Aldon Company has introduced SaberTooth brand portable derails for wood or concrete track ties. A series of seven, ½ in. tall steps or notches allow derail to fit a variety of rail sizes without any adjustment. The notches make contact with the edge of a tie plate (wooden ties) or the edge of a concrete tie, or the rail anchor clip on concrete ties. The tie brace terminates in a stout, sharp pointed safety hook. The derails offer tool-free installation with finger-tight pressure on four stainless steel thumb screws that secure the derail to rail. Watch video demonstrations at www.cpec.news/asw.

Aldon Company

www.aldonco.com

www.cpec.news/asw

MoistTech moisture sensors provide a quick test of the moisture levels of the manufacturer’s raw ingredients, such as the materials used throughout the food and baking process for quality control. Its NIR IR33000F online moisture sensor for food applications sense moisture content throughout the process to provide cost savings in energy and fuel costs, as well as having less product waste. The sensor can also provide spot tests near lines or in quality control labs. On moisture analysis involving dried products, accuracy can be expected to be 0.1%. On higher moisture applications, accuracy can be expected to be 0.2 and 0.5%. Fat/oil measurement and protein accuracy are subject to application. Watch video at www.cpec.news/y61.

MoistTech

www.moisttech.com www.cpec.news/qdq

The Kobold LNM microwave level switch is used for detecting levels of fill. The microwave field penetrates several millimetres into the medium. Foam, condensate or remains of the transported medium that have stuck on to the tank are not detected. By using this principle of measurement, it is also possible to detect non-conductive media. The level switch is particularly suitable for use with foaming media because the foam itself is not detected. The output of the level switch only switches when the coupling section is completely covered by the medium. This means it is possible to install it into tanks regardless of position. In combination with the KOBOLD LZE or LZE-R weld-in sleeves, the probe provides a measuring point that has no dead space and meets hygiene standards, suitable for CIP/SIP cleaning.

Kobold Canada www.kobold.ca www.cpec.news/z12

The NS series floating ball valves and butterfly valves from A-T Controls are certified to meet the requirements of NSF 61 (Drinking Water System Components–Health Affects) and NSF 372 (Drinking Water System Components–Lead Content). This means that NS series valves are certified for use (by Underwriters Laboratory) in water treatment, water purification, potable water, reverse osmosis, desalination and water distribution systems and conforms with North American lead content requirements for “lead-free” plumbing. The valves hold CRNs (Canadian Registration Numbers). The company advises users the search bar on its site to access the CRN certificates with the term “CRN”. Butterfly valves are available in sizes 2 to 24 in. and have Class 150 wafer or lug flanges. Ball valves are available with threaded, socket weld, butt weld, Class 150, and Class 300 end connections. Watch video at www.cpec.news/tq2.

A-T Controls www.atcontrols.com www.cpec.news/ngx

As with most industrial control projects, cost is king, but you don’t have to sacri ce quality to keep your budget intact. C-more HMIs are built to last and provide many advanced capabilities, including object animations, logic and math operations, web server/mobile app access, and data logging, all for a surprisingly low price.

C-more Touch Panel HMIs starting at: $487.00 (EA9-T7CL-R)

C-more HMI design software can now be downloaded free-of-charge. Get started on your project today or take it for a test drive.

Download as often as you need. No license or key needed.

Get your copy now at: www.go2adc.com/cmoresw

Research, price, buy at: www.automationdirect.com/cmore

Our shipping policies make it easier than ever to order direct from the

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days.

*Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

The Endress+Hauser Gammapilot FMG50 level measurement device incorporates a 2-wire compact transmitter that requires only a fraction of the energy of its predecessor to achieve comparable measurement performance. This technology, the first of its kind, the company says, offers many user benefits over existing compact radiometric measurement transmitters, all of which require external power supplies that add to their cost and complexity. The unit uses a unique, patented high voltage generation to overcome that limitation; its 2-wire con-

nectivity supplies signal and adequate power without the need for external power. The device adds many enhancements over its predecessor in performing level measurement for liquids or solids in process vessels such as reactors and autoclaves. It also performs density and interface measurements and is suitable for use where other measuring principles cannot be applied due to corrosion, abrasion, viscosity or toxicity. Watch video at www.cpec.news/nai.

Endress+Hauser Canada www.ca.endress.com www.cpec.news/57x

Cameron Instruments has introduced the MAKO by Arbiter Backflow. The instrument is a tool for the backflow and cross connection control industry and is said to provide a tough, water resistant digital solution with benefits and features unseen in a traditional mechanical (analog) gauge. The unit can perform all standard backflow testing procedures as well as others. Use the capture button to store readings while you test, the company says, so there is no need to write things down on paper or start all over after being interrupted during a test. The tool offers increased stabilization and accuracy over traditional gauges allowing you to spend less time waiting, it adds. The product comes with a high visibility backlit display and a swivel hook allows the user to hang the gauge onto a pipe or ladder and spend less time dealing with rope. Included with the unit are hoses and adapters — the hoses are designed with food grade material and are said to be more flexible than traditional hoses. The soft rubber grips and ergonomic design are also said to make it easier to hold and use than an analog gauge. It is available in both 3 and 5 valve options. Watch video demonstration at www.cpec. news/qwi.

Cameron Instruments

www.cameroninstruments.com

www.cpec.news/eop

HYGIENIC FLOW METER CONTROLLER SERIES CONFORMS TO 3-A

The Bronkhurst ES-103I flow meter series with Tri-Clamp flanges from Hoskin Scientific is authorized by 3-A Sanitary Standards and can be supplied with a GEMÜ 650 control valve. In addition, it has various other improvements like a higher rangeability, a new PC board and Ethernet based fieldbuses. The volume flow meter and controller has an improved accuracy of ≤0.8% Rd ± ≤ 0.4 ml/min ZS, improved rangeability (lower full scale & minimum flow), with range extension (higher and lower flow rates) to follow. Hoskin Scientific

www.hoskin.ca

www.cpec.news/kfq

see if your company now qualifies and to calculate its subsidy rate. Mike Edwards medwards@cpecn.com

content is linked to images that have this symbol: These items also contain a bit.ly link to view video content.

For even the harshest chemical processing environments to sterile pharma/biotech applications, you’ll find the right solution, the right documentation and the right team with LJ Star flow indicators, fused sight glass windows and high-lumen lights and cameras.

n Standard view and full-view sight flow indicators

n Rotary, flapper, flutter, ball or drip indicators available

n Highest quality glass and materials that meet or exceed industry standards

LJ Star’s METAGLAS® fused windows, MetaClamp® and Lumiglas® explosion-proof and Non-Ex lights are found in the most demanding applications in the world. Call or visit www.ljstar.com for detailed CAD files, specs and tutorial handbooks.

-Reduces Cooling Energy Costs

-Boosts Operational Efficiency

-Curtain Lok™ Retention System

-Resists Blow-out

-Releases on Accidental Impact

-Quick & Easy Door Reset

-Improved Drive System

-Heated Guides and Bottom Edge

-Plug and Play Cable System

Medium temperatures of -60°C don’t even make the designers of electrical thermometers shrug their shoulders –but when one speaks of ambient temperatures of -60°C, then one often hears a sharp intake of (cold) breath.

It quickly becomes clear that one cannot readily use standard instruments here. Global warming on the one hand, requests for equipment for use at very low ambient temperatures on the other –they don’t really fit together. Nevertheless, that’s the reality. Until recently, -40°C was used as the lowest test temperature (ambient temperature), today this temperature is moving more and more towards -60°C.

One of the reasons for the growing demand for instrumentation for use at such uncomfortably low ambient temperatures is man’s push into colder regions in search of oil, gas and other minerals.

But it is not only meteorological and geographical causes that lead to these extended requirements. Applications in the field of liquid gases also require the use of suitable electrical thermometers.

for electrical thermometers suitable for low ambient temperatures

Special versions – even when you can hardly distinguish them visibly from standard instruments – place high demands on the design, construction and materials used. In order to achieve optimum operational reliability, the components of these special thermometers are made exclusively from materials suited to low temperatures.

The demands on the components and the complete instruments are high. The impact resistance must, for example, be tested at the weakest points of the outside of the test item. These tests must be carried out on mounted thermometers which are ready for service.

Standard resistance thermometers are not suitable for these low ambient temperatures. The development of special low-temperature resistant thermometers which also withstand icy ambient temperatures of -60°C is the logical consequence.

