A PARTNERSHIP ROOTED IN YOUR SUCCESS.

At SMS Equipment, we’re more than machines from trusted brands like TimberPro, we’re the people beside you—today and every day—bringing industry-leading technology and expertise to your job site.

Because the right partnership makes everything possible.

S:9.625"

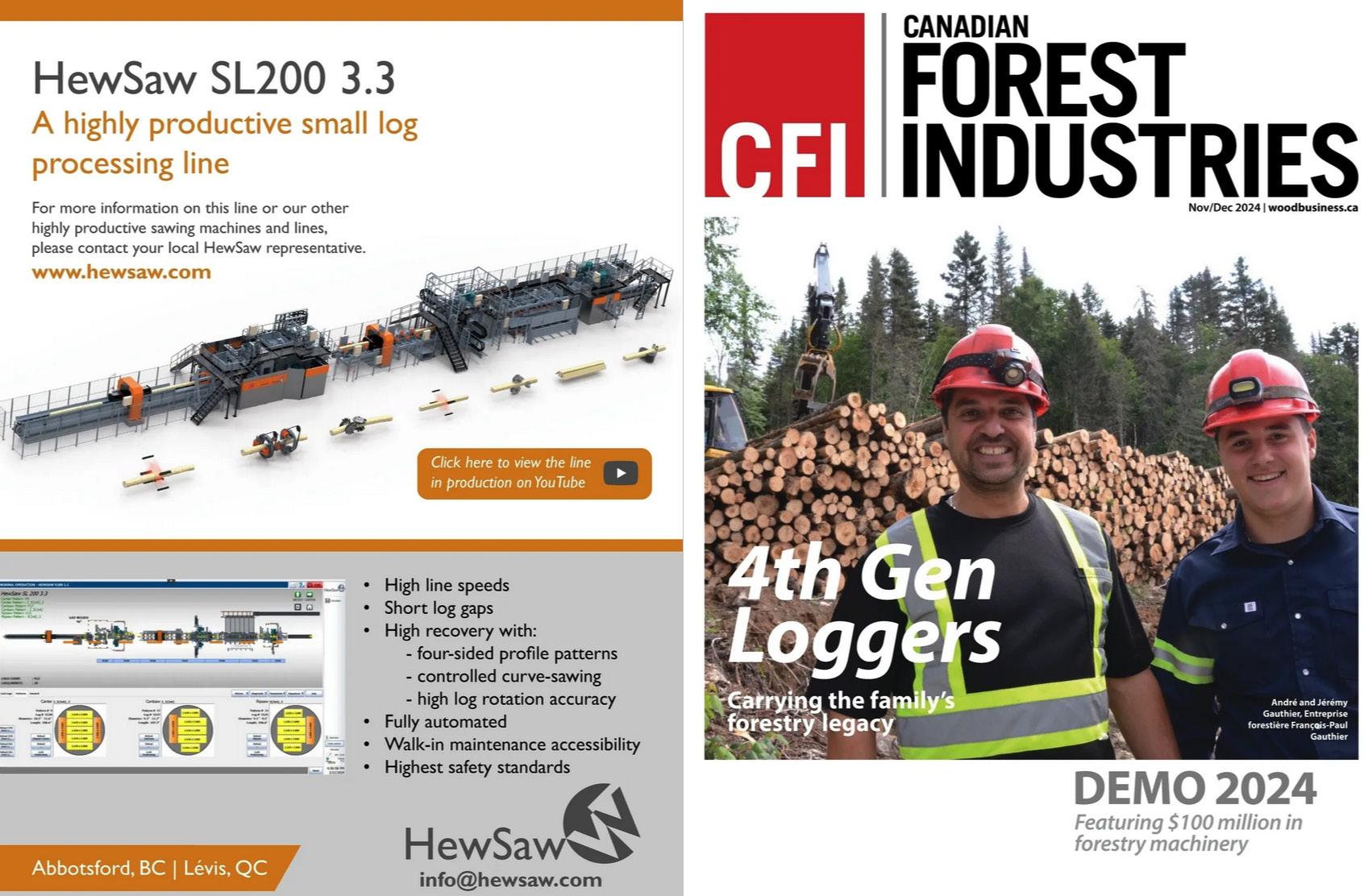

QUALITY DRAG C HAIN ENSURES A QUALITY MILL

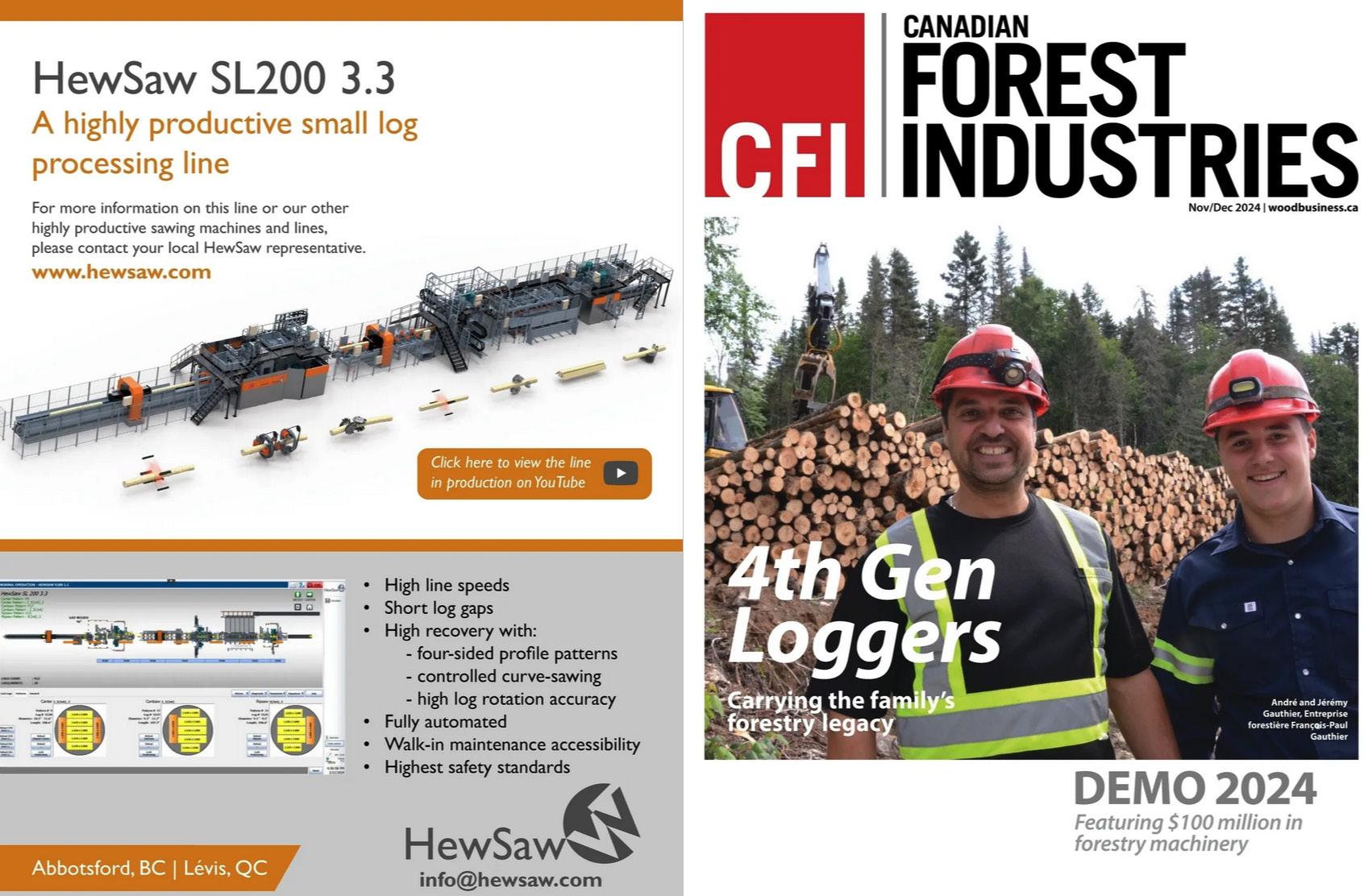

Training the 4th generation of foresters

Laying the groundwork at the Entreprise forestière François-Paul Gauthier

Small town, big impact

Spruce Products’ deep

Year-end update

Snapshot of the softwood lumber market

Saw filer shortage

Keeping, finding skilled saw filers DEMO International 2024

$100 million of forestry machinery

TP&EE 2024

A showcase of sawmill equipment innovation AFPA ’24

AFPA’s 82nd annual conference

With a solid team in place, André Gauthier is laying the groundwork for training the fourth generation of foresters at the Entreprise forestière François-Paul Gauthier. For the full story, turn to page 10.

Introducing Sawbox: The innovative Wood Processing solution

Cutting capacity: Up to 8.5 million board feet of wood in two-shift operation.

Log diameters: 10 to 42 in, lengths: 10 to 16 ft 2 in (20 ft on request)

100% self-sufficiency: Cut your own logs, optimize production costs.

Space-saving: Optimum use of floor space from 5,400 ft² to a maximum of 10,800 ft².

Long-term predictable prices: Own production ensures stable product prices.

Sustainability and regional added value: Use of local wood, recycling of all wood waste.

Board dimensions: Wide range possible through chipper head, band and rip saws.

Green footprint: up to 75% yield, maximising log utilisation.

first cut

JENNIFERellson jellson@annexbusinessmedia.com

Wrapping up 2024

Looking back and moving forward

Here we are again – the last issue of the year!

It’s hard to believe how fast 2024 has flown by. What a year it’s been for the forest industry, from exciting innovations in sustainability to major shifts in how we approach forest management.

Looking back, 2024 was packed with stories about resilience, adaptation, and progress. Wildfires, mill closures and curtailments dominated headlines once more, and many of our colleagues and communities felt the impact firsthand. But, as always, the forest industry showed its strength. We’ve seen companies rise from the ashes – literally for some, and metaphorically for others – implementing new strategies to not only bounce back but to do so with a stronger focus on sustainability and safety. It’s these stories of grit and determination that make me proud to be part of this industry, and it’s been an honour to share them with you.

zine to stay in the loop, we want to say a huge thank you. You’re the reason we do what we do, and we’re so grateful to be part of this community.

Looking ahead to 2025, there’s a lot to be excited about. We’re seeing more digitalization in forestry operations, new technologies transforming the way we work, and a stronger focus on safety and training, especially for the younger generation coming into the industry. We can’t forget the continued push for sustainability, with the young crop leading the charge. There’s a lot on the horizon, and I can’t wait to see how it all unfolds.

“AS WE WRAP UP 2024, I WANT TO EXTEND A HEARTFELT THANK YOU TO EVERYONE WHO HAS BEEN PART OF OUR JOURNEY THIS YEAR.”

One of the most exciting developments this year has been the growing adoption of mass timber. It’s really gaining momentum, and the benefits are clear – not just for the environment, but for the way we build. It’s great to see sustainability becoming more than just a buzzword; it’s becoming a way of doing business. That’s something we can all get behind.

