SHELLFISH SPECIAL

Oyster growers are optimistic about continued recovery despite lingering issues

P. 10

SOCIAL LICENSE

The tide is turning

A positive public opinion poll is among the signs that aquaculture in Nova Scotia is getting recognized.

P 8

REGULATIONS

Slowly, carefully

Newest aquaculture sector in Texas is inching along as growers and authorities navigate new terrain

P. 12

ALTERNATIVE PROTEINS

Lab-created oysters in the pipeline

Two young Californians among the latest to jump on the cellular agriculture bandwagon

P. 14

BLUE FINANCE

Investing with a conscience is on the rise

Sustainability becoming an increasingly prominent consideration for financial backers P. 20

SHARE HER STORY

Reader Service

Print and digital subscription inquiries or changes, please contact Urszula Grzyb,

Audience Development Manager

Tel: (416) 510-5180

Fax: (416) 510-6875

Email: ugrzyb@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Liza Mayer lmayer@annexbusinessmedia.com

778-828-6867

Regular Contributors Ruby Gonzalez, Arsenia King, Matt Jones, Nestor Arellano Associate Publisher / Advertising Manager Jeremy Thain jthain@annexbusinessmedia.com +1-250-474-3982

Account Manager Morgen Balch mbalch@annexbusinessmedia.com

Media Designer Svetlana Avrutin savrutin@annexbusinessmedia.com

Group Publisher Todd Humber thumber@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLISHED BY ANNEX BUSINESS MEDIA 105 Donly Drive South, Simcoe, ON N3Y 4N5

Aquaculture North America is published six times a year by Annex Business Media. The authority for statements and claims made in Aquaculture North America is the responsibility of the contributors. Reference to named products or technologies does not imply endorsement by the publisher.

Subscription rates (six issues) Canada: $37.00+Tax Within North America: $48.00 CAD Outside North America: $62.00 CAD To subscribe visit our website at www.aquaculturenorthamerica.com

PRINTED IN CANADA ISSN 1922-4117 Publications Mail Agreement #PM40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1 UNITED STATES MAILING ADDRESS

Aquaculture North America, 815 1st Ave, #93, Seattle, WA, 98104

Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

The contents of Aquaculture North America are copyright ©2022 by Annex Business Media and may not be reproduced in whole or part without written consent. Annex Business Media disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

Next Ad Deadline

The advertising deadline for the May/June issue is March 29th. Don’t miss the opportunity to be part of this exciting aquaculture publication. For more information, or to reserve space in the next issue, call our Advertising Department at +1.250.474.3982 jthain@annexbusinessmedia.com

Next Editorial Deadline

The editorial deadline for the May/June issue is March 29th. Contact Liza Mayer at lmayer@annexbusinessmedia.com for details. Material should be submitted electronically with prior arrangement with the editor.

BY LIZA MAYER

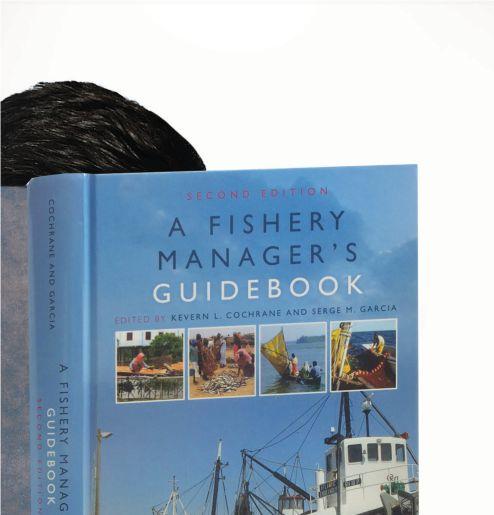

Cell-based seafood is inevitable

The world arguably first heard of lab-created or cell-based meat in 2013 when Dr Mark Post, a professor at Maastricht University, unveiled in London the proof of concept, a burger patty “grown” in the laboratory from cells from a cow. Just seven years later, in December 2020, cell-based chicken nuggets from San Francisco, CA start-up Just Eat Inc got regulatory approval in Singapore – the world’s first.

Several iterations of cultured meat and cultured seafood are now being developed and tested. There’s already cell-based salmon, mahi-mahi and tuna in the seafood space (but not yet commercially ready). And, as you will read on page 14, moves to create oyster meat in the laboratory have commenced.

The millennials behind Pearlita Foods (as, indeed, does the whole cultured meat sector) still have a long way to go: lots of questions to answer and millions of dollars to raise before the first oyster meat comes out of their North Carolina laboratory.

There’s contentious discussions on social media among vegetarians on the issue of whether cell-based proteins are vegetarian or not. Other questions include how sustainable lab-created foods are, and how the products compare nutritionally with their farmed or wild counterparts.

Those questions aside, creators of cultured meat are disrupting the meat and seafood industry. The farmed seafood industry needs to step up its game in telling its story, leveraging aquaculture’s position as producer of the most sustainable farmed animal protein on the planet.

One would think finding content to communicate to consumers would be the hardest challenge for aquaculture, muses Catarina Martins, chief sustainability officer at Mowi (see page 20). But it’s really not, she says; it’s making sure the message gets out there.

The ball is in your court.

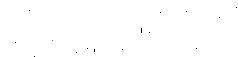

Made-in-Canada solution helps salmon farmer cut emissions

An award-winning technology made in Campbell River, British Columbia has helped a salmon farmer reduce its carbon emissions by 76 metric tonnes – that’s the amount of greenhouse gases you would have produced had you driven a diesel car for 456,000 km (283,000 miles).

Called Flowpressor, the compressor system from Poseidon Ocean Systems was one of the two top-prize winners at the BC Aquaculture Innovation Awards in 2021.

The reduction in emissions was seen when the technology was field-tested from May through November 2021 at Cermaq’s 16 farms in BC. In the trials, Cermaq used Flowpressors to power its standard Harmful Algae Bloom systems instead of using conventional diesel compressors.

“The trial demonstrated the viability of the Flowpressor technology to power our existing conventional bloom mitigation equipment, while producing 60-percent less greenhouse gas emissions. The overall result is that we have slashed emissions and dramatically reduced our fuel costs while improving overall performance of the mitigation system,” said Brock Thomson, Cermaq Canada’s Innovation Director.

Salmon farmers have a lot to be optimistic about in 2022

Consumer demand for salmon will outstrip supply in 2022, a scenario that will keep prices at well-above-average levels, according to RaboResearch.

Global salmon supply is projected to grow by only 5 percent in 2022, a rate that is considered “below demand growth and thus supportive to prices.”

The think-tank says shifting consumer behavior because of the pandemic favors farmed seafood.

It said the increase in beef and poultry prices globally as well as consumers’ quest for healthier protein will drive seafood demand, and seafood could gain more traction if the industry expands product ranges to include more seafood in formats convenient to cook at home.

While the seafood industry is also feeling the sting of price increases, the reopening of foodservice channels will potentially trump inflationary challenges, it said.

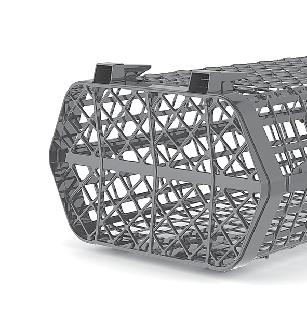

Net pens made completely of recycled plastic in the works

As part of an industry-wide effort to make aquaculture as environmentally sustainable as possible, the AKVA Group of Norway says it will produce entire net pens using recycled plastics, an initiative meant to also prove the point that such recycled materials meet quality standards.

Under the standard (NS9415) that defines the components of a fish farm, including net

And while there is clearly a need to fill the supply gap, it should be done sustainably, cautioned Novel Sharma, seafood analyst at Rabobank.

“For many countries, 2022 will be the year they make reducing GHG emissions their leading policy. With COP26 in Glasgow nearly coinciding with the GSA GOAL conference, commitments to reduce emissions are more than just top of mind for the aquaculture industry; they are a new key priority for many companies in the industry,” she said.

pens, only virgin plastic should be used. But the AKVA Group says it will challenge this requirement by showing that recycled plastic from a discarded net pens from aquaculture facilities has the qualities that meet the requirements.

The technology provider will use “carefully tested high-quality plastic granulate” made from old net pens that recycler Oceanize has reprocessed in its factory.

AKVA noted that it already uses recycled plastic on the pen walkways, but this is the first time it will produce entire pens out of recycled plastic from discarded pens.

