orth American aquaculture has its fair share of challenges ranging from complex regulations to worker shortages, rising costs and growing environmental concerns. But it also has serious talent in its corner: young entrepreneurs and innovators who are putting their stamp on the industry. They’re passionate about fish, they have their fingers on the pulse of the market, and they’re always looking for better ways of growing more fish for the planet. Six young entrepreneurs, students, and farm managers speak to us about their enthusiasm for aquaculture. Special section on Aquaculture Education and Training begins on page 20.

Nre you thinking about shifting to land-based aquaculture but don’t know where to start? If you, like many others, find it hard to quantify adequately the risks and rewards of a land-based recirculating business, who better to ask than someone’s who’s been through the process of building one? Samuel Chen has, over the past five years, led the development of Hudson Valley Fish Farms, one of the first commercial land-based recirculating farms in North America. During this time, he had the opportunity to evaluate numerous aquaculture facilities from net pens to the full range of closed-containment farms. His role has been to oversee business development, marketing, sales, regulatory affairs, and HR. Samuel doesn’t sugarcoat it for you. Starting a land-based farm, which he likens to “birthing,” isn’t easy. There’s a steep learning curve, he writes, and the Financial Office plays a crucial role from Day 1. See Viewpoint on page 12.

Project aims to start first commercial farming of signal crayfish in Canada

BY TOM WALKER

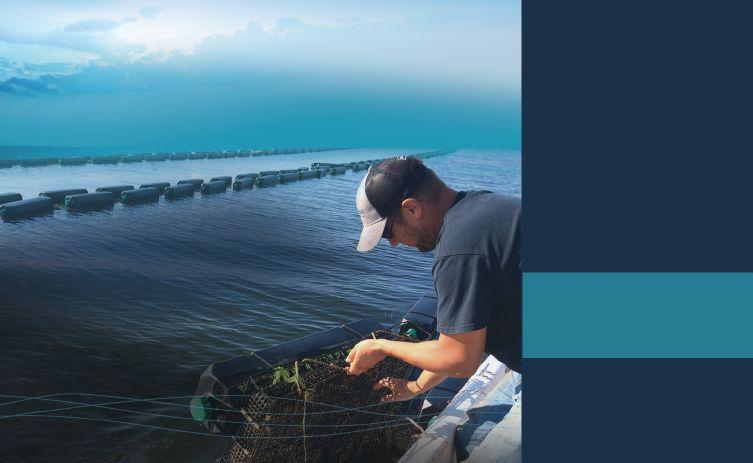

Zeljko Djuric reaches into the chilly 5˚C water and brings out a small plastic cage. He deftly lifts the lid and nimbly grabs a small crustacean mid-body to avoid the waving pinchers.

“Look at how healthy they are,” beams Djuric as he turns the berried female over to reveal a belly covered in eggs. “You can tell by the clean and bright exoskeleton and the way they hold their tails up.”

It’s a local freshwater signal crayfish (Pasifastacus leniusculus), indigenous to Vancouver Island, BC and Pacific Northwest lakes and streams. “The food of nobles,” Djuric notes. Crayfish can fetch up to $150/kg in European markets, he says.

Local, minimal water use, sustainable feed, low environmental impact and high market value would make the signal crayfish an ideal candidate for aquaculture. Indeed, it is farm-raised in Sweden (from imported North American stock) and other European countries, but not in Canada.

Djuric hopes that a recent startup with a local First Nation will help him move into commercial production. Together with members of the Malahat nation, located some 50 kilometers north of Victoria, BC, Djuric is working to install a juvenile rearing and pond grow-out system on Malahat land.

“The Malahat nation are always looking for economic opportunities that they can do in their community,” explains Marguerite Parker, Director of Development with the Aboriginal

continued on page 11

Aquaflor® is now approved for use in all freshwater-reared finfish at dose rates of up to 15 mg/kg*. I t ’s cleared for use in recirculating aquaculture systems, too.

S o whether you raise trout, tilapia, bass, c atfish or even baitfish or ornamentals, you can turn to Aquaflor for managing the toughest bac terial diseases of farm-raised fish.*

For the full stor y, call our fish-health specialist, K asha Cox, at 662.907.0692 or visit our new website at Aquaflor-USA.com.

It just keeps getting better

A Q U AF L O R ®

* In the USA, Aquaflor is approved for use at 10-15 mg/kg in freshwater-reared salmonids for the control of mor tality due to furunculosis associated with Aeromonas salmonicida and coldwater disease associated with Flavobacterium psychrophilum; in catfish for the control of mor tality due to enteric septicemia of catfish associated with Edwardsiella ictaluri; and in all freshwater-reared finfish for the control of mor tality due to columnaris disease associated with Flavobacterium columnare At 15 mg/kg, Aquaflor is also approved in freshwater-reared warmwater finfish for the control of mor tality due to streptococcal septicemia associated with Streptococcus iniae. LABEL CLAIMS NOT APPROVED IN CANADA.

CAUTION: Federal law restricts medicated feed containing this veterinary feed directive (VFD) drug to use by or on the order of a licensed veterinarian.

© 2015 Inter vet Inc., doing business as Merck Animal Health, a subsidiar y of Merck & Co Inc All rights reser ved MAH-AQF-38 ( or fenicol) T

Washington State Gov Jay Inslee has signed the bill that will kill the state’s salmon farming industry and hundreds of jobs.

House Bill 2957, signed on March 22, will phase out non-native fish farming of Atlantic salmon in the state by 2025. New leases and permits for farming non-native finfish will be no longer be issued.

Canadian company Cooke Aquaculture is the only fish farming operations currently affected by the new law. The company said it is “deeply disappointed” with the decision but will respect it.

“Our employees remain our top priority, and Cooke Aquaculture Pacific will continue to take the time we need to fully evaluate our operations and investments in Washington and explore all our available options. We will also continue to work with tribal, state and community partners,” it said.

Washington State Governor Jay Inslee has signed the bill that signals the end to salmon farming in the state

F

ederal authorities in British Columbia have closed two oyster farms implicated in the latest norovirus outbreak.

The BC Centre for Disease Control says 40 cases of acute gastrointestinal illness have been reported to public health authorities since early March.

In late 2016 and early 2017, 347 norovirus outbreak cases associated with raw or undercooked oysters were reported in BC Alberta and Ontario. That outbreak was declared over in April 2017.

Norovirus cases have resurfaced in BC

The Washington Department of Ecology has banned a pesticide that was approved two years ago for oyster growers to kill burrowing shrimp.

The department said it made the decision after a lengthy evaluation of the environmental impacts of the pesticide, imidacloprid. The pesticide belongs to a class of chemicals called the neonicotinoids, which act on the central nervous system of insects.

The state announced that it is too harmful to the ecosystem and decided to deny a request for its approval.

“The science around imidacloprid is rapidly evolving and we can’t ignore it. New findings make it clear that this pesticide is simply too risky and harmful to be used in Washington’s waters and estuaries,” state Ecology Director Maia Bellon said in a press release.

The pesticide in oyster farms causes significant negative impacts to water quality, crustaceans in the area, and affects fish and birds by killing sources of food, the state said earlier.

Questions over the integrity of British Columbia’s Animal Health Centre (AHC) can now be put to rest after a review panel found no evidence of “dubious data or conflict of interest.”

The lab, based in Abbotsford, BC, is the leading accredited full-service veterinary laboratory in Western Canada, whose tasks include diagnosing farmed fish diseases that are viewed by some as a threat to wild salmon. AHC also conducts testing for private fish farms for a fee, which Agriculture Minister Lana Popham called into question in October.

The review conducted by the independent consulting firm Deloitte and Premier John Horgan’s deputy minister,

Don Wright, gave the lab a clean bill of health.

“Our independent assessment of the AHC did not identify any evidence of financial or technical conflict of interest regarding the diagnostic activities of the AHC,” said Deloitte.

Don Wright said he was “impressed with the professionalism, the attention to quality control and the dedication to good science that I observed during my visit.”

“I am satisfied that the Animal Health Centre operates with strong professional, scientific and ethical integrity. My review process found no evidence of ‘dubious data or conflict of interest,’” he said.

