Festo Canada has announced the MS series of pre-assembled filtration products designed to lower the risk of particle contamination when compressed air comes into direct contact with food or packaging in the food zone. The three different models in the series — MS4, MS6, and MS9 — conform to FDA and US Food Safety Modernization Act guidelines or clean air. The filtration systems are rated for air flow ranging from he MS4 at 360 l/min to MS9 at 7,800 l/min. In addition to the threestage filters, MS air preparation units come with a lockout/tagout feature. Red/green gauges indicate when filers require replacement.

Festo Canada

www.festo.ca www.cpec.news/4vx

The MIM electromagnetic flowmeter from Kobold Instruments measures and monitors small to medium sized flow of conductive liquids in pipes. According to Faraday’s Law of magnetic induction, a voltage is induced in a conductor moving through a magnetic field. The voltage induced in the measured media is proportional to the flow velocity and is therefore a value for the volumetric flow. The flow rate will be calculated based on the cross-sectional area of the pipe. The measurement does not depend on the process liquid and its properties such as density, viscosity and temperature. The two outputs can be independently set to switch or provide an analog or fre quency output. A batching function can also be selected. Watch demo at www.cpec.news/xke. Kobold Instruments Canada www.kobold.cawww.cpec.news/t4q

The series EASMT/EASYMT PTFE bellows solenoid valve from Plast-O-Matic is designed for severe service applications with most types of liquids. Units are suitable for pressure, drain or vacuum service, and sizes range from 1/4 to 1 in. Valves are spring return normally closed and direct-acting with a simple push-pull plunger design. There is no minimum pressure equired for operation. The PTFE bellows shaft seal is said to eliminate the need for an elastomer seal which can weaken as a result of chemical attack. The PTFE bellows assures smooth, non-sticking operation, the company says, and has a cycle life of over 2 million in laboratory conditions. The bellows design also allows a stock valve to be used for vacuum or pressure. The poppet seat ensures bubble-tight shutoff Plast-O-Matic www.plastomatic.com www.cpec.news/6h8

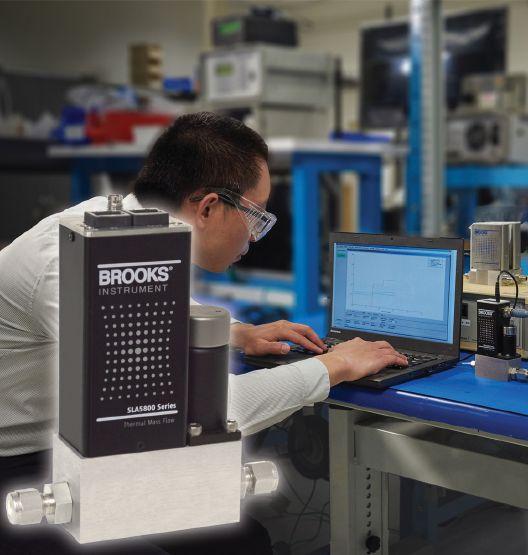

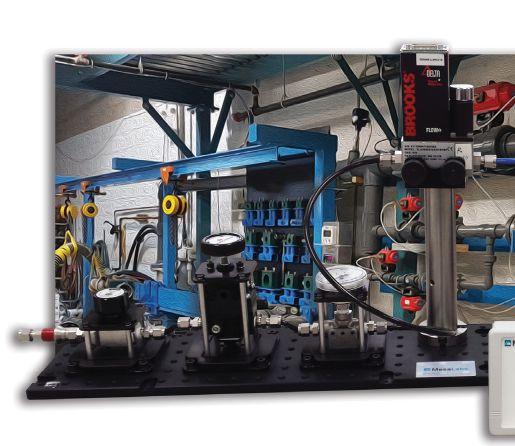

Brooks Instrument has made ISO/IEC 17025 certification available as an option on its SLA series Biotech mass flow controllers (MFC). Engineered specifically for the needs of the biotechnology market, the MFCs are used to precisely measure and control the delivery of process gases necessary for cellular metabolism in biotech applications, the company says. This certification, in addition to FDA/USP class VI/ADI-free elastomers and other certificates, satisfies even more regulatory compliance requirements for biopharmaceutical manufacturers that depend upon accurate flow control calibration for their applications. Highlights of the series also includes a broad range of analog and digital I/O options suitable for most biotech applications. An independent diagnostic/service port permits users to set alarms and diagnostics, tune, troubleshoot or change flow conditions without removing the mass flow controller from service. The series is said to provide a highly configurable platform based on a simple modular architecture. The feature set was carefully selected to enable dropin replacement and upgrade of many brands of mass flow controllers. Watch product video at www.cpec.news/hls.

Brooks Instrument

www.brooksinstrument.com www.cpec.news/loo

Are you getting the best possible price from your supplier on every purchase, or do you have to buy in bulk to get the lowest price? The buy more, pay less game works great for those with big budgets and big projects, but if you only need a handful of components it doesn’t work at all. At AutomationDirect, we never play games with our prices, you get the lowest price possible no matter if you buy one or a thousand.

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days. *Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

“...You cant beat the prices I will always keep coming back for all our Automation needs from switches to Frequency Drives.”

Daniel in PHOENIX, AZ

“Always quality products for system integrators with excellent pricing and delivery.”

Leonard in SUWANEE, GA

“I have been in the Industrial Maintenance/ Automation eld for over 20 years and had used AB almost exclusively, until I was introduced to Automation Direct 3 years ago. They have a wide variety of high quality parts available, with quick turnaround times, at very good price points...”

Cleigh in HEBRON, OH

Safety Light Curtains

SAFETY IS NOT OPTIONAL

Get your safety and other automation components from AutomationDirect, a trusted supplier in the industry for over 25 years. We offer high-quality safety products at great prices, so you can afford to protect even the simplest systems.

Safety Relays Starting at $95.00 (LG5924-02-61-24)

Starting at $468.00 Sender/Receiver Pair (YBES-30K4-0170-P012)

Safety light curtains use an array of photoelectric beams to sense intrusion into a plane of detection.

Type 4/Category 4 curtains achieve high fault tolerance through redundancy/ monitoring, have a tighter field-of-view and are less susceptible to optical short circuits. We offer many sizes, styles and brands such as Contrinex, Datalogic and ReeR.

Safety relay modules are a simple and reliable method of controlling a safety system that uses positive guided contacts and redundancy for fail-safe systems. Available models include E-stop, two-hand, safety gate, safety mat, light curtain, and speed safety relays.

Safety Controllers Starting at $299.00 (MOSAIC-M1)

Safety controllers use monitoring logic, overvoltage / short-circuit protection, redundant relays, and positive guided contacts to provide a high level of failsafe operation. The modular MOSAIC safety controller is an expandable, cost-effective choice (vs. standalone safety relays) as the required number of relays/channels increases.

Safety Switches Starting at $16.00 (SP2K61X11)

Safety switches are interlocking devices used to monitor (and sometimes lock) machine guards, doors, gates or windows. New stand-alone non-contact magnetic coded safety switches protect personnel and machinery without the need for a separate safety relay.

Our shipping policies make it easier than ever to order direct from the U.S.!

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days.

*Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

What's that I hear? Applause coming from an industry association for government initiatives instead of Bronx cheers?

Yes, the Chemical Industry Association of Canada (CIAC), has gestured thumbs up to the feds for its 2021 budget and for tabling legislation to modernize the Canadian Environmental Protection Act, 1999 (CEPA).

For more than 35 years, Canada's chemistry sector has led the journey towards safe, responsible, and sustainable chemical manufacturing through its U.N.-recognized sustain-

ability initiative, Responsible Care. Founded in Canada in 1985, Responsible Care is now practiced in 73 countries and by 96 of the 100 largest chemical producers in the world.

According to Bob Masterson, president and CEO of CIAC, the CEPA Bill "offers a well-balanced approach to addressing identified shortcomings in the current legislation while preserving the essential, risk-based approach to the regulation of chemicals in the Canadian economy."

In the budget, CIAC has identified a number of initiatives that will bring

benefits to Canada's chemistry and plastics sectors, including: a Chemicals Management Plan of $476.7 million for a further five years to "continue to protect the environment from ... chemicals that can be harmful"; and a $7 billion commitment to a fund that support projects to help decarbonize heavy industry and help accelerate domestic greenhouse gas emissions reductions.

