Wanner Engineering has announced Hydra-Cell Q330 series pumps that feature a seal-less design to avoid the maintenance problems of mechanical or dynamic seals and packing that can leak and wear. Medium pressure models offer flow rates up to 153 gpm and a maximum pressure rating of 3500 psi. High pressure models offer flow rates up to 118 gpm and a maximum pressure rating of 4500 psi. The series can run dry without damage, will operate with a closed or blocked suction line, and can pump hot abrasive fluids effectively. The patented pumps employ hydraulically-balanced, multiple diaphragms that enable the pump to handle high pressures with low stress and process abrasive particulates up to 800 microns in size, according to the company. Wanner Engineering is represented in Canada by John Brooks Company. John Brooks Company www.johnbrooks.ca www.cpec.news/agz

Hoskin Scientific has introduced the BD Sensors DMP pressure transmitter. The pressure transmitter was designed for pressure measurement in hydrogen applications as well as technical gases such as oxygen. The unit is said to have an impressive resistance to pressure spikes and a high overload capacity, both of which the DMP 336 model encounters when another gas depot is connected to the pipe system, for example. Optionally, the device is available with ATEX approval in an intrinsically safe, explosion-proof version for zone 0. Specifications include: nominal pressure of 0 ... 16 up to 0 .... 1000 bar; media temperatures of -40° to 125°C; and, measures the pressure with an accuracy of 0.5% FSO. Features include: dry sensor – no oil filling, no elastomers; wetted parts in special stainless-steel; insensitive to pressure peaks; and, oil and grease free according to ISO 15001 (e.g. for oxygen applications). Hoskin Scientific

www.hoskin.ca

www.cpec.news/j32

Werma EvoSIGNAL signal beacons that warn, guide and protect are a modular alternative for signaling from AutomationDirect. The IP66-rated visual and visual-audible signal devices are available in Mini, Midi and Maxi versions with common signal module voltages (115-230 Vac, 12/24 Vac/Vdc) and with base, tube, bracket and wall mounting options. Mini and Midi audible signal horn versions offer 2-tone continuous or pulse sounds at 95-110 dB, 1 m. Mini beacons are 62 mm in diameter, Midi beacons are 85 mm Maxi beacons are 120 mm in diameter. Maxi series beacons are suitable for building services engineering, door and gates, machinery and plant equipment systems. Watch product launch video at www.cpec.news/t87. AutomationDirect www.automationdirect.com www.cpec.news/2uf

Endress+Hauser Canada has introduced the Proline t-mass F/I 300/500 flowmeter series that is said to provide additional benefits like bidirectional measurement and reverse flow detection. The flowmeters are used in a wide range of process industries for pure gases and gas mixtures like measuring flare stack and flue gases in HVAC, for utilities in monitoring air, oxygen, nitrogen or argon or in the food and beverage industry for consumption of natural gas or for carbon dioxide measurement. The measuring system comes with a Gas Engine as standard that offers 22 gases to choose from and corresponding gas mixtures with up to eight components. The units comprise an in-line version for pipes DN 15 to 100 and an insertion version for pipes and ducts DN 80 to 1500. Both provide dynamic correction for changes in pressure, temperature and gas composition, and the possibility to change programmed gases without recalibration. The SiL-compliant thermal flowmeters offer measuring accuracy of ±1.0%, repeatability of ±0.25%, turndown up to 1000:1 and are suitable for temperature measurement up to 180°C at pressures up to 40 bar. Watch video demonstration at www.cpec.news/em4. Endress+Hauser Canada www.ca.endress.com www.cpec.news/uvx

As with most industrial control projects, cost is king, but you don’t have to sacri ce quality to keep your budget intact. C-more HMIs are built to last and provide many advanced capabilities, including object animations, logic and math operations, web server/mobile app access, and data logging, all for a surprisingly low price.

C-more Touch Panel HMIs starting at: $487.00 (EA9-T7CL-R)

C-more HMI design software can now be downloaded free-of-charge. Get started on your project today or take it for a test drive.

Download as often as you need. No license or key needed.

Get your copy now at: www.go2adc.com/cmoresw

Research, price, buy at: www.automationdirect.com/cmore

Our shipping policies make it easier than ever to order direct from the

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days.

*Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

With rugged construction and ±0.1% Full Scale accuracy, the new Field Gauge LC20 from Ralston Instruments is said to be an affordable reference-grade digital gauge with customization options. The gauge can switch from among 15 standard engineering units or create custom units using the included FieldLab software. Set up the software for logging and live viewing of pressure over USB or choose the Wireless option and monitor tests from the comfort of a nearby vehicle,

the company says. The field gauge unit is suitable for pressure monitoring, calibration of analog pressure gauges and transmitters, pressure switch testing, and leak testing. Units are available in 11 pressure ranges from 5 psi/35 kPa to 10,000 psi/70 Mpa, a compound vacuum/pressure gauge from ±15 psi, and a digital vacuum gauge measuring up to 30 inHg /760 mbar.

Ralston Instruments

www.ralstoninst.com

The Rechner capacitive sensor model KAS-80-A24-A-M30PA-120C-Z02-1-NL is designed for dryer applications for powder bulk solids. With a temperature rating of 120°C, the sensor has a polyamide housing resistant to abrasion. Granular material not an issue for the fully potting sensor,

www.cpec.news/ebl

the company says, and high vibration not a problem. Rated watertight and dust tight to IP67 and 12 to 30 Vdc, units provide a 20-turn trim pot and sensing range from 2 to 25 mm. The non-flush mountable sensor is available in either PNP or NPN configurations.

Rechner Automation Inc.

www.rechner.com

www.cpec.news/a26

Pepperl+Fuchs has introduced the Bebco EPS purge and pressurization system designed specifically for use with large enclosures in Zone 1 hazardous areas. The 6100 series system can purge an enclosure over 450 cubic feet (12.2 cubic meters), making it the largest purging system available from the company. The series is suitable for applications in the chemical/petrochemical and oil and gas industries. It is a fully automatic system that does not require an operator to initiate purging or pressurization. It offers optional temperature sensors that can be mounted around the enclosure for alarm notification or cooling.

Pepperl+Fuchs

www.pepperl-fuchs.com

www.cpec.news/e8y

As the health of the natural resources sector goes in Canada, so goes the health of the economy. And, of course, if the U.S.A. sneezes, we catch a cold (or worse these days).

President Biden warned us (Alberta) that the Keystone XL pipeline project would be dead on his watch, and danged if he didn't deliver on his promise within hours of taking office. Of course the reason for the decision is supposedly climate change, underscored by his decision to also re-join the Paris Accord on reducing greenhouse gas emissions.

Electric vehicles are being touted as a possible carbon consumption saviour, at least for now. Certainly in jurisdictions where hydro- and nuclear-generated electricity drive the grid, these vehicles make sense.

GM has tapped Canadian automotive plants to bring its EV strategy forward, and may consume materials for its batteries from our mines to do so.

The Government of Prime Minister Trudeau II called upon a plan in 2019 at the Ministry of Natural Resources that would make Canada "a leader in the critical minerals sector, acknowl-

edging the importance of metals to a lower-carbon economy," according to S&P Global Market Intelligence.

"The increased policy focus on critical minerals in Canada comes as the U.S. and other countries push to lessen their reliance on China for critical minerals and rare earth metals in particular," S&P says.

Business activity in this sector, especially in Quebec, is certainly hot right now. Watch our newsletter to see how this "pans" out.

Mike Edwards medwards@cpecn.com

April Issue

Focus on

Plant Communications Supplement:

Bulk Powders & Solids

Editorial closing date: March 5

June Issue

Focus on Maintenance & Safety Supplement: Instrument Calibration Labs

Editorial closing date: April 30

August Issue

Focus on Environment Supplement:

Wastewater Management

Editorial closing date: July 16

October Issue

Focus on Fluids Handling Supplement: Sensor Technology

Editorial closing date: September 3

December Issue

Focus on Plant Automation Supplement: Fittings & Couplings

Editorial closing date: October 22

To contribute, contact the Editor, Mike Edwards medwards@cpecn.com 905.251.5524

Newsletter submissions welcome anytime for every second Wednesday — Hump Day!

