FOCUS ON AQUAPONICS

See pages 20-31

See pages 20-31

BY TREENA HEIN

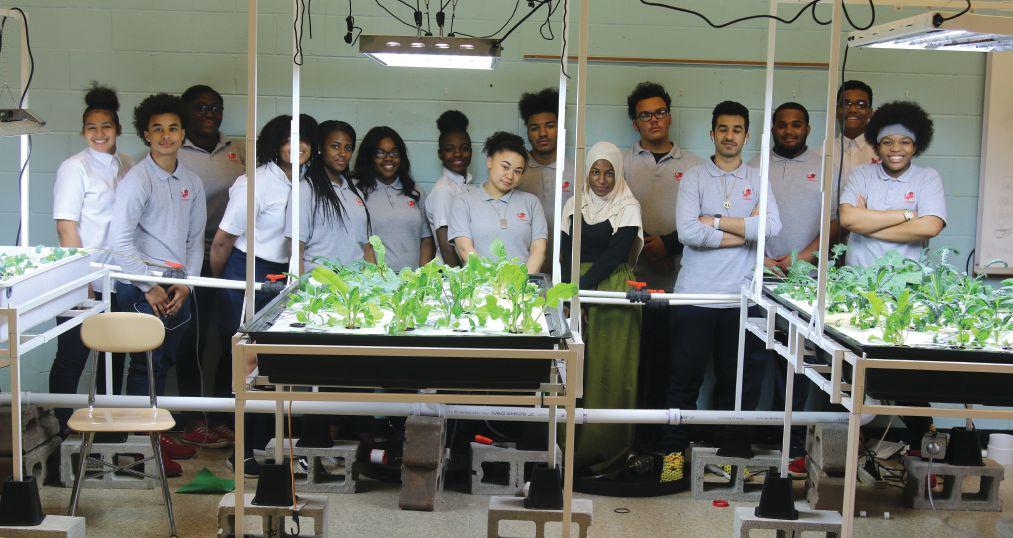

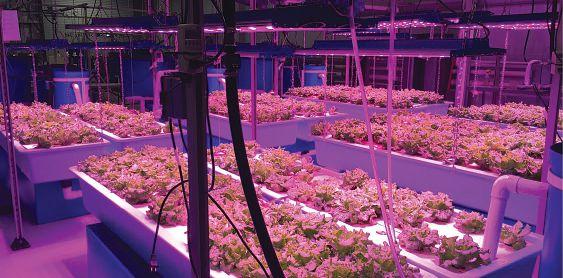

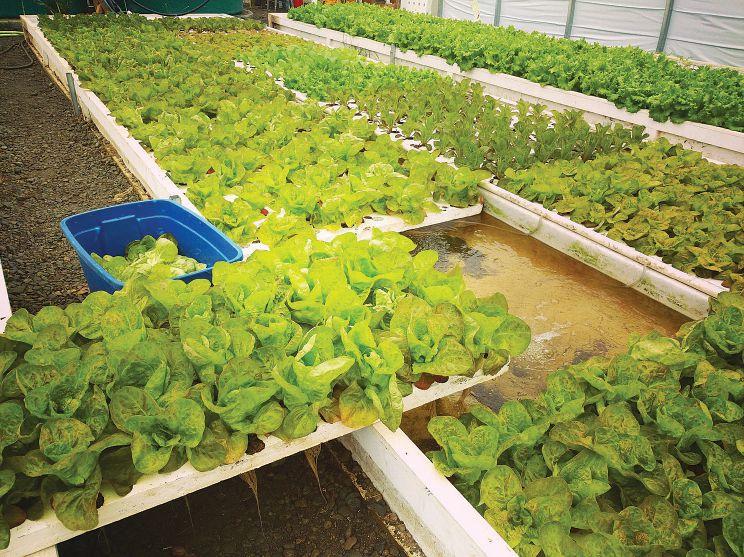

It’s pretty easy to understand why aquaponics is growing in North America and around the world. Local food, especially that produced in urban areas and available even in the winter, sees robust demand because of its freshness. Locally produced food also provides consumers with peace of mind about where their food comes from. “People are more conscious about the carbon footprint of their food – how far it has to travel,” notes Dr Chris Hartleb, a professor of fisheries biology at the University of Wisconsin-Stevens Point and the director of the Northern Aquaculture Demonstration Facility & Aquaponics Innovation Center.

Producing greens by themselves in aquaponic systems is very profitable due to the large amounts that can be produced and a quick turnaround. So why produce fish? Hartleb says fish represent only about 10 percent of profits – at least it typically does in aquaculture operations in the upper Midwest where mostly tilapia is grown. However, he notes that there is strong interest among aquaponic growers in higher-value fish such as Atlantic salmon, perch and walleye that can fetch three times the price. (Superior Fresh is leading the charge on that front, with salmon.)

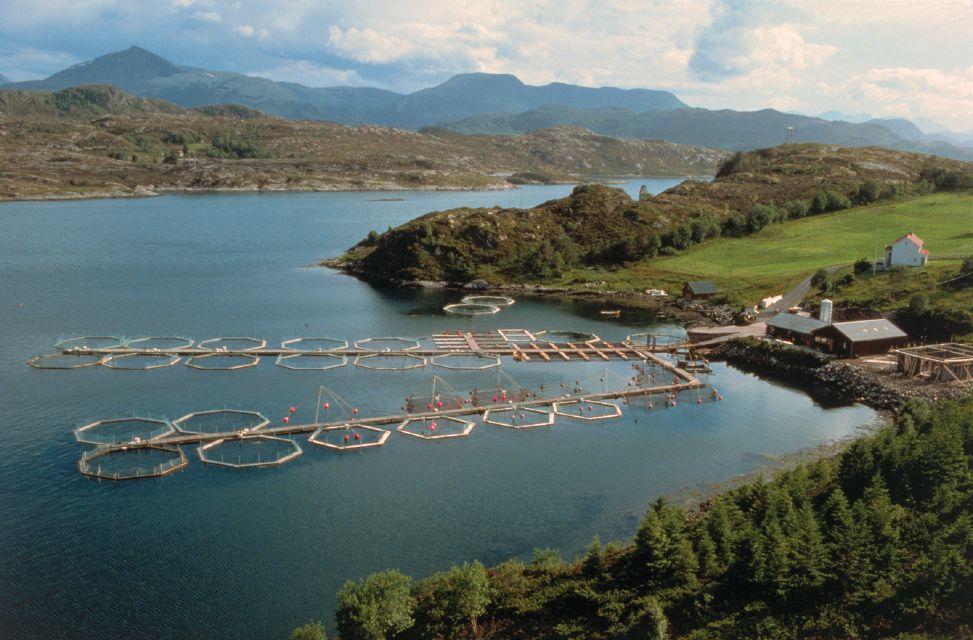

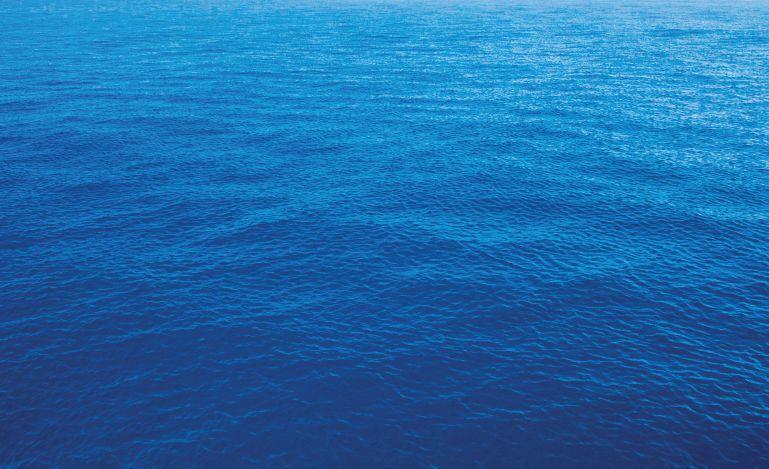

Rebranding integrated multi-trophic aquaculture into ‘3D Ocean Farming’ inspires, draws followers beyond industry borders

Connecticut shellfish farmer Bren Smith promotes the benefits of ‘regenerative ocean farming’ to people across the US and overseas

BY TOM WALKER

Scontinued on page 23

Aquaculture’s crucial role in feeding the world’s growing population is underscored yet again in the United Nations Food and Agriculture Organization’s (FAO) biennial report, “The State of World Fisheries and Aquaculture.”

Global fish production peaked at about 171 million tonnes in 2016, of which aquaculture accounts for 53 percent (excludes non-food uses) or 80 million tonnes, with first-sale value of $231.6 billion.

continued on page 9

ometimes you can see the future by looking to the past. Connecticut shellfish farmer Bren Smith would walk by a mural on the wall of the Madison post office that depicts farmers gathering seaweed from the beaches of Long Island Sound in the 1930s. “I didn’t make the connection until I was growing kelp myself. One of the things it was used for was fertilizer.”

“The last thing I really wanted to do was grow kelp,” admits Smith, but kelp’s nature as a fast-growing crop that requires low maintenance was hard to resist. “You do almost nothing to it, just a drive-by every two weeks to be sure the gear isn’t broken,” he says.

The need to generate various sources of income led Smith to adopt the IMTA model. “Every commercial fisherman (he used to be one) knows one needs a diverse source of income. I was also looking for other things to grow to use all of the water column.”

continued on page 12

Publications Mail Agreement #PM40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

(parasiticide)

The SLICE® Sustainability Project is the latest global initiative from Merck Animal Health — the world’s leader in health management tools for farm-raised fish.

Based on four core actions — Protect, Conserve, Renew, and Succeed — the field-proven, science-driven program is helping the world’s salmon farmers develop long-term, sustainable control programs for sea lice.

To help ensure success, The SLICE Sustainability Project also involves a global network of analytical laboratories that conduct bioassays, feed and tissue analysis, and other tests needed to implement the program effectively.

Your Merck Animal Health representatives are ready to take an active role in your sea lice control program — training farm personnel and developing site-specific strategies that ensure product efficacy and longevity.

