BY AARON ORLOWSKI

he US aquaculture industry faces numerous hurdles: a negative image, a difficult regulatory environment and, crucially, a shortage of educated, skilled workers.

Low level of pollutants in farmed salmon due to changes in fish-feed content

That lack of professionals, in turn, threatens to hold back the industry even as demand for farmed seafood and fish is rising and Americans grow increasingly aware of the origin of the food on their plates.

Well-trained workers with the necessary skills are hard to come by, Michael Schwarz, a past president of both the World and United States Aquaculture Societies, told Aquaculture North America (ANA). In the 25 years he’s been in the industry, Schwarz has seen only attrition.

“As soon as you start looking for experience

on page 22

Aquaponics facility will yield 120,000 lbs of salmon and 40,000 lbs of trout annually and 4,500 lbs of leafy greens per day

BY TOM WALKER

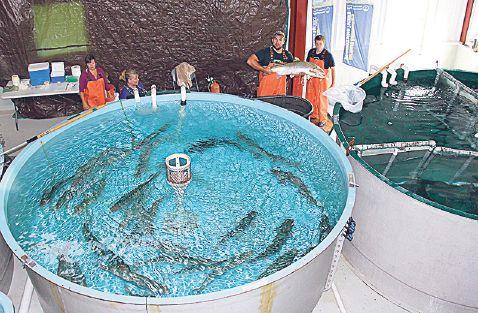

he first commercial scale indoor Atlantic salmon RAS facility in the US is up and running in Northfield, Wisconsin.

“Our initial cohort of year-old Atlantics are moving through the system,” says Superior Fresh COO Brandon Gottsacker. “We expect to harvest them in the second quarter of 2018 at a target weight of 4-5 kilograms.” Next door is a standalone glass greenhouse, where the company has just completed planting their first batch of leafy greens.

armed salmon contains less environmental pollutants than its wild counterpart, according to a Norwegian study that’s been described as the biggest research of its kind so far. The study involved 100 samples of wild salmon caught in the sea in Northern Norway, and 100 samples of farmed salmon.

“It was previously widely thought that farmed salmon contained more environmental pollutants than wild salmon, but this proves not to be the case,” Anne-Katrine Lundebye, study co-author and senior scientist at the National Institute of Nutrition and Seafood Research (NIFES), said in a NIFES article.

Lundebye explained that the differences between wild and farmed were due to their diets. “Fish are what they eat, both in terms of environmental pollutants and nutrients. This can be controlled in farmed fish, while what fish eat in the wild varies,” Lundebye was quoted as saying.

The relatively low level of organic pollutants in farmed salmon has been attributed to changes in the composition of fish feed, among others. Today’s fish feed contains less fish oil, which was previously the main source of many of the undesirable substances in the feed, said the NIFES report.

The study, Lower levels of Persistent Organic Pollutants, metals and the marine Omega 3-fatty acid DHA in farmed compared to wild Atlantic salmon (Salmo salar), demonstrated that the concentrations of dioxins, polychlorinated biphenyls (PCBs), DDT, dieldrin, lindane, chlordane, Mirex, toxaphene and

The SLICE® Sustainability Project is the latest global initiative from Merck Animal Health — the world’s leader in health management tools for farm-raised fish.

Based on four core actions — Protect, Conserve, Renew, and Succeed — the field-proven, science-driven program is helping the world’s salmon farmers develop long-term, sustainable control programs for sea lice.

To help ensure success, The SLICE Sustainability Project also involves a global network of analytical laboratories that conduct bioassays, feed and tissue analysis, and other tests needed to implement the program effectively.

Your Merck Animal Health representatives are ready to take an active role in your sea lice control program — training farm personnel and developing site-specific strategies that ensure product efficacy and longevity.

http://aqua.merck-animal-health.com

Acommercial facility for producing omega-3 fatty acid products from natural marine algae for salmon aquaculture is being planned in the US.

A new company, called Veramaris, formed out of a joint venture between Royal DSM and Evonik Industries, will build the facility.

The joint-venture company will be based in the Netherlands but the facility will be built at Evonik’s existing site in the US. It is expected to start producing omega-3 fatty acid products in 2019. The initial annual production capacity will meet roughly 15 percent of the total current annual demand for EPA and DHA by the salmon aquaculture industry, the companies said.

The firms claim that their alternative omega-3 source is the first to offer both EPA and DHA and will be aimed at initial applications in salmon aquaculture and pet food.

“The algal oil from DSM and Evonik means that the vision of salmon farming without using fish-based resources is, for the first time, becoming realistic. By replacing fish oil in salmon feed with this EPA- and DHA-rich alternative, the fish-in-fish-out ratio could be reduced significantly. This alternative will enable the aquaculture industry to continue to grow sustainably,” they said in a statement.

LoveTheWild, a Colorado-based company that offers farm-raised readyto-cook seafood kits, says AcademyAward winner and environmental activist Leonardo DiCaprio has invested in the company and will also join its advisory board.

“Proud to invest in @LoveTheWildCo who are pioneering responsible aquaculture as a sustainable solution to feeding our growing population,” DiCaprio tweeted days after the announcement.

“Seafood is a primary source of protein for nearly a billion people – but climate change, acidification and over fishing are putting increased pressure on our oceans’ natural stability,” DiCaprio said in a statement. He believes that LoveTheWild’s “approach to sustainable, responsible aquaculture is promoting the development of a secure and environmentally-conscious solution” to feeding the planet.

The company’s gourmet, frozen seafood products utilize traceable, farm-raised fish sourced from wellmanaged aquaculture facilities, said the company.

Earlier, the Netherlands-based aquaculture investment firm Aqua-Spark also invested in the company (See ANA, March/April 2017, page 25).

he Namgis First Nation, sole owner of Kuterra, on April 6 voted “overwhelmingly” in favour of pursuing a process to look for outside investment in the company to maximize its value, the company tells Aquaculture North America (ANA)

The land-based Atlantic salmon farm on northern Vancouver Island in British Columbia is looking to break even this year, but the “Namgis are no longer in a position carry the financial risk of the venture, and are keen to see other investors share in the development of Kuterra,” the company said in March.

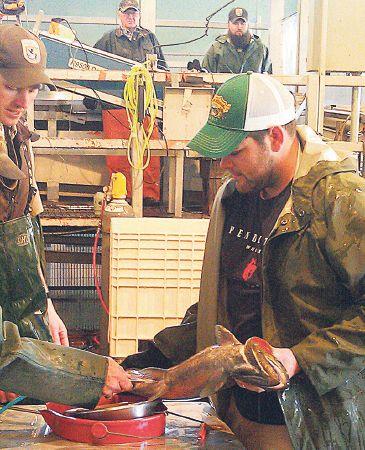

(L to R) Gerry Alfred and Richard Smith at a weekly harvest of Kuterra salmon. Kuterra is in talks with potential investors

The vote on April 6 is a “key element” of the process to look for a buyer or partner to pursue the company’s development. “Because Kuterra is on reserve land, there are very special rules and federal regulations covering what can and can’t be done with reserve land in Canada. So the Namgis members had to vote on whether they could designate a parcel of their reserve for lease purposes,” spokeswoman Josephine Mrozewski tells ANA

Mrozewski says the result of the vote is crucial. “It is allowing Kuterra to undertake a sale process because it will offer security to any potential buyer or investor,” she says. Kuterra is now waiting for approval of the leasing process by the Federal Minister of Indigenous and Northern Affairs in Ottawa. “The timing of that process is, to a large extent, controlled by the Federal Government and we will just wait for that to play out,” says Mrozewski.

She adds that Kuterra’s team continues to talk with potential investors; however, a sale cannot be made until the ministerial approval of the lease process is obtained.

BY LIZA MAYER

The permitting process allowing commercial fish farming in the Gulf of Mexico has been in place for a little over a year now but no one has applied for a permit, acknowledged the National Oceanic and Atmospheric Administration (NOAA) recently.

Harlon Pearce, chairman of the Gulf Seafood Institute and owner of Lousiana Fish & Seafood, raised the issue at the Federal Town Hall Meeting held at Aquaculture America in San Antonio, Texas in February. “Nobody wants to be the guinea pig. We’ve lost lots of people to Panama and Mexico already. They couldn’t go through this supposedly simplified permitting process [in the Gulf of Mexico] because it is not simple,” Pearce later told Aquaculture North America (ANA) at the sidelines of the conference.

Michael Rubino, director of the Office of Aquaculture at NOAA and a panelist at the Town Hall Meeting, said the lawsuit that the agency is facing is “delaying people from applying.” The plaintiffs, comprised of fishing and public interest groups, argue that NOAA exceeded its authority to regulate fishing under the Magnuson-Stevens Act by including offshore aquaculture as “fishing” activity (see ANA May/June 2016, page 5).