Want to give yourself a hand? Turn off the A/C and sit under a shady tree.

Mike Edwards medwards@cpecn.com

August Issue

Focus on Environment Supplement: Wastewater Management

Editorial closing date: July 16

October Issue

Focus on Fluids Handling Supplement: Sensor Technology

Editorial closing date: September 3

December Issue

Focus on Plant Automation Supplement: Fittings & Couplings

Editorial closing date: October 22

Harting has developed new interfaces for the power supply of trains that are optimized for a long service life. The Han HPR High Performance Transformer Connector (HPTC) is a transformer interface especially developed for railway customers and optimized for outdoor use. The unit connects the converter to the transformer. The new interface is available in the 400, 850 and 1400 A power classes, while voltages up to 3.6 kV/4.8 kV can be transmitted. In addition, the Han HPR VarioShell (left) was specifically developed for jumper applications. The

two-part enclosure achieves protection class IP69K by using a counterpressure frame, in connection with a circumferential internal seal. The enclosure cover is removable, allowing efficient assembly from both inside and outside the wagon. Han HPR TPL train power line (right) for power distribution in underfloor areas ensures that there is only one completely pre-assembled Y-distributor as standard interface as well as single poles for the pluggable connection of the cables.

Harting Canada www.harting.ca

The new Fluke 377 FC and 378 FC non-contact voltage True-rms AC/ DC clamp meters minimize the risk of encountering a live conductor because they make accurate non-contact voltage measurements without test leads, the company says. Simply clip the black test lead to any electrical ground, put the clamp jaw around the conductor and see reliable, accurate voltage and current values simultaneously on the dual display, it adds. Both clamp meters offer complete 3-phase voltage and current tests in three quick steps. A full set of phase-to-ground and phaseto-phase values are displayed on the meter. These measurements along with phase rotation information are displayed on your smart phone and saved to the cloud via Fluke Connect software, eliminating the need for handwritten notes or complicated math. The 378 FC also includes a power quality indicator that senses PQ issues — relating to current, voltage, power factor, or any combination of the three. Watch video demo at www.cpec.news/v1h.

Fluke Electronics Canada www.fluke.com/en-ca/ www.cpec.news/o25

CORIOLIS FLOWMETERS IMPROVE MEASUREMENT ACCURACY BY 50 PERCENT

NSF 61 & 372 Certified

The NS Series ball valves are available in sizes 1/4”-6” with threaded, socket weld, butt weld (3-piece) and flanged (2-piece) connections.

The NS Series butterfly valves cover 2”-24” sizes in wafer and lug style.

APPLICATIONS

• Water Treatment

• Potable Water Service

• Reverse Osmosis

• Desalination

Hoskin Scientific has introduced Coriolis flowmeters from Rheonik that offer 50 percent more accuracy than previously. When used with Series 20 and Series 40 transmitters, models RHM30 to RHM100 Coriolis flowmeters provide 0.1 % instead of 0.15% with “S” version sensors, thereby offering improved Gold Line accuracy with larger meter bodies. Applications for the flowmeters include general flow control, plant balance, additive dosing, high temperature fluids, viscous fluids mixing, blending, batching, package and container filling. Sensor benefits include a torsion oscillator design said to assure a stable and drift free measurement with excellent signal to noise ratios. Resilient to external noise and vibration, the corrosion-resistant units are also said to be insensitive to pipe pressure changes. In addition, the tube wall thickness provides increased operational safety in abrasive applications. Long sensor life is guaranteed due to low mechanical stresses in the meter mechanism and there are no moving parts to wear or fail.

Hoskin Scientific

www.hoskin.ca

www.cpec.news/976

Predictive maintenance, a system where inputs from electronic sensors and transmitters are used to help forecast when equipment needs to be serviced or replaced, is the key to minimizing downtime, maximizing efficiency, and saving money.

Whether production lines are manual, automated, or a hybrid of the two, the goal of every manufacturer is to keep things running without a hitch. The same with off-road machinery like forklifts and agricultural sprayers. Equipment malfunction and failures mean accidents and unscheduled downtime, both of which can be costly and devastating.

The solution: predictive maintenance. In industrial and process applications, pressure sensors and transmitters serve as the backbone of a monitoring system that warns users when equipment needs to be serviced or replaced. In today’s smart factories and mobile working machines, these electronic components can be easily incorporated into existing processes. The predictive maintenance market was worth $2.39 billion in 2018 and is expected to reach $18.55 billion by 2026.

What is predictive maintenance?

Predictive maintenance means using electronic pressure sensors and transmitters to monitor the smooth running of a production line and, more critically, to connect those sensors to software that can create models that accurately predict when equipment will degrade or performance will fall off.

Compare predictive maintenance to other forms. Corrective maintenance means fixing equipment when it breaks, while scheduled maintenance services or replaces parts on a set timeline. Take automobiles as an example. Which

is most efficient:

• Changing the oil every 5,000 miles or six months?

• Changing it when the engine seizes from too much metal-on-metal friction?

• Changing it when the oil is about to pass its peak performance level?

Scheduled maintenance (A) is fine, but it doesn’t take into account other factors such as driving habits, type of oil, the vehicle’s age, climate, and so on. There’s also the possibility of changing the oil when it’s still serviceable, which not only takes time and money, but also wastes resources and unnecessarily adds to the waste stream.

When it comes to most machinery, including cars, corrective maintenance (B) is very expensive and dangerous. Only a fool would spend thousands of dollars on replacing an engine – and risk personal injury – rather than spending $25 to $50 for routine oil changes.

Predictive maintenance (C) is the smart, just-intime approach: changing the oil only when electronic sensors indicate it needs to be changed.

PM calls for electronic pressure sensors and transmitters In many industrial processes and mobile machinery, safe and efficient operations depend on maintaining the right pressure in equipment, such as the fluid moving through a pipeline or hydraulic hose. A drop in pressure might indicate a partial blockage or other internal issues, while a spike in pressure could mean that a breakage, eruption, or even explosion is about to occur. Electronic pressure sensors let users “see” inside equipment and take preventive actions, before problems become too big to easily correct. In a

process involving many parts and steps, multiple electronic transmitters will measure and set norms for a host of pressure variables, and also give a warning if anything is amiss.

Electronic pressure instruments remove the guesswork from taking readings and can also send the information to a nearby computer or remote monitoring station. What’s more, a network of sensors and transmitters allows operators to compile accurate trend data, allowing them to plan ahead for repairs and part orders.

Electronic pressure instruments

At WIKA Canada, the company offers a wide variety of electronic pressure sensors and transmitters for general purposes or specialized applications, including medical gases, refrigeration and HVAC, off-road machinery, liquid gas tanks, and sanitary applications.

These pressure sensors are constructed almost entirely from solid-state electronics with few or no moving parts, thus offering a long, maintenance-free service life. They’re also highly customizable, with a wide selection of pressure ranges, pressure types, accuracies, materials, process connections, electrical connections, and output signals. A complete predictive maintenance system combines high-performance pressure sensors with advanced computing technology to keep in-plant or off-road machinery working at their peak.

Engineers at WIKA can also customize sensors for specific applications. Each instrument is tested and calibrated prior to shipping.

This article was excerpted from a blog by WIKA Canada. WIKA

Ralston Instruments has introduced compressed gas cylinder adapters, an addition to its broad line of pressure calibration products. Made of stainless steel with a knurled knob for easy grip, compressed gas cylinder adapters make it easy to connect and disconnect a hose or regulator to inert gas cylinder valves without a wrench or thread tape, the company says. The compressed gas cylinder valve adapters are said to be a practical and functional option for pressure calibration applications in the oil and gas, healthcare, pharmaceutical, aerospace, and plastic industries, along with processes involving the use of inert gas cylinders. The five available models connect to CGA 580 (US and Canada), BS 341 Type 3 (UK), NF E29-650 Type C (France), DIN 477 Type 10 (Germany) and AS 2473.2 Type 50 (Australia). Watch video at www.cpec.news/dm4.

