Volume 48, No. 1 February 2020

Volume 48, No. 1 February 2020

Compact level sensors from VEGA with 80 GHz radar technology are said to provide reliable measurement results under all conditions. The VEGAPULS sensors, as well as switches and controllers, provide level, point level, and pressure measurement instrumentation. Due to their physical measuring principle, ultrasonic sensors are exposed to influences because the sound running time changes with temperature, e.g. due to solar radiation and gas composition. Even in heavy fog, wind or rain, the sound waves are additionally attenuated and the measuring range further restricted. Radar sensors, however, are unaffected by temperature, pressure or vacuum and provide correct readings. Radar sensors also allow a safe measurement up to the sensor antenna, even in case of flooding. Due to the process, flooding of the sensors occurs in some applications. Ultrasonic sensors are therefore often protected by mechanical flooding sleeves. However, such components can easily become contaminated and impair the reliability of the measurement. Radar sensors have no dead zone, do not require protective sleeves and measure reliably even in case of flooding. VEGA

www.vega.com

ProSense FG1 series mechanical variable area flow meters from AutomationDirect provide visual indication of flow rate for water or petroleum-based fluids. The meters provide ±5% full scale accuracy and a repeatability of ±1%, important for cyclical applications requiring consistent readings. Two adjustable flow limit pointers are available to provide preset indication of high, low, or normal flow rates. The flow meters are constructed of polysulfone plastic (body, piston, cone) with brass fittings (1/2 and 3/4 NPT models). The units are available with 1/2, 3/4 or 1 in. NPT process connections and have flow scales in both gallons/minute and liters/ minute. Measurement ranges are from 0.25 to 2.5 gal/min (1 to 10 liters/min) to 4 to 28 gal/min (20 to 100 liters/min).

AutomationDirect

www.automationdirect.com

The Endress+Hauser Liquiphant FTL51B vibronic point level detector for liquid measurement in storage tanks and pipelines is available in a range of variants designed to meet Industry 4.0 requirements, notably for the addition of a mobile communication capability that can greatly simplify maintenance inspection and safety monitoring and even optimize process efficiency. Operators can communicate with the detector by using the SmartBlue App from the company. The app, based on Bluetooth wireless technology provides onsite access to all product and diagnostic data, including information such as manuals or certificates, and is available for iOS and Android mobile devices. This mobile digital communications capability can speed inspections in hard-to-reach areas, where scaffolding may have to be provided to employees in order for them to read data on the device display. With mobile monitoring, employees can choose a safe, convenient location within a radius of 20 m of the detector from which to receive the same data. The app’s new SIL Wizard also guides the user through the periodic proof test required for SIL2 and SIL3 applications.

Endress+Hauser Canada www.ca.endress.com

The Jofra Ametek RTC Reference Temperature from Cameron Instruments is a portable temperature calibrator with the wide temperature range. A key feature is the patented DLC system (dynamic load compensation) for temperature uniformity in the insert — even when calibrating large sensors or many sensors at a time. The DLC compensates for the negative effect on calibration accuracy that heat exchange between a dry-block calibrator and the sensor-under-test creates. When a sensor is inserted into a dry-block calibrator, the sensor size (diameter and length) and the difference between calibration temperature and ambient temperature, create an axial gradient deviation inside the insert. The calibrator DLC compensates inside the insert. The DLC, combined with an RTC Calibrator, is said to create the only dry-block that compensates for the heat dissipation caused by sensor loading.

Cameron Instruments www.cameroninstruments.com

Features include:

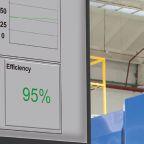

With the C-more headless HMI, you can display your factory floor data how and where you choose. The EA9-RHMI has all the powerful functionality of the C-more Touch Panel HMIs, but without display size restrictions. This HDMI-enabled device works with televisions, monitors, projectors, and most any other HDMI display device of any size to display real-time operational data or messages. Use the C-more Remote HMI mobile app or the embedded Web Server if you prefer no local display at all.

• HDMI Video/Audio output with multiple resolutions

• All the functionality of a C-more Touch Panel without the display size limitation

• VGA 640x480, SD 720x480, XGA 1024x768, HD 1280x720

• Compatible with ELO Resistive Touch screens

• Multiple connections

• Ethernet and RS-232/422/485 serial ports support programming and device connections

• USB-B port for programming, monitoring and configuration

• USB-A port for USB HID devices such as pen drives, touch screen displays, keyboard, mouse and bar-code scanners

• SD card slot for log files, project memory or graphic media

• Get control on-the-go with the C-more Remote HMI mobile app and embedded Web Server

• 82MB of user memory

Remote access and control on the go!

Available now in your app store.

Our shipping policies make it easier than ever to order direct from the U.S.!

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days. Order by 6pm ET and in-stock orders ship the same day!

*2-day free shipping does not apply to drop-ships, or orders requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

Emerson has introduced the redesigned ASCO series 353 Pulse Valve, designed to achieve a more effective, efficient and convenient bag cleaning. With a higher peak pressure, temperature range of -40° to 140°C, patented quick mount clamp connection and overall part simplification, the series provides longer bag and filter life and lower maintenance, the company says. The valve can be used in a wide range of applications, including concrete processing, grain, agriculture and feed, metalworking (abrasive blasting), food processing, found

COMPLIANT

Gas detection and analysis instrumentation specialist Bacharach has introduced the Monoxor XR (extended range) hand-held exhaust gas analyzer for measuring CO (carbon monoxide) in ambient air or directly from the exhaust pipe of forklifts, floor burnishers or other equipment burning propane, gasoline, diesel or CNG (compressed natural gas). The instrument is suitable for verifying worker safety and achieving compliance with government air quality regulations. The analyzer provides visual and audible alarming for instant alerting of personnel to dangerous CO levels. The expanded measuring range of 80,000 ppm is said to allow technicians to test even the most poorly maintained equipment without risking damage to the gas sensor. Bacharach’s Combustion mobile app allows the user to quickly and easily create and send customizable emissions reports from their smartphones or tablets. Bacharach www.mybacharach.com

ries, pharmaceutical, mining, rubber mixing/processing, metal processing, lime industry, cement factories, power plants and steel mills. A longer valve lifespan — over one million cycles on average — results in more time between valve maintenance cycles. The pulse valve series offers a patented quick mount clamp connection, providing faster, easier installation, as well as connection options, like the classic dresser connection and threaded version.

Compact pressure sensors and switches with 360°

status display

Sometimes news generated by governments can be difficult to gauge as to whether it is good — or bad.

Trade agreements in particular make you wonder who was the winner — and who was the loser. The reaction of trade associations are generally a sober way to absorb what is really going on, however.

Luckily for the chemical industries in Canada, Mexico and the U.S., the latest North American free trade agreement has received plaudits from the national chemical associations in the three countries.

Leading executives representing the U.S., Canadian and Mexican chemical industries recently reaffirmed their support for the U.S. ratification of the United States-Mexico-Canada Agreement (USMCA). The public statement was led by Chemistry Industry Association of Canada (CIAC) president and CEO, Bob Masterson; American Chemistry Council (ACC) president and CEO, Chris Jahn; and Asociación Nacional de la Industria Química (ANIQ) president, Miguel Benedetto Alexanderson.

Masterson noted, "Canadian,

Mexican, and U.S. goods – including chemicals, and goods that require chemicals as inputs – are competitive in the global marketplace because they are products of integrated North American supply chains.”

With Canada enjoying $58 billion in chemical shipments in 2018 and an industry that employs approximately 87,900 workers, any trade disagreements could prove costly.

Good news, it would seem, for all concerned.

Mike Edwards medwards@cpecn.com

For even the harshest chemical processing environments to sterile pharma/biotech applications, you’ll find the right solution, the right documentation and the right team with L. J. Star flow indicators, fused sight glass windows and high-lumen lights and cameras.

n Standard view and full-view sight flow indicators

n Rotary, flapper, flutter, ball or drip indicators available

n Highest quality glass and materials that meet or exceed industry standards

L. J. Star’s METAGLAS® fused windows, MetaClamp® and Lumiglas® explosion-proof and Non-Ex lights are found in the most demanding applications in the world.

Call or visit www.ljstar.com for detailed CAD files, specs and tutorial handbooks.

