SureFrame T-slotted aluminum rails are available in the most popular profiles and dimensions. T-slotted rails are ordered in your custom cut-to-length sections for maximum flexibility and minimum waste.

We also offer a full selection of assembly hardware for T-slotted rail systems, which includes T-nuts, fasteners, connecting components, joining plates and brackets, as well as floor, door and panel elements. SureFrame T-slotted rails, along with the assembly hardware components offered, are compatible with many other brands.

Also Available

• AC variable frequency drives (VFDs)

• Motors

• Wiring and electrical connection solutions

• Just about everything you need to complete your automation projects!

NO CUT FEES, EVER! CUT TO YOUR SPECIFICATION AND DELIVERED TO YOU IN 2-DAYS!

• You specify length and cut angles for each piece

• No cut fees

• Free 2-day delivery on all orders over $49*

• Available in 1 inch, 1.5 inch, 30mm, 40mm and 45mm profiles

• Complete selection of Fath installation hardware available tures

Research, price, buy at: www.automationdirect.com/t-slotted-rails

Our shipping policies make it easier than ever to order direct from the U.S.!

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days.

*Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

prices shown are U.S. Dollars

The Kobold MIK magmeter measures the flow of conductive liquids in applications where reliability and low-pressure loss of a magmeter are desired at an economical price compared to higher end models. The electromagnetic flow meter measures flow using the mag neto-inductive principle. The flow meter body contains a set of electromagnetic coils that generate the magnetic field. Electrodes mounted in the flowmeter body collect the current, whose magnitude is proportional to flow rate. The unit is all solid state and has no moving parts to wear, while moderately viscous and dirty liquids are measured with minimal accuracy degradation. A variety of materials for the flow body, electrodes, and seals are available. A variety of fitting styles and materials are also available, including PVC, PVDF, polypropylene and stainless steel. A wide variety of electronics packages are also available, including frequency or current out puts, adjustable flow switches and integrated totalizers or batch controllers.

Kobold Canada

www.kobold.ca

Stock Canada offers a wide range of reliable and compact semi-automatic or automatic packaging machines, made entirely of stainless steel, and are said to be designed to meet any kind of product need in terms of productivity, safety, and processing quality. The machines employ a modified atmosphere to respect and protect pasta-based products and extend their shelf-life. Modified Atmosphere food processors to best preserve their highly perishable product by eliminating oxygen. With purpose built tray

sealers and thermoformers, processors can pack fresh pasta or any other type of perishable product inside either a pre-formed or a thermoformed tray that will suit the product.

Stock Canada

www.stockcanada.ca

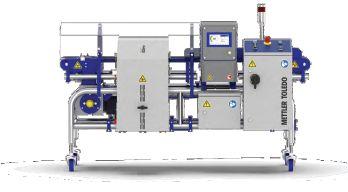

The Safeline M30 R-Series metal detection systems from Mettler Toledo are said to make it easier to achieve cost-effective compliance now and in the future. The foundation of the series is the SENSE metal detection software that improves the capability to detect smaller contaminants. It supports greater process quality by centrally coordinating every element of the metal detection system, the company says, orchestrating the integration of the metal detector, sensors and reject mechanism to work in harmony. The application combines with advanced software algorithms to make split-second judgment calls on contamination, and significantly reduce false reject rates.

Mettler Toledo

www.mt.com

With all the splashy news about battery production investments and electric vehicle-related materials being mined, traditional fossil fuels are still quietly keeping Canada motoring along.

The Canadian Association of Petroleum Producers (CAPP) is forecasting oil and natural gas investment in upstream production will hit $40.0 billion in 2023, surpassing pre-Covid investment levels. That represents $4.0 billion, or 11 per cent, more in additional spending across Canada’s economy than the prior year, the association notes.

kets shows Canada’s upstream oil and natural gas industry is the largest investor in environmental protection, spending over $3.0 billion annually in areas such as biodiversity habitat protection, air quality and water protection. Luckily, it reports that additional spending is also expected to go towards environmental protection and emission reduction technologies such as the development of carbon capture utilization and storage (CCUS).

A report issued by BMO Capital Markets arMike Edwards medwards@cpecn.com

We understand how important it is to find the right expertise for your industry application needs.

You are assured to get the best-fit products, solutions and services for your specific requirements.

READER SERVICE

Print and digital subscription inquiries or changes, please contact Angelita Potal Customer Service

Tel: 416-510-5113

Fax: (416) 510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

AUDIENCE MANAGER, Anita Madden 416.510.5183 amadden@annexbusinessmedia.com

PUBLISHER, Rob Sommerville 905.770.8077 rsommerville@cpecn.com

EDITOR, Mike Edwards 416.510.5229 medwards@cpecn.com

ACCOUNT COORDINATOR, Barb Vowles 416.510.5103 bvowles@annexbusinessmedia.com

GROUP PUBLISHER/VP SALES, Martin McAnulty mmcanulty@annexbusinessmedia.com

President/COO, Scott Jamieson sjamieson@annexbusinessmedia.com

Founder, Peter Birchard

Founder, Ray Blair

CPE&CN is published bi-monthly by: Annex Buiness Media

111 Gordon Baker Rd, Suite 400, Toronto, ON M2H 3R1

T: 416-442-5600 F: 416-442-2230

© All materials in this publication are copyright protected and the property of Annex Business Media., the publishers of Canadian Process Equipment & Control News magazine.

For permission on reprinting or reproducing any materials, e-mail your requests to cpe@cpecn.com

Canadian Postmaster send address corrections to: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Canadian Process Equipment & Control News assumes no responsibility for the validity of claims in items reported.

150.000 customer queries per year, treated and solved globally by Endress+Hauser technical support organization

Do you want to learn more? www.eh.digital/3STNrqh

With Smart Support, Endress+Hauser delivers the expertise you need remotely to resolve and prevent technical issues on your measurement instruments.

• Shorten unexpected downtimes

• Decrease the effort on maintenance staff

• Save costs of field service visits and device returns

• Increase expertise on instrumentation and application

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2384

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 0318-0859

SUBSCRIPTION

Vaisala Polaris PR53AC sanitary compact process refractometer available from Everest Automation measures Brix and other liquid concentrations. The process refractometer is said to provide reliable, modern, and modular product platform that is safe to use in food and beverage manufacturing, has 3-A Sanitary and EHEDG certifications and meets all hygienic demands. The product works in process conditions from stable to demanding, in high process temperatures, and in sticky processes. It is also compatible with clean-in-place (CIP) and sanitation-in-place (SIP) systems. Connectivity options include mA, HART, and Modbus RTU as a standard. The measurement range for concentration/Brix is 0-100 %. The measurement is based on optical measurement of the refractive index (RI). The RI can be measured from practically any liquid or slurry, and it is sensitive to dissolved material. Particles, bubbles, or colour do not affect the measurement, the company says. Everest Automation

www.everestautomation.com

AutomationDirect has added advanced panel meters and a universal power meter to its Trumeter ADM series of graphical panel meters. These easy-to-read panel meters display critical parameters, provide a user-programmable scale and custom alarm messages which will immediately alert operators when a parameter is out of range. The ADM200 advanced graphical panel meters feature a 4-in. display with a colour-changing, full-colour RGB backlight for instant alerts. Select models offer digital and analog outputs, Modbus RTU/TCP communication, and an IP65 protection rating. Available models include multi-function

meters to measure amps, voltage, frequency, or power for high voltage applications; all-in-one process meters can be configured as a process signal meter or can be used in conjunction with a shunt for low voltage applications. The ADM100 is a universal power meter that features a 3-in. backlit display, 4 alarm setpoints, and offers Modbus RTU communication via RS-485.

