focus on the Environment the Environment

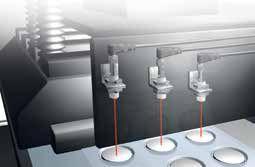

FIRE SUPPRESSION SYSTEM ADDS PROTECTION FLUID

ELECTRICALLY-ACTUATED PRECISION SPRAY NOZZLES

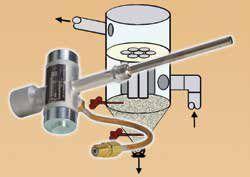

Fike has announced it will now offer 3M Novec 1230 fire protection fluid in its patented Impulse Valve Technology fire suppression system. The company’s fire suppression systems are manufactured with impulse valve technology to improve the release of the agent into the zone with greater precision and reliability. The patented valve uses the Fike AXIUS rupture disc, enabling systems with smaller diameter pipe, longer flow distances and greater design flexibility than most other systems, the company says. The fire protection fluid is waterless, discharged as a gas, leaves no residue, and is electrically non-conductive, making it suitable for quickly extinguishing fires in spaces occupied by electronics or irreplaceable assets and where business continuity is critical. Its environmental profile supports sustainability and LEED initiatives with zero ozone depleting potential and a global warming potential that’s less than one. Fike www.fikecanada.com

HAND PUMP SPEEDS PRESSURE, VACUUM CALIBRATION

The DCAP-PV pump from Ralston Instruments is said to generate pressure and vacuum easily and then control pressure to very precise test points. If the transmitter is an absolute pressure transmitter, the hand pump can generate a vacuum to reach below ambient pressure test points. The Ralston Quick-test system of hoses and connectors also lets the user connect without thread tape to each adapter and in many cases also to the device being calibrated without a wrench. For setting pressure switches, a pump with good control of pressure or vacuum is required. The fine adjust piston on the hand is said to very precise and lets the user open or close a pressure switch easily. In addition, the hand pump works well for calibrating flow computers which require precise control of pressure to each side of the differential pressure cell, the company says.

Ralston Instruments www.ralstoninst.com

BETE electrically-actuated hydropulse spray nozzles from John Brooks Company are available for hygienic (EHP) and industrial (EHPI) applications. Units are said to assure precision volumes are sprayed directly onto your processing target, with overspray waste virtually eliminated. The automated nozzles don’t require a compressed air source and are capable of cycling on/off up to 150 cycles per second. These features afford the option of using high-frequency cycling known as pulse width modulation (PWM) to vary the liquid spray flow rate at constant supply pressure with little change in spray performance by adjusting the duty cycle. When the spray cycles at a high enough frequency, coverage uniformity is maintained because the duration between pulses of spray is short enough to ensure there are no gaps in the spray coverage, the company says.

John Brooks Company www.johnbrooks.ca

CLAMP DESIGN MINIMIZES PROCESS CONTAMINATION

L..J.. Star has introduced a design concept to visual flow indicator assemblies. Designed for hygienic/sterile applications in pharmaceutical, food/beverage, brewery and biotech industries, the clamp type sterile visual flow indicator, or CT-SVFI, uses a patent-pending design to prevent the O-ring seal gaskets compression issues that lead to contamination associated with conventional screwed or threaded fittings. The unit uses a mechanical stop design rather than screw threads said to apply precisely controlled compression to O-rings and provides up to 34 percent greater view area. Units maintain an EN10204 3.1 certification, along with FDA and USP Class VI certified O-rings and is fully compliant with the requirements of the European Pressure Equipment Directive 97/23/ EC. The product uses SF4 (15Ra EP) 316L stainless steel, with full material traceability. EPDM is the standard O-ring material, with silicone and other options available in tube OD sizes from ½ to 4 in. The glass material is made from borosilicate.

L.J. Star

www.ljstar.com

Volume 48, No. 2 April 2020

Low-cost message displays

One-line display starting at: $507.00 (MD4-0112T)

Four-line display starting at: $1,066.00 (MD4-0412T)

Get the word out without spending a fortune with industry-tough LED message displays from AutomationDirect. ViewMarq LED message displays can display preformatted and real-time factory floor data messages controlled by a PLC, PC, or other master device.

Each display includes multiple options for communicating vital information:

• ASCII strings through the RS232 or RS485 port

• Modbus RTU messages through the RS232 or RS485 port

• Modbus TCP messages through the Ethernet port

Two-line display starting at: $719.00 (MD4-0212T)

The affordable ViewMarq line also offers:

• One-, two-, and four-line displays

• Right, left, up and down message scrolling options

• Viewing distances up to 400 feet and 140 degree viewing angle

• (1) RS232, (1) RS485 and (1) Ethernet port standard on all models

• FREE ViewMarq configuration software (online download) used to configure the display; create, preview and send messages from a PC; or create ASCII strings for PLC control

• NEMA 4 / NEMA 12 extruded aluminum housings suitable for harsh environments

• Mounting hardware, cable glands and Ethernet cable included

Orders over $49 get FAST FREE SHIPPING

Our shipping policies make it easier than ever to order direct from the U.S.!

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days. Order by 6pm ET and in-stock orders ship the same day!

*2-day free shipping does not apply to drop-ships, or orders requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

prices shown are U.S. Dollars

PROCESS FLOWMETERS MEASURE WET AND DRY GASES

The Endress+Hauser Proline Prosonic Flow G 300/500 flowmeters with optional integrated pressure and temperature sensors are said to provide highly accurate, real-time values in even the most demanding environments. The flowmeters measure both dry and wet gases — natural gas, process gas or gas mixtures, either offshore or onshore — using ultrasonic flow measuring technology. The units’ technology is said to ensure measured values to ±0.5% with unmatched repeatability, even when process and ambient conditions fluctuate

significantly. The flowmeters provide this accuracy in process temperatures up to 150°C and pressures up to 1450 psi. Units are constructed with high grade stainless steel for all wetted parts and the entire sensor body. An innovative sensor concept is equipped with a special drainage system that immediately dissipates any condensate forming in the sensor pocket area, assuring reliable measurement without any degradation of signal quality, the company says.

Endress+Hauser www.ca.endress.com

SHUTOFF VALVE ENHANCES SAFETY, RELIABILITY OF COMBUSTION SYSTEMS

Emerson has introduced the ASCO series 158 Gas Valve and series 159 Motorized Actuator. Designed specifically for burner-boiler applications, the products provide a new combustion safety shutoff valve option that is said to increase safety and reliability and enhances both flow and control. The valve offers a close-off pressure of 75 psi to ensure a safe shutoff in the event of a fuel train system failure and eliminates the need for additional safety components. The valve offers a flow rate which is twice that of other combustion valves on the market, the company says. Installation is also made easier with end connectors that eliminate the need for piping unions and a ventless compatible monoblock design that not only does away with the need for additional vent piping, but also limits greenhouse gas and vent emissions, it adds. The gas valve is available in sizes from ¾ to 3 in. NPT in both single and monoblock constructions. The motorized actuator can mount in any position and offers a visual indication of opening.

VALVE AUTOMATION DESIGN SERVICES

John Brooks Company provides a sole-source service for valve and valve automation application requirements. If an application requires an automated valve, the company’s application experts are on hand to assist with requirements — not only selecting the best valves and components for an application — but also with complete in-house assembly and in-house operational testing. The company is said to offer an extensive lineup of global valve and valve component manufacturers and its experienced technical sales team is on-hand to assist with whatever selection or operation challenges that are being faced.

JB Valve Automation

www.johnbrooks.ca

Editor’s Forum

Don't know about you, but I have been really enjoying the new Star Trek: Picard series on TV these days. It's a little darker than The Next Generation, but with the requisite healthy disregard for physics, still entertains this old engineering technologist.

The Coronavirus outbreak must have many now wishing teleportation wasn't just science fiction. The airlines and cruise ship companies certainly could use that technology to beam passengers to their destinations instead of transporting them in

expensive sardine cans. But there is more than one way to get to far-off lands, even if the solutions are a bit of a cheat.

Immersive technologies such as virtual and augmented reality software can put you on any beach — or factory floor, if that is your objective. With certain hardware, for example, your avatar can interact with people in a meeting room across the planet somewhere. The problem with avatars, however, is the lack of realism in front of a live audience.

