NEW! AchieVe PSA Series DC Power Supplies starting at $25.50

AchieVe PSA series value power supplies offer prices well below the competition and are ideal for price-sensitive users who require basic yet reliable power output for general industrial applications. Their overcurrent protection is designed to operate in constant current mode, making the PSA series suitable for inductive and capacitive loads.

• Universal 85-264 VAC/120-375 VDC input voltage

• 12, 24, or 48 VDC adjustable output options

• 75, 120, 240, and 480 Watt models

• Rugged plastic or aluminum housings

NEW! WAGO Eco2 Series DC Power Supplies starting at $60.00

WAGO Eco2 series power supplies offer performance and value, featuring high efficiency and a compact design. These economical power supplies provide reliable performance and long service life for a variety of applications, such as industrial automation, machine control, and robotics.

• Universal 90-264 VAC input voltage

• 24 VDC adjustable output

• 30, 120, and 240 Watt models

• Rugged plastic or aluminum housings

NEW! More WAGO Pro2 Series DC Power Supplies starting at $179.00

More power output options have been added to expand our selection of high-efficiency WAGO Pro2 series performance power supplies.

• Models with outputs up to 40A/960W

• 120, 220, 240, or 480 VAC input voltage options

• 12, 24, and 48 VDC output options

• Single- and three-phase models

• Free configuration and monitoring software

NEW! WAGO Pro2 Communication Modules starting at $69.00

WAGO Pro2 communication modules easily snap into place as an add-on to Pro2 power supplies, allowing connectivity to PLCs for programming and monitoring, providing accessibility to select features and real-time data, and supporting the following protocols:

• Modbus RTU with (2) RS-485 (RJ45) ports

• EtherNet/IP with (2) Ethernet 10/100 Base-T (RJ45) ports

• Modbus TCP/IP and UDP/IP with (2) Ethernet 10/100 Base-T (RJ45) ports

• IO-Link with (1) 3-position removable terminal port

Our shipping policies make it easier than ever to order direct from the U.S.!

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days.

*Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

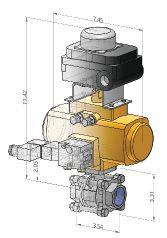

Starting at $210.00

ProSense PLS series rotating paddle level switches are point-level switches for dry, granular bulk solids. These rugged level switches are highly reliable, can operate in harsh environments, and are unaffected by vibration, dust, or moisture.

• Available in three different shaft lengths or rope version

• Rope version can be field shortened to fit application

• SPDT relay output included allows use with PLC inputs or direct control of handling equipment

• Optional switch status indicating light

• IP66 environmental protection rating

Starting at $243.00

Endress+Hauser Nivector® FTI26 bulk solid capacitance level switches are contact sensors that provide point-level detection of powders or fine-grained bulk solids in silos, hoppers, and bins.

• Polycarbonate or stainless steel housings

• IO-Link on select models

• Stainless-steel versions are FDA compliant and marked with the 3-A symbol for food industry hygienic applications

Starting at $793.00

Endress+Hauser Micropilot FMR10 series pulsed radar liquid level sensors provide accurate, reliable non-contact liquid level measurement and offer one of the best price-to-performance ratios on the market.

• CSA approved for general-purpose or hazardous locations (depending on model) Orders over

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days.

*Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees. See Web site for details and restrictions at: www.automationdirect.com/canada

Starting at $298.00

AchieVe ELT series general-purpose submersible level sensors are ideal for water applications where small size, weight, and low cost are required.

ProSense NFLT series non-fouling, submersible level sensors feature a rugged construction with superior abrasion and puncture resistance for challenging wastewater applications.

FROM THE EDITOR

4 Tightening dust regulations. NEWS

5-7 Noteworthy industry news briefs.

PRODUCTS 17, 24, 26

BULK POWDERS & SOLIDS SUPPLEMENT

24 The latest technologies and products.

New regulations coming for B.C. industries.

10 Translating Canada’s critical minerals strategy to action

The Mining Association of Canada’s Budget Submission 2024.

18 Optimizing dust collector systems from floor to cloud

Using a three-level approach to digital transformation, manufacturers can simultaneously improve sustainability, streamline maintenance and empower their workforce.

21 Canadian processors moving beyond break/fix to prevent downtime of critical conveyors

To optimize production and extend the lifespan of tubular drag cable conveyors, it is ideal to involve an expert OEM for total preventative maintenance.

The LLT100 revolutionizes the level measurement industry. It provides continuous, non-contact level measurement of any material, solid or liquid, independently of its properties or conditions. It is designed for industrial applications and replaces open-path radar and other level transmitters, meeting the demands of process automation and inventory management. With its narrow laser beam, the LLT100 can avoid obstructions, vessel wall build-up, can be installed near vessel walls, or in tanks with mixing blades or grids. abb.com/laserlevel or contact us at lasers@ca.abb.com

Back in 2015, I took on the role of editor for Canadian Forest Industries, Canada’s longest running trade publication dedicated to covering the country’s logging and forest products sector; and Canadian Biomass, which covers Canada’s growing biomass and bioenergy sectors.

Working on these two trade publications was where I first learned about the importance of having effective dust management strategies, staff trained in the latest regulations and best practices, and the latest dust collection and dust control technologies.

A few years earlier, multiple tragedies had struck the forest products sector in British Columbia’s Northern Interior. Two sawmill explosions took place in 2012, both ending in lives lost and many injured.

The Babine Forest Products sawmill in Burns Lake experienced an explosion in January 2012 that took the lives of two workers and injured 20 more. Then only a few months later, the Lakeland Mills sawmill in Prince George also suffered an explosion that took the lives of two people while injuring 22 others. The investigations into both explosions showed that combustible dust was responsible for both explosions.

Despite it being three years since these incidents, they were certainly still fresh in the minds of people in the industry. Every conference I attended during my time as editor had sessions on dust safety management best practices, regulations, case studies, and technology showcases. And without fail, the sawmill explosions at Burns Lake and Prince George were always discussed.

This included all of the biomass-related conferences, as wood pellet manufacturing, woody biomass-fuelled boilers (wood pellets, wood chips and other forest residuals), and district energy systems, make up a significant percentage of

Canada’s biomass and bioenergy sectors.

This came as little surprise, since these incidents were shocking to the industry and were such terrible and avoidable tragedies.

Dust safety is something that many process industries need to take very seriously. I’ve spoken to people in various process industries over the years that were, in some cases, shocked to learn they were dealing with combustible dusts in their day-to-day operations.

Most people think of wood dust as combustible dust, but don’t consider other potentially combustible materials like agricultural products such as flours; some plastic dusts; and processed powders. This may be because these types of dust have not been the main focus of dust management regulations in Canada. But that is changing.

In British Columbia, where failure to have proper dust management systems in place ring the loudest, WorkSafeBC is in the process of proposing new regulations that will change the regulations to include any type of dusts handled or generated at a workplace through pulverizing processes, grinding processes, material size reduction processes, material conveying, handling and storage (for more details on this topic, check out our cover story on page 14).

These proposed changes are long overdue and will hopefully assist in improving the safety of operations so Canada’s process industries can avoid the types of tragedies that occurred in B.C.’s forest products sector.

After all, everyone has the right to go to work and come home safe.

ANDREW SNOOK, editor editor@cpecn.com

Reader Service

Print and digital subscription inquiries or changes, please contact

Angelita Potal

Customer Service

Tel: 416-510-5113

Fax: (416) 510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Audience Manager Anita Madden 416.510.5183 amadden@annexbusinessmedia.com

Brand Sales Manager Pat Lorusso 416.518.5509 plorusso@annexbusinessmedia.com

Editor Andrew Snook 416.510.6801 editor@cpecn.com

Account Coordinator Barb Vowles 416.510.5103 bvowles@annexbusinessmedia.com

Group Publisher/VP Sales Martin McAnulty mmcanulty@annexbusinessmedia.com

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

CPE&CN is published bi-monthly by: Annex Business Media

111 Gordon Baker Rd, Suite 400, Toronto, ON M2H 3R1 T: 416-442-5600 F: 416-442-2230

© All materials in this publication are copyright protected and the property of Annex Business Media., the publishers of Canadian Process Equipment & Control News magazine.