“So that [lawsuit] has to be settled in the courts. It doesn’t mean someone cannot apply for a permit now but I think it has dampened the desire to apply for a permit so far,” said Rubino.

Neil Sims, President of the Ocean Stewards Institute and co-founder and co-CEO of Kampachi Farms, told the crowd that as a potential investor, he is “intimidated” by two things: the “strident opposition from fishermen” that would be displaced by the buffer zones around the facilities where fishermen can’t go, and the “convoluted, multilayered permitting process” involving six agencies. “No-one has done this before, and so everyone is fearful of getting tied up in an expensive process with no clear pathway to an end point,” Sims told ANA

Speaking to the Town Hall crowd, he said: “I don’t think the lawsuit is really what is scaring people away because there is plenty of legal precedent there; decisions have been made that define pretty clearly that aquaculture is fishing, and it is my belief that it would be almost incomprehensible that a judge would overturn that at this stage.

“As a potential investor who would [consider a] move to the Gulf of Mexico, the lawsuit doesn’t scare me. What scares me is the opposition from the fishermen that will be displaced because the current rules exclude all fishing from around the permit area. And the permit area has to be twice as large as the actual farm structure. Fishermen will feel rightly feel that access is being denied to them, and for no good or apparent reason. We have talked about this at length before and I’ve pointed out that the problem is it makes it really intimidating for a project proponent. Are there moves at the Gulf of Mexico to change that, and if not, what has to happen to make that part of the rules change?” Sims asked.

Rubino said there is room to modify the regulations for fish farming. “We have come as far as we can under the direction of the Gulf of Mexico Fishery Management Council on this, but we can go back to the council to make so-called framework adjustments or even make changes to the rule. But that takes going to the council and working with the council,” he said.

On the issue of the permitting process, Sims wondered whether a “fomento” permit, which allows for up to 12 months of exploratory aquaculture, might be considered in

“So that [lawsuit] has to be settled in the courts. It doesn’t mean someone cannot apply for a permit now but I think it has dampened the desire to apply for a permit so far.”

— Michael Rubino

Scuba diver swims near net pen in an offshore fish farm. The permitting process is now in place in the Gulf of Mexico but no one has applied so far

this case. “It is a permit that lets you go out there for 12 months and have a go at it. There’s ample science out there that shows that even if you did badly, if you pull out the offending pen out of the water after 12 months, everything reverts back to its original state. And so is there some way that we can get that established as a rule, or is that something that has to come from legislation?”

Rubino said such fomento permits are issued in the state of Maine. “It would have been great if we had thought about that back in 2000 when we were putting

together this fishery management plan,” he acknowledged. But he said this is something that can be considered through a framework action.

He added that NOAA has a “wish list” of things that it would like to work on with the council going forward. “There are imperfections in the system that need to go back to the Gulf council at some point to fix them. But that program is ready to go. It’s not perfect but it’s a good start. We are ready to work with the permit applicant,” he said.

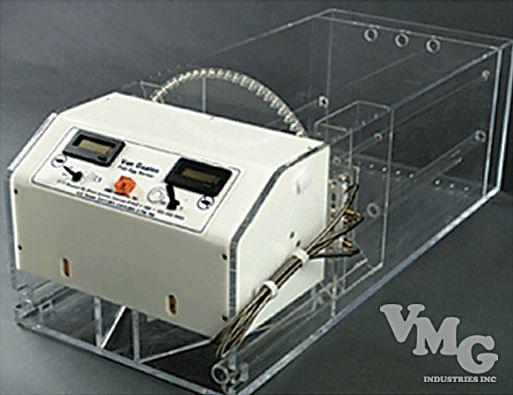

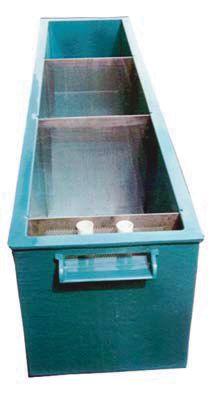

The Van Gaalen Fish Egg Sorter uses the most current technology to bring you an egg sorter that offers: variable egg sizes, speed, accuracy, egg counts, safety and versatility. VMG Industries Inc. 2972 Bellmeade Way Longmont, CO 80503

T: 303.682.8890 F: 303.682.8892 www.vmgindustries.com

Clinical trials show tilapia treatment cuts down healing time and reduces the use of pain medication

reliminary results of clinical trials in Brazil show tilapia skin has the potential to someday replace the conventional gauze-and-cream dressing used to treat burn patients.

Analysis of tilapia skin showed it is abundant in types 1 and 3 collagen proteins — even more than in human skin and other skins — which are very important for scarring, reported STAT, a publication specializing on health, medicine, and scientific discovery.

Researchers, led by Dr Edmar Maciel, a plastic surgeon and burn specialist, noted that its use as “bandage” cuts down healing time and reduces the use of pain medication. They also discovered that “the amount of tension, of resistance in tilapia skin is much greater than inhuman skin,” as well as the amount of moisture.

Burn patients treated with the conventional gauze-and-silver-sulfadiazine cream combination need to have the bandages changed every day, which Maciel noted is a painful process. Trials using sterilized tilapia skin as bandage helped patients avoid this pain because the tilapia skin stays on and doctors leave it on until the patient scars naturally, said the report. It noted, however, that for deep second-degree burns, the tilapia bandages must be changed a few times over several weeks of treatment, but still far less often than the gauze with cream.

The use of animal skin in the treatment of burns is not new in developed countries, said the report, but Brazil lacks the human skin, pig skin, and artificial alternatives that are widely available in the US. This inspired researchers to study the potential of using the skin of tilapia, a fish that is abundant in the country, it added.

While delivering Marine Harvest’s fourth-quarter 2016 financial results, CEO Alf-Helge Aarskog confirmed that the global supply of farmed salmon had fallen by 10.5 percent. The reduced supply caused prices of Norwegian salmon to rise earlier this year to $9.44 (€8.68) per kg before bouncing between €6 and €7 in March. Norway is the world’s top salmon exporter.

Reports have linked the decrease in supply to sea lice issues which have been exacerbated by climate change. In February, Norway’s Food Safety Authority (FSA) advised Marine Harvest that they would cut the company’s biomass quota — or how much fish is held in a fish farm — at their Bukkholmen salmon farm for two years due to sea lice. Reuters quoted the FSA as saying that the company has been too slow in implementing measures to reduce sea lice, and the effect of measures has not been satisfactory in several cases.

Though prices are beginning to return to normal, it is still a challenging market. A seafood exporter told Reuters on condition of anonymity, “It’s a poor market. We have lost a lot of sales due to high prices in recent months.”

While the rise in prices was challenging for many in the industry, Marine Harvest themselves reported a 133-percent increase in sales year-on-year in “consumer products,” which includes salmon products. The increase was attributed to operational improvements and adjusting their sale prices to reflect the increased salmon costs.

“Excellent” fatty acid composition could command premium price

BY RUBY GONZALEZ

Good news for tilapia aficionados: tilapia has always been good for you.

A study showed tilapia’s Omega-6 to Omega-3 (n6:n3) ratios is relatively low compared to normal US diets. This disproves the “worse than bacon” allegation made in 2008 that was based on a study conducted by a research team that exaggerated its interpretation of how tilapia’s n6:n3 ratios were bad for the health.

An even better development is that, with customized feeds, tilapia can be developed into a premium product with specifically designed lipid content and/or fatty acid composition (FAC) profile (see side bar.)

“Consumers have shown high interest in these premium value-added products, and tilapia has huge potential in valueadded segment of the marketplace,” cited Hyun Sik S. Chu et al in the abstract of 21st Century consumer behaviors - Why we are interested in value-added “Gucci” tilapia.

The research team is from the Department of Food Science and Technology, Virginia Polytechnic Institute and State University in Blacksburg.

With a healthy fatty acid composition, the so-called “designer” tilapia will cater to consumers, millennials included, shifting to healthier, less processed, and more sustainable products.

“We are seeing changes in consumer behavior. Interesting patterns are coming up,” Chu said during his presentation at Aquaculture America 2017 held in February in San Antonio, Texas. “People want transparency in products. That means people want to know what goes into the product.”

In wanting to “feel safe” in eating the product, the consumers check out the information label to check if the ingredients are safe and the products, less processed. They even consider if the packaging materials are earth-friendly.

Chu said that in terms of fresh fish, consumers are starting to prefer the whole fish, not fillets. “They also want more sustainable product, they look at the producer and want to know if it has sustainable practices.”

People usually buy fish for the taste and assumed health benefits, compared to other meat proteins. Wild-caught fish is preferred and considered as a premium product. Aquaculture products, however, are starting to be viewed favorably as a sustainable alternative.