On the policy side of things, there have been plenty of changes too. This year brought important discussions around carbon credits, renewable materials, and how government policies can help – or sometimes hinder – the industry. Keeping up with these changes is no small task, but that’s where we come in. Canadian Forest Industries has been here to keep you informed, and we’ll continue to do so in the coming year, helping you navigate this ever-evolving landscape.

But let’s talk about you! We couldn’t do any of this without our readers, contributors, and partners. Your input, your ideas, and your support have made all the difference. Whether you sent us a story idea, provided feedback on an article, advertised with us, or just picked up the maga -

In-person events continued to be a cornerstone of our industry this year, and it was a pleasure to meet many of you at gatherings like the quadrennial DEMO International and various regional conferences. These face-to-face interactions remain invaluable, sparking fresh ideas, fostering partnerships, and driving the industry forward. The energy at these events was palpable, and I know I’m not alone in saying that the conversations and connections made were highlights of the year. Here’s to more of that momentum in 2025!

As we wrap up 2024, I want to extend a heartfelt thank you to everyone who has been part of our journey this year. To our readers, contributors, advertisers, and the entire forest community – thank you for your support, your engagement, and your dedication to making this industry better. Whether you’re a seasoned veteran or just getting started, your passion for forestry is what keeps this industry moving forward, and it’s been a privilege to share your stories.

So, what’s next? Well, we’re already gearing up for 2025, and we’re excited to bring you more stories, more insights, and more opportunities to connect. There’s plenty to look forward to, and I’m sure we’ll be seeing some of you at industry events in the new year.

See you soon!

U.S. adjusts antidumping rates for some Canadian softwood lumber

The U.S. Department of Commerce has amended the final results of its administrative review on antidumping duties for some Canadian softwood lumber products, correcting ministerial errors.

West Fraser Mills saw its antidumping duty rate lowered to 5.04 per cent from 5.32 per cent. The rate for companies not selected for individual review dropped to 7.66 per cent from 7.80 per cent. These changes apply to the review period of Jan. 1 to Dec. 31, 2022.

The original final determinations were published on Aug. 19, 2024, with corrections made after a request from West Fraser Mills. Photo: Annex Business Media

CANADIAN MILLS UPDATE: OCTOBER 2024

Company Location Timeline Details

Western Forest Products Various locations in B.C. Oct-Dec Curtailment due to market challenges

Tolko Industries (Soda Creek) Williams Lake, B.C. 4 weeks 30-day shutdown due to market challenges

Mercer International Peace River, Alta. mid-Oct Repairs to digester

Tolko Industries (Armstrong) Armstrong, B.C. Sept 16 - Oct 1 Curtailment due to market challenges

Kruger Kamloops, B.C.. 2026 $32M investment to diversify products

Canfor Vanderhoof and Fort St. John, B.C. End of 2024 Closure due to market challenges

San Group Port Alberni, B.C. Oct/Nov Curtailment for at least 2 weeks due to log shortage

Source: Madison’s Lumber Reporter

One Sky to build OSB mill in Saskatchewan

One Sky Forest Products plans to begin construction on the $400 million oriented strand board (OSB) plant in 2025 and open it in 2027, creating an estimated 800 direct and indirect jobs. Indigenous Forestry Investments (IFI) will partner with One Sky on this project.

The Government of Saskatchewan has allo-

cated nearly 1.2 million cubic metres of timber to One Sky, setting the stage for the company to open the mill in Prince Albert.

One Sky was formed in 2020 by Montreal Lake Business Ventures, Meadow Lake Tribal Council, Big River First Nation and Tatanka Oyate Holdings, who brought in B.C.-based Peak Renewables.