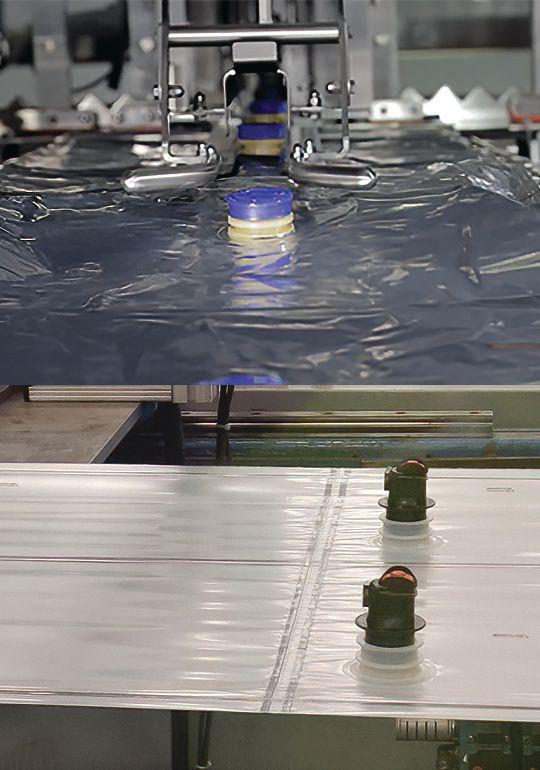

Innovation comes in all shapes and sizes. One company perfectly positioned to validate this piece of wisdom is Scholle IPN Canada, a packaging company recognized as a pioneer in providing bag-in-box solutions that themselves come in all shapes and sizes. The company specializes in aseptic packaging, a manufacturing process in which packages and containers are sterilized separately from their content. Today, Scholle IPN Canada has a strong industry presence as a bag-in-box supplier for electrolytes, dairy products and more.

About a year ago, Scholle IPN Canada realized they needed to tap into their history of innovation to optimize their workflow on the production

The NS Series ball valves are available in sizes 1/4”-6” with threaded, socket weld, butt weld (3-piece) and flanged (2-piece) connections.

The NS Series butterfly valves cover 2”-24” sizes in wafer and lug style.

Reverse Osmosis

• Desalination

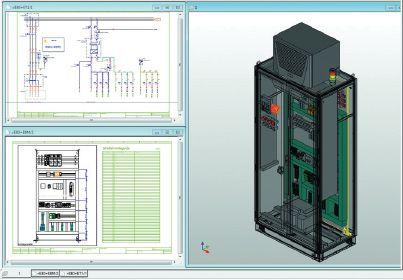

floor. The company started their transition using the EPLAN software for assistance in engineering the electrical panels for their production robots and are now looking ahead to a promising future. Machines on the production floors often need to be reconfigured and electrical designers require enough versatility to be able to do so in the most efficient way for the company. This is precisely where EPLAN comes in handy and has proven itself to be an indispensable time savior for the company.

From juice pouches to dairy bags, Scholle IPN Canada can pack various types of goods through any of the machines at its location in Montreal. But because of the legacy processes that have always been in place to properly retrofit the machines for new tasks, the company would constantly hit a productivity wall.

“We used to rely on old technology, and everything needed to be converted from manual drawings into a CAD software,” explains Jean Philippe Linteau, engineer and EPLAN user. “However, as the machines have become more complex, the tasks are becoming more complex as well. The modifications required by the machines are now too important for us to rely on how we used to do things. EPLAN is the ideal solution for us if we

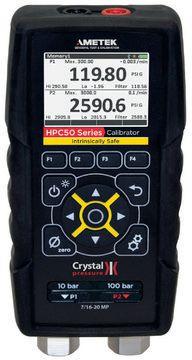

You put in the time and effort to select the best instruments for your test system. You want to be sure that you can rely on those instruments to provide accurate measurements that meet your specifications. For your company, it also means that these expensive test instruments need to last as long as possible. Instrument calibration not only keeps your business profitable and inline it can also save you expenses in the long run.

Calibration defines the quality of the measurement parameters – such as range, accuracy, and precision – as recorded by an instrument. It forms a crucial aspect of the quality assurance and testing phase, which is a critical part of many industries and sectors. This makes calibration important for virtually every industry, especially those regulated by authorities like the U.S. Food and Drug Administration (FDA), and the Canadian Standards Association (CSA).

Over time, there is a tendency for results to ‘drift’ when using particular technologies or measuring particular parameters such as temperature and humidity. To be confident in the results being measured, there is an ongoing need to maintain instrument calibration throughout its lifetime for reliable, accurate, and repeatable measurements.

Delaying calibration is a tactic that businesses may consider in order to try to save money. In the short run, yes, it may save you however; it keeps an inaccurate tool in use. The long-term effect is far more damaging.

Risks that are associated with uncalibrated measuring devices could be much higher than the cost of calibration include: distort findings; safety; inferior work product; penalties for non-compliance; and, product recall.

In pharmaceuticals, any change in the quality of the product can directly affect the health and lives of the users.

Your equipment and instruments have suggested recommendations from the manufacturer about how often it will need to be calibrated. Whether that calibration timeline is monthly, quarterly, or yearly is based upon several factors. However, there are situations where alterations to the timeline will need to change:

need a quick turnaround to build the robot that’s tailored for the new job.”

Last year, the decision was made to adopt EPLAN. Since then, panel design and production time have drastically improved. According to Linteau, the company moved away from drafting their designs on paper before having to redraw everything on a computer software.

“Now, it’s all directly done through EPLAN,” he explains. We’re talking numbering, cross references, billing of material, etc. Even the fact that electrical symbols are integrated within the EPLAN helps making things easier for the company. In fact, Linteau claims they have reduced by 50% the time spent on drawings. It used to take them 1 month to draw schematics and now, it’s down to approximately 2 weeks and they have done away with the risk of mistakes when transposing everything from paper to software.

Another benefit for them is the presence of the EPLAN Data Portal accessible within the software. “The data portal is something we have never had, and now, it has become a must! We use it all the time to complete our ordering.”

The EPLAN Data Portal is a repository of parts and data sets sourced and updated directly by their manufacturers, which ensures the information is always accurate. Being available within the EPLAN software helps companies like Scholle IPN Canada find the exact parts with the right specifications within a few clicks of their design projects.

Before settling with EPLAN, the company evaluated other well-known competitors and their electrical add-on. Linteau and his team found that alternative much less user friendly and also felt EPLAN offered greater software stability.

So far, the results have impressed even Linteau beyond expectation, despite having been among the first to buy into the promises of EPLAN at Scholle IPN Canada. “At the end of the day, we decided to put complete faith in the software and found that it really worked for us.”

Today, Scholle IPN Canada seems geared toward establishing itself as a dominant player in its industry.

This article was contributed by EPLAN Canada. EPLAN Canada www.eplancanada.com

Workload – If the use of the instrument is a lot, then it should be calibrated more.

Environment – If you use an instrument in extreme environmental conditions, calibration will be more than one used in stable conditions.

Transportation – If the instrument is in transportation frequently, then it will need to be calibrated more often.

Accidental Drop – If you drop an instrument, then it must be re-calibrated.

Checks – For some instruments, it can be checked against another instrument. Check temperature sensors by using an ice-bath. This intermediate check will let you know if it needs full calibration.

After an instrument is no longer current, repair and calibration services help extend the life of your test system. This makes the transition seamless when you are ready to migrate to new instruments or when it is in the budget to acquire new instruments.

Parts can go out of tolerance, however, testing them regularly by an ISO 17025 accredited lab they will be able to pinpoint the problem. So rather than having to get a completely new piece of equipment you can repair or recalibrate the one that you already own.

Calibration results provide a full record of the instruments for a database and any audits. Think of instrument calibration as an insurance policy that can save you from having more costly issues in the long run. This article is from the SRP control systems blog, How Calibration Services Extend the Life of Test Instruments. SRP control systems www.srpcontrol.com

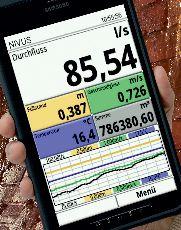

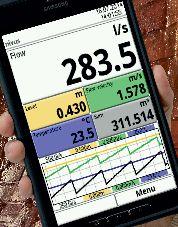

The MIS electromagnetic flowmeter from Kobold was developed for measuring and monitoring medium-sized flow of conductive liquids in pipes. The electromagnetic measurement principle used by the flowmeter follows Faraday’s Law of magnetic induction, whereby a voltage is induced in a conductor moving through a magnetic field. The electrically conductive measuring agent acts as the moved conductor. The voltage induced in the measuring agent is proportional to the flow velocity and is therefore a value for the volumetric flow. The flowing media must have a mini-

mum conductivity. The induced voltage is picked up by two sensing electrodes which are in contact with the measuring agent and sent to the measuring amplifier. The flow rate is calculated based on the cross-sectional area of the pipe. The measurement does not depend on the process liquid and its properties such as density, viscosity and temperature. The two outputs can be independently set to switch or provide an analog or frequency output.

