AT THE SHOWTIME SUGAR SHACK

Maple syrup producer hits the packaging sweetspot with high-speed flowwrapping machinery

Story on page 12

MANUAL Pages 19-98

CONNECTING THE DOTS

Packaging for the 21st Century

Maple syrup producer hits the packaging sweetspot with high-speed flowwrapping machinery

Story on page 12

MANUAL Pages 19-98

CONNECTING THE DOTS

Packaging for the 21st Century

The PAXIOM name might not sound familiar, but our brands are world-famous: Eagle Packaging MachineryTM, WeighPack SystemsTM, SleekWrapperTM, and CombiScaleTM

Here’s something else to remember: Our Xperience Centers™. Four strategically-located demonstration centers, housing a variety of machinery for the sole purpose of allowing you to see, touch and operate our equipment...even with your own product.

In fact, hundreds of buyers have already been through our doors, making PAXIOM’s re-invention of the sales process the talk of the industry.

new Videojet 1860 Continuous Inkjet Printer

1. True predictability

Industry-first ink build-up sensor provides true predictability and warnings of possibly degrading print quality, even before a fault occurs.

True remote services*

Multiple access options (Ethernet™, WiFi) and secure VPN communication meet highest standards in the industry as part of VideojetConnect™ Remote Service, and help to improve machine uptime and customer experience.

* Subject to availability in your country

True IP rating

Optional IP66 rating for entire cabinet and hygienic design following industry guidelines; easier integration with slanted printhead design.

True scalability

Workflow modules help to customize the printer to perform the exact need required. It is easy to adapt the printer with new capabilities and functionalities, and to meet growing demands.

Pedigree Ovens (www.thepoundbakery.com, Harvard, IL) is a contract manufacturer in the niche market of high-end dog treats. Baking and packaging products for 60 brands, Pedigree produces an array of treats packaged in cartons of varying sizes and configurations. To do so, it’s critical that its packaging systems be flexible enough to handle high throughput, short turnaround times and fast changeovers between jobs.

The company recently decided to invest in cartoning technology to improve productivity and increase capacity. It chose the compact Veronica Vertical Cartoner from Ultra Packaging, Inc. (www.ultrapackaging.com, Bensenville, IL), which operates with a complete Bosch Rexroth control and drives solution.

The market for specialty pet treats is competitive, with

retail shelf space at a premium. Manufacturers need to find ways to stand out from the competition, and eyecatching packaging is an important and successful technique.

While some of Pedigree’s clients use conventional folded top cartons, others request a gable-top closure for improved shelf appeal. In addition, Pedigree supports multiple package dimensions, ranging from 4 to 10.5 inches high, 3 to 9 inches wide and .75 to 3.5 inches deep. With approximately 60 clients—each with multiple treat types or flavors and up to five packaging variations—Pedigree’s success depends on its ability to meet all client requests. Until recently, the company used a manual cartoning process to fulfil customers’ needs. Once treats were bagged, a conveyor brought the filled bags to manual stations where they were inserted into erected boxes. The boxes were then manually sealed with glue guns. “When we were smaller, we were able to do everything manually,” said Kurt Stricker, owner of Pedigree Ovens. “But when we started getting larger requests, only to turn them down because we didn’t have the cartoning, we knew it was time to expand our limited capacity.”

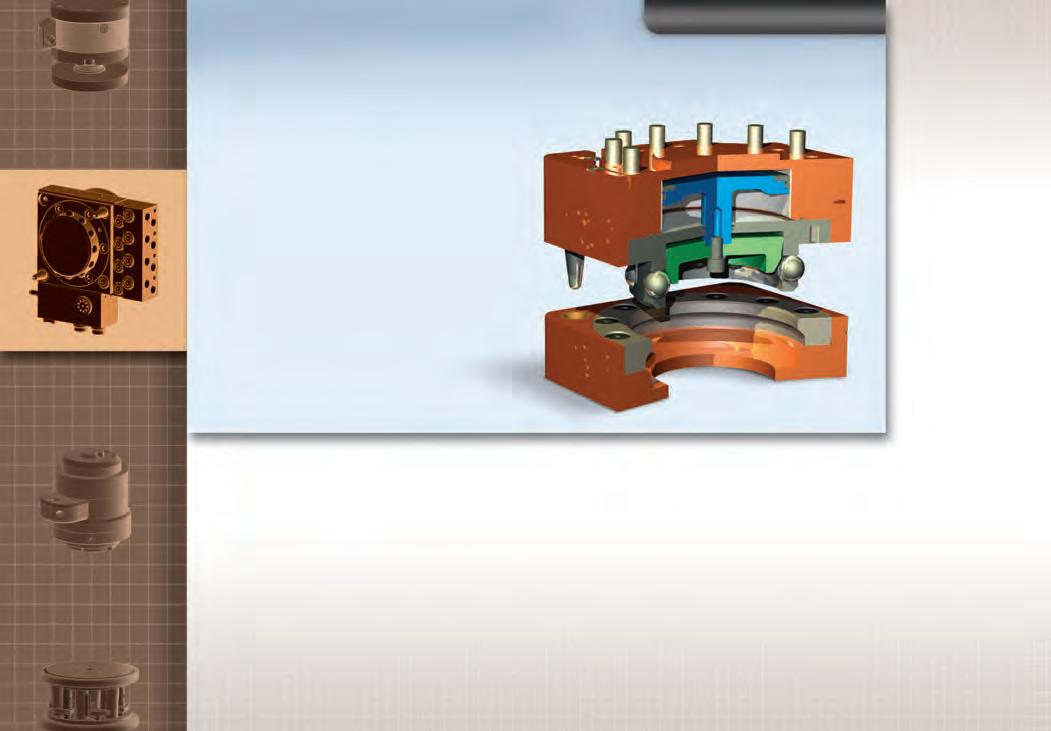

Eager to boost throughput and enable expansion without adding significantly to costs, Pedigree researched several machines and selected Ultra Packaging’s Veronica cartoner. The Veronica is a user-friendly seven-axis cartoner that erects cartons from flat paperboard blanks and efficiently transports, closes and glues the cartons.

It is engineered to be a cost-effective solution for growing companies that need fast changeovers and flexibility; key to the Veronica’s versatility is its advanced control and drives platform from Bosch Rexroth.

“Rexroth components help make the Veronica as powerful and as versatile as it is,” said Bob Stockus, owner of Ultra Packaging. “With Rexroth’s components, the Veronica is userfriendly and can be adapted for each user’s needs, while staying within a budget.”