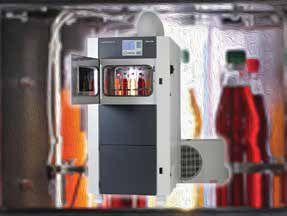

Kaye has introduced the Kaye Log -80 Vaccine Temperature Logger and KayeTrack Cloud Kaye while it applied the same quality principles to ensure the validation and safety of the cold chain. Available from HWMR, the NFC Logger with external probe, the system allows the precise recording and monitoring of products that are using dry Ice pellets for cold chain shipment and storage. Shipments of vaccines and plasma at -70°C are very sensitive for breaking of the container seal, the company says, which will quickly allow the internal temperatures to rise to a critical level. The data logging system is suitable for COVID-19 and other

vaccines, as well as providing fast access to the temperature data without disturbing the integrity of the packaging. Any removal of the logging device from the package, use of USB and local software applications will impede the process flow, the company says. Threshold LEDs allow the recipient to quickly see if the threshold limits have been breached, and with a quick swipe of an NFC device, all data is loaded to a local smart phone application and to the KayeTrack cloud, with corresponding email alerts, emailed PDF reports and GPS location information.

HWMR

www.hwmr.ca

www.cpec.news/hst

The Type 303 Stainless Steel 3 NPT Threaded Line Vac Air Operated Conveyors from Exair are said to convert ordinary pipe into a powerful conveying system for parts, scrap, trim and other bulk materials. This chemical and corrosion resistant Line Vac operates seamlessly at higher temperatures, the company says, providing a long-lasting and low maintenance solution suitable for food, chemical, pharmaceutical and medical processes. The durable construction of the conveyors employs a larger inside diameter, aiding in conveying bigger parts and larger volumes of material over long distances with ease. In addition, it’s designed for simple attachment to standard plumbing pipe couplers in order to take advantage of common pipes and fittings that are readily available, it adds. Three NPT 303SS units are CE compliant and meet all OSHA pressure requirements. Ranging from 3/8 NPT through 3 NPT, all models are also available in type 316 stainless steel. Watch video at www.cpec.news/fgf.

Exair

www.exair.com

www.cpec.news/uir

Software introduced by AHED for the design of shell and tube heat exchangers is not only said to be more accessible, but it also offers greater freedom for teams to collaborate on projects, improving project flow and speeding up design, approval, and manufacturing. Unlike other systems, the AHED (Advanced Heat Exchanger Design) application uses a combination of local cloud-based design software to allow users anywhere in the world to share their designs and collaborate on projects. At the same time the software has been designed to be useful for anyone with a moderate understanding of the engineering or thermal basis of heat exchange technologies, the company says. From engineering companies and contractors in petrochemical and other industries, and those who evaluate designs, a software video demonstration and a free two-week trial are available at www.cpec.news/vhb.

AHED

www.hrs-ahed.com

www.cpec.news/vhb

Pharmaceutical companies all over the world are diligently working overtime to produce an accepted COVID-19 vaccine. While this work continues, other companies are already planning how to distribute a potential vaccine. Perhaps the most significant challenge exists in temperature control, as some COVID-19 vaccine candidates will require ultra-low temperatures (ULT), typically ranging from -86°C to -45°C.

For COVID-19 vaccines requiring ULTs, maintaining these freezing temperatures throughout the process, from manufacturing to delivery to patients, is necessary. Failure at any point to do so can result in wasted vaccines, which are so desperately needed.

Because the temperature level is critical to keeping the COVID-19 vaccine at maximum efficacy, the equipment to monitor and document temperature levels is essential. In particular, the ability to document storage conditions is critical. Temperature sensors help monitor and provide documentation, but they drift over time. To assure maximum efficacy and reduce waste, these temperature sensors must remain accurate. This is where high-quality temperature calibrators come into effect.

Facilities that manufacture or house the potential COVID-19 vaccine may need to invest in infra-

structure improvements and storage freezers if they don’t already exist. As keeping the temperature inside these super freezers at correct ULT levels is a must, advanced HVAC systems might be needed to properly control the room temperature. Even the slightest unexpected change of ambient temperature could cause a significant extra workload for the HVAC system, shortening its life cycle. An overworked HVAC system also means an increase in electricity, further adding to an expensive undertaking.

Because of the significant monetary investment that companies will make in each facility, they will want to base their decisions on accurate temperature readings. This burden falls on temperature sensors mounted inside the freezers. If these sensors are faulty, they could indicate incorrect temperatures, causing the system to react unnecessarily, thus wasting money and time.

After a COVID-19 vaccine leaves the manufacturing facility, it will embark on potentially the most challenging of segments on its way to the patient. Transferring the vaccine from the storage freezer to a container to a portable freezer and then to the distribution center must occur while maintaining the optimal freezing temperatures. After the distribution center, it will make its second trip, ultimately culminating

in its arrival at a health care provider or a pharmacy.

As multiple transfers of the COVID-19 vaccine occur, audited temperature tracking will ensure the correct temperature control. Just like at the manufacturing facility, temperature sensors will play the crucial role of measuring and reporting the temperature at all times. If even one of these transfers breaks down and temperatures rise outside ULT levels, the COVID-19 vaccine is lost.

Some companies will use advanced temperature sensors with wireless capabilities or datalogging, allowing them full-time access to the current temperatures inside the containers. These records will provide proof of transit temperatures, protecting the transportation companies. However, even these advanced temperature sensors require calibration to remain accurate.

The final leg in delivering a COVID-19 vaccine to the patient will take place at health care providers or pharmacies. The burden of keeping the vaccine at ULTs now falls to locations that won’t typically have the equipment to store vaccines at this low temperature. Many will opt for portable freezers rather than the expense of a more permanent solution.

Regardless of the selected option, the freezer will contain sensors to continue the COVID-19 vaccine temperature’s constant record keeping. Like every stage before this, ensuring proper calibration of these temperature sensors is essential.

From manufacturing to distribution to patient delivery, temperature sensors play a critical role in maintaining the efficacy of the COVID-19 vaccine. They assist in preventing waste, maintaining proof of temperature control, and most importantly deliver-

When it comes to buying criteria for inspection equipment, commercial viability will often make or break decisions. Yet right now, the COVID-19 crisis is pushing space-optimized design and remote diagnostics to the top of the agenda.

To mark the launch of their new compact Raptor Combination metal detector and precision check-weigher system, Fortress Technology explores why smaller-footprint food inspection systems are rapidly becoming the ‘new normal’.

Footprint has long been a consideration when choosing packaging and processing equipment. In North America, rent per square foot in industrial manufacturing plants currently averages US$6.36. Given that factory space is at a premium and the ever-increasing cost of real estate, each cubic foot has to be maximized.

In production and packaging facilities where every inch matters, establishing new practices that will enable factory personnel to work safely during the COVID-19 pandemic is a huge challenge. Preventing the spread of the virus within the workplace is all about creating distance and physical barriers between workers, but space is in short supply in most facilities.

Redesigning factory layouts is not easy, requiring considerable investment. However, producers have a duty of care to operators to ensure they are working in a safe environment. Rather than reconfiguring production line layouts, companies are examining how they can redeploy and organize operators in a safer way, for example, by altering shift patterns. In other words, the focus is on moving people rather than machinery.

As factories adapt to these new ways of working, Fortress Technology Engineer Matthew Gidman anticipates equipment compactness will become even more important.

“From a factory floor perspective, adapting to COVID-19 is all about creating space. Smaller footprint equipment creates more space for people to move around without being restricted to certain pathways,” he comments.

One of the ways in which companies can save line space is to opt for a combined check-weighing and metal detection system —mounting these systems on the same conveyor results in a far smaller footprint than stand-alone units would occupy.

Combination metal detector/check-weighers are not a new concept. Fortress itself recently unveiled at Pack Expo Connects its first ever offering in the space under the Raptor brand. Available as a standalone checkweigher or combination system utilizing Fortress Stealth or Interceptor metal detector models, the system delivers flexibility, hygienic design and user-friendly operation, with the Raptor Combi starting at 1.7 m in overall length, virtually half the length of comparable models on the market.

The machine dimensions have been minimized via several innovative design features. Intelligent configuration of the reject mechanisms, for example, means that this new system occupies much less space without sacrificing the exceptional performance that Fortress strives to deliver.