AutomationDirect

www.automationdirect.com

Atomizing spray nozzles from Exair create a fine

liquid mist suitable for washing, coating, cooling, and dust control. The nozzles offer an assortment of flow rates and patterns including flat fan, round and hollow cone patterns and are said to be highly effective with a wide range of liquids. Exair

www.exair.co/20-lanvid

Realize your vision with Festo’s approach to smart automation. Partner with Festo today.

By Luis Duran, ABB

Attention is increasingly being focused on the metamorphosis of Distributed Control Systems (DCS) into the automation systems of tomorrow as plant owners accelerate the adoption of Industry 4.0 and embark on their digital transformation journeys. This article looks at some of the initiatives facilitating the development of systems with openness, security, and interoperability at their heart.

Although Distributed Control Systems (DCSs) were originally based on purpose built Operational Technology (OT), they have since evolved and adopted commercial off-the-shelf technology (COTS). The result is more flexibility and options available to users as well as Information Technology (IT) to link up previously isolated islands of control.

This profound evolution has seen DCSs add more functions and offer more benefits over the 40 years since their launch, yet current users are demanding even more — they want their DCSs to become ever more open, expandable, and flexible.

Whereas the traditional DCS market was largely based on hardware with hard coded functionality baked into its design, today’s DCSs largely rely on all software. Shifting knowledge from hardware to software, enables the DCS to become much more agile. This offers the opportunity to introduce plug and play components and shifts the industry away from proprietary solutions that tie users to a single manufacturer.

Developments in the Internet and enhanced connectivity have highlighted deficiencies in DCSs, most notable among these being their lack of robust cybersecurity. Over the last decade, many industries have come to see this as a critical issue, one which is increasingly driving changes in

the way the DCS handles information and indeed how it works.

Another factor is the way that some major industries use DCSs, which can differ greatly. An example could be a pharmaceutical company experimenting on ways of producing a new drug. It knows it will need to scale up to mass produce the new product and will need different ways to reconfigure equipment to achieve this scale up. For maximum flexibility, elements will require a high degree of modularity.

This modular approach to production, which allows reconfiguration at will, requires a DCS that can control changing processes without affecting core functions such as control, safety, history logs and alarms.

Modularity also offers the chance to achieve a more cost-effective deployment. Although an end-user company may have planned a DCS as a large capital investment project, it may nevertheless want to begin with a lower level of production to keep initial costs to a minimum. Copying infrastructure and using it for other applications would allow a more cost-effective scale up of production. It also allows the user to manage capital costs and optimize its investment strategies.

As the Industrial Internet of Things or IIoT has developed, users have seen the need to get more value from their information. There is a lot of data generated from sensor readings and production machinery, most of which is today largely trapped within the DCS. This information needs to be processed and made available to specific users. Many of these will not be regular users of the DCS and will in fact be from the latest generation of engineers who have grown up with today’s immersive digital technologies. As such, they expect to connect with professional tools such as a DCS in ways more like the tablets and smartphone devices they interact with in everyday life. Similarly, some information doesn’t need to be in the DCS and could instead be made available in different ways. Today’s DCS requires a different, more digitalized, more open infrastructure, driven by the rise of new technologies such as wireless and 5G and smart digital devices such as sensors and motors. Restructuring the DCS will also help users add new technology to their system without disrupting the existing set up.

Open communications allow more interoperability, ensuring a more cost-effective integration of system components. It also allows software to be uncoupled from hardware and ensures that users can adopt hard-

ware from multiple vendors.

Across both the EU and US markets, DCS users are taking the initiative to tackle the information access challenge and make more efficient use of technology. This user driven process is leading to a radical transformation of the very nature of the DCS.

In the past, DCS providers have been torn by the need to adopt the latest developments in IT and communications technology, while also providing a stable, reliable DCS solution for users. However, these very users are now driving fundamental change in DCSs as they push for more openness, security, and interoperability.

One of these groups is the Open Process Automation Forum (OPAF). Made up of oil & gas and chemical companies, together with automation providers such as ABB, the group aims to define a new standards-based, interoperable architecture, one that is both open and secure and that will set the pattern for future Process Automation Systems.

With this architecture, DCS will users gain readier access to leading-edge capabilities, allowing best-in-class components to be integrated into a DCS. At the same time, it aims to preserve asset owners’ application software and avoid the additional cost of replacement. The standard promotes innovation and value creation and meets the needs of multiple industries. In addition, it is commercially viable and allows collaboration among both DCS users and suppliers.

Another user group is NAMUR. A global consortium of process industry end-user organizations, the group has defined an open architecture model known as NOA (NAMUR Open Architecture).

By segregating core control and automation functionality from non-time-critical monitoring and optimization, this architecture separates out information that is less critical and that can be used for optimising the company’s facilities. This in effect creates a new maintenance and optimization layer that has separate access to information currently trapped in the DCS.

NAMUR seeks to helps its member companies avoid wrong investments, adopt promising technology as early as possible and work with standards bodies to take account of user interests.

Although they are approaching their goals in different ways, both OPAF and NAMUR are trying to define a common communications interface and a common information model. OPAF is attempting to redesign the DCS to be more interoperable and simpler to upgrade, while NAMUR seeks to create a structure to work alongside the DCS to obtain the information needed, without fundamentally changing how the DCS operates.

In the area of modularity, the Modular Automation initiative aims to move away from monolithic automation systems and towards more flexible modules that can be more easily combined to build a rapidly deployable system. The aim is to allow faster process implementation, an easier scaling of capacity and more rapid changeovers of users’ products.

Open standards define how we communicate with the different equipment spread across the plant.

Early adopters are found among companies

of all sizes, with smaller companies particularly benefitting from the modularity and the scalability offered. Although change is often resisted, many companies are now realizing that open DCS standards offer access to the data they need, allowing them to be more efficient and effective as the business environment becomes ever more challenging and changeable.

Luis Duran is Global Product Line Manager Safety at ABB in Richmond, TX. ABB

https://new.abb.com/control-systems

Our new solid metal, heavy-duty hose reels keep your Quick-test hoses organized and off the ground. They include our low volume, high pressure Quick-test hoses that stay pressurized and can be extended or retracted under pressure.

• Easy-to-mount base plate for quick installation on walls or trucks

• Powder-coated steel frame holds up in all weather conditions

• Sturdy crank for smooth winding and unwinding

Quick-test hoses are available in imperial and metric sizes, with your choice of brass or stainless steel connections.