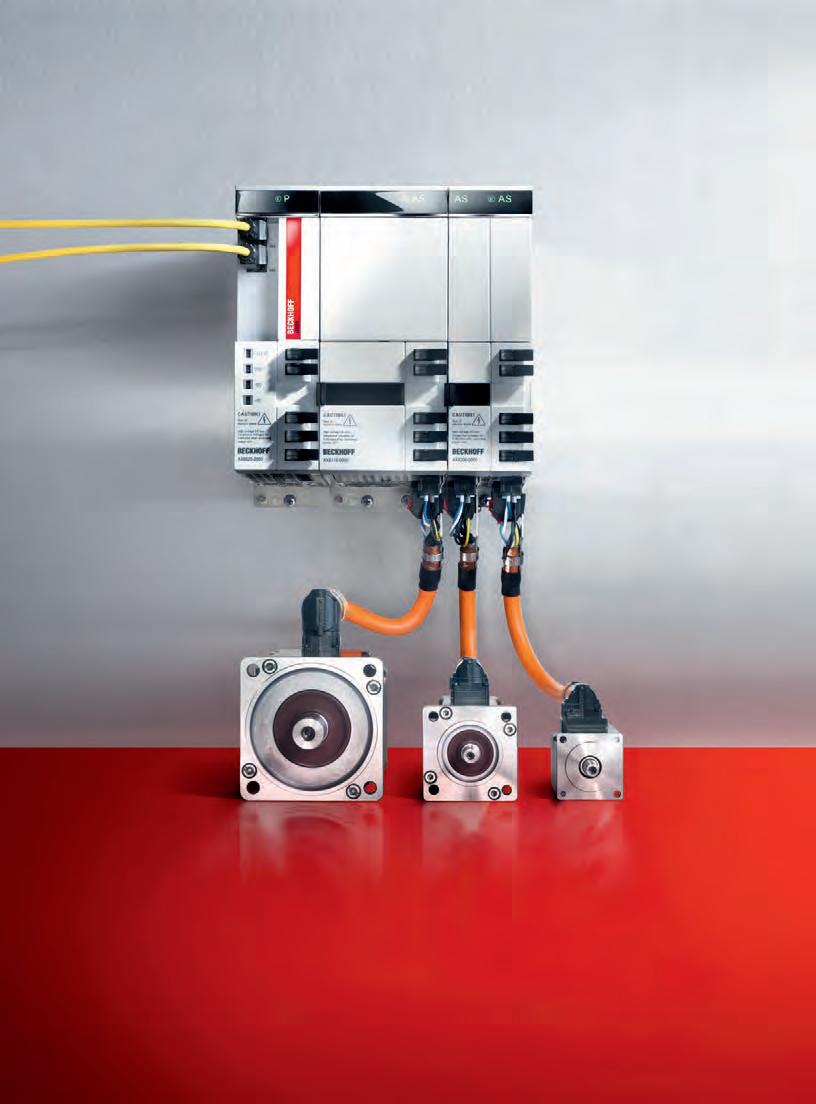

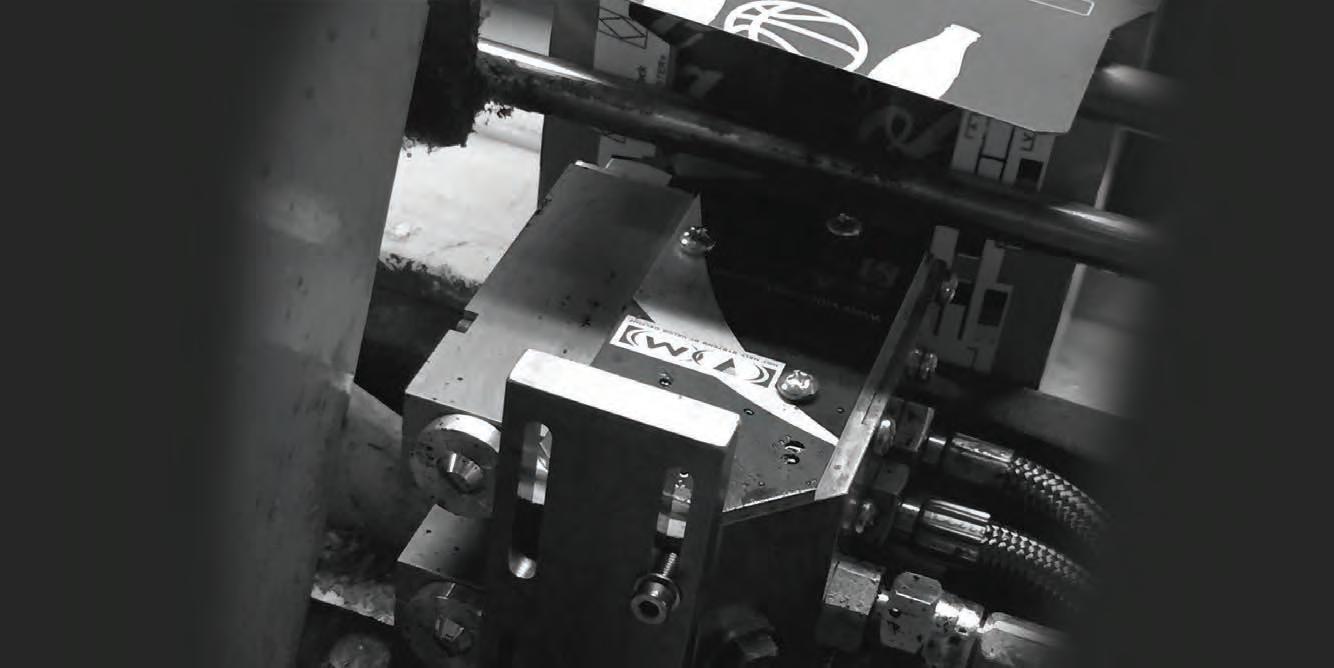

The Veronica uses the IndraMotion XLC motion logic controller, Bosch Rexroth’s premiere platform for motion, robotic, logic and hydraulic control applications, that is programmed according to the PLCopen standard IEC 61131-3. For the Veronica, it provides synchronized motion control on each axis as well as logic programming and features a wide range of open interfaces, including Sercos III, PROFINET and EtherNet/IP.

Rexroth’s IndraDrive Mi cabinet-free drive/motor system drives each axis. With drive electronics integrated into the motor housing, servo units can be housed on the

RIGHT:Multiple Rexroth IndraDrive Mi cabinet-free drive/motor units drive all the major axes on the machine, including this portion of the machine which closes the carton top, shown here closing a conventional carton.

machine itself; this helps make the Veronica a very compact and modular machine that can be easily fit into tight factory workspaces.

The integrated motors and drives offer additional benefits like reduced space and cooling requirements in the control cabinet. This system also reduces the machine’s component cost; a single cable for power and communication runs from the power supply, and each IndraDrive Mi is daisy-chained to the next for significantly reduced cabling.

“Rexroth’s control and drives platform gave us the flexibility we needed,” Stricker said. “It was critical for our dual fold capabilities.”

The Pedigree application is the first that uses the Veronica for gable-fold closures, but the cartoner proved extremely well-suited for the job. Once the pet treats are bagged, they are transported to the cartoner via a conveyor controlled with the same IndraMotion XLC used for the Veronica. The conveyor lifts the products about six feet to reach the Veronica.

The Veronica’s first step is to erect each carton and seal the bottom. The product is inserted at a manual production station, and the Veronica then seals the filled box. For conventional closures, this is the same process as sealing the bottom: The Veronica kicks a flap into place, applies glue and kicks the second flap into place.

Gable-top closures require an additional step. After

the carton is erected, the bottom sealed and the product inserted, the Veronica must create gussets on the sides. The machine has a mechanism that moves up and down on either side of the box to push the sides in. Then the machine applies the glue and folds the flap over the top to create a gable-top closure resembling a milk carton.

The changeovers between conventional and gable folds can be done quickly, thanks to a special sub-assembly Ultra Packaging added to the Veronica for Pedigree. All the components necessary for each type of fold are grouped together on one plate so the machine operator can change them all at once.

“Rexroth’s control and drives platform provided essential programming capabilities,” Stockus said.“Because the Rexroth IndraDrive Mi drive platform is extremely accurate regarding the timing of the drives’ position, we were able to accomplish this and keep the changeover times to a minimum.”

For Pedigree, this was an important benefit of the Veronica. While most manufacturers would have two separate systems in place to handle two different folds, Pedigree can do everything with just one machine.With greater capacity for changeovers, the company now does up to three a day and 10 to 12 per week, enabling faster turnaround times and greater flexibility.

Overall, the automated cartoning process is five to seven times faster, creating significant improvements in throughput. Five to six people working together with the Veronica can package 40 to 60 bags per minute.

And for easier jobs that simply require repackaging into shelf-ready boxes, the team can reach 60 to 70 bags per minute.

“We were able to reduce labor and increase speed immediately, and the return on investment was really quick,” Stricker said. “A job that used to take us three days can now be done in an afternoon. It’s no comparison from before.”

The Veronica met all of Pedigree’s objectives and exceeded target production rates.The Rexroth XLC controller and IndraDrive Mi drive system provided the modular technology and intelligent automation platform that enabled Ultra Packaging to efficiently modify the Veronica to integrate conventional and gable-top cartons on a single machine.

“New opportunities are key as we grow the company,” Stricker said. “We can definitely look at bigger jobs and larger customers, knowing that we can fill the orders.” He added that Pedigree has recently added a new customer worth several million dollars a year in additional contract packaging revenue—new business that’s a direct result of adding the Veronica to

“We pride ourselves in our flexibility, in manufacturing and in packaging,” Stricker said. “That’s where the Veronica’s really helped us. It’d be hard to imagine getting all this work done without the Veronica.” Pedigree’s production operations.

Custom

Automated

Assembly Equipment

JANUARY/FEBRUARY 2018

VOLUME 71, NO. 1

SENIOR PUBLISHER

Stephen Dean • (416) 510-5198

SDean@canadianpackaging.com

EDITOR

George Guidoni • (416) 510-5227

GGuidoni@canadianpackaging.com

FEATURES EDITOR

Andrew Joseph • (416) 510-5228 AJoseph@canadianpackaging.com

MEDIA DESIGNER

Brooke Shaw • (519) 428-3471 bshaw@annexweb.com

ACCOUNT COORDINATOR

Barb Comer • (888) 599-2228 ext 235 bcomer@annexweb.com

CIRCULATION MANAGER

Anita Madden • (416) 442-5600 x3596 AMadden@@annexbusinessmedia.com

VICE PRESIDENT

Tim Dimopoulos • tdimopoulos@annexbusinessmedia.com

COO

Ted Markle • tmarkle@annexbusinessmedia.com

PRESIDENT & CEO Mike Fredericks

ANNEX BUSINESS MEDIA

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA

ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

CIRCULATION

e-mail: rthava@annexbusinessmedia.com

Tel: 416-442-5600 ext. 3555

Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE): Canada $77.00 per year, USA $135.00 US per year, Outside Canada

$153.50 US per year, Single Copy Canada $10.00, Outside Canada $27.10.

From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

ANNEX PRIVACY OFFICER Privacy@annexbusinessmedia.com

After the United States abruptly pulled itself out of the Paris Agreement on Climate Change last year, in spite the nearly unanimous international scorn and condemnation, it may have been very tempting for many global corporations with a massive environmental footprint to ease up on their own environmental sustainability initiatives and promises to clean up their act. Happily, some of the world’s leading multinationals had other ideas.

Earlier this year, fast-food giant McDonald’s announced plans to completely eliminate foam packaging from its global operations by the end of 2018, which will provide a massive boost for fledgling efforts to clean up the world’s oceans being overwhelmed with all manner of packaging waste.

While waste from plastic flexible packaging and plastic bottles has been getting the lion’s share of blame for the global marine pollution crisis, expanded polystyrene foam is an especially nasty and insidious ingredient in the oceanic garbage depository.

Rarely recycled for any worthwhile end product, at least to date, foam beverage cups and takeout containers break down in indigestible pellets that marine animals often mistake for food, tragically to their own premature demise. Moreover, its hazardous constituent chemical tend to accumulated water-borne toxins in a very short time-frame, which has prompted the International Agency for Research on Cancer to identify styrene as a possible human carcinogen. No wonder the stuff has already been banned in nine countries and more than 100 U.S. cities and counties.

As a welcome complement, McDonald’s has also pledged to make all of its packing 100-percent fiber-based from certified or recycled sources by 2020, compared to the estimated 64-percent level obtained to date.