“Pens today are not a big litter problem, but there is a great potential for using the plastic in new pens. In this project we will achieve short, national value chains as the project participants are all established in Norway,” says Trude Olafsen, project manager, AKVA Group.

The company hopes to share the knowledge on this innovation with other fish farming nations.

Tech provider AKVA Group of Norway says it will produce an entire net pen out of recycled plastic from discarded pens PHOTO: AKVA

Market trends bode well for farmed salmon in 2022 PHOTO: GRIEG SEAFOOD BC

Healthy fish, healthy planet.

PHOTO: CERMAQ CANADA

Fallout from Canada’s decision to shut down salmon farms continues Former Fisheries and Oceans Minister Bernadette Jordan’s decision in December 2020 to shut down salmon farms in the Discovery Islands in BC has claimed another victim: 80 jobs at a Mowi Canada West fish processing plant in Surrey, British Columbia.

The salmon producer has announced that it will permanently close its fish processing plant in the Vancouver suburb as the imminent closure of its farms on the Discovery Island will wipe out 30 percent from its overall production volume in the province.

This makes the 23,000-sq-ft processing plant with 80 employees “no longer viable,” said Mowi. Processing of salmon grown by Mowi in BC will be done at its plant in Port Hardy, BC from March 2022.

“This is devasting news to the employees and families who have relied on this operation for their livelihood. It is clear that the decision of the former minister has lasting implications. Her decision is far reaching and continues to be incredibly damaging to the communities where we operate. It has been more than a year and we have yet to hear from either the former Minister or the new Minister, Joyce Murray,” said Dean Dobrinsky, spokesperson for Mowi Canada West.

The phaseout of net pen salmon farms on the Discovery Islands announced in December 2020 requires that all farms in the area must be fish-free by the end of June 2022.

Purchasing behavior of seafood consumers is changing, but will it stick?

The Virginia Seafood Agricultural Research and Extension Center has conducted a consumer survey that looks at how consumer trends in seafood purchase changed during the pandemic.

Jonathan van Senten, assistant professor at Virginia Tech and lead for the USDA-funded research, said the survey is critical because its findings, though focused on consumers, will impact seafood producers as well.

The survey involves 2,000 respondents from 20 areas in the United States that are important for aquaculture products. Launched in 2021, the survey was conducted on a quarterly basis last year and will be administered every six months through the end of 2022 in order to assess “what’s changing, whether it is continuing to change and whether these are permanent shifts.”

The consumer research spun out of the “Impacts of COVID-19 on US aquaculture, aquaponics, and allied businesses” study, which van Senten also led in 2020.

The preliminary results shared by van Senten at the Virginia Aquaculture Conference early this year focused on trout, but the survey also includes questions focused on oysters and catfish – spe cies relevant to Virginia aquaculture.The survey collects information about how frequently people buy seafood, what species they buy, how much they spend, and whether they prepare seafood at home or purchase it at restaurants.

“For example, we found that during the pan demic, people ate more trout at lunch, and less trout at dinnertime, compared to their habits before the pandemic,” said van Senten.

Convenience in preparing seafood is becoming a priority for consumers, while price is becoming less important as a factor in purchasing decisions, survey finds

PHOTO:©ELDARNURKOVIC/ADOBE STOCK

He noted that while price remains in the top 5-10 factors people consider, other factors like convenience are becoming higher priorities for seafood consumers.

Interestingly, when the research asks people “why are you not buying trout”, 40 percent said they did not buy trout because it is hard to find, or it was not convenient for them to buy.

“This means that potentially there are more people who would buy this product if they can find it,” he said.

He clarified that the trends he identified so far are consistent across types of farmed seafood.

“Our research showed that people have adjusted to the pandemic,” adds van Senten.

The marketing channels that emerged or strengthened in response to the pandemic, such as curbside pick-up services, online sales, home delivery services, drop off/pick up locations, setting up kiosks and participating in farmers markets or food hubs “seems to be working,” he said.

— By Arsenia King

Another trend they are seeing is price becoming a less important factor in purchasing decisions.

“Price has always been so important with seafood, but we’re starting to see more and more that price is not always ending up in the top three most important attributes,” he said.

Eighty people will lose their jobs when Mowi’s processing plant in Surrey, BC shuts down this March PHOTO: BCSFA

The tide is turning

A positive public opinion poll is just one of the recent signs aquaculture in Nova Scotia is gaining further recognition, community trust BY

Nova Scotians think the province’s aquaculture industry positively impacts the economy, employment, and sustainability of a local food source – this is the key takeaway of a recent opinion poll commissioned by the Aquaculture Association of Nova Scotia (AANS).

The poll, conducted by Narrative Research on behalf of AANS between November and December 2021, surveyed 400 Nova Scotians aged 18+ on aquaculture themes including the industry’s economic impact, related industry regulations and the career opportunities it presents to young people.

The poll revealed that respondents have heard of aquaculture – associating it with year-round farming industry – and are aware that the province produces farmed salmon, mussels, oysters and trout.

Nova Scotia produced $71.13 million (C$90.15 million) in aquaculture products in 2020, up almost 10 percent from 2019, and employed 877 people full-time and part time, according to the province’s Department of Fisheries &

ARSENIA KING

Aquaculture. Of the total value, 76.27 percent is Atlantic salmon, mainly produced by the province’s sole ocean-based farmed salmon producer, Kelly Cover Salmon Ltd, the Atlantic Canadian farming division of Cooke Aquaculture Inc.

The poll also confirmed the respondents’ interest in the industry by how they proactively seek industry information and identify the farmed seafood sold in retail outlets within the province.

However, despite their awareness of how the industry provides viable career path for young people, the respondents admitted they are not familiar with the diversity of career options the industry offers.

Finally, the poll showed the respondents wanted assurance that appropriate legislations are in place to safely regulate the aquaculture industry in the province.

“This polling shows the need to make Nova Scotians aware of just how well this industry is governed and that it is full of opportunities for the whole province,” said Tom Smith, executive director of the AANS.

Alignment with industry vision

The optimism of Nova Scotians over the aquaculture industry as indicated in the report aligns with the vision of Steve Craig, the province’s newly appointed Minister of Fisheries and Aquaculture, who, upon oath-taking last year said he is determined to make aquaculture a part of the solution for rebuilding the province’s economy.

Craig said the new government in Nova Scotia supports low-impact/high-value, sustainable aquaculture and is cognizant that effective regulations, legislation, and science-based decision making are critical to the industry’s growth.

One proof of the government’s effort to implement effective regulation is the January 2022 announcement that Atlantic salmon producer Kelly Cove has been granted approval to redraw the boundary of its fish farm in Rattling Beach after thorough and rigorous approval process implemented by the Nova Scotia Aquaculture Review Board.

Craig’s appointment, the optimistic findings of the AANS survey and the rigorous process applied to the proposed farm boundary amendment of Kelly Cove’s facility may help further lift public perception of the industry, which appeared to have suffered setbacks in 2019 when Norwegian salmon farming giant Cermaq abandoned its plans to expand in six locations around the province. While the company says the lack of enough sites for its needs was the reason it scrapped its plan, there were also community concerns about its arrival in the province.

Craig said the Nova Scotia government will further promote responsible aquaculture expansion by encouraging greater community trust, working closely with First Nations, and ensuring a proper regulatory regime is in place.

Aquaculture authorities in Nova Scotia have allowed Kelly Cove Salmon Ltd to re-draw the boundary of its Rattling Beach salmon farm in order to optimize its use

PHOTO: COOKE AQUACULTURE

A public opinion poll shows Nova Scotians aged 18+ think the aquaculture industry positively impacts the economy and contributes to job creation and food security PHOTO: AANS

West Coast industry groups cooking up innovation center

Customer-driven exploration of seafood high on the agenda of the innovation hub being planned for the US west coast PHOTO:©KANTHITA/ADOBE STOCK

Telling the story of farmed seafood is the mission for a new customer-experience center that three aquaculture industry groups and a non-profit are envisioning for the west coast.

Thanks to a $197,000 grant from the USDA Local Food Promotion Program, the Steward Foundation and industry partners – the Oregon Aquaculture Association, Northwest Aquaculture Alliance and the California Aquaculture Association – can now conduct an implementation plan for the Pacific Aquaculture Marketing & Innovation Center.

The implementation plan will have the specific details about what the project would cost, what it would look like, who the beneficiaries would be and what the operating cost would be, said John Moehl, advisor to the Oregon aquaculture Association and aquaculture development specialist.

He said the idea was born several years ago when an opportunity to repurpose a defunct cannery in Oregon opened up.

