MOBILE BIOCHAR PRODUCTION

The CharBoss®, the world’s first mobile biochar production system, can help on both fronts and turn unwanted wood waste into nutrient-rich biochar. This valuable soil amendment can either be recycled onsite, enriching soils, or bagged as a product for sales. Go deep into the woods to manage forest growth and mitigate wildfires safely. Air Burners® offers the most cost-effective, earth-conscious solution for organizations to sustainably manage biomass and reduce waste. SCAN TO LEARN MORE

FORESTRY WILDFIRES

Tackling wildfire risk and rehabilitating forests and wildlife habitats

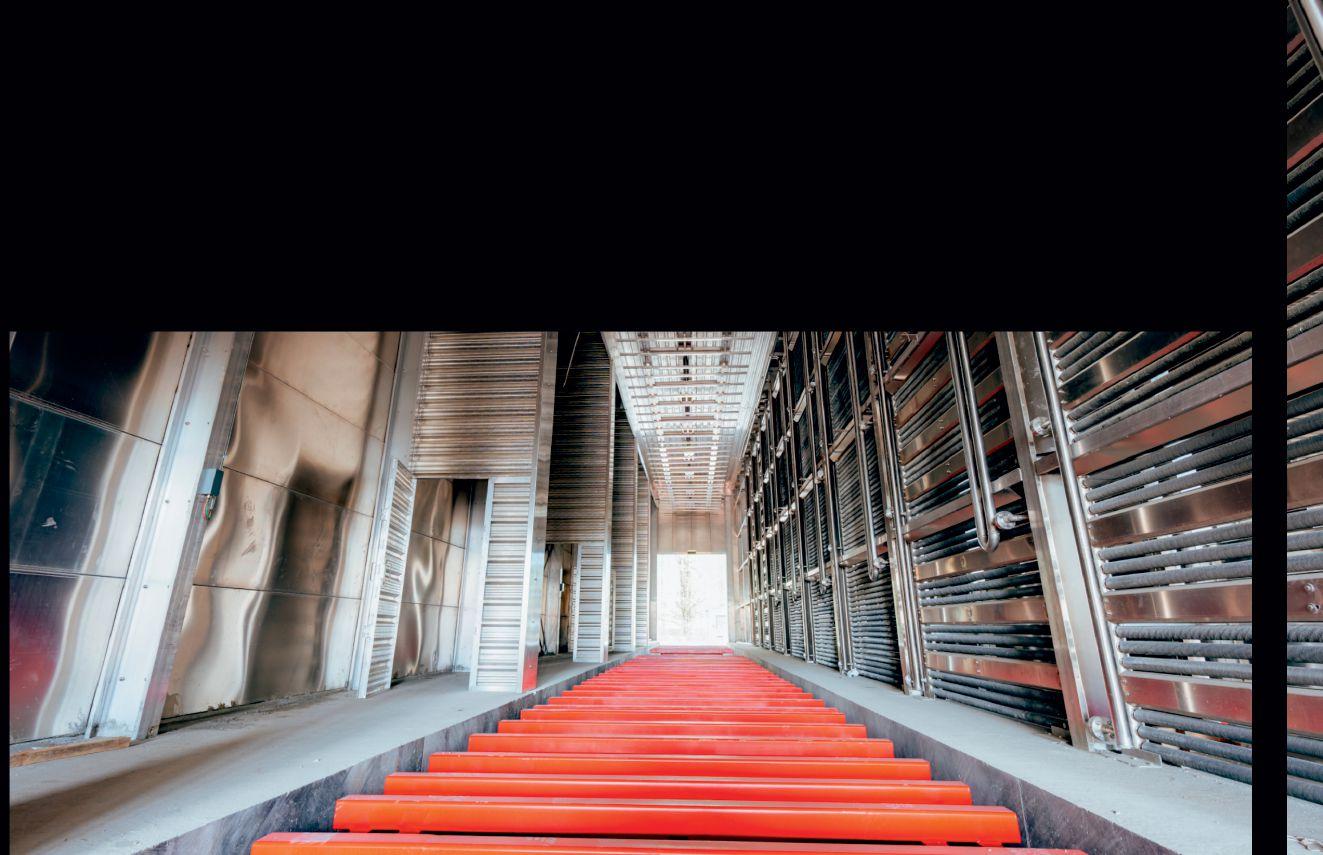

Drying

of Indigenous values. Read about it on page 10.

JENNIFERellson jellson@annexbusinessmedia.com

The math isn’t math-ing

Primary wood industry challenges in B.C. must be addressed before expecting success in secondary manufacturing

In the past few months, I have attended a couple of industry events in British Columbia where Premier David Eby, Forest Minister Bruce Ralston, and Minister of State for Sustainable Forestry Innovation Andrew Mercier have proudly touted their endeavors to bolster the value-added wood products sector. Their declarations, accompanied by substantial financial pledges and support for secondary wood manufacturing, have painted a rosy picture of where the industry is headed.

But stepping outside the conference halls, the reality on the ground tells a different story. There’s a palpable concern within the forest sector about the struggling primary industry and the shrinking annual allowable cut. Industry leaders are sounding the alarm about a fiber shortage, regulatory uncertainty, and a whirlwind of policy changes that are scaring away investors.

Notably, Canadian forestry enterprises have gravitated towards the Southeastern U.S. over the past two decades, enticed by the allure of managed forests in the region. This trajectory was initiated in 2006 when Canfor made significant acquisitions in South Carolina.

Moreover, recent news from Canfor about the closure of its sawmill in Bear Lake, B.C., a pulp line in Prince George, and the suspension of reinvestment plans in Houston, B.C., underscores a distressing trend. Canfor’s announcement regarding the closures delivered a stark assessment of B.C.’s forestry policy, saying there’s enough timber to continue operations, but the prevailing forest policies have caused uncertainty, making it unstable to invest in the province.

Other companies have similarly blamed the low availability and high cost of fibre in the past when announcing closures and curtailments.

At the COFI Convention in April, COFI president and CEO Linda Coady highlighted a significant decline in wood harvests, now at 32 million cubic meters annually – merely half of what it was five years ago. She stressed that this is simply not enough to sustain the industry’s workforce.

“The overwhelming number of policy changes is creating an unsustainable environment for businesses,” she mused.

Similarly, at the Truck Loggers Convention in January, Inland Truck and Equipment’s Tracey Russell echoed these sentiments and directly appealed to Premier Eby, highlighting the discord between the government’s buoyant forecasts and the industry’s harsh reality. The reduction in harvesting rights, he emphasized, represents a massive setback, comparing the current financial challenges to those faced during the 2008 financial crisis.

Despite these warnings, the premier and his ministers remain optimistic, highlighting significant investments in value-added products. But, when you look at the struggling primary wood industry, it’s hard to share that optimism. The disparity is glaring – how can one envision a flourishing value-added and secondary manufacturing sector when the primary wood industry languishes in disarray?

The math simply isn’t adding up. It’s like trying to make lemonade when there are barely any lemons to be found.

Manufacturers and investors see things differently. It requires them to invest millions in retooling their mills to produce these new value-added products, which makes them hesitant as they need stability and surety of fiber supply.

In light of these challenges, the B.C. forest industry is calling for government intervention amidst mill closures and lumber curtailments. Coady’s plea for an accelerated effort to stabilize fiber supply underscores the urgency of the situation.

The onus lies squarely on the shoulders of the policymakers to address the fundamental issues plaguing the primary wood industry before expecting success in secondary manufacturing.

Without stabilizing the primary sector, the investments in value-added products are likely to fall short. It’s time for government authorities to heed the industry’s calls for certainty and sustainable practices to ensure a thriving future for all facets of forestry in British Columbia.

Canfor makes cuts in B.C.

Canfor has announced it is permanently closing its Polar sawmill in Bear Lake, B.C., indefinitely shutting a production line at its Northwood Pulp Mill in Prince George, and suspending its planned reinvestment in Houston, B.C.

The company cited the “persistent shortage of economically available timber and challenging operating conditions in northern B.C.” as the reason behind the decisions.

The closure of the Polar sawmill, with an annual production capacity of about 300 million board feet, will impact approximately 180 employees. The North-

wood reduction will affect around 220 jobs across Canfor Pulp. Following the curtailment, Canfor Pulp will have an annual capacity of 480,000 tonnes of market pulp.