While there are exceptions for some pre-filled food packaging like unidose packets for sauce and salad dressings, this 100-percent fiber rule will apply to all the cold and hot beverage cups, carry-out bags, folding cartons, clamshells, wraps, foodservice bags, napkins, salad bowls, Happy Meal containers and drink carriers.

According to the company’s website, “McDonald’s priority is to optimize the amount of packaging we use, and to use only sustainably sourced materials that are recyclable or compostable.

“In collaboration with our suppliers, we pursue these priorities in three critical areas:

• Design: Optimize weight and simplify the number of materials used in our packaging

• Sourcing: Increase use of recycled or certified raw materials;

• Recovery: Work to use recoverable packaging with viable end-of-life options.”

While packaging sustainability has been a hot topic for some time now, the foodsevice industry has for the most part glided under that radar of public scrutiny, with some notable exceptions.

With McDonald’s now seemingly fully on-board and committed to the cause, the time is right for all the other players in this vast market, big and small, to do the right thing—for themselves, their customers, and our planet.

George Guidoni, Editor

12 SWEET DREAMS By Andrew Joseph Maple syrup producer steps outside the traditional comfort zone through thoughtful product diversification and packaging automation.

Cover photography by Maxime Bertrand

By George Guidoni

whimsical package design gives new brand of premium household paper tissues a buoyant launching pad for connecting with Canadian families.

Upcoming industry functions. 100

By Jeff May Joe Public speaks out on packaging hits and misses.

Page-by-page

Messing around with a good thing is often fraught with risk, but after 35 years, the stalwart Diet Coke brand cola beverage of The Coca-Cola Company is embracing change on a truly epic scale in a quest to win over the hearts and minds of millennial consumers through trendier packaging and the most extensive addition of hip new flavor varieties in an effort to appeal to a broader audience.

According to Coca-Cola, the switch to sleeker and taller cans is intended to convey the message of the evolution of a brand’s personality to a more confident image projected by a taller, more assertive profile of the shiny scans.

Launched across Canada and the U.S. earlier this month, the iconic zero-calorie cola soda is now packaged in taller, slimmer 310- ml aluminum cans, manufactured by Ball Corporation, featuring updated graphics for the core Diet Coke product and graphically-enhanced, color-coded, direct-printed graphic designs for four exciting bold new flavors that include Diet Coke Feisty Cherry, Twisted Mango, Zesty Blood Orange and Ginger Lime

The splashy Diet Coke brand relaunch follows two years of intensive product development and market research that involved interviews and taste tests with over 10,000 millennial consumers, according to CocaCola, along with detailed package redesign work by Coke’s in-house creative team, the brand team and the London, U.K., office of global design specialists studio Kenyon Weston

“For a design team, the opportunity to rethink such an iconic brand with the scale and reach of Diet Coke— to build on its heritage and create a visual language that will help write its next chapter—is a rare design brief,” says James Sommerville, vice-president for Coca-Cola Global Design. “This visual evolution elevates the brand to a more contemporary space, while still using at its foundation the recognizable core brand visual assets.”

“Anchored by its iconic silver color, the new Diet Coke features a sharper logo, bold colors to represent each new flavor and a sleek vertical ‘high line’ that extends across all packaging,” notes Carolyn Harty, group director for sparkling brands for Coca-Cola in Canada.

“This visual evolution takes the brand to more contemporary space, while still being anchored in its core recognizable elements.”

Now retailing across Canada as singles and in eightcan variety packs, the four new fruit-infused flavors were selected from over 30 different recipes that were extensively tested and critiqued by millennials living in large metropolitan areas around the U.S.

“We cast a very broad flavor net after looking at what millennials are eating and drinking, and what food and beverage trends and insights told us,” says Diet Coke senior brand manager Melissa Schwartz.

“We tried everything from spicy notes to exotic superfruits from around the world,” she relates, before finally setting on the four “fruit-forward, but with an unexpected twist” flavors.

“We took cherry and lime–two very popular Diet Coke flavors–and gave them a bit of a modern facelift,” Schwartz states. “And we added two completely new tropical tastes not usually associated with the Coca-Cola trademark.

“This new line-up has something for everyone,” she concludes, “and we hope Diet Coke fans love them just as much as we do.”

While most nutritionists will agree that truly healthy potato chips are a great idea that is still waiting to be invented, an innovative snack-food producer in Calgary just may have happily stumbled onto the proverbial next best thing.

Produced by Left Field Foods, the newly-launched SPOKES air-puffed potato snacks are lightly oil-misted and seasoned puffs of light and crunchy potato goodness developed as an entry into the fast-growing BYI (Better-For-You) snack category driven by consumers’ preference for simple ingredients and no preservatives.

“Created by a Canadian mom who wanted a Better-For-You (BFY) snack for her family, SPOKES was born as a result of many years’ work refining product development and consumer research,” explains Left Field Foods chief executive officer Dave Pullar.

“We’re naturally curious, and are always experimenting with new things,” says Pullar, citing the broad variety of tantalizing flavor variations that include Sea Salt, Mango Habanero, Sea Salt & Vinegar, Barbecue, Dill Pickle, Salt & Pepper, Fiesta Salsa, Sea Salted Caramel and Simply Bare

Packaged in clean and elegant 80-gram chip bags adorned with simple nature-inspired hand-drawn graphics and folksy type fonts, “The new brand is quickly gaining traction with extremely positive consumer response so far, and for good reason,” says Pullar, citing the product’s exceptionally low caloric intake of only 40 calories per cup.

Produced at a certified peanut-free facility, the gluten-free, nonGMO-certified SPOKES puffs are free of the 11 major allergens such as dairy, wheat, soy and egg.

Retailing across Canada in most natural, conventional and independent grocery and drugstore retailers—including Whole Foods, Kardish, Goodness Me!, Planet Organic, Blush Lane, Safeway, Sobeys (western Canada), Thrifty Food s, Metro (Quebec) and London Drugs —the SPOKES puffs contain no artificial preservatives or colors, transfats or cholesterol.

“Selective about everything we do, we listened carefully to our customers,” Pullar relates. “This is the driving force behind what we do every day—from sourcing simple, quality ingredients to our product innovation and production, to ensuring consumer satisfaction and, above all, creating a naturally delicious taste experience for families to enjoy, without all the bad stuff.”

SKU proliferation, limited space, rigorous uptime requirements – why not meet that complexity with flexibility? Honeywell Intelligrated robotic palletizing solutions can handle a variety of SKUs, packaging types and stacking patterns, all in the most restrictive layout requirements. That’s automation that delivers.

For more information, please visit www.intelligrated.com or call 1-866-936-7300.

nWinnipeg-based flexible packaging products manufacturer Winpak Ltd. has become the first plastic products company in Manitoba to receive the SAFE Work Certified

recognition as part of the Made Safe industry imitative administered by the Manitoba branch of the Canadian Manufacturers & Exporters (CME) organization. “The difference between a good and a great company is always the people element,” says Winpak’s division president James Holland. “Our people are and always have been our most valuable resource in our pursuit of excellence and a safe work environment [and] we are proud of this accomplishment.” Adds Made Safe executive director Neal Curry: “Not only has Winpak gone above and beyond fulfilling the requirements of the certification program, their safety culture and commitment to celebrating achievements together can serve as an example to the industry.

n St. Louis, Mo.-headquartered packaging equipment and systems group Barry-Wehmiller has completed the merger of its Hayssen Flexible Systems and Thiele Technologies subsidiaries into a single corporate entity now operating under the BW Flexible Systems name, while also merging company’s BW Container Systems division with the end-of-line packaging assets of Thiele Technologies to form the newly BW Integrated Systems business unit. “Over the last 30 years, Barry-Wehmiller has acquired more than 50 companies in the packaging industry, bringing together a large base of talent and technology,” says BarryWehmiller’s chief executive officer Bob Chapman. “This new alignment will better position our packaging companies for organic growth, provide more opportunities for our team members, and take better care of our customers.”

nMembers of Schneider Electric Canada’s fundraising team (above) celebrate the presentation of a $101,840 cheque donated to support local children’s causes after taking part in the 17th annual Tremblant 24h corporate fundraising event last December in MontTremblant, Que. Since first participating in Tremblant 24h in 2010, Schneider Electric Canada has raised more than $350,000 for the long-running charity fundraiser in support of important Quebec-based charity and community organizations such as the Foundation Charles-Bureau, the Ottawa Senators Foundation, and Foundation Tremblant

nPrivate capital investment group Platinum Equity has reached a definitive deal to acquire Bolton, Ont.based Husky IMS International Ltd., a leading manufacturer of injection molding equipment used to produce plastic bottles and other containers for the global food and beverage industries. “Husky is an extraordinary company with a well-deserved reputation for developing the industry’s most innovative technology,” says Platinum Equity partner Louis Samson. “As one of Canada’s most successful enterprises and a truly world-class industrial company, we are excited to partner with

such an exceptional leadership team as we aim to help them continue raising the bar.” According to Platinum Equity, the deal is expected to conclude in the second quarter of 2018 pending all the regulatory approvals.

nWeber Packaging Solutions, Arlington Heights, Ill.-based manufacturer of custom labels for industrial and commercial markets, has achieved the ISO 9001: 2015L standard certification for the company’s rigorous quality management system (QMS) implementation covering new ISO criteria such as risk-based thinking to enhance the process approach, increased leadership requirements and improved applicability for services. “The certification provides evidence that Weber is committed to meet customer requirements, which can be accomplished with our quality management system,” says Weber’s quality assurance manager Derek Podejko, noting the certification’s emphasis on consistency of the manufacturing process ensure that Weber will reliably print labels with the same high quality standards every time.

