Rittal Systems has introduced Blue e+ IoT-enabled air conditioners and climate control systems said to help decrease enclosure energy costs by up to 75% while enhancing efficiency and ROI, both in industrial as well as IT scenarios. The company offers climate audits through its experts, as well as various Climate Control Configuration software tools. Stainless-steel variants of the Blue e+ cooling unit series protection category IP55) are suitable for demanding environmental conditions, the company says. Enclosure heaters regulate relative humidity, prevent temperatures from dropping below the dew point, and stop condensaion forming inside the enclosure.

Rittal Systems www.rittal.ca

www.cpec.news/6w0

The Arjay Engineering 2852-DPM dry pump monitor and phase detector uses capacitance technology with what is said to be an ingenious non-intrusive design to protect pumps and equipment from damage due to dry or low volume conditions. The unit employs embedded sensing plates in a PVC wafer flange said to provide easy installation and no interference to the product flow. The sensor locks in on the capacitance field of the fluid passing through and accurately detects changes resulting from lower levels, different fluids, or changes of phase, to initiate an alarm, the company says. The monitor has UL, CAN/CSA, IEC and CE approvals and an Intrinsically Safe option. Arjay Engineering

The LevelMaster Capacitive Sensor from Rechner is said to be a high-performance sensor designed to solve applications with highly conductive or viscous products such as ketchup or honey. The sensor has no moving parts and accurate level control can be accomplished with either digital or analog (4 to 20 mA) output. The LED is a 2-colour device for viewing of operation tatus. The onboard electronics includes Easy Teach by Wire (ETW) for simple and efficient set up, the company says. If EHEDG (European Hygienic Engineering & Design Group) is required, the company is said to have the appropriate mounting hardware. The housing is IP67, IP69K and is designed for clean

DIFFERENTIAL PRESSURE GAUGES EXPLOIT MAGNETIC MOVEMENT AT TWO POINTS

www.cpec.news/z7j.

Rechner www.rechner.com www.cpec.news/re5 w T s b c n T w

Orange Research differential pressure gauges from Cameron Instruments are designed to measure the difference in pressure between two points in a system and present the resultant differential pressure directly on a single gauge dial. A magnetic movement allows the simultaneous sensing of both pressures while completely isolating the differential pressure gauge function from the pressure chamber without the use of mechanical seals. Unlike ordinary pressure gauges, these differential pressure (DP) gauges are said to indicate small values of differential pressure even when used at high line pressures. Units are supplied with reed switches or relays to initiate alarms, activate other equipment, or shut the system down. Two switches are installed when high and low limit control is desired. Orange Research has also developed a series of differential pressure transmitters with the ability to transmit data signals. The microprocessor-based instruments are equipped with Hall Effect sensors that convert the differential pressure gauges' normal magnetic movements into electric signals. After processing, the DP gauge units provide analog output for remote location monitoring.

Cameron Instruments

www.cameroninstruments.com www.cpec.news/hll

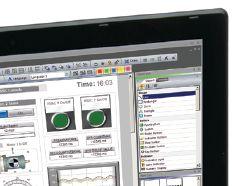

As with most industrial control projects, cost is king, but you don’t have to sacri ce quality to keep your budget intact. C-more HMIs are built to last and provide many advanced capabilities, including object animations, logic and math operations, web server/mobile app access, and data logging, all for a surprisingly low price.

C-more Touch Panel HMIs starting at: $487.00 (EA9-T7CL-R)

C-more HMI design software can now be downloaded free-of-charge. Get started on your project today or take it for a test drive.

Download as often as you need. No license or key needed.

Get your copy now at: www.go2adc.com/cmoresw

Research, price, buy at: www.automationdirect.com/cmore

Our shipping policies make it easier than ever to order direct from the

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days.

*Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

Ralston Instruments full calibration kits for differential pressure (DP) transmitters include a precision digital test gauge, hand pump, hose, adapters and carrying case. The calibration of DP transmitters is said to be very important to maintain correct flow data for oil and gas pipelines or anywhere that orifice plates are being used for flow measurement. Pressure transmitters today are quite accurate and often only need zero and span adjustments done during commis -

sioning and periodically to adjust for head corrections, drift and other factors, the company says. Kits meet the challenge of having the correct equipment that can apply the correct pressure without leaks, especially in remote or hard to reach areas. In field applications, they can also document the results of a calibration if weather or the environment do not cooperate, the company adds.

Ralston Instruments www.ralstoninst.com www.cpec.news/6mp

SPX Flow has added direct drive models to its Seital centrifuge line. Direct drive centrifuges are said to utilize less energy, require less maintenance and take up less space. The centrifuges are suitable for dairy, beverage, brewing and other industries for applications including beers, wines, teas, milk skimming, whey processing, bacteria clarification and oil refining. In the direct drive centrifuge, the motor shaft also functions as the bowl shaft. This is said to eliminate the need for gears, belts or other intervening mechanisms that might otherwise be needed to transfer the energy from the motor to the separation process. Direct drive units are now available for a range of the company’s centrifuges including separators with milk-skimming capacities of 5-10,000 l/h and standardization capacities of 8-14,000 l/h. Watch video demonstration at www.cpec.news/hwi.

SPX Flow

www.spxflow.com

www.cpec.news/x3y

Rittal Systems has announced the launch of its TS IT Pro enclosures. The cabinets are suitable for a range of applications, from large scale deployments ready to roll in place, to high density cooling and cabling solutions. The enclosures come with a perforated single front door and split rear doors keyed alike, leveling feet, casters, roof with brush baffle cable access channels, and vertical cable walls with dual PDU mountings. The flexible and scalable network and server rack products can be deployed quickly to address a variety of needs, enabling companies to adapt their IT infrastructures to the growing demand for more complex challenges at higher speeds. Rittal Systems

www.rittal.ca

www.cpec.news/dtg

Green Acres is the place to be. Farm livin' is the life for me. The theme song to late 1960s rural TV comedy Green Acres poked fun at a fish-out-of-water couple that embraced life in Hooterville over Manhattan. Today, husband Oliver Wendell Douglas would want to know about how to make his one dairy cow farm more sustainable — to make his acres greener

The Canadian Biogas Association (CBA) has just received funding from Agriculture Canada's Agricultural Clean Technology Program for farms

across the country, including Harcolm Farms in Woodstock, ON, who installed a Belgium-based, factory-built Biolectric mini anaerobic digester system on its 72-head dairy farm.

Biogas from animal waste no longer has to add to the farm's carbon footprint as it is converted into electricity. The 20 kW mini digester system is feed only on-farm material from the 72 cow dairy farm which includes dairy manure and small amounts of corn silage fed at an average daily rate of 10 cubic metres a day. The system has a split connec-

tion comprised of two engines that fulfill a 10 kW MicroFIT and a 10 kW Net Meter contracts.

With other technologies, the CBA (www.biogasassociation.ca) says that biogas can also be captured and purified to create renewable natural gas. The association has just launched www.farmingbiogas.ca, a new website with resources to help farmers evaluate the opportunities of biogas.