Editor Liza Mayer

Tel: 778.828.6867 lmayer@annexweb.com

Advertising Manager Jeremy Thain Tel: (250) 474.3982 Fax: (250) 478-3979 Toll free in N.A. 1.877.936.2266 JThain@annexbusinessmedia.com

Media Designer Graham Jeffrey gjeffrey@annexbusinessmedia.com

Circulation Manager Barb Adelt Tel: 416-442-5600 ext. 3546 badelt@annexbusinessmedia.com

peter@capamara.com

Regular Contributors: Ruby Gonzalez, Treena

sjamieson@annexbusinessmedia.com

COO – Ted Markle tmarkle@annexbusinessmedia.com President

Smaller fish farms, not large corporations, have driven global aquaculture growth and are the key to feeding the world’s poor

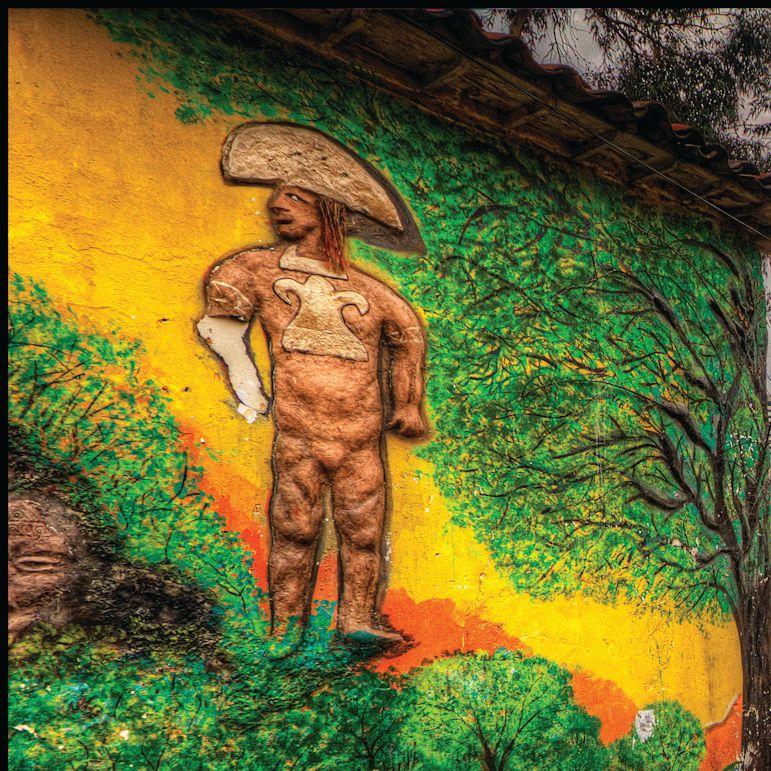

The ‘quiet revolution’ in farmed fish supply has been driven neither by corporate agribusiness nor by tiny backyard farms, but by small- and medium-sized commercial fish farms such as this one, say three academics

Contrary to popular belief, small- and medium-sized commercial fish farms growing affordable fish were behind most of the growth in the global aquaculture industry over the past three decades and not large corporations growing fish for export nor tiny backyard farms growing fish for family consumption, according to three prominent academics.

Simon Bush (professor and chair of Environmental Policy, Wageningen University, NL), Dave Little (professor of Aquatic Resources Development, University of Stirling, UK) and Ben Belton (assistant professor of International Development, Michigan State University, USA) recently published their views on this topic on the World Economic Forum website.

Bush, Little and Belton say that while the aquaculture industry has advocated very small farms to feed the poor, their research shows that most of the fish being eaten by poor people in developing countries “comes from a dynamic new class of small- and medium-scale commercial farms, the existence of which is rarely recognized.” The trio point to Bangladesh as an example, where the farmed fish market grew by a factor of 25 over the last 30 years to exceed 2 million tons in 2015. This growth in supply caused the price of farmed fish to fall by almost 10 percent from 2000 to 2010, and its consumption by poorer householders increased rapidly over this period.

“The ‘quiet revolution’ in farmed fish supply has been driven neither by corporate agribusiness nor by tiny backyard farms,” conclude Belton, Bush and Little. “Rather, most of aquaculture’s growth over the past three decades has come from a dynamic and increasingly sophisticated segment of small- and medium-sized commercial farms and the myriad businesses that support them…Rather than focusing on producing expensive species for export markets or wealthy domestic customers, these unsung heroes have focused on growing affordable fish such as carp. Where these species are produced in large quantities, they have become affordable for huge numbers of low- and middle-income consumers close to home.”

many small and medium operations growing affordable fish is yet to come in many developing countries, particularly in Africa, these countries can make this transition through learning from peer nations where aquaculture has boomed.

— Treena Hein

Stakeholders in the aquaculture industry should be vigilant when hiring staff as this could be a way for activist groups to infiltrate the farm’s operations, according to Hannah Thompson-Weeman Communications Director at the Animal Agriculture Alliance.

At Aquaculture America 2018, ThompsonWeeman said the number of undercover videos from activist groups who paid individuals to gain employment on farms increased in 2017. Sometimes the activists who are hired at farms have caused the issue they’re filming or failed to prevent an issue from occurring by deviating from farm procedure, she said.

In a contributed piece to Drovers, a beef industry publication, she wrote that farms and companies should review and refresh their hiring procedures by always checking references; reviewing the candidate’s social media postings; and keeping an eye out for red flags, such as whether the candidate’s responses seem overly rehearsed.

These academics believe that while the existence of

report from a provincial advisory council concerning the future of British Columbia’s aquaculture operations has, for BC salmon farmers, left a major issue ambiguous.

While there are many positives in the report of the Advisory Council on Finfish Aquaculture, the recommendation that First Nation agreement be a condition for tenure approval and renewal is unworkable, says the industry.

“The report recognizes the advancements salmon farmers have made over the past 30 years in fish health, environmental protection, and in developing relations with Indigenous governments, while also making recommendations for advancing that work in the coming years,” says Rocky Boschman, a BC Salmon Farmers Association director and managing director of Grieg Seafoods BC, in a news release. “The report also contains some recommended actions that we agree with in principle, but will be unworkable in practice without further clarification.”

The recommendation that concerns the industry reads: “Acknowledge and incorporate First Nations’ rights, title and stewardship responsibilities in all aspects of fish farm governance, including tenuring, licensing, management and monitoring in a manner consistent with the United Nations Declaration of Rights of Indigenous Peoples (UNDRIP).”

“The Association cannot support that recommendation as written, but would welcome the opportunity to work with other stakeholders and government to clarify it,” the news release continues.

The salmon farm tenure process in BC currently requires First Nations’ consultation and many of the farms are covered under the 20 agreements that they voluntarily made with the First Nations

whose territories they operate in, but the tenure license is with the provincial government.

Marine Harvest director of public affairs Ian Roberts describes the situation as “a quagmire.” “As it’s written, it just seems very unclear and unworkable because you are investing millions of dollars into an area that could have started with support and, before the tenure renewal, a change of leadership would change their direction,” says Roberts. “If the government choses to proceed with some recommendations specific to First Nations or others, they must provide clarity to BC business about the process involved.”

Twenty BC salmon farm tenures are up for renewal in June of this year. Eleven of those are held by Marine Harvest.

— Tom Walker

• Strengthening the regulations governing salmon farming in BC, including an area based management approach that could include relocating existing farms

* Increasing community, stakeholder and local government engagement to improve public trust in aquaculture siting and operations

* Establishing a science council to direct more research to understand the risk salmon farming poses to wild salmon from the transfer of pathogens

• Providing incentives for the continued research, development and adoption of salmon farming technologies that reduce the risk to wild salmon, including land-based

BY MATT JONES

Federal nutrition guidelines recommend that Americans should double their seafood consumption. This presents a significant challenge at a time when 91 percent of seafood is imported into the country. Dr Michael Rubino, Director of NOAA Fisheries Office of Aquaculture, who recently spoke on this topic at the Seafood Expo North America in Boston, spoke with Aquaculture North America (ANA) about the challenges that NOAA sees on the horizon and the efforts to address them.

According to Rubino, acquiring the social licence to operate in the marine environment, and educating people about aquaculture are two major issues that need to be addressed to help advance aquaculture.

“We all grew up reading or having books read to us about the family farm – we grew up knowing what pigs, cows, chickens and horses are,” says Rubino. “We don’t know what an oyster farm is, or what a fish farm is. So there’s this cultural issue of the unknown. When we’re talking about marine aquaculture and using public waters, when you’re proposing new uses of public waters, it gets tough to find acceptable sites despite our long coastlines because we’ve got a lot of users of coastal space from recreation to boating to shipping to fishing to sensitive ecological areas and so on. How do we make room for aquaculture in our collective backyard? We need to if we’re going to address these challenges of increased seafood consumption and growing more at home instead of importing it.”

The social licence challenges are compounded by a complex regulatory system involving a variety of agencies, all with their own permitting processes. As a result, NOAA is pursuing three key actions to catalyze smart growth in the sector – streamlining the regulatory process, promoting regional partnerships and pilot projects, and promoting science and R & D.

While the need to streamline regulations and promote R&D are likely very well understood by anyone reading this magazine, the need for regional partnerships may

be less immediately clear. Rubino cites one of the many examples of these sorts of partnerships.