nCincinnati, Ohio-headquartered flexible packaging manufacturer ProAmpac has completed the acquisition of Bonita Pioneer Packaging Products, manufacturer of paper-based packaging products such as custom and stock shopping bags, merchandise bags, foodservice packaging, and folding cartons based in Portland, Ore. “The acquisition of Bonita expands ProAmpac’s paper packaging manufacturing footprint in the western and southeastern U.S., creating more value and optimizing services for our customers,” says ProAmpac’s chief executive officer Greg Tucker.

nAtlanta, Ga.-headquartered corrugated packaging manufacturing group WestRock Company has completed the acquisition of Plymouth Packaging, Inc., Plymouth, Mich.-based corrugated producer specializing in “box on demand” systems and corrugated fanfold extensively used in e -commerce packaging applications. “The addition

of Plymouth Packaging and its ‘box on demand’ capabilities furthers our differentiated packaging and packaging machinery strategies, and we look forward to growing this business in our portfolio,” says WestRock’s president of corrugated packaging Jeff Chalovich.

nSt. Louis, Mo.-headquartered rigid plastic products group TricorBraun Inc., has completed the acquisition of Bayport, N.Y.-based healthcare packaging product supplier Package All Corp. “Package All has significant expertise in rigid packaging for the healthcare industry, and we are excited about the opportunities this acquisition creates to provide customers of both companies with expanded services,” says TricorBraun’s

executive chairman Keith Strope. Founded 34 years ago, Package All is a leading stock distributor to the overthe-counter (OTC) generic pharmaceutical and nutraceutical industries, operating seven locations across he U.S. with a combined 350,000 square feet of warehouse space. “There is strong equity in the Package All name and business model,” says Strope, “and we will continue using both.”

nFood processing and packaging equipment group Duravant of Downers Grove, Ill., has completed the acquisition of Ohlson Packaging, a prominent manufacturer of a comprehensive range of weighing, counting, filling and bagging machinery based in Taunton, Ma.

Faster on the market with your machines. Very easily.

Schneider Electric‘s PacDrive 3 system delivers 50% more power and now syncs up to 130 servo axes including robot axes with new controllers. From now on, automate a large number of your machines with just one technology and thus get to the market faster. Made possible by the motion control solution PacDrive 3 from Schneider Electric.

Leading industrial automation supplier Bosch Rexroth Canada now offers free Automation Resource Kits to provide extensive useful technical information and advice on a broad variety of engineering and automation-related topics. Available at www.boschrexroth.ca/resourcekits, this valuable reference resource includes handbook excerpts, case studies, technical papers, videos and online tools to providing engineers with the latest information on topics such as:

• Lean Production and Automation Insights, featuring a broad range of instructional videos and expert technical white papers, including Lean Production and Automation: How to find the right mix ;

• Linear Motion & Mechatronics @ Work, which includes a digital copy of the 350-plus page engineering reference book, Linear Motion Technology Handbook, in addition to white papers, how-to guides, and other exclusive Rexroth engineering content;

• Advancing Factory Automation, which includes a hard copy of the Special Machine Tool application excerpt from 10 Steps to Performance Level: Handbook for the Implementation of Functional Safety According to ISO 13849 ;

• Hydraulics Performance;

• Mobile Hydraulics Solutions

Available free of charge and delivered on a 2GB flash drive, the disks contain a wealth of information based on Rexroth’s extensive experience with lean manufacturing challenges to help customers discover new and creative ways to use lean production and automation technology, according to the company. Bosch Rexroth Canada

The new model LX2000 color label printer from Primera Technology is designed for reliable and robust performance for endusers ranging from fledgling startups to established cosmetic companies requiring seamless in-house labeling. Employing full-color thermal inkjet technology to produce the highest-quality labels at the most economical price-point, the LX2000 desktop system uses professional-grade pigment ink to produce both water- and UV-resistant labels in dimensions up to 8.25-inches-wide to six-inches-tall at robust throughput speeds of six inches per second, using an automatic “pizza-wheel” style cutter to ensure exceptionally user-friendly operation. Primera Technology

The new six-axis HC10 collaborative robot from Yaskawa Motoman is a highly configurable robot offering 10-kilogram payload and 1,200-mm reach to perform a broad range of material hand -

ling, machine tending, packaging or light assembly tasks in close proximity to human operators. In addition to traditional robot programming through the teach pendant, the user can also hand-guide the HC10 robot when teaching new program paths, according to the company, allowing it to be quickly deployed or redeployed on demand to reduce system downtime and increase ROI (return-on-investment) payback. Designed to eliminate operator pinch points, the new robot features dual torque sensors in all joints for constant monitoring of force to react to operator contact instantly, while through-arm utilities hide cabling and provide enhanced safety by reducing the risks of snagging or interference with other equipment.

Yaskawa Motoman

Developed by FlexPak Leak Detector Inc., the new FlexPak Package Leak Detector and Seal Tester unit features an ambidextrous lid that has eliminated the need for lid stay normally used in leak detection applications by replacing it with a stainless-steel gas spring that allows operators to close the lid with just one hand-right or left. According to the company, the new system provides a reliable and user-friendly quality control assurance for numerous manufacturers of packaging materials and end-user packagers of dairy, meat, seafood, confectionery, snacks, pet food, cereals, baked goods, coffee, medical, pharma and any nonfood packaging items with critical requirements for optimal package seal, seam or closure integrity.

FlexPak Leak Detector Inc.

Designed for high-speed processing of sterilized vials with RayDyLyo safety caps, the new Dara SX-310-RDL aseptic filling and closing machine— manufactured by the NJM Packaging division of ProMach —eliminates the crimping required with traditional aluminum closures to simplify the packaging operation and speed throughput, while offering fast and easy changeovers and new container size set-ups for future needs. Featuring

fully servo-driven automation, the linear, intermittent-motion Dara SX-310-RDL is ideal for 503B pharmacies and biotech manufacturers filling solutions, suspensions, diagnostics, vaccines or cellular tissue in glass, plastic or metal vials. The dual-station SX-310-RDL/D handles vials up to 75-mm-tall and 36-mm-diameter at

speeds up to 120-cpm (containers per minute), while the single-station version can handle vials up to 210-mm-tall and 65-mm in diameter at speeds up to 60-cpm. Designed to seal vials with ARaymondlife’s patented RayDyLyo caps—available in 13mm and 20-mm sizes and two tear-off options— the new SX-310-RDL

seals the vials using simple vertical pressure on the caps, eliminating the need for a crimping station and ensuring less particulate generation compared to traditional filling, stoppering and capping systems. Designed as an alternative to aluminum caps, these pre-assembled RayDyLyo plastic closures feature a rubber stopper within the cap, minimizing the ‘pop-off’ effect and preventing stopper gap by reliably adhering to the freeze dryer plates.

NJM Packaging (Div. of ProMach)

Quebec business thriving in the world of handmade maple syrup candy production with new high-tech packing system

BY ANDREW JOSEPH, FEATURES EDITOR

Synonymous with Canada, maple syrup has been collected and used since pre-European days by the indigenous peoples of North America.

After Europeans in Canada learned of the practice and refined its methods, Canada has become the world’s largest supplier of maple syrup, exporting some $487 million worth in 2016.

The concept of maple syrup was first “discovered” by Europeans in 1534 when Jacques Cartier on his first voyage to Canada heard about a tasty, delicate sugar that flowed from the trees when tapped with an axe by the indigenous peoples.

Maple syrup is derived from sugar maple and red maple trees that typically take the starch stored within it during the growing season and convert it to sugar.

The sugar combines with water taken in by the tree’s roots, and in the Spring—between late February through early May—when temperatures start to go up, the sweet sap within the trunk and roots of the tree begins to expand. The freezing at night and thawing during the day causes the sap to run, which is then harvested.

While harvesting was done as the aboriginals had done it through the mid-19th century with axe tapping, advancements such as wood and steel spouts, and buckets were introduced.

Nowadays, tubing and reverse osmosis play key roles, as the tubes connect to collector pipes that carry the sap by gravity or pumping to a sugar shack where it is collected in large stainless steel tubs, and sent to an osmosis system before boiling turns it into maple syrup.

The province of Quebec is by far the largest producer of maple syrup in Canada, with some 13,700 companies that are able to process about 110 million pounds of the gooey stuff on average.

While it considers itself to be a small company, Les Productions Agricoles Beaudry Ltee. of St-Patrice-de-Beaurivage, Quebec, is a family-owned business that makes its living creating the Beaudry brand of maple products, selling maple syrup, but mostly producing a host of other sweet delights from the main ingredient.

Founded in 1984, but currently owned by Roger and Denise Beaudry, the reins of the business will be passed down to son Christian and wife Edith Mercier later this year, but will still continue its fine tradition of producing and packaging maple syrup, maple butter, maple taffy, granulated maple sugar, maple fudge, maple cone, maple cotton candy and more, including moving into maple butter chocolate and maple popcorn.

“As you might suspect, everything we produce revolves around maple syrup products,” company director Christian Beaudry told Canadian Packaging magazine during a recent interview.

“The company began processing just maple syrup around 1984,” begins Beaudry noting that at that time bulk maple syrup did not have much value.

“In order to get a better price for the syrup, the current owners decided to transform the company to one that manufactured different products that could be sold directly to customers in various public markets in Quebec City.

