AutomationDirect has added cable entry system options to its Murrplastik product line. Murrplastik cable entry systems easily allow installation of non-terminated or pre-made/terminated cables through an enclosure or other bulkhead surface. The new KDP/R series offers a general-purpose, round, one-piece frame available in two different sizes, capable of holding up to 46 non-terminated cables in a single frame. The new KDL/H-VA-FDA series FDA-compliant stainless-steel split frames, available in three sizes, use FDA approved grommets and can hold up to 12 pre-made or terminated cables. Also added is the KDP series FDA Cablequick system, a one-piece stainless-steel frame that can hold up to 48 non-terminated cables. AutomationDirect

www.automationdirect.com/cable-entry-systems

Emerson has introduced the ASCO Series 209 proportional flow control valves said to offer high standards of precision, pressure ratings, flow characteristics and energy efficiency available in a purpose-built, compact architecture. The valves allow users to precisely regulate the flow of fluid in a wide range of devices that require exacting performance, the company says, like those found in the medical equipment, food and beverage, and HVAC industries. Series 209 valves have a hysteresis less than or equal to 5%, repeatability of less than or equal to 1% and sensitivity less than or equal to 0.2%. Emerson www.emerson.com/proportional

Series VB/VBM vacuum breakers from Plast-O-Matic have a Patented diaphragm design said to assure dependable, repetitive, bubble-tight sealing to protect enclosed tanks from collapse or structural damage during draining. The units also eliminate siphoning of dangerous fluids, the company says, and prevent vacuum damage to sensitive instruments and filters. Sizes include 1/2, 3/4 and 1 in. in a wide range of materials and connection types. Series VBM vacuum breakers are molded of type 1, grade 1, PVC, glass-filled polypropylene, Kynar PVDF and Corzan CPVC. A machined version, series VB is available in PTFE in sizes 3/4 and 1 in. Series VBS PFA encapsulated spring and special poppet provide performance identical to VB/VBM types in sizes from 1-1/2 to 4 in.

Plast-O-Matic www.plastomatic.com

The Sensi+ analyzer announced by ABB is said to offer a reliable new solution which simplifies and reduces the cost of pipeline operation and maintenance. It enables safer, easier, and more efficient pipeline monitoring and operations through a single device, the company says, that can analyze up to three contaminants (H2S, H2O, CO2) in any natural gas stream accurately and in real time. It adds that the unit’s fast response also enables quick reaction to process upsets, thus helping to reduce waste and methane emissions. The analyzer requires about six times less sample flowrate for its measurement than other technologies reducing the total carbon emission of the analyzer and natural gas wasting in the atmosphere. The unit includes the company’s AnalyzerExpert features that provide experts with actions and insights directly from the device. Capabilities include built-in self-diagnostics, automated laser line-locking, real-time cross-interference compensation, and health monitoring.

ABB

www.abb.com

AutomationDirect has the industrial control products you need to keep your projects on time and under budget. Over 35,000 low-cost components including PLCs, HMIs, VFDs, sensors, pneumatics, wire, and so much more are at your fingertips to order 24/7. Access technical documentation and drawings, product configuration help, and account tools easily. And if you need extra help, just call or chat our helpful customer service stars during business hours. So don’t wait, buy direct today and save with AutomationDirect!

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days.

*Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees. See Web site for details and restrictions at: www.automationdirect.com/canada

With a metering accuracy of ±1%, the Seepex D line of metering pumps available from John Brooks Company are said to be used wherever low-to-highly viscous media, media containing solids, or chemically corrosive media are processed, all with low pulsation. The features and advantages of these six models include a modular system for fast and simple conversion, low pulsation pumping, and easy maintenance with a plug-in connection, the company says. Material combinations are available for different conveying products, and various drive combinations are possible.

John Brooks Company www.john brooks.ca

number covering all components in the kit.

Festo www.festo.com

Wajax has introduced the UE One Series line of programmable electronic pressure and temperature products. The series provides explosion (flame)-proof, intrinsically safe and non-incentive models that monitor gage pressure, differential pressure, or tempera-

ture. An advanced low-power microcontroller provides four SMART model platforms — a NAMUR NE 43 standard and HART-enabled transmitter (model 1XTX00), two discrete (digital input)-powered electronic switches

Festo has introduced an online 3D CAD Configurator for pneumatic actuators and associated accessories such as fittings, lengths of tubing, and sensors. Once the actuator is selected from a choice of either cylinder, drive with guides, or semi-rotary drive, the engineer simply clicks on accessory hot spots to identify and select each accessory. The configurator ensures compatibility between actuator and accessory and eliminates any possible type of error code, the company says. A 3D CAD file of the actuator assembly is read for download at the end of the configurator’s streamlined design process. Actuators and accessories are shipped in a one-bag kit with a single unique Festo ID

(1XSW) that operate on the existing application’s 2 wires, a transmitter-switch hybrid with two independent and programmable solid state relays (1XTXSW), and a 4-wire switch that provides high-power switching for local control of loads directly and at the point of measure. With no moving parts, the company says, the versatile instruments can be used in a wide variety of safety control, alarm, and interlock applications (SCAI).

Wajax www.wajax.com

Imagine a bumper crop of wheat grown entirely without chemical fertilizers. Or a swarm of drones that use artificial intelligence to identify every plant in a field, sniping only the weeds with a precision spray. Or a fresh slice of salmon sashimi that was grown in a bioreactor, not caught from the sea.

These imaginings are from The Transformative Seven: Technologies That Can Drive Canada’s

Next Green Revolution, the latest in a series of reports from RBC Economics and Thought Leadership, BCG Centre for Canada’s Future and Arrell Food Institute at the University of Guelph (https:// bit.ly/3w66NxB). They identify seven key innovations or “agtechs” that can both meaningfully reduce emissions and present opportunities for Canada to lead.

The Seven are: precision technology (smarter, more fertilizer

efficient farming); carbon capture, utilization, and storage (CCUS); anaerobic digesters; controlled environment farming; feed additives and supplements; agricultural biotechnology; and cellular agriculture.

Personally, I look forward to the day when I can ask my fridge to make supper, just like a Star Trek replicator.

Mike Edwards medwards@cpecn.com

We understand you need insightful process information to help you run your plant efficiently.

READER SERVICE

Print and digital subscription inquiries or changes, please contact Angelita Potal Customer Service

Tel: 416-510-5113

Fax: (416) 510-6875

save costs:

• Permanent diagnostics of processes and devices guarantee an economical maintenance and safe plant operations.

• Verification of devices happens without process interruptions. It ensures high plant availability.

• Monitoring of all information enables predictive maintenance and process optimizations.

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

AUDIENCE MANAGER, Anita Madden 416.510.5183 amadden@annexbusinessmedia.com

PUBLISHER, Rob Sommerville 905.770.8077 rsommerville@cpecn.com

EDITOR, Mike Edwards 416.510.5229 medwards@cpecn.com

ACCOUNT COORDINATOR, Barb Vowles 416.510.5103 bvowles@annexbusinessmedia.com

GROUP PUBLISHER/VP SALES, Martin McAnulty mmcanulty@annexbusinessmedia.com

COO, Scott Jamieson sjamieson@annexbusinessmedia.com

Founder, Peter Birchard

Founder, Ray Blair

CPE&CN is published bi-monthly by: Annex Buiness Media Volume 51 No. 1 January 2023

111 Gordon Baker Rd, Suite 400, Toronto, ON M2H 3R1 T: 416-442-5600 F: 416-442-2230

© All materials in this publication are copyright protected and the property of Annex Business Media., the publishers of Canadian Process Equipment & Control News magazine. For permission on reprinting or reproducing any materials, e-mail your requests to cpe@cpecn.com

Canadian Postmaster send address corrections to: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Canadian Process Equipment & Control News assumes no responsibility for the validity of claims in items reported.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2384

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 0318-0859

By Greg James, Festo Didactic

With the baby boom generation of engineers and technicians fading into retirement, the Canadian process sector has good reason to give added weight to a third P — People — in their operational strategizing along with Production and Product. The challenge is really two-fold: Qualified replacements for those leaving the work force are increasingly hard to find. And with technological change coming faster than ever, there is a need to ensure that current workers can update their knowledge and skillset accordingly, lest a company or utility begin to lag its peers.

