Part of the SmartLine series of products, the SLN 700 from Honeywell Process Solutions is an 80 GHz non-contact radar level transmitter that is said to offer high accuracy and stability over a wide range of level applications. The series is also fully tested and compliant with Experion PKS. The SLN 700 utilizes Frequency Modulated Continuous Wave technology and has a measuring range up to 30 m (liquids) or 120 m (solids). Accuracy is to ±2 mm, with a process temperature range of -40° to 200°C, process pressure range of -1 to 25 bar, operating voltage 12 to 30 Vdc, and output signal choices of 4 to 20 mA and HART. For setup, the SmartLine Application and Validation Tool (AVT) allows users to specify their tank level application and options.

https://process.honeywell.com

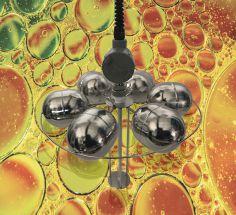

Arjay Engineering 4100-HCF series float sensor monitors employ HF capacitance for continuous monitoring of separated oil thickness on a water surface. A capacitance approach eliminates routine cleaning of the monitor systems, the company says. There are also no moving parts, while control and interface panel mounts are situated safely away from the process. The float sensor monitors the capacitance field of the water surface so that as the oil accumulates on the surface, the sensors capacitance changes. This interface signal is used to provide outputs, displays and relay control. The Arjay PMC (pulse module circuit) embedded within the float sensor converts the oil/water signals to a frequency pulse. This allows the controller to be safely mounted up to 1 km away from the sensor with virtually no loss to signal stability.

www.arjayeng.com

KNF has announced the UFK 1.1100 EX, a low pulsation, high flow liquid pump for HazLoc areas. The chemically resistant unit is said to provide performance required by oil and gas, extraction, and cooling circuit applications. The pump has a flow rate of up to 11.5 lpm, doubling the company’s previous maximum for HazLoc liquid diaphragm pumps. It has a single inlet and single outlet, with three diaphragms that are offset by 120° to each other and connected in parallel. Pulsation values below 200 mbar at the inlet and outlet can be achieved, with lower pulsation available with a damper. The unit provides continuous operation with up to 6 bar back pressure. Customers can choose between different protection levels with standard being C1, D1, Groups C&D single-phase AC motors.

www.knf.com

The VEGAPULS 6X radar sensor from VEGA is said to handle many applications, whether the medium to be measured is liquid, solid, hot, cold, hazardous, or corrosive. The user specifies the operational parameters and process conditions, and the company configures and delivers the application-ready level measuring instrument. Using a custom radar chip, the level sensor now combines features of the company’s previous 80 GHz, 26 GHz, and 6 GHz sensors, such as VEGAPULS 64 and VEGAPULS 69, in one device. The instrument has Bluetooth for wireless adjustment with the VEGA Tools App and is equipped with SIL 2/3, as well as the latest IT cyber security standard IEC 62443-4-2.

www.vega.com

CPU starting at $93 with FREE software

Since 2008, and with close to a million components sold, CLICK PLCs have become an industry favorite for simple, affordable control. This popular PLC family has now been supercharged with features you wouldn’t expect from a low-cost controller. Data logging, Wi-Fi, MQTT communication and increased security measures are just a few of the impressive features that make the new CLICK PLUS PLC series a “must have” for simple control...with a kick!

The NEW 2-slot CLICK PLUS CPUs provide even more versatility, offering over 400 standalone PLC I/O combinations with plenty of analog, discrete, relay, and combination I/O option slot modules available. Or easily add more serial communication ports with the NEW C2-DCM serial communication option slot module.

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days.

*Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

Our shipping policies make it easier than

SAFETY IS NOT OPTIONAL

Get your safety and other automation components from AutomationDirect, a trusted supplier in the industry for over 25 years. We offer high- quality safety products at great prices, so you can afford to protect even the simplest systems.

Safety Relays

Safety Light Curtains

Starting at $487.00 Sender/Receiver Pair (YBES-30K4-0170-P012)

Safety light curtains use an array of photoelectric beams to sense intrusion into a plane of detection.

Starting at $103.00 (LG5924-02-61-24)

Type 4/Category 4 curtains achieve high fault tolerance through redundancy/monitoring, have a tighter field-of-view and are less susceptible to optical short circuits. We offer many sizes, styles and brands such as Contrinex, Datalogic and ReeR.

Safety relay modules are a simple and reliable method of controlling a safety system that uses positive guided contacts and redundancy for fail-safe systems. Available models include E-stop, two-hand, safety gate, safety mat, light curtain, and speed safety relays.

Starting at $323.00 (MOSAIC-M1)

Safety controllers use monitoring logic, overvoltage / short-circuit protection, redundant relays, and positive guided contacts to provide a high level of fail-safe operation. The modular MOSAIC safety controller is an expandable, cost-effective choice (vs. stand-alone safety relays) as the required number of relays/channels increases.

Safety Switches

Starting at $16.50 (SP2K61X11)

Safety switches are interlocking devices used to monitor (and sometimes lock) machine guards, doors, gates or windows. New stand-alone non-contact magnetic coded safety switches protect personnel and machinery without the need for a separate safety relay.

Our shipping policies make it easier than ever to order direct from the U.S.!

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days.

*Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

To my regular readers, an explanation, and to IPP/T readers, welcome. After being acquired by Annex Business Media, Canadian Process Equipment & Control News has folded Industrial Process Products & Technology into its pages to take on a look that resembles a hybrid of the two for the moment. A redesign/rebrand is planned for later in the year to further celebrate the 50th anniversary of CPECN

For those of you just getting acquainted, a little about myself.

I’m an electronics engineering technologist who worked in product manufacturing for 10 years, primarily in quality control. Next came publishing, first as a technical editor on an electronics engineering title, then on to greater responsibilities with magazines serving information technology and mechanical engineering communities.

It’s a privilege to have been serving Canada’s process industries over the past five years on CPECN and I look forward to continuing to do so for IPP/T readers as well.

My email remains the same, medwards@cpecn.com, but I now have a new telephone number, 416-510-5229.

Mike Edwards medwards@cpecn.com

We understand how important it is to find the right expertise for your industry application needs.

You are assured to get the best-fit products, solutions and services for your specific requirements.