Nova Scotia and Finland boost forest sector collaboration

Nova Scotia and Finland signed a five-year action plan on April 26 in Helsinki to enhance cooperation in forestry and bioeconomy. The agreement, between Finland’s Ministry of Agriculture and Forestry and Nova Scotia’s Department of Natural Resources, aims to share expertise and improve efficiency in forest management, digital solutions, and technologies. The collaboration will also focus on industry and research, promoting commercial cooperation and creating opportunities for Finnish companies in Nova Scotia. The plan emphasizes the forest-based bioeconomy, fostering innovation in wood-based products and materials. Increased contacts between research, development, and education sectors in both regions are also a key goal. Photos: © GO Akara, CGinspiration / iStock / Getty Images Plus

U.S. updates antidumping duties after NAFTA decision

The U.S. Department of Commerce recently reassessed its antidumping duties for certain softwood lumber products imported from Canada. This review, initiated on April 30, 2024, was prompted by a directive from a NAFTA Chapter 19 Binational Panel issued on October 5th, 2023. The investigation period spanned from Oct. 1, 2015, to Sept. 30, 2016. In their reassessment, the department determined new estimated weighted-average dumping margins for various Canadian lumber companies.

These margins are as follows: 6.63 per cent for Canfor, 3.08 per cent for Resolute, 7.14 per cent for Tolko, and 5.18 per cent for West Fraser. For all other Canadian softwood lum-

ber producers, the recalculated rate is 5.66 per cent, which is slightly lower than the original rate of 6.04 per cent. This all-others rate was derived from a weighted average of the dumping margins calculated for the mandatory respondents.

Photo: Annex Business Media.

B.C. funds wood manufacturing businesses

The B.C. government has announced new financial support for wood products manufacturers through the BC Manufacturing Jobs Fund (BCMJF).

Houston’s DH Manufacturing, a secondary wood-product manufacturer specializing in finger joint lumber, dunnage, strips, and lathe products, will receive $480,000. This funding will support the installation of a new finger jointer to enhance productivity and create higher-value products from residuals and lower-grade fiber, while protecting 40 existing jobs.

Tsi Del Del Development Corp., a business 100 per cent owned and operated by the Tŝideldel First Nation, is allocated $422,000 to be used to purchase equipment for a biomass sort yard, centralizing the processing of waste wood that would otherwise be burned. This project will manufacture higher-value products and create 16

Alberta backs wood industry

Alberta’s government has launched the Alberta Value-Added Wood Products Program, a move aimed at bolstering small business operators in the province. With collaboration from Alberta Forestry and Parks, Alberta Wood WORKS!, and the Alberta Forest Products Association, the initiative has received an investment of $2.25 million over five years.

The program’s primary focus is on research, innovation, and market entry for new products within the wood industry. This investment aims to optimize the utilization of Alberta’s forest resources while fostering innovation and creating employment opportunities.

West Fraser completes sale of two pulp mills

West Fraser Timber has completed the sale of its Quesnel River Pulp mill in B.C., and Slave Lake Pulp mill in Alberta, to an affiliate of a fund managed by Atlas Holdings. This follows the completion of customary regulatory reviews and satisfaction of customary closing conditions.

The mills will be operated by Millar Western Forest Products, which joined Atlas in 2017.

Quesnel River Pulp and Slave Lake Pulp both produce bleached chemi-thermomechanical pulp used to make paper products.

new jobs.

Meanwhile, the BCMJF is contributing up to $8 million to help Tolko Industries expand its Heffley Creek operation, including construction of a facility that will house a new Heffley Creek Engineered Wood Division. Another $45,760 in BCMJF funding will also support Tolko’s Lake Country Division to explore the use of robotics in the production of non- residential, made-in-B.C. wood products.

Interfor to curtail lumber production

Interfor plans to reduce its lumber production by approximately 175 million board feet between May and September 2024, representing just under 10 per cent of its normal operating stance. The temporary curtailments are in response to persistently

weak market conditions, the company said, and will impact all of Interfor’s operating regions through a combination of reduced operating hours, prolonged holiday breaks, reconfigured shifting schedules and extended maintenance shut-downs.

RYAM to halt operations at Quebec HPC plant

Rayonier Advanced Materials will suspend operations at its Temiscaming High Purity Cellulose (HPC) plant for an indefinite period, effective July 2. The move will result in approximately 275 layoffs.

The company said that given current market conditions and high capital and fixed costs associated with the HPC plant, the decision will help mitigate the plant’s ongoing operating losses and improve the company’s consolidated free cash flow.

The HPC facility has an annual production capacity of approximately 150,000 metric tons, with roughly 30 per cent historically dedicated to specialty cellulose materials.

Reader Service Print and digital subscription inquires or changes, please contact Angelita Potal, Customer Service Tel: 416-510-5113 Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR - Jennifer Ellson (438) 483-7451 jellson@annexbusinessmedia.com

GROUP PUBLISHER - Anne Beswick (416)510-5248 • Mobile: (416) 277-8428 abeswick@annexbusinessmedia.com

ACCOUNT COORDINATOR - Shannon Drumm (416) 510-6762 sdrumm@annexbusinessmedia.com

MEDIA DESIGNER - Alison Keba akeba@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER Serina Dingeldein (416) 510-5124 sdingeldein@annexbusinessmedia.com

NATIONAL SALES MANAGER - Josée Crevier Ph: (514) 425-0025 • Fax: (514) 425-0068 jcrevier@annexbusinessmedia.com

WESTERN SALES Tim Shaddick 1660 West 75th Ave Vancouver, B.C. V6P 6G2 Ph: (604) 264-1158 Kevin Cook lordkevincook@gmail.com Ph: (604) 619-1777

CEO - Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATION

FORESTRY wildfires

REGROWTH AND RENEWAL

First Nations, industry, communities collab to

tackle wildfire risk and forest rehabilitation

BY PRIYANKA KETKAR AND JENNIFER ELLSON

Wildfires are becoming an ever more frequent threat, and with BC Wildfire Service’s Spring 2024 Seasonal Outlook forecast suggesting a high potential for an active spring wildfire season in British Columbia, the threat of these wildfires looms large. As of mid-May, there already are 118 active wildfires in the province this year, showing an early start to the season. More than 4,700 people in Fort Nelson and the Fort Nelson First Nation were forced to evacuate their homes as of May 13 because of a wildfire spanning approximately 123.5 square kilometres.

Historically, we have seen the devastating impact of damaged homes, livelihoods, habitats, and ecosystems across the country’s most western province. In response, the industry, many local communities and First Nations are proactively working to shape a hopeful future. The strategies are the result of meticulous planning, deep consultation with First Nations, and robust scientific research.

In Williams Lake, Clinton, and Logan Lake, many such forerunners have emerged over the past few years, showing a commitment to not just sur-

First Nations and local communities are proactively addressing wildfire risk while improving wildlife habitats.

Photos: Annex Business Media.

“STRATEGIC THINNING CAN HAVE A BIG IMPACT ON CLIMATE CHANGE, FIRE MITIGATION, BIODIVERSITY ... AND PROTECTING THE MULE DEER HABITAT.”

viving the threat of wildfire but thriving, enhancing biodiversity, economic stability, and community strength. Canadian Forest Industries visited these communities in May last year to observe their initiatives firsthand.

WILLIAMS LAKE FIRST NATION PROTECTING HABITATS, PROTECTING THE FUTURE

In Williams Lake, the forests surrounding Bond Lake are an excellent example of meticulous care under the guidance of John Walker, RPF, and his team in charge of Forest Stewardship for Williams Lake First Nation.

The wildfire in the summer of 2017, which devastated over 60 properties and led to many evacuations, provided an opportunity to learn how to better protect communities and became the impetus for the extensive wildfire risk reduction work undertaken by the First Nation. Through strategic thinning, Walker and his team are creating conditions that are more resilient to climate change and wildfire and help ensure wildfires stay on the ground, giving firefighters the best chance to knock them down. This reduces the risk of wildfires and creates better habitats more conducive for wildlife, like mule deer, and traditional vegetation to flourish.

“Strategic thinning can have a big impact on climate change, fire mitigation and biodiversity,

especially when it comes to protecting the mule deer habitat,” Walker says as he points to a deer grazing in the community forest. “We are creating old growth conditions by making the forest thinner so trees have more space to grow. Heathier trees are more resilient,” he explains.

Walker further emphasizes that the Nation has three simple yet profound goals: minimize ground fuel, discourage fires from climbing to the treetops, and ensure fires remain low. It’s a strategy First Nations adhere to from years of observation and learning from nature.

TŜIDELDEL FIRST NATION’S WORK IN SUSTAINING FORESTS FOR GENERATIONS

About 188 kilometres west of Williams Lake is Alexis Creek, known as the Tŝideldel First Nation, part of the Tŝilhqot’in Nation, which has been undertaking extensive forest rehabilitation work through its ventures, including Central Chilcotin Rehabilitation (CCR), Tsi Del Del Enterprises, and Tsi Del Del Development Corporation. The rehabilitation work, the Nation says, reflects their strong commitment to sustainable development, community stewardship, and upholding Indigenous values.