“The cannery seemed like a very ideal facility because it has City water rights so we actually worked on developing an outline of how that facility could be used as an innovation center. We tailored our initial thoughts to a specific site, a specific locale, a specific structure.”

would be retail sales. We would have restaurants there or some kind of cooking presentations. So people could look at different types of seafood that maybe are not readily or highly consumed along the west coast, different ways of preparing seafood. So, this would be kind of like ecotourism, a learning experience for visitors.”

The Steward Foundation helped the associations secure the USDA grant. In this capacity, the foundation will oversee and coordinate the PAMIC project to ensure it fulfills all grant goals and obligations.

The cannery was eventually sold to another entity but the idea remained. Moehl noted that while there are a few aquaculture innovation centers in the US, many are tied to universities and there’s none that cover multiple states or share this groups’ specific vision.

They envision a world-class aquaculture hub that brings together farmers, value-added food producers, distributors, and retailers from across the region. Establishing the center will provide infrastructure and capacity to drive new aquaculture business formation, accelerate market growth, create jobs, and establish robust supply chain infrastructure to serve a diverse consumer base.

“Our vision is for a unique center that focuses on innovations that are as much for seafood marketing, including culinary options, and adult education and outreach as they are for the technologies, economics, and impacts of production or the policies and regulations governing these operations,” said Moehl.

“We see the center having retail sales. We see it being open to the public. We see it having an education function – both in terms of formal education, having training sessions, dealing with Cooperative Extension, dealing with sessions that are done through aquaculture associations. As it will be open to the public, there

Leaders in Aquaculture Education and Training

New! Aquaculture Foundations Certificate

2 semesters online + work placement

Unique focus on Indigenous environmental studies

Aquaculture Co-op Graduate Certificate

3 semesters + a paid co-op experience

Hands-on training in our campus

fish hatchery

Learn more: flemingcollege.ca/senrs

Prospects are looking up for oyster growers

Many are optimistic about continued recovery despite lingering issues

BY JULIA HOLLISTER

The COVID-19 pandemic has entered a new phase which offers what the World Health Organization calls “a plausible hope for stabilization.” It is a sentiment shared by oyster farmers, who bore the brunt of the damage caused by restaurant closures in phase one of the pandemic.

Despite the labour shortages and disruption in the supply chain, oyster growers are confident they are more equipped to deal with this wave because of the adaptations they made earlier.

San Francisco-based Hog Island Oysters, which raises four million oysters annually on 150 saltwater acres in Tomales Bay, increased outdoor dining at its five restaurants and ramped up its direct-to-consumer business during the first wave. It now has a robust direct-to-consumer department as a direct result of its early-COVID pivot.

Direct-to-consumer business is up at Hoopers Island Oysters in Cambridge, Maryland but it remains a small part of the business

But while these have helped, CEO John Finger anticipates some continuing disruptions in terms of labor availability.

“During the current Omicron wave, we’ve been extremely short handed at our farm and restaurants due to difficulty filling positions. Additionally, we’ve had employees out with COVID-19. It has definitely affected the level of business at our restaurants as well,” he said.

Brie Mazurek, communications director of the Center for Urban Education about Sustainable Agriculture, applauded Hog Island Oysters and other local farmers “for continuing to provide a vital lifeline to bring fresh, local seafood directly to the public” during this difficult time.

“We have been proud to partner with Hog Island to bring their high-quality, sustainably farmed shellfish to our Bay Area community

at the Ferry Plaza Farmers Market for more than two decades. With disruptions to restaurants, the pandemic has been especially hard on local farms and aquaculture,” said Mazurek.

Alaska Shellfish Farms in Halibut Cove, AK, is seeing fluctuating sales. Oyster consumption in restaurants is down because customers aren’t dining out, said owner, Weatherly Bates.

She noted, however, that oyster shortages in other states due to climate-induced farm closures have boosted demand for oysters from Alaska, where water is colder.

Michael Mastin of Hump Island Oyster Co in Ketchikan, Alaska, is seeing steady sales.

“Our wholesale customers are placing orders at similar levels as last year, taking seasonal variations into account,” he said. “Winter-season orders are down significantly compared to our summer tourism market and pre-COVID. But, seasonal variations are normal for us.”

Mastin said he is seeing more farm-tour bookings than this period last year.

Charlie Phillips, owner of Sapelo Sea Farms in Townsend, GA, harvests wild oysters and farms clams while waiting for his oyster permits to come through. “I am optimistic about 2022 and a good, strong summer; but then again, a lot can go wrong with the economy,” he said. “It’s also still pretty tough to find enough help to do the work.”

In Grand Isle, Louisiana, Nathan Herring of Bright Side Oyster Co says damage from the pandemic doesn’t even compare to the damage from the hurricane last August.

“Hurricane Ida, a Category 5 hurricane, smashed the oyster business. Around 80 percent of our oysters died when they were smothered in the mud,” said Herring. “We are still recovering. We began

PHOTO: HOOPERS ISLAND

Hog Island Oyster Farm in Tomales Bay in Marin County, California. Oyster growers are confident they are more equipped to deal with this wave of the pandemic because of the adaptations they made earlier PHOTO: REMY HALE

home deliveries for our customers because people are eating at home and not in restaurants.”

Still, he is hopeful. “I hope we can plant more seed oysters and sell them by the end of the year.”

At Hollywood Oyster Co, one of Maryland’s largest oyster farms, the impact of the Omicron wave has been negligible so far, said Tal Petty,owner of the business.

“In fact, there are more customers during this wave. We’ve been pleased by the resilience of restaurants and their customers.”

Petty said the farm is going into the year with good growing inventory and demand for farmed oysters.

Meanwhile, business is going smoothly at Hoopers Island Oysters in Cambridge, Maryland.

“Fortunately we have several business units, all of which are doing well at the present time,” said David Vincent, director of business development.

The company is an oyster farmer and manufacturer of oyster aquaculture equipment. Vincent said the COVID relief funds that farmers received helped boost orders for its farming equipment. For its part, Hoopers used the relief funds it secured to retain staff and develop online sales.

“We have recently opened a retail store in conjunction with our online marketing efforts to grow our brand name. While this is largely focused on retail sales, it added to our credibility as a commercial supplier.”

Vincent added that online sales have been on the rise over the two years since the onset of the pandemic. But he noted that online sales are still only a small percentage of the total annual revenue.

“We are very optimistic about 2022,” said Vincent. We certainly have things to improve on, but we project a strong year for equipment and oyster orders.”

Labor shortage is a recurring theme in oyster farming operations PHOTO: LIZA MAYER

Slow uptake of oyster farming permits in Texas

Potential growers are taking the time to conduct thorough due diligence prior to putting in applications, says state exec

BY JULIA HOLLISTER

Roughly eight months since Texas approved three permits for oyster leases (one of them conditional), there still are no new permit holders in the state.

“The permit process is extensive due to the number of agencies farmers have to work with,” said Hannah Kaplan, co-owner of Texas Sustainable Oyster Company, who holds the second of the two unconditional permits issued so far.

Texas Sustainable Oyster Co GM Gordon Lipscomb helps Hannah Kaplan put oyster seed into Intermas bags in October 2021. The seeds were spawned at Auburn University from broodstock provided by Kaplan

Washington State Sea Grant funds aquaculture research

Combined funds totalling over $2.5 million have been granted to projects that will promote marine research and develop the next generation of marine professionals in Washington State.

Washington Sea Grant provided the majority of the funds, while the Puget Sound Partnership contributed $432,000. Three of the nine projects that received funding are focused on

She says she has had to secure permits from both state and federal agencies, including the Coast Guard, the US Army Corps of Engineers , Texas Parks and Wildlife Department (TWPD) and the Texas General Land Office. The agencies were “very helpful” but the entire process still took about six months, she says.

“I believe as more people go through the process, it will become easier as the agencies already have answers and process in place.”

Emma Clarkson, manager of TWPD’s Ecosystem Resources Program, confirmed that two final permits and one conditional permit have so far been issued since the state opened applications online in August 2020.

Clarkson attributes the small number of permits issued to the small number of applicants, not to the laborious permitting process.

“To date, we have issued a permit to everyone who has applied,” says Clarkson. “There may be numerous reasons that we have so few applicants. We have done pre-application coordination with more than 10 applicants who are at various stages of the process. The majority of these prospective applicants are working out their business needs before they commit to applying for a site.”

Three applications are currently on the pending list. They are for sites in Matagorda Bay System, Aransas County and Galveston County.