Manpower shortages have been a challenge for many years, but never more so than now. It has been estimated that 25 percent of the Canadian manufacturing work force will retire by 2030. Job vacancies across all economic sectors hit an all-time high in Q2 2022. All industrialized countries are facing a similar situation. For example, the Water Environment Federation, whose global membership includes five Canadian water and wastewater associations, estimates that 37 percent of water utility workers and 31 percent of wastewater utility workers will retire by 2030, numbers representative of the situation in Canada. In Quebec, according to provincial estimates, there were about 7,000 operator positions at public and private water facilities in 2020. By 2024, replacements will be needed to fill 2,000 of those jobs.

While the challenge is global, the solutions must be local. Immigration is only a partial answer. Au-

Festo Didactic has developed the Edukit PA, now the preferred training system for the WorldSkills competition. For the further development of water professionals, the system allows employers to replicate water plant processes using real industrial instrumentation and control devices, various communications protocols, and basic to advanced control strategies.

tomation and digitization can pick up some of the slack. But replacing skilled workers as they retire or ensuring sufficient qualified staff for growth or expansion requires made-in-Canada educational and training approaches.

That’s not just a matter of churning out a greater number of graduates, but also anticipating the changing nature of work. To use that well-known hockey aphorism, we have to skate to where the puck is going, not to where it is. Each process industry sector has needs that will change in adopting IIoT/Industry 4.0 ways of doing things. For example, with the proliferation of artificial intelligence-based solutions, data scientists and especially the subset who qualify as machine learning engineers are in short supply today and will be even more so tomorrow. Technicians will need familiarity with the “smart” systems being installed throughout the operation. Transitioning the plant’s data communications architecture to 2-Wire Ethernet enabling an integrated field to cloud network will require an understanding of Ethernet principles and protocols. (The good news is that through industry partnerships, post-secondary STEM programs are getting better at keeping up with emerging technologies, which wasn’t always the case.)

Canadian trade schools, colleges and universities will contin-

ue to be our front-line developers of new technicians and STEM professionals. They will need an even larger supply of smart, enthusiastic learners. That starts with persuading more young people to pursue such careers, that they can offer a better, faster pathway to stable employment than a humanities degree. Entry-level STEM salaries average about $43,000/year. There are excellent candidates to be discovered in non-traditional pools — such as women, indigenous youth, visible minorities, and mature students including parolees. There is a role for all stakeholders in promoting STEM pathways. Opening up a facility to tours or presenting at job fairs can reveal a world of possibilities to high schoolers. Later, as they move into STEM programs, offering internships and mentorships can put you at the head of the line for their services.

As the global leader in technical education, Festo Didactic works with educational and business partners to stimulate interest among Canadian high schoolers for STEM education. Once they enter post-secondary programs, many will learn on Festo Didactic learning systems for their chosen fields.

Employers should also view a STEM diploma or degree as a means, not an end. The knowledge and skillset young people have upon entering the work

force will need to be updated throughout the course of their careers. Not only is that an operational necessity as technologies evolve and new ones emerge, but in a tight labour market, employers can offer staff continuing education as a recruiting and retention tool. Training and upskilling done on the corporate dime will speak to how you wish to be perceived as an employer. It can offer new challenges to employees, so they don’t feel bored or stuck, or qualify them for extra compensation or for promotions. Continuing education can be provided on site, at educational institutions or by employing the learning tools offered by third party providers like Festo Didactic.

People have many demands on their time; new learning and teaching approaches are responding to that reality. Last year, Festo Didactic launched Festo LX to help achieve this. The LX online portal is for teachers and learners to engage in customized learning experiences without having to be in a classroom.

Greg James is Regional Sales Manager with Festo Didactic Ltd. and a member of the Editorial Advisory Board at Canadian Process Equipment & Control News.

Festo Didactic www.festo-didactic.com

Chemline Plastics has introduced AlfaRapid grooved end system of mechanical piping connections. The pipe clamps, fittings, and valves are designed for use with rolled or cut grooved PVC or PE pipes. Flexible pipe couplings are constructed of glass-reinforced polyamide and stainless steel bolts in sizes ranging from 1½ to 6 in. The couplings are said to offer quick alignment, installation, and disassembly, as well as compensate for expansion, shrinkage, and bending, eliminating the need for piping accessories to correct these issues. The coupling gasket acts as a damper to reduce vibration and noise. A range of grooved end pipe fittings in polypropylene are available 1-1/2 to 4 in. Chemline Plastics www.chemline.com

Durham Instruments represents Teledyne Hastings which makes three categories of thermocouple vacuum gauge tubes and sensors. The selection includes the original DV-4 and DV-6 models of these sensors and tubes, in addition to the DV-5 range — all of which are said to offer accurate measurement and vacuum control. The thermocouple vacuum gauge tubes and sensors are fully compensated for temperature and rate of temperature change, and each one uses the THI thermopile sensor. The standard gauge tube has a hermetically sealed base with glass, stainless steel- and nickel-plated components, and

a colour-coded label. It operates at a maximum temperature of 100°C and has a maximum pressure of 150 psig.

Durham Instruments https://disensors.com/

Emerson has introduced the enhanced Rosemount 3051 model pressure transmitter that adds new capabilities to the device. The pressure transmitter user interfaces have been redesigned to

provide a simplified, task-based menu structure with common navigation across host and configuration tools for a faster, more intuitive user experience. The new Bluetooth wireless technology simplifies configuration and service tasks without having to physically connect to a device. Additional transmitter upgrades include the ability to configure the device to measure flow rate as well as track total flow. Level measurements are simpler with a built-in configurator to set up level outputs. Volume measure-

ments are also possible for common tank styles or even customized tanks that require a strapping table.

Emerson www.emerson.com

These digital sanitary gauges maintain accuracy around vibrations, pulsations, hot caustic rinses, and other harsh processes common in the food & beverage, pharmaceutical and biotech industries.

• ± 0.1% full scale accuracy (ASME B40.100 Grade 4A/ISO Class 0.1)

• 3-A certified sanitary Tri-Clamp® diaphragm seals

• Clean or steam in place (CIP/SIP)

• 316L SS body and diaphragm

• 18-24 RA wetted surface finish

• High temperature pipe sealant and tamper-proof inspection seal used on all threaded joints