CCR, a joint venture between the Tŝideldel First Nation and the Tl’etinqox Government, was formed in 2017 to tackle the rehabilitation of 100,000 hectares of dead pine forests in the Chilcotin region. The wildfire that year shifted the organization’s focus to rehabilitating the fire-devastated areas and reforesting through the lens of Indigenous values. CCR wasted no time seeking solutions and applied for funding through the Forest Enhancement Society of BC (FESBC). The joint venture has since worked on several wildfire risk reduction projects in and around the community while also partnering with Natural Resources Canada’s 2 Billion Trees Program to replant forests and collaborating with Shell Canada on a Carbon Initiative project.

“Using every tree, every branch, at the same time creating jobs; being involved in every aspect of rehabilitation, from surveying, planting trees, creating healthy, strong, resilient communities –there is a connection between healthy forests and communities,” Percy Guichon, CCR executive director and councillor of Tŝideldel First Nation proudly tells CFI.

This spirit of building up the community is reflected through the many ventures of Tŝideldel First Nation, such as the Red Stone Gas Bar, Barney’s Lakeside Resort, Tsi Del Del Enterprises, Redstone Health Clinic, etc. Both Tŝideldel First Nation and Tl’etinqox Government are driven by a deep desire to reclaim their heritage and promote self-sufficiency. They both have undertaken their collaborative joint venture, plus other business ventures, each

Charred remnants of trees stand as stark reminders of the devastating wildfires that swept through the forest near Williams Lake.

Adam Sullivan, RPF, talks about forest rehabilitation and wildfire mitigation work at Logan Lake.

Clinton Mayor Roland Stanke (left) and community forest GM Steve Law are proud of how they’ve salvaged burnt fibre and better fortified their community from wildfire.

rooted in the principles of sustainability and community well-being. Their endeavours are not only generating economic prosperity but are also serving as a platform for cultural revival and intergenerational learning.

“The Nation is the constant that gives the sector stability – the companies move, but the Nation stays,” says Philippe Theriault, general manager of Tsi Del Del Enterprises.

CLINTON’S HOLISTIC RESPONSE TO ENSURE WILDFIRE RISK REDUCTION

In Clinton, the scars of the 2017 wildfire are still visible, as is the community’s resilience. The Clinton Community Forest, 100 per cent owned by the Village of Clinton, started doing wildfire mitigation work in 2007 to address the community’s concerns regarding the constant threat of wildfire and wanted to do something about it.

Touring with Clinton Community Forest’s general manager Steve Law, Clinton Mayor Roland Stanke, and FESBC’s executive director, Steve Kozuki, there was a palpable pride in how they’ve salvaged burnt fibre and better fortified their community from wildfire.

After the 2017 Elephant Hill wildfire, the community got to work to salvage what they could of the burnt wood. With funding from FESBC, they found ways to use burnt wood, turning it into hog fuel to create green energy. They also created a fuel break – or a wide section without trees - to slow down future fires and help make the routes to fight fires more accessible for crews.

“Our community protection plan is much more than forestry,” asserts Law. “It allows for emergency access, egress and making sure all services are maintained so that first responders can help when needed.” Clinton’s plan is a holistic approach to community safety, blending traditional forest management with proactive preparation.

LOGAN LAKE’S COMMUNITY UNITES TO BECOME FIRESMART

In Logan Lake, ensuring the forests were wildfire resilient was not just a community forest goal but something the entire community of 2,000+ residents embraced. It was proof of the municipality’s collective spirit, with residents, local officials, and organizations like the Logan Lake Community Forest (LLCF) working hand in hand to prepare for the future threat of wildfires. Together, they achieved an impressive milestone: making Logan Lake the first FireSmart Community in Canada. Today, the homes and more fire-resistant landscapes show all the signs of a prepared community.

All this FireSmart work was tested in August of 2021 as the Tremont Creek Wildfire moved toward the community, leading to an evacuation order. However, the community’s proactive efforts to ‘FireSmart’ their surroundings paid off, ultimately preventing widespread devastation and loss of structures, saving the town from the potential impacts of the wildfire.

Forest rehabilitation is also a big part of the ecological stewardship underway. When it comes to rehabilitation, collaboration is key.

“Forsite wrote the prescription for the rehabilitation work, but the local Nation was awarded the contract,” explains Adam Sullivan, RPF, planning forester with Forsite, while pointing to the reseeding measures and rehabilitation of the fireguards being done

in the community forest to help promote the regrowth of vegetation.

Much of Logan Lake’s wildfire resiliency has resulted from LLCF’s consistent, proactive work and the community’s buy-in and participation. For the wildfire risk reduction work, LLCF utilized funding support from FESBC and employed the crews from Skeetchestn Natural Resources, who led the charge of clearing dead and downed trees.

As summer approaches, the experiences of these B.C. communities shine a light on the critical importance of wildfire risk reduction work in communities and the local forests. wThe efforts help better ensure the sustainability and resiliency of more rural communities. Through dedicated leadership and actions, First Nations and local communities are raising the bar, showing how to manage natural landscapes to better protect community assets from the increasing threat of wildfires.

Priyanka Ketkar is a B.C.-based journalist and communications professional working with Amplify Consulting, a Kamloops-based firm working with First Nations, forestry companies, and associations, among others.

A young seedling, symbolizing the ongoing efforts in forest rehabilitation and regeneration.

The crew at CCR, with a focus on rehabilitating fire-devastated areas and reforesting through the lens of Indigenous values.

WOODPRODUCTS

GENERATIONS OF SUCCESS

BY JENNIFER ELLSON

While many family-run businesses succumb to competition or fade into obscurity, one Alberta family attributes their success to relentless hard work, continuous innovation, and the ability to adapt.

For the Moen family, the forest industry isn’t just a business – it’s a legacy. Since 1971, Edmonton’s Moen Lumber Sales has been a cornerstone of the lumber sector, evolving through three generations of leadership. From their early days in pallet building to remanufacturing and reloading business, the Moens have navigated the industry’s highs and lows with resilience and foresight. By staying ahead of

market trends and continually innovating, they’ve maintained their foothold in a challenging field, demonstrating the strength and adaptability that defines their family enterprise.

In September, Canadian Forest Industries had the pleasure of touring Moen Lumber’s eight-acre facility, where we met the entire family and gained insight into the secrets behind the family’s success.

A FAMILY AFFAIR

The journey of Moen Lumber Sales is a testament to the family’s dedication and entrepreneurial spirit.

From their early days in pallet building to remanufacturing and reloading business, the Moens have navigated the industry’s highs and lows with resilience and foresight. Photos: Annex Business Media.

It was started by the late Don Moen and his wife Luane, now 85-years-old. Shortly after, the rest of the family, including the couple’s daughter Debbie, now 63, her husband Brady Compo, 67, and Don’s son Jeff, got involved in the family venture.

Over the decades, they have weathered economic fluctuations and industry shifts by making strategic pivots. Their ability to read market trends accurately and implement innovative solutions has ensured their longevity and success. Whether it was transitioning from pallet building to reman and reloading services or adapting to new technologies, the Moen family has always been proactive in finding ways to thrive. This forward-thinking approach, combined with their deep-rooted commitment to quality and service, has solidified their reputation as leaders in the forest industry.

Continuing this legacy, Debbie’s son Robert Moen started his journey into the forest industry at a very young age. Every weekend, he would accompany his grandfather Don and uncle Jeff to the family-owned lumber and remanufacturing yard, helping with routine maintenance. By the age of 14, Robert was already deepening his knowledge by attending the Alberta Forest Products Association’s lumber grading program. His commitment grew stronger when he turned 16 and, after obtaining his driver’s license, began working at the family mill after school and on weekends. He took on various tasks, from feeding the saws and piling lumber to machine maintenance and general equipment repairs.

After high school, Robert earned his millwright certification and joined Moen Lumber full-time, focusing on machine maintenance and repairs.

“Maintenance is such a huge cost of running a business, so it’s a big advantage that I can do maintenance myself,” Robert muses.

With the untimely passing of his uncle Jeff at age 46, Robert

Visit us online at www.wallingfords.com 800-323-3708 • info@wallingfords.com

The 8-acre Edmonton site serves as a reman and reloading facility.

Wallingford's is honored for the opportunity to distribute the cutting-edge grapple technology from HSP Gripen of Sweden, here in North America.

Announcing Wallingford's partnership with

Wallingford's, Inc. is the North American leader in logging supplies; offering forestry tracks, tire chains, harvester bars, saw chain, grapples and more.

Unique claw design Facilitates smooth and rapid operation across various materials, ensuring seamless engagement and high filling ratios.

High strength steel Laser, gas, and plasma cutting operations, coupled with robotic welding with modern machinery, ensures efficient production. The grapples undergo meticulous finishing, including powder-coating, and are subjected to rigorous testing.

Twin cylinders Contributes to a low axle load and end position cushioning, resulting in exceptional handling characteristics.

Saw cassette option available

stepped up to manage the company. Now, at 40 years old, Robert acknowledges the changes and challenges the industry has faced – from “the cutthroat pallet building business after 30 years to remanufacturing and reloading” – but remains committed to the family legacy. He plans to keep the business thriving for many years to come, continuing to innovate and adapt in an ever-evolving industry.

