Bonomi North America www.bonominorthamerica.com

Pulsafeeder Engineered Products PulsaPro & Pulsa series petrochemical pumps are available from John Brooks Company. For high pressure injection of hydrocarbons, catalysts, peroxide, hexane or where process chemicals are flammable and atmospheres are hazardous, PulsaPro hydraulically actuated diaphragm metering pumps are said to provide dependability and safety. Full motion stroke length control yields 0 to 100% linear flow adjustment over a 10:1 turndown range at ±0.5% accuracy from set point. Pulsa versions include a proven hydraulic management system said to assure consistent performance and rapid recovery from system upsets

John Brooks Company www.johnbrooks.ca

Bonomi North America has announced CSA approval on the company’s Valbia electric actuators, models VB030M and above. This approval is important in Canada where it is required for installation, the company says. Valbia electric actuators are built with water-tight cast aluminum or techno-polymer enclosures that can be used indoors or outdoors, the company adds. The electric actuators feature steel and techno-polymer gears with hardened steel pinions said to provide long life and quiet operation. Benefits include two extra limit switches, a heater and thermostat, and a 75% duty cycle motor. All models are dual voltage. A manual override is also standard.

ACTUATION DEVICES PROVIDE AUTOMATIC VOLTAGE SENSING AND IP67 PROTECTION

R. STAHL has expanded its range of intrinsically safe ISpac isolators portfolio. The isolators are 17.6 mm wide and are available as a single- and dual-channel in typical applications, ranging from analog inputs, analog output, discrete input, solenoid driver, RTD, and TC, as well as some specialized applications like frequency converter, serial communication, and vibration transducers. The isolators are globally certified (NEC, CEC, ATEX, IECE, EAC, DNV, PESO, KCS) for installation in Zone 2, andClassI, Div. 2 with I.S. signal to Zone 0, and Class I, II Div 1. ISpac modules from series 91XX and 92XX fulfill the functional safety criteria according o SIL2 or SIL3. All modules can be mounted directly on he DIN rail and, snapped onto a pac-Bus, combine across all models to make them future-proof, the company says R. Stahl www.rstahl.com s a a K n 9 t t a

Plast-O-Matic has introduced CAFE actuators that provide automatic voltage sensing from 24 to 240 Vac/Vdc, with standard manual override, position indicator, LED status lights, overtorque protection, condensation heater and thermal protection. Standard actuation time is 5 s with 15 Nm torque. The CAFE NITRO model includes programmable options via OLED screen, complete menus, fully directional keypad, and onboard diagnostics. Variable speed can be set from 4 to 6 s via the OLED screen. Both models include mounting kit, multi-mode electronic over-torque protection against valve jam, brushless motor with ICP protection, thermostatic anti-condensation heater, remote position indicator via programmable relays, and barrel style visual position indicator. Units also include weatherproof anti-corrosive and UV protected, and are CE marked with IP67 ingress protection. The actuators are designed for 2-way valves, the company says, with 3-way valves available with a factory consultation.

Plast-O-Matic www.plastomatic.com

(Starting at $49.00)

• Can be used with a broad range of conductive media

• Probes do not have to be installed vertically in the tank

The NEW ProSense CLC Series liquid level controllers offer very simple, low-cost, stand-alone level control with no programming required.

• Cuttable probes are available in lengths from 240 mm to 1600 mm

• Any conductive material can be used as a probe

(Starting at $192.00)

ProSense PLS Series rotating paddle level switches are commonly used to detect the full or refill (empty) status in silos, hoppers and bins containing bulk solids.

Guided Wave Radar Level Sensors (Starting at $349.00)

erential

(Starting at $795.00)

• Hazardous location models are available with FM Certified Dust Ignition Proof, Class II, III, Division 1, Groups EFG rating

ProSense guided wave radar level sensors provide a low-cost solution for measuring levels of water and oil-based media, soiled or viscous liquids prone to the formation of deposits.

• Not affected by foam, vapor, turbulence and dust

• Can be used to measure the interface between two liquids such as oil on water

• Cuttable probes are available in lengths from 240 mm to 1600 mm

Submersible Level Sensors

(Starting at $349.00)

ProSense submersible level sensors provide continuous liquid level measurement by sensing the hydrostatic pressure produced by the height of liquid above the sensor.

• Ideal where foam, vapor, turbulence, condensation and splashing would affect the operation of non-contact type sensors

ProSense differential pressure level transmitters are precision engineered for accurate differential or gauge pressure measurement of a wide variety of liquids.

• Ideal for use in sealed tanks where pressure or vacuum pressure is applied above the liquid

• Can be easily mounted or retrofitted to the surface of a tank

• Can be isolated via block valves for maintenance and testing

Flowline Ultrasonic Level Sensors (Starting at $304.00)

Ultrasonic standard and reflective technology level sensors provide reliable, accurate, non-contact level measurement with high sensitivity.

• Ideal for dirty, sticky and scaling liquids which cause contact sensors to fail

• Accurately measures levels of media with varying specific gravities

• Reflective technology models deliver reliable level measurement, even in condensing environments

• Intrinsically safe models are available

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days.

*Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

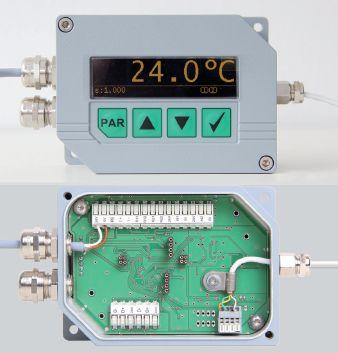

REFERENCE-GRADE DIGITAL GAUGE PROCESS METER

The Process Meter LC30 from Ralston Instruments is a reference-grade digital gauge that’s optimized for fixed installation in panels and enclosures. With a ±0.1% full scale accuracy, intuitive controls, and convenient design features for easy installation, the company says, the meter is suitable for lab and OEM applications that require high-precision from a panel-mounted gauge. Perform live viewing of pressure or set up tests for continuous monitoring, it adds, and easily customize the gauge

to needs using the included FieldLab calibration management software. Designed to run on AC power, the meter includes country adapters for Canada, U.S., and Europe, with backup battery power. It is available in 11 pressure ranges from 5 to 10,000 psi (35 kPa to 70 MPa), a combination pressure/vacuum gauge from ±15 psi (±100 kPa), and a vacuum gauge measuring up to 30 inHg (760 mmHg).

Ralston Instruments

www.ralstoninst.com

Turck Canada has announced that with the TN-R42/TC-Ex, it is not only offering the world’s only HF RFID read/write head certified for direct use in ATEX Zone 1/21, but also a reliable and simple alternative for applications where previous implementations were impossible or very difficult. The slim-line TN-R42/ TC-Ex is therefore suitable for the contactless identification of correct hose and flange connections, which ensure investment and product quality in the chemical and pharmaceutical industry. The interface connection operates like a standard read/ write head for the safe area. It is connected to the company’s BL20 or TBEN RFID interface series and can also be installed in protective housings in Zone 2/22 if required. It can also process other information in addition to hose identification, such as socket, data, time, or the degree of hose contamination. Turck Canada

www.turck.ca

A compact and integrated instrument from Ecotherm has been introduced that offers a complete and fully configurable solution to control various models of bipolar electronic expansion valves, in addition to superheating, room temperature, defrost, pressure, ventilation, lighting, and alarms control. Full Gauge Controls Valex VX-1050E plus replaces the controller or thermostat in the installation, as it controls the refrigeration processes, in addition to the liquid flow, the company says. The UL certified instrument can be configured in “driver” mode, where VX-1050E plus is exclusively responsible for controlling the bipolar electronic expansion valve and the superheating of the refrigeration system. Thus, it can be used as part of a control system and interconnected with other controllers. Ecotherm Inc.

www.ecotherm.ca

A new member survey by Canadian Manufacturers & Exporters (CME) shows that nine out of 10 Canadian manufacturers are encountering supply chain issues, indicating that whatever business you're in, you're not alone in your frustrations.

In addition, Canadian manufacturers surveyed in February say they have lost about $10.5 billion in sales because of disruptions in the supply chain and are now experiencing nearly $1 billion in increased costs.