Micropilot FWR30 – The cloud connected radar level sensor

Print and digital subscription inquiries or changes, please contact Barb Adelt, Audience Development Manager

Tel: (416) 510-5184

Fax: (416) 510-6875

Email: badelt@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

PUBLISHER, Rob Sommerville 905-770-8077 rsommerville@cpecn.com

EDITOR, Mike Edwards 416.510.5229 medwards@cpecn.com

ACCOUNT COORDINATOR, Barb Vowles 416.510.5103 bvowles@annexbusinessmedia.com

GROUP PUBLISHER/VP SALES, Martin McAnulty mmcanulty@annexbusinessmedia.com

COO, Scott Jamieson sjamieson@annexbusinessmedia.com

Founder, Peter Birchard

Founder, Ray Blair

CPE&CN is published bi-monthly by: Annex Buiness Media

111 Gordon Baker Rd, Suite 400, Toronto, ON M2H 3R1 T: 416-442-5600 F: 416-442-2230

© All materials in this publication are copyright protected and the property of Annex Business Media., the publishers of Canadian Process Equipment & Control News magazine. For permission on reprinting or reproducing any materials, e-mail your requests to cpe@cpecn.com

Canadian Postmaster send address corrections to: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Canadian Process Equipment & Control News assumes no responsibility for the validity of claims in items reported.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2384

Do you want to learn more? www.eh.digital/3P8yNch

• Transparency – full and secure access to information on asset and inventory status, from everywhere at any time

• Simplicity – from procurement to operations, simplified commissioning, handling and processes

• Flexibility – suitable digital services defined by user need, scalable from Netilion Value via Netilion Inventory to SupplyCare Hosting

• Reliability – precise measurements with wireless high-end 80Ghz sensor technology

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 0318-0859

Aeroqual Ranger | Dust is a real-time, active-sampling monitor from Cameron Instruments that provides simultaneous measurements of multiple particle fractions (PM1, PM2.5, PM4, PM10, TSP) along with temperature and relative humidity, in a connected, handheld solution with cloud-based data visualizations. It is said to be rugged and easy to use, featuring a long-life lithium battery and a lightweight, ergonomic design. All logged data is backed up on Ranger Cloud, in real-time, wherever Wi-Fi is available.

Cameron Instruments

www.cameroninstruments.com

AutomationDirect has added additional safety mats, edges, and bumpers from ASO Safety Solutions. The safety products are designed to protect people and machinery from harm.

Mats detect the presence of personnel on horizontal surfaces (usually the floor), edges can be used on any surface, usually near possible crushing or shearing points, and bumpers are used in applications involving vehicles or other moving equipment. Safety mats include five additional sizes of the standard black mats with straight or tapered edges, and four new mats in safety yellow. Safety edges include additional 25 x 30 mm profile edges with a sealing lip and a new 30 x 70 mm profile option. They are available in lengths up to 5 ft. Safety bumpers increase the existing 60 x 100 mm offering to a maximum length of 6 ft; 100 x 200mm profile bumpers, in lengths from 1 to 6 ft, were also added. The bumpers are resistant to vibration and excellent for mobile applications such as industrial vehicles. Mounting rails are included to simplify installation.

AutomationDirect

www.automationdirect.com

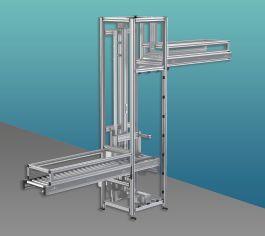

Robotunits has launched its Powered Roller Conveyor series of 24-V components designed to make it quick and easy for plant managers and control engineers to configure and build a complete transport system. The conveyors have individual components and production zones that feature a modular design and ready-to-use controllers to allow maximum flexibility for present and future system needs, the company says. Providing precise and efficient transport of containers, totes and

boxes, the series product range consists of straight and curved powered roller sections, lift stations, 90-degree transfer units and turntables. To enhance oper-

ator safety, the conveyor systems feature patented finger guard technology. Robotunits www.robotunits.com

NSF 61 & 372 Certified

The NS Series ball valves are available in sizes 1/4”-6” with threaded, socket weld, butt weld (3-piece) and flanged (2-piece) connections.

The NS Series butterfly valves cover 2”-24” sizes in wafer and lug style.

APPLICATIONS

• Water Treatment

• Potable Water Service

• Reverse Osmosis

• Desalination

Dust collectors help keep personnel and machinery safe in manufacturing facilities. If they don’t do their job effectively, plants can suffer from high costs, including worker injury, equipment failure, regulatory non-compliance, and production downtime. To reliably remove particulates, a dust collector must operate efficiently.

Like any other machine on the plant floor, dust collector efficiency is determined by the performance of its components — and some make a bigger impact than others. When specifying or selecting a dust collector, it’s vital to choose the right pulse valves.

To understand just how important pulse valves are, it’s helpful to imagine how reverse pulse jet dust collectors work. When a dust collector is in operation, it draws dusty particles onto its filters. As particulates accumulate, they compress into cakes. When cakes become thick and dense, they block filters, reducing the dust collector’s efficiency. To continue removing dust particles from filters, a line of pulse valves, in turn, periodically emit a blast of compressed air that sends a shockwave through the filters. When the shockwave hits dust cakes, it causes them to crumble off filters and collect in the hopper.

Pulse valves, then, are the critical components that deliver the blasts of compressed air that continually clear filters and free them up to collect more particulates.

Some dust collector systems may have only a few pulse valves, while others may have more than 50; the number depends on the size of the collector, and the frequency of compressed air activation depends on the needs of the application.

While the number of pulse valves and frequency of activation can certainly affect dust collector efficiency, it’s how pulse valves deliver that blast of air that really matters. This is determined by a pulse valve’s peak pressure

and valve response time. Peak pressure is the force that affects the air blast’s speed and power. Valve response time is the time it takes the pulse valve to open and close, which controls the duration of the air blast and influences peak pressure.

If a pulse valve provides inadequate peak pressure and slow valve response time, the force of the compressed air and resulting shockwave will be too weak to completely break up cakes and will leave residue on the filters. Saturated filters are not as efficient as clear filters, and the dust collector system must work harder to compensate. This inefficiency increases the frequency of filter replacement and can prematurely wear system components, raising maintenance costs and creating downtime.

Yet, if a pulse valve provides too much peak pressure and a slow valve response time, the overpowering strength and duration of the shockwave can destroy more than dust cakes — it can damage filters. This, again, increases filter replacement, downtime, and related maintenance costs.

Pulse valves that provide optimal peak pressure and have a quick valve response time emit the precisely controlled burst of compressed

A pulse valve’s peak pressure and valve response time determine the efficiency of a facility’s dust collector systems, which can significantly affect the plant’s efficiency overall.

air that is required to effectively remove dust cakes, improving overall dust collector system efficiency, extending component and filter life, and lowering maintenance costs.

The design of a pulse valve can affect peak pressure and quick valve response time. While most conventional pulse valves use closing springs, some new pulse valve designs use a one-piece diaphragm. The single-piece design permits airflow to travel beneath the diaphragm instead of over a wall, allowing it to flow faster and more freely. This new design offers a response time of 8 to 14 ms and provides a 14 percent increase in peak pressure over legacy pulse valves.