Examples

One of the main reasons for the need for such elaborate investigations and their documentation is the behaviour of plastics at low temperatures. Here, the increasing embrittlement at decreasing temperatures indicates the limits of the usability of these materials (e.g. in cable glands and their seals).

But it is not only seals, but also sealing compounds, adhesives, painted surfaces and (often

overlooked) the sheaths on connection cables inside cases, that must meet the demands defined by the test temperatures. Cables are preferably stationary in these ambient temperatures, i.e. installed fixedly. This prevents micro-cracks and thus possible ingress of moisture. Electronic components such as displays and transmitters have already been developed for applications in extreme ambient conditions. Here, retroactive matching to low temperatures is often no longer possible.

In order to ensure process safety at the low temperatures mentioned, the test temperatures are subjected to a safety factor. Instruments with explosion protection are tested at a test temperature of -70°C.

Ambient temperatures which are not problematic for stainless steel can lead to problems with aluminum alloys. Therefore, the metallic components of the thermometers are also tested for impact resistance at -70°C. Both the individual critical components and also the finished products thus undergo a wide number of specific tests before the thermometers are sent to the customer after they have been approved. This article is from the WIKA blog available at www.cpec. news/qi1.

By Greg Tischler

When it comes to non-contact continuous level measurement, radar and ultrasonic are two of the most common technologies used. Both technologies are used for similar applications across industries, and both types of devices use similar principles to make a level measurement. However, each technology has varying degrees of success in different applications.

This paper will compare and contrast 80 GHz radar sensors with ultrasonic transmitters for liquid and solid level measurements. Users must consider many variables when choosing a level measurement technology, and this paper will discuss how each technology performs relative to several of these.

Radar and ultrasonic instruments operate similarly. They both face downward, emitting a signal that reflects from the product surface, and the sensor electronics use the time of flight to calculate a measurement. The type and shape of signal each technology uses is where they begin to diverge. All radars, including 80 GHz radar sensors, emit radio microwaves, while ultrasonic transmitters use sound waves.

Radar microwaves are electromagnetic waves, which means the signal doesn’t require a medium – it can travel in a vacuum. This is why radar signals are unaffected by process conditions like temperature and pressure. This makes radar technology a versatile level measurement technology across industries and applications.

The newest radar sensors using a higher 80 GHz frequency have a very narrow beam angle – as small as 3.6˚. Most of the energy from the radar signal is focused in a small area, and this allows the radar to avoid internal obstructions, mixers, or agitators inside the vessel. The exceptional focus of the radar beam also minimizes any additional “noise” or unwanted reflections that bounce around inside the vessel.

An ultrasonic sensor’s sound wave is a mechanical wave, which means it needs a medium to travel through, and most of the time, that medium is the atmosphere or the air inside the vessel. The speed of the signal is contingent upon the environment in which it’s traveling. Sound waves travel at different speeds depending on the air temperature, pressure, density, and gas composition. If any of these properties are changing during the process, it can result in measurement errors, which is why ultrasonic sensors are more ideal for simple level measurements in processes with little to no changing conditions.

Ultrasonic signals operate using frequencies ranging between 30 kHz and 240 kHz. Unlike radar, frequency is more of a function of measuring range, with low frequencies used for measuring longer distances and high frequencies used for measuring small distances. Some ultrasonic sensors can focus most of their signal as small as a 4 or 5˚ beam angle, but because of the shape of the acoustic waves, ultrasonic sensors are more likely to receive unwanted reflections from within the vessel.

To begin choosing the right level measurement sensor, users must understand the shape, size, and material of their vessel. This will provide a better understanding of the measurement required by the sensor. It can also determine how and where the sensor will be mounted to obtain an accurate, reliable level measurement.

Radar sensors have traditionally been used for longer range level measurements in bigger tanks while ultrasonic sensors have excelled with shorter distances. As technology has developed, however, these conventions have begun to fade. Ultrasonic sensors are still more accurate with exceptionally small measurements less than six inches. For most small vessels, however, today’s 80 GHz radar sensors perform just

Continued from previous page

as well as their ultrasonic counterparts. Plus, these new sensors have small antennas with correspondingly small process fittings that make them suitable for these small tanks.

In large tanks with longer measurement spans, both radar and ultrasonic sensors perform well. However, users should be ready for a tradeoff when using ultrasonic sensors. The low frequency ultrasonic sensors used for long ranges typically require a larger opening at the top of the tank. Plus, all ultrasonic sensors have a near zone, or a “dead band,” which is essentially a blind spot near the sensor where it can’t make a measurement. Long-range ultrasonic sensors may have near zones exceeding three feet, while radar sensors enable users to measure all the way to the top of the tank.

The tank or vessel’s construction can also play a factor in which technology to choose because this can factor into how a sensor is mounted. Radar signals can penetrate non-conductive materials like polyethylene, fiberglass, and glass. This allows radar sensors to measure through plastic vessels or sight glasses. An ultrasonic sensor would require a new process connection while the radar can simply be mounted above the vessel and make the same measurement non-intrusively.

Every process has its challenges to obtaining an accurate level measurement. Steady, predictable conditions are a luxury in the process industry. Changing temperatures, foam, product reflectivity, dust, condensation, buildup, and noise are just a handful of potential hurdles to obtaining an accurate level measurement. It’s up to the user to find the best technology for the task at hand.

Radar level sensors are immune to any changing temperatures, while ultrasonic sensors’ accuracy can vary drastically. To combat this, ultrasonic transducers come equipped with the ability to measure the temperature at the transducer. However, if the transducer temperature significantly varies from the air space near the product surface, the level measurement will be off.

Similar to temperature, the composition of the gas between the sensor and the liquid surface has an effect on ultrasonic sensors’ sound waves. The speed of sound varies greatly depending on the gas type, which can lead to measurement errors. Vapours from acids and solvents are especially susceptible to this, and it can greatly affect the accuracy of ultrasonic devices. Radar microwaves, on the other hand, travel at the same speed regardless of the air space, so the measurement will remain the same.

Foaming is another universal setback for any non-contact level measurement technology because foam absorbs both microwaves and sound waves. Complete absorption is rare, and in those extreme instances, a guided wave radar is the user’s best bet. In most applications with light foaming, an 80 GHz radar can make a measurement through the foam as if it’s not even there. Many ultrasonic manufacturers would require a standpipe for the same application.

The high sensitivity of VEGA’s 80 GHz radar sensors allow them to measure even the most unreflective products. Liquids and materials previously unmeasurable with older radar sensors can now provide a strong enough signal to deliver an accurate, reliable level measurement. Unlike radar’s electromagnetic waves, an ultrasonic’s mechanical waves reflect off of most surfaces, despite its reflective properties.

Valve Control

POSITIONERS – POSITION MONITORS

• Digital – Hi air delivery

• Zero bleed

• Certified for natural gas

• Highly reliable – User friendly

Position – Speed

INDUSTRIAL ENCODERS

• Incremental

• Absolute

• General purpose

• Explosion proof

3D SONIC

POSITIVE DISPLACEMENT

• High accuracy – Repeatability

• Install in any piping configuration

Users rarely find dust, condensation, and buildup in the same application, but all three have similar effects on ultrasonic sensors. Sound waves emitted from ultrasonic sensors require a medium to transmit energy from one place to another. Dust in the air presents a physical barrier for the energy transmission, which weakens the amplitude of the return signal. With condensation or buildup, the transducer diaphragm acts as the medium when it vibrates to produce a signal. Condensation or buildup here dampens the signal from the start. Yet, some ultrasonic sensors with low frequencies are better at handling these situations because the mechanical wave vibrates the sensor face, keeping it free of water droplets or buildup.

• Broad range of sizes

ADDITIONAL

• True average level measurement of complete surface of product

• Accurate volume

• Self Cleaning no purge required

ELECTROMECHANICAL

• Robust long life

• Digital and analogue outputs

OPEN PATH RADAR

• Not affected by foam, temperature or pressure effects

• Superior DSP for difficult applications

• Thermal mass – Transit time – Electromagnetic

ULTRASONIC

• Totally Hermetically sealed

• Narrow beam angle for tight applications

GUIDED WAVE RADAR

• Compact loop powered 4 to 20mA

• Measures whilst filling

• Not affected by build up or material changing properties

DIRECT STRAIN CELL

WEIGHT MEASUREMENT

• Easy retrofit to existing I beam or round legs or skirted silos

• Web connectivity

Mississauga, ON Montreal, QC (800) 595-0514

www.cancoppas.com controls@cancoppas.com

Radar sensors are unaffected by dust, condensation, and buildup. Sophisticated sensitivity software in VEGA’s 80 GHz radar sensors ignores any signals returning to the sensor too quickly, removing the possibility of a false high-level resulting from condensation and most buildup. As for dust in the air, dust particles are 0.5 to 1.0 micrometers in size, much too small to affect the radar’s microwaves with wavelengths measuring 3.5 to 4 mm. This means radar is able to continue measuring during filling and emptying cycles of the most dusty environments. This allows radar to accurately make a level measurement in any application.