Ralston Instruments

www.ralstoninst.com/cpn-cgcva

www.cpec.news/62i

WIKA offers welded units of diaphragm seal and measuring instrument with Tri-Clamp connection for process integration. A combination of this connection with easy-to-clean NovAseptic connecting pieces is possible without further modification. In sanitary applications, the diaphragm seal systems ensure a safe and precise monitoring of the process pressure. The connection is used, among other things, for tanks and similar vessels. Measuring instruments are installed, without tools, using a clamp connection. When installed correctly, the connecting nozzle welded in flush to the tank wall ensures a connection without dead space. This fulfills an essential prerequisite for effective and, at the same time, rapid CIP/SIP processes, the company says. Watch video at www.cpec.news/f4f.

WIKA Canada Group

www.wika.ca

www.cpec.news/g1i

Available from Turck Canada, the Grace Technologies Inside-Outlet is said to be unique because it has three GFCI-protected receptacles — two outside and one inside the panel. Additionally, the GFCI receptacle provide companies a trouble-free step toward complying with jurisdictions that require externally mounted utility receptacles be GFCI protected and tested every 30 days. Non-GFCI outlets inside a panel can be wired through the device, which is then externally mounted on the panel door. Testing is as simple as walking up to the door, flipping the protective cover, and pushing the button, the company says. Units maintains enclosure rating and are approved to UL E207344 Type 4 (Gray) and 4X (Black), IP-65 (Outdoor Use), and CSA LR110845 (where applicable).

Turck Canada

www.turck.ca

www.cpec.news/f20

Something is obviously broken.

By Rahul Chaturvedi

The median cost of maintaining a manufacturing facility is $2.60 per gross square foot (ft2). It is only slightly less ($2.36/gross ft2) for office buildings, which makes maintenance even more expensive than the average cost of utilities ($2.10/ft2) in commercial buildings. In fact, typical maintenance costs are as much as double the cost of leasing the space and are a large contributor to the Total Cost of Ownership (TCO) of any equipment. Thus, maintenance is a time and resource intensive process.

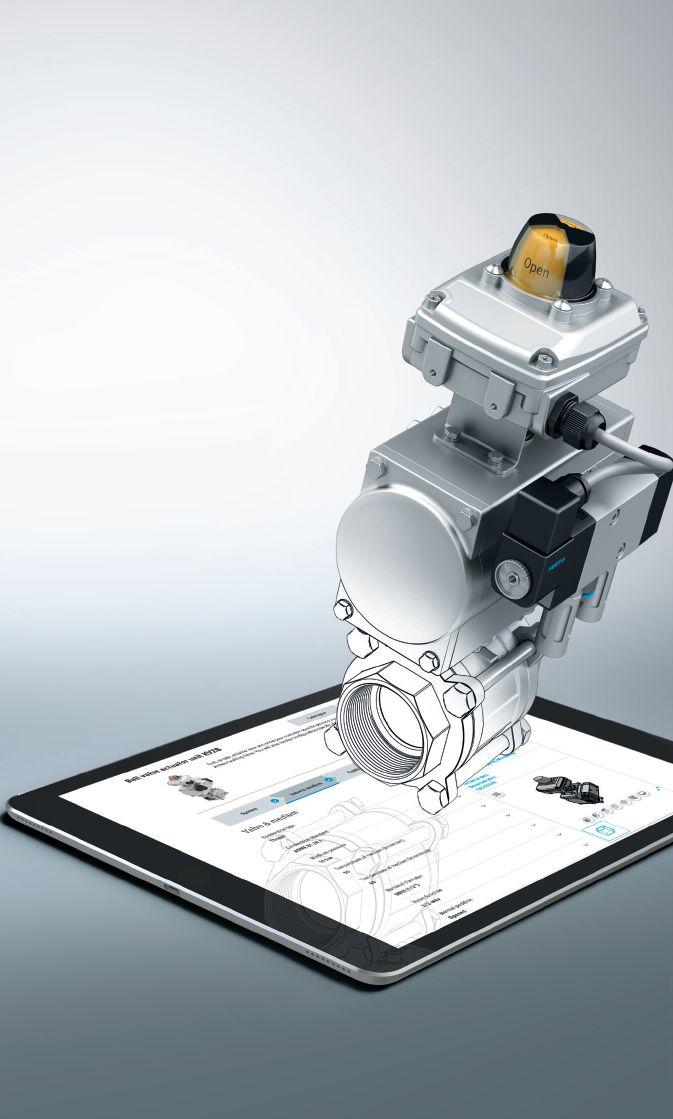

Get into the flow.

Configure your process valve units in minutes. It’s easy, intuitive and quick.

Start today at festo.us/flow

Despite such high costs of maintenance, a 2015 survey of 761 companies by the American Productivity and Quality Center (APQC) showed that the median organization experiences 4% unplanned machine downtime as a percentage of scheduled run time. Further, per a 2016 study by the Aberdeen Group, these unplanned downtime incidents average 4 hours each and cost an average of $260,000 per hour. Additionally, the Information Technology Industry Council (ITI)’s independent survey data indicates that the cost of hourly downtime has risen from 25% to 30% since 2008 when ITI first began tracking these figures.

Unfortunately, due to its excessive reliance on preventative maintenance (PM), the industry, regardless of maintenance spending, continues to experience significant downtime events. The median 4% unplanned downtime in the APQC survey is simply too high. Worse still, IBM reported that a big portion of the money spent on PM is wasted. The negative impacts of these failures are often exponentially more expensive to the organization than the replacement value of failed equipment. In other words, for far too long, too many maintenance dollars have been spent with too few benefits.

This wastage occurs primarily because PM is only effective for age-related failures, which represent a mere 18% of all failures. In its Reliability Centered Maintenance Guide for Facilities and Collateral Equipment, the US National Aeronautics and Space Administration (NASA) says, “Despite the time-honored belief that reliability was directly related to the intervals between scheduled overhauls, searching studies based on actuarial analysis of failure data suggested that the traditional hard-time policies were, apart from their expense, ineffective in controlling failure rates.”

Exclusive use of PM was understandable at a time when actionable machine data was hard to come by. Maintenance teams were naturally forced to rely on a combination of experience, intuition, and original equipment manufacturer (OEM) prescribed service schedules.

The advent of high computational densities that facilitate edge learning, the Internet of Things (IoT), and Artificial Intelligence (AI) have made it possible to eliminate these limitations and are promising to finally re-make maintenance into a predictive and proactive function. For instance, VIE Technologies offers an end-to-end service that combines these new technologies to deliver a highly machine-specific predictive solution that informs the user of future failure events in any type of rotating machinery.

Today’s maintenance problem

Overall equipment effectiveness (OEE) and return on assets (RoA) are two metrics commonly used to compare the performance of disparate operations. OEE measures how well a manufacturing operation is utilized (facilities, time, and material) compared to its full potential during the times when it is scheduled to run. It identifies the percentage of manufacturing time that is truly productive. An OEE of 100% means that only good parts are produced (100% quality) at the maximum speed (100% performance), and without interruption (100% availability). Improving OEE increases revenues due to greater throughput and profitability due to better quality. RoA is a measure of how efficiently a corporation uses its assets to generate earnings. It assesses the return on the capital investments made by a company. The higher the asset utilization in revenue generation the better the RoA. Maintenance organizations exist to improve OEE and RoA.

North American companies average only 40% OEE, which is less than half of what world-class standards consider acceptable. Further, the median RoA for food processing stands at 4.24% in Q1 for 2021, according to CSI Market.

Predictive maintenance adoption

The airline industry was the first to realize the value of predictive and condition-based maintenance. Airlines abandoned scheduled time between overhauls (TBO) in favour of condition-based approaches for the vast majority of their components.

The results were astonishing. DC-8 aircraft required 4 million labour hours of major structural inspections during the aircraft’s first 20,000 hours in service following TBO-based maintenance programs. Just as the DC-8 was being retired and replaced by the Boeing 747, the industry started adopting reliability-centered maintenance (RCM)

principles that favoured condition-based approaches. The new maintenance program set up for the Boeing 747 called for only 66,000 labour hours for the first 20,000 hours of service; a reduction of nearly two orders of magnitude. In addition, the new RCM programs improved the safety and performance of the equipment.

