Cameron Instruments has introduced the Variotec 460 Tracergas, developed for leak detection on underground pipes, gas and water distribution networks, pipelines in buildings, and heating systems. Detecting gas leaks by tracer gas involves feeding a mixture of 95% nitrogen (carrier gas) and 5% hydrogen into the system. The hydrogen escapes through the leak and is detected by the highly sensitive sensor. Tracer gas always looks for the shortest route from the leak to the surface, the company explains. The low amount of hydrogen means that the gas is incombustible as per ISO 10156, it adds. Measurements can be saved, and the results transmitted using the USB interface to a PC.

Cameron Instruments

www.cameroninstruments.com

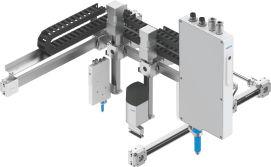

Festo has introduced the DHOP closed-loop pipette head for high-speed robotic pipetting applications delivers consistent volumes over a wide range of liquid viscosities. Liquid aspirates into the disposable tip using vacuum and dispenses using pressure to increase microfluidic speed and flexibility. By measuring the pressure change when a liquid is aspirated or dispensed, the device can calibrate for different viscosities without user input. Faster changeover between liquids leads to higher throughput and maximum device utilization, the company says. The pipette system integrates with Festo’s mechatronic systems, including the new EXCL multi-axis gantry (shown). Festo www.festo.com/ca

Endress+Hauser has introduced the Picomag, a pocket-sized device for measuring the flow of electrically conductive fluids, their process temperature and conductivity. The Picomag measurement device offers commissioning with Bluetooth using its free SmartBlue App, as well as system integration via an on-board IO-Link connectivity, making it Industry 4.0 ready, the company says. The device is suitable for cooling, warm or process water. Endress+Hauser Canada www.ca.endress.com

The XPR105MCP calibration balance from Mettler Toledo is said to be the high-speed solution for ISO 8655-compliant calibration of multichannel pipettes. It has a readability of 10 μg and supports multichannel pipettes with up to 12 channels and nominal volumes from 0.5 to 1000 μL. With a readability of 10 μg and repeatability of 15 μg, the system fulfills the requirements of ISO 8655 for multichannel pipettes with dispensing volumes as small as 0.5 μL. The weighing performance ensures accurate calibration, the company says, even at such small volumes. The results of a single dispense of up to 12 channels are calculated in under one minute. The unit tests each pipette channel individually on the same load cell to ensure equal measurement performance. The load cell is protected from any spills to ensure lifelong performance. The 360 measurements needed for a full calibration (12 channels, 3x10 repetitions) can be completed in as little as 25 minutes. The system can also be connected to a second calibration balance for increased throughput.

Mettler Toledo www.mt.com/lab

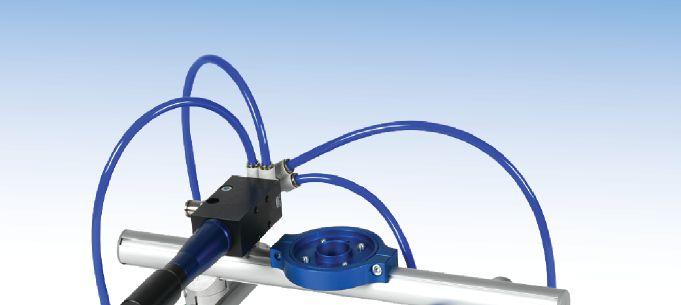

Schmalz End-of-Arm Tooling Kits

Features

• Starter kits are easily assembled

• Includes structural rail, connectors, cup mounts, vacuum tubing, vacuum cups, fittings, basic ejector, flange for Universal robot, and a blank robot flange

• Can be built to use internal or external vacuum

• Additional robot flanges are available to connect to Fanuc, Rethink, Universal, and Yaskawa robot arms

End-of-arm tooling starter kits include all the components needed to create a single-beam or dual-beam end-of-arm tool for a vacuum pick-and-place application. Kits are simple, save time and money, but still allow a degree of customization.

First, cut the structural rail to the desired length, determine the location of the suction cups, and then assemble the unit. Once assembled, add the robot interface flange for your brand of robot or drill your own using the included blank robot flange. That’s all it takes and your tooling is ready to go!

• Single profile kit with minimum active 20 pound-force load (90 N), maximum active 78 pound-force load (350 N)

• Double profile kit with minimum active 56 pound-force load (250 N), maximum 140 active pound-force load (625 N)

Also Available

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days.

*Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

• Vacuum suction cups in flat and bellowed styles made from Elastodur, silicone, or Nitrile in sizes up to 78mm

• Vacuum ejectors with a high suction rate of up to 860 I/min

• Spring plungers for vacuum cup mounting

• Couplers in G1/8 and G1/4

AutomationDirect carries a full line of almost 4,000 sensors from photoelectric to limit switches, proximity, and ultrasonic. Our sensors have the best pricing available with fast FREE shipping on orders over $49*. When it comes to buying sensors, it makes sense to choose AutomationDirect.

NEW! Contrinex DW Series

Small Rectangular Inductive Proximity Sensors

Starting at $22.00 (DW-AD-611-C12P)

Contrinex DW series small rectangular inductive proximity sensors feature a compact footprint suitable for mounting in tight spaces. They are non-flush mounted and offer NPN or PNP switching outputs with N.O. or N.C. operation.

• 4mm sensing distance

• Models with top or front sensing

• 10-30 VDC operating voltage

NEW! ProSense D80 Series

• IO-Link v1.0 (PNP models only)

• IP67 protection rating

Large Rectangular Inductive Proximity Sensors

Starting at $146.00 (D80-AP-3H)

NEW! Wenglor OPT Series

Ultrasonic Proximity Sensors

Starting at $127.00 (OPT2200)

Wenglor OPT series ultrasonic proximity sensors offer sensing distances up to 2000mm, rugged stainless steel and plastic housings, and protection ratings up to IP68 for use in challenging industrial environments.

• Sensing distances up to 2000mm

• Analog or discrete output options

• IO-Link v1.0

NEW! ProSense F18 Series Photoelectric Sensors

• Advanced configuration options such as through-beam, synchronous, and mute operating modes, window teach-in, and external temperature compensation

ProSense D80 series “pancake” style large rectangular inductive proximity sensors are available with AC- or DC-power options and a variety of termination styles. They offer long sensing distances, large sensor faces, and robust PPE housings for harsh industrial environments.

• 50mm (flush) and 60mm (non-flush) sensing distances

• Large active sensor face

• AC and DC operating voltages

• Select models with potentiometer sensitivity adjustment

• PPE housing with diecast zinc nickel-plated mounting clip

• IP65 or IP67 protection rating

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days.

*Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

Starting at $32.00 (F18I2-0N-0E)

ProSense F18 series photoelectric sensors feature rugged PBT thermoplastic housings and an IP67 protection rating. They are available in diffuse, diffuse with adjustable background suppression, polarized retroreflective, and throughbeam sensing styles.

• Sensing distances up to 25m

• 10 to 30 VDC operating voltage

• LED light status indicators

• IP67 protection rating

• Complete protection against electrical damage

• M12 quick-disconnect (purchase cable separately) or pigtail with PVC jacket

Our shipping policies make it easier than ever to order direct from the U.S.!

To see

Whether you sing Our home and native land or Our home on native land, you may have noticed indigenous-run businesses across Canada are gaining traction, especially in the energy sectors.