In addition to improving dust collector performance, pulse valves can increase efficiency in other ways, too. One way is by using less compressed air. Compressed air can be quite expensive for processing facilities, and plants that have multiple dust collector systems may use a lot of it. The length of time the valve is open determines how much compressed air is used. Pulse valves with a quick valve response time use less compressed air than pulse valves with slow valve response time. In a dust collector with 40 pulse valves, the high flow

and fast valve response time of single-piece diaphragm designs use about 15 percent less compressed air than pulse valves with standard designs.

While all processing facilities can minimize compressed air use, the opportunity to see substantial energy savings grows the more pulse valves a plant has. Online valve manufacturer tools or consulting services can help calculate a processing facility’s approximate compressed air savings.

Another way the one-piece diaphragm design improves efficiency is by streamlining installation and maintenance. It is in any OEM’s or plant manager’s best interest to keep time required for installation and maintenance as short as

can minimize unplanned downtime. For facilities that operate in locations subject to extremely low temperatures, some pulse valves fail when it gets too cold. Pulse valves with a wide temperature-performance range offer reliable, long-term dust collector operation even during the coldest days. There are now pulse valves with operating ranges from -40° to 140°C.

In processing facilities, dust collector systems must reliably operate to remove particulates before they accumulate and affect plant safety and productivi-

ty. Pulse valves are critical components that can improve their performance and efficiency, as well as that of the plant overall.

Selecting pulse valves that provide the greatest benefit starts with a supplier that has a comprehensive dust collector portfolio. Ensure that their solutions include monitoring and diagnostic options and meet all approvals, ratings, and certifications. Technical support, quick shipments and short lead times are also essential. Through expert partnership, OEMs can offer greater value to their customers,

possible to minimize downtime and costs. A valve’s connection and part count determine how quickly and easily it can be installed and maintained. Certain connections may require special tools or additional sealing, and high part counts take more time to disassemble and reassemble. Even if it’s planned, downtime can add up quickly in facilities with large dust collector systems and hundreds of pulse valves.

Conventional pulse valves have threaded or dresser connections, which require a wrench for tightening, and a spring-loaded diaphragm that may contain washers, islets and rivets that must be installed and serviced. Springless, one-piece diaphragm designs have only one part to service and feature a quick-mount clamp connection that quickly, easily, and securely connects to pipework, reducing installation time by 60 percent compared to threaded and dresser connections.

In addition to minimizing planned downtime, pulse valves

and facilities can gain greater efficiency and a cleaner, safer work environment.

By knowing what to look for in a pulse valve — and a supplier — OEMs, engineers and purchasing managers can choose components that improve dust collector system performance, extend component and system life, reduce air consumption, and streamline installation and maintenance.

This article was contributed by Emerson.

By Nick Hanson

Water facilities are tasked with the difficult job of maintaining water quality for safe consumption and sanitary disposal, while simultaneously lowering energy consumption and complying with local, provincial, and federal environmental initiatives. Injecting unreliable data into operations makes meeting these objectives nearly impossible. By investing in smart instrumentation with capabilities for online diagnostics and predictive maintenance, plant and facility staff can ensure reliable data is provided. This data can be used to control processes more efficiently and make informed decisions when it comes to maintenance — saving costs, time, and energy. These modern instruments communicate diagnostic data via digital communications, and staff can use this information to proactively address issues, reduce unscheduled outages, and improve operational performance.Online diagnostic

data is generated via Heartbeat Technology, incorporated into its modern instruments. To get this data to an asset management system (AMS) or a control and monitoring system, users can take advantage of HART over existing 4 to 20 mA analog loops. Staff can also use instruments’ WirelessHART communication protocols. These wired and wireless digital data links make instrument primary and secondary process variables, along with diagnostic information, avail-

able to host systems, which can in turn generate alerts informing plant personnel of anomalies and issues. The control system is normally the host for wired HART connections because these systems use the 4 to 20 mA signal proportional to the process variable for real-time control. The additional data provided by HART superimposed on the 4 to 20 mA signal can be monitored with the control system, and/or be sent to another host system, such as an AMS.

Many of these host systems now have web server functionality, which means data can be securely accessed via any device capable of hosting a web browser — such as a laptop, smartphone, or tablet. Some instruments also have web server functionality, allowing data to bypass the control system, a much less expensive option than adding input points to a control system. Wireless signals can be sent to the control system but are often not because they are typically not used for real-time control. These signals are more typically sent directly to an AMS, or to the cloud via a gateway. WirelessHART instruments typically send and receive as much or more diagnostic and process data as their wired HART counterparts. While this data can provide immense benefits to a wide range of host systems and applications, many facilities don’t take full advantage of what this data

has to offer. When this information is ingested by intelligent plant analysis systems, facilities increase their ratio of proactive to reactive maintenance, reducing unplanned downtime, as well as equipment and human safety hazards. For example, instead of waiting to get an alert indicating a high-temperature condition, process data can be used to provide an alert when conditions are detected that would lead to this type of issue – which is truly predictive maintenance.Once connected to a Bluetooth instrument via a smartphone or tablet, a technician can monitor instrument health, and with proper authorization can change tags and other configuration parameters if desired. This is all done without any industrial network configuration because the smartphone handles communication. These interfaces include guided procedures for in-situ testing, and they provide traceable verification logs because records are stored in instruments’ local memory. These procedures comply with ISO 9001 for instrumentation verification without interrupting the process, eliminating the need for device removal and process downtime. Third-party attested verification and automatically generated verification reports enable optimization of calibration and proof test cycles in a compliant manner. And when anomalies and issues are detected, Bluetooth smartphone interfaces provide easy-to-follow recommendations for remedial actions. When instrument diagnostic data is integrated into host systems, it can be analyzed to provide advance warning of instrument failure or troubleshooting insight in the event of failure. Because calibration and nameplate information are also internally stored in each instrument, tracking, and managing assets is easier throughout an instrument’s lifecycle. Data provided by Heartbeat Technology can be analyzed to provide:

• Increased uptime by predicting failures

• Improved efficiency due to fewer process interruptions

• Increased measurement reliability due to proactive alerts

• Improved safety by reducing the need for techs to manually connect to instruments in the field

• Condition monitoring for predictive, intelligent, and timely issue detection

• Reduced maintenance costs due to proactive rather than reactive work

• Higher confidence in device performance due to verified readings

• Efficient troubleshooting and remediation according to NAMUR NE 107

• Certified verification of measuring instruments

• Ensured regulatory compliance

When looking to optimize plant processes, smart instrumentation provides indispensable data for generating operational and maintenance insights. By ingesting and processing this data in an AMS, a control system, or wirelessly in the cloud, facilities can leverage proactive maintenance procedures,

improving process efficiency and reducing unplanned downtime.