Loud noises are common in bulk solids applications and inside silos as falling material creates a deafening environment. The loud noises create additional sound waves, and depending on an ultrasonic transmitter’s frequency, this can interfere with the sound waves being used to make a measurement. This can lead to measurement errors during filling, emptying, and in noisy processes. Because radar level sensors use radio microwaves, the noise has no effect on the measurement.

In most level measurement applications, users would be wise to choose an 80 GHz radar over an ultrasonic transmitter. This doesn’t mean ultrasonic sensors are obsolete — they are a cost-effective, non-contact means of level measurement, but they’re not as reliable or accurate in changing or difficult environments. Most industries don’t have the luxury of stationary product in a stable environment, which is why an 80 GHz radar sensor is the right instrument for the job more often than not. Greg Tischler is Product Manager at VEGA Americas, Inc. This article is from his blog posted at www.cpec.news/pu0.

VEGA

www.vega.com

www.cpec.news/pu0

Festo has expanded its technology for energy conservation and early leak detection in pneumatic production with two more intelligent energy efficiency modules – the MSE6-C2M and MSE6-D2M. The units join the MSE6-E2M to form a comprehensive lineup of condition monitoring devices that are said to optimize compressed air usage during normal operations and halt or reduce consumption during scheduled stoppages as a further economy. The MSE6 series modules can be fully integrated into the machine’s control system via fieldbus nodes to cyclically exchange important energy consump-

tion and availability data regarding production. That data can inform more targeted preventive maintenance practices, or for even bigger cost savings, a predictive maintenance program. In the case of the -E2M, this data can be uploaded to the cloud and recorded and analyzed. The -C2M combines a pressure regulator, on/off valve, flow and pressure sensors and fieldbus communications in one unit. Watch video at www.cpec.news/akt.

Festo Canada

www.festo.ca

IDEC has introduced the 4.3 in. LCD screen size HG1P handheld human-machine interface (HMI). At 500 g and with contoured hand grips, a hand strap, and a wall hanging bracket, the unit’s ergonomic design makes it comfortable for long duration and fatigue-free use by technicians and engineers, the company says. The design is tested to withstand 1.5 m drops, and it uses a flush mount selector switch to prevent breakage. Competing products in this category are typically heavier, bulkier, and more prone to inadvertent damage, it adds. The touchscreen is bordered with 12 physical momentary function keys (F1 to F12) with click-feedback, which write to internal memory bits within the HMI. In addition, a hardwired emergency stop button, selector switch, and a 3-position enabling switch make this unique handheld HMI flexible for designers and convenient for users. Xtronics

www.xtronics.ca

www.cpec.news/ua2

www.cpec.news/akt

Enfield electrofusion acid waste systems from IPEX are available in Schedule 40 and Schedule 80 pipe sizes from 1 1/2 to 12 in. IPS. Both flame-retardant and non-flame-retardant pipe is available. The electrofusion fittings are molded with an integral resistance wire in the socket, with jointing completed by energizing the resistance wire via a microprocessor controlled Enfusion Control Unit. The result of these innovations is an unparalleled level of joint reliability and repeatability, the company says, including controlled fit, controlled temperature and controlled time. Pipe and fittings are made from flame retardant polypropylene (FRPP). A black non-flame retardant polypropylene is also available upon request (NFRPP). The pipe and fittings comply with ASTM F1412 Standard specification for polyolefin pipe and fittings for corrosive waste drainage systems. All pipe and fittings are listed to NSF 14 standard and IAPMO. IPEX

www.ipexna.com

www.cpec.news/7nu

Toronto-based John Brooks Company Limited, experts in pumps, spray nozzles, filtration, valves, and engineered systems, has acquired ASL Roteq Ltd. of Brampton, ON. “This acquisition will create value for our customers through our increased pump repair, field service, preventative and predictive maintenance, pump training, installation and startup,” according to Gord Bell, president of John Brooks Company.

“Many of our customers are continually seeking larger profit margins and are driven to maximize return on their net assets,” he says. “As a result, they are often focused on maintaining, rebuilding and repairing equipment they already have on hand.

"With the acquisition of ASL Roteq, John Brooks significantly expands its resources of expert service technicians, millwrights and machinists that are available to serve our pump customers in the Ontario region.”

ASL Roteq was founded in 2003 by Jeff John-

son. It is focused on providing end-to-end pump repairs, service, training and helping customers solve their pumping requirements. Johnson has been involved with the Water Environment Association of Ontario for several years and currently chairs the Operator’s Challenge Committee and is the Pump Maintenance, Event Coordinator. He is also an MOE Director Approved trainer for his Understanding Pumping Systems training course.

ASL Roteq’s entire team, including Johnson, will be integrated into the John Brooks pump team, and, as a group, Bell looks forward to continuing to serve and support its valued customers.

John Brooks Company was founded in 1938 and is a distribution specialist for fluid handling companies.

John Brooks Company www.johnbrooks.ca ASL Roteq http://aslroteq.com/

Pittsburgh-based NOVA Chemicals Corp. has agreed to sell its expandable styrenics business to a subsidiary of Alpek S.A.B. de C.V. The parties expect to close the transaction in the fourth quarter. The sale of its expandable styrenics business is an important step in NOVA Chemicals’ plan to focus on its olefin and polyethylene business.

“This transaction provides us with immediate cash generation to further strengthen our balance sheet and focus on the safe and successful completion and start-up of our, world-class Advanced SCLAIRTECH technology facility under construction in (Corunna) Ontario,” stated Luis Sierra, president and CEO of NOVA Chemicals.

According to José de Jesús Valdez, Alpek’s CEO, “We look forward to welcoming our new team members.”

Chemicals www.novachem.com

Long time forensic engineering leader, Chris Giffin, B.A.Sc., P.Eng., is heading up the Canadian expansion of multi-disciplinary, large loss engineering firm Haag Global Inc. and the establishment of the Haag Canada headquarters in Toronto, ON.

As CEO of Haag Canada , the company says, Giffin will usher in a wealth of resources and unrivalled experience assembled throughout Haag’s 96-year legacy of handling complex losses in the most insured and

litigious markets in the world. The opening of its inaugural Canadian office marks the beginning of a determined effort by Haag to grow the firm internationally and service clients across the globe.

Giffin is joined by industry veterans Sasa Dzekic, M.Eng., P.Eng., Sr. Civil/Structural Engineer, Dr. Peter Ostrowski, M.Sc., M.Eng., Ph.D., P.Eng., Sr. Structural Engineer, and by Patrick Foisey, Sr. Building Envelop Expert & Appraiser.

“Haag has a trusted reputation built on the scientific rigour, precision, and clarity with which it services clients,” says Giffin.

“It’s clear that demand is strong across Canada for unbiased, multi-specialized experts in the growing complex and large loss forensic

engineering market. We’re here to answer this call and are confident Haag Canada will prove to be a vital resource for legal and insurance providers across the country.”

Haag Canada is said to accurately determine and clearly communicate cause, quantum and mitigation of loss to help clients make difficult decisions with confidence. Catering to the growing complexity of client needs in Canada the firm provides a national resource of core services, including: forensic engineering, loss remediation and mitigation, physical damage quantification and appraisal, and risk and project management.

Within this service offering, Haag Canada provides a broad offering of engineering expertise, including:

• Chemical

• Geotechnical & Mining

• Environmental/Health & Safety

• Industrial

• Civil / Structural

• Construction

• Natural Catastrophe

• Cranes & Aerial Lifts

• Heavy Equipment

• Infrastructure

• Mechanical

• Materials

• Electrical and Electronics

• Electric Power and Machinery

• Marine

Giffin has devoted his entire career to the forensic engineering field. After having founded and led one of Canada’s engineering consultancy firms for more than 16 years, it follows that Giffin was selected to lead the Canadian-based

operations of Haag, one of the world’s most respected firms, the company says.