AI trained by vibration science promises to revolutionize maintenance practices

Even so, most other industries still largely use time-based preventative maintenance methods. Unfortunately, all maintenance activities suffer from the Waddington Effect, a phenomenon named after a World War II British Royal Navy officer and scientist who found that the scheduled preventive maintenance prescribed for RAF Consolidated B-24 bombers was actually doing more harm than good. Unfortunately, the Waddington Effect remains true to this day. In their 2020 paper - Causes and Impact of Human Error in Maintenance of Mechanical Systems — Nkosi, Gupta, and Mashinini found that 15% to 20% of the failures, incidents, and accidents are due to maintenance errors.

Any effort to improve the effectiveness of the maintenance organization must begin with the process itself. Much of maintenance scheduling, planning, and performance today is formulaic. It relies on a combination of ad hoc human experience and generic OEM prescriptions. Condition-based aspects of maintenance that present quantifiable evidence are largely confined to trending historical data gathered from a few monitoring sensors on critical equipment. Such trending has limited predictive quality since these measurements are coarse and easily influenced by many confounding operational variables such as load changes, capacity sharing, the use of variable frequency drives, etc.

Improvements to the maintenance function requires an organization to convert uncertainty— the situation where either all outcomes or their probabilities are unknown—to risk (where the outcomes and probabilities are all known) so that the costs and benefits can be quantified, modeled, and managed.

Traditionally, all predictive methods that help identify and quantify such risks have been a purview of human subject matter experts (SME) such as the Category III and IV vibration analysts who provide valuable failure prediction services by applying their deep understanding of both vibration science and its applications in diverse operating environments. These vibration analysts are all certified to the ISO 18436-2 specification by one of just a handful of groups. The certification process has technical competency, field experience, and training hours requirements, in addition to an exam.

The shortage of vibration analysts is quite alarming. A 2011 report from Deloitte and the Manufacturing Institute entitled “Boiling Point? The Skills Gap in US Manufacturing” provides more interesting insights into the labour situation and its impact on the need for highly skilled manufacturing workers. The survey polled a sample of 1,123 U.S. manufacturing executives and found that the shortage of vibration analysis technicians is part of a nationwide pattern.

Therefore, Category III and Category IV vibration analysts are called upon very sparingly and only for large and expensive equipment. A typical plant may have a vibration analyst visit once every 3 to 6 months and only collect data on a few pieces of large equipment. While this coverage is useful, it is nowhere near complete. As a result, operations remain vulnerable during much of the year and from failures of smaller pieces of equipment that go unexamined. Depending on the circumstance, the failure of a $20,000 pump may be more costly than the loss of a $1 million backup generator.

Thus, there is a need for an affordable solution to continuously monitor and specifically identify impending random failure modes. Such a solution will also facilitate the gradual transfer from expensive and ineffective “as-scheduled” maintenance to “as-needed” programs. A thoughtful deployment of such predictive tools can greatly reduce uncertainty.

This article is excerpted from a white paper and can be downloaded at www.cpec.news/n0j. Rahul Chaturvedi is the founder and CEO of VIE Technologies Inc., an end-to-end Industrial Internet of Things solutions provider. Chaturvedi can be reached at rchaturvedi@vietechnologies.com.

VIE Technologies Inc. www.vietechnologies.com

www.cpec.news/0gy

inert gas cylinder valves

• Easily connect a pressure regulator to a nitrogen cylinder

• Make secure connections without a wrench or thread tape

• Fill multiple gas cylinders quickly and easily

• Models available for all standard inert compressed gas cylinder valves used in North America, Germany, France, UK and Australia

KSB Pumps of Mississauga, ON, has announced its NSF/ANSI/CAN 61 North American certification for horizontal split case pumps, models Omega and RDLO. This certification ensures that these engineered pumps meet all regulatory requirements across North America for clean municipal drinking water, the company says.

In celebration of achieving this certification, KSB donated to Water First (www.cpec.news/kw2), a charity focused on addressing water challenges in Indigenous communities in Canada through education, training and meaningful collaboration.

Water First’s internship program trains indigenous youth to become certified water treatment plant operators. This approach is said to not only supports the sustainability and longevity of infrastructure investments made in these communities,

but also gives program participants an excellent career path.

“KSB wholeheartedly agrees with Water First’s values that everyone has a right to safe, clean drinking water, and that the water crisis in Indigenous communities in Canada is unacceptable. We are proud to support their important work,” KSB’s Water Market Leader, Marcus Henderson explains.

“Please consider joining us in supporting their incredible work.”

KSB Pumps Inc.

www.ksb.ca

Kurita Water Industries of Tokyo has announced that it acquired 100% of the equity interests of Keytech Water Management of Kitchener, ON. Keytech manufactures and sells water treatment chemicals and equipment systems, through Kurita Canada, Inc.

The eastern region of Canada around Ontario where Keytech is located is a major industrial cluster, home to a wide range of manufacturing industries, including Japanese enterprises. Over its 40-year history, Keytech has built a production and sales structure deeply rooted in the Ontario region, providing solutions that combine water treatment chemicals with equipment systems to help save water and reduce CO2 emissions across a wide range of industries including biofuels, healthcare, comfort heating and cooling, and food & beverages.

By using Keytech’s customer base and sales network, the Kurita Group plans to expand its water treatment chemicals sales and services network from Western Canada to Eastern Canada. More-

www.cpec.news/hx3

over, by combining its products, technologies and services with those of Keytech, the Kurita Group hopes to create synergies and advance its proposal of solutions, further accelerating business expansion in Canada.

Keytech Water Industries www.keytech.ca

Arianne Phosphate of Saguenay, QC, a development-stage phosphate mining company, advancing the Lac à Paul project in Quebec’s Saguenay-Lac-Saint-Jean region, has announced advancements in the design of its future tailings facility.

Arianne has partnered with the Quebec Center of Geomatics (CGQ) to advance research and development on a new method for the design and future monitoring of the company’s tailings operations.

Brian Ostroff, CEO of Arianne Phosphate said, “we know that many challenges surrounding mining operations stem from failures at their tailings facilities and, our work here goes a long way towards reducing these threats. Arianne will produce a high-purity, low-contaminant phosphate concentrate that provides for society’s needs but, in as safe and effective manner as possible.”

Arianne partnered with CGQ, a group within the College of Chicoutimi, to develop a new way to use geomatic and remote sensing instruments and monitor this information through a solution that uses artificial intelligence. It is during the construction process that sensors will be built in throughout the tailings dam that will measure, in real-time, data points such as moisture and pressure and, make adjustments as necessary to allow for smooth and safe operations.

This research project was funded by the Natural Sciences and Engineering Research Council of Canada (NSERC) through its Partnership Engage Grants.

Arianne Phosphate www.arianne-inc.com

Endress+Hauser Group has weathered the 2020 pandemic year well. Despite declining sales, the company, which specializes in measurement and automation technology, maintained profitability at a high level and strengthened its financial power. The Group created new jobs and expanded its global sales and production network.

CEO Matthias Altendorf sees Endress+Hauser as well positioned, both for uncertain times and for economic recovery.

Endress+Hauser succeeded in protecting people’s health and continuing to provide solid support to customers, CEO Matthias Altendorf said at the annual press conference in Basel, Switzerland.

“We helped to keep important areas of our daily lives running during the pandemic. Our work is important for our customers and for society.”

Endress+Hauser products are used, for example, to produce vaccines; subsidiary Analytik Jena sup-

plies PCR technology to detect the coronavirus.

Digitization played an important role, the company says, picking up speed during the pandemic — in products, in collaboration, in internal processes. Customers have long been able to conduct everyday transactions via the Endress+Hauser website. The number of registered users on the platform doubled, and online business grew by 39 percent. If needed, the Visual Support app brings service technicians virtually to customers’ plants. Even factory acceptance tests can now take place remotely with video support, it adds.

Individual regions, industries and segments developed differently. Of the three countries with the highest sales, only China achieved growth and is now Endress+Hauser’s largest single market. In Germany and the U.S., on the other hand, sales declined. In contrast to process engineering, laboratory instrumentation recorded strong growth. Cyclical industries suffered in the crisis, while non-cyclical sectors were stable. “The broad backing in the market helped us,” said Altendorf. Endress+Hauser’s profitability did not suffer last year. On the cost side, exchange rates had a positive effect in 2020, for example on ma-

Two agricultural business enterprises, Cargill and Viterra, have announced plans for new canola processing facilities in Regina to support the growing global demand for canola products. Cargill expects to begin construction on a $350 million project, which will have a similar design to Cargill’s existing Camrose facility, early next year with plans to be operational by early 2024.