Oliver, are you listening? Mike Edwards medwards@cpecn.com

June Issue

Focus on Maintenance & Safety Supplement: Instrument Calibration Labs

Editorial closing date: April 30

August Issue

Focus on Environment Supplement: Wastewater Management

Editorial closing date: July 16

October Issue

Focus on Fluids Handling Supplement: Sensor Technology

Editorial closing date: September 3

December Issue

Focus on Plant Automation Supplement: Fittings & Couplings

Editorial closing date: October 22

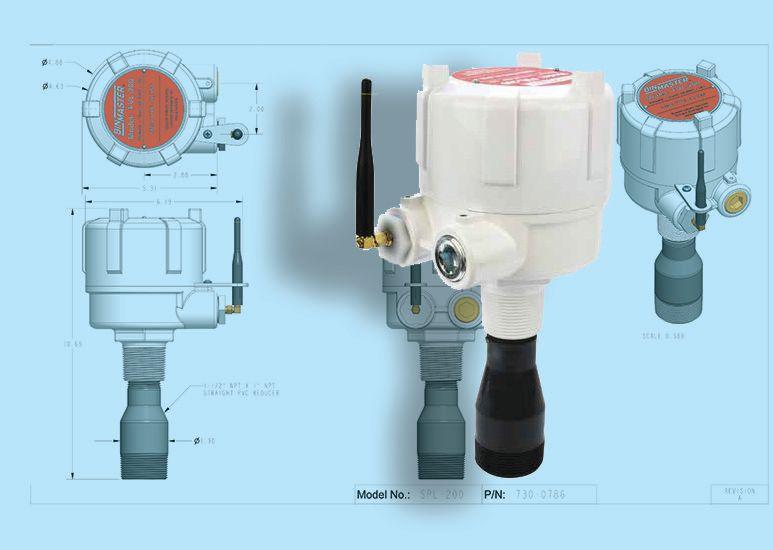

BinMaster has introduced battery-powered level sensors that mount on silos without the complexity or expense of wiring. A single point laser installs through a 1.5” NPT connection on silos or in remote locations where inventory monitoring has not been feasible. Powered by a replaceable lithium battery, the model SPL-200 measures solids in silos up to 98 ft tall in low or no-dust environments. The model FVL-200 measures livestock feed in silos up to 35 ft tall. Both models take interval readings from once per hour to once a day with a battery life of three to five years. The laser utilizes an integrated wireless LoRa long range transceiver to send data to a LoRa modem. Data measurements from the SPL-200 are transmitted to the BinView web application or Binventory software for easy access from your phone, tablet, or desktop PC, the company says. Data from the FVL-200 is used exclusively with the FeedView application. Watch video demonstration at www.cpec.news/wga.

BinMaster

www.binmaster.com

www.cpec.news/hhz

WAGO has introduced the 750 series (750-498) 8-channel thermocouple analog input module. The module is 12 mm wide and can be configured by channel for thermocouple types B, C, E, J, K, N, R, T, and S using the company’s WAGO-I/O-CHECK software or e!COCKPIT configuration tools. It can also be used to measure mV ranges -30…+30, -60…+60, -120…+120, and -240…+240. Users can select between internal and external cold junction temperature compensation. The module has gained approvals from cULus for standard and Hazardous Locations plus marine DNV certification. WAGO

www.wago.com www.cpec.news/nkp

VorTek Instruments has released the Pro-V M24 Multivariable Vortex Flowmeter. The flowmeter is said to offer accurate and reliable flow metering in a multivariable design with a variety of data communication and power options. The multivariable design incorporates a high-accuracy velocity sensor, a precision platinum RTD temperature sensor, and a solid-state pressure transducer, the company says. The meter can deliver volumetric flow, mass flow, temperature, pressure, density, and energy (BTU) measurements from a single installed device. The instrument includes a reduced bore option. The meter’s process connections match the line size but using integrated reducing flanges, the meter body is reduced in diameter. Increasing the velocity by this method extends the meter’s measuring range to capture lower flow rates that might otherwise be missed in a full line size meter.

VorTek Instruments

www.vortekinst.com

www.cpec.news/mx4

Though a dust collector is a vital component in the safety of almost every manufacturing plant, it is usually a reluctant purchase.

By Brian Richardson

Few plant professionals get excited about buying a dust collection system; and as a result, they will often select the lowest-cost equipment available for the job.

Sadly, the cheapest solution can prove to be the most costly in terms of worker safety, production downtime, regulatory compliance and other problems that plague companies when dust collectors do not perform properly.

While the most basic function of a dust collector is to keep workers and workplaces safer, not all collectors are created equal from a safety standpoint. Here are some tips for ensuring that your dust collector is as safe as possible.

Consider following all these guidelines if you are selecting new equipment – but even if you are only looking to improve an existing system, many of these tips will still prove useful.

If your dust collector handles combustible dust, you must equip it with deflagration protection. Although there are many forms of deflagration protection, a common, cost-effective passive method is venting. An explosion vent opens when predetermined pressures are reached inside the collector, allowing the excess pressure and flame front from the deflagration to exit to a safe area. It is designed to minimize damage to the collector and prevent it from blowing up in the event of a deflagration, thereby reducing the hazard. A flameless vent is designed to install over a standard explosion vent and extinguish the flame front exiting the vented area, not allowing it to exit the device. This allows conventional venting to be accomplished indoors where it could otherwise endanger personnel or ignite secondary explosions. If you cannot vent the pressure wave and fireball to a safe area, discuss another method with your dust collection professional.

Understanding the pressure capabilities of your collector is important in the specification and selection of vent sizing. Comparing venting vessel strength to the deflagration strength and vent burst pressure are key to effective deflagration protection. Some of the combustible dust properties required to understand this concept are described by the Kst (bar m/s – normalized rate of pressure rise) and Pmax (bar – maximum pressure for an unvented dust explosion) values. For example, burst pressure of the vent is designed to be lower than

enclosure strength, which will relieve the pressure of the deflagration before it can build to levels that would destroy the collector enclosure.

Even if a collector has rugged construction and a properly sized explosion vent, you still need to protect the ductwork that serves the dust collector. Ducting should be equipped with dampers and valves designed to minimize the risk of explosion within these components due to back pressure from a deflagration event in the main dust collector housing. This is a task that is overlooked with surprising frequency.

Factories and process manufacturers sometimes store products in hoppers. However, the hopper required with a dust collector should not be used to store dust. The hopper is only intended to funnel process dust to a storage bin. Dust that has accumulated in a hopper creates a potential fire or deflagration risk. Dust in the hopper may also diminish the collector’s performance by clogging the system and preventing the pulse-cleaning system from doing its job.

Self-dumping hoppers provide easy dust disposal while protecting against unwanted dust leakage between the collector and hopper. A slide gate and flexible quick-disconnect hose connect the two components together, and the hopper lid is fastened with rubber clamps that create a gasketed seal to prevent dust from escaping. When the hopper is full, you can detach it from

Mining, food and beverage, oil and gas, chemical processors and manufacturers rely on many disparate systems and devices to get the job done, each with a unique role to play in the safety, productivity, and efficiency of operations.

This article from Motorola Solutions outlines five strategies businesses can take to expand critical communications further in the factory and job site of the future. See how technologies used to help keep your operations safe can do even more — minimize downtime, drive efficiencies, improve productivity, and generate better outcomes.

STRATEGY ONE: BRING MANUFACTURING COMMUNICATIONS INTO THE FUTURE

The move to the future in communications begins with digital two-way radios. Radio communication remains a critical foundation for manufacturers and other industries. Radios are dependable, durable, and easy to use – and digital radios offer these advantages in addition to many more.

While some manufacturers still rely on legacy analog hardware, the number of digital radio users in the industry has almost doubled in the last two years, according to Motorola Solutions 2019 Manufacturing Communications Survey Report. In fact, 70% of survey respondents indicated they are already utilizing digital radios in some capacity and more than half said they expected to fully adopt digital radio communications within the next 5 years.

Many manufacturers have and are moving from analog to digital radio for a simple reason. Performance.

The shift to digital is a natural extension of evolving business needs and increased demand for more reliable, real-time communication. Digital radio is better suited to meet those demands, offering a host of benefits including: better voice quality; greater bandwidth; stronger coverage with built-in error correction; and, longer battery life.

STRATEGY TWO: ENABLE TEAMS TO COMMUNICATE ACROSS DEVICES AND NETWORKS

As the number and type of devices we use in our personal life grows from smartphones, to tablets, to computers and more, it’s only natural that the desire to connect with colleagues on our preferred devices does, too. Based on our communications survey, workers are almost universally using more than one device to communicate on the job with 81% saying they use multiple devices, including smartphones, landline and IP-based phones, PCs and laptops, and tablets.

Manufacturing workers ranked the ability to communicate with colleagues on any device and to reach workers at any location as the two most important factors in a communication system. They overwhelmingly believe it would be valuable to connect all devices, allowing anyone to communicate using any device.

And 66% of manufacturers believe it’s important to have access to nationwide communications. With warehouses and distribution centers often across multiple cities and states, workers must be able to communicate with colleagues wherever they are-- across networks and across devices.

Yet, operationalizing effective communication remains a challenge across many industries and manufacturing is no exception. Many manufacturers both large and small utilize and support multiple communications devices, networks, and technology systems. This can hinder collaboration, create information silos, and slow response time when incidents occur, and impact the productivity of your plant or employee safety.

Maintaining disparate technology can also burden already stretched IT teams, who must manage multiple vendors and maintain multiple communications devices and systems. In addition, 47% of respondents to the same survey say they only perform radio service “as needed” — and 13% said they never service radios.

