JENNIFERellson jellson@annexbusinessmedia.com

@CFIMag

CanadianForestIndustries

@cfimag

Canadian Forest Industries

JENNIFERellson jellson@annexbusinessmedia.com

@CFIMag

CanadianForestIndustries

@cfimag

Canadian Forest Industries

This year marks the 12th edition of our Top 20 Under 40 awards, and once again, we’re in awe of the talent emerging in our industry. Usually, we stick to honoring just 10 young professionals, but just like last year, we were overwhelmed with nominations – so many brilliant, young minds doing extraordinary work. Whittling it down to just 10? Near impossible. That’s why, for the second consecutive year, we’ve decided to honour not 10, but 20 of these trailblazers, thanks to the incredible participation of our readers. You made your voices heard, and we couldn’t ignore the quality of the candidates you nominated.

persistence pays off!

“WE’VE ONCE AGAIN DOUBLED THE FUN BY EXPANDING THE TOP 10 TO A TOP 20 UNDER 40, THANKS TO AN OVERWHELMING NUMBER OF STELLAR NOMINATIONS.”

The future of forestry is bright, and this year’s cohort proves that the next generation is ready to lead. These young professionals aren’t just filling roles; they’re driving innovation, solving big problems, and setting new standards. Whether they’re working on sustainable forest management, advancing cutting-edge technology, or improving safety protocols, their passion is undeniable. They’re not just waiting for the future – they’re creating it.

Last year, we thought we’d hit a new high with the quality of submissions, but this year? Even more outstanding nominations! This made the selection process both exciting and challenging. How do you choose just 10 from the short list when there are so many worthy contenders? Well, we decided the answer was simple – don’t! Instead of narrowing it down to 10, we’ve embraced the opportunity to spotlight 20 exceptional leaders. And who knows? Maybe next year, we’ll break even more records.

For all of you who took the time to nominate someone, thank you. Your input helps us discover the best of the best. If your candidate didn’t make it this year, don’t be discouraged – many of our past awardees were repeat nominees. So keep those nominations coming because we know that

What stands out about this year’s Top 20 is not just their impressive résumés, but their vision for the future. These young professionals are driven by purpose. They’re the innovators who are tackling the tough issues – sustainability, safety, and efficiency – and turning challenges into opportunities. They’re the ones leading with passion and creativity, not just following the playbook, but rewriting it. It’s truly inspiring to watch them grow and influence the industry. They’re pushing boundaries in ways that are making our industry safer, more efficient, and more sustainable for the future. And it’s not just the companies they work for that are benefitting – it’s the entire sector.

To everyone who sent in nominations, thank you again. Your enthusiasm helps us highlight the outstanding young professionals shaping our industry. And don’t worry if your nominee didn’t make it this year – there’s always next year. Again, I would like to stress that many of our past honourees have been nominated before, so keep those submissions coming!

Now, it’s time to meet the future of forestry. These 20 leaders are the ones to watch. They’re bringing fresh perspectives, new energy, and a drive to make a lasting impact. As you read through their stories, I hope you’ll feel the same sense of optimism that I do. The challenges facing our sector are real, but with leaders like these at the helm the future feels brighter than ever.

So let’s raise a toast to this remarkable group of young leaders. Their drive, creativity, and resilience are setting the stage for a vibrant future in forestry. We can’t wait to see where their talent takes them next.

Congratulations to this year’s recipients of CFI’s Top 20 Under 40 Awards!

The Canada Industrial Relations Board (CIRB) has ordered operations to resume at Canadian Pacific Kansas City Railway (CPKC) and continue at Canadian National Railway (CN) while the ongoing disputes proceed to binding arbitration.

In August, the BC Council of Forest Industries (COFI) issued a statement urging all parties involved – including employers, unions, and the federal government – to urgently resolve the situation to avoid widespread disruption. COFI said rail transportation is crucial for moving lumber, pulp, and paper products across North America and to global markets.

Company Location

Timeline Details

Conifex Timber Mackenzie , B.C. August

Moving to a single shift due to market conditions

Rockshield Engineered Plywood Cochrane, Ont. Unknown Fire damage disrupting operations

Canfor Corp. Fort St. John, B.C. Permanent Closure due to industry challenges

Canfor Corp. Vanderhoof, B.C. Permanent Closure due to industry challenges

Hampton Lumber Fort St. James, B.C. Aug/Sept Curtailment for 5 weeks due to log shortage

Source: Madison’s Lumber Reporter

Starting Nov. 1, new occupational first aid requirements will be enforced across B.C., as announced by WorkSafeBC.

The updates, which amend the Occupational Health and Safety Regulation, are designed to align with Canadian Standards Association standards and enhance first aid provisions in

workplaces, particularly in high-risk and remote industries.

Key changes include updated certification levels, stricter requirements for first aid kits, mandatory workplace first aid assessments, and annual drills. Employers are urged to review and comply with these new standards to ensure worker safety.

Canada is escalating its dispute over U.S. softwood lumber duties by launching two new legal challenges under the Canada-United States-Mexico Agreement (CUSMA). Trade minister Mary Ng has announced that the challenges target the U.S. Department of Commerce’s re -

cent decision to further increase duties on certain Canadian softwood lumber imports.

The legal actions focus on contesting U.S. anti-dumping and countervailing duties, which have been applied to Canadian lumber exports for several years. Canada has con-

Canfor Corp. has announced the closure of its Vanderhoof and Fort St. John sawmills in northern B.C., citing ongoing financial losses, weak lumber markets, and increased U.S. tariffs.

The closures will affect approximately 500 employees and reduce 670 million board feet of annual production capacity.

CEO Don Kayne emphasized the impact of regulatory complexity, high operating costs, and reduced timber supply on the decision, which marks a significant setback for the province’s forest industry.

The company plans to wind down operations by the end of the year and explore divesting some northern B.C. tenure.

sistently opposed these duties, arguing they are both unfair and damaging to the Canadian lumber industry. Ng described the latest increase in tariffs as “unjust,” saying they not only hurt Canadian businesses and workers but also drive up housing costs for U.S. consumers.

FPInnovations has secured nearly $3 million in federal funding to advance sustainable wood construction and zero-emission vehicle technologies in the Montreal region.

The majority of the funding – over $2.5 million – comes from Natural Resources Canada’s Green Construction through Wood program. This will enable FPInnovations to conduct market research and testing, paving the way for low-carbon wood-based systems to be integrated into Canadian building codes. An additional $212,000 from the Zero Emission Vehicle Awareness Initiative (ZEVAI) will support FPInnovations’ projects aimed at accelerating the adoption of zero-emission vehicles in the forestry and commercial transportation sectors.

FPInnovations will also develop resources to support the use of vehicles that are zero-emission or use clean fuels through demonstrations and short operational trials.

inquires or changes, please contact Angelita Potal, Customer Service Tel: 416-510-5113 Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR - Jennifer Ellson (438) 483-7451 jellson@annexbusinessmedia.com

GROUP PUBLISHER - Anne Beswick (416)510-5248 • Mobile: (416) 277-8428 abeswick@annexbusinessmedia.com

ACCOUNT COORDINATOR - Shannon Drumm (416) 510-6762 sdrumm@annexbusinessmedia.com

MEDIA DESIGNER - Jaime Ratcliffe jratcliffe@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER Serina Dingeldein (416) 510-5124 sdingeldein@annexbusinessmedia.com

NATIONAL SALES MANAGER - Josée Crevier Ph: (514) 425-0025 • Fax: (514) 425-0068 jcrevier@annexbusinessmedia.com

WESTERN SALES Tim Shaddick 1660 West 75th Ave

CEO

BY EUGÉNIE ÉMOND

TRANSLATED

BY

KEVIN FERNANDEZ

“This morning, I’m managing a crisis,” says Kevin Therrien as he climbs into his pickup truck. It’s only mid-February, but the recent mild weather has him worried about the thaw. “I have a hundred trips to make, and I don’t think I’ll have time to get all the wood out because it’s going to sink,” explains the owner of AKT Enterprises.

Therrien and his employees are close to finishing a job on the Côte-du-Sud region for a client who owns nearly 300 woodlots in the area. The expected warm weather in the coming days has forced him to revise his plans. “I’m sending my trucks as far as I can, to a hardwood mill that’s a seven-hour round trip away, so they won’t come back and play in the mud here,” he explains.

Co-ordinating operations is now more than a full-time job for the entrepreneur. Until last year, in addition to managing 14 employees and handling wood marketing, he also operated the machinery. “We target cutting areas, market the wood, cut it, and then deliver it to the mill,” he says. This workload left him working no less than 110 hours a week without ever taking a break. Over the past year, he’s had to resign himself to leaving the machines to his employees.