“For example, the Port of Ventura, CA would like to set up a 2,000-acre pre-permitted area for mussel farming, either in state or federal waters off Ventura, and then sub-lease or sub-permit it to 10 to 20 mussel farmers,” says Rubino. “How can we work collaboratively to do this spatial planning, the site analysis, looking at gear types, and doing the National Environmental Policy Act work proactively so that the burden of proof is not on each permit applicant coming in. And then through our competitive grants, perhaps there’s some particular issues with hatchery bottlenecks that you could work with local universities or with private sector to get them over that hump.”

Rubino says that much of the work that needs to be done is already taking place in coastal communities. The changing demographic make-up in these communities — where the share of young people is increasing — helps form vibrant marine aquaculture communities. Rubino noted that a few years ago at the North East Aquaculture Conference, half of the 600 to 800 people in the audience was under 40. “There were a few graduate students in there, but a lot were young guys and gals, many sons and daughters of fishermen, or people from seafood business families, getting into aquaculture.”

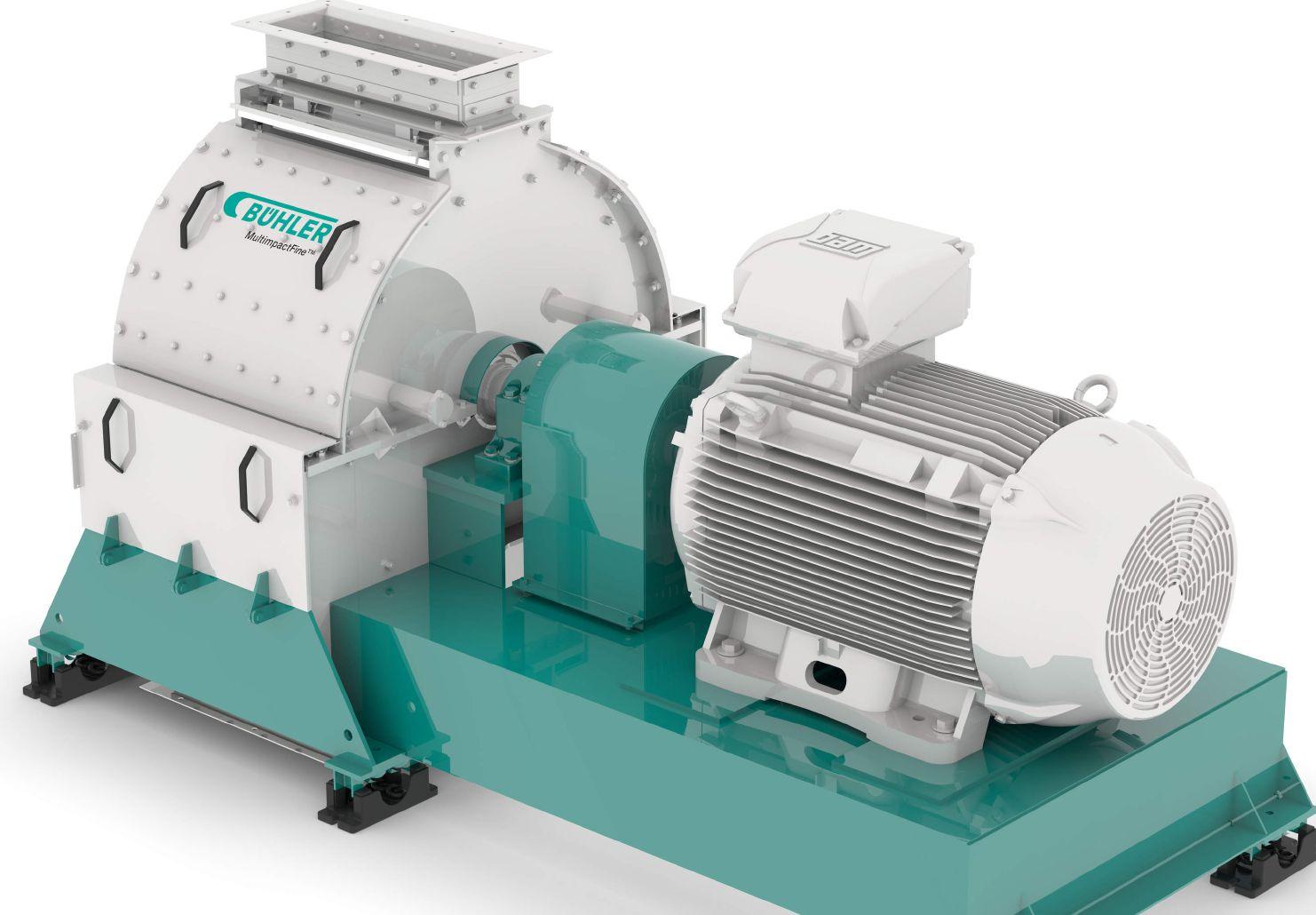

As the industry begins to see a paradigm shift in fish farming, an expert in recirculating aquaculture systems couldn’t emphasize more the production challenges land-based aquaculture companies will face.

“These companies will need to prepare for increased fish biosecurity, welfare and health, water quality, and optimal facility design as they aim to increase their annual production yield,” said Dr Frédéric Gaumet, business development manager of aquaculture at Veolia Water Technologies.

He said that “optimizing facility design for fish handling and resource management, along with having bio and business plans that are both realistic and flexible will help ensure success in these largescale facilities.”

Gaumet spoke at the 2018 Aquaculture America Conference in Las Vegas, where Veolia also exhibited its portfolio of recirculating aquaculture technologies, the RAS2020 and the Kaldnes RAS, to attending aquaculture professionals.

There’s plenty of environmentally suitable areas around the world for marine aquaculture but factors other than space availability could limit its development, a study suggests.

The study, Global Estimation of Areas with Suitable Environmental Conditions for Mariculture Species, defined “suitable areas” as those that can support the physiological needs of farmed species for

sustainable mariculture production.

The study estimates that 72,000,000 km2 of ocean would be environmentally suitable to farm one or more species. About 92 percent of the predicted area or 66,000,000 km2 is environmentally suitable for farming finfish, 43 percent or 31,000,000 km2 for molluscs and 54 percent or 39,000,000 km2 for crustaceans.

The University of British Columbia study team, led by Muhammed A. Oyinlola, suggests that suitable mariculture areas along the Atlantic coast of South America and West Africa appear to be most underutilized for farming.

“Our results suggest that factors other than environmental considerations are currently limiting the potential for mariculture expansion in many areas,” says the study.

The limiting factors include: the socio-economics of producing countries, including capacity and political instability; technology, its availability and cost effectiveness; trades; aqua feed availability; aquaculture development-related policies and competition for space within countries’ exclusive economic zones (EEZs), for instance — shipping, oil and gas, as well as tourism — all play major roles in the development of mariculture operations and their future expansion.

The results reflect those of an earlier study, Mapping the global potential for marine aquaculture, conducted by UC Santa Barbara researcher Rebecca Gentry, et al.

More than 50 chefs in British Columbia are calling on the provincial government to end Atlantic salmon farming in the province.

The group outlined its concerns about open net-pens presenting a risk to wild salmon from parasites and disease in a letter to Doug Donaldson, the BC minister of forests, lands, natural-resource operations and rural development, and Lana Popham, the minister of agriculture.

It is interesting to note that the advisory council that Minister Popham created in 2016 did not reach a consensus on the potential risks associated with salmon aquaculture in BC.

“Council members diverge on their views on the level of potential risk that farms pose to wild salmon and as a result views on how to address the overall risk of salmon farming are not uniform,” the council said in a report released in April.

Feeding farmed fish with live feeds that are nutritionally enhanced with nutrient-dense liposomes could become a reality sooner than later. Researchers at Oregon State University (OSU) have been studying ways to deliver water-soluble nutrients to aquatic organisms. The problem is that water-soluble nutrients can be rapidly lost from artificial feeds when they are added to the water, resulting in nutrient losses and poor water quality.

Liposomes are microscopic particles that are constructed very similar to cell membranes. They are small enough to feed to rotifers and Artemia that are used as live feeds in marine finfish hatcheries. Importantly, liposomes very effectively retain water-soluble compounds when suspended in water. OSU researchers are exploring the use of soy-based liposomes for delivering essential nutrients to larval fish and other aquatic organisms.

During his PhD studies, Dr Matt Hawkyard collaborated with researchers from Norway to develop larger scale batches of liposomes to match the scale of aquaculture production. Through feeding nutrient-dense liposomes to Artemia and rotifers, Hawkyard hopes that they can make a drastic impact on mortality rates and improve larval quality in the industry.

“We can actually boost the level of, say, taurine, that we know is an essential compound, very much like amino acid, and we can boost those concentrations in rotifers to levels that are beneficial to fish,” says Hawkyard. “These [particles] are extremely efficient and deliver a pretty high payload.”

Hawkyard says that after feeding liposome-fed rotifers to Northern Rock Sole larvae they found a tremendous impact on growth after a six-week feeding trial, compared

to control groups. Since establishing the potential of the liposomes for such work with taurine, researchers have successfully utilized liposomes to deliver vitamin C, iodine, selenium and other nutrients.

