up to 10 kilograms, while allowing food and pharmaceutical manufacturers to inspect up to 600 products per minute. Boasting superior protection against vibrations caused by other production machinery, the machine’s stability is further enhanced by its rapid throughput rate and a modular design to allow for a variety of configurations as dictated by space constraints. Moreover, the system is offered with a range of optional product inspection technology combinations—such as metal detection (CM model) or vision inspection (CV model)—to ensure that the checkweighed product are free of metal contaminants and other imperfections. The system’s single HMI (human-machine interface) seamlessly controls the checkweighing and metal detection technology—thereby reducing programming time and the risk of operational error—while also integrating centralized inventory management technology to enable faster, more effective reporting on product changeovers and the rejection of defective products.

Mettler-Toledo Product Inspection 401

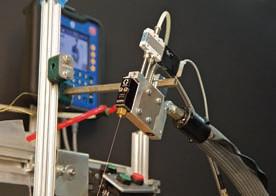

PASSING THE TEST

The new PERMATRANW Model 3/34 G system from permeation instrumentation specialists MOCON, Inc. is claimed to be the first-ever, fully-automated water vapor transmission rate (WVTR) testing system for packaging and other barrier structures, according to the company. Boasting superior capability to test for WVTR—the steady-state rate at which water vapor permeates through a film at specified conditions of temperature and relative humidity this new PERMATRAN-W Model 3/34 G can save significant time and associated costs for food, pharma, beverage, medical device and electronics companies in selecting and qualifying optimum barrier materials for

their moisture-sensitive products, as well as for converters and resin producers who want to test film materials and the finished packages.

MOCON, Inc.

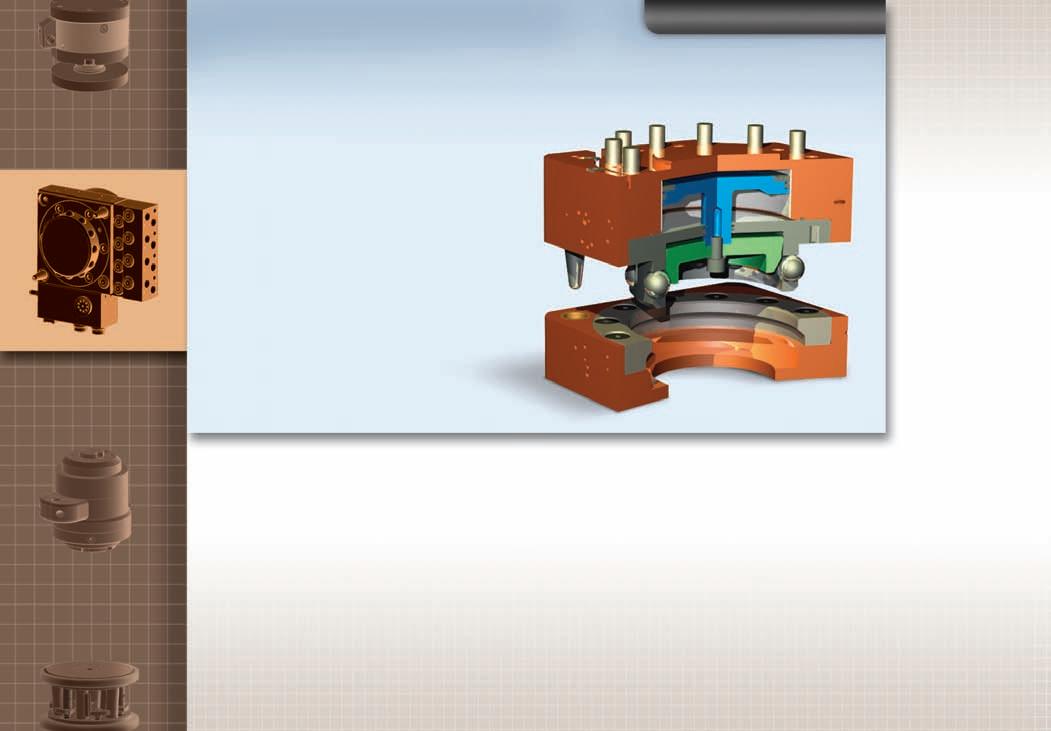

TO SERVE AND PROTECT

40 2

Applied directly onto coffee packaging to prevent premature product deterioration, the new V55 external coffee protection valves developed by Bosch Packaging Technology claimed to have been meticu lously designed to enhance product protection, while offer ing significant material, logis tics, and storage space savings, along with changeover time reduction. According to Bosch, coupling this technology with its existing, welltested applicator systems for equipping soft bags or cans of coffee with external valves can enable cof

FIRST GLANCE

fee manufacturers to apply up to 150 valves per minute. With 1,000 grams of roasted coffee beans estimated to emit around six liters of carbon-dioxide within five weeks, the V55 valves allow for the roasting gas to escape without letting oxygen and external odors to enter the bag or can to degrade the aroma of the premium product inside, while also preventing the bag from bloating.

Bosch Packaging Technology 40 3

INVISIBLE TOUCH

The new InvisiPac GM100 Plug-Free hot-melt applicator from Graco Advanced Fluid Dispense is claimed to offer all the benefits of plug-free adhesive dispensing in a compact design that fits tight spaces and mounts seamlessly into existing packaging lines currently using other alternatives, according to the company, making it especially well-suited for both original equipment manufacturers (OEMs) and end-use packaging equipment for the food-and-

FIRST GLANCE

beverage industry. Taking less than 10 minutes to warm up, the durable, highly reliable applicator features an innovative, patentpending module tip filter that eliminates nozzle plugging, ensuring optimal uptime performance at speeds of up to 10,000 cycles per minute.

Graco Advanced Fluid Dispense 404

SPLICE OF LIFE

JOINT EFFORTS

Designed primarily for the food-and-beverage industry packaging applications, he new SP1 series automatic film splicer from Butler Automatic is designed to eliminate the packaging line downtime caused by manual film roll changes, according to the company. Featuring simple mechanical design and capable of running at speeds of up to 600 feet per minute, the splicer is designed to ‘sense’ the expiring roll of film and automatically splice the end of each expiring roll onto the new roll, thereby eliminating interruptions to the production process.

Butler Automatic 405

Developed jointly with WeighPack Systems Inc., the new custom-built packaging solution from Eagle Packaging Machinery offers everything required for fully-automatic filling and sealing of stand-up pouches; erecting, loading and sealing cases; and palletizing ship-ready cases for customer delivery or storage. Featuring WeighPack’s auger filler and horizontal bagger, the system consists of Eagle’s Boxxer T12 case-erector, which erects and tapes 12 cases per minute and transfers them to the box indexing machine. While the cases are formed and indexed, the product is weighed and filled into stand-up pouches, which are indexed and arranged in alternating patterns in preparation for case-loading. Once the case is in position, the bags are dropped directly into the case, which is then transferred to the EZ-Tape case-sealer for sealing, picked up by the Z.Zag palletizer, and transferred to a pallet for shipping.

Eagle Packaging Machinery 406

FREEZE FRAME

Designed specifically for frozen food packaging applications, the new BVC 400 V/F/F/S (vertical fill/form/seal) bagging machine from Rovema North America is a continuous-motion, dualaxis, servo-driven system deigned to offer broad

flexibility in product sizes and shapes demanded by the frozen-foods sector. Capable of running up to 150 cycles per minute at a maximum forming width of 400-mm, the highly-hygienic BVC 400 machine boasts a patentpending Sense & Seal quality control system that determines if there is any product present in the cross-seal area—automatically discharging the affected bag without applying seal pressure.

Rovema North America 407

LIFE SENTENCE

Developed to maximize the print quality and performance levels when used with HP ’s pigmented Digital Electroinks range of printing inks, the Durable Digital film label materials from Weber Packaging Solutions are engineered to remain fully attached to durable goods throughout the product’s life. Covered with a layer of Digilam PET coating over laminate film for optimal durability, they are supplied in three versions:

• Digiflex BOPP, an economical material for printing decorative graphics;

• Digiweb Vinyl material for curved surfaces;

• Digiplate PET for flat industrial surfaces.

Weber Packaging Solutions 408

PREMIUM PACKAGE

Coding and Marking.

Domino’s unique i-Tech features make coding and marking operation easier –with lower maintenance, less servicing and simpler installation.

Domino allows you to focus on your production.

Relieving your coding headaches… one reliable code at a time.