Dzekic joins Haag Canada as a highly accomplished engineer. His contributions to over 1,000 forensic engineering cases speaks to a storied career between his early years in Europe, to his eventual relocation to Canada in 1995. His experience is working on issues relating to structural design and forensic engineering assessment.

Ostrowski offers particular expertise in structural engineering, nuclear systems, temporary structures in construction, piping support failures, welding and industrial accidents (notably cranes and lifting equipment).

Foisey joins as a senior inspection and prop-

erty insurance appraisal professional to provide support to the insurance industry in the wake of wildfires, tornados, ice storms, flooding and more. Regarded as a leading educator in the industry concerning issues around construction, inspections and pre/post-loss property appraisals, he brings 30-plus years of experience.

Haag Canada www.haagcanada.ca

Mississauga, ON-based Rittal Systems Ltd. has announced the winners of the Electro-Federation Canada (EFC) ‘Women in Tech’ Scholarship program cheques of $1,750 each to pursue their careers in the electrical and manufacturing industries. Melissa Montenegro, Mohawk College, and Itohansose Itua, University of Waterloo, were the recipients.

Rittal Systems

www.rittal.ca

Electro-Federation Canada www.electrofed.com

In February this year, EFC announced an annual scholarship program that provides university and college students, who are interested in pursuing a career in the electrical industry, with funding to support their academics.

Watch their videos: (Montenegro) www.cpec.news/pdf and (Itua) www.cpec.news/ksj.

Mississauga, ON-based systems integrator

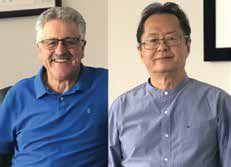

Summa Engineering has announced that it is celebrating its 40th anniversary this year.

Company leaders Frank Cosentino and Fernando Chua met in the late 1970s on a water treatment job site, working as a systems integrator and consultant respectively. Being self-described as “young and foolish,” the duo went on together to find something more challenging elsewhere. Cosentino, president, and Chua, director, now boast a successful company and a strong team of over 40 dedicated employees. By building on each other’s strengths, the pair have been able to overcome adversity, and build a strong reputation as trustworthy systems integrators.

The two are said to have no regrets either, as they are proud to know that their work has contributed to the infrastructure of Ontario and strengthened its automation of water and wastewater.

The company has a staff of professional engineers, programmers, field technical specialists and a CSA-certified panel shop. Summa Engineering www.summaeng.com

The American Water Works Association has presented Halton Region with the Directors Award, recognizing an outstanding commitment to high drinking water quality and treatment. Of the 250 water service providers and 400 treatment plants that belong to the international Partnership for Safe Water Program, the region is the first municipality in Canada to receive this prestigious award.

“Halton Region continually meets and exceeds (Ontario) Provincial drinking water standards and this achievement is a testament to our track record,” said Halton regional chair Gary Carr. Since Halton Region joined the Partnership in 2016, Regional staff have been using the processes and tools provided by the program to optimize plant performance and deliver high quality drinking water beyond regulatory requirements.

The Ministry of Natural Resources has announced that the Government of Canada approved the NOVA Gas Transmission Ltd. (NGTL) 2021 System Expansion Project with 35 conditions. The project is part of a natural gas gathering and transportation system that spans much of Alberta and parts of northeast British Columbia.

The $2.3-billion project is said to be significantly important in Alberta and for economies across the country. It will help power the successful restart and recovery of our economy by creating up to 2,920 jobs and contributing about $1.2 billion to Alberta’s GDP, the federal government says.

NGTL 2021 will give natural gas producers better access to markets for their products, it says, adding that the Project will also help facilitate the phase out of coal-fired electricity by 2030.

In making this decision, the Government of Canada has made amendments to the Canada Energy Regulator’s conditions for approval, related to caribou and Indigenous engagement. In particular, it strengthened five conditions proposed by the regulator and added one new condition in order to better address impacts to section 35 Indigenous rights and help mitigate the disruption

of the project’s construction on caribou habitat.

As part of these updated conditions, NGTL will now be required to restore 3,840 hectares of caribou habitat (30 times the size of the habitat impacted by the project) and seek to establish an Indigenous Working Group to assist with the planning for restoration and monitoring for the protection of the Little Smoky Caribou range. The government also approved a new accommodation measure to expand eligibility for the Terrestrial Cumulative Effects Initiative to monitor the cumulative impacts on the environment.

In total, the proponent must comply with 35 binding conditions related to safety, environmental and wildlife protection, Indigenous engagement, and protection or Indigenous rights and interest.

Reconciliation with Indigenous peoples remains a core priority for the Government of Canada. Over the past 17 months, Natural Resources Canada undertook extensive Crown consultations as part of fulfilling our duty to consult and, where appropriate, accommodate and mitigate potential impacts on the rights and interests of Indigenous communities.

Sean Kozicki, Western Canadian sales manager at Calgary-based Westech Industrial Ltd. has been introduced as the newest director of the Canadian Process Control Association (CPCA). Kozicki has been in the instrumentation and automation industry for over 25 years, starting his career as a technologist in an instrument and valve shop.

“I am really excited to join the CPCA board of directors,” states Kozicki. “Westech has been a long-time supporter of the CPCA, and we really see a lot of value in the association. It is my hope that I can continue to help with the current CPCA initiatives and help promote and grow the membership across Canada.”

Peter Dello, central region manager at ThermoKinetics of Mississauga, ON, is departing the association’s board after 13 years.

Meet the CPCA board at www.cpec.news/shm. CPCA https://cpca-assoc.com

Calgary-based Canadian Utilities subsidiary ATCO Gas and Pipelines Ltd. (ATCO) has entered into an agreement to acquire the Pioneer Pipeline from Tidewater Midstream & Infrastructure Ltd. and its partner TransAlta Corporation for a purchase price of $255 million. The 131-km natural gas pipeline runs from the Drayton Valley area to the Wabamun area west of Edmonton.

The transaction is subject to regulatory approvals, which are expected by the second quarter of 2021. The Pioneer Pipeline will be integrated into NGTL’s and ATCO’s Alberta integrated natural gas transmission systems to provide reliable natural gas supply to TransAlta power generating units.

Canadian Utilities www.canadianutilities.com

The Association of Consulting Engineering Companies – Canada (ACEC) based in Ottawa is has announced that Anthony Karakatsanis, P.Eng., president and CEO of the Morrison Hershfield Group has been named to the position of Chair of the ACEC board of directors for the 2020-2021 term. ACEC has also announced that Sylvia Jungkind, CIP, CRM of WSP Canada in Edmonton is the recipient of the 2020 ACEC Chair’s Award.

Morrison Hershfield of Toronto is an employee-owned professional services firm providing engineering and management consulting services and WSP Canada of Montreal is a Canadian business providing management and consultancy services to the built and natural environment.

ACEC represents companies in Canada that provide professional engineering services to both public and private sector clients.

ACEC www.acec.ca

Hatfield, PA-based Brooks Instrument, a specialist in advanced flow, pressure and vapour delivery solutions, has expanded its authorized service partner program with more locations so customers can access mass flow controller (MFC) calibration and repair services closer to their places of business. The company has added authorized service and support partners in the Raleigh, NC, area and in Ontario and Quebec.

Used in many applications ranging from biopharmaceutical production to oil and gas refining, all MFC instrumentation is subject to wear and tear from the operating environment, the company says. Because MFCs are typically a critical component in gas manage-

ment subsystems, Brooks Instrument recommends having these instruments certified annually by an authorized repair center that can provide calibration or repairs using proper metrology equipment, MFC software and service methods.

Unauthorized, third-party vendors may only provide verification service instead of true calibration, it adds. In addition to offering limited warranties, they may also use refurbished parts for their repairs instead of genuine Brooks Instrument components.

In Canada, the Brooks Instrument service locations are available in the Greater Toronto Area through the company’s independent authorized representative,Markham, ON-based Trillium

Measurement and Control, and in the Montreal metro area with independent authorized representative Polycontrols in Brossard, QC.

“We are excited to expand our service and repair partner programs in the U.S. and Canada,” said Stephanie Vinger, manager of Brooks Instrument’s service and repair business.

“When customers need calibration or repair work, we want to serve them as quickly as possible to keep their equipment and processes up and running. Adding these locations makes it easier for customers to get faster turnaround time, while also guaranteeing quality so their Brooks Instrument mass flow controllers and meters can be used for as long as possible.”