“You can’t get away from the fact you need separate rejects for weighing and metal as the rework required for rejected products is very different. However, Fortress has designed the Raptor check-weigher so it can slot alongside existing metal detectors with opposing rather than sequential rejects. This helps to reduce the length of the reject system by nearly 20 inches,” explains Gidman.

“Twenty inches might not sound like a lot of space. Yet, it can be the difference between a safe working space and one that doesn’t meet requirements. Also, if you equate it to the amount you are paying per square foot, it translates to a tangible cost saving,” he adds.

Another way in which the Raptor system offer space-saving advantages over rival systems is through the flexibility this platform offers. Although Fortress manufactures a standard Raptor system for customers wanting a short lead-time system for handling products up to 15 in. (500 mm) in size and up to 17 lb in weight, the company can also custom manufacture a system that’s virtually half the length for inspecting smaller products.

Continued on next page

The Fortress Raptor Combi features a reject system, reducing the machine length to 1.7 m. Plant layouts face new challenges under COVID-19 spacing guidelines, including where to place test and measurement workstations that ensure quality control is maintained in process and discreet manufacturing.

Reference-grade accuracy in a durable, hand-held gauge

• Maintains calibration at an impressive ±0.1% of full-scale accuracy.

• Connects to a PC via USB or wireless to change settings or to perform data logging.

• Features clear, intuitive controls and a large, back-lit display.

• Tough, powder-coated aluminum exterior protects the internal components so it holds up to abuse in the field. It’s also waterproof up to 1 meter (IP67).

Choose the wireless option and monitor tests from the comfort of your truck!

Visit ralstoninst.com/cpn-LC20 or scan the QR code to find out more +1-440-564-1430 | (US/CA) 800-347-6575

One scenario where space-optimized Combi systems can really come into their own is on labor-intensive food production lines, where multiple ingredients are added manually. Here, where individual working space can’t be maintained, factories have had to install physical barriers to separate operators. Either solution increases the line space required to safely perform this operation, so downstream equipment space savings are needed to free up space.

As well as creating a further driver for more compact systems, the COVID-19 pandemic is accelerating adoption of remote access functionality on inspection equipment.

“Most modern metal detectors and check-weighers have in-built remote diagnostics but until now this function has been under-utilized. However, recent months have seen it taking on increasing importance as companies seek to protect staff and reduce travel and face-to-face contact,” notes Gidman.

There are several reasons for this shift in behavior. Some areas of the food industry have faced unprecedented demand in recent months as consumer spending has shifted from the hospitality and food service sector to retail grocery. Additionally, food supermarkets have grappled with unpredictable purchasing behaviors and patterns.

Issues with equipment have had to be resolved as quickly as possible, with minimal disruption and person-to-person contact. In these circumstances, remote troubleshooting is the ideal solution. Even if the issue cannot be resolved remotely, it can serve as a first line approach, arming engineers with valuable information so that site visits can be as brief as possible. A practice that Fortress has always encouraged to bring value to its customers.

Now that companies have started to realize the benefits of remote assistance, Fortress believes it is unlikely that the industry will revert to a more traditional face-to-face approach and that it will be a focus for innovation in years to come.

Likewise, the food industry will continue to demand inspection systems with ever more compact dimensions. Whilst technological progress will continue to forge ahead in this area, there comes a point when both physics and the need to guarantee product quality, place limitations on reducing system size. It is about finding that sweet spot, where footprint, reliability and cost of ownership can all be balanced.

This article was contributed by Fortress Technology Ltd., a privately-owned Toronto based company.

The Motion Terminal (VTEM) from Festo employs digital pneumatics said to be capable of delivering sweeping upgrades to common automation processes like pick and place, dosing and parts handling. Digital pneumatics has been developed to be more precise and considerably more flexible than standard pneumatics. On a life cycle basis, it can perform many applications more efficiently and cost-effectively, the company says. VTEM software apps enable extremely fast changeovers for different sizes or shapes of workpieces, products

or packaging. Adjustments that take hours with conventional pneumatics, the company adds, can be completed in minutes, and all processes can be managed, or reconfigured, remotely. The function integration achieved by software apps and the piezo valve technology in the terminal dispenses with the need for up to 50 downstream components such as sensors, regulators, flow control valves and shock absorbers. Watch video at www.cpec.news/fxz. Festo Canada

www.festo.ca

www.cpec.news/tdz

Valve specialist GEMÜ has announced its M75 process solenoid valve with pressure compensation. The valve is said to use an innovative double bellows principle to compensate for pressure forces. The principle means that the new valve can be used for processes with an operating pressure of up to 6 bar, the company says. The directly controlled, fully pressure-relieved 2/2-way process solenoid valve has a plastic encapsulated coil, available in a range of different supply voltages. The valve is also said to help to save resources thanks to an energy-saving reduction in holding current. Dynamic and static pressure forces are compensated for by the double bellows. Body materials of PP, PVC and PVDF, and a hermetic separation between the medium and the actuator using O-rings resist corrosive media. The valve can also be used for gaseous and liquid media and is suitable for vacuum applications. Watch video demonstration at www. cpec.news/6h7. GEMÜ Group

www.gemu-group.com

www.cpec.news/l8a

Hospeco has introduced ProWorks Stretch Polyethylene Gloves, made from thermoplastic elastomer (TPE). The formula helps assure exceptional value while providing better strength, performance, and protection, the company says. The gloves are said to be soft, comfortable, and stronger than standard polyethylene and CPE gloves. They are more stretchable than vinyl disposable gloves, it adds. Their 10-inch length is longer than standard nine-inch vinyl gloves. The gloves meet FDA Standard 21 CFR 177 for handling of food in food service applications. Available in clear or blue, they are suitable for use in colour-coding programs to reduce the risk of cross contamination. The stretch poly gloves, with their very unlike-poly fit, are also said to be well-suited for more nimble-fingered applications such as janitorial, light industrial or assembly, and as a general-purpose hand covering. Hospeco

www.hospeco.com

www.cpec.news/7l7

DT series transmitters from Acromag are designed to offer a cost-effective space-saving solution to interface a variety of process and sensor signals to plant control systems. Each model supports several input ranges and can output a proportional 0/4-20 mA, 0-10 V, or ±10 Vdc signals. The series features USB-programmability (allows easy selection of options that is not possible with pots or jumpers), a dual unit with two independent signal conditioning channels in a 17.5mm wide module to save space and reduces cost, signal splitter capability, selectable filtering levels, configurable output clamp levels (NAMUR) and removable, front-facing terminal blocks (to simplify wiring tasks). Units also have rail power bus and redundancy, supports sink/source wiring and -40° to 70°C operation (DT330 Series) or -40° to 80°C operation (DT230 Series). Safety specifications are to Hazloc approvals UL C1D2, ATEX/IECEx Zone2. Watch video at www.cpec.news/uzl.

www.cpec.news/44h

www.acromag.com

Shermco Industries, Inc. of Irving, TX, has acquired Ready Engineering, based in Spruce Grove, AB, and Olympia, WA. The Ready management team will remain with the company following the acquisition.

Ready is a specialty industry-leading provider of electrical, controls and industrial information systems. It operates in a diverse range of sectors across North America. Its specialty services include design and field engineering, power system designs, NERC/CIP compliance testing, control system installations and upgrades, and other value add engineering services.

The combination of Shermco and Ready is said to immediately provide the firm’s collective customers with a unique and market-leading bundled services offering, while simultaneous-

ly broadening Shermco’s reach into new and developing markets.

“Shermco is very pleased to welcome Ready to the family,” states Tom Bartolomei, Shermco CEO. “The acquisition delivers on our strategic objective of expanding our specialty electrical engineering capabilities to our customers across our core service offerings. Shermco is also focused on market leading electrical and engineering capabilities. The acquisition provides us with further depth in power, transmission and distribution, as well as oil and gas system protection.”

Jeff Whitt, Ready’s president, states, “We are excited to combine Ready’s niche skills with Shermco’s national reputation. Shermco Industries, Inc. www.shermco.com

of pump head and diaphragm materials

Learn more at knfusa.com/ExProof

Mississauga, ON-based Schneider Electric has promoted Adrian Thomas to country president, Canada. Thomas succeeds Susan Uthayakumar, who held the role for the past three years.