Nick Hanson is the Water & Wastewater Industry Marketing Manager for Endress+Hauser USA. Endress+Hauser Canada

www.ca.endress.com

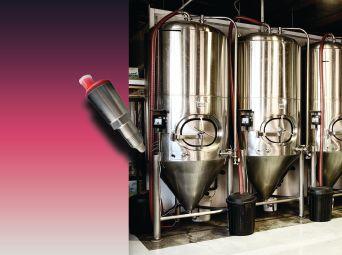

The Endress+Hauser in-line Teqwave H analyzer is said to enable users to reliably monitor fluids in the food and beverage industry. In soft drink and fruit juice production, the measuring device assures product quality through its reliable determination of sugar content and invert sugar content. For production of distilled beverages, it ensures that the alcohol content remains consis-

tent. In addition, it simultaneously measures the sugar content. When cleaning plants, bottles and kegs, the analyzer also monitors different concentrations, and it supports precise dosing of cleaning agents. If the cleaning agent needs to be changed, this can be done easily without recalibration. Continuous in-line mea-

surement also means no sampling is required, the company says. The analyzer simultaneously records multiple measured values that are essential for process control, such as concentrations, speed of sound, acoustic density, and temperature in many different fluids, and then forwards them to the process control systems.

Endress+Hauser Canada www.ca.endress.com

The V200 positioner incorporates the flexibility of converting from a pneumatic unit to several versions of an electropneumatic unit, and the ability to add position feedback, in a matter of minutes, all in one compact and rugged housing.

Canadian Master Distributor: Belletek Controls Inc.

2535 Stallion, St. Lazare, Qc, Canada J7T 2E4

J.C. Labelle: (514) 916-5895

Fax: (514) 500-5802

Email: jc@belletek.com

Snapshot Logging is a new FieldLab feature from Ralston Instruments that lets users record multiple single data points and save them in one data set. There is an option to label test points and include the time, date, target pressure and/ or permissible error for each dataset to facilitate standard operating procedures and save each test mode so it can easily repeat specific tests whenever necessary. The feature is said to provide clear, traceable results that can be stored digitally and exported easily to a PDF or CSV file. The tool is suitable for tank pressure tests, logging tire pressure on vehicles or aircraft, testing boilers that need daily pressure measurements, or any application that requires a user to log observed pressure at irregular or infrequent intervals.

Ralston Instruments www.ralstoninst.com

The Flexi-Flow model in the Bronkhorst Mass Flow Controller series is not only able to measure and control gas flow and measure the temperature, but also to measure and control the upstream and downstream pressures in a process with one flexible instrument. Features include simple and secure connection through Bluetooth and controller app, adaptability to many applications through wide dynamic flow range, and a NAMUR status indication. Hoskin Scientific Ltd.

www.hoskin.ca

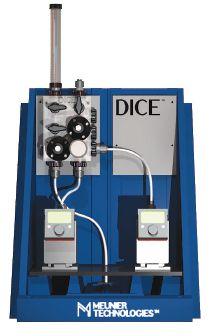

The Meunier Technologies DICE dosing module available from Visser Sales is said to integrate all the necessary discharge components required for a typical chemical dosing system. The block type design allows for a rigid, compact, and reliable product, the company says, and the significantly reduced number of connections is a major benefit as it greatly decreases the leakage potential. The module is also said to allow for better precision and protection in the dosing system. It also features great quality due to its machined fabrication. The dosing module overcomes the many fundamental problems of the current piping system design such as: poor quality of the piping connections, many potential leakage points, excessive vibration caused by the pump pulsation (which leads to mechanical fatigue on connections and components) and the unjustified large footprint required. Vissers Sales www.visserssales.com

The Dollinger LL-142 liquid filters available from John Brooks Company are created to remove final traces of dirt, pipe scale and other solid contaminants from process liquids. Unlike conventional multiple-cartridge filters, the Dollinger Element Design Concept is said to maximize the effective filtration area for a given vessel size resulting in lower differential pressure and extended service life. In addition to the standard range of filters, the company can offer customized filter designs and capacities to suit the process application demands of the customer. As standard, the filter housing is designed and constructed in accordance with the ASME VIII, Division I Pressure Vessel construction code. In addition, it can also provide full design services to other pressure vessel codes – Canadian and European.

John Brooks Company www.johnbrooks.ca

Kinitics Automation has launched the KVA, a shape memory alloy-based valve actuator that uses proprietary Bundled Wire technology to maintain precise control of gas and fluids in process control applications. Designed to replace traditional pneumatic and electric actuators, it can be mat-

ed to a wide variety of globe valves, the company says. The technology used in the valve actuator allows for a robust drivetrain with only one moving part. The innovative mechanics develops smooth motion and generates force in a purely linear way, it adds, eliminating the mechanical backlash and slop inherent in traditional gearboxes. The unit was developed in response to the natural gas industries need for a zero-bleed actuator that can fail closed in the event of a power or signal interruption. The valve actuator is said to fully comply with incoming environmental regulations while eliminating the reliance on process gas.

Kinitics Automation

www.kiniticsautomation.com

The 3-way sealed gravity diverters series L from Lorenz Conveying Products is suitable for chemicals, food and pet food, grain milling and food and beverage. For dry gravity flow applications, units provide a seal to the atmosphere while polymer blade seals prevent cross contamination. The diverters are available in sizes from 4 to 18 in. and in aluminum, carbon steel or stainless steel construction. Units have square inlets and outlets, a replaceable active compression shaft seal and urethane blade seal, and a blade pocket that protects the leading edge of blade from wear and directs flow of material away. The di-

verters are suitable for applications up to 104°C and have a removable door for cleaning and seal replacement Lorenz Conveying Products www.lorenzproducts.com

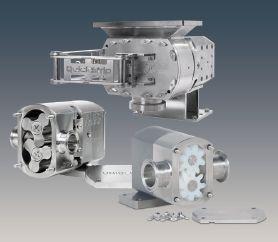

Kobold DON oval gear positive-displacement flow meters are suitable for measuring clean, high, and low viscosity liquids. The metal flow meter uses 2 precision-machined oval gears which allow for a very specific volume of liquid to pass through the meter with each rotation, the company says.

Kobold

www.kobold.com

QuickStrip FoodFirst 600 series pumps from Unibloc are engineered from stainless steel, with a free-floating rotor design that con-

tains no rotor bolts. This upgraded rotor design is specifically for food processing applications requiring daily strip-down sanitization. Features include a patented design, assembly/reassembly without tools, operates without a front cover O-ring, and a safety swing arm. Unibloc Pump

www.uniblocpump.com

Local control and monitoring of applications wirelessly can be performed with the WAGO industrial-grade PFC200 controller with integrated cellular modem. The company says the all-in-one PLC controller and cell modem eliminates extra hardware reduces set up time.