Customers who own Brooks Instrument MFCs in these markets can now have their out-of-warranty components serviced and repaired locally with authorized partners using new Brooks Instrument parts. These services include verification of thermal mass flow meters and controllers, ISO/IEC 17025 certified calibration, cleaning and reconditioning, repair and rebuilding. In addition, Brooks Instrument partners provide expert consultation and specifying help for retrofits, upgrades and new equipment for specific applications.

Brooks Instrument

www.brooksinstrument.com www.cpec.news/0vf Trillium Measurement & Control

www.caflow.com

Polycontrols www.polycontrols.com

By Michael Mohlenkamp

It is not always easy for fluid system operators to maximize the value from their systems. Common inefficiencies throughout a fluid system can make it difficult.

Managing those inefficiencies is increasingly challenging in today’s industrial environment. Processing facilities are seeing a growing skills gap as the most experienced employees are retiring. In addition, budget cuts designed to maximize profits are eliminating in-house technical staff positions that would normally identify and handle the aforementioned inefficiencies.

Specifically, maintenance and instrumentation technicians are becoming increasingly rare, even though their skills are more important than ever. Keeping critical applications throughout fluid systems in proper working order and good health is crucial even in a world of smaller in-house maintenance staffs.

So how do plants reckon with this troubling dichotomy? It may be possible to partner with outside providers to perform some common but critical fabrication and assembly functions. Doing so would reduce costs and allow fluid system operators to focus on maximizing the value of the end product. However, seeking external help is not a decision that can be taken lightly.

This article will examine what common, essential applications could be delegated to partners and why it might make sense to do so.

For any fluid system that produces precise chemical compositions, high-quality grab sampling practices are essential. Proper assemblies can help guarantee sample accuracy, which is critical to ensuring product quality. And since technicians take samples from ongoing processes, proper design and fabrication of the systems are necessary to ensure everyone’s safety.

Older fluid systems often feature basic grab sampling systems designed for regular sample retrievals. For example, the system might consist of a single valve connected to a process line with no additional safety measures in place. In addition to being unsafe, such an arrangement could also jeopardize the integrity of the sample, depending on the process

or application. Making sure these designs are up to date is critical to protecting employees and the integrity of the samples. Unfortunately, it is not always easy to get the necessary resources to update outdated grab sampling systems. It is possible today to purchase custom grab sampling systems with different arrangements that are specific to various application needs (Figure 1, right). To produce safe, accurate sampling systems, designers must take into account pressure, time delay, temperature, hazardous materials, construction materials, surface treatments, and purging. It can be helpful to rely on an outside team of experts to manage the fabrication and assembly of these essential systems, particularly for sampling system engineers who do not have the financial backing to design the systems themselves.

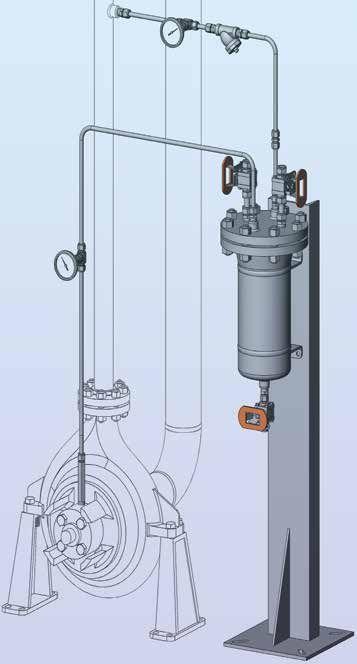

Pumps, compressors, and a variety of other rotating equipment require mechanical seals to function properly. As a result, it is important to make sure those seals are performing reliably through the use of seal support systems.

The reliability of seal support systems is a major consideration for operators, especially given that many systems are required to run 24 hours a day, seven days a week. As a result, these systems must be designed and constructed with the highest level of dependability, using only the most durable individual components (Figure 2, next page). Failure of seal support systems can lead to leaks, resulting in costly, unplanned downtime for the plant.

Despite the critical nature of seal support systems, monitoring the systems continuously or even ensuring they are serviced suitably is not always possible. An outside partner can help by proactively performing seal support system inspections and maintenance. When vetting such providers, the plant manager should consider the vendor’s supply chain reliability, proactive service and support, and the quality of the parts provided. Vendors who can meet all those criteria can provide consistent operational efficiency.

Finally, many industrial plants use gases that are distributed via glass bottles, bulk gas storage systems, or on-site generation. Yet, regular maintenance of these systems is often overlooked because plant managers have so many other diverse and critical responsibilities. As a result, plants often lose money because of unnoticed leaky systems, which can also create potentially serious safety risks, particularly if the gases are hazardous.

Continued on next page

It is as important to design gas systems with quality components and leak-tight designs as it is for any other critical application in the plant. It is also critical to engage in ongoing maintenance and inspection (Figure 3, below). That is why gas distribution assemblies are ideal systems to rely on a knowledgeable vendor to design, build, and support, especially if the plant is resource-strapped.

Today, in-house technical instrumentation resources are something most plant managers do not have available to them. As a result, many operators and engineers are focused on fixing problems after the fact instead of proactively maintaining systems, which otherwise mitigates issues arising and provides additional value to the facility and business.

That is where partnering with external vendors can help plant managers overcome resource constraints. It is vital to find vendors with the proper attributes that will improve operations. Plant managers should pay particular attention to engineering expertise, stringent testing, and the quality of the components the vendor uses. They should also seek vendors who will be proactive in providing design assistance and can work to customize solutions to solve specific problems.

Michael Mohlenkamp is the Director, Global Tech Centers for Swagelok Company. An original version of this article appeared on the Swagelok Reference Point blog here: www.cpec.news/n2k. Swagelok www.swagelok.com www.cpec.news/n2k

Advantech has announced the SPC-800 series of arm-mounted human-machine interfaces (HMI) with full IP66-rated protection that provides a cabinet-free solution for operation in challenging industrial environments. The series features an integrated support arm system mount adapter and a customizable extension unit to facilitate diverse visualization and control applications. The extension unit supports a wide range of additional peripherals and controls such as an RFID reader, key-operated selector switches, LED indicators, push buttons and emergency stop buttons. This allows the sys-

tem to be flexibly configured and the functionalities expanded for specific usage requirements, the company says. The integrated mount adapter supports both pendant and pedestal mounting to enable optimal positioning and ergonomic control. Available in a 15 in. (SPC-815) or 21 in. (SPC-821) form factor, the system’s 25-mm wide front bezel, lightweight, snap-fit design allows for single-person installation, ensuring easy deployment, it adds. Watch video demonstration at www.cpec.news/v6l.

Advantech www.advantech.com www.cpec.news/fzx

Stockwell Elastomerics now offers closed cell silicone sponge and silicone foam adhesive-backed gasket tape with DP-1001 polyimide film supported silicone adhesive backing in slit to width rolls. Three gasket tape products are initially offered with DP-1001 silicone adhesive: R10470M red/orange closed cell silicone sponge, BF-1000 white, low density silicone foam and HT-800 red, medium density silicone foam. The polyimide film layer is said to improve the shelf life of the silicone adhesive backing by preventing migration of the ad-

hesive into the silicone sponge or foam. The film also withstands a temperature range of -100° to 500°F. The silicone adhesive is a total of .005 in. thick and has an easy peel release liner to aid installation, the company says. The gasket tape products have been specified for long-term sealing of outdoor enclosures, industrial ovens and dryers, ventilating and airflow applications subject to temperature extremes.

Watch video at www.cpec.news/l8v.

Stockwell Elastomerics www.stockwell.com www.cpec.news/l8v

The Specialty Manufacturing Company manufactures suction strainers — also commonly referred to as sump strainers — that feature type 304 stainless steel mesh sizes from 4 to 100 with a 1/8 to 3 in. Nylon NPT base. The strainers are rated for continuous use up to 200°F, and custom mesh sizes are available. CAD models and product drawings for the complete offering are available. The suction strainers are most commonly used in hydraulic applications but can protect pumps from damage by the ingress of foreign debris in any application involving air or liquid media, the company says. Suction strainers are available from order in 2

weeks with many popular sizes shipping the very next day, it adds.