Thomas brings over 20-years of experience in the electrical and automation industry to the role. Since 2016, he has been with Schneider Electric Canada, most recently serving as vice president, home and distribution, and power products. He has also lead Schneider's Digital Energy and Low Voltage Power Systems businesses.

Uthayakumar has been appointed as the global leader for Schneider Electric’s new Sustainability Business Division.

Schneider Electric www.se.com/ca

Solon, OH-based Swagelok has announced the launch of its gas distribution program that offers a suite of services and fully engineered subsystems designed to help enhance safety and increase uptime of gas distribution systems in industrial facilities.

Through the Swagelok gas distribution program, advisors and technicians collaborate with customers to deliver fully assembled and tested gas distribution systems.

Maintaining optimized performance throughout the entirety of a gas distribution system can pose an operational challenge, the company says, as nonintuitive system design or inaccessible components can make service difficult to perform. As a result, leaks may go unnoticed or unaddressed, putting operators and equipment at risk, and causing system inefficiency that negatively affects profitability.

Swagelok’s gas distribution program includes services and subsystems designed to alleviate these challenges. The company’s gas distribution advisors provide a comprehensive evaluation of existing gas distribution systems to identify any potential leak points, as well as opportunities to improve performance and simplify maintenance. They then provide actionable recommendations to improve existing system designs or explain how standardized Swagelok gas distribution subsystems can be incorporated to overcome challenges.

Available Swagelok-produced subsystems include:

• Swagelok source inlets: These assemblies establish a reliable and highly configurable connection between high-pressure source gases and the rest of the distribution system.

• Swagelok gas panels: These modular, easy-to-service panels ensure source gases are delivered at the correct flow rate to their destination.

• Swagelok changeovers: These automatic subsystems switch from one gas source to another for uninterrupted supply.

• Swagelok point-of-use: These assemblies grant technicians a convenient method of accurately adjusting pressure to meet equipment needs.

Request more information about the Swagelok gas distribution program at www.cpec.news/ouh Swagelok www.swagelok.com www.cpec.news/ouh

The executive board at Mississauga, ONbased SPD Sales Ltd. has announced the appointment of Shailesh Parmar as VP of Sales and Business Development. Since he joined SPD Sales in October 2006, Shailesh has held numerous positions in its sales department. Not only does he possess excellent sales acumen, the company says, but also has the strong technical background required to support what SPD’s sales initiatives.

SPD Sales is a supplier and supporter

of instrumentation and chemical feed products for the process control market with additional offices in White Rock, BC, and Kirkland, QC. Parmar completed his technical training from the D.D. Institute of Technology, Gujarat University in India, and graduated with a B.Eng. in instrumentation and control engineering. Additionally, his post graduate study at Schulich School of Business at York University in Toronto has provided the knowledge to enhance the performance of other departments to support his vision of SPD Sales, the company adds.

In his recent role as

Burlington, ON — Since the onset of COVID-19, there have been few opportunities for professionals to meet face-to-face. While most major trade fairs and industry events adopted virtual formats Endress+Hauser Canada says it is giving its version a different twist.

Rather than running for a few days, the company’s new virtual exhibit booth will be available 24/7 throughout the winter, so customers can visit it at their leisure. The 3D virtual trade fair booth is said to bring them closer to a comprehensive array of the company’s newest, ground-breaking products, solutions and services in a flexible and informative way, rather than require them to fit their visit into somebody else’s schedule.

The booth has another unique feature. Visitors with a smartphone and VR glasses can enjoy an enhanced visual experience.

The Endress+Hauser booth is accessible around-the-clock from anywhere in the world from every Internet-capable device by visiting the following link: www.cpec. news/fed.

According to Anthony Varga, general manager of Endress+Hauser Canada Ltd. “We’re anticipating that our virtual fair experience will be close to the traditional Hannover booth.”

The virtual booth highlights several innovative products that are ready for the IIoT, helping companies move forward with their digital transformation. This includes the Cerabar and Deltabar pressure instruments featuring advanced connectivity and Heartbeat Technology, as well as the thermal flowmeters t-mass 300/500, which offer several new features such as bidirectional measurements. Endress+Hauser Canada Ltd.

www.ca.endress.com

www.cpec.news/fed

area sales manager, Parmar was instrumental in securing numerous contracts for the company.

According to SPD Sales president Frank Cosentino, ”Parmar will assume the role of leading SPD Sales growth in the future, growing our client network, and capturing and expanding our market presence in chemical dosing, instrumentations and services.”

SPD Sales Ltd. www.spdsales.com

The NS Series ball valves are available in sizes 1/4”-6” with threaded, socket weld, butt weld (3-piece) and flanged (2-piece) connections.

The NS Series butterfly valves cover 2”-24” sizes in wafer and lug style.

APPLICATIONS

• Water Treatment

• Potable Water Service

• Reverse Osmosis

• Desalination

By Art Womack

Aleading supplier of landfill gas extraction and recovery systems located in the Midwest region of the U.S. relies on flow meters from Fluid Components International (FCI) for gas flow measurements in landfills. The company has developed hundreds of landfill gas system fares and extraction system skids that are in operation worldwide, which all require accurate gas flow measurement.

With the help of landfill gas extraction and recovery systems, landfill owners and operators are solving the challenges and meeting ever increasing regulations to reduce greenhouse gas emissions, meeting good neighbor goals and reducing operating costs. Decaying organic materials in landfills are a continuous, rich source of biomethane gas that can be harvested for the production of onsite electric power generation for and/or be delivered and sold to the local power grid, either as electricity or as natural gas to support nearby homes and businesses.

The biomethane gas is extracted from the landfill with multiple wellhead taps and collected via a network of pipes leading to a common header pipe. This main pipe collects enough gas to fuel to drive turbines that in turn produce clean electric power (Figure 1). Typical landfill gas extraction systems for co-gen electric power require turbines, compressors, blowers, pumps, flow meters, knock-out pots and a fare burner or oxidizer gas unit.

Accurate landfill gas flow measurement is essential to the gas extraction system to measure and control the system’s operation. In addition, data is reported to the operators and regulatory agencies on the amount of gas being extracted and utilized and/or disposed of via the fare or gas oxidizer system.

Landfill gas flow is measured at several points in the system to provide landfill operators with critical information for optimal gas production, control, safety and reporting. Landfill gas applications present several challenges in selecting the proper flow meter:

• Low flow sensitivity during start-

up and for seasonal changes, which produce lower flow rates

• Temperature compensation for correct readings in varying temperatures

• Calibration for mixed gas composition of CH4 + CO2 + trace gases

• Wet, dirty gas with corrosive H2S content

• Potentially flammable or explosive gas installation environment

• Easy, low cost installation and low maintenance

• Complies with GHG regulations

Landfill gas is primarily a mixture of methane (CH4), carbon dioxide (CO2), hydrogen sulfide (H2S) and traces of oxygen (O2), nitrogen (N2), other gases and water. While a typical landfill gas mix could be 50%-55% methane and 45%-40% CO2, actual compositions can vary widely depending on the location, refuse types and age. An actual on-site gas analysis is always required before specifying equipment to harvest and measure it effectively.

Also dependent upon site conditions the landfill gas can be dirty and wet, which can be highly corrosive when it comes into continuous contact with the equipment necessary to harvest it. Extreme conditions may dictate filtering, gas drying and/ or the use of specialty metal components, such as Hastelloy, to mitigate corrosion and ensure long service life of the components.

The gas flow rates can be widely variable depending on the volume of refuse and seasonal changes in temperature and humidity, which means instrumentation and other equipment must be able to measure effectively with wide swings in gas flow. Therefore, a flow meter with a wide turndown is essential. Another consideration for flow meter selection is its capabili -

ty to support different or changing gas compositions. A flow meter with on-board storage of multiple calibrations that can be user assigned in the field is ideal, but a flow meter manufacturer with field service technicians who can

perform site calibration verification and adjustments is an acceptable alternative.