"Demand for manufactured goods is strong but we are increasingly

unable to keep up let alone take advantage of this boom," says Dennis Darby, president and CEO of CME. "Labour shortages, supply chain challenges and higher input costs are big problems."

So, it's not all a pity party, but strategizing by producers and the Canadian government will be necessary. Although these disruptions are largely global in nature, addressing them still requires significant Canadian government action, according to the CME. Manufacturers feel the government needs to increase the

inflow of temporary foreign workers and immigrants to ease labour shortages, provide financial supports to help scale-up domestic manufacturing, and increase investments in transportation infrastructure.

"Bottom line, there are many things Canada must do to tackle the supply chain problem. But it all starts with a firm commitment from government to work with industry to resolve these challenges," concludes Darby.

Mike Edwards medwards@cpecn.com

June Focus on... Maintenance & Safety Supplement: Pumps, Seals & Piping

Editorial closing date: April 29

August Focus on... Environment Supplement: Motors & Drives

Editorial closing date: July 8

October Focus on... Fluids Handling Supplement: Data Acquisition

Editorial closing date: September 4

December Focus on... Plant Automation Supplement: Fittings & Couplings

Editorial closing date: October 21

CONTACT:

AW-Lake Company has introduced a Water Inline (WIN) ultrasonic flow meter said to provide a highly accurate and reliable flow measurement of cooling water, condensing water, and water/glycol solutions. Designed for process cooling applications including industrial cooling circuits, the flow meter has no moving parts for long-term reliability and low maintenance costs, the company says. By incorporating two wetted ultrasonic transducers that face each other directly in the flow tube, the meter is said to reduce wear associated with moving parts and maximizes signal strength. The unit offers +1.0% of reading over 25:1 turndown, 100:1 total turndown over a wide flow range with minimal pressure drop. Holding an IP67 rating, an LCD display version comes with Modbus RTU communications, providing an output of flow rate, volume total, run hours, alarms, and diagnostics. AW-Lake Company www.aw-lake.com

Blue-White provides chemical metering capabilities with the Flexflo A3 peristaltic metering pump. The pump combines accurate metering at discharge pressures up to 125 PSI, intuitive icon-based touch screen controls, and IP rated M12 connection ports that protect against moisture, dust, vibration, and any temperature change, the company says. Remote control signal options include pulse input, frequency I/O, 4 to 20 mA, Modbus TCP, EtherNet IP, and PROFIBUS for what is said to be enhanced supervision and automation for critical metering and transfer applications. The self-priming chemical metering pump delivers smooth chemical feed, it adds, with Tube Failure Detection (TFD) that senses tube rupture. Blue-White www.blue-white.com

The NS Series ball valves are available in sizes 1/4”-6” with threaded, socket weld, butt weld (3-piece) and flanged (2-piece) connections.

The NS Series butterfly valves cover 2”-24” sizes in wafer and lug style.

APPLICATIONS

• Water Treatment

• Potable Water Service

• Reverse Osmosis

• Desalination

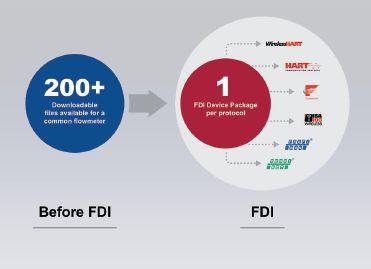

Emerson has announced that its device management software is the first host software to be fully registered by FieldComm Group to support the Field Device Integration (FDI) standard. This is a further step in Emerson’s ongoing efforts to reduce the time and effort spent installing and configuring the field devices plants rely on to achieve their digital transformation goals, the company says. Full FDI registration is important to avoid having a patchwork of systems and devices that only support individual elements of FDI but still require extensive integration effort, it adds. Because manufacturers can pick and choose individual FDI features to support, some device management applications will likely not contain every feature a plant requires. The company says it worked side by side with FieldComm Group for nearly two years to enable AMS Device Manager to pass the group’s rigorous testing process for registration, which requires all features to be supported by the software. Emerson www.emerson.com

In the Canadian food processing industry, walking onto the production floor with conveyor tubes winding this way and that, in and out of machinery can seem to visitors like they have stepped into a Dr. Seuss book or Willy Wonka and the Chocolate Factory movie.

For example, at a glance even industry veterans can be challenged to distinguish whether the conveyor tubes they see are screw (augur), pneumatic, vacuum, aeromechanical, tubular drag chain and disc or tubular drag cable and disc, unless they are the plant engineer or maintenance crew. In fact, many specifiers, architects, engineers, and other professionals lack substantial technical or hands-on experience with such conveyors.

This knowledge gap can result in extreme consequences when delicate materials or precise blends must be reliably conveyed but instead, costly product destruction or inaccurate blends occur.

Misconceptions about tubular drag cable and disc conveyors will be the focus of this assessment, addressing six widely held viewpoints in the industry.

Tubular drag cable conveyors gently move product through a sealed tube using a coated, flexible stainless-steel drag cable pulled through on a loop.

Solid circular discs (flights) are attached to the cable, which push the product through the tube without the use of air. These conveyors excel in transporting delicate, precise blends for a wide variety of food types in versatile layouts and configurations.

Misconception #1: These Conveyors are the Same as a Screw System

“One of the most common misconceptions is that tubular drag cable and screw conveyors are identical, which is far from the case,” says Karl Seidel, marketing director of Cablevey Conveyors, a mechanical conveyor manufacturer that serves the specialty food, coffee, powder, nut, and pet food markets.

Screw systems, also known as auger conveyors, typically utilize a helical blade that moves granular materials within a tube. However, augurs can cause product damage and compromise blends. So, the units tend to be an option when material integrity is not critical, such as when conveying food waste.

Seidel notes, “The key difference to look for is that augurs convey material with a helical screw. The transfer speed is directly proportional to the rotation speed of the screw. On the other hand, tubular drag cable conveyors transfer material between two discs pulled by a sealed cable and are designed to protect delicate products and blends.”

Misconception #2: Conveyors Are Not Designed to Protect Blends and Mixes

When transporting a blend of product with a conveyor system, maintaining a consistent mix ratio is essential, whether a fine powder, coarse mix, or

larger variable-sized amalgams of different weights and shapes.

However, conventional conveyor systems are not specifically designed to precisely transport blends without changing the mix ratio. Various product material weights, sizes, and shapes can shift and disperse in open systems like bucket conveyors, and vibration can cause the blended product to shift throughout transport. Vacuum and pneumatic systems can cause smaller lightweight particles in a blend to move at different speeds than heavier or larger particulates, resulting in significant blend restructuring when the product reaches its discharge point.

In contrast, tubular drag cable conveyors are engineered to maintain precise blend ratios, which can be important to food industry professionals from nutritionists to farmers feeding livestock, according to Seidel. As an example, the company’s engineers have resolved the issue with a completely enclosed, compartmentalized tubular conveyor system.

“Not unlike an endless succession of train cars, each space between solid circular discs holds a predefined volume of product. Based on the manufacturer’s specifications and requirements, engineers can calculate the optimal speed of the system, the most appropriate tube angles, and the proper construction design to guarantee their blended product remains consistent from input to discharge, even at high volumes,” says Seidel. His company has designed, engineered, and serviced enclosed cable and disc tube conveyors for 50 years in over 66 countries including Canada.

Tubular drag cable systems like Cablevey’s convey food materials in a wide variety of forms and states including powdered, pureed, chopped, moist, hot, and frozen with throughput rates up to 80,000 pounds per hour. The systems can convey material with high moisture content such as soaked beans and chickpeas when some water is being conveyed along with the product.

While the tubular conveyors are constructed of plastic components, the standard units are designed to operate at 82°C with a high-temperature option up to 110°C, so can receive the product from ovens, fryers, or dryers, according to Seidel. Even frozen products can be conveyed, although it is important that the temperature is controlled along the path, so no melting occurs with water freezing later in the system.

Misconception #4: Conveyor Footprint and Expansion Limitations

Some in the Canadian food industry do not consider tubular conveyors because they mistakenly believe that the systems cannot fit within their facility’s available space or accommodate its layout, which may include significant inclines or elevation changes. However, this is not the case.