Added Clarkson: “Business needs such as selecting gear, financing and understanding about logistics and operations should be considered before applying. Because the industry is so new in Texas, many prospective applicants need to do quite a bit of research to familiarize themselves with the logistics of running an oyster farm before they commit to an application. To that end, we often refer prospective applicants to the Sea Grant Oyster Mariculture liaison, Mario Marquez, who offers guidance and training on the business aspects of the program.”

“The remaining prospective applicants are proceeding with site surveys, and we expect their applications within the next few months. TPWD has worked very hard to streamline the permitting process, and offers pre-application consultations with prospective applicants,” she added.

This allows applicants to review any permitting concerns with their proposed site before applying so that the application process is expedited and not delayed due to site conflicts. During this process, she works with the applicant to resolve any site selection issues, such as the potential for damaging sensitive habitats.

“It is likely that universal issues associated with COVID (such as shipping and production delays) may be impacting the availability of aquaculture gear.”

Brad Lomax, who made history as the first ever recipient of an oyster farming permit in Texas, seeded his lease with just over one million oyster seeds in October 2021 – five months from the time he got his permit.

“So far, so good. They appear to be growing well and we expect them to reach market size next summer,” says Lomax, owner of Texas Oyster Company in Copano Bay, Corpus Christi and Water Streets Restaurants.

the aquaculture. One will explore the resilience of bivalves to ocean acidification, while the other two are related to seaweed aquaculture.

“We are thrilled to be joining forces with Puget Sound Partnership to fund important science projects relevant to the Puget Sound region,” said Russell Callender, director of Washington Sea Grant. “The new fellowship complements the research component by providing practical, on-the-job training for future marine professionals.”

PHOTO: JOE FOX

PHOTO: JOHN SCARPA

Funds available to BC shellfish growers

Funding is available to shellfish growers in British Columbia to support their adoption of new or improved traceability systems. Under the Traceability Acquisition Program, the British Columbia Shellfish Growers Association offers 95 percent reimbursement on expenses for traceability solutions that the program have identified as being suitable.

“Essentially we provide a ‘shopping list’ and growers can select the option best suited to their needs and we cover 95 percent of that cost,” said Nico Prins, who was named as executive director of the BCSGA in November 2021.

BlueTrace, an app that helps shellfish growers trace the journey of their product from tide to table, is among those on the list, as is Compass Aquaculture Solutions. “We’re are looking at including Vericatch also,” said Prins.

About 30 members of his association have adopted BlueTrace since the program’s launch in October 2021, Prins said.

“We estimated that we would get about 40 members subscribed before the end of the fiscal year (31 March 2022). We have approximately 150 members, but many of them already have custom solutions and would not need to adopt our program.”

The funds are from the British Columbia Salmon Restoration and Innovation Fund and Fisheries and Oceans Canada (DFO). Members of the BC Shellfish Growers Association could reach out to the association to avail of the funding and, if funds allow, it is also open to other shellfish growers in BC who are not members of the association.

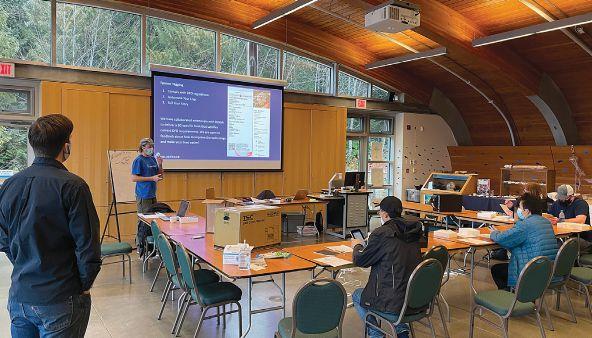

Shellfish growers attending a traceability workshop hosted by the BC Shellfish Growers Association in Deep Bay, BC. The federal and provincial governments provide funding for farmers who want to adopt new or improved traceability technology

The Province of British Columbia has a similar program that offers funding for traceability solutions. Called Traceability Adoption Program, the initiative is available to a much wider group of industries, not just farmed shellfish. Application for funding under the program is expected to re-open in the new fiscal year starting April 1, 2022.

Let’s Tie One on Together in 2022

Flag Tie Markers

Cable Ties

PHOTO: BLUETRACE

of the many

Carolina biotech firm hoping to produce cellbased oysters is how to make its product look like the real thing (pictured) to make it attractive to consumers

PHOTO:©ANA/ ADOBE STOCK

LAB-CREATED OYSTERS in the pipeline

The intention is noble, but will the cell-based product stack up to the real thing?

BY LIZA MAYER

Two Californians want to make history by becoming the world’s first producers of cellbased oysters – oyster meat made in the laboratory using oyster cells and tissue cultures.

Science-and-tech storyteller Nikita Michelsen and marine biologist Joey Peters are among the latest to jump on the cellular agriculture bandwagon, an emerging industry that McKinsey & Co analysts predict will grow to $25 billion globally to 2030. (This is from zero in 2013, when the first lab-created meat was presented to the world by Dutch pharmacologist Dr Mark Post.)

As co-founders of Pearlita Foods, the goal of Michelsen and Peters is to create cell-based mollusk products that would reduce the burden on the ecosystem while providing food that consumers enjoy.

They chose North Carolina as site for the company’s

headquarters and laboratory because of its robust biotech sector and a coastline rich in wild oysters.

The idea of oysters being created in the laboratory seems counterintuitive. After all, oysters take up nitrogen and phosphorus through feeding and growth, which good for the marine environment.

But Michelsen says the idea of raising them in a lab that one could keep contaminant-free is alluring. “Some of these areas (where farmed oysters are grown) are still polluted so the oyster meat itself can potentially have toxins and contaminants in them. That’s not really something that farmers can do anything about so that’s one of our leg-up on the product that we’re going to create.”

Peters says the ability to engineer the product in the lab to shape its nutritional composition is also enticing, although he acknowledged that this is also true

in aquaculture, where farmers can control it through diet and environment factors.

Still, he is excited about the prospect of yielding a certain nutritional profile through cellular aquaculture.

“We actually have the ability to control the amount of nutrition that would be in it by creating a medium with the right formula of ingredients. For example, everything we have in seafood, the reason why it has that definitive seafood taste to it is actually because of algae. So when factoring in the media for growing oysters, something we might have to think about is: how do we put algal oils or something that gives it that definitive flavor? Otherwise, it would just be a weird, bizarre flavor, right? So we have control in the lab.”

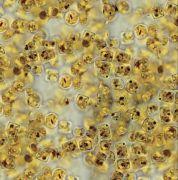

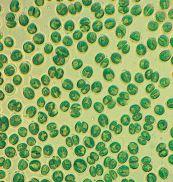

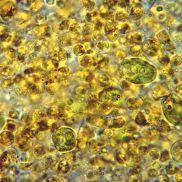

So, how is cell-based protein made?

Any cellular-based meat product starts with the original animal, which in this case is an oyster.

Peters explains: “You dissect it and you take cells from the different tissues inside the oyster meat, and you have to isolate those

primary cells that we’re going to eventually grow into more oyster meat. But you have to recreate the same conditions that the oyster animal has in its body. You have to create a medium for these cells to divide in, and that’s the real task – determining the right mixture of nutrients and amino acids and healthy fats that are part of the fluids that are inside the tissues that help incubate these cells.

“So we’re going to have to basically recreate that in the lab, in the controlled environment. We’ll use equipment, such as incubators, that keep things at a certain temperature and allow the cells the environment to thrive in, and then you’re actually in charge of the cell-division process. So, you have to play a pretty strong role in ushering along the cell growth and, over time, it starts to become its own little machine. And then, you can have a reactor – which is basically the size of the big vats that you’d see in a brewery – that can do it to generate products on a larger scale.”

That’s the theory; however, the business partners know they still have a lot of practical things to address before they even see their first cellular-based oyster meat product.

One

challenges before the North

“The main thing that we have to get down is the isolating of the cells themselves from a particular species of oysters or other shellfish and we have to develop the medium to grow them in. It’s not a heavily studied area of research. So part of our research program is understanding that medium,” says Peters.

Another challenge is how to make the cell-based oyster look like the real thing.

Says Michelsen: “For us, of course, the end goal is to have a product that looks exactly like an oyster. And that is a challenge for a lot of cell-based meat companies right now; how to make it look right. There are a lot of different strategies out there like, perhaps do a mix of plant-based and cells, or maybe make it cell-based all the way. It is a little too early for us to make that decision at this point.”

How to position their product in the market is also still up in the air. One question would be

whether cell-based products can be considered vegetarian.