A report just published by the Canadian Chamber of Commerce called Canada and Global Energy Security: The Role of Natural Gas in a Lower Carbon Future takes note of this. Authored by Eric Miller, Fellow Canadian Chamber Future of Business Centre and president, Rideau Potomac Strategy Group, the report points out that Canada is the fifth largest Mike Edwards medwards@cpecn.com

natural gas producer in the world, now partly with the cooperation of our First Nations. Natural gas also offers opportunities for First Nations to lead projects and build wealth, states Miller. The Haisla people, for example, have proposed building their own $3-billion floating gas export terminal across the Douglas Channel from LNG Canada in Kitimat, BC.

“If approved, it would be the largest First Nations-owned infrastructure project in Canada.”

READER SERVICE

Print and digital subscription inquiries or changes, please contact Angelita Potal Customer Service Tel: 416-510-5113

Fax: (416) 510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

AUDIENCE MANAGER, Anita Madden 416.510.5183 amadden@annexbusinessmedia.com

PUBLISHER, Rob Sommerville 905.770.8077 rsommerville@cpecn.com

EDITOR, Mike Edwards 416.510.5229 medwards@cpecn.com

You are assured to get the best-fit products, solutions and services for your specific requirements.

150.000

customer queries per year, treated and solved globally by Endress+Hauser technical support organization

We understand how important it is to find the right expertise for your industry application needs. Do you want

With Smart Support, Endress+Hauser delivers the expertise you need remotely to resolve and prevent technical issues on your measurement instruments.

• Shorten unexpected downtimes

• Decrease the effort on maintenance staff

• Save costs of field service visits and device returns

• Increase expertise on instrumentation and application

ACCOUNT COORDINATOR, Barb Vowles 416.510.5103 bvowles@annexbusinessmedia.com

GROUP PUBLISHER/VP SALES, Martin McAnulty mmcanulty@annexbusinessmedia.com

President/COO, Scott Jamieson sjamieson@annexbusinessmedia.com

Founder, Peter Birchard

Founder, Ray Blair

CPE&CN is published bi-monthly by: Annex Buiness Media

111 Gordon Baker Rd, Suite 400, Toronto, ON M2H 3R1

T: 416-442-5600 F: 416-442-2230

© All materials in this publication are copyright protected and the property of Annex Business Media., the publishers of Canadian Process Equipment & Control News magazine.

For permission on reprinting or reproducing any materials, e-mail your requests to cpe@cpecn.com

Canadian Postmaster send address corrections to: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Canadian Process Equipment & Control News assumes no responsibility for the validity of claims in items reported.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2384

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 0318-0859

SUBSCRIPTION

(Plus

Emerson has launched its new ASCO series 262 and 263 biodiesel valves, said to be the first combustion valves certified for use with biodiesel blended fuel in industrial and commercial boilers in the Americas and Asia. The biodiesel valves make it possible for district heating and commercial boiler burner applications to transition to a more sustainable energy source, the company says, simplifying compliance with evolving regulations while reducing boiler users’ greenhouse gas (GHG) emissions and carbon footprints. Underwriters’ Laboratories (UL) recently updated its oil burner standard, UL 428B, to include biodiesel blends up to 20% (B20). Series 262 and 263 valves feature an elastomer that is compatible with B20 and are certified under UL 428B.

Emerson

Pepperl+Fuchs has just released the new KCD2-SCS-EX2, said to be the first 2-channel, dual-function AI/AO intrinsic safety barrier in a compact 12.5 mm housing. The two channels of the KCD2SCS series interface modules can be configured individually for analog input or analog output control signals. Units are also HART compatible and can function as output drivers for SMART valve positioners or as a power supply for SMART 2-wire transmitters. For analog input signals, the control side can be operated either as a current source or current sink via selectable DIP switches on the front panel. The KCD2-SCS-EX2 can be used for hazardous area applications (approved to ATEX, IECEx, and UL). A version for non-Ex signal conditioning in safe area applications is also available. The modules are also suitable for applications up to SIL 2 (SC3) according to

IEC61508 ed2 (TÜV Rheinland). Pepperl+Fuchs

www.pepperl-fuchs.com

The configurable ball valve unit KV2B from Festo can be actuated automatically a pneumatic quarter turn actuator, or manually using a hand lever. EX certification of II 2GD provides ATEX category for gas II 2G, type of ignition protection for gas c T6 … T3 X, ATEX category for dust II 2D, type of ignition protection for

dust c T80 °C … T200 °C X, and explosion-proof ambient temperature rating 0°C ≤ Ta ≤60°C. In controlled mode, the required position of the process valve is specified via an analog positioning signal, e.g., 4 to 20 mA, while in the open/closed mode, the process valve is moved into both end positions.

Festo Canada

www.festo.ca

By Jeff DeWitt

Repairing gas pressure control panels can be complicated by how the pipes are laid out. Poor design could result in systems that are more prone to damage. In addition, maintaining older gas panels can be time consuming, labor intensive, and costly (Figure 1). Facilities that require gas systems to function — like food and beverage operations, wastewater treatment plants, chemical plants, and others — must be able to depend on those systems. That is why you should consider updating your gas pressure control panels to help reduce downtime and lower maintenance costs.

Historically, gas panel design has not always been straightforward. Systems designed without careful attention to details can leave safety relief valves and regulators accidentally obscured by enclosures. Alternately, extensive tubing — which requires disassembly and reassembly for maintenance to be done — also increases the possibility of unintentional damage or restricted access during repairs.

These complicating factors can confuse maintenance technicians, slowing down the repair process. Long repair times can also result in unplanned downtime or potential safety risks to employees. One way to avoid these distractions is to update your gas panels with more contemporary designs.

Modern gas panels can eliminate some of those problems by improving component

visibility and labeling, particularly for components that may need frequent maintenance like regulators and pressure valves (Figure 2). In addition, many of today’s panels are designed with component replacement in mind. Their modular designs mean technicians can quickly and easily replace faulty parts without taking the entire panel out of service (Figure 3). Be sure to work with a supplier that can help evaluate your system’s specific needs

and make recommendations about what panels will work best for your situation.

It is traditional to use threaded connections between components in your gas panels. The challenge with these more complex connections is that there is a greater chance they may fail prematurely or be accidentally damaged. To reduce this possibility, tube fittings may be a

better solution.

Tube fittings are more effective at stopping small, unnoticed leaks that can increase production costs over time. Moreover, small leaks can also pose significant safety issues for workers near the leaks.

Unfortunately, small leaks can go undetected for long periods. Plant operators often have other priorities to keep the production line performing well and may not have time to check the gas distribution system for leaks. As a result, small leaks do not receive the attention they need to keep them from happening. Choosing high-quality tube fittings can prevent troublesome leaks with reliable, leak-tight performance throughout the system. Facilities should partner with reputable suppliers who can inspect your system on an ongoing basis. Through these regular audits, they may be able to provide actionable insights into where improvements can be made.

Choosing high-quality components for your gas panels and distribution systems can lower maintenance costs over the life of the system by reducing leaks and potential system failures. For example, tradition suggests regulators should be replaced on a rigid five-year schedule. Since this is standard industry practice, most plant operators do not question why they must replace their regulators that often, even considering the significant disruptions that occur when a gas distribution system must be shut down for repairs.

The expected five-year replacement schedule may not be necessary if higher-quality regulators are used. Typically, plant operators should seek regulators that have undergone rigorous testing — including millions of production cycles — before they ever reach your plant floor (Figure 4). If these regulators are used, it could eliminate the need to replace them at all, which lowers labour costs and keeps your facility working at peak performance.

As you evaluate your oil and gas, food and beverage, pulp and paper, chemical, or wastewater treatment facilities, improving your gas panels can provide significant savings and improved efficiencies throughout the distribution

system. Modern gas distribution panels need less ongoing maintenance, allowing facilities to save money on labour-reduced system downtime. The return on investment for modern gas panels is significant, so you should prioritize updating your gas panel systems.