Consumers’ “willingness to buy” is steadily increasing, he said, due to

the entry of millennials in the market, changing consumer patterns, and producers’ educational and marketing efforts.

“Producers are getting the word out that it is a sustainable alternative: it involves controlled feed, water. So people believe in these things now,” he said.

During his presentation, Chu profiled the millennials, or those born in the 1980s to early 2000s, who are entering the workforce and becoming economically independent. “These are the people raised on information or know how to get the information. Albeit they are not necessarily getting the factual information, but they know how and where to get some sort of information,” he said.

Designer tilapia, or what he fondly referred to as “Gucci” tilapia, offers a healthier fish product to the consumer and bigger profits for the farmer.

“Tilapia is a cheap product. Where I am from, it is $5 per lb for fresh fillet. It is lower compared to salmon and tuna. With the value-added tilapia, the tilapia industry can get into that market in terms of price.

“People are willing to pay extra for a premium product. However, I haven’t seen any such premium product from the tilapia industry yet. Why not try to create it, right?” he said.

It could command a high price, based on the amount being paid for premium products, like GMO-free corn and red beans, and antibiotics-free chicken. These are two to three times the amount of their regular counterparts, Chu said.

The team analyzed the FAC of tilapia fillets in US supermarkets in order to understand the claims about poor lipid quality of tilapia. Although samples from different countries of origin showed high variations in FACs, the market study indicated healthy FAC in tilapia fillet lipids.

Acknowledging that there is a need for more premium products, the researchers conducted growth trials to improve FAC through enhanced diets.

The effective customized diet has “excellent n-6 to n-3 ratios, especially compared to the current American diet of 10:1.” It is composed of algae oil, fish oil, high oleic sunflower oil and soybean oils at various concentrations.

Someone from the audience asked Chu: “Why not just inject the healthy fatty acid in tilapia fillet?”

Chu replied that consumer perception plays a big factor. “If you go to the consumer and say, ‘I injected oil into this fillet,’ would you want to eat it? A big

Consumers checking out seafood at the Pike Place Public Market in Seattle. With customized feeds, tilapia can be developed into a premium product with healthier fatty acid composition that would appeal to consumers’ changing purchasing patterns, say researchers

Credit: Liza Mayer

problem for the food industry now is we have to worry about what the consumer is thinking of us. It’s across the whole food industry,” he said, using Subway as an example. Subway had to change a bread ingredient when consumers found out that it is the same item used in making yoga mats.

“Consumer perception plays a big factor. Less-processed, wholesome products — people pay extra for these things,” he said.

Tilapia ranks fifth among the most eaten seafood in the US, according to the National Marine Fisheries Service. Its image, however, suffered from the “worse than bacon” backlash in 2008. The comment was based on study conducted by a research team in Wake Forest that exaggerated how tilapia’s n6:n3 ratio was bad for the health.

To create the value-added product, Hyun Sik Chu and his team focused on enhancing the fatty acid composition of fish by feeding it customized feed. The researchers outlined the types of fatty acids they wanted to increase or reduce:

Omega-3. Improve Omega 3 fatty acid because it is an extremely important part of human diet, especially in young children. It has antiinflammatory characteristics.

Omega-6. Minimize the impact of Omega 6. Too much Omega-6 fatty acid exacerbates health problems: atherosclerosis, which causes cardio-vascular diseases, the leading cause of death for most ethnicities in the US.

Omega-9. Increase the impact of Omega-9 fatty acid. It has been known to reduce LDL (low-density lipoprotein) cholesterol and atherosclerosis.

While the middle of Wisconsin may seem a strange place to be raising salmon, trout and lettuce, it makes sense when you consider Gottsacker’s background.

“I attended the University of Wisconsin Stevens Point (UWSP) focusing on Biology and Aquaculture,” says Gottsacker. “I was intrigued by both the challenges and opportunities aquaculture presented.” Shortly after college he received an internship opportunity at the Conservation Fund’s Freshwater Institute (FWI) in Shepherdstown, West Virginia. The Freshwater Institute is known for their work with RAS systems for salmonids. FWI’s team designed the Superior Fresh facilities and they, and UWSP Northern Aquaculture Demonstration Facility, continue to consult on the project.

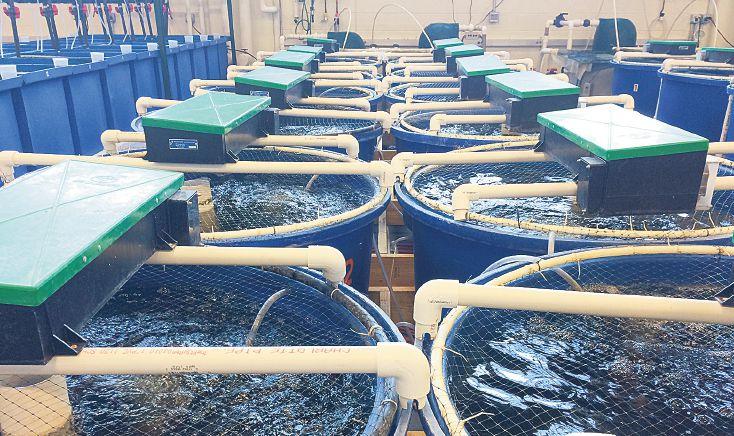

Superior Fresh sits on 720 acres of family property that is being restored and managed as a native vegetation habitat. The 40,000-square-foot “fish house” was completed in late 2016 and the 123,000-square-foot greenhouse, in early in 2017.

Gottsacker says their original business plan was for a 1,000-metric-tonne walleye farm. “We realized that it would be very costly to deal with the phosphorus in the

discharge,” he says. “We would have had to construct a waste water treatment plant.” The greenhouse solves that problem and creates an additional revenue stream for the company.

Two wells on the property provide 10C water, which is UV-treated. Currently, the company is sourcing all-female Atlantic salmon eggs from Stofnfiskur in Iceland. Superior Fresh received their first shipment of salmon eggs in January 2016 and expect the trout eggs to arrive in the next couple of months. They have incubation systems onsite and plan to keep the fish, from egg through to processing.

In full production, the company aims for 120,000 lbs of salmon and 40,000 lbs of trout a year, within their 500,000-gallon capacity. They expect to begin harvesting 1-kg trout by the second quarter of 2018.

They aim to produce a wild fish in, farmed fish out ratio of zero, as defined by the Monterey Bay Aquarium Seafood Watch program. “To keep the diet sustainable, we are sourcing fishmeal and fish oil from trimmings collected from sustainable fisheries for the protein portion

• Our tanks are available in many colors, shapes and sizes from 25 to 3000 gallons

• Smooth inside surfaces prevent damage to your fish

• Edge lips provide wall strength & minimize deformation

• Custom installation of optional drain fittings • FDA and UV sterilized

We also offer Vertical Storage , Horizontal, Cone bottom, and General Purpose tanks- see our website for details.

of our feed,” explains Gottsacker. “In addition, all major ingredients are sourced from North America.”

Feed is the largest expense in an aquaculture operation, Gottsacker points out. “Some producers look to cut costs on the important ingredients and you start to see the Omega-3s drop out, or the color of the fillets drop out,” he says. “That lessens the quality of the fish.”

“We are working with a couple of different feed companies to develop specific recipes for our fish and plants,” says Gottsacker. He expects a feed conversion ratio (FCR) of 1:1. “Our timetable of two years — from growout to market-size — will be much shorter than other types of salmon farming.”

“We have about 350,000 gallons of water in our largest grow-out system in eight different grow-out tanks, each around 22,000 gallons,” Gottsacker explains. The salmon and trout systems are completely separate, due to biosecurity. “We expect these systems will slightly differ in operations and water qualities.”

3 YEAR WARRANTY ON

or

Aquaculture and hydroponics is how Gottsacker describes the decoupled system. “We recycle a small amount of water between the two facilities. We don’t have to worry about heating or cooling water as much,” he says. “It is really modeled after a commercial aquaculture facility and a commercial hydroponic facility.”

Not only are the fish and greenhouse systems in separate buildings, but fish production is not limited to the capacity of the greenhouse to accept waste. “Any additional waste that is generated from our farm is either land applied or composted for later use on conventional agriculture land,” Gottsacker says. “Nothing is wasted.”

“Our hydroponics greenhouse is a deep-water culture growing application, with nearly 100,000 ft2 of growing space,” says Gottsacker. “The greenhouse temperature is maintained with an advanced hydronic heating system and 1,100 LED’s provide the lighting.” The European greenhouse design is intended for northern climates. “We are looking to maintain a year round growing environment of 65-75’F.”

“Our anticipated production of about 4,500 lbs of leafy greens and herbs a day will reach out to approximately 700 grocery stores between Minneapolis and Chicago,” says Gottsacker. “We plan to harvest between 16-40-day-old plants depending on the variety.”