Kobold

www.koboldusa.com

Alliance Sensors Group has introduced the S2A and SC-200 DIN-rail-mounted, push-button-calibrated LVDT signal conditioners for gas turbines, half-bridge pencil gaging probes and RVDTs. Calibration time is now reduced from at least 20 minutes per channel to just a minute or two, the company says. Features include: power inputs from 15 to 30 Vdc or ±15 Vdc; cyber security; additional diagnostic features; choice of four LVDT excitation frequencies; choice of 6 voltage and two current loop analog DC outputs; unique

auto-mastering for master/slave operation — even if a master were to fail, the S2A and SC-200 signal conditioners can eliminate beat frequency effects in remaining units; RS-485 digital communications link with an available graphical user interface and hot swapability; and, built-in diagnostics for LVDT winding failures or cable disconnection. Watch video at https://bit.ly/36JGcrc.

Alliance Sensors Group

www.alliancesensors.com

ControlAir has announced the expansion of the Type 2000 electro-pneumatic valve positioner series to include worldwide safety approvals for use with natural gas when paired with the Type 950 explosion-proof I/P transducer. The valve positioner mounted with transducer is CSA, FM and ATEX approved for use with natural gas. The natural gas package (CA2022/2023) was designed as an option to deliver safe, stable and accurate control of rotary and linear valves in applications using sweet natural gas in hazardous environments. The CA2022/2023 electro-pneumatic positioner is a NEMA 4X (IP 66) enclosure is designed for both intrinsic safety and explosion-proof operation. Units typically consume .05 SCFM of air in operation. The positioner is suitable for natural gas extraction and transport applications such as natural gas gathering stations, compressor stations, pipeline feed, and booster stations that are in remote locations and often do not have access to compressed plant air for operation of pneumatic valve actuators. ControlAir

www.controlair.com

NORD Drivesystems has announced a drive package for bulk material handling with the new Maxxdrive XT series. The new gear units achieve very high thermal ratings as result of a new and optimized housing design, the company says. Together with the increased surface design and optimized fan design, the gear units are suitable for continuous industrial conveying and bulk material handling applications. In many cases, additional cooling is not required. The new generation of IGUs supplement the company´s application-optimized right angle gear units and is especially suitable for conveyor belt systems in applications such as continuous bulk material handling, mining and conveying aggregates (coal, copper, lithium, quarried materials). Seven sizes cover a power range of 67 to 2,000 hp with speed ratios of 6.3/1 to 22.4/1. Output torque ranges from 132,000 to 660,000 lb-in.

NORD Drivesystems

The Noshok 20, 25 and 30 series of intelligent pressure and level transmitters are designed to address the specific requirements of the food and beverage industry. The transmitters are suitable for hygienic applications and harsh, aggressive ambient conditions. Transmitters feature a design which positions the pressure and temperature sensors directly behind the diaphragm, which minimizes fill fluid and allows the use of a smaller diaphragm. This provides active temperature compensation at the point of measure-

ment to minimize temperature and position error. Turndown ratios up to 10:1 allow greater rangeability, minimizing inventory requirements. Accuracies are based on percent of adjusted span, not full scale range. Constructed of polished stainless steel, the intelligent transmitters feature programming via a standard onboard display with no pressure source required and are also available with Hart protocol. Noshok

www.noshok.com

WeighPack Systems has designed and delivered its new USDA Sanitary PrimoLinear V-25 bulk weigh filling machine for frozen poultry. Engineered using solid tubular stainless steel as opposed to angled steel or a hollow frame, this sanitary design was engineered specifically for the meat and poultry industry in achieving the highest sanitation standards for its customer. The weigh filling system is designed to automatically weigh and dispense products up to 50 lb into corrugated cases or bags at rates of up to 40,000 lb per hour. View video at https://bit.ly/36LFn16.

WeighPack Systems

www.weighpack.com

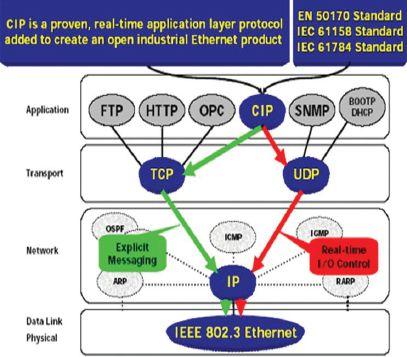

WAGO has announced that its latest line of Ethernet/IP couplers (750-363) and PLCs (750-823/750-893) have passed the ODVA EtherNet/IP conformance tests. ODVA’s conformance testing provides assurance that products built to the Common Industrial Protocol (CIP) Network specifications comply with those specifications. CIP Networks follow the Open Systems Interconnection (OSI) model, which defines a framework for implementing network protocols in seven layers: physical, data link, network, transport, session, presentation and application. EtherNet/IP utilizes the CIP for its upper layers and is the only industrial Ethernet network that is proven, complete and ready for IIoT. WAGO

www.wago.com

Madison Chemical introduces Madison Green, a mildly alkaline, environmentally friendly, biodegradable general-purpose cleaner that is said to be highly effective on greasy and waxy soils in applications such as conveyors, floors and packaging equipment. Acceptable for use in food and beverage plants, the product meets the previously accepted guidelines for us on all surfaces in inedible product processing areas, non-processing areas, and/or exteriors. A free-rinsing product, it does not leave a white alkaline film on the cleaned surface and has a pleasant wintergreen odor. It is safe for use on all ferrous, zinc, aluminum and brass alloys when used as directed. Suitable for immersion, manual spray-and-rinse, or manual spray-and-wipe methods, at concentrations from 5% by volume with water of any temperature, to full strength. Some applications may provide better results when followed by a water rinse. Madison Chemical www.madchem.com

With the new Festo Process Valve Configurator, process and application engineers can configure butterfly or ball valve assemblies for their application online in minutes. Whatever the job requires, the company says, be it a manually actuated combination, a unit with pilot valve and sensor box, or a unit with a positioner for modulating or throttling applications, the user simply enters the process and ambient conditions of their application along with the desired method of actuation.

Festo

www.festo.ca

Precision manual pressure controller built for the way you work

• Compact and portable — fine-adjust piston, fill, balance and vent valves are in one light-weight, compact unit with included handle and storage space for hoses, adapters and accessories

• Extremely precise, finger-tip control of pressure at 0.03 psi (2 mbar) to 3,000 psi (210 bar) with the pressure-balanced, fine adjustment piston

• Soft-seated valves make filling and venting the system very precise

• Rugged and durable plastic case that will stand up to use in the mud, sun, and cold weather better than bench-mounted volume controllers

• Multiple outlet ports — connect a calibrator directly to one port or with a hose, and connect a hose connected to the device under test to the second port

• Quick setup and breakdown with Ralston Quick-test™ hand-tightening outlet connections, hoses and adapters — without the need for thread sealant or a wrench

Noshok, Inc. of Berea, OH, has announced the acquisition of King Engineering, Inc., including King-Gage and King Filters. This acquisition supports the strategic expansion of Noshok’s Level Measurement Solutions portfolio and strengthens the company’s presence in the food, beverage, dairy and marine markets.

also address the chemical, industrial, offshore, marine and water/wastewater markets.

“We view the addition of King-Gage products to our portfolio as a seamless extension to our current Measurement Solutions offering,” said Jeff Scott, president of Noshok.

Pembina Pipeline Corp. of Calgary along with Petrochemical Industries Company K.S.C. of Kuwait, has announced that Canada Kuwait Petrochemical Corporation (CKPC) has executed a lump sum engineering, procurement and construction (EPC) contract related to the construction of the propane dehydrogenation (PDH) facility within its integrated PDH and polypropylene upgrading facility (PDH/PP facility).

The brand will be renamed King Engineering, Inc, A Noshok Company.

King Engineering of Newell, MA, a global supplier to the food and beverage industry for over 80 years, specializes in the design and manufacture of liquid level tank gauging equipment and compressed air filtration components. King products

“With Noshok’s strong sales, marketing, engineering and product development resources, and world-class customer support now powering the King-Gage brand, we look forward to continued growth and expansion in the food, beverage, dairy and marine markets.”