• Wireless Option

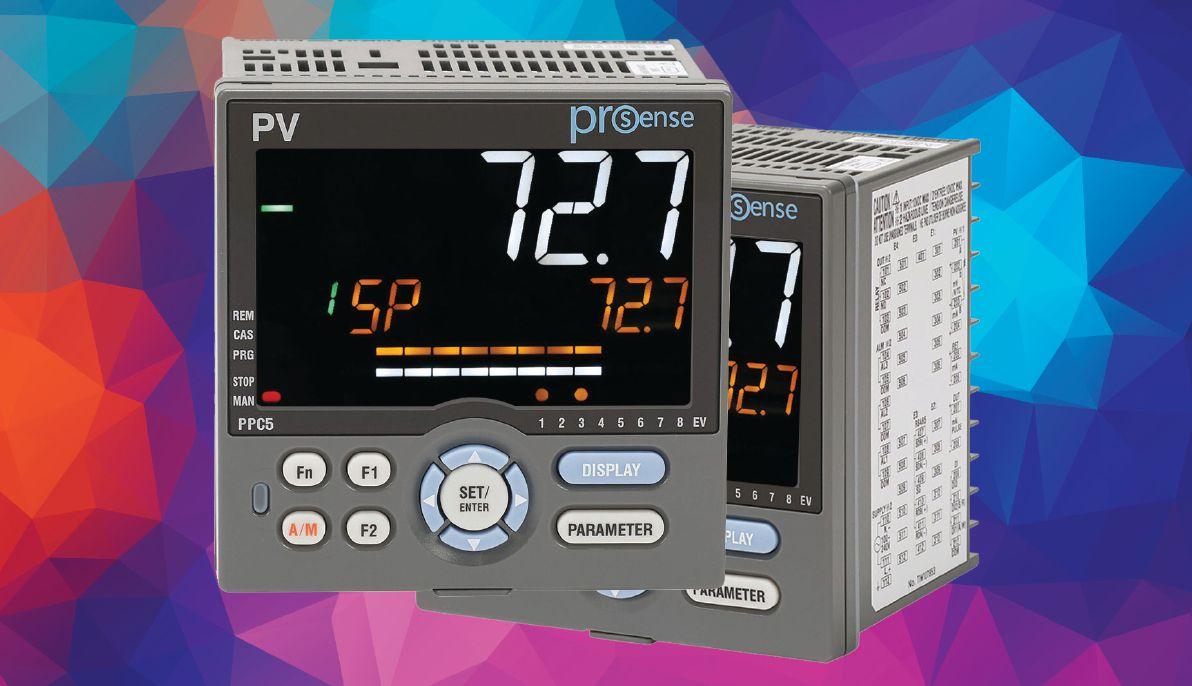

PID is an acronym for Proportional, Integral and Derivative. It is a control function that is frequently used in process control. You take a reference signal in from your process, compare it to your setpoint, and then change the output to the control device accordingly to minimize the error. Think of the cruise control in your car.

You set the speed you want to travel at, your car’s computer will compare that to the current speed, and either accelerate or decelerate to match that setpoint and remove the error. The bigger the error, the bigger the gain or response. For example, when your car on cruise control revs the engine when you start up a hill, the error between the setpoint and the current speed increased so much that the response was also greatly increased.

PID is the most common industrial technology for closedloop control. Despite the elegant mathematics behind PID loops,

they are easily implemented with modern PLC technology.

Closed-loop control, where a digital system monitors a measured value and then controls some device to accurately drive the process to a desired setpoint, is a fundamental strategy widely applied to equipment and processes. Although there have been many computing advances over the years, traditional proportional-integral-derivative control remains the leading workhorse for closed-loop process automation. PID control can be accomplished with a dedicated hardware controller, within a PLC or an industrial PC, or within another intelligent device like a VFD or a servo controller. The math behind PID control may look intimidating, but the reality is that suppliers like AutomationDirect offer a wide variety of products to help users easily implement this high-performance control method.

Many designers find it necessary to control an industrial-grade operation so that a process variable achieves the target value as closely as possible, even in the face of disturbances and changing conditions.

The process variable could be one of the “big four” — flow, level, pressure, or temperature — or another characteristic, such as an analytical value, or even the position of a mechanism. Each of these characteristics are analog because they can vary over a range, as opposed to discrete which is simply on/off.

Control of the process variable is commonly implemented with an analog device, such as a modulating valve or a variable speed pump. However, sometimes control is implemented using a discrete device, like an open/close valve or an on/off heating circuit. In this case, most applications will need a pulse width modulation function, or time-proportioned control logic, so that this method

of discrete control behaves much like an analog function.

A PID control loop involves the following analog variables:

• Process variable (PV): The characteristic measured by the PID equation.

• Controlled variable (CV): The output signal as commanded by the PID equation.

• Setpoint (SP): The desired value for the PV to reach and remain at.

The PV and SP are usually expressed in engineering units, such as PSI or DegF, but it is also possible for these to be represented in %, such as for a tank level. The CV is often expressed in %, such as 0 to 100% for a valve opening or pump speed, but it can also be in other engineering units. It is important for the user to carefully assign and scale the associated real-world signal values, which may interact with the controller via wired 4 to 20 mA signals or communicated over a serial or network connection, and then apply them with reasonable limits.

There are several forms of the PID equation itself, and it is beyond the scope of this blog to describe the equation in detail, but users typically need to apply the following tuning parameters, or terms:

• Proportional (P): Also known as gain, associated with the scale of corrective action based on the error (or the difference between PV and SP).

• Integral (I): Also known as reset, associated with the scale of corrective action based on the integral sum of errors over time.

• Derivative (D): Also known as rate, associated with the scale of corrective action based in the rate of change of error. Simplistically, the P term acts on the immediate error, the I term acts increasingly as error persists over time, and the D term acts to anticipate error as it changes. Many applications run fine with only PI terms, and some work adequately with just a P term. More difficult applications, notably temperature control, often require all three PID terms.

It is possible to manually tune a PID equation, but it is difficult to tune all three terms at once, and users need to ensure the process continues to operate safely during the tuning. For manual tuning, a user typically would:

• Start with only the P term (I and D set to zero).

• Raise the P term to provide quick response, but once the PV becomes unstable and oscillates, then reduce the P term until stability is achieved with only a slight oscillation or error.

• With a stable PV, raise the I term slightly to help reduce the error to zero.

• If desired, increase the D term slightly to reduce overshoot, although this can slow the response.

Automatic tuning — also called autotune — if available in the controller or separate software, reduces or eliminates the trial and error of manual tuning. AutomationDirect hardware PID controllers, and the PID algorithm in several PLC families, include integrated autotuning.

A typical autotune cycle controls the CV, sometimes in a step

wave format, and measures the rate of change, overshoot, and response time of the PV to calculate the ideal PID terms. Sometimes a little further manual adjustment is needed, but in most cases a built-in autotune capability quickly provides workable parameters, saving time and effort.

manual, and they may need to be warned of limit, deviation, and rate-of-change alarms.

For a wide variety of process situations, PID loop control is the best solution.

There can be many other loop implementation and tuning considerations, such as the sample time of the loop, how aggressively the loop is tuned to minimize rise time, and the acceptable percent overshoot, settling time, and steady-state error. Some loops experience a large deadtime—which is a delay introduced due to the mechanics of control, physics of monitoring, or inherent characteristics of the process—which complicates tuning, and in extreme cases may preclude the use of PID control. Other methods of control are available for these situations.

In other instances, multiple loops may interact with each other, or one loop may need to be operated as a cascade of another. On occasion, a loop may be split-range because it performs two functions (like both heating and cooling), with each needing their own tuning terms. Users may need the ability to place a loop controller in automatic or

AutomationDirect panelmounted process controllers — and PLCs like the Productivity, BRX, and CLICK families — include easily configured PID functionality and autotuning capabilities, helping

users get up and running quickly. AutomationDirect offers many resources — including specifications, documents/drawings, and videos — all accessible through the website, along with support staff ready to help designers identify the right solutions for their applications. This article is from blogs at Library. AutomationDirect.com.

wastewater 1c ad 4/5/05 2:53 PM Page 1 The PID controller can be mathematically written out as shown where a control signal is a summation of three mathematical operations.

AutomationDirect www.automationdirect.com

• Manual, automatic and actuated (pneumatic & electric) valves; relief, check, diaphragm, ball, solenoid, and shut-off. Also pressure regulators, metering pumps, basket strainers, sight glasses, and gauge guards.

• Innovative Engineering –Dedicated Craftsmanship.

• 100% inspection and individual testing of each product, to ensure dependable performance and long-life.