“Today, there are not very many options in this part of the country to purchase fresh, local, healthy produce, especially this time of year,” Gottsacker says. “Superior Fresh also plans to pursue USDA organic certification for all its leafy greens.”

RECEPTIVE CHEFS

Aquaculture North America (ANA) spoke to Gottsacker during a break from his presentations at the recent Vegas Food Expo. He was showcasing Springhill Atlantic salmon raised at the Freshwater Institute’s research facilities, while he is waiting for his own fish to reach market size. “The chefs are in love with it,” says Gottsacker.

“We are raising the most premium salmon in the world. The pristine water and the absence of antibiotics or pesticides, is something today’s consumers are demanding,” says Gottsacker. “Today, our prices will reflect those husbandry practices, although the goal is to grow the best, healthiest food in the world and make it affordable for everyone.”

mercury in wild Atlantic salmon were higher than in farmed Atlantic salmon.

The same findings also applied to the levels of the essential elements selenium, copper, zinc and iron, and the marine Omega-3 fatty acid, docosahexaenoic acid (DHA). DHA and EPA (eicosapentaenoic acid) are kinds of Omega-3 fatty acids that are found in certain fish.

“The PBDE (polybrominated diphenyl ethers), endosulfan, pentachlorobenzene, hexachlorobenzene, cadmium and lead levels were low and comparable in both wild and farmed fish and there was no significant difference in the EPA concentration,” said the study.

PBDEs organobromine compounds are used as flame retardant. PCBs are a group of manmade chemicals that are either oily liquids or solids, clear to yellow in color, with no smell or taste.

BOTH ARE SAFE TO EAT

“The total fat content was significantly higher in farmed than wild salmon due to a higher content of both saturated and monounsaturated fatty acids, as well as a higher content of Omega-6 fatty acids. The Omega-3 to Omega-6 fatty acid ratio was considerably lower in farmed than wild salmon due to the high level of Omega-6 fatty acids,” it said.

Analyses indicated that the contaminant concentrations in wild, escaped and farmed salmon are well below maximum levels applicable in the European Union. This makes Atlantic salmon – regardless of origin – safe for

FORTE micro® the first ever reduced dose salmonid vaccine for North America.

Multiple disease protection in a new smaller 0.05ml dose.

consumption and a good source of EPA and DHA. A 200-gram portion per week contributes 3.2 grams of EPA or 2.8 grams of DHA, almost double the intake considered adequate by the European Food Safety Authority.

Fish samples of wild, escaped farmed and farmed salmon, caught in Norway, were analyzed for polybrominated diphenyl ethers (PDE), pesticides and metals. Homogenized samples were extracted for total lipid determination.

“Total arsenic levels were higher in wild Atlantic salmon than in farmed salmon in the present study, in contrast to higher arsenic concentrations found by Foran et al (2004) in farmed Atlantic salmon compared to wild salmon,” the researchers said.

Despite the different levels of nutrients and environmental pollutants in Norwegian farmed and wild salmon, Lundebye recommends both types of salmon to consumers.

“Consumers have nothing to worry about because both types are a good source of omega-3 fatty acids and do not contain alarming levels of environmental pollutants. We can safely say that they are both healthy,” Lundebye said in the NIFE report.

The study was funded by the National Institute of Nutrition and Seafood Research, the Institute of Marine Research (IMR) and the Norwegian Food Safety Authority’s (NFSA) monitoring program for directive 96/23 on farmed fish. The analysis of scale samples was funded by the European Union, through the Kolarctic Salmon ENPI CBC project.

— Ruby Gonzalez

®

BY JOHN G. NICKUM

hould a young person preparing for a career in aquaculture pursue a broad-based, biologyfocused education program, or a highly specialized vocational training program in aquaculture? What about an older individual who wants to, or has to, change careers? There has been a lot of discussion within the aquaculture community about these questions. I am not aware of a consensus on these questions and I doubt there will be one; so much depends on individual interests and circumstances.

I suspect that opinions about “the best option,” including my own, are influenced by the path the speaker/writer followed for their career. My first experience with fish propagation involved rearing rainbow trout for a local restaurant 55 years ago when I was a graduate student. My education had been strictly academic, but my training in fish propagation was all “O-J-T” (on-the-job training). I like to claim that I have some experience with both training and education as it pertains to aquaculture, based on my own experience as a university teacher and career as a manager with the US Fish and Wildlife Service. I must acknowledge, however, I identify more strongly as an educator.

Although the terms “education” and “training” are frequently used interchangeably, they are different; at least in the mind of this “old professor.” Training a student is typically focused on developing a specific set of skills that are needed to do a specific job, or jobs, efficiently. Training is job-focused. Education typically takes a broader approach, including greater emphasis on critical thinking. An education program may enable students to acquire many of the same skills taught in training programs, but it usually is less job-focused. Education programs attempt to provide broad foundations that will be useful in many occupations, not just a few targeted jobs. Broadbased education programs typically include an array of formal courses to provide the background necessary for understanding principles behind the myriad aspects of propagating aquatic animals, or, increasingly, plants. I probably am somewhat biased toward programs based

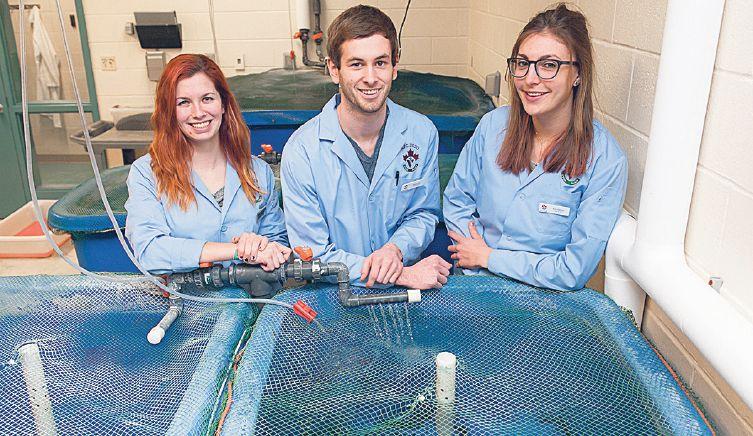

Students use math and chemistry principles learned in the classroom to calculate salinity levels and analyze water quality in grow-out tanks. Without learning the “how to do it” skills, students’ “book learning” may leave them ill-equipped to meet the demands of their employment, believes this columnist

on a broad foundation of academic coursework, followed by training in specific skills; that was the path I followed. I think a college education should be just that… an education; specialization comes later. Most young people in the age range of 18 to 20/21 really don’t know yet what they want in terms of employment; therefore, they need a broad background. When I entered college, I was trying to decide whether to be a high school football-baseball coach, or a nuclear physicist. It was only after being exposed to courses in math, physics, chemistry, and biology that I learned my real interests were in vertebrate zoology, ecology, and ultimately aquaculture and fish health. A broad educational program equips students, and workers, to deal with the ever-changing demands within specific jobs, as well as evolving job markets. An aquaculturist with experience in the methods used in 1900, or even 1950, would experience a very steep learning curve if placed in a present day aquaculture production facility,

especially if that person had only hands-on skills she/he had learned on the job. A combination of “book learning” and O-J-T would make the individual much more adaptable to dynamic job requirements.

I suggest the first step for most students preparing for a career in aquaculture, whether their career goal is rearing fish, or shellfish, or crustaceans should start with basic coursework in biology. Biology provides the foundation for later specialization; however, becoming a competent biologist in today’s world requires more than just biology. Modern biology requires a foundation in mathematics, physics, and chemistry, as well as biology. Additional basic courses, such as animal physiology, vertebrate anatomy, embryology, genetics, and ecology strengthen the foundation before specializing in ichthyology, fisheries ecology, limnology, invertebrate zoology, algalogy/aquatic plants, marine ecology, and other courses pertaining to aquatic animals. Basic microbiology and pathogenic microbiology, plus, parasitology are needed to equip the student for solving disease problems. Inasmuch as feeds and feeding are typically the most expensive aspects of aquaculture production, at least one course in animal nutrition would be very useful. An argument can be made that the program I envision would require an undergraduate major in biology/zoology followed by a Master’s degree in some aspect of aquaculture.

Training programs typically do not require a long list of courses, but emphasize working environments in which the student learns about measuring and maintaining essential water quality parameters, spawning, recognizing early signs of disease conditions, normal feeding behavior, proper feed storage, signs of environmental stress; as well as, how to maintain and repair the mechanical and electrical systems of the facility.

Whichever path a student follows, a few fundamental concepts must be central to his/her education and/or training: “Know your fish; or shellfish; or crustacean.” Also, “know the system/environment in which you are rearing them;” and “clean water equals few problems, but dirty water and stressful environments equals endless problems.” Whether an individual is trained, or educated, she/he must understand these basic concepts. Broad-based education programs help workers understand the “why” factors of their jobs, but without learning the “how to do it” skills, their “book learning” may leave them ill-equipped to meet the demands of their employment, and their employer. Aquaculture is not a career for the ill-prepared.