Brink submits bid to acquire Canfor sawmills

Brink Forest Products has submitted a formal proposal to acquire four sawmills from Canfor Corp. The acquisition includes B.C. mills in Bear Lake, Fort St. John, Vanderhoof, and Houston.

Brink said it is aiming to safeguard over 5,000 jobs in Northern B.C. amid significant industry challenges, reinforcing its commitment to sustaining regional economies and protecting local jobs. Brink has engaged Industrial Forest Service to perform a detailed analysis of the renewable timber tenures associated with each mill.

San Group curtails B.C. mill operations

San Group has announced temporary curtailments at its sawmill and remanufacturing plant in Port Alberni due to limited log supply on the B.C. coast.

The move, which will affect around 75 employees, was described as “temporary in nature” by CEO Kamal Sanghera.

He said log shortages, particularly from suppliers on the North Island and Central Coast, are impacting operations. San Group is a non-tenured company and relies on open market purchasing, timber sales and First Nations partnerships in accessing logs, Sanghera added.

While the company’s small log line continues to run on local sources, the value-added facility will shut down for at least two weeks starting Oct. 21.

Interfor exits Quebec operations

Interfor Corp. has announced plans to sell its Quebec manufacturing facilities and close its Montreal corporate office as the company shifts its focus to other parts of its business. This decision follows challenges in accessing economic fibre, which CEO Ian Fillinger attributes partly to the impact of recent forest fires.

The $30-million deal includes the sale of sawmills in Val-d’Or and Matagami, along with the Sullivan remanufacturing plant in Val-d’Or. The buyer, Chantiers Chibougamau, will also enter a multi-year agreement to supply machine stress rated lumber to Interfor’s I-Joist facility in Sault Ste. Marie, Ont.

Western Forest Products cuts lumber production

Western Forest Products (WFP) is reducing lumber production at its B.C. sawmills by around 30 million board feet from October to December 2024. The company projects a total reduction of 90 million board feet for the year, which represents approx-

imately 10 per cent of its annual capacity. WFP attributed the temporary cuts to weaker lumber demand, higher U.S. softwood lumber duty rates, and a limited supply of economically viable logs at certain sawmills.

Reader Service Print and digital

or changes, please contact Angelita Potal, Customer Service Tel: 416-510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR - Jennifer Ellson (438) 483-7451 jellson@annexbusinessmedia.com

GROUP PUBLISHER - Anne Beswick (416)510-5248 • Mobile: (416) 277-8428 abeswick@annexbusinessmedia.com

ACCOUNT COORDINATOR - Shannon Drumm (416) 510-6762 sdrumm@annexbusinessmedia.com

MEDIA DESIGNER - Graham Jeffrey gjeffrey@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER Serina Dingeldein (416) 510-5124 sdingeldein@annexbusinessmedia.com

NATIONAL SALES MANAGER - Josée Crevier Ph: (514) 425-0025 • Fax: (514) 425-0068 jcrevier@annexbusinessmedia.com

WESTERN SALES

Tim Shaddick 1660 West 75th Ave Vancouver, B.C. V6P 6G2 Ph: (604) 264-1158 Kevin Cook lordkevincook@gmail.com Ph: (604) 619-1777

CEO - Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATION MAIL AGREEMENT #40065710 RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATON

TRAINING THE 4TH GENERATION OF FORESTERS

With a solid team in place, André Gauthier is laying the groundwork for training the fourth generation of foresters at the Entreprise forestière François-Paul Gauthier

BY GUILLAUME ROY TRANSLATED BY KEVIN

A Tigercat harvester is hard at work in a mixed forest near the Saguenay fjord, in Sainte-Rose-duNord. The spruce budworm has severely affected most of the balsam firs, but the black spruce and hardwoods are in good shape.

“This forest should have been harvested three years ago,” says André Gauthier.

Walking through the cutting area, he explains

that yellow birches with a diameter over 40 centimeters must be left standing, as there is no market for wood of that size. “It makes for a nicer landscape for the public and hunters,” says the

ABOVE: André and Jérémy Gauthier form an operator duo, taking on maintenance and ensuring equipment is ready to go. All photos: Guillaume Roy

forester, who works for Groupe Forestra.

For the past four years, André has been training one of his sons, Jérémy, in forestry work.

“He does the cut-to-length on the forwarder, while I operate the harvester,” says the 45-year-old forestry entrepreneur, who leads a team of six.

“For me, working in the forest comes naturally,” notes Jérémy. “I would have liked to start even younger, but my father wanted me to wait a bit to make sure I wouldn’t get bored of it. I really enjoy working in the forest, and I’m going to make a career out of it.”

Jérémy’s presence allows the team to stay ahead of schedule, particularly for maintenance and repairs, as there are two people available to handle these tasks.

When we visited, the work area was spotless, the service truck was shining, all the chains were sharpened, and oil changes were up to date.

Now 18, Jérémy is finishing high school and will soon start a professional diploma in heavy equipment mechanics at the Roberval Vocational Training Center.

“He’s already very skilled at operating the machinery, but the training will give him an extra edge in mechanics,” says André, who plans to introduce his other son to more forestry work next summer.

André is taking things step by step to ensure

The Elephant King forwarder in front of the cutting area, with large yellow birches left standing.

his sons develop a passion for forest work, which, despite its unconventional hours, offers unmatched freedom.

To improve his team’s working conditions, André has set up a four-day work schedule.

“We work unconventional hours, so we try to improve the conditions as best we can,” says André, who wraps up the workweek by logging with his son on Friday mornings.

“The guys rotate between the harvester and the forwarder every three hours,” he adds, a technique to help prevent burnout and to ensure they don’t get bored with their tasks.

A FAMILY LEGACY

The Entreprise forestière François-Paul Gauthier was founded in 1984 by André’s grandfather. His uncles, Fabien and Paul, then took over the business. André became a shareholder in 2012 before buying the entire company six years ago.

With six workers operating a Tigercat 855E harvester equipped with a Ponsse H7HD head and an Elephant King forwarder, André is considering

Today’s forestry equipment, including log loaders, is likely already equipped with fleet tracking technologies, called telematics, to track and report data in real time.

André Gauthier in the cutting area.

whether to add another harvester to his lineup.

“I’m debating because I’m comfortable with just one set of equipment, and our production is good,” he says, though he adds that he is eager to involve his son.

OUTSOURCING FOR EFFICIENCY

Interestingly, the forestry company doesn’t own a garage for springtime repairs.

“I don’t have a garage, and I don’t want one,” says André.

“I prefer taking the machines to the dealerships, which provide excellent service and ensure we have all the necessary parts.”

“I’LL NEVER GET TIRED OF THE FREEDOM OF WORKING IN THE FOREST.” - ANDRÉ GAUTHIER

On average, his company harvests around 76,000 cubic meters of wood annually. During the visit of Canadian Forest Industries, production was a bit lower than usual – about 30 per cent less, according to André – since the yield is reduced in forests affected by the spruce budworm.

At Groupe Forestra, contractors don’t receive extra compensation for harvesting budworm-affected wood, but areas are allocated to ensure that all contractors can operate profitably, explains the general manager, Claude Dupuis.

THE CO-OPERATIVE ADVANTAGE

Working for a forestry co-operative like Groupe Forestra comes with many benefits, André notes, such as being able to sleep at home about 70 per cent of the time.