Brantford, ON:

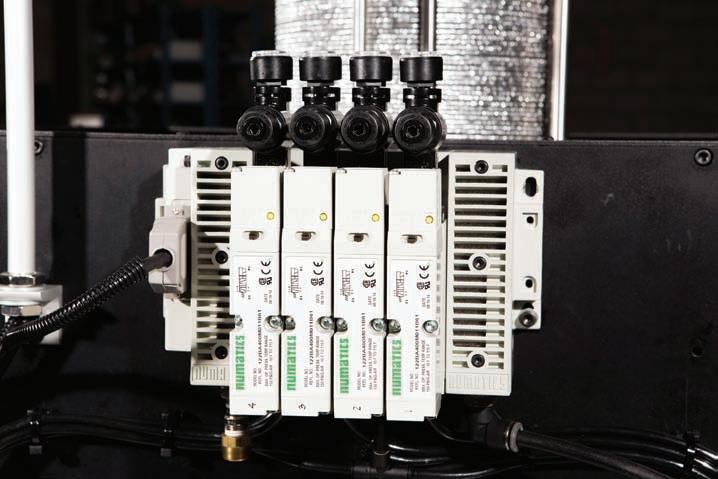

ASCO Numatics –Emerson Industrial Automation has appointed John Lamb as National Segment Manager – Packaging, Food & Pharma for Canada.

John has many years of experience within the fluid power and fluid control industries and is the Chair for the Canadian Fluid Power Association. “I am excited to work within a well established field for ASCO Numatics and help support our customers by learning their needs and offering solutions.”

More about ASCO Numatics:

ASCO fluid control and Numatics fluid power products have been on the job in food and beverage applications for more than 100 years.

Today, ASCO Numatics provides superior fluid automation solutions for engineers, purchasers, and managers at original equipment manufacturers (OEMs), skid and panel builders, engineering houses, and leading food and beverage plants worldwide. ASCO Numatics is the source of fluid automation products for process/packaging automation in splash/wet areas and other parts of the food and beverage plant.

• Processing - from mixing, stirring, sterilizing, and pasteurizing to filtering, dosing, and ensiling

• Packaging - from filling, capping, labelling, and shrink wrapping to case erecting and palletizing

• Infrastructure/utility - from boiler or compressor room to transport lines and comfort heating

• Water/wastewater - from clean water supply to recycled discharge

ASCO Numatics products emphasize durable build quality and robust components for greatly extended life cycles, to cut maintenance costs and maximize uptimes. This dependability is attested by the industry’s widest range of third-party certifications – CSA, UL Listed, NSF, UL Recognized, IECEx, FM, and more. Furthermore, increase plant throughput via our sophisticated integration of advanced fieldbus electronics and proportional technology.

Omron’s Laura Studwell Appointed to Emerging Leaders Committee by The Association of Processing & Packaging Technologies (PMMI)

HOFFMAN ESTATES, IL (March 10, 2015) – Omron Automation and Safety (www.Omron247.com) announced that Laura Studwell, Food, Beverage & Packaging Industry Marketing Manager, has been appointed to the Emerging Leaders Committee of The Association of Processing and Packaging Technologies (PMMI). During her four-year term on the committee, Studwell will mentor future industry leaders as well as provide expertise and insights on issues addressed by PMMI.

PMMI’s Emerging Leaders Network engages future leaders while building a network of peers and industry advocates. The committee is made up of 14 members and includes several industry leaders, such as: Scott Chehak (Arrowhead Systems), Greg Berguig (Packaging Aids), Christopher Canna (Schneider Packaging Equipment), Brian Ormanic (ARPAC), Mark Suchy (MASSMAN) and Matt Job (Hartness International).

“I’m excited and honored to be selected for the Emerging Leaders Committee,” said Laura Studwell. “I look forward to fostering the growth of the packaging and processing industry’s next generation of leaders, and helping them to realize their potential.”

Founded in 1933, PMMI is a leading trade association with the mission to improve and promote members’ ability to succeed in the global marketplace. PMMI has more than 700 member companies in North America and includes manufacturers of packaging, processing and packaging-related converting machinery, commericallyavailable packaging machinery components, containers and materials.

Studwell has an extensive background in the food and packaging industries, working with associations and governing bodies throughout the PanAmericas to drive standards for food safety and quality. In addition to her new role on the Emerging Leaders Committee, Studwell is an active member of PMMI and the Packaging Association of Canada. Prior to joining Omron, Studwell worked at Loma Systems (an ITW company), Xerox and IBM. She received her MBA from Northern Illinois University.

Careers at Weber - Marking Systems of Canada

Account Sales Representatives

Western Canada (Calgary and BC)

Job Description: Successful candidates will have direct selling and business development experience in the labelling and/ or industrial packaging industry or similar. Responsible for maintaining already developed territory and developing new sales opportunities. Must be highly motivated, driven, responsible and demonstrate unquestionable integrity and honesty.

Candidates must have the following minimum qualifications:

• a college/ university degree preferably in Business or Marketing

• minimum of 5 years proven outside sales performance

• a clear and clean drivers abstract

• proven track record

• experience in Labels, Print & Apply labelling systems

• other marking and coding technologies will be considered a tremendous asset

Desired Skills & Experience: You are highly motivated, driven, honest and are willing to invest the time and effort to enhance and enjoy your career. You are professional in all aspects of your business life, you develop strong business partnerships through excellent service and integrity and you have a strong desire to succeed!

Contact Mark Quinn at 905-564-6881 or at mquinn@webermarking.ca

JEFF JONES has been appointed General Manager for FlexLink Canada. FlexLink is a leading provider of automated production flow solutions-giving improved production efficiency to industry.

Having extensive experience in the Canadian manufacturing and packaging industries, he has held various positions with Domino Printing Solutions for the past 10 plus years and most recently Jeff held the position of National Sales Manager for the past 5 years.

He states; “I am excited to work with the talented and experienced team at FlexLink who value their customers and their commitment with the Canadian marketplace. I look forward to leading this team.”

FlexLink Canada has offices and production facilities in Burlington, Ontario. Jeff goes on to say “It is an exciting time for FlexLink Canada and FlexLink globally with the introduction of new products and processes that our customers are quickly adopting”.

FlexLink is part of Coesia, an innovation based Group consisting of 14 companies, specialized in automated machinery and industrial process solutions.

FlexLink Systems Canada, Inc. 1-1549 Yorkton Court Burlington, ON L7P 5B7 / Canada

T +1-905-639-6878

F +1-905-639-4632 www.flexlink.com

John Lamb

John Lamb National Segment Manager

POPULAR JERKY BRAND BEEFS UP ITS SUSTAINABILITY CREED THROUGH RECYCLING

Linking consumer-friendliness with eco-minded sensitivity is a tricky balancing act, but it’ll soon become second nature for the Jack Link’s Beef Jerky brand of dried beef strips produced by the Minong, Wis.-based Link Snacks, Inc.

As the latest high-profile recruit into the Fresh-Lock Zipper Spool Recycle and Reuse program implemented by leading plastic closures manufacturer Presto Products Company, the brand is expected to support the reuse of 30,000 pounds of HIPS (high-impact polystyrene) plastic per year.

“This is part of an comprehensive sustain ability program at Jack Link’s, where we always strive to be great stewards of our natural resources,” says the company’s director of corporate sustainability Thomas Myers.

“Our policy is to incorporate sustainability throughout our business practices and procedures, with the ultimate goal of minimizing our environmental impact and strengthening the communities where we do business.

“There are three key initiatives driving our current sustainability efforts: reducing energy consumption, reduction in overall waste, and increasing our supply chain and packaging efficiency,” says Myers, noting that improvements in all three areas have enabled the company’s meatsnack manufacturing facility in Alpena, S.D., to achieve zerolandfill status in the past year.

As a supplier of choice for the Jack Link’s brand business for nearly a decade, the Appleton, Wis.based Presto Products provides Jack Link’s with press-to-close (PTC) zippers for all the small, medium and large pouch formats used for all of its branded products, as well as technical service and consultation to support the company’s proactive commitment to green initiatives.

Last year, Presto used its proprietary soft-seal resin to develop a new blend of ethylene vinyl acetate (EVA) and low-density polyethylene (LDPE).

According to Presto, this innovative material provides a high melt index that gives operators more time to ensure the zipper adheres properly to film pouches, while reducing the number of imperfect pouches that come down the line. By minimizing the number of imperfect pouches, the material helps to decrease costly product waste and increase process efficiency and product quality.

“By minimizing the number of imperfect pouches, the solution helps to decrease costly product

waste and increase the efficiency and quality output of the facility,” says Myers.