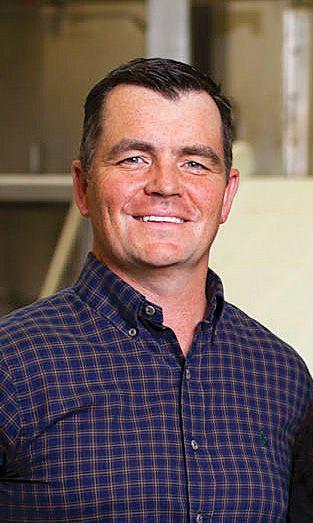

RAS MILESTONE. The first harvest of Atlantic salmon from the first commercial-scale land-based aquaculture facility in the United States hit the market on July 4. Superior Fresh harvested 2,000 lbs HOG (head-on-gutted) salmon during the last week of June. It took the company approximately threeand-a-half years from concept to harvest. ‘There are no other facilities that are currently growing Atlantic salmon in the United States, let alone in conjunction with a commercial greenhouse,’ says Brandon Gottsacker, president of the Northfield, Wisconsinbased company. The aquaponics component of the business is anticipated to produce about 4,500 lbs of leafy greens and herbs a day.

Superior Fresh aquaculture manager Kyle Woolever holds Atlantic salmon raised inland by the company

The United States imported more than 6 billion lbs of seafood valued at more than $21.5 billion in 2017, the highest on record, while exporting more than $3.6 billion lbs valued at about $6 billion, data from the NOAA show.

Commerce Secretary Wilbur Ross and NOAA are looking at new strategies to cut the deficit, including increasing the amount of aquaculture-based farming, said Jennie Lyons, a NOAA spokeswoman.

Earlier this year, Ross said the deficit represents “untapped” potential opportunities in the nation’s aquaculture industry. “Expanding our nation’s aquaculture capacity presents an opportunity to reduce America’s reliance on imports while creating thousands of new jobs,” he said.

One needs only to mention erratic shrimp prices, disease outbreaks and supply shortage and it becomes clear that the shrimpfarming sector is in dire shape.

Global Aquaculture Alliance (GAA) President George Chamberlain believes the future of shrimp aquaculture lies primarily in breeding innovations.

“I want to make the case with you that there’s nothing we can do in any aspect of aquaculture that has the cumulative benefit year after year as breeding. I would say it is the primary driver of improvement,” he told the audience at Aquavision 2018 in Norway. Shrimp diseases such as early mortality syndrome and Enterocytozoon hepatopenaei (EHP) “slowed down the industry’s growth to a crawl,” he said, and impacted prices. “Shrimp prices are very volatile due to high prices when there’s a disease outbreak and a shortage in supply, and a plunge in prices when there’s a recovery.”

Chamberlain said breeding innovations would be key to addressing the industry’s challenges.

“In breeding it’s reasonable to expect a 10-percent improvement every generation. If you’re a feed supplier for example, you would be lucky to get a 2-percent improvement each year and can’t probably do it every year. I would say that’s true in every aspect of the value chain, such as processing, hatchery etc. So breeding is super important.”

Breeding today is focused on “agronomic traits,” characteristics that farmers want, he added. These include traits for growth, resistance to multiple pathogens, reproductive performance and soy tolerance.

No change in workplace rules, focus will be on workforce education, safety

The legalization of recreational marijuana looms in British Columbia this Fall but employers in the province’s aquaculture industry interviewed by Aquaculture North America (ANA) say there will be no change in their current policies concerning controlled substances in the workplace.

“Although much talked about, the upcoming legislative changes around recreational cannabis don’t change current workplace policies. We are planning some outreach to remind staff of this, but impairment in the workplace is a safety issue and is governed by WorkSafe BC (a provincial government agency responsible for workplace safety.) At Creative Salmon, recreational cannabis use/impairment in the workplace is forbidden. Post legalization, that will still be the case,” Lisa Stewart, human resources manager of Tofino-based Creative Salmon, tells ANA

Policies are also in place regarding the use of controlled substances at Marine Harvest Canada (MHC), says Jeremy Dunn, director of community relations and public affairs. “Recreational cannabis will be added to the list of controlled substances in BC (along with alcohol) and our policies will be updated to include where appropriate,” says Dunn.

In the shellfish industry, “anecdotal evidence suggests shellfish farmers will not allow pot in the workplace or during work hours any more than alcohol is permitted,” says Darlene Winterburn, executive director of the BC Shellfish Growers Association. WorksafeBC regulations set the standard for industry rules that pertain to employee impairment by alcohol, drugs and other substances. The safety of our workers is paramount.”

But aquaculture diver Kelly N. Korol is concerned. The director of training and owner of DIVESAFE International says that a lot of dive companies and dive supervisors are worried about rules and how this will affect the workplace.

“It will be available as readily as alcohol,” says Korol, but unlike alcohol intoxication, which gives off clues such as smell and behaviors, and where tests are available to determine the level of intoxication, pot intoxication does not, he wrote in DIVESAFE newsletter, which the company shared with ANA

“Who can say if glassy eyes are a result of pot or simply allergies?,” Korol asks. He says it is not about the diver’s ability to dive, but rather it is about responsibility to coworkers because it could put others in harm’s way. “The bottom line is that responsibility must fall on the diver. No matter how together one feels after smoking a big fatty (a marijuana cigarette), they should not be diving commercially.”

The provincial government says recreational marijuana will be legal beginning October 17, 2018. “We’re now focused on developing the regulations and supporting policies for the implementation of our provincial regulatory regime. We are also working on provincial public awareness and education campaigns, to ensure British Columbians have the information they need regarding legalization and our provincial regulations when they come into force,” said Mike Farnworth, Minister of Public Safety and Solicitor General, in announcing the federal Cannabis Act.

— Liza Mayer

Seventy-two percent of the 30 fish processing facilities in British Columbia are not compliant with permit conditions, and the province says there is a need to strengthen requirements for fish processing operations in order to protect the marine environment.

The sector-wide audit was conducted after the online publication in November of a video by diver Tavish Campbell that shows fish blood and waste being pumped out of a salmon processing plant in Brown’s Bay near Campbell River.

Results of the audit, released in July, shows the majority of non-compliances with permit conditions were administrative, such as failing to post signage, but there were a few fish processors that exceeded volumes and the quality of fish processing effluent discharged, than is allowed under their permits.

“This audit clearly tells us more work needs to be done to ensure our coastal waterways are safe for all wild fish stocks,” said George Heyman, Minister of Environment and Climate Change Strategy. “The industry has been largely operating under an outdated permitting regime, going back several decades. We are taking immediate steps to ensure permits are updated and strengthened at fish processing facilities throughout BC.”

The ministry recommends modernizing existing permits to include additional environmental protection provisions, such as more rigorous discharge requirements and increased monitoring, and requiring fish processing facilities to update their update their standard operational procedures to reduce the volume of effluent discharged into the environment.

Review shows majority of fish processors in BC do not follow regulations.

Editor Liza Mayer Tel: 778.828.6867 lmayer@annexbusinessmedia.com

Advertising Manager Jeremy Thain Tel: 250-474-3982 Fax: 250-478-3979 Toll free in N.A. 1-877-936-2266 jthain@annexbusinessmedia.com

Art Director Svetlana Avrutin savrutin@annexbusinessmedia.com

Regular Contributors Ruby Gonzalez, Treena Hein, John Nickum, Matt Jones, Tom Walker

President & CEO Mike Fredericks

Circulation Manager Barb Adelt Tel: 416-442-5600 ext. 3546

badelt@annexbusinessmedia.com

Subscriptions Angie Potal apotal@annexbusinessmedia.com Tel. 416-510-5113

or 416-442-2191

The potential for using Camelina sativa as a substitute for fish oils and fishmeal in aquaculture feeds has been explored in recent years, but now it’s time to test its mettle

Researchers at the University of Stirling in Scotland have launched a study to look into the effects of a camelinaoil-based diet on farmed Atlantic salmon.

The farmed salmon will be fed a new feed solution that contains oil extracted from camelina crop that was genetically modified make health-beneficial Omega-3 fish oils.

Current industry practice involves feeding farmed fish with feed containing marine fish oil, sourced from the sea, and vegetable oil. Supply from the wild fisheries is, however, unsustainable.

The new study will determine if Omega-3 fish oils coming from the GM camelina plant will be a worthwhile substitute.

The researchers will compare the performance of the fish fed the new feed solution in terms of weight and growth of the fish, with farmed salmon fed a standard diet. They will also compare their tissue and molecular samples.

Plant scientist Professor Johnathan Napier, who developed the GM plants at Rothamsted Research, and fish nutritionist Professor Douglas Tocher, of Stirling’s Institute of Aquaculture, will jointly lead the study. Dr Monica Betancor, a Research Fellow at Stirling, will also play a crucial role by checking on the health of the fish and collecting data.

The potential for using Camelina sativa as a substitute for fish oils and fishmeal in aquaculture feeds has been explored in recent years. In April 2017, the Canadian Food Inspection Agency approved mechanically extracted camelina oil for use as a feed ingredient for farmed salmon and trout.

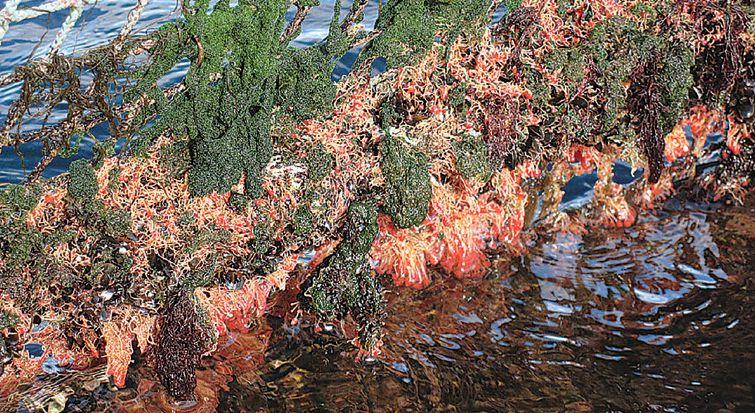

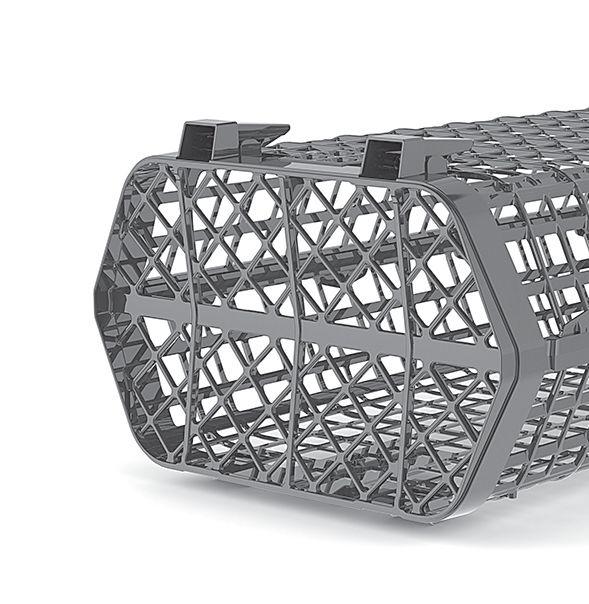

Rough conditions in the open ocean and biofouling are two biggest threats facing ocean farms, an experimental farm finds

Fish farmers are learning valuable lessons as they get their feet wet in ocean farming.