“WORK IS WHAT SAVED ME AND MADE ME FORGET MY DEMONS. THAT’S WHY I WORK 100 HOURS A WEEK.”

“I don’t like delegating, but I’m learning.”

In the forest, two new harvesters are at work. The most recent one arrived just two weeks ago, the other last May. “In six months, prices have gone up,” Therrien laments. To illustrate, he reveals that the two harvesters, each worth around a million dollars, were bought from the same manufacturer just a few months apart, yet there’s a price difference of $35,000.

He shares that the scarcity of parts and the increase in fuel and equipment prices since the pandemic are the biggest challenges he faces.

“And I can’t raise my prices too much because the competition is there too,” he states. So, Therrien spends a lot of time seeking the best-selling price for his wood from the sawmills. “It’s the transportation cost that hurts.”

Therrien also invests heavily in his employees, whom he trains fresh out of school. He offers them four-day work weeks with 13-hour days, during which he provides lodging. He also ensures they work with the best equipment –top-of-the-line in both technology and comfort.

“I try to give my employees what I wanted when I was an operator.”

When asked where he got his management skills,

Therrien quickly responds, “I didn’t finish high school and only took a logging and processing course in Dolbeau. It sounds silly, but when you don’t have money, you have to be creative. It’s the school of life,” he explains.

Therrien comes from a modest family in Saint-Cyprien, Chaudière-Appalaches. “When my mother left, my father raised us alone with help from food banks. When he sent me to study, he had to sell his house to pay for everything,” he gratefully recalls.

It was while flipping through a career book that he discovered the forestry operator trade. “I saw that a forestry guy could make a decent living,” he remembers. At 16, Therrien left for Dolbeau and completed his vocational diploma.

He then worked as a forestry operator, but his delinquency and daily drug use took a toll. He accumulated debts. “I owed $50,000 to the credit union and didn’t even have a car,” he recalls. Meeting his partner, who still accompanies him today, changed everything.

To get back on track and repay his debts – including a car his partner paid for – he left for two years to work as an operator in Fermont. “I’d be gone for 42 days and back for three,” he sums up. Therrien managed to pay off his debts and saved $30,000, enough to take out a $150,000 loan from the bank. He bought used machinery and started his own company, even hiring his father as a truck driver.

Nine years later, his turnover reached

several million dollars. “We’re in full expansion,” he proudly shares.

Therrien’s clients today are large landowners. He begins his season in June in Stoneham, then moves his equipment to Saint-Raymond-de-Portneuf and finishes on the Côte-du-Sud at the end of winter.

“My added value is the turnkey service; not many do that.”

AKT Enterprises handles everything from land management, logging, transportation, to hauling. During the pandemic, the number of forestry contractors increased, fueling competition. “Fuel was cheap, and many people became entrepreneurs, but now it’s starting to balance out a bit because many have given up,” he says.

Today, he’s trying to diversify even further. “You have to understand that a forestry company has to make money the second you cut down a tree. It’s not like real estate, where you make money over time,” he explains. Given the rising expenses he’s faced in recent years, he’s trying to stabilize his income by buying woodlots. He now owns 53 of them. “I want to diversify because in terms of cutting, I’m pretty much at my limit.”

On the back seat of his pickup, Therrien has placed his backpack. He often sleeps in his truck.

“I’m where the job requires.”

He goes home on weekends. And still, the dynamic 40-year-old is a workaholic and doesn’t hide it. “Work is what saved me and made me forget my demons. That’s why I work 100 hours a week,” he justifies. “Now it’s settled, but I’m caught in the wheel. It’s gotten so big that I’m forced to work,” he adds. But Therrien doesn’t complain. He enjoys his job and is especially proud of how far he’s come.

AKT Enterprises has built a large fleet to serve private forest land. For forest transport, the company owns five Kenworth trucks and four Manac forest trailers, as well as a Manac self-loading trailer.

For equipment transport, AKT has a Manac lowboy trailer with a Jeep dolly and a 4th axle, as well as two Prentice 210 loaders for loading.

For harvesting equipment, the company operates two Tigercat harvesters and a Logset forwarder. Finally, AKT owns two 10-wheeled trucks and a Cat excavator for road repairs.

Designed for the most demanding applications, FORESTLAND is BKT’s most recent and innovative bias tire for the agro-forestry sector, but it can also be employed in some agricultural operations such as landscaping and light mulching. Its polyester carcass and specific tread compound make it particularly cut-and-chip resistant, while the robust sidewall ensures a long product life cycle. FORESTLAND’s key features are excellent traction on soft terrain, good grip on any ground thanks to stiff and reinforced tread lugs, a high level of stability thanks to the strong bead construction and top self-cleaning properties.

BY NELSON THIFFAULT, WITH T. JONES, M. HOEPTING, AND J. FERA

Climate change is an undeniable reality that presents challenges and opportunities for forest management across Canada. With rising global temperatures and shifting precipitation patterns, traditional silvicultural prescriptions are increasingly at risk of producing forests that are no longer adapted to their future climate.

The need for adaptive strategies is particularly pressing in the Great Lakes-St. Lawrence Forest Region, where the impact of climate change is already being observed.

To address these challenges, we implemented a comprehensive research initiative, the Adaptive Silviculture for Climate Change (ASCC) experiment, at the Petawawa Research Forest (PRF) in Chalk River, Ont.

Our research aims to develop, test, and refine adaptive silvicultural treatments that can help sustain forest ecosystems in the face of changing climatic conditions.

The ASCC project at the PRF is part of a larger international network of experiments designed to explore climate-adaptive forest management strategies. The Petawawa site focuses on white pine-dominated forests, due to their significant ecological and economic importance

in the region. The study area covers approximately 212 hectares and is divided into four replicate blocks, each containing five distinct treatment units: control, business-as-usual, resistance, resilience, and transition. Each treatment is designed to address different climate adaptation strategies, ranging from maintaining current forest conditions to facilitating the transition to new, climate-adapted forest types. We implemented the treatment on an operational scale, making the findings directly applicable to real-world forest management.

Control treatment: This serves as a baseline, representing natural forest succession without human intervention. It provides a crucial reference

point for comparing the effects of the other treatments.

Business-as-usual treatment: This approach replicates the standard management practices currently used in white pine-dominated forests. It involves a two-cut uniform shelterwood system aimed at regenerating a wellstocked stand of white pine.

Resistance treatment: Our goal here is to maintain the current forest structure and composition, with an emphasis on enhancing the genetic diversity of white pine to improve resilience against future climate stressors. This treatment also uses a two-cut shelterwood system but incorporates seedlings produced from seeds from various climate-adapted sources.

Resilience treatment: This focuses on creating a structurally diverse forest that can better withstand disturbances. We implemented an irregular shelterwood system with expanding gaps, creating a multi-aged stand structure, and enhancing species diversity by incorporating more species and more climate-adapted seed sources.

Transition treatment: The most proactive of the treatments, this approach aims to create a new forest composition that is better suited to future climatic conditions. We carried out a clearcut with seed trees, with a focus on establishing species such as pitch pine ( Pinus rigida Mill.), red oak ( Quercus rubra L.), and white oak ( Quercus alba L.), which are expected to perform well under warmer and drier conditions.

Future research will focus on a wide range of forest attributes, including overstory tree health, species diversity, and soil moisture levels.

The implementation of the treatments began with the first round of harvesting in 2021, followed by mechanical and chemical site preparations in 2022 and 2023. In August 2023, we planted over 173,000 seedlings across the experimental units, with 17,000 of these being individually tagged for long-term monitoring. In 2024, we performed a first complete assessment of seedling survival and height, along with continuous measurements of environmental variables in a subset of experimental units.

Early observations suggest that the different species and sources are already leading to varied responses in terms of survival and early growth. Seedling mortality was highly variable across the different treatments but was typically below 20 per cent. Seedling heights at the end of the first growing season were around 25 cm with some individuals reaching as much as 70 cm after a single growing season. We are looking forward to looking at the data in more detail this fall and reporting back on which species and treatments were performing well.