WAGO

www.wago.us

Trust KNF Neuberger has introduced diaphragm pumps with explosion-proof CSA/UL HazLoc compliant motors. The motors are compliant with NEC/CEC Class 1, Div. 1, Groups C/D, and Div. 2, Groups A/B/C/D. Units offer self-priming liquid flow rates to 11.5 L/min and 88 psi. In addition, gas flow rates to 300 L/min, pressures to 176 psi, vacuum to 29.86 in. Hg are offered.

KNF Neuberger www.knf.com/exproof

Swagelok has expanded its engineered combinations offering — the pairing of dissimilar fitting and tube materials — to address growing customer needs in offshore and near shore environments as they maintain existing systems and plan new ones. The solutions are said to provide rated, corrosion-resistant, cost-effective alternatives to fully exotic alloy solutions in certain applications where those traditional choices may be expensive and unnecessary. A superior tube grip is also said to be achieved with the company’s hinging-colleting back ferrule design translates axial motion into radial swaging action on the tube yet operates with a low assembly torque requirement. Its SAT12 low-temperature carburization process is used to case-harden the surface of the back ferrules in all offered materials. Swagelok www.swagelok.com

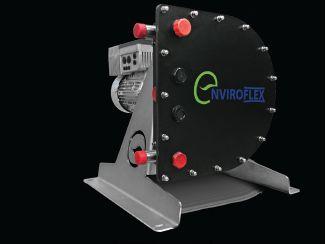

Thompson Pump and Manufacturing Company has announced the model 6JSCE 6 in. solids handling pump with Enviroprime System. The portable compressor-assisted unit is said to lead the industry in sewer bypass, emergency response and any high-head/high-volume applications. With its heavy-duty cast-iron construction and fast priming capabilities, the pump is designed for flows up to 2,680 gpm, and heads up to 190 ft, with maximum solids handling up to three inches. This end-suction centrifugal pump has the ability to dry-prime and re-prime automatically. The Enviroprime System does not allow product blow-by of pumped materials, the company says. Thompson Pump and Manufacturing Company www.thompsonpump.com

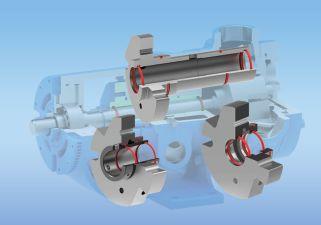

Viking Pump has introduced patented O-Pro Seal technology. The technology uses a series of O-rings to create a robust seal and lubrication chamber, all in one, the company says. The O-Pro Barrier seal variant functions as both a seal and bracket bushing; O-Pro Cartridge & Guard seals are simple retrofit options, it adds. The Barrier seal replaces packing or mechanical seal by occupying the internal bracket cavity with a machined seal gland, utilizing O-rings to seal externally on the bracket and internally on the shaft. A combination of O-rings and lubricating fluid provide a robust seal preventing process fluid from leaking out of the pump. The Cartridge seal replaces packing or mechanical seal by using O-rings to seal externally on the bracket and internally on the shaft. The O-Pro Guard seal replaces packing or mechanical seal by sealing between the bracket, sleeve, and shaft surfaces with a series of O-rings.

www.vikingpump.com

Build it, See it, Price it, Order it.

Point and click or tap to specify valve type, end connections, actuator, and accessories. Model number, price, description, and photo all update instantly!

Endress+Hauser Canada has erected one of the country’s “greenest” commercial buildings for 20 million euros. The recently opened customer experience and process training centre in Burlington, ON, is energy-autonomous and CO2 neutral. The 4,400-square-meter facility — twice the size of the current location — houses a process training centre, a large calibration lab, repair facility, and state-of-the-art office and recreational space for around 120 people.

The new building in Burlington reflects the solid growth of the past years. “The Customer Experience Centre is an impressive example of Endress+Hauser’s global strategy of cultivating and managing customer partnerships. This is how we grow — in Canada and worldwide,” says Matthias Altendorf, CEO of the En-

the

suppliers, and students will all be welcomed.

dress+Hauser Group. He added that the centre will invite pre- and post-secondary students to both generate interest in STEM (science, technology, engineering, mathematics) careers and to augment them.

“This building is also designed for people to collaborate, whether they are suppliers, distributors, universities or customers, to become creative and find new solutions.”

The building represents the brand values of the Group, he adds. “It demonstrates our dedication to customers and our commitment to sustainability.” This commitment began at Endress+Hauser over ten years ago as customers approached the company about its plans for sustainability.

“We measured waste in our factories and redesigned packaging to meet new sustainability goals,” says Altendorf. One goal became to reach the top 25 percent percentile in the EcoVadis sustainability audit rating. “We’ve reached the top 1 percent,” he explains.

Endress+Hauser has maintained a presence in Canada since 1990 with its own sales centre, which manages customers from Manitoba to the Atlantic provinces. The employees at the headquarters in Burlington, in addition to locations in Montreal, Calgary and Edmonton, are supported by various sales representatives. Whether primaries, metals and mining, oil and gas, food, chemicals, life sciences, water and wastewater,

wastewater 1c ad 4/5/05 2:53 PM Page 1

• Manual, automatic and actuated (pneumatic & electric) valves; relief, check, diaphragm, ball, solenoid, and shut-off. Also pressure regulators, metering pumps, basket strainers, sight glasses, and gauge guards.

• Innovative Engineering –Dedicated Craftsmanship.

• 100% inspection and individual testing of each product, to ensure dependable performance and long-life.

• PVC, CPVC, Polypropylene, PTFE and PVDF. Valves from 1/8'' to 3'',Sight glasses to 8'' and Basket Strainers to 14''.

Endress+Hauser USA’s GM and corporate sales director of North America, Paul Sharman, Burlington Ward 5 councillor, Anthony Varga, managing director, Endress+Hauser Canada, Burlington Mayor Marianne Weed Ward, Dr. Klaus Endress, President Supervisory Board, Endress+Hauser, and Fiona de Vet, member of the Endress family and shareholder, also participated.

and power and energy, the resource-rich country is home to virtually all industries.

“The new building is designed to express our standards as a company, not only to our customers but the public as a whole,” emphasizes managing director Anthony Varga. In planning the project, Endress+Hauser Canada focused on the needs of the customers. “We can provide the best possible support to our customers over the entire lifecycle of their systems. We offer an inviting environment while setting standards for ecological building design.”

Endress+Hauser Canada www.ca.endress.com

EFC RAISES OVER $160,000 FOR SCHOLARSHIPS

Electro-Federation Canada (EFC), representing over 200 organizations in the electrical industry, continues to support university and college students with funding through the EFC Scholarship Program. A record of over $160,000 raised will offer 63 scholarships supported by leading Canadian electrical manufacturers and distributors this year.