Modular systems like tubular drag cable conveyors are an excellent option for complex layouts that could require curves or changes in direction, says Seidel.

“Tubular conveyors do not have to be installed at 90 degrees and can use angles so can go in between, around, above or below existing equipment or other obstacles. That is important for existing facilities that may not have the flexibility to move something out of the way,” says Seidel.

In addition, tubular conveyors are quite space efficient. Seidel notes that to conserve space, the conveyor turnaround and its inlet can stand on end, so it is only one foot across instead of three. If conveyor discharge occurs best using gravity, tubing can be run through walls and discharge out of the building roof, which saves interior space.

Misconception #5: Cleaning Requires Dismantling and Extended Downtime

Between product changeovers, many conveyor systems must be disassembled, cleaned, or soaked, and then reassembled. However, this is not necessary for tubular conveyors.

With tubular conveyors dry, wet, and in-line cleaning options are available, according to Clint Hudson, Cablevey Conveyors engineering manager. Among dry options, brush boxes and airknives can clean the cable. Brushes and wipers can wash the tubes.

To sanitize, a sponge soaked in sanitizer can be used without getting the system fully wet.

For the most thorough cleansing, the cable conveyor’s wet cleaning process internally washes the tube in several steps, starting with a water rinse followed by a foaming agent, a sanitizing rinse, and a final water rinse. Once the system is thoroughly flushed out, drying is achieved by attaching urethane wipers to the tubular conveyor’s discs, which “act like a squeegee” to remove any residual water.

Misconception #6: Conveyors are for Indoor Installation Only

It is a misconception that tubular conveyors are only installed indoors. In fact, it is common to see portions of equipment extending outdoors. This may occur when conveying product from outside to inside such as when unloading raw material from a truck or railcar or loading finished product

helpful to wrap the tubes in heat tape to prevent moisture from condensing or freezing in the tubes. The conveyor manufacturer can also provide a range of accommodations to account for the effects of wind, dust, rain, insects, and direct sunlight.

This article was contributed by Cablevey Conveyors.

Cablevey Conveyors https://cablevey.com

The electric actuators you need for every application are built by Bonomi and CSA approved.

Our Valbia electric actuators can be used with confidence everywhere in the US and Canada in almost any industrial or commercial application. They are built for long life and quiet operation indoors or outdoors. Heater, thermostat and 75% duty cycle motor are standard. And they make a perfect package with our superior-quality, low-torque direct mount Valpres and RB ball valves. Call Bonomi today and stock the best in electric actuators and automated valve packages.

company is moving a moist product, it can be

Technology and automation continues to up-end the boundaries between man and machine. While machines are now more involved in manufacturing processes via artificial Intelligence and cloud computing, people still run process manufacturing plants and are accountable.

The ideal environment is one where Plant Process Management (PPM) combines the natural attributes of people with technology to assure optimal communication, safety, and production — in a symbiotic relationship. PPM describes applications that help manufacturing organizations manage, monitor, and optimize work activities and production assets with a central digital repository of information.

In this environment, the importance of the process technician and the role of technology to support human factors and machine collaboration is critical.

For many chemical and pharmaceutical companies, process technicians are key operators working in shifts for either a batch process or continuous manufacturing environment. They operate equipment, monitor the machinery, and document results in strict adherence to protocols. The processes may involve a chemical reaction or blending of ingredients (liquid, powder, or gas) continuously or in a batch before they become finished products. Process technicians may work as process operators, chemical process technicians, bioprocess technicians, cleanroom operators, or system operators.

This involves the production of chemicals, drug substances, or active biological substances – while following Good Manufacturing Practices (GMP) and ensuring compliance with the pharmaceutical or chemical company’s Standard Operating Procedures (SOPs) and meeting many regulatory guidelines.

Because technical operations run as a team, all need a solid understanding of procedures, techniques, tools, substances, and equipment. Workflow needs to be prioritized and team members should be contributing to the team’s success by sharing their previously acquired knowledge using an automated approach with PPM. This is extremely important because while everyone is accountable for their own results, what happens during one shift can substantially impact the team members coming to join the next shift. Another area not to be overlooked from one shift to another involves maintaining area housekeeping standards and hygiene specifications by using a variety of sanitizing aids. For the team lead, they may also have to support the implementation of new technology for process execution and/or analysis. They must ensure and maintain all current training statuses on all applicable SOPs as well as execute SOPs for unit or equipment operations.

Realize your vision with Festo‘s approach to smart automation. Partner with Festo today.

While machines are very good at capturing and storing data, humans can remember perceptions, images, and feelings. Thus, only people can draw on human attributes to create a better understanding from what been experienced or memorized from past experiences.

Technology can only do what we’ve asked it to do while people are able to create new processes or situations when the unexpected arises.

As the price of storing data has declined and cloud-based systems have emerged, more and more information is available for data mining, but in general, the process manufacturing industry has not invested the millions of dollars necessary to ensure that the data can be utilized effectively.

When it comes to the implementation of a PPM platform with use cases such as shift handover, incident reporting, or routine inspections, it is important to strive for a wide acceptance of the lower-level plant worker.

It is crucial for the success of a digitization initiative to make allies of shift workers. With plants running 24/7, there is generally less management around during nights and weekends. With self-service configuration those users can change and adapt their set-up according to new regulatory requirements, equipment, or process updates which keeps the ownership of the application in the plant.

Adapting the behavior of a shift team with people who have worked in the same plant for decades is an endeavor that needs to be well-prepared.

Today’s systems are intuitive to learn, which means that many operators can embrace new procedures with relatively little training. However, appointing an early adopter in the concept phase and providing training and hand-holding procedures helps to bring along the people who may be uncomfortable or skeptical of digital technology. Often these people can be long-time contributors who bring decades of experience and their perspectives can be very impactful in creating an important knowledge base. This is all good preparation for the great “crew change” — the year when several people may retire.

In global rollouts there needs to be strong local teams, each with management support as well. Today, with a capable PPM solution and an experienced consulting team, rollouts can even be done remotely. For example, one company that benefited from PPM, executed a global rollout across 10 countries, 6 time zones, and 40 different plants in less than 6 months.

In a 12-hour shift, how much data is retained or forgotten during that shift? On a good day, a high proportion of data generated may be retained. On a stressful shift, it may be only half. Transfer of data to the next team will be directly affected by this, especially when errors and omissions of communication are factored in.

Relying on process technicians to remember all information and to communicate it reliably either verbally or via written documents will always be problematic. Inaccurate communication can result in many

different problems, including safety issues, especially considering they can be involved at all stages of a manufacturing process. Their role requires that they follow strict internal protocols and SOPs as well as following cGMP. There is a tremendous amount of responsibility given to individuals within these roles. Any deviation from these practices or any mistake made could have serious repercussions, resulting in potentially unsafe defective products or expensive destruction of batches.

A process technician will typically be responsible for a single specific step in the manufacturing process as it is their job to know this process in great detail and identifying when the process deviates from the norm. They are enlisted to take action to correct a deviation or involve senior members of staff, usually a process engineer, if and when they aren’t able to correct the problem. Additionally, equipment within their process must be kept in good working order. This involves regular inspection, cleaning, servicing, and maintenance. Considering this tremendous responsibility, it makes sense to use an automated system to maintain accurate and clear documentation to prove - and to show upon request by auditors - that these processes are being carried out in accordance with both internal and external regulations.

Automating the information shared between teams ensures continuity and mitigates risk. It serves as a running protocol of relevant events and conditions that together describe the state of manufacturing processes within a specific timeframe. To align all these sources, automation can help by providing an accurate, formal digital record of the plant operations and can be used by any team member who needs it.

Poor communications at shift handovers have been identified as one of the causes of two particularly notable plant disasters. For example, the Piper Alpha explosion, which occurred on a North Sea oil rig in 1988, resulted in the deaths of 167 and impacted, at the time, 10 percent of North Sea oil and gas production. There appeared to be two communication failures that occurred around the time of handover between day and night shifts.

First, maintenance personnel did not communicate effectively that the relief valve had not been returned as originally planned. They returned a ‘suspended’ permit to work to the permit office but did not talk to anyone about the work or inform about the delay.