Robert’s siblings, Robin Moen and Zack Compo, have joined the ranks of the family business, contributing their talents

and expertise to its growth and success.

REMAN, RELOAD

Debbie explains that the remanufacturing segment of their business involves various processes, “including cutting full lifts on our L-M Saws bundle saw, resawing using one of our Baker bandsaws, as well as offering custom cutting to length services and crafting custom pallets.” Currently, this remanufacturing work represents approximately 20 per cent of Moen Lumber’s total sales, Debbie adds.

A LONG WAY TOGETHER

BKT Tires 1/2 Island 16

FORESTLAND

Designed for the most demanding applications, FORESTLAND is BKT’s most recent and innovative bias tire for the agro-forestry sector, but it can also be employed in some agricultural operations such as landscaping and light mulching. Its polyester carcass and specific tread compound make it particularly cut-and-chip resistant, while the robust sidewall ensures a long product life cycle. FORESTLAND’s key features are excellent traction on soft terrain, good grip on any ground thanks to stiff and reinforced tread lugs, a high level of stability thanks to the strong bead construction and top self-cleaning properties. For info: 514 -792-9220

Debbie elaborates on the reloading aspect of the business: “We often receive wood from lumber brokers or directly from lumber yards. Sometimes, obtaining trucks for direct transportation from the mill to their intended destination can be challenging. Edmonton serves as a convenient hub for trucking, so mills and lumber brokers frequently send shipments to us.”

Additionally, lumber brokers purchase blocks of loads (multiple truckloads) from the mill and have them shipped to Moen’s facility until they are ready to sell.

“Our loading and unloading operations are carried out using a variety of forklift sizes. Primarily, we utilize Linde, DaeWoo, and Hyundai forklifts.”

Robert adds: “We get products from around 20 different mills in Alberta and B.C., and we ship all over Canada and the U.S.”

Moen Lumber has seven full time employees, with 10 others working as subcontractors.

SECRET RECIPE

Luane, the 85-year-old matriarch, believes that hard work and total involvement are the cornerstones of multigenerational success. She recalls how her husband would deliver products tirelessly, often working until midnight. Remarkably, Luanne herself remains active, still visiting the loading yard.

“In this business, there is no nine-tofive. Instead, there are many, many hours of hard work – that’s the secret,” Luane says with a smile.

Moen Lumber Sales was started in 1971 by Don and Luane Moen.

A PARADIGM ON EFFICIENCY

BY SARAH STOTLER

Consumers are asking more questions than ever about their homes: how much greenhouse gas emissions are produced during the construction phase? How much off-gassing is happening within the home? How eco-friendly is it? How much will it cost to heat or cool, and how affordable is it?

Paradigm Building Solutions, a Louis Creek, B.C.based company, attempts to answer these concerns through their products. Paradigm operates a fully automated 23,000-square-foot manufacturing facility that produces open and closed wall panels used in wood-constructed buildings. Paradigm also

offers fully finished single and multifamily homes. Last February, Paradigm took a major step forward when they announced the acquisition of additional land in the Louis Creek Industrial Park to build a new 30,000-square-foot, state-of-the-art facility.

FROM WALLS TO HOMES

Established in 2016, Paradigm started undergoing exponential growth in 2018. It initially focused on open-wall systems but quickly expanded to offer closed-wall systems. Their high-performance

Paradigm’s manufacturing facility leverages Industry 4.0 and robotics for precision and efficiency. Photos courtesy Paradigm Building Solutions.

Paradigm is building a new 30,000-squarefoot, state-of-the-art facility near its existing operations.

components achieve a Step 5 energy rating, a B.C. building code indicating the home has been constructed as net-zero energy-ready. The B.C. Energy Step code was introduced as a strategy designed to help meet the government’s target of all new homes being net-zero energy-ready by 2032. Components such as windows, siding, and insulation are pre-installed at Paradigm’s manufacturing facility. As Paradigm grows, they’re focused on becoming a full-service home provider, specializing in energy-efficient, ecofriendly, healthy, affordable, and fireresistant houses.

Innovation is at the core of the company. CEO Philipp Gruner emphasizes their commitment to pushing boundaries. “We are an organization that moves quickly,” he says. “We even have monthly innovation meetings scheduled to explore new approaches. We are always looking to try new and different ways of doing things, whether that is adding a new piece of equipment to our factory or trying a new way of onsite construction.”

Paradigm’s team helps drive this innovation. ”We have assembled a team of high-energy, efficient people who believe in our product and are passionate about making a difference in what we do,” Gruner adds. “We believe that when you hire the best in the industry, others follow. The result is a dynamite team. One of my personal emphases is that we sink or swim together. If there is a mistake, we collaborate to get back on track, and if we have a success, we celebrate together.”

Paradigm is a major employer in the Barriere region with over 70 employees –99 per cent of their manufacturing staff are local residents. Their facility is currently running seven days a week, 10 hours per day.

ROBOTIC TEAMWORK

Paradigm’s manufacturing facility leverages Industry 4.0 and robotics for precision and efficiency. Their process starts with high-grade lumber from B.C. forests. Its first stop on the manufacturing floor is Paradigm’s Hundegger Turbo-Drive saw. The design of each wall panel is uploaded

to the saw software. It optimizes a cutting pattern, ensuring that the maximum yield is achieved and minimizing waste. Next, the stud wall is assembled and nailed according to specifications at the Randek automatic framing station.

Conveyors then transport the wall panel to the zero-labour cell, where two synchronized Kuka robots position the sheeting, fasten it, and route any openings. Recently, Paradigm was able to significantly boost productivity by

Combustible Dust Specialists

Allied brings 49 years experience to help you meet current NFPA Standards with: system design/documentation, spark detection, isolation, grounding, PLC, venting, blast path management, clean-up systems and duct audits — CWB certified and member SMACNA.

Sawmill – Biomass – Boardplants – Pulp & Paper – Power Generation – Mining 50 years of Industrial Air Systems www.alliedblower.com ◆

upgrading their robot and framing table software.

The wall panel then travels to the final quality check and outfeed station where it will either be bundled for shipping or transferred to the Randek butterfly tables for the next steps of closed wall finishing.

For closed wall panels, a paper-based vapour barrier and an interior service cavity are added. This allows for electrical and plumbing to be installed at the construction site. The butterfly table then flips the wall panel to the other side exposing the open wall cavity. Recycled dense-pack cellulose insulation is then blown in using an X-Floc machine. Optimal insulation levels are

SIMPLY

achieved by using a calculated recipe. Once insulated, the wall is closed with a tongue and groove hardwood fibreboard layer.

The final stages include application of the rain screen, bug screen, window installation, metal flashing, and cladding. Paradigm uses premium European Internorm windows for energy efficiency.

In addition to working with third-party developers and framers, Paradigm also offers start-to-finish projects such as single-family or multi-unit homes.

Gruner elaborates, “We are currently engaged in a fire recovery project building 16 new units at Skwlāx te Secwepemcúlecw ... We just handed over the keys to the first home after only seven weeks of manufacturing and onsite construction.”

He adds: “We are sometimes lumped into the same category as volumetric or modular manufacturing. We are a very different product with higher quality, energy efficiency, and longevity while maintaining a much smaller carbon footprint when looking at the full production cycle from start to finish. We were also just awarded another affordable housing project with an indigenous group in Northern B.C.”

Paradigm’s focus on affordable and sustainable homes has gained support from the provincial government. Funding has helped them acquire manufacturing equipment such as a Hundegger saw, and they received the manufacturing jobs grant.

“Louis Creek’s Tolko sawmill was a major employer in the region. It tragically burned down in a wildfire, displacing over 200 workers, so when we came in and brought an alternative

Above: Paradigm CEO Philipp Gruner.

Right: Paradigm is a major employer in the Barriere region with over 70 employees, almost all are local residents.

product that was still directly tied to the forest industry, it offered a bridge to the community’s past, and brought employment for local residents,” explains Gruner.

BUILDING FOR THE FUTURE

Fueled by rising consumer demand and provincial legislation promoting energyefficient BC Energy Code Step 5 builds, Paradigm is expanding its operations and building a second facility. They have acquired a lot within the Louis Creek Industrial Park, just a stone’s throw from their current facility. They have already established a temporary operation there to alleviate some of the pressure on their original facility.

Paradigm plans to break ground on their new facility this summer, with completion of the state-of-the-art 30,000-squarefoot facility targeted for the first quarter of 2025. This expansion is anticipated to triple production capacity and create at least 30 new jobs in Barriere.