Proponents behind a yellowtail kingfish experimental ocean farm in New South Wales, Australia found out the hard way the destruction biofouling could inflict on ocean pen structures.

Huon Aquaculture of Tasmania and the New South Wales Department of Primary Industries, who are behind the ocean farm, acknowledged that barnacles and mussels believed to have been introduced from a nearby port damaged one of the sea pens and caused 20,000 fish to escape early this year.

“This was an unexpected problem and to develop the equipment needed to address this problem will take time,” Pender Bender, CEO of Huon Aquaculture, told ABC News. Huon is working with an American manufacturer to design new net cleaning equipment and said it will not install additional pens in the meantime.

Initial results of the five-year kingfish research project have otherwise exceeded expectations. The kingfish (Seriola lalandi) grew to market size faster than expected and there were no issues with feeding or pathogens.

The 62-hectare research site is situated six-km from land and is said to be subject to some of the roughest sea conditions in the world. But while it has so far withstood swells up to six meters and some waves up to 11-meters high, the proponents are not taking any chances so they’ve bolstered the structures, the report said.

Healthy fish is our shared commitment. With one small dose of FORTE VII®, you can help protect your fish against six naturally occurring bacterial, and one viral salmon pathogen. Sharing your

NORTH AMERICA: +1-877-544-4966 INTERNATIONAL: +1-902-367-7482

© 2018 Eli Lilly and company, its affiliates or subsidiaries.

The study suggests that readers should be wary of aquaculture journals that were established after 2010, publish less than 20 papers per year and publish articles rapidly, defined as less than 80 days after submission

Marine scientists are warning the aquaculture community about the rise of so-called predatory journals, scientific research papers that are not peer-reviewed, have questionable quality and are freely available on the internet.

In their paper Predator in the Pool? A Quantitative Evaluation of Non-indexed Open Access Journals in Aquaculture Research, marine ecologists Jeff C. Clements, Rémi M. Daigle and Halley E. Froehlich said predatory journals can pose a threat to aquaculture if policy makers rely on them.

“Policy makers, managers, fish farmers, and the general public rely on sound and reliable science for a successful and sustainable aquaculture industry”, says Clements, a visiting post-doctoral fellow with Health Canada and the Public Health Agency of Canada. “If they aren’t trained to properly recognize good science from bad science, they run the risk of interpreting predatory open access journals as high-quality scientific journals.”

Such journals get published in dubious online publications that charge academic authors prohibitive fees. The researchers found that predatory journals were more likely to be found during a Google search.

“This is concerning given the public perception of aquaculture is often negative, despite research showing positive benefits too,” Clements said.

He believes that open access publishing is a benefit to aquaculture science—and indeed all of science—but that it is important to understand that some scientific information may not necessarily be correct or factual.

“Science communication, like any form of communication, is a two-way street: readers need to be aware that not all science is created equally and that some science is flawed; at the same time, scientists need to connect with a broad audience to quell some of the misinformation that exists in scientific literature.”

Awareness and recognition is key to identifying and avoiding predatory open access aquaculture journals. To recognize whether or not a scientific journal may not be legitimate, here are some tips:

• Readers should be wary of aquaculture journals that were established after 2010, publish less than 20 papers per year and publish articles rapidly (less than 80 days after submission)

• If a journal is deemed suspicious based on those criteria, the reader should then go online and search for the name of the journal in the Directory of Open Access Journals (www.doaj.org)

• If the journal shows up in that database, it is good, but if it doesn’t show up in that database, it should be read with caution

• For interpreting science, non-scientists should seek the advice of trained scientists

Pending US tariffs on $200-billion worth of Chinese imports has opened conversations on who will win or lose in the trade spat. But according to the NRF, American families and workers would be the clear losers.

“The latest list of $200 billion of products to be subject to tariffs against China doubles down on a reckless strategy that will boomerang back to harm US families and workers,” said the National Retail Federation (NRF).

“The threat to the US economy is less about a question of ‘if’ and more about ‘when’ and ‘how bad.’ Tariffs on such a broad scope of products make it inconceivable that American consumers will dodge this tax increase, as prices of everyday products will be forced to rise. And the retaliation that will follow will destroy thousands of US jobs and hurt farmers, local businesses and entire communities,” the association said.

The US decision to impose higher tariffs stems from China’s “unfair” and “harmful” industrial practices that restrict trade between the two countries. Under the plan, the US will levy 10-percent tariffs on a list of imports from China. The list includes a wide range of seafood that go to China for reprocessing and then imported back into the US for the local market.

Increasing tariffs has its share of supporters, however. Some US shrimp suppliers believe the tax will help curb oversupply. Some tilapia producers believe the tariffs will make trade with their Chinese counterparts more equitable.

“It’s about time we did something to level the playing field as it were, through shrimp and tilapia, two of the major seafood coming out from China. Cannery is a government-subsidized industry in China. They keep the prices low to keep competition out,” commented Bill Martin, president and CEO of Virginia-based Blue Ridge Aquaculture.

Martin noted that as a live-tilapia supplier, the tariffs issue has no impact on Blue Ridge Aquaculture, known as the world’s largest producer of indoor-raised tilapia. “But we hope down the line when we start to process fish this will give us a level playing field,” he told Aquaculture North America (ANA)

He is confident the tariffs will not have much of an impact on US tilapia prices. “I would be surprised it if it will be much of an increase. Central America suppliers and Brazil are moving into tilapia in a big way, Chile is moving into it in a big way. I expect

for the local market. Credit: Adobe Stock

that void to be filled very quickly [by them].”

The planned tariffs will be finalized in late August after the public-comment period. Martin is hopeful the trade spat will be short term and a deal will be struck before it will have any impact.

NRF is meanwhile urging the Trump administration to strike a deal with China. “The administration has been pursuing tariffs now for months and we still don’t know what the endgame is. Now is the time to get back to the negotiating table with China while working through a global coalition that shares our concerns. The way things are shaping up, it may be too late, but we hope the administration changes course before we lose the momentum from tax and regulatory reform and return to an era of high prices, job loss and negative growth in our economy,” the group warned.

With Extru-Tech’s ADT (Advanced Densification Technology), the possibilities are far reaching. ADT technology gives you the option to produce sinking feeds with excellent consistency and density. That same ADT technology can produce floating feedswithhighproteincharacteristicsallfromasingleextrusionsystem feeds with high protein characteristics … all from a single extrusion system. In the aquafeed business, you either sink or swim. Contact Extru-Tech today at 785-284-2153 or visit us online at www.extru-techinc.com

extru-techinc@extru-techinc.com www.extru-techinc.com

Forty-two oyster farmers in British Columbia have so far applied for the $1.3-million BC Oyster Recovery Fund that will support this year’s oyster stock re-seeding efforts.

The application intake remains open until March 31, 2019 or until funding is exhausted, according to the Ministry of Agriculture.

The Fund will also support a marine norovirus pilot research survey that will monitor the travel patterns of pathogens through Baynes Sound. Another project it will fund is research that could lead to the development of an early warning system for pathogen transfer.

“Oyster growers in our province work hard to support their families in coastal communities,” said Lana Popham, Minister of Agriculture. “Right now, they need our help, and the BC Oyster Recovery Fund will provide key supports for the sector to address the recent challenges they have faced, and will increase consumer confidence in our amazing oysters.”

“We are grateful for the assistance provided by the Ministry of Agriculture to help farmers recover from the impacts of environmental issues beyond their control,” said Darlene Winterburn, executive director, BC Shellfish Growers Association (BCSGA).

“This emergency funding will go a long way to build confidence and to provide stability for our farmers. The research will benefit everyone who lives on BC’s coasts.”

Ashrimp farmer in Dallas, Texas is field-testing a technology that it developed to keep indoor shrimp farms safe from bacteria.

NaturalShrimp, a publicly traded agro-tech company, has started testing the patent-pending technology in a 65,000-gallon tank at its pilot production farm near San Antonio, Texas.

The company says the technology is “potentially disruptive to the entire shrimp farming industry.”

“NaturalShrimp’s patent-pending Vibrio Suppression Technology effectively eliminates water-borne bacteria and other harmful organisms and keeps ammonia at safe concentration levels, thus eliminating one of the historically most difficult problems in shrimp aquaculture,” it said on its website.

With 5.8 percent annual growth rate since 2010, aquaculture continues to grow faster than other major food production sectors. In 2016, aquaculture production increased by 4 million tonnes over the previous year.

In contrast, capture fisheries production was at 90.91 million tonnes, relatively unchanged since the late 1980s. This shows aquaculture has been responsible for the continuing impressive growth in the supply of fish for human consumption, says the report.

Heavy dependence on wild spat is a cause for concern among oyster producers in New Brunswick. Credit: GNB.ca

ne commercial hatchery currently serving New Brunswick’s 90 oyster growers will not be sufficient to supply future demand for the growing industry, according to the province’s Department of Agriculture, Aquaculture and Fisheries.

The Canadian province aims to grow the industry by 10 percent annually over the next five years but oyster farmers mostly depend on seed supply from the wild, an unsustainable practice.