Lorenz Conveying Products has introduced a pneumatic actuated, 2-way diverter valve for vacuum or low pressure conveying systems. Units are manufactured for vacuum or dilute phase (15 psi max) pneumatic conveying systems. An unobstructed flow improves system performance and eliminates product degradation, the company says. The system can be installed horizontally or vertically. Aluminum body construction, stainless steel blade, and active compression seals are temperature rated for up to 82°C. Inlets and outlets are available in tube and pipe sizes in stainless steel, Aluminum, and carbon steel. Lorenz Conveying Products www.lorenzproducts.com

NewTek Sensor Solutions the NTC-6000, an LVDT signal conditioner that pairs with AC-operated linear and rotary position sensors to deliver reliable feedback in DC voltage, current and digital outputs for use in factory automation, materials testing, packaging, and dimensional gaging applications. The smart signal conditioner diagnoses and indicates LVDT failures, disconnects or short circuits for fast resolution of problems. Cybersecurity lockout and tamper detection ensures its safekeeping in locations without supervision, the company says. The

LVDT signal conditioner incorporates a two-wire RS-485 digital communications port and offers hot swapability so setup can be saved and reloaded via the RS-485 port. Digital outputs can include CANbus, Modbus, RS-485, and others. The DIN-Rail mountable unit is RoHS compliant and CE-certified for use in Europe. NewTek Sensor Solutions www.newteksensors.com

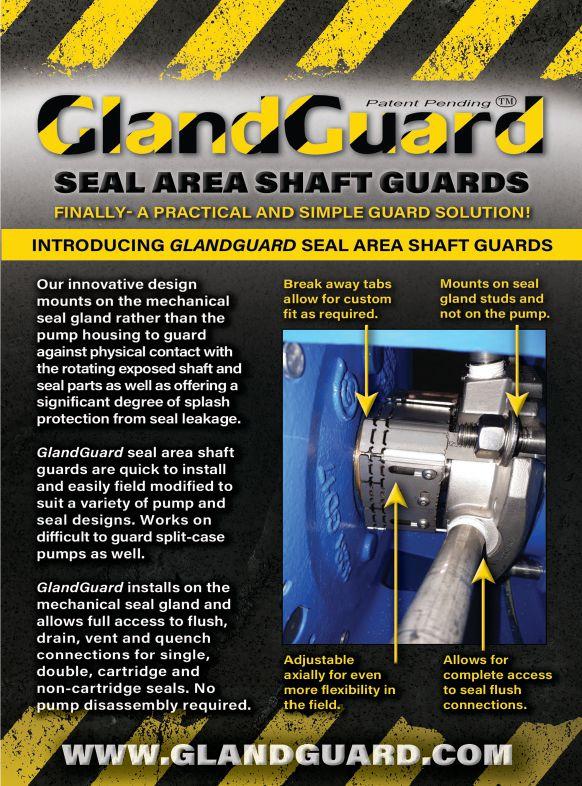

ProSpec Technologies has introduced GlandGuard seal area shaft guards, designed to protect a pump shaft between the casing and the bearing housing. The design mounts on the mechanical seal gland rather than the pump housing to guard against physical contact with the rotating exposed shaft as well as offering a significant degree of splash protection. Traditional guarding of this area of the pump is varied and often questionable, the company says, if it exists at all. The seal area shaft guards are said to be quick to install and easily field modified to suit a variety of pump and seal designs. The unit installs on the mechanical seal gland and allows full access to gland flush, drain, vent and quench connections for single, double, cartridge and non-cartridge seal designs with no pump disassembly required. Breakaway tabs and adjustable slotted mounts are also said to allow for easy field fitting to accommodate various pump and seal configurations.

ProSpec Technologies www.prospectech.com

The APFCL Online Chlorine and pH Analyzer from Blue-White employs the FCL700 smart sensor for a turn-key monitoring solution to clean water applications. FCL700 three-parameter composite sensor for residual free chlorine, pH and temperature complies with USEPA 334.0 guidelines. An advanced sensor PCB offers built-in temperature and pH parameter compensation (up to pH 9.0) algorithms, the company says. The bare-gold electrode technology for residual chlorine measurement eliminates membranes and electrode solution replenishment commonly associated with conventional sensors, it adds. The flat bubble pH electrode is designed for reduced fouling potential. The WR05 sensor flow reservoir provides sample calming for dissipation of air-bubbles and settling of suspended solids, foam or other impurities commonly observed in drinking water influent. Blue-White www.blue-white.com

Ensign Equipment has announced bulk bag unloading systems that are designed with features to help move bulk materials efficiently and effectively. Whether the process requires a stand-alone unit or a fully integrated system, the company can build what is required, it says. Standard products include the 1-ton manual (forklift loaded) model and the 2-ton hoist model. From there equipment is designed to meet specific process requirements and can discharge into Porta-Stors, Gaylords, surge bins, vacuum systems, and screw conveyors. Key features include steel construction, integrated rest pan, easy access untie chamber, adjustable for various bag sizes, trolley end-stop limit switches standard on all hoist models.

Ensign Equipment Inc.

www.ensigneq.com

KECO has introduced the model 204 PermaStream Process Analyzer that provides real-time measurement of VOC leaks in clean or dirty water. More economical and accurate than lab analyzers prone to analytical errors, the company says, precisely measures total VOCs including aliphatic and aromatic hydrocarbons without

false high readings or high alarms associated with UV fluorescence methods. Requiring no filters or liquid sample conditioning, the analyzer strips hydrocarbons as water samples continuously flows through it. Carrier air sweeps hydrocarbons at a rate of 200 ml/min to an advanced VOC sensor for quantitative analysis in ppb, ppm, or “up to” saturation levels. The company’s membrane technology creates a sample for the VOC sensor that has an average life of 5 to 10 years. No costly consumables are needed for analysis. The sensor quantities and displays values on a colour touch-screen HMI system, through a 4to 20 mA output loop or via RS-485, TCP/IP Ethernet, and Modbus. The analyzer offers remote and web-based monitoring along with optional concentration relay alarms and diagnostic/fault alarms. Units comply with Division 2 and Zone 2 hazardous area installations.

KECO www.liquidgasanalyzers.com

ORDER BY 6 PM FOR SAME DAY SHIPPING

The AirCube 2000 from Dustcontrol Canada is an air cleaner driven by a fan having a capacity of 1800 m³/h. The air cleaner is equipped with a variable knob to allow different levels of operation. This could be utilized when less demand is needed of the air cleaner or when quieter operation is required. The unit has a 0.7m² pre-filter and a certified HEPA H13 microfilter with 10m² of filter area, capturing nearly all dust particles 0.3 microns and larger. Certified HEPA filters are individually tested for their effectiveness. A filter indication lamp list when it’s time to change the filter. An inlet hose could be used to make a space negative with the air cleaner placed outside of the space. As in previous designs the air exhaust is directed upwards in order to prevent dust to whirl up from the floor. The unit can be positioned horizontally flat on the floor, with the exhaust pointing to the side if desired.