For permission on reprinting or reproducing any materials, e-mail your requests to cpe@cpecn.com

Canadian Postmaster send address corrections to: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Canadian Process Equipment & Control News assumes no responsibility for the validity of claims in items reported.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2384

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 0318-0859

Following its September 2023 acquisition by Hillenbrand, Schenck Process Food and Performance Materials (FPM) is transitioning its name and brand to Coperion.

The full legal change to Coperion will be completed by August 1, 2024. Coperion is an operating company of Hillenbrand with 140 years of experience in some of the world’s most critical processing industries. Schenck Process FPM has contributed an integral part to its divisions, which support processing solutions for manufacturing in polymers/performance materials, food, health and nutrition, and aftermarket sales and services. Schenck Process FPM expertise, team members, manufacturing sites, test and innovation centres, and technologies remain in place. This includes flagship brands such as RBS, Stock, Baker Perkins, Kemutec and Mucon.

The Espoo, Finland-based company stated that it would be starting local consultation processes that will affect parts of the minerals equipment business and the related market area operations. These planned changes include organizational realignment and other efficiency measures as well as permanent and temporary layoffs.

The company estimates that it will need to reduce its employees by 240 positions globally, including 90 positions in Finland.

As part of its growth strategy for innovative resin technologies for coatings, Lubrizol announced a $20-million investment to its plant in Gastonia, N.C., to enhance production of innovative acrylic emulsions. Dating back to the 1950s, Lubrizol has a long history of innovating and manufacturing acrylic emulsion technologies used in a variety

“The acquisition of Schenck Process FPM in 2023 has been an essential step for the development of Coperion toward a more diversified company and an expanded footprint. With the transition of the FPM brand name under Coperion, we take the next step in our journey,” said Ulrich Bartel, president of Coperion.

The company’s website and emails, including those from technology brands such as Baker Perkins, will change. The new website can be found at: coperion.com/fpm.

The Metso Corporation has announced that it will be making “structural adjustments” in some areas of its minerals equipment business. The company stated that these measures will address changes in the market environment driven by factors like the increasing emphasis on strategic minerals that support the energy transition.

“The planned changes will improve agility, extend customer reach and coverage, and enable better alignment towards customers,” the company stated, adding that Metso seeks to also improve efficiencies to “compensate for slow decision making that is influencing large customer investments.”

of coatings formulations commonly used in diverse applications, including paper, textiles and construction materials. With over a dozen patents throughout the years in North America, Lubrizol’s acrylic emulsions have pioneered step changes in coating performance, from UV and chemical resistance to hardness and toughness improvements to self-dispersibility to lower VOCs and more, the company stated.

“Our commitment to innovation and production of world-class acrylic emulsions will continue, as evident by this significant investment,” shared Luis Carthery, senior business director, Americas, Lubrizol. “While some Hycar Acrylic Emulsions first commercialized in the 1960s continue to have significant sales volumes today, we continue to innovate and bring modern resin technologies to customers, helping them achieve advanced performance capabilities for their coatings.”

ABB has announced that has made a minority investment in GridBeyond, a technology provider of energy management solutions based on artificial intelligence and data science. Based in Ireland, GridBeyond’s solutions are designed to allow its customers to optimize distributed energy resources and industrial loads. ABB stated that this strategic partnership “will contribute to the continued expansion of ABB’s sustainability advisory services portfolio, and help customers and operators across utilities, industry, infrastructure, and transportation to transition to net zero.”

“Our investment in GridBeyond reflects our commitment to driving technological innovations and creating an ecosystem of partners to enable customers’ energy transition to net zero,” said Stuart Thompson, president of ABB Electrification Service. “We are helping to transform the way industries generate, distribute and consume energy. We greatly look forward to working with GridBeyond’s team of experts to help drive their next phase of growth.”

GridBeyond works with over 900 clients across four continents to deliver technological solutions to the world’s energy challenges. Through its AI platform, GridBeyond enables its customers to precisely control the energy consumption profiles of their assets, allowing them to unlock new revenue streams, deliver energy and cost savings, optimize production

processes and increase resilience by predicting and preventing system failures.

The investment was made through ABB Ventures. ABB joins investors EDP, ESB, TotalEnergies, Act and DublinBIC. Financial terms of the transaction were not disclosed.

The Copper Development Association, Inc. (CDA) has announced the promotion of Adam Estelle as its new president and CEO, effective May 1, 2024. Estelle has worked with the association for almost 16 years, joining in 2008. He has held various roles over his time with the CDA, including project engineer for seven years; director of rod and bar; and vicepresident of the association, his most recent role which he has held since 2022. Estelle is the sixth leader in the history of the CDA. He will succeed Andrew Kireta, Jr.

“As president and CEO, Estelle is well equipped to oversee a team of subject matter experts who work toward CDA’s mission of bringing the value of copper and its alloys to society to address the challenges of today and tomorrow,” said Michael O’Shaughnessy, Chairman of the CDA Board.

Over his time with the CDA, Estelle

has led several strategic initiatives with impactful results, including raising market awareness to the antimicrobial properties of copper; demonstrating the high-speed machining advantages of brass rod; and developing new industry datasets and standards to protect the viability of the scrap stream. He has also played a key role in the development and implementation of CDA’s new subscription-based business model, which empowers members to set strategic priorities and align their CDA investment with where they see value, the association stated.

“I’m honoured and incredibly grateful for the opportunity to lead the next chapter in CDA’s bright future,” Estelle said. “With a strong team in place, I look forward to sharpening our mission focus, enhancing our member value proposition, and strengthening our strategic partnership with the International Copper Association.”

The Genuine Parts Company (GPC), a leading global distributor of automotive and industrial replacement parts, has announced that it has appointed James F. Howe as the new president of Motion, the company’s industrial business, effective April 1, 2024.

With almost three decades of dedicated service to the company, Howe will bring “a wealth of experience

and expertise to his new role,” the company stated.

Howe’s most recent position held at Motion was executive vicepresident and chief commercial and technology officer. He will report directly to Randy Breaux, group president, GPC North America.

“James has an impressive history, having served in numerous executive roles during his long career at Motion,” said Paul Donahue, chairman and CEO. “His extensive experience makes him an excellent choice to lead Motion. We feel confident that under James’s leadership, our talented and experienced Motion team will continue to achieve great results.”

Honeywell has announced that it has combined its gas and flame detection portfolio with the company’s measurement and control portfolio into one business unit called Process Measurement and Control (PMC).

The company stated that PMC offers a wide range of products and solutions

including: gas and flame detection products and solutions for safer industrial environments, protecting both people and assets; oil and natural gas custody transfer products and solutions for highly accurate transfer of products from buyers to sellers along oil and natural gas transmission and distribution infrastructure; pressure, temperature, level and flow measurement products for industrial facilities; process control and safety solutions in industrial facilities; and measurement products and solutions for asset management and sustainability.

“PMC’s mission is to deliver reliable detection and accurate measurement solutions to enable superior business outcomes for our customers in a wide range of applications and industries,” stated Srikumar Srinivasan, president of PMC. “We are excited to offer a wide portfolio of Honeywell products and solutions to our customers. The combined entity’s shared expertise in measurement, communication technologies, and intrinsic safety will help us create innovative products and solutions to solve customer problems in detection and measurement.”

Valmet is taking process automation further by introducing the next-generation distributed control system (DCS), the Valmet DNAe.