STRATEGY THREE: CONNECT INTELLIGENCE AND COMMUNICATIONS

The speed and complexity of manufacturing demands more from communication than simply a voice conversation. It requires intelligence and useful applications that help automate tasks and expedite assignments. Manufacturing workers indicated that text messaging and alerting,

Continued on next page

The move to the future in communications begins with digital two-way radios. Radio communication remains a critical foundation for manufacturers and processing industries. Radios are dependable, durable, and easy to use – and digital radios offer these advantages in addition to many more.

The Field Gauge LC20

Reference-grade accuracy in a durable, hand-held gauge

• Maintains calibration at an impressive ±0.1% of full-scale accuracy.

• Connects to a PC via USB or wireless to change settings or to perform data logging.

• Features clear, intuitive controls and a large, back-lit display.

• Tough, powder-coated aluminum exterior protects the internal components so it holds up to abuse in the field. It’s also waterproof up to 1 meter (IP67).

Choose the wireless option and monitor tests from the comfort of your truck!

Visit ralstoninst.com/cpn-LC20 or scan the QR code to find out more

Continued from previous page

as well as work order and job assignment applications, would be the most helpful on the 66% job. Indoor location tracking, alarm and event management, Industry 4.0 and the Internet of things powered applications were also key selections. All of these applications help manufacturing workers be more productive, efficient, and connected, on top of voice communications.

Moving from analog to digital radio communications provides an entry point to a range of integrated applications and solutions that can unify communications from end-to-end, transforming the way manufacturers operate. This includes video and security, dispatch, work ticketing, and more.

When it comes to safety and security, manufacturing operations have unique needs. Worker safety and security. Hazardous machinery and heavy equipment. Diverse areas to monitor both inside the plant and outside and across multiple buildings. This makes safety and security a top challenge. In our survey, workers listed video surveillance and access control as the top two security capabilities their companies employ. But only 5% said their company leveraged video analytics. This highlights a great opportunity for processors and manufacturers as advances in artificial intelligence (AI), machine learning, and analytics are helping transform video security, offering more visibility and insight with much less effort.

We understand the challenge of finding the right balance between plant efficiency and compliance with industry standards and legal requirements.

Everyday incidents, such as unexpected downtime, accidents on the line or on the premise, and power outages threaten to disrupt the productivity of manufacturing facilities and impact performance and profitability. Enabling security and operations teams with the technology to respond and manage both the everyday incidents and critical emergencies, and to also recognize patterns, anticipate actions and help prevent situations before they happen helps transition your security and operations from reactive to a proactive strategy.

You meet your e�ciency goals and reduce costs without compromising on water quality.

With capabilities to detect, analyze, communicate, and respond to potential incidents, businesses can bridge key areas of risk which often thrive in the unknown, so factories and job sites are better equipped to prevent threats to the business from impacting performance — or becoming tragedies. By enabling modern incident and operational management, they ensure the business is running efficiently and that workers are safe and can remain focused on the job at hand.

Whether it’s tracking inventory in the warehouse, sharing critical information with your team, or monitoring production lines – or the perimeter of your campus or key entry points — manufacturers depend on data. In fact, data has become the “fourth utility” — considered to be as vital as power, water, and heating/cooling.

The demand for data in the process industries and manufacturing is limitless. While these businesses turned to Wi-Fi as a valuable tool to support their data needs, an increasing number of devices and evolving needs are highlighting the disadvantages of Wi-Fi for business-critical installations. As a result, manufacturers employing smart manufacturing strategies integral to safety, production, and operations need a reliable solution for all their data, voice, and video needs.

Proline Promag W 0 x DN full bore – The world’s first electromagnetic flowmeter for unrestricted measurements

• Measure reliably – independent of flow profile and mounting location

• The first and only electromagnetic flowmeter with no inlet and outlet runs (0 x DN) as well as no pipe restriction (full-bore design) and thus no pressure loss

• Installation directly after bends, perfect for space-restricted areas and on skids

A new type of radio spectrum to complement Wi-Fi — Citizens Broadband Radio Service (CBRS) has been approved and is based on LTE technology and operates on a 150 MHz slice of the 3.5 GHz radio spectrum that was formerly underutilized by government satellite and radar systems. Unlike Wi-Fi, CBRS enables private LTE broadband for a manufacturing facility – enabling better coverage, capacity, and security.

With CBRS, spectrum is not shared, allowing businesses to use fewer, but ultimately more powerful, transmitters. A single CBRS access point can cover the same large area as five or six Wi-Fi access points would have – requiring fewer installations and lower maintenance costs. And because CBRS is based on LTE, devices are optimized to deliver seamless handoffs between access points, which has traditionally been a challenge for Wi-Fi devices as employees move between floors in a building or from one building in a campus to another.

This article was excerpted from a white paper by Motorola Solutions and is available at www.cpec.news/fd5.

Motorola Solutions www.motorolasolutions.com www.cpec.news/9y4

CECO Environmental Corp. of Dallas, a global provider of environmental and equipment solutions to a variety of end markets, has announced an agreement signed with John Brooks Company. The Canada-wide distribution agreement with Mississauga, ON-based John Brooks Company expands CECO’s market access and presence locally for the CECO Dean and CECO Fybroc product lines in Manitoba and Saskatchewan.

“CECO’s fluid handling brands are well-respected leaders in a variety of critical industrial pump segments around the globe, but we have significant opportunity to expand in key Canadian markets,” according to said Chris Tsourides, president of CECO’s Industrial Air and Fluid Solutions segment. “The addition of John Brooks Compa-

ny, a highly-regarded pump industry specialist in Canada, is a great fit to distribute and service our CECO Dean and CECO Fybroc pump solutions.”

The CECO Dean metal pumps are known for their durability and performance in high temperature applications, the company says, while CECO Fybroc pumps are constructed from fibreglass reinforced plastic (FRP) making it a suitable choice for critical applications requiring chemical resistance like acids, bases, solvents, and briny water.

“We serve a number of industries that are ideal markets for Fybroc and Dean,” said Gord Bell, president of John Brooks Company. “We have been in business for more than 80 years and understand the fluid handling needs of customers

Georgetown, ON-based Flodraulic, a fluid power company, has announced the launch of its Archimedes Precision Spreader, a “next-generation” precision snowplow and salter. Working with the University of Guelph, the Town of Halton Hills, and the City of Guelph, Flodraulic has redesigned salt management to accurately measure the salt applied on roadways in real-time.

across water, wastewater, oil and gas, mining, chemical and other markets.”

John Brooks Company www.johnbrooks.ca

Canada Economic Development for Quebec Regions (CED) has awarded grants valued at $801,500 in support for three regional businesses In the Cantons-de-l’Est region of Quebec.

Unlike current road salters, the Archimedes Precision Spreader uses a LiDAR-based sensor array to measure the salt applied on roadways. This sensor data is then instantaneously fed back into the control system to dynamically control salt application rates to be as precise as possible. This solution can also detect over-salting, under-salting, as well as blockages.

In tandem, Flodraulic also developed a cloudbased command structure and web centre that can assign salt application rates to specific GPS coordinates. “Snow and ice vehicles are large and by definition are only operated when road con-

ditions are at their most dangerous,” said Chris Passmore, director of technologies at Flodraulic.

“The Archimedes Precision Spreader will increase the safety of drivers by almost entirely removing salt control from their operational procedure. The municipalities will now be conscious of salt usage and environmentally sensitive areas without adding a layer of complexity for their drivers.”

Through Ontario’s Autonomous Vehicle Innovation Network (AVIN), led by the Ontario Centre of Innovation (OCI), Flodraulic received support to commercialize this advanced R&D. Watch salt spreader video at www.cpec.news/qtw. Flodraulic

www.flodraulic.com

www.cpec.news/6l9

ACTIV Foods, popularly known as Happy Yak, has received $166,500. The CED assistance will focus on the acquisition of advanced processing equipment and the costs related to the purchase and installation of an ERP system. This project, aimed at expanding the business by increasing its capacity to produce freeze-dried meals and meal components, will lead to the creation and maintenance of four jobs.

In addition, machine shop Eddynet will receive $435,000 and kitchen builder Cuisine Idéale Cabinet will receive $200,000.

The contributions to these three SMEs have been granted under the Regional Economic Growth through Innovation program.