Dustcontrol Canada

www.dustcontrol.ca

Camfil has announced an upgrade to its Hi-Flo brand of bag filters. The Hi-Flo bag filter is characterized by its energy saving properties combined with stable and reliable performance. This upgrade has been designed to continue this tradition but also provide added customer benefits including being able to improve its carbon handprint by over 25,620 tonnes of CO2 emissions and provide a reduction in energy consumption. The filter range also comes with an Environmental Product Declaration (EPD). Camfil www.camfil.com

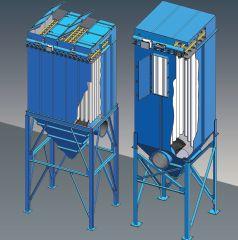

N.R. Murphy Ltd.’s MK Series dust collectors offer a square or rectangular design with tube style filters and mechanical shaker type cleaning. The MK Series maximizes the airflow to filter media ratio for efficient dust collection in a compact design across multiple industries. The MKOB dust collector is an open bag unit flexible enough to meet most regulations allowing the unit to sit inside the building. Available in a wide variety of filter diameters, and options for drums, or self-dumping hopper bin. The MKF dust collector is said to be very rugged, reliable and is available in a variety of sizes to suit all operations and waste volumes. The 5-1/2 in. diameter filters used in this shaker style dust collector allow easy release of the collected material while the rectangular design maximizes filter area. The MKA dust collector is available in drum storage, dumpster bin or with a hopper bottom for continuous discharge through a rotary air lock. With 3 different diameters of filter bags, the unit provides capacities for small and medium size facilities.

N.R. Murphy www.nrmurphy.com

Sly Inc. has introduced the Square Series of pulse-clean dust collectors. Model STJ top bag removal dust collectors have 50 to 200,000 ACFM capacities, 20 to 80 in. w.g. design pressures, and construction to 500ºF design temperature. Top bag removal options include a hinged hatch top and walk-in plenum. Model SBR side bag removal dust collectors have 50 to 50,000 ACFM capacities, 20 to 80 in. w.g. design pressures, and construction to 500ºF design temperature. When headroom is tight, the collectors can fit where top removal units can’t, the company says. Sly Inc. www.slyinc.com

By Mike Maxwell

Afine dust coating anywhere on equipment, ductwork or other areas of your facility means it is past time to institute proper housekeeping measures, and/or to evaluate the dust collection system. Even small quantities of dust, any accumulation, may be considered a workplace hazard depending on the type of dust, potential ignition sources and other circumstances.

A proper dust control system, such as industrial dust collectors, or baghouses, can help with combustible dust and air quality control. Dust mitigation procedures and equipment can help prevent profound consequences that can occur due to combustible dust. This includes preventing potential explosions or fires, but also extends to air permit compliance, regulatory fines, damaged equipment and more.

While this applies to any type of dust, whether simple nuisance dust destined for disposal or dust collected for recovery and recycled back into the production stream, it is especially important regarding combustible dusts. It is the responsibility of every business owner and manager to ensure worker safety and site health by prevent-

ing dust explosions. If your facility has dust, the potential exists for a combustible dust event, and the need to design your dust collection system accordingly.

Regulatory agencies use standards such as NFPA 652 and, for applicable industries, require a dust

hazard analysis (DHA). If your facility creates or handles particulates that are combustible, you likely need a DHA.

Dust collection systems are a leading source of combustible dust incidents due to the concentration of fine particulates inside the equipment. Therefore, during the DHA, the system’s design will be reviewed. Inspectors will take a close look at the housing, hopper, inlet ducting, and outlet or return ducting of your dust collector to ensure your system was properly designed for explosion protection.

While every application and dust collection system must be individually addressed to see how to best mitigate the risk of an explosion, there are some general tips that you can follow. Here are five steps plant managers, company owners or maintenance personnel can take to increase site safety and better adhere to regulatory guidelines:

Standards bodies recommend facilities analyze their particulate material to determine whether it is combustible. According to current NFPA guidelines, combustible dust can be any solid material comprised of particles less than

500 microns in size that are a fire hazard when suspended in air or a similar oxidizing medium.

Companies might be working with materials that do not seem combustible at first. However, as they break down in processing and particulates fall off from handling, it can result in combustible dust. Certain industries’ manufacturing processes are more susceptible to combustible dust production than others.

Some common materials include agricultural products such as soy flour, sugar, protein powders or powdered milk; carbonaceous dusts such as charcoal and soot, metallic dusts like aluminum and magnesium, and many different dusts from polymers.

No matter the type of combustible dust, a first step involves determining the Kst (the dust deflagration index) and Pmax (maximum explosive pressure) of your dust. The larger these values, the more severe the potential explosion.

Testing for explosive properties is typically done in a 20 litre or one cubic meter container. Additional testing for minimum explosive energy (MIE) and minimum and maximum explosive concentration (MEC) are also often done and helpful in determining the dusts’ combustibility and explosion risk. There are many companies that can provide this testing.

This is also the time to determine if your dust has any other special qualities, such as:

• Are there oils present? (i.e., a hybrid material of mist and powders combined)

• Is the dust water reactive? (Certain metal dusts are highly reactive to water)

• What is the dust loading? (minimum/maximum explosive concentration)

• Does it flow easily or is it an exceptionally fine and abrasive material?

Understanding the nature of the dust is critical to designing your dust collector.

The inside of a dust collector supplies a prime location for a dust

explosion when the system is not properly designed. Risk factors that need to be considered include ignition sources like static discharges, the dust cloud confinement, and potential buildup of dust on ledges or in pockets.

For combustible applications, specify a dust collector that eliminates internal ledges and potential static buildup by proper bonding and grounding. When handling dusts prone to self-ignition such as coal, it is imperative to avoid storing any dust in the hopper itself, due to potential fire or deflagration risk.

The collector housing must be designed to withstand the maximum expected internal pressure that may result from a dust explosion. This pressure may be either the dust tested Pmax or a lower dust Pred (reduced pressure) that results when explosion mitigation features are added.

3.

Once the results of the DHA reveal the level of risk, the next consideration is the location of the dust collector. Its location can influence a facility’s risk for damage and injuries, in addition to affecting selection of explosion-proof auxiliary equipment.

The collectors that pose the greatest safety risk to workers are those located inside the facility, due to their proximity to workers and explosion proof options are more limited. It is easier to locate a nuisance dust collector at the end of a process line or outside of the plant, while process dust collectors typically must be inside a facility and integrated into the system.

Housekeeping is a prime consideration when mitigating explosion risks and is especially critical for equipment located inside the plant building.

Alleviate the risk of an explosion with auxiliary equipment that is integrated into your dust collection system. The three main types of auxiliary equipment include flameless vents, suppression systems and explosion venting.

The above options are all available for use in outdoor dust collectors. Explosion venting is the most selected option because it is easy to design and use and the most cost effective. Indoor systems are limited to flameless vents and suppression systems, with flameless vents being the most expensive. In some instances, explosion vents can be used on indoor units provided properly sized clear ducting can be installed to vent combustion products to a safe outdoor location.

Deflagration venting auxiliary equipment consists of the following:

• Flameless vents—A flameless vent is also referred to as a quench tube because it quenches a flame arising from a deflagration. Its design allows for relieving the explosive pressure while retaining the flame within the vent housing to mitigate the potential explosion.