The fully web-based process control system comes with a new cybersecure system architecture, control software and hardware, engineering and analytics tools, helping customers improve efficiency, productivity, sustainability and safety of their operations.

“The new Valmet DNAe represents a major milestone in process automation. It provides a solid platform for moving towards more digitalized, autonomous operations, helping our customers thrive in the changing business environment. In the development of this new system, we have focused on usability and performance, with a modular approach that enables upgrade paths also from our previous system generations,” says Emilia TorttilaMiettinen, president, Automation Systems business line at Valmet.

The launch is a major step in the company’s roadmap for growing its automation business further and in bringing future-proof automation solutions to a wide base of process industries globally.

Valmet DNAe is developed with a design philosophy to empower people to perform and collaborate better across the organization. The system provides a common user interface for controls, analytics, configuration, and maintenance.

Learn more at: www.valmet.com/ automation/control-systems/dnae.

In December 2022, Minister of Natural Resources, Jonathan Wilkinson, unveiled his government’s Critical Minerals Strategy.

The strategy is a recognition that Canada urgently needs to speed up regulatory decisions on critical mineral projects if it wants to become a global leader in battery manufacturing, electric vehicles, wind turbines, solar panels, and other low carbon technologies.

Minerals like nickel, cobalt and copper are critical ingredients for electric vehicles and computer chips. Uranium is critical for zero-emission energy. Rare earths are needed for many high tech and defence systems. Many other mined materials not currently on Canada’s critical minerals list, such as iron ore, silver, gold, steel-making coal and petroleum products, are all needed to build the energy infrastructure critical to the energy transition. To produce these materials needed to fight climate change, Canada must create a permitting, regulatory, and operating environment that is not only globally competitive, but also much more efficient and rapid than ever before. Investment dollars need to be attracted to the mining sector so that new mines can be built and that existing mines can be expanded, where applicable.

The success of any strategy depends on the effective implementation of appropriate programs, measures and tactics. In this case, the Critical Minerals Strategy will require careful design and implementation of legislative, regulatory, and fiscal frameworks. As government works to develop these frameworks, as part of the government’s budget consultation process, MAC is pleased to provide a number of concrete and specific recommendations that will allow Can-

ada to capitalize on the opportunities before it, in the most responsible manner possible. The recommendations are grouped into 5 subject matter areas:

1. Battery manufacturing;

2. Efficient permitting for new mines;

3. Partnerships with Indigenous people;

4. Prioritizing nature conservation; and

5. Workforce supply.

One set of MAC’s recommendations focuses on battery manufacturing. The World Bank foresees a 500% increase in minerals crucial for clean technology, vital to limiting global temperature rise. The International Energy Agency projects EVs and battery storage to drive half of the mineral demand growth from clean energy technologies by 2040. The average electric vehicle battery contains about 185 kilograms of minerals, including lithium, cobalt, nickel, manganese, graphite, copper, iron, and aluminum –all produced in Canada and with extensive untapped reserves.

Canada’s clean electricity grid, along

The Critical Minerals Strategy will require careful design and implementation of legislative, regulatory, and fiscal frameworks.

with lower carbon-intensive finished products from domestic mineral production, positions our country favorably on the global stage. To secure Canada’s role in a low-carbon future, expedited policies, adequately funded programs, and the implementation of Canada’s Critical Mineral Strategy are vital.

Insufficient financing for mine production, particularly for smaller companies, can be addressed with venture capital (like EDC and BDC support) and tailored financial instruments.

Infrastructure investments, such as in energy grids and communications, are essential for a resilient mining supply chain. While Canada’s appeal for battery manufacturing is evident through recent investments, building more mines and refineries is crucial.

Since 2020, automotive and battery manufacturers have invested over $31 billion to transition to electric vehicle production and establish a battery supply chain. Three electric vehicle factories have been announced: Stellantis-LGES, Powerco-Volkswagen, and Northvolt, with the possibility of more

announcements on the horizon.

These battery factories have chosen Canada as their preferred location due to the close proximity, access to critical minerals and a reliable clean energy grid.

According to Natural Resources Canada, to meet the demand from four battery factories:

• Fifteen new mines are needed, creating 40,000 direct, indirect, and induced jobs in the upstream and midstream. Many of these will be in remote locations, providing jobs and business opportunities for Indigenous peoples.

• Without upstream mining, midstream processing is unlikely to progress. If minerals are mined in Canada, it is likely they will stay in the domestic value chain through to battery production.

• To create the upstream and midstream value chain, a further investment of $8.1 billion in new mines and $16.1 billion in midstream processing is needed.

• Compared to the rate at which Canada opened mines in the past 15 years, we need to move forward more than five times as fast to meet the EV battery factory demand.

RECOMMENDATION 1 – MINES TO MOBILITY: MAKE CANADA A GLOBAL CENTRE FOR ELE EV MATERIAL PRODUCTION

To enhance Canada’s attractiveness in battery

manufacturing, MAC calls for increased government involvement in supporting the critical minerals value chain. Prioritizing a secure and sustainable domestic supply of battery-grade materials, along with expanding essential raw material production, is crucial to position Canada as a prominent hub.

Additional measures include to:

• Expedite the tabling and passage of legislation to create the Clean Technology Manufacturing Investment Tax Credit (CTMITC) and:

o Expand the scope of the credit to encompass mine development-related expenditures, including mine development costs such as shaft-sinking, ventilation, and underground vertical and lateral development and infrastructure.

o Adjust the eligibility threshold from ‘all or almost all – 90%’ of production value to recognize polymetallic deposits, particularly in copper projects found with other non-critical priority minerals.

• Improve coherence between climate and industrial policy by recognizing the importance of off-grid critical mineral mines for battery-grade materials and manufacturing.

• Direct Export Development Canada (EDC) and the Business Development Bank of Canada (BDC) to prioritize investments in upstream critical minerals projects. Enable

the Strategic Innovation Fund (SIF) to invest in these projects.

• Accelerate funding for trade-enabling infrastructure, including energy infrastructure, to support Canada’s EV supply chain goals. This includes strategic investments in northern regions.

• Reclassify the costs incurred during the construction and production of Canadian mines primarily focused on critical minerals. Consider categorizing these expenditures as Canadian exploration expenses (CEE) rather than Canadian development expenses (CDE) for Canadian income tax purposes (reverting to the pre-2013 treatment).

• Extend the Mineral Exploration Tax Credit (METC), set to expire at the end of March 2024, for a minimum period of five years until 2029.

• When Canada supplies low carbon critical minerals, it benefits the world on climate. Expanding market access through Free Trade Agreements (FTAs) and Foreign Investment Promotion and Protection Agreements (FIPAs) is crucial for success. Invest in the Canadian Trade Commissioner Service (TSC) to support mining companies in new markets/countries.

The urgency of addressing climate change, the

need for materials to support technological evolution including the transition to electric vehicles, the electrification of the Canadian economy, the fragility of supply chains exposed by the pandemic and geopolitical conflicts have all highlighted the need for new mines and infrastructure projects.

Yet Canada’s numerous complex processes that a project must navigate before receiving approval to proceed result in these projects not being built in time to meet our shared climate change, clean energy and supply chain security goals, thereby letting our automotive sectors and allies down. In order to achieve these goals, we must reduce timelines associated with project permitting.

RECOMMENDATION 2 – IMPROVE THE PREDICTABILITY AND TIMELINESS FOR PERMITTING FUTURE MINES AND MATERIAL MANUFACTURING FACILITIES

• Improve coordination and alignment between provincial and federal approval processes and across federal departments to materially shorten project permitting timelines and reduce the consultation burden imposed on Indigenous communities.