Due to the fact that landfill gases can create a potentially explosive situation, engineered safety is a must and instrumentation must be suitably rated and approved for the installation. While some situations might allow for remotely locating electronics outside of the defined hazardous environment, the safer, best-practices approach is to install instrumentation that have received suitable agency approvals. Flow meters should have full instrument (sensor element, electronics and the enclosure.) approvals, not just the enclosure. Applicable approvals include FM, FMc/CSA, ATEX, IECEx, and others, depending on the country.

The engineers at the gas extraction system manufacturer iden-

tified multiple flow measurement technologies that could potentially support their applications. Their primary objective was to find a flow meter technology that provided accurate measurement of mixed composition gas, which also was suitable for wet, dirty gas, carried global agency approvals for installation where methane gas was present, was easy to install and required no maintenance to provide worry-free continuous operation.

After identifying several potential flow meter technologies for its landfill applications, the systems manufacturer contacted FCI for assistance. FCI specializes in thermal dispersion technology for the direct mass flow measurement of gas and is one of the industry pioneers of its application in rugged environments. Thermal mass flow meters provide a landfill gas flow measuring solution that is accurate, repeatable, easy to install

and requires virtually no maintenance (Figure 2).

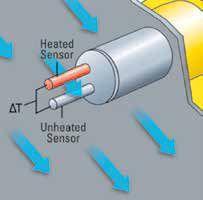

FCI’s thermal dispersion mass flow measurement technology, constant power, places two thermowell protected platinum RTD tempera-

Continued on next page

ture sensors in the process stream. One RTD is heated while the other senses the actual process temperature. The temperature differential between these two sensors is measured and is directly proportional to the mass flow rate of the fluid (Figure 3).

In moist landfill gas measurement applications, FCI’s constant power technique provides superior accuracy and repeatability. The alternative thermal dispersion technique, constant deltaT, can read erratically in moist gas applications. FCI’s constant power provides a light heating effect which actually dries condensate moisture off the sensor to ensure stable readings and performance.

Thermal mass flow meters provide a landfill gas flow measuring solution that is accurate, repeatable, easy to install and requires virtually no maintenance

FCI recommended to the gas extraction systems manufacturer the installation of its ST98 flow meter (Figure 4), which is ideal for landfill gas measurement and features high accuracy to ± 1% of reading, ± 0.5% of full scale. Exceptionally consistent, the meter offers repeatability to ± 0.5% of reading and is fully temperature-compensated for accurate measurement under variable environments.

With its highly reliable thermal mass sensing element, the FCI meter delivers precision gas flow rate, totalized flow and temperature measurement. This insertion style meter operates over a wide flow range from 0.75 SFPS to 600 SFPS (0.21 NMPS to 172 NMPS). It features a wide, 100:1 turndown ratio and operates at pressures up to 250 psig [17 bar (g)].

The meter’s transmitter features robust, microprocessor-based electronics. The transmitter can be integrally mounted with the sensor or remote mounted up to 1000 ft [300 m]. Its enclosure is NEMA/CSA Type 4X (IP66) rated and it carries global agency approvals on the full instrument for explosion-proof, Division 1 [Zone1] installations. FCI calibrates the meter and its other product lines in its own Calibration Laboratory. All labora-

tory equipment is National Institute of Standards (NIST) traceable, as well as certified to ISO 9001:2000 and AS9000. The laboratory also meets MIL-STD.45662A and ANSI/NCSL-Z-540 requirements.

FCI’s flow calibration laboratory provides gas flow calibration capabilities ranging as low as 0.001 SCFM (0.00017 NCMH) to ranges that exceed 5000 SCFM (8500 NCMH) and can match installation conditions for applications with temperature ranges from –100 °F to 850 °F (-73 °C to 454 °C).

When choosing a flow meter for landfill gas measurement, there are a number of key criteria to review:

• Accuracy and calibrated for mixed methane landfill gas composition

• Low flow sensitivity with wide turndowns to accommodate variable gas flows

• Multi-functional with the ability to measure both the flow rate and totalized flow

• Temperature compensation to ensure accuracy in widely variable outdoor landfill operating conditions

• No moving parts to clog or foul in the presence of wet, dirty gases, as well as special materials available to resist corrosion

• Agency approvals for use in Division 2 (Zone 2) and Division 1 (Zone 1) hazardous environments where combustible gas is a threat to people and plant equipment

• Complies with GHG regulations

The meter provides flow rate and totalized flow data from each landfill gas well to ensure continuous operation and optimal data collection. The meter was selected by the landfill gas extraction systems manufacturer because of its ease of installation, in-place agency approvals for hazardous gas locations (Div 1) and because FCI is able to calibrate the meter to the systems manufacturers’ requirements for mixed composition gases.

This article is from a Technical Publication by Art Womack, Member Technical Staff, Fluid Components International.

Fluid Components International www.fluidcomponents.com www.cpec.news/98r

Continued from page 6

ing a working vaccine to patients. Because they are the source trusted to measuring and provide important temperature data, some users might make the mistake of thinking they are automatically accurate. In reality, temperature sensors drift and degrade over time, so periodic checking and adjustment or complete replacement is a critical step that cannot be forgotten. However, finding the equipment to accurately test and calibrate to ULT temperatures of-86°C is a challenge.

Ametek STC has a solution in its Jofra RTC Reference Temperature Calibrator Series, in particular the RTC-159 model. The RTC159 has a low temperature range of-100°C, giving it plenty of available range to calibrate temperature sensors used in ULT measurement. Apart from its range, the RTC-159 features accuracy to 0.06°C, stability to 0.03°C, and two patents making it the ideal calibrator to verify these critical sensors.

The first of the patents is the DLC system, which brings unmatched temperature uniformity and accuracy in the insert. All temperature sensors have a thermo sensitive area where the sensor collects its readings. In standard temperature calibrators, if the temperature sensor’s sensitive area isn’t in the same place as the calibrator’s reference sensor, differences in temperature may occur, and create calibration errors. This is because temperature dissipates the further towards the top of the insert you go. Jofra’s patented DLC removes this difference by measuring the temperature homogeneity inside the insert at multiple places, then provides feedback to the RTC calibrator to implement tiny temperature adjustments as needed.

This feature assures that accurate calibration occurs no matter where the sensing element is located inside the insert.

The second patent covers the very broad temperature calibration range of -100 to 155°C. This means that the same calibrator trusted for ULT

sensor calibration may also be used for other, higher temperature sensor applications.

While the world anxiously anticipates a COVID-19 vaccine, the infrastructure around ultimately delivering the vaccine to patients is already underway. Temperature control and audits must be in place, both for the safety and efficacy of the vaccine, and to limit spoilage and waste. JOFRA temperature calibrators are already trusted throughout the pharmaceutical industry for their reliability, accuracy, and ease-of-use. As we enter this critical moment of public health, only the best should be trusted to provide reliable temperature calibration.

This article is from a White Paper contributed by Cameron Instruments. Cameron Instruments www.cameroninstruments.com www.cpec.news/4mm

Alliance Sensors Group has introduced the SS-7 series LVIT (Linear Variable Inductive Transducer) designed for subsea environments and the demands of oil and gas exploration. The series is designed to be embedded into a hydraulic cylinder and utilizes the gun-drilled piston rod as a target, sensing its position with-out the need for a magnet. The series can be submerged to a depth of 12,000 ft or installed in a PBOF (pressure balanced oil filled) chamber to provide position feedback on Blow Out preventers, ROVs and relief valves. Features include a 316 Stainless Steel 25 mm diameter housing and measurement ranges from 1 to 24 in. The sensors use a simple coil design rather than “time-of-flight” technology or resistive film. They are based on con-

tactless LVIT inductive sensing technology that employs a solid probe construction style which requires only a simple conductive tubular target or a small diameter gun drilled hole in the cylinder rod for operation rather than needing a permanent magnet ring or some other type of special target.