“People are getting nervous about what the wild can provide. Hatcheries will become more and more popular in serving the industry in the future,” said Marie-Josée Maillet, department coordinator.

This could be an invitation for commercial hatcheries to set up shop in New Brunswick. The province, in its 2017-2021 Shellfish Aquaculture Development Strategy, pledges to support the development of hatcheries or nurseries when business rationale is demonstrated. Support for R & D projects that aim to produce healthy and diseaseresistant spat is also at hand.

New Brunwick’s oyster industry is currently operating at only 20-percent capacity.

“Demand is greater than what oyster farmers can produce right now,” said Maillet. “The industry is still growing, there’s still room to grow, all our sites are not at capacity but once they are, that’s going to be our biggest challenge.”

Last year, its oyster exports grew 18.6 percent to $5.8 million in 2017 from the previous year, continuing the industry’s rally. Overall industry growth was at 57 percent over the past five years, measured in terms of oyster bags in water, which in 2017 was at 518,000.

Fish consumption is also at an all-time high at 20.3 kg per capita in 2016 versus just under 10 kg per capita in the 1960s. The report attributes this too to increased production via aquaculture.

By 2030 the world will eat 20 percent more fish (or 30 million tonnes live equivalent) than in 2016. Aquaculture production that year is projected to reach 109 million tonnes, a growth of 37 percent over 2016.

The projected increase in global fish consumption raises concerns over sustainability of fish farming and fisheries, however. The United Nations warns future growth will require continued progress in making aquaculture and fisheries more sustainable. For instance, the sectors can improve efforts in reducing the amount of fish being discarded at sea or thrown out post-capture by using discards and trimmings to produce fishmeal, it said.

EWOS ADAPT PARR’s unique fatty acid blend imitates the natural diet of pre-smolt salmonids in freshwater. With a specialized formulation and optimal functional ingredient mix, EWOS ADAPT PARR ensures best health prior to saltwater transfer and supports osmoregulation and saltwater adaptation in combination with EWOS ADAPT MARINE post-transfer.

BY LIZA MAYER

In June 2022, applicants will have to meet two new criteria when seeking new, or renewal of, fish farm licenses in British Columbia. First, applicants must obtain consent from local First Nations that control the territories in which the fish farms are located and, second, get a stipulation from the Canadian fisheries department that the farm’s operation won’t endanger BC’s wild salmon stock.

How the farmers are to acquire First Nations approval is unclear. How “consent” is defined and who gives it is also ambiguous. For instance, is it the hereditary chief or the elected chief that grants approval? What if one band says yes and another says no? Also, what if band councils do not agree with their leadership? Can approval be taken away when a new chief is elected or appointed? Many more questions remain to be cleared up.

“Right now we are working with the word ‘agreement.’ And so, as far as the technical details around that, I think we’re going to have to see how that works and that’s why we have this four-year transition time,” said Agriculture Minister Lana Popham at a press conference in June.

Popham denied the new policy effectively gives First Nations veto power over fish farm tenures. “There is no veto. We’re looking at this as a framework to reach agreements. Agreements have been made with First Nations and fish farm operators in the past. They exist right now. So we’ve set forward a framework for those discussions to happen,” she said.

When asked: “If the salmon farm operation does not have First Nations approval in 2022, they’ll (the operators) potentially vacate or be evicted; how is that not a veto?”

Popham replied: “I think that if there is an agreement on the table between First Nations and a fish farm operator, they’ll both have the opportunity to say no to that agreement.”

The BC Salmon Farmers Association (BCSFA) told Aquaculture North America (ANA) in August that salmon farmers are currently in dialogue with the government. “We have a long history of productive dialogue with First Nations, such that today more than three-quarters of the salmon our members produce is done so in partnership with a First Nations. We are all interested in sitting

The recent changes in British Columbia’s salmon farm licensing policy could spur more changes in the government’s oversight of the industry

down to find creative solutions that allow us to continue providing this important food while employing First Nations’ members,” said BCSFA spokesman Shawn Hall.

AUDIT AS CATALYST

The proposed changes in BC’s salmon farm licensing policy have also raised questions about how these will affect the way Fisheries and Oceans Canada (DFO) administers licenses for fish farms. Current fish farms in BC hold tenures issued by the federal DFO, which means these farms are already meeting DFO standards.

“The DFO must look at the farm site through an environmental lens…I think we’ve seen over the last while [some] reports, such as the audit, that showed that may not have been the lens that they were using,” Popham said.

The minister was referring to a recent review by a federal government watchdog that gave the federal government’s management of the salmon industry a

DISTRIBUTED BY:

failing grade. The report produced by Julie Gelfand, Commissioner of the Environment and Sustainable Development, found that the DFO has no national standard for nets and other equipment to prevent escapes, nor has it set limits on the amount of drugs and pesticides fish farms can use to treat diseases.

The report brings to light the lack of an agency at the federal level dedicated to overseeing the aquaculture industry, which many of Canada’s seafood farmers have been pushing for. The assessment could prove to be a catalyst for the establishment of such an agency and for the introduction of a Federal Aquaculture Act.

“A Federal Aquaculture Act can address many of the issues raised in the Commissioner’s audit and clarify roles and responsibilities of federal regulators, critical for protecting the environment and growing sustainably,” said Timothy Kennedy, Executive Director of the Canadian Aquaculture Industry Alliance (CAIA).

“While a new Act by itself will not address all of the Commissioner’s findings, Canada will finally join other major international producing countries in adopting a modern Act that will enhance performance of the sector, environmental protection and economic growth.”

Citing other salmon-producing nations, such as Norway, which have “a very strong growth and support component,” Kennedy believes Canada’s salmon farming industry will also flourish if the country has a Federal Aquaculture Act.

“We cannot grow this sector and compete effectively unless we have clarity around the responsibility of the federal government,” Kennedy said.

Susan Farquharson, Executive Director, Atlantic Canada Fish Farmers Association, said however, “It is important to remember that the DFO is not the primary regulator of salmon farming in Canada.”

“The report does not take fully into account the vital role that other federal agencies and provincial governments play in regulating the salmon farming industry in Atlantic Canada. The provincial regulations work well. Our farmers adhere to rigorous environmental regulations, policies and codes of practice developed by government, scientists and industry. These codes ensure our fish are healthy, properly contained in their pens and that waste is managed responsibly to avoid benthic impact,” Farquharson said in an email to ANA.

BY MATT JONES

TThe industry saw a consolidation in recent years with new private sector investors such as Cole-Munro Fisheries purchasing some existing farms and upgrading them, leading to expansions in processing infrastructure

Credit: Cole-Munro Fisheries

hings are looking up for Ontario’s freshwater aquaculture industry, with market conditions coming together to present opportunities for significant growth. However, there are still some challenges that will need to be overcome for the industry to live up to its full potential, said Rich Moccia, professor and director, Aquaculture Centre, at The University of Guelph.

Moccia discussed the prospects of the Canadian province’s freshwater aquaculture industry at Aquaculture Canada 2018 in Quebec City.

He said the province has easy access to very large and affluent markets. A diversified population base -- with large demographic groups of new Canadians having arrived in the last generation -- is creating demand for new and different types of products. Ontario has very strong infrastructure capacity and is very well positioned to support aquaculture development. And there has been some consolidation in recent years with new private sector investors purchasing some existing farms and upgrading them, leading to expansions in processing infrastructure.

‘We’re at a tipping point where we’re having enough production to be able to go after some of the larger marketplaces, like Costco and WalMart,’ says Rich Moccia professor and director, Aquaculture Centre, at The University of Guelph

Cole-Munro Fisheries, for example, has invested heavily into purchasing existing fish farms and upgrading their technology, as well as building a new, state-of-theart processing facility to accommodate this growth. The company has entered into partnerships with hatcheries to develop an integrated approach to production, which will supply their processing facilities and allow them to expand into larger markets.

“We’re at a tipping point where we’re having enough production to be able to go after some of the larger marketplaces, like Costco and Wal-Mart, and supply them with various products domestically,” says Moccia.

“If we went back even five or eight years ago, we didn’t quite have enough production to be able to go after those kinds of market opportunities.”

There’s also been a surge in interest in aquaculture from First Nations communities. Communities such as the Moose Cree First Nation have pursued opportunities to use aquaponics as food-production method for food security, job creation and wealth generation (see “Aquaponics for remote communities,” ANA Nov/Dec 2017, page 10).

Another development that bodes well for the industry is improving access to private sector capital investment. “They’re really seeing Ontario as a truly viable place to put in major investment capital to build aquaculture,” says Moccia. “That’s one thing that has to continue to happen if we’re going to realize the longer term growth.”

Other key issues that Moccia has identified as crucial to continued growth include obtaining Best Aquaculture Practices certifications over the supply chain and Ocean Wise certification for environmental data transparency, and moving towards larger net pens and automated feeding systems to improve efficiency and environmental performance. And, like most jurisdictions in Canada, the province will need to continue to address conflicts with tourism, recreation and environmental groups objecting to the use of public waterways that will be essential for the expansion of the industry.

Today’s modern aquaculture farmer needs a partner that is able to help with the scope and variety of challenges they face every day. That is why Pentair has assembled a team of experts with diverse backgrounds in aquaculture, biological and technological engineering that is grounded in decades of research and commercial industry application experience. We help our customers run successful operations by providing the design expertise they need, a responsive service team and the largest selection of equipment and supplies in the industry. Trust in a team that’s here to help you.

continued from cover

IMTA as a farming concept has been introduced in the Western world in 2004, although the process of rearing multiple fish species (polyculture) in one location is ancient; the Chinese have been doing it for ages.

Smith shares with others the IMTA “gospel” but he thinks IMTA’s full name — integrated multi-trophic aquaculture — is “horrible and alienating.” “We are trying to attract people to ocean farming so we call it 3D Ocean Farming,” he says. (Dr Thierry Chopin, whose research focuses on IMTA and was instrumental in promoting the concept, says there has been over 1,300 publications on IMTA since it was introduced in the Western world in 2004, so he won’t change its name, he said at Aquaculture Canada 2018.)