In addition to providing Jack Link’s with PTC closures that advance sustain ability and efficiency, Presto also provides the company with technical service and support to speed delivery times, streamline processes, and respond rapidly to urgent order requests, as well as proactive consultation for implementing ‘big picture’ improvements to packaging operations.

ward here,” says Brad Hansen, president of the Presto Specialty Group business.

“Closures represent a frequent point of interaction between the product and the consumer, so it is critical for brands to put their best foot for -

“We love working with companies that share this belief and understand that the design, engineering, materials and natural resources that go into delivering a quality closure are all important factors that can impact their supply chains in a positive way and contribute to building brand loyalty.” Since launching its Fresh-Lock Zipper Spool Recycle and Reuse program to help manufacturers enhance the sustainability of their supply chains in 2009, Presto has championed the reuse of 3,000,000 pounds of HIPS plastic across various product categories—diverting this material from landfills and reusing the spools in new shipments of Fresh-Lock Zipper brand closures.

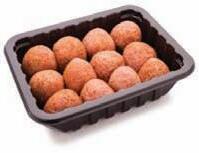

Nothing keeps your product fresher than MAP packaging produced on a Ross IN inline tray sealer.

n Produces MAP packages using preformed trays of almost any size or shape –easily packages your entire product line.

n Consistently produces packages with reliable, high-quality seals that extend shelf-life.

n Fast, highly flexible, and extremely easy to operate.

n Innovative tool/storage cart allows rapid, tool-less changeovers between tray sizes in 10 minutes or less.

n Stainless steel washdown construction and IP67 components.

n Compact footprint allows it to fit into tight areas.

n Test the Ross IN for yourself. Contact us to set up a demonstration at the Reiser Customer Center.

BACK BY POPULAR DEMAND

See six schools compete in our Interactive Student Packaging Design Competition… join in the fun of imagining the next Walmart

PACKAGING FOR SHELF-LIFE

MAKING THE BEST OF A DAILY GRIND

Quebec meat and poultry processor enjoys improved machine uptime achieved with a new VC999 rollstock thermoformer that also reduces operating costs and extends product shelf-life

ANDREW JOSEPH, FEATURES EDITOR PHOTOS BY PIERRE LONGTIN

Life may sometimes seem a grind to some folks, but for one Quebec-based meat processor, grinding massive cuts of raw meat down to shreds is a beautiful way to make a living. Based in Terrebonne, Que., Les Aliments BestCo Foods is a family-owned and operated business specializing in mincing and grinding of various types of meats for the retail and institutional sectors within the province and throughout the rest of Canada.

“We are a production facility, not a distributor, supplying distributors who do not have the necessary specialized equipment or access to a HACCP (Hazard Analysis and Critical Control Points) facility dedicated to food safety,” BestCo president Dino Scopelleti explained to Canadian Packaging magazine in a recent interview.

Although situated within a large 30,000-squarefoot facility, Scopelleti and his 10 employees run the busy operation out of a compact rented 5,000

square-foot space that he has turned into a Goldclassified operation inspected annually by the GFTC (Guelph Food Technology Centre)

“Dealing with meat and poultry, we are fully cognizant of the health and safety issues our customers and their customers face,” states Scopelleti.

“It’s why we work with a healthy and safe work ethic which we follow stringently, working with an exterior laboratory to analyze our products to ensure we maintain our industry-respected level of quality.”

Started up in March of 2000, BestCo Foods initially had a different vision than what currently exists, acknowledges Scopelleti.

“I started the company with the intention of producing a high volume of fresh and frozen kebobs.

“I did that for a few years, and had good success with it,” Scopelleti recalls.

“But the problem with that as my main focus was the fact that it’s a highly seasonal product, with a very high volume for five months of the year.”

Seeking to avoid the seasonal ups and downs of capacity, in 2004 Scopelleti decided to shift BestCo’s

focus to specialize in producing ground meats and other different products for foodservice distributors as the core customer base.

“It meant reinventing ourselves, but doing so provided my company and our employees with a much more stabilized yearly production,” he notes.

Nowadays BestCo Foods produces and packs

Processed and packed for industrial sale, packs of ground meats exit a VC999 RS420c thermoformer that has helped BestCo Foods achieve notable reductions in packaging time and costs.

BestCo Foods president Dino Scopelleti (left) and son and vice-president Vincent examine the high-quality pack seal created by the model VC999 RS420c rollstock thermoformer.

about 30 different products, with about 60 per cent of its production being minced (ground) or cubed products, including beef, veal, pork, lamb and chicken, and has at times produced marinated duck breast and roasts for a key customer.

“Our production is split between processing and packaging for distributors and cooking facilities, like those that make different sauces,” Scopelleti relates.

Over an eight-hour daily shift, BestCo produces between eight to 10,000 kilograms of product, which in 2014 added up to volumes of 550,000 kilograms of minced meats, as well as 50,000 kilos of lamb and 20,000 kilograms of duck products and more.

By meat type, production of BestCo Foods breaks down to: 40 per cent beef; 20 per cent pork; 20 per cent lamb; 10 per cent duck; five per cent apiece for veal and chicken.

Scopelleti says he is not bothered in the slightest by the inherent anonymity of his line of work.

“Nothing is actually packed under the BestCo name,” confides Scopelleti. “My customers are distributors, and I mostly pack under their brand names, so you won’t see my company’s name anywhere on the packaging.”

With about 60 per cent of the product processed and packaged by BestCo destined for hospitals, schools, hotels and restaurants, the remaining 40 per cent of output is supplied to the retail sector.

“About 12 years ago, BestCo Foods began processing products for the renowned Knowlton, Que.-based duck meat specialists Brome Lake Ducks (Canard Du Lac Brome),” recalls Scopelleti.

“We now produce a wonderful marinated duck breast consisting of a Dijon mustard and honey mixture that we pack in Brome Lake-supplied

425-gram paperboard packs, as well as 800-gram duck roasts for their label.”

Scopelleti’s son Vincent joined the business in 2013 as both partner and vice-president, around the same time as the company moved into its current facility, which enabled it to essentially double its production output.

Proud papa Dino adds that thanks to the work of Vincent, BestCo will probably double its grinding capacity in the very near future.

“Right now, we are in the last stages of achieving our Halal certification,” points out Scopelleti. “We always work closely with our customers in the research-and-development of new products, while also offering them personalized packaging.

“Attaining the Halal-certification will open up brand new growth opportunities for BestCo,” he enthuses.

Despite still being a relatively ‘small’ company in terms of volumes, Scopelleti says that maintaining a high degree of flexibility for changing customer needs is both a priority and a competitive advantage.

Helping BestCo achieve that flexibility on a consistent basis is VC999, a Switzerland-headquartered global designer and manufacturer of vacuum chamber machines, thermoform (rollstock) packaging machines, tray-sealers, skin packaging, and flowwrappers, as well as related robotics, vision inspection systems, conveyor/converger systems, weighing, labeling and product scanning machinery.

After assessing BestCo’s production needs, VC999 supplied it with a full packaging solution, featuring a RS420c compact rollstock thermoformer and a XtraVac CM640 double-chamber vacuum machine.

“BestCo has never been down with work stoppages since acquiring this equipment,” relates

VC999 sales manager for East/Atlantic and distribution sales leader Carl-Michel Cloutier. “It shows just how reliable and well-built the equipment is.”

According to Scopelleti, BestCo Foods first began working with VC999 in 2008, when it purchased the RS420c thermoformer, adding different types of tooling since then to provide it with new packaging options.

Cloutier says the rs-Series thermoform packaging machines produce precision deep-drawn packages from plastic high-barrier films, while the XtraVac CM640 uses FlexOStar vacuum pouches supplied by XtraPlast Packaging Materials, a VC999 sister-company.

“With the ease of changeover we get from the thermoformer, we can pack product anywhere from 300 grams to five kilos,” notes Scopelleti, adding that the only product packaged in trays are the duck roasts it does for Brome Lake.

“We run it to its full capacity every day, packaging more than 960 packages per hour,” he extols.

“It’s a great machine that produces clear, tight packaging; plus it has really helped us save on packing time and dollars.”

Scopelleti says the RS420c provides BestCo a maximized shelf-life for fresh products, delivering a value-added package presentation while also providing a high level of product protection and hygienic cleanliness.

According to VC999, the numerous advantages of rs-Series thermoformers include:

• Longer product shelf-life;

• Reduced associated labor costs;

• Precise control over package sizes and shapes;

A BestCo Foods employee manually places precise portions of meat into the VC999 RS420c thermoformer, which can process over 960 units per hour.