Holograms are a step forward in

this arena as there is more of a comfort level all around, both by the presenter (the hologram) and the audience, wherever it is. Toronto startup ARHT Media is currently promoting its holographic telepresence in the teleconferencing market as a way to reduce carbon footprints.

When you don't have to fly to China to be in the room with engineers or investors, everybody wins. And the only virus in the room can be blamed on hackers.

Mike Edwards medwards@cpecn.com

With Visual Flow Indicators and Sight Glass Windows from L. J. Star

For even the harshest chemical processing environments to sterile pharma/biotech applications, you’ll find the right solution, the right documentation and the right team with L. J. Star flow indicators, fused sight glass windows and high-lumen lights and cameras.

n Standard view and full-view sight flow indicators

n Rotary, flapper, flutter, ball or drip indicators available

n Highest quality glass and materials that meet or exceed industry standards

L. J. Star’s METAGLAS® fused windows, MetaClamp® and Lumiglas® explosion-proof and Non-Ex lights are found in the most demanding applications in the world.

Call or visit www.ljstar.com for detailed CAD files, specs and tutorial handbooks.

www.ljstar.com • +1-330-405-3040

Founder Ray Blair

Cameron Instruments has announced the intrinsically safe HPC50 series pressure calibrator from Ametek STC – Crystal. The units combine features from the previous 30 series, like ease of use, ruggedness, compactness, and reliability with improvements such as a larger display, more measurement options, temperature measure, and external modules. Similar to the earlier series, the new units are also CSA intrinsically safe rated for the North American market. It is also fully temperature compen-

sated for pressure, temperature, and electrical measurements. The connection ports on the side support new intrinsically safe pressure (APMi) and temperature (ATMi) modules. The ports are identical, so users can connect two separate temperature modules, which allows the measurement of both ambient and process temperatures. Users can equip the series with four pressure ports and view all four.

Cameron Instruments www.cameroninstruments.com

BACKGROUND SUPPRESSION PHOTO SENSOR

Two configuration methods are available with the new Balluff background suppression BOS 08E sensor family from Manufacturers Automation. The builtin potentiometer allows users to set the detection range from 7 to 30 mm. The IO-Link version offers more advantages such as setting the range, hysteresis, and switching modes. Features include a focused bright light spot for easy setup, parameterization with IO-Link and a rugged, IP67 stainless steel housing. The ambient temperature range is from -5º to 55ºC. Manufacturers Automation

COMBINATION AIRFLOW JUMBO WALK-IN OVEN

The NS Series ball valves are available in sizes 1/4”-6” with threaded, socket weld, butt weld (3-piece) and flanged (2-piece) connections.

The NS Series butterfly valves cover 2”-24” sizes in wafer and lug style.

APPLICATIONS

• Water Treatment

• Potable Water Service

• Reverse Osmosis

• Desalination

The model No. 999 is an electrically-heated, 350ºF jumbo combination walk-in oven from Grieve, suitable for curing composite parts. Workspace dimensions measure 10 x 40 x 8 ft. (W x D x H). Incoloy sheathed tubular elements rated at 160 kW heat the unit, while two 20 hp recirculating blowers with total 49,500 cfm capacity provide combination airflow to the load. The oven features 4 in. insulated walls throughout, removable top-mounted heat chamber (shown removed in photo), aluminized steel interior and exterior, front and rear double doors with air-operated opening assist plus an 8 x 10 in. double pane Pyrex window in each door, ¼ in. thick plate floor and four interior oven lights. The unit is equipped with safety equipment for handling flammable solvents, including explosion venting door hardware, 2600 cfm powered forced exhauster and motorized dampers on intake and exhaust for accelerated cooling. The unit is built to NEMA 12 electrical standards. Grieve www.grievecorp.com

WEIGHERS/FEEDERS OPERATE IN WILD-FLOW OR CLOSED-LOOP CONFIGURATIONS

Acrison offers its various high capacity, heavy-duty model 260 weigh belt weighers/feeders to accurately weigh and/or totalize the flow of dry materials in a “Wild-Flow” configuration, or to meter dry solid materials in a controlled, “Closed-Loop” configuration as a weigh feeder. The model 260 (WF), operates as a weigher and/or totalizer, continuously weighs material passing across the belt while producing an output signal directly proportional to the weight of product flow. Belt speed is constant, and the rate of flow is not controlled, only weighed, by the weigher’s multiprocessor controller. When operating as a weigh feeder, the model 260 (F) continuously controls the feed rate (or rate of product discharge off the belt) in relation to a feed rate setpoint via modulation of the belt speed by a multiprocessor-based control system. . Acrison www.acrison.com

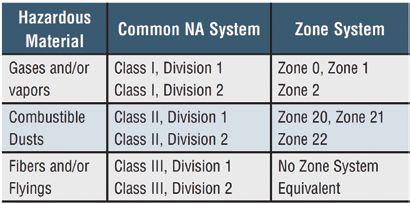

Hazardous area classification considerations: flammability and combustibility risks

By Wayne Perry

In the past, seeing the term “Hazardous Location” usually meant that the equipment being requested was destined for a chemical plant, refinery, or drilling platform. Today, we are seeing hazardous locations in sugar mills, grain storage facilities, and anywhere there may be flammable liquids, gases, or dust present. Hazardous areas are defined as areas where the presence of flammable gases or liquids, combustible dusts, or easily ignited fibers exist in sufficient concentrations to cause a fire or explosion, provided a source of ignition. These areas range from portions of a room to whole plant sites.

Partly due to this expanded use of the classification system, specifiers are increasingly citing requirements for equipment suitable for use in classified areas. When properly used, the hazardous area classification system makes for a safer work environment. Too often, however, hazard classes are specified without concern for the significantly higher design and procurement costs they bring. In many cases, an open mind and a little ingenuity can avoid excessive costs for compressors and other equipment, without compromising safety.

Classification Systems

There are some differences between the classification system in North America and the system used in other parts of the world. In North America, the most common method for defining hazardous areas is by Class, Division, and Group.

Classes are used to identify the type of material that may be found in the atmosphere:

• Class I – Flammable gases and vapours in quantities sufficient to produce ignitable or explosive mixtures

• Class II – Combustible or conductive dusts present in the atmosphere

• Class III – Ignitable fibres or flyings are in the atmosphere, but not likely to be in sufficient quantities to produce ignitable mixtures.

Divisions are used to identify the probability that an ignitable substance will be in the atmosphere in concentrations that would support ignition:

• Division 1 – The substance is present during normal operating conditions. This is further defined as being more than 10 hours per year.

• Division 2 – The substance is not present during normal operating conditions and is present only when an abnormal condition exists. This is further defined as being between 1 hour and 10 hours per year.

• Unclassified – In a facility with Class I or Class II areas, any area where concentrations of gases, vapours, or dust sufficient for ignition are present less than 1 hour per year are listed as Unclassified.

Groups are listed as A through G. Groups A through D identify gases and vapors and apply to Class I locations. Groups E through G identify combustible dusts and apply to Class II locations. The degree of flammability is alphabetical, with A being the most flammable and D being the least flammable gases and vapours, and E being the most flammable and G being the least flammable dusts.

These classifications can be found in National Fire Protection Association (NFPA) Section 500 and 505. Section 505 is a newer s In Europe and other parts of the world, a Zone rating is used. This is similar to the North American system with some slight differences.

• Zone 0 – An atmosphere where a mixture of air and flammable gas, vapour, or mist is present frequently, continuously, or for long periods of time. This is further defined as 1000 hours per year or more.

• Zone 1 – An atmosphere where a mixture of air and flammable gas, vapor, or mist is likely to occur during normal operations occasionally. This is further defined as more than 10 hours but less than 1000 hours per year.

• Zone 2 – An atmosphere where a mixture

The location of plant compressors layout poses particular risks, but that can still be overcome.

of air and flammable gas, vapour, or mist is not likely to occur in normal operation but, if it does occur, will persist for only a short period of time. This is further defined as more than 1 hour but less than 10 hours per year.

• Unclassified – Flammable mixture is present less than 1 hour per year.