Through GreenWave, a nonprofit Smith founded (see side bar), people across the US and overseas are learning about the benefits of “regenerative ocean farming.” “Shellfish like mussels taught me that we can farm to restore rather than deplete. As farmers, our crops can breathe life back into the oceans while feeding local communities,” Smith wrote on the website of a GreenWave sponsor.

TWEAKING IMTA

Smith took his cue from the oysters when he was developing his version of IMTA. “I like growing things that don’t need to be fed and can’t swim away. With all of the things we grow we are able to do simple rope culture and that keeps the

Without fish in the IMTA equation, 3D Ocean Farming makes much more economic sense for small to medium size farmers, Smith says

infrastructure costs down.”

Without fish in the IMTA equation, this method of farming makes much more economic sense for small to medium size farmers, Smith says. “Most IMTA starts with fish, to which other things are added. What I’ve done is I simplified it and lowered the barrier to entry by making things cheaper.”

“From my 20 acre farm I harvest 10 to 30 tons of seaweed and 250,000 shellfish per acre a year. With our model, an ocean farmer can gross $300,000 a year and provide two to three full-time jobs and seven to 10 seasonal jobs,” he adds.

Smith grows clams on the ocean floor at the bottom of his lease. But having his oysters buried by storm surges led him to pull them off the bottom. Oysters are in suspended trays, scallops are in lantern nets and mussels in socks all hanging from a long line. The kelp is grown on the long lines in the winter.

While labour is the top input in this model, Smiths says it varies between crops. “Clams just sit in the mud, we don’t cover them with nets so we lose some, but we also don’t have to do anything,” he says. “Oysters require a fair amount of work for a good product, and scallops are just a pain.”

Kelp harvest is labor-intensive. When Aquaculture North America spoke to Smith in May, he was in the midst of harvest and watching out for the sweet spot that would allow for maximum growth. “They can double in length in May. But we have to harvest them before they start to become bio-fouled in the warmer water temperatures, or they will have to go to fertilizer.”

Smith sells his harvest locally under the brand Thimble Island Ocean Farm. “Our scallops don’t grow very big adductor muscles in the lantern nets so we sell them whole to restaurants and people eat them raw like oysters.”

Kelp presents a different marketing challenge. “The problem with kelp is nobody wants to eat it,” says Smith. But significant progress is being made, he says, by marketing kelp as “the new kale,” by moving it to the center of plates, and talking about “merroir” (like “terroir” in wine jargon) and “arugula from the sea.”

There are high-end chefs experimenting with everything from kelp pasta to using it to flavor cocktails. Smith says they have also had success partnering with other food processors, including one that’s making kelp-and-mushroom jerky.

“I thought it would take 20 years to build a market for those specialty items, but we have back orders for half a million pounds of kelp right now,” Smith says.

The other strategy was to take a page from the soy producers’ playbook. “The soy industry got together and realized they weren’t going to get many Americans to eat soy, so they put it into everything,” Smith explains, only half joking. “The great thing about seaweed is that it’s a human and animal food, it goes into cosmetics, pharmaceuticals, fertilizer and biofuels. We can stuff it into everything.

“We’ve had a lot of success with it, our challenge now is permitting and developing hatcheries fast enough to meet the demand.”

Smith is now exploring ways to stabilize output from a given lease using remote sensing. “As an ocean farmer, your soil turns over a thousand times a day. Some years we get kelp that is three feet long, some years it is 20 feet. I need to know about the current, light penetration, and where the nutrients are in the water column. Then I can go out and raise or lower the farm to where those nutrients are.”

GreenWave is a farmer-run organization that helps attract, educate and support new shellfish farmers. “My first goal is to create jobs,” says Bren Smith, the organization’s founder and executive director. He knows from experience that new farmers need all the help they could get. “I was a terrible at first, I killed most of them,” says Smith, recalling his first foray into shellfish farming.

The nonprofit helps farmers with site selection and the permitting that will get them started. They build hatcheries for seed and provide a distribution hub and market research. “The US simply does not have a functioning government to do this kind of training and industry development, like you would find, say, in South Korea,” says Smith. “We decided we would do it ourselves.”

Training is free, thanks to generous sponsors like outdoors clothing company Patagonia. GreenWave has supported new farmers in New England and Alaska and is moving into California. “We’ve had requests from virtually every coastal state and over 20 other countries,” says Smith. “We have always been open source but we have a grant now to put all of our material into online learning, which we hope to have up by this fall.”

GreenWave’s program has resulted in 17 farm startups, which are all currently operating. Eight farmers are currently enrolled in the FIT (Farmer-In-Training) program, and 10 more are expected to be part of the FIT program in July.

Astartup is developing fish feed ingredients derived from black soldier fly (BSF) that will not only provide fish with sustenance but also boost their health and overall wellbeing.

Entomics Biosystems Ltd of Cambridgeshire, England says merely drying insects (in this case BSF) and milling them into powder misses many of their potential nutritional, health and wellbeing benefits. A proprietary bioprocessing technique that Entomics developed, which it calls “metamorphosis,” boosts the nutritional and functional benefits of such insect-derived feeds.

“There are several benefits to this process,” explains Miha Pipan, Chief Scientific Officer and company co-founder, in an article published in the University of Cambridge website. Benefits range “from affecting the gut’s microbiome and trying to preserve a healthier bacterial community there, to training immune systems to make livestock more resistant to disease challenges and at the same time reduce the need for veterinary medicines, antibiotics and vaccines.”

“We are currently focusing our efforts on developing

Scientists want to know whether wild salmon are interacting with farmed salmon in open-net pens and how often

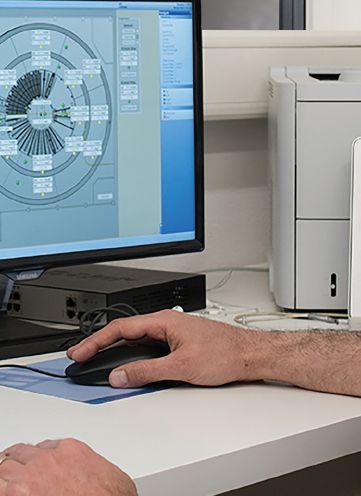

Do wild salmon interact with farmed salmon? If so, how often? These are just some of the questions that a new project hopes to answer to determine why wild salmon populations are declining.

The $500,000 study launched by Department of Fisheries and Oceans Canada (DFO) in New Brunswick is in cooperation with the aquaculture industry. It involves establishing 24 receiver sites on Passamaquoddy Bay and the river system. Sixty young salmon were tagged in the river system and then released. Those tags trip a sensor in the receivers when the fish swim within range. That information will inform scientists whether wild salmon are in fact interacting with farmed salmon in open-net pens and how often.

“There are concerns about the potential transfer of disease from wild salmon to aquaculture, but also the potential for transfer of disease from aquaculture to wild salmon,” DFO researcher Marc Trudel told Global News

With this being a pilot project, it’s not known how long it will take to gather the needed information, or how that data may shape future policies, Trudel added.

functional insect meals for atlantic salmon (Salmo salar), in particular in our meals’ ability to stimulate salmonid immune system strengthening and overall wellbeing,” said the Entomics team, whose members are University of Cambridge graduates.

They are currently working with partners including the University of Stirling to validate and test their products in the field.

Entomics CEO and co-founder Matt McLaren noted how the world is looking for more sustainable sources of feed. “I think increasingly there’s a recognition that it’s not just about basic nutrition, but it’s about overall health,” he says.

“We’re trying to take a promising, sustainable ingredient of the future – these insect-derived feeds – and trying to add a bit of biotechnology or science focus to it, to really enhance what the effect is in the end application and reduce reliance on traditional antibiotics and veterinary medicines.”

There are several efforts currently looking into developing fish feed out of BSF because fish feed derived from fishmeal is deemed unsustainable.

US Senator Roger Wicker (R-Miss.) has introduced a legislation that aims to streamline the permitting process in aquaculture and fund industry R&D. “Aquaculture is the fastest-growing sector of the agriculture industry,” Wicker said. “This bill would give farmers a clear, simplified regulatory path to start new businesses in our coastal communities. The “AQUAA Act” (short for Advancing the Quality and Understanding of American Aquaculture) would also fund needed research to continue the growth and success of this important industry.”

Over 90 percent of the seafood in the United States is imported, 50 percent of which is derived from aquaculture. Currently, the United States does not have a comprehensive, nationwide permitting system for marine aquaculture in federal waters, and there are no aquaculture farms in federal waters.

The AQUAA Act would establish an Office of Marine Aquaculture within the National Oceanic and Atmospheric Administration (NOAA), which would be charged with coordinating the federal permitting process. Additionally, a permit would be established through NOAA that would give an individual the security of tenure necessary to secure financing for an aquaculture operation.

The legislation would also maintain environmental standards and fund research and extension services to support the growth of aquaculture in the United States.

A company in Newfoundland, Canada is gearing up to do commercial grow-out trials of sea urchins for the second time after securing access to a specially formulated feed.

‘We are taking barren urchins, harvesting them sustainably and using a land-based system to turn them into a high-value product that can support our Canadian labor costs.’

Back in 2000, Green Seafoods did grow-out trials but the biggest problem was securing the right feed to increase the roe (gonads) to a marketable size. “Fresh kelp is difficult to gather year-round here and when we fed them any fish for protein, they ended up tasting like what they had just eaten. We couldn’t sell them,” recalls Mark Sheppard, operations manager.

He hopes to change that with a new license to farm sea urchins and feed them with feed developed by Norwaybased Urchinomics and Nofima.

Nofima feed holds its form in water for between seven to 14 days without dissolving, a quality important for urchins because they take a long time to eat. Green Seafoods of Newfoundland, Canada hopes that this feed will be a game changer. Credit: Urchinomics

Urchinomics has been supplying feed for grow-out trials at the Ocean Sciences Center of Newfoundland’s Memorial University over the last several years. What makes the feed special is that it holds its form in water for between seven to 14 days without dissolving, a quality important for urchins because they take a long time to eat. Sheppard believes this feed will be a game changer. “We know that it works in the lab. We are going to do some fullblown commercial trials this fall.”