Specialty Manufacturing Company

www.specialtymfg.com www.cpec.news/rxa

Swagelok has announced FK series two-ferrule tube fittings for medium- and high-pressure fluid system applications. By switching from traditional cone and thread fittings to these, the company says, assemblers are able to complete fitting installations approximately five times faster, while virtually eliminating rework needed during hydrotesting and acceptance test steps. In service, the series of two-ferrule tube fittings is said to help to improve system reliability and reduce overall maintenance needs. These efficiencies deliver significant savings and a reduced total cost of ownership, the company adds. Swagelok Company

www.swagelok.com

www.cpec.news/5ru

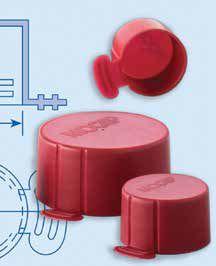

The MOCAP line of tear-tab plastic caps are designed to fit over threaded tubing and rods and are suitable for a wide variety of applications. Among the common uses for these caps are as shipping caps, end caps, pipe caps, product protectors, or thread protectors. A key benefit that the tear-tab plastic caps offer is said to be their innovative lock function. Each cap has inner rings that lock it onto threads securely, and after the application is complete, the user merely pulls an easy-grip tear tab to break the seal, the company says. All of the caps are made from low-density polyethylene. Units available in the following four models: TSC series for straight threads in 14 sizes and constructed to fit from 3/8-24 to 1-7/16-12 in.; TCM series for metric threads in six sizes that go from M12 to M22; TCBSP series for BSP threads in seven sizes from ¼-19 to 1-11; and, TCNPT series for NPT threads available in 11 sizes from 1/8 to 3 in.

MOCAP

www.mocap.com

The Omron compact and easy-to-use V410-H general-purpose, handheld code reader is said to boast the highest-resolution sensor in its class and works well for a broad range of industrial, life sciences and healthcare applications to provide traceability. With X-Mode algorithms along with an intuitive WebLink PC utility and runtime that provides image storage, statistics, reader discovery, troubleshooting and extensive tool tips, the handheld device is also said to maximize barcode reading productivity and provides im-

portant operational insight. Key features and benefits include: reliably reads challenging and ultra-compact codes; supports operator comfort while meeting latest hygiene requirements; provides a clear and intuitive way to configure and manage settings, including data formatting, OCR and barcode image capture; and, employs standard USB or serial connection to PCs and PLCs along with optional serial-to-Ethernet adaptor.

Omron Automation Americas https://automation.omron.com www.cpec.news/337

The ITC-XXX-XX-DC is a signal isolator with dual outputs providing high isolation from Input to Output1, to Output2, and to Power in a small easy to install package. It’s universal DIN rail mount makes it possible to install right next to the instrument that is to be isolated. The many different input and output configurations allow it to be used in a great variety of applications ranging from PLC front end conditioning to adding an extra loop with lots of drive to an existing, almost fully loaded loop. Contact us for

Freshway Dr., Unit 57, Concord, Ont., L4K 1R9

(905) 660-5336 Fax: (905) 660-4068

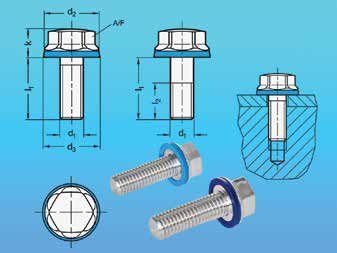

GN 1581 hexagon head screws with low-profile head from JW Winco are suitable for use in hygienic areas and expand the company’s hygienic design product family. The sealed mounting surface creates a tight seal, which prevents the accumulation of dirt and facilitates cleaning. Made from AISI 316 material, the screws are available with a matte or a polished finish and, depending on the application, users can choose between two different FDA compliant sealing materials. The sealed mounting surface enables fastening without dead spaces. The high quality finish as well as the large corner radii and closed surfaces prevent adherence of dirt and facilitate cleaning, the company says.

JW Winco Canada www.jwwinco.ca

www.cpec.news/esp

Igus has introduced the E4Q energy chain, a flexible cable carrier system, which is said to offer a smooth, contoured design and a completely new crossbar concept with weight-reducing locking straps. The new design ensures that the e-chain can be opened and closed in seconds without tools. The energy chain has been specifically developed for the special requirements of unsupported lengths. High unsupported lengths and long travels with large fill weight create extreme stress on energy chains, the company says.

Company developers have designed its latest e-chain intended for such application scenarios, as well as providing a long service life and a high degree of modularity. To provide additional noise reduction, igus has integrated an optional system in the inner horizontal stop-dog whereby two connected balls dampen the impact during the radius and extension stop. Watch video demonstration at www.cpec.news/03u. igus Inc. www.igus.ca www.cpec.news/ew2

The new Allen-Bradley Compact GuardLogix 5380 SIL 3 from Rockwell Automation allows engineers to scale applications up to and including SIL 3/PLe performance with 1oo2 architecture. The controllers are designed to help companies build smarter, simpler, and better-performing machines. The SIL 3 controllers are an addition to the company’s GuardLogix 5380 series. The devices can achieve up to SIL 2/PLd with 1oo1 architecture or up to SIL 3/PLe with 1oo2 architecture and offer standard memory options from 0.6 to 10 MB and safety memory options from 0.3 to 5 MB. In terms of connectivity, the SIL 3 controllers have a gigabit embedded Ethernet port that enables CIP safety connections, I/O, and safety devices. All standard and safety controllers use the Studio 5000 Logix Designer application, to allow users to work collaboratively to design and maintain their systems. Rockwell Automation Canada www.rockwellautomation.com

www.cpec.news/kdb

NON-CONTACT IO-LINK

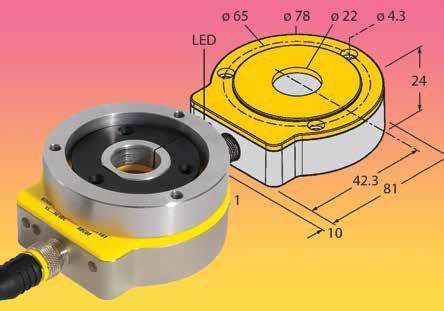

Turck Canada has introduced the QR24 non-contact encoder for use in explosion-proof areas (Zones 2, 22 or 3GD). The sensing unit and positioning unit are designed as two independent, fully encapsulated parts. As a result, the QR24 is protected against dust, vibration, shock and impact. With certifications for hazardous areas, it is suitable for use in the chemical, mining and food processing industries. IO-Link can be used to easily set parameters and other functions, the company says. The encoder can be used as a single-turn and semi-multiturn encoder. Also available is a stainless steel EQF24 variant for use in the food industry as well as in many other applications. With the V4A stainless steel housing (1.4404) and the active surface made of PA12-GF30 plastic, the device withstands even aggressive chemicals and high pressures in the cleaning process. The EQF24 is available with incremental output and SSI interface.

Turck Canada

www.turck.ca

Bionomic Industries, a manufacturer of air pollution abatement, product and heat recovery technologies, has announced NOx control chemistry for a wide range of scrubber system operations and applications. Unlike typical NOx sulfide/caustic control chemistry, the company says, low toxicity BIONOxSOLVER will not liberate flammable and dangerous hydrogen sulfide gas at pH use conditions and its special proprietary formulation of powerful nitrogen dioxide reducing agents can achieve over 33% greater removal efficiency with a simple addition to caustic. Typical applications include removal of nitrogen dioxide emissions from catalyst calcining and preparation, precious metals dissolving, acid dipping and pickling of metals, silicon wafer and circuit board etching, nitrite and nitrate chemical production, medicinal production, nitric acid storage and purging, and nitrogen dioxide removal.

Bionomic Industries

www.bionomicind.com www.cpec.news/mf1

www.cpec.news/jfe

The Conveyor Components Company model TPS — Tripper Position Switch — is designed to indicate when the tripper of a shuttle conveyor is located on a multiple discharge point and will “trip” or activate the dumper when signaled. The unit is commonly used in the coal and metal and non-metal mining industries. The device has two SPDT micro switches rated for 20 A at 120 Vac, 240 Vac, or 480 Vac. The switch actuation is bi-directional, and the roller orientation is field adjustable with a simple hex bolt adjustment. The white acetyl roller is bi-directional and is 3 in. diameter by 1-5/8” wide. The housing is a cast aluminum enclosure rated for NEMA 4 weatherproof, or NEMA 7/9 explosion proof. Black epoxy powder coating is optional.

Conveyor Components Company www.conveyorcomponents.com www.cpec.news/9j6

ery 18 t. It closes Sept. 11. Stay safe everyone.