• PVC, CPVC, Polypropylene, PTFE and PVDF. Valves from 1/8'' to 3'',Sight glasses to 8'' and Basket Strainers to 14''. CEDAR GROVE, NJ 07009 (973) 256-3000 • Fax: (973) 256-4745 info@plastomatic.com•www.plastomatic.com

The ability to accurately measure the flow of gas in the pipeline is critical for custody transfer.

In particular, the measurement uncertainties count against the seller’s favour and can therefore not be invoiced. For example, a leading pipeline operator of natural gas used an RTD (resistance temperature detector) temperature calibrator to improve temperature accuracy in their gas flow measurement.

In recent years the industry has switched to using more precise ultrasonic flow meters as the technology has matured and price levels come down. Ultrasonic sensors have no moving parts, do not suffer pressure loss, and provide virtually maintenance-free operation. However, an often overlooked fact is that without an equally reliable temperature reading the actual gas volume through the pipeline cannot be correctly determined.

If accuracy improvements from using the new ultrasonic flow meters were to be realized, the pipeline company needed the right solution to verify the temperature sensor measurements. With an accuracy of ±0.3% from the ultrasonic flow meters, it was determined that an uncertainty of less than 0.1°F (0.06°C) was required from the temperature calibrator for the RTD probe verification.

Historically, lower-priced temperature calibrators with a higher uncertainty had been used. Several calibrators had been tested and found lacking for the new requirements.

The company tested and decided to standardize on the Ametek Jofra Reference Temperature Calibrator type RTC-157 together with a reference probe.

The RTC-157, with its active dual-zone heating technology, was capable of measuring with an accuracy of ±0.07°F (0.04°C), sufficient for the verification.

The following conservative assumptions were applied for the

calculation on savings and ROI:

• Pipeline diameter: 10 in. (0.254 m)

• Gas flow velocity: 50 ft/s (15.24 m/s)

• Static pressure: 1080 psi (74.11 bar)

• Gas price: $4.4/MMBTU ($0.16/ m3)

• Temperature: ~69°F (~20.56°C)

• Calibrator accuracy provides >1000% Return On Investment

• 1% improvement in gas flow accountability

• Reduced uncertainty enables invoicing of an additional $216,000 annually

With an improved temperature accuracy of 0.2°F (0.11°C) the error in the calculated flow volume per hour is reduced by 5.7 MMTBU (161 m³) corresponding to $25.83 per hour or $18,597 per month of previously unaccounted gas value.

This article was written by Jofra Calibration, represented in Canada by Cameron Instruments. Cameron Instruments www.cameroninstruments.com

AutomationDirect has added IDEM Skorpion rotary trapped key systems. The safety systems control access to running equipment with locks and rotary keys. To disable power to machinery and unlock a gate, the key is turned and removed from the control switch. The released key is then inserted into the gate access module to unlock the gate. Standard and solenoid-locking control switches and associated gate sets (sold separately) are available for one to three stations and provide mechanical safeguarding in partial or full body access versions. The systems are rated for safety applications up to Ple/Category 3 according to EN/ISO 13849-1. AutomationDirect www.automationdirect.com

Eriez ProGrade tubes, grates and liquid line traps are now available with the Xtreme RE7 Rare Earth Tube Circuit, said to be 13 to 40 percent stronger than other magnets on the market today in headto-head pull tests. The rare earth magnetic separators are designed to remove weakly magnetic fine ferrous contamination to ensure ultimate product purity and equipment protection. The company contin-

ues to offer ProGrade products in lower-powered models for customers with less stringent separation requirements.

Eriez

www.eriez.com

Acromag’s Busworks NT series permits the expansion I/O modules for what is said to be a high-density, cost-efficient remote I/O solution. Base unit NTE Ethernet models handle the network communication and interface up to 16 analog or digital I/O channels for remote monitoring or control applications. NTX Expansion models provide a cost-effective way to add a mix of I/O signal types under a single IP address. The

NTE Ethernet I/O modules are pre-programmed to support Modbus/ TCP, Ethernet/IP and Profinet protocols. Modules also support direct i2o peer-to-peer communication without a master. The series can provide up to 64 I/O channels per port and allows users to ix analog, digital, and temperature I/O on one port. It also features-40° to 70°C operating range and hazardous location approvals.

Acromag

www.acromag.com

23_000092_CPECN_FEB_CN Mod: January 4, 2023 5:14 PM Print: 01/13/23 page 1 v2.5 ORDER BY 6 PM FOR SAME DAY SHIPPING

Biomind Labs Inc., a Toronto-based biotech company focused on developing pharmaceuticals to treat patients suffering from neurological and psychiatric disorders, has announced progress in its pursuit of scientifically harnessing the medicinal power of psychedelic molecules. The company says that it has successfully completed the development of a novel sublingual formulation to be used in the Phase II trial for its 5-Metoxi-N,N-dimethyltryptamine (5-MeO-DMT)-based BMND08 candidate for the potential treatment of depression and anxiety in Alzheimer’s disease.

Commented Alejandro Antalich, CEO of Biomind Labs, “anyone who has a relative with a neurodegenerative disease such as Alzheimer’s, would give everything to stop the invisible, slow, and irreversible suffering that completely extinguishes the quality of life.”

Added Paola Díaz Dellavalle, PhD., chief scientific officer of Biomind Labs, “the main objective of developing this formulation was based on providing a scalable formulation that would be inexpensive, convenient for repeated and prolonged use, and pain-free.” Biomind Labs www.biomindlabs.com

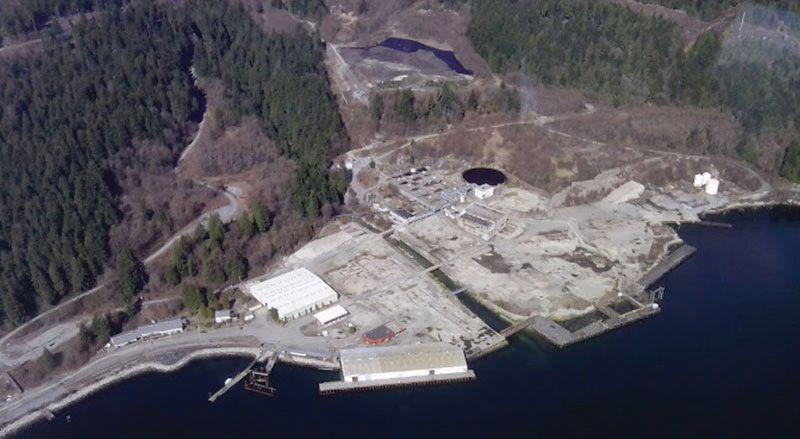

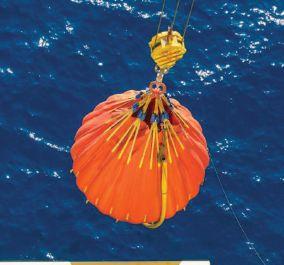

Enbridge Inc. of Calgary has completed the previously announced transaction relating to its partnership agreement with Nanjing, China-based Pacific Energy Corporation Ltd. to jointly invest in the construction and operation of the Woodfibre LNG project, located near Squamish, B.C. (above).

Enbridge now has a 30 percent ownership stake in the Woodfibre LNG project, with Pacific Energy retaining the remaining 70 percent stake in the project.

Pacific Energy and Enbridge will each make pro-rata contributions during construction through a combination of expected asset level financing and equity investments. In exchange for its capital contribution, Enbridge will receive a preferred equity interest that provides predictable future cash flows.

The partners will jointly participate in the project’s execution and governance of ongoing operations, while Pacific Energy retains responsibility for daily operations.

Preliminary construction activities, including site preparation are underway. The project remains on track for its targeted in-service date of Q4 2027.

Woodfibre

www.woodfibrelng.ca

The new Endress+Hauser Customer Experience Centre in Burlington, ON, has been named winner of the Rethinking The Future Award 2022 in the Industrial (Built) category. Rethinking The Future is an annual award program which aims to promote outstanding work in the field of architecture and design across the world.