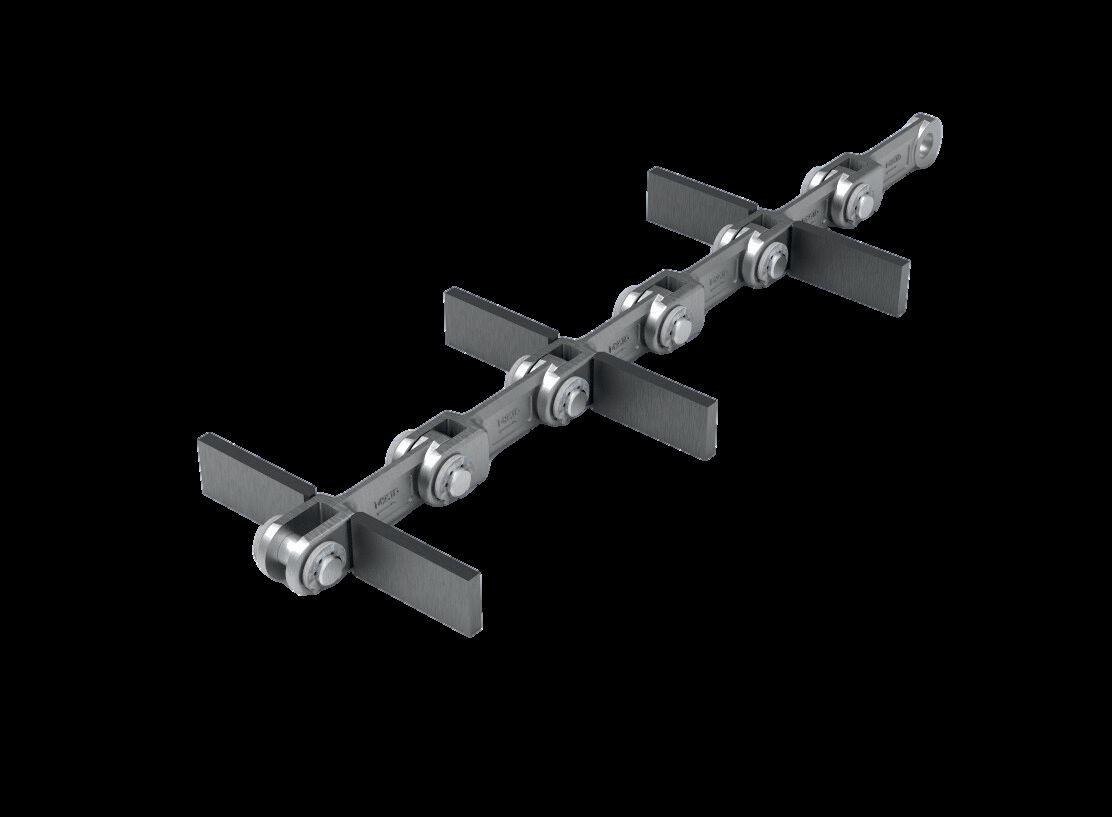

Wallingford’s is the North American leader in logging supplies; offering forestry tracks, tire chains, harvester bars, saw chain, teeth, grapples and more.

pewag forestry tracks are developed in various sizes and designs to suit virtually any terrain, the harshest climates, and all machine types.

Contact a Wallingford’s rep or visit us online:

Lydia Stone : 207-250-3284 (français, english)

JD Moore : 548-887-2626 (english)

www.wallingfords.com

The ASCC installation at the PRF provides a unique opportunity to assess the long-term effectiveness of adaptive silvicultural practices. Future research will focus on a wide range of forest attributes, including overstory tree health, species diversity, and soil moisture levels. These treatments are aimed at creating an ecological lifeboat for forests. The common metrics of silvicultural success: stand density, height growth, and volume, are less important than forest diversity and fecundity of future climate adapted species and seed sources. We have also put a strong emphasis on evaluating the treatments’ effectiveness in reducing fire risk and enhancing forest resilience to disturbances.

Moreover, the study’s integration within the broader ASCC network will allow for cross-site comparisons, providing valuable insights into the applicability of these adaptive strategies across different forest types and climatic conditions.

The ASCC initiative at Petawawa is a forward-thinking project that directly addresses the urgent need for adaptive forest management strategies in the face of climate change. By testing a range of treatments designed to enhance forest resilience, our research will contribute to the development of best practices for sustaining forest ecosystems in the Great Lakes-St. Lawrence Forest Region and beyond. As climate change continues to reshape our natural landscapes, initiatives like ASCC will be crucial in guiding the future of sustainable forest management.

Dr. Nelson Thiffault is a forest engineer and research scientist at the Canadian Forest Service, specializing in silviculture and vegetation management. He is an adjunct professor at four Canadian universities and serves as an associate editor for the Canadian Journal of Forest Research. He also contributes to international forestry initiatives.

Olofsfors is the market leader in bogie tracks for CTL machinery and wheel tracks for skidders and wheeled feller bunchers. Under the brand names, ECO-Tracks and ECO-Wheel Tracks, Olofsfors offers the widest range of track models and linkage systems for various machine configurations and ground conditions. Superior quality, performance and a proven track record for increased productivity and durability.

NO MATTER THE CONDITIONS - OLOFSFORS HAS YOU COVERED!

754-2190 info@olofsfors.com

BY JENNIFER ELLSON

We’re beyond excited to introduce this year’s Canadian Forest Industries Top 20 Under 40 award winners, listed in no particular order. Every year, the nominations blow us away, and this year was no different. We planned to keep it to 10 winners, but with so much talent, we just couldn’t – so here we are, celebrating 20 of the brightest young professionals in the industry.

Now in its 12th year, this award highlights those who are shaking things up in forestry – whether they’re leading teams, driving innovation, mentoring others, or making their mark in their communities. We’re proud to recognize young leaders from every corner of the industry – whether they’re working in sawmills, logging, administration, or as suppliers, among others. These young pros are pushing boundaries and setting new standards, proving that the future of forestry is in good hands.

ALEXANDER RYERSON Manager of client services, Lim Geomatics, Ottawa, Ont.

Alexander has been a key player in developing innovative forestry softwares like Stratus and Prism

As the product owner, the 39-year-old engaged stakeholders worldwide to ensure adaptability in various forest environments. His journey into forestry began at age 10 after getting lost in a forest, leading to a lifelong love for the outdoors.

“My journey came full circle – I’m now working my dream job, a perfect blend of my parents’ careers in remote sensing and software engineering,” says Alexander. He encourages young people to join forestry because of its diverse career paths. “It’s one of the few industries where you can follow nearly any professional interest.”

His rapid rise from forest information specialist

to manager of client services showcases his dedication to innovation and sustainability in forestry. “Alexander’s work is making a real difference in how we think about sustainable forestry,” says his mentor and colleague Diana Davies-Harju.

BROCK MULLIGAN

Senior VP, AFPA, Edmonton, Alta.

Brock has been a cornerstone of the Alberta Forest Products Association (AFPA) for 14 years. Over the past two years as senior VP, he has leveraged his political acumen and extensive network to advocate for the industry at all levels of government.

His journey into forestry began while working for George VanderBurg, MLA for Whitecourt Ste. Anne, where he built connections with forest companies and communities. “One day, Brady

Whittaker, AFPA’s CEO at the time, came and offered me a job as the association’s director of communications. I readily accepted. It’s been a great journey over the past 15 years,” Brock shares.

Brock’s leadership shines through in the multistakeholder rail advocacy alliance he co-founded, and the Love Alberta Forests public awareness campaign, which significantly boosted the province’s understanding of forestry’s importance.

He also co-leads AFPA’s regulatory reform efforts, advocating for streamlined approval processes that have saved members millions in potential costs.

When it comes to keeping young people in the industry, the 39-year-old believes the key lies in showcasing its diversity and culture. “I meet many folks who started their

Congratulations, Brock!

The Alberta Forest Products Association and their members proudly congratulate our Senior Vice President, Brock Mulligan, for his recognition as one of the Top

forestry career in one place and are now somewhere completely different, but still in the industry.

It’s a very family-oriented industry, with companies that feel like families, too,” he says.

“Brock’s deep network and advocacy skills have made him indispensable to our organization and a trusted advisor to industry members,” says AFPA president and CEO Jason Krips.

DANA COLLINS

Manager of partnerships, Mosaic Forest Management, Nanaimo, B.C.

At 36, Dana is making a significant impact in the forestry sector as a leader in partnerships and advocacy for equity, diversity, and Indigenous relations. She joined Mosaic two years ago, where she plays a pivotal role in fostering relationships with First Nations and Indigenous business partners across Coastal B.C.

Dana’s path to forestry wasn’t a straight line. “I stumbled into forestry through a mandatory science credit at university,” she shares. That course, ‘Forests and Society,’ shifted her entire academic and career trajectory. After earning her master’s in forest conservation, she joined the Canadian Institute of Forestry, eventually becoming its youngest executive director. Now at Mosaic, she applies her experiences to strengthen Indigenous partnerships and contribute to the forest sector’s future.

To attract and retain young people in the industry, Dana believes visibility is key. “When equity-deserving groups can see themselves in this industry, it inspires them to explore exciting and dynamic careers in the forest sector,” she says.

Dana’s efforts helped Mosaic achieve PAIR Gold certification, recognizing the company’s commitment to Indigenous relations. “Dana’s leadership in partnerships and her dedication to Mosaic’s core values have been remarkable,” says Trevor Joyce, Mosaic’s director of Indigenous investment.