Alliance Sensors Group www.alliancesensors.com

The Dust Suppression Hopper system from Sioux Steel is said to reduce total dust by 98 percent, reducing product shrinkage. The system is installed under a feed point where it can be suspended above the target and kept at operating level. A small degree of natural agitation as the hopper is filled helps exclude air from the material being transferred. At the point of loading, or transferal, the system concentrates the discharge of dry goods as a solid column through free air into any target repository including trucks, rail cars, storage containers, bags or stockpiles. Previously,

trucks taking on a load literally disappeared in the dust cloud, the company says. Uncomplicated to install and easy to operate, the dust suppression system will reduce hazards and health risks, dust and wastage. Models are robust and easy to operate and maintain, the company adds. The system is suitable for fertilizers, superphosphates, foodstuffs, minerals and quarry products, as well as grains and stock foods. Watch video demonstration at www.cpec.news/uiw. Sioux Steel Company www.siouxsteel.com www.cpec.news/zje

N.R. Murphy Ltd. offers abort damper units recommended for businesses that face fire/explosion risks. When installed in the clean air stream of a filtering system, an abort damper serves as an instant aborting device that expels the air to the atmosphere when activated by a spark- or fire-detection system. Made out of heavy gauge reinforced steel, the abort dampers are available in 14 different sizes; each one is good for a different kind of material-handling exhaust system. The dimensions range from 43 x 20½ x 37¾ in. – size 11 – to 107 x 58½ x 114¼ in., or size 48; weights of these units run from 195 to 1,545 lb. The abort dampers comply with the standards of the National Fire Protection

Bin vents from Camcorp have the features and benefits of a pulse jet baghouse and cartridge filter collectors. Bin vents do not typically incorporate a hopper, but

instead are mounted on top of dust gen erating equipment such as silos, mixers, scale hoppers and mechanical conveyors. Instead of discharging the captured dust into a hopper, when using these bin vents, the pulse-cleaned dust falls directly back into the process equipment it has been mounted to. The bin vent dust collector is also designed to meet critical combustible dust standards and can include OSHA approved service platforms and ladders. The filtering system can be designed to use bags and cages, or cartridges, or tailored to fit applications.

Camcorp www.camcorpinc.com

Bulk bag fillers manufactured by Best Process Solutions are designed to fill any size bulk bag with high accuracy, while offering years of trouble-free maintenance. The model BBF loader features an inflatable fill head that offers a dust-free seal when loading, the company says, dust port with dust cartridge, and manually adjustable bag supports for varying bag heights — suitable for lower ceiling heights. Many options are available, including a vibratory deck, roller conveyor, screw jack, metering device, bag support arm extensions, bag inflation prior to filling, a drum adaptor, load cells and system controls. The company manufactures a broad line of custom-engineered, bulk-processing equipment and systems for a wide variety of dry processing industries from chemicals and food to aggregates and recycling. Best Process Solutions www.bpsvibes.com

www.cpec.news/fkf

Werma Signaltechnik has announced the CO2 Traffic Light stack that monitors the current carbon dioxide (CO2) concentration in the ambient air and makes it visible. The light is designed to avoid high concentrations of CO2 and aerosols in the ambient air, helping to reduce transmission of COVID-19. An increased CO2 concentration in the room is said to correlate with an increased bacterial concentration as well as increased infection and absence rates. The unit continuously measures the current carbon

dioxide concentration in the ambient air and shows precisely whether or when it is time for the next ventilation. If the CO2 concentration is below 1,000 ppm, the traffic light is green, indicating that the air quality is OK. If the CO2 concentration exceeds 1,000 ppm, the traffic light turns yellow and indicates that ventilation is recommended. The red signal indicates that significant ventilation is necessary as the CO2 concentration is above 2,000 ppm. If the limit value of 3,000 ppm is exceeded, a red flashing light indicates the acute urgency of ventilation. Watch video demonstration at www.cpec.news/jcw. Werma www.werma.com www.cpec.news/s09

wastewater 1c ad 4/5/05 2:53 PM Page 1

AND

• Manual, automatic and actuated (pneumatic & electric) valves; relief, check, diaphragm, ball, solenoid, and shut-off. Also pressure regulators, metering pumps, basket strainers, sight glasses, and gauge guards.

Winters Instruments has introduced the WinAIR Compact low pressure differential gauge. The unit is a diaphragm actuated, frictionless pressure gauge which can be used for measuring positive, negative or differential pressure. Along with the original WinAIR and the WPS series pressure switch, WinAIR Compact has been engineered to measure the pressure of air and non-corrosive gases, the company says. With a full scale 5% accuracy rating, the new gauge has been designed for monitoring status on filters, ventilation and duct systems, clean rooms, fans and blowers, paint booths, dust collectors and other applications.

Winters Instruments

www.winters.com

www.cpec.news/2n4

FTI Flow Technology, Inc. has introduced the QCT_PA12 series of in-line liquid ultrasonic flow meters. The compact and lightweight meters are said to be a cost-effect and versatile solution for measuring low-viscosity liquids in a wide range of industries, such as chemical, food and beverage, pharmaceutical, plastics, power generation, pulp & paper and steel. The meters’ construction and Nylon-12 (PA12) material make them suitable for many high purity and corrosive liquids, the company says. Typical applications include water treatment for boilers and cooling towers, cleanin-place (CIP) systems, mechanical seal flushing/cooling, process water, cooling loops, reverse osmosis (RO) systems, small-line injection systems, and larger DI water distribution systems and high-purity filtration systems. The flow meters have non-wetted sensors, no moving parts, and there is nothing in the flow stream that will cause an obstruction to the flow path. The meter is available in sizes 1/8 to 2

in., accurate to ±0.5 percent of reading plus zero stability, and repeatability is ±0.2 percent over 10:1 calibration range. It has a 0.035 to 250 gpm flow range, -10° to 80°C temperature range, and analog, scaled frequency and Modbus RTU outputs.

Flow Technology, Inc. www.ftimeters.com www.cpec.news/e89

SHUT-OFF BUTTERFLY VALVES FOR GAS APPLICATIONS

• Innovative Engineering –Dedicated Craftsmanship.

• 100% inspection and individual testing of each product, to ensure dependable performance and long-life.

• PVC, CPVC, Polypropylene, PTFE and PVDF. Valves from 1/8'' to 3'',Sight glasses to 8'' and Basket Strainers to 14''. CEDAR GROVE, NJ 07009 (973) 256-3000 • Fax: (973) 256-4745 info@plastomatic.com•www.plastomatic.com

In order to offer an alternative for industrial gas burners and gas applications with a working pressure up to 5 bar, Desponia and Desponia plus (DN 50-250) butterfly valves from InterApp have passed the requirements of EN 161 and obtained the approval by the DVGW. The certification guarantees that the valve closes in less than one second, so that dangerous operating conditions are avoided, and the system is protected. The shut-off valves are composed by selected components for a reliable operation: IA motion, single acting pneumatic actuator; quick exhaust block; solenoid valve; limit switch box (optional); air filters (optional); and, control panel (optional). InterApp AG www.interapp.net

www.cpec.news/bo1

The AutomationDirect process control temperature sensor lineup now includes RTD versions of the M12 connection transmitters, transmitter versions of the RTDs without process connection, and sanitary 3-A versions of RTDs and transmitter probes. Temperature measuring ranges for ProSense Pt100 type RTD probes with sanitary connections are available from -58 to 400 degrees F. ProSense XTP series temperature transmitters combine a Pt100 or Pt1000 RTD sensing element and transmitter electronics in a single stainless-steel body. Available in three preconfigured measuring ranges, XTP series transmitters are ready to use out-of-the-box or use the free XT-SOFT software to program transmitters with a custom measuring range. ProSense Pt100 RTD sensors and transmitters with sanitary connection probes have a one-year warranty and are cURus, CE approved.

AutomationDirect

www.automationdirect.com

The Ashcroft 1147 differential pressure gauge is said to deliver a high quality, cost effective measurement solution for tank level, filtration and flow monitoring. Available in 4 ½ and 6 in. diameter dials, the gauge introduces a 270° dial arc for increased resolution. It also features an upgraded movement that ensures smoother pointer motion when subjected to shock and vibration, the company says. The gauge is available in low DP ranges from 30 to 2000 in. H2O and manages liquid or gas pressures up to 1000 psi. Options include additional body materials and various mounting capabilities along with a switch feature for control of a pressure alarm or shutdown. The case is designed to allow easy removal of the gauge window for cleaning.