• In response to the Supreme Court of Canada’s opinion on the constitutionality of the Impact Assessment Act (IAA), amend the IAA to appropriately focus on effects in federal jurisdiction. This includes amendments to the decision functions of the Act -- including the designation decision, screening decision and public interest decision – for provincial activities as well as the definition of effects in federal jurisdiction. Amendments to the Act should be supported by clear guidance to proponents and potentially impacted communities to support the transition to an amended Act and mitigate investment uncertainty.

• Amend the Physical Activities Regulations (Project List) as part of the mandatory fiveyear review of the regulations by:

o Materially increasing production-based thresholds for greenfield mining projects. In doing so, thresholds for new uranium mines should align with other metal mines.

o Excluding underground, fully electric mines given their smaller footprint.

o Excluding brownfield projects from the Project List entirely.

o Materially increasing thresholds for expansions, or alternatively excluding expansions from the Project List.

• Amend Section 79 of the Species at Risk Act (SARA) to ensure compatibility with the Supreme Court of Canada’s opinion on the Impact Assessment Act. Section 79 currently requires all federal assessments to assess, mitigate and monitor adverse effects on SARA-listed wildlife species and its critical habitat. This is not consistent with the Supreme Court’s opinion and needs to be deleted or amended to apply only to projects carried out or financed by federal authorities on federal lands or outside Canada (Sections

81-91 of the Impact Assessment Act).

• The Impact Assessment Agency should continue its efforts to improve the tailoring of assessments to key issues in the federal jurisdiction that address gaps not captured by other processes as well as the scoping of Indigenous engagement and participation.

• Develop pragmatic compliance tools for routine projects under the Fisheries Act. While there has been some progress, with the release of new Codes of Practice for some routine activities, Fisheries and Oceans Canada must accelerate the development and publication of Codes of Practice and Prescribed Works and Waters Regulations for routine works, undertakings and activities with known low impacts and mitigation measures.

• Fisheries and Oceans Canada should plan for the necessary amendments to address legislative shortcomings in the Fisheries Act that prevents the use of viable fish habitat banks by third-parties. The absence of thirdparty banking remains a roadblock to habitat banking provisions serving a useful function in encouraging restoration of high priority fish habitat. Enabling Indigenous-owned habitat banks would be particularly beneficial.

• Transport Canada needs to develop clear and pragmatic guidance on identifying navigable waters and when a Governor in Council Order may be necessary, as well as a timely and coordinated process for obtaining an Order. The 2024 review of the Canadian Navigable Waters Act should address this by changing the requirement for cabinet involvement for unscheduled navigable waters, which adds many months to the decision-making process, to either a ministerial or departmental approval.

Participation of, and partnerships with, Indigenous peoples is a top priority for the mining sector. MAC members are among the largest industrial employers of Indigenous peoples and are major customers of Indigenous-owned businesses. There are over 500 active mining relationship agreements with Indigenous communities to help advance economic reconciliation.

Across the country, partnerships between companies and communities are directly contributing to reconciliation and the implementation of the Truth and Reconciliation Commission’s (TRC) Calls to Action and UNDRIP. Notable action has come via recent updates to Towards Sustainable Mining (TSM), a madein-Canada globally recognized sustainability program that supports mining companies in managing key environmental and social responsibilities.

It incorporates measurable criteria reflecting the TRC’s call to the corporate sector and establishes what is considered good practice in TSM that includes aiming to achieve FPIC before proceeding with development where impacts to rights may occur.

To strengthen Indigenous participation in mining, the government should:

• Ensure that that the Indigenous Loan Guarantee Program, announced in the 2023 Fall Economic Statement, is broad enough to capture the range of opportunities in the mining sector, including investments in ancillary infrastructure and Indigenous-owned businesses in the supply chain.

• As part of the National Benefits Sharing Framework, position Indigenous peoples to meaningfully participate in mining development and take advantage of the opportunities associated with it through:

o Strengthening internal capacities to facilitate meaningful engagement and participation throughout all stages of the mining life cycle.

o Business development initiatives that enable Indigenous entrepreneurs to effectively compete in the mining sector.

• Strengthen processes and tools to support Crown consultation, including:

o Improving federal-provincial and inter-departmental coordination of consultation activities to avoid duplicative engagement.

o Strengthening tools such as Aboriginal Treaty Rights Information System (ATRIS) and the Open Science and Data Platform to support meaningful and informed Indigenous consultation.

Responsible mining development includes biodiversity conservation and MAC members have publicly committed to positively contributing to the conservation of biodiversity through all stages of the mining life cycle. This commitment is supported by a strong track record of prioritizing action to avoid and minimize impacts on nature, as illustrated by actions in our sector that align with nature positive commitments, investments in robust wildlife monitoring, habitat restoration and contributions to science.

The development of a renewed National Biodiversity Strategy in response to the Kunming-Montreal Global Biodiversity Framework provides an opportunity to further increase the mining industry’s contribution to nature through policy that encourages and incentivizes private sector action, including through:

• Tax incentives that encourage private sector investment in biodiversity conservation through new and enhanced tax incentives, including mechanisms that consider benefits for biodiversity and climate change.

• The development of guidance and policy that clarify how habitat banking may be recognized in the context of a regulatory decision.

While our nation has an abundance of the critical minerals required for the world’s transition to a low-carbon, clean economy, long-term social and demographic challenges undermine the mining sector labour supply and its ability to respond to industry growth. Canada’s mining industry is facing a people crisis, with the industry’s tightening labour market being caused by numerous factors, including:

• An aging workforce with rising retirements, while fewer young people enter the industry.

• Shrinking post-secondary mining programs (e.g., undergraduate mining engineering enrolment is down over 50% since 2015).

• A historically low mining unemployment rate (under 1% in July 2023) while total employment has grown over 40% since January 2022.

• Continued challenges to attract and retain underrepresented groups.

An independent, non-profit organization, the MiHR Council delivers the needed solutions by driving collaboration among sector stakeholders to identify opportunities and address the human resource and labour market challenges facing the Canadian minerals and metals sector. The MiHR Council is the sole mining workforce-focused organization in Canada and provides the industry with critical labour market information and analysis, key to industry intelligence, planning and recruiting. Canada needs MiHR to meet ambitious critical minerals aspirations that will require more mining and therefore, a larger pool of skilled workers.

RECOMMENDATION 5 – RENEWED AND STABLE EMPLOYMENT AND SOCIAL DEVELOPMENT CANADA (ESDC) FUNDING OF THE MINING INDUSTRY HUMAN RESOURCES (MIHR) COUNCIL

Currently, MiHR is facing an ESDC funding gap/cliff this year (2024) that will have potentially detrimental impacts on the organization. As such, MAC recommends either the extension of existing MiHR-funding ESDC programs outlined here, or new funding source(s) that would meet these MiHR programmatic needs:

• Extend the delivery of the Sectoral Workforce Solutions Program (SWSP) from March 31, 2024, to at least March 31, 2025, for MiHR (and all existing SWSP recipients).

o In 2022, MiHR was provided $14.5M in SWSP funding (plus a recent $1M for a one-time scholarship program) for MiHR’s Sector Skills and Solutions Strategy for the Clean Economy (M4S).

o ESDC/SWSP funding for M4S is currently slated to end March 31, 2024.

• Extend the delivery of the Sectoral Initiatives Program (SIP) to support MiHR’s work on Labour Market Analysis (LMI).

o ESDC has traditionally provided $1.5M annually on average in SIP funding to MiHR. The latest phase of the SIP programs ended March 31, 2021.

• A long-term funding commitment for the Student Work Placement Program (SWPP): $18M/over the past 7 through SWPP has helped MiHR provide wage support to over 200 mining and mining support services companies with over 2,000 co-op placements.

o MAC welcomed the one-year exten -

sion announced in Budget 2023 and recommends a long-term commitment to SWPP funding beyond 2025.