Secondly, communication at the operations shift handover meant that the night shift knew that condensate Pump A had been isolated in preparation for its overhaul, but the overhaul had not started. However, the removal of the relief valve was not communicated and so the night shift was not aware that it was or could have been missing. The conclusion was that a shift handover had taken place as some information about plant status had been communicated (i.e., pump being isolated); but it had not been effective because other information (i.e., relief valve being removed) was not. This meant that the night shift operators made decisions when facing a potentially serious loss of production based on an inaccurate knowledge of plant status.

In another example, the BP Texas City refinery explosion, which occurred in 2005, resulted in the deaths of 15 workers, 180 injured and severely damaged the refinery. In this case the night shift operator left early, and subsequent shift handovers were minimal. Records in the shift log were brief and ambiguous and thus mis-interpreted by the incoming shift. A root cause of these failures was that BP did not have a shift turnover communication requirement for its operations staff. Also, the investigation found that key messages were often not written down but passed verbally over the phone and radio. This resulted in the board and outside operators interpreting a message regarding routing of raffinate differently. The Board operator closed a control valve. The outside operator manually opened that valve, which ultimately caused the explosion.

While these examples are only two of the most notable communications failures, many other crises that have had less significant outcomes, have occurred due to incorrect or missing information that could have been avoided with a PPM platform.

Success stories have also been documented by those who have implemented digital transformation programs. Polymer manufacturer, Covestro, undertook a digital transition in all its plants after realizing that a combination of Excel sheets, phone calls, and logs books could be easily replaced with a webbased shift handover system that could be accessed universally. An interface with the company’s SAP platform empowered employees to retrieve information from a central location and greatly increase quality, efficiency and, importantly, improve plant safety in more than 30 global locations.

The technology delivered via a PPM platform plays an important role in alleviating miscommunication, thus averting possible critical failures and better yet, empowering people to assure smooth, efficient, and safe plant operations.

Technology won’t replace people. Successful manufacturing enterprises will embrace an approach that elevates the attributes of both people and technology to help the human-machine network work together in a more collaborative way. This will ensure more transparency, reliability, and visibility across all plant functions to help teams better communicate and optimize outcomes. This article was authored by Andreas Eschbach CEO, eschbach and Dr. Andy Brazier, Industry Consultant for Risk and Process Safety. eschbach www.shiftconnector.com

With impressive +/-0.1% full scale accuracy, intuitive controls, and convenient design features for easy installation, it’s the ideal reference-grade gauge for panel mounted applications.

• Perform live viewing of pressure or set up tests for continuous monitoring.

• Test multiple pressure ranges at one station.

• Easily customize the gauge to your needs using the included FieldLab Desktop software.

•

•

Red Lion has introduced its next generation of panel meters, PM-50. The graphical panel meter is available as a 3.5- or 4.3-in. touchscreen display. Using simple “swipe” technology, the company says, users can easily switch between relevant screens and receive comprehensive operational data for monitoring equipment and production. Visual alerts notify the user that immediate action is necessary, either on the unit itself or via PM-50 app, available on Google Play or Apple Store. The panel meter offers built-in Wi-Fi connectivity for users to remotely access workflow and process data from the confines of the plant floor to create a smarter plant floor, it adds. Wired connectivity is also an option via Ethernet and Modbus. The unit can replace a meter with a 1/8 or 1/16 DIN panel cut out. An on-device programming wizard, mobile app, or web browser is said to provide an easy and intuitive setup. Additional capability is available with field-installable modules to provide outputs, communications, and AC power functionality when needed.

Red Lion

www.redlion.net

• Simple: Get started with digital liquid analysis easily and quickly

• Safe: Increase the availability of your measuring points

• Networked: Boost plant efficiency by networking all measurement processes

Siemens has announced the Simotics SD200 severe-duty motor in frame size 440 as its latest offering in the low-voltage Simotics motor series. The cast-iron NEMA motors are built to power pumps, fans, compressors, hoists, winders, and similar equipment in environments with Division II, Class 1 and 2 conditions present. With a three-year warranty, the motors offer 75 to 800 hp output and feature 4445013 cast-iron frames for operation in 460 V and 575 V ranges. The units meet or exceed NEMA Premium MG1 Table 12-12 efficiencies. Options offered include IP56 ingress protection, encoders, brakes, and blowers plus others to suit the applications presented. For insulation, the Class-H non-hygroscopic system with NEMA Class B temperature rise provides an extra margin of thermal life. The insulation system meets or exceeds NEMA MG1 2014 Part 31, making these motors suitable for variable speed drives in constant torque (4:1) and variable torque (20:1). Siemens http://usa.siemens.com/simotics-sd200

Model AD aerators from Conveyor Components Company provide positive flow of dry, finely ground materials from any bin using the proven principle of aeration. Low pressure air is introduced into the product, restoring its natural ability to flow, the company says. In this way congestion, bridging and rat-holing are overcome without resorting to brute force, it adds. Almost all flow problems inherent to dry, fine materials are caused by compaction. When low pressure air is introduced to a finely ground material it will flow like water, uniformly and quickly. The aerators are non-clogging and provide equal distribution and consumption of air. The units are said to feature simple and quick installation — simply drill a 7/16 in. hole in bin wall insert special tank nipple through hole and secure with lock nut. Aeration gives the best results on materials with a 60-mesh size or smaller and with a 3 percent or less moisture content. Materials that respond well to aeration include lime, Portland cement, diatomaceous earth, flour, soda ash, pigments, soap powders, bran, clay, cereals, and detergents. Conveyor Components Company www.conveyorcomponents.com

Carlo Gavazzi has introduced model EM530 and EM540 three phase energy analyzers. The EM530 is a Class 0.5S (kWh) analyzer which measures currents up to 10,000 A via 5 A current transformers, and the EM540 is a Class 1 (kWh) analyzer which measures current up to 65 A via direct connection, the company says, eliminating the need for current transformers. The 3-phase power analyzers can be used for two and three phase systems, as well as wild-leg systems. Units can measure most relevant instantaneous electrical variables, energy consumption, and harmonic distortion, it adds. Both models feature high speed 100 ms serial data refresh rates, making them suitable for load balancing energy storage or EV charging applications. Fast commissioning is said to be possible thanks to an intuitive wizard setup menu, along with instant notification of wiring errors and suggestions for correcting them.

Carlo Gavazzi

www.gavazzionline.com

Can-Am Instruments has announced that it is now an authorized representative and distributor for LogTag temperature and humidity loggers, and Thermco Products liquid filled and digital thermometers.

“We are very excited to be a Canadian distributor for LogTag and Thermco,” says Ryan Schooley, sales director for Can-Am Instruments.

“We are very selective when we look for companies to represent and LogTag and Thermco fit well with our requirements. They both have high quality products, exceptional service, and a degree of flexibility that allows customization to our customers’ needs.

“Strategically both companies are a great addition to our portfolio as there is demand though our existing customer base and an opportunity to expand into new markets.”

LogTag, headquartered in New Zealand with offices in Hong Kong and the U.S., manufactures temperature and humidity loggers. From single-use to continuous-monitoring, LogTag dataloggers are used extensively in the medical/laboratory industry for vaccine monitoring and in the food/transport industry for food safe safety.

Thermco Products, based out of New Jersey, manufactures high end digital and liquid filled thermometers. From its ISO/IEC 17025-approved facility it provides fully calibrated, NIST traceable temperature measurement devices.

Can-Am Instruments, based in Oakville, ON, represents manufacturers that also include Ametek Brookfield, HunterLab, Hach Flow & Sampling, Highland Tank, and Arjay Engineering; Can-Am provides full sales and service to its laboratory and environmental customers, the company says.

Can-Am Instruments

https://can-am.net

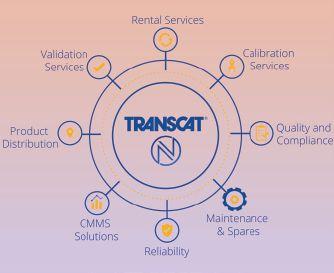

Multinational calibration services firm Transcat has acquired NEXA | EAM, a global enterprise asset management services company. The acquisition was initiated to grow and strengthen the service portfolio of Transcat in the highly technical life sciences industry.