“That is such an interesting new problem that I think a lot of cell-based meat industries are facing. Because in a way you can call it ‘animal-free’ because you’re not really slaughtering animals, you’re growing them. It’s not like you’re killing them. So in some sense, I guess it depends upon where your own positioning is, like your own standpoint of why you (as a consumer) are vegetarian or vegan. So it’s really, I think, up to the consumer to decide what they feel comfortable with.”

The duo still has a very long way to go and needs massive capital requirements to get there. So far, they have received an undisclosed amount from early-stage funders: Big Idea Ventures and Sustainable Food Ventures.

“We don’t have all the answers just yet because it is an emerging industry,” says Peters. “But I think the nice thing about it is

Pearlita Foods co-founders Nikita Michelsen and Joey Peters want to help the ecosystem recover through technologically driven approaches, such as cellular agriculture

PHOTO: PEARLITA FOODS

the intention behind all of these companies is that they all want to make a sustainable difference. Decades from now, one would probably see this being a pretty

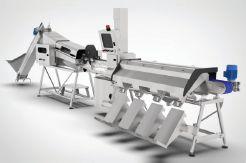

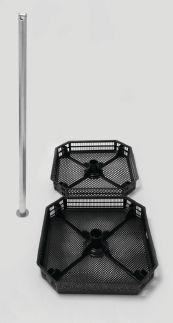

OYSTER GRADING TECHNOLOGY

its finest.

SED Vision Grader

Fully automated. Cleans, measures, sorts, counts and bags up to 8 per sec.

big deal, not just for Perlita Foods, but also the amalgam of cellular-based seafood making a positive impact on the ecosystem.”

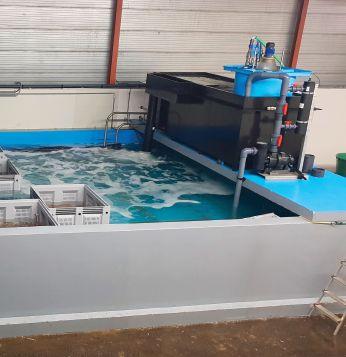

STOP KILLING YOUR OYSTERS!

SED Water Grader for seed and juvenile oysters. Fast but very gentle, significantly lower mortality rates than dry barrel or shaker graders.

WORTH THE WAIT

Kumamoto oyster takes three times as long to grow, but it always delivers

BY JULIA HOLLISTER

“The small and tasty West Coast Kumamotos are always popular for two reasons,” says Steve Sancimino, owner of the Swan Oyster Depot in San Francisco. “They are creamy with a briny flavor and customers love the small size.” Not to mention the very deep cup that holds its juices.

More than 75 years since Kumamoto (Crassostrea sikamea) oyster seeds first arrived in the United States from Japan, “kumies” have cemented their place in tahe market. Washington State-based Taylor Shellfish Farms, the largest producer of farmed shellfish in the US, says they share the top rank as “many people’s favorite” along with tide-tumbled Shigoku and Fat Bastards.

“They tend to be in nice condition for eating raw throughout the year,” says Bill Dewey, director of public affairs at Taylor Shellfish. “They require warmer temperatures to condition and spawn than Pacific oysters so they stay firm and

marketable well into the summer. They are one of the more expensive oysters mainly because of their long grow-out period compared to the other species. As a result, there are more costs in producing them as far as tying up ground, crop maintenance, etc.”

Although more expensive than other oyster varieties, Kumamoto oysters are a favorite of many consumers

PHOTO:©ANDRIY BLOKHIN/ADOBE STOCK

Seed production can be challenging for all species and Kumamotos are no different. “We have good and bad years with Kumamoto seed production and, as is most often the case, we struggle to understand the reasons,” says Dewey. Farming methods are similar to other bottom cultured oysters. Seed production starts in the hatchery and transitions to a floating upweller system, or “flupsy,” a nursery in open water where they stay for a period of time until they are large enough to survive being out on the farm for growout. The process takes three to four years compared to 12 months for Pacific oysters.

Taylor has a site dedicated to growing Kumamotos. The Chapman Cove site in Oakland Bay, WA has lots of food available for the oysters. Two crops are farmed on the site: Manila clams are growing in the ground under the Kumamoto crop. Once the oysters are harvested, a clam-digging crew harvests the clams then reseed the site with both crops to start the cycle again.

In the early days, scientists discovered that the small oysters hybridize with Pacific oysters (Crassostrea gigas). This made true Kumamoto broodstocks very difficult to find. Taylor Shellfish went back to the Kumamoto prefecture in Japan to secure true Kumamotos, rearing them through F2 generation in quarantine at the Oregon State University to address any disease concerns, then bringing them to the Taylor hatchery to produce true Kumamoto seeds.

It took two trips to Japan to accomplish this. The first year ended with the discovery – upon returning with what appeared to be Kumamotos – that they were actually hybridized. They went back a second year and did the genetic analysis before returning home with them.

“Beyond the initial challenges of securing true Kumamoto seed I would say they are not harder to grow than other oysters,” Dewey says.

Martin Seiler of Tomales Bay Oyster, located north of San Francisco, concurs.

“The best part of raising Kumamotos is the harvesting schedule. We can harvest them year-round, and I feel they are at the best quality in late Fall through early Spring.”

Manila clams are growing in the ground under the Kumamoto crop at Taylor Shellfish Farms.

Mussel farmer embraces modified polyculture system

“Mussel farming is the most sustainable and low-impact way of producing food I have ever heard of,” Matt Moretti told Aquaculture North America back in 2017. As part of the father-and-son duo running Bangs Island Mussels in Casco Bay, Portland, Moretti was back then just starting to scale up Integrated Multi-Tropic Aquaculture (IMTA), a farming concept where complementary marine species are raised in one location to each other’s benefit.

Moretti has since discovered that a “simpler version” of the farming concept works better for the company. “Our particular form of IMTA is the extractive shellfish and algae,” he says. He says the idea of adding finfish to the mix was explored earlier, but it would require technical and operational changes and new permits. Besides, they are already seeing positive benefits with using just the two trophic levels.

“Our particular form of IMTA is the extractive shellfish and algae.”

“Casco Bay is very prolific and a great place for mussels. There is a reason we’re here,” Moretti says. “IMTA is what we want to do and for us that means mussels and kelp. Both sides have scaled up, and they embody what we are trying to accomplish as a company. Both species have similar, positive, environmental benefits, and they complement each other well.”

Recent collaborations with teams at the University of New England, Atlantic Sea Farms, Bigelow Laboratory for Ocean Sciences, and the Island Institute have allowed them to expand the kelp side of the operation

into a sustainable part of the business model.

According to some studies, kelp can create a “halo effect” around shellfish when raised in a polyculture setup by raising pH (reducing acidity) and increasing oxygen. This is beneficial to both bivalves and the marine environment.

Dr Nichole Price of Bigelow Laboratory, who started the pilot study into these benefits in 2018, said: “The study at Bangs Island stemmed from funding by the Nature Conservancy and NOAA, and since then we have received additional interest from the World Wildlife Foundation and the Bezos Earth Fund to look at similar operations in Alaska and in Norway. We are trying to determine if the ‘halo’ effect is reproducible on other farms in order to bring the same wate-quality benefits.”

To focus more resources on the two species, the company abandoned scallop farming despite successfully growing scallops during a multi-year experiment. Many other groups continue to explore scallop farming in other regions in Maine and have experienced various levels of success.

While the company continues to evolve, it remains a family-owned business just like when it started in 1999.

The pandemic presented Matt’s sister, Annie Simpson, a career opportunity at the company. With her into the fold, their father Gary now works just part time.

“It’s great. I have completely switched careers but had done some management work in my past, so there was a good synergy. There’s a great group of employees and I have learned so much about the impact of mussels and kelp,” said Annie.

The former health care worker has brought great benefits to the company, noted Matt. “Annie really brings skills that we have not had before. She has helped us become a more mature company. It’s wonderful to have the entire family involved.”

– Tim Harder

S4000

S1000

Portland-based Bangs Island Mussels grows shellfish and kelp together, two species that complement each other well, says co-owner Matt Moretti PHOTO: JOSH KUCKENS / BATES COLLEGE

A new report reveals that endangered wild salmon passing along Alaskan rivers on their way home to spawn in BC are being caught ‘in the millions’ by Alaskan fishermen PHOTO:©CASSIS/ADOBE STOCK

Report offers another clue as to why BC’s wild salmon numbers are falling

BY LIZA MAYER

Thirteen years after Canada launched an inquiry into the decline of sockeye salmon in the Fraser River in British Columbia, there remains no clear-cut answer as to why wild Pacific salmon populations are fluctuating.