GREENER FEED

“Our first major step was to replace all animalbased ingredients (fishmeal and fish oil) with sustainably harvested kelp alternatives,” this makes our feed even more environmentally sustainable as we are now fish-meal, fish-oil as well as hormone- and antibiotics-free.”

Urchinomics president Brain Tsuyoshi Takeda says they have continued to tinker with their feed formulations to see if they could improve both performance and ecological footprint. “Our first major step was to replace all animal-based ingredients (fishmeal and fish oil) with sustainably harvested kelp alternatives,” explains Takeda. “This makes our feed even more environmentally sustainable as we are now fish-meal, fish-oil as well as hormone- and antibiotics-free.” The company has adjusted the quantity and balance of different sustainably harvested kelp that goes into the feed. “For example, the largest kelp variety that is now used in the feed is Japanese kombu (Laminaria japonica). This kelp species is naturally incredibly high in ‘umami’ (savory taste) so we have

high hopes that by using the best ingredients, we can also make the best urchins.”

Green Seafoods is experienced in processing and marketing wildcaught urchins. “We stopped processing urchins from the dive fishery about 10 years ago. There are others that still do it, but we weren’t seeing the return for the risk we were taking,” he says. Sheppard believes a ranching system makes sense for the area, where green urchins (Strongylocentrotus droebachiensis) are abundant and available year-round. “We are taking barren urchins, harvesting them sustainably and using a land-based system to turn them into a high-value product that can support our Canadian labor costs.”

Green Seafoods will initially raise the urchins in a flow-through system, but it is also doing trials raising them in a recirculating system at the Marine Sciences Center. Sheppard is optimistic that recirculation could work. He says urchins don’t have the same water flow demands that finfish require.

Takeda adds that nearly all of Urchinomics’ partners around the world prefer land-based systems, one reason being the ability to regulate water temperature. If all goes well, Sheppard is looking at marketing the sea urchins in Europe. “Given our proximity to Europe, we are going to look for markets in that direction first,” he says.

— Tom Walker

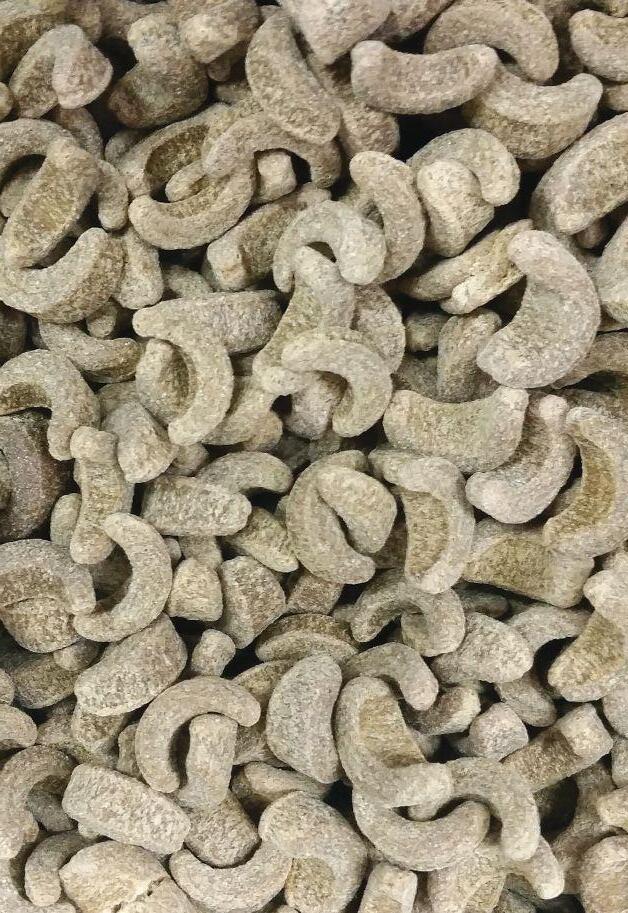

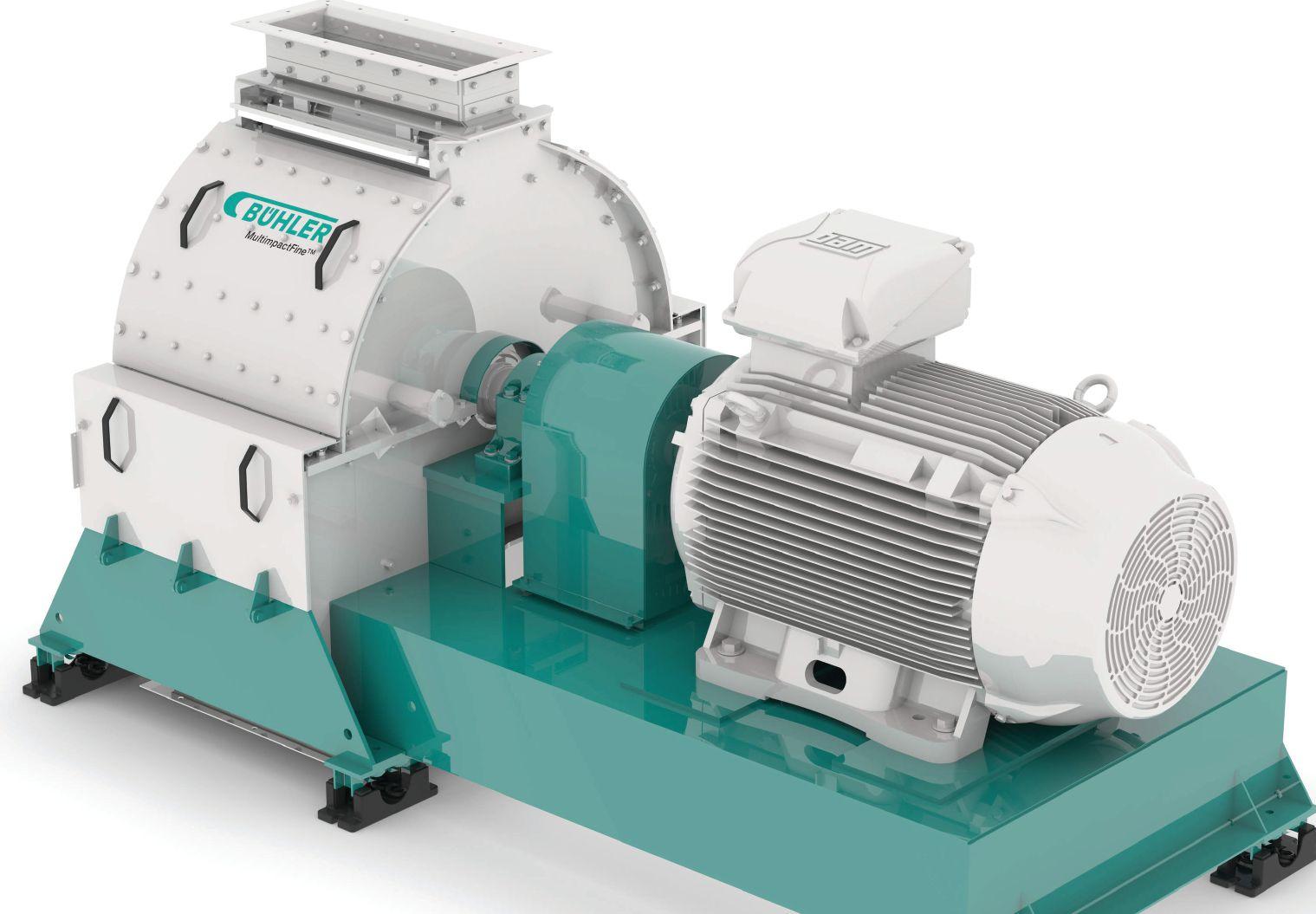

The heavy-duty MultimpactFine™ hammer mill uses proven, innovative technology to combine high-capacity grinding with uniform particle size distribution. From coarse to fine grinding to extrusion, drying and coating Bühler offers a complete line of flexible processing solutions that result in exceptional quality of floating and sinking aquafeed pellets.

Have a question? Let’s talk about it. buhler.minneapolis@buhlergroup.com www.buhlergroup.com

BY JOHN G. NICKUM

H.R. 3144, which opponents have dubbed the ‘Salmon Extinction Act,’ prioritizes power generation over the protection of migrating wild salmon, says columnist

Aquatic ecosystems are incredibly complex systems with many interacting components and related functions. The primary factors affecting them are difficult, perhaps even impossible, to predict. Nevertheless, I have enjoyed a career developed around fish and the aquatic ecosystems they inhabit. I am reminded of a question from a young engineering student, accustomed to using predictable equations and formulas. “Why do you environmental scientists want to work with things that are so complex and unpredictable?” he asked. By way of comparison, rocket science is relatively simple and predictable for him and his colleagues. Environmental science is not rocket science; it’s much more complicated.

The introduction of H.R. 3144 in the US House of Representatives and the subsequent debates in Congress and in an array of public forums brings the complexities of aquatic ecosystems back to mind. H.R. 3144 is a bill introduced to deal with the operations of the Federal Columbia River Power System, but it is also known informally as the “Salmon Extinction Act,” a name bestowed by opponents of the bill. Resource managers, scientists, and environmental activists contend that the operational procedures and priorities mandated by H.R. 3144 place endangered salmon and steelhead at additional risk of extinction, and, therefore undermine the standards of the Endangered Species Act (ESA) and the National Environmental Policy Act (NEPA). Proponents of the legislation, including its primary sponsor, US Representative Cathy McMorris Rodgers (R-WA) contend it would clarify operational priorities without causing any harm to salmon and other fishes. “Dams and fish can co-exist,” according to McMorris Rodgers.

•

•

•

The action by the congresswoman and four co-sponsors (all from Washington or Oregon) was precipitated by a decision by the 9th US Circuit Court of Appeals which recently upheld a lower court’s decision requiring the US Army Corps of Engineers to allow more water through the dams’ spillways instead of through electricity-generating turbines because additional water is needed to support the migration of endangered salmon and steelhead populations from the areas above the dams to the sea. Proponents of H.R. 3144 argue that hydropower and fish must coexist because 70 percent of the electrical energy for Washington State comes from hydropower, much of it from dams in the Columbia River Power System. These proponents argue further that the recent increases in the survival rates of migrating salmon are due to transporting the salmon around dams in barges, not to higher spill rates over the dams.