Leclerc Foods of St-Augustin-de-Desmaures, QC, a North American snack food manufacturer, has acquired a 790,197 square-foot production plant in Brockville, Ontario.

Production is planned to start gradually from July 2022, achieving full capacity in January 2023. The plant will be in the Brockville Industrial Park at California Avenue.

“Brockville offers a strategic location within North America, near US customs and our other Leclerc plants in Canada and the USA. This new facility will allow us to continue to grow our operations in full expansion,” said Denis Leclerc, president of Leclerc Foods.

Resulting from an investment of more than one hundred million dollars over five years (including production equipment), this will be Leclerc’s largest facility, which will promote the development of new markets and new product and category development.

Leclerc Foods

www.leclerc.ca

Rittal Systems of Mississauga, ON, has announced that Black Controls Company is its first Rittal Certified Systems Integrator of 2022. Black Controls provides automation and controls solutions for clients in North America, Europe, and Asia in the areas of material handling, consumer products, and sterilization.

Headquartered in their new location in Barrie, ON, Black Controls consists of skilled designers, electricians, and programmers who create the industrial control systems.

Black Controls has joined Rittal’s qualified group of Certified System Integrators, the company says, who have demonstrated exceptional knowledge and experience in specifying and configuring Rittal enclosure and climate control systems, with great proficiency.

Rick Black, owner, Black Controls stated, “We are pleased to become a Rittal Certified Systems Integrator, which endorses our team’s technical excellence in mastering Rittal’s range of market-leading enclosures and climate control systems.

“This certification will provide us with further training and the opportunity to collaborate globally with Rittal’s team of experts. Our end goal is always to ensure that our customers receive the highest levels of service and the most comprehensive, integrated automation solutions for their needs.”

Vernon Mascarenhas, technical account representative, Rittal Systems, said, “It has been a pleasure to be part of Black Controls’ phenomenal growth over the last 2-1/2 years. Rick has taken the company to new heights from the time he started building panels in his garage to the forward-thinking and fast-growing global company that it has become today.

“Rittal is delighted to welcome Black Controls as our valued Certified Systems Integrator, and we look forward to playing a role in their future growth.”

Rittal Certified Systems Integrator Program www.rittal.ca/rcsi

Despite the challenges posed by the ongoing global coronavirus pandemic, fragile supply chains and supply bottlenecks, the Harting Technology Group, based in Espelkamp, Germany, has continued its path of growth in the 2020-21 business year. Harting Canada is located in Montreal.

The family-owned and operated global company generated sales of US$956 million, up 14.5 percent on the previous year.

“We’ve successfully overcome the challenges of the coronavirus pandemic and have enjoyed strong growth,” explained Philip Harting, chairman of the board of the Technology Group.

To maintain operations and continue to support customers globally, Harting set up an inhouse pandemic response team in 2020. The team oversees all communications regarding the pandemic and set up several protocols to protect customers and staff alike. This team enabled the company to continue to deliver reliable and robust products on a global scale.

“We’re very happy with the outstanding result and proud of what we’ve achieved over the past few months.”

All global regions in which Harting operates performed positively during the period, with many enjoying substantial growth. Sales in Europe (excluding Germany) were up by 15 percent to US$44 million, while the Americas region (in-

cluding Canada) posted gains by 14 percent or US$13 million, followed by Asia with sales growth of 6 percent or US$14 million. Leading the field was Germany, where sales were up by 23 percent or US$44 million.

The company intends to keep on mastering the challenges of the future with powerful connectivity solutions for the transformation of industry. The company has put forth plans for continuing to overcome obstacles resulting from challenging conditions. These obstacles include inflation, supply bottlenecks caused by a shortage of materials, fragile supply chains, rising energy prices and the significant commitment and work involved in bringing about the energy transition. The coronavirus pandemic will also continue to have an impact on market trends and company performance.

The Harting Technology Group’s various divisions have been focusing on a range of key trends in recent months. Under the tagline “All for Energy”, the company is tackling the energy transition by making energy storage systems quick and safe to scale up. Meanwhile, “All for Railway” is addressing key trends in the rail sector: transmitting higher currents and voltages and reducing CO2 by making rail vehicles more lightweight. As one of the founding members of the “SPE Industrial Partner Network”, Harting has proven its commitment to promoting the new global infrastructure stan-

After a coronavirus-induced absence, the Honeywell Users Group (HUG) Americas conference is set to resume with in-person sessions in 2022. HUG provides users of Honeywell process control and industrial automation systems with a forum to exchange technical information and give feedback to Honeywell on their equipment and service needs.

All present and future Honeywell users and OEMs are eligible to become members of the Honeywell Users Group conference.

Honeywell Process Solutions has also introduced a new website, https:// process.honeywell.com. The enhanced website provides sleek and intuitive navigation, the company says, for quick and simple access to the solutions for the process industries. Users are also said to benefit from seamless e-commerce capabilities and easier access to their account information.

HUG conferences in 2022 will take place May 22-26 in Orlando, and October 24-27 in Madrid.

On February 24, McCain Foods of Toronto stopped construction at its Russian production facility in the Tula Oblast region. The company has now made the decision to discontinue the project entirely. In addition, it is also suspending all shipments of products into the Russian market.

“The Russian invasion of Ukraine has been deeply concerning to all of us at McCain Foods,” the company states.

“Our thoughts continue to be with those affected by this crisis and we have done everything in our power to put the health and safety of our employees at the centre of our response.”

To help contribute to the global relief efforts underway, the company recently donated $200,000 to the Red Cross Ukraine Humanitarian Crisis Appeal.

To donate to the Canadian Red Cross in support of the Ukraine Humanitarian Crisis Appeal, go to https://rb.gy/dounhp.

dard for the digitalization of industry in the form of single-pair Ethernet (SPE). This new form of data transmission for industrial automation allows the field level to be connected seamlessly to the cloud.

With the company’s Customized Solutions Global Business Unit, the Technology Group is bringing together elements from three divisions: Engineering, Connectivity and Cabling. Co-engineering, customer proximity and developing integrated solutions together with partners are all ingredients in the recipe for success that is being driven forward by the Application Engineering Centers in the regions.

Harting Canada www.harting.ca

Emerson has expanded the manufacturing capacity of its Brantford, ON, facility to better serve Canada’s immediate-demand automation market. Emerson has added production of its complete range of Aventics Series PRA Profile Cylinders, Series TRB Tie Rod Cylinders and Series TaskMaster TM5 NFPA Profile Cylinders.

The company’s investment in local cylinder production will give Canadian automation customers shorter lead times for customized cylinders, estimated at just one to five business days, as well as after-market service. Receiving critical components so quickly can help customers across all industry segments get their products to market faster and minimize end users’ downtime.

Canada has a strong automation industry, and the 63,000-squarefoot facility is in the same province as more than 350 automation and robotics-related companies, the largest concentration in the coun-

try. The Brantford expansion is part of Emerson’s global business strategy to provide its customers with the highest level of service and strengthen the supply chain through regional manufacturing.

According to Stephane Meunier, national sales director, Emerson, “The automation industry in Canada continues to grow, and we want to ensure our customers’ success by getting them components critical to their product designs as quickly as possible.”

Emerson’s Brantford facility also produces pneumatic actuators and valves under its Aventics and ASCO brands, including its Aventics Series 2000 and Series 500 valve manifold solutions, Aventics Series 650 air preparation units and Series A and C NFPA actuators as well as customized actuator and integrated enclosure solutions.

Emerson www.emerson.com/en-ca

Emerson fluid control and pneumatic devices incorporate sensing and monitoring capabilities to improve performance, enhance safety and optimize energy usage at industrial and food plants.