Jeff DeWitt is an Applications Engineer for Swagelok Company. The original version of this article appeared on the Swagelok Reference Point blog here: www.swagelok.com/en/ blog/gas-panels-distribution-systems#. Swagelok Company www.swagelok.com

By John Bernet

The past several years has brought massive change for manufacturing — with the COVID-19 pandemic both creating new challenges and exacerbating existing challenges. Most recently, one of the biggest challenges has been a shortage of skilled labour that has left many employers scrambling to fill open roles. The shortage has been driven by multiple factors, including the overall job market, wage stagnation, burnout, and more.

The question for organizations is not only how they can overcome hurdles and maintain business continuity in this worker’s economy, but also how they will position themselves advantageously for the future.

First, businesses need to understand why there a worker shortage.

The worker shortage first appeared in low-wage jobs like fastfood service and manual labor. These front-line workers were hit hardest by the pandemic, driving many to seek alternative career paths, including what’s become known as “gig” work, to gain more control over their health and livelihoods.

This trend spread like wildfire across almost every industry, leading to an unprecedented shakeup of the worldwide labour market. Overall, employees have become burnt out for various reasons and more apt to prioritize their health and wellness over a particular job. It’s a complex crisis, and one that’s still shifting with the evolving economic state. However, there are many ways to bridge employee shortages using Industrial Internet of Things (IIoT) technology.

The industrial space is feeling the impact of the labour gap. Skilled tradespeople were already in high demand before the pandemic, and that gap has only worsened as knowledge is actively walking

out the doors. In addition, with fewer employees, keeping up with standard preventive maintenance tasks has become a challenge in and of itself, forcing some organizations to all but abandon their journey toward predictive maintenance. However, the connected reliability technologies that drive predictive maintenance are actually key to solving today’s labour shortage challenges.

What is connected reliability?

Connected reliability means that there is a continuous and effective stream of communication between all systems, assets, and people. It means that your critical assets are connected to the cloud via devices that collect comprehensive data on asset health, runtimes, and performance. Workers can then use that data and insight to make smart decisions and focus their maintenance efforts where they are needed most—avoiding unnecessary busy work and making the most of the resources available.

Connected reliability makes the data available and usable for your team to act on the findings in the most productive and efficient way. Connected reliability also means that workers can leverage existing data in new ways. For example, with a condition monitoring service, external experts can remotely monitor assets and identify faults

average time to repair an asset after failure. Long repair times significantly impact a business’s bottom line, translating into missed orders or objectives. Managers can use MTTR to determine minimum staffing, inventory, and repair/replace requirements. While MTTR may not solve worker gaps, it will help you find its impact on your organization.

prior to a failure, so your team can focus on the easy-to-resolve challenges before they turn into more complex repairs—or worse catastrophic failures. In other words, IIoT technology gives your team the ability to work smarter and more effectively, even with fewer workers available. Many IIoT technologies are also easy to use and interpret, even without extensive training and experience.

Backlog accumulation often goes hand in hand with worker shortages. The longer work goes uncomplete, the most your maintenance backlog piles up and the higher the risk of costly failures or safety issues. Therefore, maintaining control over your backlog is critical to safe, smooth operations.

With the data from IIoT, you can more effectively track your maintenance KPIs, prioritize work orders based on criticality, and assign tasks according to the skills and experience of your current employees. Even with worker shortage issues, this will slowly but surely help you regain control of your backlogs.

Mean Time To repair, or MTTR, is one of the most important metrics to track as you get a handle on your backlog. MTTR is a maintenance metric that calculates the

Finally, it goes without saying that tracking work order completion rates is a must during normal operations, but even more so during labour shortages. Connected reliability can help by freeing workers from routine measurement-taking activities and giving them the time back to complete maintenance jobs.

Condition monitoring devices installed on the right assets throughout your facility can give you real-time visibility into asset health and performance without requiring time-consuming and error-prone manual measurements. For example, wireless vibration sensors can detect early signs of failure in your rotating equipment. This not only offloads routine measurement from your team’s workload, but it also gives you plenty of advance warning to plan and schedule maintenance before a failure occurs. Another example of condition monitoring is thermal and acoustic cameras, which can detect leaks, insulation gaps, electrical buildup, and other failure-causing issues quickly without the need for highly specialized staff.

With the help of continuous remote condition monitoring, organizations can send technicians to work on jobs, not measurements.

John Bernet is a mechanical application and product specialist at Fluke Corp. He holds a Category II Vibration Analyst certification and is a Certified Maintenance Reliability Professional (CMRP). Fluke Corporation www.fluke.com

Alpha Controls & Instrumentation has announced that Particle Measuring Systems (PMS) has introduced the latest in its line of Lasair airborne particle counters. The Lasair Pro is said to support a complete contamination control solution including clean area monitoring (portable and remote) while meeting global requirements for data integrity. Designed for intuitive and reliable aerosol particle counting, the company says, this addition to the PMS fleet supports a variety of applications while meeting, and anticipating future, international cleanroom certification standards. The programmable unit can store up to 10,000 data samples and the collected data is securely saved and transferred meeting data integrity related standards such as FDA 21 CFR Part 11 and EU GMP Annex 11. Additionally, operators can securely configure up to 100 users on each instrument or use the NFC card capabilities for unlimited users.

Alpha Controls & Instrumentation

www.alphacontrols.com

AutomationDirect has added frequency signal conditioners from ProSense. The SCU-2200 universal analog-to-frequency converters accept mA, voltage, RTD, thermocouple, or potentiometer inputs and provide a scalable single-frequency output (up to 25 kHz). The units are said to be helpful when a controller does not have any analog input points available but does have a frequency input. The SCU-2500 series frequency (input) conditioners are useful for converting frequency sig-

nals from encoders, magnetic pick-ups, variable speed drives, and flow meters to an analog signal for a PLC, recorder, or digital display. The devices accept frequency signals up to 100 kHz and provide unipolar or bipolar analog, relay, or frequency (up to 100 kHz) outputs. An optional square root relationship between the input and output is also available for flow measurement applications.

AutomationDirect

www.automationdirect.com

The Kobold liquid level switch NWS is designed as a 2-and 3-wire switch and can be universally used in tanks and pipelines. The switch operates on the tuning fork principle in air at resonance frequency. A piezoelectric crystal is used for excitation of oscillations and for monitoring the actual oscillation frequency. When the fork is immersed in liquid, the frequency changes: this change is detected electronically, and the output signal is changed. The unit operates as a 2-wire switch in series with the load. The simple electronic switch is operated by the liquid. The device can also be connected to a PLC and has an output state indicator with an LED that can be seen though a lens in the cover. The LED flashes about once a second when the unit has switched off and is permanently illuminated when it is switched on.

Kobold

www.kobold.ca

The Busworks NT series from Acromag permits expansion I/O modules for what is said to be a high-density, cost-efficient remote I/O solution. Base unit NTE Ethernet models handle the network communication and interface up to 16 analog or digital I/O channels for remote monitoring or control applications. NTX Expansion models provide a way to add a mix of I/O signal types under a single IP address. The NTE Ethernet I/O modules are pre-programmed to support Modbus/TCP, Ethernet/IP and Profinet protocols. Modules also support direct i2o peer-to-peer communication without a controller. Link up to three NTX expansion I/O modules to an NTE Ethernet I/O module over the integrated DIN rail I/O bus connectors. Users can also connect NTE Ethernet I/O modules with a daisy-chain topology using the internal dual-port switch to simplify network cabling, as well as have a built-in web server for convenient configuration without installing any software.