• Suppression systems—A suppression system can be installed on industrial machinery that handles combustible dust and can take the form of pressurized cylinders similar in nature to a fire extinguisher. Their suppressive action is automatically triggered in the event of a deflagration to help mitigate its affects.

• Explosion venting—An Explosion vent helps relieve internal pressure in the AMS (Air-Material-Separator) by blowing open during an event. They vent the pressure and combustion products outside the “exclusion zone,” or the immediate area surrounding the collection equipment, with a distance range that depends on multiple variables.

In addition, relief vents should be located away from other dust hazard zones. Special attention should be paid to the ductwork that connects the dust collection system or baghouse to other pieces of equipment.

A connected system of ductwork has, in the past, been associated with the spread of an initial explosion. Ductwork should undergo regular inspections to

evaluate dust accumulation. SLY Inc. can supply isolation solutions for dusty air inlets, clean air outlet, and dust discharge.

Another feature that can aid with reducing combustible dust incidences are grounded and/ or conductive filter bags, external grounding of housing, and, of course, ensuring enclosures and wiring meet NFPA-70 (NEC).

Other equipment, such as a sprinkler system, can also help if your dust is not water reactive. In cases where the material involved is water reactive, such as zinc dust or alkali metals, a dry chemical extinguisher kept on hand in the plant can provide an effective safety measure if a fire breaks out. Carbon dioxide suppression systems may also be employed. Sly representatives are prepared to assist in determining the best location and design equipment to protect your facility and personnel.

Take the time to properly train employees about proper maintenance and housekeeping procedures and why they are important. In addition, have an incident response plan and techniques in place for safe work practices and ignition source control. Health and safety incident reports often cite lack of proper training contributing to the severity of an event. Companies should also obtain the proper extinguishing media related to the type of combustible dust produced in the facility, and train workers how to use these extinguishers. It also helps to alert local emergency responders to the type of combustion situation they might encounter if called out to the facility and whether the dust is reactive to water. Fire extinguishers are rated according to the type of material they are designed to control. Keeping the proper safety equipment on hand can help control or diminish a fire to prevent it from growing.

Mike Maxwell is Engineering Manager at Sly Inc. This article is taken from his blog. Sly Inc. www.slyinc.com

LEMO has announced the expansion of its high-speed data transfer connector portfolio with the release of USB 3.1 and Single Pair Ethernet versions. Adding to its existing USB 2.0 compliant line, the company has a new range of USB 3.1 connectors providing data transfer speed up to 10 Gb/s. The connector inserts are said to ensure optimum shielding and absolute signal integrity. Units are also equipped with a pair of USB 2.0 contacts to ensure backwards compatibility as well as a low voltage power contact. The company is also extending its Ethernet compliant portfolio that includes 1000 Base-T4 and 10G Base-T4 compliant solutions with a new range of Single Pair Ethernet connectors providing data transfer speed up to 1 Gb/s. Proposed with either 1 or 2 High-speed SPE pairs, the miniature models ensure robust, safe, and lasting compact integrations, the company says.

LEMO

www.lemo.com

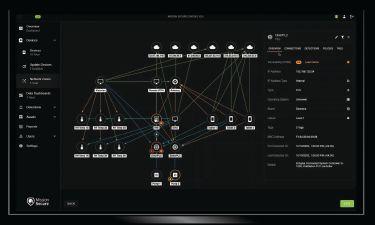

Mission Secure has announced the release of its Sentinel 5.0 platform, said to be a milestone in enabling Zero Trust security architectures for critical infrastructure. The platform provides dynamic, context-aware cybersecurity policy monitoring and enforcement for operational technology systems, the company says. Zero Trust is a well-established IT cybersecurity principle that has yet to be widely adopted in industrial OT. It eliminates implicit trust in the network perimeter by validating every stage of digital interaction continuously. The new platform release allows operators to define and enforce granular policies based on a wide range of inputs, including network traffic, attempted remote access,

asset firmware versions and vulnerabilities, and the actual digital or analog signal generated by physical devices. While the Sentinel 5.0 platform includes standard capabilities such as passive monitoring, asset discovery, and alerting, the platform’s core component is a fine-grained policy engine that enables OT-specific workflows, the company says. Mission Secure

www.missionsecure.com

The model HD-2.5-5-SSI Sanitary Paddle

Blender from Munson Machinery is said to provide added shear to de-agglomerate dry bulk solids, pastes, slurries and/or emulsions of low- to medium-density materials in batches up to 0.71 m3. Fabricated of #304 stainless steel, it features a stationary U-shaped vessel with a flat cover, bottom discharge valve, and horizontal flange-mounted agitator. Munson Machinery Company www.munsonmachinery.com

Fluke has announced Baseline Team, software for thermography workflows. The application helps thermal imaging (TI) teams automate their work, route execution, and reporting to optimize asset maintenance. The first cloud-based, TI solution, the company says, the software platform allows users easy access from any smart device without installing a desktop app. The software supports both technicians and their supervisor’s workflows to improve scheduling, planning, and tracking allowing service organizations to realize significant efficiency gains. The application features image management and analysis functionality as well as report automation tools said to reduce reporting time by up to 75 percent. The technician or manager can review and analyze images and indicate a final result of the inspection such as pass, fail, watch, or skip, and fill in any recommendation. Once they are satisfied, a PDF report can be generated to share and distribute.

Fluke Baseline https://software.fluke.com

Eriez has announced 6- and 18-in. belt sizes are now available for the company’s Xtreme metal detector conveyor systems with automatic rejects. The units, along with the 12-in. belt systems launched last year, are equipped with new options, and offered for fast delivery through

the Eriez Quick Ship program. Just like the 12-inch systems, the standard 6 and 18-inch systems are designed with push arm or air blast rejects, lockbox, reject confirmation, stainless steel motor/reducer, improved guarding, emergency stop and side guides. Features include 7-in. touch screen interface, multiple pre-programmed languages, easy set-up and reporting, multiple USB and interface ports, remote access and 24/7 technical support capabilities.

Eriez

www.eriez.com

The SmartBob sensor from BinMaster works like an automated tape measure. Mounted on top of the silo, the sensor drops a weighted cable to the material surface. Upon impact, the cable retracts while counting pulses that are converted to a level measurement. Measurements are programmed at predetermined time intervals to monitor changes in inventory over time. The sensor is ideally mounted 1/6 of the diameter from the outside perimeter for center-fill, center-discharge silos, the company says. This distance is proven to provide the most accurate inventory data, it adds, accounting for the angle of repose in free-flowing materials. Level data from the sensor can be sent to the company’s Binventory software installed on a PC on a local area network. Alternatively, data can be accessed from the internet using the BinView web app on a smartphone, tablet, or PC. A SmartBob sensor with an analog output option sends data directly to a PLC. The sensor is used in vessels up to 150 feet tall that contain solids, powders, liquids, slurries, or in brine tanks.