One of the key benefits of the liposomes is the prevention of nutrient leaching. One could achieve similar growth results through taurine by simply dissolving a great deal of taurine into rotifer water, says Hawkyard, however that would take 60 to 100 times more taurine because much of the nutrient doesn’t make it to the rotifer. Plus, the wasted nutrients provide a “broth” for bacteria.

By improving the quality of live feeds, Hawkyard hopes that they are not only able to reduce mortality rates, but also malformation rates.

“Even as we decrease mortality rates and increase

enriched with liposomes containing taurine were much larger and more developed than control groups (left) after a six-week feeding trial.

survival, you see a pretty high rate of malformations in a lot of marine fish juveniles,” says Hawkyard. “Jaw deformities are really common in a number of species, and fin development and scoliosis – a wide variety of these kinds of physical malformations show up in the later phases. But they look like they’re related to things that are happening in the larval stage and, probably, a large number of that, or at least a fraction of those malformations are due to nutritional deficiencies or imbalances.”

Going forward, Hawkyard says OSU are working on a few other particle types, including a complex particle where they are trying to integrate liposomes into a larger particle to feed directly to fish.strontf

— Matt Jones

lastics have transformed our world, and are now found in everything from clothing to cosmetics. Production of plastic materials has increased dramatically since the early 1950s, reaching 322 million tons in 2015with current levels expected to double by 2025. A study in Frontiers in Marine Science found that these plastic compounds, praised for their durability, are now finding their way into our food supply. Researchers found microplastics in the stomachs of nearly three out of every four fish caught in the Northwest Atlantic middle pelagic waters. Scientists are worried that as these smaller fish become prey for larger migrating species like tuna and swordfish, microplastics will spread throughout

the food chain and across ocean bodies.

“Microplastic ingestion by marine animals has actually been reported in over 600 marine species ranging from zooplankton to finfish, shellfish, sea birds, turtles on up to marine mammals, says Amy Uhrin, NOAA Marine Debris Program.

Plastics found in marine species range from fibers in synthetic clothing (most commonly found ingested), to styrofoam, fragments of hard plastics, filaments from fishing line and rope, and microbeads found in makeup and cleansers. They pose a threat not only as particles that become obstructions in the digestive system, but also for the toxins they contain.

For now, the risk of accumulated toxins including endocrine-disrupting

chemicals, carcinogens, and heavy metals found in plastics are still being assessed, but are thought to be low. Ingestion of actual plastics by humans is reduced in fish consumption by the removal of the gastrointestinal track before eating.

However, for shellfish like mussels, oysters, and clams that are consumed whole, the risk of microplastic exposure is much higher, and could be a cause for concern.

Two cultured species of shellfish commonly consumed, the mussel Mytilus edulis and the oyster Crassostrea gigas, were recently found to contain enough microplastics to amount to an annual human intake of 11,000 microplastics per year.

Along the Oregon coast, a project funded by Sea Grant aims to look at nine different sites for razor clams and five sites for oysters “…. to look for geographical hotspots for microplastic concentrations and share this information with state agencies to hopefully address the problem,” says Brita Baechler, graduate student at Portland State University.

The greatest accumulations of plastics and plastic particles tend to be found in coastal waters, which is also where most shellfish farms are operating. And a recent study in Nature suggests oysters that consume plastics will have reduced reproductive success. NOAA estimates “more than one-third of the shellfishgrowing waters of the United States are adversely affected by coastal pollution.”

Ironically, the aquaculture industry itself owes many of its advancements to the manufacture of plastics and plastic fibers that are lighter, stronger, and more durable than natural materials for fishing and mariculture equipment.

More research needs to be done to discover any long-term negative health effects of plastics in seafood, so for now the aquaculture industry is reminding consumers of the many known positive health benefits from eating fish and shellfish, like heart- healthy omega-3 fatty acids and iodine for proper metabolism.

— Heather Wiedenhoft

• EPA registered broad spectrum disinfectant and virucide*

• Maximum 10 minute contact time

• For use in cleaning and disinfecting environmental surfaces associated with aquaculture

continued from cover

Aquaculture Association in BC. “They had land that was suitable for crayfish development.”

“Funding through the Aboriginal Aquaculture in Canada Initiative was available for project-based, community aquaculture,” explains Parker. “This was one of six projects in the Western region that was recommended for funding in 2017.” The Malahat nation put in funding of their own and is in partnership with Djuric’s Asturia Aquaculture, which is providing technical support and supplying juveniles for growout.

Djuric, who is directing the project, says the limestone content of the water at the former cement quarry at the Bamberton site is important for rearing the crayfish. “Correct calcium levels and a high Ph are a necessity for crayfish,” he explains.

“We are using gravity fed flow-through technology,” says Djuric. Water comes from a lake several hundred meters up a steep hillside and does not require filtration. A converted shipping container will house the juveniles to be raised in standard Capilano aquaculture troughs. The adjacent grow-out pond is about onethird of an acre.

Also a stonemason, Djuric has built a rock wall to create an artificial waterfall that tumbles oxygen into the water. “Crayfish are prone to air bubble disease,” warns Djuric, giving credence to the gravity fed system.

The pond will hold cubic-meter-size growout pens. “We can have up to 1,000 crayfish in each pen,” says Djuric, adding that if the chemistry and feed is correctly balanced, the crayfish do not live up to their cannibalistic reputation. “When they are happy they don’t eat each other,” he explains.

Water from the pond will circulate through an artificial wetland containing watercress and other aquatic plants that will act as a filter before discharge into a nearby stream. The watercress can be cultured year round in the mild southern Vancouver island climate and it is sold to

Victoria and Vancouver restaurants for about $15.00/lb, says Djuric.

Djuric gathers wild broodstock from lakes on Vancouver Island to produce juveniles in his hatchery about 20 kilometers away, in Chemainus BC. “This is like a poor man’s hatchery,” quips Djuric. “It is not commercial size.” But the small scale would make an excellent teaching facility, he adds. The round tanks hold both juveniles and broodstock together.

“We are using all natural feed,” says Djuric. “They are basically scavengers and we are using mostly plant material.” An adjacent pond is used to culture duckweed (Spirodela polyrrhiza), an invasive species on Vancouver Island, but a key feed ingredient for the crayfish. A second pond holds growout cages.

Djuric adds that the company is developing diets with Fisheries and Oceans Canada researchers. “We are working with a multi-trophic system,” says Djuric. The waste from the crayfish can fertilize the duckweed, which the crayfish eat, and some of the waste supports the watercress.

“Depending on water temperatures, we are looking at two years to growout, post hatch,” he says.

Djuric says he has been interested in crayfish since his childhood in Yugoslavia. He managed a commercial crayfish aquaculture operation in the Balkans for five years, before coming to Canada 20 years ago to work with crayfish aquaculture for the Canadian government.

The crayfish will be processed in a plant in Nanaimo, about 80 km to the north. Initial markets are high-end restaurants in the Victoria and Vancouver areas but their sights are on Europe.

“Aquaculture is something new to the Malahat nation,” says Parker. “Our hope is always that it will encourage youth to go on with their education when they can see an end goal right there at their village.”

With a VAKI Biomass Daily frame placed permanently in each cage, fish are continually measured with pinpoint accuracy. For every site and every cage, the daily overview of average weight, size distribution, condition-factor and growth is available 24/7. Accurate, real-time data support optimal decision-making.

Pentair has assembled a team of experts with diverse backgrounds in aquaculture and decades of research and commercial industry application experience. Trust in a team that’s here to help you— ASK US!

Visit PentairAES.com/VAKI today for more about how the VAKI Biomass Daily can improve your operations.

BY SAMUEL CHEN

Our vision at Hudson Valley Fish Farms (HVFF) to raise “Wildly Delicious Steelhead”™ in land-based recirculating systems has been a five-year journey before seeing our first fish come to market. This was a leap of faith driven by a vision to be the tip of the spear for a hyper-sustainable way to farm seafood in urban centers across the US.

Our journey has not been a project but the birthing of a business, which has no defined end but rather is a process of bringing together people, process and technology. A project mindset is inevitably finite and short term in nature. A business venture is a going concern that is supported by multiple functions including finance and accounting, which provide a lens to the best path forward and an objective report on progress. These are functions that help us understand execution challenges and risks. However, the Financial Office (FO) cannot be the driver of the vision. The financial view, just like a regulatory-legal view, is not the singular lens for go-no-go decisions.

This is what troubles me as I see new or prospective land-based systems being proposed. Too many of these new ventures are sold to investors as projects with unrealistic financial expectations. The business plans are grossly oversimplified and borrow on models like Michael Porter’s Five Forces to show business viability and competitive positioning.