Acromag

www.acromag.com

The Berthed LB 571 microwave resonator for online measurement of moisture content in bulk materials is based on the resonance technology. This technique is determined by electromagnetic waves (microwaves) in a dielectric cylindrical resonator. The sensor with integrated

signal processing unit can be used for a wide range of bulk materials in a moisture range of between 0 and 30%. The parts in contact with the media are made of ceramic or stainless steel and the electronic housing is made of aluminum, making the unit suitable for use in the food industry. Calibration is carried out directly on site, conveniently and quickly using the supplied PC software, the company says. The online determination of the moisture during the active process allows for a reduction in production costs through continuous quality monitoring, it adds, for example by reducing energy consumption in drying processes and by reducing the number of rejects.

Berthold

www.berthold.com

Softwall clean rooms introduced by HEMCO are designed to meet ISO 5 –ISO 8 requirements and feature a flexible design that allows them to locate over and around equipment, with the option of being mobile with casters. The structural framework is of aircraft anodized aluminum with clear vinyl curtains around the unit. The curtains can be strips or solid depending on restriction of access in clear or opaque white vinyl. Fan powered HEPA filter and fluorescent lighting modules along with blank ceiling tiles are positioned into a ceiling grid system and optional entry airlocks can be incorporated into the design. The HEPA filter modules have power cords and speed controls and can operate on 115 or 220 Vac power.

HEMCO

www.hemcocorp.com

Q.E.D Environmental Systems has announced the En Core Sampler, which collects, stores, and delivers soil samples within a single, easy-touse device. The disposable volumetric sampling device was developed to empower field personnel to take soil samples with minimal handling and maximum accuracy, the company says. The one-use, self-contained, inert composite polymer sampling cassette is suitable for airtight sample collection and sealing. The airtight sealing cap prevents the loss of volatiles as the sampler becomes its own self-contained package. This is said to allow the sampler to ensure accuracy when identifying the types and concentrations of volatile organic compounds (VOCs) in soils and solid materials via a closed-system purge-and-trap process. Available in 5 and 25 g options, the disposable sampler can serve in a variety of applications. It also comes with a reusable, 4.5 in. long stainless steel En Core T-handle that allows the handler to push the sampler into the soil for a measured soil sample.

Q.E.D. Environmental Systems

www.qedenv.com

The TOPLINE single bag filter system from Eaton has a 316 stainless steel housing with a top inlet design that is said to require less headroom and directs liquid flow through the cover to improve sealing, reduce product loss, and makes filter bag change-outs cleaner. Applications that require the installation of gauges, vents or pressurized air connections are accommodated by two ¼ in. NPT threaded cover taps. A smooth, bead blasted finish, coupled with unit’s minimum weld design, makes it easy to completely clean the interior of the vessel, the company says. All vessels have an ASME Code Stamp. The filter system is suitable for industries such as food and beverage, chemical processing, paints, inks, resins and coatings, petrochemicals, municipal and industrial water treatment, pulp and paper, and pharmaceuticals. Eaton www.eaton.com/ca/

GF Piping Systems has expanded upon its extreme chemical line of SYGEF fluoropolymer piping solutions with the ECTFE product line of pipes, fittings, and the necessary joining technology. When materials such as PP, PE, CPVC, PVC or PVDF have reached their limits with aggressive chemicals, the line is the most effective option, the company says. The high chemical resistance of the product line allows it to safely transport bases and highly concentrated acids, even when pH values are lower than 2 or higher than 12. The product line’s mechanical properties allow it to handle pressures up to 150 psi and temperatures up to 176°F when transporting aggressive chemicals. Installation is up to 85% faster than for a comparable system of lined steel, the company says, and initial costs for an ECTFE system are typically 50% lower than they would be for IR-welded PFA. GF Piping Systems www.gfps.com

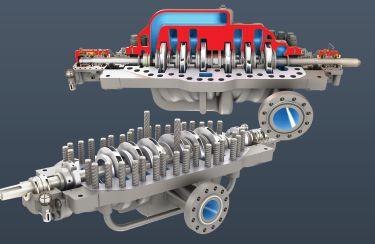

The Flowserve DMX multistage, axially split pump is compliant with API 610 (BB3) and engineered for long-lasting performance in high-pressure, heavy-duty applications. Its comprehensive hydraulic range, along with numerous materials, bearings, and lubrication options, are said to allow for precise selection to ensure the best hydraulic fit, high operating efficiency, and stability for each application. The pump is suitable for applications involving high-flow, high-pressure movement of water, hydrocarbons, CO2, and other process liquids.

It is suitable for use in refinery process, pipeline, boiler feed water and amine services. Flowserve www.flowserve.com

The Ralston LC20 Field Gauge with FieldLab Mobile App gives you the freedom monitor and log pressure remotely from your phone or tablet with lab-grade accuracy.

• Control and monitor via Bluetooth on a mobile device

• Log pressure at custom intervals with streamlined data collection

• Monitor readings from a safe distance in hazardous or difficult-to-reach areas

• Instantly share data logs over email, network drives or text

• Available in vacuum and pressure ranges up to 30,000 psi / 200 MPa

In industry, gas-fired boilers have largely been the standard for many decades to produce steam as well as heat process water. However, not all boilers are created equal in terms of safety. By definition, combustion-fueled boilers can emit harmful vapours, leak gas, and even cause explosions and fires.

In a recent example, a natural gas boiler was cited as the cause of a massive explosion and fire at a food processing plant in eastern Oregon that injured six and caused severe damage to the facility’s main building. Given the risks, many processors are turning to a new generation of electric boilers to dramatically reduce these hazards.

“With gas burning boilers, any gas leak can increase the risk of an explosion wherever there are fuel lines, fumes, flames, or storage tanks. So, gas units must be continually monitored or periodically inspected,” says Robert Presser, VP of Acme Engineering Products, who notes that state and municipal safety guidelines vary depending on boiler type and the expected frequency of inspection. Acme Engineering is a North American manufacturer of boilers for large industrial and commercial applications. The company is an ISO 9001:2015 certified manufacturer of environmental controls and systems with integrated mechanical, electrical and electronic capabilities.

In gas-fired boilers, explosions can result in the ignition and instantaneous combustion of highly flammable gas, vapour, or dust that has accumulated in a boiler. The force of the explosion is often much greater than the boiler combustion chamber can withstand.

Minor explosions, known as flarebacks or blowbacks, can also suddenly blow flames many feet from firing doors and observation ports, seriously burning anyone in the path of a flame.

Natural gas-fired boiler emissions also pose potential hazards in the form of emissions. This can include nitrogen oxides (NOx), carbon monoxide (CO), nitrous oxide (N2O), volatile organic compounds (VOCs), sulfur dioxide (SO2), and particulate matter (PM), as well as the greenhouse gasses carbon dioxide (CO2) and methane (CH4), which accelerate global warming.

In addition, fossil fuel burning boilers can also face potentially dangerous operational issues stemming from excessive heat accumulation, particularly if the water is too low in the system to properly absorb the heat. High heat conditions can compromise the boiler,

electrodes, and other equipment essential to operation.

To dramatically improve operator and environmental safety, industry is turning toward modern electric boilers that eliminate many of these risks. The most advanced electrode boilers not only match the capacity of large gas or oil-fired boilers but are safer and more compact, maximizing energy efficiency, improving reliability, and minimizing maintenance.

Although many facility engineers are familiar with gas-fired boilers, many believe that electric boilers cannot match the output of the traditional, fossil fuel burning units. Due to considerable advances in electric boiler technology, however, such technology can now match the capacity of large gas or oil-fired boilers in a much smaller footprint.