JESSE HENRICH

JESSE HENRICH

Owner, Lands and Forests Consulting, Owen Sound, Ont

Jesse has been a driving force in forest restoration and sustainable management across southern Ontario. After joining Lands and Forests Consulting in 2006, he took over the company in 2015.

With degrees in forestry from Lakehead University and environmental and resource studies from Trent University, the 39-year-old’s expertise spans sustainable forest management, prescribed burns, and large-scale tree planting. As a registered professional forester and a trained wildland firefighter, he has personally planted over 250,000 trees and overseen the planting of over one million more.

Jesse’s dedication to forest health and biodiversity has earned him recognition, including OPFA’s 2017 Fernow Award for his early contributions to the profession. “Jesse’s thoughtful and professional approach to every project makes him an invaluable leader in the field,” says colleague, Val Deziel.

KERRY MCLAVEN

CEO, FGCA, Kemptville, Ont.

At 36, Kerry is already leading the Forest Gene Conservation Association (FGCA) as CEO, where she has expanded programs related to species at risk and reforestation at both the provincial and federal levels. With a geography degree from Wilfrid Laurier University and a master’s in forest conservation from the University of Toronto, Kerry’s passion

for the forestry industry was sparked during a season of tree planting. “I caught the bug for the forest industry and decided to pursue this career path,” she says.

Kerry’s leadership has seen FGCA grow in staffing and expertise, helping to further the organization’s mission. Her success, she believes, is due to accessibility and mentorship.

“A lot of my success has come from people who opened their doors to me. Mentors have so much to offer – positive feedback, respectful criticism, and plenty of stories about both successes and failures.”

Kerry’s ability to connect with diverse stakeholders, from Indigenous communities to government ministries, has made her an influential leader in the forestry sector. “Kerry’s leadership and ability to bring people together is unmatched,” says colleague Matt Mertins.

Thank you for your dedication to sustainable forest management and successful restoration of forest and grassland ecosystems.

CHRIS DUNCAN

Partner and national leader, forestry & forest products, MNP, Duncan, B.C.

Chris, 38, has risen to become the national leader of the forestry and forest products practice at MNP, where he leads a team serving over 1,700 forestry clients across Canada. Growing up in a familyrun logging business on Vancouver Island, Chris’s connection to the industry runs deep. “I remember taking days off school to watch my dad work as a logging contractor,” he says. “When I started with MNP, I naturally gravitated toward our forestry clients.”

Over his 14-year career at MNP, Chris has earned a reputation for being a “dirty boots accountant,” regularly visiting client sites to offer hands-on business advice. His work spans accounting, tax services, and strategic consulting, and his influence extends to contractors, tenure holders, and Indigenous organizations, helping the industry adapt to evolving economic and environmental challenges.

To attract young people to forestry, Chris believes in highlighting the diversity of roles. “There are so many different aspects to the industry that people can get involved in and have successful and satisfying careers,” he explains.

“Chris’s leadership and dedication to our forestry clients have been invaluable,” says Peter van Dongen, his colleague at MNP.

Join us in congratulating Chris Duncan on his nomination as one of Canadian Forest Industries’ Top 20 under 40. This is a special and well-deserved nod to Chris, our National Leader of Forestry and Forest Product Services, as well as a testament to MNP’s commitment to this vital Canadian industry.

With our deep roots in the sector, our advisors offer accounting and consulting services to help your forestry business meet its unique needs.

KYLE SIA-CHAN

Manager, economics and finance, COFI, Vancouver, B.C. At 31, Kyle is already making his mark as a manager of economics and finance at the BC Council of Forest Industries (COFI). Over the past three years, he has contributed significantly to COFI’s Economic Impact Study and played a key role in developing the new data analytics platform, COFI Connect. He has also tackled critical policy issues like carbon pricing, trade, and value-added initiatives for the province.

Kyle’s journey into the forestry sector began after meeting a classmate who had spent much of his career in B.C.’s forest industry. “His passion for the sector, combined with my understanding of its importance to B.C.’s economy, convinced me to join the industry, and I haven’t looked back since!” he says.

To attract and retain young talent, Kyle believes the sector needs a unified vision for its future. “Young professionals seek industries with a promising future, and we must demonstrate that our sector offers just that,” he explains. Sharing stories of the inspiring people and work already happening in the industry will help showcase the exciting opportunities available, he adds.

“Kyle is an emerging leader with loads of talent,” says his supervisor Kurt Niquidet. “His contributions to COFI’s work have been outstanding.”

Forestry superintendent, CCR, Williams Lake, B.C. Daniel, 33, has made a significant impact on forest rehabilitation projects in the traditional territories of the Tŝideldel First Nation and other parts of B.C. Since joining Central Chilcotin Rehabilitation (CCR) just over a year ago, he has played a key role in leading forest planning activities and overseeing crucial projects like the restoration of wildfire- and mountain pine beetledevastated forests through the 2 Billion Trees project.

Daniel’s journey in forestry began when he was 14, planting trees in northern Sweden. “This experience sparked my interest in forestry, which has motivated both my education and career choices,” he says. He later earned a master of science in forestry from the Swedish University of Agricultural Sciences and brought his innovative techniques to CCR.

Daniel is passionate about reshaping public perceptions of forestry. “I wish the public saw forestry more as a solution to climate change, conservation, and wildfire mitigation rather than something negative,” he explains. He believes this shift could attract more young people to the industry.

“Daniel’s leadership, cultural awareness, and dedication to forest management have been invaluable to our team,” says Percy Guichon, director of CCR.

CFO, Taylor Lumber, Middle Musquodoboit, N.S.

Jocelyn brings nearly 20 years of experience to Taylor Lumber, a fifth-generation family business and zero-waste facility. Beginning her career in silviculture, Jocelyn has risen to the role of chief financial officer, showcasing her adaptability and leadership across both operational and financial aspects of the company.

“I started in the forest industry doing silviculture work for a summer job, and it progressed from there,” recalls the 39-yearold. With a bachelor of commerce in finance from Dalhousie University, Jocelyn has also earned certifications in scaling, watercourse alteration, and workplace safety, making her a key player in Taylor Lumber’s success.

Jocelyn’s leadership extends beyond the family business. She is the first female director and chair of the Maritime Lumber Bureau, current president of Forest Nova Scotia, and a pivotal figure in the Forestry Sector Council. She also dedicates her time to mentoring young professionals, especially women, encouraging them to explore the wide range of roles available in the forestry sector. “There are jobs across the entire supply chain, not just in the woods,” she emphasizes.

“Jocelyn’s work ethic and commitment to the industry are unmatched,” says Forestry Sector Council executive director Heather Boyd.

CRAIG GALLOWAY

Project lead, Gorman Bros. Lumber, West Kelowna, B.C. At 38, Craig has quickly risen through the ranks at Gorman Bros. Lumber. After joining in 2016, his background in drilling optimization helped him take on key roles in improving the company’s production processes, including implementing AIdriven technologies to enhance value recovery. His commitment extended beyond the mill when he led the development of the Gorman Family Vineyard, praised as one of the best in the Okanagan Valley.

Craig’s journey into forestry began after he left a career in the oil field to spend more time with his family. “I was fortunate to join Gorman Bros. as several optimization projects were underway,” he says.

He believes education is key to attracting young talent. “The investment in AI and data creates a greater need for talented people in a resource sector crucial for our economy and communities.”

“Craig’s passion and dedication make him an invaluable part of our team,” says manager Will Verner.

JUSTIN LEVINSKY

Owner/operator, West of the 5th Sawmill, Bluffton, Alta. Justin is living his dream of owning and operating his own sawmill. Over the past three years, the 39-year-old has dedicated himself to building West of the 5th Sawmill from the ground up, working long hours to ensure the business provides top-quality products at fair prices. His commitment to his customers and community has earned him a reputation for being reliable and always willing to collaborate on new projects and ideas.

Justin’s passion for the sawmill industry is matched only by his dedication to his family and community. “He puts his whole heart into his business while always making time for his family,” says his wife Brittany.

With a focus on innovation and quality, Justin continues to push the sawmill toward success, showing perseverance and leadership in every aspect of his work.

Forestry technician, LFV, Mount Currie, B.C.

At 32, Hayden has spent 11 years with Líl̓wat Forestry Ventures (LFV), rising from a firefighting crew member to a key leader in the company. His journey began with little knowledge of forestry, but he quickly advanced by completing a silviculture survey accreditation and earning a diploma in forestry from BCIT. He is currently working toward becoming a registered professional forester while continuing his education at the University of Northern British Columbia.