Canadian Economic Development https://dec.canada.ca

Lactalis Canada Inc. of Toronto, formerly Parmalat Canada Inc., a subsidiary of Lactalis Group, has acquired all shares of Agropur Cooperative’s Canadian yogurt business, Ultima Foods Inc.

The acquisition includes the IÖGO and IÖGO nanö yogurt brands as well as the Olympic yogurt, sour cream and kefir brand. In addition, Lactalis Canada has acquired Ultima Foods’ production facilities in Granby, QC, and Delta, BC, a leased distribution centre in Longueuil, QC, and a service contract with a third-party operator of a distribution centre in Richmond, BC.

“Lactalis Canada’s investment in Ultima Foods and its yogurt brands speaks to the significant opportunity we see in growing the yogurt category in Canada,” according to Mark Taylor, president and CEO, Lactalis Canada.

“With this acquisition, we expand our footprint nationally, reinforce our long-term investment in the country and the Canadian food processing sector and welcome approximately 450 employees who passionately share our dedication to providing Canadian consumers with healthy, nutritious and high-quality dairy products.”

Lactalis Canada brands include Cracker Barrel, Black Diamond, P’tit Québec, Balderson, Cheestrings Ficello, aMOOza!, Astro, siggi’s, Stonyfield, IÖGO, IÖGO nanö, Olympic, Lactantia, Beatrice, Galbani, and Président. Lactalis Canada is a subsidiary of Lactalis Group, the world’s leading dairy group, headquartered in Laval, France. Lactalis Canada www.lactalis.ca

ITC Electrical Components, a master distributor based in Richmond Hill, ON, now offers the Magna-Plug magnetic connector. Made by Exceltec of Le Corbusier, QC, the connector (see page 18) has been designed primarily to reduce cable and probe breakages in manufacturing processes such as food production, for reduced workflow interruptions.

“Only one possible connection between the male and female parts allow easy coupling in difficult situations,” according to Philip Parsons, ITC business analyst, “such as high temperatures and where using gloves is necessary.” The magnetic coupling prevents damage to the connectors when uncoupled due to strain, ITC says.

ITC Electrical Components www.itcproducts.com

ONLINE AND PORTABLE INSTRUMENTATION

Multi Parameter Single – Dual – Multi-Channel-Wireless

Optical Fluorescence Dissolved Oxygen Near Infra Red Total Suspended Solids

pH, ORP

Microwave Density

Ultrasonic Interface Level

Spectrophotometric Online

FLOWMETERING

Ultrasonic Doppler – Transit Time

Insertion/Immersion/Clamp-On

Federal, provincial and municipal levels of government have announced joint funding for improvements to the Rodney Wastewater Treatment Plant in the Municipality of West Elgin in Ontario.

Venture/Flume Partially Filled Conduit

Non Contact Radar

WASTEWATER SAMPLERS

Indoor or Outdoor

Refrigerated or Non-Refrigerated Portable or Stationary

SEPTAGE RECEIVING SYSTEMS

Integrated Billing System

ADDITIONAL SOLUTIONS FOR:

The Government of Canada is investing $942,000 in this project through the Green Infrastructure Stream of the Investing in Canada plan, with the Government of Ontario contributing over $784,000. The Municipality of West Elgin is contributing over $628,000 toward this project.

Fully Automated Control and Data Collection

Flow – Level – System Integration – Field Service

Mississauga, Ontario Montreal, Québec

The project includes the rehabilitation of a secondary clarifier, the replacement of a storage tank, and upgrades to the lagoon decant system. The upgrades will improve the reliability and effectiveness of the wastewater treatment process, extending the facility’s performance lifespan, and reducing future maintenance costs. It will also ensure area residents have efficient wastewater services while also protecting local waterways and supporting a healthier living environment.

All orders of government continue to work together for the people of Ontario to make strategic infrastructure investments in communities across the province when they need it the most.

Through the Investing in Canada plan, the Government of Canada is investing more than $180 billion over 12 years in public transit projects, green infrastructure, social infrastructure, trade and transportation routes, and Canada’s rural and northern communities.

The Government of Canada has invested more than $8.2 billion in over 2,770 infrastructure projects across Ontario under the Investing in Canada plan.

Ontario is investing over $10.2 billion under the Investing in Canada Infrastructure Program to improve public transit; community, culture and recreation; green, and rural and northern community and other priority infrastructure.

Ontario is investing more than $40 million and Canada is investing more than $100 million under the first intake of the Green Infrastructure Stream. Federal infrastructure investments in Ontario www.cpec.news/lsl

A survey by the Calgary-based Canadian Association of Petroleum Producers (CAPP) of oil sands producers shows the increasing role of Indigenous suppliers to the industry. In 2019, about $2.4 billion was spent on procurement from Indigenous businesses; 16 per cent higher than in 2018 and 53 per cent higher than in 2017.

The number of Indigenous suppliers has also grown from 263 in 2017 to 275 in 2019, with cumulative procurement spending in the three-year period totalling about $5.9 billion. The oil sands companies that participated in the survey are responsible for more than 95 per cent of Canadian oil sands production.

Indigenous supply chain businesses contribute to oil sands operations in a variety of areas including construction, camps and catering, equipment services, transportation, environmental, drilling, engineering services, and retail among others.

In addition, the survey shows oil sands producers are continuing their commitment and engagement

in the communities where they operate, increasing the total amount of money put into community investment, consultation funding and other initiatives in Indigenous communities. The total for these activities reached $64.2 million in 2019, compared to $58 million in 2018, and $41.8 million in 2017.

Community investment can include things such as education initiatives for Indigenous communities, training programs, physical infrastructure and cultural program funding specific to local communities. Consultation funding applies to ongoing operations in an Indigenous community, but also includes project specific consultation, site visits, technical reviews, and funding for studies and agreement negotiations.

As Indigenous businesses grow their participation in resource development, Indigenous people are a grow-

Last year, Rittal Systems Ltd. of Mississauga, ON, launched the premier Canadian ‘Advancing Women in Tech’ Scholarships as part of Electro-Federation Canada’s annual Scholarship Program. Following the successful recognition of two previous worthy recipients, Rittal Canada has once again announced that it will be awarding two ‘Advancing Women in Tech’ scholarships of $1,750 each, to female Canadian undergraduates to help further their studies and careers in the electrical and associated industries.

The EFC Scholarship Program for attracting and supporting technical talent has made over $130,000 available for university and college students, through corporations such as ABB, Eaton, 3M, E.B. Horsman & Son, Rockwell Automation and Schneider Electric. The deadline for applications is May 31, 2021 at www.cpec.news/dl1.

ing proportion of oil and natural gas employment, making up 7.4 per cent of the industry’s workforce in 2019 (up from 4.8 per cent in 2018).

According to Tim McMillan, CAPP president and CEO, “The oil and natural gas industry is continuously working to enhance opportunities for reconciliation, including business partnerships that generate sustained economic, social and community benefits for Indigenous communities through resource development."

CAPP

www.capp.ca

The NS Series ball valves are available in sizes 1/4”-6” with threaded, socket weld, butt weld (3-piece) and flanged (2-piece) connections.

The NS Series butterfly valves cover 2”-24” sizes in wafer and lug style.

APPLICATIONS

• Water Treatment

• Potable Water Service

• Reverse Osmosis

• Desalination

For eligibility requirements, the applicant must be a citizen of Canada or a legal permanent resident, must be a current post-secondary undergraduate student, enrolled in a full-time appropriate field of study (e.g., Electrical Engineering/Apprenticeship or Electrical/Electronic Technologist or Technician) at an accredited college or university program.

The successful student must have competitive grades in their current program and additionally be able to demonstrate leadership and involvement in their community. Any examples of unique projects showing expertise with industry-relevant software for solution design, would be a welcome addition to the application.

According to Andre Bousette, president, Rittal Systems, “at Rittal, we believe in diversity and inclusivity, and what better way to embody this philosophy than by encouraging young women to join the manufacturing and electrical industry.

"We hope that this ‘Advanced Women in Tech’ scholarship will encourage women to join our industry and help them to pursue a career in this field.”