The model RS420c rollstock thermoformer manufactured by VC999 provides a high level of product protection and hygienic cleanliness for the BestCo Foods plant.

The XtraVac CM640 double-chamber vacuum packing machine from VC999 is used by BestCo to package portioned meat products weighing up to 30 kilograms in weight.

To ensure optimal food safety compliance, BestCo Foods uses a Mettler-Toledo Safeline metal detection system, distributed in Canada by Shawpak Systems Ltd.

PAC BOARD OF DIRECTORS

Chair

Bruce Smith

Director of Global Packaging Molson Coors Brewing Company

Immediate Past Chair

Robert Cockerill, BC Inc.

First Vice Chair

Kim Rapagna KR Inc.

DIRECTORS AT LARGE

Alan Blake, Executive Director PAC NEXT

Kevin Brown, Sales Director Bemis Co Inc.

Parbinder Cheema

Director of Pkg Innovation & Sust.

Maple Leaf Foods

James Davidson

VP: Sales, Marketing & Product Development Western Concord Mnfg

James D. Downham, Pres.& CEO PAC, Packaging Consortium

Keith Fanta, Senior Engineer, Global Pkg

Sustainability Procter & Gamble

Sheldon Gouthro VP Sales

Maritime Paper Products Ltd.

Jennifer Hottinger-Sloan Director: Packaging Coca-Cola

Karimah Hudda, Sustainability Manager Mondelez International

Louis Lemaire, VP Sales

Graphic Packaging Int’l Canada

Julie May-Rogers

Manager Gov’t Relations McDonald’s Restaurants

Linda McGregor, VP Acct Director Davis

Erica Ocampo, Sustainability & Advocacy

The Dow Chemical Co.

Richard Pileski, Senior VP, Bus. Development Jones Packaging

Mike Richmond, Vice President

Packaging Technology Integrated Solutions

Yasmin Siddiqi, Global Packaging Relationship Manager DuPont Pkg & Industrial Polymers

Louis St. Amand

Director of Pkg: R&D North America McCain Foods

Scott Tudor

Director Sustainability Sobeys Inc.

Denis Vachon, Sales Manager O-I Canada Corp.

CELEBRATING GLOBAL PACKAGING EXCELLENCE & LEADERSHIP

A Message from the PAC President & CEO

The PAC Global Leadership Awards competition continues to attract some of the most innovative packaging entries from across the global packaging community—as evidenced by the super cool award-winning entry submitted by Molson Coors Japan in this year’s competition.

This year we received over 240 submissions in the competition’s primary categories: the PAC Packaging Competition celebrating innovation, branding, graphic design, in-store marketing and technical achievement; and the PAC Sustainable Packaging Competition for recognizing environmental sustainability leadership.

Always striving to be the pioneer, we are also pleased to introduce the inaugural PAC Food Waste Competition, which is the first awards program in North America dedicated to raising awareness of the important role that packaging will play in coming years to mitigate food waste.

In the secondary categories we received a record number of dynamic Brand Marketing submissions, while Rigid Packaging and Flexible Packaging categories featured some of the most technically advanced innovations we have seen in years. For their part, the Fiber-related categories comprised a number of leading-edge complex structural designs, while showcasing the powerful capabilities offered by today’s increasingly mainstream digital printing technologies.

Over 65 dedicated industry experts selflessly gave up their Saturday earlier this year— diligently grading every entry in the competition with scorecards in hand. For their part, our 10 sustainability and food waste experts performed deep online evaluations of packaging entered in these key categories. I wish to extend my gratitude to all participating judges for their continued commitment to this long-running PAC competition, as well as for ensuring that all the entries received objective and expert scoring and evaluation.

Under the leadership of Michael Hill, our awards committee added several high-quality new members this year, which has resulted in some great improvements to the competition, the gala and the awards. We are most grateful for their enduring commitment to overseeing such a dynamic competition and for bringing the fun and energetic awards gala to life, most notably to Shirley Buchanan of Davis , Joe Campbell of

Special

Michael Hill, Committee Chairman TC Transcontinental Shirley Buchanan, Davis

Joe Campbell, Atlantic Packaging Products Ltd.

Atlantic Packaging Products , Elizabeth Ferrier of Molson Coors , and Mark Spurgeon from SGS

We would also like to extend our thanks to the Canadian Packaging magazine—our long-standing media partner and sponsor of the competition’s Consumer’s Voice award—for its continued support to both the PAC community and the packaging industry at large. We are also delighted to have the Applied Arts magazine present a Best of Show award at this year’s competition.

This year we are presenting a total of six Best of Show (BOS) awards, including:

• PAC Leadership Award. Presented to the brand manufacturer recognized as the “Leader among Leaders,” as selected from all submissions.

• Consumer’s Voice Award from the Canadian Packaging magazine, as selected from all entries by a panel of regular contributors to the publication’s Checkout column of new product packaging reviews.

• Design and Craft Award from the Applied Arts magazine, as selected from all submissions

• PAC Packaging Award , as selected from all submissions.

• PAC Sustainable Packaging Award , as selected from the Sustainable Packaging category submissions.

• PAC Food Waste Award , as selected from the Food Waste Packaging category submissions. Congratulations to all of the 2015 competition winners for their brilliant packaging submissions and leadership to our industry! Please remember to drop by the PAC, Packaging Consortium booth at this year’s PACKEX Toronto 2015 national packaging technologies exhibition, June 16-18, 2015, to get a more close-up look at all of the competition’s entries and winners.

Sincerely,

James D. Downham, President & CEO, PAC, Packaging Consortium

Kevin Collins, Rayment & Collins Ltd.