Viterra has announced its intent to build a world class canola crushing facility in Regina and is in the feasibility stage to finalize the plant’s capabilities and design, with an initial targeted annual crush capacity of 2.5 million metric tonnes, which would make it the world’s largest integrated canola crush facility.

Cargill will also update and modernize its canola facilities in Camrose and Clavet over the next 12 months to increase volume and broaden capabilities at both locations.

The new Cargill facility is projected to have an annual production capacity of 1 million metric tonnes and will provide a consistent and fast point of delivery for farmers and end users. This investment will generate approximately 1 million hours of employment throughout the construction phase.

The Regina, Camrose and Clavet projects build upon Cargill’s work to modernize and expand capacity across its North American oilseeds network. In March, Cargill announced a series of other projects across its U.S. soy processing facilities, valued at $475 million dollars.

Completion of the Viterra project in Regina is subject to successful negotiation and finalization of various permits, licensing, agreements with third parties and final approvals both internally and externally. The plant is targeted to be operational in late 2024.

Cargill

www.cargill.com

Viterra

www.viterra.com

terial expenses. Because many business trips and activities were canceled, operating expenses fell. Personnel expenses grew at a below-average rate. Overall, operating profit (EBIT) decreased by only 1.9 percent to 337.1 million euros.

In 2020, Endress+Hauser pushed ahead with major investment projects, spending 205.9 million euros (10.9 percent less than the previous year) primarily on production. The two largest projects relate to the expansion of the plants in Maulburg, Germany, and Reinach, Switzerland. In addition, the sites in Gerlingen and Waldheim in Germany and in Aurangabad in India are being expanded. The sales centres in Canada and Mexico are also building new facilities.

In 2021, Endress+Hauser aims to grow in the mid-single-digit percentage range. The Group started the current year with momentum. In the first three months, incoming orders were above the company’s own targets as well as above the still strong first quarter of 2020.

Endress+Hauser Canada www.ca.endress.com

Measurements play an important role throughout everybody’s life. From monitoring the weight and height during a medical check up to controlling and measuring the temperature of the fridge at the local supermarket. Accurate measurement is essential to our wellbeing.

Test and measurement devices are required for the production of millions of products and services such as cars, smartphones, food, medication etc. Calibration is the process that ensures these devices measures accurately.

If your equipment is not calibrated, what does that mean?

When your equipment is not calibrated, it may produce inaccurate results. This may affect the compliance with regulatory and safety requirements, the overall quality of your product, increase the risk of supplying faulty products and

The ITC-XXX-XX-DC is a signal

Pribusin Inc. www.pribusin.com

lower your customer confidence.

To ensure that your test and measurement device stays accurate throughout its lifetime, it needs to be recalibrated periodically and adjusted if necessary. These tasks are performed by a calibration laboratory.

When choosing a calibration laboratory, you need to evaluate their competence to carry out calibration.

You need to ensure the laboratory has a quality system and follows it, has high level primary calibration standards, has appropriate operating procedures, has a training program and training records for staff, can evaluate calibration uncertainty, and maintains traceability to national standards. You can carry that evaluation yourself or choose an accredited laboratory.

Choosing an accredited laboratory means choosing a laboratory that has been evaluated by a formal third-party authority. The assessment criteria are based on the international standard ISO/ IEC 17025 which is used for evaluating laboratories worldwide.

The International Organization for Standardization (ISO) is a non-governmental body that promotes worldwide standards that facilitate world trade and businesses improve productivity while minimizing errors and certifying conformity to standards.

The ISO/IEC 17025 standard specifies the general requirement for the competence of testing and calibration laboratories.

In Canada, the accreditation of calibration laboratories is the shared responsibility of the Standards Council of Canada (SCC) and the National Research Council of Canada (NRC) Calibration Laboratory Assessment Service (CLAS). The measurement experts from National Research Council of Canada will assess the technical capabilities of the laboratory.

To maintain this recognition, accredited laboratories are re-evaluated periodically.

The Benefits of working with an ISO/IEC 17025 accredited lab

An NRC SCC CLAS Accredited laboratory demonstrated that it can operate competently and generate valid results thereby promoting confidence in its work nationally and internationally.

Working with an accredited lab guarantees that:

• Your test results are trusted and traceable

• Your measurements can be re-

lied upon and are accepted worldwide

• Your equipment is handled by trained personnel

• You prevent costly measurement errors or downtime

• You save time and money by avoiding retesting

• You save time and money by having the laboratory competence evaluated by a third party

Your company can achieve its goals

SRP control systems has been helping corporations in a variety of industries calibrate equipment so that they can operate without costly errors or downtime.

Its laboratory is accredited by Standards Council of Canada and certified by NRC CLAS. The company uses state of the art calibration standards, highly trained personnel, and internationally recognized calibration methods.

There are never any surprises as your instruments and equipment return accurate, compliant, and with the proper documentation, the company says.

This article was contributed by SRP control systems. Find out more about the importance of calibration at www.cpec.news/0hd. SRP control systems www.srpcontrol.com www.cpec.news/nk2

IN TODAY’S FAST PACED AND CONNECTED WORLD, WE ARE ALL EXPECTED TO DO MORE WITH LESS, MAKING TIME ONE OF OUR MOST IMPORTANT ASSETS

By Eric Moore

These workplace norms are also the case for today’s food safety and public health professionals who need to be sure of the of the accuracy of the information that is being recorded.

Technology today allows for more efficient and accurate data collection for those using thermometers and managing food safety programs that require the use of thermometers. As defined in the FDA Food Code, certain foods require time and temperature controls to limit the growth of harmful bacteria. Utilizing a food thermometer is the most accurate and effective way to monitor these foods while ensuring the highest level of product quality for customers. Thermometers also provide an easy way of making sure that prepared food is kept at the appropriate temperature prior to being served.

Since a food thermometer is such an important tool during various steps of food preparation, it has become essential that accurate and reliable thermometers be readily accessible. With so many cheap, poorly manufactured thermometers available, many businesses are tempted to purchase a lower quality product. This is understandable to an extent; if the person responsible for sourcing the company’s equipment is looking through a brochure or website, it can be hard to differentiate between models when it comes to things like accuracy, toughness and build quality. If all the options look the same, I might as well buy the cheap one, right? In the short term, perhaps this is the case, but a few months/years down the line, try taking another look at the numbers when it comes time to replace units. You’d be surprised.

In many cases, we’ve found the frequent replacement of low-cost thermometers is more of an issue than you’d think, particularly for those organizations purchasing thermometers in large quantities. With costs continuing to rise in the restaurant industry, any way a business can cut costs and improve efficiency is of course very welcome.

Some of the cheaper models of thermometers are flimsy and built with such poor quality that they should almost be considered disposable. For example, say you’re paying as little as $15 for a bi-metallic stem pocket thermometer; these thermometer types require daily calibration to ensure accuracy (possibly more frequent calibration if they are not handled correctly), and on average need to be replaced every 2-3 months because they get lost, get dropped repeatedly, get wet, the probe snaps or the unit just stops working. Taking the time for employees to calibrate at least once a day can start to

add up, and the need to buy and keep replacement units on hand isn’t doing much good for your labor and equipment budget. Not to mention the risk of a situation where there isn’t a thermometer available for employees to check final cooking temperatures. This leaves you with no adequate way of making the required checks, and ultimately puts your customers and your brand’s reputation at risk.

In this situation, it may make sense to explore a higher quality option, like a robust waterproof thermometer that could last 5 to 6 times longer. Some manufacturers, like Testo, offer a 2-year warranty on all thermometers, so you can be sure they have been built to last. With so many things in life, you get what you pay for, and thermometers are no exception.

In addition to longevity, cheap thermometers cause issues regarding functionality and, more importantly, accuracy. They will only offer basic functions while top quality thermometers can offer more than one measuring function. For example, Testo offers a thermometer with both an infrared sensor for non-contact measurement as well as a penetration probe for core temperatures. When you use a cheap thermometer, you can’t be certain you are even getting

the correct measurements. Of course, when using a measurement device, accuracy is critical. Eric Moore is Director of Food Safety and Regulatory Compliance at Testo Solutions USA. Testo is represented in Canada by ITM Instruments. ITM Instruments

www.itm.com

www.cpec.news/xt3

• Manual, automatic and actuated (pneumatic & electric) valves; relief, check, diaphragm, ball, solenoid, and shut-off. Also pressure regulators, metering pumps, basket strainers, sight glasses, and gauge guards.