The new facility will house the corporate office, a warehouse, a

PARADIGM’S EXPANSION IS ANTICIPATED TO TRIPLE PRODUCTION AND WILL BE EQUIPPED WITH TOPOF-THE-LINE AUTOMATED MANUFACTURING TECHNOLOGY.

manufacturing facility, and a showroom to allow customers to see and interact with Paradigm’s products firsthand. Like its predecessor, the new facility will be equipped with top-of-the-line automated manufacturing technology.

The original facility will continue producing Paradigm’s open-wall products. Meanwhile, the new facility will focus on closed-wall products and complete home kits and it will also allow Paradigm to introduce some new offerings such as floor panels and insulated roof panels. Essentially the new facility will be capable of producing all the building components required to bring a structure to life.

The expansion complements Paradigm’s commitment to continuous improvement. Gruner explains, “As an organization one of our goals is not to sit still. We constantly analyze best practices and explore new approaches to become more efficient. Ultimately, we hope to leverage Industry 4.0 technologies and research and development to drive the costs of home building down. We believe this will make high-quality homes more affordable, as we all know this is a significant challenge in today’s market.”

Although the new facility is in its early stages, Paradigm already has their eye on the future. They plan to continue expanding, possibly venturing beyond B.C. in years to come.

WOODPRODUCTS CANADIAN

GUARDING MINDS

PATRICKmcdonald

Patrick McDonald is the owner of Kootenay Safety Services in Cranbrook, B.C. He is a seasoned safety consultant with over 15 years of experience specializing in industrial manufacturing. Reach him at patrick@ kesafety.ca

In the tumultuous landscape of the Canadian wood products industry, specifically in B.C. where mills are shutting down and jobs are being lost, the importance of psychological health and safety (PH&S) has never been more pronounced.

Despite the industry’s struggles, there’s a growing recognition of the need to nurture a supportive and inclusive work environment. Before delving into practical strategies for prioritizing PH&S, it’s crucial to understand the core functions of the Guarding Minds at Work framework. This framework provides a structured approach to assessing and enhancing PH&S, encompassing three main components: the Employee Survey, the Organizational Review, and the Stress Satisfaction Scan.

UNDERSTANDING EMPLOYEE EXPERIENCES

To effectively address PH&S concerns, it’s imperative to understand employee experiences and stressors. Insights learned from stress satisfaction scans shed light on key factors impacting employee well-being. Statements related to involvement in decision-making, recognition for effort, time pressure, mental fatigue, fairness, and supervisory support offer valuable insights into the stressors and satisfiers present in the workplace.

TAILORING INITIATIVES

Armed with knowledge of employee experiences, companies and management teams can tailor initiatives to mitigate stressors and enhance satisfiers. For instance, addressing concerns regarding time pressure and mental fatigue through workload management strategies can alleviate stress and improve overall job satisfaction. Similarly, fostering a culture of fairness, respect, and recognition can bolster employee morale and engagement.

EMPOWERING EMPLOYEES

Empowering employees by involving them in decisions that affect their work can serve as a potent stress mediator. Management teams can champion initiatives aimed at increasing employee autonomy and decision-making authority, thus fostering a sense of control and ownership over their work.

Regular feedback mechanisms and participatory decision-making processes can further reinforce employee empowerment and well-being. A good example of an employee driven safety initiative would be to introduce a MOC (Management of Change) process, which includes various employee levels during the planning stage of a workstation change.

ENHANCING SUPERVISORY SUPPORT

Supervisory support plays a pivotal role in mitigating workplace stressors and promoting PH&S. Ensuring that supervisors, including safety managers as part of the management team, are equipped with the necessary skills and resources to support their teams effectively is paramount. Training programs focusing on communication, conflict resolution, and supportive leadership can empower supervisors to provide the guidance and assistance needed to navigate challenging situations and support their teams.

MONITORING PROGRESS AND ADAPTATION

Continuous monitoring and adaptation are essential components of a robust PH&S strategy. Management teams should regularly assess the effectiveness of initiatives through employee feedback, stress satisfaction scans, and performance indicators. By staying attuned to evolving employee needs and adjusting strategies accordingly, organizations can cultivate a culture of resilience and well-being.

In the face of industry challenges, prioritizing psychological health and safety is not just a moral obligation but a strategic imperative. By leveraging insights from employee feedback and stress satisfaction scans, companies and management teams can develop targeted initiatives to address stressors, enhance satisfiers, and foster a supportive work environment. Through proactive measures and ongoing adaptation, organizations can navigate turbulent times while safeguarding the well-being of their most valuable asset, their employees.

For more information, check out Guarding Minds at Work at www.guardingmindsatwork.ca.

GROUPE LEBEL AIMS TO NEW HEIGHTS WITH THE HELP OF FINNOS

To boost the productivity of their sawmill in Squatec, Groupe Lebel has chosen Finnos as their Yield Enhancement Partner (YEP)™️. And for good reasons too, make no mistake.

1. ADVANCED LOG SORTING

With Finnos, log sorting is so simple, it’s practically automatic. Our scanners analyze all things wood, such as wood species, under bark, geometry, shape, and internal quality of a given log. They also detect foreign objects lodged in the log. Now that we have all the data, our bespoke algorithms take care of the sorting business on their own.

2. DAPTING AD INFINITUM

Let’s face it. Each project has some hurdles to overcome, and each customer their own challenges. With Groupe Lebel, the challenge was geographical: our R&D happening primarily in Finland we had zero to none previous experience with wood species around the Quebec area. But this is something we had planned for (thanks, our ingenious engineers)! See there’s this small tool called AI that handles the detection of species and many other things as well for us, so the basic principle of recognizing a given species works, we just have to teach the machine with different types of data.

3. GREEN. SO MUCH GREEN.

Green as in money. Also trees. But mainly money. See the thing is more yield = more money, and Finnos is an expert in maximizing yield: for example our log scanners, equipped with myriad sensors (X-ray, lasers, color cameras, etc.), are capable of measuring the ins and outs of a log e.g. the under bark diameter, knots and rot. This, when met with any log receiving, is a surefire way to acquire material in a more transparent manner, and also to optimize sawing patterns down the line. Which is important to, again, maximize yield.

4. COOPERATION

This is the best part, the fruitiest fruit of our already fruitful customer relationship. It takes the power of something magical called cooperation to streamline the process and ensure a fluent project. And cooperation with Groupe Lebel has been quite smooth indeed thanks to mutual and thorough planning and preparation, both of which were started early on. Due to this early planning phase, our customers get to help us help them customize our scanners to fit their needs. For Groupe Lebel one such customization was rot detection with end cameras, which is under development in – you guessed it – cooperation with the customer.

All in all, we are already seeing promising yield results from the new Groupe Lebel log sorting line, and we’re only just getting started.

Ready to join the revolution? Get on board: finnos.fi

Finnos Fusion’s user interface visualizing laser, x-ray and colour images of logs

HewSaw’s Patented dx Sawing™ Technology Provides Benefits to Sawmillers Worldwide

It has been 10 years since HewSaw started developing and testing the ground breaking sawing technology, dx sawing™, which provides sawmills with the opportunity to process cants at a faster speed and with thinner kerf saws. This results in increased throughput, higher recovery and improved efficiency.

HewSaw’s optional dx sawing™ system can replace the company’s standard double arbour sawing technique with a four-arbour system. The first set of arbours will house the saws for an initial or pre-saw cut into the cant, while the second set of saws finishes the job.

How dx sawing™ works

dx sawing™ works well with all HewSaw control systems, ranging from the most simple mechanical log alignment all the way to the most sophisticated CNC shape sawing.

On a sawline equipped with dx sawing™ the log is presented in the usual way to the HewSaw scanning conveyor. After the log is scanned, it is then positioned for the HewSaw with the company’s highly accurate rotary

log positioner, followed by four-sided chipping to produce the cant. This is the point where dx sawing™ comes into the process. In a standard HewSaw line, saws on a single set of double arbours remove the sideboards from the left and right side of the cant but with dx sawing™ this first set of saws only pre-cuts the sideboards. Then just downstream a second set of saws finishes the job. As with HewSaw’s standard sawlines, edging tools complete the process meaning the boards do not require any downstream edging. Once the cant reaches the ripsaw, a HewSaw line equipped with dx sawing™ will repeat the process for sawing the centre stack – the first set of saws makes the pilot or pre-cut while the second set of saws completes the cut. As with the cant saw, edging tools following the ripsaw further process the outer boards.

Advantages of dx sawing™

As the cant passes through a dx sawing™ cant saw, the first set of saws makes an initial cut while the second set of saws finishes the job.

With dx sawing™ the saws are not cutting all the way through the cant in a single cut, which means the depth of cut is substantially reduced resulting in higher processing speeds with smaller diameter saws and thinner kerfs. This results in:

• More production volume per shift or the same production volume in less time

• Higher recovery or yield from each log

• Improved surface quality and exceptional saw deviation

• Less wear on the saws resulting in more time between saw changes

The Development of dx sawing™ technology

HewSaw’s in-house engineering team developed dx sawing™ technology at the company’s factory and worldwide headquarters in Mäntyharju, Finland. The dx sawing™ technology was then initially tested and proven successful in the field on November 1, 2014 at the Idaho Forest Products (IFG) Lewiston sawmill in the USA with several IFG representatives and HewSaw staff on hand.