MAC welcomes the opportunity for continued collaboration with government in the design, development, and implementation of Canada’s Critical Minerals Strategy for the benefit of all Canadians.

Submitted by the Mining Association of Canada.

Process improvement is like cycling. Everything runs more efficiently with the right partner.

Energy optimization is the key to sustainable production. As a strong partner for strategic energy management, we help you cope with rising energy costs and tighter environmental targets. We are at your side – uncovering the ways to save and be resourceful while maintaining safety, quality, reliability, and uptime.

Do you want to learn more?

www.ca.endress.com

By Andrew Snook

In British Columbia’s forestry sector, there has been no year in recent history filled with more preventable tragedies than 2012.

In January of 2012, the Babine Forest Products sawmill in Burns Lake suffered an explosion that resulted in the deaths of two workers while injuring 20 others. A few months later in April 2012, about a 2.5-hour drive from Burns Lake in B.C.’s Northern Interior, the Lakeland Mills sawmill in Prince George exploded, killing another two workers and injuring 22 more people. The investigations into these explosions found one culprit responsible: combustible dust.

Since that time, regulations have been tightened to ensure better management of combustible dust throughout the province.

B.C.’s management of combustible dust was the topic of the closing keynote presentation for the 2024 Global Dust Safety Conference, which took place earlier this year. The presentation, “Upcoming release process for the proposed British Columbia regulations for combustible dust. Why they are needed and what it means for industries in B.C.,” was presented by Rodney Scollard, senior policy and legal advisor, and Mike Tasker, CRSP occupational safety officer with WorkSafeBC.

They reviewed proposed upcoming regulation changes regarding combustible dust in the province; provided a background on what drove regulation change in B.C. over the past decade; the timeline for the new regulations to come into effect; the roadmap to combustible dust hazard assessment and management provided in the regulations; and what these changes may mean for industries in B.C.

When the sawmill explosions took

place in 2012, WorkSafeBC had enacted Workers Compensation Act policies related to the general duties of employers, workers and supervisors in relation to how they identify and manage the risk associated with wood dust. The currently proposed regulations expands on the policies related to wood dust.

“The provisions we have currently around combustible dust, and controlling the hazards associated with it, is very limited, and not very detailed,” Scollard explained. “So, there’s been this drive now to introduce specific dust-related regulations within our occupational health and safety regulation. And in doing so, these new regulations

The currently proposed regulations expands on the policies related to combustible wood dust.

will ultimately replace those three current policies that were introduced after the 2012 incidents.”

While the focus of WorkSafeBC has understandably been on regulations related to combustible wood dust, the proposed regulations would expand the types of dusts within the regulations.

“Most of our focus from a regulation perspective has been devoted to combustible wood dust. Certainly, that is an issue that we needed to address. So, under the proposed regulation, it’s been greatly expanded to any dust that is handled or generated at the workplace,” Tasker said. “That ‘handled or generat-

ed’ is an important aspect. We’re not talking about the dust that might accumulate on a windowsill. We’re talking about dust that is either handled or generated. So, handled or generated through pulverizing processes, grinding processes, material size reduction processes, and that sort of thing. Handled meaning things like conveying it, moving it, storing it, those kinds of examples.”

The type of dust within the proposed regulation could include wood dust, agricultural dust, plastic dust, manufactured powders and lint.

“If it’s if it is combustible, then it’s covered by the regulation,” Tasker said.

Dust that is in sealed commercial packaging is excluded from the proposed regulation.

“A sealed bag of shavings for a rabbit cage in a pet store is not covered by this regulation, it’s excluded,” Tasker said, as an example.

While the current version of the proposed regulation on the WorkSafeBC website, “Part 6, Substance Specific Requirements: Combustible Dusts,” is not the finalized approved version of the regulation, Tasker said that he believes it is very close to a final version.

“We don’t know exactly what the final version of the regulation is going to look like. However, I think, in my personal opinion, we’re getting pretty close to that,” he told attendees. “We’ve been working through the consultation process now for over a year, where we’re pretty clear on what has been recommended and what has been adopted. So, I don’t foresee a lot of significant changes. But we just want to make it clear that the version of the regulation that you may access from our website is still a working draft, until it actually gets finalized and approved by our board of directors, and then moves forward through the rest of the approval process.”

When putting together the proposed regulations, Tasker said they tried to find a balance between performance-based regulation and prescriptive-based regulation.

“Because this regulation is intended to cover workplaces that are both simple and complex, very large to very small, we had to strive to find a scalable regulation that could be applied across the board, regardless of the size or complexity of your operation,” he said. “In order to do that, we had to find a balance between those two regulatory methodologies.”

To address the performance-based aspect of the regulation, they expanded the requirements around conducting a risk assessment, so the risk assessment takes into consideration the characteristics of the dust, as well as the machinery and equipment that exists at a given workplace. It also expands the requirements for employers that have combustible dust, to have a combustible dust management program, Tasker explained.

“We also have a section that is more specific, more prescriptive in nature, that stipulates specific control measures that must be in place for particular risks or particular types of equipment. And it does provide some guid-

ance specifically to those,” Tasker said.

An assumption clause has been put into the proposed regulations to help address a notion of understanding about particular dusts, while reducing costs for employers.

“For every employer to take representational samples of every dust they have, and to send it to a lab for testing, paying the money for that, and all the associated costs with it, was just overly burdensome, especially for small- and medium-sized employers,” Tasker said. “We

also recognize that some dusts are easily recognizable as combustible. We don’t need to conduct those tests in order to understand and manage those dusts.”

To simplify things for employers, the assumption clause states if a workplace handles or generates a dust, employers must assume it’s ignitable and deflagrable, unless they do one of two things: test the dust or show evidence that it is not combustible.

“If you believe that the dust that you have at

your workplace is not a combustible dust, you can send a sample to a lab, follow [WorkSafeBC’s] methodology and confirm that it is, in fact, not a combustible dust,” Tasker said. “Because we understand that there’s access to published data on various dusts, if you believe that your dust at your workplace is not combustible, you can rely on that objective published data, provided that it’s been derived from the prescribed testing method that’s indicated in the regulation.”

Once a company has dealt with the assumption clause, they can proceed to the next step in the process, which is to begin a risk assessment. Every employer in B.C. that has a combustible dust at the workplace is required to conduct a risk assessment in consultation with a qualified person.

“Within the regulation, it outlines the risk assessment process that needs to be followed; the types of things that need to be considered, in order for it to be a valid risk assessment. And we also provide language as to when that risk assessment has to be reviewed and updated,” Tasker said. “For example, if there’s a change in materials or machinery or processes, then there’s a requirement to go back and review and update your risk assessment to reflect those changes.”

For the definition of a qualified person used by WorkSafeBC for the proposed regulation, the organization adopted the universal definition of qualified that WorkSafeBC relies on in Occupational Health and Safety Section 1.1.

“We didn’t come up with a specialized definition of qualified for the purposes of combustible dust,” Tasker explained.

After a risk assessment is completed and combustible dust has been identified in a workplace, the next step is to develop a combustible dust management program.

The combustible dust management program should outline how to manage that risk, and what controls need to be put in place.

“Those controls can be many, can be few, depending on the on the nature of the workplace and the nature of the risk,” Tasker said. “This program is a written program that has to be developed by the employer, and once again, under consultation with a qualified person. And within the regulation, we also stipulate the basic elements of a combustible dust management program in order for it to be considered adequate to manage the risk.”

The risk assessment and specific requirements that flow from within the

When putting together the proposed regulations, WorkSafeBC tried to find a balance between performance-based regulation and prescriptive-based regulation.

proposed regulation are aimed at tackling these factors:

- What is the type and amount of fuel (dust) that’s present at the workplace? How much of it and what type is it?