This is what troubles me as I see new or prospective land-based systems being proposed. Too many of these new ventures are sold to investors as projects with unrealistic financial expectations.

— Samuel Chen, Corporate and Business Development, Hudson Valley Fish Farms

The pitch usually goes a bit like this – “with control of upstream supply (e.g. broodstock or eggs), securing of downstream sales through off-take agreements (which are actually more letters of intent than agreements), and a team with strong credentials, one is competitively positioned to deliver expected annual returns of 15 percent and a return on capital is possible in three years.” Business plans like these are driven by spreadsheets developed by FOs.

History shows a rule I once heard in an aquaculture short course with Michael Timmons…the 2:2:1 rule. The build will cost you twice as much, take you twice as long as you planned and you will get half of what you projected for your product.

But why is this? I have had the opportunity to experience first hand the development of HVFF and my belief is that it is a matter of understanding phases of development in the birthing process. I propose that landbased recirculating farming should be broken into three key phases – BUILD | OPERATIONS | MARKET ALIGNMENT. The FO has the opportunity to play a lifegiving role in both the pre-venture stage as well as in each of

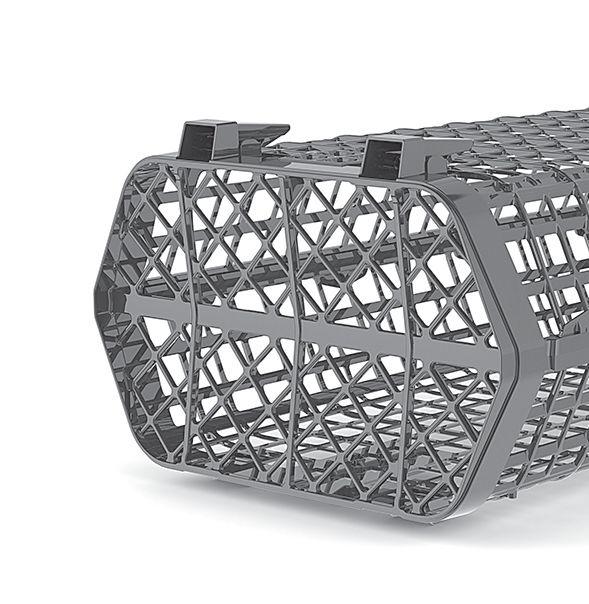

For over 30 years oyster growers worldwide have trusted our S1000 Oyster Tray and S4000 nursery tray, to produce the highest quality half-shell oyster for today's demanding consumers. Featuring our 6061 T-6 aluminum suspender pole which stands up to the harshest of salt water environments.

Phone: 604-926-1050 Cell: 604-833-5311

these phases through risk management. This necessitates an FO that learns together and evolves with the core business. In the pre-venture stage, rather than focusing on manipulating spreadsheets and estimating cost and returns (which if provided should be at best understood as a level 5 estimate as outlined by AACE with a range of +100 percent or -50 percent) – FOs should focus on cash flow and burnrate analysis. It is easy to underestimate costs and timing of returns as there are many variables that only become clear through the subsequent phases once a commitment has been made. The right investor will have the ability to absorb a burn rate for four to five years without seeing any revenue come in from the fish. A rough timeline with milestones should be developed and refined at each stage. Tax implications should be looked at against other investments or business operations that the investor has.

This is the only phase that should be managed like a project with a defined beginning and end. In fact, one of the key roles that the FO should play is a disciplined approach to ensuring completion by the planned date. Delays mean increased costs due to changes in cost of materials, longer time frames to continue paying contractors, and most importantly deferred revenue. This would also mean that finance should be reviewing vendor contracts with the builder/project manager to assess risk of cost and delivery overruns. This phase is about cash-burn and finance can play a critical role in managing the timing of these spends (looking at offsets), potential hedging on currency if supplies are being brought in from out of country (at HVFF, we have equipment from nine different countries), ensuring quoting across multiple vendors and clarifying responsibilities for changes to design. Changes to design result in multiple iterations of as-builts and accumulating unused equipment and supplies (every farm will have a bone yard).

As an aside, it is often in executing this role that the FO can alienate themselves from the build and operations team by taking the controllership role to mean catching what the build team is doing wrong. I remember an instance in our journey where someone from the FO accused our builder of stealing because the price of concrete was triple to what he was told was common in the construction world. Instead of being inquisitive and educating himself on what he does not understand, he made accusations. If he had asked, he would have found out that there were special additives to

ensure water impermeability and that using certain types of concrete (common to construction) could leach out toxins that would kill fish. The inability to ask the right questions or foster open dialog will kill the FO’s ability to be involved and contribute. During this phase, there is industrial-scale plumbing, infrastructure build and electrical that need to come together with location specific permitting requirements. It is not possible for any one person to have in depth expertise in all areas. The FO needs to learn together and work collaboratively with the build team if they are to be able to be a trusted ally and source of objective reality for the project.

During this phase, one of the FO’s key roles would be to begin classifying heads of expense. An Activity-Based Costing approach should be taken to ensure there is full absorption in the cost of production (CoP) calculation. There will be a lot of “noise” in the numbers that should be filtered out and the FO has a key role in identifying true categories of expense. A high-level business plan may have been developed in the pre-venture stage but it is only in this phase and the next that it is refined into something meaningful.

It took Hudson Valley Fish Farms five years to deliver its first RAS-bred steelhead to market

Amortization and depreciation is perhaps one of the most complicated aspects when it comes to working this into the CoP. I have heard many a conversation around the time frame one should look at for the investment and how to work this into depreciation. This is a gross oversimplification and the FO should really be looking at the lifespan of different capital both from a depreciation and a maintenance budget perspective. There are categories of assets that are more consumables than long-term assets. For example, pumps will have a known lifespan by hours used and would fall under the previous category whereas tanks would fall under the latter. Rather than coming up with an annual maintenance budget that is just a percentage of capital investment (few farms would have the financial luxury to actually set this aside), the FO could delve in deeper with the builder/operational team to understand the likelihood of different categories of equipment that need to be replaced or maintained.

Another key role of the FO is to ask questions regularly around things that concern the operational team and to translate this into a probability and severity to quantify the risk financially. Two years ago, I came up with the following mind-map after many a sleepless night. I decided to start jotting out all the different things that kept me awake from an operational perspective.

A good FO will help the business systematically and regularly evaluate financial implications of the different aspects in the inner ring and elicit the business to look in more detail at the outer ring to develop plans.

Once the farm is operational, as defined by the ability to consistently produce fish, it is the phase in which costs need to be optimized and markets need to be aligned to ensure profitability and returns. It is also during this phase that business processes should begin to be standardized. Again, the FO could plan a significant role in modelling

scenarios and provide analysis for operations to explore efficiencies and for sales to focus on channels that offer higher returns. As an operation matures, it also has the ability to explore different product forms, ranging from head-on gutted fish to fillets to portions to specialized cuts. This kind of segmentation by both product and customer creates the need for analysis of complex blended margins and ultimately contribution to the bottom line.

It is also at this stage that Porter’s Five Forces are more relevant. The FO has an opportunity to facilitate strategic discussions at the leadership level around upstream and downstream integration through the value-chain. As an organization moves from the operational to market phase of a business, data also begins to become more stable and

the opportunity for reports and the development of key performance indicators are also made possible. The FO should be providing cash flow reports, trial balances, sales reports and analysis of receivables.

In summary, land-based recirculating aquaculture is a long-term venture that goes through different phases of development as it journeys towards a viable business. Finance and accounting can play a much greater enablement role than providing spreadsheet economics if it learns with and evolves with the core business.

The views presented in this article do not necessarily represent the official views of Hudson Valley Fish Farms but are the personal opinions of the author.

Recirculation aquaculture systems (RAS) are becoming increasingly popular for a range of fish species, including salmon.

RecircReady is our dedicated feed range for RAS. RecircReady utilizes specialized feed components to facilitate biofilter operations by reducing the load of organic materials in the water, reduce phosphorus and nitrogen accumulation and discharge, and reduce turbidity or particular matter. This improves and stabilizes water quality, thereby enhancing filtration efficiency and fish welfare. Since RAS allow for increased effluent control monitoring and collection, special diets like RecircReady can also be used to reduce the level of dissolved nutrients in the culture water.

To learn about how your fish could benefit from this innovative feed range, contact your local representative or visit our website: www.skretting.ca

Opportunities for telling the aquaculture story often start when someone asks a question that skews toward less-than-favorable terms, says columnist

When was the last time you tried to convince a wary seafood buyer that farmed fish are every bit as safe and tasty as their wild counterpart? Or, have you tried to explain that high-density rearing conditions are necessary for fish farming to be profitable, but it’s not a problem to the fish because the water actually must be cleaner than “wild” habitats for the farmed fish to thrive? Opportunities for telling the aquaculture story often start when someone asks a question that skews toward less-thanfavorable terms.