Noshok www.noshok.com

Russ Bauer has taken over as national sales manager of Kalenborn Abresist Corp. and has full responsibility for the company’s North American sales operations. Located in Urbana, IN, Kalenborn Abresist is a leader in the design and supply of wear solutions for a wide range of industries utilizing various mineral and metallic solutions.

Bauer first joined the company in December of 1980, starting in the shop while attending college. He became a sales engineer in 1984 and a regional sales manager in 2016.

Craig Frendewey, Kalenborn Abresist president, says “We are really happy to move Russ to the head of our sales operation. There may be no more experienced

hand in this industry than Russ. We feel that experience will really add value throughout the department.”

Kalenborn Abresist’s wear and abrasion resistant linings and coatings reduce downtime and maintenance and are marketed throughout the U.S., Canada and Mexico. These wear resistant linings and coatings serve a variety of processing equipment including hydraulic and pneumatic components and pipes handling large quantities of bulk materials. A variety of industries are also served, including the mining, iron and steel, mineral processing, chemical, pulp and paper and food processing industries. Kalenborn Abresist www.kalenborn.us

With this contract, CKPC has fixed approximately 60 percent of the cost of the PDH/PP Facility thus far. Pembina has revised its proportionate share of the capital cost of the PDH/ PP facility, including the 100 percent directly owned supporting facilities, to $2.7 billion.

The increase over the prior estimate is associated with the PDH facility, which is now fixed under the lump sum EPC contract. The revised capital cost estimate will not affect Pembina’s previously announced 2020 capital budget. CKPC now expects the PDH/PP Facility to be placed into commercial service in the second half of 2023.

Said Mick Dilger, Pembina’s president and CEO. Dilger added, “This project is highly strategic for Pembina and our producer customers in the Western Canadian Sedimentary Basin. It offers a new demand source for domestically produced propane and supports ongoing development of Canada’s world-class hydrocarbon resources.”

CKPC has selected Heartland Canada Partners, a 50/50 partnership between Fluor Canada Ltd. and Kiewit Construction Services ULC as the EPC contractor for the PDH facility. Both companies are said to bring extensive EPC track records for safety, quality and delivery in the petrochemical space in Canada. The contractor selection process for the PP facility is ongoing. Pembina Pipeline www.pembina.com

North Kingstown, RI-based Clarke Valve, a portfolio company of Saudi Aramco Energy Ventures, Chevron Technology Ventures, and OGCI Climate Investments, has announced that it has expanded its growing collection of global patents.

The Canadian Intellectual Property Office has awarded Canadian Patent number 2,892,194 to Clarke Valve. Titled “SHUTTER VALVE WITH PIVOT ARMS,” this patent protects the unique low-torque design of the Shutter Valve, which is validated by the oil and gas industry and others as a highly reliable and important innovation in control valve and isolation valve technology.

“We are proud to have earned this patent and look forward to increasing our market presence in Canada,” said Kyle Daniels, president and CEO of Clarke Valve.

View a demonstration of the valve's features at https://bit.ly/2RFSZ9G. Clarke Valve

www.clarkevalve.com

Aquiline Drones of Hartford, CT, has announced plans to launch the industry’s first dedicated drone cloud in 2020.

Designed with extreme security and compliance, the Aquiline Drones Cloud (ADC) supports real-time and autonomous drone operations and can be remotely deployed. ADC is said to be easily scalable and allows for third-party development (Platform-as-a-Service — PaaS). ADC is the world’s first aviation-inspired drone cloud, the company says, capable of supporting a wide variety of drone solutions by gathering, analyzing, modeling and storing data/video for applications such as public works departments, oil and gas pipeline monitoring, agriculture, ranching, geodetic surveys for mining, law enforcement agencies and the military.

regards to potential supply chain support for key AD drone prototypes.”

Barry Alexander, CEO and Co-Founder of Aquiline Drones, notes that drone technology has come along way and that his company is poised to become a leader in the field. “We intend to provide full lifecycle solutions for our customers,” he told CPECN. “Toys are useless unless they are able to gather information that can tell a story.”

Alexander notes that Aquiline isn’t just going after U.S. business targets and has already gone global, offering services in China, Singapore, the Middle East and Canada.

According to Alexander, the company has “had conversations with two Canadian companies with

“Both our company and our team are unique,” says Alexander, “we are finalizing the purchase of a small airline making us one of four drone airline companies in the US operating under a FAA 135 Air Carrier Certificate.” Similar companies include Amazon Prime Air, UPS and Google’s Alphabet Wing.

Future plans of this burgeoning company include the deployment of its novel Drone-onDemand mobile app, expansion of its customer-facing cloud services and a nationwide MRO infrastructure supported by its cloud.

“We envision a world in which humans and drones live and operate in harmony, using their real-time control, autonomy and analytics to reduce costs, maximize return on investment (ROI) and create new business value,” says Alexander. Aquiline Drones www.aquilinedrones.com

Wajax Corporation of Toronto has announced that it has acquired all of the issued and outstanding shares of Calgary-based NorthPoint Technical Services ULC The Shares were acquired from an affiliate of Denver-based Lion Equity Partners for an aggregate purchase price of $18 million.

NorthPoint was formed in 2018 as a national electro-mechanical services provider and serves a broad range of resource and industrial customers. Specializing in the repair of rotating industrial equipment, including motors, generators, gearboxes, switchgear, transformers, pumps, fans and turbines, NorthPoint operates nine branches across Canada and employs

approximately 177 people. NorthPoint’s branches are located in Grand Prairie, AB, and Calgary; Regina; Winnipeg; Kirkland Lake, Sudbury and Sarnia, ON; Moncton, NB; and St. John’s, NF.

“We are extremely pleased to welcome North Point and its team of dedicated professionals to Wajax,” said Mark Foote, president and CEO of Wajax. “The addition of NorthPoint gives our ERS platform strengthened national coverage, complementing the expanded footprint we acquired with Groupe Delom in 2018 and allowing us to better serve our customers.”

Paul Crawford, CEO of NorthPoint, stated, “Partnering with Wajax provides our team with a significant opportunity to

grow our volume nationally, leveraging Wajax’s extensive sales, marketing and customer relationships.”

Consistent with Wajax’s strategy, the acquisition of NorthPoint is expected to provide meaningful growth in the corporation’s Engineered Repair Services (ERS) business, the companies say. For the twelve months ended December 31, 2019, North Point had revenues of approximately $49.2 million.

NorthPoint is complementary to Wajax’s existing ERS business, which includes the aforementioned Montreal-based Groupe Delom.

Wajax www.wajax.com

Schneider Electric Canada of Mississauga, ON, has announced that Montreal-based Alithya has joined the company’s System Integrator Alliance Program as a Certified Alliance System Integrator for Control Systems.

In joining Schneider Electric as a Certified Alliance System Integrator, Alithya leverages Schneider Electric’s innovative solutions to help customers modernize in areas like Industry 4.0, Industrial Internet of Things, analytics, Artificial Intelligence and Machine Learning.

“We are very pleased to establish this alliance with Schneider Electric,” stated Nigel Fonseca, senior VP, Ontario and Western Canada, Alithya. “Alithya’s deep experience with control and information systems combined with Schneider’s platform and broad software and hardware offerings allow us to provide best-of-breed solutions for our customers and help accelerate

their digital transformation.”

“I would like to welcome Alithya and express my appreciation for the beginning of a long-lasting relationship between both our organizations,” said Olivier Cousseau, VP of Industrial Automation at Schneider Electric. “This partnership will bring a unique blend of talents and abilities for providing exceptional client services.”

The System Integrator Alliance program is a broad network of over 1,000 independent system integrators and solution providers spanning various industries to offer the best service for customers worldwide. The program pairs the specialized knowledge of each independent partner with the best available technological solutions from Schneider Electric.

“Today’s automation systems offer huge opportunities to improve efficiency across numerous industries,” said Adrien Lemaire, national

system integrator channel manager, Schneider Electric. “We believe the best way to seize these opportunities is by collaborating with expert partners like Alithya that can use their knowledge to better serve customers, in this case offering strategic and analytical guidance in enterprise software.”

Alithya has developed several specialties, namely as a Software Design Service Provider. As such, Alithya designs control systems, develops software, and provides information technology services. Our expertise spans from the control room to the boardroom – from the design and development of safety systems and control systems to monitoring and HMI/SCADA systems, plant data historians, cyber security and delivering IT solutions, including analytics solutions.

Schneider Electric www.se.com/ca Alithya www.alithya.com

Industrial Ethernet protocols are the leading method for gathering smart instrument data and pending developments will allow improved implementation of this technique with two-wire instruments.