Presser explains that electric boilers utilize the conductive and resistive properties of water to carry electric current and generate steam. An A.C. current flows from an electrode of one phase to ground using the water as a conductor. Since chemicals in the water provide conductivity, the current flow generates heat directly in the water itself. The more current (amps) that flows, the more heat (BTUs) is generated, and the more steam produced.

As an example, in Acme’s CEJS High Voltage Electrode Steam Boiler, almost 100% of the

electrical energy is converted into heat with no stack or heat transfer losses. The electrodes of the jet type electrode steam boiler are vertically mounted around the inside of the pressure vessel. This enables the unit to produce maximum amounts of steam in a minimum amount of floor space, with boiler capacity from 6 to 52 MW. Operating at existing distribution voltages, 4.16 to 25 KV with up to 99.9% efficiency, the boiler can produce up to 170,000 pounds of steam per hour. With pressure ratings from 105 to 500 psig, the boilers are designed to ASME Section 1, and are certified, registered pressure vessels at the location of the boiler.

“With the jet type electrode boilers, there are no combustion hazards because there are no flames, fumes, fuel lines or storage tanks, which minimizes the risk of explosions and fires,” says Presser. In case of an electrical short, the breaker that protects the high voltage circuit trips in a matter of milliseconds, protecting the boiler and the electrical network. There is no chance of electrical mishap or fire from the boiler.

Since the design does not rely on combustion, it does not create emissions that would endanger the operator or environment. In addition, the design eliminates many environmental issues associated with fuel burning boilers such as fuel fumes, fly ash, and large

obtrusive exhaust stacks.

The approach resolves safety issues related to potentially excessive heat accumulation with the system as well. Low water protection is absolute since the absence of water prevents current from flowing and the electrode boiler from producing steam. Unlike conventional electric boilers or fossil fuel boilers, nothing in the electrode boiler is at a higher temperature than the water itself. This prevents the risk of dangerous heat buildup in the boiler, electrodes, and other important components even if scaling should occur, and thermal shock is eliminated.

“Electric boilers, and specifically the electrode units, are inherently the safest boiler design today. These units do not need an operator because if anything goes wrong, the breaker trips, preventing further escalation of the issue,” explains Presser.

The electric boilers also improve safety by reducing industrial noise, which is a CCOHS regulated issue. Under CCOHS’s Noise Exposure Limits, the employer must lower noise exposure through engineering controls, administrative controls, or Hearing Protection Devices (HPDs) to attenuate the occupational noise received by the employee’s ears to within levels specified.

In this regard, the electric units are also exceptionally quiet compared to fuel fired boilers. “Unlike gas-powered burners that throttle like turbine engines almost continually, electric boilers keep operational noise levels down,” says Presser. “Because the loudest boiler component is a circulating pump motor, you can have a conversation next to one without the need to elevate your voice.”

While safety of the electrode units is superior, there are also significant benefits in terms of reliability and maintenance. The absence of excessive temperatures and burnout assures longer operating life. The boilers have a minimum number of components and electrical controls. With no fuel residues, along with fewer parts and simple control systems, cleaning and maintenance requirements are reduced, and reliability is enhanced.

Processors have long sought to improve safety, yet options have been limited. Now, as safer, more energy-efficient alternatives become more widely available in the form of state-ofthe-art electrode boilers, companies can protect their people and processes more completely while minimizing required maintenance.

This article was contributed by Acme Engineering. For more info, contact Robert Presser at Acme Engineering at rpresser@ acmeprod.com or (888) 880-5323.

Acme Engineering www.acmeprod.com

ASHRAE will award a total of $163,000 for 2023-24 academic year to fund 34 projects through ASHRAE Undergraduate Program Equipment. Three Canadian institutions have been announced as recipients: “Novel Phase Change Material (PCM) Ventilation System,” Concordia University, Montreal; “Building Materials and Their Thermal Properties,” University of Alberta, Edmonton; and “Plug and Play Potable Heat Exchanger with BMS,” University of Regina

The ASHRAE Undergraduate Program Equipment Grants provides grants to engineering, technical and architectural schools worldwide. Its goal is to increase student knowledge, learning and awareness of the HVAC&R industry through the design and construction of senior projects. Grants are used to fund equipment and supplies from one academic term up to one year.

For more information about the program, please visit ashrae.org/ grants.

ASHRAE www.ashrae.org

Celanese Corporation, a global specialty materials and chemical company, has announced the completion of an ultra-low capital project to repurpose existing manufacturing and infrastructure assets to unlock additional ethylene vinyl acetate (EVA) capacity at its Edmonton facility. The expansion supports significant growth in the Acetyl Chain’s downstream vinyls portfolio.

The expansion provides approximately 35 percent incremental EVA capacity starting in the first quarter of 2023.

The Acetyl Chain’s reactor capabilities and unique footprint allow for a more customized approach to product manufacturing with the flexibility to produce a full range of EVA products to serve demand in growing solar applications, wire and cables, food packaging, medical

devices, and drug delivery solutions. Celanese EVA products are sold under the product names including Ateva EVA and Ateva G Medical Grade.

Celanese Corporation www.celanese.com

Emerson of St. Louis, MO, and Austin, TX-based NI (National Instruments) have announced that they have entered into a definitive agreement under which Emerson will acquire NI for US$8.2 billion. Emerson already owns approximately 2% of shares outstanding in NI.

NI provides software-connected automated test and measurement systems designed to bring materials and products to market faster and at a lower cost, the companies say.

The transaction is expected to close in the first half of Emerson’s fiscal 2024, subject to the completion of customary closing conditions, including regulatory approvals and approval by NI shareholders.

Emerson www.emerson.com

National Instruments www.ni.com

Fluor has announced that it was awarded a reimbursable contract by Dow to provide front-end engineering and design (FEED) and engineering, procurement, and construction management (EPCM) services for the world’s first net-zero carbon emissions (scope 1 and 2 carbon dioxide emissions) ethylene cracker and derivatives complex in Fort Saskatchewan, AB.

Fluor will book the initial FEED award in the first quarter and anticipates the additional EPCM scope will be awarded throughout 2023 pending a final investment decision by Dow’s board of directors.

Dow’s net-zero emissions ethylene cracker and derivatives complex, which is subject to approval by Dow’s board of directors and various regulatory agencies, would decarbonize approximately 20 percent of its global ethylene capacity while growing its polyethylene supply by about 15 percent by 2030.

The additional project scope to be awarded in 2023 includes integrated project management team services for the entire Fort Saskatchewan Path2Zero program and EPCM services for the ethane cracker and associated utilities, power, and infrastructure.

Dow www.dow.com

Fluor www.fluor.com

Chicago-based United Airlines has announced an $5 million investment in carbon capture technology company Svante, who provides materials and technology with the potential to convert CO2 removed from the atmosphere and from industrial emission sources into sustainable aviation fuel (SAF).

This investment will fund and support Svante’s commercial-scale filter manufacturing facility in Vancouver. Svante is working with organizations around the world, including Dimensional Energy, a carbon utilization — CO2 to jet fuel — company that UAV (United Airlines Ventures) invested in last year.

Svante’s manufacturing facility is anticipated to produce enough filter modules to capture millions of tons of carbon dioxide per year across hundreds of large-scale carbon capture facilities.

SAF is an alternative to conventional jet fuel that, on a lifecycle basis, reduces GHG emissions associated with air travel compared to conventional jet fuel alone. SAF is made from used cooking oil and agricultural waste, and, in the future, could be made from other feedstocks, including household trash, forest waste, or compressed CO2, the end product of Svante’s carbon capture process. Svante

https://svanteinc.com/

Thermo-Kinetics of Mississauga, ON, has announced two regional manager appointments.

Adam Dello, a third generation member of the Dello family, the family who founded Thermo-Kinetics, has been promoted to central region manager in Canada, while Normand Bellisario has been named national sales manager.