Zones 0 and 1 would be roughly equal to Class I, Division 1. Zone 2 would be roughly equal to Class I, Division 2. Zones 20, 21, and 22 are for dusts with the second digit corresponding to Zones 0, 1, and 2 as far as likelihood of being present in the atmosphere.

Designations

When determining a hazardous area designation, the following things have to be considered:

A) Is the hazard a gas, vapor, mist, dust, or fibre?

B) What is the actual hazardous substance (gasoline, coal dust, sugar, etc.)?

C) How often will the hazardous substance be present?

D) How large of an area might it cover?

From that information, the classification can be determined using either the Class/Division or Zone methods. The degree of classification will determine the type of equipment that can be installed in that area.

There are a number of methods that are commonly used to protect equipment in classified areas. They are all designed to prevent the equipment from becoming a “source of ignition”. Commonly used terms include:

Explosion-proof – This term does not mean that the equipment is built in a manner that it will prevent it from exploding. Explosion-proof equipment is built so that if a flammable mixture enters the equipment and there is a source of ignition (spark, internal heat, etc.) the equipment will contain the explosion without damage and be able to cool the hot gases that escape the equipment to the point where they cannot ignite the flammable mixture outside of the equipment. This equipment must also be designed so that the exterior does not get hot enough during normal or abnormal operation to ignite a flammable mixture that might surround the equipment.

Intrinsically Safe

– Intrinsically safe equipment is equipment that does not contain enough energy to provide a source of ignition. Generally, this means that the equipment must be below 30 volts and

have a current of less than 300 mA.

Encapsulation – Some electronic devices can be encapsulated in a resin to protect them from explosive mixtures. Care must be taken to make certain that the device will not generate sufficient heat to either damage the internal components or the resin.

Purged or Pressurized –

An example of this would be a sealed electrical cabinet that maintains a positive internal pressure of inert gas, such as nitrogen, or clean air to prevent the ingress of a flammable mixture. Care must be taken with this type of system to ensure that the cabinet is purged prior to being energized.

Immersion – As the name implies, immersion involves placing the electrical equipment in a suitable liquid so that any flammable material in the atmosphere is not able to contact the equipment.

Hermetically Sealed – This commonly involves encapsulating an electrical device in glass, with its leads fused to the glass. Due to the possibility that the glass may break, this method cannot be used in Division 1 or Zones 0 or 1 locations.

Managing Costs and Risks

The goal of any facility that deals with hazardous materials should be to confine that hazard to as small an area as possible. This makes for a safer facility and minimizes the areas where equipment has to be modified at great expense to make it safe for operation. Modification of equipment to meet the requirements of classified areas can multiply the cost of that equipment two or three fold, and some equipment simply cannot be modified to meet those requirements.

In the case of air compressors, there are alternatives. In some cases, simply moving the proposed compressor installation location a

short distance into a better ventilated area can change the classification from Class I, Division 2 to being Unclassified.

The expense of 100 feet of piping will almost always be less than the modifications required to install the compressor in a classified area. In the case where the hazardous material is heavier than air, for example, siting the compressors up one floor may also change the location to Unclassified.

Or conversely, if the hazardous material is lighter than air, locate the compressed air equipment down one floor. Here’s another point to consider: having the compressor in an unclassified area improves the safety of the entire facility. A serious concern with compressors in classified areas is the possibility that they will pull in and transport flammable mixtures through the distribution piping into unclassified areas with other equipment not designed for classified areas.

In short, every effort should be made to locate compressors outside of classified areas. For both cost and safety, a little extra head work may reduce capital costs and improve safety.

Wayne Perry is Senior Technical Director at Kaeser Compressors, Inc. He can be reached at wayne.perry@kaeser.com.

Kaeser Canada Compressors www.ca.kaeser.com

Flomatic has introduced the new efficient American Iron and Steel (AIS) compliant model 745 to its Flo-Flex line of rubber disc swing check valves. Designed and manufactured according to ANSI/ AWWA C508 Standard, the model 745 AIS is available in a size range of 3 to 12 in. for the water and wastewater industry. The swing check valve features a valve body with full flow area equal to nominal pipe diameter and a 45° angle seat providing short disc travel with faster closure for non-slam

performance. An EPDM-molded, one-piece disc features an integral molded O-ring on the seating surface and is reinforced with steel. The hinge is reinforced with nylon and carries a 25 year warranty. The ductile iron 150# flanged body and cover are fusion bonded epoxy coated, inside and out. The valve can be installed in a vertical (flow up) or horizontal position.

Flomatic

www.flomatic.com

PLATINUM CURED HCR SILICONE MADE FOR FOOD, MEDICAL APPS

Stockwell Elastomerics has announced the availability of its SSP4749/Platinum Cured HCR Silicone Touch Brochure highlighting the SSP4749 materials used to manufacture gaskets and other components. The SSP4749 material is a unique family of high consistency rubber (HCR) that is platinum-cured. A suitable choice for medical device (non-implant) applications meeting USP Class VI, food contact applications that need to meet FDA CFR 21 177.2600 and other applications that may be sensitive to outgassing or leaching. Platinum cured silicones are often used in medical and food contact applica-

tions as a result of the “cleaner” curing process, the company says. Because of this platinum-curing process, SSP4749 materials have advantages over peroxide-cured HCR or liquid silicone rubber (LSR) for certain applications. The touch brochure includes seven sample tactile buttons of the platinum cured HCR materials and has been created to assist engineers tasked with specifying this material in certain applications. There are seven different hardnesses, ranging from 10 to 70 durometer.

Stockwell Elastomerics

www.stockwell.com

IP69K RATED SENSORS FOR WATER SPRAY

Posital has expanded its portfolio of rotary encoders and inclinometers (tilt sensors) to include more devices with IP69K level environmental protection. These sensors, which are designed to stand up to repeated exposure to the hot, high-temperature water jets used in pressure washing systems, are now available with a wider range of mechanical options and communications interfaces. In the case of encoders, this includes more shaft diameters and more flange types — hub and square. For both encoders and inclinometers, the range of available interfaces now includes analog, CANopen, J1939, SSI, Modbus and IO-Link. Incremental encodes are also available with HTL/TTL serial interfaces. POSITAL/Electromate www.posital.com

PRESS FITTINGS IN LARGER SIZES SAVE LABOUR

MegaPress G press fitting technology from Viega is now available for carbon steel pipe in 2-1/2, 3 and 4 in. sizes. The new fittings join the current MegaPressG offerings of 1/2 to 2 in. fittings to create a wider lineup of fittings approved for use in gas and fuel oil applications. The system allows secure press connections on gas lines in 16 seconds or less and can reduce labour costs by as much as 60 to 90 percent over traditional methods. Constructed of carbon steel with a corrosion-resistant zinc nickel coating and graphite separator ring in larger sizes, the technology is suitable for use with ASTM Schedule 5 to Schedule 40 carbon steel pipe. Configurations include elbows, couplings, no-stop couplings, reducers, tees, reducing tees, adapters, reducing adapters, caps and flanges. Viega Canada www.viega.ca

Quick-disconnect cables from AutomationDirect have a 3, 4 or 5-socket M8 female connector on one end and 3, 4 or 5 open leads on the other end designed to provide fast and easy connection between field devices and terminal connections. A “lock in place” nickel-plated brass or zinc coupling nut resists high levels of shock and vibration. The 5-pole, M8 (Pico) quick-disconnect cables are available with axial or right-angle female connectors and pigtail wiring in 1.5, 5 and 10 m cable lengths. The black PUR jacket

of these cables is suitable for oily, direct sunlight and robotic applications. The 5-pole cables are IP67 rated, UL and CSA approved and have a 1-year warranty. The 5-pole, 125 Vac/Vdc, right-angle female M12 screw connectors are field wireable, IP67 rated once properly assembled and accept various cable gauges and diameters. Plastic housings offer good resistance against chemicals and oils. AutomationDirect

www.automationdirect.com

OEM COMPACT OVAL GEAR FLOW METER

AIR-OPERATED CONVEYOR FOR STANDARD PIPE

Type 303 Stainless Steel 2-1/2 NPT Threaded Line Vac

DOE oval gear positive-displacement flow meters from Kobold Instruments Canada are suitable for OEMs that want to measure viscous, non-abrasive, clean liquids such as lubricating and hydraulic oils, diesel fuels, chemicals, solvents and resins. The compact flow meter uses two precision-machined oval gears which allow for a specific volume of liquid to pass through the meter with each rotation. The gears enable the units to precisely measure liquid flow over a very wide viscosity range. Product specifications include: 0.14 to 9.5 gph and 16 to 634 gph measuring range; 1/8 to ½ in. NPT, G1/8 to G1/2 process connection/type; maximum pressure of 928 psig; maximum temperature up to 176°F; stainless steel housing; and, PEEK or PPS rotor material. Kobold Instruments Canada www.kobold.ca

DATA TRANSMISSION POSITION INDICATORS

JW Winco has introduced EN 9153 Digital Position Indicators with data transmission via radio frequency said to be particularly suited for frequent format adjustments and that can be mounted quickly and easily. The indicators are connected to the EN 9150 Control Units by radio frequency as a wireless system for quick positioning. The control units are required for the system to function, forming the interface between the position indicator and the machine control. A target position value is sent by the machine control to the control unit, which transmits this via radio frequency to the position indicator. The position indicator signals its current position value back to the control unit.