By Keith Riley, Endress+Hauser

Industrial Internet of Things (IIoT), the use of smart instruments to enhance industrial processes through real-time analytics, requires the generation of massive amounts of big data, which is collected and stored in host systems for evaluation. Main sources of this data are the smart instruments installed throughout plants and facilities.

These instruments transmit basic process variables — along with extended data such as calibration parameters, diagnostics and other information — over digital networks. This data becomes valuable when analyzed by end users with the expertise to perform predictive maintenance, reduce downtime and make other operational improvements.

This description assumes every smart instrument is connected via a digital network, but in many instances the information present in the instruments is unavailable due to communication protocol limitations. Bridging the gap between smart instruments and data repositories is where industrial Ethernet protocols such as EtherNet/IP and PROFINET enter the picture.

This data-gathering aspect of analytics will be the focus of this article, which will show why industrial Ethernet protocols are so popular. It will also explain why two-wire instruments with Power over Ethernet (PoE) are not yet available, and then discuss developments with two-wire instruments to enable connectivity.

Most end users prefer industrial Ethernet protocols over other traditional industrial fieldbus protocols for three main reasons:

1. Facilitates unification of an Ethernet infrastructure throughout a plant or facility

2. Provides extensive bandwidth, enabling access to more information at a faster speed

3. Supports ease and economy of setup and use due to widespread familiarity with and availability of Ethernet

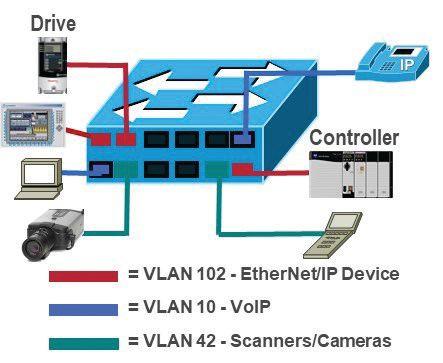

Will a plant be able to unify its operational technology (OT) and information technology (IT) networks using industrial Ethernet? Yes, but only with the proper network architecture. Smart switches or routers expressly designed to manage the information traffic from both networks are essential.

One example is the Stratix family of industrial managed Ethernet switches from Rockwell Automation. These switches separate office Ethernet TCP/IP traffic from industrial EtherNet/IP traffic by using freely assignable ports (Figure 1, below).

Ethernet TCP/IP is a common IT network protocol, and there are several industrial Ethernet OT network protocols. All these protocols follow the same OSI Layer Architecture model and comply with the IEEE802.3 communications specifications.

However, industrial Ethernet protocols modify the application layer. For example, with the EtherNet/IP protocol, the application layer in the OSI model is slightly different from IT protocols because it includes the common industrial protocol (CIP). CIP improves access to data used for control of network devices by separating it into implicit and explicit data packets, or messages (Figure 2, right).

Explicit messages are for node-to-node communication and use TCP delivery. They move large amounts of data, with variable-payload sizes, only as needed. Implicit messages are for compact high-speed communication and use UDP delivery. They are most commonly used for pre-configured high-speed input/output (I/O) messaging. EtherNet/IP adds this explicit or implicit distinction to the information packets to optimize performance for these types of transmitted data.

A standard IT Ethernet TCP/IP network communicates information upon request. Managing this traffic without negatively impacting the speed of the network or resulting in significant delays is relatively easy through the strategic use of the switches and routers commonly applied in IT networks.

However, OT industrial Ethernet networks are used for both I/O and control, with information broadcast continually. If a system is attempting to transmit both Ethernet TCP/IP and industrial Ethernet messages on the same network, it would quickly become overwhelmed and the speed would degrade to an unacceptable level.

Therefore, proper management of the available bandwidth through the use of special managed switches or routers is crucial. Routers can be used to segment networks, and managed switches can be used to manage traffic on each segment.

Industrial Ethernet protocols such as EtherNet/IP are very useful for transmitting large amounts of data quickly, making them a good fit for smart instruments. While an EtherNet/IP network is user friendly it has not yet reached the same level of functionality most people have come to expect from a standard home or office Ethernet TCP/IP network.

Compared to the maturity of Ethernet TCP/IP, industrial Ethernet networks are still relatively young, meaning the critical mass necessary for the market to provide expected true “plug and play” functionality has not yet arrived.

If a plant has an EtherNet/IP network installed, the physical connection of four-wire smart instruments into the network is much like any other Ethernet device. The host system is also connected to this network and is capable of obtaining process data from the instruments. Hosts can include control systems, asset management systems, process historians and others.

Integration of smart instruments directly into a host system requires coordination among the smart instrument, the host system and the smart switches. For example, three main tools are needed to easily integrate smart instruments into a Rockwell Automation PlantPAx control system based on a ControlLogix hardware platform:

1. An Add-On Profile (AOP) Level 3 is required data integration. AOPs are software packages loaded into the control system and are:

• specific to individual instruments

• developed in coordination with the control system manufacturer

• supplied to the end user or system integrator by the smart instrument manufacturer

2. Add-On Instructions (AOIs) are supplied as a pre-engineered function blocks, and each must be configured by the end user. AOIs are used to define data, arguments, parameters, algorithms and other functions required for processing data from the instruments.

3. Instrument faceplates and Global Objects are supplied to provide human–machine inter-

face (HMI) visualization of instrument data, transparency of extended field instrument information and assistance with diagnostics. These are typically supplied by the control system manufacturer.

If multiple instruments from more than one instrument manufacturer are connected, then AOPs, AOIs and faceplate software will need to be loaded and configured for each type of smart instrument. In addition to the software requirements listed above, hardware connectivity considerations arise with two-wire instruments.

Most users have heard of PoE, and many question why manufacturers have not implemented this functionality into their smart two-wire instruments. A PoE standard exists in the form of IEEE802.3 AF/ AT, and there are also commercially available switches on the market to manage and distribute PoE.

The main issue is that IEEE802.3 AF/AT compliant switches are rated for up to 52 Vdc at 2.5 A. This relatively high level of power makes it very difficult to use these switches in the hazardous areas commonly found throughout process plants and facilities. This is true regardless of whether the installation is designed using an intrinsically safe or explosion proof concept.

Therefore, only areas classified as non-hazardous are viable for PoE installations, but even here challenges exist. Per NEC500 (National Electrical Code), working on live energized parts operating with a voltage greater than or equal to 50 V is a safety issue and requires the use of personal protective equipment. In many instances, the benefits of PoE implemented in compliance with IEEE802.3 AF/AT simply do not provide sufficient value to justify the effort or expense required for design, installation and maintenance.

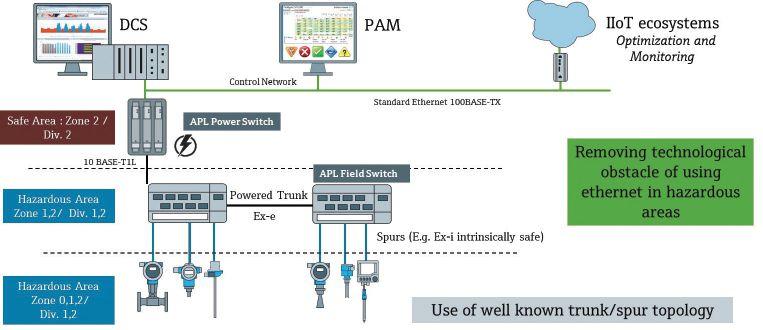

The problem of not being able to directly use two-wire smart instruments in industrial Ethernet networks has been recognized. A consortium of organizations including FieldComm Group, ODVA, PROFIBUS, PROFINET International and manufacturers of process instrumentation and control systems have joined to build upon the work of the IEEE802.3cg Task Force. This consortium is referred to as the Ethernet Advanced Physical Layer (Ethernet-APL) group.

IEEE802.3cg (draft) is a physical layer specification and management parameter for 10 Mb/s operation and associated power delivery over a single balanced pair of conductors (Figure 3, above). Implementation of this draft will eventually make Industrial Ethernet protocols suitable for use in hazardous area locations.

Ethernet-APL is exactly what the name implies: a new physical architecture designed specifically for industrial Ethernet protocols (Figure 4, above, opposite page). Ethernet-APL will not impact the protocol stack, so it will be suitable for use with PROFINET, HART-IP or EtherNet/IP Industrial Ethernet protocols, and open their use to two-wire topologies.