• Innovative Engineering –Dedicated Craftsmanship. • 100% inspection and individual testing of each product, to ensure dependable performance and long-life. • PVC, CPVC, Polypropylene, PTFE and PVDF. Valves from 1/8'' to 3'',Sight glasses to 8'' and Basket Strainers to 14''.

Many companies are now in the habit of calibrating their instruments once a year, although there is perhaps no need to pay the same degree of attention to every measuring point. In many cases, it is sufficient to focus on the instruments that play a critical role.

For example, Endress+Hauser has helped customers implement a calibration plan on many occasions. What are the factors to bear in mind when defining which measuring points to include?

To start out, the company says recommends noting every measuring instrument in the plant. Identify and make a list of all the equipment parts and all the instrument-related systems. This list should also include details such as description, local information, working range and history, and any other points that provide a better understanding of the part’s function.

The first stage in any analysis of the data gathered is to identify which instruments are critical to the application, the production environment, and operator safety. This calls for teamwork. Endress+Hauser will set up a meeting with the Head of Metrology (or Quality), the Head of Production — who has in-depth knowledge of the process and the related instruments — and the Head of Maintenance. Besides generally being the person in charge of calibration, the Head of Maintenance will also be able to contribute what they know about the process environment, the condition of the installed instruments, the type of maintenance work carried out and, finally, any limitations imposed by the plant in terms of servicing. With this working group, E+H will start from the finished product — and the tolerance permitted

in relation to its quality — and go back through the various stages in the production process. At each stage, it will look at the instruments in place and ask the question: ‘Does this instrument have an impact on the quality of the product (or any intermediary product), on process functionality, or on operator safety?’

Why start with the finished product? Users frequently define Maximum Permissible Errors (MPE) on the basis of the instruments they purchase, when what should be most important are the application specifications in relation to the quality of the finished product. Tolerances at all levels of the process should be defined in relation to desired results. In the context of instrumentation, MPEs express defined tolerances for the function being monitored. Taking it a step further, MPEs should provide a basis for deciding what instruments to install, not vice versa!

Let’s take a simple example to illustrate this thinking: a good cookie should be baked to just the right degree, taste good and be the right size. The first thing to look at, then, is the cooking phase and the parameters impacting the result: essentially cooking time and oven temperature in this case. The next stage is to try to identify the elements likely to influence the quality of the pastry, e.g. quality and quantity of ingredients and adherence to the recipe.

The relative importance of some of these parameters will help identify measuring points that merit particular attention in relation to metrology. Having defined parameters in terms of their importance for the product, this step is repeated with regard to the process, and then with regard to operator safety. On completion of this first stage of analysis, the working group will have compiled a list of instruments ranked in order of critical importance, i.e. ‘high’,

‘average’, ‘low’, and a list of noncritical instruments. The primary benefit of this work? Instruments classified as noncritical do not require any metrological monitoring in particular, periodic calibration intervals are decreased. As long as the user can prove to the auditor that these instruments have no impact whatsoever on the quality of the finished product, they are entirely at liberty to decide if they would like to calibrate that instrument or not.

In many cases, the second benefit is a re-appraisal of the choice of instruments in the context of the application. A Ferrari is not the ideal car for an uphill race and may even cause other challenges to occur. The same goes for the instruments you employ.

How do you define the calibration frequency of instruments deemed “critical?” The ideal calibration frequency should be ‘just what it takes’ to guarantee the instrument specifications in the context of the production process. To achieve that, we will consider both the factors in favor of frequent calibration and those against it.

The key factor, of course, is the desired measuring precision — which is closely linked to the Maximum Permissible Error tolerated in order to guarantee the quality of the final product. But decisions will also be influenced by the varying nature or condition of the product in contact with the instrument, the continuity (or discontinuity) of the process, the relative severity of the ambient conditions or the presence of CIP (Cleaning in Place). Similarly, considerations such as whether the instrument is used continuously or at intervals, time available for calibration, ease of disassembly and possibility of on-site calibration will also influence calibration plans. And an analysis of calibration history will allow frequency to be adjusted in relation to any non-conformities that are identified.

A final parameter to consider when deciding whether to reduce the frequency of calibration is the risk associated with an excessively long period without calibration. It is useful at this point to re-

member that the purpose of calibration is to certify the quality of the products that have already been manufactured, not of those yet to be manufactured. Will non-conformities be detected if the instrument is not calibrated for a certain time? Will the production operator, wanting to compensate for a production non-conformity, add too much raw material or modify the process, thereby causing additional costs? This is why the interval between two calibrations rarely exceeds two or three years in the case of critical apparatus.

Why do companies tend to opt for a one-year interval? Companies may have set up one-year intervals because it is suitable for everyone, including au-

a longer interval, you will need documentation to support your decision.

Despite being the usual practice, one-year intervals could actually increase risk within the process. Whereas a flowmeter can go for two or even three years without calibration (depending on the application), a year is generally too long in the life of a pH measuring device.

As an instrument manufacturer, Endress+Hauser applies its measuring systems’ know-how to its client’s application conditions to best support customers. And the company has the tools to implement, in the initial phase, its method for drawing up a metrological plan, then for implementing the plan itself. The company supports its customers achieve dynamic management of their installed instruments, i.e. it ensures they are capable of planning, triggering and documenting maintenance and calibration operations.

At the operational level, Endress+Hauser utilizes its teams' expertise, mobile equipment and accredited laboratories in carrying out calibration, in combination with customers’ own resources.

Finally, the company's contribution helps the Head of Metrology to emphasize the importance of process optimization to their team. For in many cas-

process control are well understood. And with the current context making it more necessary than ever to economize raw materials, energy and water, an ever growing number of industry practitioners now have a better understanding of the role of metrology in cost control.

Endress+Hauser performs instrument calibration across a variety of measuring principles — flow, pressure and temperature. Calibration can be performed at its calibration laboratories or at a customer's facility via its mobile calibration labs. Due to regulations regarding Greenhouse Gas reporting, traceable calibration is more critical than ever before.

This article was created from white paper by Endress+Hauser. Read more at www.cpec.news/rl3. Endress+Hauser Canada

www.ca.endress.com www.cpec.news/8ot

Running process operations requires constant vigilance when it comes to monitoring and measuring with accurate, well maintained test instruments.

When seeking out an instrument calibration laboratory that can fulfill operational requirements, it helps to find one with a breadth and depth of services.

For example, the company should offer a wide range of in-house and on-site calibration services including temperature, humidity, dew point, pressure, flow, gas, particles, and analytical concerns. Utilizing its on-site calibration services means you can minimize interruptions to your business, reduce instrument downtime, and mitigate the need for spares.

Any good lab understands that having accurate instruments are critical for your business. Whether you’re purchasing a brand-new product, require service to your existing instruments or need on-site support, its team will ensure your instruments are functioning at optimum capacity.

Premium calibration services accredited to ISO/IEC 17025 by the American Association of Laboratory Accreditation (A2LA), one of the most stringent accreditation authorities accepted worldwide, provides the assurance that the lab is going to do the right job protecting your operational assets.

Fully trained metrologists in the lab that use only state-of-the-art equipment from proven leaders in the industry such as Fluke Calibration, Thunder Scientific, and Fluke Electronics are an-

other benchmark. By utilizing leading-edge technology, the lab ensures your instruments will operate at peak efficiency and provide the results you expect every time.

Instrument error can occur due to a variety of factors such as drift, the environment, electrical supply, and process changes. Trustworthy metrologists ensure that your instruments are providing accurate measurements and achieve the highest level of quality standards.

One such instrument calibration laboratory that provides all of these services is Alpha Controls & Instrumentation. For over 40 years, the company has been one of Canada’s leading suppliers and service providers of measuring, sensing, and controlling instruments. It provides technical solutions and support to numerous in-

dustries including pharmaceutical, automotive, food and beverage, cannabis, water and wastewater, aerospace, chemical, power, and HVAC.