“Over the years,” continues Beaudry, “the company has evolved to where we now have seven employees in a 9,000-square-foot processing plant where we produce a wide range of maple-based products for numerous tourist shops as well as for 200plus convenience stores throughout the province of Quebec.”

Les Productions Agricoles Beaudry purchases maple syrup from the Fédération des producteurs acéricoles du Québec, an organization that represents Québec maple syrup producers who produce 72 percent of the world’s supply.

“Every year, we have to obtain the right to be an authorized buyer of maple syrup from the Federation,” relates Beaudry, adding that for quality control purposes each purchased barrel is inspected by an independent quality control company.

He says that their Beaudry brand (Produits d’érable Beaudry) maple syrup products “are of a high quality, but that the company’s main strength over its competitors is our ability to produce a wide range of maple products that they can sell to their customers.

“It enables us to become more of a one-stop-shop for our customers, who no longer need to deal with multiple suppliers,” Beaudry reveals.

At Les Productions Agricoles Beaudry, after the initial quality control is completed,

the maple syrup is heated or boiled at different temperatures to be either bottled— heated and filtered—or processed—boiled and filtered into different products.

After the batch of boiled syrup is cooled, the gooey remnants are brewed to obtain different consistencies, which gives them maple butter, maple taffy, soft maple sugar and more.

“For maple fudge, maple cotton candy and other products,” explains Beaudry,“we have recipes that we make with granulated maple sugar.”

He says that the company’s production line isn’t really automated because its high-quality products are mostly hand-made.

For packaging purposes, however, Les Productions Agricoles Beaudry sought out an automated flowwrapper machine from VC999 Canada Ltd. / Xtravac to increase the packaging speeds of its fudge and maple sugar cone products, as well as looking ahead to eventually use it on other products.

VC999 Canada is a part of VC999 Americas that is headquartered in Kansas, MO., a global-leader in the design and manufacture of vacuum chamber machines, horizontal thermoformers (rollstock), tray sealers and skin packaging, as well as packaging materials and supplies.

As well, via its sister brands XtraVac packaging machines and XtraPlast packaging materials, it offers vertical and horizontal flowwrapping machine systems, packaging robotics, vision inspection systems, conveyor and converger systems, weighing, labeling and product scanning.

VC999 maintains a manufacturing facility in Kansas City and sales and service offices throughout the Americas, including Canada, Mexico and Columbia.

The Kansas City facility designs and manufactures the P- and i-Series thermoformer machines and manages the XtraVac and XtraPlast brands.

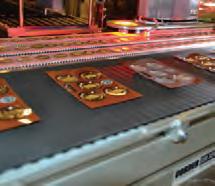

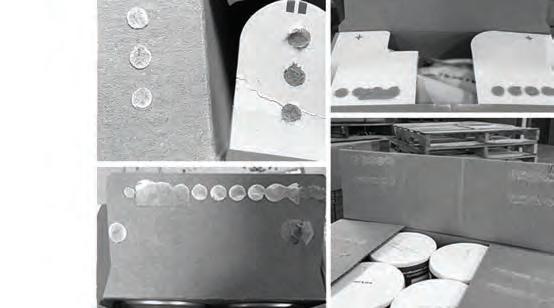

Beaudry says his company purchased and installed an XtraVac B Series flowwrapper in January of 2017, and immediately saw a huge increase in packaging line speeds.

“We typically run the XtraVac flowwrapper at a speed of 40 units per minute, but it can wrap as fast as 250 units a minute,” says Beaudry. “One person can pack 35 to 50 products per minute manually supplying the flowwrapper.

“It is very easy to use—even the loading of the plastic film wrap itself only takes between three to five minutes.”

Features of the XtraVac B Series flowwrapper include:

• A user-friendly interface control;

• A dialogue screen providing operation convenience;

• Memory function that makes it simple to switch from job to job;

• Overload sensing diagnostic function for each servo motor that examines for parts wear-and-tear;

• Auto-splicer option;

• Self-diagnostic capabilities for easy troubleshooting;

• Robust, high productivity, low-noise servomotors.

Beaudry says that after making the decision to better automate the packing of products, and after looking at models from other manufacturers, they visited the PackEx Montreal trade show and talked with VC999 representatives there.

“They were still packing by hand, and wanted equipment that would speed up

the process while maintaining the high-quality look of the product to match its high-quality taste,” reveals VC999 director of sales at the St-Germain-DeGrantham, Quebec office Daniel Gardner.

Gardner notes that VC999 does have its hands in the candy business with other customers, but that wasn’t a factor in Les Productions Agricoles Beaudry choosing its machine.

“Our XtraVac B Series flowwrapper is a very quick and accurate machine and is very robust,” says Gardner. “But just knowing that we could service them in French and English and are only two hours away helped put their mind at ease. Plus, we do not contract out our services.We service all VC999 / Xtravac machines ourselves.”

Beaudry agrees, “While VC999’s proximity to us is such that downtime won’t be a factor, we also chose them because we talked to other customers of theirs who thought their service was fantastic.

“After the machine was purchased, they continued to talk to us and make sure the XtraVac B Series flowwrapper was working to our expectations,” Beaudry notes.

While one might think that simply adding a flowwrapper to the packaging line was a cut-and-dry solution, both Gardner and Beaudry reveal that there was one issue, and it was taken care of before the machine was installed on site.

The issue revolved around the fact that the maple syrup products were sticky, but Gardner says it was resolved quickly simply by choosing the right belt.

The clear plastic film used to pack the fudge and maple sugar cone products is supplied by VC999’s XtraPlast division.

While there is nothing overly special about the type of film used, Gardner says the Les Productions Agricoles Beaudry products required film with a high OTR (oxygen transmission rate) where the oxygen gas permeates through the film relative to specific temperature and humidity within the pack to ensure a long shelf-life.

Additional equipment used by Les Productions Agricoles Beaudry include a Markem-Imaje X40 coder system and a high-quality Primera color label printer featuring a 2,400-dpi (dots per inch) resolution and a high-speed print operation.

The X40 thermal transfer coder provides an advanced coding solution that provides long-term cost control, a green design, greater uptime and great performance.

Capable of print speeds up to 600 mm/second, the X40 uses an intelligent printhead with automatic set-up and dead-dot detection for optimum print quality of 300-dpi resolution.

“We are very happy with the packing success we have achieved with the VC999 XtraVac B Series flowwrapper,” sums up Beaudry.

“Not only has it made our job easier to pack and get the product out to the customer quicker, we have also increased our product’s shelf-life.

“And through it all, we couldn’t be happier with VC999,” he continues.

“We were optimistic when we purchased the system, yet the service we have received from VC999 is exactly what we had hoped we would receive. We are very satisfied with VC999.”

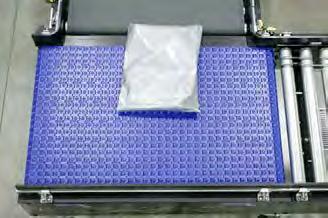

The modular roller top belt station is a completely new concept for transferring and diverting a wide variety of packages and packaging. Designed to meet the industry’s needs for diverting, transferring and sorting product, it can solve a range of increasingly challenging transfer and diverting problems complicating operations in distribution centers, particularly retail e-commerce distribution. Using a matrix of freely rotating balls imbedded into a continuous flat belt, the rolling top belt station diverts and transfers products of any kind by using precise, controlled and impact-free motion to divert and transfer products on motorized conveyor lines.

With no auxiliary diverting equipment, its smooth and precise packaging positioning control minimizes packaging impact, and its multipurpose, modular design allows it to be positioned wherever it’s needed within conveyors for any transfer or diverting application. The high degree of motion control comes from the simplicity of the concept: use rotating spheres to convey packaging in any direction, making use of all 360 degrees of potential motion.

The roller top belt embeds a uniform array of independent, 1-inch, on-center spheres on the surface of a continuous, low-profile, gap-free interlocking plastic belt. Packaging of all types, from standard cartons to small boxes, soft polybags and flat envelopes can be conveyed. The belt and spheres are powered by one or more activated running belts or a rotating disc underneath the station, using motorized drive rollers and controls. By using different configurations of motorized roller belts or discs underneath the roller top belt, and controlling the relative speeds of the different belts, the modular station can be configured to accelerate or decelerate objects, move any object to an angle vector at a given speed, or simply stop and rotate a product into a specific orientation, regardless of the size, shape or composition of the product. No other handling equipment is needed. The roller top belt uses a

minimum of moving parts and has minimal power demands — while providing the flexibility and simplicity of a modular, easily configured and maintained system.

The modular roller top belt addresses the limitations and risks of existing transfer technologies while expanding a distributor’s ability to handle, precisely control, and transfer packaging of all sizes and materials. Although designed for motorized driven roller conveyor (MDR) systems, integrators can also adapt the belts to support other conveyor systems. Roller top belt modules are currently optimized for medium-range conveyor systems to process up to 45 parts per minute, and support for faster systems is in development.

Several of the development team’s basic design considerations turned out to have ancillary system benefits beyond precise motion control.The modular belts are made of interlinked and rugged blue acetal, imbedded with spheres made from tough and wear-resistant Polyamide. The result is high belt strength combined with low friction — at a much lower weight than metal components. This low weight and friction contribute to a significantly lower power demand. Combined with their smaller, variable speed, run-on-demand motors, modular roller top belt systems can achieve energy savings between 50–60 percent compared to other conveyor transfer systems — in addition to the savings realized by eliminating the labor-intensive step of re-processing small or plastic packages conveyed in tubs.