BY ERICH LUENING

quaculture researchers and other stakeholders are worried that US President Donald Trump’s recently released fiscal 2018 budget proposal will cut funding to marine agencies and completely eliminate the national Sea Grant program, which acts as the federal extension and research service to fisheries, including shellfish and finfish farming.

The proposed cuts to the National Oceanic and Atmospheric Administration (NOAA), which oversees the Sea Grant program, would also eliminate funding for a variety of smaller programs including external research, coastal management, estuary reserves and “coastal resilience,” which seeks to bolster the ability of coastal areas to withstand major storms and rising seas.

According to a leaked memo from the federal Office of Management and Budget (OMB), first reported by the Washington Post, the budget plan would slash funding for a number of federal agencies, including NOAA, the US Coast Guard, Transportation Security Administration and the Federal Emergency Management Agency. The memo reportedly cites the Trump administration’s goal of redirecting the funding for rebuilding the US military.

NOAA would face the steepest cuts, including $513 million from its Satellite and Information Service, and $126 million from its Office of Oceanic and Atmospheric Research. The $73-million Sea Grant Program would be eliminated entirely.

NOAA doesn’t comment on legislature of any kind and recommended contacting the Department of Commerce for further information. There’s been no response to several calls and emails sent to the public affairs office.

Sea Grant offices receive federal funds and tries to match it with private and state investment for research. But without a federal commitment, the program would be finished, MaryAnn Wagner, a spokesperson for Washington Sea Grant, told the online reader-supported news service grist.com

Robert Rheault, the executive director of the East Coast Shellfish Growers Association (ECSGA) and longtime advocate for domestic aquaculture of all types, says the proposed elimination of the Sea Grant program would immeasurably hurt the domestic aquaculture industry in the US.

“I suppose the industry would continue to grow without the assistance of Sea Grant, but it would certainly slow the process, and states would be challenged to replace the educational outreach and research capacity that Sea Grant brings to the table,” Rheault tells Aquaculture North America (ANA). “I view the proposed cuts to Sea Grant as job killers.”

He says his members rely on Sea Grant support in several ways.

Sea Grant supports 33 college programs and dozens of aquaculture extension agents around the country, he explains.

Sebastian Bell, executive director of the Maine Aquaculture Association says he’s concerned about the cuts. “It does not make a lot of sense to cut something that creates jobs,” he says. “The Sea Grant program has been important to the aquaculture industry across the country particularly on the shellfish aquaculture side. It’s not just the jobs part. There’s the research side as well. And Sea Grant research has been integral in building sustainable aquaculture in the US.”

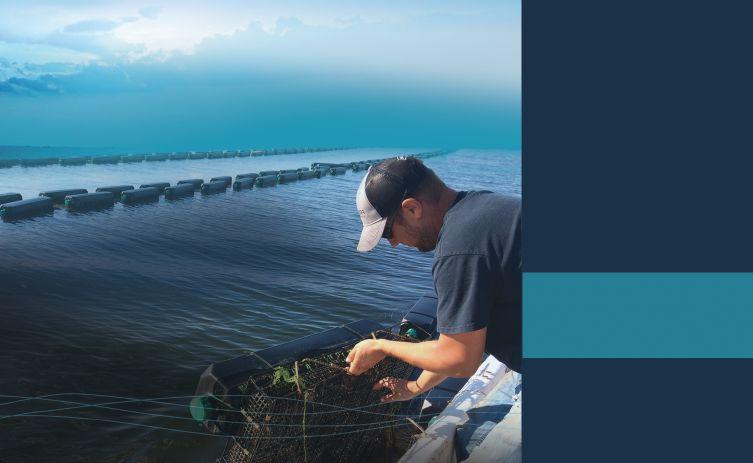

Rheault agrees. “Especially now, as new entrants are jumping into oyster farming, we need extension agents to

In-Situ Ad – Aquaculture North America Size: 6.84” x 5” print: 4-color / CMYK SCD# 16INST206 / Date: November 2016

Students at Port of Los Angeles High School measure and weigh juvenile white seabass before putting them into a new aquaculture tank in their classroom. Sea Grant supports 33 college programs and dozens of aquaculture extension agents around the country and its elimination would constrain the growth of fisheries and aquaculture

Credit: Holly Rindge, USC Sea Grant

help these folks navigate the permit process and establish viable farms — just like county agricultural agents help start-up farmers in square states,” he says. “If we really want to create jobs we should double our extension capacity instead of eliminating it.”

The Sea Grant research program is a largely industrydriven request for proposals that funds work to solve key issues that constrain the growth of fisheries and aquaculture, explains Rheault.

The Sea Grant program cuts are part of a huge budget proposal by the Trump White House, but they are far from being in a final budget that has to go through Congress, where representatives from the 33 states that rely on the program have a final vote.

After concluding a long week in Washington DC where Rheault and some of his ECSGA members met with over 40 members of Congress, he is hopeful that the Sea Grant program will stay afloat in the final budget.

Under the threat of serious budget cuts, the US federal Sea Grant program in February announced a 2017 aquaculture initiative worth $15 million for research proposals targeting barriers to aquaculture development and domestic aquaculture production for the next couple of years.

If proposed cuts to financing the National Oceanographic and Atmospheric Administration (NOAA) Sea Grant program is stopped in Congress, the funding will be available for a few more years, according to the agency.

Depending on appropriations, NOAA Sea Grant expects to have available a total of $10 million to $12 million between fiscal years 2017, 2018, and 2019 for a national initiative to increase aquaculture production in the short-term (two to four years).

continued on page 13

With the SMARTROLL™ Handheld System, you can easily check the water quality of your aquaculture ponds. Measure pH, ORP, salinity, optical dissolved oxygen, and more.

• Instantly see results on your Android or iOS mobile device –just plug in the probe, launch the app, and go.

• Email or log data to your smartphone.

• Save time monitoring large facilities.

• Lower costs with durable sensors, cables, and battery pack. Learn more at

Products for aquaculture sector become an increasingly viable market for large

BY MATT JONES

s aquaculture continues to produce an increasingly larger portion of seafood consumed in the world, it also becomes a larger and more lucrative market. In recent years that market has attracted the attention of a variety of big grain trading companies that have sought to diversify their products. Companies such as Archer Daniels Midland (ADM), Bunge Ltd and Terra Via shared with Aquaculture North America (ANA) why they wanted to become a part of the aquaculture market.

“ADM has both the production scalability and a global supply chain well-positioned to service many of the requirements of the aquaculture industry and took this as opportunity to help producers with this challenge,” says Alex Anderson, sales manager for ADM

Animal Nutrition. “With demographic trends driving rapid demand and growth, aquaculture represents one of the fastest growing segments of the feed industry.

Feed costs, across all species, represent over 50 percent of all production costs. As feed prices increase, producers will continue to look for alternative feed and feed ingredients.”

ADM offers “customer-focused initiatives” in the areas of complex proteins, fish meal and fish oil replacements, as well as health, wellness and nutrition solutions. One of their most notable products is DHA NATUR, which is dried algal biomass, and a highly concentrated, Omega-3 fatty acid and vegetarian source of DHA (docosahexaenoic acid), produced by a heterotrophic process at their facility in Clinton, Iowa.

Bunge Ltd’s foray into the aquaculture sector came as a result of their partnership with Terra Via.

“I think it becomes a logical path to explore what you can do with the material you already have,” says Miguel Oliveira, the company’s vice-president of Global Innovation. “Pretty much everything we introduce ends up feeding animals across the world. In a way, finding higher value applications for feed in the fish segment is one of our strategic drivers. It quickly became apparent that the capability the technology affords would allow you to play in that market too.”

From Terra Via’s perspective, Walter Rakitsky, senior vice-president of Emerging Business, says that the company has long sought opportunities to expand the use of their technology platform, spanning everything from pharmaceuticals to fuels to chemical food ingredients.

“I would say in the last three to five years, we’ve started to emphasize more human and animal nutrition and looking for opportunities to create real value out of products with our technology platform and with the assets that we co-own with Bunge in Brazil,” says Rakitsky. “We’ve always looked at our micro algae technology platform as having the ability to address many different markets. We saw a real need as well as an opportunity in the Omega-3 space to create the capacity that we have now to deliver these Omega-3s.”

Bunge and Terra Via’s joint partnership developed the feed ingredient AlgaPrime DHA (See ANA July/August 2016, page 27).

says Alex Anderson, sales manager for ADM Animal Nutrition

Oliveira says that their partnership was very beneficial – with Terra Via supplying their technological muscle, there were few infrastructure investments needed to be made on Bunge’s side. He also notes one of their biggest advantages is that they have a product that’s already on-sale as opposed to developing an idea that will still need to be produced into a working form.