The 47,000 sq. ft. Customer Experience Centre established a new sustainability standard for the family-owned, Swiss-based, industrial process measurement and analysis company’s global portfolio of facilities. The centre, official inaugurated last May, also is the first privately owned project in Canada to pursue both ZCB Certification and LEED Gold simultaneously. It recently attained that ZCB Certification, the standard demonstrating that a building has achieved zero carbon operations. It is anticipated the site will produce more energy than the facility will require on an annual basis through a combination of rooftop double-sided solar panels, heat pumps supplemented by a geothermal system, and innovative energy conservation practices.

The centre is home to workplace and administrative zones, a Process Training Unit (PTU), multipurpose training rooms, workshop/repair area, Factory Acceptance Testing and calibration labs, kitchen and cafeteria areas, fitness room, and warehouse space.

Endress+Hauser Canada www.ca.endress.com

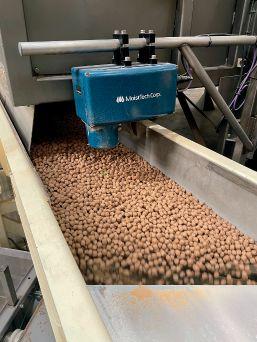

Demand continues to grow from original equipment manufacturers (OEMs) for the Eriez vibratory feeding solutions for integration into packaging systems, according to Eric Confer, Eriez market manager for

Vibratory feeder sorts shredded cheese (above). Electromagnetic feeders are suitable for packaging applications because they can be rapidly cycled on/off and feed material evenly and consistently, Eriez says.

Light Industries.

“Packaging system OEMs rely on vibratory feeders to meter and convey a variety of bulky and free-flowing material to provide greater economy and efficiency in feeding and filling, and Eriez delivers,” Confer says.

Erie, PA-based Eriez offers High Speed (HS) and High Deflection (HD) feeders, suitable for use with weigh scale and packaging machines. The Eriez team works with OEMs to develop custom solutions for the most unique applications and requirements, adds Confer.

“In the world of packaging,” says Confer, “efficiency on the plant floor is a top priority. Feeding components play an especially critical role in the overall speed, accuracy, and reliability of a packaging line system solution. Electromagnetic feeders are ideal for packaging applications because they can be rapidly cycled on/off and feed material evenly and consistently.”

Eriez

www.eriez.com

NOVA Chemicals Corp. of Sarnia, ON, has announced that its second Advanced SCLAIRTECH technology (AST2) facility and the third phase of the Corunna Cracker Expansion Project have each reached mechanical completion.

The world-scale AST2 facility, located at the new Rokeby Site in St. Clair Township, ON, will have a production capacity of approximately one billion pounds of polyethylene per year. The Cracker Expansion will provide ethylene feedstock to the new AST2 facility, expanding the existing cracker’s current capacity by more than 50 per cent.

Both projects are said to represent a significant investment bringing new technology, jobs, and long-term economic viability to the region. Since the growth projects began in late 2017, NOVA Chemicals has added approximately $2 billion to the provincial economy and over 7,000 workers were involved in construction.

NOVA Chemicals’ Corunna Site produces 1.8 billion pounds of ethylene and approximately 700 million pounds of co-products annually. Corunna provides feedstock to NOVA Chemicals’ Moore and St. Clair River Sites where they convert ethylene into up to 1.3 billion pounds of polyethylene per year. Ethane, a component of natural gas, is the primary feedstock for ethylene production at the Corunna Site.

NOVA Chemicals www.novachem.com

Prairie Lithium Corp. of Emerald Park, SK, has announced the commissioning of the third iteration of their direct lithium extraction (DLE) pilot plant at the Emerald Park testing facility.

The DLE pilot is designed to process deep subsurface brines sourced from the company’s Fall 2022 drilling program when 600 m3 of lithium rich brine was reserved for ongoing DLE technology testing.

The pilot plant utilizes Prairie Lithium’s Ion Exchange (Plix) material designed to selectively extract lithium from the produced brine water, purposely reducing the number of contaminants that are carried over into the production stream.

The new plant builds on the experience and knowledge gained from its predecessors, which processed close to 400 m3 of lithium rich brine over the lifespans. Significant changes to the plant’s design include new equipment to reduce processing time, improved configuration to enable continuous flow and increased processing capacity.

Prairie Lithium www.prairielithium.ca

The Valve Manufacturers Association membership has elected its 2022-2023 board of directors. VMA’s chairman of the board for the 2022-2023 year is Matt Thiel, president of AUMA Actuators, Inc.

Andy Duffy, VP Sales, Emerson/ASCO, will serve as the 2022-2023 vice chairman of the board and treasurer. Other members of the executive committee include:

Nathan Brunell, product line general manager, Baker Hughes Kirk Wilson, president, Flow Control Division, Flowserve; and

Ron Warren, president and COO of Bray International, Inc., who serves as immediate past chair.

Valve Manufacturers Association www.vma.org

Jo Ann Dizy, co-founder and CEO of #GrowTogether, has announced she will headline the 2023 Advance: Women in Manufacturing virtual event on March 2.

Her keynote presentation on, “How Mentorship and Sponsorship can Move the Dial in your Early Career,” will highlight the benefits of having mentors and sponsors in your professional networks to achieve career goals. Dizy will offer strategies to help participants obtain and maintain both relationships.

She will also touch upon the limitations to mentorship, and why your ultimate networking goal must be to develop sponsorship relationships.

Join the virtual event at 1 p.m. ET March 2 to hear Dizy and other leaders from the Canadian manufacturing sector. The half-day virtual event is hosted by Annex Business Media’s manufacturing group, Manufacturing Automation, Canadian Process Equipment & Control News, Canadian Manufacturing Online, PLANT, MRO, EP&T, Canadian Plastics, Canadian Packaging, Design Engineering, PrintAction, Frasers, Glass Canada, Fenestration Review and Food in Canada Advance: Women in Manufacturing www.automationmag.com/virtual-events

Food safety expert Hygiena of Camarillo, CA, has announced the expansion and relocation of its Canadian offices in Mississauga, ON. Having tripled sales in the last five years, the company says, the business has outgrown its current location and the new facility will better accommodate the increased workforce and necessary extensive warehouse space to support increasing demand.

According to the Data Bridge Market Research Report, the Canadian food safety testing market is expected to witness market growth at a rate of 7.7 percent in the forecast period of 2021 to 2028.

Steve Nason, CEO of Hygiena states, “Canada’s food safety market is segmented to include environmental monitoring, allergen, pathogen, GMO and mycotoxin testing, nutritional labelling, pesticide testing, contaminant testing and others.