BinMaster

www.binmaster.com

4B Components has introduced the Encoder-Flex 1024 rotary shaft encoder that uses leading technology to monitor slide gate position. The compact design is said to be easy to use and easy to calibrate. Specifications include 1 to 1024 programmable pulses per revolution with up to 500,000 rotations and 4 to 20 mA input. Suitable for retrofit or new installations, the units feature quadrature pulse (speed/relative rotation), and Modbus RTU output. Users can know the precise position of their gate (0 to 100% open), the company says. The stainless steel enclosed rotary encoder memorizes shaft position in the event of power loss.

4B Components

https://encoderflex1024.com/

FIPA has extended its range with the wear-resistant Monoflex bellows vacuum cups from the SP-BX1 (1.5 folds) and SP-BX2 (2.5 folds) series. The vacuum cup material is said to combine the elasticity of rubber with the durability of polyurethane. The almost non-marking bellows vacuum cup is suitable for gripping cartons and other uneven and porous materials, such as cardboard, textured plastics and composites with a raw surface. The vacuum cup is made from polyurethane (hardness 50° Shore A). Folds provide good height and angle compensation, the company says. The oil- and ozone-resistant vacuum cups are offered in versions from 10 to 75 mm diameter. Bellow vacuum cups with a filter disc can be used in a dusty environment.

FIPA

www.fipa.com

IDEC Corporation has introduced a line of CW low-profile touchless switches suitable for many hygienic industrial and public automation applications. Because there is no contact involved, users do not need to dispose of gloves or wash after using the switches. The touchless switches are designed with a sleek and nearly flush (2 mm rise) low-profile surface silhouette. They are built for an industry standard 22 mm mounting hole and require a 35 mm space behind the panel face, plus room for the wiring connector. The typical installation pitch is 30 mm width and 50mm height. Operating temperatures range from -25° to 55°C. A rubber washer and locking ring ensure IP65/67 and NEMA Type 4X ratings are maintained. Switch output is a non-contact photoMOS relay, available without a timer or with a 0.5 s on-delay and a 2.0 s off-delay. Reverse connection protection is included, and the switch operates at a nominal 12 to 24 Vdc with 100 mA max load current.

IDEC Corporation

www.idec.com/usa

HSM-03V benchtop lift mixers from INDCO feature automatic torque control, allowing them to mix high- or low-viscosity materials, the company says, or perform high-speed dispersions, with a single mixer. A 3 hp DC motor provides constant torque, allowing mix viscosities exceeding 100,000 CPS to be achieved with supplied bowtie style impeller. Marine style, hydrofoil, or turbine impellers can be used for materials with lower viscosities. Dispersion blades can be used for highspeed dispersions up to 50,000 CPS. Standard

speed range of 60-1,200 rpm can be changed to 135-2,800 rpm. The small batch mixer for up to 5-gallons is suitable for use in product development labs or production environments across a wide range of food processing applications.

INDCO

www.indco.com

By François Gagné, Endress+Hauser Canada

Do you know what information your instrument is able to share with you? Though weightless, that data can really pull its weight if you give it a chance.

Digital add-ons can extract more intelligence to optimize production or inform preventive maintenance, reducing unscheduled downtime. In some cases, simply repurposing your measurement and analytical devices’ existing data can provide you with a deeper, real-time understanding of your operation so you can be proactive instead of reactive in addressing actual or potential anomalies before they become disruptive.

In Canada, we’re largely at the starting line, or not too far beyond it, in adopting more aggressive uses of data to improve operations. There are still a lot of 4-20 mA connected devices basically running to fail, and providing minimal intelligence about the state of things.

Operations that are in the IIoT/ Industry 4.0-ready mode are still a tiny minority. Much of the process world will be shifting over time to field to cloud connectivity with a digital protocol because of the enormous benefits it can provide. However, many also will delay such conversions beyond current amortization cycles, often well beyond. That’s not necessarily unreasonable, but there are opportunities far short of adopting, for example, Ethernet-APL throughout a plant to begin incorporating IIot/Industry

4.0 smarter technologies. Smaller turnkey projects to expand the role of data generation and/or transmission need not be particularly expensive or disruptive. The insights gained can be immediately realizable and impactful. Often, it makes use of your existing instrumentation; little or no additional hardware required. It may involve adding either Bluetooth or wireless connectivity so data can be transmitted directly to a tablet/ smart phone or control system, or even onward to the cloud where it can provide condition monitoring or be archived as metadata for trend analysis and rapid report generation.Endress+Hauser’s digital Heartbeat diagnostic, monitoring and verification add-ons can be installed on almost every device we offer. It makes today’s smart measurement and analysis instruments smarter, and provides indepth device insights for process optimization, condition monitoring and for predictive or preventive maintenance approaches that reduce or eliminate unscheduled downtime.

Adopting Heartbeat is one way to begin implementing an Industry 4.0 environment.When we talk to customers, the real or perceived concerns of many about enhancing data generation revolve around more than cost: Many cite a lack of time, mind space or the in-house staff resources to plan and implement such projects or make use of the added intelligence. In reality, vendors can provide turnkey solutions based on getting to know the customers’ needs, and provide all installation, commissioning and training functions. We’re not just shipping boxes, and saying good luck with that. There may even be opportunities to leverage existing device data merely by visualizing it differently, giving staff to gain a greater understanding of an operation and making their jobs easier, not harder. It can reduce operational risks, facilitate planning and stream-

An industrial customer of Endress+Hauser Canada in rural Ontario has level, flow, dissolved oxygen (DO) and pH instruments monitoring the phases of its wastewater treatment process. With Netilion Network Insights, plant managers can go online instantly in the plant office or remotely for a graphic visualization of the same device data super-imposed on the entire treatment process.

line reporting, as this case study demonstrates. An industrial customer of Endress+Hauser Canada in rural Ontario has level, flow, dissolved oxygen (DO) and pH instruments monitoring the phases of its wastewater treatment process. Until recently, that raw instrument data was updated hourly in a data manager. Staff would view it by logging into the latter via an often quirky cellphone connection.

Since the readings for each instrument would fluctuate through the course of treatment cycles, this raw data, viewed in isolation, provided a limited understanding of the state of entire operation.By having us install our Netilion Network Insights — including a small hardware bolt-on to upload the data to the cloud every 15 minutes, plant managers can go online instantly in the plant office or remotely for a graphic visualization of the same device data super-imposed on the entire treatment process. This full-system imaging allows them to recognize — even anticipate — anomalies in one stage that could impact subsequent stages — so they can make adjustments proactively and save themselves some headaches. Netilion sends text and email alarms about irregular DO levels

which would suggest a blower used for aeration in the sequential batch reactor is offline. That’s critical on nights and weekends when the wastewater plant, which functions 24/7, isn’t staffed; a manager receiving such an alert now drives in to address the issue before it becomes a costly out-of-compliance problem. Netilion also generates and transmits compliance and corporate reports in minutes rather than the hours it used to take, and archives all data securely. For other operators, automated uploading of existing instrument data to the cloud can replace manual data collection.

Digitalization is the future of industry, the basis for artificial intelligence, machine learning, and advanced communications and controls architectures. If you aren’t doing so already, you can begin embracing that future by making your instrument data play an active rather than a passive role in your success.