Jim Downham, PAC, Packaging Consortium

Elizabeth Ferrier, Molson Coors Brewing Company

Mark Spurgeon, Southern Graphic Systems

Stuart Werle, Werle Design Associates

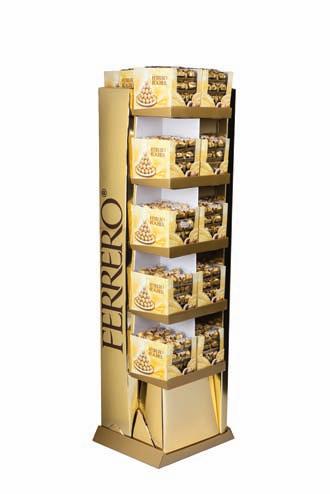

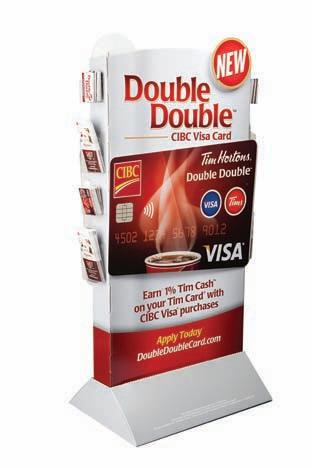

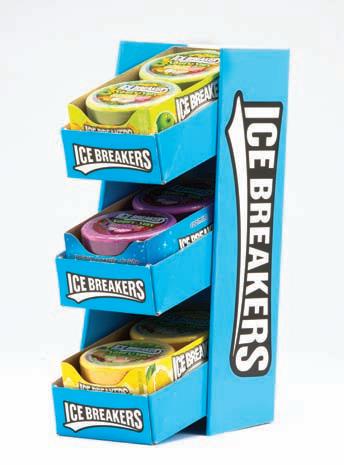

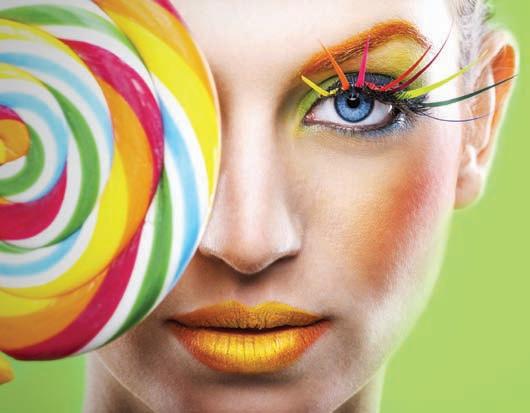

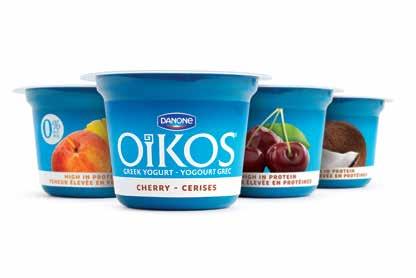

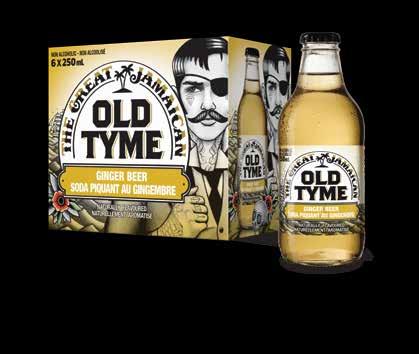

BRAND MARKETING: NEW BRAND – NON-FOOD

BRAND MARKETING: NEW BRAND – FOOD

2015 BEST OF SHOW

PAC LEADERSHIP AWARD

LEADER AMONG LEADERS

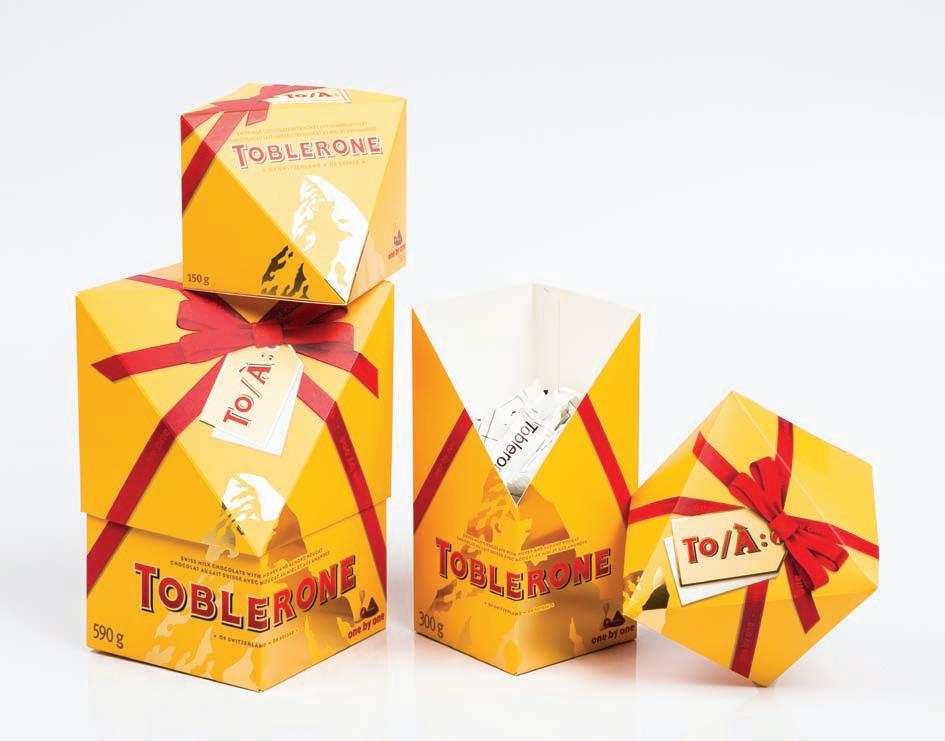

Mondelez International

Mondelez US.; Mondelez Canada, Inc.; Mondelez International, Inc.

Winner of 4 Gold and 4 Silver awards. Exceptional technical reproduction and innovative levels for graphics and structure.Robust brand identity and package integrity. Leadership in flexible pkg, brand marketing (new brand and revitalization), paperboard and in-store marketing floor display.

PAC PACKAGING AWARD

Kawartha

Bridgemark

Kawartha is a family owned business, making quality dairy products since 1937. With deep roots in Canadian cottage country, the key marketing objective was to leverage the brand’s emotional appeal through its strong association with cottaging and summer vacations.

PAC FOOD WASTE AWARD

DOUBLE WINNER!

CANADIAN PACKAGING CONSUMERS’ VOICE AWARD and APPLIED ARTS DESIGN & CRAFT AWARD

Red Prince Apples

St. Joseph Communications Content Group

The poly bag is transformed to represent a hand crafted paper bag with letterpress era graphics style, telling an editorial story about the artisan journey of the uniquely cultivated Red Prince apple variety. The bag led a repositioning campaign that spanned in-store display and web site redesign (redprinceapple.ca). The new position and graphics have massively improved store listings with major grocers in Canada and the northeastern US.

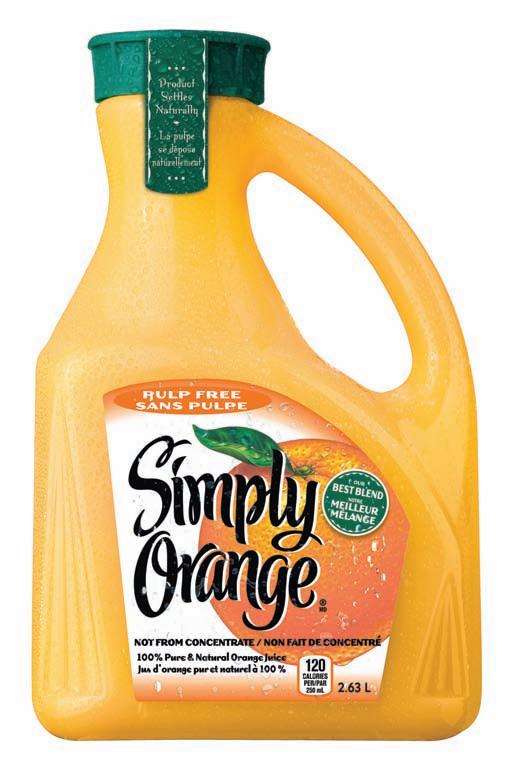

PAC SUSTAINABLE PACKAGING AWARD Simply Bottle - EPET Extrusion

Coca-Cola Canada

Partnering with Plastipak Packaging, Coca-Cola Canada worked to develop a new 2.63L Simply™ jug using 100% a mono-layer PET through a modified wheel extrusion technology called Gem-Pak™. They were able to overcome many technical challenges to manufacture a virtually crystal clear jug that was an invisible change to their system and the consumer. The package remains safe and healthy, is made from a more sustainable material as it can be more easily recycled, and the package is desiged to optimize materials and energy in manufacturing.

EcoCup™ Capsules with FlavorMax filter technology

Mother Parker’s Tea & Coffee

The introduction of single serve coffee and tea capsules has grown rapidly over the past 5 years. A study to analyze the comparison of traditional drip brew coffee vs single serve coffee was conducted in partnership with Quantis, PAC and Club Coffee. The results of this study indicated that these two preparation methods (assuming no waste) are not significantly different. However, once waste due to product expiry or over preparation in the traditional drip brew scenario was incorporated, the single serve solution was found to be beneficial in reducing the food waste. Through single serve capsules, there is an opportunity to increase the freshness of the product that the consumer enjoys while providing a controlled dosage to reduce wastage.

SILVER WINNERS

IN-STORE MARKETING – FLOOR DISPLAY MERCHANDISER

Working side-by-side with

From materials and design, to automation and fulfillment we provide award-winning solutions that deliver on both form and function. And with approximately 170 distribution centers in North America, our reach is extensive – but we hang our hat on localized and personal service.

• Gain greater efficiencies in your supply chain

• Improve the visual and physical design of your packaging

• Develop a process that reduces steps and increases speed to market

• Meet your sustainability goals and earn certifications

Your packaging needs to perform – from concept to destination. Learn more about our offerings by contacting your Veritiv representative, or visit veritivcorp.com.

2015 FOOD WASTE COMPETITION AWARDS

MATERIAL, PRODUCT OR ANCILLARY SERVICES

SILVER

Congratulations to our award-winning clients!

1Your success is our greatest reward

Packaging That Inspires Unforgettable Moments

Graphic Packaging* offers our customers the capabilities and resources needed to succeed at retail. Through global scale, local execution and insight-driven innovative packaging solutions, many of the world’s leading brands turn to Graphic Packaging to provide paperboard cartons that inspire unforgettable moments. Our paperboard mills, converting assets and robust integrated supply chain make us uniquely equipped to meet our customers’ packaging challenges. Let us inspire your consumers. For more information please visit www.graphicpkg.com

Norampac, a division of Cascades Canada ULC for Hartmann Hybrid Egg Carton, 2014 PPC Package of the Year

MAKING THE BEST OF A DAILY GRIND

Continued from page 14

• Robust stainless-steel construction;

• Quick-change tooling;

• Sanitary design for easy and effective washdown;

• A reliable PLC (programmable logic controller) platform;

• Ease-of-operation, thanks to the user-friendly multilingual machine HMI (human-machine interface);

• Free lifetime technical support.