The 76 Series— the largest model in the Eriez line up of vibratory feeders — supports trays up to approximately 200 lb and is offered in most common voltages. In designing the powerful and unique feeder, the company says it filled a void in the marketplace by providing a feeding solution for applications where trays are often too heavy for smaller models and using multiple drives is not practical. Large bucket elevators require high capacity feeders with long tray overhangs to reach the in-feed section of the elevators, making the series a suitable choice. With its ability to easily handle larger trays with multiple features such as screens, covers, inlet spouts and downspouts with a single compact drive unit required by bulk bag dischargers, the series is also well suited for bulk bag unloading. For scale feeding — which requires wider, longer trays to reach to the centre of radial combination scales — the series of vibratory feeders is said to offer superb performance. Eriez www.eriez.com

Flexicon has announced a portable half-frame bulk bag discharger with manual bag dump station and integral flexible screw conveyor that transfers material discharged from bulk bags and/or manually dumped from hand-held sacks into downstream process equipment or storage vessels, dust free. Mounted on a mobile frame with locking casters for in-plant mobility, the system is said to minimize weight and maintains a low centre of gravity by eliminating upper frame components, relying on the user’s forklift or plant hoist to suspend bulk bags above the discharger during unloading. The flexible screw conveyor transports both free- and non-free-flowing bulk materials including products that pack, cake, smear, seize or fluidize, with no separation of blends. The conveyor support mast cantilevers from the frame, and runs parallel to the conveyor tube, allowing the caster-mounted system to maneuver in restricted areas or be rolled to a cleaning station.

Flexicon Corporation

www.flexicon.com

Spencer Strainer has introduced sanitary self-cleaning filters for process flows of up to 400 gpm. Constructed of 316-L stainless steel, the food grade strainers work continuously in a sealed environment. There are no bags or elements to replace, so there is no inherent downtime for filter changes, the company says. With no filter disposable elements to dispose of, it adds, the strainers are an environmentally friendly option which helps companies meet their sustainability goals. Wedgewire or perforated screens of various openings are available and interchangeable, allowing one strainer to be used for multiple applications. The units are said to be a reliable, cost-effective solution for many types of food processing applications, including peanut/almond butter, chocolate, pizza sauce/tomato sauce, cheese, orange juice, alcohol, and dairy products, as well as non-food products including oil, acrylic, polymers, paint, biofuel, toothpaste, caulk, and bath tissue. Food grade models are available for process flows of 100 gpm and 400 gpm; they are rated at up to 180 psi and up to 400 PSI respectively. 3A sanitary designs also available.

Spencer Strainer www.spencerstrainer.com

The NCR-80 from BinMaster is a non-contact radar level sensor designed for extremely dusty powder and bulk solid applications. It operates at 80 GHz frequency, focused in a narrow 4° beam angle with a measuring range up to 393 ft and accuracy within 0.2 in., meaning it excels in tall and narrow vessels, company says. The beam angle allows for precise aiming to avoid the flow stream, internal structure, or sidewall buildup, it adds. Narrow focusing also simplifies setup, as the signal will reflect only from the measured material being targeted. The radar level sensor is resistant to interference, while its filters are said to ensure rapid signal processing and an update rate of less than 1 s, while firmware constantly tracks echoes and automatically eliminates false echoes for reliable performance. The sensor is offered with a 10° swiveling, stainless steel flange for more precise targeting; a lightweight plastic antenna with an 8° swiveling flange or a mounting strap for adjustable targeting; or a 1-1/2 in. NPT mounting option for use in an existing process connection. BinMaster www.binmaster.com

Over the past century the industry has realized unprecedented advances in human health, yet the pharmaceutical industry is struggling to keep up with demands. Increased demand results in the need for increased production which poses a complete set of new challenges for companies in the supply chain.

Such production challenges were realized by A&C, a service driven organization finding unique solutions to its customer’s Good Manufacturing Practices (GMP) challenges. It is a custom manufacturer and supplier of excipients, process solutions, buffers, and APIs. They are audited by both FDA and Health Canada affirming their constant and stringent efforts to meet regulatory requirements for pharmaceutical and biopharmaceutical raw material suppliers.

With two GMP facilities located in Montreal, A&C manufacture, pack and distribute bioprocessing liquid and bulk materials under Good Manufacturing Practices with full compliance to all international regulatory requirements.

With product demand increasing A&C realized the need for significant investment in bulk material handling capabilities to support expanding business and increased production, while focusing on minimal downtime. As part of this initiative, A&C continually focused not only on process, but also on end-product quality, safety, and compliance. “A major challenge our customers face is the way bulk materials are supplied to the market,” according to Damien O’Rourke, VP and COO at A&C.

“We needed a material handling system that would keep up with our demand, ensure worker safety and limit manual manipulation of material.”

A&C promotes a leadership position in providing full transparency in the supply chain, as demonstrated through EXCiPACT, GMP & GDP certifications. EXCiPACT (International Pharmaceutical Excipients Certification) is a non-profit organization that owns and manages oversight of an independent, high-quality, third-party certification available to pharmaceutical excipient manufacturers and distributors worldwide. “The Vac-U-Max team designed and manufactured a material handling system capable of conveying over four and half million pounds of powders per year that now allows us to continually meet our growing business,” continues O’Rourke.

“A&C’s quality management system is based on

When pharmaceutical supply chain companies work with expert vacuum conveying manufacturers to design equipment that will perform well with existing equipment and specific processes, they are accessing not only industry specific know-how, but expertise in powder characteristics that transfer from industry to industry assuring processors, through written guarantees, that the equipment will perform the way it is supposed to.

providing the highest quality product to companies worldwide while safeguarding public health. We place strong focus on plant and personnel safety, product lead times, minimizing product contact and manual manipulation of product in support of GMP initiatives.”

Among A&C’s service offerings, the powders processed are supplied in custom packaging meeting customer specific requirements. Product must be conveyed from different containers to the discharge point at a rate of 2,200 lb/h. Manual handling of product poses its own set of challenges including slip and fall hazards, fugitive combustible dusts and other sanitary issues that may result in decreased production and lengthy downtime. Employing vacuum conveying technology for dust containment, labor savings, cleanliness, or safety and environmental reasons lies in the ability of vacuum conveying experts to understand powder characteristics and how those characteristics interact with equipment design. A&C also wanted the best ergonomics for their employ ees, so they also selected a Vac-U-Max LoadLifter for the repetitive action of lifting bags from a pallet and depositing it on the bag-opening grate of the bag dump station.

how many cubic feet per minute (CFM) of air is needed to move the material through the convey line. In A&C’s case, the bulk densities were on the heavy side at 95 and 133 lb/ft3.

Attention is given to the prospect of segregation especially during manual transfer of materials in drums or other containers, to the next process vessel in the production process. Vibration caused by moving containers promotes segregation. While each application requires a unique resolution based on distinctive environments and equipment, systems are generally built using standard components and customized according to the application requirements. A&C’s process requires the convey and discharge of multiple

As most pharmaceutical and nutraceu tical processes start with a powder or granular material, material character istics must first be defined with focus on the materials attrition and segrega tion, vacuum conveying behavior, flow properties, and particle properties like shape, size, cohesiveness, and bulk density. The bulk density of a material is one of the first indicators of design in terms of sizing various system compo nents such as vacuum receivers and air sources. Bulk density helps determine

materials, from diverse types of packaging (bags, bulk bags, and drums), in a clean room environment which is subject to washdown sanitation.

Introduction to the Process

Equally important is the introduction of material to the process (i.e., the pickup point). Product can be introduced via simple suction wand (from a drum), or a sanitary bag dump station with integral dust hood or via bulk bag (a.k.a. super sac) unloading systems. A&C introduces product to the process via the Vac-U-Max sanitary bag dump station and the Activator bulk bag unloading system with “chisel bottom” screw dischargers. The bulk bag unload system features a dust-tight cover and cantilevered open flight 150 mm auger to provide a consistent, controlled flow of powder into the convey line.

typical I-beam and hoist rated for up to 1800 kg.

The unloader is equipped with a manual iris valve in the bag access housing which allows the operator to untie a full bulk bag discharge spout without any release of product. All product contact surfaces are designed in 316 stainless steel including the sealing collar, operator housing with access door, conical pickup adapter and screw discharge devices. The entire bulk bag unloader is constructed in stainless steel to meet A&C’s current GMP program.