Francois Gagne is marketing manager at Endress+Hauser Canada and a member of the Editorial Advisory Board at Canadian Process Equipment & Control News. Endress+Hauser Canada www.ca.endress.com

Pfannenberg has announced the re-launch of its PYRA LED series — now featuring a 360° colour-changing LED light. Used wherever warnings and information of machines and equipment, rooms, or areas need to be displayed, the new series features an RGB LED, with selectable, multiple colours available to provide indication on several situations in one light. The updated LED series can now show three out of four available colours — red, yellow, green, and blue. Offered as a single-colour LED, it can be field-selected to be steady on, blinking, or flashing to meet the needs of a facility. With or without an audible alarm, the series offers selectable blink and flash frequencies adaptable to a wide variety of applications.

Pfannenberg

www.pfannenbergusa.com

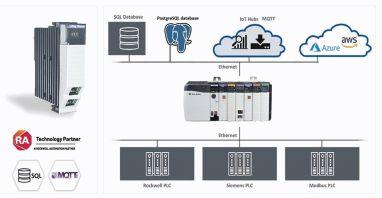

Softing has extended its tManager connectivity for Rockwell PLCs by adding a connector to PostgreSQL databases to provide easy, secure, and robust production monitoring, recipe downloading, high-speed sorting and industrial analytics at scale. The connector module inserts into the ControlLogix or CompactLogix PLC chassis. The PLC module enables bi-directional data movement between the PLC and databases or cloud — no server, no coding and no protocol translation required, the company says. The connectivity is said to simplify access to plant-floor data for production monitoring, analytics, dashboards, recipe downloads, high-speed sorting, and key performance indicators.

Softing

http://industrial.softing.com/us/

• Water Treatment

• Potable Water Service

• Reverse Osmosis

• Desalination

Nano One Materials Corp. of Vancouver has announced an award of $10 million in non-dilutive, non-repayable contributions from Sustainable Development Technology Canada (SDTC).

These funds will support the conversion of Nano One’s recently acquired Candiac facility to the patented One-Pot Process for industrial-scale pilot production of lithium iron phosphate (LFP). SDTC’s continued support has been an important contribution to Nano One’s success and will accelerate the LFP piloting while advancing the plan towards commercial operations.

The SDTC project also includes financial support for the design, construction, and operation of a multi-cathode piloting hub (MCPH) to help customize and advance Nano One’s OnePot and metal-direct-to-CAM (M2CAM) processes for the industrial scale pilot production of next-gen LFP, NMC and LNM cathode active materials (CAM). These processes are being developed independently by Nano One and jointly with global cathode partners, and various automotive collaborators for future licensing, joint venture, and independent production opportunities.

Nano One will lead the project with valuable contributions from consortium partners Rio Tinto, Lithion Battery Inc., and an undisclosed automotive OEM.

Sustainable Development Technology Canada www.sdtc.ca

Nano One Materials

www.nanoone.ca

one day make our everyday electronics, such as cellphones, cheaper and more environmentally friendly.

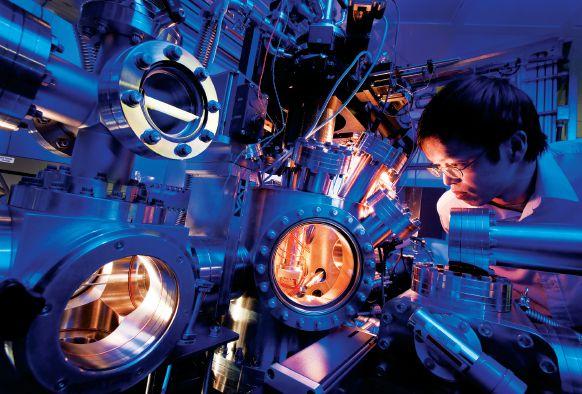

The REIXS beamline of the Canadian Light Source (CLS) at the University of Saskatchewan in Saskatoon, was a critical tool in quantifying the material’s behaviour, said lead researcher Alannah Hallas.

“We’ve recently discovered a family of materials that have an exciting property of having very adjustable magnetic properties,” said Hallas, an assistant professor in the Department of Physics and Astronomy at UBC in Vancouver.

The material discovered by Hallas is known as a high-entropy material, meaning that it is composed of a disordered mixture of five or more elements. While entropy, or the disorder of a system, is usually considered a disadvantage, this new material proved to have useful properties such as its adjustable magnetism.

The research, conducted through UBC’s Stewart Blusson Quantum Matter Institute, involved creating the material under high heat and rapidly cooling it to create a disordered crystal lattice. This disorder was then imaged at the CLS.

Canadian Light Source www.lightsource.ca

Joe Ferraro, chair of the board at the Toronto-based Canadian Process Control Association, has introduced its new five-member CPCA Management Team.

“Trish Torrance, who had served as CPCA’s manager for many years has retired, and we are pleased to welcome this new team and look forward to working with them,” says Ferraro.

Peter Waite, executive director is the contact for the board of directors, polices, strategic planning, awards, nominations, and budgeting, while Matthew Ford, manager, Programs, is the primary contact for memberships (new and renewals), event registrations, industry surveys and reports and committee support.

Faith Featherstone is manager, Administration, the contact for marketing, Chris Dawkins is manager, Member Services, is responsible for event logistics, and Erica MacCallum, administrative assistant and bookkeeper, is the contact for accounts payable and receivables.

“They look forward to meeting you at our Annual Conference at the Pillar and Post Hotel in Niagara-on-the-Lake on May 25-27,” adds Ferraro.

Please note the new office address and ensure that records for membership renewals and other correspondence are updated, he adds:

CPCA

20 Carlton Street, Suite 123 Toronto, ON M5B 2H5

416-585-3000

CPCA

www.cpca-assoc.com

NRStor Inc. of Toronto has announced that the Independent Electricity System Operator (IESO) has entered into an Energy Storage Facility Agreement (ESFA) for the Oneida Energy Storage Project.

The Oneida Energy Storage Project is the largest of its kind in Canada and amongst the largest in the world.

NRStor and Six Nations of the Grand River Development Corporation (SNGRDC) have been jointly developing the project since 2018 and have announced Northland Power’s participation as an equity and operating partner.

With the finalization of the ESFA, the project proponents have now finalized and executed a battery supply agreement with leading global battery manufacturer Tesla Inc., and an engineering, procurement, and construction agreement with Aecon Group Inc., to advance into the construction phase. The Project will supply the Ontario electricity system through a 250 MWh/1,000 MWh-hour Tesla Megapack system in southwestern Ontario and is scheduled to be completed in 2025.

In addition, Natural Resources Canada has provided $50 million in funding from the Smart Renewables and Electrification Pathways program.

NRStor

www.nrstor.com

Thermo-Kinetics of Mississauga, ON, has announced two regional manager appointments.

Adam Dello, a third generation member of the Dello family, the family who founded Thermo-Kinetics, has been promoted to central region manager in Canada, while Normand Bellisario has been named national sales manager.

Dello (adello@thermo-kinetics.com) has been a valuable member of our team for the past four years, the company says, consistently demonstrating exceptional leadership skills, industry knowledge, and a deep commitment to customer satisfaction.