Campbell

and

CEDAR GROVE, NJ 07009 (973) 256-3000 • Fax: (973) 256-4745 info@plastomatic.com•www.plastomatic.com

Students pursuing a career in electrical engineering, electrical technologist/technician, industrial distribution, sales, marketing, finance, human resources, supply chain operations, logistics, data analytics management, or information technology are eligible.

Electro-Federation Canada www.electrofed.com

Endress+Hauser Canada and Intrepid Group Ltd are broadening their Authorized Channel Partnership to cover Saskatchewan. The expanded agreement allows Intrepid Group to provide customers in that province with Endress+Hauser’s measurement and analysis products as well as the enhanced services and support Endress+Hauser users in Alberta have enjoyed from Intrepid Group since the channel partnership was announced in 2017.

Intrepid Group

www.intrepid-group.ca

Oracle and Festo are joining forces to help educators create new opportunities and solve tough challenges at the Oracle Industry Lab in Chicago. The facility is said to provide hands-on, simulated industry settings for customers to experiment, learn, and bring transformative technologies to life.

At the lab, visitors will interact with a sophisticated Festo “Learning Factory” used in training and workforce development programs worldwide.

The Learning Factory models the next generation of Industry 4.0 production facilities and provides students with a holistic platform to understand Smart Manufacturing. The automated machinery uses advanced sensors, controllers, and software to produce “Lot Size One” simulated cell phones. Students learn and follow the process from order entry through production to final distribution.

“The demand for skilled workforce in manufacturing is skyrocketing, and innovations such as this will prepare the next generation of workers,” according to Ted Rozier, Director of Engineering, Festo Didactic Inc.

The 30,000-square-foot Oracle Industry Lab brings customers, technology partners, and the entire Oracle portfolio of solutions and decades of deep industry expertise together to incubate and demonstrate new solutions across industries. Supported by Verizon 5G Ultra Wideband, the Oracle Industry Lab will first focus on use cases in utilities, construction and engineering, communications, and manufacturing.

Festo Canada www.festo.ca

Eriez story began in 1942 when founder O.F. Merwin installed a permanent magnet in a grain mill. The Erie, PA-based company today, built of a workforce of more than 900 individuals located throughout 12 wholly owned international subsidiaries on six continents, is a global specialist in magnetic separation, flotation, metal detection and material handling equipment technology.

Over eight decades, the company says, Eriez has worked diligently to advance the mining, processing, packaging, food, recycling, aggregate and metalworking industries it serves. It adds that company process engineers and scientists have developed countless product breakthroughs in the areas of rare earth magnets, superconducting technology, flotation, vibratory feeders, metal detection, auto scrap recycling equipment, suspended electromagnets, eddy current separation, and proprietary manufacturing techniques.

Eriez is a family-run company with O.F. Merwin’s grandson Richard Merwin currently serving as chairman. Richard’s late father, Bob Merwin, had a global vision for Eriez and took the company into international markets in the 1950s. Eriez

www.eriez.com

Moderna, Inc., a biotechnology company pioneering messenger RNA (mRNA) therapeutics and vaccines based in Cambridge, MA, has announced its plan to build a state-of-the-art mRNA vaccine manufacturing facility in Quebec that will support a long-term strategic partnership with the Government of Canada to enhance pandemic preparedness.

This milestone follows the signing of a Memorandum of Understanding between Moderna and the Government of Canada in August 2021. Once the facility is certified by Health Canada, it is expected to provide onshore respiratory vaccine manufacturing capabilities and support future pandemic readiness. The partnership is expected to be finalized following approval of the final agreement by the Government of Canada.

Once operational, the facility is expected to provide access to a domestically manufactured portfolio of mRNA vaccines against respiratory viruses, including COVID-19, seasonal influenza, respiratory syncytial virus (RSV), and other potential respiratory viruses, contingent on approval by Health Canada.

As part of the ten-year partnership, Moderna is also expected to support R&D and commercial collaborations in the country.

Moderna www.modernatx.com

By Steve Bain

The ongoing need to make process adjustments in modern automation systems opens itself up to unwanted device tampering. This article outlines a five-step process to ensure effective, error-free process adjustments of pneumatic components.

Modern automation systems increasingly need to adapt to various products in multiple sizes and configurations. And one result of this variability is having to make frequent process adjustments to flow, pressure, end-stop limits and machine speed, to name a few. All too often, however, this ongoing need to make process adjustments opens itself up to unwanted device tampering, which can easily cause a machine or process to spiral out of control.

Step 1: Eliminate unnecessary process adjustments

Your first step is to eliminate process adjustments wherever you

can. For example, you can weld or secure machines in place if they never have to change position. Other solutions involve the use of fixed-orifice flow controls, correctly sized products, modular valve manifolds and cylinders with self-adjusting cushioning capabilities. These include fixed-orifice flow controls, proper dimensioning, modular valve manifolds, self-adjusting features, and lockable adjustments.

Your next step is to specify pressure regulators, actuators, and other components with built-in automation capabilities, removing human error from the equation. For example, proportional pressure regulators like the VPPM automatically adjust the output pressure via a 0 to 10 V or 4 to 20 mA signal from the programmable logic controller (PLC). Thanks to its two-stage circuit and multi-sensor control, this device provides precise, reliable pressure regulation. You can also preset parameters like

pressure, piston speed and rotational speed with the push of a button — no technical specialists required.

Other examples include advanced electric or servo-pneumatic actuators, which you can configure according to your exact speed and force requirements without additional pressure regulators or flow controls, as well as intelligent servo motors. The SMS electric actuator for example, combines a motor,

controller, and electric axis package, facilitating changeovers and enabling fast, consistent process adjustments.

In addition to the examples mentioned above, look for digitized pneumatic solutions like the Festo Motion Terminal VTEM (see sidebar for more information). By combining pneumatics and electronics in a single package, the VTEM functions as the world’s first app-controlled valve, enabling you to digitally define,

control and analyze valve function, flow rate, pressure, and other process parameters:

• Air flow control. The VTEM removes separate flow control valves on the actuator, allowing you to set tamper-proof travel speeds at the push of a button. It also provides the option to implement new motion sequences like dynamic flow control.

• Pressure levels. With the option to input pressure levels, the VTEM saves energy. Simply select the movements and set the pressure to the level of your choice. You can even control the speed by adjusting the flow control valve setting.

• Leakage diagnostics. With separate diagnostic cycles and defined threshold values, the VTEM lets you detect and localize leaks, minimizing your downtime.

The third step is to monitor and detect the status of processes that may be affected by any process adjustments. Examples include:

• Differential pressure monitoring solutions that can help you determine when you may need to replace your filters.