“It hardly seems necessary considering its robustness,” opines Scopelleti, but after having grown fond the RS420c, when the time came to expand in 2014, he got in touch with VC999 again, purchasing a double-chamber XtraVac CM640 vacuum packing machine to package portioned product up to 30-kilos in weight.

Compact in design, the economical XtraVac CM640 is considered ideal for small- to mediumsized production runs, but providing excellent product shelf-life and a handsome product presentation.

“From the moment it was delivered, the VC999 team was here helping us program the machine to our specifications,” he relates.

“And, should we require any additional information, we’re confident help is just a phone call away,” says an impressed Scopelleti adding that VC999 has an excellent preventative maintenance program to support its equipment.

Adds Cloutier: “We have a preventative maintenance service program for their machine, which helps explain why their operating costs are so low.

“We take very good care of their equipment.”

VC999 also supplies BestCo with quality XtraPlast film, that enables the thermoformer and the vacuum-packing chamber machines to achieve superior

Say Cheese

forms and seals, virtually eliminating the meat processor’s concerns about package rejects.

“It shows how important it is when a customer deals directly with us for both machine and film requirements,” explains Cloutier. “It’s their best guarantee of performance, peace-of-mind and trouble-free packaging.”

Scopelleti is also quick to extend special praise to Bertoldi’s, a Montreal-headquartered equipment supplier specializing in industrial knives and cutting machinery.

“With Bertoldi’s, we purchased and set up a meat grinding line where we run a pair of Biro AFMG industrial grinders, helping us output 2,000 kilograms of meat per hour,” explains Scopelleti.

He adds that BestCo also recently purchased a 2501CE Hydrauflaker —combination flaker and slicer—from the Sheboygan, Wis.-based GMC (General Machinery Corporation), enabling BestCo to flake over 3,000 kg of meats per hour.

Scopelleti relates that the equipment supplier performs weekly maintenance, and the sharpening of all the blades and grinding plates.

Other equipment used by BestCo to create their packages include Protec DDC 9600 and Zebra printers, which take care of all the thermal heat label requirements, producing durable labels containing clearly etched lot code data for easy traceability.

“The processing and packing services provided

Increased uptime provides many reasons to smile

A leading food manufacturer was experiencing significant delays in packaging their cheese slices. The valves that came with their count and stack equipment were breaking down, causing production delays.

ASCO Numatics provided 2005 series valves to replace the five malfunctioning valves on each of the two systems.

That first month, 24 hours of downtime were eliminated and 2.3 million more cheese slices were produced. This put a smile on the maintenance manager’s face.

For more information contact asconumaticscanada@emerson.com

Visit us at PackEx Toronto booth number 1278

by BestCo are superb, and I am cognizant of the fact that along with the wonderful work provided by my employees, the equipment we’ve purchased from companies like Bertoldi and VC999 are key to the positive reputation we have enjoyed in the industry,” sums up Scopelleti.

“I’m confident that our equipment and they way we utilize it hold the key to our continued success.”

For More Information:

BestCo Foods uses its VC999 XtraVac CM640 double-chamber vacuum-packing machine to create the inner pack of the premium-quality Dijon mustard and honey-flavored boneless duck breasts on behalf of its retail customer Brome Lake Ducks.

THE BEAR ESSENTIALS

An inspired top-to-bottom packaging redesign helps Canadian consumers reconnect with one of their most cherished childhood food brands

“The longevity of our relationship with Kraft is really something unheard of in this industry,” says Pigeon, whose company’s ever-growing product portfolio nowadays comprises an elite blue-chip roster of leading Canadian CPG (consumer packaged goods) brand-owners, with its founder widely acclaimed to be one of the country’s most knowledgeable and authoritative thought-leaders in the graphic package design field.

In part because of the brand’s extraordinary prolonged grip on the market-leading position in Canada, major packaging redesigns have historically been relatively few and far between over the years, Pigeon acknowledges.

TIME TO ACT

BY GEORGE GUIDONI, EDITOR PHOTOS BY COLE GARSIDE & PIGEON

If getting to the top is indeed the easiest part of staying there, then the venerable Kraft Peanut Butter brand has got to be one of the hardest-working brands in the history of Canada’s food marketing. And it just may be. At least since about a year ago, when Toronto-based food giant Kraft Canada Inc. relaunched Canada’s bestselling peanut butter with a fresh new look and brand identity across the country in a concerted, multimedia marketing blitz that has lifted its legendary mass appeal amongst Canadian consumers to a whole new level of branding and packaging excellence.

First introduced to Canada in 1960, Kraft Peanut Butter quickly rose to emerge as Canada’s clear Number One peanut butter brand by 1962—a market-leading position that it has not only held with an iron grip over the years, but has solidified it with unrivaled market share dominance and consumer reverence.

Familiar to millions of Canadian households from coast to coast, the brand also enjoys a unique status within Kraft’s vast product portfolio as one of its select few products line that is produced exclusively for the Canadian domestic marketplace, where its remarkably long-enduring love affair with consumers has made it one of the parent company Kraft Foods Group, Inc.’s most celebrated branding success stories worldwide.

Perhaps even more remarkably, Kraft Canada has retained the services of the same package design agency

for the last 38 years—a virtual eternity in today’s constantly shifting marketing business landscape.

“Kraft Canada was my very first client, and their support over the years means a whole world to me both on a personal and professional basis,” says Thomas Pigeon, founder and chief executive officer of the Oakville, Ont.-headquartered branding services provider Pigeon Brands

“It really is a dream client that in many ways enabled my company to become the well-recognized design agency it is today,” Pigeon told Canadian Packaging in a recent interview.

Since the last major comprehensive package redesign in 1994, the family-size jars had remained looking largely the same—receiving a fairly minor graphic makeover during the wide-scale conversion of the jars from glass to PET (polyethylene terephthalate) plastic back in 2006.

But as sales for the entire spread products category began to soften across Canada in recent years, it started to become clear to both Kraft and Pigeon that a further packaging upgrade would ultimately be required to revitalize and play up the brand’s credentials as the category leader, as confirmed by an astounding 70-percent market share for its Kraft Smooth Peanut Butter anchor brand, according to Nielsen Marketing

This realization ultimately led to last year’s dramatic reemergence of the Kraft Peanut Butter brand in stylish, contemporary new packaging, an expanded range of flavors, and a vastly increased emphasis on using the brand’s iconic bears as a key sales driver and brand-builder.

“The early thinking on the next redesign began about five years ago, when we started to seriously try to understand what it is that drives the Canadian consumers’ connection to this brand,” relates Pigeon Brands creative director Todd Ellis.

“After an extensive, in-depth exploration of the

Amy Rawlinson, Kraft Canada’s director of marketing for the Kraft Peanut Butter brand, describes the phenomenal success of the Stick Together marketing campaign based on a comprehensive packaging redesign and rebranding.

From Left: Kraft Canada’s senior brand manager Aaron Nemoy, finance manager June Au, category sales planning manager Caroline Drolet, senior director of grocery brands Leisha Roche, Amy Rawlinson, and associate brand manager Ananda Smith are joined by Pigeon Brands’ Todd Ellis (second from right) and Jeffrey Weaver.

Pigeon Brands founder and chief executive officer Thomas Pigeon (above) and his team have worked on a broad variety of package designs and other branding projects with Kraft Canada over the last 38 years.

brand, it became clear to us that the bears really are the brand,” he recalls.

“This made us believe that in order to solidify the brand’s iconic status as Canada’s dominant brand of peanut butter, we would need to bring the bears front-and-center and elevate them from just being photos of stuffed teddy bears on the label into real-life, loveable, recognizable and transportable physical entities that Canadian families, both children and adults, would instantly relate to,” Ellis explains.

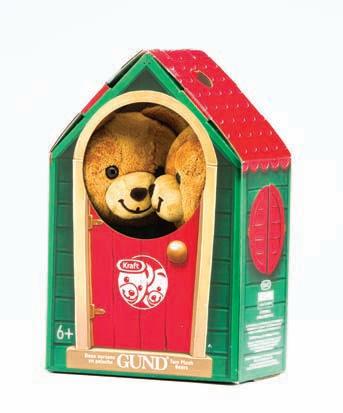

To accomplish that, Kraft and its partner agencies turned to Canada’s leading toymaker Gund Canada to produce the custom-designed, brandtrademarked iconic bears—distinguished only by their red and green bow-ties—that would go inside some 100,000 special-edition gift-boxes containing newly-redesigned Kraft Smooth Peanut Butter as well as to be used at in-store promotions across Canada to draw public attention the brand makeover.