“With our ever-expanding portfolio, we offer a very board portfolio of new solutions including ATP, Lateral Flow, PCR, ELISAs and intuitive data analysis software that meet the growing testing needs of food safety and beverage industries.” Hygenia www.hygiena.com

Global software developer eschbach, the provider of Shiftconnector digital manufacturing software for process manufacturing, announces that Artificial Intelligence (AI) is now an integral component of its enterprise platform. Now with AI search engine capabilities, the software platform will bring a new level of intelligence to the plant floor, the company says. Shiftconnector’s software platform enables process industry manufacturers to enhance communications among shift teams for effective shift handovers, transparent team communications, and increased asset performance. It adds that with the addition of AI’s Smart Search capabilities to the Shiftconnector platform, teams will now be able to improve plant performance by quickly finding solutions based on the history of documented tribal knowledge from plant operations teams. eschbach www.eschbach.com

itors are manufactured according to ISO standards and meet the criteria of the Underwriters Laboratories and CE safety standards. Mod-Tronic Instruments www.mod-tronic.com

The Grace Technologies GraceSense Hot Spot Monitor (HSM) is a non-conductive, continuous temperature monitoring and alarming device that identifies potential hot spots and enables users to predict the failures in electrical equipment. Intended for locations that are difficult and hazardous to access, the patented fibre optic technology provides constant temperature data from up to 9 or 18 independent sources (based on model selected). The non-conductive fibre optical probes can be mounted onto busbars, splices, disconnects, cable connections, or any source of resistive heat. The monitor is said to identify faults before they occur which saves money by preventing unplanned downtime, service interruptions and equipment failures. Grace Technologies www.turck.ca

Available via Mod-Tronic Instruments, the Shinko JIR-301 series of temperature and process monitors each measure 96 x 48 mm. The JIR-301 line includes such standard features as multiple inputs, retransmission, and three standard programmable alarm outputs. Offered in a 1/8 DIN size, the digital indicators come with NEMA 4X protective construction and black enclosures. The multi-input capabilities of each instrument accommodate ten thermocouple types, two types of resistance temperature detectors (RTDs), two current inputs, and four voltage inputs. Each unit also has standard 4 to 20 mA process variable retransmission, and optional outputs are available. Another key feature of the series is a large dual LED display, with four red digits for PV and four green digits for the alarms. The mon-

N.R. Murphy Ltd., a maker of dust-collection solutions, also manufactures abort dampers. The units are highly recommended for sawmills and other work environments that face fire and explosion risks. When users install them in the clean air streams of their filtering systems, the company says, the abort dampers serve as instant aborting devices that expel the air to the atmosphere whenever they are activated by spark- or fire-detection systems. Abort dampers are designed to protect employees and facilities in such industries as forestry, wood processing, pulp and paper, and other fields in which fire and explosion are significant hazards. The company constructs them out of heavy gauge reinforced steel, and they are crucial for workplaces that pneumatically convey combustible material. Users of these abort dampers should wait until after switching off the exhaust system before manually resetting them.

N.R. Murphy Ltd. https://nrmurphy.com

Ecosorb has released EcoLink, an online portal for remote monitoring and control of industrial odor neutralization systems. With this advancement, the company says, users can now manage their equipment from anywhere in the world with any device capable of hosting a web browser, such as a smart phone, tablet, or PC. Using the portal, Ecosorb units can be managed remotely in the cloud, lifting local limitations for monitoring operations and adjusting. EcoLink provides a range of benefits, including the ability to: remotely start, stop, and change vaporization system operating mode; identify low product levels; track and trend flow rates, energy use, downtime, and other key performance indicators (KPIs); send alerts and notifications to an operations team; adjust product dosage to coincide with fluctuating odor-producing periods; encrypt data for transit and storage; and, view metrics, charts, and diagrams on an intuitive dashboard. Ecosorb

www.ecosorbindustrial.com

Fluke Reliability has introduced the Fluke 3562 Screening Vibration Sensor system. With its battery less technology, long-range sensor-to-gateway communication, and ability to connect to 1,000 sensors to a single gateway, the system is said to be a “set it and forget it” solution that can operate continuously, even in hard-to-reach places. When used with the recently released Fluke 3563 Analysis Vibration Sensor for critical machines and LIVE-Asset management software, maintenance teams now have a comprehensive solution for virtually every asset in the plant, the company says. The screening vibration sensor draws power from a machine’s heat or the light in the room using thermoelectric or photovoltaic energy harvesters. The sensor screens overall vibration levels, temperature, and humidity, as well as trends the nine highest FFT peaks by magnitude.

Fluke Reliability

https://flukereliability.info/3562Sensors

NewTek Sensor Solutions offers its hermetically sealed position sensors with a 4 to 20 mA current loop output. The HI series of hermetically sealed 4-20 mA LVDTs require less power than similar DC-operated LVDTs and signal conditioners, the company says. The sealed LVDTs are available with either a radially- or axially mounted connector. Units are available in ranges of 0.1 to 20 in. and operate from-25° to 85°C. NewTek Sensor Solutions www.newteksensors.com

Rechner Automation has announced Senotec S-series sensors for hot melt glue level detection sensing. The S-series sensors feature a metal probe, unique nonstick coating, and tapered design, the company says. Mounting can be done either vertically or horizontally. The sensor will detect liquids, granulates, or material in mixed states at temperatures up to 250°C. The sensors are suitable for PUR glues and can also reliably detect other non-conductive media such as hot glues, adhesives, waxes, oils, and greases. All sensors can be used for low-level time-filling, or high-level filling shutoff systems. Probe lengths from 15 to 85 mm. The 15 mm length model with a right-angle cable has an overall length of only 65 mm. The M18 threaded body and two included nuts will securely mount the sensor. Rechner Automation Inc. www.senotec-sensors.com

Rosta offers anti-vibration suspension systems with high levels of isolation and efficiency for free oscillating vibrating systems, from onion sorting shakers to dewatering screens in mines. Units are said to be highly elastic and tearproof mounts for passive and active vibration dampening. System models offer vibration-free mounting of motor test stands, emergency generators, and compressors; tearproof mounting of suspended loads such as crane tracks and cable car cabins; anti-vibration machine leveling feet with balancing ball joints; impact-resistant vibration dampers for energy dissipation at belt transfer stations; and a standardized product range for high load capacities. Vibration dampers are designed for the absorption of tensile, pressure and shear load, and are also suitable for wall and ceiling installations. Shown is the model ESL damper available in 8 element sizes from 200 to 19,000 N. The units offer a natural frequency between 3.5 to 8Hz. Rosta

NSF 61 & 372 Certified

The NS Series ball valves are available in sizes 1/4”-6” with threaded, socket weld, butt weld (3-piece) and flanged (2-piece) connections.

The NS Series butterfly valves cover 2”-24” sizes in wafer and lug style.

APPLICATIONS

• Water Treatment

• Potable Water Service

• Reverse Osmosis

• Desalination

The GEN-N Ethernet multiprotocol gateway from Turck makes its excom remote I/O system compatible with Industrial Ethernet networks. The gateway makes it possible to integrate the company’s system in higher-level Ethernet networks with the Profinet, Ethernet/IP and Modbus TCP protocols. The connection is implemented via RJ45 connectors with at least CAT5e cable quality. The integrated switch enables a ring topology to be implemented in accordance with DLR or MRP, which considerably increases the availability of the overall system. The gateway supports 10/100 MBit/s, half/full duplex transmission, auto negotiation and auto crossing. A GSDML and EDS file containing all the necessary configuration files and parameter sets are provided for configuring the relevant system. Besides the standard diagnostic scope of Ethernet protocols, the gateway offers manufacturer-specific error codes that provide information on both the status of the system as well as that of the connected HART field instrumentation. Turck Canada

www.turck.ca

Earlier this year, VEGA unveiled and released its innovative new radar sensor, VEGAPULS 6X. Powered by the company’s custom radar chip, the 6X sensor is designed to provide precise and reliable measurements for a wide range of applications. Now that the new sensor has spent some time in chemical operations around the world, the company says, it can now share a couple success stories it has heard from customers.

A specialty chemical company that supplies the construction and industrial markets utilized

Guided Wave Radar (GWR) sensors on six sand silos at one of their plants. Due to abrasion from the contacting sand, the probes on these GWR sensors required regular maintenance and cleaning and would sometimes even get damaged.

Seeking an alternative measurement method that would save them from the mounting time and costs being put into maintenance, the company reached out to measurement experts at VEGA.

In this example, VEGA personnel visited the plant to assess the troublesome application. After a careful examination of the process, company experts recommended the non-contact radar technology of VEGAPULS 6X as the ideal solution for the company’s sandy predicament. Since the sensor is able to make reliable measurements without touching potentially abrasive or damaging process materials like sand, the plant agreed to test out a VEGAPULS 6X unit on one of the sand silos to see if it could truly live up to the challenge.