“They have a very people-oriented approach, and it’s easy to talk to management. I like the co-operative spirit,” says the forester, who has worked with the co-operative for six years.

With his brother, who also runs a forestry company logging for Groupe Forestra, there’s a healthy and friendly competition between them.

Forestry companies and operators aren’t members of the co-operative, but they’re part of a larger family, says Dupuis. To instill co-operative culture among all forest operators, Groupe Forestra has implemented a bonus that shares profits.

“Even though they’re not members, we want operators to feel like they’re part of the team for the long term, creating a sense of belonging,” says Dupuis.

“It’s also a tool to attract and retain the workforce that supports our contractors.”

LOOKING TO THE FUTURE

For André, the only downside is the uncertainty surrounding the protection of woodland caribou.

“We have no control over it, and it’s quite worrisome,” he notes, hoping that

a final plan will be presented soon to alleviate the uncertainties.

With a strong team in place, André still loves his job.

“I’ll never get tired of the freedom of working in the forest.”

A LONG WAY TOGETHER

FORESTLAND

Designed for the most demanding applications, FORESTLAND is BKT’s most recent and innovative bias tire for the agro-forestry sector, but it can also be employed in some agricultural operations such as landscaping and light mulching. Its polyester carcass and specific tread compound make it particularly cut-and-chip resistant, while the robust sidewall ensures a long product life cycle. FORESTLAND’s key features are excellent traction on soft terrain, good grip on any ground thanks to stiff and reinforced tread lugs, a high level of stability thanks to the strong bead construction and top self-cleaning properties.

SMALL TOWN, BIG IMPACT

BY SARAH STOTLER

Founded and incorporated in 1942, Spruce Products Ltd. has deep roots in Manitoba’s Swan River community. Located northwest of Winnipeg, and bordering Saskatchewan, the picturesque area offers a diverse landscape featuring boreal forests, spruce, fir, aspen, birch, peaty bogs, wetlands, and numerous oxbow lakes, making the area rich in wood resources.

In addition to being a longstanding member of the community, the mill also has a significant economic impact as a major employer in the area. With 95 employees, it operates a single 10-hour

shift Monday to Thursday with a five-hour overtime shift on Fridays.

“One of the best things about our mill is the supportive workforce with many years of experience,” says mill manager Rod Pidskalny. Spruce Products is privately held with the shareholders forming a portion of the board of directors.

LEADING THE WAY IN MANITOBA

Spruce Products is the top producer of lumber in Manitoba. It produces 55 million board feet of dimensional lumber annually for the Canadian

ABOVE: Spruce Products Ltd. is committed to continuous improvements in recovery and efficiency for both its processes and equipment. All photos: Spruce Products

market. Products range from 1x4 6-foot boards to 2x10 16-foot boards. All of the lumber it produces is graded under the supervision of the Central Forest Products Association and is SFI-certified. Spruce Products also produces custom timbers using their Cardinal round saw carriage.

Sustainability is a priority – it has committed to achieving utilization of all harvested timber. To reach this goal, it also produces several subproducts. Its premium softwood pellets are made from kiln-dried planer mill trim blocks and are suitable for use in residential pellet stoves or as animal bedding. Wood shavings from the planer mill are sold domestically and internationally to the American market as high-quality animal bedding. Chips are trucked daily to the Canadian Kraft Paper Industries paper mill in The Pas, Man. Hogfuel, bark, and sawdust go to three biomass boilers. These provide all the heat for the site and power the lumber-drying kilns. No other heat or energy sources are used.

As the name suggests, Spruce Products mainly processes white and black spruce, along with jackpine, and balsam fir. The mill can accommodate log sizes ranging

from five to 35 inches in diameter. Pidskalny notes that the timber profile in the area has significant taper, which can present processing challenges and can have

an impact on recovery.

Spruce Products holds timber quotas and sources the majority of its volume from the nearby Duck Mountains and Porcupine

INNOVATIVE SOLUTIONS FROM LOGS TO LUMBER

THANKS TO SPRUCE PRODUCTS LIMITED FOR FEATURING OUR PRODUCTS IN THEIR MILL!

Spruce Products mainly processes white and black spruce, along with jackpine, and balsam fir.

Provincial Forest.

“The land base we operate on is shared with LP Building Solutions,” explains Pidskalny. “We have a very synergistic relationship with them, as they take the hardwoods in a cut block, and we take the softwoods. LP has been an excellent business partner.”

There are a number of logging contractors in the area that deliver to both Spruce Products and LP Building Solutions.

Spruce Products also owns a forest renewal company. It ensures that all harvested areas are promptly reforested according to provincial standards, planting approximately 2 million trees every year. Its reforestation operation is unique as approximately one-third of seedlings are

snow cached due to the local terrain.

EFFICIENCY AND TECHNOLOGY

The mill’s process begins when cut-to-length logs are delivered to the log yard. They are pre-sorted by size and length before being forwarded by Volvo wheel loaders to the log infeed deck. A Carbotech stream feeder then singulates the logs and sends them to a Carbotech 4-bin log sorter. The sorter’s controls and 2-axis scanning, provided by Stadia Inc., accurately measure log size distributions and detect defects.

Logs that are over 16 inches in diameter are redirected to a Cardinal 44-inch round saw carriage with Autolog scanning and controls. Cants are processed through a Comact gang and shifting saw edger. Lumber

from both saw lines is further processed through a Carbotech multi-saw trimmer with Autolog optimization and controls.

The lumber is then sorted and stacked by a 40-bin TS Manufacturing sorter and stacker. Green lumber is staged and prepared for drying in an 8-zone Valutec TC Continuous kiln, which is the mill’s most recent upgrade and was commissioned in January 2024. After drying, the lumber is planed using a Yates A20 planer, then processed through an Autolog pro-grader, Carbotech Trimming, and a 16-bin sorting line. Finally, completed packages are wrapped and strapped with a Samuel strapping machine.

Shavings from the planer are packaged with a Premier Tech bagging machine before being stacked by a robotic Robovic Stacker. The robotic stacker is just one example of how Spruce Products utilizes technology to optimize its processes.

A BRIGHT FUTURE

What’s down the road for Spruce Products?

Like many other modern operations, it is committed to continuous improvements in recovery and efficiency for both its processes and equipment. It is currently exploring options for stacking and green strapping of lumber packages coming from the sorter. Additionally, it is examining improvements to the mill’s main canter line. Although current market conditions have temporarily delayed some capital projects, the company has observed positive pricing trends for certain lumber dimensions and has an optimistic outlook for the future.

Pidskalny notes, “The Manitoba government has taken an interest in Spruce Products, and is actively working with us to chart a path for the next 80 years of contributing to the Manitoba economy.”

Founded in 1942, Spruce Products Ltd. has deep roots in Manitoba’s Swan River community and is the top producer of lumber in the province.

WOODPRODUCTS CANADIAN

TACKLING SAW FILER SHORTAGE

Paul

A major concern for sawmills this year has been finding and keeping skilled, experienced saw filers. Modern, high-production mills depend on knowledgeable saw filers to maintain both quality and output. When production goals aren’t met, it’s often the filing department that’s called on for answers. In the past, saw filers were commonly recruited from other mills, but despite some mill closures, qualified saw filers remain in short supply.