JW Winco

www.jwwinco.com

HMI/SCADA SOFTWARE PLATFORM

Air Operated Conveyors from Exair convert ordinary pipe into a conveying system for parts, scrap, trim and other bulk materials. The product is suitable for food, chemical, pharmaceutical and medical processes or areas likely to be wet and corrosive which require the benefits of 303SS, including excellent chemical and corrosion resistance, performance in higher temperatures, long service life and low maintenance. The conveyors are designed to attach to standard plumbing pipe couplers.

EXAIR Corporation

www.exair.com/2.5tlv.htm

Ralston ControlPak

Manual Pressure Controller

Precision manual pressure controller built for the way you work

• Engineered specifically for calibrating pressure instruments with compressed gas in the field

• Compact and portable — controls are in one light-weight, compact unit with included storage space for hoses, adapters and accessories

Adisra has announced its SmartView 4.0 software platform, a human machine interface (HMI) and supervisory control and data acquisition (SCADA) package designed specifically for machine builders and OEMs. Said to be powerful and easy to configure, the package allows users to develop effective interfaces displaying the critical information they need to deploy, monitor, and analyze a machine’s operation and overall status. Users are able to design interfaces that can be linked to manuals, drawings, animations, and videos to assist in operation and troubleshooting. The platform is built on HTML5 so displays are automatically optimized for target devices, and is scalable to support Industrial Internet of Things (IIoT) applications. Adisra

www.adisra.com

• Extremely precise, finger-tip control of pressure at 0.03 psi (2 mbar) to 3,000 psi (210 bar) with the pressure-balanced, fine adjustment piston

• Rugged and durable plastic case that will stand up to use in the mud, sun, and cold weather better than bench-mounted volume controllers

• Quick setup and breakdown with Ralston Quick-test™ hand-tightening outlet connections, hoses and adapters — without the need for thread sealant or a wrench

TNR DOORS ANNOUNCES TOP LEADERSHIP CHANGES

Cathy Buckingham, founder and president of Barrie, ON-based TNR Doors has handed over the reins of her long held leadership role to a new president, Marcus von Reden. Buckingham has lead TNR through phenomenal growth and success and has been the key to assembling and inspiring a successful team and building a leading high performance door company for more than sixteen years.

Since June 2019, after moving and settling in Barrie as executive vice president at TNR, von Reden has been working closely with Buckingham and the management team at TNR Doors.

During this period he has been learning about the operation, working with employees, customer and suppliers and other industry stakeholders. With years of door industry experience with the Hormann Group and with an MBA from Spain's renowned IE Business School, von Reden is ready to take on the challenges of his new role as president, the company says.

TNR Doors

www.tnrdoors.com

DIGITAL MINING FIRM HEXAGON ACQUIRES BMT

Hexagon Mining has announced the acquisition of Blast Movement Technologies (BMT) from RCF Jolimont Mining Innovation (Jersey). BMT supplies a unique blast movement measurement technology to the global mining industry.

BMT’s technology enables accurate delineation of ore boundaries after blasting in open cut mining. This enables miners to recover more of the earth’s valuable resources, increasing efficiency and profitability.

Nick Hare

“This is great news for Hexagon customers,” said Nick Hare, Hexagon’s Mining division COO. “The Blast Movement Technologies system is the only one of its type and generates significant profits for customers in every blast at over 120 open pit mines globally. The company is rapidly growing and is becoming standard best practice for open cut mining operations. It will be a highly valuable and complementary addition to

our suite of pit-to-plant digital solutions.” The ability to accurately track blast movement is a huge benefit for mines striving to be smarter and more sustainable. Blasting is a highly variable process and movement of the ore during blasting can cost mines millions of dollars in lost revenue per year from ore loss.

BMT’s solution is said to provide customers with accurate blast information that is used to recover all of a mine’s resources, allowing the valuable ore to be sent to the mill, avoiding dilution and misclassification.

Hexagon is a global provider of sensor, software and autonomous solutions. Hexagon’s Mining division, with a location in Vancouver, solves surface and underground mine challenges with proven technologies for planning, operations and safety. Hexagon Mining Canada www.hexagonmining.com

YOKOGAWA LAUNCHES NORTH AMERICAN TECH CENTRE OPENINGS

As technological advances fuel a constant state of transformation across North American process industries, Yokogawa Corporation of America has opened four new technology service centres across the U.S.

These new centres reflect the company’s commitment to meeting growing regional demand for its state-of-the art measurement, control and information products and services, the company says.

The new technology service centres in Utah (Salt Lake City), Texas (The Woodlands), Louisiana (Baton Rouge) and Pennsylvania (Philadelphia) provide expanded access to Yokogawa’s global resources and capabilities. This expansion in local delivery and support infrastructure enables customers to enhance the efficiency and productivity of the investments they make in Yokogawa control systems, advanced solutions, field instruments and analyzers, the company adds.

The Yokogawa Open Process Automation (OPA) Test Bed Collaboration Center, is located six miles north of ExxonMobil’s Houston campus in The Woodlands, Texas. The opening of the centre follows the announcement in July 2019 of Yokogawa’s selection as ExxonMobil’s OPA Test Bed system integrator. The centre will house the Test Bed being used to evaluate candidate components and standards which will provide the basis for moving OPA technology into initial industrial field trials.

Yokogawa Corporation of America has a 60-year track record in North America delivering leading-edge measurement, control, and information solutions, the business is headquartered in Houston, TX, and is supported by domestic manufacturing and service locations across the U.S, Canada and Mexico.

Yokogawa Canada www.yokogawa.com

• Temperature Calibrators: Includes 6 series with more than 25 models and temperature ranges from -100 to 1205°C

• Dual Pressure Calibrators with external temperature & pressure modules

Above: Entrance to the Yokogawa Salt Lake City location. Below: Team at The Woodlands, TX, Collaboration Center.

Cathy Buckingham (left) and Marcus von Reden of TNR Doors.

Industry News

MEMBERS

The Canadian Process Control Association (CPCA) has been working with a CRN coalition with the ultimate aim to harmonize the CRN (Canadian Registration Number) process for pressure vessels. There has been significant progress to date, the CPCA reports, but the process is un-

DOW TO EXPAND ETHYLENE CAPACITY IN CANADA

Dow is incrementally expanding its Fort Saskatchewan, AB, ethylene facility by approximately 130,000 metric tons through the addition of another furnace and associated equipment.

The additional ethylene will be consumed by existing polyethylene assets in the region. The expansion cost of the facilities expected to be between US$200 million and US$225 million.

This project has received all regulatory approvals from Alberta Environment and Parks, the company says, and construction is underway. Facility construction and equipment installation will support an average of 700 jobs per year in Alberta, including indirect and induced economic activity. Start-up is anticipated to occur during the first half of 2021.

https://ca.dow.com/

fortunately a slow one.