In his new role, Adam will be responsible for overseeing Thermo-Kinetics’ operations in the central region of Canada, including sales, service, and support.

Bellisario (nbellisario@ thermo-kinetics.com), an integral team member for over three decades, will oversee Thermo-Kinetics’ national sales operations, focusing on expanding our customer base, cultivating strategic partnerships,

and driving revenue growth across all regions.

For over 50 years, Thermo-Kinetics has manufactured TK brand process and control measurement products, and maintained exclusive distribution partnerships with brands such as Honeywell and Krohne. Thermo-Kinetics https://thermo-kinetics.com

The present and future of process technologies were on display at the new Endress+Hauser Canada headquarters late January in Burlington, ON.

The one-day Partners in Process: Technology Symposium provided registered users from industry sessions to learn about how to improve their plant performance, support an installed base through a plant’s lifecycle, control valve sizing and selection, and integrate the E+H Netilion platform across an enterprise.

Tarang Patel, product manager of Solutions and Service at E+H Canada, presented the session Heartbeat Technology for improved plant performance and reduced operating expense

With Heartbeat ISO 17025 traceable verification, “we can build the confidence in device performance and extend the calibration interval to two years or even three years, depending on application and customer confidence,” says Patel.

Stephen Claffey, service outside sales at E+H Canada, presented How Endress+Hauser can support your installed base through every phase of the plant life cycle. Claffey notes that not all companies need handholding when they map out their maintenance strategies.

“However, when it is realized there is a potential to reduce maintenance costs and have a more controlled approach to budgeting for maintenance, we move into a systematic approach to developing the ideal outcome for a customer based on their business,” says Claffey.

Joe Ferraro, president and CEO of Samson Controls Inc. in Markham, ON, covered the session Control valve sizing and selection using engineering best practices. He noted that achieving the lowest life cycle costs (LCC) is the goal when selecting the optimal control valve.

ponents,” says Ferraro. “For valve sizing and selection, this means at minimum the process data should be specified.”

Sandy D’Souza, director of Product Marketing at Toronto-based Fiix by Rockwell Automation, presented Enabling Data-driven Maintenance with Fiix, an enterprise-wide multiple user platform. The application communicates with Netilion Network Insights, E+H software designed to monitor networked devices used in the process sector, as well as manage other production and business platforms.

Fiix software is a scalable CMMS (computerized maintenance management system), according to D’Souza. The platform can take data from a variety of sources and generate work orders for managers and technicians. “The built-in intelligence of Fiix means that users get full value from the platform when 200 or more work orders per year

are generated and will flag a work order for management if a deviation occurs.”

D’Souza observes that his company has plans to incorporate advanced AI (artificial intelligence) into Fiix in future releases to extend condition-based maintenance practises into the realms of predictive and prescriptive maintenances.

Claffey at E+H Canada admits “there is certainly an appetite to

adopt AI and more sophisticated approaches to predictive maintenance.

“However, the business case needs to be strong, there needs to be a clear and immediate ROI in order for it to make sense.”

Endress+Hauser Canada www.ca.endress.ca

Fiix by Rockwell Automation www.fiixsoftware.com

Samson Controls Inc. www.samsoncontrols.com

“When it comes to reducing LCC, the control valve needs to be viewed as a comprehensive package composed of different comTrust KNF diaphragm pumps with explosion-proof CSA/UL HazLoc compliant motors. Compliant with NEC/CEC Class 1, Div. 1, Groups C/D, and Div. 2, Groups A/B/C/D. Self-priming liquid flow rates to 11.5 L/min and 88 psi. Gas flow rates to 300 L/ min, pressures to 176 psi, vacuum to 29.86 in. Hg. KNF Neuberger Inc. www.knf.com/exproof

Join CPECN for its Process & Automation Show in Sarnia, ON, on April 26. Industry expert exhibitors will be there to answer your operations and maintenance questions. Register now for this FREE one-day event and for events held later in Lethbridge, Saskatoon, and Saint John. Sarnia Process & Automation Show www.processautomationshows.ca

Rittal outdoor enclosures are designed to protect sensitive electronics from adverse weather conditions. The modular system of outdoor enclosures was developed specifically for these operating conditions and offers electronic components maximum protection, the company says. The outdoor enclosures are available in a broad portfolio of standard modular products, including climate control solutions, offer security and a long service life, come with a graffiti repellent coating, and offer protection against vandalism, cyberattacks and climate changes.

Rittal Systems

www.rittal.ca

Hello valued readers!

Spring is finally here and after a tough winter in parts of Canada. It’s a welcome sight.

After a disappointing ice fishing season, it’s time to dust off the open water gear. The local spring Fishing Show is on this weekend and that always gets me in the mood. Who doesn’t need a fishing boat that will do 100 kph?

Speaking of shows, join us in Sarnia on April 26th at the Dante Club at 1330 London Road between 10 and 4. It’s always free to get in and you’ll see lots of new technology and be able to catch up with friends in the industry.

Series ECWS supply-side or Series ECWR return side are water cooling stick assemblies from Plast-O-Matic said to simplify piping and provide strength. PVC construction with EPDM seals and socket connections; the only selection necessary is the flowmeter range on the return side, the company says. The optional Series ECWST has temperature/pressure Tridicator in place of pressure gauge. Plast-O-Matic www.plastomatic.com

Lutz Pumps, Inc.

1160 Beaver Ruin Road, Norcross, GA 30093-4898

info@lutzpumpsamerica.com

Phone: (770) 925-1222

Tollfree: (800) 843-3901

Fax: (770) 923-0334

Our next issue up is our June issue with a focus on Maintenance & Safety just ahead of summer maintenance shutdowns and the Supplement from editor Mike Edwards will feature all things pertaining to Bulk Powders & Solids. It closes May 5th. If you’d like to be a part of this edition contact Mike at editor@cpecn.com

Enjoy the spring. Cheers, Rob Sommerville

MONITOR: Process Optimization and Monitoring Creates Increased Efficiency and Less Waste

ADJUST: Operational Personnel Are Able Crucial, Immediate Adjustments

CLOSED LOOP: Measure Moisture Direct online with Instant Data Communicated to a PLC

IMPROVE: Maintain Product Quality Control, Integrity & Prevent Wasted Produ

Red Lion has introduced N-Tron series NT5000 Gigabit Managed Layer 2 Ethernet switches. The ATEX/IECEx rated switches are said to maximize operating performance and system uptime through seamless integration, advanced management and diagnostic capabilities, network redundancy and layered security. The switches are available in 6, 8, 10, 16 and 18 port configurations in all copper or a mix of copper and fibre options that can meet specific installation requirements. Red Lion

www.redlion.net

Tel-Tru Manufacturing Company has introduced the Digi-Tru Thermometer Series. Suitable for dairy applications, the thermometers are equipped with a digital sensor that provides quick readings on a 10 mm high LCD display, and an accuracy of ±0.4°C (max) from -55° to 150°C. Temperatures are displayed at a 1 s response time; and the battery will last a minimum of eight years in most applications. The thermometers feature a 77 mm round stainless steel case, and are available in back, bottom, or adjustable angle configurations. Tel-Tru Manufacturing Company www.teltru.com