While the inquiry body, the Cohen Commission, listed more than 20 activities affecting Pacific salmon populations – among them climate change, loss of habitat, predators, non-point sources of contaminants and forestry – the farmed salmon industry has disproportionately been blamed and condemned by activists for the phenomenon.

It is against this backdrop that the BC provincial government announced a landmark decision in 2018 to shut down 17 Atlantic salmon farms in BC’s Broughton Archipelago “to help reduce harm to wild salmon.” Then, in December 2020, Fisheries and Oceans Canada (DFO) announced plans to shut down 19 farms in the Discovery Islands in BC despite its own scientific studies proclaiming salmon farms pose only “minimal risk” to wild salmon in the area.

Information regarding the phenomenon continues to evolve. In January 2022, a new report revealed that “millions” of wild salmon passing along Alaskan rivers on their way home to spawn in BC are being caught by Alaskan fishermen.

The report was a result of an investigation commissioned by the Watershed Watch Salmon Society and SkeenaWild Conservation Trust as part of the annual review of the Pacific Salmon Treaty between Canada and the United States. The treaty manages transboundary interceptions of Canadian wild salmon between the US and Canada. It was set up with the idea that the salmon in the ocean belonged to the country where the salmon originated from (were born), not where the salmon fed. It is a contentious part of the treaty because of its impracticality –whose fish are they? The identity of the salmon can only be evaluated long after they are caught (laboratory analysis required) not before they are caught.

The new report identified those in southeast Alaska’s District 104, located on the outer

coast of the Alaska panhandle, as the most prolific harvesters, where “nearly all” of the salmon and steelhead caught are bound for streams in Canada, elsewhere in Southeast Alaska, or other US states such as Washington and Oregon.

In 2021, they harvested roughly 800,000 sockeye of mainly Canadian origin, in addition to “tens of thousands” of Canadian Chinook and Coho, and “a large but unknown numbers” of co-migrating Canadian pink, chum, and steelhead. Many of these species are threatened and endangered populations, the report said.

The fact that “salmon adults migrate back to their home rivers and streams to spawn, some are caught, or intercepted, by commercial fishing” is acknowledged in the Pacific Salmon Treaty between the two countries. But the sheer numbers of Canadian wild salmon intercepted in Alaskan fisheries caught conservations groups by surprise.

“We knew the Alaskans were intercepting a lot of BC salmon, but the numbers in this study are staggering. I’m also appalled at their

failure to study their bycatch of non-target species, which Canadian fishers are required to do,” said SkeenaWild Executive Director, Greg Knox.

The Pacific Marine Conservation Caucus says it is difficult to have accurate numbers because of the “lack of assessment information.” It also said that because of this, “it is unknown what the impact of this fishery was on other Canadian-origin salmon (pink, chum, Coho, and chinook) and steelhead.”

At the time the investigation was conducted, Canadian fisheries have been closed since June 2021 (until further notice) in order to rebuild depleted stock of BC wild salmon.

Aaron Hill, executive director of Vancouver, BC-based Watershed Watch Salmon Society, noted the irony:

“Alaskan fisheries are now the biggest harvesters of a growing number of depleted Canadian salmon populations. Canadian fishers and taxpayers are making incredible sacrifices to protect and rebuild our salmon runs, while the Alaskan interception fishery continues unchecked. It is irresponsible of both countries to continue to allow this.”

Adding to the irony is the fact that Southeast Alaska seine fishery is Marine Stewardship

“We knew the Alaskans were intercepting a lot of BC salmon, but the numbers in this study are staggering.”

– Greg Knox, Executive Director, SkeenaWild

Council-certified. MSC certification means that a fishery is “working to minimize harm to the ocean overall, not just to specific species.”

In an email to Aquaculture North America, MSC said the Southeast Alaska seine fishery’s MSC certification is valid for five years and expires in May 2024. It and other MSC-certified fisheries undergo annual audits to ensure they continue to meet the standard.

“Fisheries operate in dynamic environments that are constantly changing. New information about a fishery or status can be submitted to an assessor for consideration during annual audit cycles for certified fisheries,” it said.

The Pacific Marine Conservation Caucus notes that a “loophole” has allowed the fishery to get away with MSC certification because the fish are returning to another jurisdiction.

“The Southeast Alaska seine fishery would likely not have been certified if the endangered or threatened BC and southern US salmon and steelhead populations caught in the Southeast Alaskan seine fishery were returning to Alaska,” as such, there is no requirement by the MSC for the fishery to record and publicly report catch and mortality data.

“The BC salmon industry lost its MSC certification when it could no longer convince MSC that it was sustainably managing its salmon fisheries. Alaska could face similar risks,” it added.

Closing interception fisheries in Southeast Alaska may solve the problem but there’s little incentive to do this because of sockeye is worth ten times the value of a pink salmon, it added.

The organization acknowledged that with today’s consumers increasingly insisting on knowing where their food comes from or how it was caught or raised, the reputation of wild salmon from Alaska could suffer because of this issue.

“If the market were to lose confidence in the sustainability of Alaskan salmon management, it would erode Alaska’s reputation in international markets.”

Investing with a conscience trending up

Sustainability of aquaculture operations increasingly becoming an important consideration for financial backers

oncerns about the environmental and social impact of their portfolios is more pronounced than ever among those considering investing in aquaculture not only because more consumers are demanding it but also because society’s values have changed due to the pandemic.

“There is a much closer link between sustainability and the finance world,” observed Catarina Martins, chief sustainability officer at Mowi. “(Our) meetings with environmental, social, and governance (ESG) investors have become much more frequent … and there is really an increase in granularity on the discussions and on the interest from an investor’s perspective.

“There’s a feeling that sustainability work is really becoming much more closely linked to the financial world, which I think it’s really important and great to see.”

Blue finance – financial instruments focused particularly on the ocean economy –have reached new heights because of growing awareness of the blue economy and ESG, says business intelligence provider Oxford Business Group.

“Given the increasing focus on environmental, social and governance metrics in both the public and private sectors, the development of debt-for-nature deals and blue finance could

Growing awareness of the blue economy and ESG is driving blue finance to new heights

PHOTO:©ATSTOCK PRODUCTIONS/ADOBE STOCK

“There is a much closer link between sustainability and the finance world.”

set a precedent for emerging markets looking to raise funds,” said the group.

Martins said aquaculture should leverage the attention given to the blue economy at the UN Climate Change Conference (COP26) held in Glasgow in November.

“What we have seen in COP26 in particular was very interesting because it was the first time that we have actually had the ocean economy on the stage, discussing the role of seafood in fighting climate change. That was in itself, I think, a great achievement for all of the seafood industry.”

The second sustainability related trend that Martins is seeing is the more prominent attention given to greenhouse gas emissions. It is an area where aquaculture could still improve but also something where the industry is already ahead of the curve compared to other protein producers, she said.

“Greenhouse gas emissions is a challenge but it’s also a great opportunity for our industry. Seafood clearly has a lower carbon footprint as compared to land-animal proteins. So it’s a fantastic communication that we should really leverage.”

Thirdly, there is now more focus on human rights in the seafood value chain as part of the ESG discussions, she said.

“The social element, the human rights in our value chain, is also increasing in importance also from a regulatory perspective in the EU and in different countries. I think that we will see increasing in scope and in granularity, in due diligence processes, mitigation processes, etc.”

She said the challenge now is to make sure the message is simplified and “gets to the to the right audience.”

One would think finding content would be the hardest challenge, she said, but she believes the actual challenge is in communicating them.

“There’s actually really enough material to be proud of that we could communicate to consumers, for instance the Coller-FAIRR Protein Producer Index where aquaculture has outperformed other animal protein producers on ESG factors for years, as well as The High Level Panel for a Sustainable Ocean Economy which positions aquaculture as one of the sustainable economies from the ocean.

“But I believe the industry has to learn to communicate in a much more proactively, in a much simpler way and much more emotional way, especially for the young generations using social media and other type of tools that maybe the older degeneration is not so used to.”

Martins shared her insights into sustainability trends at the IntraFish Seafood Sustainability Forum in December 2021.