“I think that helps significantly to introduce it in the marketplace,” says Oliveira.

Bunge Ltd’s foray into aquaculture came as a result of their partnership with Terra Via. ‘I think it becomes a logical path to explore what you can do with the material you already have,’ says Miguel Oliveira, Bunge Ltd’s vicepresident of Global Innovation

from page 11

The competition is designed to boost expansion of sustainable US marine, coastal, and Great Lakes aquaculture. Successful applications must outline integrated projects that clearly address major constraints, barriers, or hurdles limiting US aquaculture production.

The first Federal Funding Opportunity provides information for applications requesting between $100,000 and $1 million in total federal funding for a two- to three-year period. Non-federal matching funds of at least 50 percent are required (for example, a project receiving $1 million in federal funding must include at least $500,000 in matching funds, for a total project budget of $1.5 million).

All project applications must focus on expanding domestic aquaculture in the US.

The second funding opportunity under the Sea Grant aquaculture initiative calls for applications for projects that specifically explore impediments to the expansion of domestic aquaculture in the US.

Depending on appropriations, NOAA Sea Grant expects to have available a total of $3 million between fiscal years 2017 and 2018 for a national initiative focused on answering key questions impeding the development and expansion of sustainable US marine, coastal, and Great Lakes aquaculture.

Successful applications must outline small scale projects, business plans, workshops, etc, that seek to address key questions, barriers, or hurdles impeding the advancement of new or developing aquaculture initiatives that will contribute to the continuing growth of US aquaculture production.

Applications for the first funding opportunity were due May 9 while the applications for the second funding offer addressing obstacles to domestic aquaculture were due April 18.

— Erich Luening

Credit: Innovasea

The cash infusion will help Innovasea’s R&D efforts

InnovaSea Systems Inc has received $15 million in funding from private equity fund Cuna del Mar.

The Boston-based company designs and develops open-ocean fish pens, including the “Aquapod” spehericalgeodesic fish pens, which are used year-round in demanding marine environments.

“The financing was part of a planned strategy to support the continued investment in making the farm platform,” said David Kelly, the CEO and chief technology officer of InnovaSea, told Boston Business Journal.

Cuna Del Mar invests in early stage private companies and is backed by Walmart founders, the Walton family, say reports.

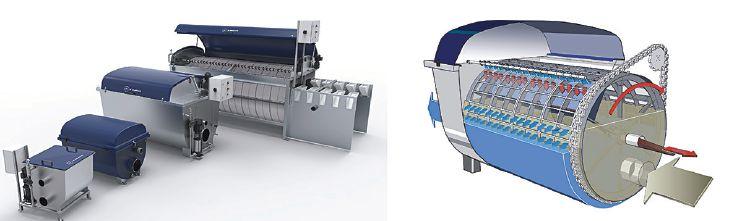

Innovative design delivers improved structural integrity, reduced weight and increased submergence. These innovations reduce investment and ownership cost.

• Increased Drum length to diameter ratio

• Support Shaft and slide bearings at each end.

• Peripheral drive with lubricant-free non-metallic chain

• Single FRP access cover

• Integral emergency bypass

• Modular design

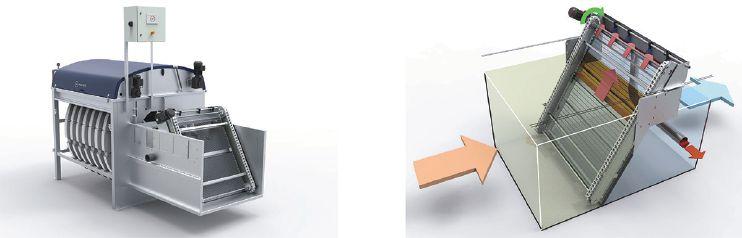

Compact modular microscreen for high flows and fine filter openings.

• Applications - Intake, E uent, RAS

• Delivers 3X lter area as a Drum lter occupying the same footprint

• Up to 65% submergence

• Moving spray bar, Non-Metallic chain drive

ideal from RAS applications

Roughing filter installed upstream or Drumfilter or Discfilter.

• Reduces load and permits ner lter element openings

• Interchangeable wedge-wire screens

• Shared sludge discharge

• Satis es a wide range of applications

• Can be employed as a standalone unit or paired with either microscreen

• Enhances bio ltration, O2 injection and disinfection

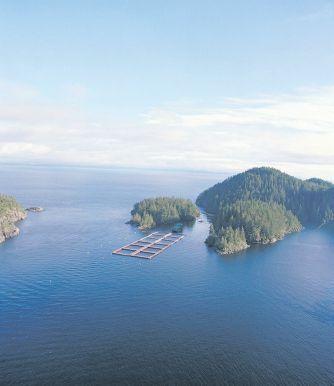

he opportunities for offshore aquaculture are huge in America and around the world, but there are challenges in the way to tapping its full potential, according to speakers at the 7th Offshore Mariculture Conference held in Ensenada, Baja California, Mexico, in March.

They acknowledged that the bottom line is that the world will need more protein, and aquaculture plays a key role in answering that need. Shifting aquaculture offshore ticks all the right boxes in terms of efficiency and environment, they noted, but there are still barriers.

“Growth is going to come from aquaculture,” said Omar Alfi, managing director at Pacifico Aquaculture. “This business is a lot harder than we expected… It’s a game about quality and price, and constant production is critical.”

Robert Orr, CEO and managing director of Cuna Del Mar, said that for aquaculture to grow, the Norwegian model is the ideal, with its alignment between the private sector, government and academia. These sectors need to

come together for that to become reality. “There are massive opportunities for Mexico, and for the US and Canada if regulatory issues can be solved,” he said. He cited some figures illustrating how far China has gone in this direction, with 6,000 cages offshore already and a 200,000gt former tanker operating as a floating fish farm village. He noted that cobia alone has the potential to be 20 times the size of the salmon industry. “Access to finance and government policy are the two big challenges,” he said. “It’s not a 50,000-tonne issue – it’s a 50-million tonne issue.”

In a session on “Offshore Aquaculture in the Americas,” Neil Sims, co-Founder and co-CEO of Kampachi Farms LC and founding president of the Ocean Stewards Institute, reflected that offshore mariculture is pushing the boundaries, literally. “The industry needs to show investors success and scale. Offshore aquaculture works

Speakers at the 7th Offshore Mariculture Conference. They acknowledged the bottom line is that the world will need more protein, and aquaculture plays a key role in answering that need

— and works really well. It has improved performance, excellent parasite control and minimal environmental impact,” he said, adding that less stressed fish in better health are great for the bottom line. It was also clear from the presentations that the market needs some education in terms of quality and responsible production. Buyers are still reluctant to accept that farmed fish is as good as wildcaught fish, even though it has much in its favor, including control over production, proper handling and is killed and processed properly.

Rex Ito, owner of Prime Time Seafood Inc, commented: “Logistics can make the difference between making and losing money.” He also said that handling can be the difference between a shelf life of weeks and just days. “Quality product and repeat performance is what we’re looking for.”

Victor Pak, CEO of JJWV Marketing Corporation, stressed that supply must be constant. There is no option to not supply. “If there’s a war, there’s a war. But you still have to supply that fish,” he said.

arine Harvest’s new salmon processing plant in Surrey, British Columbia will start operations in July, and process approximately 12,000 tonnes of salmon annually, said the company.

The value-added processing facility is the third plant operated by Marine Harvest in the province and will serve customers in Western Canada and North West USA.

Vincent Erenst, Managing Director at MHC, said there is an increasing demand in the North American market for healthy, tasty and convenient food. “With the new plant we can provide customers with delicious and easy-to-prepare meal options made from high-quality, fresh salmon,” he said.

Marine Harvest’s business expansion will increase its employee base of 530 by up to 75 full-time positions.

We are your source for professional aquatic and aquaculture products and services.

Our hands-on experience allows us to offer practical solutions to your situation, big or small. We have years of experience in retrofit and new construction and understand your needs.

Contact us today to learn more!

Phone: +1 407 995 6490

Web: AquaticED.com

Proven bio-security; over 35 years, 380 installations, more than 740 million gallons per day

Lifetime Disinfection Performance Guarantee

Aquafine Genuine parts program provides this peace of mind

Long-term Industry Commitment

Collaboratively advancing UV research in aquaculture

aquafineuv.com

The technology has ‘dirty secrets’ that the public needs to know about, says expert

BY RUBY GONZALEZ

Educating the public about recirculating aquaculture systems (RAS) in a “balanced and comprehensive perspective” could push this production technology further, according to a presentation made at Aquaculture America 2017 held in February at San Antonio, Texas.