The 2018 Aquaculture America conference theme was “Shaping the Future – Telling Our Story.” The theme leads to the questions: What is our real story? To whom are we telling the story? and, Are we all story tellers? The theme also suggests that each of us must take control and tell our story based on facts if we are going to shape the industry’s future. If we wait for others to frame the discussion, we have lost the opportunity to do this.

We live in a time where politicians level claims of “fake news” at news reporters and even at scientists discussing scientifically valid evidence and conclusions. Aquaculture is not immune from attacks by its opponents, or well-meaning individuals who have simply believed an “urban legend” presented by a trusted friend. This reality of claim and counter-claim begs the questions: who can you believe and how do you distinguish between facts and fiction, or, in today’s parlance, “alternative facts?”

How we tell our story as well as the facts we include can often determine whether or not our story is believable. Not everyone is born a story-teller, but we can improve our skills at presenting our story to an audience by developing a thorough understanding of the issues facing aquaculture and the story we want to tell. We must also learn simple communication techniques that draw our

Consumer buying fish at the Granville

Public Market in Vancouver,

When was the last time you tried to convince a wary seafood buyer that farmed fish are every bit as safe and tasty as their wild counterpart, this columnist wonders

audience into the discussion. A question that causes the audience to examine what they know, or what they think they know, is often the best way to engage them without causing a confrontation. Direct confrontation is rarely a winning strategy because it causes the audience to defend their existing beliefs rather than consider new information. Changing their mind becomes even more difficult, and often, impossible.

A conference, such as Aquaculture America 2018, provides many positive story lines that all of us can use as we tell aquaculture’s story. Managing water quality within rearing units was a major theme at the trade show, in the poster presentations and oral presentations during technical sessions. High quality “onceand-done” single use, pass-through water supplies have become hard to find and unaffordable. Recirculation systems have emerged as a preferred solution in many situations where water supplies are limited

or the cost of not reusing water is costprohibitive. Recirculation systems also carry the advantage of allowing producers to locate their production facilities closer to the markets they serve.

The issues surrounding offshore locations for marine fish production received considerable attention during the conference. Secure grow-out units that prevent escape or theft but are stationed in locations that are easy to service may provide answers to critics who oppose all operations in “the commons.” However, some aquaculturists argue that onshore marine production systems may provide a more defensible solution to environmental charges such as escapement, pollution, and transfer of disease agents. The issues related to the best locations for producing marine fishes were not resolved during the Las Vegas conference, but the ability to have calm, rational discourse was demonstrated. The active programs established by the National

BY JOHN G. NICKUM

Oceanic and Atmospheric Administration to address issues related to marine aquaculture demonstrated an approach by a Federal agency that must be applauded. The “aquaculture story” at Aquaculture America 2018 included additional topics such as alternative feed ingredients, aquaculture development in emerging nations, the increasing role of women in “third world” aquaculture, and culture of non-traditional species. A session on public perceptions of aquaculture expanded on the keynote plenary presentations with discussions of actual experiences related to “telling our story.”

A three-day conference with 12 concurrent sessions explored far more issues and stories than I can describe in a brief article. Speaking as an irascible curmudgeon, a right I claim by virtue of age and experience, I consider the number of concurrent sessions at most large conferences to be a very negative aspect of these conferences. I also object to the number of initial concept and early progress reports that are accepted for presentation. Unfortunately, accepting greater numbers of presentations ensures larger attendance, which attracts more trade show exhibitors and ensures a positive bottom line for the conference organizers.

A final complaint about the recent conference involves a somewhat unstated, “below the surface” theme that emerged far too often in my opinion; namely the claim that regulations cause substantial costs and an array of negative effects for fish farmers. Regulations are necessary, because too many individuals fail to acknowledge the effects of their actions on other individuals and the “commons” that belongs to all of us. I suggest that complaints about regulations are not a good way to tell our story and shape our future. These complaints will be perceived as whining when told to the general public. I suggest further that the real problem is the lack of uniform national regulations, not the regulations themselves. Stated as a request for uniform regulations it becomes a story we can tell effectively and even get aquaculture opponents to add their voices in support. We need all the help we can get in telling our story.

Shellfish farmers are joining the effort to add 10 billion new oysters to the Chesapeake Bay by 2025. The Chesapeake 10 Billion Oysters Partnership aims to restore the Bay by rebuilding its oyster population from a variety of sources, including the Bay’s oyster aquaculture industry.

Among the oyster farmers that have committed to the restoration efforts are Orchard Point Oyster Co, Mudgies Oyster Farm and Hoopers Island Oyster Co.

“Oyster farming plays a pivotal role in oyster restoration, primarily via shell production. Restored reefs need large volumes of shell to thrive, and the tremendous shell

efficiencies generated by our collective farming practices will be key in sustaining this project as well as in all restoration efforts that require a high-level of shell input,” said Scott Richard Budden, founder/operator of Orchard Point Oyster Co.

Promoting and increasing oyster aquaculture is an essential pillar of the project. The Chesapeake 10 Billion Oysters Partnership said it will support the continued growth of the industry to provide economic development opportunities, enhance water quality, reduce dependence on wild oyster stocks, and provide habitat for commercial and recreational fishes.

Fsindings of infectious salmon anemia (ISAv) virus in samples during a routine inspection at a Cooke Aquaculture site in Newfoundland has forced the early harvest of salmon in that site.

Cooke Aquaculture harvested the entire salmon population in that farm. It said the discovery of the virus at the site in March proves that the province’s surveillance program is effective. “This proactive approach to harvesting fish immediately following a positive diagnosis has proven to be the most successful method for managing this virus,” it said.

In October 2017, a Cooke Aquaculture site in the same province also tested positive for ISAv. ISA is a naturally occurring virus and is not a human health issue or a food safety issue, said the company.

Gravity pushes water to flow through the farm, first into the hatchery and then after removal of solids, is mixed with more well water before entering the outdoor tanks

points. Products include whole fish between 1 and 2 lbs, and fresh, frozen and smoked fillets. In January 2018, Ballow added a fresh, made-to-order smoked trout spread to his lineup and it’s selling very well. It comes in retail packs and also five-lb tubs for restaurants, which offer it as part of appetizer dishes.

BY TREENA HEIN

o to Jackson, an hour west of Detroit between Ann Arbor and Kalamazoo, and you’ll find the Indian Brook Trout Farm, which sits atop the largest aquifer in Michigan. It’s this unique location, where the aquifer level is only about 180 feet below the ground, that enables the farm to raise large amounts of rainbow trout with minimal environmental impact.

Owner Owen Ballow and his 10 staff produce 250,000 lbs of trout annually for over 3,000 stores and restaurants across six states. “We harvest six days a week from 500 to 3,000 lbs a day,” says Ballow. When the operation started in 2014, production was a mere 20,000 lbs, so it’s grown more than tenfold in the last three or so years. And more expansion is in the works. “We can’t keep up,” he says.

All Indian Brook products are either picked up by distributors or dropped off to grocery store distribution

“We are able to draw, under permit, 3 million gallons a day for flow through the farm from several artesian wells,” Ballow explains. “The aquifer is mostly at least 600 feet below the ground in this region and not used by the public. It’s below the drinking water aquifer used in this area and contains trillions of ft3.” Gravity pushes water to flow through the farm, first into the hatchery and then (after removal of solids, sold to local hops growers for fertilizer) mixed with more well water before entering the outdoor tanks. It then moves into holding ponds where some nutrients are removed by plants, and finally into nearby wetlands before, in a very clean state, it enters the Grand River and then Lake Michigan.

However, before the well water is used, it must be treated. “Coming out of the ground, it’s under pressure to about two atmospheres, and therefore can hold more gases than surface water,” Ballow explains. “In the hatchery, we remove the nitrogen using a negative-pressure degassing

system, which requires no electricity. The water wants to equalize and degasses in milliseconds. Then we inject oxygen from pressurized tanks.”

For the grow-out tanks outside, however, because the volume of water to be treated is much larger, oxygenation is passive and on a much larger scale. It’s a technique that Ballow says is commonly used in the water treatment industry. He notes that most other trout operations use surface aeration, which requires lots of power.

At the literal base of Indian Brook’s passive oxygenation system is corrugated PVC material that comes in cubes and can be rearranged in any configuration desirable. Fast-flowing water from the hatchery is mixed with fresh well water and then sprayed onto vertical sections of PVC and then falls onto level sections. Algae growing on all sections creates a hydrophilic (water-attracting) surface and a sheen (a thin layer of water) is continually created. Because the sheen water is very low in oxygen, oxygen from the air naturally enters it until the water has reached its maximum oxygen-carrying capacity. This capacity, says Ballow, is quite high in water that is 51°F (10.5°C) year round.