As a family owned and operated business, Alpha says it truly values the customers that have placed their trust in it. The company strives to provide industry leading turnaround times, competitive pricing, and most importantly, exceptional customer service, it adds. This article was contributed by Alpha Controls & Instrumentation of Markham, ON. To view the company’s range of calibration capabilities, go to www.cpec.news/kl1 or watch video at www.cpec.news/qmv.

Alpha Controls and Instrumentation www.alphacontrols.com www.cpec.news/jhs

In Canada, the accreditation of calibration laboratories is the shared responsibility of the Standards Council of Canada (SCC) and the National Research Council of Canada (NRC) Calibration Laboratory Assessment Service (CLAS).

The CLAS program provides quality system and technical assessment services and certification of specific measurement capabilities of calibration laboratories in support of the Canadian National Measurement System.

Eligibility for CLAS certification is required for SCC accreditation of calibration laboratories. The SCC grants accreditation to ISO/IEC 17025 for qualified laboratories. The SCC/NRC Agreement of Collaboration contains a detailed description of shared responsibilities in the accreditation of calibration laboratories.

CLAS maintains a directory of accredited calibration laboratories providing a network of calibration laboratories to ensure clients across Canada have access to calibration services with certified traceability to national and international measurement standards. Calibration laboratories certified by CLAS offer mea-

surements traceable to the International System of Units (SI). This traceability provides the basis for fair trade, increased global market acceptance of test reports and products, enhanced product quality, and demonstration of conformance to such international quality standards as ISO 9000 series.

International arrangements are in place to help ensure that calibration laboratories that are certified by CLAS and accredited by the SCC are recognized by over 50 accreditation systems worldwide. In its role as Canada's national standards laboratory, NRC maintains close ties with the Bureau International des Poids et Mesures (BIPM) and a number of other international organizations such as the Inter-American Metrology System (SIM), the International Laboratory Accreditation Cooperation (ILAC), and the Inter-American Accreditation Cooperation (IAAC), as well as the national laboratories of other industrialized countries. Find directory of approved labs in Canada at www.cpec.news/emv.

NRC CLAS

https://nrc.canada.ca/ www.cpec.news/r1c

Instruments that are used to take accurate measurements typically require periodic calibration to ensure reliable readings. They are sometimes tested in a highly controlled laboratory setting while for some devices, at the actual site of field use. The certification process is done by qualified personnel who are properly trained to service the specific types of devices under test. They follow formalized Standard Operating Procedures which document the method of testing, the NIST traceable standards that are suitable for use and list any other rules that may be pertinent for regulatory compliance to quality and safety issues. In large organizations, multiple technicians work under the supervision of a calibration manager.

Although highly experienced in the work methods, a Calibration Manager’s daily routine may be less “hands-on” but rather his time may be used solely to supervise the activities of his subordinates. He oversees productivity, schedules, quality of workmanship and overall team performance. In today’s world, good managers understand that important productivity tools to include highly functional calibration management software. Effective programs are designed for planning workflow, scheduling, creating standardized templates for data capture, managing change control, assigning electronic stamps of approval and other functions. Some can also interface to higher level ERP and CMMS systems.

Depending on the organization, duties for Calibration managers often extend beyond workflow management, including:

• Employee hiring, training & termination

• Performance reviews

• SOP development

• Measurement uncertainty calculations

• Historical record keeping

• Change control processing

• Out of Tolerance reporting

• Test standard selection & recertification

• Document & final work approvals

• Reverse traceability reporting

• Productivity & profitability metrics

• Vendor selection

• Audit participation

Often calibration managers are required to participate in regulatory audits. The purpose is to demonstrate that operations are proceeding according to established practices, that routine testing of devices achieve accurate results and that any identified shortcomings are documented and resolved through a systematic approach for continuous improvement. Here is where full-featured calibration management software is especially useful. The ability to instantly retrieve the history of records and relevant requested documents will demonstrate that the organization is compliant, operating at peak performance and increasing efficiency.

Older calibration management methods using pen and paper are obsolete. Calibration Managers facing an ever-growing volume of workload, have learned to rely on feature rich software and automated systems to significantly improve productivity.

This article is courtesy test and measurements distributor techniCAL, from a blog by principal Prime Technologies. techniCAL Systems

www.technical-sys.com www.cpec.news/aga

ProCal V5 from Prime Technologies is calibration and maintenance software available through techniCAL Systems. The program is 21 CFR Part 11 compliant.

Food and beverage, dairy, pharmaceutical and life-science industries have additional requirements for the temperature measurement sensors because of their processes. They require temperature sensors that are “sanitary”, meaning that these sensors need to be suitable to be installed in hygienic and aseptic process environments.

These industries have dedicated strict regulations concerning calibration, such as various Canada Food and Drug Act regulations.

Sanitary sensors need to be hygienic and designed to be easy to clean, often supporting the clean-in-place (CIP) process (cleaning without disassembly). The mechanical design needs to be free from any cavities, dead-pockets, gaps or anything that would complicate the hygienic cleaning.

Surface finishes of these sensors are hygienically graded and need to meet the strict standards in these industries, such as the 3-AR (https://www.3-a.org/) or EHEDG (European Hygienic Engineering & Design Group) https://www.ehedg.org/.

The material of the wetted parts in these sensors is often high-grade stainless steel, suitable for these applications.

Why are sanitary sensors difficult to calibrate? Let’s discuss next why these sanitary sensors are difficult to calibrate.

1. Sanitary sensors are very short

As mentioned earlier, these sanitary temperature sensors are typically very short. Most often less than 100 mm, typically around 50 mm, but can also be as short as 25 mm. The outer dimension of the sensor typically is 3 mm or 6 mm.

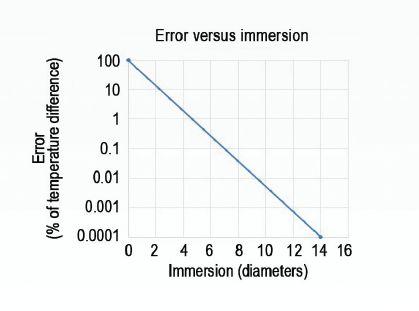

The commonly used practice in temperature calibration (and an Euramet guideline recommendation) is that a temperature sensor should be immersed deep enough to achieve sufficient accuracy. The recommendation is to immerse into a depth that is 15 times the sensor diameter (plus the length of the sensor element). But with these short sanitary sensors, it is simply impossible to immerse the sensor into sufficient depth during the calibration, because the sensor is so short compared to the diameter. For example, a typical sanitary sensor with a diameter of 6 mm should be immersed (15 x 6 mm) into at least 90 mm depth during the calibration, to ensure accurate results. But if that 6 mm sensor has a length of only 50 mm, sufficient immersion is simply not possible. When not immersed deep enough, additional error and uncertainty will be caused in the calibration.

Please see some rules of thumb for the immersion depth (when calibrating in liquid bath):

• 1% accuracy - immerse 5 diameters + length of the actual sensing element inside the sensor

• 0.01% accuracy- immerse 10 diameters + length of the sensing element

• 0.0001% accuracy - immerse 15 diameters + length of the sensing element

The “accuracy” in the above rule is to be calculated from the temperature difference between the block temperature and the environment temperature.

Example: if the environment temperature is 20°C and the block temperature is 120°C, there is a 100°C difference. If you then immerse the

probe only 5 times the dimension (plus the sensing element length) — say you have 6 mm probe with a 10 mm sensing element inside of it — and you immerse it 40 mm (5 x diameter + sensing element) — you can expect about 1°C error due to the low immersion (1% from 100°C).

The above chart illustrates the commonly used relationship rule between thermometer immersion depth (in diameters) and the relative error of the temperature difference (of the temperature block and environment temperatures). So, if you don’t immerse at all, you naturally get a 100% error, and if you immerse deep enough the error caused by immersion becomes insignificant. Somewhere around where the immersion is 5 times the dimension, the error is about 1% of the temperature difference.

This rule of thumb can become quite significant at higher temperatures and/or for extremely short sensor lengths. So, keep this in mind with sensors less than 40 mm or 1-1/2 in. Also, it may be worth having a conversation with a design engineer to figure out a way to increase the sensor length.