Another benefit inherent in the belt design is worker safety. With no gaps or pinch points anywhere on the roller-free belt, workers have a much lower risk of injury.

Driven by a variable speed, run-on-demand, 24-volt DC motor, the module is not only energy efficient, but also allows for flexibility and simplicity in wiring and control, safe and quiet operation (>70 dBA), and mini-

mal, easy maintenance. Its modular design allows the belts to be swapped out for repairs or replaced quickly. Motor controls support standalone programming, can interface with a programmable logic controller (PLC) in a customer’s network, or be hardwired into a customer’s preferred control system.

Further cost savings are achieved by simply eliminating the high cost of maintaining fixed lift, pneumatic or Z-direction position feedback systems. It is cheaper, simpler and faster to maintain a spare parts inventory of modular plastic belts that can be replaced in minutes rather than an inventory of pneumatic lifter and compressor systems and spare parts that require hours of downtime for repairs.

Modular roller top belts are available as turnkey units for new lines, or as a retrofit to replace existing systems. An integrator can install a module simply by removing the existing pneumatic or pusher system and putting the module in its place.

With the logic of its modular design and the simplicity and efficiency of its use of motion control to transfer, divert or channel products, the roller top belt offers distributors significant cost advantages — and multiple directions to increase throughput.

Cascades pulls a rabbit out of a hat with an irresistibly cute and adorable package design graphics created for its new national brand of household tissues

BY GEORGE GUIDONI, EDIITOR

Standing out in a sea of white is no easy feat when you’re a white product like toilet paper.

But that does not mean one should stop trying, as Canada’s leading paper products group Cascades Inc. discovered with last year’s highly successful and high-impact launch of the Cascades Fluff & Tuff brand of super-soft and super-strong bathroom tissues.

Capping off more than a year of intense in-house product development and expert packaging design work carried out by the Montreal-based branding specialist Bo Branding & Design, the new toilet paper brand has not only been flying off the retail shelves across Canada, but also garnering serious international accolades for its bold innovation and stunning shelf impact.

In late November last year, the new Cascades brand picked up the Tissue – Innovation Award at the annual Pulp & Paper International Awards gala in Brussels, Belgium, gathering special praise for the product’s market presence and customer satisfaction.

“We launched a line of toilet paper and paper towels that is among the softest and strongest on the market, while maintaining all of the green properties our products are known for,” says Jean Jobin, president and chief operating officer of Cascades Tissue Group in Kingsey Falls, Que.

“Our objective was simple: to offer consumers the comfort and performance they’re looking for in a product, while also protecting the environment,” says Jobin, reiterating the company’s long-standing firm commitment to make all of its paper products from recycled paper fibers.

Only launched nationally last March, the new brand has enjoyed not only robust sales growth, according to Cascades, but also remarkable brand recognition and loyalty from Canadian consumers won over by the brand’s cheerful and whole-

some marketing pitch and message.

“We wanted our new and improved products to become the brand of choice for more and more families across the country,” says Jobin, “and we are achieving this goal.

“Convincing the industry of the innovative value of our products and winning over consumers in a matter of months was a considerable but a worthwhile challenge.”

It’s a challenge that also brought out the best in the Bo Branding creative team, which helped Cascades develop the new brand’s adorable Fluff & Tuff bunny mascots strongly featured on new packaging that is worlds away removed from the fairly generic and rudimentary package graphics previously used for the branded

Cascades tissue products.

“The new Cascades Fluff and Tuff packaging evokes softness and strength through the use of mnemonic bunny mascots that mesmerize and attract consumers to their glare,” says Mylène Boucher, director of marketing and innovation at Cascades ULC in Candiac, Que.

“The accompanying colored backgrounds provide the ideal environment for each bunny to stand out,” Boucher adds, “while providing consumers with an easy identifiable product segmentation system.

“Once on the shelves, these packages become real attention grabbers.”

As Boucher relates, “We wanted to develop a new connection with our consumers and win their hearts with the two bunnies: the cute and puffy Fluff and strong and confident Tuff.

“They both generate passion in different ways,” says Boucher, citing the design’s effective use of soothing, comforting blue, green and pink colors to differentiate between the different subbrands, such as Ultra (soft), Strong, Enviro and Absorbent.

“The organic curves in the graphics, combined with the vibrant colors, really help to convey the product benefits,” she notes, while providing consumers with an easy identifiable product segmentation system.

“The color combinations enable a use of subtle tones that emphasize the various product benefits that both Cascades Fluff and Tuff offer,” says Boucher, citing the inherent challenge of achieving impactful product differentiation in highly competitive product category dominated by legacy brand names and limited format flexibility.

“The key challenge in this category is to stand out against the competition,” she says, “which is why the bunny mascots were developed with large, friendly, softgreen eyes that mesmerize and attract consumers with their stare.”

Whereas the previous Cascades branded household tissues had brand equity more closely to that of a private-label product than a national brand, Boucher says the adorable bunny graphics were readily embraced by the targeted consumer audience across Canada—primarily women in the 35- to 54-year-old age group with young families.

“Since their launch, our rabbits have become so popular that we get thousands of requests week after week from consumers wanting to buy not only our products, but also a stuffed animal version of Fluff and Tuff,” she chuckles.

According to vice-president of marketing and innovation Thierry Trudel, the success of the Fluff & Tuff launch was underpinned “by our diligent development and marketing efforts.”

Says Trudel: “Our teams worked closely together for over two years reviewing each step in the manufacturing process in order to provide the superior quality that Cascades Fluff and Cascades Tuff products deliver.

“No detail was ignored to improve the products for the families, beginning with the manufacturing formula for the paper all the way through to its embossing and packaging,” he says.

“This [PPI] award definitely brings value to everything that we’ve accomplished,” Trudel declares, also noting the new brand picked up a 2017 Davey Award from the Academy of Interactive and Visual Arts (AIVA) for its in-store marketing

campaign. Also selected as a finalist in the annual innovation awards of the Innovation contest of L’Association des Détaillants en alimentation du Québec (ADAC) and the upcoming 2018 PAC Global Leadership Awards competition of PAC Packaging Consortium, the new Cascades Fluff & Tuff brand was also a big winner where it really counts the most—at the store-shelves.

“We are currently on track for 55-percent sales growth compared to a year ago, which is actually four times our initial objective,” beams Boucher.

“We also gained important new distribution among our existing retail customers,” she confides, “while obtaining completely new listings because our trade customers believed in our new image and its shelf impact.

“Our main goal was, of course, to sell more, but also to be positioned where we belong in consumers’ minds, among national brands.

“And after only three months in the market, the Cascades Fluff brand had reached 86-percent awareness among our target consumers,” says Boucher, noting Bo Branding made full use of its creative licence to completely revamp the packs.

“The packaging design was completely remodeled,” she asserts. “In fact, we have nothing left from the previous one, except for the Cascades name that remains our company brand.

“As it existed before, the Cascades household tissue brand was mainly focused on ‘green’ consumers looking for green products,” Boucher explains.

“With this relaunch, we re-engineered the whole product line to answer different needs, while staying true to our sustainable roots, by rebranding everything under the new Cascades Fluff and Cascades Tuff umbrella.

“In doing so, we went from an austere package appealing to a very small group of the population to a fun and engaging image able to reach the vast majority of Canadian consumers,” she says, citing extensive back-and-forth consumer research conducted by Cascades for over a year leading up to the March 2017 launch.

“We undertook multiple consumer studies: both qualitative and quantitative in nature,” Boucher recounts. “We started with a completely different set of ideas and adjusted to consumer feedback along the way, making this an interactive process.

“While this added time to our product development,” she acknowledges, “it ultimately ensured success in the market.”

Says Boucher: “One of the key things we learned from this project is that consumers want to see the actual product: the whiteness of the paper, the design of the embossed pattern and the overall quality of the product.

“They spoke, we listened, and in the end we delivered bright and colorful packaging with the essential transparent zones to achieve remarkably strong market presence and shelf impact.”

2018

Feb. 28 – March 1

Birmingham, England: Empack 2018, packaging technologies exhibition by Easyfairs. At the National Exhibition Centre (NEC). To register, go to: www.easyfairs.com

March 7-8

Cleveland, Ohio: ADM (Advanced Design & Manufacturing) Expo, comprising Design & Manufacturing, PackEX, PLAST-EX and ATX (Advanced Technology) exhibitions by UBM. At the Huntington Convention Center of Cleveland. To register, go to: www.cleveland.am.ubm.com

March 11-13

Boston, Ma.: Seafood Expo North America 2018, international seafood industries exhibition by Diversified Communications. At Boston Convention & Exhibition Center. To register, go to: www.seafoodexpo.com

March 12-14

Chicago: Sustainability in Packaging US 2018, conference by Smithers Pira. At

InterContinental Chicago Magnificent Mile. To register, go to: www.sustainablepackus.com

March 15-16

Rome, Italy: European Thermoforming Conference, by the European Thermoforming Division of the Society of Plastics Engineers (SPE). At Rome Marriott Park Hotel. To register, go to: www.e-t-d.org

March 20-23

Cologne, Germany: Anuga FoodTec 2018, international food and beverage technologies exhibition by Koelnmesse GmbH. At Cologne Exhibition Center. To register, go to: www.anugafoodtec.com

April 4-5

Atlanta, Ga.: Industrial Pack 2018, industrial, transit and protective packaging exhibition by Artexis Easyfairs. At the Cobb Galeria Center. To register, go to: www.easyfairs.com