Rittal Systems

www.rittal.ca

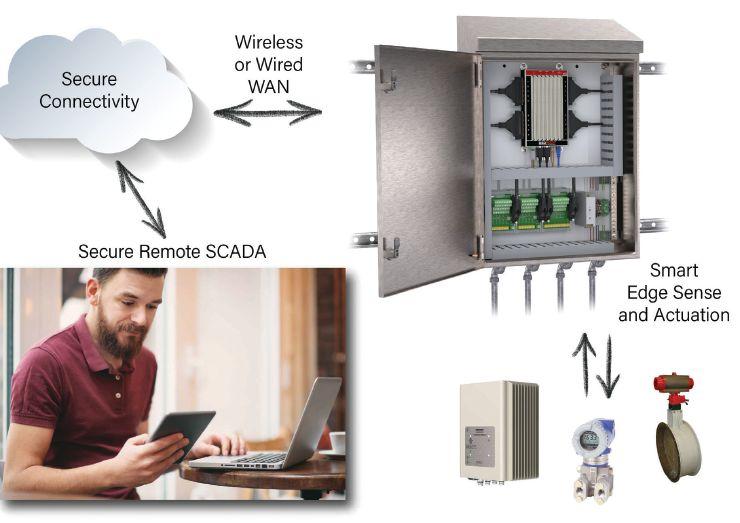

For some time now, automation vendors have been promoting anytime, anywhere access to your process data, but delivering on the promise has been technically and commercially challenging to scale. Now that this actually is within reach, you may be suspect. But don’t be deterred, as the future is now with open and secure IIoT solutions finally available. The core ideas that make it real include:

• Maturing and convergence of IT/OT open standards in software, applications, and connectivity, collapsing the cost of both engineering and deployment.

• The Internet as the Zero Trust OT backbone, vetted and secured by e-commerce. When this model is applied in automation systems and sensors, innovation and user value is boundless.

• A new generation of OT devices at the edge, built upon new secure digital computing components and supply chain.

With these elements, anytime, anywhere access to process data is affordable and real, be it producing oil or gas, distributing water or power, or any other activity that must be physically detached from a central command-and-control point.

From any mobile device or platform, your supervisors and operators can participate in decentralized monitoring, control and maintenance. Huge volumes of data can be available as it is needed – in the plant, at the edge, or in the cloud. By leveraging public networks, communication costs are low-to-zero, and your critical data and processes are safe because your automation is secure.

The greatest return on operations depends on your data access and data analytics model, which is no longer hampered by limited access to data.

Here is an example of a company that has boosted remote operations management efficiency by more than 50 percent using an architecture like this.

OPEN SECURE REMOTE OPERATIONS IN PRACTICE

Ttween water supply storage facilities and well sites, which typically involves using 3 to 10 miles of temporary 12-inch diameter flat hose. Keeping millions of gallons of water moving through that channel requires synchronizing operation of multiple pumps along the way, many of which may be deployed in remote points, often accessible by dirt roads only. For most of today’s transfer services, operating these pumps manually involves deploying field operators to monitor each pump, start or stop them as required, spot and fix leaks, and keep accurate records of transfer volume.

This involves controlling the operation of two to four large diesel pumps spread out over the entire length of the transfer line. The pumps must be started and brought up to operating speed in series and then ramped down in series to a stop every few hours. The process is repeated around the clock with each stage of the fracking operation, which can run for several weeks. This may also require multiple boosters, which must be sequenced manually, in stages. Lag times, pressure, pump speeds must all be managed.

he ability to monitor and control remote equipment without having to locate or deploy field technicians is one of the great benefits of upgrading automation on remote sites. Flowpoint Water Solutions, a Midland, TXbased company that delivers the millions of gallons of water it takes to frack a single site estimates that it has increased operating efficiency by more than 50 percent once it moved its distribution management information system into the cloud.

Flowpoint has automated these processes through a combination of software applications that calculate flow rates, a cyber secure automation platform, cloud-based data storage and analytics, and a SCADA interface through which operators interact with the system from anywhere using an internet connection.

The Flowpoint data model is built on transfer line hydraulics that determine the number of pumps required to satisfy the design flowrate and route topography. It then subjects this to transfer calculation software that provides a simple, intuitive user interface that models the entire flow operation. At job startup, the results are reconciled with readings from pressure sensors, level sensors, and flowmeters to identify equipment problems that could lead to downtime. These readings go to a Bedrock OSA Remote control node that provides the PLC functionality to implement the flow models. The control node has built-in cyber security which enables Flowpoint to use lower-cost open technologies by eliminating vulnerability to cyberattacks. Reed Taylor, founder and CEO of Flowpoint, says that a system designed to resist current and future security threats is important because the application is sensitive to interruptions in data communications.

Flowpoint’s automation integrator Flow-Sync of Dallas/Ft. Worth, TX, deploys the OSA Remote control modules in the wiring cabinet of self-contained, portable skids. These connect to the pumps so that the entire transfer operation can be effectively monitored and controlled remotely. The OSA Remote control node reads the tags from the skid’s sensors and uses OPC UA communications capability to integrate this data into the broader system.

Flowpoint manages transfer of water be-

Users interact with the automation system via SCADA software that manages integration between the Bedrock controls and the AWS cloud, where Amazon Elastic Compute Cloud EC2 servers host an SQL

database. This IIoT architecture is fully scalable in terms of processor memory and disk storage. The OPC UA connection with the Bedrock OSA Remote is what extends the secure PLC architecture to remote locations via TCP/IP.

The combination of the Bedrock OSA Remote, the AWS cloud, and the SCADA database provides real-time status of all operations. This improves operator productivity by enabling them to see and interact with the entire operation from any location.

“If you are trying to start up multiple pumps at once or bring things up or down in series without exceeding pressures or overfilling pit levels, having access to real-time information to support your decision making is invaluable. Or maybe your tanks are getting low and you need to increase the speed of your pumps to boost the supply, you can see exactly what you need to do and the impact of the adjustment. This is IIoT the way it’s meant to be,” said Flow-Sync owner and CEO Harry Browne.

Added Taylor, “you are just putting the whole process in the operator’s hand. You can start or stop

Automation that is both open and secure also helps drive down administrative costs, which can also be critical to profitability. As Taylor puts it:

“We must be able to track and monitor expenses and inventory accurately. We must map expenses to projects. Without an automated system, if expenses come when we’ve already moved on to another project, we’d have to go back and find the paperwork, read the meters manually, map the data to the appropriate particular project, etc.

“Now we generate reports every day, essentially in real-time. We provide the data to bill or to reconcile, for royalties. We’re capturing all metering and flow rates into a database that we can make accessible for both our customers and water suppliers.

“From a single screen, we can control activity on any job site, commit inventory, or otherwise manage hundreds of thousands of gallons of wa-

the pump, change speed, spot trends or check level or pump speeds easily. You can check the flow rate of any of those parameters across your entire line.”

An important component of that big picture is the ability to detect and respond to leaks remotely. Leaks are unavoidable in above-ground temporary water transfer operations so how effectively a water transfer company manages leaks can impact budgets well into six-figure totals. The Flow-Sync software monitors the line from beginning to end.

Once the pump starts up, it takes about 10 minutes to achieve a steady-state and the software application at the other end of the line knows what to expect. A significant deviation, the software signals the Bedrock controller which might sound an alarm, shut the process or some segment of it or take other preset mitigation steps. Where one operator might traditionally manage one or two pumps, the automation system enables them to control an entire transfer operation with even greater reliability and decision making. And, because problems are detected immediately, costly downtime and leakage are minimized.

ter from multiple pit locations. This puts massive amounts of data in the hands of our operators.”

While this application was focused on a water transfer application, it demonstrates the following capabilities that can be applied broadly:

• Real-time visibility into all operations and ability to monitor multiple devices, empowering operators with control over a larger portion of operations.

• Automated problem detection, alarming and intervention. While in this case, the problem was leakage and water loss, it could easily be any variable that could potentially impact material flow, system downtime, emissions, or anything else that impacts costs and profitability.

• Reduced administrative costs in managing and reporting.

• Process optimization and design improvements.

This successful collaboration shows that great strides in productivity and cost control can be achieved with secure open technologies and the cloud. Given the current cost-cutting focus in the oil and gas industry, such efficiency improvement enables suppliers like Flowpoint to be more aggressive on pricing in competitive situations. Moreover, running this automation on a rugged Bedrock OSA platform with built-in cyber security shows that such gains can be achieved with a significantly reduced risk of cyberattack.