Cheers, Rob Sommerville

The Fisher V280 three-piece, trunnion mounted, fullbore control valve from Emerson is capable of handling full CL900 pressure drops. It is designed with features for optimized pressure, flow and process control. An optional drilled attenuator controls noise and vibration from high pressure drop liquids and gases. Specifications include: an ASME pressure class; CRN, CUTR, NACE, PED certifications; NPS 6, NPS 8, NPS 10, NPS 12, NPS 16 valve sizes; flanged end connection; operating temperature from <-40°F to >250°F; and, Class IV (FCI 70-2), Class VI (FCI 70-2) shutoff. Aerodynamic performance up to -20 dBA acoustical attenuation can be in a single stage construction and dual-stage construction can provide up to -25 dBA attenuation.

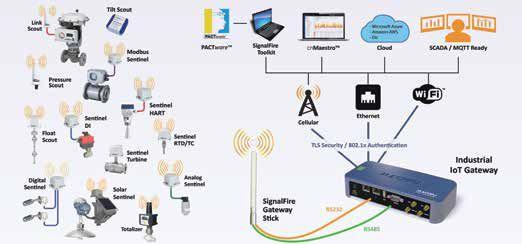

SignalFire Wireless Telemetry, a manufacturer of industrial wireless telemetry products, and Machfu, an industrial IoT specialist, have announced the integration of SignalFire’s wireless sensor network with Machfu’s Industrial IoT Gateway. The Machfu IIoT Gateway incorporates edge intelligence, multi-protocol translation capabilities, and multi-dimensional security features, resulting in a versatile and secure sensor-to-cloud solution, the company says. Operating the SignalFire Edge Application on

Verotec manufactures three different rack case designs, available in different sizes and with several options. The heavy-duty RackCase PRO is EMC screened as standard, making it suitable for housing heavy equipment in electrically noisy environments. It is a 3U high unit, available in standard depths of 240, 350 and 460 mm, with custom depths available to special order. The Veroshield EMC rack case can be used to reduce cost in larger 19 in. rack-mounted systems where only some elements of the overall equipment require elevated levels of EMC capability. These units are available

Machfu’s Edge Gateway, users are said to easily and wirelessly bring all sensor measurements from a SignalFire sensor network into their cloud application. With a single click, the IIoT Gateway automatically communicates with the SignalFire Gateway to discover wireless nodes in a network, collect measurements from sensors, and transmit them over cellular, Wifi or Ethernet connections.

SignalFire Wireless Telemetry www.signal-fire.com www.cpec.news/w1j

as standard in three sizes: 1U high and 265 mm deep, 2U and 3U high and 365 mm deep Typical attenuation figures are in excess of 110 dB up to 10 MHz, falling linearly to 40 dB at 1 GHz. Standard general-purpose rack cases are also available in heights of 1 U to 6U and depths of 250, 350 and 450 mm. Users can specify either vented or unvented top and base covers, a 3 mm clear anodized or 2 mm black painted steel front panel and optional grey or black front handles. Verotec

www.verotec.us

www.cpec.news/t02

Carlo Gavazzi has launched capacitive proximity sensors with Integrated IO-Link communications. The new sensors are housed in AISI316L stainless steel housings or PTFE Teflon housings for high chemical resistance. Based on the company’s 4th generation Tripleshield sensors, the CA18.. and the CA30.. series sensors are suitable for industrial automation equipment in applications where the sensing performance needs to be constantly and accurately monitored and logged. The IO-Link mode enables functionalities such as: QoR (Quality of Run), QoT (Quality of Teach) and diagnostic parameters.

Carlo Gavazzi

www.gavazzionline.com

www.cpec.news/1da

Beckhoff has introduced XPlanar, a system for flying motion control in which planar movers float freely above planar tiles arranged in customizable layouts.

The system is said to enable flexible, precise and highly dynamic positioning. It combines the individual arrangement of planar tiles with multi-dimensional positioning capability of the planar movers floating above them. The movers en-

able jerk-free and contact-free motion in two dimensions at up to 4 m/s with 2 g acceleration and 50 μm positioning repeatability — completing movements without any noise or abrasion. The system can be used to automate packaging, assembly, sorting and order picking processes. A free choice of mover surfaces – easy-to-clean glass, stainless steel in hygienic design or plastic film — makes the motion technology particularly well-suited to many industries, including food, pharmaceuticals and laboratory automation, the company says. Watch video demonstration at www.cpec.news/tui.

Beckhoff Canada

www.beckhoff.ca

www.cpec.news/tui

Metso Outotec has introduced a Filter Optimizer to further boost the performance of its Larox PF filter in the mining and chemical industry processes. The optimizer improves the PF filter performance by enabling more precise control over the solid/ liquid separation process. The optimizer stabilizes the effect of upstream process variations, provides tools for improved process control and reduces the need for manual intervention. In mining processes, the new product complements the company’s other advanced control solutions for concentrator plants consisting of the Grinding Optimizer, Flotation Optimizer and Thickener Optimizer. The Filter Optimizer enables automatic adjustment of filtration as well as pressing and air drying setpoints based on filter performance. Compressed air usage is optimized in the controlled air-drying sequence, resulting in optimized energy consumption, the company says.

Metso Outotec www.mogroup.com

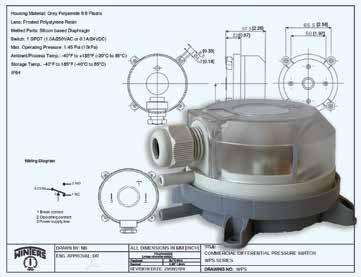

Winters Instruments has announced the WPS series low-pressure differential switch for monitoring and controlling air and non-aggressive gases. Designed to handle pressure, vacuum, and differential pressures, the switches are suitable for HVAC applications and simple to integrate into BAS systems, the company says. The adjustment knob allows for field changes to be made without the use of a reference pressure gauge. The silicone diaphragm is able to sense pressure as low as 0.08 in. of water (16 Pa) up to 20 in. of water (4,000 Pa).

www.cpec.news/065

Denso ColorTape is composed of a non-woven synthetic fabric carrier, fully impregnated with a stable pigmented petrolatum compound for long term corrosion protection to wet or dry pipes, flanges, valves and related surfaces. It is specially stabilized and pigmented for use above ground where appearance is important, or underground. The tape is designed to withstand temperatures up to 60°C, is UV resistant, meets NACE RP0375-2006 and does not require a primer.

Denso North America www.densona.com www.cpec.news/xhm

www.cpec.news/ns7

The Multiturn Counter Module from Posital is a zero-maintenance rotation counter designed to be integrated into motors or other types of rotating machinery to provide their control systems with a reliable count of the number of rotations the machine has completed. The modules can be used in many situations where rotation counts are needed, including positioning tasks in machine tools, robots, packaging machinery and medical equipment. A special feature of the multiturn counter module is a Wiegand wire-based energy harvesting system that powers the counter and memory circuits, completely eliminating any need to check, replace and dispose of backup batteries, the company says. Output from the Wiegand system is nearly speed-independent, so that the counter module will reliably record rotations for speeds ranging from near-zero to 12,000 rpm. The measurement range is 43 bits, or almost 9 trillion net turns. The multiturn counter module is mounted on a 35 mm PCB, designed to fit easily into the housing of the host machine. Watch installation video at www.cpec.news/bgp. Electromate www.electromate.com

• Manual, automatic and actuated (pneumatic & electric) valves; relief, check, diaphragm, ball, solenoid, and shut-off. Also pressure regulators, metering pumps, basket strainers, sight glasses, and gauge guards.

• Innovative Engineering –Dedicated Craftsmanship.

• 100% inspection and individual testing of each product, to ensure dependable performance and long-life.