Working closely with Kraft’s internal branding team and the company’s Toronto-based advertising agency partner Taxi, Pigeon designers used a combination of traditional illustration and CGI (computer-generated imagery) to develop the bears’ new look for the labels, jar closures, POP (point-of-purchase) merchandising displays, toy sets and other multimedia marketing platforms utilized in the nationwide Stick Together market

Kraft’s director of marketing for the brand Amy Rawlinson.

“We wanted to make the gift of a teddy bear as personal as possible for our consumers with this one-of-a-kind packaging, and we were really excited by their overwhelmingly positive response,” says Rawlinson, complimenting the entire Pigeon Brands project team—comprising 10 designers, account reps, graphic consultants and production artists—for their tireless work and efforts in helping make Stick Together an unqualified marketing success surpassing all expectations.

According to Rawlinson, Kraft has already ordered another large quantity of the truly collectible teddy bears—reportedly fetching more than 10 times their original price on eBay and other online shopping sites—for the next “two waves” of Stick Together promotions to unfold later this year.

FAMILY VALUES

“In addition to contemporizing the brand, we have elevated the bears to be the brand in order to make that all-important emotional connection with Canadian families,” reveals Rawlinson.

“We worked closely with Gund to help them create the plush bears, from specifying the body dimensions and proportions to choosing the fur material and the eyes, to ensure that the bears were exact representations of the new Kraft Peanut Butter bears used in the icon,” adds Ellis.

Produced at Kraft Canada’s venerable MontRoyal manufacturing plant in Montreal, the re -

launched Kraft Peanut Butter product family now comprises 11 different flavor varieties— Smooth, Smooth Light, Crunchy, Crunchy Light, Extra Creamy, Whipped, Unsweetened/Unsalted, All Natural Smooth, All Natural Crunchy, Honey and Chocolate —retailing across Canada in 500-gram, 750gram and one-kilogram jars featuring their own unique color schemes and graphic treatment to easily identify each flavor to the consumers.

Packaged in lightweight, high-impact, coextruded, food-grade PET plastic containers expertly produced by nearby rigid plastic packaging manufacturer Silgan Plastics Canada in Lachine, Que., the relaunched Kraft Peanut Butter is quickly garnering due peer recognition for its store-level impact and enthusiastic consumer response.

In addition to being selected as a finalist in this

Produced by the Silgan Plastics Canada manufacturing facility in Lachine, Que., the new lightweight, impact-resistant plastic jars used to package Kraft Peanut Butter have helped the brand to achieve significant carbon footprint reductions by virtue of lighter weight and close proximity to Kraft Canada’s Mont-Royal manufacturing facility.

year’s Canadian Grand Prix Awards competition of the Retail Council of Canada (RCC), the brand has also picked up a Silver Award in the In-Store Marketing category of this year’s PAC Global Leadership Awards competition of PAC, Packaging Consortium, for the attractive, high-impact POP display (picture on previous page) designed by Pigeon Brands and as -

sembled by the Toronto-based structural design specialists Pro Print Services Inc.

According to Rawlinson, Pigeon Brands duly deserves all the accolades it gets for the outstanding project execution involving one of Canada’s most important brands.

“It is the largest business within Kraft Canada’s grocery sector,” says Rawlinson, defining Kraft Peanut Butter as a core “focus brand behind which we will continue to invest and innovate.

“Faced with an ever-changing landscape of the spread products category, we saw a unique growth opportunity in the ‘all-naturals’ product segment, which is growing in double-digits, so that is our primary focus for continued product development and innovation,” says Rawlinson, while citing a “very positive” consumer response to the Honey and Chocolate sub-brands introduced into the market last year.

ROOM TO GROW

“There is also good growth potential for the product in terms of usage occasions, in going beyond just using it to spread on a piece of toast,” says Rawlinson, adding that Kraft is now marketing over 20 different snack recipes featuring Kraft Peanut Butter as one of the main ingredients.

With an estimated 79 million pounds of Kraft Peanut Butter products sold in Canada in the last year, representing 37 million units, the comprehensive packaging makeover was as timely as it was effective, according to Rawlinson.

“Although the whole peanut butter category has essentially been flat for the last four years,” she says, “this relaunch has enabled us to increase the product’s household penetration in Canada by 1.6 percent up to 61.8 percent, representing seven-percent growth in the brand’s sales.”

Rawlinson attributes such stellar results to a flawless execution of

Pigeon Brands designers and graphic artists produced a multitude of sketches and preliminary design concepts leading up to the nationwide relaunch of the Kraft Peanut Butter brand in 11 different flavor varieties, each easily distinguished with its own unique color scheme and graphic treatment.

Each jar of different Kraft Peanut Butter flavors is topped off with a color-matching lid embossed with a graphic of the iconic brand’s mascot bears.

Kraft Canada’s “purpose-led marketing initiatives” like the Stick Together campaign, the introduction of the plush Gund bears to generate industry hype and buzz, and the high-impact packaging redesign delivered by Pigeon Brands.

“The are a fantastic and very collaborative partner to work with, being open to co-creation and feedback from our end, while maintaining a progressive, keen eye for all the design possibilities, to present a broad range of new concepts,” Rawlinson reflects.

PROUD HISTORY

“We have historically enjoyed a strong relationship with Pigeon Brands because they have always strived hard to help set us apart from the competition,” she relates.

“With this project, they have once again created a brilliant shelf presence and a fantastic bear icon that has really brought the brand into the 21st Century,” she asserts.

“If you look at the whole peanut butter category out there on the shelves, there is no shadow of a doubt that we are the category leader,” says Rawlinson.

“I am very proud of our graphics and the quality of our packaging— right down to the embossed lids and all the other finishing touches and flourishes throughout the packaging.

“Our ambition is for this brand to be the icon of ‘family togetherness’ in Canada, and the new design really captures the brand’s nearly 60 years of heritage of bringing Canadian families together, resonating with consumers of any age,” Rawlinson states, citing a “tremendous amount of positive support from consumers” for the new packages and brand mascots.

“We have had over 15,000 contest entries from people writing in to comment on the new packaging and to send us pictures of themselves with the bears,” she reveals, saying the relaunch helped the brand to reignite its love affair with the all-important “millennial family” demographic of 18- to 34-year-old consumers.

Says Rawlinson: “According to

Expand Your Horizons, Zero in on Solutions

“Not only does the product taste great, but it is also a good source of key nutrients such as Vitamin B, Vitamin E, niacin, foliate and magnesium, while also being transfat-free and low in saturated fats,” she point out.

“For the vast majority of individuals who can consume nut products, it can certainly play an important role in helping them maintain a wellbalanced diet,” Rawlinson states.

Adds Kraft Canada’s senior manager of design strategy and capabilities John Kissoon: “There are remarkably few brands that have become a part of a nation’s culture, and Kraft Peanut Butter has done just that.”

States Kissoon, “This is why it is incumbent upon all of our partners who touch the brand to protect it with enthusiasm and ownership.”

June 16–18, 2015

Toronto Congress Centre | Toronto, Ontario

PACKEX has the answers you need today and the inspiration for tomorrow. PACKEX is the place to go if you’re looking for solutions to a speci c challenge. Don’t have a particular project in mind but want to jump start your idea process? It’s an ideal event for that too. With hundreds of knowledgeable suppliers, educational and networking opportunities, AND something no other packaging expo has—access to ve other related manufacturing events and features—you’ll nd ideas and solutions around every corner.

the Canada Food Guide, one serving of Kraft Peanut Butter equals a half-serving of meat or other alternatives.

Kraft Canada’s Amy Rawlinson shares a light moment with Pigeon Brands creative director Todd Ellis (left) and group account director Jeffrey Weaver.

The increased prominence of the brand’s twin bear mascots has enabled Kraft Peanut Butter to reignite the product’s endearing love affair with Canadian consumers.

A BRAND NEW EXPERIENCE

Technological and marketing innovation help hardworking package design agency in graphic communications

responsible for steering its dramatic transformation through the years from a tiny six-employee prepress/print shop into what he calls “an integrated marketing communications company” employing over 40 high-skilled professionals boasting a vast pool of collective expertise and knowledge across a broad range of communications disciplines.

“Our clients expect a lot from us because they know they can get it from us,” says R&C creative director Brian Dilts, pointing out the company runs a busy, two-shift operation daily to keep up with its growing and highly-demanding client base.

“A project may start off with one thing, like a photoshoot of a new packaging design, and before you know it we are creating new point-ofsale (POS) materials, print advertisements, product literature, signage for delivery trucks and so on,” Dilts relates.