Hayden’s leadership and innovation have been instrumental in LFV’s success. Most notably, he played a vital role in the Q̓welq̓welústen/Mount Meager Landslide Restoration project, which focused on reducing flood risks and enhancing natural colonization. The project earned LFV recognition as a finalist in the 2024 B.C. Land Awards.

“Hayden’s dedication and passion for sustainable forestry, combined with his commitment to his community, make him an inspiring leader,” says supervisor Klay Tindall.

WILLIAM EVERITT

VP, Princeton Wood Preservers, Princeton, B.C.

The 36-year-old William, or Bill to colleagues and friends, has demonstrated dynamic leadership as VP of Princeton Wood Preservers (PWP), a family-owned business he’s been involved with for most of his life. From starting as a young worker painting fences to becoming co-owner and VP in 2021, he has guided the company toward growth and innovation, focusing on sustainability and cutting-edge technologies in wood preservation.

“The forest industry is in my DNA,” Bill shares. “I’ve worked at PWP in various roles since I was 13, and after finishing my education, I returned to take over sales and eventually became

general manager.”

Bill believes the industry needs to engage young people by showing its potential as a force for good. “We need smart, technical people from diverse backgrounds to help the industry pivot toward a future-focus,” he explains. He also advocates for attracting more women to the sector, recognizing their vital contributions at all levels.

“Bill’s leadership and commitment to sustainability have made a significant impact on both PWP and the industry,” says Wood Preservation Canada executive director Natalie Tarini.

Gorman Bros. Lumber is proud to congratulate for being named one of CFI’s Top 10 Under 40 in 2024!

We are honoured to have you on our team!

A legacy of leadership. A future of opportunities.

For 100 years, we’ve led the way in transforming the wood processing industry and now, we’re taking the next step forward as Comact. Our new identity reflects our unwavering commitment to performance, innovation, and excellence—values that have driven us for a century and will guide us for the next hundred years.

Our sector is experiencing a period of rapid transformation. And Comact is proactively shaping the future of sawmilling with cutting-edge technologies and greater use of artificial intelligence. What’s more: our stellar customer support will continue to help you optimize your operations.

We’re the same leading OEM partner—but we’re evolving to power your future.

NAUMAN HAFEEZ

CEO, co-founder, NetNow, Toronto, Ont.

Nauman, 32, has made a significant impact on the lumber and forestry industries through his technology company, NetNow. Over the past four years, he has led the company in developing digital

solutions that help lumber yards and forestry wholesalers manage credit and collections, saving them significant costs. Under his leadership, NetNow has grown rapidly, earning recognition such as the Most Customer Obsessed Company award from Intuit.

Nauman and his co-founders entered the forestry industry after realizing that many businesses were still using outdated methods to manage credit accounts. “We saw how much inefficiency there was, leading to high costs, fraud, and late payments,” he explains.

To attract young talent, Nauman believes in offering dynamic roles with leadership and autonomy. “Young people want to make a meaningful impact. Empowering them to embrace new technologies and streamline operations is key,” he says.

“Nauman has positioned NetNow as a major player in the technology space for lumber yards and forestry wholesalers,” says his colleague Soroush Arghavan.

“His innovative approach has transformed the way many Canadian lumber suppliers and distributors operate,” adds friend Eli Costea.

COO, Conception RP, Quebec, Que. At 28, Camille Tremblay has quickly established herself as a leader in the woodworking industry. As chief operating officer of Conception RP, Camille has brought a fresh perspective and innovative strategies to optimize operations, significantly improving the company’s efficiency and effectiveness. Her ability to anticipate market demands and implement cutting-edge solutions has positioned the company as an industry leader.

Camille is also a passionate advocate for diversity and inclusion, fostering a supportive work environment that encourages more women to enter woodworking and manufacturing fields. Her leadership style focuses on empowering her team, ensuring they have the tools and support needed to excel in their roles.

“Camille’s innovative mindset and commitment to excellence have revitalized our operations and created a motivated workforce ready to tackle modern industry challenges,” says colleague Isabelle Tremblay.

Manager, forestry, City of Mississauga, Ont. Amory has built a career championing urban forest management across North America’s largest cities. Starting as a forestry intern with the New York City Department of Parks and Recreation, he discovered his passion for urban forestry. Now, at 33, he leads forestry operations in Mississauga, where he has achieved FSC certification for the city’s woodlands and implemented innovative forest management practices.

“I loved the idea of being a forester in a city,” he says, reflecting on his career path. His work has taken him to key roles in Toronto and York Region, where he developed groundbreaking forestry strategies.

To encourage young people to join the industry, Amory believes in breaking stereotypes. “There’s a lot of myths about who we are and what we do. While I do wear plaid from time to time, I work for big cities, which isn’t what people typically think of when they hear ‘forest industry.’”

“Amory’s leadership has transformed urban forestry practices, making him a true leader in the field,” says colleague Alex Martin.

Owner, Mazereeuw Timber Ltd., Vanderhoof, B.C.

Lane, 27, is making waves in the forestry industry with his innovative approach to logging. After starting Mazereeuw Timber in 2022, he has brought newer technology to the area, using equipment that leaves a smaller environmental footprint while maintaining efficiency. Despite the challenges posed by the current downturn

Allied brings 49 years experience to help you meet current NFPA Standards with: system design/documentation, spark detection, isolation, grounding, PLC, venting, blast path management, clean-up systems and duct audits — CWB certified and member SMACNA.

Driven by passion and the idea of bringing about a positive change in forest management practices, Daniel Persson joined our team over a year ago and has made an incredible impact on our operations. He has facilitated large-scale forest rehabilitation projects throughout our traditional territories and other parts of the province.

Our entire team at Central Chilcotin Rehabilitation Ltd. extend our congratulations to our Forestry Superintendent, Daniel Persson.

in the industry, Lane has faced them head-on, showing remarkable resilience and leadership.

“I got started in the forest industry pretty young,” Lane shares. “My dad worked in the bush most of his life, and I was always around, learning the ropes.” After becoming a heavy-duty mechanic and working with logging equipment, he took the leap into running his own company.

Lane believes education is key to keeping younger generations engaged in forestry. “As a logging company owner now, I see the importance of showing what we do in the forest and taking on more sustainable practices, which seems to be more appealing to the younger generation.”

“Lane’s passion, work ethic, and commitment to sustainability make him a standout leader,” says his mother, Barb. His wife, Hannah, adds, “I’m excited to see what kind of legacy Lane can create for the generation to come.”

General manager, La Maison Verte, Hearst, Ont.

As general manager of La Maison Verte, Mireille, 29, has shown leadership and innovation in the tree nursery business, playing a vital role in supplying trees for Ontario’s forests. Her journey into the forestry industry began as an assistant to the GM, where she

quickly developed a passion for growing trees and contributing to the local environment.

“I was captivated by the process of growing trees and the role it plays in both our environment and local economy,” she says, reflecting on her start in the industry. Since then, Mireille has risen to lead the team with a focus on providing high-quality trees while navigating financial challenges with creativity and resilience.

To keep young people engaged in the industry, Mireille believes in emphasizing the positive impact of forestry on the environment. “Many young people are motivated by work that contributes to a greater cause, like sustainability and combating climate change,” she explains.

“Mireille’s passion and commitment to both her team and her work make her an inspiring leader,” says colleague Stefany Lozier.

JORDEN ILNICKI

Owner, Jordco Enterprises, Williams Lake, B.C. Jorden has spent his life immersed in the forest industry. Growing up in a logging family, the 30-year-old’s passion for the work started early. “From as young as four years old, I would go out to the bush on weekends to help my dad with

whatever I could,” he recalls. At just 18, he purchased his first piece of equipment and began subcontracting, eventually growing Jordco Enterprises into a successful logging business with over 20 machines, 8 logging trucks, and more than 30 employees.

Despite the challenges of the industry downturn in Williams Lake, Jorden expanded his operations into Alberta, demonstrating resilience and dedication to his employees. He is also committed to supporting his hometown and local First Nations communities through partnerships and small business ventures.

To attract young people to the industry, Jorden believes in showing the rewards of hard work. “It’s a great industry to be a part of, and there’s always room for advancement if you’re willing to endure the sacrifices,” he says.

“Jorden represents our industry and his community with passion and professionalism,” says Interior Logging Association’s general manager Todd Chamberlain.

JEAN-FRANÇOIS MARTEL

Director, energy division, Groupe Savoie, St-Quentin, N.B.

Jean-François, 33, has steadily climbed the ranks at Groupe Savoie, starting as

a salesman at just 23 and now serving as director of the energy division. With bachelor’s degrees in finance and accounting, he began his career in the forest industry with a drive to bring innovation to the company. One of his first initiatives was renaming the division “energy,” expanding its vision to include new projects like creating energy from bark by-products.