This article is from a Flowpoint white paper by Bedrock Automation. Download other white papers at www.cpec.news/rhw. Bedrock products are distributed by Rotalec (www.rotalec.com) in Eastern Canada and represented by Kymera Systems (www. kymerasystems.com) in Western Canada. Bedrock Automation

www.bedrockautomation.com

Hardy Process Solutions has announced the Hardy Caseweigher series, fully automated checkweigher scale systems designed to continuously weigh larger items while in-motion. Said to be flexible and highly accurate, the series weighs products in containers such as cases of cans, bottles, rigid shrink-wrapped packages, bags or pails. Featuring PLC control architecture and a large touch screen HMI display, operators can easily navigate between different product recipes or adjust machine set-up parame-

ters, the company says. The heart of the machine, which is said to deliver fast, accurate, and stable weight readings, continues to be based on the company’s HI 4050CW high-performance check weight controller and a Hardy C2 load cell. The check weight controller can communicate seamlessly both upstream and downstream across the Connected Enterprise Network when built with either an Allen-Bradley CompactLogix PLC or via an optional EtherNet/IP connection when built with a standard PLC Platform.

Hardy Process Solutions www.hardysolutions.com www.cpec.news/36u

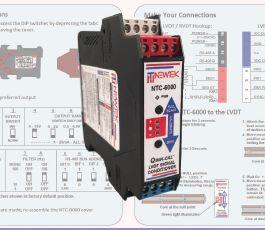

The NTC-6000 Qwik-Cal LVDT signal conditioner from NewTek Sensor Solutions is said to complete the measurement system for AC-operated LVDTs by providing the excitation and digital output required by many laboratory, industrial automation, and process control applications. Compatible with both new and legacy AC-LVDTs, RVDT or LVRT half-bridge sensors, the signal conditioner offers a variety of selectable excitation frequencies, analog output types (0 to 10 V, 0 to 5 V, 0.5 to 4.5 V, +5 V, +10 V, 4 to 20 mA) as well as digital communications to a host computer via RS-485 output. The RS-485 port also supports the hot swapability of sensors by saving set-up parameters and automatic excitation synchronization for multiple unit systems. The signal conditioner features front panel null indicators and pushbuttons to set zero and full-scale output positions along with automatic excitation synchronization for multiple unit systems. The smart signal conditioners also self-diagnose for LVDT failure, disconnects, or short circuits.

NewTek Sensor Solutions

www.newteksensors.com

www.cpec.news/dzy

The Click Plus PLC series from AutomationDirect builds on the existing Click PLC series with advanced options like Wi-Fi communication and data logging. The new CPUs are offered in wired-only, wireless-only, and wireless/ wired styles. All three CPUs offer USB programming and support the IIoT standard MQTT protocol as well as Modbus TCP. CPU modules with a built-in Ethernet port also support EtherNet/IP communication, and serial-capable models utilize Modbus RTU. Wi-Fi-capable CPUs are said to provide time-saving installations as no new network cabling is required (antenna sold separately). Each CPU has a slot for an optional I/O module so it can be configured as a stand-alone PLC with the user’s preference of I/O. Numerous Option Slot I/O modules are available to add discrete I/O with high-speed capability, analog I/O, or combinations of both. For larger systems, up to 8 stackable I/O modules can be connected to the side of the Click Plus CPU providing an additional 128 discrete or 48 analog I/O points. Watch view demonstrations at www.cpec.news/uqf. AutomationDirect

www.automationdirect.com

www.cpec.news/0y3

LJ Star offers a line of Anti-Galling Clamps that are designed to prevent the adhesion of materials due to friction and to keep processes running smoothly. The line is said to be produced to the highest hygienic engineering standards and are constantly being updated based on customer feedback and industry requirements. With anti-galling clamps, the nut and bolt are made of dissimilar materials so that adhesion, or galling, is less likely to occur. The company’s BPE compliant clamps are available in a variety of materials, including 304 and 316 stainless steel. With higher quality and durability than lower-grade stainless, 316 stainless is suitable for pharmaceutical, food/beverage and biotech applications. The company has also created a patented anti-galling safety clamp for processes that are subject to vibrations or installed on a

pressurized line. Watch video demonstration at www.cpec.news/max. LJ Star

www.ljstar.com

www.cpec.news/rxs

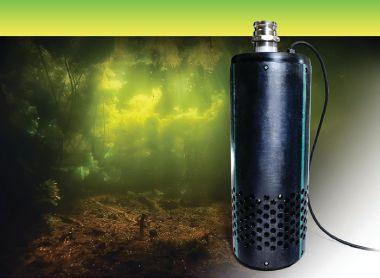

Q.E.D. Environmental Systems has announced its Torpedo G1275 pumps, a series of largebody pumps designed for aggressive pumping applications. The pumps work by means of a powerful stirring motion in the influent stream, the company says, to allow slurries and solids to pass through. Units are designed for use in applications including landfill liquid management and remediation pumping applications. To prevent failure, the pumps are constructed of cast iron and stainless steel and fitted with heavy-duty bearings and seals. The hardened, highchrome impeller assembly can pass solids that would stall using most pumps available on the market. The pumps resist corrosion by means of an HDPE-encapsulated body, stainless steel water jacket and polymer power cable. The pumps have a 5 hp motor to provide the torque required for pumping silt, slurry and solid contaminants.

Q.E.D. Environmental Systems

www.qedenv.com

www.cpec.news/k84

DJ Level Detectors from Dynatrol have been introduced as plugged chute detectors for most types of conveying. Units are also said to be suitable for high, mid or low point level detection providing dependable operation in dusty environments as well as on vessels, storage bins or hoppers equipped with vibrators. The detectors can easily obtain accurate measurement for applications such as bulk solids flakes, powders, pellets and heavy granular materials, the company says. The durable level detectors are also said to be virtually wear-free since they contain no moving parts, gaskets

or seals and rely on mechanical oscillations to determine if the probe is covered or uncovered. Signals from the level detector operate a single pole double throw relay within the control unit and the relay contacts actuate alarms, indicator lights or process control equipment. The units are factory calibrated with no field calibration required and approved for Class I,

Group C & D; Class II, Groups E, F & G; and Class III Services.

Automation Products, Inc. –Dynatrol Division www.dynatrolusa.com www.cpec.news/37h

The sanitary model RCM-60X20-SS rotary continuous mixer from Munson Machinery blends primary bulk ingredients, minor ingredients and/or liquid additions uniformly in one to two minutes residence time (typical), at low cost per volume of material blended. Unlike mixers that force agitators through stationary material, the company says, the rotary continuous mixer design employs a 20 ft long x 60 in. diameter rotating cylinder with internal mixing flights that impart a gentle tumbling action, distributing particles with each degree of drum rotation with no shear or heat generation, eliminating or minimizing degradation. A 30 hp gear-reduced motor rotates the mixing drum at slow speeds on external trunnion rollers, minimizing energy consumption and eliminating the need for shaft seals. The mixer’s

stationary inlet and outlet allow hard connections to upstream and downstream process equipment, while an internal stainless steel spray line plumbed through the stationary discharge end permits liquid coating, de-dusting or perfuming of dry ingredients.

Munson Machinery Company www.munsonmachinery.com www.cpec.news/4l6

The EV-VF VigiFlap from Boss Products is an explosion isolation valve designed to prevent propagation of overpressure or flame front caused by an explosion downstream in vessels such as dust collectors, cyclones, and filters. The valve is held open either by air flow or proprietary locking mechanism. As a result, the valve can be used as an explosion isolation device for both the inlet and outlet of a vessel, the company says. The explosion isolation valve complies with NFPA guidelines and is an ATEX Certified device for the containment of explosion. The unit’s unique inlet and outlet “Straight Through” design is said to ensure very low static resistance and reduces dust accumulation. Body is painted stainless steel AISI 304, diameters range from 6 to 52 in., and gasket is made from EPDM (Silicone FDA 200°C option). Watch video demonstration at www.cpec.news/w50. Boss Products www.bossproductsamerica.com www.cpec.news/eum

The OptimaDry microwave mixing and drying system from Eirich Machines offers Fluidizing Paddle Blender technology by American Process Systems combined with microwaves, resulting in what is said to be a highly accurate and controlled heating/drying method for a wide range of products. The blender’s fluidization action assures homogeneous mixes independent of large range of particle size, shape, or density. It is also said to be extremely gentle with fragile ingredients. The OptimaBlend Fluidizing Paddle Blender is available in capacity sizes from 1.5 to 400 ft³. Drying through microwave heat offers precise, uniform, and consistent temperatures, the company says, as well as fast processing times and low energy consumption. The drying technology is suitable for heat-sensitive products where aroma, color, nutrition, consistency, and other characteristics must be maintained. Product applications include herbs and botanicals, biomass, coffee, spices, powders, nutraceuticals, pharmaceuticals, chemicals, lithium-ion batteries, polymers and minerals. An in-house test lab, permits companies to test their products(s) in the microwave mixing and drying system.