With the many benefits it offers, RAS has been described as the “future of fish production.” But it has another side, too, that the public must know about.

“The community of aquaculture professionals needs to be responsible to investors, environmentalists and the general public in describing the advantages and disadvantages of RAS technology. A balanced and comprehensive perspective about what RAS can and cannot do can foster a realistic outlook and, thereby, serve to promote further commercial applications of this promising production technology,” Dr. John Hargreaves cited in the abstract, Finding the proper place for recirculating aquaculture.

Hargreaves is an independent consultant with Aquaculture Assessments LLC and an aquaculture expert with over 35 years of experience.

RAS may provide the solution to many of the negative impacts of aquaculture in open systems, he said, but only to a certain extent.

“One of the main misconceptions is that RAS represents the solution to many of the negative impacts of aquaculture in open systems. This is true, but only to a certain extent. Production of fish in every aquaculture system has impacts, but all impacts must be seen not in absolute terms but in the context of the limiting factors of the environment in which they are embedded,” he told Aquaculture North America (ANA) in an email correspondence.

“Another misconception is the equation of the control over production that occurs in RAS with product quality. Aquaculture in RAS has some dirty secrets, including off-flavor and disease,” he continued.

RAS has been described as having “low water footprint.” Its carbon footprint, however, is another thing.

“The environmental NGO community considers the RAS approach to be ‘“ecofriendly” ’ aquaculture. This myopic view is based on the capacity of RAS to address certain environmental impacts associated with shrimp or salmon farming. However, RAS is very energy- intensive, resulting in increased carbon footprint per unit production relative to most other production systems,” he cited in the abstract.

The eco-friendly characteristics of RAS appeal very much to environmental NGOs.

“In the view of the environmental NGO community, RAS solves a lot of the problems of net pens, especially escapes, sea lice treatment, and waste discharge. However, this view is only part of the story,” Hargreaves said.

Citing impacts on salmon farming such as waste discharge issue, he explained how it is a local and short-term problem that can be solved through site fallowing or rotation to allow recovery of the sediment.“.”

“What the environmental NGO community selectively ignores is the greater carbon footprint of fish production in RAS, associated with the greater direct energy requirement. It seems that the environmental NGO community would rather advocate for solving short-term, local problems with RAS, rather than the global-scale problem of climate change, and are willing to accept the greater energy cost per unit protein production in RAS,” he said.

PROPER PLACE FOR RAS

There is no single solution for aquaculture to meet the growing demand for seafood in a sustainable way, Robert Jones, Global Aquaculture Lead at The Nature Conservancy, told ANA

“We need to advance a variety of production methods to improve aquaculture’s triple bottom line and create sustained growth. Depending on the circumstance, certain production methods may be preferable to others when taking into account environmental, economic, and social conditions. Globally, there is an important role for all production methods to play – RAS systems, ponds, and near and offshore pens,” Jones said.

So what is the proper place for RAS? Hargreaves said these would be hatchery and nursery settings, where control over water quality and the ability to hold fish at high densities are advantageous.

RAS, he added, would also do well in hobby aquaculture and in primary and secondary education.

The latter would serve a good venue, where RAS could serve as “an excellent tool to teach ecology, nutrient recycling and using waste as a resource.”

In using RAS for grow-out, he said a location-specific set of conditions must be considered.

“In many cases, RAS-based operations target specialty or local niche markets because they cannot compete with lowcost commodity producers. Furthermore, isolated and dispersed RAS facilities make it difficult to achieve economies-of-scale with respect to other parts of the value chain, such as feed supply and processing.

Regional production from multiple RAS facilities is needed for successful sector development. Initiatives are underway for land-based grow-out of Atlantic salmon in RAS,” he said in the abstract.

High-value fish in and scale of growout operations are important because of the high capital investment requirements of RAS.

“One of the key issues for the success of any commercial fish grow-out operation in RAS is scale. Most operations are simply too small to be successful, unless there is a high-value niche market to supply. To

compete with net-pen production, where capital investment costs are much less, of a commodity fish like salmon, the scale of production operations must be large to achieve economies of scale. The prevailing view is that RAS production of salmon can be profitable at production levels of 5,000 tons per year,” he said.

Although investments in RAS technology for grow-out continue, he concluded that the business success of companies using it for this “is rather dismal.”

The Canadian Aquaculture Industry Alliance (CAIA) has named Tim Kennedy as its new executive director. Kennedy assumed leadership of the organization on April 1. He succeeded Ruth Salmon, who held the role for a decade.

“We are very pleased that Tim has accepted this important leadership position with CAIA as we set a new strategic direction for the future,” says Cyr Couturier, CAIA President. “Tim is a seasoned and versatile government relations and public affairs executive. He brings experience leading large-scale coalitions to successfully address regulatory and legislative concerns. His sound understanding of federal government inner

workings and approaches to driving regulatory change will ensure a smooth transition.”

“At the same time, CAIA expresses its deep appreciation to Ruth Salmon, the outgoing Executive Director who led the association for ten years as a dedicated advocate for Canada’s aquaculture sector. The Board acknowledges her reputation as a consensus builder with a deep understanding of the complexity of the industry and the variety of issues that are important to each region.”

CAIA is the national association that speaks for Canada’s seafood farmers, representing their interests in Ottawa to regulators, policy makers and political leaders.

Consumers check out fresh seafood at a public market in Vancouver, BC. Cermaq expects the seafood category to grow significantly in North America as consumers change their diets to focus more on health

Salmon farming giant switches attention away from price and supply

he world’s second largest salmon company said it is shifting its focus away from price and supply and moving towards growing consumption and sustainable farming practices.

TThe Norwegian salmon farming giant, Cermaq, expects the seafood category to grow significantly in North America as consumers change their diets to focus more on health as well as taste. This will require the whole value chain to evaluate what is required in order to meet consumer requirements for important issues such as transparency, nutrition and sustainability, it said in a statement.

Cermaq said it is committed to forging stronger partnerships with processors, distribution centers and retailers in order to change the focus from price and supply to growing consumption and sustainable farming practices.

“Our strategy is to work closer with our customers from now on to contribute and share in their success,” said CEO Geir Molvik. To strengthen client relationships and meet their needs, the company is investing in communication strategy — something that Molvik said the industry, including Cermaq, has underestimated greatly.

“We are proud to present our product honestly and without filter. Cermaq has until now, acted like we had very little to say or promote. This will change,” he said.

The company defined transparency in the supply chain as not just being upfront about technical facts, “but also about being able to tell how we do what we do in a clear and simple professional way so that those who do not know the industry will have a much greater understanding of it going forward.”

Molvik added: “There is an increasing demand from consumers who focus on health that want to know where food comes from and how it has been produced. If the seafood industry is to take part in the expected growth, this issue needs to be addressed, and we will work through proactive partnerships as a way to help customers develop their business.”

BY LIZA MAYER

The livelihoods of oyster farmers in British Columbia, Canada are at risk from a norovirus outbreak that has sickened hundreds in three provinces and forced the closure of nine shell sh farms as of April.

e investigation into the cause or causes of the contamination is ongoing and complex, according to the Public Health Agency of Canada.

A number of shell sh farms have ceased operations either under orders from Fisheries and Oceans Canada (DFO) or voluntarily, until the issue is resolved.

“Nine shell sh farms where oysters are harvested in British Columbia have been ordered closed by DFO on recommendations from the Canadian Food Inspection Agency and health authorities. ose recommendations are based on sample results, epi-assessments and consultation,” Darlene Winterburn,

executive director of the BC Shell sh Growers Association (BCSGA), told Aquaculture North America (ANA).

THREAT REMAINS

While the potential economic impact is di cult to gauge, it presents real threat to BC’s shell sh industry.

A number of employees have been laidoff and some are working reduced hours as oyster farms wait out the situation

“Whether voluntary or not, farmers who do not harvest do not generate income; the work that is farming must continue to care for the animals and to ensure they are ready to harvest when the time comes. ere have been layo s and reduction of hours and there will be more,” she said.

BC’s shell sh industry in 2015 harvested 9,100 tonnes of oysters, fetching farm gate value of $10.8 million (C$14.4 million) and wholesale value of $30.6 million (C$40.7 million), according to data from the Ministry of Agriculture.

Tilapia farmer Regal Springs says it has reached its goal to donate 5,000 lbs of tilapia to SeaShare, a non-pro t dedicated to supporting hunger relief e orts in the United States.

Regal Springs reached its target after serving over 1,000 ‘tilapia power bowls’ at Seafood Expo North America in March.

“ e Tilapia Power Bowls were a huge hit! Every person who came by our booth was happy to help us reach our goal,” said Francis Yupangco, head of global marketing at Regal Springs.