• PVC, CPVC, Polypropylene, PTFE and PVDF. Valves

The XTHP hydraulic hand pump from Ralston Instruments is a pump that generates up to 10,000 psi (70MPa). The liquid reservoir is made from molded polysulfone, which makes it resistant to high temperature fluctuations, shock and hazardous chemicals and less likely to crack over the life span of the pump. The body of the pump is made from machined stainless steel to eliminate porosity issues. The unit was designed with a pressurized section much lighter than comparable pumps and positioned below the res-

ervoir giving it a low centre of gravity. The pump is designed with all Viton seals but is available for purchase with EPDM seals, making it Skydrol compatible. The cast aluminum handles are said to offer better grip and are more durable than plastic. Included with the pump is a high volume primer to quickly remove air from the valve and fill a test hose with only a few strokes of the priming piston. Watch video demonstration at www.cpec.news/euw. Ralston Instruments www.ralstoninst.com www.cpec.news/4t9

Lenox Instrument Company has introduced a new FireSight explosion-proof camera system said to provide real time, high-resolution, colour video monitoring and digital recording capabilities of the inside of hazardous area process/fired heaters found in gas plants, oil

www.cpecn.com

refineries and petrochemical plants. By viewing directly inside the furnace, operators can optimize fuel/air ratios by safely monitoring 24/7, burner performance and identifying potential problems such as such as burner lightoff failure, flame lift-off, flame impingement on tubes, tube displacement, tube leaks, irregular flame patterns, smoky flames, and flame instability. A specially designed corrosion resistant and weatherproof camera enclosure can contain an explosion from the inside of the enclosure and preventing sparks within the enclosure from igniting vapors and gases in the environment surrounding it. The Ex-Proof cameras are approved for Class I, Division 2, Groups A, B, C, D, T4 and equivalent ATEX and IECEx ratings. The air-cooled camera systems operate in temperatures up to 1,649°C and are available with a 24- or 36-in. long air-cooled lens assembly, in either direct or right-angle view configuration, and a choice of analog or Ethernet/IP camera output.

Lenox Instrument Company www.lenoxinst.com

www.cpec.news/mug

Bonomi North America has announced CSA approval on the company’s Valbia electric actuators, models VB030(M) and above. The electric actuators are built with water-tight cast aluminum or techno-polymer enclosures that can be used indoors or outdoors. Units feature steel and techno-polymer gears with hardened steel pinions for long life and quiet operation. Included are VBM model with NEMA 4 die-cast aluminum housing, raised position indicator, two extra limit switches, a heater and thermostat, ½ in. conduit connections and a 75% duty cycle motor. The VB electric actuator has a NEMA 4, 4X techno-polymer housing, two extra limit switches, a heater and thermostat, torque limiter and a 75% duty cycle motor. All models are dual voltage. A manual override is also standard.

Bonomi North America

www.bonominorthamerica.com www.cpec.news/u63

The PTC series portable temperature calibrator from Ametek is now compatible with JofraCloud, the company’s cloud-based solution for remote reading and setpoint entry. The unit is said to match lab features like, a wide temperature range, high accuracy, stability, and speed with our well-known, long lasting quality into a single industrial calibrator. Three temperature calibrator models are available, from the basic unit to a full model including signal inputs and external reference sensor. The series features an active dual zone temperature control which provides excellent temperature homogeneity in the well, the company adds. Temperature range from -90° to 660°C with 5 models, accuracy is to ± 0.06°C and stability to ± 0.01°C. JofraCal calibration software and inputs for thermocouple calibration are included. Watch video how a PTC and JofraCloud work together www.cpec.news/1wi. Ametek www.ametekcalibration.com www.cpec.news/ioi

The DustAlarm ES and DustTrend ES, a series of broken bag detectors and dust emission trend monitoring systems from Monitor Technologies, are now available with hazardous location approv-

als. In addition, the systems have intrinsically safe probes for ultimate hazardous location protection. The monitors are said to provide excellent repeatability that is not affected by variations in relative humidity, process temperature or pressure. They use proven AC Triboelectric technology with advanced algorithms to filter out noise and provide the most accurate dust measurement. The monitors have an easy auto set-up function that is activated by pressing a button to automatically configure parameters/alarms. The systems contain externally viewable bi-colour LED indication on ordinary location units. The units are suitable for monitoring the level of dust emission in applications such as dust collection system exhausts. The monitors can be connected with the company’s free DustConfig software to set custom alarm points, view live activity within the duct, or review data history for up to a 24-hour period.

Monitor Technologies www.monitortech.com www.cpec.news/ax1

SPRING-LOADED LVDTS SERVE AS SURFACE MEASUREMENT TOOLS

Spring-Loaded LVDTs from NewTek Sensor Solutions feature a stainless-steel probe assembly and hermetically-sealed construction that enables operations in harsh industrial conditions such as exposure to water, sawdust, flying chunks of wood and other debris. The gage heads have an operating temperature range -65° to 185°F with linearity of ±0.15% of full range. The LVDT gage heads provide highly reliable output for over one million cycles with near-zero drift, the company says. Available in measurement ranges of ± 0.04 to ± 2 in., units are available in a variety of custom options including right-angle connectors, temperature ranges up to 400°F, mild radiation resistance to 30 MRad and pneumatic probes. The LVDTs are offered with AC, DC voltage, or 4-20 mA current outputs. View demonstration at www.cpec.news/d36. NewTek Sensor Solutions www.newteksensors.com www.cpec.news/8ro

The ATC 365C Long-Ranger Computing Timer from the Automatic Timing Controls division of Marsh Bellofram is adjustable from one-hundredth of a second up to 999 hours. The microprocessor-based digital timer has three rotary knobs for setting and adjustment of the preset. Its plug-in panel mounting is said to allow for easy installation and replacement without the removal of field wiring for minimal downtime. The units is suited for a wide range of industries that rely on process controls to run smoothly and efficiently, including power gen, petrochemical, manufacturing, automotive, pulp and paper, and steel. The decimal and range of the timer are switch selectable and two heavy-duty 7A DPDT relays provide instant, interval, or delayed output control. Full gasketing and O-ring seal keeps the unit dust tight.

Marsh Bellofram

www.marshbellofram.com www.cpec.news/o42

PYROMETER SERIES PROVIDES MEASUREMENTS TO 3000°C

Process Sensors, the IR Temperature Division of KPM Analytics, has introduced the one- and two-colour pyrometer series PSC-55N. Designed for use by the steel and metals, ceramic and furnace industries, the units are suitable for precise temperature measurements from 200° to 3000°C. The sensors operate in the shortwave spectral range with an adjustable response time of 5 ms to reduce or compensate for changes in target or surface emissivity. Three sighting methods for precision aiming are available: through-lens sighting, an integrated red laser aiming light or colour video. The video version is recommended for remote real-time viewing via a video monitor in a control room or laboratory.

Process Sensors

www.processsensorsir.com

www.cpec.news/gow

Thompson Pump has introduced the model 6RW-DIS-4LE2T-X 6 in. rotary wellpoint pump. With unassisted priming and automatic re-priming, the pump features high air handling and large water volume capabilities – up to 1,400 gpm and heads up to 80 ft; operating speeds up to 2,000 rpm; and a low hp engine for better fuel efficiency – an EPA Final Tier 4 Isuzu engine (model 4LE2T), with diesel oxidation catalyst (DOC) after treatment. The pump is designed for wellpoint and sock dewatering applications and can be used in place of a comparable 6 in. vacuum or piston pump, making it a cost-effective dewatering option, company says. Thompson Pump www.thompsonpump.com www.cpec.news/7xe

Sterling Systems & Controls has announced it has custom engineered and manufactured automatic batching system for the ingredient batching of the rubber compounding process. A hybrid ingredient bulk material batching system combines minor bin and bulk bag ingredient batching providing automatic batching for a rubber manufacturing compound. The automatic batching system is said to successfully replace the unproductive, slower and labour intensive manual batching process with a more profitable, efficient, fast and accurate automated system. The minor ingredient batching system is customizable and can be configured with virtually any number of bins and/or bulk bag stations. Custom batching control software provides storage of formulas and ingredients, lot tracking and traceability and batch validation.

The P series of quarter-turn industrial actuators from ProMation Engineering now include CSA and ATEX certified explosion proof and ignition proof actuators. Certifications include: Class I, Division 1, Groups C, D; Class II, Division 1, Groups E, F, G; Class III; T6 (85°C); Ex d IIB Gb T6; Ex tb IIIC T85°C Db; Class I, Zone 1, AEx d IIB Gb T6; Zone 21, AEx tb IIIC T85°C Db. The hazardous location electric actuators are designed for use in oil and gas, mining, food processing, chemicals and power applications, and control butterfly valves, ball valves, high performance valves, plug valves, gate valves and dampers. Control options are Premium Proportional or On/Off and products can be configured for specifications such as rotation from 0° to 180° of rotation for ball valves or custom proportional spans for dampers.

ProMation Engineering www.promationei.com

“excellent use of my time and my company’s time”

Plant Manager, REFINERY

We’re bringing world class experts to your neighbourhood for one day only at our Process & Automation Shows

• Face to face access to national and local experts in their field

• Try out products right at the show

• Save time and visit as many companies as you like in one day

• Compare technologies and pricing from leading companies