Together, Ethernet-APL and IEEE802.3cg (draft) will enable industrial Ethernet-based communication protocols for two-wire field instrumentation by:

• Allowing power and data to be carried on the same two-wire shielded cable

• Permitting installation in plant areas classified as hazardous

• Providing high bandwidth of 10 Mb/s

The work being conducted by the Ethernet-APL group and the IEEE802.3 cg Task Force is ongoing and expected to be finalized soon. Once this work is completed, instrument manufacturers and component suppliers can respond with the equipment necessary for a complete network.

Until this solution is available, the alternate method for integrating legacy two-wire instruments to an industrial Ethernet control system is through a gateway. While highly functional, this method does limit the data available from each instrument to typical primary or HART values. One Ethernet example of a device with Industrial Ethernet gateway capability is the RSG45 from Endress+Hauser (Figure 5, above).

The RSG45 is available with either EtherNet/IP or PROFINET slave functionality. This allows a user to easily incorporate up to 20 traditional twowire HART, analog, thermocouple or RTD instruments into an industrial Ethernet system. The existence of a second industrial Ethernet port, separate Ethernet TCP/IP port and integral web server means a user can also access individual HART-capable instruments directly over the network for additional diagnostics or setting adjustments.

Smart instruments are a vital component for process owners to implement IIoT strategies. However, users can only realize the full value of these devices and the subsequent potential of IIoT analytics when their systems can quickly and easily access the growing amount of available data.

STATIFLO MOTIONLESS MIXER... the modern, cost effective answer to a wide range of process problems – mixing, blending, dispersion and emulsion formation, mass transfer, laminar flow heat exchange and chemical reactions – in a wide range of industries, including:

• Water and Waste Water Treatment

• Hydrocarbon and Chemical Processing

• Food and Pharmaceutical Production

• Pulp and Paper Production, and more

•

•

•

•

Industrial Ethernet enables this digital transformation by providing simple and fast access to the required real-time instrument and process data. Today, four-wire instruments can easily connect to industrial Ethernet networks, and traditional two-wire instruments can be integrated with gateways.

In the future, two-wire instruments will be able to connect more directly as a result of Ethernet-APL and IEEE802.3cg (draft). This will enable improved operations through the use of analytics applied to data gathered using industrial Ethernet networks.

Keith Riley is the National Product Manager for Pressure and Temperature at Endress+Hauser USA. He has been with the company since 2008. This article first appeared in Chemical Engineering online. Endress+Hauser www.ca.endress.com

HORIZONTAL VACUUM FILTER OFFERS SYSTEM FLEXIBILITY

The Kek Centrifugal Sifter from Kemutec is fitted with a standard cantilever shaft and is said to deliver not only the best standards of hygiene and cleanliness but also unsurpassed reliability with minimal maintenance requirements. Principle processes include: policing — removal of extraneous material; scalping — removal of small percentage of oversize product; classification — separation by size; de-dusting — removal of fines; conditioning — provides uniform density for easy ow; de-agglomeration — breaking of soft lumps and agglomerates; and, liquid straining — removal of excess liquid from solid products. Special applications and designs cover: recovery of products from packaging; de-agglomeration of raisins and other dried fruits; in-line vacuum conveying centrifugal sifters; in-line positive pressure pneumatic conveying centrifugal sifters; powder paint spray booth recovery; flour sieving using Kek centrifugal sifters; Kek ‘insertable’ mini sifter; and, extruder protection. Kemutec www.kemutecusa.com

The HX series Round Separator from SWECO is said to improve technology and performance while increasing safety and simplifying clean-up and maintenance. The vibratory screening series features the ProGlide, a new top and bottom “no-tools” weight system, which presents fine proportional motion adjustment, enabling the user to move a single weight set radially to dial in on the optimal horizontal and vertical amplitude and force to improve efficiency and throughput. A new lower weight guard encloses the motor and lower weight assembly,

reducing the risk of reach-in injuries while complying with CE Standards. The guard can be easily removed without disassembling the drive, the company says. Separate solids from liquids or segregate dry materials into various sizes. Particles as fine as 400 mesh (37 microns) can be screened, with up to 4 screen decks incorporated in one separator.

SWECO www.sweco.com

The model SFA from the Vorti-Siv division of MM Industries, is a fine mesh wet or dry deblinding system utilizing high- speed gyration (up to 3450 rpm) and ultrasonic energy. A standard stainless steel removable probe is specially mounted to a bonded or soldered mesh screen assembly. The system is available on all Vorti-Siv 115/230 Vac, 37kHz generator system models ranging from 8 and 10 in. to 60 in. screen diameters and in mesh sizes as fine as 20 microns. For 8 in. diameter sizes, mesh sizes to 3 microns are available. The smaller fixed design utilizes an aluminum transducer for 8 to 24 in. sizes.

Vorti-Siv

www.vorti-siv.com

The K-S CIX horizontal vacuum filter from Komline-Sanderson is a top fed filter that can perform filtration, extraction and drying in one machine. Slurry is fed continuously and forms a filter cake, which can then be washed as it is progressively indexed through discrete zones. It is ideal for applications requiring counter current washing and precise separations. Features of the CIX include: continuous indexing filter; excellent cake washing; filter dense materials; and, process flexibility. The horizontal vacuum filter is typically used for the filtration of crystalline slurries and washing of the filter cake. Applications include pharmaceuticals, fine chemicals, gypsum, zeolytes, mineral concentrates, pigments/dyestuffs, and, pulp and vegetable matter. The benefit of the filter is what happens between the continuous feed and continuous discharge. Komline-Sanderson www.komline.com

The ITC-XXX-XX-DC is a signal isolator with dual outputs providing high isolation from Input to Output1, to Output2, and to Power in a small easy to install package. It’s universal DIN rail mount makes it possible to install right next to the instrument that is to be isolated. The many different input and output configurations allow it to be used in a great variety of applications ranging from PLC front end conditioning to adding an extra loop with lots of drive to an existing, almost fully loaded loop. Contact us for more information

By Linda Mioduszewski

Vibratory feeding and conveying equipment have been used in the chemical processing industry for several decades to move fine and coarse materials which tend to pack, cake, smear, break apart or fluidize. The information in this article will assist plant managers and equipment operators in selecting the proper feeder to effectively handle various materials, particularly in dry chemical settings where hazardous dust is present.

In a chemical processing plant, vibratory feeders meter product from hoppers and deposit them onto conveyors, elevators, calciners, screeners or other processing equipment. Vibratory equipment is also utilized for many types of screening—including size separating, scalping or removing oversized product and conglomerates—as well as de-dusting or removing fines.

Manufacturers have upgraded and modified vibratory feeders and conveyors over the years to meet the demands of chemical processing applications. The latest equipment offers increased energy savings, more precise control over material flow, easier maintenance and a broader variety of options.

Vibratory equipment, regardless of its type or size, is built to withstand the harsh environment of the chemical industry. For example, vibratory feeder trays from Eriez® are manufactured from 316L stainless steel which is far less susceptible to corrosive materials. Dust-tight construction and splash-proof design make internal drive components more suitable for dusty or wet environments. Some feeders are built with galvanized, nickel-plated or Teflon-coated drives.

Dealing with hazardous dust in many dry chemical operations is an ongoing safety issue. Electromagnetic vibratory feeders from Eriez are available with electromagnetic drives that can be used in a Class II hazardous dust environment in groups F

and G, as defined by the National Fire Protection Association. Eriez also has specially built drives that can operate in temperatures up to 300ºF.

Chemical materials which are dry, free-flowing, pelletized or granulated are typically conveyed using an Eriez model A or C high frequency electromagnetic feeder. These units, which are mainly used for regulating granular flow from a hopper to a second process before final packaging, control material flow from a few pounds to several tons per hour. They are custom designed to accommodate material flow from a few feet with a single drive to up to 20 feet with multiple drives.

for food, chemical and pharmaceutical applications. Some trays are constructed of corrosion-resistant alloys such as titanium or Hastelloy. Tray lining options include abrasion resistant steel, stainless steel, urethane, rubber and other coatings.

Another type of feeder is the High-Speed (HS) unit, which is ideal for rapid on/off cycling and features a faster speed rate. This feeder is ideal for use with weigh scale and packaging machines. Like other feeders in the Eriez line, HS units install easily in tight spaces.

Eriez’ newer model electromagnetic feeders— called High Deflection (HD) feeders—effectively convey fine powders. These low-frequency HD feeders feature increased feed rates and handle a broad range of materials.

wastewater 1c ad 4/5/05 2:53 PM Page 1

Materials from -50 mesh to -400 mesh tend to fluidize and flush on traditional electromagnetic feeders. After significant research and development efforts, Eriez HD Feeders now offer high deflection of up to 3/16-inch (4.8 mm) and lower frequency (30 cycles per minute) to handle finer products.