“I was looking to come back to my hometown of Saint-Quentin and applied for a senior salesman role at Groupe Savoie,” he says. “Even though I had no experience, I got the job and have worked my way up since.”

Jean-François believes the forest industry offers diverse opportunities. “I would encourage people who love different challenges to join the forest industry. It’s always evolving and needs people from all backgrounds.”

“Jean-François’ leadership and vision have brought innovation to the energy division, making him an invaluable part of the company,” says colleague Jason Somers.

BY JENNIFER ELLSON

Mercer Mass Timber (MMT) is shaking up the North American construction scene with its innovative approach to sustainable building. With cutting-edge facilities in Okanagan Falls, B.C., Spokane, Wash., and Conway, Ark., the company is setting new standards for mass timber production.

It’s not just about expanding operations, senior vice-president Brian Merwin tells CFI It’s also about enhancing MMT’s commitment to sustainable and innovative construction practices and focus on modernization that has pushed MMT to the forefront of the mass timber industry.

In 2021, Mercer International ventured into the mass timber industry with just eight employees

in Spokane, Wash. The company’s modest beginnings didn’t hold it back.

“We built a center of excellence for engineering and design in B.C., prior to acquiring Structurlam,” says Merwin.

Structurlam, a mass timber company, was a key acquisition for MMT in 2023, providing them with additional facilities and expertise. “Structurlam’s HQ was in B.C. too, so we were able to marry their design team with our engineering group,” Merwin explains, which helped the company scale quickly.

This acquisition expanded MMT’s production capacity to an impressive 255,000 cubic metres of cross-laminated timber (CLT) and gluelaminated timber (glulam) annually. “We’re still hiring, we’re growing!” Merwin says, noting that MMT now employs 289 full-time employees

across North America, with 131 based in Canada.

The Okanagan Falls facility was particularly significant for MMT’s expansion plans. When Mercer acquired it, the plant was insolvent.

“We refocused the operations and brought back all the employees who had been laid off. Now, we’re hiring even more.” This move has revitalized the local economy and solidified MMT’s commitment to sustainable manufacturing.

The acquisition was part of a broader vision to increase MMT’s foothold in the mass timber market. “The provincial government’s support gave us confidence to retool Okanagan Falls,” Merwin notes. The retooling project is well underway, with the goal of completing it by 2025.

One of MMT’s key modernization projects is the ongoing retooling of the Okanagan Falls facility. With the help of a $7 million grant from the BC Manufacturing Jobs Fund, the company is installing advanced manufacturing equipment that will boost efficiency and increase glulam production capacity by 25 per cent.

“Some equipment has already arrived

and been installed, like the Hundegger Robot-Max for finishing glulam beams,” Merwin shared. This cutting-edge machine, which cost several million dollars, is central to MMT’s strategy of using value-added lumber to meet the growing demand for sustainable building materials. The entire retooling project, which began in April 2024, is expected to be completed in 2025, further solidifying MMT’s capacity to lead in the mass timber sector.

Merwin sees this investment as a pivotal moment for MMT: “We are retooling to make use of value-added lumber, which is a pretty important aspect of our business plan.” With B.C. still producing a significant amount of lumber, MMT is strategically positioned to make the most of its resources while providing high-quality timber products across North America.

Sustainability is at the core of MMT’s operations. The company sources its wood from certified forests in Canada and the U.S., utilizing species such as Spruce-Pine-Fir (SPF), Douglas FirLarch, Southern Yellow Pine, and Alaska Yellow Cedar. This approach not only ensures the durability and quality of

their products but also reduces their carbon footprint.

MMT’s flagship projects reflect this commitment. Their work on Google Borregas, a five-story office building in Sunnyvale, Calif., showcases how mass timber can revolutionize commercial construction. The building, which uses 3,100 cubic metres of CLT and 2,000 cubic metres of glulam, is a prime example of sustainable design.

“Google Borregas achieved LEED Platinum certification, aligning perfectly with their sustainability goals for carbon-free operations by 2030,” Merwin explains. The project’s biophilic design integrates natural materials, daylight, and organic textures, creating a healthy and environmentally friendly work environment.

Another notable project is the Theodore Roosevelt Presidential Library in Medora, N.D. MMT is supplying nearly 1,800 cubic metres of CLT and glulam for the construction of this 93,000-square-foot museum. The library is targeting LEED Platinum and Living Building Challenge certifications, demonstrating how mass timber can contribute to ambitious sustainability goals.

“Public congregation buildings like

this help educate people about the use of mass timber,” Merwin says, referencing the positive perception of timber in public spaces.

Mass timber is on the rise, not just in Canada but also in the U.S.

“The U.S. market is looking to grow, following the European growth rate,” Merwin observes. Europe is about 10 years ahead of North America in terms of mass timber adoption, he explains, but the progression is happening similarly on this side of the Atlantic.

The Canadian market, bolstered by initiatives like the Green Buildings Strategy, is poised to take the lead. “We are going to see Canada at the forefront of mass timber policies and building codes,” Merwin predicts, citing examples like Ontario, where the building code allows for mass timber structures up to 18 storeys.

practices. Similarly, in California, forward-thinking policies are helping mass timber gain traction in public and private projects.

a full suite of options – from just supplying materials to offering design assistance and installation services.” Mass timber pairs well with steel, Merwin adds, and MMT offers solutions for hybrid buildings, combining the benefits of both materials. “We are one of the few companies that can provide these options.”

With its strategic expansions, innovative retooling projects, and a strong commitment to sustainability, MMT is wellpositioned to lead the mass timber revolution in North America, says Merwin. By integrating advanced technology, offering flexible solutions, and tapping into both Canadian and U.S. markets, as well as Asian markets in the future, MMT is setting new standards for the construction industry, he adds.

of North American construction. This is the future of construction – innovative, responsible, and built upon the

BY FRANCIS CLÉMENT

Over the past 10 years, we’ve seen that artificial intelligence (AI) is more than just a buzzword. It is about to revolutionize all fields of our society.

From image recognition to visual art creation and from text and speech analysis to content generation, the AI is advancing at a breakneck pace. The sawmilling industry is no exception – 20 years ago, automation and optimization of the most complex tasks in the woodworking process were rare or non-existent. Then came the automated graders. It was a huge step forward in performance. Today, we’re on the verge of another industrial revolution: that of AI. It is now possible to envision the factory of the future.

The sawmill of the future will be a fully integrated and connected site, where human intervention will be increasingly rare. Processes will be controlled on a global scale thanks to AI, instead of acting locally without knowing the global impact of a change along

the production chain. We are not that far from that ideal factory. Comact has already assembled many key components with its digital platform, AI-powered optimization, and Smart Tools for quality control. More recently, the introduction of Smart Vision applications has elevated production flow management to a level of intelligence that surpasses both traditional photocells and human oversight.

The Smart Vision systems are engineered to monitor and interact with plant operations, offering advanced capabilities for regulating and optimizing processes such as log infeed and deck management. These systems can detect anomalies and halt the line promptly

ABOVE: Intelligent monitoring systems are constantly striving to maintain or even improve production rates, while ensuring that no employee is put at risk by any production anomaly. Photos: BID Group.

to prevent issues, as well as enhance worker safety by monitoring environmental conditions. Each module is designed for simplicity and minimal maintenance, featuring a high-resolution camera and a rugged enclosure connected to artificial intelligence engine.

The first type of application is transverse production line monitoring for sawmill and planer mills. It can detect skewed boards, double or short boards, as well as jammed trim blocks and stop the line before a major blockage occurs. It reduces considerably false positives and misfires made by traditional photocells sensors. The system also ensures correct board loading at the lug loader and validates the size of each input package at the planer mill infeed, preventing production interruptions caused by packages of incorrect dimensions being sent to the tilt hoist.

On top of that, the Smart Vision can be used to act on the line flow. We’re talking about adjusting stem position at the merchandiser, monitoring and filling management for log or trim block decks, and log singulation. At the merchandiser, it guarantees that the stems will be cut correctly, thus avoiding the problem of excessively

short and long logs. The next areas where it intervenes are the log decks, ensuring that the fill rate optimizes the line flow. This task is neither easy nor interesting for a human being but can quickly cause productivity losses if not managed properly. Moving on to the next stage, the Smart Vision can optimize log feeding and gap control at the Wave Feeder for instance. This helps to maintain a superior pace while avoiding blockages or safety problems.

Finally, as a tireless eye on the production, such monitoring devices can greatly improve environmental security for workers. Defining safety zones, for instance, will make sure that the line stops if a board or log enters an area where workers can stand or pass. A log getting out of the step feeder and falling on the catwalk, or a board thrown out of the trimmer have been seen in the past in several places. Of course, these systems cannot replace good practices and security programs, however, they should be seen as complementary barriers to prevent serious threat to employee well-being.