In his new role, Adam will be responsible for overseeing Thermo-Kinetics’ operations in the central region of Canada, including sales, service, and support.

For over 50 years, Thermo-Kinetics has manufactured TK brand process and control measurement products and maintained exclusive distribution partnerships with brands such as Honeywell and Krohne. Thermo-Kinetics https://thermo-kinetics.com

Ingersoll Rand of Davidson, NC, has announced that it is partnering with HD Compression, headquartered in Montreal.

Ingersoll-HD-news-print.psd Al Giffen, president of HD Compression.

HD Compression will offer reciprocating, rotary and centrifugal compressors along with a full suite of Ingersoll Rand’s air treatment equipment, replacement parts and CARE offerings in the province of Quebec.

HD Compression is led by long-time Ingersoll Rand employee, Al Giffen, who is now president of HD Compression. Customers will also have the full support of Ingersoll Rand, its products and resources. Ingersoll Rand www.ingersollrand.com HD Compression www.hdcompression.com

Bellisario, an integral team member for over three decades, will oversee Thermo-Kinetics’ national sales operations, focusing on expanding our customer base, cultivating strategic partnerships, and driving revenue growth across all regions.

The bulk bag filler with wooden pallet dispenser from Best Process Solutions automatically places an empty pallet under a bulk bag before filling. Between 14 to 16 pallets can be loaded for staging into the pallet dispenser. Controls automatically remove the bottom pallet from the stack and place it below the bulk bag before filling occurs. Once the bulk bag is filled, a power roller discharges the filled bulk bag and pallet onto an accumulation conveyor (not shown) for transport to warehouse. The wooden pallet dispenser reduces the need for an operator to place an empty pallet under each bag, thus reducing the operators needed to maintain a high bag filling rate.

Best Process Solutions www.bpsvibes.com

VR Series vibrating rods from BinMaster feature a unique, sword-shaped blade said to encourage material to flow by it easily to resist buildup and false alarms. The single rod design prevents bridging that can be associated with tuning fork designs, the company says. The sensor is appropriate for materials such as Styrofoam, plastic pellets, sawdust, carbon black, chalk, and flour that can be hard to measure. A switch on the sensor board inside the housing of the VR-21, -31, -41, and -51 has three sensitivity settings: high sensitivity for extremely light or fluffy materials with a low dielectric constant; medium sensitivity is used for a broad range of materials and applications; and low sensitivity for materials that might tend to cling to the blade or heavy materials. The standard VR-21, rigid extended VR-41, and flexible extended VR-51 are available with optional CSA hazardous location approvals. The VR-90 and VF-90 can be made for ATEX, FM, and CSA Class I environments. BinMaster www.binmaster.com

Automation Products, Inc., has introduced the Dynatrol DJ level switch for bulk solids factory direct to a variety of industries. The units are suitable for the chemical, food, or plastic Industries for high-, mid-or low-point level detection on materials ranging from low-density flakes and powders, to heavy granular and pellets. The detectors are constructed with no moving parts, gaskets, or seals to deteriorate. The detectors are factory calibrated with no field adjustments required before installation. They provide dependable operation in dusty environments and in vessels equipped with vibrators. Specialized units can be used with temperatures in excess of 300°F. Automation Products, Inc. www.dynatrolusa.com

Series A maintenance gates from Lorenz Products are available in square gate or round gate configurations. The units mount above airlocks or below bins and hoppers for periodic shutdown/maintenance applications. The polymer lined gates are hand crank actuated for vacuum, dilute phase pressure or gravity systems. The square gate model has 304 stainless steel and polymer contact points, and a stainless steel blade, while the round gate has 304 stainless steel, polymer, and aluminum contact points. Lorenz Products www.lorenz.ca

ILME SQUICH push-down inserts from ITC Electrical Components are said to provide easy quick-connect solutions for a variety of industrial machinery in rugged industrial environments. With the SQUICH push-down technology, no tool is required to install solid and or stranded wires (up to 14 AWG) to the contacts in the connector. Safety is assured as the connection system is resistant to vibration and is suitable for any wire type, the company says.

ITC Electrical Components www.itcproducts.com

Rockwell Automation has announced the release of FLEXHA 5000 I/O products that offer high availability and continued evolution of the PlantPAx Distributed Control System (DCS).

Process customers will see more flexibility and reliability, the company says, enabling integrated control for their Connected Enterprise production system, while decreasing total cost of ownership and enhancing productivity through reduced downtime and time to engineer. The new FLEXHA 5000 input/output (I/O) module, is an I/O platform said to help reduce hardware complexity and cost by using a more conveniently integrated design. The modules provide 1 Gb EtherNet/IP network connectivity and are designed to reduce both downtime and engineering time while limiting costs.

Rockwell Automation www.rockwellautomation.com

The magnetic flowmeters CA series from Yokogawa can measure fluids that are difficult to measure with other magnetic flowmeters. For example, high-concentration slurry fluids, insulator-adhesive fluids, and ultra-low-conductivity fluids, the company says. In addition, the series is designed with the company’s Total Insight transmitter concept. The display provides good visibility due to its dot matrix and backlight. Also, if the verification function is used, equipment status can be checked and diagnosed equipment. The CA series is the successor to the ADMAG CA series, with the sensor structure inheriting the structure of ADMAG CA. The CA series electrode is structured so that it does not contact the highly concentrated slurry fluid. Therefore, electrical noise generated by contact between the slurry and the electrode is not physically generated, the company explains. Yokogawa www.yokogawa.com

Ralston Instruments has introduced the Bluetooth-equipped Field Gauge LC20, a reference-grade data logging pressure gauge said to give users the freedom to monitor and log pressure from a safe distance, even in dangerous or difficult-to-reach areas. Use the company’s FieldLab Mobile App to initiate pressure logging and monitor readings remotely from a mobile phone or tablet from up to 30 m. Control and monitor multiple gauges at the same time, in real time, can easily share pressure data over email, network drives, or text message.

Ralston Instruments

https://ralstoninst.com/ippt-LC20BL

Alfa Laval ThinkTop V20 hygienic valve indication units for process industries have IO-Link interface capability. The valve is maintenance-free and does not require manual adjustment or programming, the company says. It enables 360° LED visual status indication from all directions. It also provides convenient control-room monitoring of the real-time status of the company’s hygienic valves used across the dairy, food, beverage, home and personal care, biotechnology, pharmaceutical, and other industries.

Alfa Laval

www.alfalaval.com/thinktop-v20

Conveyor Components Company has announced the Mag-Neat-O, a self-contained motion control device that magnetically couples to the end shaft of the tail pulley and indicates when a conveyor belt has slowed or quit moving altogether. The pulse output of the product can be wired into a PLC or DCS, which can easily determine under speed, overspeed or zero speed of the conveyor, the company says. The motion control device can shut down rotating equipment before severe damage is encountered as it provides protection for interlocked conveyor belts, especially if one of the belts fails due to overloading or quits due to conveyor belt tearing/separation. The standard construction is a chemical and impact resistant polymer material, with stainless steel internal parts. The main advantage of the device is that no drilling or tapping of the tail pulley shaft is required, as the unit is held in place with a strong magnetic connector on any non-driven pulley shaft. Conveyor Components Company www.conveyorcomponents.com

The VACON NXP Air Cooled drive from Danfoss is said to provide optimized motor control for both induction and permanent magnet motors, and gearless drive applications and paralleling solutions for high-power motors. The air cooled drives offer precision and power to applications that require a robust and dynamic performance, the company says. Available in a complete power range up to 2 MW, units are provided as wall-mounted, standalone enclosed and IP00 modules. Fast fieldbus options and programming flexibility ensure the drives are easily integrated into any plant’s automation system, it adds.