“IF YOUR SAWMILL IS STILL USING EQUIPMENT THAT’S 10 TO 20 YEARS OLD, IT’S LIKELY TIME FOR AN UPGRADE— ESPECIALLY IF YOU PLAN TO STAY IN BUSINESS FOR ANOTHER DECADE OR TWO.”

In 2024, there was a clear need to expand saw filing education, and vendors, industry professionals, and organizations responded. Many equipment and saw manufacturers have historically offered limited training at their facilities, often requiring mills to purchase products or pay for specialized training. While helpful, these efforts haven’t significantly increased the number of new saw filers. Some master and consulting saw filers also offer on-thejob training, which has proven effective, with mills covering the cost of these services.

Young entrepreneur Paolo Morales saw the need for more skilled saw filers and launched a training program through his company, Reliability Solutions, in the U.S. This program partners with sawmills to deliver thorough training, equipping filers to maintain productivity and quality. They also collaborate with organizations that share their educational mission. I’ve spoken with several students enrolled, who have praised the course. While it may take time to meet industry demand

fully, this well-planned initiative is a promising step forward.

New products, manufacturing processes, and materials are starting to reshape sawmill tooling, which could be a positive development. For saws, the ultimate test is research – sometimes even “research and destruction.” Modern highproduction mills need increasingly advanced saws. In 2024, we’ve seen faster feed speeds, higher RPMs, larger tooth bites, and larger gullet areas to handle the extra strain. I recommend testing and documenting each change individually to understand the impact. Proper records will help saw manufacturers and sawmills collaborate effectively, creating the best saws for specific applications – benefiting everyone involved.

A key achievement this year has been the ability to predict and maintain filing room costs at a fixed, minimal level. By assigning serial numbers to each saw and implementing a tracking system, mills can now closely monitor saw costs on a perthousand ratio. If I owned a sawmill, I’d ensure our accounting practices included detailed tracking of both saw and filing room supply costs. In modern mills, filing room expenses should be nearly fixed. Budgets only work when you have a clear understanding of your spending.

Overall, 2024 has been a strong year for the filing room and for saw filers. Technological advancements have brought improved equipment, enabling us to produce sharper, better-quality saws across the industry. If your sawmill is still using equipment that’s 10 to 20 years old, it’s likely time for an upgrade—especially if you plan to stay in business for another decade or two. While equipment and grinders will continue to evolve, I believe we’ve seen the most significant advancements for the next few years. As we wrap up 2024, I hope filers will combine traditional techniques with new technology to boost productivity, reduce costs, and enhance safety.

PAULsmith

Smith is a saw filing consultant and founder of Smith Sawmill Service, now part of BID Group. You can reach him at paul.smith@comact.com.

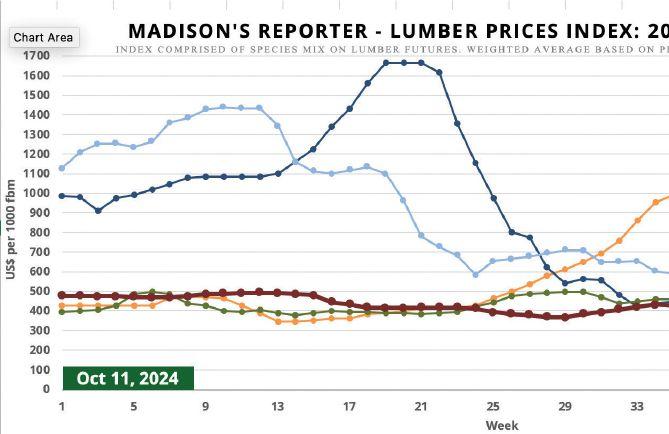

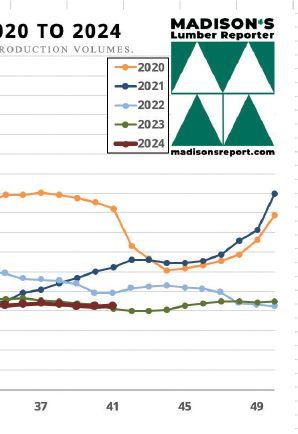

2024 YEAR-END UPDATE

BY KETA KOSMAN

Hurricane Helene cut a path much further inland than is normal for such storms, affecting areas which do not typically have this type of weather event. As a result, Florida, Georgia, North Carolina, and Tennessee all suffered significant damage to infrastructure, specifically transportation and power supply. There are three major sawmills in these areas: two West Fraser mills and one Canfor. One of the West Fraser mills, in Florida, was very recently curtailed. There are also more than 10 medium-sized mills and a large number of smaller mills throughout these states.

More than a week after Helene, many of these locations were still without power, not to mention inability to transport timber into the mill and lumber out. As a result, prices of Southern Yellow Pine started to rise immediately. This is due to the ongoing customer habit of not stocking inventory, so any need for wood brought an increase in orders directly to producers. Naturally, demand also flowed to Eastern S-P-F as customers sought value as well as avail-

ability. This, however, did not affect prices even while sales volumes rose.

Meanwhile in the west, the usual seasonal slow-down in lumber sales following Labour Day was on.

In the week ending Oct. 11, the price of benchmark softwood lumber item Western Spruce-PineFir 2x4 #2&Btr KD (RL) was US$388 mfbm, which is flat from the previous week. That week’s price is down $16, or four per cent from one month ago when it was $404. Compared to the same week last year when it was $382 mfbm, that week’s price was up $6, or two per cent. Compared to two years ago when it was $445, that week’s price is down $57, or 13 per cent.

KEY LUMBER PRICES AND MARKET CONDITIONS TAKE-AWAYS

• Western Spruce-Pine-Fir producers in the U.S. held dimension asking prices at or around the previous week’s levels.

•Western Canadian and U.S. sawmill order files were around twoto three-weeks.

•Ongoing tight supply created the impression that increased buying would quickly clean up available material.

•Eastern Spruce-Pine-Fir prices climbed amid limited supply.

•Disruptions to sourcing Southern Yellow Pine timber and shipping lumber were significant as several facilities still didn’t have power.

•Scarce Southern Pine supply flowed demand to Eastern SPF, thus suppliers there turned down counter offers and leaned on firm pricing

The Madison’s Lumber Prices Index for the week ending Oct.11 was $426 mfbm. This is up 0.5 per cent, or $2 from the previous week when it was $424, and is down 13 per cent from the same week last year when it was $490.

The latest data for U.S. housing starts show that for year-to-date 2024, there was a 10 per cent increase in single-family starts (not seasonally adjusted). While the monthly data is useful to watch, especially in comparison to same month the previous year, the cumulative numbers tell a more accurate story. The most recent update from the Census Bureau shows that for January to August 2024, single-family housing starts were 691,200 units, compared to 625,900 for the first eight months of 2023 (not seasonally adjusted).

Should this upward trend continue to the end of this year, confidence in new housing construction will also increase. Historically, the large U.S. home builders start ordering their lumber in February, which is when prices start their seasonal rise. As the full-year 2024 new housing starts data is released, expectations for next year spring building activity will be confirmed.

There was some movement in the background with the softwood lumber duty, as in its ruling of May 6, the NAFTA Chapter 19 Panel ordered the U.S. Department of Commerce to correct errors in its setting of countervailing duties on Canadian softwood lumber. The five-page list of inconsistencies pointing out duty miscalculations named Canadian sawmills from coast to coast. The Panel ordered Commerce to make a determination on remand consistent with the findings and instructions of its opinion, with a due date of 90 days.