As we can see from these applications, intelligent monitoring systems are constantly striving to maintain or even improve

Systems can detect anomalies and halt the line promptly to prevent issues, as well as enhance worker safety by monitoring environmental conditions. production rates, while ensuring that no employee is put at risk by any production anomaly. Among other benefits, they will help attract and retain younger employees in addition to reduce the total number of people required in a context of labor shortages. Moreover, they will strengthen the mill management team’s decision making. Finally, they will reduce downtime due to lock-out periods, improve efficiency, cut labor costs and prevent equipment breakages in some cases.

In a nutshell, the industry is on the brink of a new revolution. Improved efficiency and autonomous production are the key words here. With intelligent systems such as the Smart Vision applications,

the company has taken a step towards the mill of the future and asserted its leadership position. In-house developed, lumber oriented AI engine has been Comact’s success story over the last few years. Looking forward, there is a bright future ahead for the whole industry especially after the labor shortages of recent years.

Francis Clément has been with Comact’s R&D department for 23 years. He played a key role in the development of the technologies behind the GradExpert, automated grading system and its derivatives. Specialized in computer vision, Francis holds a degree in engineering physics from Laval University.

Hurst biomass systems lead the alternative energy boiler market with innovative solid-fuel-combustion design

Hurst is a custom manufacturer of engineered packaged steam and hot water boilers and integrated boiler systems, renewable fuel fired gasification/ combustion/heat recovery systems, biomass & hybrid boiler systems, CHP/ co-generation systems, PLC-integrated boiler controls, parts & boiler room accessories. Fire-tube, water-tube & feedwater equipment for all industrial heating & process applications. Low NOx modular boilers & burners available.

Hurst Biomass Systems lead the alternative energy boiler market with innovative solid-fuel-combustion design.

Complete modular construction for easy low cost installation.

Hurst has specialized in custom design of biomass steam plants and cogeneration systems since 1967.

Offering integration and scalability, the new, high efficiency Integrated Control Systems from Hurst Boiler for boiler room monitoring and communications provide advanced supervisory boiler controls for all new and legacy Hurst products.

PAULsmith

Paul Smith is a saw filing consultant and founder of Smith Sawmill Service, now part of BID Group. You can reach him at paul.smith@bidgroup.ca.

Today’s saw filing rooms are starting to integrate equipment and software with limited artificial intelligence (AI). Some have even fully embraced machine learning and robotics. In my area, however, most mills are relying on what I like to call “Head Saw Filer Intelligence” (HSFI – the vast knowledge base that will shape future AI systems. The issue with HSFIs is that there simply aren’t enough skilled professionals to meet the demand. As this shortage grows, filing rooms will increasingly turn to AI-powered machines to fill the gap. AI has many potential applications beyond the filing room, and it’s only a matter of time before we see significant advancements across our industry. When I first began my career in sawmilling years ago, there was no shortage of labor, and plenty of people I considered career sawmillers – sawyers, millwrights, and saw filers – were readily available. Back then, many employees were eager to learn new skills and move between roles within the mill, increasing their value to the mill owner. Saw filers, in particular, often learned their craft from a family member.

Occasionally, someone with a natural interest would catch the attention of a head filer, who would then invest time in training them, despite the lack of formal “saw filing schools.” This is where AI, in my view, could play a pivotal role in the future of our profession. By capturing the expertise of these seasoned head filers, millwrights, and sawyers, we could create programs that not only retain their knowledge but also develop more efficient ways to build and maintain saws and cutting tools.

It’s fun for us older guys to reminisce, but to keep the industry moving forward, we need to apply the lessons we’ve learned to invest in its future. When it comes to AI, it’s important to remember that the goal is not to replace the human workforce. Nor do we want technology that ties up a mill with expensive, hard-to-find equipment that only a handful of people

can service. Like any new advancement, adopting AI requires careful planning. Can the AI system be bypassed if there’s an issue, or will it shut down the entire production line? Are the CPUs, GPUs, TPUs, and other parts readily available? How easy is it to find qualified service technicians? In the past decade, we’ve seen constant innovations in technology and how lumber is manufactured – these rapid changes are making some hesitant to invest in newer AI equipment. Much like smartphones that are upgraded every six months to a year, how long will this new technology be supported? The COVID crisis, if it taught us anything, showed us how the inability to source parts and services can grind an entire industry to a halt.

Manufacturers of saw sharpeners have done a commendable job incorporating both robotics and machine learning into their equipment. Now comes the question of AI. I like to imagine an AI assistant –one that can monitor every step in saw repair.

From my experience working with saw filers, I’ve noticed a recurring issue where critical steps in the process are either rushed or overlooked entirely. An AI assistant, programmed with the head saw filer’s knowledge, could help address this. The apprentice saw filer would be guided by the AI through each stage of saw repair, with the assistant walking them through the steps and answering questions along the way. Questions could range from “What’s the hook angle on the #1 edger saw?” to “When should I change the grinding wheel?” The head saw filer would then be able to monitor the apprentice’s progress and evaluate how well they performed their tasks. As head saw filers or corporate filers move between mills within the same company, they could update and fine-tune the AI’s knowledge base. I think I saw something like this on an episode of The Jetsons – for those reminiscing about your filing days! And for you younger filers, you can catch it on YouTube.

It’s not an offer. It’s a promise. That you can count on us to deliver the equipment you need when you need it with flexible payment options and world-class support. We offer creative solutions that allow you to manage cash flow effectively while meeting the rigorous demands of your operation. Whatever you need to succeed, we deliver. Time

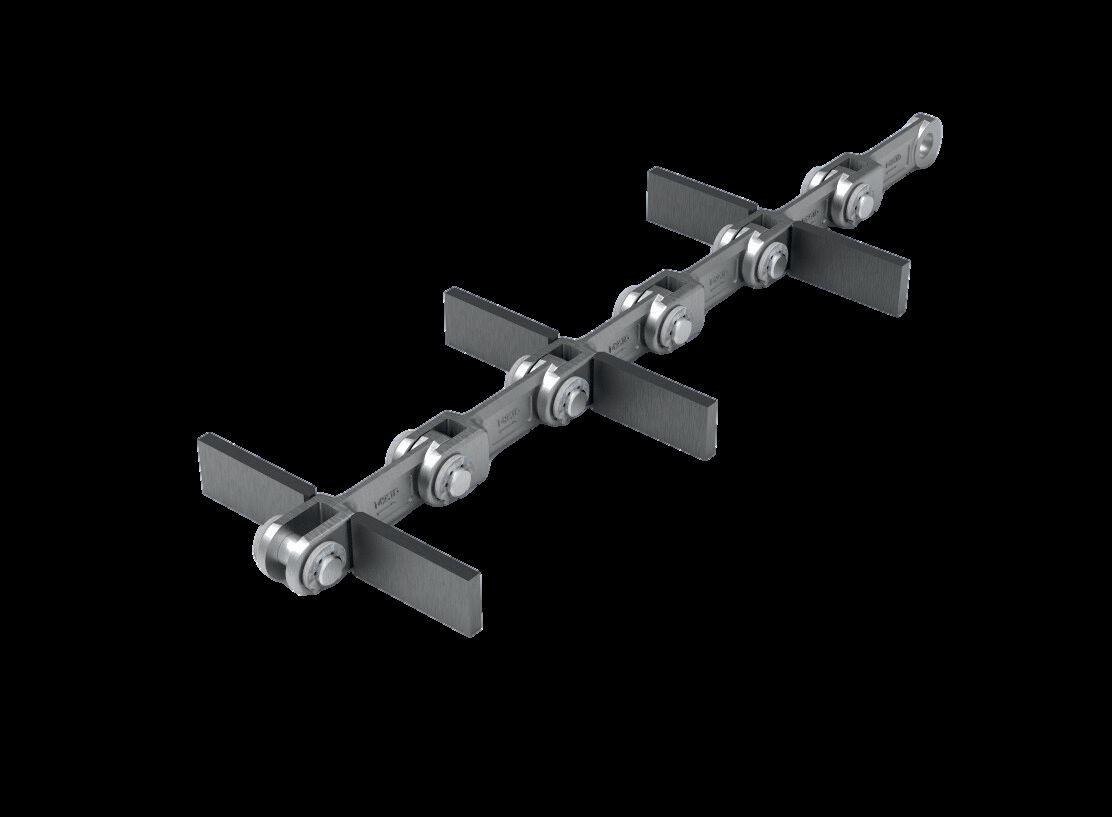

BY THOMAS LEE

Winter weather can create challenges for forestry equipment. That includes log loaders and road builders. These machines need special care during harsh conditions.

Here are five tips to help make sure your equipment runs smoothly this winter.