Danfoss

www.danfoss.com

Sabo Industrial Corp., a manufacturer, distributor and integrator of industrial waste treatment equipment and solutions, including batch and fully automated systems, has introduced Cleartreat separating agents, bag filters, and accessories. The systems are said to not only reliably meet regulatory wastewater requirements, but also significantly reduce the cost of treatment, labour, and disposal when the proper separating agents are also used. The company uses a special type of bentonite clay in this line of wastewater treatment chemicals. The separating agent chemicals are formulated to break oil and water emulsion, provide heavy metals removal, and promote flocculation, agglomeration and suspended solids removal. Sabo Industrial http://saboindustrial.com

With the new wash-down vacuum pumps DV 650 and DV 800 FP-r of the established, dry-running DRYVAC series, Leybold has developed two models that facilitate production, increase food safety, and extend the shelf life of foodstuffs. The compact screw vacuum pumps are said to offer a low noise level to enable uncomplicated, near-machine installation in the immediate vicinity of the production line. The advantage for users: during daily cleaning of the system, the pumps can be washed down with the production equipment in one process. The DV 650 and DV 800 FP-r models are equipped with a frequency converter for easy monitoring and control, the company says. Units are also said to provide a high tolerance to vapour, liquid slugs, and soft particles thanks to the implementation of the dry screw principle. Leybold www.leybold.com

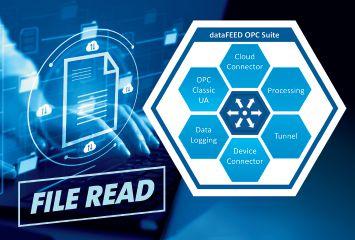

The new “File Read” function of dataFEED OPC Suite Extended V5.25 from Softing Industrial enables access to process data available via XML files. The suite is said to be an all-in-one solution for OPC communication and cloud connectivity, providing access to controllers and IoT devices of leading manufacturers. With the new File Read functionality, the company says, the suite ensures access to brownfield PLCs, devices and machines that deliver data via XML files. File Read allows process values from XML files to be integrated quickly and securely into production control applications such as MES or OEE via the standard OPC Classic or OPC UA interfaces, it adds. The production data can also be integrated into IIoT cloud solutions via MQTT or REST. The suite enables access to the controllers of manufacturers such as Siemens SIMATIC S7, Rockwell ControlLogix, B&R, Mitsubishi as well as Modbus controllers. Softing Industrial https://industrial.softing.com

In response to growing demand for flexibility in process water treatment, Marmon Industrial Water has introduced Graver mPowdex condensate polishing trailers. As the first precoat filter demineralizer on wheels, the company says, the mPowdex system will allow plants to reuse and recover steam condensate on an as-needed basis, providing water, energy, and capital savings across manufacturing sectors, including power generation, refining and petrochemical applications. The system is a precoat filter demineralizer that combines ion exchange and filtration to remove solid and dissolved particulates, such as iron and copper, from high value process steam. By removing these contaminants, it is said to protect generation assets, such as turbines and deaerators, and maximize plant uptime. Marmon Industrial Water www.marmonindustrialwater.com/mpowdex

DENIOS-US has introduced the Falcon Funnel Model XL for what is said to be the fast, safe, and efficient refilling of IBC totes. Constructed of polyethylene, the model XL is said to be easily fitted to a standard IBC tote and includes a storage pocket for IBC locking lid, and a discharge basin with side storage areas. Liquids run off the domed base and through a large, 6-in. drain opening. Each unit includes an integral 2-inch connection for an optional level indicator. The model is approximately 31 x 29 x 7 in. and has a 4-gallon capacity.

DENIOS

www.denios-us.com

accommodate a wider range of chemical purification applications for rCPC, RotaChrom offers custom modifications, all while maintaining regulatory requirements.

RotaChrom

www.rotachrom.com

A new Mobile Tilt-down Flexible Screw Conveyor from Flexicon is said to fit restrictive processing situations and offers a low centre of gravity and full accessibility from standing height. Positioning of the support boom against and parallel to the conveyor tube minimizes the height needed to maneuver the system under doorways and mezzanines, and to fit the conveyor’s discharge between process equipment inlets and overhead obstructions. A low centre of gravity maximizes stability during operation and when rolling the unit between multiple processing tasks and wash down stations, the company says. When fully lowered, the tilt-down mechanism positions the clean-out cap of the conveyor tube higher off the plant floor, and the conveyor’s discharge closer to the floor, allowing removal and re-insertion of the flexible screw from standing height during cleaning and inspection.

Flexicon Corporation

www.flexicon.com

RotaChrom has announced its rCPC platform conforms to Current Good Manufacturing Practices (cGMP) for the pharmaceutical industry, allowing the use of its rCPC purification and separation systems within cGMP.compliant laboratory and manufacturing environments. Designed for pilot-scale centrifugal partition chromatography (CPC) in laboratory environments, the rCPC platform accommodates both small and large batch sizes, operates continuously and is ideal for all types of research projects. This platform also functions as an at-line purification platform in conjunction with its industrial-scale purification unit, enabling orthogonal separation. A cost-effective purification solution, it delivers excellent throughput, purity, and yield for lab-scale separation applications. To

Torrey Pines Scientific has announced EchoTherm stackable/programmable vibration free chilling incubators for protein crystallography and other life science uses. The incubators are 27 litre capacity and Peltier-based for heating and chilling. Units have no compressors or CFCs and are vibration-free making them ideal for doing protein crystallography. Other applications include incubating marine samples below room temperature, enzyme reactions and deactivations, hybridizations, ligations, storing oocytes and general lab incubations. The model IN35 is a fully programmable unit that can store 3 programs in memory and features precise temperature ramping both up and down. Temperatures are settable from 4.0° to 70.0°C controllable to ±0.1°C and accurate to ±0.2°C. Chamber size is 12 x 10 x 14 in. (H x D x W) and comes with two stainless steel racks with room for four racks.

Torrey Pines Scientific www.torreypinesscientific.com

Powder and bulk solids processing and handling are essential components of almost every industry worldwide. This article explores the key considerations to averting issues that lead to delays in start-up time, bottlenecks and stopgaps in the processing and handling of powders and bulk solids.

Key considerations are:

• Resources & Capabilities

• Material Characteristics

• Equipment & Application

• Equipment Design

• Lab Testing

There are no shortages of process equipment suppliers in today’s market. Many manufacturers build reliable equipment and offer design and engineering expertise. However, finding a single resource that can provide design, manufacturing and most importantly, testing of materials through processing or handling steps can be challenging.

Testing in a competent and fully equipped lab can provide the advantage of being able to test several technological solutions to ascertain the best solution for economic value and product quality. Furthermore, testing delivers peace of mind because it mitigates surprises and provides assurance that the process will work as intended.

Understanding material characteristics including particle size distribution, bulk density, moisture content and other factors such as heat sensitivity, fragility, cohesiveness, etc., are often necessary parameters for designing an efficient process system. By performing a full analysis of material characteristics and measurements of material behaviour in specific processing applications, operators are assured an efficient and reliable process solution. Having the materials analyzed will help identify operational parameters such as flow-

ability of the materials through specific types of equipment. Factors to consider are particle size distribution, bulk density, and moisture content are paramount.

Process engineers are faced with a mountain of options when it comes to selecting suitable process equipment for various applications. Most pieces of process equipment are designed to perform specific, singular process steps or tasks (e.g., mixing, conveying, screening, drying, cooling, etc.). Some pieces of equipment are designed to be multi-functional, performing several steps such as conveying, heating, cooling, and screening.