Eirich Machines

www.eirichusa.com

www.cpec.news/gd7

The ITC-XXX-XX-DC is a signal isolator with dual outputs providing high isolation from Input to Output1, to Output2, and to Power in a small easy to install package. It’s universal DIN rail mount makes it possible to install right next to the instrument that is to be isolated. The many different input and output configurations allow it to be used in a great variety of applications ranging from PLC front end conditioning to adding an extra loop with lots of drive to an existing, almost fully loaded loop. Contact us for more

the bottom of the collector, lift the hopper onto a fork truck, and simply pull a lever to swing the lid open and dump the contents into a larger disposal container.

Self-dumping hoppers are used for a range of dry dusts, including those that must be reclaimed or recycled after the collection process.

The dust collector’s cleaning system design works in conjunction with filter design. Selective cleaning controls provide an easy, maintenance-friendly way to keep filters clean. You can select from three cleaning options: continuous cleaning, on-demand cleaning and downtime cleaning. Continuous cleaning is suited for porous dusts, such as silica and other minerals, high dust loading applications like thermal spray or plasma cutting, or lightweight dust such as fumed silica and paper fines.

On-demand cleaning is recommended for most dust types. This setting monitors the differential pressure across the clean-air section and the dirty-air filter section of the collector. On-demand cleaning allows you to set a very narrow range of differential pressures to activate and stop the cartridge cleaning. This setting uses the least amount of compressed air and provides optimum filter cleaning efficiency and filter life. Note that the on-demand settings will need to be adjusted to compensate for the slow but continual rise in filter pressure drop over the life of the filter set.

Downtime cleaning allows for time-based pulsing at the end of a plant shift, after completing a batch process or after an upset condition that may affect the filter’s performance. Downtime cleaning allows you to shut off the fan and clean the filters during a set duration of time. After the cleaning period is finished, the unit will shut off completely. This is an important feature because over-cleaning the cartridges during operation causes higher

emissions, shorter cartridge life and higher energy costs due to overuse of compressed air.

You might also want to equip your collector with a safety monitoring filter. This is a secondary bank of high efficiency air filters that prevent collected dust from re-entering the workspace if there should be a leak in the dust collector’s primary filtering system.

A safety monitoring filter is a required component in a recirculating dust collection system that recycles air downstream of the collector. By recirculating heated or cooled air back through the plant, the cost to replace that conditioned air is eliminated, with rapid paybacks in energy savings. Another advantage of recirculating systems is a reduction in regulatory paperwork. By containing the air indoors, you can avoid the time-consuming permitting involved when contaminated air is exhausted outside.

Using filter percentage efficiencies and Minimum Efficiency Reporting Value (MERV) ratings to predict emissions compliance isn’t enough. The MERV scale provides a good indicator of a filter’s initial efficiency, however, it does not measure pressure drop, emissions while pulsing, energy performance or the other parameters that better reflect dust collector efficiency. The safety and regulatory agencies want to know that emissions will be at or below their required thresholds. Ask the filtration manufacturer for a written guarantee of emissions performance stated as grains per cubic foot.

Ideally, workers should never have to enter the dust collector to change the filters. Dust collectors that require entry during service, put workers at risk and require companies to file confined space entry permits and monitor for gas. Many cartridge-style dust collectors offer ease of filter changeout. For optimal safety, filters should be positioned for ease of access and slide in and out of the housing readily.

change filters when airflow through the system reaches a differential pressure limit as prescribed by the manufacturer or when the pressure drop across the collector is negatively affecting the ability of the dust collection system to capture the dust, thus allowing it to escape into the facility. Some long-life cartridge filters can operate for two years or even longer between change-outs. However, for heavy dust-loading applications, filter replacement might be much more frequent. Moreover, extended-life cartridge filters can reduce replacement frequency and minimize worker exposure to dust. Reducing filter change-out frequency also saves on maintenance and disposal costs and reduces landfill impact. Ask your filter supplier for a written guarantee on filter life.

For spark-generating applications, a range of features and technologies are available, while fire sprinkler systems may also be required with some installations.

Simple, quick-open heavy gauge doors can provide access to a fast cartridge change-out system that does not require entry into the collector. We recommend looking for doors that are fully reversible for access from either side and have an exclusive lock-out feature for worker safety.

Pulling out a dirty overhead filter that weighs 100 pounds can result in neck, back and foot injuries. Avoid threaded connections on the filter access doors or hoppers because dust tends to build up in the threads and cause connections to stick. Camlock-style devices are not subject to this problem and make for easier service.

8

A simple but important safety requirement is to

Dust collectors that use vertically-mounted cartridges also reduce fire and explosion risks. With horizontally-mounted systems on heavy dust loading applications, dust becomes entrained at the top of the filters, and there is no pre-separation of heavy or abrasive particles from the air stream. This situation can shorten filter life and provide a dusty surface for sparks to ignite. Vertical mounting reduces heavy loading dust on the filters and helps eliminate these problems.

10

Regulatory-compliant railed safety platforms and caged ladders can prevent slips and falls when workers access the collector for service.

Lock-out/tag-out doors prevent injury caused by inadvertent opening of doors during a pulsing cycle and/or exposure to hazardous dust. Where highly toxic dust is being handled, a bag-in/bagout containment system may be required to isolate workers from used filters during change-out. This article is from a white paper (www.cpec. news/pce) written by Brian Richardson, Technical Departments Manager, Camfil Air Pollution Control. He can be reached filterman@camfil.com.

Moisture measurement and control analyzers can be found in thousands of applications all over the world, saving manufacturers a large amount of time and money by quickly detecting out of specification moisture ranges on the manufacturing line. Operating personnel can make immediate line adjustments based on real-time data.

MoistTech Corp. has introduced Near-Infrared (NIR) technology for moisture measurement and control process applications.

During various stages of processing, moisture levels are critical as the product can quickly become too wet or dry, wasting time, effort, and product. An ideal moisture control system accurately detects the moisture levels at different stages of the process, is easily maintained and has the ability to withstand even the harshest of manufacturing conditions.

The IR3000 series of on-line sensors manufactured by MoistTech are specifically designed to be unaffected by ambient light, material variations such as particle size, material height and color, and provide continuous, repeatable accurate readings.

LOWER ENERGY COSTS & LESS WASTE

With a non-drift optical design and low to zero maintenance, MoistTech’s IR3000 sensor provides immediate process adjustments to increase efficiency and minimize costs. Implementing production operations to improve the process with proper moisture control begins with a non-contact, pre-calibrated, plug and play solution that is easily incorporated into the manufacturing line with no downtime.

The ability to reduce waste and keep the production line moving is essential to plant operators. Moisture measurement and control plays a large role in this ability. With the implementation of MoistTech’s IR3000 system, plants can now make major reductions in waste — wasted time, wasted effort and wasted product. Catching out of tolerance readings as quickly as possible allows for the most opportune ways to increase plant efficiency.

The on-line sensors are mounted several inches above the material and can be placed before or after the dryer, on a belt, screw or drag conveyors, chutes, cyclones and bins, pipelines, and pneumatic conveying as well. The MoistTech sensors are not limited to the type of installation and can be mounted in any orientation using many of our measurement accessories. Typical analog range is 1-10% moisture with 0.1-0.2% accuracy.

MoistTech has designed a suite of high-tech Windows programs to provide user-friendly interfaces for configuration, data logging, and monitoring of diagnostics.

Our configuration software provides the operator with the capability to monitor up to three constituents and the addition of the temperature option. Output trending is displayed to take corrective action prior to reaching determined

thresholds. The MoistTech software is easy to use and compatible with any PC platform.

NIR technology has both performance and accuracy benefits over competing technologies currently being used to measure moisture content. NIR spectroscopy is a fast, non-destructive method of analyzing the chemical and physical information of a product in virtually any matrix.