Global Affairs Canada said the NAFTA panel granted an exten-

sion to the U.S. Department of Commerce following its request. The re-determination, originally due on Aug. 5, was expected by Oct. 18.

Keta Kosman is the owner of the weekly Madison’s Lumber Reporter. Established in 1952, Madison’s Lumber Reporter is your premiere source for North American softwood lumber news, prices, industry insight, and industry contacts. It publishes current Canadian and U.S. construction framing dimension lumber and panel wholesaler pricing information 50 weeks a year and provides access to historical pricing as well.

The WM2500 Industrial Sawmill is a game changer tailored for peak production, operating seamlessly as a standalone primary headrig to saw pallet boards, grade or dimensional lumber, or as a vital component of a complete sawmilling system.

—Corey White, Hill & Hill Sawmill

EVENT coverage

TP&EE 2024

Featuring $100 million worth of forestry machinery

BY JENNIFER ELLSON

The 2024 Timber Processing & Energy Expo (TP&EE), held at the Portland Exposition Center from Sept. 25-27, brought together the leaders and innovators of the sawmilling and panel manufacturing industries. As the sixth biennial event since its inception in 2012, TP&EE continues to serve as a vital hub for professionals looking to explore the latest technologies and trends in timber processing. This year’s event featured 170 exhibitors spread across 45,000 square feet, attracting a lively crowd of 1,200 attendees over the three-day expo.

Here are some of the featured technologies and innovations at the show.

HewSaw showcased the brand new SL250 5.5 dx V1 line, soon to be delivered to Stimson Lumber in Oregon. The advanced line features three cant saws and HewSaw’s patented dx sawing technology, which increases production speed while reducing saw kerf and extending the time between saw changes. Additionally, the line allows

TP&EE continues to serve as a vital hub for professionals looking to explore the latest tech and trends.

for the splitting of edged sideboards in two of the three cant saws, further enhancing efficiency. USNR exhibited its new Compact Shape Saw system. The system integrates Bioluma scanning, optimization, and information management, along with full support for curve sawing. A standout feature is SAM Sensing, which uses self-adjusting

machine technology to automatically keep pieces on-size, enhancing durability, reliability, and accuracy.

Comact showcased their advanced sawmilling equipment and announced their rebranding from BID Group to Comact. The company is celebrating 100 years of excellence in the wood processing industry and as Comact continues “to pioneer cutting-edge solutions for the wood processing sector, the focus remains on elevating operational efficiency and business results for customers,” said VP Anne-Marie Levesque.

In addition to showcasing their latest products, JoeScan collaborated with optimization partners to develop new solutions and welcomed visitors from across the globe. Based just three highway exits away from the Portland Exposition Center in Vancouver, Wash., JoeScan took full advantage of the close proximity to connect with sawmill operators and managers about the scanning issues affecting their production.

CalSaw showcased their precision-engineered saws and cutting technologies. Known for delivering custom-designed saws for circular twins, quads, edgers, and trimmers, their booth featured patented saws, a saw centering device, detailed saw tooling, saw filing hammers, hand tools, and even mechanized food processing blades.

Mühlböck Drying Technology highlighted their cuttingedge drying solutions, focusing on their High Capacity CDKs. These systems are designed to reduce energy usage by up to 50 per cent with advanced heat recovery technology, while also minimizing VOCs released into the atmosphere.

Advanced Material Handling showcased its custom turnkey conveyor system, highlighting its expertise in large-scale conveyor projects. The display featured high-quality chains and durable cast sprockets, demonstrating the company’s commitment to providing robust and reliable solutions for the industry.

The Gilbert Sales team showcased their advanced planer, which was sold and delivered directly to GreenFirst in Ontario following the event, marking the first of three planned projects with GreenFirst.

UBSafe attended the show with a clear mission: to promote a strong safety culture across the timber industry. The company engaged in productive discussions with mills, manufacturers,

and suppliers about the importance of keeping safety in focus while driving productivity improvements.

Springer showcased its advanced sorting system for logs up to 20 feet. The system integrates a high-efficiency V-Chain and E-Kickers, which work together to transfer and position logs with precision. The V-Chain centers the logs, ensuring accurate movement, while the E-Kickers enable a smooth transition to the catcher with minimal gaps between blocks. The catcher aligns the logs for easy transfer into bins, where loaders then handle storage in the logyard.

Drying solutions were featured at the event.

Saw filers were treated to some product showcase at the trade show.

DEMO 2024

Featuring $100 million worth of forestry machinery

BY JENNIFER ELLSON AND GUILLAUME ROY

The highly anticipated DEMO International, co-hosted by the Canadian Woodlands Forum, SBC Cedar, and Master Promotions, returned in 2024 to the forest region of Venosta, Que. The three-day event, held every four years, showcased cutting-edge forestry equipment, with visitors treated to $100 million worth of woodlands operation machinery and live demonstrations.

Here are some of the equipment on display at the show.

LIEBHERR

Liebherr showcased its LH 50 M Industry material handler and other machines. Designed for the Canadian forest industry, it offers a balance of power and efficiency. Its regenerative power system aims to reduce fuel consumption, while a robust undercarriage ensures stability, even during operations with heavy payloads.

OLOFSFORS

Olofsfors’ HarvX Bar attracted significant attention. Like the Blue Line series, the HarvX features a replaceable nose tip to extend the life of the saw bar and simplify maintenance. It has been tested in various harsh field conditions, where it demonstrated strong performance. The bar is designed to reduce vibrations, improve cutting accuracy, and increase longevity.

VALLÉE

Vallée unveiled its 4DA25 XRT electric forklift, a rough terrain articulated 4x4 machine with a 25,000 lb capacity. Designed for demanding environments, the forklift features an ergonomic cabin for improved operator visibility and comfort. Powered by Volvo Penta’s electric battery and powertrain, the 4DA25 XRT offers zero emissions and reduced operating noise.

BRON

BRON showcased its 300 and 450B mulchers. Designed for projects ranging from utility clearing to fire breaks and recreational developments, these mulchers feature heavy-duty final drives and Cummins engines, with the option for a D6 undercarriage. To improve serviceability, the engine bay offers expanded access, and the cab tilts for convenience.

EMPIRE ATTACHMENTS

Empire Attachments showcased a wide

range of vegetation control equipment at DEMO. “We have equipment for every overgrown vegetation problem, from huge dangerous trees over power lines to cutting grass along highways,” said Jason Frigon, territory manager.

As the national distributor for Shearex, Empire Attachments drew a crowd with their live demos.

GROUPE PG

Groupe PG showcased their new SaaS solution, Arrime, designed to streamline

bulk road transport transactions by enabling real-time documentation. Originally developed for bill of lading creation in the forestry industry, Arrime simplifies the identification of key transaction details and allows for the addition of photos and GPS coordinates.

GROUPE CARVI

Groupe Carvi, a forestry tech startup, unveiled their ScanTree device. Still in development and currently being patented, it uses lidar sensors and cameras to scan

THE WOOD TRADE EVENT

LIEBHERR

OLOFSFORS’

VALLÉE

cutting logistics Visit us at SB-48

2024-08-21 10:29 AM

the environment around harvesters, identifying key tree characteristics such as diameter, height, and species. This realtime data helps operators make informed decisions, increasing productivity and reducing mental workload during logging and thinning operations.