After spending time monitoring the sensor’s performance, the company was so pleased by the lack of maintenance and cleaning and by the reliability and precision of the measurement that they opted to equip the other five sand silos in the plant with the 6X sensors as well.

In a second example, a major provider of gypsum used Guided Wave Radar sensors in short vessels filled with foam and sticky process materials. Worried about the potential maintenance and failure risks posed by the buildup of materials on the sensor rods, the company contacted VEGA, who came out to assess the vessels in order to discover an ideal solution.

Upon examining this literally sticky situation, VEGA personnel determined that VEGAPULS 6X would be the right sensor for the job; they equipped one of the vessels with a demo unit to verify the measurements and demonstrate the sensor’s prowess.

The gypsum company was delighted to find that the sensor was capable of making precise measurements without any part of the sensor contacting the process, and an 80 GHz config-

uration is capable of measuring through complex vessel geometry like stirrers and mixers.

Impressed by the sensor’s performance, the company outfitted each of the vessels with a VEGAPULS 6X, ensuring maintenance-free measurements for a long time to come.

This article is from the VEGA blog, VEGAPULS 6X Successes in the Chemical Industry VEGA www.vega.com

Sierra Wireless has announced the AirLink RX55 LTE cellular router designed to bring advanced networking capabilities to the Industrial IoT (IIoT) and deliver intelligence securely at the edge for mission-critical network applications. The cellular router is said to provide ultra-low power consumption, which combined with its wide operating voltage, makes it suitable for solar or battery powered remote monitoring installations. The Ethernet and dual-serial port make it available for use in both fixed and mobile industrial applications including power and water utilities, oil fields, pipelines, mines, agriculture, manufacturing, waste management, private networking, and SCADA applications. The product delivers multi-band, world-wide support providing extensive public network coverage and best-in-class private networking coverage, the company says. The router supports Band 71 as well as most private networking bands including CBRS Band 48 in the U.S., and private Band 42 and Band 43 in Europe.

Sierra Wireless www.sierrawireless.com

product line is said to offer benefits over traditional in-plant building, it adds, including simplified deployability resulting in a rapid installation to production timeline. Using membrane-based technologies, the company’s system removes suspended solids, dissolved solids and organics, and remaining trace ions to produce demineralized water.

Marmon Industrial Water

www.marmonindustrialwater.com

Verder Liquids has introduced the Verderflex Ds500 metering and dosing pump, designed to challenge traditional technological solutions to chemical dosing in municipal and industrial pumping applications. A key advantage of the pump is that it has an easy ‘click and go’ cartridge change, the company says. The main wearing component, the peristaltic cartridge, can be changed in one minute

DON-H high pressure oval gear positive displacement flow meters from Kobold are said to offer reliable flow rate measurement for demanding process conditions. The flow meters are suitable for clean, high, and low viscosity liquids such as lubricating/hydraulic oils, petroleum, grease, diesel fuels, chemicals, solvents, resins, and pastes. Because of the mechanical nature of the measurement principle, media with particulate matter is not suitable for use with the units. The flow meter uses two precision-machined oval gears which allow for a very specific volume of liquid to pass through the meter with each rotation, providing a true volumetric flow measurement. The gears enable the DON-H to precisely measure liquid flow over a very wide viscosity range, accommodate fluctuating flow rates, a provide accuracy for applications with intermittent flow, the company says.

Kobold Canada

www.kobold.ca

Marmon Industrial Water has introduced its Containerized WT Solutions line. The compact water treatment containers contain a combination of ultrafiltration (UF), reverse osmosis (RO) and electrodeionization (EDI) technologies to produce ultrapure demineralized water for industrial processes, the company says. Designed and assembled using a 20- or 40-foot shipping container as both the skid structure and building, the

giving minimal maintenance time and spare part components. RA (Remote Assistant) IOT Monitoring ensures accuracy in the process and alerts to any problems. Changes are predicted, so maintenance can be scheduled. Performance is recorded and feedback provided. As a result, downtime is managed and minimized. The pump can deliver up to ±1% accuracy with a smoothed flow (i.e., reduced pulsation due to the design). Furthermore, this pump has an accurate flow performance from 0.1 up to 500 ml/min and pressures of up to 7 bar.

York Fluid Controls

https://yorkfluid.com

NewTek hazardous location position sensors monitor the structural integrity of LNG tanks where natural gas is cooled to cryogenic temperatures at liquefication facilities, then stored as a liquid until pumped into LNG tanker ships for export. Approved for use in Class 1, Zone 0, and Zone 2 locations, the hazardous location certifications of the company’s NT-HL-750 series of LVDT are said to be preferred in this application. Even though the space between the inner and outer tank containers is normally filled with nitrogen, the company says, a leak in the inner tank can result in gas seeping into the space between the tanks where the sensors operate. Intertek-approved and holding an ETL certification for use in hazardous locations throughout North America, the sensors also operate safely and accurately in hazardous and explosive environments with the presence of flammable or ignitable gases and liquids such as those found in refining and petrochemical plants and pipelines.

NewTek Sensor Solutions www.newteksensors.com

The Cure-Met UV radiometer from Gigahertz-Optik is a portable flat-cordless-datalogger designed to handle the high temperature and intense UV or blue light levels normally found in UV curing processes. The radiometer monitors and displays its internal temperature and corrects its reading to compensate for any temperature coefficient differences. Irradiance profiling is possible with its internal datalogger and graphical display mode. A reference measurement can be set enabling the percent difference between subsequent test measurements and the reference to be displayed. All measurement data can be exported to a PC via the device USB port and supplied user software. The unit is also recharged when connected to the USB port.

Gigahertz-Optik

www.gigahertz-optik.com

Ashcroft has announced that its model 1209 4-½ in. pressure gauge is now available with overpressure option XRA. The feature is designed to restrict the motion of the bourdon tube once the specified fullscale pressure value has been attained. As a result, the company says, instrument capacity is enhanced to withstand up to 417% overpressure without incurring damage and reduces the need for an external pressure limiting valve. It is said to be especially useful for applications where pressure spikes, surges and water hammers are a concern. The model also provides solid front and pressure relief back for operator safety; ASME B40.100, Grade 2A provides consistent ±0.50% of span accuracy; 316L stainless steel case, ring and wetted parts resist corrosion from the environment and the process media; ranges 15 to 600 psi; and, an optional Liquid Fill or PLUS! Performance to dampen shock, vibration, and pulsation.

Ashcroft

www.ashcroft.com

of trim materials, including bronze, 300 stainless steel, 17-4pH stainless steel, and Alloy 6 (cobalt-chromium-tungsten). Available valve body styles include 2-way single seat unbalanced, 2-way cylinder balanced, 2-way double seat balanced, 3-way mixing, and 3-way diverting. The equal percentage and linear plugs in the 2-way valves and linear plugs in the 3-way valves are said to provide excellent modulating control of a wide variety of fluids.

Warren Controls

www.warrencontrols.com

Pepperl+Fuchs has announced Industrial Box Thin Client products — pre-installed with its RM Shell firmware, suitable for applications from the control room down to hazardous areas. The firmware is based on Windows 10 IoT Enterprise 2019 LTSC, which includes long-term support by Microsoft. Thin client product highlights include: dual or quad video options with 4k monitor support; 0° to 55°C operating temperature with IP4x passively cooled aluminum housing; flexible mounting with desktop, wall, DIN rail or VESA mount options; and hazardous location installation with optional UL Division 2 certified units.