“We were pleased to be part of HewSaw’s first on-site test of their dx sawing™,” explains Jesse Short, Director of Idaho Lumber Production for IFG. “The technology performed as expected and we were impressed with the test results including the opportunity to have thinner kerf saws and faster speeds.”

Further successful testing of the dx sawing™ technology followed at Metsä Fibre’s Vilppula Sawmill in Finland and dx sawing™ is now in use on several HewSaw lines worldwide, including the HewSaw line at the brand new Metsä Fibre Sawmill at Rauma on the west coast of Finland. Metsä Fibre notes the Rauma mill is “the world’s most modern sawmill” and the company invested approximately EUR 260 million in the project which started up in 2022. This new mill will produce around 750,000 cubic metres of pine sawn timber per year.

HewSaw is the only sawmill equipment producer that can offer the dx sawing™ technology as after the first pioneer tests of the technology in 2014, they applied for a worldwide

patent in 2015 and it was awarded in 2018. The name dx was chosen by HewSaw as dx is a term used in mathematics to describe an infinitely thin slice used in integrals.

About HewSaw HewSaw is recognized as a leader in developing, manufacturing and supplying new sawmill technology and has delivered almost 500 sawing machines to customers in over 30 countries on six continents. In addition to the company’s operations in Finland, they also maintain offices and warehouses in Canada, USA, Australia, South Africa, Netherlands, Sweden and Uruguay. The company has been in business for 60 years and employs almost 300 people worldwide.

A look at the dx sawing™ process inside of a HewSaw SL250 Cant Saw.

A HewSaw SL250 cant saw with dx sawing™ offers higher processing speeds with smaller diameter saws and thinner kerfs.

The initial cut on a HewSaw SL250 cant saw equipped with dx sawing™.

WOODPRODUCTS CANADIAN

CHOOSING CIRCLE SAW GRINDERS

PAULsmith

Paul Smith is a saw filing consultant and founder of Smith Sawmill Service, now part of BID Group. You can reach him at paul.smith@bidgroup.ca.

The mill has nailed down their saw specs, chosen their primary and hopefully secondary saw supplier, and have decided to sharpen in-house. But selecting filing room equipment can be a daunting task if one doesn’t analyze what is wanted out of, let’s say, the new grinder.

In my opinion, accurate grinding of the saw’s teeth is one of, if not the most important part of preparing the saw to cut lumber. Most all of today’s sharpeners can do this and more. How much more is needed for a particular operation can be a big question. Of course, we all have our preferred name brand equipment – but to keep advertising and politics out of this article, we will just discuss available options and technology.

The important question is what your filing room needs to keep the saws in your mill running at their maximum potential. Another question is, will you be only repairing saws or purchasing plates and building new saws? When purchasing grinding equipment, a great deal of thought needs to be put into not only current needs but what the mill’s future plans may be – some mills have a three-year or a five-year plan.

Although management and the proverbial bean counters may want to cut some corners with a machine’s bells and whistles, to be able to make transitions later, it’s better to fully research all the machine’s options and whether or not they can be added later. I am simply saying, purchasing more than you need will help you grow to fulfill the mill’s future needs. Today, a certain amount of automation is practically standard on new equipment. For this article, I will focus the discussion on automatic top and face grinders.

In years past, sawfilers were more plentiful and a mill’s filing room might have anywhere from two to four experienced, professional sawfilers employed. With the shortage of sawfilers in our industry today, many mills are struggling to be fully staffed. However, because of automation and technology in the up-to-date filing centers, some are getting

by with one or two experienced, professional sawfilers. But let’s be honest, automation doesn’t replace experienced filers – it only helps them safely manage their work load.

When purchasing saw grinders, one will find a long list of options. Let’s consider what is needed for your particular filing room:

First, consider your saw specs and determine if the machine that has caught your attention will accept your maximum diameter and automatically feed the tooth pitch without manual intervention.

Next, a major consideration is deciding on the machine coolant, oil or water. Most of today’s sawfilers will suggest always going with oil coolant. By using it instead of water, it will give you a sharper tooth while keeping the correct temper. Oil also adds years of service life to your purchase and makes maintenance and day to day operations easier for the filer.

Another consideration is whether one should purchase a saw grinder to do both facing and topping of the same saw, at the same time, on the same cycle. I personally would answer yes on this question. Saws will be finished in almost half the time, and it frees your sawfiler to work on other projects such as benching and inspecting.

Although most machines offer both without an option fee, make sure your machines can be operated in metric or both U.S. customary and metric. The metric system may have taken a long time to make its way into the U.S. filing rooms, but now professional sawfilers find the system to be more accurate when it comes to grinding off exactly what is needed each pass. The metric system allows for tighter tolerances and in our industry, it is now considered the standard in many mills and filing rooms.

A few other options to consider:

CNC controlled machining is certainly a must, and with today’s high-tech machines, may be an absolute. By purchasing controlled axes, you will be able to grind most all tooth geometries in one cycle.

Oscillation grinding, in my opinion, should be a must. During my time in filing rooms repairing and sharpening teeth, a light finish grind will always make a sharper tooth.

Automatic lubrication system is without a doubt the way to go. Take the time to read my article Saw Filing 101, in CFI’s Jan/Feb 2022 issue: A properly greased filing room.

Grinding wheel wear programs, honestly with me, is debatable. While I see it as a must with automatics, lights off, grinding, I question it with machines sharpening one saw at a time when manually operated. With lights off sharpening, you will have to find the correct sweet spot that will keep the correct advancement sequence while sharpening the tooth, keeping the wheel in the correct match with the tooth. It’s my belief when a filer is controlling the sharpening of the teeth, that filer will adjust as needed during the setup of each individual saw.

show management why another machine is needed.

Wheel rotation programming will be needed when grinding alternate top bevel teeth such as seen in trim saws.

Tracking software: I do believe in the ability to keep up with how many teeth the grinding wheel grinds. This will help with determining which grinding wheel performs the best and will help to prove purchasing a cheap wheel may not be the best choice in the bottom-line vs. performance quandary.

It’s also a good option to be able to know how long the machine has been on and how long the machine has been working actually sharpening saws and how many teeth were ground. When asking to add a sharpener to your filing room, it’s wonderful to be able to

HAMMER HOG series

The transformation of your waste by grinding adds value to the process and reduces production costs in addition to eliminating your waste.

Our hammer hog is designed according to your needs, and manufactured for use in applications requiring robustness and reliability. Its design allows for easy and quick maintenance. Available with vertical or horizontal inlet, residue extraction is done by suction.

Applications: Hardwood / Softwood / Particle board, OSB, MDF

Selection

Capacity

Desired

Type

Variable grinding speeds are also important. This will be a big factor if you’re rough grinding or finish grinding.

Sensors to automatically adjust for tooth pitch will be needed if teeth are not the same distance apart, such as a welded tooth not getting centered properly; variable pitch tooth spacing; and will make for a quicker grind without having to drop your feed pawl so low under the next tooth.

There are many other options to consider when purchasing grinding equipment, but we can cover more in future articles.

DRYING EXPERTS: A RARE BREED

BY FRANCIS CHARETTE

It’s no secret in the industry that drying experts are thin on the ground.

Indeed, expertise in all areas is becoming increasingly scarce. However, I have the impression that this scarcity is more strongly felt when it comes to the wood drying process. It’s certainly not the most attractive process in lumber processing –with cycles that last several hours without having any visual in the kiln – but the importance of kiln drying on the final quality of the lumber and the complexity of the operations should attract workers looking for jobs with impactful and tangible results.

I can’t explain this lack of interest of the new generation for the drying process, having the chance to work with drying experts whose passion for this process is noticeable. Drying is a complex process,

as you are working with a living material that is constantly interacting with the ambient conditions. Mastering this process requires knowledge of the physics of materials, but above all, attention to details and an understanding of the impact of drying on the final quality of products.

As far as I know, there are general training courses in drying at the college and university levels, as well as more specific training offered by FPInnovations, and some manufacturers. However, these alone cannot generate state-of-theart process expertise.

As supporting evidence: kiln dryers audit, operation support, and training are among the most popular services at FPInnovations, thereby indirectly illustrating the industry’s need for expertise.

SMART VISION

Ever seen a log like this? Even with safety as a priority and measures in place to ensure it, accidents can still occur.

BID's Smart Vision can stop operations before accidents happen, increasing safety without compromising production.