LOGSET

Logset is now looking to expand into the North American market. Partnering with LN Machinerie, the company

introduced its 8H and 12H models. So far, three machines have been sold in North America, with ongoing studies to evaluate the reduction in greenhouse gas emissions. The hybrid engine complements the combustion engine, ensuring a consistent feeding speed of 1500 RPM.

PONSSE

Ponsse displayed several machines, but none garnered more attention than the Scorpion Giant. Even more powerful than

the original Scorpion, this machine can be equipped with an H8 harvester head, offering improved traction and greater lifting power.

LANDRICH

Landrich was also in the spotlight with its Landrich 2.0 harvester, a tracked machine optimized for cut-to-length harvesting. With a new manufacturing plant in New Brunswick, Landrich has ramped up production capacity, allowing the company

to better serve its growing customer base.

CAT

Since acquiring CAT’s forestry division, Weiler has focused on enhancing its equipment to better meet foresters’ needs. The company has made significant strides, including reducing fuel consumption on machines like the H457 harvester, from 30 to 24 liters per hour, thanks to improved hydraulic management. In the five years since the acquisition,

NISULA

Nisula harvesting heads, distributed in Quebec by Équipements JYL in Saguenay and Mécanique F. Turmel in Estrie, are gaining traction in the region. Made from Hardox, a lighter metal than iron, these heads can be installed on smaller excavators while still handling large capacities. The forged, not welded, knives are also more durable.

MALWA

Malwa machines, originating from Sweden, are compact forestry units only seven feet wide, perfect for precision forestry while maintaining the power for professional work. These machines consume between 3 to 6 liters of fuel per hour, making them highly efficient. Depending on forestry practices, users can opt for a harvester and forwarder or the 560C Kombi model, which transitions from a harvester to a forwarder in just 20 minutes.

FMDC

FMDC Watermist Canada showcased its Fogmaker Fire Suppression System. The system stands out as the only ULC-listed

and FM-approved fire suppression system for heavy-duty mobile equipment, offering triple action fire suppression. It rapidly cools the area, extinguishes the fire, and prevents re-ignition. The system uses an environmentally friendly, fluorine-free ECO1 suppressant that smothers the fuel, stopping further combustion. Additionally, its ability to operate in any orientation ensures functionality, even in the event of a rollover.

FRONTLINE MACHINERY

Frontline Machinery announced its expansion as the authorized distributor of CBI grinders and chippers in Quebec, Newfoundland and Labrador, P.E.I., Nova Scotia, and New Brunswick. This expansion brings CBI’s durable and advanced wood and material processing equipment to Eastern Canadian businesses, supporting biomass production and sustainability efforts in the region.

Combustible Dust Specialists

EVENT coverage

AFPA ’24: RENEWAL & RESILIENCE

Alberta’s forest industry gathers in Banff to address wildfire challenges, market shifts and Indigenous partnerships

BY JENNIFER ELLSON

The majestic backdrop of Banff, Alta., provided the setting for the 82nd annual Alberta Forest Products Association (AFPA) Conference from Oct. 9-11. Despite a last-minute venue change due to the Jasper fires, the conference saw strong attendance, bringing together leaders in forestry, government, and Indigenous communities to address the industry’s evolving challenges.

The conference opened with AFPA president and CEO Jason Krips leading a tribute to firefighter Morgan Kitchen, who lost his life in the line of duty during the Jasper fires. He led the audience in a moment of silence to honour Alberta’s brave firefighters.

Banff’s Mayor Corrie DiManno welcomed the attendees, emphasizing the forest industry’s role in sustaining Alberta’s communities. “Your success has

a real impact on the well-being of our communities,” DiManno said, highlighting collaborations such as fire breaks that help mitigate wildfire risks in the area.

The following day began with a blessing from Elders Karla and Mike Onespot of the Treaty 7 Nation, followed by a keynote from Deputy Premier Mike Ellis, who is also the Minister of Public Safety and Emergency Services. He stressed the need for proper forest management and provincial autonomy in decision-making, using the Jasper fires as an example of the federal overreach he argued has hindered local responses.

ADDRESSING WILDFIRE MANAGEMENT

The Wildfire Panel, featuring leaders such as FPAC CEO Derek Nighbor, Michael Norton of the Ca-

nadian Forest Service, Assistant Deputy Minister of the Forestry Division Dan Lux, and Jennifer Beverly, a fire behavior specialist from University of Alberta, underscored the need for active forest management.

Norton discussed the impact of historical fire suppression policies, saying we have to acknowledge the impact of colonial practices on Indigenous fire management. He emphasized the importance of collective action and mentioned the Canadian Council of Forest Ministers’ recently developed wildland strategy.

Beverly, a former Ontario fire ranger, noted the shift from fire suppression to wildfire mitigation. “The pendulum has moved from suppression to mitigation,” she said, adding that Alberta should expect severe fire seasons to become the norm. She highlighted the importance of Indigenous knowledge and traditional practices, stating that we need to prepare decision-makers with tools to ensure social and ecological systems thrive in fire-prone environments.

Lux highlighted the increasing frequency and severity of wildfires in Alberta, noting that what once were rare events have now become annual occurrences. “We’re overwhelmed beyond resources,” he explained, emphasizing the need for more proactive strategies and resources to manage the growing wildfire threats.

Nighbor expressed frustration over the lack of progress in addressing wildfire risks. The industry has been having these same conversations since the 2017 Williams Lake fire in B.C. and the 2019 extreme Alberta wildfires, he said, calling for a more unified response.

He pointed out that Canada could learn from the U.S., where wildfire management involves clear crisis planning.

“We are not doing enough,” he asserted, noting that “we need to move with more urgency.”

NAVIGATING MARKET CHALLENGES

Paul Jannke of Forest Economic Advisors provided a market outlook, noting that while 2024 looks strong, a potential economic downturn may impact demand for wood products. “The U.S. economy is unbelievably resilient,” Jannke observed, though he expects a recession in the coming months. He added that labor and regulatory issues will continue to pose challenges for the forestry sector.

Jannke discussed housing market shifts and labor shortages affecting wood product demand. “People are staying in their homes rather than upgrading due to the cost of new mortgages,” he explained, noting that this trend limits new construction and demand for materials.

GOVERNMENT INSIGHTS

The Government Panel, with assistant deputy ministers Dan Lux, Andrew Horton, Thomas Djurfors, and Liam Stone, discussed Alberta’s different programs and the role that the industry and government play in creating sustainable, vibrant communities, as well as the importance of collaboration between government and the private sector.

PROMOTING EDI

An Equity, Diversity, and Inclusion (EDI) panel explored the role of diverse voices in forestry. Speakers included Wendy Crosina of

Weyerhaeuser, Robin McCullough of Brinkman Reforestation and Sithara Fernando from NorQuest College.

They discussed the business case for inclusivity and introduced the Forestry Together alliance, an initiative promoting diversity in Canada’s forestry sector.

“There’s a place for diversity in your organization to put your organization higher,” said Fernando, highlighting the value of inclusive practices.

INDIGENOUS PARTNERSHIPS AND WORKFORCE INTEGRATION

Another session focused on Indigenous partnerships, with speakers Joseph Jobin and Loleen Flynn sharing insights on recruiting and retaining Indigenous employees.

Jobin emphasized the importance of respecting treaty rights, saying, “If you want to hire Indigenous employees, be prepared to allow them to practice their treaty rights, like hunting.”