Innovative Solutions for Tough Water/Wastewater Applications!

Trays that include features such as a tray cover or screen deck incorporate quick-release fasteners that enable these components to be removed without tools. Once the fasteners are loosened, the component simply lifts and disconnects from the tray for easier cleaning.

Springs are an integral part of the feeding system process because they transmit the vibration from the drive into the tray, causing the material in the tray to move. Like trays, springs now come in a variety of materials, sizes and configurations to meet application requirements.

Small electromagnetic feeders, light to medium duty conveyors and most high precision vibratory equipment use fibreglass or carbon fibre as their primary spring action material.

• Manual, automatic and actuated (pneumatic & electric) valves; relief, check, diaphragm, ball, solenoid, and shut-off. Also pressure regulators, metering pumps, basket strainers, sight glasses, and gauge guards.

• Innovative Engineering –Dedicated Craftsmanship.

• 100% inspection and individual testing of each product, to ensure dependable performance and long-life.

• PVC, CPVC, Polypropylene, PTFE and PVDF. Valves from 1/8'' to 3'',Sight glasses to 8'' and Basket Strainers to 14''. CEDAR GROVE, NJ 07009 (973) 256-3000 • Fax: (973) 256-4745 info@plastomatic.com•www.plastomatic.com VALVES AND CONTROLS

Electromechanical feeders are also well suited for the chemical industry. These low-profile units are mainly used for metering product below hoppers or transferring product from one conveyor to another. They are equally as rugged as their electromagnetic counterparts but operate at a lower horsepower to enable greater energy savings.

Mechanical drives create a vibratory motion of a tray. This motion is caused by either a direct mechanical linkage (pushrod) or by a stimulating motion with out-of-balance weights and then amplifying that vibration into the tray through a set of springs.

The shape, length and width of modern feeder trays are practically limitless. Customers can order custom feeder trays to satisfy their unique process requirements. Every configuration of flat, curved, v-channel and tubular designs are available.

Trays are typically fabricated from mild steel for general purpose processing or stainless steel

Other types of spring materials are also incorporated according to the application. Steel springs are commonly used on heavy-duty and high temperature applications. These springs are effective in ambient temperatures up to 300° F.

Dense rubber springs are used on heavy-duty feeders and conveyors to provide stability and motion control between the drive and tray. However, rubber springs are limited to use in environments below 120° F.

Purchasing and installing a vibratory feeder poses fewer risks today because of the availability of technical assistance before and after the sale. Before a purchase is made, material samples can be tested at the Eriez Technical Center to determine the optimum piece of vibratory equipment.

The experienced staff at the Technical Center can perform tests on representative material samples to determine the proper model and size of feeder/conveyor for any given operation.

Customers can visit the facility, located near Eriez’ World Headquarters in Erie, PA, to witness tests firsthand. Alternatively, they can choose to view the testing online in real-time or request a video of their product test.

This article was written by Linda Mioduszewski, Eriez Senior Technical Sales Representative. She can be reached at lmiodus@eriez.com or by calling Eriez at 814-835-6000. Eriez www.eriez.com

Flomatic has announced additional sizes and flow ranges to its constant flow control valve Flo-Trol Model CD900 line, all in a stainless steel body. The automatic flow control valves are designed to give constant flow over a wide pressure range. The valve design has no moving part; rather, a self-cleaning flexible orifice that varies in size with applied pressure so that a constant flow rate is maintained. Flow rates are maintained to within ±15% between 15 and 125 psi. Each valve is laser engraved with flow rate, size, and certification.

Flomatic www.flomatic.com

Carlo Gavazzi has launched the MC36C series Compact Safety Magnetic Sensors, designed for safety-related applications, such as the monitoring of swinging, sliding or removable safety guards, which keep personnel safe from dangerous areas. The series can work as standalone or in conjunction with a safety module to reach a safety category 4, according to the EN ISO 13849-1 Standard. Features include: compact size (36 x 26 x 13 mm); output configuration (2 NO or 1 NO and 1 NC); and, availability with 2 m cable or M8 quick disconnect (left or right exit). Specifications include: assured switching range of 5 mm w/MC36CM model; assured switchoff range of 15 mm w/MC36CM; operating range of -25° to 80°C; rated operating voltage of 12 to 24 Vac/Vdc; 0.25 A (resistive) rated operating current; 6W (resistive) maximum switching load; 100 Hz maximum operating frequency; optional LED indication; IP67 protection; and, CE and cULus approved.

Carlo Gavazzi

www.carlogavazzi.com

U.S. Gauge has announced a broad selection of submersible level transducers that includes intrinsically safe approved sensors for hazardous applications such as oil and gas, and general industrial units to measure clean water. Five different models are available for immediate delivery, from the low-cost SDT to the Intrinsically Safe

Model 675 Shark Cage unit for applications in lift stations, sludge tanks, or process sumps. The Slimline SST is said to be one of the few units on the market that has an outside diameter of less than 1 in. and is suitable for deep wells and small-bore applications. The sensors are configurable on the company’s webshop. Configuration options range from the output needed, feet or pressure range, to the type and length cable. U.S. Gauge www.usgauge.com

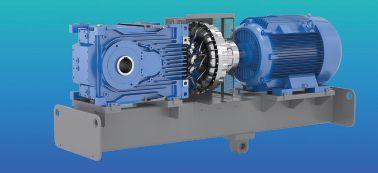

AutomationDirect IronHorse HBR series of helical bevel gearboxes combine a helical gearset with a bevel gearset to create an output that is perpendicular to the input. The gearboxes have a hollow shaft output and accept double or single shafts. Dual and single output shaft kits are available. Helical gears offer a smoother, quieter operation than most other gear types, the company says. The universally interchangeable compact design is said to ensure easy OEM replacement and provides flexible installation with C-face and TC-face inputs, perpendicular output and 6 mounting positions. Five gearbox sizes support 56C up to 254/6TC NEMA motor frames and 6 ratios are available from 10:1 to 120:1. The helical bevel gearboxes are sized to handle from 1 to 24 hp motors. The helical bevel gearbox series features cast-iron (FCD45) onepiece housings and high hardness alloy steel (20CrMO) pinion and gears.

AutomationDirect

www.automationdirect.com

The model AD aeration pad by Conveyor Components Company is suitable for aerating a variety of dry, bulk materials in order to promote flow. The aeration pad is available in the standard zinc plated steel body, as well as optional stainless steel bodies and mesh. The construction features internal stiffeners to prevent crushing of the air compartment and is said to provide long life of the aerator. Minimal air pressure (6.5 cfm at 3 psi) is required to adequately fluidize most dry bulk materials. Conveyor Components Company www.conveyorcomponents.com

Krohne has announced the Optibar PM 3050, a pressure transmitter for general pressure and level applications. The unit comes in a wide range of pressure ranges and diaphragm styles and is said to have a high overload resistance. The device is also vacuum resistant with measuring accuracy up to ±0.1% of set span. The device’s compact design with a recessed metallic diaphragm and full stainless-steel construction provides it with the robustness necessary for a variety of different industries,

the company says. For example, the range of hygienic process connections with front flush diaphragm compliant with 3A Sanitary Standard and EHEDG hygienic design makes the transmitter a suitable choice for food and beverage pressure and level applications. It may also operate as an absolute and gauge pressure measurement of gases, vapours and liquids as well as a hydrostatic level measurement in open tanks. Krohne www.us.krohne.com

CLOUD-BASED SCADA CAPABILITIES ADDED TO ALARM SYSTEM

RACO has introduced cloud-based SCADA enhancements to its AlarmAgent.com product. AlarmAgent.com provides real-time visibility that protects remote critical assets through an easy-to-configure interface. Newly expanded human-machine interface (HMI) customization options allow users to visualize their AlarmAgent.com data within their preferred dashboards and screens, the company says. The resulting real-time views can reveal the state of the customer’s entire facility ecosystem. The cloud-based SCADA capabilities also enables the use of OPC connections to integrate AlarmAgent.com functionality with their existing supervisory control and data acquisition (SCADA) tools.

RACO

www.racoman.com

www.alarmagent.com

IP65-RATED STEP MOTORS DESIGNED FOR WET & DUSTY ENVIRONMENTS

Applied Motion Products has announced an extended line of stepper motors with IP65 ratings that are dustproof and resistant to water pressure impact, making them suitable for use in wet and dusty applications. The IP65-rated step motors feature sealed laminations, an oil shaft seal, internal corrosion-resistant film coating, gaskets for mechanical joints and an integral 10 ft shielded cable that offers protection against the ingress of dust and resistance to low-pressure water jets. For improved protection in high-humidity environments, an advanced coating is available as an option. The step motors are available in NEMA sizes 23, 24 and 34. A double-shaft version is available with an optional IP65-rated encoder for applications requiring feedback Applied Motion Products

www.applied-motion.com

2020 is the year of the Rat! Should be the year of perfect vision!