BID’S SMART VISION STREAMLINES PROCESS MONITORING BY:

• Detecting production irregularities to prevent significant interruptions and equipment failures

• Enhancing control mechanisms to optimize product singulation, maximize process efficiency, and minimize operational downtime

• Minimizing accidents through reduced reliance on human intervention

THE SYSTEM CAN BE DEPLOYED AT ANY STAGE OF THE PROCESS.

See how Smart Vision would have prevented this near miss.

Contact us to learn more.

450-435-2121 | info@bidgroup.ca | bidgroup.ca

THE IMPORTANCE OF GOOD-QUALITY DRYING

INDUSTRIAL ELECTRICAL PRODUCTS AND SERVICES

I have often heard the following comment when talking about drying: alone, the drying process does not increase the quality of the sawmill, but uncontrolled drying can greatly deteriorate the final quality.

And it’s true that uncontrolled drying will cause downgrading and direct monetary losses. In addition, a drying process that is not optimized will be less productive, which will result in higher operating costs. The impact of sub-optimal drying is also felt at the planer mill: overdried lumber causes a lot of breakage problems, which causes the planer to stop.

Beyond the process itself, the entire management of the raw material in its green state greatly influences the quality of the lumber when it dries. Depending on the species and the storage time, a difference will be noted on the evolution of the moisture content of the wood.

In the hope of obtaining optimal quality at the end of the drying process, it will be necessary to ensure batches have similar moisture contents. It is certainly not easy to quantify the monetary losses associated with kiln drying, since the final distribution of grades is influenced by several factors, including the final moisture content, natural defects, as well as all the practices related to wood processing. However, according to FPInnovations experts consulted, traditional coaching work in drying generates gains of around $5/Mbf in product value increases and five per cent in productivity increases.

TECHNOLOGY AS A PARTIAL SOLUTION

Can technology help fill this gap?

Personally, I think so – I see technology working on many levels to alleviate the shortage of drying experts.

Overdried lumber causes a lot of breakage problems, which causes the planer to stop.

✔ INCORPORATING HIGHEST ENERGY EFFICIENCY WITH HILDEBRAND GREENKILNS SYSTEM

✔ BEST PERFORMANCE DUE TO HILDEBRAND TURBO TECHNOLOGY AND POWER VENTS

✔ PRESSURE FRAMES AND HILDEBRAND WEIGHT PRECISION TECHNOLOGY GUARANTEE HIGH QUALITY

✔ INDIVIDUAL ZONE DESIGN PRIME ZONE ALLOW DIFFERENT LUMBER DIMENSIONS

First, the technological transition can be a motivator for the new generation hungry for technology. In addition, I also see expert systems like Algorex’s helping operators and supervisors, on a daily basis, performing their tasks as well as facilitating and speeding up their understanding of the process. Technology can reduce the mental load of drying managers by giving them a better view on process performance and create attraction for this key position in the industry.

The addition of mill-wide wood traceability systems also allows for better overall decisions to be made to maximize the

Drying is not the most attractive process in lumber processing – with cycles that last several hours without having any visual in the kiln.

value of the wood by taking into account the gains that each process, including drying, can make.

Finally, the technology will allow drying experts to be more efficient and support multiple plants remotely at the same time, in a more efficient way than before, with increased access to operational data.

I hope that after reading this text, some people will have the interest of investigating a career in wood drying.

Francis Charrette is the president and CEO of Algorex.

PROMOTING OR HIRING

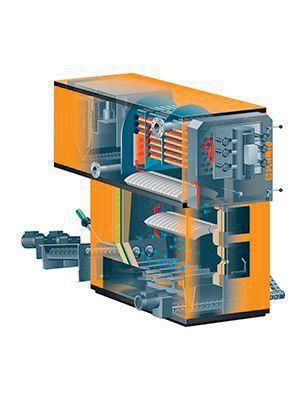

Continuous wood drying greatness

“The TC kiln saves up to 50% energy, compared to traditional batch kilns”

JD Irving, Canada

“They further the development of lumber drying”

Moelven, Norway

“A faster and better way to dry lumber”

Pleasant River, USA

“A partner in our development”

Setra, Sweden

“An automated drying process with high capacity”

Egger Brilon, Germany

Valutec’s state-of-the-art TC continuous kilns meets the highest standards of drying quality with minimal moisture content variation and risk of cracks. They also provide fast drying processes, low energy consumption and high flexibility. All covered in a robust stainless-steel construction with no need for re-skinning.

No wonder they have become the most exciting choice for future-oriented sawmills in North America. Read more at valutec.ca

“The TC kiln offers superior capacity” Hasslacher Group, Austria “Energy efficiency is optimized and the carbon footprint is minimized”

Ha-Sa, Finland

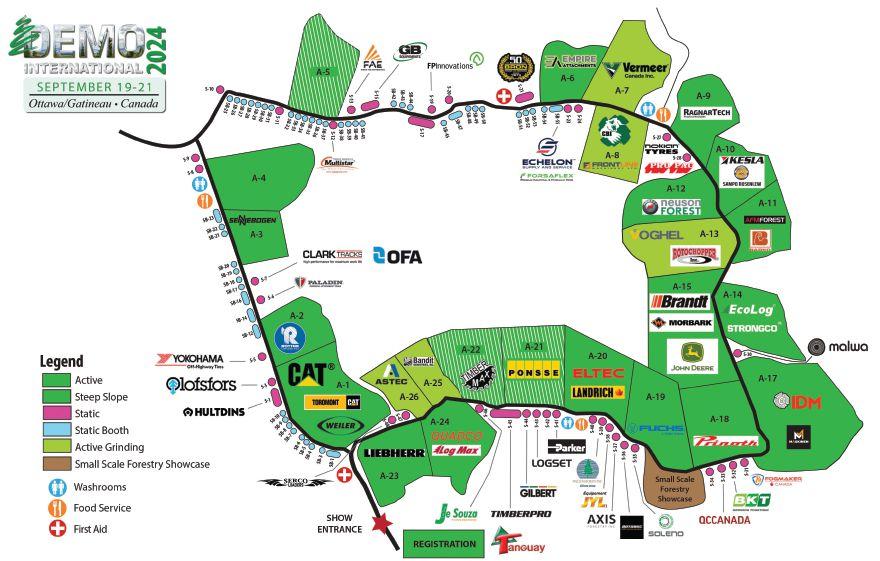

DEMO Expo heads to the capital

Pre-conference

to kick off in Ottawa while expo will be in nearby Venosta

North America’s premier forestry equipment expo, DEMO International, will take over the Ottawa-Gatineau area from September 19 to 21. Held every four years in different regions across the country, this year marks the 14th edition of DEMO International. Over its 50-year history, DEMO International has evolved into one of North America’s largest and most unique outdoor equipment shows.

The festivities will kick off with the DEMO International pre-conference at the Delta Ottawa City Centre on September 17-18. Attendees will have the opportunity to delve into key industry topics, with presentations covering research, automation, digitalization, logging and trucking, biodiversity,

and sustainability practices. Additionally, international forestry outlooks from Sweden and Finland will provide valuable perspectives on global trends and best practices.

DEMO International is renowned for its dynamic demonstrations of cutting-edge forestry equipment, offering attendees a firsthand glimpse into the future of the industry. From state-of-theart machinery to groundbreaking technologies, exhibitors will showcase their products live in the woods, demonstrating their capabilities in action. According to the organizers, the “all live and in action, in-woods” event will attract thousands of leaders in the equipment manufacturing sector, featuring the latest technologies in forestry equipment, products, and services covering all aspects of woodland operations, from fully mechanized to small-scale forestry.

As the flagship event of the Canadian Woodlands Forum, DEMO International is a must-attend for forestry professionals, showcasing the latest innovations amidst a stunning woodland backdrop. This edition will be hosted by SBC Cedar on one of their forest properties in Venosta, Quebec.

Registration opens in June. Learn more and register at www.demointernational.com.

DEMO International’s site plan, courtesy of Canadian Woodlands Forum.

Building workforce resilience through inclusion

Introducing the Forest Sector EDI Alliance

The complexities of recruiting, retaining, and managing a diverse workforce were at the center stage during the 2024 Council of Forest Industries (COFI) annual convention – the largest gathering of the forest sector in Western Canada. An insightful presentation on building workforce resilience through inclusion was delivered by Louise Bender, vice-president of people and administration at Mosaic Forest Management, and Jason Krips, president and CEO of the Alberta Forest Products Association (AFPA).

“Think about the workforce – have we provided a welcoming environment so they would want to work at our mills?” Bender asked the attendees.

The pair emphasized the importance of fostering diversity and inclusion from the boardroom through the production chain, and all the way to

the forest floor, while also unveiling an emerging alliance dedicated to advancing equity, diversity, and inclusion (EDI) across Canada’s forest industry. This marked a significant step towards a more inclusive future for the sector.

“We want to make sure that the underrepresented are supported in this sector,” Krips stressed.