Use your owner’s manual as a guide to perform pre-operation inspections. When examining log loader and road builder undercarriages, look for signs of damage. Inspect for loose components on the machine’s tracks, rollers, idlers and sprockets. Adjust the track tension and lubricate as needed.

Failing to maintain your machine’s undercarriage

can lead to premature component wear. It may also cause unplanned machine downtime.

Use the proper engine oil during cold winter months. When the temperatures drop, oil can get dense. It may have a hard time at start-up circulating through the system without proper lubrication. Avoid using oil that is too thin. If the oil is too thin, it won’t stick to the components.

It’s always a good idea to confirm the quality of your diesel engine fuel. In winter, use high-quality winter-grade fuel. Consider cold-weather additives. Inspect your machine’s fuel filters and replace them as needed.

ABOVE: Logging equipment needs special care during harsh winter conditions. Fall is a good time to check the overall health of your diesel engine. Photo: DEVELON.

For more than 20 years, Lico Machinery Inc. has stood out for the quality of its equipment, its adapted solutions, as well as its unique and unbeatable service. Lico specializes in the design and manufacture of sawmill and flooring equipment ranging from standalone machines to complete solutions. No compromise is made on the quality of the equipment, from design to installation, because we know that in a world where profitability depends on productivity, only quality performs.

Fall is a good time to check the overall health of your diesel engine. It’s a good idea to make sure it’s in good working condition before temperatures start to drop. Contact your local dealer’s service department if you have any concerns about the engine.

It’s also a good idea to check your machine’s battery and wires. You want to make sure they haven’t frozen and aren’t stressed due to very cold temperatures. This may depend on where you’re operating in North America. Don’t forget that there is always a draw on the battery. It should be fully charged after use unless it has been maintained or disconnected.

Consider using a trickle charger to help build the voltage at a lower rate. This can improve the battery life. Maintain the battery terminals by cleaning the connections. A battery blanket or insulation can also help keep the battery warm when your equipment is not in use. Again, this will depend on where your machines are working and the temperatures at night.

Warm up the engine before starting work with a block heater. These are available as an option on most forestry equipment. Run the engine for five to 10 minutes to prepare the equipment and essential components for work.

Operator comfort and safety are essential for maintaining productivity and minimizing accidents. Here are some helpful reminders when working during winter.

• Wear warm winter clothing and PPE.

• Consider adding insulation to the cabin to enhance operator comfort.

• Keep the cab warm and enhance visibility by maintaining cabin heaters and windshield defrosters.

• Remove snow and ice from the cabin windows, mirrors and lights.

• Clear snow and ice from the steps leading into the cab.

Examine attachments for wear and tear, bent components or any signs of damage. Repair or replace any damaged parts. Clean each attachment, removing dirt, debris and rust. Make sure all moving parts are well-lubricated. Grease joints, hinges and pins to prevent freezing and reduce friction.

Consider applying protective coatings to metal surfaces to prevent rust and corrosion. Check for leaks, ensure that hydraulic lines are well insulated and maintain appropriate fluid levels. Cold temperatures can affect hydraulic performance, so consider using low-temperature hydraulic fluids.

Keep a stock of spare parts and maintenance kits specific to your attachments. Store attachments in a dry, sheltered area when not in use. Train operators on the proper use and care of winterized attachments.

Follow these recommendations to maintain your logging equipment this winter and minimize machine downtime.

Thomas Lee is a product strategy manager at DEVELON. With over 13 years of experience in the heavy equipment industry, Thomas brings a wealth of knowledge to his role.

Log Max Forestry Inc., based out of Moncton, New Brunswick are pleased to announce that they have entered into an exclusive Canadian distributorship agreement with Plantma AB, the Swedish manufacturer of the PlantMax X2 planting machine.

The PlantMax X2 unit is typically mounted on a forwarder chassis, 14 ton size class or larger and incorporates a mid-mounted MidiFlex scarifier. Site preparation, soil compaction and seedling planting is completed in one pass! As a bonus, in the planting off-season the carrier can be converted back to a full-time forwarder within 3-5 days.

The PlantMax X2 is performs whether rain or shine, day or night with data collection recorded throughout the process.

For more information on how the PlantMax X2 unit can assist you in your silviculture needs, contact your Log Max Forestry Inc. rep at 506-869-2325 or visit plantmaforestry.com

BY LAUREN COOPER

With recent headlines, it’s not as often one hears the words good and fire used together in a sentence. Indeed, communities across North America are grappling with more frequent and destructive wildfires. It can be difficult to see through the smoke and understand that sometimes fire can be beneficial. Fire presents both challenges and opportunities across American and Canadian forests.

In the southeastern U.S., controlled burns are

essential for regenerating longleaf pine forests, now endangered due to fire suppression. In contrast, the boreal forests of Canada naturally experience intense wildfires that are becoming increasingly unpredictable due to climate change. While these fires pose significant risks, strategic sustainable forest management, including prescribed burns and fuel reduction, can mitigate threats and promote resilient landscapes. We must be open to fire as a forest manage -

ment practice. Forest fire can have a spectrum of impacts—from being catastrophic and damaging to being a beneficial disturbance that can encourage healthy forests and resilience.

The SFI Forest Management Standard emphasizes fire resiliency and includes limiting the susceptibility of lands owned or managed by certified organizations to the unwanted impacts of fire.

Longleaf is a rather remarkable pine tree: it can live for hundreds of years. The tree has uses as utility poles and to produce lumber. Its needles, which can grow as long as your forearm, are useful too; some Indigenous communities, including the Alabama-Coushatta Tribe in Texas, weave the needles into baskets, and garden -

ers prize longleaf pine needles as an attractive mulch for erosion control and to block weeds.

Forests of longleaf pine, a southern yellow pine tree, once stretched across 90 million acres of the U.S. southeast, from Virginia to Florida and out to the piney woods of Texas. Today, the longleaf pine is an endangered species. Longleaf pine forests shrunk to just three million acres and have since made a modest comeback, now covering five million acres. The main reason for this pine’s disappearance: the suppression for more than a century of fire from the landscape. This species requires fire to grow, which creates optimal conditions for germination. The thick bark on older trees prevents them from burning.

“This is truly a forest that fire made,” Carol Denhof, president of the Alabama-based Longleaf Alliance, told the attendees at the Sustain -

Wildfires engulfed forests across Canada in 2023, torching a record 17 million hectares, an area larger than Greece, and forced mass evacuations.

able Forestry Initiative annual conference in Atlanta this summer. “It will not exist without the use of fire in the system. We preach the word of good fire.”

The controlled use of fire to promote longleaf pine has many benefits. The bobwhite quail, gopher tortoise, eastern indigo snake, red-cockaded woodpecker, gopher frog and reticulated flatwoods salamander are just some of the species that thrive in a longleaf pine forest. To expand the habitat of these species, it is not enough to just plant longleaf pine trees, according to Denhof.

“Without fire, those longleaf stands that have been freshly planted will eventually become something else,” Denhof said. “They will not be longleaf for very long. We work a lot with private landowners, and many of them don’t have resources or knowledge or capability to implement fire on their lands.”

The Alliance helps landowners bring fire into their forests to regenerate longleaf pine and has even created a mascot: a bobwhite quail named Burner Bob, who travels to communities with an oversized blowtorch to espouse the uses of fire as a forest management tool.

Forest fires are also a way of life in another forest ecosystem: the vast boreal forests that stretch across Canada. Intense fires that ascend from the ground and spread to the canopy are a natural disturbance regime, and suppression efforts will never eliminate fire from this forest, according to Jen Beverly, associate professor of wildland fire at the University of Alberta.

“It’s amazing. It’s a spectacle,” shared Beverly, who earlier in her career served on a helitack crew, a team of firefighters transported by helicopter to wildfires. “I saw lots of this fire, and it’s really quite phenomenal … until it impacts something that you care about.”

Wildfires engulfed forests across Canada in 2023, torching a record 17 million hectares, an area larger than Greece, and forced mass evacuations. This amount of area burned, many times the annual average, underlined one lesson for Beverly: it is now impossible to predict when a fire will occur. “We can no longer rely on the past to prepare for the future,” she said. However, her team does have suggestions on how to cope with wildfire.

Sawmill, Planer Mill & Rolling Stock

Day 1: 10AM MST | Oct. 30 - Nov. 6

Day 2: 10AM MST | Oct. 31 - Nov. 7

Day 3: 10AM MST | Nov. 1 - Nov. 8

By studying fuel – trees and other things that can burn – her team is able to map the threat from fire. Once communities know what local pathways could spread wildfire, residents can take steps to “harden” their properties, so they are less likely to burn, Beverly said.

Beverly’s research offers some glimmers of hope. For one, fires since 2010 have reduced fuels, lowering the threat of catastrophic fire in some forests.