Here is an update on the process to date:

• First Ministers requested that the negotiation of the agreement be expedited;

• The reconciliation agreement is based on the mutual recognition of design reviews to: Reduce the number of CRN applications required to be submitted by manufacturers, and reduce the number of CRN design reviews needing to be conducted;

• Entered into force for participating jurisdictions on January 1, 2020;

• As of Jan. 1, 2020, the Reconciliation Agreement (RA) for CRN is in effect in British Columbia, Manitoba, Northwest Territories, Nova Scotia, Ontario, Prince Edward Island, Québec, Saskatchewan, and Yukon (Nunavut has indicated that it is intends to sign, but has not yet done so);

• Manufacturers need only have their design reviewed in one of these jurisdictions, and that review will be recognized as valid in the others;

• Pressure equipment must still be registered in each province or territory (P/T) where it will be used (This is to ensure that regulators remain aware of what equipment is approved for use in their jurisdictions);

• P/Ts still control their own design review and registration processes (mutual recognition means that there was no requirement to change these processes);

• Some P/Ts have arrangements to facilitate registration in other provinces and territories, but there is currently no common system;

• Work is underway to identify and pursue additional improvements in the efficiency of CRN de-

sign review and registration processes;

• Steering committee formed – PTAC, ACI (Association of Chief Boiler and Pressure Vessel Inspectors) and NPSAC (National Public Safety Advisory Committee);

• Steering Committee is working with P/Ts to develop clearer communications (a summary of the RA for CRN is available on the RCT website, https://bit.ly/3d4xiJ1);

• Steering Committee is working with P/Ts on investigating possible information-sharing solutions that may further improve and streamline review and registration processes for manufacturers; and,

•Steering Committee is working with P/Ts to explore development of other improvements such as a standardized/common application form.

Update on the CPCA AGM

In addition, the CPCA Executive is actively monitoring the ever changing COVID-19 situation. At press time, plans were to continue with the annual general meeting planned for May 28-31 in Whistler, BC.

The association feels that this is the strongest lineup of speakers and social events it has had and wants to ensure that the national event continues — provided it can do so without endangering participants.

In the meantime, the CPCA has assured members that any deposits will be reimbursed in full should it become necessary to make any changes to ensure the health and safety of delegates. CPCA www.cpca-assoc.com

Magnet & Metal Detector In One Unit

Dow's Fort Saskatchewan, AB, ethylene facility is set for expansion and future growth.

Industry News

CORONAVIRUS OUTBREAK LEADS TO HANNOVER MESSE 2020 POSTPONEMENT

The trade fair in Germany, Hannover Messe 2020, has been postponed from April to the week of July 13 to 17. Deutsche Messe AG is thus responding to global developments related to the Coronavirus.

Deutsche Messe made the decision to postpone Hannover Messe 2020 to July 2020 in close cooperation with the Hannover Region Health Authority, the Hannover Messe Exhibitors’ Council and the partner associations VDMA (German Engineering Federation) and ZVEI (German Electrical and Electronic Manufacturers’ Association).

The Hannover Region Health Authority had strongly recommended that Deutsche Messe follow the advice of the Robert Koch Institute, which includes comprehensive measures to safeguard health when hosting major events. For instance, fever measuring stations at all entrances and not allowing people from risk areas or those who have had contact with people from risk areas to enter the exhibition centre. This would have entailed a comprehensive evaluation of all trade fair participants — from exhibitors and visitors to service providers, exhibit builders and catering companies.

Deutsche Messe is unable to implement the proposed measures. In addition, their implementation would impair the staging of the event to such an extent that the event would not fulfill its purpose or would do so only with considerable restrictions for exhibitors and visitors.

Since the health of exhibitors, visitors, employees, and the public is the top priority for Deutsche Messe, the decision was made in consultation with Hannover Messe’s exhibitor advisory councils to switch to the July date.

Since 2001, Valve Accessories & Controls has built a reputation as a company comitted to quality products, and a commitment to service, second to none.

• Pneumatic, Analog, and Digital Positioners

• Wide selection of Mounting Kits

• No Phone Mazes to Navigate

• Experienced Staff

• Service and Technical Support

Canadian Master Distributor: Belletek Controls Inc.

2535 Stallion, St. Lazare, Qc, Canada J7T 2E4

J.C. Labelle: (514) 916-5895

Fax: (514) 500-5802

Email: jc@belletek.com

WIKA BUILDS FULL-SIZE INSTRUMENT TEST PROCESSING UNIT FOR PROCESS INDUSTRY

WIKA has announced it has built its own full-size test process unit, complete with a reactor and gas-fired furnace, to test measuring instruments under specific conditions and configurations.

The goal was to create a laboratory tests that can duplicate real-life conditions and testing in active processes. To properly test WIKA’s portfolio of thermocouples and other measurement instruments, the company has created a solution that is said to combine the best of both worlds: an actual process unit that its engineers could start, stop and manipulate as needed — all without having to inconvenience anyone in the process industry, it says. Read more about WIKA’s Design Center and Testing Facility at https://bit.ly/2wM2CLQ.

WIKA Canada

RITTAL INTRODUCES ADVANCING WOMEN IN TECH SCHOLARSHIP WITH ELECTRO-FED

In the spirit of advancing women in technical education and careers, Mississauga, ON-based Rittal Systems Ltd., Canada, has announced two scholarships of $1,750 each, to female undergraduate students in Canada, who are passionate about a career in the electrical, and related, industries. The scholarship is part of The Electro-Federation Canada scholarship program that provides university and college students, who are interested in pursuing a career in the electrical industry, with funding to support their academics.

According to Tim Rourke, president, Rittal Systems, “Rittal celebrates 25 years in Canada in 2020, and what better way to give back to our industry and community than by supporting EFC’s Scholarship Program, that encourages the next generation of leaders to power a changing world in the Canadian Electrical industry.”

The EFC Scholarship program provides post-secondary students who are interested in pursuing a career in the electrical industry, with funding to support their academics. To apply for the Rittal ‘Advancing Women in Tech’ Scholarship, female Canadian citizens or permanent residents must be enrolled in a full-time appropriate field of study (eg. Electrical Engineering/Apprenticeship or Electrical/Electronic Technologist or Technician) at an accredited college or university program. Students can apply at scholarship.electrofed.com. or view https:// bit.ly/3cIGump. Rittal Systems Canada www.rittal.ca

GORDON MCKENZIE APPOINTED PRESIDENT AND CEO OF CANPOTEX

The board of directors of Canpotex Ltd. has announced the appointment of Gordon (Gord) McKenzie as president and CEO of Canpotex, a Canadian potash exporter.

“Gord is an outstanding leader with a proven ability to deliver strong operating and financial performance in an internationally-focused organization,” said Joc O’Rourke, president and CEO of The Mosaic Company and chair of Canpotex’s board of directors. “The Board believes that Gord is the right choice to lead Canpotex.”

Over the past 25 years, McKenzie has achieved success in a variety of senior global sales and marketing positions in the fertilizer sector, the company says. Headquartered in Saskatoon, Canpotex is said to be the world’s largest supplier of potash overseas. Canpotex Canada www.canpotex.com

WIKA’s Design Center and Testing Facility.

Gordon McKenzie

By Ted Mielnik

Sight glasses allow operators to see within their process vessels and pipelines in order to ensure optimal system performance. With humble origins dating back to the locomotive industry in the early 19th century, modern industrial sight glasses have become vital to process control… and for a good reason. Also called view ports, these critical pieces of process equipment offer a safe way to see the levels of liquids or gases that are traveling through a critical point of a design, monitor any pressure changes, and identify any harmful contaminants at early stages before they become a bigger issue.

When it comes to selecting a sight glass, there are a number of factors that need to be considered if the sight glass is to meet the needs of a specific operation. From how it’s mounted and gasket type, to choosing between an assembled or a fused sight glass, design engineers must be precise in their selection. However, nothing is more important than the selection of the glass itself.

While there are many different options to choose from when it comes to glass selection, the choice usually comes down to a decision between two types of glass: soda-lime or borosilicate. Which glass is the best choice for a particular sight glass will depend entirely on its application.

It’s important that the right glass is chosen… and that the glass is what it says to be. Recently, an inferior glass from an overseas supplier entered the North American market, claiming to consist of borosilicate glass and meet DIN 7081 standards. A chemical analysis of its material at a certified lab revealed this to be false. While it was presenting the glass as equivalent to the MAXOS gauge glass, this is not the case, leading to a serious safety concern. Additional testing also revealed that the glass counterfeits could not meet required threshold values for pressure and tension performance, meaning the glass is likely just soda lime glass rather than the borosilicate glass it claimed to be. This is a serious misrepresentation.