A VISION FOR AN INCLUSIVE FOREST SECTOR

Bender and Krips introduced the beginnings of the new Forest Sector EDI Alliance (FSEDIA), with the vision to position the forest sector as a desirable industry for all. Statistics show that only 19 per cent

STAFF REPORT / FSEDIA

Jason Krips and Louise Bender highlighted their vision of a more inclusive future for the forest sector. Photo courtesy FSEDIA.

Boost Efficiency and Profits

Heat Recovery Vents

•Saves Up To 80% Of Lost Heat

•Pay Back Period Of 2 - 10 Months

•Ensures Your Kiln Runs At Peak Efficiency

NDKR Kiln Controls

•Enhanced Sensor Technology

•Felxible Control Modes

•Can Be Retrofitted To Any Kiln Regardless Of Manufacturer.

of the workforce are women largely working in administrative roles, which is slightly up from 17 per cent in 2016. Around 15 per cent of the workforce are Indigenous, largely working in mill operations; nine per cent are under the age of 24, while temporary foreign workers comprise one per cent of the workforce. The pair noted that these numbers seem to have little movement year-over-year, indicating a plateau in EDI outcomes and reinforcing the need for more work to be done in this space. The alliance strives to remedy this and ultimately for the sector to be more representative of the communities that it is a part of.

THE NEXT EVOLUTION OF SAFETY

Both emphasized the need to nurture cultural and psychological safety in the workplace, asserting that this is the next evolution of health and safety at work. They stressed that ensuring these fundamental elements are in place is integral to creating a work environment where employees feel valued, respected, and empowered to contribute to their fullest potential. This is particularly important in an industry like forestry, where the workforce is traditionally underrepresented by diverse groups.

“We collaborated to make sure safety is a priority to increase our workforce talent pool,” Krips explained.

By providing opportunities for new stories to be told and

heard, leaders can foster an inclusive environment that will help retain the existing workforce and simultaneously attract new talent. The alliance is poised to play a pivotal role in supporting this transformation by offering more opportunities for collaboration and the exchange of best practices across the industry in Canada.

PURPOSE AND OBJECTIVES

The Forest Sector EDI Alliance is an initiative aimed to achieve meaningful inclusion for current and future employees in Canada’s forest sector. The alliance is focused on increasing equity for all individuals, including Indigenous Peoples, visible minorities, women, 2SLGBTQI+ individuals, people with disabilities, and newcomers to Canada. The alliance’s mandate is to create cultural safety within the forest sector, making it an industry of choice for everyone.

BUILDING A NETWORK OF ALLIES

One of the key strengths of the alliance is its focus on building a network of organizations committed to advancing EDI within the forest sector. By bringing together representatives from across Canada, the alliance aims to create a united front that can drive change and foster a more inclusive industry.

This network will provide a valuable resource for organizations looking to improve their EDI resources. Through the exchange of ideas and best practices, members can learn from each other and work together to overcome common challenges.

SPARKING EDI CONVERSATIONS

Bender and Krips shared that another key component of the alliance is to spark dialogue about EDI both internal and external to the alliance. Externally, a great example was the panel that the alliance assembled for CFI’s Women in Forestry Virtual Summit earlier this year, titled Branching out: Cultivating change in the forest sector.

Internal to the alliance, the members have committed to

Louise Bender: “Think

Photo: Annex Business Media.

rooting their work in making space for lived experience stories, where individuals working in a broad cross-section of roles from across the sector share about some of the barriers they have experienced and some of the supports they wished they had access to.

Bender and Krips both remarked on some of the memorable stories they had heard to date, reflecting on the women who don’t have access to appropriately sized personal protective equipment (PPE), or the faller who is openly a part of the 2SLGBTQI+ community and will wake up in the morning ready to start their day just to find that someone has stolen their boots or hidden their equipment.

The pair cited how important it is for these stories to be shared, for they serve not only as a reminder that there is more work to be done, but also as a guiding light that helps identify where we can all work to create positive change.

SHARE BEST PRACTICES

The alliance is comprised of forest sector companies, contractors, non-profits, post-secondary, and others who touch the forest sector in some capacity and are motivated to create change in Canada’s forest sector. The pair emphasized that the power of bringing together a group like this lies in the recognition that everyone is in different places in their journey, and that every entity has a perspective or experience to share that everyone can all learn from. Some organizations may have an innovative program that works to integrate newcomers to Canada, others may have an advanced method of measuring cultural and psychological safety, while others might facilitate an impactful peer mentorship program. Everyone can learn something from one another

“[THERE IS] A NEED TO NURTURE CULTURAL AND PSYCHOLOGICAL SAFETY IN THE WORKPLACE [...] THIS IS THE NEXT EVOLUTION OF HEALTH AND SAFETY AT WORK.”

and that sharing these best practices is a core component of the alliance.

LOOKING AHEAD

As the forest industry looks to the future, the pair said initiatives like this alliance are a significant step forward in ensuring that Canada’s forest sector remains a vibrant and attractive environment for all. They shared that the alliance is expecting to launch a website in the coming months and looks forward to welcoming more folks from across the sector into the fold. By working together and embracing the principles of equity, diversity, and inclusion, the forest sector can build a more resilient and sustainable workforce for the future, the pair concluded.

Jason Krips: “We collaborated to make sure safety is a priority to increase our workforce talent pool.” Photo: Annex Business Media.

EVENT coverage

COFI 2024 CONVENTION

B.C. forest industry faces investor exodus amidst fibre shortage, regulatory uncertainty

BY JENNIFER ELLSON

Industry players gathered at the 2024 BC Council of Forest Industries (COFI) Convention in Vancouver last week, delivering a stark message: the province’s forestry sector is in the midst of a crisis. With dwindling wood fibre supply and regulatory uncertainty looming large, private equity experts and industry heads warned of an alarming trend – investment in British Columbia’s forests is plummeting.

COFI president and CEO Linda Coady highlighted a significant decline in wood harvest at 32 million cubic metres annually, which is only about half the volume compared to five years ago.

“This is too low to sustain the workforce in our industry,” Coady stressed.

“There’s been too much change happening at the same time,” she added, emphasizing the urgent need for certainty in the industry.

“NOWHERE

TO GO BUT UP”

During a panel discussion featuring Minister of Forests Bruce Ralston, Minister of State for Sustainable Forestry Innovation Andrew Mercier, and B.C. First Nations Forestry Council CEO Lennard

The Squamish Nation extending a warm welcome to the delegates.

Joe, Coady raised concerns about BC Timber Sales’ inability to meet its annual allowable cut in recent years.

Coady expressed her skepticism, stating, “A lot here in the room would argue that it’s broken …

hurdles to salvage remaining wood and bolster the province’s fibre supply.

“I was surprised by the whole bunch of barriers and the amount of red tape … there’s a short-term crunch here,” Mercier said, acknowledging the

don’t we need to start thinking about what a new system would look like?”

In response, Ralston acknowledged the challenges faced by BC Timber Sales but expressed optimism about the future, anticipating an increase in wood sales in the next fiscal year.

Addressing the room, Coady emphasized, “You’ve heard it directly from the minister. It’s bottomed out. Nowhere to go but up.”

The forestry sector, which has historically been a cornerstone of British Columbia’s economy, has received an estimated $15.8 billion in investments over the past decade, supporting approximately 100,000 jobs across the province. However, recent shifts in government policies have left investors wary.

Amidst the discussion, Mercier shared insights from his recent engagements across the province. Having assumed his role just three months ago, Mercier said he has been actively touring to grasp the challenges confronting the forestry sector firsthand.

He recounted his visits to fire-ravaged forests, where companies grapple with bureaucratic

BREAKTHROUGH AGREEMENTS

Coady highlighted positive developments in First Nations involvement, noting an increase in revenue sharing, more equity agreements, and emerging collaborations in technology. She emphasized the significance of breakthrough agreements, citing the recent landmark deal between the ‘Namgis First Nation, Western Forest Products, and the provincial government.

“We need more of these breakthrough agreements – that would be such a powerful signal to send to the investors,” Coady asserted.

Lennard Joe echoed Coady’s sentiment, expressing First Nations’ readiness to actively participate in such agreements. He pointed to the recent formation of Iskum Investments, a consortium of 20 B.C. First Nations, as a notable achievement.

“We need 200 First Nations to work together,” Joe said.

“Yes, 205!” Coady emphasized, underscoring the diversity and potential collective impact of the 205 distinct First Nations in the province.

“WE NEED MORE OF THESE BREAKTHROUGH AGREEMENTS – THAT WOULD BE SUCH A POWERFUL SIGNAL TO SEND TO THE INVESTORS.”

Ministers Bruce Ralston (left) and Andrew Mercier during the panel discussion on B.C.’s strategy for stabilizing fibre supply.

NEW NARRATIVE

In a separate panel discussion focusing on the economic and investment outlook, industry experts shed light on the challenges facing British Columbia’s forest industry.