Ballows chose to farm trout for a whole host of reasons. “The location here is perfect for trout production with the water volume and temperature,” he says. “We are able to grow large amounts of trout with very minimal impact on the environment. Rainbow trout have the highest feed conversion rate of all coldwater fish species, needing about a quarter of the feed of most salmon and producing only about a quarter of the waste.”

In terms of market demand, Ballows says consumers

like trout and like that it’s locally grown. His fish is also very pristine; because of the farm’s water source, the fish are not exposed to any pollution or disease factors. Ballows says the FDA has done fish and water tests for numerous chemicals and pharmaceuticals and found none. “The most important reason I chose trout, however, is that there’s been a huge market opening created by the situation in Idaho,” he explains. “About 80 percent of rainbow trout for US was produced there but production has dropped due to water restrictions.”

Challenges have included dealing with lots of

oversight related to farm water discharge, and procuring investment. Ballows says grants from the state of Michigan (two grants totalling $260,000, one to create a processing facility in 2015 and another in 2017 to expand it) have been vital. “Without that help,” Ballows says, “we would have had to continue to sell fish wholesale at a very small margin and it would have been impossible to build a processing facility, which provides much greater profits.”

The outlook for Indian Brook is bright. “We plan to expand trout production and add whitefish, coho salmon and saugeye,” Ballows says.

pisodes of earthy and musty offflavor of catfish reared in split ponds are similar in incidence, timing, and intensity as those in conventional earthen ponds, a study has found.

As such, both grow-out systems can use similar management approaches to mitigate earthy and musty off-flavor problems in catfish, according to the study, Earthy and musty off-flavor episodes in catfish splitpond aquaculture systems.

Conducted by Kevin K. Schrader et al in Mississippi and Alabama, the study’s findings buck the popular belief that offflavor incidence is reduced in split-ponds.

“In a practical sense, the results of this study mean that catfish farmers using split-ponds will use the same management approaches as those used for dealing with earthy and musty off-flavor problems in catfish raised in conventional ponds,” the study said.

“Most catfish producers do not try to prevent off-flavors from developing in fish, but rather they monitor fish flavor in the weeks before projected harvest, and, if fish are found to be off-flavored, they use algicides to eradicate the odor-producing cyanobacteria, which then allows fish to purge odorous compounds.”

The two most commonly used algicides for catfish off-flavor management are diuron in certain states for the control of 2-methylisoborneol (MIB)-producing cyanobacteria and chelated-copper compounds to manage other types of noxious cyanobacteria such as species

producing geosmin.

“In addition, pre-harvest sampling of catfish to monitor for the presence of these two common off-flavors can be performed in the same manner used for catfish raised in conventional ponds,” the study said.

The concentration of the compounds — geosmin and MIB — in water and in the fish flesh causes the off-flavor. This frequently happens during the warm months of the year when certain cyanobacteria associated with the compound thrive.

“These compounds will rapidly bioaccumulate in the fish flesh, and offflavor catfish must be withheld from market until they lose their earthy–musty taints, thereby causing large economic losses to producers from the costs associated with delayed harvest.”

Allowing fish with off-flavor to reach the market could lead to economic losses to the farmer as well. “Consumers don’t want to eat fish with that flavor and they won’t likely buy it a second time. An even bigger problem is that they may stop buying that genre of fish altogether,” Justin Henry, former general manager of Northern Divine Aquafarms, a sturgeon and salmon RAS in British Columbia, cited in his article published in Hatchery International. In RAS, Henry said, the solution to offflavor is depuration, which “requires taking your fish out of the RAS and putting them either on flow-through water or onto another water source that does not contain off-flavor compounds.”

— Ruby Gonzalez

Anationwide survey conducted to better understand American consumer perception of aquaculture found that the growth of US aquaculture rests on consumer education and strategic outreach.

Globally, the marine aquaculture industry generates roughly $166 billion per year and is predicted to see steady growth for years to come, but the US, in contrast, lags in terms of production levels, said the study from the University of Maine.

It noted there is growing interest in the industry in cities and towns across the country, but there must be a general understanding and acceptance of farmed seafood by the public in order for the industry to grow.

With a better understanding of consumer decision-making and awareness, stakeholders would be better able to recognize the challenges and opportunities that the industry faces in terms of growth potential and visibility, suggested researchers at the University of Maine.

The survey, which generated more than 1,200 responses from across the country, found “numerous gaps in consumer knowledge about the industry.”

“Public opinion, as we know it, is somewhere in the middle,” says Ross Anthony, a graduate student in resource economics and policy at UMaine, who

There must be a general understanding and acceptance of farmed seafood by the public for the industry to grow, says study

analyzed survey data. “There’s a lot of uncertainty in how people feel about aquaculture and there is a lot of work left to be done.”

Data also revealed a need for targeted efforts to address knowledge gaps in various demographic groups, including people who are older, have less education, and live in landlocked states.

Interest and engagement with aquaculture increases in communities with high rates of seafood consumption, the survey found. For instance, in Maine where the sea-to-table relationship is more pronounced, fish farmers can use this information to design impactful marketing campaigns and educational programs to increase consumer awareness.

Enterra Feed Corporation of Langley, British Columbia has received new approvals to sell its insectbased feed ingredients in the United States, Canada and the European Union.

The Association of American Feed Control Officials (AAFCO) in the United States has agreed to Enterra’s request to include black soldier fly larvae (BSF) meal in feed for salmonids, which includes salmon, trout and arctic char, in their list of authorized feed ingredients. The supporting material and the change in the definition was reviewed and supported by the Food and Drug Administration (FDA).

BSF larvae are 40-percent protein and 40-percent fat, and contain essential omega fatty acids, says Enterra

“This is the first time an insect meal product has been approved in North America for the aquaculture industry and we’re excited to be the first to market,” said Andrew Vickerson, Chief Technology Officer at Enterra.

The company’s first product, Enterra Whole Dried Larvae, was approved by AAFCO in 2016.

end glassware access makes for easy maintenance when replacing lamps and quartz sleeves

- Thermoplastic or Fiberglass NEMA 12 Power supply enclosures with Standard HMI control package or optional HMI Pro Series control package.

- Electronic ballasts matched to the performance of the specific lamp for optimal UV-C output and longest useful lamp life - Standard Over Temperature Safety Cutoff Switch thermally protects reactor when water temperature reaches 120 Degrees F

- American made low pressure amalgam (ALH/AUH models) and high output (HLH/HUH models) lamps are rated 80% efficient at the end of 12,000 hours

North American aquaculture has its fair share of challenges ranging from complex regulations to worker shortages, rising costs and growing environmental concerns. But it also has serious talent in its corner: young entrepreneurs and innovators who are putting their stamp on the industry. They’re passionate about fish, they have their fingers on the pulse of the market, and they’re always looking for better ways of growing more fish for the planet. Below are six faces to watch in 2018 and beyond. Special Feature on Training and

BY LOU CORPUZ

JENNY

WEITZMAN

PHD STUDENT, DALHOUSIE UNIVERSITY, HALIFAX, CANADA

As a young girl growing up in downtown Ottawa in Canada, Jenny Weitzman looked forward to her family’s annual vacations in Florida, visiting aquariums and the ocean and feasting on seafood. Her love for all things marine eventually brought her to Dalhousie University on Canada’s Atlantic coast, where she is currently focused on developing tools to guide marine resource policymakers as part of her PhD work. A system view is critical when siting a fish farm, Weitzman explains: “We should

look not only into the specific dynamics of water or what’s best for the growth of the species; we should also consider the jobs aquaculture will provide and the social issues it will create. We should recognize that the coastal areas where these fish farms are being placed are increasingly crowded with other, equally important users, and that there are enduring challenges with public trust and social relations.”

Weitzman is a keen advocate of Canadian-grown fish and often volunteers to help promote seafood at public events and aquaculture conferences. “In Canada, we grow some amazing products from aquaculture. We need to recognize that and involve the community so that they know where their food is coming from and how their fish is grown.”

NICOLAS E. MENDOZA FOUNDER AND CEO, ONEFORNEPTUNE, WASHINGTON

Nick Mendoza lights up when people ask him how he came up with the company name. “One for Neptune” references an old sailing tradition

of pouring a drink onto the ocean to pay homage to the god of the sea. But while the name is steeped in the past, Mendoza’s sights are fixed firmly forward. He dreams of making dried fish a popular snack among Americans as it was for the ancient Vikings and the Roman legions, who all relied on dried cod or tuna jerky to fuel their many voyages.

A marine scientist who trained at Stanford and the University of Stirling in Scotland, Mendoza could easily have pursued a research career but, as he puts it, the prospect of being on the cutting edge of aquaculture was hard to resist.

“The market for alternative jerkies like deer and bison is growing, and the US palate is expanding,” says Mendoza. “At the same time, I was concerned about reducing waste in the supply chain and making use of undervalued species. A high-protein snack food that’s shelf-stable, made from sustainably sourced, traceable seafood, and manufactured close to the source hits home on all these areas.”