- What sources of ignition are around in that workplace that could ignite the dust?

- What degree is there potential is for confinement of the dusts?

- What is the possibility of the dust being dispersed or suspended in the air?

- And to a lesser extent, what amount of oxygen is present?

“That’s really what a lot of the provisions and requirements in the draft are flowing from, and what they’re aiming

towards is having the employer control those five factors at their workplace,” Scollard explained.

At the time of this article’s publication, the proposed regulation was still undergoing consultation in its draft format and is subject to change. Feedback was being accepted until May 17, 2024.

“Part 6, Substance Specific Requirements — Combustible Dusts” is available to download at the WorkSafe BC website at: www.worksafebc.com/en/resources/lawpolicy/discussion-papers/part-6-substance-specific-requirements-combustible-dusts-2024-may?lang=en.

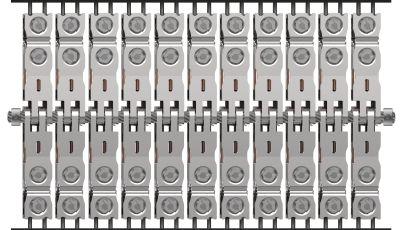

Flexco recently announced the addition of the FXC Steel Cord Belt Fastening System to its line of heavy-duty mechanical belt fastening systems. When an operation needs to reduce downtime from a damaged belt, the FXC can provide an immediate solution as a temporary splice or to pull a belt onto the conveyor system. Although the FXC Steel Cord Belt Fastening System is designed to be a temporary solution, users can expect full performance at normal levels to fill stockpiles and continue operations while vulcanization is scheduled. This patented fastener design has undergone extensive internal and field testing to ensure strong performance in the most demanding environments. Having a kit on hand at a facility essentially acts as an insurance policy that allows users to spring into action when belt issues arise, drastically reducing production downtime. The FXC Steel Cord Belt Fastening System can even be

pre-spliced to belt ends ahead of a belt pull, making stringing a belt onto the system even faster. Because there are many different steel cord belt constructions, a datasheet is used to collect the belt’s specifications so a custom splice kit can be made for a specific belt. Customers are asked to provide the belt rating (currently available for belts up to ST2500), cord diameter, cord pitch, and belt width. After submission, a quote can be provided along with additional details about the splice kit and installation. The FXC can be used in heavy-duty applications, and is ideal for use in aggregate, cement, coal-fired power plants, open pit hard rock, metals, and underground mining.

Flexco www.flexco.com

Moore Industries has announced the 330R2 1/8 DIN Process and Temperature Panel Meter to replace the discontinued 330R Process Monitor. The 330R2’s universal input and dual process relays satisfy a wide variety of process and temperature applications. Thanks to the 300R2’s UV-resistant and sunlight-readable 4-digit display and an operating temperature range of -40 to 65°C, it is particularly well suited for harsh outdoor environments. The 330R2 is housed in a 1/8 DIN enclosure and accepts a wide array of analog inputs including process voltage (0-5V, 1-5V, 0-10V, ±10V) and current (0-20mA, 4-20mA, ±20mA) inputs, 100 Ohm RTDs, and the four most common

thermocouples.

Among the 330R2’s highlights is its ability to provide 24VDC to power the transmitter’s 4-20mA signal with the high-level input-powered units, simplifying wiring and reducing overall installation costs. Additionally, an isolated 4-20mA output option is available for retransmission of process and temperature inputs.

The 330R2 is a versatile and durable panel meter enclosed in a shallow-depth 1/8 DIN casing with a NEMA 4X & IP65 front panel with adjustable display intensity, making the 330R2 especially effective for outdoor applications. Featuring 2 form C (SPDT) relays the 330R2 provides alarm and control flexibility for critical temperature and process loops including pump control applications. UL and Canada-UL Listed, the 330R2 adheres to the safety standards of UL 508 Industrial Control Equipment. The meter can be programmed quickly and easily either on a PC or in the field. Field programming is accomplished via the four push buttons on the faceplate, or the unit can be programmed with free programming and monitoring software. This programming software enables you to save configuration settings to a file, facilitating easy programming across multiple meters.

Moore Industries www.miinet.com

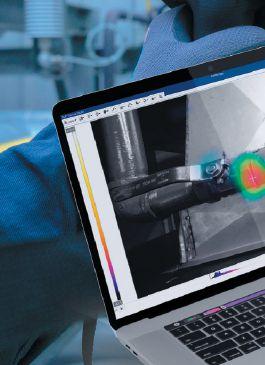

Machine learning-powered analytics provide data-driven decision support on the Acoustic Viewer and FLIR Thermal Studio.

ON-SCREEN GAS LEAK QUANTIFICATION DETECT FAULTY BEARINGS INSPECT FROM SAFE DISTANCES REDUCE OPERATING COSTS

Using a three-level approach to digital transformation, manufacturers can simultaneously improve sustainability, streamline maintenance and empower their workforce.

By Samuele Oliva

Dust collector systems are the lungs of a factory. These systems capture powder and solid particulates to filter the air in processing plants across many industries. However, there are multiple challenges that today’s manufacturers face that affect the performance of these systems. They must meet ambitious sustainability targets while experiencing ongoing labour shortages and skills gaps in the workforce. At a time when factories need to operate as efficiently as possible, labour challenges often negatively affect equipment performance and energy consumption.

By using a Floor to Cloud approach to the digital transformation of these systems, manufacturers can gain the visibility and control to simultaneously address these challenges and significantly improve dust collector performance. In this approach, there are three layers of technology, from the factory floor up to the cloud, that can optimize dust collector systems. A combination of dust collector components, sensors, controllers and advanced software can provide greater overall facility sustainability, reduced maintenance and a more empowered workforce.

Dust collector systems can clean the air inside the factory as well as the air that is ventilated outside. In this way, an effective dust collector system already helps facilities reduce their impact on the environment while providing a cleaner and safer work environment. However, an optimized dust collector system can help facilities significantly improve their sustainability efforts in two ways: by more efficiently capturing particles to keep them from entering the atmosphere and by minimizing compressed air use by up to 40%, reducing energy use, carbon dioxide (CO2) emissions and waste.

As they work, dust collector systems use a lot of compressed air. Producing compressed air requires a compressor, which uses electrical energy. If the electrical energy is produced using fossil fuels, this results in more CO2

With high peak pressure and single-piece diaphragm, the ASCO Series 353 Pulse Valve from Emerson is designed to reduce air consumption and improve efficiency in reverse jet-type dust collector systems.

emissions. However, not all compressed air is used efficiently. Some may be lost to inefficient pulsing or leaks, resulting in waste.

At the component level, the pulse valves that a dust collector system has can affect how much compressed air the system uses. Pulse valves with a single-piece diaphragm are often more energy-efficient. They can quickly open and close, reducing compressed air consumption by 15% without sacrificing performance. In fact, the high peak pressure of these valves can increase pulsing efficiency by about 14% over conventional pulse valves. In addition to reducing compressed air use, facilities can reduce the amount of particles that they release to the atmosphere. At the sensing level, there are smart particle sensors sensitive enough to detect the number of particles that the system emits after the

filtering stage. They feature contact and non-contact technology to sense particles, which is more accurate and requires less maintenance compared to conventional particle sensors. They can also identify early-stage breakage in filter bags and leakage in the filtering system. This makes it possible for personnel to address the issue and improve filtration.

And at the control and software level, there are industrial controllers and advanced software specifically designed for dust collector systems. The controllers aggregate all system data streams, while the software translates that data into meaningful insights and displays it in intuitive, easy-to-understand dashboards. This makes it possible for operators to gain real-time visibility and control of dust collector systems to continuously improve system sustainability and performance.