Choosing the wrong type of glass can quickly lead to a broken glass and site glass failure. Glasses can break from corrosion, being over-pressurized, from impact with operators or other process equipment, or from thermal shock, like when a cold wash down hits the sight glass on a hot vessel. If the contents of the hot vessel are pressurized, then a broken sight glass can lead to a jet of boiling liquid or steam and shards of glass flying at ballistic speeds. This type of breakage has been known to injure or kill operators on top of costly equipment damage, process downtime, and scrapped batches of products.

Soda-Lime Glass

Soda-lime glass, often used to manufacture bottles, light bulbs, and windows, is a common sight glass material due to how cheap it is. This type of glass is made from silica, soda, lime, magnesia and alumina. Together, these materials combine into a rather unremarkable glass that usually does little more than get the job.

There are two main types of soda-lime glass: annealed soda-lime and tempered soda-lime.

Annealed soda-lime is what’s used in drinking glasses and other common applications. As anyone who has ever dropped one of these glasses on the floor would know, annealed soda-lime is very easy to break. It’s also extremely susceptible to thermal shock, has poor chemical resistance, and limited operating temperatures, making it a horrible choice for critical applications. Be warned — many suppliers try to repair broken sight glasses with annealed soda-lime.

Tempered soda-lime refers to soda-lime that’s thermally tempered to have up to 10,000 psi of compressive stress at its surface, more than double that of annealed soda-lime. The tempered version is also more resistant to thermal shock. As such, tempered soda-lime is the only decent choice when considering soda-lime for sight glass applications. Unless stated otherwise, further mentions of soda-lime glass in this article will refer to its tempered version going forward.

Borosilicate Glass

Borosilicate glass, used to manufacture laboratory equipment and pharmaceutical-grade glass pipes, is increasingly becoming the go-to choice for sight glasses in more demanding applications. This type of glass is made similarly to soda-lime, but with a portion of the silica replaced by boric oxide.

Compared to soda-lime and other common sight glass options, borosilicate glass is more resistant to thermal shock due to its lower coef-

ficient of thermal expansion. It can also handle a greater range of temperatures and is significantly more resistant to corrosion and chemical attacks. When the risk of glass scratching or scuffing is higher, either from inside a process vessel or from the outside environment, borosilicate reigns supreme due to its better abrasion

Solutions For

Continued on next page

TEWATER TREATMENT

ONLINE AND PORTABLE INSTRUMENTATION

Multi Parameter Single – Dual – Multi-Channel-Wireless

Optical Fluorescence Dissolved Oxygen

Near Infra Red Total Suspended Solids

pH, ORP

Microwave Density

Ultrasonic Interface Level

Spectrophotometric Online

FLOWMETERING

Ultrasonic Doppler – Transit Time

Insertion/Immersion/Clamp-On

Venture/Flume Partially Filled Conduit

Non Contact Radar

WASTEWATER SAMPLERS

Indoor or Outdoor

Refrigerated or Non-Refrigerated

Portable or Stationary

SEPTAGE RECEIVING SYSTEMS

Fully Automated Control and Data Collection

Integrated Billing System

ADDITIONAL SOLUTIONS FOR:

Flow – Level – System Integration – Field Service

L.J. Star’s MAXOS gauge glass consists of borosilicate glass.

resistance. Overall, borosilicate offers superior, industry-grade toughness and durability that can hold up to significant pressure and sudden impact conditions. This unmatched strength and integrity are why borosilicate glass is used in advanced products like the METAGLAS series of sight glass windows.

Beyond its higher safety and durability, borosilicate glass also offers better performance in what sight glasses are made to do — viewing inside a system. These glasses remain highly transparent, even when exposed to extreme temperatures or fluctuating process conditions.

Soda-Lime vs. Borosilicate

The advantages of borosilicate glass over soda-lime glass are clear. Overall, soda-lime, commercially known as BoroPlus, just can’t hold up to the superior qualities of borosilicate glass. However, in the name of efficiency, let’s compare them in greater detail to see when it’s okay to use soda-lime glass and when borosilicate glass absolutely must be used.

Quartz is an excellent material for thermal shock and steam. However, due to its brittle and often costly nature, it’s typically only used in applications where temperatures rise significantly higher than 500°F, such as in high-temperature steam applications. In fact, quartz can withstand temperatures as high as 1832°F when used properly.

Sapphire is the strongest and most resistant window but is generally not used in process observation equipment because it is expensive and cannot be molded and fused to metal. However, it can be used as a shield to protect a less resistant glass.

Due to its inferior thermal properties, soda-lime glass can only be used in applications where temperatures remain lower than 300°F. For any application that’s temperatures rise somewhere between 300° to -500°F, borosilicate must be used. Even if an application constantly stays under operating temperatures of 300°F, borosilicate glass should be specified in areas where hot equipment may experience washdowns with cool water. That’s because its higher thermal shock resistance will allow it to withstand the quick temperature functions that would cause soda-lime to break.

Borosilicate glass must also be used in any application that requires contact with caustic or acidic chemicals. Soda-lime is more likely to experience clouding and erosion in these scenarios. Even more, borosilicate glass meets the requirements of USP Type I and may be used with non-parenteral process media, such as with injectable drugs. Soda-lime, on the other hand, has more of a tendency to leach into the process media. After all, glass itself is a chemical compound that can, under the right conditions, react with different media, even water.

Borosilicate glass’ superior resistance is why it’s used in the MetaClamp LED Ring Light Series SGL, a powerful sight glass and system lighting combination.

Even though soda-lime glass is cheaper than borosilicate in the beginning, the total cost of ownership with soda-lime can creep up over the life of a sight glass operation.

Other Options and Considerations

While soda-lime or borosilicate glass will be the top contenders for glass selection in most applications, certain niche or high-level applications will call for another type of glass. Or, better put, another type of material entirely. This is referring to quartz and sapphire.

Unlike glass, in which its molecules are arranged randomly, quartz and sapphire are more technically described as crystals due to the rigid alignment of their atoms. This is the secret to their high durability.

Beyond extreme temperatures, sight glasses that have to deal with highly-caustic chemicals will also need special considerations beyond soda-lime or borosilicate glass. Chemicals like sodium hydroxide, hot concentrated alkaline solutions, phosphoric acid or fluorine are especially difficult on sight glasses. For applications involving these chemicals, it is necessary to protect the glass with a mica or Teflon film shield.

Making the Right Choice

Choosing the best type of glass for any viewing window will always depend on the specific application of the sight glass. While annealed soda-lime glass is almost never recommended, tempered soda-lime can hold up to certain less-critical applications. However, borosilicate glass remains superior in nearly every property and should always be chosen wherever possible over its soda-lime counterpart. You can find more tutorials, white papers, and videos about glass quality and how to specify the proper glass material at www.ljstar.com.

Ted Mielnik is the President at L.J. Star. He received his Bachelor of Science in Mechanical Engineering from Pennsylvania State University and his Master of Business Administration from Gannon University.

L.J. Star www.ljstar.com

L.J. Star’s METAGLAS sight glass window can withstand temperature and pressure extremes common to harsh environments. Watch video demonstration at https://bit.ly/32YgvTp.

Dust Control supplement

DRUM DUMPER FOR HAZARDOUS MATERIALS

Emerson has announced its ASCO series 353 pulse valve has been redesigned to help OEMs and end-users achieve a more effective, efficient and convenient bag cleaning. With a higher peak pressure, wider temperature range, patented quick mount clamp connection and overall part simplification, the series is said to provide longer bag and filter life and lower maintenance. Without optimum peak pressure, the company says, dust collector cleaning becomes inefficient and the consumption of compressed air rises. Because it hits peak pressure quickly, the valve series is said to create a more effective cleaning process. The design is also said to lead to improved airflow through the filter bags or cartridges for optimized dust collector performance while reducing costly compressed air consumption. Valve lifespan is over one million cycles on average. The new valve can be used in a wide range of applications, including concrete processing, grain, agriculture and feed, food processing, pharmaceutical, mining, rubber mixing/processing, metal processing, lime industry, cement factories and steel mills. Emerson Electric Canada www.emerson.com

DUST EXTRACTOR GOOD FOR CLEANING AND SOURCE EXTRACTION

The DC 11-Module from Dustcontrol is a dust extractor which is made for source extraction of dust and chips and for cleaning. The dust extractor and the turbopump are mounted on a common chassis. The unit can be connected to a fixed pipe system. The machine can be used with turbopumps rated at 5 to 11 kW, with or without integrated control box and with several emptying alternatives such as sacks or containers of different volumes and other handling systems. It can be mobile with wheels or stationary, automatic or manual filter cleaning

and equipped with or without HEPA micro filter. The dust which is heavier than the air is forced against the walls of the cyclone by centrifugal force and falls down to the cyclone bas, where the outlet is. The air is forced to the middle of the cyclone and upwards through a fine filter. The filter is cleaned by a compressed air pulse or manually operated reverse pulse jet.