“It’s a constantly changing and highly exciting work environment, where you just don’t have the time to be bored by doing the same thing over and over.”

Recalls Collins: “Soon after I joined the company, we started changing our focus on becoming a complete, end-to-end solutions provider that would deliver more services to our clients to help develop more revenue streams.

“To do that, we developed ourselves around the four pillars of creative, production, technology and fulfillment services,” says Collins, who was instrumental in guiding the firm to invest in leadingedge equipment and technologies that would make it a true one-stop-shop for graphic communications, offering exceptional flexibility, agility and customer service.

In addition to purchasing a new-generation Hewlett-Packard Indigo 5000 digital press to enable short-run print production and full-color packaging mock-ups, the company also installed a six-color offset Heidelberg Speedmaster printing press with inline UV coating to provide customers with short-run requirements with finished packaging, commercial print, and POS products with exceptionally quick turnaround.

PHOTOS BY COLE GARSIDE

While successful brand-building is undoubtedly a far more daunting marketing challenge in today’s digital, social media-driven environment than it’s ever been, the role of packaging design as a key ingredient of a brand’s marketplace success or failure has not waned in the slightest, according to one of Canada’s leading package design and branding services providers.

“The role of packaging is more critical than it was 10 years ago in a sense that excellence in a package is just expected by clients, almost as if being taken for granted,” says Kevin Collins, president of thriving Canadian graphic communications agency Rayment & Collins (R&C).

“The real question today is, ‘What else are you doing to differentiate yourself, aside from just put-

tion that you need to sell that product?’

“You need to know who your audience is and to touch the right trigger points to get its attention,” Collins told Canadian Packaging on a recent visit to the company’s lively headquarters in Markham, Ont.

Strategically located a short 20-minute drive north of Toronto, the 24,000-square-foot facility houses a diverse range of Digital Age technologies used for creating, imaging, proofing, printing and producing packaging mock-ups, prototypes and samples, as well as other graphic communication products increasingly utilized by some of Canada’s leading brand-owners to boost their sales and market share.

“Not only is there a vast difference between how we do business today from what we did in the past, but things will also differ vastly in the future,” he says.

Joining the company in 2000, Collins is largely

“There is a wide variety of work we can produce on that Heidi press: from packaging, calendars to commercial print work,” says Collins, adding R&C’s formidable in-house skillset also includes a full range of large- and wide-format printing capabilities.

“Just being good in one environment is not enough nowadays: it is essential for us to possess

Game changer

Combining high-quality colour with the efficiency of digital printing, HP Indigo will take your business to the next level.

Engineered for mid-web packaging applications such as flexible packaging and label printing, the HP Indigo 20000 Digital Press is a superior alternative to analog technology. It brings the same quality as gravure to your operation so you can meet all your client demands for medium and short runs while minimizing your operational costs.

Grow your business with the HP Indigo 20000.

Find out more at www.hp.ca/go/indigo or call 866.828.3649.

PACKAGE DESIGN

“We’ll do anything to keep our clients ahead of the game, even before the product has actually gone into manufacturing. That is what having so many capabilities in-house allows us to do.”

Ryan Gibbons, Business Development Manager

different levels of expertise that allow us to be involved in different activities to satisfy our clients,” Collins explains.

“Pure package design still accounts for 15 to 20 per cent of our current business,” he confides, “but it is our experience and track record in packaging that allowed us to move into the other creative fields.

“We already have some clients for whom we do promotional campaigns on social media only— using no print at all,” Collins points out.

“We need to speak to the next generation of consumers growing up right now in ways they want to be spoken to, like through social media, so it

time people.

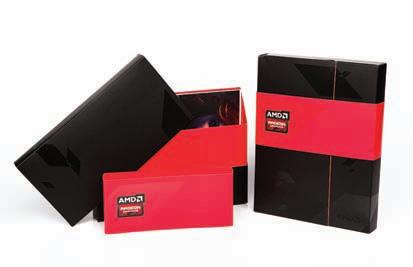

These capabilities came in handily in a recent global marketing campaign the company did for leading global component and graphics card manufacturer AMD (Advanced Micro Devices), which involved creation of high-end media kits, graphics stickers, branded memorabilia, and generation and redemption of vast amounts of individual product codes for gamers to activate online through the tech center.

In addition, R&C developed the proprietary architecture for delivery and security for AMD gaming promotions, adds vice-president of sales Gabriel Araish.

“Over the past four years and four iterations, we have continually improved upon the initial solution to improve security measures, reduce risk and enhance portal site framework infrastructure,” Araish explains.

“There are many packaging forms, many printing disciplines, and many design specifications to be taken into consideration to ensure that all products look the same on the shelf wherever they are sold.”

Bryan Dilts, Creative Director

quicker-to-market, using one single location that will take care of all their different needs and requirements,” Collins states.

“Our technology department is really an R&D tech center,” Collins asserts.

“What comes out of there is what we employ in our daily business—not only to help support the business we currently have, but also to win new business and new markets.”

Other notable clients within the company’s growing portfolio include:

• The Minute Maid Co Canada Inc. Working with the beverage producer’s internal sales and marketing team on a product launch involving brand new and rebranded products in four new package types and seven different flavors, R&C produced over 2,850 physical color-accurate package mock-ups to match the end product,

Vice-president of operations Ross Benns (foreground) and president Kevin Collins stand in front of the Heidelberg Speedmaster six-color offset printing press with inline UV coating, installed in 2011 for processing short- and mid-sized print runs in-house.

The HP Indigo 5000 digital printing press at Rayment & Collins mimics offset printing capabilities with high definition and patented HP ElectroInk printing inks to produce color-accurate packaging mock-ups from a broad range of common packaging materials.

“Today’s technological sophistication creates a level playing field for everybody, but it’s about using that technology to your advantage that ultimately provides the key winning edge.”

Kevin Collins, President

Printed and assembled in-house, the multicomponent merchandise kits for AMD’s gaming software are fully supported online by R&C’s technical help center.

PACKAGE DESIGN

including generating functional UPC barcodes specific to the product, end market, and 17 shipping destinations across Canada.

• Pet Valu Canada. The R&C staff created an array of eye-catching POS materials to support the pet-food retailer’s monthly in-store marketing campaigns in timely manner.

With two campaigns per month, the project required ongoing production of 900 fully-assembled kits per month–with 10 to 25 items like discount coupons, inserts, information leaflets, and other components for each kit—along with printing an annual calendar.

Vice-president of operations Ross Benns says he takes immense pride in the close business relationship and rapport that R&C has cultivated over the years with Sleeman Breweries Ltd. of Guelph, Ont., the country’s third-largest beermaker.

Says Benns: “It is a big business for us: We’ve been working with them formally since 2000 and have a history with them going back years before then.

“As Sleeman has grown and become more successful, we have grown and become more successful in step with them, as real partners should.”

It is such a close partnership, in fact, that Benns often assumes a role of a Sleeman representative when traveling on the beermaker’s behalf to make presentations to prospective new customers.

It makes perfect sense, Benns point outs, because he has become more familiar with the brewer’s market-

specific packaging, branding, promotional and other key requirements than many of Sleeman’s own staff.

Says Benns: “There are many packaging forms, many printing disciplines, and many design specifications to be taken into consideration to ensure that all Sleeman products, which is hundreds of SKUs (stock-keeping units), look the same on the shelf wherever they are sold.

“For example, a 12-pack case being filled at the Guelph brewery may not be executed with the same precision as their Vernon brewery in British Columbia because it has to travel up an incline conveyor during the filling process,” Benns points out.

“That means the case has to be reprinted with a special coating to keep it transferring at the right speed,” he points out.

“For a company doing business across Canada, knowing and accounting for all these subtle differences is an important part of operating a successful business.”

Gibbons explains this familiarity and mutual trust has enabled R&C to develop a customized online Sleeman Brewhouse internal project management system that enables all Sleeman reps and customers across Canada, such as bars and restaurants, to or -

places an order online, gets an approval, we produce it here, and ship it anywhere across Canada with a detailed shipping report for their records, with all those steps recorded and entered into the Brewhouse digital asset management system.

“That is what having so many in-house creative, production and order-fulfillment capabilities allows us to do for our customers,” Gibbons points out.

“We can even produce mock-up packaging, labeling or shrinkwrap for a product that’s not even on the market yet the very same day we photograph it,” he extols. “We’ll do anything to keep our clients ahead of the game, even before the product has actually gone into manufacturing.”

This ability to anticipate market trends and shifts proactively, rather than merely react to them, is a core R&C competency that will help the company grow its client base and product portfolio well into the future, Collins sums up.