In the first picture (top left) the Beamex MC6-T (see www.cpec. news/n6v) with a dedicated insert for sanitary sensors calibration is seen. The second picture (top right) shows how the short reference sensor (SIRT-155) is being installed. Third picture (bottom left) shows the sanitary sensor to be calibrated being installed. Finally, the fourth picture (bottom right) shows all installations being done and we are to start the automatic calibration. Watch video demonstration at www.cpec.news/d06.

Naturally this accuracy limitation is valid also when the sensor is installed in the process and measuring the process temperature - being too short, the sensor is not able to accurately measure the process temperature!

It is not always easy to know the length of the actual sensing element inside the probe. If that is not mentioned in the datasheet, you can ask the manufacturer.

2. Sanitary sensors often have a clamp connection with a flange

As mentioned above, these sanitary sensors are too short compared to their diameter to enable a proper immersion causing temperature leaks, adding error and uncertainty to the calibration. Like this would not be enough, these sensors also often have a so-called clamp connection (Tri-clamp, ISO 2852, DIN 11851, DIN 32676, BS 4825, Varivent, etc.) configuration, so there is a relatively large metallic flange, that is causing temperature to conduct/leak from the sensor to the flange. In practice, this temperature leak means that the temperature

from the sensor is conducting to the large metallic flange, so the flange causes the sensor to read a bit of a lower temperature (when calibrating temperature higher than environment temperature).

This kind of flange makes the calibration more difficult is several ways; the flange adds temperature leak from the sensor to the flange, the larger the flange is, the larger the temperature difference is to the environment temperature. While at the same time the sensor is very short, this temperature leak causes the sensor to measure erroneous temperature.

Liquid bath or a dry-block?

Generally, you can calibrate temperature sensors in a liquid bath or in a dry-block. This is also the case with the sanitary temperature sensors.

As the name suggests, a temperature liquid bath has liquid inside. The liquid is heated/cooled to the required temperature and the temperature sensors to be calibrated are inserted into the liquid. Often the liquid is stirred for even temperature in the liquid.

Pros and cons with a liquid bath

Aliquid bath makes it easier to insert any shape of sensors in it and you can also use a reference probe inserted at the same time. Depending on the size of the liquid bath, you may insert several sensors to be calibrated at the same time. In case the sensor to be calibrated is an odd shape, a benefit is that it will still fit inside the liquid bath. A liquid bath often enables better uniformity and accuracy than a dry-block due to better heat transfer of liquid.

Even though this sounds like a favourable option, a liquid bath has anyhow several drawbacks as to why it is not always the best option:

• A liquid bath always includes some sort of liquid, such as silicone oil, and often you don’t want to contaminate the sanitary sensor in such a liquid. There is a lot of cleaning after the calibration to ensure that the sensor is clean when installed back into the process.

• Handling of hot oil is dangerous and any spills may cause injuries.

• Any oil spills make the floor very slippery and can cause accidents.

• Liquid baths are very slow. Even if it could fit several sensors in at the same time, it is often several times slower than a dry-block, so overall effectiveness is not really any better. Sometimes people may have several baths, each set to different temperature, and they move the sensors manually between the baths to skip the waiting time of the bath to change temperature. This may work in a calibration laboratory but is naturally a very expensive way to calibrate.

Over the past year, Cameron Instruments has invested in its ISO 17025 accredited pressure calibration facility by adding three key pieces of equipment. The purpose of these additions was to increase throughput, provide quicker turnaround times, improve uncertainties and add to their scope.

The laboratory provides high accuracy pressure and temperature calibrations, using Fluke Piston Gauges and AMETEK JOFRA dry block and liquid bath temperature calibrators. The lab’s current scope for pressure provides coverage from 5kPa (0.7 psia) to 200 MPa (30,000 psia) in either gauge or absolute mode. Temperature capabilities cover an effective temperature range from -100° to 660°C.

Watch intro video for Fluke 8270A/8370A Modular High-Pressure controllers (right) at www.cpec.news/6tg. The Fluke Ruska 2465 deadweight tester (below right) and the JOFRA RTC159 ultra-cooler dry block temperature standard (below left; watch video at www.cpec.news/csm).

pass for Pressure Software, providing fully automated calibrations of multiple devices.

The first piece of equipment (top right) added during the expansion was a Fluke 8370A Modular High-Pressure controller to 10,000 psi. The unit is a sister controller to the lab’s existing Fluke 6270A, that covers gas pressure to 3000 psi. The Fluke 8370A provides a second workstation that goes to higher pressure and provides additional leak testing capabilities. Together, the two workstations integrate seamlessly with the Fluke Com-

The second piece of equipment added was with the purpose of expanding the ability to provide low pressure draft calibrations. To do this, the company acquired a Ruska 2465 deadweight tester, a low-pressure piston and an additional mass.

• The sanitary sensor should be placed so that the surface of the liquid touches the bottom of the flange, but in practice this is not always that easy to do. For example, silicon oil has pretty large thermal expansion, it means that the surface level is changing slightly as the temperature changes. So, you may need to adjust the height of the sanitary sensor during the calibration. Also, due to the stirring of the liquid, there are small waves on the surface and the liquid level is often deep in the bath, so it is difficult to see that the sensor is at the right depth.

• Liquid baths are often large, heavy and expensive equipment.

Pros and cons with a dry block

As the earlier chapter discussed the pro and cons of a liquid bath in this application, let’s look at the same also for the dry-block. The main pros of calibrating the sanitary sensor in a dry-block include:

• As it is a dry, it is also clean and does not contaminate the sanitary sensor to be calibrated. Sure, the sensor should still be cleaned after calibration, but the cleaning

The Cameron Instruments laboratory manager, Andreas Stachyra, has the responsibility of testing this new piston, developing procedures, and determining uncertainties. "Our hope is to have this piston included in our scope of accreditation by the end of 2021,” he says.

“There will be a lot of proficiency testing and work that will go into adding this piston to our scope.”

The Ruska unit also comes with other piston types which will eventually be added to their scope to increase capabilities further. Once completely commissioned, it will tighten up specifications and accuracies, thus providing additional low pressure calibration options for customers, according to Stachyra.

The third piece of equipment added to the lab was a JOFRA RTC159 ultra-cooler dry block temperature standard. The unit, along with an existing CTC660 dry block, increases temperature capabilities to cover the temperature range from -100° to 660°C. When asked what other areas his laboratory could expand into Stachyra mentioned

is way easier than with a liquid bath.

• A dry-block is also a very fast to change temperature.

• When using a dedicated insert with proper drillings, it is easy to insert the sanitary sensor always the same way (no adjustments), and the calibration is repeatable every time and with different users.

• A dry-block is light and easy to carry compared to liquid bath.

• Typically, a dry-block is also cheaper than a liquid bath.

On the downside, a dry-block is a less accurate than a liquid bath, it typically only calibrates one sanitary sensor at a time and needs different inserts drilled for different diameter sensors. Despite these downsides, customers often prefer to make the calibration of their short sanitary sensors in a dry-block.

This article was excerpted from the white paper contributed by Beamex available at www.cpec.news/scn. Beamex Canada www.beamex.com www.cpec.news/n6v

“possibly adding temperature to our ISO 17025 accreditation.

“This would likely be something that happens further down the road into 2022.”

With a steady flow of calibrations through the laboratory, the company says it made sense to invest in standards and accreditations to meet these growing demands. Currently, Cameron Instruments is accredited through A2LA in accordance with ISO 17025 for technical competence in the field of pressure calibration.

Cameron Instruments

www.cameroninstruments.com

www.cpec.news/42h

Point and click or tap to specify valve type, end connections, actuator, and accessories.

Model number, price, description, and photo all update

ISO/IEC 17025 is the main quality management system standard for calibration laboratories internationally. The standard evaluates and recognizes the technical competence of a calibration laboratory in addition to the management requirements laid out in ISO 9001.

In order to obtain accreditation, a calibration laboratory must undergo an independent assessment by a third party to ensure that the quality management system (QMS) is in compliance with this international standard. Only after the QMS undergoes this thorough review is a laboratory deemed technically competent and obtains the ISO/IEC 17025 accreditation by an authorized accreditation body. In addition to the initial assessment, the laboratory must also undergo regular reviews in order to ensure that compliance is maintained.

While the decision to pursue ISO/IEC 17025 accreditation is completely voluntary, a laboratory chooses to do so to provide customers with the utmost confidence in calibration results.