April 16-18

Philadelphia, Pa: PACK EXPO East, packaging and processing technologies

show by PMMI, The Association for Packaging and Processing Technologies. At Pennsylvania Convention Center. To register, go to: www.packexpoeast.com

April 17-18

Green Bay, Wis.: 2018 Converters Expo, package converting technologies exhibition by BNP Media. At Lambeau Field Atrium. To register, go to: www.convertersexpo.com

April 18-20

Atlanta, Ga.: AWA International Sleeve Label Conference & Exhibition 2018, by AWA (Alexander Watson Associates). At Crowne Plaza Atlanta. To register, go to: www.awa-bv.com/events

April 24-26

Vancouver: Live Healthy: Eat FreshCPMA 2018, annual convention and trade show of the Canadian Produce Marketing Association. At Vancouver Convention Centre. To register, contact Jennifer Oakley of CPMA at (613) 226-4187, ext. 218; or via email joakley@cpma. com

April 24-27

Shanghai, China: CHINAPLAS 2018, international trade fair for the plastics industries by Adsale Exhibition Services Ltd. At the National Exhibition and Convention Center. To register, go to: www.ChinaplasOnline.com

May 7-8

Indianapolis, Ind.: INFOFLEX 2018, package printing and converting exhibition by the Flexographic Technical Association. Concurrently with the Forum 2018 conference. To register, go to: www.flexography.org

May 7-9

Muscat, Oman: Oman Plast 2018, international plastics, rubber, petrochemicals, printing and packaging industry exhibition by Silver Star Corporation LLC. At Oman Convention & Exhibition Centre. To register, go to: www.silverstaroman.com

May 7-10

Orlando, Fla.: SPE ANTEC (Annual Technical Conference) by the Society of Plastics Engineers (SPE). At the Orange County Convention Center. To register, go to: www.4spe.org

May 7-11

Orlando, Fla.: NPE2018: The Plastics Show, by the Plastics Industry Association. At the Orange County Convention Center. To register, go to: www. plasticsindusry.org

May 16-18

New York City: Sustainable Cosmetics Summit, international conference by

Ecovia Intelligence. At Park Central Hotel New York. To register, please go to: www.sustainablecosmeticssummit. com

May 23-24

Toronto: CPES 2018 , Printable, Flexible & Wearable Electronics Symposium by intelliFLEX. At Centennial College. To register, go to: www.intelliflex.org

May 23-24

Boston, Ma.: Robotics Summit & Showcase 2018 , international technical design end development event for robotics and intelligent systems by WTWH Media, LLC. At Weston Boston Waterfront. To register, go to: www.roboticssummit.com

May 29 – June 1

Milan, Italy: IPACK-IMA 2018 , international processing and packaging technologies exhibition by UCIMAItalian Packaging Machinery Manufacturers Association. Concurrently with MeatTech, Plast, Intralogistica and Print4All (including Grafitalia, Converflex and Imprinting) exhibitions. All at Fiera Milano. To register, go to: www.ipackima.it

June 4-6

Osaka, Japan: Biopolymers Summit 2018 , international conference on biopolymers and polymer chemistry by ConferenceSeries LLC. At Hyatt Regency Osaka. To register, go to: www.biopolymerscongress. conferenceseries.com

June 5-8

Mexico City: EXPO PACK México 2018 , international packaging and processing technologies exhibition by PMMI, The Association for Packaging and Processing Technologies. At Expo Santa Fe México. To register, go to: www.expopack.com.mx

June 6-7

Chicago: American Packaging Summit 2018 , conference by Generis. At Hyatt Regancy O’Hare. To register, go to: www.uspacksummit.com

June 13-14

Paris, France: Pack&Gift, promotional and event packaging trade fair by Idice. At Paris Expo Porte de Versailles. To register, go to: www.packandgift.com

June 19-22

Munich, Germany: Automatica 2018 , industrial automation and robotics exhibition by Messe München GmbH. At Messe München. To register, go to: www.automatica-munich.com

Check the list of packaging machinery headings to discover the heading which addresses your packaging needs.

Under each heading appear the names of manufacturers who supply packaging to the Canadian market. Manufacturers are listed alphabetically.

Following the name of the manufacturer is a notation indicating a Canadian supplier, if one exists.

Under the name of the manufacturer is a list of the machinery that the firm produces for that packaging application. A capsule description of speeds, sizes, materials handled, packaging materials, etc., is included to help you identify packaging machinery that might be of interest to you.

To contact a manufacturer, or a Canadian representative, turn to the section immediately following the list of manufacturers. There you will find an up-to-date list of addresses, including phone and fax numbers, to which you can forward your inquiry.

Abbey Packaging Equipment Ltd.

5030 South Service Rd Burlington ON L7L 5Y7

Tel: 9056813010 Fax: 9056813018

President: Robert McNaught

Year Established as a Packing Line

Integraotor: 1990

Services Offered: A complete Sales and Service provider for a select group of specialized equipment manufacturers. Planning, project management, radiation safety training, installation & commissioning, on-site operator and maintenance training, technical services, after hours support, field service support, preventative maintenance training, calibration and certification, spare parts inventory.

Markets/Industries Served: Food Products, Pharmaceutical, Beverage, Industrial/Chemical

Accent Packaging Equipment

6791 178B St Surrey BC V3S 9E1 Tel: 6044951997 Fax: 6044951989

President: Juergen Flachowsky

Year Established as a Packing Line

Integraotor: 2005

Services Offered: Labeling Equipment

including:

APEL40PL pouch labeler, APEL50 wrap labeler, APEL60 front and back labeler, APEL70 top and bottom labeler, Micro420 10 lane cannabis weigh filler, Inline filling systems, ActionPac weigh fill systems, Novexx labeling heads, ArtyPac system including, ARTY75 horizontal flow wrapper, Atyband 50 shrink sleeve applicator, Arty80V vertical form fill seal system.

Markets/Industries Served: Cannabis, Food and Liquids

Aesus Packaging Systems, Inc.

188 Oneida Ave Pointe-Claire QC H9R 1A8 Tel: 5146943439 Fax: 5146944107

President: Samantha Lewis

Year Established as a Packing Line

Integraotor: 1995

Services Offered: OEM of packaging machinery. Be it stand alone or fully integrated lines.

Markets/Industries Served: Medical Device, Pharmaceutical, Nutritional, Vitamin, Cosmetic, Personal Care, Food, Beverage, Industrial, OEM

Alex E. Jones & Associates Ltd.

8-785 Pacific Rd Oakville ON L6L 6M3 Tel: 9058470166 Fax: 9058470123

President: Paul Duke

Year Established as a Packing Line

Integraotor: 1976

Services Offered: Sales and Service of “Best In Class” Fillers, Cappers, Labellers, VFFS, Scales, Cartoners, Case Packers, and Palletizer’s.

Markets/Industries Served: Food & Beverage, Pharma, Industrial, Chemical, Health and Beauty.

ARPAC LLC

9555 W Irving Park Rd Schiller Park IL 60176 Tel: 8476789034 Fax: 8476717006

President: Rick Allegretti

Year Established as a Packing Line

Integraotor: 1971

Services Offered: OEM with full line integration.

Markets/Industries Served: Food, beverage, dairy-ice cream, consumer goods, building products, pharmaceutical, industrial products.

ATS - Tanner Banding Systems Inc.

A-2390 Wyecroft Rd Oakville ON L6L 6M8 Tel: 9058159999 Fax: 9058150443

President: Denise Gachter

Year Established as a Packing Line Integraotor: 2005

Services Offered: Sales and support for ATS Banding Machines and Systems

Markets/Industries Served: Canada

Auger Fabrication

418 Creamery Way Exton PA 19341 Tel: 6105243350 Fax: 6103632821

President: Eric Edginton

Year Established as a Packing Line

Integraotor: 1984

Services Offered: New replacement and custom tooling for filling machines, paddle screws, mixing blades, feed screws and more.

Markets/Industries Served: Filling Machines, Packaging, Manufacturing

Banding Systems Bandall

289 Broadway Ave Orangeville ON L9W 1L2

Tel: 8667791492 Fax: 4164790787

President: J.P Perreault

Year Established as a Packing Line

Integraotor: 2014

Services Offered: Bandall is a patent technology that eliminates the need for pressure-sensitive labeling on your products by securing a 360 degree band around the

package of the product. The banding material is available in plain or printer paper or plastic film and will allow your products to stand-out and get noticed! The system is used in 2 main applications: replacing a paper sleeve or PS label or to bundle products together for club packs. Systems are available as stand-alone units or can be fully automated to band over 100 ppm. Banding Systems will design, install, and commission the system that is right for any size of application.

Markets/Industries Served: Food and Beverage, Pharma, Industrial, Health and Beauty, Graphics, Logistics etc.

Baumer hhs Corp. 10570 Success Lane Dayton OH 45458 Tel: 9378863160 Fax: 9378863161

President: Chris Raney

Year Established as a Packing Line Integraotor: 1986 Services Offered: Full field and technical services available.

Markets/Industries Served: Folding Carton, Corrugated, Commercial Print Finishing, Tobacco and End of Line.