Dustcontrol Canada www.dustcontrol.ca

The Dynatrol DJ Level Switch is designed for application to either high or low point level detection of bulk solids. The detector operates successfully on applications such as baghouses, cyclone separators or above airlocks. The units are said to maintain consistent results on materials ranging from fine to granular. The level detectors require no adjustments and have no moving parts — there are no gaskets or seals to deteriorate. They withstand dusty environments and work well in vessels equipped with vibrators, and are virtually wear-free, the company says. The level switch mounts through a ¾ in. half-coupling at the point of desired level detection. Units are approved for Class III services, as well as for Class I, Groups C & D; Class II, Groups E, F & G; Class III. Dynatrol www.dynatrolusa.com

The Flexicon TIP-TITE Drum Dumper transfers hazardous bulk material from small and large drums into downstream processing equipment or storage vessels automatically and dust-free, maximizing worker safety. The unit accommodates drums up to 55 gals measuring up to 36 in. high, with an outside diameter up to 24 in. and weighing up to 750 lb. A discharge cone adapter (shown) allows dumping of smaller drums measuring 20 in. high and 15 in. in diameter. The dumper is mounted on an elevated base frame to accommodate an integral powered roller conveyor matched to the elevation of plant roller conveyors. It features dual hydraulic cylinders that work in tandem to raise and seat the container rim against the discharge cone, and then tip the container to an angle of 45º, 60º or 90º with a motion-dampening feature.

Flexicon www.flexicon.com

Dual Output Isolated Signal Conditioner or Loop Extender

The ITC-XXX-XX-DC is a signal isolator with dual outputs providing high isolation from Input to Output1, to Output2, and to Power in a small easy to install package. It’s universal DIN rail mount makes it possible to install right next to the instrument that is to be isolated. The many different input and output configurations allow it to be used in a great variety of applications ranging from PLC front end conditioning to adding an extra loop with lots of drive to an existing, almost fully loaded loop.

How the food industry can save time, money and resources on cleaning

By James Miller

Dust is a major issue in the food industry thanks to the presence of airborne allergens, which, while a problem for workers’ long-term health, can also pose issues further down the line for consumers.

Failing to undertake appropriate cleaning measures and tackling dust in hard to reach areas can affect product quality, while also running the risk of cross contamination — with potentially fatal consequences in the event of an extreme allergic reaction.

For the workers themselves, exposure to fine dusts from flour, cotton and pollens can cause inflammation of the airways, which can develop into infections such as bronchitis.

Overexposure to hazardous dust for a prolonged period of time can also cause permanent disabilities, and even death.

It is therefore essential that efficient measures are put in place within the food industry to ensure the protection of workforces and the quality of products, while adhering to the relevant health and safety regulations.

The food industry has special requirements and control of components and equipment used in production is extreme, with a special focus on migratory risk, surface finish and antistatic properties.

The new Dustcontrol Good For Food (GFF) process extraction and general cleaning range includes flap valves, suction brushes, flat nozzles, hose connectors, tubing system, joints, pre-separator, automatic shutter valves and filter units. Watch a video demonstration of GFF brushes at https://bit.ly/39qxmR8.

As a deeper understanding of the harmful properties of dust are better understood, businesses are taking steps to control and confine ar-

eas in the workplace where excessive dust is created, but the necessary cleaning required often takes a considerable amount of time, money and resources.

Research we carried out found that a third of UK food businesses spent between 11 and 20 per cent of their annual revenues on cleaning, with a further one in six claiming to spend even more than that.

On top of unnecessary costs, we also discovered one in four food companies spent more than 21 hours a week cleaning, while a third assess their cleaning processes at least once a week, on top of the time they spend actually cleaning.

It’s a snowball effect — not having the equipment to effectively capture dust at its source, both where and when it’s created, leads to an accumulation of dust, which in turn will naturally increase the time and money spent to combat it.

We understand how you strive for constant product quality and optimized costs. You are poised to meet your safety and quality requirements while optimizing resources and securing process repeatability.

100% traceability ensured with calibration services

CONSISTENT

Streamlining cleaning processes and using the optimum equipment for each scenario plays a large part in reducing time consumption, as well as unnecessary costs. Source extraction systems are one of the most effective ways of achieving safe and hygienic food production, as they are designed to ensure food processing areas are the cleanest they can be – keeping the potentially serious side effects of dust to a minimum.

With hygiene requirements within the food industry being extremely stringent, a complete source extraction system can be fully integrated into the production process for recycling or used as a centralized vacuum cleaning system.

Improve your plant availability, and ensure quality with optimized calibration

• Traceable on-site and laboratory calibration of various parameters

• We are a leading manufacturer of process instrumentation – uniquely qualified to calibrate

• Our global, harmonized calibration standards provide consistent service quality

At Dustcontrol, we’ve just launched a new Good For Food (GFF) process extraction and general cleaning range that, when integrated with our GFF components, includes flap valves, suction brushes, flat nozzles, hose connectors, tubing system, joints, pre-separator, automatic shutter valves and filter units. All material is approved for food contact and several have been designed to be installed in Zone 22, according to ATEX Directives 2014/34/EU.

By combining safe food contact, autoclavable, colour-coded, detectable, anti-static and FDA compliant properties to fully integrate a comprehensive system, food processing companies can yield higher quality products, whilst making savings on factory-wide cleaning costs.

Overall, cleaning is a serious business in the food industry, courtesy of strict process and control. With companies spending considerable amounts of time and money on cleaning, it pays to make sure they’re doing it right. Streamlining cleaning processes and using the optimum equipment ensures businesses are utilizing resources and saving valuable time and costs on creating a safer working environment.

Watch a video demonstration of GFF brushes at https://bit.ly/39qxmR8.

James Miller is Managing Director at Dustcontrol of Milton Keynes, UK. Dustcontrol Canada is located Barrie, ON.. Dustcontrol Canada http://dustcontrolfood.com

ERGONOMIC HAND-HELD ENCLOSURES

Hammond Manufacturing has launched its new 1552 family of hand-held enclosures. Initially available in six sizes, the IP54 rated UL94-V0 flame-retardant ABS enclosure features an ergonomic design that fits comfortably into the hand, enabling it to be used for long period in applications such as a machine controller or an electric hoist control. The end panels are removable for easy modification, and for use with flying cables, an alternative end panel with an integral rubberized cord protector and a strain relief bracket is available. An optional wall mounted holder allows the unit to be stored in a convenient location when not in use. The 1552 can also be used as a desktop enclosure. All the launch sizes are 50 mm wide and either 22 or 30 mm high, with both heights available in lengths of 70, 110 and 150 mm. Hammond Manufacturing www.hammondmfg.com

CYBERSECURE SMART AC-LVDT SIGNAL CONDITIONER

Alliance Sensors Group has introduced the SC-200, an LVDT signal conditioner said to offer smart and fast LVDT/RVDT setup and has been engineered to work with the widest range of LVDTs, RVDTs, and inductive half-bridge sensors including 3-wire industrial LVRTs. The signal conditioning module has cyber security tamper prevention and notification features that provide confidence that the unit has not been compromised, the company says. Operating features include: push button calibration; built-In null indication; 4 excitation frequencies, 8 analog DC outputs (6 DC voltage and 2 current loop outputs); 16 addresses for RS-485 digital communications; and, hot swap capability. Alliance Sensors Group/Hoskin Scientific www.alliancesensors.com

TRANSMITTER HANDLES PRESSURE, LEVEL APPLICATIONS

Krohne has announced the Optibar PM 3050, a pressure transmitter for general pressure and level applications. The transmitter comes in a wide range of pressure ranges and diaphragm styles and has a high overload resistance. The device is also vacuum resistant with measuring accuracy up to ±0.1% of set span. A programmable optional display module is available, which offers response times of less than 50 ms. The device has a compact design with full stainless-steel construction and front flush diaphragm compliant with 3A Sanitary Standard and EHEDG hygienic design suitable for food and beverage pressure and level applications. Additionally, it may operate as an absolute and gauge pressure measurement of gases, vapours and liquids as well as a hydrostatic level measurement in open tanks.