Pepperl+Fuchs

www.pepperl-fuchs.com

Warren Controls has announced the Series 2900 industrial control valves, suitable for food and beverage, packaged water heaters, pharmaceutical, and general service applications, as well as wastewater applications with moderate pressure drops and temperatures from -20° to 400°F. The series features cast iron bodies and is available in a variety

Valmet has introduced a flame profiling application that enables real-time flame detection and monitoring in a pulp mill’s lime kiln environments. The new flame profiling software is an add-on application for Valmet Visible Thermal Imaging System. The software detects the flame, measures its relative size, and provides distance measurements from the end of the detected flame to user defined markers. These features are said to help to optimize fuel combustion, increase availability, and reduce emissions, as well as improve safety.

Valmet

www.valmet.com

It’s probably too late for Happy New Year greeting, but what the heck, Happy New Year! Each new year brings new optimism and hope for a good year. 2023 is no exception.

The CPECN Process & Automation Shows are back in a big way. We kick off the season with Richmond, BC, March 2 at our usual spot the Executive Inn. Then it’s off to Sarnia, ON, for April 26 at the Dante Club. Please mark it your calendar and plan to attend.

Four shows throughout the country will follow this fall.

Exhibitors can go to our web site to apply for space visitors to register at www.cpecn.com. It will be so good to get back to face to face interaction and away for zoom and email. See you there!

Our next issue up is our April issue closing March 3rd. The focus will be on Plant Communications and Mike’s supplement will look at Dust Control.

If you have something you’d like to share with our 21,000+ print audience, contact me early and we’ll set you up. If your products are good — don’t keep them a secret.

Spring is around the corner as the days get a little longer everyday now, enjoy the winter.

Cheers, Rob Sommerville

HEPA filtered clean rooms from HEMCO feature a modular construction design that is said to be cost effective and time efficient compared to traditional construction. An entire laboratory workspace is pre-engineered including the structure and the lab furniture/fume hoods to outfit the interior, the company says. The clean rooms wall panels have a white fibreglass surface for chemical resistance and provide light reflectivity. Because of the modular construction, the structure can be easily assembled, modified in the future, or disassembled and moved if required, it adds. Ceiling HEPA filtration is designed to meet needs from just a cleaned-up area from the surrounding environment to class 1000 (ISO 6). Door, lighting, and electrical options are provided as requested.

HEMCO

www.hemcocorp.com

Bally Ribbon Mills has announced the availability of a wide range of lightweight two-and three-dimensional woven materials that serve as the structure or substrate for critical rigging and tie down applications that require strength, interlaminar shear, enduring resistance, or conductivity. The company custom-designs specialty applications with high strength to weight ratios, flame/heat resistance, flexibility, low elongation, and abrasion resistance. Available in widths from one to six inches, rigging and tie-down materials are manufactured in such high-performance fibers as Kevlar, Vectran, Technora, Spectra, and Dyneema.

Bally Ribbon Mills

www.ballyribbon.com

HMS Networks has expanded its second-generation Anybus Communicator range of gateways. Thirteen new versions for data connectivity between EtherCAT, EtherNet/IP, Modbus TCP, PROFIBUS, and PROFINET make it simple for users to connect between different control systems, remove automation islands and maximize operational performance. Featuring new hardware and software, the gateways enable up to 10 times faster data transfer than their predecessors. Users can also exchange significantly more data between the networks as the gateways transfer up to 1500 bytes to and from connected PLCs. the gateways are designed to handle harsh industrial environments. To protect users from cyberattacks, the gateways have an onboard physical security switch that prevents unauthorized configuration changes and secure boot functionality to resist attacks and infections from malware.

HMS Networks

www.anybus.com

Pilz has introduced the PITreader system for implementing tasks relating to access permissions for plant operations and machinery. The options range from a simple enable and user authentication to a complex permission matrix and company-specific coding. The system is flexible as a standalone device, or it can be used in conjunction with a Pilz controller. The transponder keys with RFID technology are available in freely writable versions and with fixed, stored permissions. Software tools are available, the company says, for fast and simple programming of the PITreader keys and the PITreader settings.

Pilz Automation

www.pilz.com

Q.E.D. Environmental Systems has announced its AutoPump Ultra 4+ aggressive fluid duty landfill liquid pump features upgraded materials to extend the pump’s service life and expands its use cases to a wider set of conditions. The pump’s non-metallic internal parts are polyvinylidene difluoride to retain higher strength at elevated temperatures and provide broad chemical resistance. The unit can provide reliability and safety in the following conditions: hydrocarbon (LNAPL and dissolved phase) remediation; landfill leachate and methane condensate pumping; solvent (dissolved phase and DNAPL) cleanup; suspended solids, silts, and corrosives; high viscosities; high temperatures; and frequent starts and stops. The pump is available as either a 4-inch bottom inlet or a 4-inch top inlet and can withstand temperatures up to 180°F. It has a maximum fluid viscosity of 1,000 cSt, a maximum depth of 250 ft, and a flow range of 6-14 gpm.

Q.E.D. Environmental Systems www.qedenv.com

OleumTech has added a Smart Differential Pressure (DP) Transmitter to its H series line of hardwired process instrumentation. The new DP transmitter provides multiple measurement ranges from -5 to 5 psi through -1500 to 1500 psi with a reference accuracy of ±0.075% of full span. It offers up to a 100:1 turndown ratio while all models support Primary Value (PV) reversal (high side/low side) except for the 1500 psi option. The DP transmitter can be ordered with an output option of 1 to 5 V, 4 to 20 mA, 4 to 20 mA/HART, or RS485 Modbus. All models carry the Explosion-Proof rating, while the 4 to 20 mA/HART model can be ordered with the optional Intrinsically Safe rating. In addition, magnetically coupled integral pushbuttons are provided both internally and externally for ease of use. OleumTech

www.oleumtech.com

The Marion WaveMix industrial drying system available from Firing Industries combines microwave, vacuum, and mixing technologies for what is said to be a cost-effective, high-precision thermal processing solution. The system is designed for handling sensitive materials and for preserving the colour, nutritional, and chemical value of materials. The technology has been utilized in a variety of industrial applications across a wide range of industries, processing materials such as carbon black, calcium carbonate, titanium dioxide, chlorine powder, dried foods and pharmaceuticals, food-grade gelatin, ceramic proppants, and green coffee beans. The quicker, more efficient drying technology eliminates case hardening and material loss caused by burning, overprocessing or underprocessing, the company says.

Firing Industries www.firing.com

The Berthed LB 571 microwave resonator for online measurement of moisture content in bulk materials is based on the resonance technology. This technique is determined by electromagnetic waves (microwaves) in a dielectric cylindrical resonator. The sensor with integrated signal processing unit can be used for a wide range of bulk materials in a moisture range of between 0 and 30%. The parts in contact with the media are made of ceramic or stainless steel and the electronic housing is made of aluminum, making the unit suitable for use in the food industry. Calibration is carried out directly on site, conveniently and quickly using the supplied PC software, the company says. The online determination of the moisture during the active process allows for a reduction in production costs through continuous quality monitoring, it adds. Berthold www.berthold.com

METTLER TOLEDO’s new Process Analytics Catalog provides up-to-date information on equipment for measuring analytical parameters related to pure water analytics, as well as industrial processes in biotechnology, pharmaceutical, chemical, and food and beverage manufacturing. Also included is information on amperometric sensors, tunable diode lasers (TDL) and other solutions for gas analytics, such as Intelligent Sensor Management (ISM®) technology, designed to help ensure reliable measurements and maximum uptime via unique predictive diagnostic tools.

A sample of applications found in this catalog include:

• Sensors and analyzers for pH, ORP,dissolved oxygen,dissolved carbon dioxide, turbidity and conductivity

• Water monitoring equipment for total organic carbon, conductivity, dissolved oxygen, dissolved ozone, pH, sodium, silica, chloride, sulfate and bioburden

• Gas analyzers for a wide range of process gasses, including oxygen, moisture, methane and ammonia

• Full portfolio of analog and Intelligent Sensor Management sensors

Download the catalog today by visiting www.mt.com/ca-pro-catalog-2023