To complicate matters, equipment suppliers may offer multiple pieces of equipment that perform the same process step or task (e.g., fluid bed dryers, belt dryers, flash dryers, rotary dryers, etc., for a drying process).

Testing the equipment will disclose the advantages and disadvantages of each and provide the basis for the supplier to make equipment and process recommendations to handle specific

the unique characteristics of the materials, start-up time can be significantly delayed, and design capacity may never be reached. Decisions made during the preliminary stages of a project are critically important to the success of an operation and should be included in the risk mitigation and reward strategy.

Comprehensive material and equipment testing in a qualified lab has proven to avert common issues associated with processing bulk solids material. Testing can also bring to light new challenges which can be circumvented before any problems may arise, validate new equipment designs and processes, and facilitate a quicker return on investment.

materials and applications.

Process engineers should work with the supplier to find ways to reduce uncertainty and eliminate inconsistencies.

Designing reliable and efficient process systems that deliver required parameters is always the goal. Contributing factors include the actual process used, design attributes such as construction materials, temperature settings and variability, and equipment designed to achieve mass flow to promote uniformity and consistency while eliminating uncontrolled flooding, caking or product degradation.

Material flow, material degradation, temperature, retention time, and air pollution control are the primary factors that go into equipment.

As mentioned, bulk solids processing systems engineered without proper vetting through a qualified lab could cause delays and other inefficiencies or bottlenecks. When bulk solids systems are not properly engineered to handle

Thorough testing can validate new equipment designs and processes against material and process parameters and improve existing process lines. Conducting tests with a variety of custom-engineered equipment, modern diagnostic tools, computerized data collection, and real-time information should always be considered.

The cost of testing material, equipment, or processes prior to commissioning is negligible when compared to calculating the cost of downtime resulting from equipment that was not properly vetted. With thorough risk analysis through lab testing, factors such as successful increases in capacity and energy efficiencies will be discovered, facilitating a quicker return on investment.

This article is excerpted from a white paper by CPEG — Carrier Process Equipment Group. CPEG offers laboratory services that simulate user operating conditions can also provide field testing with rental equipment. CPEG

www.cpeg.com

Leuze has introduced the KRT 3C contrast sensor, the company’s smallest contrast sensor for the packaging industry. The contrast sensors are developed to detect defined markings on objects during packaging processes. The contrast markers are located on film, bag, and blister packaging or on labels. The new compact contrast sensor of the 3C series can be used flexibly with different transmitter colors (RGB light, white light, or laser-generated red light) for common colour and gray value combinations. It is said to detect even slight contrast differences reliably and precisely, as well as print marks even on glossy materials. The sensor housing is 11 x 32 x 17 mm. The plastic housing covers degrees of protection IP67 and IP69K. ECOLAB certification confirms the housing’s resistance against cleaning agents commonly used in the packaging industry. All settings for integration and operation of the sensors as well as for the case of format changes of the products can be easily performed via the IO-Link interface, the company says.

Leuze

www.leuze.com

CIRCOR International has introduced the Zenith C9000 series precision metering gear pump, suitable for use in hydrogen fuel cell MEA gasket ing sealants and adhesive applications. The metering pumps are said to de liver accurate and repeatable flow of metering additives, sealants, or chemicals in a compact and ef ficient design. The pumps offer near constant flow without the need for expensive flow meters and control systems, the company says, while also featuring an extended mean time between failure (MTBF). The pumps are available with a magnetic drive (mag-drive) sealing option, designed to eliminate shaft leakage of fluids, improve plant safety while reducing VOC emissions and seal failures. Units are available in flow ranges up to 9,000 cubic centimeters per minute and are made in 316 stainless steel. The gear pumps also work from -40° to 350°F.

CIRCOR International www.circor.com

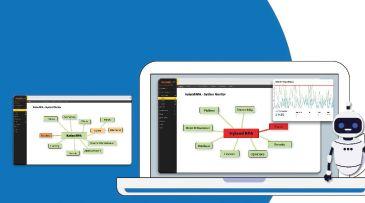

Reveille Software has announced new Hyland RPA and Kofax RPA (robotic process automation) platform support. The software provides agentless management and monitoring capabilities to ensure the continued health and productivity of the platforms. This includes managing robots at scale, measuring platform operating performance, and

It’s May 15 and as I write this all the Canadian NHL teams have been once again eliminated from the playoffs. As a long-suffering Toronto Maple Leafs fan, I’ve learned to deal with it. There must have been a hidden curse somewhere around 1967, the Leafs last cup win. It would have at least been nice to cheer for another Canadian team like the Oilers but not this year — now a 30-year milestone (millstone?) drought — with the last win by the Montreal Canadiens. The futility means that summer activities can begin early again for all long-suffering NHL fans this side of the U.S. border.

Thanks to all of you who joined us for our three Process & Automation shows this spring. We have three more scheduled for the fall: Lethbridge, AB, September 19, Saskatoon, SK, September 21 and finishing up with Saint John, NB, October 24th. Hope to see you there.

Next up in the magazine will be our August issue with our Focus on the Environment in the process sector and Mike’s Supplement will address Fittings & Couplings. If you’d like to contribute, get your submissions to editor@cpecn.com by the July 14 deadline. I hope everyone has a safe and enjoyable summer. Put down those gaming consoles and get outside!

Rob Sommerville.

triggering automatic recovery actions, the company says — enabling Hyland and Kofax users to understand RPA service levels through a single comprehensive dashboard view. The new automated RPA functionality allows organizations using Hyland RPA and Kofax RPA to simplify their platform’s management by: eliminating the manual observation of RPA platform health with active service level management; automating recovery actions for RPA component errors and robot execution bottlenecks; and verifying target application availability and minimizing error recovery logic in robots.

Reveille www.reveillesoftware.com

The Trafag model NAI 8273 IO-Link pressure transmitter, available from X Tronics, is designed as a smart sensor and provides application-relevant information in addition to the process data. The process data contains the pressure value and the media temperature, which is measured directly at the long-term stable thinfilm-on-steel pressure sensor cell, the company says. The small sensor dimension combined with the pressure and temperature value of the media make the IP65/67-rated device a suitable choice in various applications. For the use of the conventional switching outputs, the polarity NPN and PNP is configurable. X Tronics www.xtronics.ca

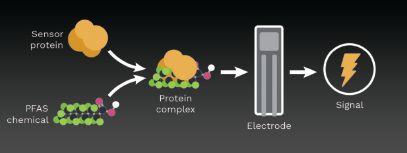

FREDsense Technologies Corp., a manufacturer of field-ready water testing kits that detect chemicals in drinking and wastewater, announced that its platform can detect and measure PFAS in just hours, compared to traditional methods. The new FREDPFAS system will integrate a PFAS-responsive biosensor solution into the company’s field-based platform for rapid measurement. The company’s patented electrochemical technology is uniquely suited to monitor very low concentrations of contaminants, making it ideal for PFAS monitoring, it says. FRED-PFAS will be a scalable and customizable solution to enable field monitoring of PFAS. The company plans to deliver the system as a consumable grab sample field kit.

FREDsense

https://fredsense.com/

Klinger Ballostar KHA ball valves are offered in a wide range of types due to the modular construction system. The customizable approach characterizes these 3-piece ball valves, the company says. Three kinds of connections, six types of sealing elements and three stuffing box designs are said to ensure that the ball valves are suitable for many different operating conditions and applications. Product advantages of the maintenance-free ball valves include support for pressurization on both sides, bidirectional flow, ball with a cylindrical full bore, prestressed and elastic sealing system, bidirectional sealing in accordance with EN 12266 — leakage rate A, modular selection of system components, and serviceable without removal from the line. Klinger Advantage

www.klingeradvantage.com