The sanitary 316 stainless steel Vac-U-Max bag dump station is equipped with an integral dust collector that automatically turns on when the dump station door is opened, to keep dust from the bag opening away from the operator. Dust that is collected on the static-conductive filters is pulsed automatically into the bottom

The Activator version bulk bag unloader features four pneumatically operated actuator petals to massage the lower portion of the bag in an alternating-side pattern to promote optimal material flow toward the centre of the bag. “We have tested two-sided actuators, but the four-petal design is far more effective in promoting material flow to the bag outlet,” states Doan Pendleton, VP of Vac-U-Max. The Activator assembly includes a NEMA 4X control panel and level control so that the bag is only massaged when powder is needed. The bag access door is capped for dust collection during bulk bag discharge. The Activator uses lubrication-free pneumatic lifters that consume 50 percent less compressed air than air-cylinders, providing A&C with lower operating costs.

A&C can minimize material handling devices such as forklifts in the work area by leaving the bulk bag on a pallet, lifting, and placing it into the bulk bag unloader with its integral I-Beam and 2 hp hoist. The operator controls the hoist from a remote pendant, taking them safely away from the lifting zone. The "I" beam and bag lift frame are constructed in 304L stainless steel and handle bags up to 122 cm high with weights up to 1020 kg, with

of the dump station so that no material is lost. The materials have high bulk densities, so the bag dump station has the same screw discharger on the bottom to provide a metered feed of material into the convey line. Like the Activator bulk bag unloader, the screw discharger has a pneumatic poppet valve on its outlet to prevent any dribbling of powder into the convey line which might affect the accuracy of the conveying process.

Bulk density, while one of the most important factors in sizing a system, is not the sole criterion used to determine components. Another key factor in sizing and determining the type of system needed is the distance that the material is traveling. In pneumatic conveying, the more tubing incorporated into the bulk material handling system, or the further the conveying distance, results in larger vacuum pumps since it takes more airflow to pull (or push) the air through the tube. Vacuum conveying systems move product vertically and calculated the same as moving product horizontally — in linear feet. However, each 90-degree sweep in the system equals 20 linear feet; thus, moving material horizontally 110 ft and vertically 110 ft with four 90-degree sweeps results in an overall conveying distance of 300 ft. Vacuum conveying technology was selected by A&C. Any potential leaks in a vacuum system will be inward, where a positive-pressure system leak results in a cloud, or pile, exposed to the work environment. This not only reduces exposure for the operators, but also aids in reducing combustible dust, sanitation, and product yield issues.

A&C's team: An Activator version bulk bag unloader features four pneumatically operated actuator petals to massage the lower portion of the bag in an alternating-side pattern to promote optimal material flow toward the centre of the bag.

ating position above the drum on a scale, and to lower it to a travel position which is also a convenient height that encourages good maintenance and sanitation of the equipment.

A good vacuum conveyor needs a good vacuum producer. The vacuum producer selected for A&C’s system is a continuous-duty 5HP regen blower unit due to its good vacuum production and airflow, compact size, direct-driven impeller, and low noise level — perfect for a pharmaceutical environment. If the vacuum conveyor is the heart of the system, the controls must be the brains of the operation. Vac-U-Max has been selling equipment in Canada for decades and was able to provide A&C with a C-UL-labelled main control panel in compliance with Canadian electrical standards. “This is a great benefit for my customers in Quebec,” states John Hamilton of Hamilton Process Systems Inc; the Vac-U-Max representative for the province for over 16 years.

Self-sufficient and the heart of the process, the sanitary pharma-grade Vac-U-Max vacuum conveyor is mounted on a rolling lift frame to allow A&C to remove the equipment from the production room for cleaning. The lifting frame allows the conveyor to be raised into oper-

The vacuum transfer principle is used as a continuous refill device for continuous operation. Pneumatic receivers use negative pressure to draw material required for refill into the vacuum receiver, which is filled to a pre-determined level, with receiver holding a charge of material until the process below requests a refill. The level of material in the vacuum receiver is determined by level sensors. When the process requires a refill, the discharge valve opens, discharging material to the process below – keeping material moving from source to process.

According to Andy Pizans, Canadian sales manager for Vac-U-Max, “this was a coordinated effort between A&C and Vac-U-Max. Without this level of cooperation, the project would never have achieved the objectives of supplying a system that was easy to operate, safe, GMP compliant and efficient. All this was accomplished within a tight delivery schedule. A tremendous effort by both companies.”

Vac-U-Max contributed this article.

Vac-U-Max

www.vac-u-max.com

The Alfa Laval ThinkTop pulse seat clean is said to make drain valves spotless while delivering savings of up to 95 percent in Cleaning-in-Place (CIP) liquid. The pulse creates high turbulent flow as the liquid passes through the narrow gap between the valve house and valve seat, effectively removing all residuals for spotless drain valves, the company says. Intended for use with single-seat valves or butterfly valves used as drain valves, pulse seat clean is a standard feature of ThinkTop V50 and V70 sensing

and control units with one solenoid valve. Regardless of actuator mode, the drain valve may be configured as a normally open or normally closed shutoff or changeover valve. The pulse seat clean is said to simplify valve commissioning, prevents pressure shocks, and reduces CIP liquid and time.

Alfa Laval

wastewater 1c ad 4/5/05 2:53 PM Page 1

www.alfalaval.com/thinktop

• Manual, automatic and actuated (pneumatic & electric) valves; relief, check, diaphragm, ball, solenoid, and shut-off. Also pressure regulators, metering pumps, basket strainers, sight glasses, and gauge guards.

• Innovative Engineering –Dedicated Craftsmanship.

• 100% inspection and individual testing of each product, to ensure dependable performance and long-life.

• PVC, CPVC, Polypropylene, PTFE and PVDF. Valves from 1/8'' to 3'',Sight glasses to 8'' and Basket Strainers to 14''.

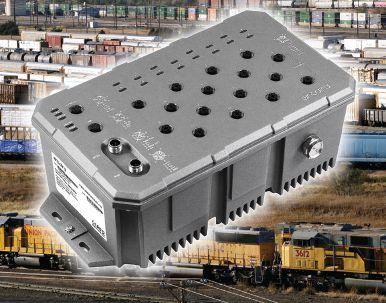

Antaira Technologies has launched a 16-port managed Gigabit Ethernet switch that is purpose-engineered for rolling stock and wayside installations. Acting as a network backbone, the LMX1600G-M12-67-110 switch series is said to offer a reliable means to configure, manage and monitor the growing data traffic generated by networked sensors, IP cameras, accelerometers, and other networked devices on-board the train. There is a USB and console port to enable faster field configuration and troubleshooting. Light Layer 3 protocols allow for VLAN creation and IP routing based on static routes. Applying the switch’s VLAN features sends traffic only where it needs to go, at the speed it needs to go, for reduced network congestion, the company says. Units meet a range of approvals including IP67 into its metal housing, and EN50155 international certification (pending) for train control systems.

Antaira Technologies

www.antaira.com

Bally Ribbon Mills has announced specialty fabrics constructed of specialty polymer fibres suitable for polymer manufacturing and break bands for rolled raw material processing. The proprietary narrow fabrics feature woven structures with finished woven structural edges said to provide a strong belting material. Able to withstand flex-fatigue caused by bending motions, the fabric’s fibre structure withstands wear surface abrasion from manufacturing processes and resists wear caused by the movement and interaction with material being processed, the company says.

Bally Ribbon Mills www.ballyribbon.com

The Cable Temporary Horizontal Lifeline (THLL) from MSA is said to allow for a 75 percent faster install compared to traditional cable systems. The completely toolless installation of helps to save time and increase efficiency when setting up lifelines on the jobsite, the company says. Integrated locking and tensioning mechanism on the handle eliminate the need for nuts, bolts, and wrenches. In addition, the lightweight, flexible cable helps make installation easy to complete by a single worker, it adds. Locking and tensioning mechanisms are on the same side with no need to travel back and forth for set up. Easy-to-read red and green visual indicators let the user know the system is locked, tensioned and ready for use. A patented bypass shuttles is said to help two users maintain 100 percent tieoff — increasing mobility without sacrificing safety. The THLL is compatible with MSA Steel and Concrete Stanchions.