In addition to helping in hunger relief efforts, guests at the expo had the opportunity to take a 360-degree virtual reality tour of Regal Springs’ lake-farms, facilities and communities in Chiapas, Mexico

“Since the beginning, Regal Springs has been committed to providing a healthy, sustainable source of protein while helping those in need. We were honored to be able to showcase the two key pillars of our brand at this year’s event and meet people who share our enthusiasm for supporting such great organizations like SeaShare.”

e company is a long-time supporting SeaShare and has donated more than 200,000 servings of premium tilapia to help ght hunger in the US. Guests at the expo also had the

opportunity to take a 360-degree virtual reality tour of Regal Springs’ lake-farms, facilities and communities in Chiapas, Mexico. “We wanted to provide the full sensorial experience, so guests could see and taste the sh rst-hand, but also see exactly where it comes from. Tilapia has been getting a bad rap in recent years, but it’s important for people to understand that not all tilapia are raised the same way or adhere to the same standards,” added Yupangco.

Some shell sh farms have the ability to harvest other species, but sales in Canada have slowed tremendously or stopped completely for many of the members of the BCSGA, noted Winterburn.

“ ere is also the possibility of future impact on sales in that this type of a scenario will make some restaurants and retailers hesitant to sell oysters in the future. ere is a blemish on the product caused by something completely outside the control of industry. Of course, people who love oysters really love oysters and

they are waiting patiently for this to pass.”

For now, the industry is working with regulators and government to provide samples, share information, brainstorm possible sources, initiate research and, generally, work through the problem, Winterburn added.

“We meet regularly and provide input into possible solutions. We have reached out to provincial and federal government. BC is exploring options that may help industry through this crisis.”

450 unfilled positions mean an 11-percent vacancy rate in Canadian aquaculture

BY MATT JONES

recent report issued by the Canadian Agriculture Human Resources Council (CAHRC) indicates that the Canadian aquaculture industry is suffering from a labour shortage. With approximately 4,000 people working full-time in the industry, there are 450 unfilled positions, which translate to an 11-percent vacancy rate, and millions of dollars in lost revenue. There are a variety of causes for the shortage, which experts say will only get worse as aquaculture becomes a more important source of protein going forward.

The report was compiled through analysis of Logistics Canada information,

including the Census and the Labour Force Survey. CAHRC also conducted a large-scale survey of over 1,000 respondents across agriculture and aquaculture, interviewed 80 key opinion leaders, conducted six focus groups and seven commodity-specific webinars. This information has gleaned key insights into the Canadian aquaculture labour shortage.

“Part of it is that aquaculture businesses are in rural and remote areas and people are leaving rural areas, so it’s difficult to get people to come to smaller rural areas,” Debra Hauer, project manager with CAHRC, told Aquaculture North America (ANA)

This has been a pressing concern for the industry, notes Susan Farquharson, executive director of the Atlantic Canada Fish Farmers Association (ACFFA).

“Our members continue to be challenged with accessing a sustainable workforce,” says Farquharson. “Our industry is based in rural, coastal communities in Atlantic Canada where there is a population deficit, and we have a limited workforce. In our region, people often have to travel longer distances to get to work and to access training, so recruiting, retention and retraining staff can be tough.”

“It’s not always easy to keep them,” says Cyr Couturier, president of the Canadian Aquaculture Industry Alliance (CAIA), of

workers in rural areas. “That may be related to the fact that they don’t have access to other things like internet or whatever. A young person coming into aquaculture, you typically want to be able to have access to recreational services, internet, otherwise you’re not going to be happy. There are still areas in the country where we don’t even have basic internet access.”

In some cases, Couturier notes, companies and even the government have made investments in that type of infrastructure to make working in rural areas more palatable to young potential employees.

“The companies have gone the extra mile and made sure they put boosters in and things like that so they could have broadband access. Companies have invested a lot to try and keep people satisfied in their employment.”

The industry and government have also taken some other approaches to bring potential workers into these communities, says Hauer. In some cases, it has involved bringing the workers to the community before they even have the job.

“There have been a couple of instances, one in Quebec and one in Alberta – in one case it was an employer, and in another case it was the government – arranged for buses

or vans of people to come out and actually see an operation. They have both had great success. They can see school where their kids will go and understand that there is a community with activities. They can see that it’s not moving to a rural community for the job only, but it’s also for the way of life. There have been successes in that regard, where bus tours that involve visiting not only the place of employment, but also the town, have led to people accepting job offers.”

Another major contributor, the report says, is that aquaculture is not on the National Commodities List, which grants employers access to the Seasonal Agricultural Worker Program (SAWP) and the Temporary Foreign Worker Program (TFWP).

“That is a program designed for agriculture, for workers that are seasonal in nature,” says Hauer of the SAWP. “Aquaculture is not considered to be seasonal in nature.”

Hauer says that access to workers through such streams would be helpful, based on the experience of agriculturists. For instance, while there were 26,400 vacancies in agriculture across the country, producers in other industries allowed to make use of foreign workers reported a lower number of vacancies.

“In terms of foreign labour, or programs, aquaculture does have access to some of those, particularly for processing programs,” said Couturier of the CAIA.

Julia Sullivan, chief of media relations for Employment and Social Development Canada, however, disputes this aspect of the report. She said there’s no stopping fish farmers from hiring foreign workers under the two programs.

“There are no program barriers to aquaculture employers being considered for an LMIA (labour market impact assessment),” says Sullivan. “Any employer can submit an application for an LMIA and can receive a positive assessment provided they meet program criteria and can demonstrate a legitimate need for a temporary foreign worker. If the industry

continued on page 21

resh from the success of its workshop on indoor tilapia and shrimp RAS, and aquaponics in March, the Kentucky State University-Division of Aquaculture held a follow-up session, featuring outdoor production systems, in April at KSU’s Aquaculture Research Center.

continued from page 20

understands there to be barriers to applying to the TFW program, departmental officials are available to make necessary clarification on program rules and the application process.”

Couturier says, however, that the foreign-worker aspect is a secondary concern.

The March event concluded on a high note, with over 70 people attending the event. The participants came from the states of Kentucky, Indiana, Ohio, Georgia, Tennessee, Michigan and Iowa.

The workshop is aimed at helping producers better understand all aspects of indoor recirculating aquaculture systems (RAS). Presentations from industry experts ranged from production technologies, water quality monitoring, proper nutrition, to marketing strategies.

Participants were also provided tours of the Aquaculture Research

Center, including its new Aquaculture Production Technologies Laboratory, which houses a state-of-the-art genetics lab, replicated aquaponics research, biofloc marine production systems, and other indoor RAS. Tours of commercial aquaponics facilities in the area were also offered.

The goal of the program was to update current and prospective aquaculture producers on developing indoor production technologies and to enhance their ability to market their products.

Idaho is the nation’s largest commercial producer of rainbow trout and is central to the recovery of many endangered and threatened fish stocks. The University of Idaho believes it is therefore in a uniquely position as a destination institution for student training and research opportunities in Aquaculture and Fisheries.

The Aquaculture Research Institute at the University of Idaho is nationally and internationally recognized as a leading institution that provides academic and research training in all areas of Fisheries and Aquaculture. Undergraduate and graduate degrees are linked to Fisheries and Aquatic studies within various colleges and departments including Fish and Wildlife Sciences, Biology, Animal and Veterinary Sciences, etc. This creates exciting opportunities for students seeking careers in Aquaculture and Fisheries Sciences, says the school.

There are four fisheries laboratories (three on campus and one in Southern Idaho) that set the university’s programs apart from other peer institutions. Such unique facilities allow hands-on training for students at the University of Idaho and expand capacity to address the research needs of state and federal agencies, private industry, and Native American tribes in the Pacific Northwest. Current strengths and specific areas of expertise of associated

faculty are focused in many areas of research, including:

• Fish Nutrition

• Fish Health/Immunology

• Fish Ecology

• Fisheries Management

• Fish Reproductive Biology

• Fish Genetics

• Fish Physiology

• Limnology

• Water Resources/Hydrology

“That’s part of the solution, but it’s not a long-term solution,” says Couturier. “If aquaculture is going to grow in this country, it’s only going to be exacerbated if we cannot recruit and retain Canadians in the longer term. It’s a perennial problem that has to be resolved. We’re working on recruitment and retention. That includes industry communications about the benefits of farming and employment in farming.”

One potential solution Couturier says is being explored is to emphasize the inclusion of First Nations people, people with disabilities and other underrepresented members of the potential workforce.

“I’m sure the industry will take advantage of those opportunities to try to solve the labour shortage,” says Couturier.

“The next couple of years will be exciting to see the strategies and actions that are taken, trying to resolve the shortage.”

Farquharson says that ACFFA’s members are investing in technology in their plants and on farms that would help address some labour needs. Some companies have in-house training programs.