Catarina Martins

PHOTO: MOWI

WOMEN IN NORTH AMERICAN AQUACULTURE

W MEN IN

North American Aquaculture

W MEN IN

North American Aquaculture

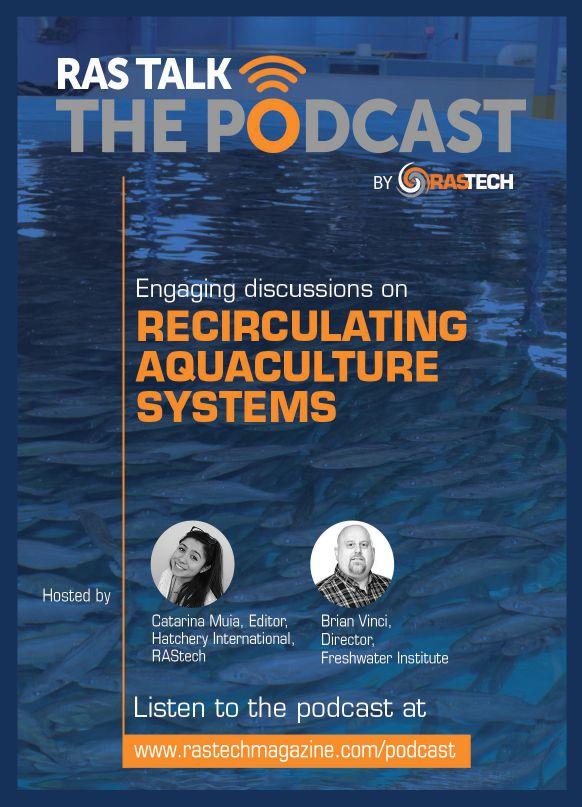

Series puts the spotlight on Women in North American Aquaculture who have carved out their own paths in the industry, a tie-in with Aquaculture North America’s newly launched podcast. For full episodes, visit aquaculturenorthamerica.com/women.

SHE CAN DO IT ALL

Jill Voorhees shares advice in finding work/life balance

BY JEAN KO DIN

Jill Voorhees was working at Walmart as a cashier when she stumbled into a career in aquaculture.

“A guy came to my line and there were some issues. So, I call a manager and of course, Walmart being slow, we had to wait. We got talking, he found out I was a college student going for Environmental Science, and he gave me his contact and that’s when the internship started,” said Voorhees.

She hasn’t looked back since. In 2009, she applied to be a part-time intern at South Dakota’s McNenny Fish State Hatchery. Twelve years later, Voorhees is the lead biologist and researcher in the same facility.

Voorhees is the first guest of Aquaculture North America’s (ANA) new podcast that celebrates Women in North American Aquaculture. In the episode, she shares how she fell into the world of fisheries and aquaculture, and has gone on to become an accomplished thought leader in the industry.

Voorhees said the best advice she’s ever received came from the same man who offered her the internship at the Walmart checkout line – Mike Barnes – who has since become her mentor and supervisor at the hatchery. He encourages her to lean in to find that work/life balance, she said.

“I just got married, I felt like it was the right time to have kids. But I was in the middle of my Master’s, I still had all my research, I still had all that. And he looked at me and he said, ‘Don’t hold back… just because of your career, don’t hold back on your family life,” she recalled.

Voorhees was recognized in 2017 for the Outstanding Performance Award in the Aquatics section of the South Dakota Department of Game, Fish and Parks. In 2019, she was given the David Willis Outstanding Young Professional Award from the Dakota Chapter of the American Fisheries Society. She also

changed the trajectory of Jill Voorhees’ career. She’s now the lead biologist and researcher

in

made it to the Top 10 Under 40 list by Hatchery International that same year.

“I don’t know if there’s really one accomplishment that I’m most proud of,” said

Voorhees. “It’s just overall, having a job I love, working with people I really enjoy, personally, professionally and ones that just encouraged me.”

A chance encounter at a Walmart check-out counter

at McNenny Fish State Hatchery

South Dakota PHOTO: MCNENNY FISH STATE HATCHERY

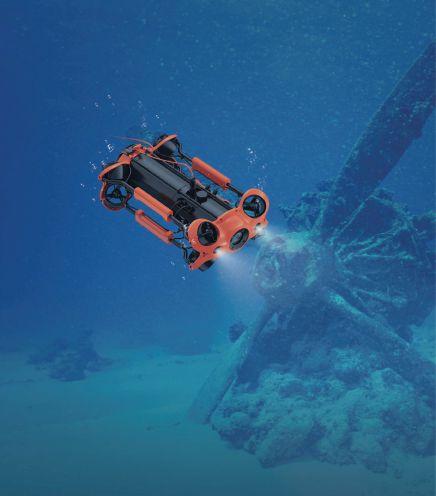

What prevents offshore aquaculture from taking off?

BY ARSENIA KING

Coastal marine aquaculture is reaching its growth limits, but don’t expect offshore aquaculture to pick up the slack and accelerate in the near term, says Rabobank.

In its report focused on the drivers and inhibitors of offshore aquaculture development in key “epicenters” worldwide, including Norway and China, Rabobank says the sector’s growth trajectory is difficult to predict due to varying technical, market and legislative challenges it confronts.

If the current performance of farmed salmon is indicative of the industry’s progress, the numbers are far from encouraging.

For instance, Rabobank estimates that only 100,000 – 300,000 metric tons of salmon could be harvested from offshore farms globally by 2030 – that’s a mere 10 percent of the current global salmon production of over 2.5m metric tons and the said output could also involve partial use of coastal farming facilities.

The report maintains that offshore farming in other species presents a bigger opportunity because the market for marine and diadromous species, excluding salmonids, has been estimated to reach 4 m to 4.5 m metric tons as of 2019.

Incentives to go offshore

Moving marine aquaculture offshore is seen as a logical solution to the decreasing availability of ideal farming locations worldwide, says Rabobank. While decision to move offshore will be difficult to execute in Norway due to regulatory restrictions, countries will less restrictive regimes allow aquaculture to reach maximum carrying capacity although it negatively impacts the environment and fish health.

Rabobank cites how pollution in some regions are making once ideal farm location difficult to operate in and how climate change is warming coastal waters in Australia forcing farmers to consider offshore production.

Growth barriers

Rabobank says offshore aquaculture could be capital intensive depending on the location. Compared to farms in tropical and Mediterranean waters, CAPEX tended to be high in Norway as the country needs substantial infrastructure to scale and manage harsh environment and wave energy.

Data from publicly disclosed project puts the CAPEX for offshore farming within the

US$11/kg to US$17/kg range – same range as that of the more cost-effective land-based recirculating aquaculture systems (RAS).

“Arguably, if there are no differences in variable cost, mortality and quality, it will probably be RAS, not offshore systems, that drive incremental growth in salmon,” the report said.

Rabobank says the salmon industry in Norway has the advantage of being well developed. It is also exposed to fewer operational risks as their farms are already equipped with husbandry, feeding, harvesting, marketing expertise to thrive.

By contrast, the aquaculture industry in China is less developed and more fragmented where farmer grow, not only salmon, but also a range of products ranging from grouper, yellow croakers, Japanese seabass, etc. Farmers in China are decades behind in farming skills and with their simple company structure and limited technology, they are unable to transition to the offshore sector.

Legislation –A Key Limitation

Rabobank said many aquaculture pioneers in the US are unable to scale because of unclear regulations and everchanging legislations. “To be able to move forward with offshore aquaculture, departments regulating marine transportation, tourism, fishing and offshore energy, as well as the military or coast guard, and environmental analysis all need to be supportive,” the report said.

Given its government support and the strategic relevance of offshore farming to the industry, China does not experience the same legislative barriers that exists in the West. However, if farms are far enough from the coast and are placed in disputed waters, it could create tension with neighboring countries.

Just like China, Norway’s regulatory environment can be restrictive. It’s production volume limited by licenses issued only every two years capped at 6 percent of the theoretical maximum production. The license will not be awarded if the industry fails to meet stringent biosecurity parameters such as lice number and medication use. This gives salmon farmers the impetus to consider moving offshore.

Despite the restrictions, Norway benefits immensely from government support. The government grants licenses to innovative products and the farm can covert these licenses to valuable coastal salmon farming licenses making experimentation with offshore farms less costly if not proven successful. So far 200 product innovation projects have been submitted, so far of which 70 has now been accepted by the government.

PHOTO: NOAA

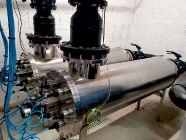

Study: Salmon farm workers are at a much higher risk of harmful noise

Subject is vastly understudied among health hazards in the field of aquaculture

Site managers have taken steps to reduce noise exposures by providing employees with some form of hearing protection, but not everyone uses them, the authors said

MOTION/ADOBE STOCK

Researchers who studied noise exposure in Canada’s salmonid aquaculture industry have found that salmon farm workers are at a much higher risk of excessive noise exposure than employees at other types of facilities due to the tasks performed and the equipment used.