Mendoza and his partners are developing new fish jerky flavours and building a facility in Bellingham, WA, with production expected to start in spring 2018.

“I predict that new shelf-stable offerings of farmed and wild seafood will be the next frontier of seafood in North America. Many factors in the market have aligned to create this opportunity for seafood,” says Mendoza.

Undergraduate

Our

Visit www.thefishsite.com/learn

“Our next product line following the jerky is a kind of bar that that will use farmed seaweed, and we are also working on vegan seaweed-based products that will use 100 percent North American farmed seaweed.”

Arlen Taylor and her brother RJ Taylor are second-generation fish farmers who run Cedar Crest, Ontario’s largest trout farm. Their parents started the business in 1995, but it was Arlen who engineered an expansion program in 2013 that catapulted the farm into an Ontario powerhouse with four land-based trout hatcheries that stock net-pen sites in Georgian Bay with more than five million fingerlings every year. Following on that success, the siblings have started introducing value-added products, including smoked trout and a line of pates and dips that they developed themselves. They also recently started a pop-up shop, making the rounds of nearby communities, taking pre-orders and generally talking about fish at local buy, sell or swap meets. Educating people what fish farming means is a cause near to both Taylors’ hearts and the pop-up shops are proving a great way to engage their surrounding communities. “Opening our pop-up shops and our processing facility has given us the opportunity to engage with the average Ontarian. We’re finding how excited people are to get this fish, and how excited they are about farmed seafood in central Canada,” says RJ.

Arlen adds: “Half my job is education in some form. We find that people want to know more about farmed fish, and by engaging with them they support us back by telling people what we do.”

Lee Scoggin, a graduate of University of Wisconsin-Stevens Point’s highly rated fisheries program, is a firm believer in aquaponics, so it makes sense that he found his way to Urban Organics just as the company was being started several years ago by founders Dave and Kristen Haider, Fred Haberman and Chris Ames.

Today the company is one of the world’s largest aquaponics operations—supplying about 475,000 lbs of organic greens and 275,000 lbs of Atlantic salmon and Arctic char each year—and Scoggin is relishing his daily responsibilities as its recirculating aquaculture system (RAS) manager. He also enjoys giving farm tours to the public, largely because they help dispel some of the misconceptions around fish farms. “Aquaponics systems work so well and have huge potential,” says Scoggin. In his mind, there’s no doubt that the oceans are being overfished. “We import so much seafood into this country so there’s a huge opportunity for land-based RAS to bring food right to the market. And it’s all done indoors with very little impact on the environment.”

LISA VOLLBRECHT RESEARCH MANAGER, KAMPACHI FARMS, LLC, HAWAII

Growing up in the farmlands of rural Ontario, Lisa Vollbrecht always felt a strong connection to nature and food production—a connection that informs her work as research manager for Kampachi Farms, the Kona, Hawaii-based aquaculture startup founded by Neil Anthony Sims. Her job involves organizing resources for Kampachi’s researchers, writing grants and nurturing collaborations and industry partnerships. Kampachi Farms specializes in researching technologies to raise fish in freefloating cages in the open ocean, a unique approach that frees it from mooring restrictions and competition with other users. The company is currently applying for permits to set up an anchored demonstration farm in the Gulf of Mexico to test the feasibility of offshore kampachi culture there, and to provide a platform for education about offshore aquaculture.

“We’re hoping to map the process for attaining commercial-scale farm permits in the Gulf of Mexico so others can follow. This would result in the first finfish farm to be permitted in federal waters in the US,” says Vollbrecht. “We’re also looking into feed alternatives, such as algae-based feed, which are an important part of expanding fish production in a sustainable manner.”

Vollbrecht sees aquaculture as a means of conservation. “My vision of aquaculture is production done in harmony with the environment. Aquaculture has minimal environmental impact if done properly.”

The Aquaculture Research Institute (ARI) provides undergraduate and graduate students with research experience and hands on fish culture experience at facilities on-campus and in the heart of the Idaho aquaculture industry.

A Bachelor of Science degree in Fisheries with an Aquaculture minor is offered through the Department of Fish and Wildlife Sciences in the College of Natural Resources.

For more information for Aquaculture Programs at UI, go to www.uidaho.edu/aquaculture; or contact director Ronald Hardy, rhardy@uidaho.edu, 208-837-9096, ext. 1105, or associate director Kenneth Cain, kcain@uidaho.edu. 208-885-7608.

Join us at one of the Northeast’s largest academic aquaculture facilities.

• New 40,000-gallon indoor cold-water Recirculating Aquaculture System (RAS)

• Bachelor degree in Fisheries & Aquaculture

• Hands-on learning

• Small classes

• Undergrad research & travel opportunities

Only at SUNY Cobleskill cobleskill.edu

As important as having the specialized skillset, an aquaculture diver should also have the temperament to get the job done, writes Kelly N. Korol.

ACobleskill _MayJune17.indd 1

2018-04-17 11:30 AM

rguably, one of the most challenging but rewarding jobs on the farm site is the aquaculture diver. Very much like the cowboys on the cattle ranch, the divers are responsible to rig the underwater system, mend the nets, deal with the predators and do their best to ensure the stock is healthy and makes it to market. Just like their cowboy counterparts, the aquaculture diver has a specialized skill set — and temperament — that helps them get the job done.

Divers are found on most all open-water sites—from finfish to oysters to scallops and geoduck (clam) operations and more. Their work focuses mostly on maintaining the underwater hardware including the anchoring systems, net inspections, floatation maintenance and more including occasional work on the underside of the farm vessels. Sometimes the work is routine, such as underwater pressure washing or mortality recovery, and sometimes specialized, such as rigging the cage system.

Divers are also in a unique position to observe the product directly in its environment. Divers can assess behaviors, water conditions, feeding response and overall health of the stock and make recommendations to benefit the stock. The divers’ keen observations can also help the managers and veterinarians make decisions necessary for the health of the herd. Not only stock health but their security is the responsibility of the dive crew. Net checks for holes, damage to the pens or cages or potential wear can save the farm costly repairs and losses.

The aquaculture diver has a unique set of trade skills. Not only is the diver an expert in the physics, physiology and equipment of diving, but they also have to be masters of knots, rigging, mechanical advantage, and mechanics. Divers are puzzle and problem solvers and enjoy the challenge of finding solutions for the underwater portion of the farm system. As well, divers know if they take care of

the stock, the stock will take care of them, so they are often self-taught biologists learning animal husbandry and techniques for caring of their product.

So it begs the question, where do these divers come from? Some are existing farm staff who want to be able to expand their use and skills on the site. Some are trained commercial divers who find employment in the aquaculture industry and discover the rewards of the lifestyle and pay. And still others are men and women who want to get into a career that is interesting, demanding and something that not everyone can do.

To become an aquaculture diver, you have to begin at a proper commercial dive school and become certified in the skills, and academics of a commercial scuba diver or surface supply diver. This certification enables the diver to safely work in the underwater environment, be self-sufficient underwater and to develop a huge set of skills from knot tying to compressor maintenance, to underwater rigging techniques and tool use. But it doesn’t end there. The most accomplished divers also get vessel operator and marine radio operator certifications, advanced first aid skills, underwater video and imaging skills in addition to many other marine related skills.

As for safety, there is no doubt that diving is one of the riskier activities on the farm but over the years regulation and procedures have made diving as safe as most other jobs on the site. I’m often asked if divers will ever be replaced with technology (Remote Operated Vehicles, automated net washers, etc).

Although there is room for technology on the farm site, nothing will ever be able to replace a set of keen eyes, dexterous hands, and the real time, problem solving brain on the underwater worksite. Overall, aquaculture divers perform a valuable and essential role on the open-water site and they draw on a very specialized skill set that enables

DiveSafe students Darcy, Spencer, Michael, Dylan and Grayson training to work in the aquaculture industry

them to have a challenging and rewarding career on the aquaculture site.

Kelly N. Korol is an aquaculture Diver Training Specialist and the Director of Training/Owner of DIVESAFE International

You want this person to listen to you. But you know that if he would, he might only give you very short time and, even then, there are other people lining up to talk to him as well.

This could very well be the same case whenever you upload an extension video on sharing sites such as YouTube.

So how do you seize the moment?

“Make sure that you have a quality opening and get into the meat of the material quickly,” Dr David Cline, an extension aquaculturist at Auburn University in Alabama, told Aquaculture North America (ANA).

Cline is behind Aquaculture Education and More channel on YouTube, which he started in 2013. His most popular video is on in-pond raceways, which has been viewed 120,000 times. Educational videos on YouTube have an average of 4,872 views.

“A good opening sequence is okay as long as it is visually compelling and high quality,” he continued. “Use good visuals early.” Interesting photos, an interview, good graphics always help.