Best Packaging Systems

1-8699 Escarpment Way Milton ON L9T 0J5 Tel: 9058643005 Fax: 9058646245

President: Dave Sweetland

Year Established as a Packing Line

Integraotor: 1987 Services Offered: 24-7 service all make Pallet Wrappers, 3M Case Sealers

Markets/Industries Served: Food, Pharmaceuticals

Bivans Corporation 2431 Dallas St Los Angeles CA 90031 Tel: 3232254248 Fax: 3232257316

President: Vivian Woo

Year Established as a Packing Line

Integraotor: 1952

Markets/Industries Served: Worldwide: Pharmaceutical, Medical device, Nutraceuticals, Cosmetics, Personal care, Contract packagers, Automotive, Hardware, Snacks/candy

BluePrint Automation (BPA)

16037 Innovation Dr South Chesterfield VA 23834 Tel: 8045205400 Fax: 8045268164

President: Robbie Quinlin

Year Established as a Packing Line

Integraotor: 1980 Services Offered: Vision Guided Robotics:

Sophisticated DELTA robots picking individual packaged and un-packaged items for loading into your container, wrapper or hffs machines. (Applications include Stacking, Wrapper Loading, Variety Pack, Dinner Tray Loading and Kit Assembly)

Case and Tray Packing:

Solutions for flexible and other tough-tohandle packages. We provide vertical and horizontal case packing solutions, including end-load cartoning and wrap-around casepacking for your retail ready packaging.

Turnkey Packaging Systems:

Complete packaging solutions taking control of your packaging line from the end of processing through palletizing!

Markets/Industries Served: Snack Food, Bakery, Dairy, Pet Food, Confectionery, Personal Care, Pharmaceutical, Household Products, Frozen Food, Beverage, Poultry, Beef and Seafood and more!

Bosch Packaging Technology

(Kliklok-Woodman)

5224 Snapfinger Woods Dr Decatur GA 30035

Tel: 7709815200 Fax: 7709877160

President: Bruno Oberle

Year Established as a Packing Line

Integraotor: 1947

Services Offered: Bosch Packaging Technology in Decatur, GA, manufactures and services Kliklok topload, endload, and wraparound cartoners, and Woodman vertical form-fill-seal bagmakers and multi-bag balers. We also build Kliklok product handling and indexing machines and other specialized machinery. As part of the Bosch Group we can offer complete packaging systems from primary packaging through case packing.

Markets/Industries Served: Bakery, snack food, frozen food, refrigerated and prepared foods, cereal, confectionery, and industries requiring related technologies.

Bradman Lake 3050 Southcross Blvd Rock Hill SC 29730 Tel: 7045883301 Fax: 8033663690

President: Gary Pickett

Year Established as a Packing Line

Integraotor: 1948

Services Offered: The Bradman Lake

Group is synonymous with providing innovative packaging solutions to a global client base; a client base that demands a partner to go ‘above and beyond’ to help them excel in today’s competitive markets.

By integrating our three key brandsAutowrappers, Bradman Lake and Europackwe are a major supplier of packaging technology to the Bakery and Biscuit, Chocolate and Confectionery, Frozen Foods, Dry Foods, Consumer and Healthcare industry sectors.

From distribution and feeding systems to flow wrapping, carton erection, loading and closing and end-of-line options of case packing and shrink wrapping, time after time many leading companies place their trust in Bradman Lake technology.

At our three factories in the UK, Beccles and Bristol and South Carolina in the USA, research and development teams strive to ensure Bradman Lake technology remains at the forefront of innovation.

The group has one clear aim – to maximize clients’ profitability by utilizing the most cutting edge technology available. With decades of experience and many thousands of installations to our credit, whether the requirement is for a single machine or a totally integrated solution. Bradman Lake makes the ideal partner.

Bradman Lake is a wholly owned subsidiary of the multi-disciplined global UK engineering group Langley Holdings plc. www. langleyholdings.com

Markets/Industries Served: Bakery, chocolate & confectionary consumer & healthcare frozen & dry foods

CAM Packaging Systems

3-226 Industrial Parkway N Aurora ON L4G 4C3

Tel: 9057375400

Year Established as a Packing Line

Integraotor: 2008

Services Offered: Machinery Manufacturer for Complete Weighing Counting and Bagging systems. Full turn key system solutions for VFFS, Stand up Pouches, Variety Pack Automatic Solutions. We also integrate other manufacturers systems into ours or on their own. Shrink wrappers case packers, pallet wrappers, robotics integration. Full technical support staff to support our clients in many categories. We also supply the materials that run on the machines. Precise, Reliable, Affordable Solutions.

Markets/Industries Served: Food, beverage, industrial, horizontal & vertical form fill and seal, primary and secondary packaging systems including end of line solutions.

Canpaco Inc.

7901 Huntington Rd Woodbridge ON L4H 0S9 Tel: 9057717791 Fax: 9057711115

President: Robert Appel

Year Established as a Packing Line

Integraotor: 1993

Services Offered: Buy and sell new and used packaging equipment. sales and service.

Markets/Industries Served: Food and pharmaceutical industries

Capmatic Ltd.

12180 boul Albert-Hudon Montréal-Nord QC H1G

3K7 Tel: 5143220062 Fax: 5143220063

President: Alioscia Bassani

Year Established as a Packing Line

Integraotor: 1964

Services Offered: Over 50 years of experience of providing Primary Packaging Solutions for the Global market. A reputation built on: quality, innovative design, accuracy and customer care. Our expertise is in: Monoblocks (Fill, Plug, Cap, Label), Feeders, Bottle Unscramblers, Bottle Orienters Cap Sorters, Elevators, Rinsers, Fillers: Liquid, Cream, Micro Powder, Tablet, Counters: Tablet, Capsule, Soft gel, Inserters: Desiccant, Cotton, Seal Induction, Orifice Reducer, Pluggers, Crimpers, Cappers, In-line Belt Cappers, Rotary Chuck Cappers, Labelers: Pressure Sensitive, Neck Band, Body Sleevers, Tamper Evident, Safety Seal,etc.

Meeting your unique requirements differentiates us from the rest.

Markets/Industries Served: Pharmaceutical, Diagnostic, Bio-Medical, Nutraceutical, Cosmetic Health & Beauty Care, Food & Beverage and Chemical Industries.

Cartier Packaging Inc.

2325 boul Industrial Saint-Césaire QC J0L 1T0 Tel: 4504693168 Fax: 4504691387

President: Stéphanie Roy

Year Established as a Packing Line

Integraotor: 1980 Services Offered: Looking for high-

performance equipment that will optimize your operations and improve your competitiveness? Compact machines that will help you get the most from your space?

CARTIER offers innovative packaging systems that will generate the best return on your investment.

Charles Downer & Co. Ltd.

7-52 West Beaver Creek Richmond Hill ON L4B 1L9 Tel: 9058822222 Fax: 9058820437

President: Jeff Downer

Year Established as a Packing Line

Integraotor: 1977 Services Offered: System engineering, planning, equipment supply, installation commissioning, training,parts,service, preventative maintenance programs

Markets/Industries Served: ALL

CiMa-Pak Corporation

3-7290 Torbram Rd Mississauga ON L4T 3Y8

Tel: 9056120053

Year Established as a Packing Line

Integraotor: 1999 Services Offered: Complete tray sealing systems including trays, film and tray sealers that seal only, MAP or skin package.

Markets/Industries Served: Food processors, Food wholesalers and retailers, Restaurants,

Delkor Systems, Inc.

4300 Round Lake Rd W St. Paul MN 55112 Tel:

651-348-6700 Fax: 6513486705

President: Dale Andersen

Year Established as a Packing Line

Integraotor: 1973

Services Offered: Delkor Systems engineers and manufactures premier secondary packaging equipment solutions including case forming, robotic case packing, case closing and palletizing. Since 1973, Delkor has served as a turn-key packaging solution provider with end-to-end capabilities from creating award-winning, retail-ready package (RRP) designs - Delkor Cabrio Case®, Delkor Turbo Case, among others - to installing complete packing lines from case former to palletizer. Delkor is where premier packaging equipment engineering meets innovative package design.

Markets/Industries Served: Cheese

Descon Conveyor Systems

1-1274 Ringwell Dr Newmarket ON L3Y 9C7

Tel: 9059530455 Fax: 9059531335

President: Dave Farquhar

Year Established as a Packing Line

Integraotor: 1993

Services Offered: Project consultation, mech. & controls design engr., controls programming, sys. integration, project mgmt., custom mfg., mechanical & electrical installation, plant layout & design, spare parts.

Markets/Industries Served: Soft drink, water, spirits, brewing, food, manufacturing, container manufacturing.

DJS Enterprises 6-2700 14th Ave Markham ON L3R 0J1 Tel: 9054757644 Fax: 9054757645

President: Darrell Shulman

Year Established as a Packing Line

Integraotor: 1991

Services Offered: DJS Enterprises buys and sells New, Used and Reconditioned Process and Packaging Equipment for the Pharmaceutical, Vitamin, Food and Confectionery Industries.

Markets/Industries Served: Process and packaging equipment to the pharmaceutical, vitamin, herbal, food, confectionery, and cosmetic industries.

Domino Printing Solutions Inc. 1-200 North Service Rd E Suite 317 Oakville ON L6M 2Y1 Tel: 9058292430 Fax: 9058291842

Services Offered: 24/7 Technical Helpdesk, Renowned Training academy, Consumable agreements that work for YOU, National network of tenured service engineers, Financial Services options.

Markets/Industries Served: Food, Beverage, Pharmaceuticals, Medical Devices, Industrial and Personal Care

Dorner Mfg. Corp.

975 Cottonwood Ave PO Box 20 Hartland WI 53029 Tel: 2623677600 Fax: 2623675827

President: Terry Schadeberg

Year Established as a Packing Line

Integraotor: 1966