Ashcroft

www.ashcroft.com www.cpec.news/x71

CLOUD-NATIVE RESERVOIR ID ANALYTICS SOFTWARE LAUNCHED

www.cpec.news/y0p

Emerson has announced the launch of SpeedWise Reservoir Opportunity, an automated, cloud-native reservoir analytics application developed in collaboration with Quantum Reservoir Impact. The software is unique in how it applies advanced algorithms, data mining and workflow automation to cut the amount of work required to identify field development opportunities from months to weeks, the companies say. The application is said to help oil and gas companies achieve greater return on investment by shortening decision-making cycles and delivering better risk management. The software features automated geo-engineering workflows for identifying and ranking recompletion, vertical sweet spots and horizontal wells.

Emerson

www.emerson.com www.cpec.news/ess

Dear Readers,

Greetings from “Lock-Down” Ontario. We’ll still be in lockdown when you receive this issue. Winter in the Great White North is long enough made even longer without participation sports like curling, skiing and rec hockey. Hang in there!

With the rollout of the vaccines there is a light at the end of this tunnel. I remember how people partied on New Year's Eve 1999 when the world didn’t end. I’m guessing that celebration will pale in comparison to the end of the COVID-19 restrictions party. We expect to see you all out for our Process & Automation Shows when we ramp up this fall.

Process E Newsletter. We deliver it to your inbox every second Wednesday. It’s free and features a lot of items not carried in our print edition. Go to www.cpecn.com and click on subscribe.

In the meantime, we need you to sign up for our bi-weekly Canadian

Next up will be our April issue with our Focus on Plant Communications and Mike Edwards’ supplement on things Bulk Powders and Solids. If you would like to contribute to this issue, we need it by March 12th.

Stay Positive, Test Negative,

HYDROGEN MASS FLOW METERS HANDLE PRESSURE AND TEMPERATURE FLUCTUATIONS

In contrast to conventional fuels, filling hydrogen-powered vehicles involves considerable pressure and temperature fluctuations. The TMU-W 004 from Kobold was designed for handling hydrogen. The flowmeter is said to be the first one of its kind worldwide with certification according to OIML R 139 2018. To ensure an economical utilization, filling vehicles with hydrogen requires a pressure of 700 bar. Such a high-pressure environment, combined with the small size of hydrogen molecules, was a particular challenge to engineers aiming to develop a device that on the one hand, the company says, ensures safe operation and on the other hand enables precise flow monitoring as the basis for correct billing of filled tanks.

Kobold

www.kobold.ca

• Advanced diagnostics (pressure sensors) -SIL2-ESD

• Very high resolution, high air delivery

• Simple intuitive push button calibration and adjustments

Controls Inc. 2535 Stallion, St. Lazare, Qc, Canada J7T 2E4 J.C. Labelle: (514) 916-5895

(514)

jc@belletek.com

www.cpec.news/f5e

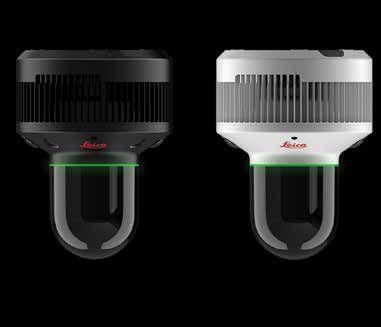

Leica Geosystems has announced the expansion of its Leica BLK247 smart 3D surveillance system said to be the world’s first 3D sensor combining LiDAR, video camera and thermal imaging technology for security and surveillance. Building owners, operators, security teams, and facilities managers can benefit from continuous monitoring of buildings and spaces including factories, manufacturing plants and offices, the company says. The system is now available in two versions, the BLK247 i5 and the BLK247 x5, which are suited to monitor and protect different working environments. The x5 offers thermal imaging, dust and water protection for both indoors and outdoors, and an expanded operating temperature range, while the i5 designed for mostly indoor environments where thermal imaging is not needed. With the smart 3D surveillance system, customers can create 3D zones by geofencing areas and applying custom alarm rules. Watch video demonstrations at www.cpec.news/w72. Leica Geosystems www.blk247.com www.cpec.news/w72

Mod-Tronic Instruments has introduced Camille Bauer Metrawatt AG products. Its SINEAX brand of signal splitters and amplifiers includes the TV 808 series

of two-channel isolating amplifiers is designed for electrically insulating, amplifying, and converting DC signals. The devices are used for electric insulation of input and output signals to amplify or

change the signal level or type (current or voltage) of the input signals. The series has two channels and provides two independent isolating amplifiers in a compact space. Units offers a wide selection of input and output ranges, and the user can set the desired one with the help of soldered jumpers and potentiometers. A model with one input and two outputs, which allows two electrically insulated outputs to be obtained from only one input signal is available. Variants of these signal splitters and amplifiers include 252 standard input and output combinations selected by soldered jumpers, as well as user-specific input and/or output ranges. Each unit operates with a 24-60-volt or 85-230-volt DC/ AC power supply.

Mod-Tronic Instruments

www.mod-tronic.com

www.cpec.news/j4b

Valley Forge & Bolt has adapted its SPC4 Load Indicating Technology to the company’s RTM (Remote Tension Monitoring) series of meters — the UHF Band RTM Meter, a wireless bolt monitoring system. The meter operates in 433/868/915 MHz frequencies, which includes the industrial, scientific and medical (ISM) frequency. The wireless sensor detects and collects the tension level in a bolted joint as read by the company’s SPC4 fastener, and then relays the data to a facility’s condition monitoring/SCADA system. Users can also program the sensor to take measurements at prescribed intervals and send alerts if a bolted joint falls out of chosen tension parameters.

Valley Forge & Bolt Mfg. Co. www.vfbolts.com

Rockwell Automation CompactLogix and Compact GuardLogix 5380 controllers are said to provide higher performance, increased capacity, improved productivity and enhanced security to help meet the growing demands of smart machines and equipment. All standard and safety controllers use a modern programming environment, Studio 5000 Logix Designer application, to allow users to work collaboratively to design and maintain their systems. This common environment optimizes efficiency, reduces time to commission and manages integrated motion over EtherNet/IP for high-

ELM72xx EtherCAT Terminals from Beckhoff are said to be fully functional servo drives in robust metal housings that deliver an output current (Irms) of up to 16 A at 48 Vdc for the power supply. The modules’ metal housings provide optimum heat dissipation even at high output power as well as optimal shielding against electrical interference, the company says. The servo terminals can connect directly to other EtherCAT Terminals as an integrated component of the company’s I/O system. The functionality includes the direct connection of the motor, feedback and brake via the connector front end, an integrated absolute value interface and One Cable Technology (OCT). Additional I/Os enable latching of position values. Watch video at www.cpec.news/bub.

Beckhoff Canada www.beckhoff.com/en-ca/

www.cpec.news/bub

The LRS510 sensor line from Turck offer analysis functions for level applications in tanks and silos. The IO-Link-capable radar sensors of the recently developed LRS series complete the company’s portfolio for level measurement in the 0.35 to 10 m range. The devices have protection to IP67/69K, can be commissioned via Turck Radar Monitor and facilitate condition monitoring applications in IIoT: besides signal strength, this includes temperature values, operating hours or switching cycles.

www.cpec.news/7dw

speed motion applications and up to SIL 3/PLe safety solutions, the company says. The controllers are suitable for process-focused applications such as food and beverage, oil and gas, chemical, plastics, life sciences, metals and mining. Units offer a 1 Gb embedded EtherNet/IP port that enables CIP safety connections, I/O and safety devices, as well as achieve up to SIL 2/PLd with 1oo1 architecture or up to SIL 3/PLe with 1oo2 architecture. Watch video at www.cpec.news/9lr. Rockwell Automation Canada www.rockwellautomation.com www.cpec.news/97a

Turck Canada

www.turck.ca

www.cpec.news/w2d

The ITC-XXX-XX-DC is a signal isolator with dual outputs providing high isolation from Input to Output1, to Output2, and to Power in a small easy to install package. It’s universal DIN rail mount makes it possible to install right next to the instrument that is to be isolated. The many different input and output configurations allow it to be used in a great variety of applications ranging from PLC front end conditioning to adding an extra loop with lots of drive to an existing, almost fully loaded loop.