The

AF2

Using the software, operators can monitor all aspects of the system to optimize performance and quickly detect and address anomalies. For instance, they can identify if there is a worn component causing a compressed air leak. Personnel can quickly replace the component, minimizing compressed air waste and energy use.

Facilities can also optimize pulse-jet cleaning. In many facilities, pulse valve frequency is determined by a preset, timed interval. This means that valves can pulse and release compressed air even when it isn’t necessary, wasting compressed air and reducing the operating life of valves and filter bags. In comparison, a dust collector control system can use real-time process data captured from sensors to only pulse valves when it is needed. By introducing a data-driven operation of the system, facilities can reduce the amount of compressed air used and also extend the lifetime of the equipment, improving sustainability and reducing system maintenance.

A dust collector system, like any other machine, requires regular maintenance, especially given the dusty environments where they work. However, many organizations take a timebased approach to dust collector maintenance, which means components are serviced or replaced at regular intervals whether they need it or not. Because it is periodic, the frequency may not be enough and can lead to system inefficiencies. It is also time-consuming, because

components must be checked one by one. A Floor to Cloud approach can help facilities optimize their maintenance procedures and move to a predictive maintenance model, which can minimize waste and unplanned downtime.

A combination of sensors, control technology and advanced software make it possible to detect and address issues in real time. For example, this intelligent approach makes it possible to quickly identify a valve with a broken

diaphragm or a broken coil from all systems of valves through a quick glance at a dashboard or an alarm. The software is intuitive and easy to use, making it clear to see what is happening in the system and when the system will require future maintenance so it can be scheduled, reducing unplanned downtime.

What’s more, many of the components and devices used in a Floor to Cloud approach to dust collection have designs that simply require less maintenance. For instance, the single-piece diaphragm on the latest pulse valves has a significantly longer lifetime than multi-part mechanisms on standard pulse valves. They require less maintenance and fewer spare parts compared to standard pulse valves.

Top: Movicon.NExT software from Emerson features intuitive dashboards that let operators easily and remotely monitor dust collector systems in real time.

Left: The ASCO P152 DPT Particle Sensor from Emerson precisely measures lowresolution particles in difficult-toaccess points of filtration systems to reliably detect leaks in dust collector systems.

The labour shortage and skills gap continue to impact many industries, including pharmaceutical, chemical, woodworking and food and beverage. As a

result, manufacturers are digitally transforming their machines and processes to empower their teams with real-time data and insights to guide them through their responsibilities. This includes the personnel who maintain and operate dust collector systems.

With so many staff who are new to the company or industry or those who take on additional responsibilities to compensate for less labour power, machine and process efficiency can suffer and cause compressed air waste and excess maintenance time and costs. And if dust collector systems are used to collect dust as product, product losses can occur.

Through intuitive dashboards and alarm notifications, the Floor to Cloud approach to dust collector systems gives personnel the guidance and insights they need to complete their responsibilities accurately and efficiently, regardless of skill level.

Many of the aspects that make maintenance easier can ease pressures of the labour shortage and skills gap. Valves and tanks that have a longer lifetime can extend maintenance intervals, and sensors that require less maintenance can reduce service frequency. However, controllers and advanced software maximize these assets and provide significant benefit on their own.

Advanced dust collector software can direct personnel as to what needs maintenance when, in an easy and straight-

forward way. By using this kind of technology, it is very easy to understand what is going on in the system, where there may be potential or future issues, and how to proactively solve them before they become problems. This level of guidance and insight can adequately substitute operator skill and experience and keep operations running. In one glance, operators can quickly and easily see such factors as particle concentration, differential pressure and valve function. Operators can also preset thresholds and receive alarms if they exceeded their values.

Even as manufacturers face simultaneous, competing challenges, they can ease their pressures and achieve the outcomes that benefit them most using a Floor to Cloud approach to dust collection. A combination of high-efficiency pulse valves, smart sensors, industrial controllers and advanced software can give operators the visibility and control of dust collector systems to improve sustainability, optimize maintenance procedures and empower staff — all at the same time.

SAMUELE OLIVA is the product marketing manager for dust filtration systems for Emerson.

To optimize production and extend the lifespan of tubular drag cable conveyors, it is ideal to involve an expert OEM for total preventative maintenance.

By Del Williams

Canadian processors in a wide range of industries rely on tubular drag cable conveyors to move sensitive materials and powders. Therefore, it is important for Canadian operations managers, plant engineers, and consultants in the chemical process and related industries to properly design, install, and proactively maintain these systems to minimize production downtime and maximize longevity.

In today’s fast-paced processing environment, it is a standard practice to run conveyors until something breaks or needs to be repaired, which can lead to significant unnecessary downtime.

“Processors traditionally have relied on third parties such as local millwrights to install and maintain conveyors. These third parties may not have access to technical specifications or have not had the opportunity to read the manual and can therefore be unaware of

system acceptable specifications and best practices. This can result in not only excessive downtime and maintenance, but also costly repairs and even premature system replacement,” says Fernando Mejia, director of product life cycle management and aftermarket for Automated Handling Solutions (AHS).

Instead of reacting to individual problems as they arise, a more effective approach for Canadian processors is to implement total preventative maintenance (TPM) for conveyors.

This involves ongoing service and engineering support, resulting

ance plan based on their needs. Failing in this, customers may continue to replace parts prematurely with all the needless downtime this involves,” says Mejia.

According to Mejia, the goal of a TPM program is to work with customers to maximize the output of their conveyors and extend the lifespan of their critical capital equipment.

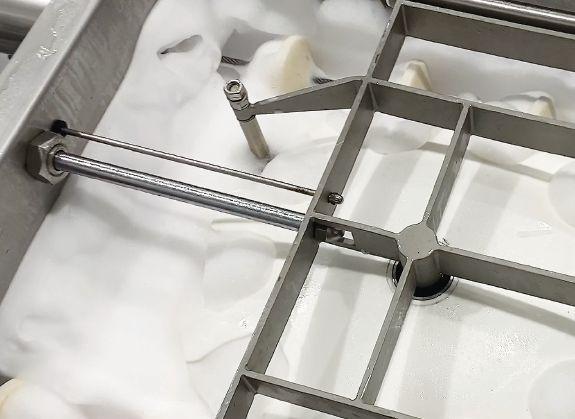

With the sophistication of stateof-the-art conveyors, proactive, preventative, and predictive maintenance is an effective strategy. This is the case with tubular drag cable conveyors, which gently move product through a sealed tube using a coated, flexible stainless-steel drag cable pulled through on a loop. Solid circular discs (flights) are attached to the cable, which propel the product through the tube without the use of air.

While it is possible to utilize third parties to install the systems and in-house maintenance teams to maintain them, there are considerable advantages to involving an OEM Supervisor, since they possess unparalleled training and expertise on the system.

OEM technicians typically have years of experience exclusively servicing and troubleshooting tubular drag style conveyors. In the case of AHS, its technicians have conducted hundreds of inspections in plants worldwide that run any material imaginable, from powders and blends to bird seed, pet food, cereals, coffee beans, nuts, and more.

“Many recurring problems stem from incorrect installation, which can involve improperly positioning the conveyor’s hangers, excessive tension, misaligning tubing, leaving gaps, or insufficient supports. All these defects can generate friction, noise, and prematurely wear parts, requiring replacement,” says Mejia.

in reduced downtime and lower operations and maintenance (O&M) costs.

“We are here to assist customers reducing their total O&M costs. We are looking forward to partnering with our customers to inspect their systems, review layouts, and formulate a total preventative mainten-

An OEM can also proactively recommend the appropriate spare parts kits or high wear parts such as cables, connectors, or sweeps that are known to have shorter lifecycles.

This method encompasses assessing both the condition and usage of the conveyor, while also leveraging predictive data to efficiently resolve numerous issues before any downtime occurs.