A light source is used to reveal transmitted light passing through the product, while backscattered light reflects from the product and is absorbed. The moisture content is determined by the amount of light that is absorbed and also reflected back to the sensor.

Other technologies require constant re-calibrations, have height interference, experience drifting over time, produce less reflected light energy and overall provide the user with more of an estimated guess of moisture content rather than true, repeatable data. MoistTech’s technology provides hundreds of readings per second with the ability to be displayed anywhere throughout the process, giving full access and capabilities to the production line.

With the ability to store up to 50 product/calibration codes, line operators can alert the sensor for changing products immediately. Streamlining the production process to include the ease of measurement not only improves the final product

but allows the plant to operate more efficiently, experience less downtime and increased production.

Immediate results can be seen when proper moisture measurement and control technology is used.

This article was contributed by MoistTech, a Sarasota, FL-based global manufacturer of Near-Infrared moisture measurement sensors and equipment.

MoistTech

www.moisttech.com

www.cpec.news/qmd

• Manual, automatic and actuated (pneumatic & electric) valves; relief, check, diaphragm, ball, solenoid, and shut-off. Also pressure regulators, metering pumps, basket strainers, sight glasses, and gauge guards.

• Innovative Engineering –Dedicated Craftsmanship.

• 100% inspection and individual testing of each product, to ensure dependable performance and long-life.

• PVC, CPVC, Polypropylene, PTFE and PVDF. Valves from 1/8'' to 3'',Sight glasses to 8'' and Basket Strainers to 14''.

Dear Readers,

Greetings again from “Lock-down” Spring has sprung and after a winter of lockdown, boy it feels great. In our area, it seems like winter decided it was over and packed up all the snow and ice and left.

Lake Simcoe had a very short ice fishing season as did most of the lakes in these parts. I haven’t mothballed the snow shovel just yet as the first week in April always delivers a nasty storm.

Our next issue is the June issue with the focus on Plant Maintenance & Safety and Mike’s supplement on Instrument Calibration Labs.

It closes May 7.

On a sad note, we lost one of the great ones. Cathy Buckingham, founder of TNR Industrial Doors, lost her long battle with cancer. Cathy received a number of awards during her business career including the 2012 RBC Hub Canadian Women Entrepreneur Award.

Cathy believed leadership through team building was the way to success and she had plenty of it. Always flashing that million-dollar smile and making everyone around her feel important.

We’ve lost one of the really good ones.

Stay Positive, Test Negative, Rob Sommerville

Emerson has released its ASCO 141 series advanced redundant control system (ARCS) to provide a redundant solution for a variety of emergency shutdown valve applications, such as those found in the chemical, power, oil and gas industries. Available globally, it includes various redundant solenoid configurations to enhance the reliability of the process and meet specific safety or reliability requirements in automation processes. The single inlet/ single outlet design is said to provide a

streamlined installation process compared to traditional bypass systems, while almost eliminating potential failure points. The series is designed for use as a component in safety instrumented systems. Utilizing 1oo2, 2oo2 or 2oo3 voting solenoids to enhance the reliability of the circuit, it functions as a redundant pneumatics tripping device to control the pilot air signal to a process valve actuator.

Emerson

www.emerson.com

The Magna-Plug magnetic connector has been announced by Exceltec. The magnetic connector has been designed primarily to reduce cable and probe breakages in manufacturing processes. The product has a male connector and a female connector. It also has a female connector variant for panel mounting. The body of the connectors is made of food grade Teflon, which meets FDA specifications. The product meets IP67/68 and the force of the magnet is 10 lb. The advantage of the force feature, the company says, is that the plug can be easily disconnected. For example, an operator moves a food shelf in which the connector is used for a temperature probe or if a manufacturing equipment is moved and the cable is pulled, connectors will be separated without damage and without interruption due to damaged cables. The magnetic connector can be used for low voltage signal applications and 4 to 20 mA. Watch video demonstration at www.cpec.news/4dh.

Exceltec

www.exceltec-inc.com

www.cpec.news/by2

www.cpec.news/q0z

Metso Outotec has added to its line of mobile and modular stationary crushing systems with a sizer option designed for soft ore and aggregate applications. The additions to the company’s mobile Lokotrack product line are equipped with Komatsu’s sizer technology and are available in five models ranging from 500 to 4500 tons per hour. Its recently launched modular FITTM crushing stations are also available with sizer configurations. Both the mobile and modular solutions were engineered in collaboration with Komatsu. The Lokotrack mobile sizers are designed for safe operation and easy application, the company says. When combined with the Lokolink and Conveying Systems, the company says it can provide a truckless configuration from the quarry to the concentrating or cement plant.

Metso Outotec

www.cpec.news/ncw

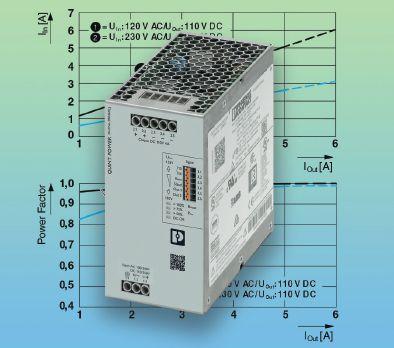

Phoenix Contact has announced the Quint Power primary-switched power supply unit. The unit is suitable for: supply and switching of 110 to 135 Vdc devices; a DC/DC converter; and, charging and support of 110 to 135 Vdc battery banks. Specifications include a rated input of 90 to 264 Vac or 90 to 350 Vdc; 4 A current up to 60°C, 5 A (static boost) up to 40°C, 6 A (dynamic boost) for 5s at 110 Vdc; 24 A for 15 ms (SFB); and, maximum reverse feed of 160 Vdc. Units have internal overvoltage protection, IEC 61850-3 certification, >93% efficiency, dimensions of 70 x 130 x 125 mm (W x H x D) and series and parallel connection alternatives. Phoenix Contact Canada www.phoenixcontact.ca

www.mogroup.com

Acromag Vertu series VPM2000 loop-powered isolators/alarms with display are 1/8 DIN digital panel meters designed for the purpose of convenient and informative displays of any 4 to 20

mA signal. The dual line display shows the process value on the top line and the units or a tag on the bottom line. Users can also display the input in one scale on the top line (e.g., height) and another

scale on the bottom (e.g., volume). A bar graph option indicates the percentage the value represents. All models include a digital input and two open collector outputs. For signal isolator and alarm trip applications, model options add two solid state relays or 4 to 20 mA analog output. In addition, the digital input enables remote reset or triggering of alarms. Open collector outputs are useful for alarm indication or pulse output. Relays support alarm activation, on/off control, and pump alternation functions. The NEMA 4X IP65 panel, conformal-coated PCBs, wide temperature operation, and a backlit LCD enable use in most environments. Additionally, intrinsically safe and non-incendive versions allow installation in hazardous areas. Watch video demonstration at www.cpec.news/ntz.

Acromag

www.acromag.com

www.cpec.news/kvf

Nidec Motor Corporation has introduced the ID300 Fusion Integrated Motor Drive that features U.S. Motors brand 1 to 10 hp UL-certified induction motors and customizable variable speed drives. The motor drive incorporates all of the functions of a variable frequency drive (VFD) into the motor. The integration is said to provide superior control and monitoring capabilities that help with real-time pump management and intelligence analytics. The drive allows manufacturers to embed the pump curve information into the drive so that the pump runs at its best efficiency point without an external sensor. An onboard programmable logic controller (PLC) can regulate the pressure (constant pressure/variable flow). When programmed with the pump curve, the ID300 PLC can perform sensor-less constant pressure control, eliminating sensor cost and simplifying its installation and commissioning. One drive unit can control up to three additional constant speed backup pumps.

Nidec Motor Corporation

www.nidec-motor.com

The Power Defense molded case circuit breaker portfolio from Eaton is globally rated in a small footprint for adaptability. The circuit breaker with communicating electronic trip units has the ability to generate the data to help optimize facilities’ performance and with the breaker ArcFlash Reduction Maintenance System helps protect workers by reducing dangerous and potential arc flash incident energy levels and enables workers to activate this system from a safe distance without altering critical protection settings of the breaker. Zone Selective Interlock (ZSI) technology protects equipment by intelligently selecting faster trip times in coordinated systems. Watch video overview at www.cpec.news/z2a. Eaton

www.eaton.com

www.cpec.news/u73

www.cpec.news/viv