Flynn stressed the value of patience and listening in building successful partnerships.

CELEBRATING FORESTRY’S IMPACT ON ALBERTA

In a post-dinner keynote, Minister of Forestry and Parks Todd Loewen spoke about the industry’s contributions to Alberta’s economy and communities. He expressed appreciation for companies that salvaged fire-damaged trees, saying, “The work you do has a direct impact on our well-being.”

Read more online at www.woodbusienss.ca.

SIMPLY BETTER

COLUMN forest management Revitalizing forests through cultural burning

Cultural burning has been a vital practice within the Lil’wat Nation’s territory for many decades, with documents noting specific records of burning dating back to 1969. Our Chiefs and Elders would reintroduce fire to the landscape every few years to preserve habitat conditions and enhance the production and growth of crucial resources like wild potatoes, pine mushrooms, xusum berries, and huckleberries. By conducting controlled burns

in specific areas based on community needs, they aimed to ensure the preservation and sustainability of these resources for the people then, and for future generations.

Today, we continue to explore and learn more about the potential benefits of cultural burning, although many Elders remain hesitant to discuss the practice. As a residential school survivor myself, I understand that this fear comes from Indigenous

JORDONgabriel

Jordon Gabriel is the lead forestry technician at Lil’wat Forestry Ventures, where he helps manage sustainable forestry practices and preserve cultural values. A residential school survivor, he spent 20 years with BC Wildfire Services and holds a forestry technician diploma from BCIT.

ABOVE: Huckleberries starting to grow in an old burn area. All photos: Lil’wat Forestry Ventures.

cultures and practices being criminalized for many years. Often, people don’t recognize that the disconnect between traditional knowledge and contemporary practices stems from the trauma experienced by these Elders, many of whom were taught that sharing their cultural heritage was unsafe. In addition to this, organized fire suppression in Canada beginning in the 1900s, coupled with dominant fire management narratives in the media discouraged any form of burning, further isolating Indigenous knowledge from land management. This has ultimately created the situation we are in now: forests that are too dense where catastrophic wildfires impact the current ecosystem and landscape.

However, we have begun to see Indigenous communities being more open to the idea of sharing this knowledge, and much research has been done to show the positive impacts of cultural burning. This is a practice that affects everybody and everything, from people to wildlife. It has become evident that introducing fire back to the landscape, in a controlled environment, not only helps spur on the growth and success of berries, mushrooms, and other plants used for food and medicine for the benefit of the community and wildlife in the area, but it also mitigates wildfire risks by reducing forest fuel buildup. Today, as we begin to look again at our forests, not just for the trees and the timber, but for all the plants and resources found there, we again find the need for cultural burning and its benefits.

With Lil’wat Forestry Ventures, a for-

estry management corporation within the Lil’wat Nation, we have completed two cultural burns in the last few years: the first one up in Owl Creek two years ago, and the other one on Tenquille Creek this summer. Both were a learning experience as we got to see the difference in how burning affected the resources in the area. With the Owl Creek cultural burn, we used a more high-intensity fire and have noticed a lot of growth happening already, probably about six to eight centimeters growth of the berry bushes. The trees we planted in the burnt areas are growing much better than those where we did not burn, further creating ecosystems that will be able to better support wildlife

like grizzly bears, as well as food and medicinal plants.

The resurgence of cultural burning practices offers undeniable benefits to the environment and people. When we manage the forest for multiple values, taking cultural, ecological and social values into account, we can enhance biodiversity and ensure a more sustainable resource for future generations, so that they too can appreciate all that we get to enjoy today. Embracing cultural burning practices will ultimately foster community resilience while also honouring the legacy of our ancestors, who understood and demonstrated the key relationship between fire and the health of the land.

Introducing fire back to the landscape, in a controlled environment , can help spur growth.

COLUMN final cut

From Jasper’s fires to Alberta’s forests: a call for action

The Alberta Forest Products Association just wrapped up our 82nd AGM and conference. This year’s event was held in Banff, which is new for us, as we’ve been going to Jasper for decades. Sadly, the fires in Jasper meant that community was not able to host us this year. As an industry, we are heartbroken to see what happened in Jasper. We were also very saddened to learn that firefighter Morgan Kitchen was killed fighting the Jasper fire. Our wildland firefighters make tremendous sacrifices to protect our communities and deserve our gratitude.

Jasper is a cautionary tale about the hazards of leaving forests unmanaged. Our industry has been expressing concerns about the situation in Jasper for more than a decade now. Our annual trips to the park have allowed us to witness the forests grow increasingly old, with a sea of red as pine beetle has ravaged stands throughout the park. Sadly, the risks of unmanaged forests were realized in an event that affected many people.

A second big focus this year in Alberta is the Species at Risk Act (SARA). Our view is that there is a fundamental flaw in the federal government’s approach to forest management. This is the assumption that older forests should remain unmanaged, regardless of fire risk. This view is not only applied in National Parks, but extended out to the broader landbase through SARA. In Alberta, companies are currently prohibited from managing large tracts of older forest because of the application of SARA to caribou management. We know, however, that these forests are at risk of the same kind of catastrophic fire that affected Jasper. And when those fires happen, it will be a bad outcome for caribou, for communities, and for the long-term sustainability of the forest industry. Forestry communities across Canada are in a similar predicament with regard to caribou and SARA. We are joining our partner associations in advocating for a collaborative approach to reform the Act.

One of the major highlights of 2024 for our indus-

try was the Mackenzie Region’s designation as Forest Capital of Canada by the Canadian Institute of Forestry. For those not familiar with Alberta’s geography, the Mackenize Region is a huge area in the province’s northwest. In fact, it is bigger than P.E.I. Despite the remoteness of the area and long distances between communities, the region is very close-knit and a there is a strong northern spirit of entrepreneurism and getting things done no matter the challenges. The organizing committee for Forest Capital of Canada put that spirit on full display, absolutely knocking it out of the park to celebrate forestry. They came up with a mascot and video games, put infrastructure in parks throughout the region to leave a lasting legacy, delivered educational kits to schools, did podcasts and videos, and held events throughout the year. A huge congratulations to co-chairs Lisa Wardley and Melanie Plantinga and volunteers in communities throughout the region for a job well done!

Finally, the AGM was a great opportunity celebrate our successes as an industry and as an association. Despite ups and downs in markets and in the forest industry across Canada, Alberta has remained relatively stable. This means that we are able to not only focus on the present, but also on the future. Three initiatives that we are especially proud of are the Work Wild Program, Love Alberta Forests campaign, and our Forestry Talks podcast. As an industry, we can’t operate without a supportive public environment. Social license is the ticket to fibre security. We are proud to be bold and loud about the incredible work that our sector does and to highlight the world-leading sustainability practices, premium products, and the wealth of local knowledge and expertise that we have here in the province. These tools are a powerful way for us to communicate with Albertans about exactly that and to let them know all the reasons they should be just as proud of Alberta’s forest industry as we are.

Read more online at www.woodbusiness.ca.

JASON krips

Jason Krips is President and CEO of the Alberta Forest Products Association. Reach him at jkrips@albertaforestproducts.ca.

ON BRANDT.

It’s not an offer. It’s a promise. That you can count on us to deliver the equipment you need when you need it with flexible payment options and world-class support. We offer creative solutions that allow you to manage cash flow effectively while meeting the rigorous demands of your operation. Whatever you need to succeed, we deliver.