• Pressure sensors and switches that can communicate with the PLC, verifying if a process is within the desired pressure range.

• Flow sensors that monitor the amount of consumed air, indicating if a process is performing as expected.

Of course, automatic process adjustments are not always possible. If you do need to make a manual adjustment, we recommend using a numerical scale to ensure the adjustments are consistent. For example, look for flow control components with position markings or digital flow meters: the GRLSA oneway flow control valve includes a labeled adjustment ring, while SFAH, SFAB and SFAM flow sensors feature an integrated display, ensuring you achieve your desired flow rate.

Your last and final step to ensure error-free process adjustments is to use pneumatic components with red and green indicators. These features offer a quick and easy way to validate

when processes are performing as expected.

For example, MA-RG pressure gauges include an adjustable red and green range, providing an extra level of safety when monitoring your compressed air usage. Units include red segments above and below the pressure gauge scale, as well as a printed green segment. Thanks to this colored demarcation, you can immediately identify when the pressure is or isn’t in its permitted tolerance range. These gauges can handle ranges from vacuum to 16 bar and include an optional flange design for panel mounting.Similarly, MS Series components, which include

pressure regulators, ON/OFF valves, soft-start valves, pressure sensors and flow sensors, feature an integrated red and green scale that displays the output pressure. SFAM flow sensors, for example, feature an illuminating display that turns red, indicating when the flow is out of the desired range.

Although making process adjustments is inevitable, it doesn’t have to result in unwanted device tampering or machines and processes spiraling out of control. By following these five steps — which includes using components with automatic adjustment capabilities, implementing sensors, using visual indicators and more — you can ensure all process adjustments to your pneumatic components are effective and correct.

Steve Bain is Industrial Segment Sales Manager – Food and Beverage, Festo Corp. Festo Canada www.festo.ca

Big news from your friends here at Canadian Process Equipment & Control News

Annex Business Media has purchased Canadian Process Equipment & Control News Ltd. and will merge IPP&T into the brand. This will create a singular strong voice for the process/ resource industries across Canada. By combining both magazines under the CPECN brand, advertisers will now have a larger extended reach across print, digital and events.

I’ll be staying on to run this brand, as well as integrating Annex’s own Industrial Process Products & Technology (IPP&T). CPECN editor Mike Edwards also remains with the brand.

“This acquisition makes perfect sense for Annex,” says Martin McAnulty, group publisher and vice president of sales, who worked with me on the deal and will manage the combined brands in his group. “The business model is very similar to ours. Rob has done a tremendous job building the CPECN brand, which has a loyal audience reach that includes print, digital and events from coast to coast to coast.”

The regional table-top shows are being re-launched in the coming months and will benefit from Annex’s professional event management team.

So, 2022 is turning out to be a tremendous year — we are celebrating our 50th anniversary and now we’ve joined Annex Business Media. The synergies between the two companies will make for a seamless transition and we can’t wait to get started and expand our brand.

And now I have two things I’d like to ask you, our valued readers:

• Be sure to come by our Process and Automation Shows this fall and say hello, and

• Sign up and re-new your subscriptions. You’ll want to see the exciting improvements we implement this fall.

Cheers,

Rob Sommerville

The MCP-300 is an extended mini-capacitance probe from BinMaster suitable for inventory, level detection, and process control in liquid-based tanks. Probes have a stainless-steel tube customized from 2.5 to 9.8 in. The point-level detector features wireless Bluetooth setup to prevent problems with dry runs that damage equipment and can detect flooding in a pump room. The unit alerts when water reaches the level of the sensor. An LED status light changes colour based upon sensor status. BinMaster.com www.binmaster.com

The Safety Station from HEMCO is a multi-purpose drench shower, eye/ face wash and safety supply storage cabinet all in one. It is suitable for laboratories where persons may be exposed to potentially hazardous chemicals. Sanitary white polypro construction means there is no wood or metal to rot or rust. The unit is equipped with a pull rod activated shower and push handle eye/ face wash for quick rinsing of eyes, face and body. Towels and first aid supplies can be stored in the cabinet below. Units available in 24, 30 or 36 in. wide x 24 in. deep and 84 in. high variations and are fully assembled and ready for installation to water supply.

HEMCO Corporation www.hemcocorp.com

ZLS series floor height lift tables from Southworth have a pan-style platform that, when lowered, sits essentially flush to the floor allowing them to be loaded and unloaded with an ordinary hand pallet truck. Forklift-free loading and unloading has become increasingly important as many facilities have established fork-free zones, and some have eliminated forklifts entirely. The lifts provide workers unobstructed access to loads from all four sides. Once loaded, the hydraulic lift table can be positioned to any height up to 35-3/8 in. The 50 x 48 in platform accepts a variety of pallet and skid sizes, including open or closed bottom. Three models are available with 2,000, 4,000 or 6,000 lb capacities. A 6 in. flexible, high-visibility yellow strip is mounted to the front edge of the platform to protect against toe injuries. Lifting and lowering is controlled by either a footswitch or pushbutton pendant. Southworth Products Inc. www.southworthproducts.com

The PCME QAL 182 Wet Stack Monitor from Avensys Solutions is suitable for measuring particulate emissions from wet scrubbers and other processes where the flue gas falls below dew point (cold stack conditions) or water droplets are present. The unit’s ProScatter forward light scatter sensor is certified for compliance monitoring. Specifications include sensitivity to <0.1mg/m³ and high stability even at low concentrations (< 0.1 mg/ m³). The modular design is said to facilitate ease of assembly, servicing and lifting to stack location. Features include isokinetic sampling with automatic adjustment, with fully automated and extensive self-checks (Zero and Span) with a dedicated audit channel. Avensys Solutions Inc. www.avensys.com

“excellent use of my time and my company’s time”

Plant Manager, REFINERY

We’re bringing world class experts to your neighbourhood for one day only at our Process & Automation Shows

• Face to face access to national and local experts in their field

• Try out products right at the show

• Save time and visit as many companies as you like in one day

• Compare technologies and pricing from leading companies

“Solved a problem we’ve had for years... now I don’t have to worry about it anymore”

Maintenance Technician, FOOD PROCESSOR

The Sensor Connection a division of Harold G. Schaevitz Industries LLC, has expanded its line of measurement and control instrumentation with the addition of the model PMD-MXT series of RTD scanner indicators. The microprocessor-based temperature scanner provides continuous monitoring of up to 32 channels of RTD sensors. The 14 mm tall digit red LED display and rows of LED annunciators warn of specific channel alarm conditions. The scanner has two user-selectable HI/LO, HI/HI, or LO/LO alarm set points, configured through the front panel push buttons. During an alarm condition a front panel LED annunciator is enabled and an internal 2 A relay contact output is engaged. The scanner’s display will auto cycle through all input channels at a user determined rate of 0.5 to 10 seconds per channel.