Krohne Canada

www.ca.krohne.com

From the Publisher’s Desk

This picture was shot through my front window. Spring must be just around the corner when the deer are getting restless.

As I write this the Coronavirus is in full swing. Unprecedented actions are being taken to protect each other. For the first time in the 45 years running the Process & Automation Shows we have postponed some of them. The Mississauga and Sarnia shows in Ontario have been postponed until the late fall. Keep an eye on our web site and emails from us about the new dates. We are making a decision about the Saint John, NB, show as we go to press. The rest of our editorial and advertising services will continue normally. If there’s a silver lining to this situation it is that people are cooperating with the direction given by authorities. (Except for the toilet paper and hand sanitizer hoarders). So hopefully we can put the Coronavirus behind us for good before too long.

Our next issue, June will feature our Focus on Maintenance & Safety. Editor Mike Edwards’ supplement will cover all things to do with Sensor Technology. The issue closes May 1st and will mail a month later. If you have something you’d like to submit get it to us by mid-April.

Stay safe, stay healthy.

Cheers, Rob Sommerville

ANALYZER MONITORS WASTEWATER GLYCOL

LINEAR GUIDE SERIES SUITABLE FOR MEDICAL, PHARMACEUTICAL APPLICATIONS

UtiliTrak linear guides from Bishop-Wisecarver are designed for commercial applications where easy installation and minimal maintenance requirements are the primary design objectives. They are constructed with the company’s DualVee Motion Technology in the vee and vee/ crown wheel, or the MadeWell crown roller designs. These, along with a variety of material and seal options, are said to provide high reliability, easy installation and low maintenance solutions in a sleek, compact design. Fit up is pre-set for the company’s PW, SW, and CR wheel plates, but is easily adjusted by rotating the eccentrically mounted center guide wheels. This allows modification of running characteristics such as drag, breakaway force and preload, the company says. The VC series wheel plate is not pre-set. Each wheel plate assembly includes a standard channel lubricator, which distributes a light coat of oil along the length of the channel during normal operation. Channels can be butt-joined for unlimited travel lengths. The linear guide series is suitable for medical, pharmaceutical, packaging and other applications.

Bishop-Wisecarver

www.bwc.com

TUBES AND RACKS ENSURE STABLE OPERATION IN BIOBANKING AND COMPOUND STORAGE MATERIALS

The Total Organic Carbon (TOC) analyzer from Electro-Chemical Devices helps manage ethylene glycol and other waste streams to safeguard water resources. TOC analyzers measure the carbon in the organic matter that is nearly always present in water, whether it is surface water, ground water or treated industrial wastewater. The analyzer measures TOCs ranging from 0-5 mg/L to 20,000 mg/L, indicating the presence of glycol. The analyzer compartment is rated IP54, NEMA 3, and conforms to EN610004-2, EN610004-4, C46-022, EN 55022 and EN 61326. Electro-Chemical Devices Canada www.ecdi.com

wastewater 1c ad 4/5/05 2:53 PM Page 1

Corrosion Resistant

VALVES AND CONTROLS

AND CONTROLS

Innovative Solutions for Tough Water/Wastewater Applications!

• Manual, automatic and actuated (pneumatic & electric) valves; relief, check, diaphragm, ball, solenoid, and shut-off. Also pressure regulators, metering pumps, basket strainers, sight glasses, and gauge guards.

• Innovative Engineering –Dedicated Craftsmanship.

• 100% inspection and individual testing of each product, to ensure dependable performance and long-life.

• PVC, CPVC, Polypropylene, PTFE and PVDF. Valves from 1/8'' to 3'',Sight glasses to 8'' and Basket Strainers to 14''.

Hamilton Storage has announced storage tubes and new RackWare racks said to offer hassle-free operation and stability in automated storage workflows. The consumables are optimized for use with all Hamilton Storage automated sample storage systems as well as robotic liquid handling platforms from the company. They are also compatible with third-party automated storage and liquid handling systems. The 96-format tubes are available in three of the most widely used volumes: 0.3, 0.6 and 1.0 mL. In addition to a low cap height to maximize available space, the tubes are internally threaded for stable processing with automated decappers such as the company’s LabElite product line. Unique 2D bar codes on the tube bottom facilitate the most accurate identification. The tubes are packaged in ANSI/SLAS compliant 96-sample RackWare racks that include lids as an extra protective safeguard along with 1D and 2D side rack bar codes. Additionally, 2.0 mL tubes are available in 48-sample format with a choice of internal or external threads.

Hamilton Storage www.hamiltoncompany.com

FLARE SMOKE AUTO-DETECTION SOFTWARE RELEASED

CyboSoft has released CyboFlare, a patent-pending flare smoke auto-detection software for oil refineries and petrochemical plants. The program can automatically detect smoking events from live flare videos, send the Smoke Level data to DCS for alarming and control override to quickly stop the flare from smoking. The software also has historical data analysis and smoke tracking functions that can help the plant comply with environmental

protection rules. The application has an online mode that can connect to one or multiple video cameras over a communication network so that live flare videos can be viewed and analyzed by a smoke auto-detection engine in real-time. The company offers the program with perpetual or annual software license options.

CyboSoft www.cybosoft.com

The Fluke ii900 Sonic Industrial Imager available for sale or rent from ITM Instruments has been introduced. The unit features a 7 in. LCD touchscreen that overlays a colour SoundMap on a visual image for quick leak location identification. Inspect for air and vacuum leaks even during peak production periods in noisy environments by isolating the sound frequency to efficiently identify leaks. The imager also features an array of microphones making it easy to scan large areas and capture leaks from a distance, the company says. The product is suitable for use in hospitals, power plants, transportation, material handling, oil and gas, mining, process manufacturing and discrete manufacturing. ITM Instruments

www.itm.com

PRODUCTION LINE COMPACT PRINT AND APPLY SYSTEMS

Matthews Marking Systems has added a new line of print and apply labeling systems to its Mperia A-Series. The latest product line consists of 3 printer body styles: the D43, T43 and T63. The D43 is the smallest system, said to be easy to integrate into various production lines due to its compact footprint. It uses Direct Thermal (DT) Technology for printing which requires just one media type, simplifying use of the machine. The T43 uses both DT and Thermal Transfer (TTO) for printing, providing the option for short- or long-term readability for longer storage. The T63 is the largest print and apply system in the line and is commonly used for pallet labeling. The T63 can print and apply labels up to 7x 9.5 in., providing greater visibility on larger items like shrink-wrapped boxes on a pallet. Common tasks like changing out labels and ribbons takes less than one minute thanks to a “one roller” design. Should the thermal print head need to be replaced, the A-Series design allows for the head exchange to occur in less than 2 minutes with no technician or tools required.

displays energy rate and totalized energy with pulse output and communication options. Units are said to be simple to install — connect power and enter the pipe inside diameter, adjust the sensors and clamp-on the pipe – no specialist skills or tools required. Features include: Modbus and Mbus communication options; ±1% to 3% of flow reading accuracy for >0.3 m/s (1 ft/s); and, flow velocity range of 0.1 to 10 m/s.

To

Matthews Marking Systems www.matthewsmarking.com

Hoskin Scientific www.hoskin.ca

WATER-RESISTANT POWER OVER ETHERNET BRIDGE FOR WET AND HARSH ENVIRONMENTS

Swift Sensors has released a water-resistant Power over Ethernet (PoE) bridge for use in applications such as industrial manufacturing, pharmaceutical manufacturing, food and beverage manufacturing, wastewater treatment facilities, refineries and restaurants.