Although an agreement reached during the Obama Administration requires the US Army Corp of Engineers to operate the Columbia River dams in a manner consistent with the Endangered Species Act’s Supplemental Biological Opinion of 2014 until September 30, 2022, H.R. 3144 requires different operational priorities. Under H.R. 3144, “no structural modification, action, study, or engineering plan that restricts electrical generation at any Columbia River Power System hydroelectric dam, or that limits navigation on the Snake River in Washington, Oregon, or Idaho shall proceed unless such proposal is specifically and expressly authorized by an Act of Congress.” H.R. 3144 gives clear priority to power generation over any environmental consideration. Attempts to dictate operational guidelines for complex ecosystems through Congressional action leads to an additional conclusion: aquatic ecosystems are far too

•

H.R. 3144 requires congressional authorization for any structural modification or action at Columbia/Snake River federal dams that would restrict power generation or navigation. ‘We must avoid misguided choices (by policy-makers) that force dam operators to choose between power generation and fish welfare,” says columnist

complex to be understood by typical Members of Congress. I suggest, however, that most Members of Congress make no effort to understand these systems and to base their actions on maintaining functional ecosystems. In the case of H.R. 3144, the Congressional sponsors clearly based their actions on political considerations driven by concern for maximizing profits from power generation. “Lip service” has been given to ecosystem issues by claiming, “We can have both, salmon and power.”

In fact, that may be true, but not by the methods proposed through H.R. 3144 where priority is always given to power generation. Migrating salmon must have additional water flows; however, the “lost” hydropower could be replaced through efficient usage and additional power generation from wind and solar. We must avoid misguided choices (by policy makers) that force dam operators to choose between power generation and fish welfare. Alternatives that support wild fish, aquaculture, and power generation are available if decision-makers are not locked in to supporting the demands of traditional profit driven corporate interests.

Corporate capitalism that is focused only on maximizing the bottom line relies strongly on manipulating our government officials. It is time, actually past time, to acknowledge the fact that corporate capitalism is closer to totalitarian systems than to main street capitalism where competition and informed consumers regulate the economic system. Our current system in which the influence of huge corporations dictates Congressional decisions is not representative democracy in action; it’s a form of cronyism, guided by corrupt influences that do not consider the long-term interests of the public and the complex ecosystems that support the existence of not only salmon, but all forms of life, including humans.

H.R 3144 is, in fact, bad legislation driven by the arrogance of political power (we have the power to do as we d**n-well want to) and disregard for compromises and sciencebased conclusions. Citizens must demand real representation of their interests, not the short-term profit-driven misguided choices provided by corporate lobbyists.

Agrosuper’s $850M deal with AquaChile will make it a major player in salmon aquaculture

Credit: Agrosuper

Chile’s largest chicken processor has announced it is buying 67 percent of Empresas AquaChile, the country’s largest salmon farmer.

Agrosuper has a salmon unit, Los Fiordos, which sells its produce under the Super Salmon brand. The company’s main markets include the United States, Mexico, Italy, Japan, China and Brazil, but most exports to these countries are broiler products. The $850-million deal with AquaChile will make it one of the world’s biggest players in salmon aquaculture.

AquaChile markets its produce under the Verlasso brand, “named the first and only ocean-raised farmed Atlantic salmon to receive the ‘Good Alternative’ buy ranking from the Monterey Bay Aquarium’s Seafood Watch program,” according to the company.

Massachusetts-based biotech company KnipBio has been awarded a grant to study how changes in diet can alleviate enteritis and other diseases in aquaculture.

The company is known for its fishmeal ingredient called KnipBio Meal (KBM), which is derived from microbes instead of wild-caught fish or agricultural crops.

Enteritis is a common diet-related disease in farmraised carnivorous fish that can lead to slower growth and increased mortality. It is estimated the disease costs the aquaculture industry more than $1 billion per year.

Preliminary feed trials have consistently found that fish and shrimp fed KnipBio Meal experience improved gut health, lower rates of enteritis, and reduced mortality levels compared to populations raised on standard industry diets. The goal of the grant is to study the mechanism by which KBM acts as a prebiotic to affect gut health of rainbow trout and identify the specific components in KnipBio Meal responsible for this effect. It will be conducted over the course of one year and, if successful, may lead to additional funding to commercialize the findings.

The grant was from Phase I Small Business Innovation Research (SBIR) grant by the National Science Foundation.

Marine Harvest says it has finalized its acquisition of Northern Harvest, a salmon farmer on the East Coast of Canada.

The Norwegian salmon producer received a “No-Action Letter” from the Canadian Competition Bureau on 22 June, which meant the company could proceed with closing the transaction.

Northern Harvest is a fully integrated operation; it has its own broodstock, smolt/hatchery, farming sites and processing operations.

It is expected to harvest 19,000 tonnes of salmon this year. It has currently 45 farming licenses in Newfoundland and New Brunswick and has applied for additional 13 farming licenses.

Marine Harvest announced in December its intention to acquire the Canadian company. It said at that time: “The potential acquisition supports Marine Harvest’s long-term strategy of being a world leading and integrated producer of seafood proteins.”

stocked its new Indiana farm with traditional Atlantic salmon eggs and has commenced grow-out activities while waiting for US approval to import its genetically modified slamon eggs from Canada.

Expenditures have driven Aquabounty Technologies’ losses to widen in the first half of 2018 to $5.2 million from $4.1 million in the corresponding period of the previous year.

The producer of the AquAdvantage genetically modified salmon attributed the losses to pre-production costs at its Indiana farm and R&D activities at the Rollo Bay hatchery in Prince Edward Island, Canada.

In an update on the Indiana farm that the company acquired last year, AquaBounty said it has stocked it with traditional Atlantic salmon eggs and has commenced grow-out activities while waiting for approval from the US Food and Drug Administration (FDA) to import AquAdvantage Salmon eggs.

The is prevented from importing its AquAdvantage Salmon eggs from Canada due to the existence of an “Import Alert” pending the FDA’s issuance of final labelling guidance for the product, it said in an earlier announcement.

“The Company has indicated that it is fully prepared to comply with labelling requirements for its product in order for this process to conclude in the near term.”

It expects the import alert on AquAdvantage Salmon to be lifted in the second half of the year.

Consumers demand safe, healthy and delicious seafood, which means that good quality fish feeds are a prerequisite for aquaculture.

Nutrace® is our commitment to supplying high quality, safe feeds for farmed fish so that farmers and end consumers alike can have full confidence in our products.

You can learn more about our Nutrace® feed quality assurance program at www.skretting.ca

Alaska

BY MATT JONES

For Weatherly Bates and her husband Greg, the challenges of operating an independent business in a remote section of Alaska are well worth the opportunities to be a part of nature and to control their own destinies. And that is what Alaska Shellfish Farms, LLC, based in Halibut Cove, AK, allows them to do.

“Being a small business owner, we love that,” says Bates. “Being able to integrate life and business and raising our kids –having flexibility. We love growing something from nothing.”

The Bates used to run an oyster farm in Maine but fell in love with Alaska while on their honeymoon there. In 2007 they moved to the state, and in 2010, they started Alaska Shellfish Farms. With occasional help from two seasonal workers, the couple grows Pacific oysters, blue mussels, sugar kelp, dulse and alaria.

“It’s really diverse around where we are,” says Bates. “There’s a lot of wild species that settle in our gear and that’s what led us to grow everything other than oysters. We get oyster seeds from a hatchery but the rest of the stuff that we grow are species that grow wild on our farm.”

Alaska Shellfish Farms grow oysters in mesh cages suspended five feet down from buoys. The 90- to 100feet deep water in the area is ideal for vertical farming. Floating culture options are not suitable in the area because of the strong waves. “We have a really big tidal influx; it’s up to 30 feet of tidal exchange. We have the second biggest tides in the world,” she says.

• 100% Titanium Heat Exchangers

• Salt & Fresh Water Safe

• Available with Tube Sheet, Helical Coil, or Plate

• Hot & Cold Water Loop Systems

• Compact Designs

• Easy Installation

• Incubator Rack Systems

• Gas Boilers

Located on the edge of Kachemak Bay State Park, the farm is part of vast swaths of underdeveloped, pristine, protected wilderness. This is behind the oysters’ freshness and it’s what makes them stand out among competitors, Bates says.

“Everyone always comments on how fresh and clean and crisp our product is,” she adds. “There’s no pollution. It’s cold water.”

The natural conditions in the area make it a thriving ecosystem with a wide variety of wildlife. In fact, the Bates don’t need to feed their oysters – nature provides.

Bates is happy the farm has become a hub for wildlife. “We’re like creature farmers – each oyster cage has thousands, if not hundreds of thousands of invertebrate, copepods, worms. We see so much diversity. So much wildlife congregates around it – birds, sea mammals.

Sometimes we see sea lions fishing around the farm. It’s home to hundreds of sea otters and birds. There’s so much life; it’s a huge wildlife sanctuary.”

But while the farm’s remote location serves their product and the local wildlife well, it has its downsides: shipping their product (marketed under the brand Glacier Point) can be challenging and it’s quite isolated from other services that a young family with children needs. The nearest city with shipping services is Homer, which is an hour away by boat and another half-hour drive. It is also where the Bates send their children to school half the time (they are homeschooled the rest of the year).

“Because we’re connected to the road and there’s an airport in Homer, usually we’re able to ship our product the same day as harvest and our customers get it the next day,” says Bates. “That makes us unique, there’s a lot of places in Alaska that are even more remote than our farm so the logistics of trying to get oysters to Boston or LA is really daunting. With the airlines we can get the product direct to Anchorage and ship it to any destination we want. Anchorage is the second biggest cargo hub in the US so we can get our product out to people fresh.”

Bates hopes to see the farm expand to other products, such as sugar kelp. “But so far it’s been a challenge marketing it, we’ve been so focused on the oysters. But if we ever find a market for it, it would be great. I know how much of it is imported to the US and if we could get a handle on processing and packaging it, we could do a lot with that.”

Farmed salmon could be contaminated with synthetic flame retardants called polybrominated diphenyl ethers (PBDEs) if their feed is sourced from regions with little or no environmental regulations, suggests a new study, but is it a reason to avoid farmed salmon altogether?