“As the OEM, we can analyze

system usage as well as component wear and lifecycle data to accurately predict when vital parts will likely need to be replaced and have them replaced before something breaks,” says Mejia.

“The more a processor adheres to this type of total preventative maintenance schedule, the more likely the conveyors will provide optimal service throughout their anticipated lifespan,” adds Mejia.

A comprehensive annual inspection of the conveyor system by the OEM is highly recommended. With the shortage of skilled mechanics combined with high employee turnover, we are here to perform in-depth inspections and recommended maintenance.

This solution is mainly targeted to processors that have one or multiple tubular drag conveyors running constantly throughout the year.

According to Mejia, detecting problems such as gaps or misalignments requires camera inspection. The annual inspection also assesses the conveyor’s tubes, walls, sweeps, connectors, input, and output. In addition, cables should be checked for integrity and tension, discs and sprockets for wear, and joints should be validated.

During the inspection process, the OEM can recalibrate or replace any components outside of system specifications. In the case of AHS, service technicians also advise on the use of any available update or retrofit kits that can further facili-

tate increased output.

While the frequency of the annual service visits depends on the system application and environment conditions, several factors can help determine the optimal frequency.

As a partial list, this can include the type of conveyor systems in the facility, system length and complexity, average daily use, environment conditions and the type of material conveyed. When these factors are analyzed, a service visit might be scheduled once or twice per year, as the situation warrants.

Many processors can benefit greatly from collaborating with a knowledgeable conveyor OEM to establish a comprehensive preventative maintenance plan. For instance, Mejia highlights the case of a coffee processor that aimed to revamp their maintenance strategy.

This customer had expanded operations and was about to double their capacity. Although their conveyors were running well, they didn’t want to risk unnecessary downtime.

“So, they told us, ‘We would like to avoid the ‘break/fix’ approach and move forward to a total preventative maintenance culture,’” says Mejia. “I was thrilled to hear that our goal and vision were aligned.”

To meet the demands of the industry and address the requested services, AHS is increasing their service capacity to assist processors in proactively miti-

gating issues and minimizing downtime.

The OEM will be establishing a service hub and parts depot on the West Coast, enabling localization, onsite inspections, and com-

prehensive preventive maintenance by qualified technicians with a local presence.

DEL WILLIAMS is a technical writer based in Torrance, Calif.

Bulk bag fillers manufactured by Best Process Solutions, Inc. (BPS) are designed to fill any size bulk bag with high accuracy, while offering years of trouble-free maintenance. BPS’s Model BBF loader features an inflatable fill head that offers a dust-free seal when loading, dust port with dust cartridge, and manually adjustable bag supports for varying bag heights—great for low ceiling heights. Many options are available. BPS manufactures a complete line of customengineered, bulk-processing equipment and systems. With more than 100 years of combined experience, the company serves a wide variety of dry processing industries from chemicals and food to aggregates and recycling.

Best Process Solutions www.bpsvibes.com

The 2852-PCD Plugged Chute Detector provides non-intrusive monitoring of chutes and hoppers for bulk material detection. Combining the technology of capacitance with unique sensor designs provide non-intrusive monitors for bulk solids handling systems. The result is a low cost and low maintenance system to determine the presence or absence of product in a pipe, chute, or other vessel. The Plugged Chute Detector monitors a chute or vessel using a sensor mounted flush with the chute wall. The sensor indicates a normal passage of product. When the product compacts due to a plugged condition, the monitor activates a relay to turn off equipment and alert operators. The 2852-PCD sensor monitors the capacitance field in front of the sensor plate. The sensing plate forms part of the chute or hopper wall to sense the product within. The increased presence of product in front of the sensor due to a plugging condition increases the capacitance field

and initiates an alarm. The sensing plates are embedded into a polyethylene plate which provides monitoring without any intrusion into the product flow.

Arjay Engineering www.arjayeng.com

Pharma grade filter receiver

Flexicon’s PNEUMATI-CON Pharmaceutical Grade Filter Receiver for medium- to high-throughput vacuum and positive-pressure conveying of extra-fine, difficult-to-handle and/or contaminationsensitive bulk solid materials, features designs to readily change/inspect filter cartridges and sanitize the interior. A gas-spring-operated lid provides access to a removable filter plate, allowing cartridge filters to be removed and inspected or cleaned from the top, eliminating product hold up points and cleaning difficulty associated with side access doors and bolted-in filter plates. Tri-clamp fittings additionally allow rapid disconnection and cleaning of all accessory parts and lines. Constructed of #316L stainless steel to pharmaceutical standards, the receiver housing is devoid of interior ledges, cavities or recesses that could harbor contamination, and features three tapered filter cartridges that separate conveyed material from the air stream. Automatic reverse pulse-jet cleaning of the pleated filter media maintains separation efficiency, while the tapered filter design improves material release.

Flexicon Corporation www.flexicon.com

Want to manage highly dynamic load cycles in harsh conditions? Whatever the environment, the iC7-Automation from Danfoss delivers the reliability and performance you need. With connectivity, security and intelligence, this drive lets you take advantage of the latest in industrial IoT. iC7-Automation gives you a whole new way to optimize your system with selectable communication protocols and Safe Torque Off

(STO) SIL3 as standard. The modular control platform allows you to expand functionality to meet your needs. Get superior shaft performance even at low speed, in open or closed loop. Commission fast with Automatic Motor Adaptation at standstill. The unit also features intelligent security ready for industrial IoT with marketleading, hardware-based protection designed to prevent unauthorized access.

Danfoss www.danfoss.com

Carlo Gavazzi has introduced three new series of M12 Capacitive Sensors with IO-Link Communications. Based on the company’s 4th generation TRIPLESHIELD sensors, these CA12 Series Sensors represent the ideal solution for industrial automation equipment in applications where sensing performance must be continuously and accurately monitored and logged. These sensors have been designed to flexibly adapt to industrial applications. A housing option is available for every application – PBT for less challenging environments, AISI316L stainless steel for strength, and PEEK offering a smooth surface to reduce accumulation of dust or liquids. In addition to the full range of technical features provided by our capacitive sensor families, the IO-Link communication allows additional advanced data, such as: QoR, QoT, temperature and dust alarms, and diagnostic parameters. With this information, predictive maintenance can be scheduled before sensors fail which increases uptime. The M12 Capacitive Sensors with IO-Link Communications are fully programmable and customizable via IO-Link. They can be used in the following industries: semiconductors, printing, plastics, packaging, conveying, agriculture, wood, and food and beverage.

Carlo Gavazzi www.GavazziOnline.com

New multi-sensor device simplifies brewery processes

Endress+Hauser’s new QWX43 fermentation monitor enables a seamless and simple monitoring of fermentation processes without manual sampling or laboratory analyses. Measuring values are taken continuously so that users receive real-time insights into the fermentation process, from anywhere and anytime. Brewers must keep an eye on numerous parameters during the fermentation process. To determine the residual extract, for instance, reference measurements are taken at every fermentation tank at least once a day using samples that are analyzed in the lab. These measurements can take up to 20 minutes per tank, including sample preparation. Furthermore, they yield only intermittent results. Fermentation Monitor QWX43 fills these information gaps by measuring the fermentation parameters in real-time. The data is directly transferred to the PLC to be used in process control. Brewers also can utilize the Netilion Value App from Endress+Hauser to retrieve the insights in the fermentation process with one click on their mobile device.

Endress + Hauser www.us.endress.com

Barcode scanners, cameras, and vision sensors

AutomationDirect has added machine-mountable barcode scanners, 2D cameras, and 3D vision sensors from ifm efector to their Barcode/RFID/ Vision category. Machine-mountable barcode scanners can read popular industrial 1D and 2D codes such as Code 128, Code 39, QR codes, and many more. They are designed for applications

requiring machine mounting, conveyor mounting, or process equipment mounting.