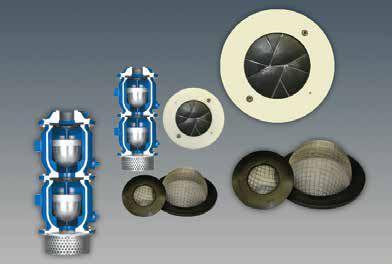

The VaultSafe line of products from Val-Matic are designed to protect potable water systems from contaminated flood waters, freezing temperatures and intentional harmful contamination. The line consists of the FloodSafe inflow preventer, the FrostSafe air damper and the VentSafe vent pipe security cage. The inflow preventer is designed to prevent contaminated water from passing through it thus preventing it from entering the air valve outlet and compromising the potable water system with its dual

chambers and float checks. The air damper is said to minimize the thermal exchange of cold and warm air in and out of a vault to help prevent freezing with a bi-directional hingeless disc and wafer design. The vent pipe security cage safeguards vent pipes against the hazards of nesting animals and intentional harmful activities because of its hemispherical screened security cage.

Val-Matic Valve & Manufacturing Corp. www.valmatic.com

www.cpec.news/apn

Wiser Systems has introduced a new set of calibration features for the Wiser Locator, an ultra-wideband (UWB) wireless location and tracking system. The new features are said to enable seamless installation of wireless location devices without a manual measurement of device locations or constant manual recalibrations. The system provides real-time location and tracking using a mesh network of antenna nodes. Users position these antennas throughout a physical space to establish a tracking arena. However, to deliver accurate timing data, the system must be calibrated to account for each antenna’s location. Unless antenna positions are determined precisely, any positioning data will be inaccurate. The new auto-calibration feature determines the relative location of each device autonomously, reducing the calibration process to one-click in most cases. Once running, it also detects in real time if an antenna is moved and notifies end-users so the mesh can be repaired without an interruption of location and tracking services.

www.cpecn.com

Wiser Systems

www.wisersystems.com

www.cpec.news/n9c

Warren Controls has announced its ILEA 2900E series of electrically actuated, industrial globe-control valves. The series is said to have a high quality, modulating, linear, industrial electric valve actuator and features a rugged cast-iron body with a variety of trim materials. The equal percentages plugs in the 2-way valves and the linear plugs in the 3-way valves provide modulating control of a wide variety of fluids. The series is suitable for applications including, but not limited to, food and beverages, packaged water heaters, wastewater, general services, and pharmaceuticals. The units’ function in moderate pressure drops and temperatures ranging from -20° to 400°F. Valves are available in four styles: 2-way balanced, 2-way unbalanced, 3-way mixing, and 3-way diverting. Sizes range from 2.5 to 10 in. with ANSI Class II, III, and IV leakage and with a rangeability of 50:1. The cast-iron body comes in ANSI Class 125 and 250 lb. with flange ends and bronze, 300SS, 17-4pH, and Alloy 6 trims.

Warren Controls

www.warrencontrols.com

www.cpec.news/tt0

Qdos chemical metering pumps from Watson-Marlow Fluid Technology Group now feature four configurable outputs to help users cut down on the need for additional PLCs and provide extra flexibility when communicating with SCADA or other external monitoring systems. The company has expanded its Qdos Universal + Relay pump series to provide four configurable outputs as well as for 4 to 20 mA current. As a result, users can access increased options for connectivity, the company says, enabling improved communication regarding pump performance and function status. Providing flow rates that remain constant up to 7 bar, the peristaltic chemical metering pumps are said to give users a unique advantage over diaphragm-based alternatives. In addition, pumps are said to offer long maintenance intervals, reducing the impact of process downtime and lowering the total cost of ownership. Watch video at www.cpec.news/u70. Watson-Marlow www.wmftg.com www.cpec.news/lwb

Brooks Instrument has added the GT1600 series of glass tube variable area flowmeters to its line of products. Suitable for a wide variety of industries from chemical manufacturing to pharmaceutical production to water treatment and distribution, the series is suitable for low- and high-flow gas

MODBUS RESISTIVE TANK LEVEL TRANSMITTER NOW AVAILABLE

and liquid applications where viewing the process is important. The flowmeter features 316 stainless steel construction and a polycarbonate shield, to ensure safety and longevity for both indoor and outdoor use. For ease of use, the adjustable, transparent scale improves readability and allows for offset correction to compensate for process variation. In addition, the process connection can be rotated 360 degrees so users can view from all directions. An alarm option is also available for automatic monitoring of critical flow conditions. Configured for simple installation, the series is available with a variety of connections to fit existing piping arrangements or mount to a panel or wall. The units are also fashioned for easy maintenance. For in-situ cleaning, the glass tube and float can be replaced without removing the flowmeter from the piping, saving time and cost. Watch video demonstration at www.cpec.news/0nf.

Brooks Instrument www.brooksinstrument.com www.cpec.news/a5k

The Xenotest Beta+ FD from Atlas Material Testing Solutions is a stand-alone rotating rack xenon instrument with a 4000 cm2 exposure area. The instrument is designed to meet the testing needs of the FMCG (fast-moving consumer goods) industry, such as drinks, foodstuffs, personal care and household products. The unit offers two custom racks — a bottle rack and a packaging rack. Both carry loads of up to 20 kg and fit various packaging shapes and sizes. Economical non-aging filters, the company says, guarantee realistic simulation of all three common light conditions — outdoor Daylight/indoor Daylight/Store Light, while a chiller keeps test temperatures at realistic levels even at high irradiance. Programming and monitoring can be done online. Atlas Material Testing Solutions www.atlas-mts.com www.cpec.news/hc9

OleumTech has introduced a local display-enabled version of its flagship Modbus resistive tank level transmitter. The HW-RL3-LCD can interface through its local display without needing any additional equipment or software. The device also offers local security protection by allowing users to enable a PIN code to access the configuration settings. Level transmitter highlights include a monitor product, interface, and temperature levels with a single sensor, with 2 discrete inputs available for independent level limit alarms. The local display interface is for programming, calibrating and reading process variables. The unit can also be configured using the H series software or Modbus master device. Model HW5800-RL3-LCD has ¼ in. resolution option (±1/8 in. accuracy) and the model HW5000RL3-LCD has ½ in. resolution option (±1/4 in. accuracy). Units are Class I, Division 1 (Zone 0), Intrinsically Safe.

www.oleumtech.com www.cpec.news/ank

E2S Warning Signals has announced product improvements to several product lines. The latest to be upgraded are the B350TLA traffic light warning signal beacons that feature a 100 x 140 mm housing. The larger 140 x 177 mm B450TLA units have also been upgraded. The light engine for both is an array of 18 high output white LEDs, which provide outputs up to 356 Candela. Also upgraded with the latest 18 white LED array light source are the STA and STB series of customizable stack signals, UL approved for general signaling applications such as status indication, security and process control. The STA stacks have a SONF1 compact 100dB(A) alarm horn sounder; the STB products are beacon-only arrays. E2S Warning Signals

www.e2s.com

www.cpec.news/hot

The QP1 and QP2 pump series from Q-Pumps are 100 percent dimensionally and hydraulically interchangeable with other brands in the market, the company says. Available from York Fluid Controls, the pumps are supplied with a 304 stainless steel gearbox and are 3-A & EHEDG certified. The circumferential piston pumps are designed to cover hygienic pumping applications in industries such as food, dairy, beverage and pharmaceutical. Due to its reduced internal tolerances, the series has a wide range of applications, from low viscosity products such as water, to highly viscous products such as toothpaste. Characteristics include helical gears, flexibility for four mounting positions, solid 17-4 ph stainless steel shafts, grease fittings on both sides, an antimicrobial lubricant, alloy 88 rotors, six threaded oil plugs with glass peepholes and self-cleaning packages in the plugs.

York Fluid Controls

www.yorkfluid.com

www.cpec.news/cr7

The Ametek JOFRA RTC-159 available from Cameron Instruments is a dry-block temperature calibrator that is part of the company’s RTC series that meets industrial temperature calibration needs within the -100°C to 700°C temperature range. A key feature is the patented DLC system for temperature uniformity in the insert — even when calibrating large sensors or many sensors at a time, the company says. The series also features active dual and triple-zone control to provide temperature homogeneity in the well. Some of the key features of the RTC family includes its accuracy to ±0.04C and stability to ±0.005C along with the option for both a dry block and liquid bath separately or combined in one unit. The series is compatible with JofraCloud, which is the Ametek cloud-based platform for remote reading and setpoint entry.