The benefits and risks are up to the consumer to weigh, says Dr Neil Auchterlonie, Technical Director at IFFO. The good news is that advances in science and technology have allowed the identification of contaminants in microscopic amounts.

“One of the facets of the continual development of analytical technology is the identification of some of these compounds in ever-smaller concentrations. Those results are often so small that they are confusing when it comes to the interpretation of risk. That risk is important to bear in mind when taken into account with the noted benefits of consuming seafood,” he told Aquaculture North America (ANA)

Auchterlonie adds that it is also important to recognize that these materials are found throughout the environment, not just in seafood. In fact, synthetic flame-retardants are everywhere. “As well as being present in the aquatic environment, PBDEs are present in the atmosphere, and in dust, which can also be sources of exposure,” he says.

A report from the Norwegian Scientific Committee for Food Safety, which covered an extensive overview of contaminants including PBDEs, concluded that the risk of adverse health effects due to PBDEs is low.

In Canada, the government health department continually monitors fish and fish products and risk assessment activities related to PBDEs. “The level of PBDEs in fish reported by Health Canada survey is 5.5ppb, considered as low and not considered to be a health concern,” Cargill tells ANA. The feed manufacturer says its own reporting indicates “very low levels” in its feeds “and this is consistent with industry reports.”

Ian Roberts, Communications and Business Development Director for Marine Harvest Scotland, emphasizes the need for better public understanding of complex issues such as PBDEs because public perception of food safety and consumer confidence are inexplicably tied together.

“Hearing for the first time that these compounds do exist in foods – most of them naturally – can strike fear into consumers who may not understand just how miniscule the levels are. It is vital that scientists effectively communicate just how the findings may or may not affect the general population not intimately familiar with the science,” he says.

A University of Pittsburgh study led by Dr Carla Ng, assistant professor of civil and environmental engineering at the Swanson School of Engineering, tracked the presence of polybrominated diphenyl ethers (PBDEs) in farmed salmon.

Despite having been banned in the United States and much of Europe in 2004 because of environmental and public health concerns, PBDEs continue to be released into the environment from products manufactured before the ban of PBDEs, the study says.

“They enter the air and water and can accumulate in prey fish which are then used in the manufacture of feed ingredients,” Ng explains to Aquaculture North America (ANA) If the exact location of the catch used as feed ingredients is unknown and/or the materials have not been tested for the presence of the pollutants, it can be difficult to tell ahead of time which animal-derived feed ingredients contain PBDEs, Ng acknowledges. But the study noted that PBDEs are particularly dense in areas such as China, Thailand, and Vietnam, countries that process a lot of electronic waste and lack rigorous regulation of their recycling industries.

o er:

• Extensive technical support with access to juveniles and seed

• Academic partnerships with the University of Maine

• Entrepreneurial training & business counseling

• RAS and ow-thru culture facilities from 50-1000 sq meters

• State-of-the-art culture systems

• Business support facilities and networking opportunities

We provide entrepreneurs and business startups professional support and excellent facilities to develop their aquaculture ideas.

• Assistance in grant writing and identifying funding opportunities

• Plus exceptionally high quality sources of water!

For more information, contact: Chris Davis, Maine Aquaculture Innovation Center 193 Clarks Cove Road, Walpole, ME 04573 Phone: (207) 832-1075, cdavis@midcoast.com

BY MARI-LEN DE GUZMAN

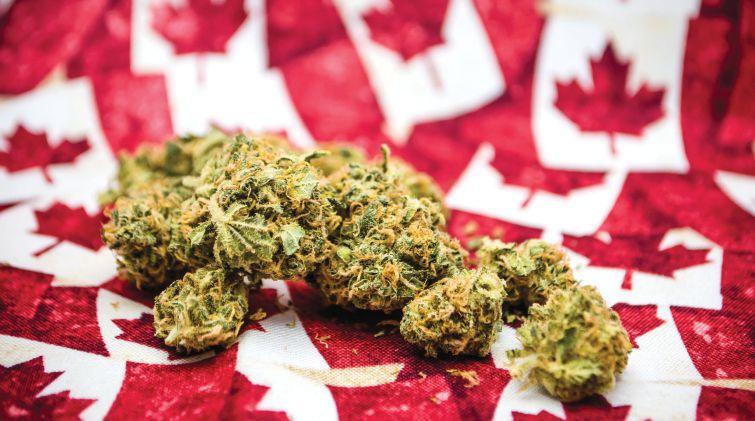

At the heart of southwestern Ontario, one crop producer has mastered the art of aquaponics, where healthy tilapia are grown alongside premium quality cannabis.

Green Relief has been growing marijuana for medicinal purposes since 2016. From the beginning, the company has made it its mission to find sustainable ways to grow their crop.

“Aquaponics started for us as a small greenhouse addition to the back of our house with a self-contained system,” explains CEO Warren Bravo. “We were going to grow vegetables for our family all year round, at a greenhouse that we can walk up to.”

Bravo’s 50-acre property in Flamborough, Ontario, is home to Green Relief’s 32,000-sq-ft indoor grow facility. Construction is underway for an additional 220,000-sq-ft building that’s expected to produce 45,000 kgs of cannabis annually. A third building is also part of the expansion plan, which will provide an additional 180,000 sq ft of production space for the company.

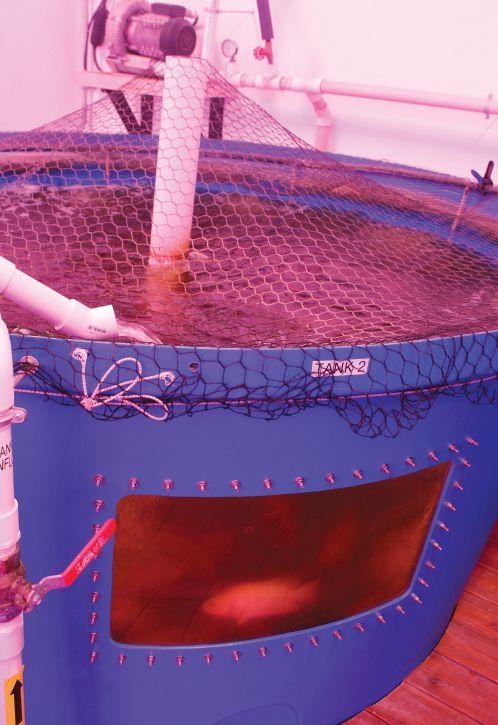

Green Relief is one of at least 114 licensed cannabis producers in Canada, but its growing technique is unique in the industry. Using aquaponics technology developed with Nelson and Pade, in Montello, Wisconsin, Green Relief uses fish waste carried through a recirculating water system to deliver nutrients to the cannabis plants. Around 300 tilapia are grown in circular tanks located inside the grow room. Upon maturity, the fish are harvested and donated to local food banks.

(L to R) Green Relief co-founders Warren Bravo and Steve LeBlanc. Fish will have a bigger role in the aquaponics facility in the future, says Bravo, who envisions a nutraceutical product that contains Omega-3 from the fish and cannabis oil extract

“The idea of having an aquaponics system at the house has morphed into what you see now as North America’s – or the world’s – only high-production cannabis facility using aquaponics,” Bravo states.

Put plainly, aquaponics is a method of growing food that uses a closed-loop process that mimics the ecosystem.

Green Relief’s aquaponic structure is powered by a recirculating aquaculture system containing 18,000 gallons of water continuously recycling through the system, explains Derek Bravo, operations manager at Green Relief. Fish start out in the system as fry. They stay in the nursery with young cannabis plants. As both plant and fish grow, they are transferred to the main grow room where they stay until ready for harvest, at which point they go their separate ways – the cannabis flowers go to the dry room for processing and the tilapia go into Second Harvest trucks for delivery to local food banks.

All the magic happens in the grow room. Derek Bravo explains they use only organic fish feed to grow the fish. Fish waste is then produced, which flows through the tank into the clarifiers. The clarifiers are the first level of filtration, consisting of a light screen in the middle. Heavy solids then sink to the bottom of the tank, while the finer solids flow through from the clarifier into the mineralization tank to be broken down further. The water then goes into the bioreactor.

Green Relief’s cost of producing cannabis is currently at $1.42 per gram.

The average sale price is $9.05 cents per gram

“That’s where the aerobic bacteria is created with heavily oxygenated tank with a bunch of bio beads where the bacteria lives on,” Bravo explains. “Once the beads get too covered with bacteria coating, it will break off, flow into our system that attaches to one of the grow beds.”

In this process, nitrification occurs and the resulting nitrate becomes nutrient for the plants.

“The plants just sit on styrofoam, and they just float on the water. Their roots go down the water and uptake nutrients whenever they need them,” Bravo says.

The water then flows back to the fish tank and the cycle repeats.

ECOSYSTEM APPROACH

Globally Trusted UV Experience in Aquaculture

- Proven bio-security; over 35 years, > 400 installations

- > 825 million gallons per day treated (3.12 million m3/day)

- Designs for control of multiple pathogens

Lifetime Disinfection Performance Guarantee

- Aquafine Genuine parts program provides this peace of mind

- Economic low pressure lamp technology

- Duplex steel configurations with corrosion warranty for seawater

Long-term Industry Commitment

- Collaboratively advancing UV research in Aquaculture

aquafineuv.com

CEO Warren Bravo notes the significant amount of research and the huge learning curve that went into the process of building Green Relief’s aquaponics facility. Bravo and Green Relief co-founder Steve LeBlanc both come from the construction industry. Their knowledge of buildings and structures only took them halfway through achieving their goal of establishing a sustainable cannabis production company that leaves as little impact on the environment as possible. The rest, they had to learn.

The pair spent over two years doing research on aquaponics, speaking with known experts on aquaponics and sustainable agriculture around the world. Among them was Nick Savidov, senior research scientist of the aquaponics program at Lethbridge College in Alberta.

“Aquaponics is an integrated multi-trophic production system,” explains Savidov. In aquaculture, an integrated multi-trophic system follows the concept of a natural marine ecosystem, where one species produces the waste or byproducts that become sustenance to another organism within the ecosystem.