MSA Safety

www.msasafety.com

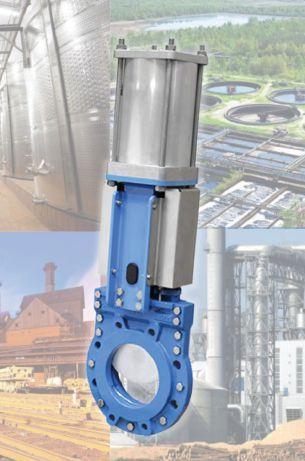

Orbinox has launched a new high pressure model bi-directional knife gate valve designed for industrial and water treatment applications. Its design focuses on meeting the needs of water treatment applications, and for general industrial processes requiring high pressure performance and reliability. The HB series knife gate valve consists of a two-piece ductile iron body and wafer style bi-directional knife gate valve, available in sizes ranging from 3 in. (DN80) up to 24in. (DN 600). All sizes are full port design and suitable for working pressures up to 20 bar (300 psi) and available with handwheel, gearbox, pneumatic cylinder, electric or hydraulic actuation solutions. The units consist of precisely machined half bodies together, the company says, with a special seal and packing solution that results in optimum tightness and low operation torque/thrust performance under high pressure and high media consistency conditions.

Orbinox www.orbinox.com

The ODT 3C sensor from Leuze can handle both measuring and switching tasks, making the 2-in-1 device suitable for a wide range of automated industrial applications. The sensor transmits measurement values and diagnostic data via IO-Link. The data includes temperature values, warnings, and signal quality. It features black-andwhite behaviour (<±3 mm at 150 mm). The operating range can be adjusted via the teach button, line, or IO-Link. The sensor also offers active ambient light suppression to prevent faulty switching, even when exposed to direct light from LED hall lighting systems, the company says. Two independent switching outputs and sensor models with warning output or a small light spot (pinpoint) round of the sensor’s functions.

Leuze electronic www.leuze.com

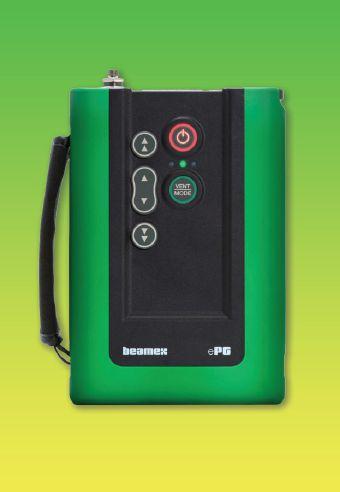

Beamex has expanded its PG pump line with the Beamex ePG, an electrical pressure pump for industrial pressure calibration applications. The portable battery-operated unit provides pressure generation from near vacuum up to 300 psi. With a field-replaceable, battery pack, users can perform many pressure calibrations on a single charge, the company says. The unit can be used together with any existing pressure calibrator, it adds, meaning users do not need to buy a new calibrator but can simply replace their manual hand pump with the electrical pressure pump. It is also said to be intuitive to use, with coarse and fine adjustment buttons to easily generate the required pressure.

Beamex

www.beamex.com

The KPM Analytics Process Sensors brand for IR temperature measurement has introduced the non-contact infrared temperature sensor model

PSC-4LT. The versatile, miniature IR sensing head has an ambient temperature rating up to 356°F and additional features, the company says, including the ability to measure the temperature of conveyed materials exiting industrial dryers or ovens without taking up excessive space in the production line. These materials include paper, plastics, coated metal, ceramics, sand, glass, aggregate, as well as liquids and powders. With the IR temperature sensor, it adds, operators can continuously monitor product temperature and keep their production throughput at an optimal level with the help of a small, compact sensor technology.

KPM Analytics www.kpmanalytics.com

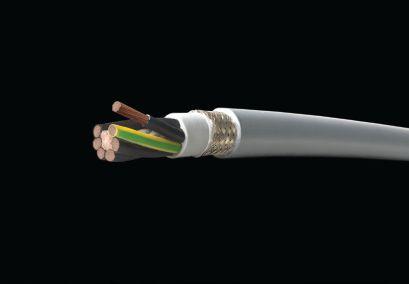

LAPP has introduced its SKINTOP MULTI-M round multi-cable bushing system for applications requiring a high packing density. Up to 30 entry points are available, depending on the bushing version, to accept cables, wires, conduits and pneumatics and media conduits. The metric-style units offer a 4 mm clamping range per entry point compared to just 1 to 2 millimeters typically offered by competitive products, the company says. Installation is said to be easy and secure thanks to the bushing system’s elastic

gel technology’s innovative membrane seal. Simply push in the cable, it adds, and the gel will hold the cable in place while providing optimal strain relief for the entire cable bundle. The gel does not apply stress to the installed cable, and unused entry points remain sealed. Operating temperature with or without an O-ring is -30° to 100°C. Protection class is IP68 -UL-approval pending. Applications include switch cabinet-, controls- and apparatus construction as well as automated machinery.

LAPP

www.lappusa.com

Dear valued reader, We are celebrating our 50th anniversary in 2022. A half-century is a long time for any business to survive. Back in 1972 the publishing business looked a lot different than it does today, that’s for sure.

took off almost right away. It’s been a terrific success story and although times have changed dramatically in the past decade, we continue to provide great value to our readers and our advertisers.

The publishing industry in Canada was controlled by two very large communication companies, Southam and Maclean Hunter. These publishing giants competed head-to-head in dozens of industries. Tabloid-sized, product-oriented magazines did not exist in Canada at that point in time. A few had started in the U.S. but had not come to Canada until Ray Blair and Peter Birchard (pictured above) came up with the idea of starting Canadian Process Equipment & Control News

Their magazine was big and bold. It carried a reader service card the readers could use to contact the advertisers and advertisers fell in love with the new approach. The first issue mailed in February 1973 and the rest is history.

The next great innovation came three years later when the Regional Process Shows were born in Sudbury, Ontario. Trade shows up until then were big booth shows in big cities only.

The idea behind the Process Shows was to take a one-day tabletop show to the communities where the processors were operating. The idea

Look for our Process & Automation Shows to resume after the summer. Let’s hope we are finished with lockdowns and Covid by then. Plan to join us when we’re in your area this fall.

Our next issue will have a Focus on Maintenance and Safety. Editor Mike Edwards's supplement will look at Pumps, Seals and Piping. The issue closes May 6th.

Stay safe, Rob Sommerville.

Krohne has introduced the Optiwave 6500C, a radar level transmitter for powders and dusty atmospheres. The instrument is said to deliver continuous high measurement in silos, hoppers, and containers. The unit is an optimal product for bulk storage in mining, minerals, chemicals, power, paper, food and beverage industries, the company says. The radar offers several advanced technological features, including an 80 GHz (FMCW) band width radar and a 2 ¾ in. lens antenna, making it suitable for environments with low dielectric media. With a measuring range extending over 328 ft, the radar level transmitter is appropriate for uneven surfaces or tanks with obstacles. Other advanced features include PEEK Lens antennas with both concave and convex lenses for distances up to 100 m and a backlit LCD screen with a 4-button keypad, ensuring flexibility for different radar usage.

Krohne Canada

www.ca.krohne.com

CONTROLLER HAS 4° TO 100°C RANGE

Wachendorff Automation has announced that it now also has a heavy-duty variant in the 36 mm design in its range of incremental encoders in the WDGP series, as well as absolute encoders in the WDGA series. Available from MDA Controls, this version is characterized by a bearing load of 300 N axial and radial, as well as the increased protection class of IP69k. This upgrade is said to make the encoders fit for high pressure/steam jet cleaning. They are specially designed for applications in harsh environments, such as mobile machinery, in the food industry or even car washes. The incremental encoder WDGP36J provides a protection rating of IP67 + IP69K, pulses up to 16.384 and output frequency up to 1 MHz. The absolute encoder WDGA36J (CANopen, SAEJ1939, SSI, RS485) is EnDra maintenance-free and environmentally friendly, offers CANopen (single-turn and multi-turn), has a communication profile according to CiA 301, and a Device Profile for encoder CiA 406 V3.2 class C2. MDA Controls

www.mdacontrols.com