Data was collected from a salmon hatchery, a salmon R&D facility, a laboratory and a salmon farm.

“Noise levels at the salmon farm are significantly higher than those observed at the other three facilities because workers were required to perform all tasks near machinery due to limited space onboard the vessels, and the equipment used to feed the salmon was installed on the vessel’s main deck where the personnel was working,” said researchers Jonathan K. Stone and Lorenzo Moro of the Memorial University of Newfoundland.

They found that hand-guided feed blowers and generators were the biggest sources of noise. The hand-guided feed blower, which is used for six hours a day by each labourer, emits noise levels upwards of 90.2 dB(A), slightly higher than the maximum permitted exposure level of 87 dB9(A) for eight hours per Canadian federal regulations and 87 dB9(A) in British Columbia.

The authors recommend that employees wear the appropriate hearing protection during certain tasks or within the vicinity of noisy machinery on site.

Except for the laboratory, three of the facilities have actively taken steps to reduce noise exposures, but not everyone use the hearing protection even if they were available, said the authors.

They further recommend that generators and compressors be properly isolated via resilient mounts and enclosed in insulated spaces since they are common sources of noise in all the facilities. All doorways accessing rooms with this equipment should always be kept closed; salmon farms should consider switching to automatic feed blowers so a worker doesn’t have to be nearby; and vessels used in salmon farms should have the engine room properly insulated when equipped with an inboard engine.

The research adds to what little information there is about noise exposures of workers in salmonid-based facilities in aquaculture. Aquaculture occupational health and safety is understudied in Canada, much like in the rest of the world, but occupational noise exposure is even more so. Existing studies focus on physical hazards such as slips, trips and falls or chemical hazards related to fish vaccines and fish care, said the researchers.

BC salmon farmers group names interim leader

The British Columbia Salmon Farmers Association (BCSFA) has announced that John Paul Fraser is leaving after almost four years as executive director and has named industry veteran Ruth Salmon as interim leader.

Salmon, who is currently senior advisor to the BCSFA, takes on the role for the next six months, the association said. She led the Canadian Aquaculture Industry Alliance for 10 years and became a member of the BCSFA in 2018.

Salmon takes over the leadership of the association at a critical time for salmon farmers in the province. Seventy-nine farming licenses and warrants are set to expire before June 2022.

“Over the next six months, our focus at the Association will be to mobilize a coordinated effort with the clear objective of supportive licence reissuance decisions,” Franze said in a letter to association members.

She added that a new campaign titled “Why Licences Matter,” will be launched “with the aim of educating, elevating, and activating our sector around this pressing issue.”

Franze says the association is grateful for Salmon’s leadership in this challenging time.

Ruth Salmon

BY MARK LANE

Kill them with kindness

History shows that activism most often results in positive steps forward for society. However, select activists ignore facts, misrepresent the truth, convolute, and pollute the public conversation.

Industries have been battling extreme anti-industry activism since the beginning of the industrial revolution, so perhaps now is the time to pivot industries’ approach to responding to those that diametrically despise what they do sustainably and responsibly. Reflecting on my tenure at the industry association in my home province of Newfoundland and Labrador, Canada, it was through kindness and telling the story of a community that won hearts and minds, not science.

Not too long ago, there were two brothers, both of whom were publicly adamantly opposed to salmon farming. Upon reaching

Growing to this level of support regionally has cost millions of dollars in educational initiatives such as awareness campaigns and advocacy, both necessary tools. In some instances, the less expensive random act of kindness that the industry offered to residents was more effective.

out to both individuals, we learned that one felt displaced from his traditional boat launch area. The other was discouraged by the tremendous volume of marine debris along the coastlines where his family’s cabin was located. In both instances, Cooke Aquaculture, under the regional leadership of Mr Sheldon George, responded to the residents’ concerns, improved the launch area for easier access for all users and in the other case, committed numerous staff, vessels and barges to removing more than 40 tonnes of marine debris and plastic refuse from eight shorelines in the area. As a side note, all involved noted that only a tiny portion of marine litter could be attributed to the aquaculture industry.

In most instances, as in the case of the two disgruntled brothers, recipients of acts of kindness and community outreach are incredibly appreciative and grateful. Those unsolicited acts of service in the community are critical to earning respect and social license to operate.

The aquaculture industry has done a great job of earning the trust and winning the hearts and minds of the majority of those who live in our areas of operations in rural communities. In Atlantic Canada, support for the industry ranges between 70-80 percent.

Growing to this level of support regionally has cost millions of dollars in educational

initiatives such as awareness campaigns and advocacy, both necessary tools. In some instances, the less expensive random act of kindness that the industry offered to residents was more effective.

So, if public support in the areas where salmon farming occurs is so high, why is the industry such a challenge for politicians? Two words: Population Density.

Canada’s coastline is the world’s longest, measuring more than 240,000 km. Canada is also the second-largest country on the earth in the total land area. Urbanization increases annually, with more than 80 percent of 38 million Canadians now living in major cities (Statistics Canada).

The Greater Toronto Area (GTA) has roughly 7 million residents, more than double the entire population where salmon is farmed. The entirety of Atlantic Canada, including four provinces, Newfoundland and Labrador, Nova Scotia, Prince Edward Island and New Brunswick, has a population of 2.4 million. Vancouver Island falls just short of 850,000 citizens.

The unfair advantage of having a concentrated population in a city such as the Greater Toronto Area is also having 19 more seats in the House of Commons than the entirety of Atlantic Canada and Vancouver Island combined.

Sadly, then, as a result of low population density and corresponding sparse

Recipients of acts of kindness and community outreach are incredibly appreciative and grateful, notes columnist

PHOTO:©TATSIANA YATSEVICH/ADOBE STOCK

K indness may be the key to winning the anti-salmon-farming activism war, writes guest columnist Mark Lane

representation in the political arena, when it sometimes comes to adopting policies, regulations and legislation regarding aquaculture, the seafood farmers, their families and the remote coastal communities that they sustain and call home are overlooked.

There is no doubt that the salmon farming industry has a considerable challenge ahead politically due to robust lobby efforts and anti-industry activism.

Just this week, I watched Netflix’s star-studded disaster satire Don’t Look Up, in which in one scene in a grocery store, Hollywood star Leonardo DiCaprio holds wild and farmed salmon and refers to the latter as looking fake. At first, I was taken back but then assumed it was part of the satirical humour of how ridiculous the whole debate of wild vs farmed is in society as Leonardo DiCaprio is a supporter of salmon farming.

In a 2018 Facebook post, DiCaprio wrote: “The end of the year is a time to reflect on the role we can play in protecting the planet. From reducing our carbon footprint to taking pressure off the ocean, there are quick ways to make a difference. Eating fish is better for the environment than other meat protein, reducing our carbon footprint and the pollution from industrial agriculture. Sustainable fish farms also take pressure off endangered ocean species so they can regenerate.”

I am also assuming comparing two different fish species was part of the comedic sketch. Whatever the intention, the debate regarding farmed salmon appears in modern-day mainstream media and is accessible to almost every home with Internet access around the world.

To shift the narrative, the industry must more impactfully engage and educate our vast country’s densely populated urban areas, those most far removed from any salmon farm. The story of their food journey from Hermitage Bay, Newfoundland, to a table in downtown Toronto must be told and understood by urban consumers. The industry needs to tell better the story of farming our oceans with care to urban Canada and their elected officials so that

when they pick up salmon in the grocery store in the city, they understand why two fish may look different or where and how one was raised by a farmer who loves their job. Where that job fed and raised a family. Where a family of farmers carefully grew food for a community of people thousands of km away with no connectivity or lived experience in relation to the sea or what it truly means to the people who do.

I know there are many possible solutions, and I am not sure any will work 100 percent. I am sure that to be most effective in sharing the story of fish farmers and the food they care for from egg-toplate is to do so through heartfelt storytelling and kindness.

I say kindness because, at an absolute minimum, exhibiting kindness fosters a positive relationship, even with the opposing force. I’ve seen this at the individual level in the scenario of the two brothers that I now consider to be my friends.

Mark Lane was the executive director of the Newfoundland Aquaculture Industry Association for seven years until December 2021. During his tenure, polls showed Newfoundlanders’ and Labradorians’ support of seafood farming increased while opposition diminished. Mark remains a part of the industry as consultant while running a number of his own family’s small businesses.

In-person-only US aquaculture conference braves Omicron

wave

Attendance numbers down but mood was ‘upbeat,’ says organizer BY