Harold G. Schaevitz Industries LLC www.hgsind.com

LJ Star has introduced a new vessel light option in its LumiStar line — the ESL 53LED EX. Made from stainless steel, the ATEX explosion-proof rated light is said to offer bright, energy efficient illumination for sight glass and process lighting. The main light housing measures 53 mm in diameter by 165 mm long, substantially smaller than other explosion-proof lights that are offered, the company says. The light comes with a hinged bracket or a sanitary flanged adapter and is compatible with round sight glass fittings as well as screw-type sight glass fittings with multiple mounting options. The LED light provides 400-500 lumens with a light color of 5700K, while drawing 7 W. LJ Star www.ljstar.com

inet Cooler System for any specific application. By providing certain information like size of the enclosure, NEMA rating needed, and environmental conditions, the new calculator will sort through our large selection of ready-to-ship systems and provide instant feedback on the best cooling solution for any applicable electrical enclosure, it adds.

Exair

www.exair.com

Safety valves from WITT are designed to provide the required precision and flow capacity for electrolyzers used to produce green hydrogen. Hydrogen electrolyzers consist of several stacks of electrolysis cells that require protection against overpressure with safety valves. To match target pressure and temperature ranges, and safety valve models AV 619 and AV 919 were created for PEM and Solid Oxide electrolyzers. The opening pressure can be set accurately anywhere in range 5 to 500 mbar, the company says, with an operating temperature can be anywhere up to 250°C. For Alkaline electrolyzers, the SV 805 model is suitable, with an opening pressure settable anywhere in the range 0.5 to 45 bar, with operating temperatures up to 150°C.

WITT-Gasetechnik

www.wittgas.com

Polytron Devices has expanded its power capability from 30 to 450 Wmax for its low-noise linear power supplies. Engineering staff can suggest solutions, create evaluation samples, safety-test units and help ensure regulatory approvals such as IEC 60601 for medical equipment. Custom needs can be accommodated, such as: providing multiple output voltages in a single model; adding programmability or ON-OFF switches; and adding a variety of types such as open frame, desktop, and wall plug-in models, in addition to enclosed units for harsh environments.

Polytron Devices

www.polytrondevices.com

Exair Cabinet Cooler Systems are said to provide a comprehensive solution for cooling and purging electronic cabinets and come in a litany of different cooling capacities, NEMA ratings and classifications. With the breadth of available options, choosing the best cabinet cooler for a specific environment can be a tedious task, the company says, and depends on a few key factors. A Cabinet Cooler Calculator has been introduced to make it easy to find a suitable Cab-

Meltric has announced the DSN100, a switch-rated, 100 A, 600 Vac plug and receptacle fitted with Decontactor technology for peak performance and user safety. The technology allows the company’s switch-rated plugs and receptacles to be safely connected and disconnected under full load, up to 200 A and 100 hp, in wet or dry conditions. The Type 4X/IP69/IP69K environmental rated units are said to combine the safety and functionality of a disconnect switch with the convenience of a plug and receptacle in one device. Meltric

www.meltric.com

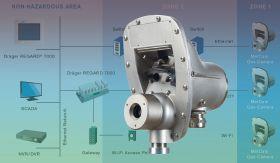

The MetCam is an explosion-proof gas camera from Draeger that continuously monitors large areas for hazardous methane leaks and fugitive emissions. The device automatically quantifies the source and intensity of the leak using advanced algorithms and transmits alarms via analog 4 to 20 mA/HART or RS485 Modbus. Visualization is via Ethernet or Wi-Fi. The camera automatically monitors a facility around the clock. Unlike point detectors, the gas source need not be in the immediate proximity of the gas camera, the company says. The source just needs

to be in the field of view of the camera, which makes detection independent of wind or similar influences, it adds. The unit is said to detect and alerts gas leaks at an early stage, providing time to react, increasing facility safety and efficiency. The gas camera visualizes the gas cloud as a coloured overlay on the blackand-white video image and independently quantifies the concentration. As a result, an event can be interpreted from a safe distance, such as, from a control room. The device can also be used to measure emissions or as a surveillance camera with a colour image.

Draeger

www.draeger.com

Qosina, a global supplier of OEM single-use components to the medical and pharmaceutical industries, has introduced a selection of pinch clamps made from polybutylene terephthalate (PBT), an alternative to nylon that is used in the manufacture of many types of single-use components. The ¾-in. pinch clamps are now available in white, red, yellow, blue, and black, making them suitable for colour-coded sets. The clamps are said to provide one-handed closure — no tools needed — and clamp materials meet USP Class VI and ISO 10993 criteria. The products are gamma and autoclave compatible.

Qosina www.qosina.com

Carlo Gavazzi has introduced model EM530 and EM540 three phase energy analyzers. The EM530 is a Class 0.5S (kWh) analyzer which measures currents up to 10,000 A via 5 A current transformers, and the EM540 is a Class 1 (kWh) analyzer which measures current up to 65 A via direct connection, the company says, eliminating the need for current transformers. The 3-phase power analyzers can be used for two and three phase systems, as well as wild-leg systems. Units can measure most

relevant instantaneous electrical variables, energy consumption, and harmonic distortion, it adds. Both models feature high speed 100 ms serial data refresh rates, making them suitable for load balancing energy storage or EV charging applications. Fast commissioning is said to be possible thanks to an intuitive wizard setup menu, along with instant notification of wiring errors and suggestions for correcting them.

Carlo Gavazzi www.gavazzionline.com

The model DB belt rip detector, manufactured by Conveyor Components Company, is a mine-duty and quarry-duty belt rip detector, which operates on a simple cable pull concept. When a belt flap or tear, or a foreign obstruction such as a wrench or screwdriver or piece of rebar has pierced a conveyor belt, the cable releases the activation ball from its protective socket and trips the device. The outputs of the detector can control up to four separate circuits, depending on the model chosen, as either SP/DT or DP/DT microswitches are available. The alarms can include one for machinery shutdown, which minimizes further conveyor belt damage, and one for alarm. Housing construction is cast aluminum, with an optional polyester or black epoxy powder coating. The protective rubber boot on the cable assembly keeps the activation mechanism clean and functional, the company says, and is easily replaced if damaged.

Conveyor Components Company www.conveyorcomponents.com

Log direct pressure readings with the push of a button. Name a preset number of points and specify target pressure and/or permissible error, or just log reading at will and capture other custom values to match your SOPs. Perfect for:

• Tank pressure tests

• Logging tire pressure on vehicles or aircraft

• Testing boilers that need daily pressure measurements

• Logging pressure for each pressurized unit of a product as it comes off the assembly line