We have two Process & Automation Shows in March. The British Columbia show in Richmond on March 4th and then the Southern Ontario show in Mississauga on March 31st.

If you’re in the area for either one, be sure to drop in and visit us. We’ll have industry experts on hand and you can win prizes and load up on swag! If you’re interested in exhibiting, contact us and we’ll let you know how it works.

Next issue up is our April issue with a focus on the Environment and Mike’s supplement will delve into the exciting world of Fittings and Couplings. If you’d like to contribute editorially let Mike know at editor@cpecn.com. April closes March 1st.

Are you getting our Canadian Process E-Newsletter every second Wednesday? If not, sign up today at cpecn.com/subscribe/— it’s free and amazingly informative!

Have a great 2020.

Cheers, Rob Sommerville

Trust KNF for proven liquid and gas pump performance in safety-critical applications.

• Suited for NEC/CEC Class1, Division1, Groups C & D; IEC EX, ATEX, and other protection levels available

• Choose from a broad range of pump head and diaphragm materials

Learn more at knfusa.com/ExProof

The ControlPak manual pressure controller from Ralston Instruments is a compressed gas volume controller that is said to provide precise control over compressed gas sources for smooth and quick calibration testing. Encased in durable, tactical plastic designed to withstand mud, intense sun, and extreme cold, it is suitable for pressure calibration and pressure testing in the field. With fine control of pressure from 0 to 3000 psi, users can perform both ultra-precise low-pressure differential or high-pressure static pressure calibrations with a single setup, the company says. It includes multiple outlet ports to connect a calibrator and a DUT directly without a tee, and soft-seated valves allow the user to pressurize and depressurize incrementally, so there’s no need for a regulated pressure supply. It also has a built in storage compartment for holding extra hose

and adapters. All outlet connections, hoses and adapters are Ralston Quicktest fittings, which create secure, leakproof connections without the need for tools or thread tape.

Ralston Instruments www.ralstoninst.com

Micromeritics Instrument has announced the Dynamic Void Volume Analyzer (DVVA) II for customers looking to characterize carbon blacks in accordance with the newly revised ASTM D1765-18 Classification System for Carbon Blacks Used in Rubber Products. Following a final balloting of ASTM Committee D24 on Carbon Black this system now includes void volume analysis by ASTM test method D7854-18c (Standard test method for Carbon Black – Void Volume at Mean Pressure) facilitating a switch to more environmentally benign testing. The DVVA delivers analysis times of approximately ten minutes.

Micromeritics Instrument

ROTARY CONTINUOUS BULK SOLIDS MIXER

The sanitary model RCM36X9SS Rotary Continuous Mixer from Munson Machinery blends dry bulk solids with or without liquid additions, in-line over long production runs. Intended for dustfree mixing of bulk materials in large volumes, it blends primary bulk ingredients, minor ingredients, and/or liquid additions and coatings uniformly with little or no degradation. It features a stationary inlet, a stationary outlet, a rotating drum with smooth interior surfaces and proprietary mixing flights that impart a gentle tumbling action.

Munson Machinery Company

www.munsonmachinery.com

The SPX Flow SRT Top Side Tensioner spring return design is said to dramatically increase productivity and safety on the job site when compared to older technology manual return tensioners. Units feature piston overstroke prevention and piston stroke indication, as well as a quick release bridge adaptation and piston/cylinder misalignment compensation. Compatible with MRT Tensioner range, bolt coverage from 3/4 to 4 in. (20 to 115 mm) is accomplished with 8 tools. Designed to fit BS1560/ANSI B16.5/ API flanges, the fully enclosed load cell design eliminates entry of debris into piston retraction mechanism and the piston over-stroke eliminator prevents over stroking and blowing a seal. Specifications include a 10 mm piston stroke, maximum tool pressure of 21,750 psi (1,500 bar) and bolt protrusion above nut of 1 x bolt diameter (minimum).

SPX Flow

www.spxflow.com

Analytical Systems Keco has introduced the 205L Laboratory H2S in Liquids Analyzer that quantifies hydrogen sulfide in crude oil, fuel oil, naphtha, water, diesel and gasoline. Results within 10 to 15 minutes are featured. The crude oil analyzer is suitable for use in refinery laboratories, vessel/tank storage terminals, loading and offloading crude oil as well as inspection and independent testing labs. While other analytical methods suffer from false positives and readings due to cross-interferences with CO, H2, hydrocarbons or other components present in liquid samples, the analyzer utilizes a ratiometric-colorimetric tape detection method that only responds to H2S. In addition, the analyzer uses a Sample Transfer Stripper (STS) technology that acts as an effective filter, blocking any mists or liquid carry-overs to radically reduce any maintenance requirements. Analytical Systems Keco www.liquidgasanalyzers.com

The SiloPatrol plumb bob style continuous level sensor from Monitor Technologies is said to provide easy set-up and flexibility for integration in process applications. The versatile sensor works reliably with a large variety of materials, includes wireless Bluetooth for simple, intuitive set-up without removing the sensor cover and offers Modbus connectivity to communicate with Modbus-compatible control systems. The plumb bob unit combines Hall Effect sensor technology, sealed bi-directional optical sensing, a split-compartment enclosure, isolated outputs and other features to produce a reliable level measuring system designed for the harshest conditions. The sensor’s SMU (silo mon-

itoring unit) lowers a weight and cable into the silo until it contacts the material surface. Upon contact the weight and cable system is immediately retracted and the measurement is fed to the plant control system or operator interface. In addition, the product automates inventory management by use of the SiloTrack Cloud web application, PC software or a variety of operator interface devices like the HMI2. Measuring range is up to 46 m for powder bulk solids material levels in vessels. It also works for some liquid and slurry applications with optional ball float plumb bob.

Monitor Technologies

www.monitortech.com

The Sensor Connection has expanded its line of measurement and control instrumentation with the addition of the model PMD-MXT series of thermocouple scanner indicators. The microprocessor-based temperature scanner provides

continuous monitoring of up to 32 channels of thermocouple sensors. The 14 mm tall digit red LED display is easy to read, even at a distance, the company says, with rows of LED annunciators that warn of specific channel alarm conditions. The scanner has 2 user-selectable HI/LO, HI/HI, or LO/ LO alarm set points, configured through the front panel push buttons. During an alarm condition a front panel LED annunciator is enabled, and an internal 2 Amp relay contact output is engaged. The scanner’s display will auto cycle through all input channels at a user determined rate of 0.5 to 10 seconds per channel. The Sensor Connection www.thesensorconnection.com

Pfannenberg PKS series air to air heat exchangers use the company’s Kinetic System cooling technology that is said to out-perform conventional heat exchangers. Lightweight and easy to install, this new air to air technology takes advantage of a cooler ambient environment when closed-loop cooling is required, sealing against gas, humidity and dust, the company says. Designed for indoor, outdoor, remote and washdown applications that require a closed loop system to protect electronics, the new heat exchangers are perfect for cooling industrial electrical and IT components that need dust protection. The units are also suitable for keeping rain

and dust from sensors and drives on outdoor systems and protecting against corrosion and contamination in the food and beverage industry. The heat exchangers are available in five configurations; 22, 45, 64, 100, 150 and 180 W/°C.

Pfannenberg www.pfannenbergusa.com

In applications with critical, highly toxic or aggressive media, hermetically sealed drives are inevitable. Permanent magnetic couplings from DST provide both environmentally friendly drive solutions and help to prevent leakages. The magnetic couplings offer a reliable alternative to conventional dynamic seals due to their contactless and leakage-free torque transmission in pumps and agitators. Performance data ranges from standard (1 to 1,200 Nm) to custom-

er-specific (0.1 to 11,000 Nm). Coupling materials include 1.4301, 1.4401, 1.4404, 1.4435, 1.4539, 1.4571, 1.4980, 3.7165

Titan Grade5, Hastelloy C-4, C-22, C-276, PTFE, PFA and TFM, with other materials on request. Applications cover process engineering, chemicals, pharmaceuticals, industrial furnaces, water management, compressors, dosing and petrochemistry.

DST Magnetic Couplings

www.dst-magnetic-couplings.com